Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Evenly dispersed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing precursor fiber of cellulose base carbon fiber

InactiveCN1587457AImprove thermal stabilityImprove carbonization yieldMonocomponent cellulose artificial filamentFiberCarbon fibers

The present invention relates to preparation process of precursor fiber of cellulose base carbon fiber in chemical fiber production. The preparation process includes mixing concentrated NMMO aqua and carbon black for carbon black water in the weight ratio of 20-10000, decomprssion distillation to obtain NMMO / carbon black solution with water content 24-28 wt%, adding the mixtue of sliced cellulose pulp and NMMO / carbon black solution in the weight ratio of 5-15 to 100 into dissolving reactor, swelling and stirring at 70-90 deg.c, raising the temperature to 90-120 deg.c, stirring and decomprssion distillation to eliminate water and form cellulose / NMMO / carbon black spinning liquid with water content of 12-14 wt%, and dry-wet spinning to obtain the precursor fiber. The present invention has high carbonizing yield, high mechanical performance of the carbon fiber, raised spinnability of the spinning liquid, non-toxic solvent, high solvent recovering rate and environment friendship.

Owner:DONGHUA UNIV

Small pore diameter silicone rubber sponge and preparation method thereof

The invention discloses small pore diameter silicone rubber sponge and a preparation method thereof and relates to the field of processing of high polymer materials. The small pore diameter silicone rubber sponge comprises the following components in parts by weight: a component A: 100 parts of liquid organic silicone rubber; a component B: 3-8 parts of hydrogen-containing silicone oil; a component C: 0.5-10 parts of an emulsifier; a component D: 2-4 parts of a catalyst; a component E: 1-2 parts of an inhibitor; and a component F: 0-35 parts of a silicon resin. An emulsion dispersion mode is adopted, the dispersion phase size is small, and the silicone rubber sponge prepared by the method has the characteristics of bubble dispersion uniformity, small pore diameter and controllable density; and moreover, water serves as a foaming agent, and the sponge has the advantage of environment friendliness. The silicone rubber sponge material prepared by the method can serve as shock absorption, insulating, sound insulation and heat insulation materials.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Propofol injection and its preparing method

InactiveCN101045042ANo side effectsLess irritatingHydroxy compound active ingredientsPharmaceutical delivery mechanismDisodium EdetateHigh pressure

Owner:SHANGHAI INST OF PHARMA IND

Cobalt-aluminum composite oxide catalyst and preparation method and application thereof

PendingCN110433806ALarge specific surface areaLarge transport channelIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsCatalytic transformationPtru catalyst

The invention relates to the technical field of catalyst preparation, and discloses a cobalt-aluminum composite oxide catalyst and a preparation method and application thereof. The preparation methodcomprises the steps that metal salt solutions of cobalt and aluminum are taken as precursors correspondingly, polymer microspheres are taken as a template agent, templates are soaked in the precursorsolutions, then impregnation and roasting are conducted, and thus the cobalt-aluminum composite oxide catalyst is obtained. A three-dimensional ordered hierarchical pore structure with a mesoporous and macroporous structure is created through the polymer microspheres, thus the specific surface area of the catalyst is increased, the prepared catalyst has a large transmission pore channel, reactantmodules enter the pore channel from all directions advantageously, the diffusion resistance is lowered, thus the convective mass transfer efficiency between gases is improved, and the catalytic activity of the cobalt-aluminum composite oxide catalyst is facilitated; and meanwhile, through the large transmission channel, the situation that the modules are blocked when reacting on the pore wall or the pore channel of the transmission channel, and consequently, the reaction progress is influenced can further be effectively avoided, and the catalytic conversion efficiency of the catalyst is improved.

Owner:FUZHOU UNIV

Thermal insulation material and preparation method thereof

InactiveCN107721451AEvenly dispersedEffective control of cell stabilityConstruction materialCeramicwareFoaming agentPolymer science

The invention discloses a thermal insulation material and a preparation method thereof. The thermal insulation material comprises a cement-based block skeleton and graphene modified polystyrene, wherein the cement-based block skeleton comprises multiple cavities; the multiple cavities are filled with graphene modified polystyrene; and graphene modified polystyrene is formed by performing melt extrusion on graphene and polystyrene resin according to a weight ratio of 1:(1-5) in the multiple cavities in the presence of an alkane foaming agent. According to the thermal insulation material disclosed by the invention, the strength and thermal insulation property are further improved.

Owner:ZHONGJING ECO IND CO LTD

TDA dehydrating tower

InactiveCN101444677AEvenly dispersedImprove throughputAmino compound purification/separationFractional distillationGas phaseEngineering

The invention disclose a TDA dehydrating tower, which comprises a tower body, a circumfluence supply pipe, a recycle gas phase inlet and a TDA feeding hole. An upper distributing groove communicated with the circumfluence supply pipe is formed at the top in the tower body, an upper packing layer is arranged below the upper distributing groove, a liquid catch plate is arranged at the lower part of the upper packing layer, a liquid receiving tank is fixed at the lower part of the liquid catch plate, a liquid downtake communicated thereof is arranged at the bottom of the liquid receiving tank, the liquid downtake is communicated with a lower distributing groove formed at the lower part of the liquid downtake, and a lower packing layer is arranged at the lower part of the lower distributing groove. The TDA dehydrating tower has the advantages of simple structure, easy disassembly and assembly, low cost, high degree of the heat change and quality change of two phases of gas and liquid, good separating effect and high efficiency.

Owner:YANTAI JULI ISOCYANIC ESTER

High-performance modified asphalt and preparation method thereof

InactiveCN106751968AEvenly dispersedExtended service lifeBuilding insulationsAcetic acidAcetylpyruvic acid

Owner:漳州新立基沥青有限公司

Connection method for carbon fiber yarns and metal sheet for heating

The invention relates to a connection method for carbon fiber yarns and a metal sheet for heating, which is characterized in that the method comprises the following steps of: 1) stranding: stranding 3-10 beams of adjacent carbon fiber yarns at the end of carbon fiber cloth into one strand; 2) coating adhesive: evenly coating conductive adhesive doped with curing agent at a position at which the stranded carbon fiber yarns are in contact with the metal sheet; 3) wrapping felts: wrapping 1-2 layers of thin carbon fiber felts on the surface of the carbon fiber yarns coated with the conductive adhesive to enable the conductive adhesive to infiltrate the thin carbon fiber felts; 4) sheathing: sheathing a metal sheet clamp on the carbon fiber yarns into which the conductive adhesive infiltrates, clockwise turning a clamping knob to tightly clamp the carbon fiber yarns until the conductive adhesive flows out of the two ends of the clamp; and 5) curing: fixing the clamp, placing at room temperature and controlling curing time to be 24-72h. Compared with the prior art, the connection method has the advantages of simplicity, effectiveness, economy, durability, even and firm connection position, stable and reliable performance and the like.

Owner:JIANGSU YUEKE NEW MATERIAL

Processing method of ultrafine grinding wires

The invention discloses a processing method of ultrafine grinding wires. The processing method comprises the following steps of preparation of a treatment solution; preparation of a master batch; andmelt spinning. In the processing method, without using absolute alcohol, the risk that the absolute alcohol is inflammable and explosive is solved; the ultrafine grinding wires do not need to be laidand aired, so that the production space is greatly saved; without tedious programs including manual pelletizing, sieving and drying, the production efficiency is improved; and with a simple and convenient technology, the loss of diamond micropowder is reduced, and the cost is effectively lowered. In addition, for the ultrafine grinding wires produced by the processing method, the content of the diamond micropowder is full in content and uniform in distribution, so that the rigidity and the abrasion resistance of brush wires are improved, and the service life of the brush wires is prolonged; inthe use process, the fine polishing effect of the surface of a workpiece can be better; the diameter can be from 0.08mm to 0.149mm, and the blank of a product in the domestic and foreign markets is filled.

Owner:赵明余

Hydrophobicity-enhanced heat-vulcanized silicone rubber and preparation method thereof

InactiveCN107286671AEnhance internal bondingImprove mechanical propertiesVulcanizationPolymer science

The invention provides hydrophobicity-enhanced heat-vulcanized silicone rubber and a preparation method thereof. The specific preparation method of the silicone rubber comprises steps as follows: divinyltetramethyldisiloxane is mixed with a mixed solution of concentrated hydrochloric acid, deionized water and ethanol, the mixture is mechanically stirred, ethyl orthosilicate is dropwise added, the mixture is subjected to hydrolytic condensation, methylbenzene is added for extraction and layering, methyl vinyl silicone resin is obtained, crosslinked polyethylene particles are added to the methyl vinyl silicone resin, the mixture is stirred uniformly and subjected to molding curing and vacuum heat treatment, and the polyethylene particle crosslinked methyl vinyl silicone resin is obtained; nano-montmorillonite, amorphous alumina and titanium dioxide are added to a polydimethylsiloxane prepolymer, the mixture is mixed and subjected to crosslinking and curing, and a reinforced material coated with organic silicone rubber is obtained; the polyethylene particle crosslinked methyl vinyl silicone resin, the reinforced material coated with organic silicone rubber, 2,4-dichlorobenzoyl peroxide, diphenyl silanediol and octamethylcyclotetrasiloxane are mixed uniformly, left to stand, subjected to open milling and secondary vulcanization, and the hydrophobicity-enhanced heat-vulcanized silicone rubber is obtained.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Caustic soda recycling device for chemical machinery

InactiveCN109173941AGuaranteed FusionJoin smoothlyAlkali metal hydroxidesChemical/physical processesChemical reactionRaw material

The invention discloses a caustic soda recycling device for chemical machinery. The caustic soda recycling device comprises a first tank body and a second tank body, wherein a feed pipe is arranged inside the first tank body; another feed pipe is fixed above the feed pipe; an auxiliary material pipe penetrates through the inner wall of the left side of the first tank body; a heating ring is arranged at the bottom of the interior of the first tank body, and a through pipe penetrates through the lower side of the right wall of the first tank body; a valve is arranged on the outer side of the through pipe; a partition plate is fixed on the inner wall of the second tank body; and the second tank body is positioned on the right side of the through pipe. According to the caustic soda recycling device for chemical machinery, due to the arrangement of the feed pipe, raw materials containing caustic soda can be smoothly added into the first tank body, and the materials are uniformly dispersed due to an inclined plate and a semicircular mesh arranged in the feed pipe, so that the materials are scattered; chemical reaction additives are introduced into the auxiliary material pipe and are usedfor reducing and purifying the caustic soda; and due to the arrangement of a first ring pipe, a second ring pipe and a third ring pipe, the addition range area of the additives is enlarged.

Owner:戴聪聪

Anti-seepage grouting material for prefabricated building and preparation method thereof

Owner:湖南加美乐素新材料股份有限公司

Non-stick coating layer and coating process thereof

InactiveCN111171682ASmall coefficient of static frictionLower coefficient of dynamic frictionPretreated surfacesSpecial surfacesPolymer sciencePapermaking

The invention discloses a non-stick coating layer, which is prepared from the following raw materials in parts by weight: 40 to 50 parts of epoxy acrylate, 25 to 32 parts of polyacrylic acid fluorine-containing ester, 25 to 32 parts of poly (vinylidene fluoride-trifluoroethylene), 10 to 15 parts of polytetrafluoroethylene powder, 2.5 to 4 parts of a suspension dispersing agent, 1 to 1.4 parts of aleveling agent and 1.5 to 2 parts of a curing agent. The non-stick coating layer has excellent lubricating performance and excellent non-stick performance, can completely meet the use requirements ofvarious processing molds (such as various plastic demolding, baking molds and papermaking and textile industries), contains no demolding agent (the production efficiency can be improved), and has excellent durability; in addition, no silicone oil is contained, and the product is prevented from being polluted; the adhesive force with a base material is large, the loading capacity is large, the impact resistance is good, the flexibility is good, the comprehensive performance is good, and the service life is long.

Owner:CHENGRUN (JIAXING) NEW MATERIAL TECH CO LTD

Formaldehyde-free super-thin glass fiber floor felt and preparation method thereof

InactiveCN103741540AEvenly dispersedDefoamers additionPaper/cardboardHydroxyethyl celluloseAcrylic acid

Owner:CHANGZHOU ZHONGXIN TIANMA FIBERGLASS PROD

Nanoscale activated calcium carbonate and processing method thereof

InactiveCN110358328AReduce surface polarityOleophilic and hydrophobicMaterial nanotechnologyPigment physical treatmentCalciteHigh velocity

The invention discloses nanoscale activated calcium carbonate. The nanoscale activated calcium carbonate comprises calcite, a dispersant and a coupling agent; a mass part ratio of the calcium carbonate to the dispersant in a grinding process is 100:(0.2-5); and a mass part ratio of the dried nanometer calcium carbonate to the coupling agent in a high-speed mixing and stirring process is 100:(0.5-8). The method reduces the surface polarity of the nanometer calcium carbonate, so the surface of the nanometer calcium carbonate has strong oleophilic and hydrophobic properties, the dispersion property is improved, the dispersibility of the nanometer calcium carbonate in the composite material and the compatibility of the nanometer calcium carbonate with an organic high polymer are improved, andthe nanoscale activated calcium carbonate is obtained. The invention also discloses a processing method of the nanoscale activated calcium carbonate. The processing method comprises the following steps: 1, raw material washing; 2, choosing; 3, coarse crushing; 4, intermediate crushing; 5, addition of the dispersant, and grinding; 6, ATP grading (fine powder + coarse powder); 7, addition of the coupling agent, and high-speed mixing and stirring; and 8, cooling and packaging. The processing method adopting dry process modification has the advantages of low production cost, and suitableness for large-scale industrial production.

Owner:LIANG DE NANO POWDER LNNOVATION & TECH (ANHUI) CO LTD

Special unsaturated polyester resin adhesive for quartz stone sheet material

InactiveCN106753148AImprove impact toughnessHigh bonding strengthNon-macromolecular adhesive additivesGas phasePhosphine oxide

The invention discloses a special unsaturated polyester resin adhesive for a quartz stone sheet material. The special unsaturated polyester resin adhesive is prepared from the following raw materials: unsaturated polyester resin, acrylic acid-2-hydroxyethyl ester, pentaerythritol triacrylate, 2-methyl-1-(4-methylthiophenyl)-2-morpholinyl-1-acetone, biphenyl-(2,4,6-trimethylbenzoyl)phosphine oxide, a flatting agent, a de-foaming agent, a silane coupling agent, gas-phase silicon dioxide, glass microsphere and modified aluminum hydroxide. The special unsaturated polyester resin adhesive for the quartz stone sheet material, provided by the invention, has high binding performance, good impacting toughness and excellent flame-retarding performance.

Owner:ANHUI AIDIBEI BIOLOGICAL CO LTD

Preparation method of low-density low-VOC scraping-resistant modified polypropylene composite material

The invention discloses a low-density low-VOC scraping-resistant modified polypropylene composite material and a preparation method thereof. The composite material consists of the following raw materials in parts by weight: 60-80 parts of polypropylene, 15.5-31 parts of a toughening-VOC adsorption compound additive, 1-2 parts of a scraping agent, 0.02-0.05 part of an antioxidant and 2-4 parts of pure water. The toughening-VOC adsorption compound additive consists of the following raw materials in parts by weight: 3-8 parts of ethylene-octene copolymer (POE), 1 part of a compatilizer, 1 part ofa coupling agent, 0.5-1 part of nano vermiculite and 10-20 parts of diatomite with micropores in the surface. The composite material has low density, low VOC and high scraping resistance, and is suitable for automotive trim.

Owner:QINGDAO DONG PLASTIC CO LTD

Xinjiang-style grease, and preparation method of micro-emulsion thereof

InactiveCN105853258AChange oil solubilityReduce the degree of oxidationCosmetic preparationsToilet preparationsSolubilityAntioxidant

The invention discloses a Xinjiang-style grease micro-emulsion and a preparation method thereof. The preparation method comprises the following steps: 1, shredding Xinjiang-style fruits; 2, squeezing the shredded fruits, and collecting squeezed crude oil and oil cakes; 3, filtering the crude oil obtained in step 2 to obtain clarified Xinjiang-style grease; and 4, uniformly stirring the Xinjiang-style grease, lecithin, tween65, ethylene glycol distearate, sodium N-lauroylsarcosinate, dodecyl glycoside, lauroyl diethanolamine, sodium dioctylsulfosuccinate, isooctyl palmitate, an antioxidant, glycerin and water to prepare the Xinjiang-style grease micro-emulsion. The above system changes the oil solubility of Xinjiang-style grease, increases the solubility, and reduces the oxidation degree and instability of the Xinjiang-style grease; and compared with traditional emulsions, the stable micro-emulsion prepared in the invention has the advantages of small particle size, uniform dispersion, high stability and convenient storage.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

Impact-resistant conductive polyphenylene sulfide material and preparation method thereof

The invention belongs to the technical field of high polymer materials, and relates to an impact-resistant conductive polyphenylene sulfide material and a preparation method thereof. The impact resistant conductive polyphenylene sulfide material is prepared from the following components in parts by weight: 60-75 parts of PPS, 0.5-1 part of a lubricant, 0.5-0.8 part of epoxy resin, 8-15 parts of a toughening agent, 17-25 parts of carbon black and 0.5-2 parts of a coupling agent. The impact-resistant conductive polyphenylene sulfide material is prepared by using a high-speed pre-mixing dispersion one-step extrusion process. The impact-resistant conductive polyphenylene sulfide material provided by the invention has the characteristics of being good in mechanical property, good in flame retardancy, good in stability, easy to process, good in impact resistance and the like, and is applicable to packages of precise and advanced products of the electronic industry, the war industry and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Glipizide orally disintegrating tablet and preparation method thereof

InactiveCN107412175AEvenly dispersedReduce usageMetabolism disorderSulfonylurea active ingredientsFiller ExcipientIrritation

The invention discloses a glipizide orally disintegrating tablet and a preparation method of the glipizide orally disintegrating tablet. The orally disintegrating tablet comprises glipizide and pharmaceutically acceptable auxiliary materials with effective doses, wherein the pharmaceutically acceptable auxiliary materials comprise a filling agent, a flavoring agent, a disintegrating agent, a lubricant and an adhesive; the filling agent is composed of mannitol and microcrystalline cellulose; the flavoring agent is mannitol; the disintegrating agent is a composition of crospovidone, low-substituted hydroxypropyl cellulose and sodium carboxymethyl starch, and the weight ratio of the crospovidone to the low-substituted hydroxypropyl cellulose to the sodium carboxymethyl starch is (5-20): (5-30): (2-10); the lubricant is magnesium stearate; the adhesive is purified water. The product can rapidly disintegrate in the oral cavity, and is good in taste, easy to swallow, and free of irritation to the oral mucosa. The glipizide orally disintegrating tablet prepared by adopting the preparation method disclosed by the invention is uniform, meanwhile, the production cost is low, and thus large-scale production can be realized.

Owner:CHONGQING CONQUER PHARML

High-temperature-resistant special water-retaining admixture for concrete as well as preparation process and application of admixture

ActiveCN109867486AImprove water retentionGood and lasting water-locking effectCarboxylic acidTartrate

The invention discloses a high-temperature-resistant special water-retaining admixture for concrete as well as a preparation process and application of the admixture. The admixture comprises the following components: 1-5 parts of a sustained-release polycarboxylic acid, 5-20 parts of a comprehensive polycarboxylic acid, 1-10 parts of a retarder, 0.1-2 parts of a biomass glue, 0.1-5 parts of an airentraining agent, 0.1-5 parts of a defoaming agent, and 63.8-92.97 parts of water, wherein the sustained-release polycarboxylic acid is composed of isopentenyl polyoxyethylene ether, water, acrylic acid, hydroxyethyl acrylate, sodium methallyl sulfonate and ammonium persulfate, and the comprehensive polycarboxylic acid is composed of isobutylene polyoxyethylene ether, water, acrylic acid, tartrate acrylate, ascorbic acid and mercaptopropionic acid. The water-retaining admixture provided by the invention has a better water-retaining effect, and the preparation process provided by the inventionmakes the obtained admixture less prone to overpolymerization; and according to the application of the water-retaining admixture, the concrete can maintain a better water lock effect for a long timein a high-temperature environment in summer, so that the phenomenon of blocking of a pumping pipe when the concrete is pumped is not easy to cause.

Owner:HANGZHOU JIANSHE NEW MATERIALS CO LTD

Water-based erucyl amide emulsion and preparation method thereof

Owner:郑州市仲达新材料科技有限公司

Passion fruit milk and preparation method thereof

InactiveCN105994640AAvoid layeringAvoid the bad effects of layeringMilk preparationFood additivePassion fruit

The invention discloses passion fruit milk and a preparation method thereof. The passion fruit milk is prepared from, by weight, 10 parts of passion fruit endothelium, 10-50 parts of passion fruit juice, 5-15 parts of milk powder or 10-100 parts of milk, 0.01-15 parts of a sweetening agent and 0-1 part of other food additives. The preparation method includes: treating raw materials, preparing juice, preparing peel pulp, mixing, homogenizing, regulating pH, mixing with milk, blending, heating sol and sterilizing to obtain the passion fruit milk. By optimization of proportional relation of the juice, peel pulp and water, regulation of acidity, optimization of a proportion of pulp to milk and addition of appropriate amount of the sweetening agent, the passion fruit endothelium and the juice are adopted as raw materials for preparing the passion fruit milk which is special in aroma, sweet and sour to taste and rich in nutrition.

Owner:谭强

A system for detecting the adsorption capacity of a molecular sieve under high-pressure conditions and a detecting method thereof

ActiveCN107340214AFlexible detectionEvenly dispersedPermeability/surface area analysisMolecular sieveLiquid storage tank

The invention relates to a system for detecting the adsorption capacity of a molecular sieve under high-pressure conditions and a detecting method thereof. The system includes an impurity injecting unit, a molecular sieve adsorption tank and a detection instrument which are communicated with an outlet of a high-pressure liquid storage tank in order, and the high-pressure liquid storage tank. The inlet of the high-pressure liquid storage tank is communicated with an external high-pressure medium conveying pipeline. A first flux control valve and a second flux control valve are respectively disposed between the high-pressure liquid storage tank and the impurity injecting unit as well as between the impurity injecting unit and the molecular sieve adsorption tank. A pressure reducing valve is disposed between the molecular sieve adsorption tank and the detection instrument. The molecular sieve adsorption tank is connected to an external vacuum pump. The impurity injecting unit includes at least one impurity tank. Compared with the prior art, the adsorption capacity of a molecular sieve material for different impurities under high-pressure conditions can be tested by the system and the method, adsorption temperatures, impurity species and impurity concentrations can be easily adjusted in the testing method, and tests on the co-adsorption capacity of a plurality of impurities can be achieved.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

Method for dyeing yellow tipping base paper

InactiveCN101967773AHigh affinityEvenly dispersedInorganic compound additionPulp material addition processesCalcium carbonateSizing

Owner:潍坊华港包装材料有限公司

Antibacterial plastic material and preparation method thereof

Owner:南京禾宇化工有限公司

Graphene/fluorine-silicon self-crosslinking resin composite heavy-duty anti-corrosion finish paint and preparation method thereof

PendingCN110642970AAvoid the disadvantages of easy reunionEvenly dispersedAnti-corrosive paintsEthyleneglycol monobutyl etherIn situ polymerization

The invention relates to graphene / fluorine-silicon self-crosslinking resin composite heavy-duty anti-corrosion finish paint and preparation thereof. The finish paint is prepared from the following rawmaterials in parts by weight through in-situ polymerization: 30 to 40 parts of hydroxyethyl allyl ether, 50 to 60 parts of vinyl acetate, 25 to 35 parts of undecylenic acid, 10 to 20 parts of ethylene glycol monobutyl ether, 8 to 10 parts of vinyl siloxane, 50 to 60 parts of chlorotrifluoroethylene CTFE, 4 to 20 parts of graphene oxide, 125 to 150 parts of a solvent and 5 to 6 parts of an initiator. A graphene fluorine-silicon self-crosslinking resin composite is prepared by performing in-situ polymerization on a part of free double bonds of graphene oxide and an olefin monomer, namely, dispersing graphene in a polymer monomer for monomer-monomer polymerization and monomer-graphene-monomer polymerization. The preparation process is simple; the graphene oxide is uniformly dispersed in theresin and is firmly combined with the resin; and the defect that the graphene is easy to agglomerate is avoided. After the finish paint is cured, interface strength is improved, so the corrosion resistance of the graphene paint is improved.

Owner:CP NANOMATERIALS RES CENT (DALIAN) CO LTD

Soft magnet core material with high saturation magnetic flux transmission performance

InactiveCN105761863AEvenly dispersedImprove performanceInorganic material magnetismTransformers/inductances detailsIonMagnetic core

The invention discloses a soft magnet core material with high saturation magnetic flux transmission performance. The soft magnet core material is prepared from the following raw materials in parts by weight: 25-26 parts of nickel oxide, 58-62 parts of ferric oxide, 21-23 parts of zinc oxide, 6-8 parts of silicon dioxide, 0.3-0.5 part of propolis, 0.2-0.3 part of diphenyl silanediol, 0.8-1.1 parts of guanidine carbonate, 0.2-0.4 part of propylene glycol alginate, 0.7-0.9 part of stearic acid, 2.6-3 parts of a silane coupling agent kh550, 0.7-0.9 part of barium titanate, 2.6-3 parts of polyamide resin, 2-2.6 parts of sodium silicate, 1-1.4 parts of silica sol, 1-1.3 parts of polyvinyl alcohol, 0.5-0.6 part of nano dysprosium, 1.3-2 parts of magnetic carbon powder, 1.1-2 parts of nano lanthanum oxide and a proper amount of deionized water. The prepared core material is excellent in transmission performance, simple in production process, high in production efficiency and high in mechanical strength, and is more suitable for durably working in a high-temperature environment.

Owner:TIANCHANG TIANHAO REFRIGERATION EQUIP FACTORY

Developing device and image forming apparatus including the same

A developing device to be installed in an electrophotographic image forming apparatus including a photoconductor drum that is to have an electrostatic latent image formed on a surface thereof, the developing device comprising: a developer vessel that accommodates a developer containing a toner and a carrier; a toner supply port; a developing roller; a developer conveying passage that is disposed between a position in the developer vessel where the toner is supplied and the developing roller; a developer conveying helical member that is rotatably disposed in the developer conveying passage to convey the developer in the developer conveying passage to the developing roller while agitating the developer; and an agitating blade member that is rotatably disposed above, near and along the developer conveying helical member in the developer conveying passage to agitate the developer on the developer conveying helical member.

Owner:SHARP KK

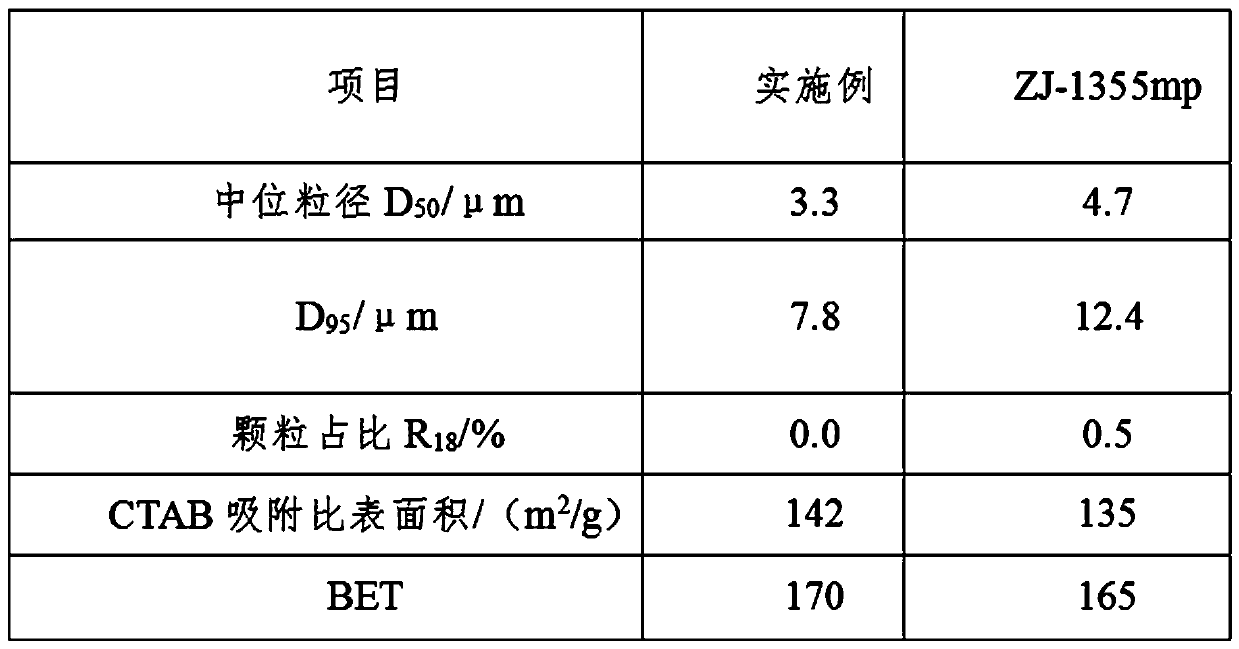

Preparation method of high-dispersion silicon dioxide

Owner:福建省三明正元化工有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap