Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about "Special surfaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

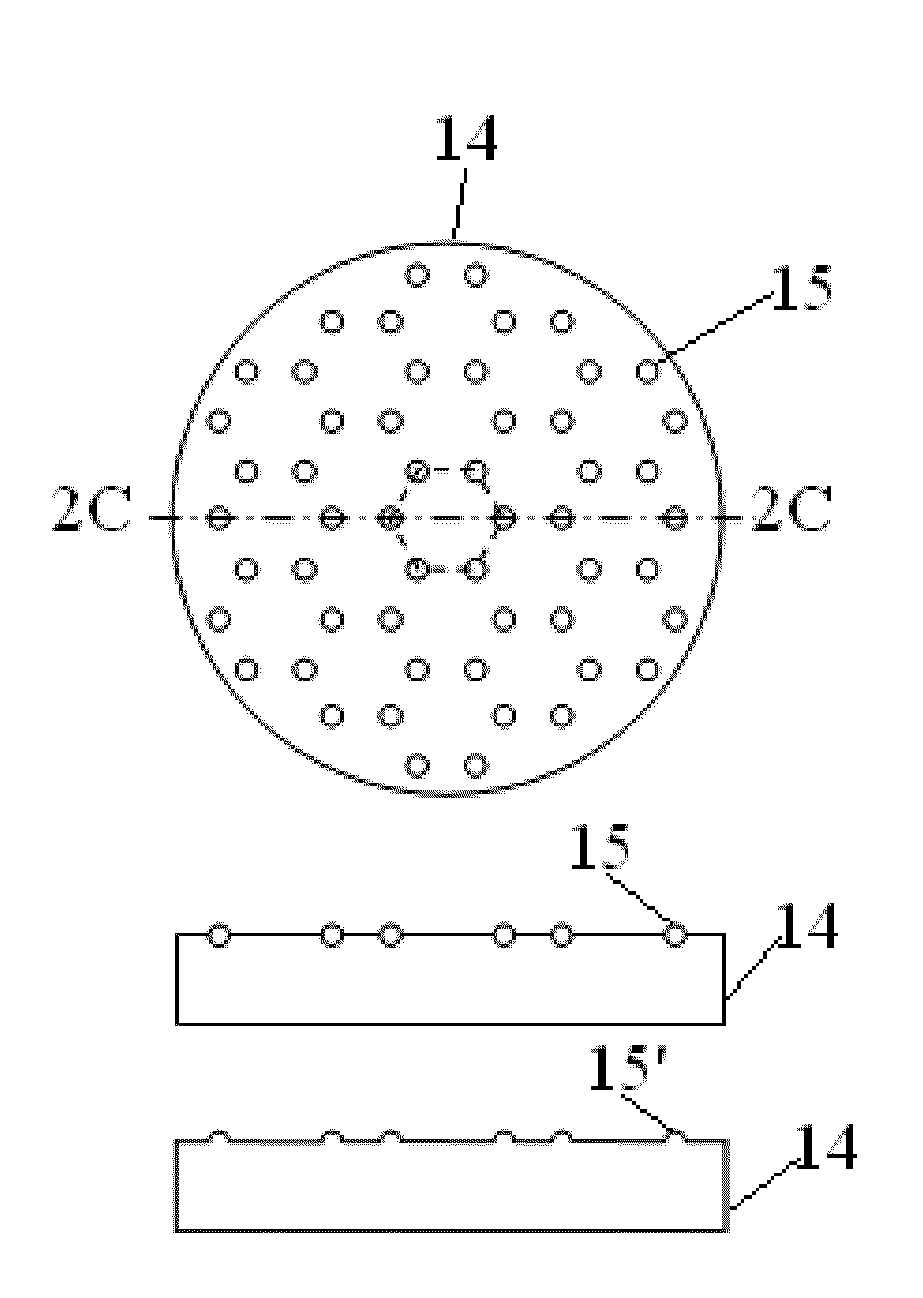

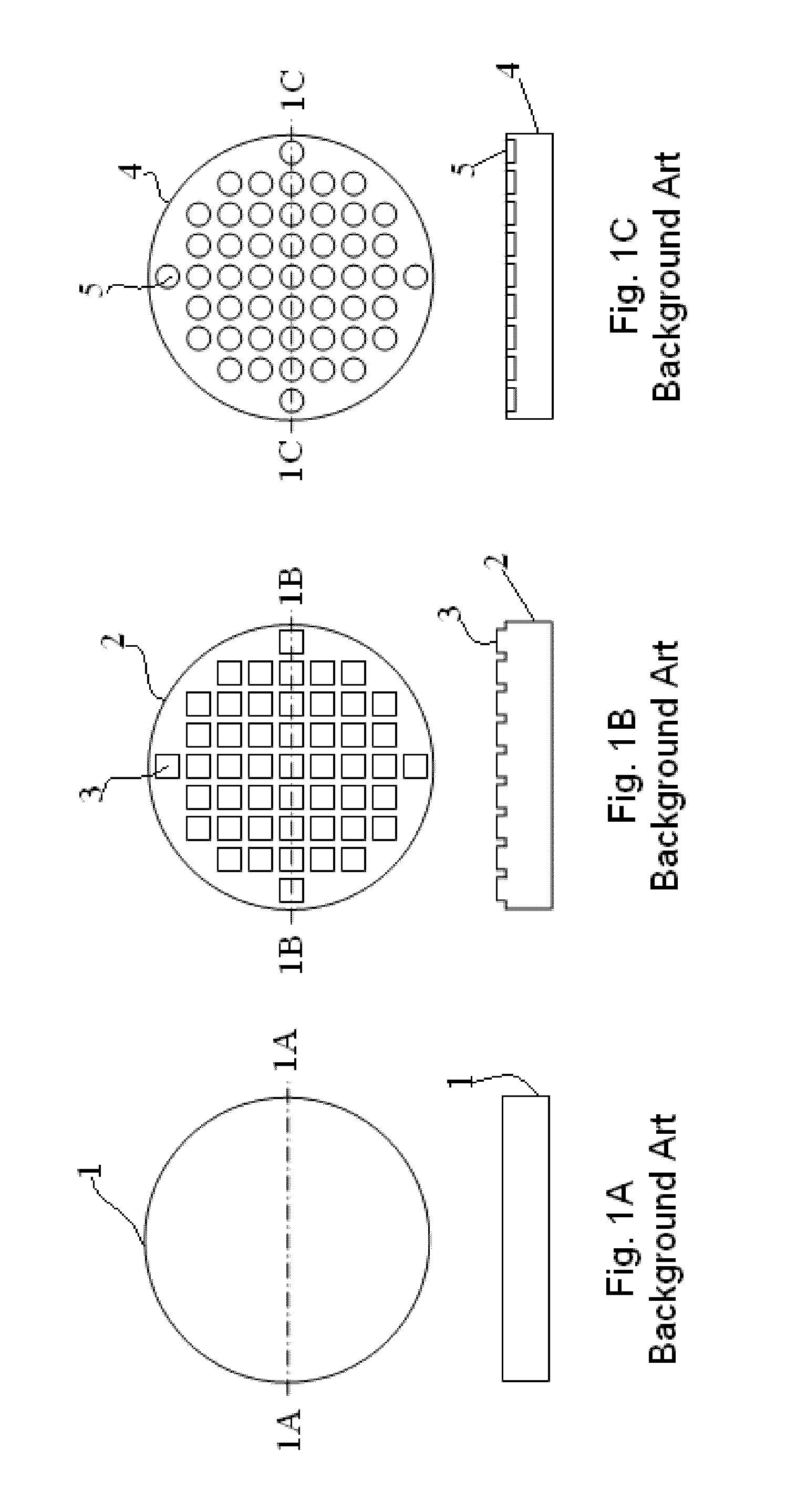

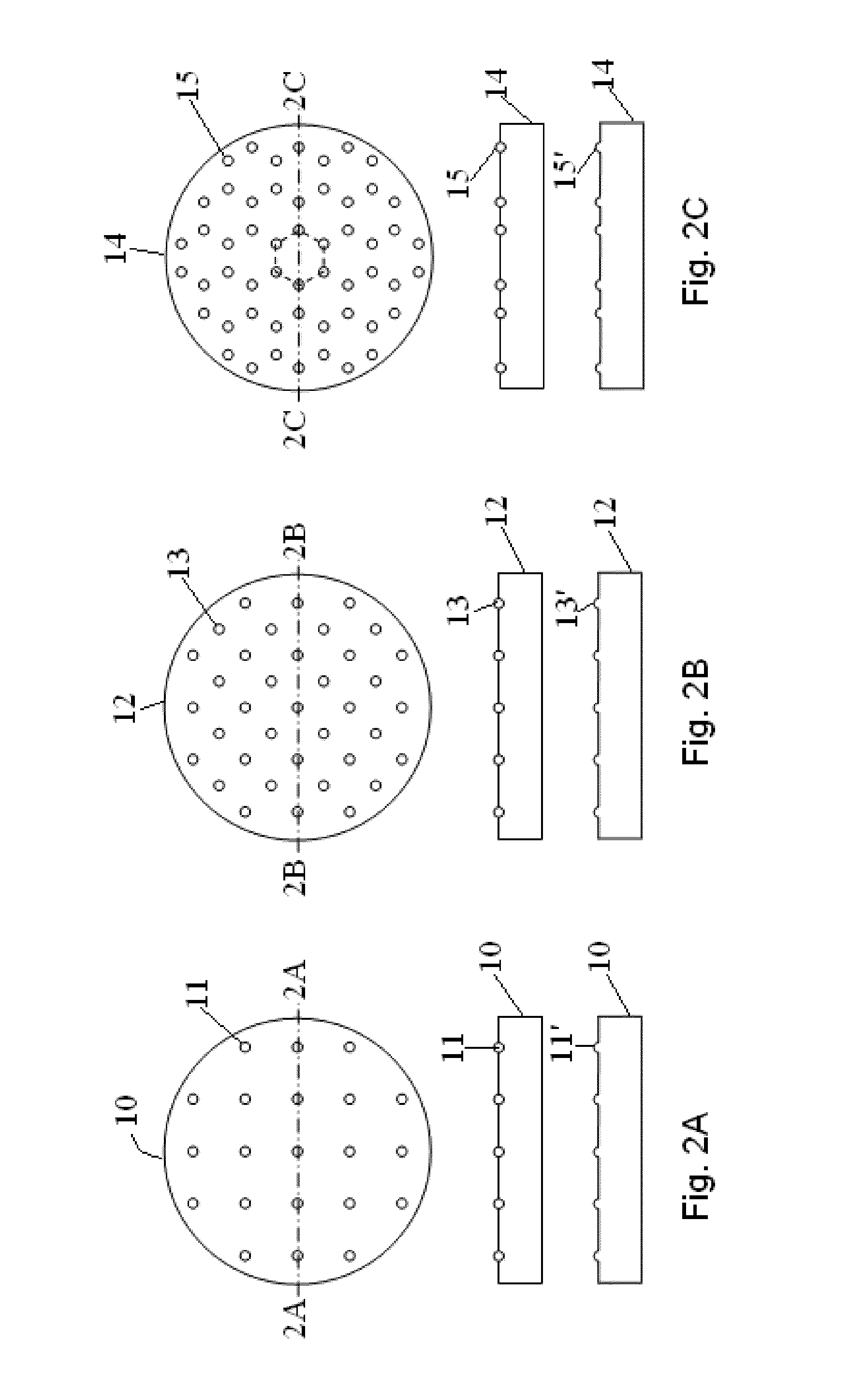

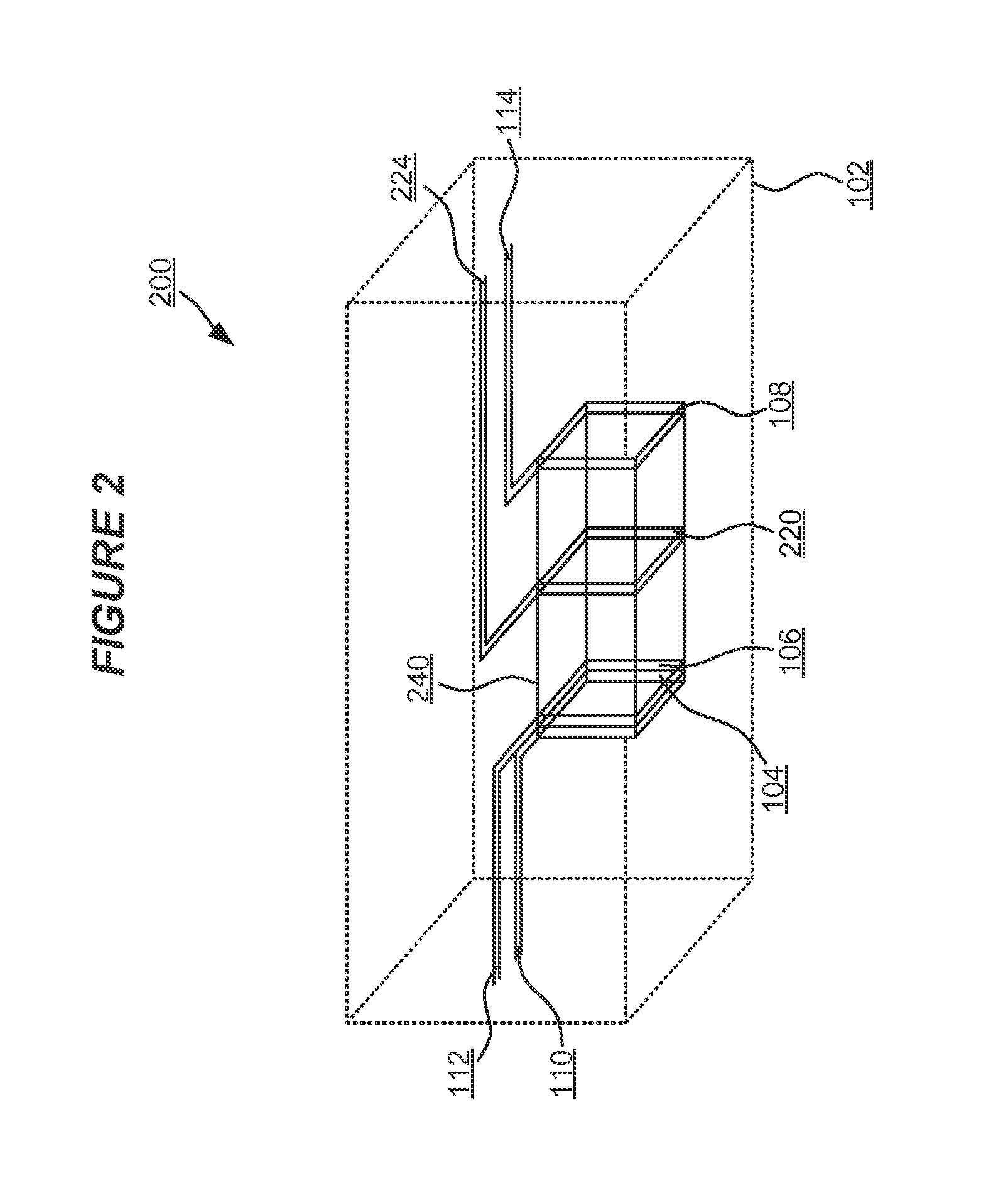

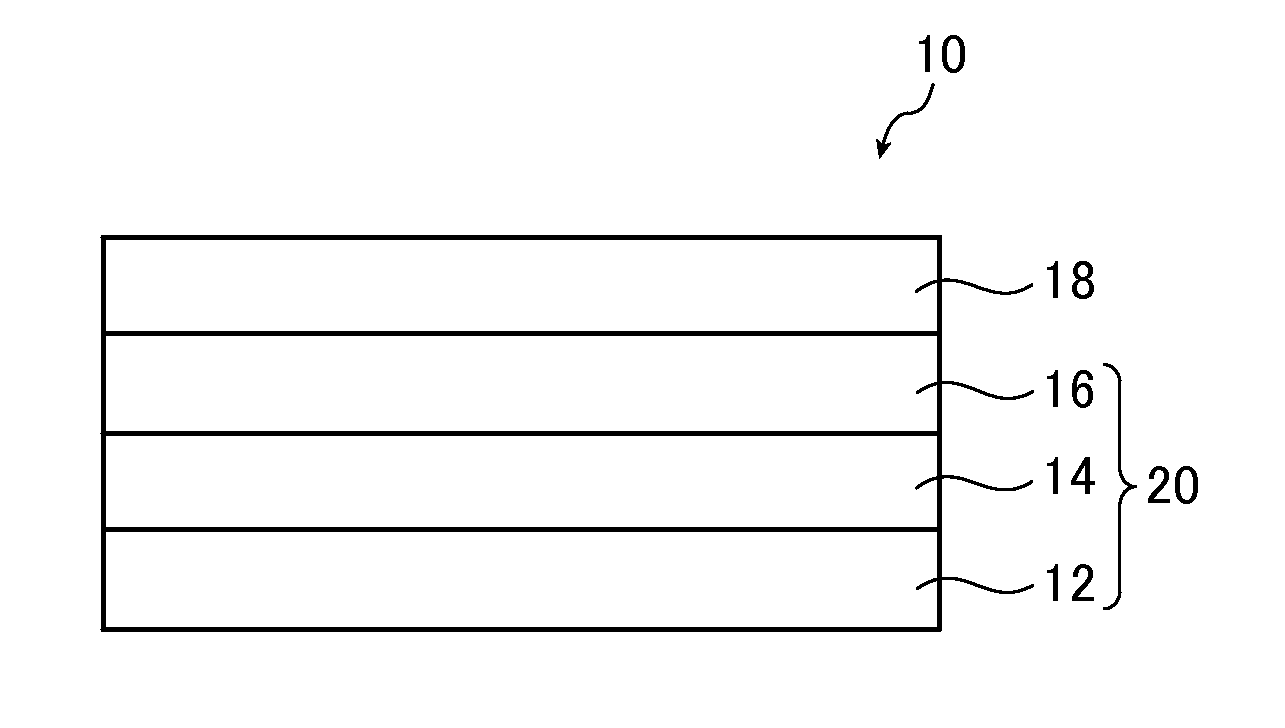

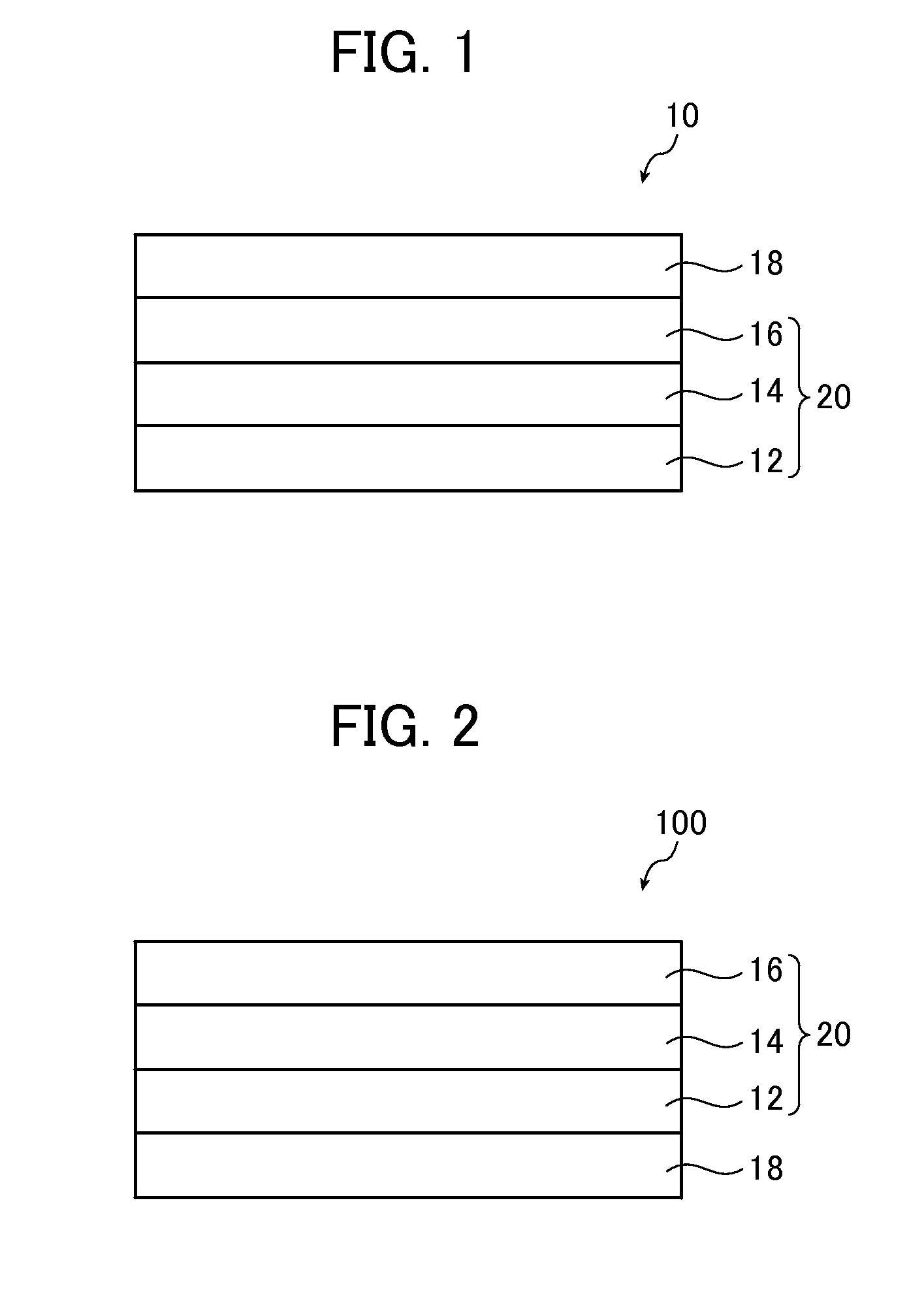

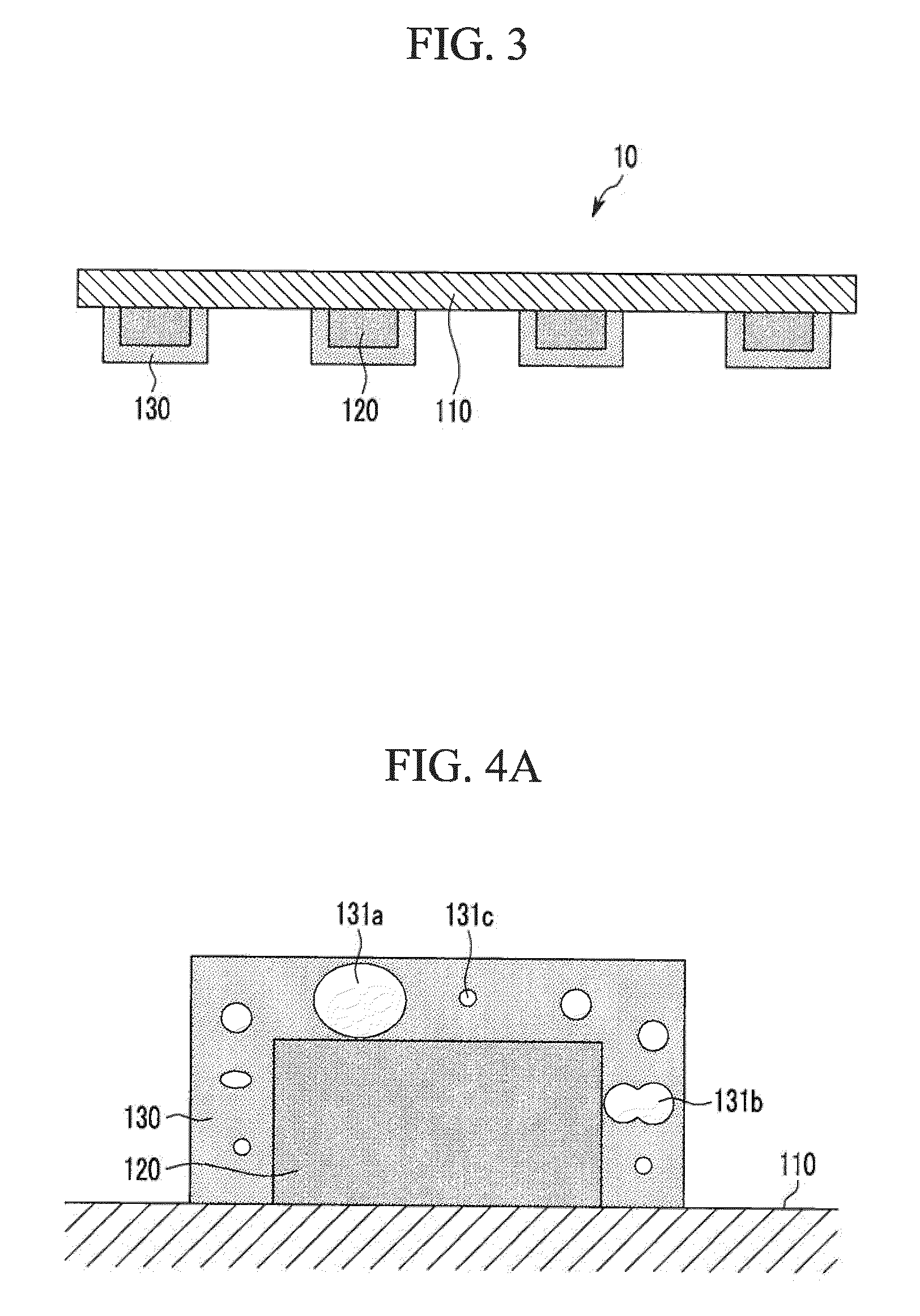

Wafer-Supporting Device and Method for Producing Same

ActiveUS20130014896A1Semiconductor/solid-state device manufacturingSpecial surfacesEngineeringSemiconductor

Owner:ASM JAPAN

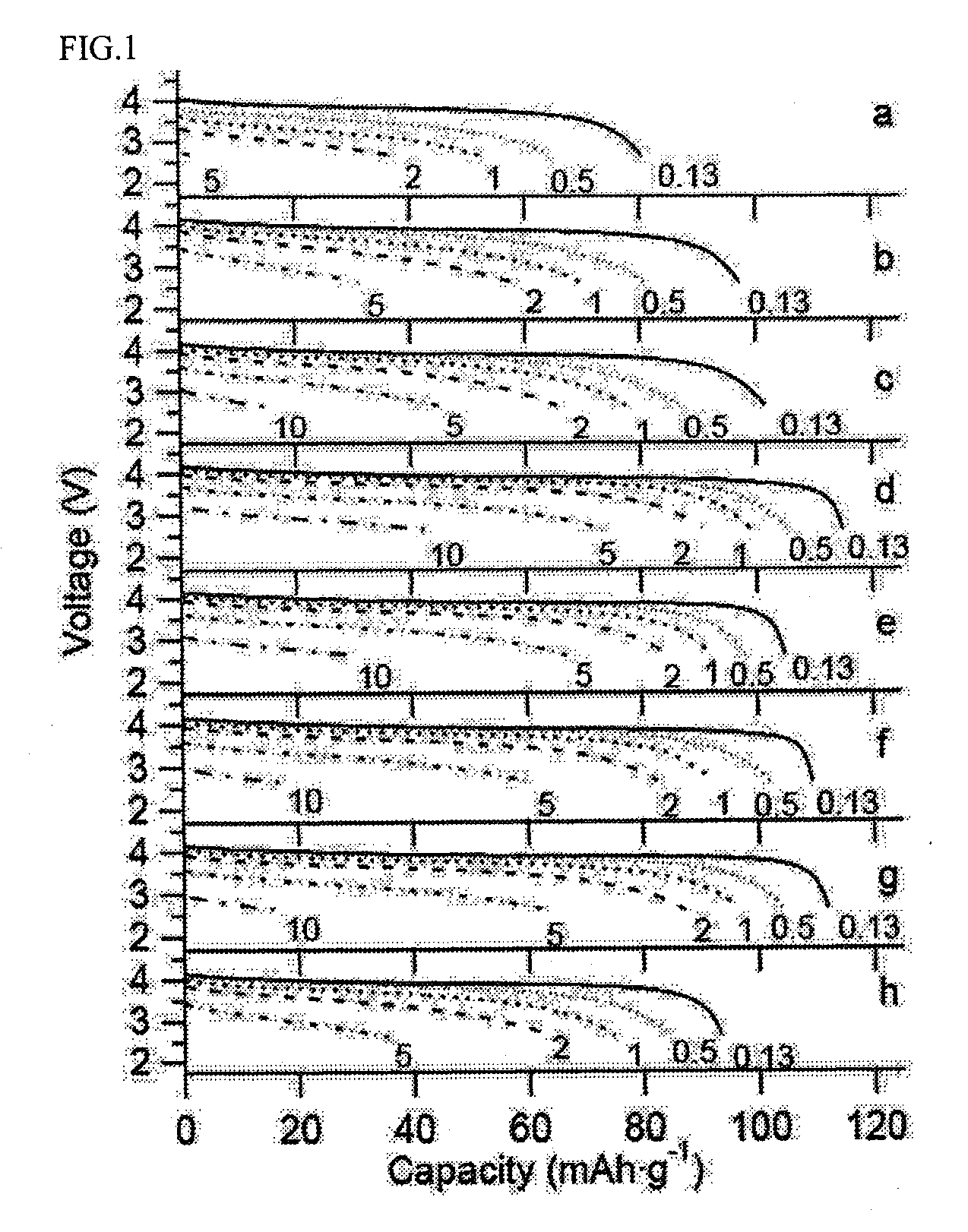

All-solid lithium battery

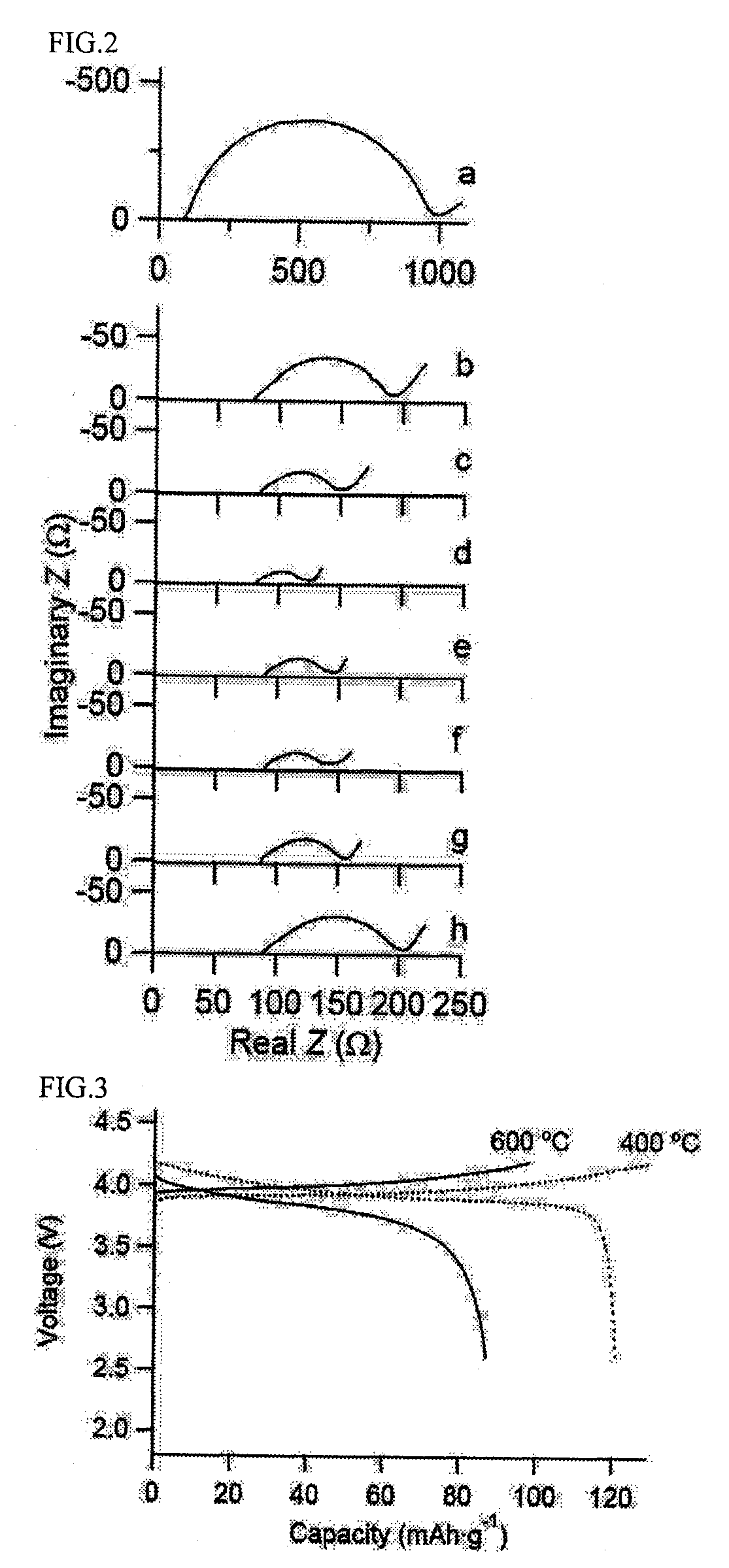

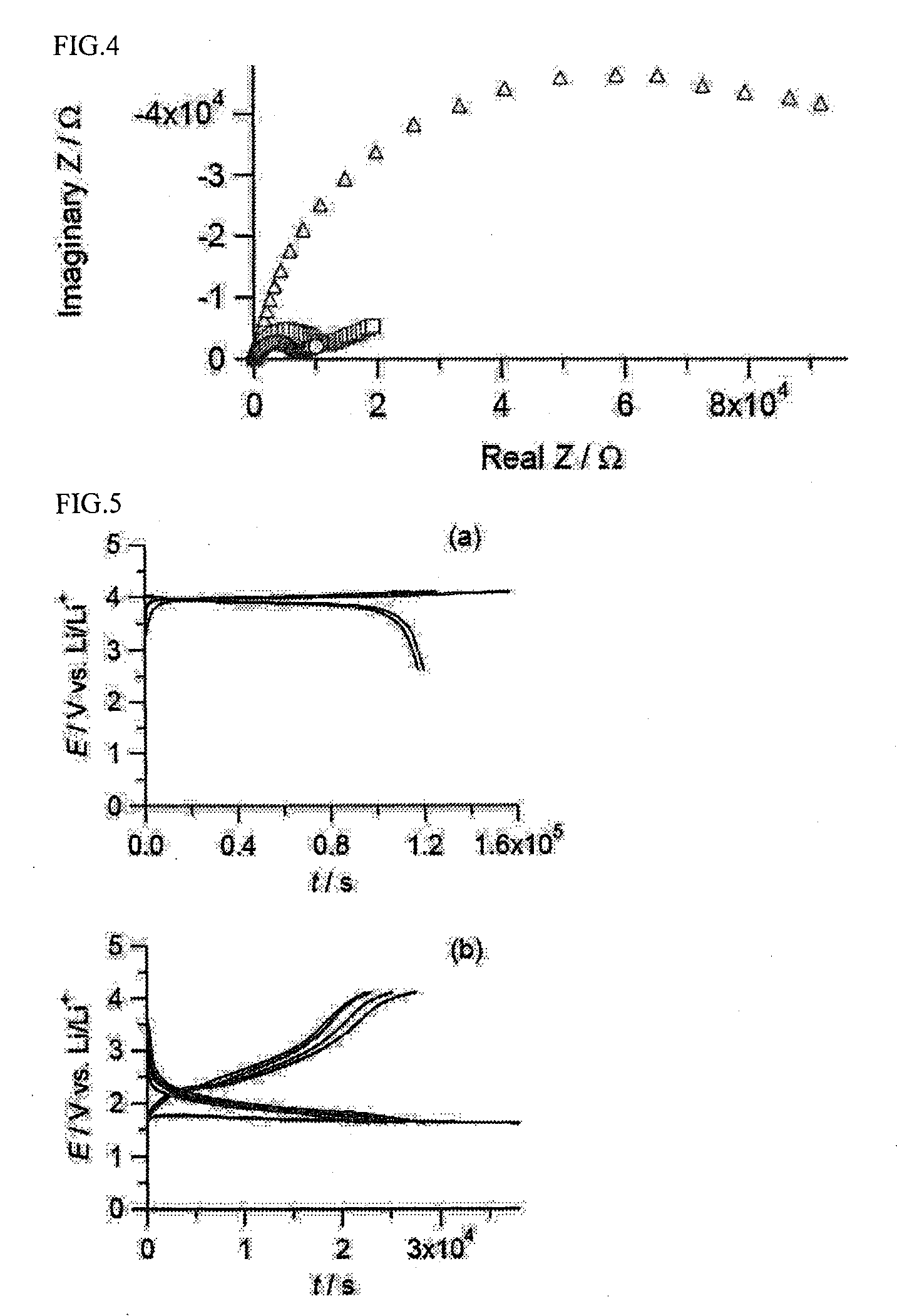

ActiveUS20090081554A1Improve output performanceLayer formationSolid electrolytesElectrode carriers/collectorsRedoxSulfide

Owner:NAT INST FOR MATERIALS SCI

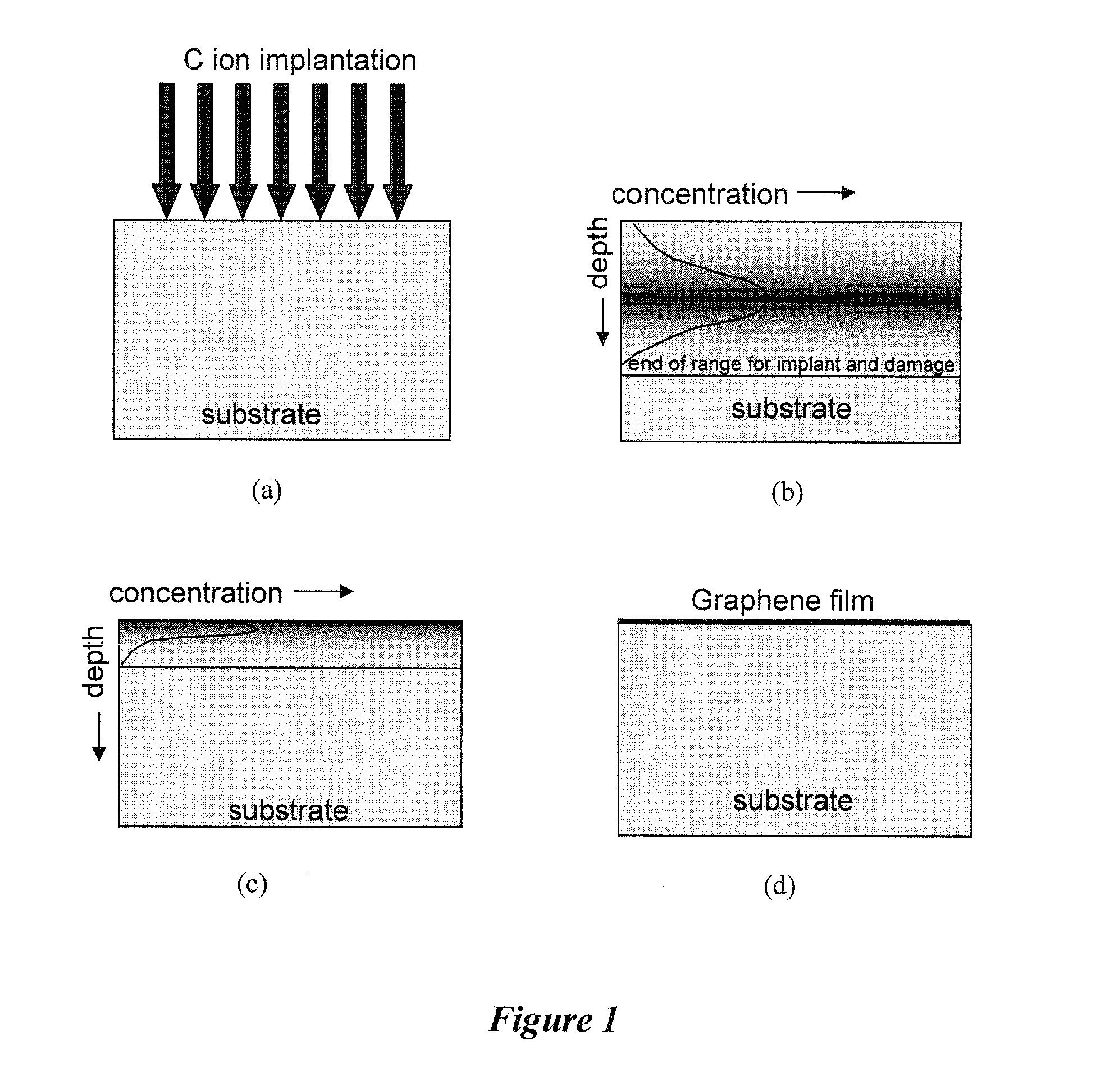

Graphene processing for device and sensor applications

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Media providing non-contacting formation of high contrast marks and method of using same, composition for forming a laser-markable coating, a laser-markable material and process of forming a marking

InactiveUS20070098900A1Semiconductor/solid-state device manufacturingSpecial surfacesHigh contrastLaser exposure

Owner:FUJIFILM CORP

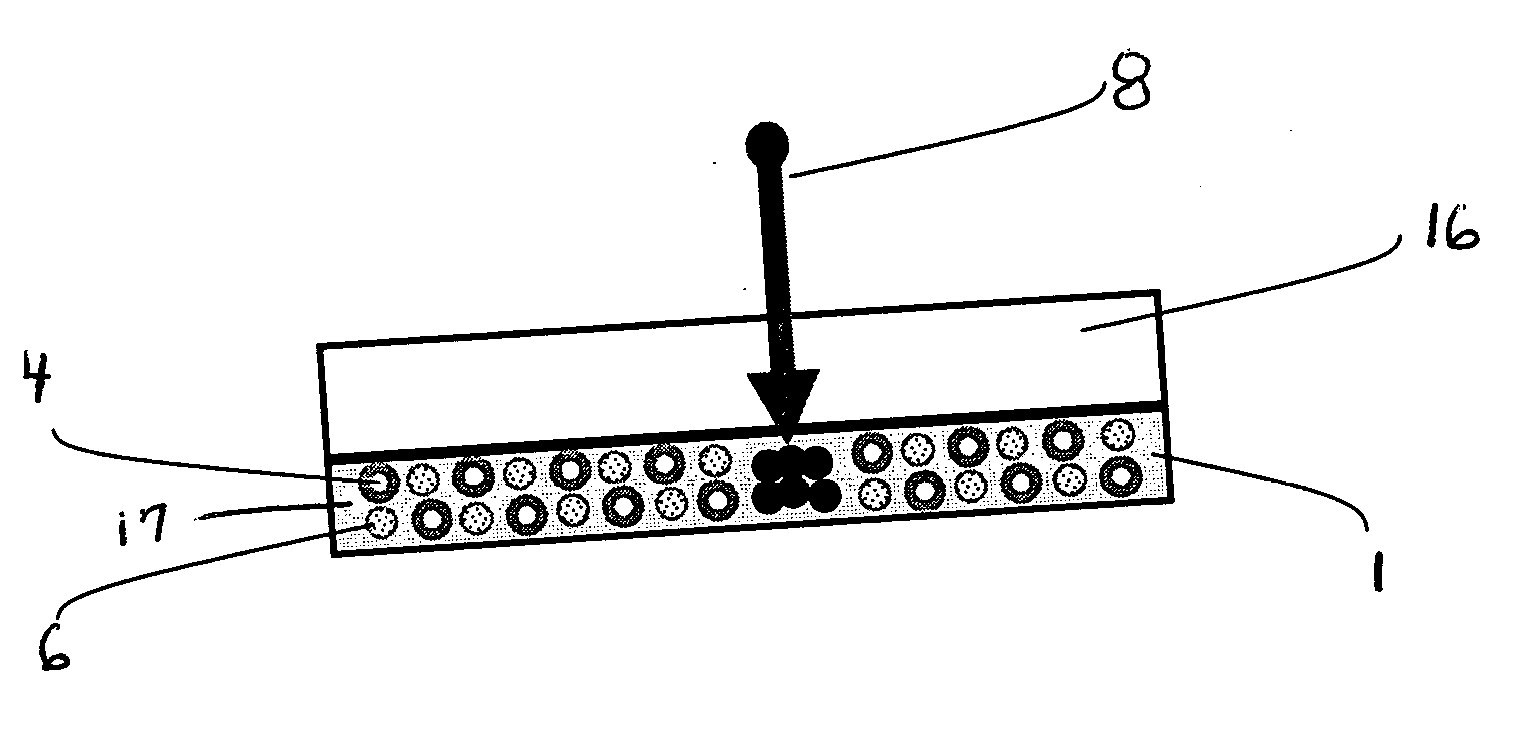

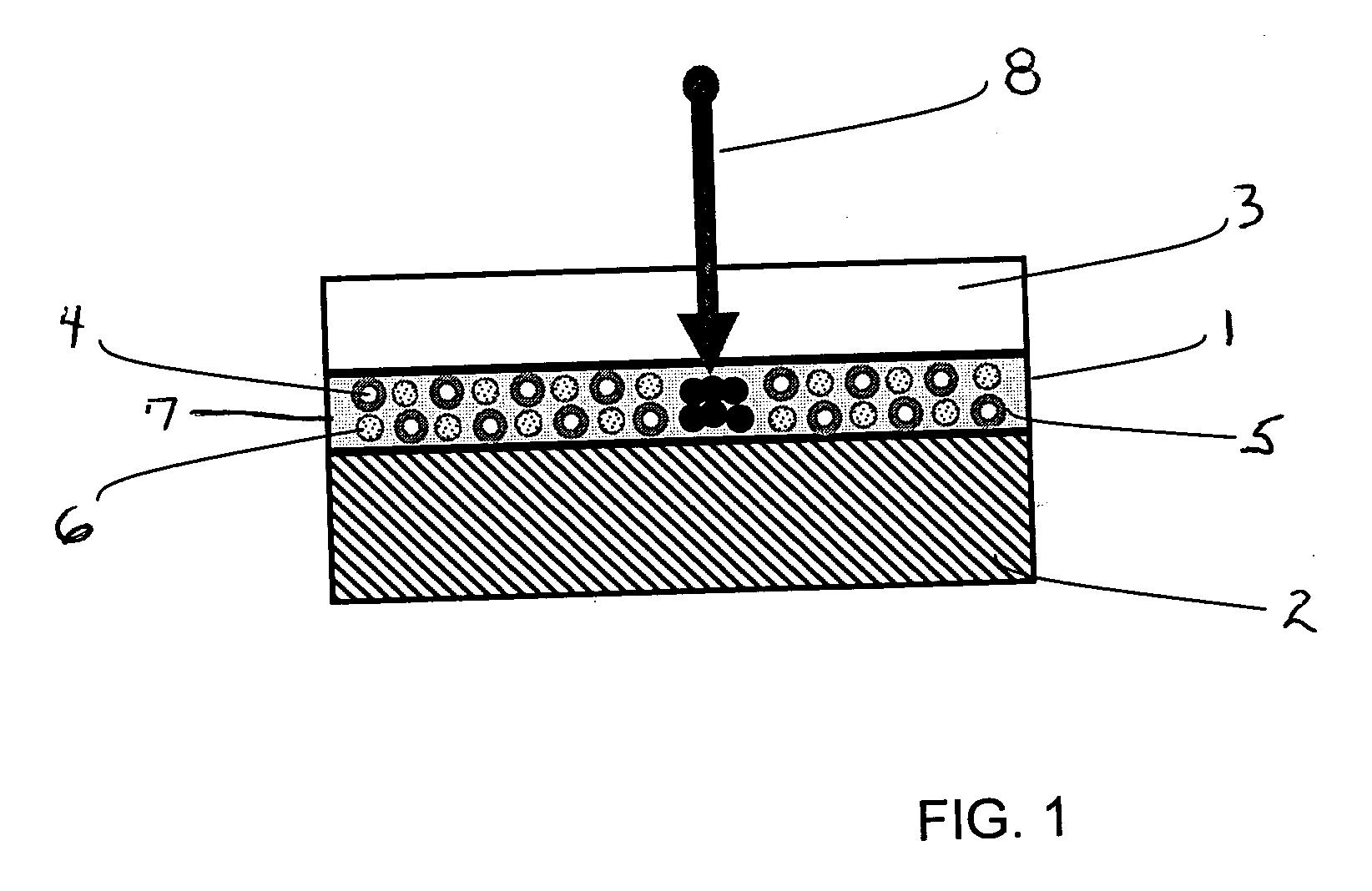

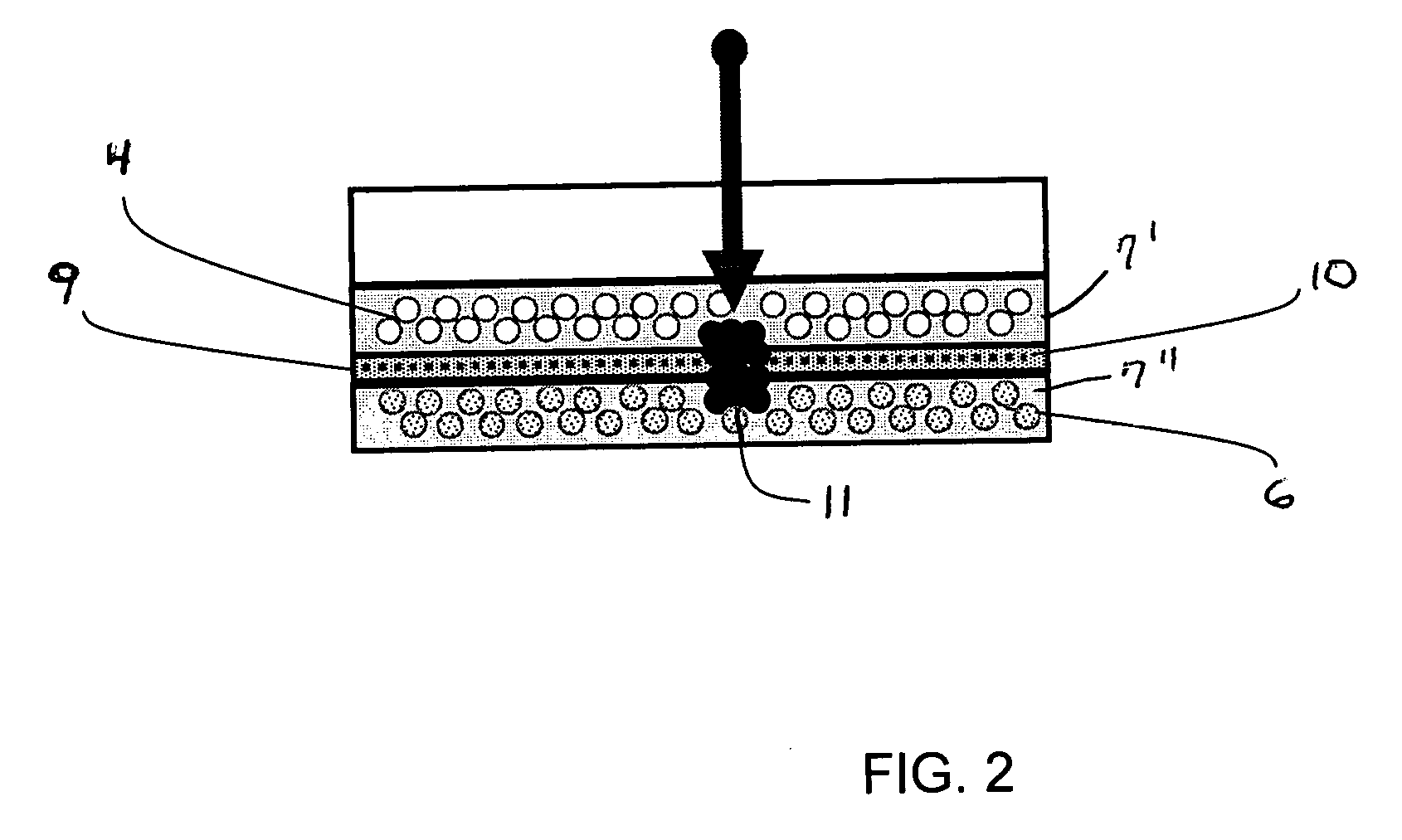

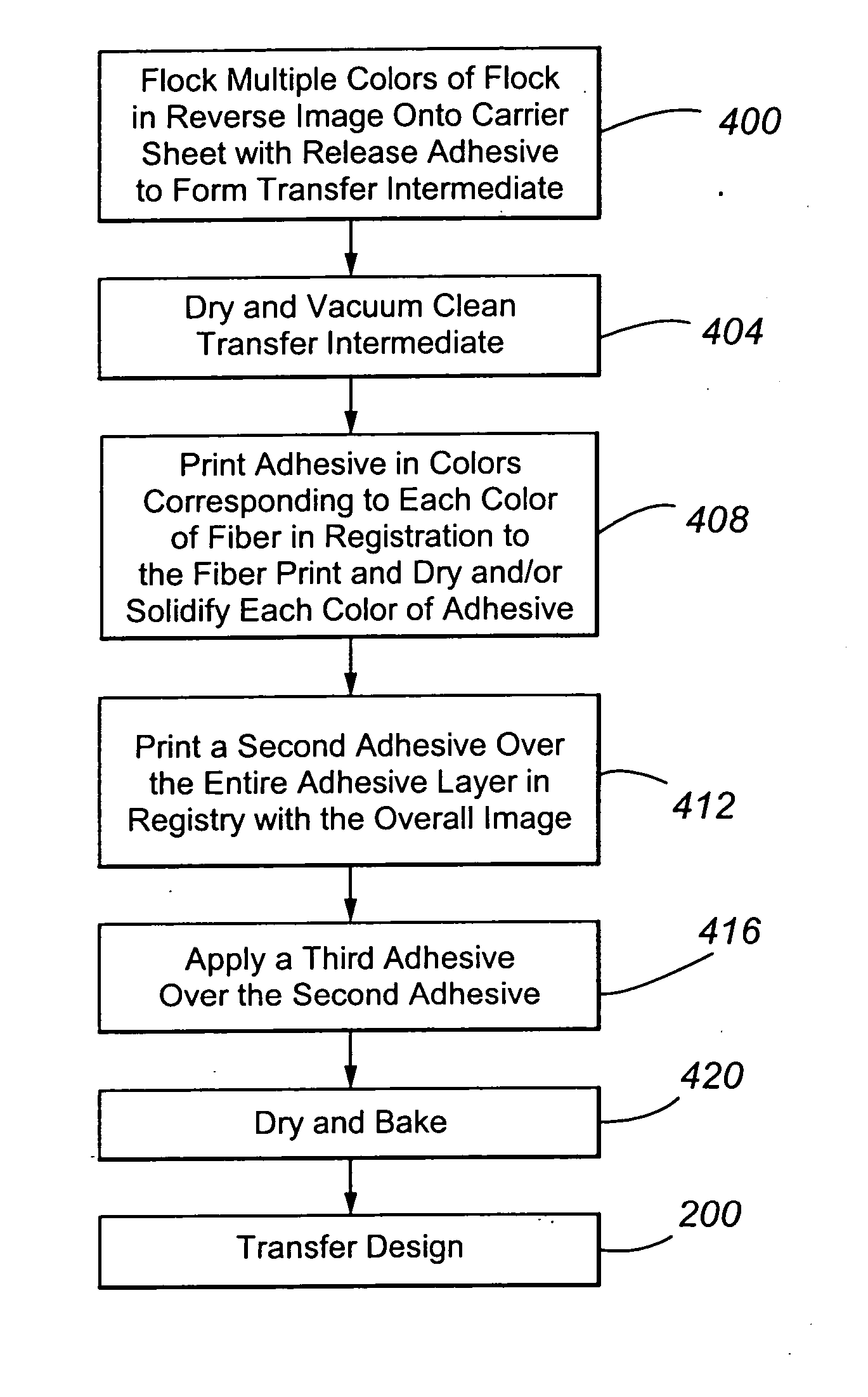

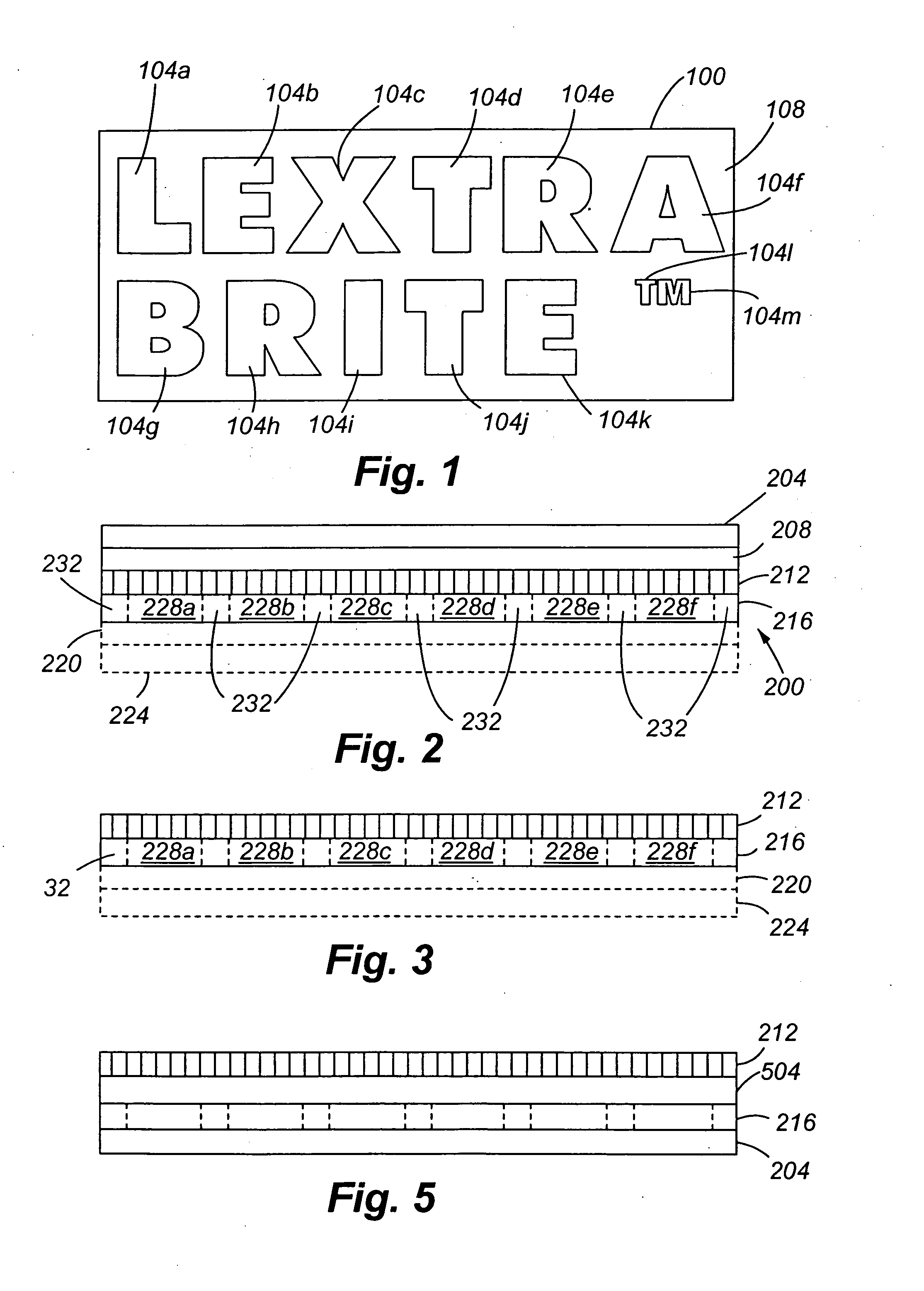

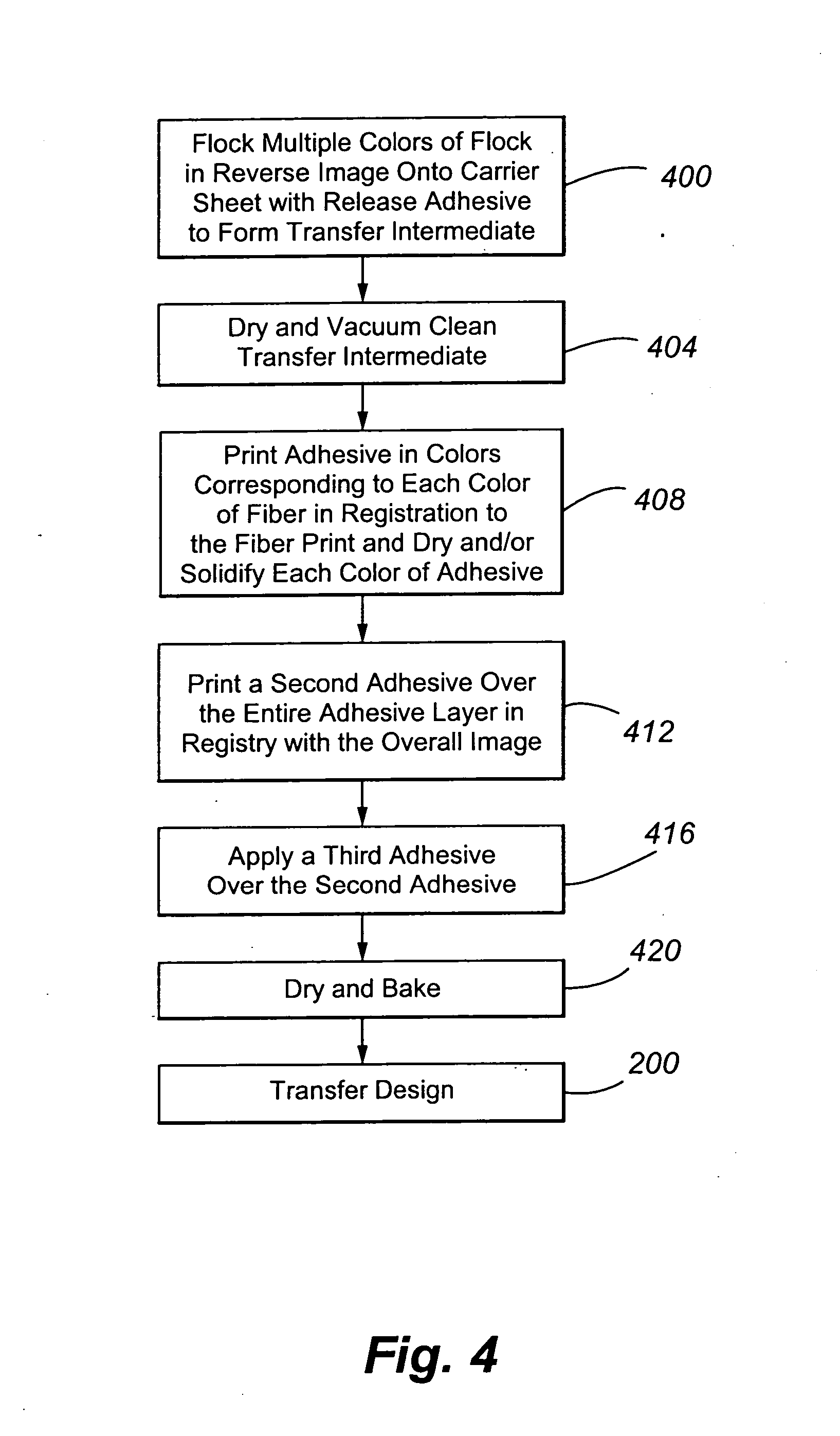

Flocked multi-colored adhesive article with bright lustered flock and methods for making the same

InactiveUS20060251852A1Reduce shadowing effectFlock densityLayered productsOrnamental structuresFiberEngineering

Owner:HIGH VOLTAGE GRAPHICS

Printed active device

ActiveUS20150270089A1Reduce manufacturing costLow costAdditive manufacturing apparatusControl electrodesElement spaceElectrical connection

Owner:BRITISH TELECOMM PLC

Apparatus and method for plasma treating and dispensing an adhesive/sealant onto a part

InactiveUS20060172081A1Minimal timeLow costMovable spraying apparatusPretreated surfacesAdhesiveSealant

Owner:NORDSON CORP

Solid Electrolytic Capacitor Containing a Poly(3,4-Ethylenedioxythiophene) Quaternary Onium Salt

ActiveUS20120147529A1Highly solubleEasily and cost-effectively formedMaterial nanotechnologyHybrid capacitor electrolytesDielectricElectrolysis

A solid electrolytic capacitor a solid electrolytic capacitor that includes an anode body, a dielectric overlying the anode body, and a solid electrolyte overlying the dielectric is provided. The capacitor also comprises a conductive polymer coating that overlies the solid electrolyte and includes nanoparticles formed from a poly(3,4-ethylenedioxythiophene) quaternary onium salt.

Owner:CENT FOR ORGANIC CHEM +1

Activatable Adhesive, Labels, and Related Methods

InactiveUS20120216951A1Improve securityEasy to operateStampsNon-macromolecular adhesive additivesAdhesivePlasticizer

Owner:AVERY DENNISON CORP

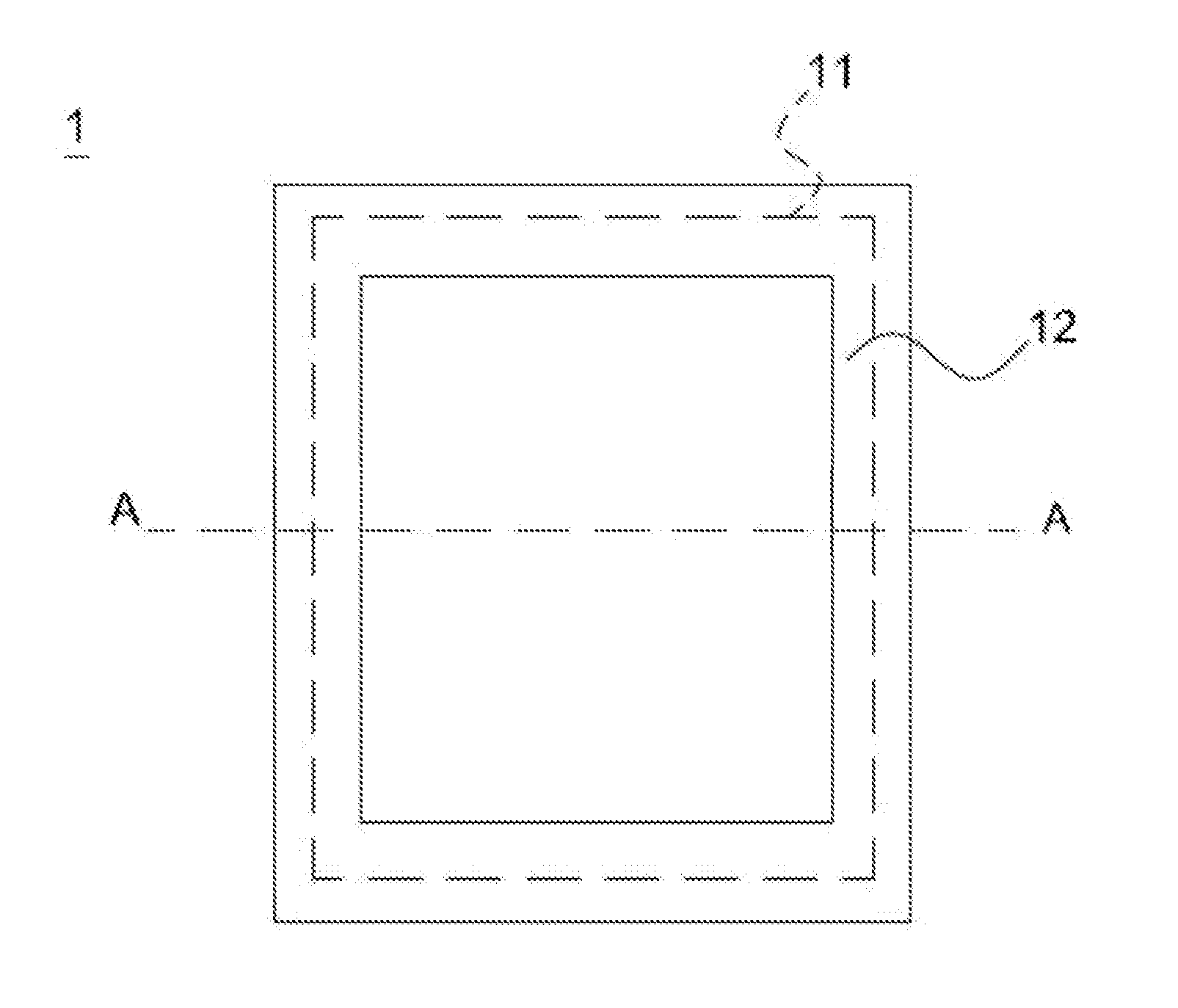

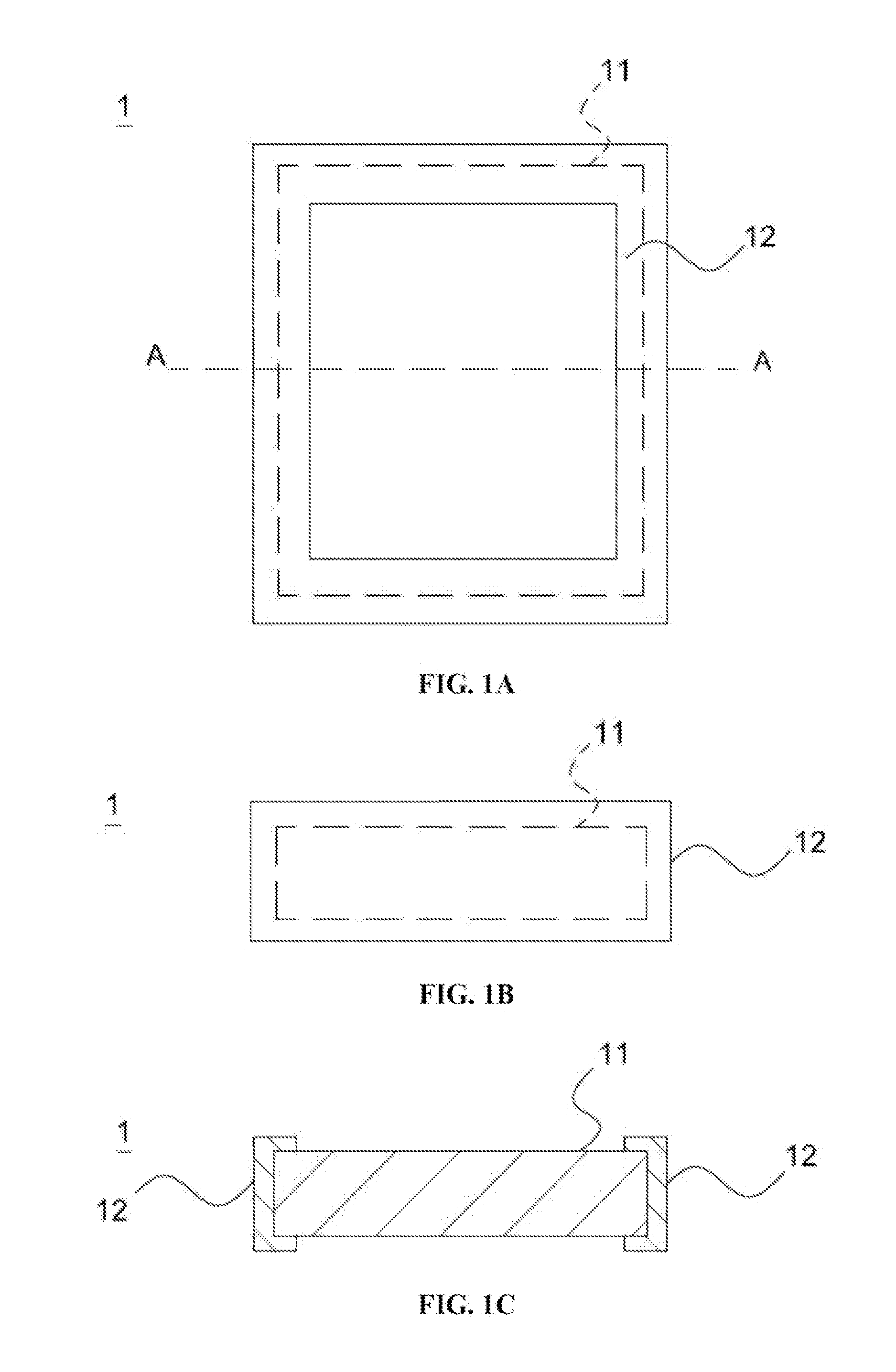

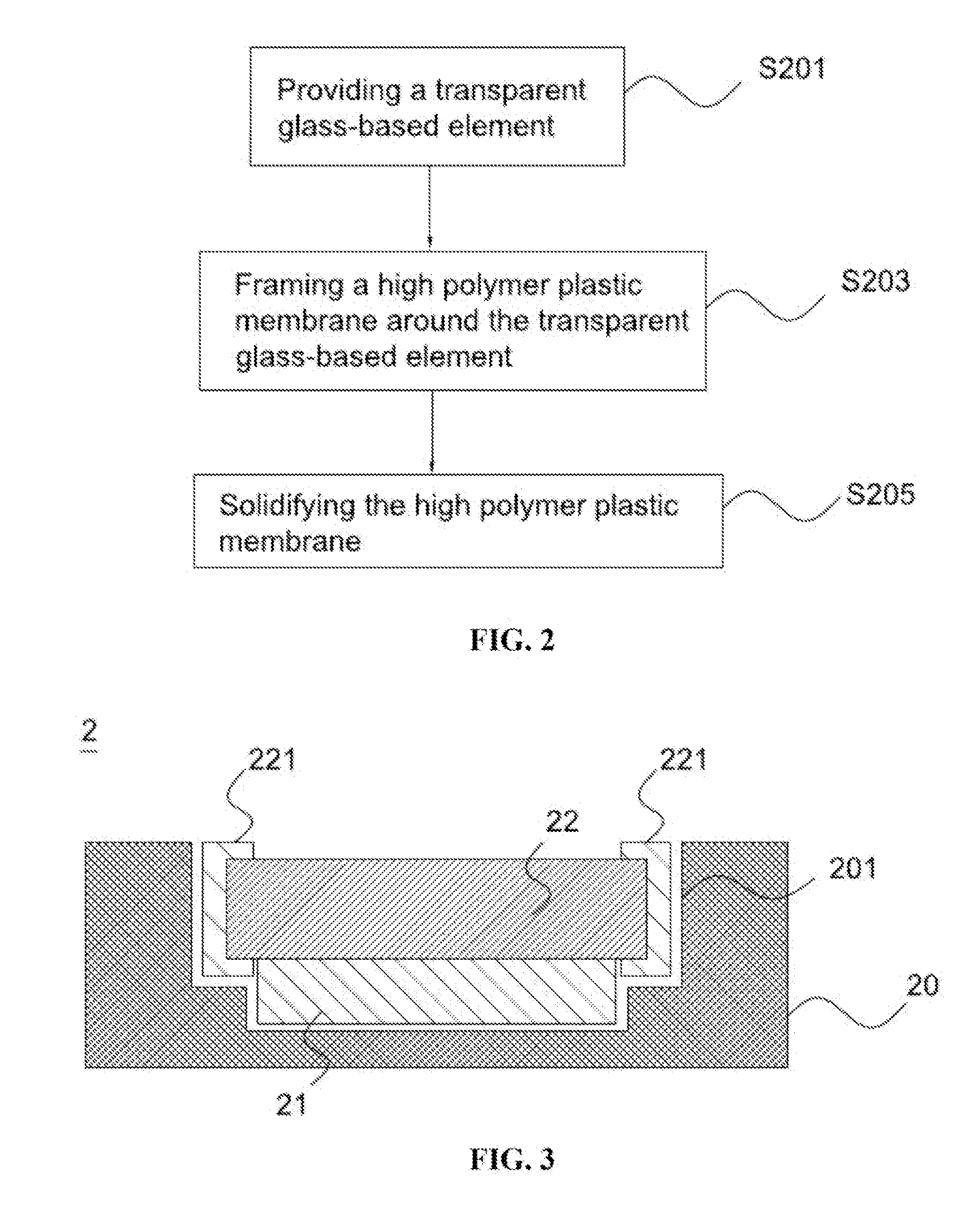

Glass plate, method for manufacturing the same, and display device, touch sensitive display using the same

ActiveUS20120135247A1High anti-cracking abilityHigh strengthGlass/slag layered productsSpecial surfacesLiquid stateDisplay device

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

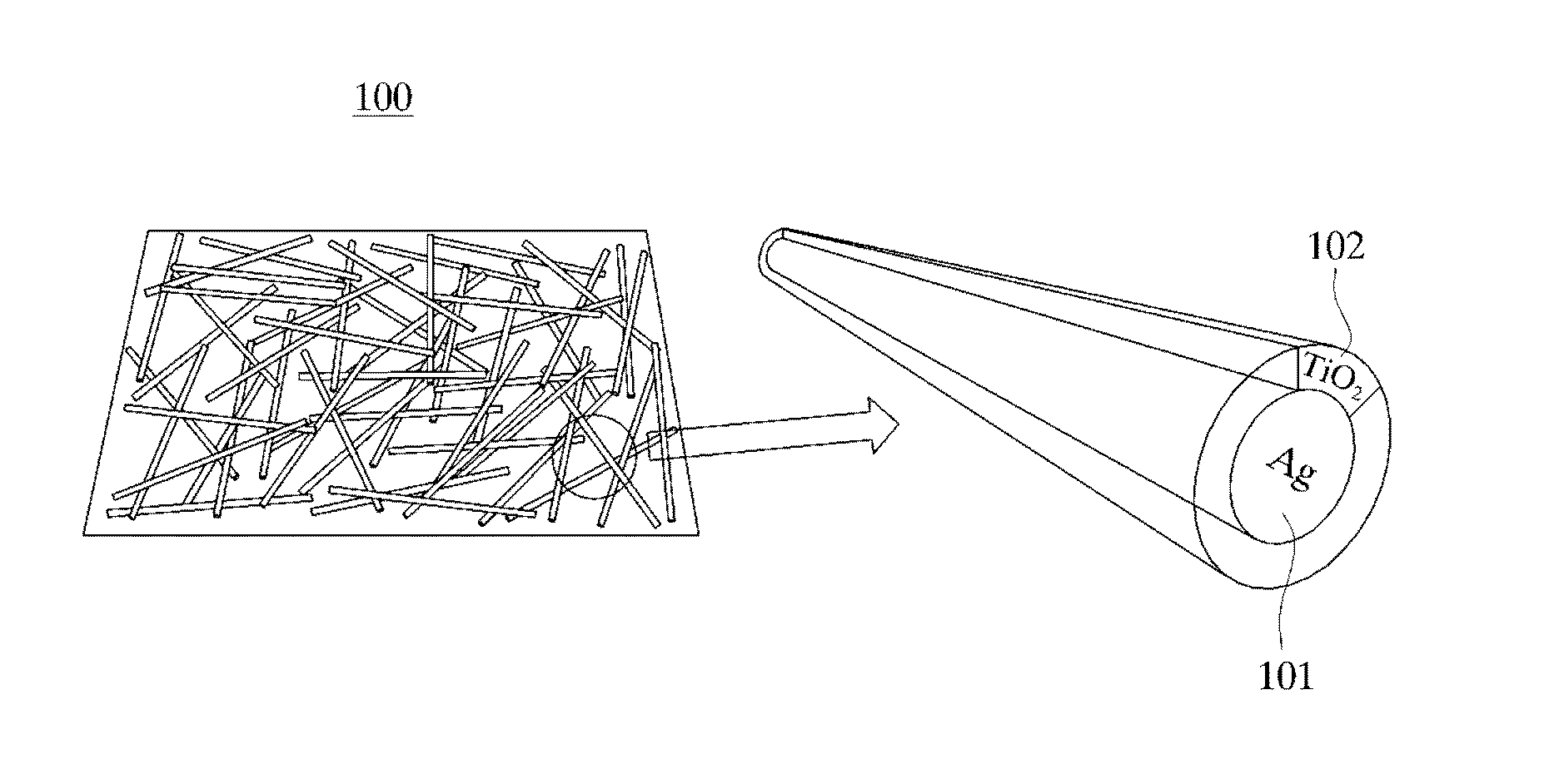

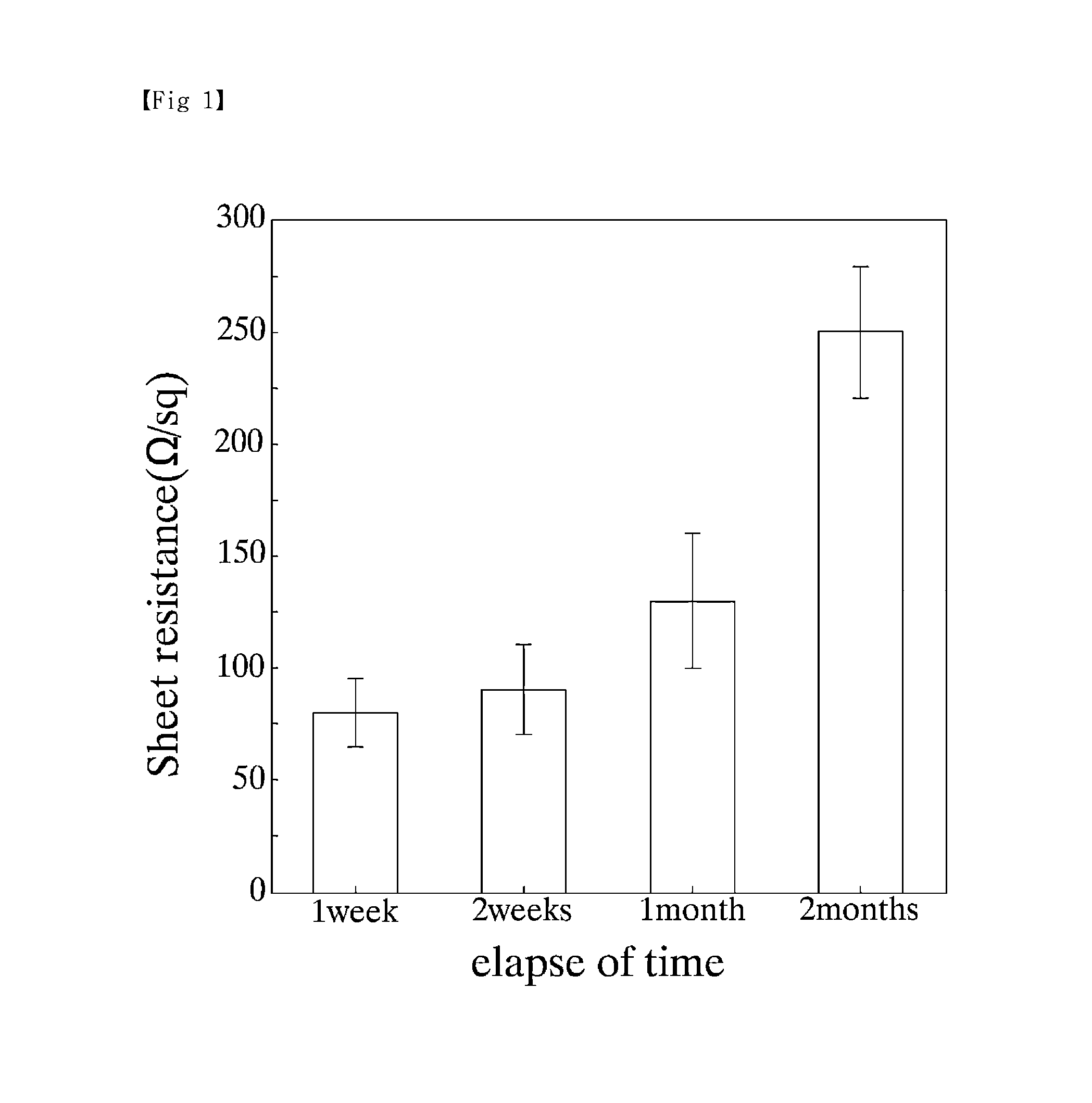

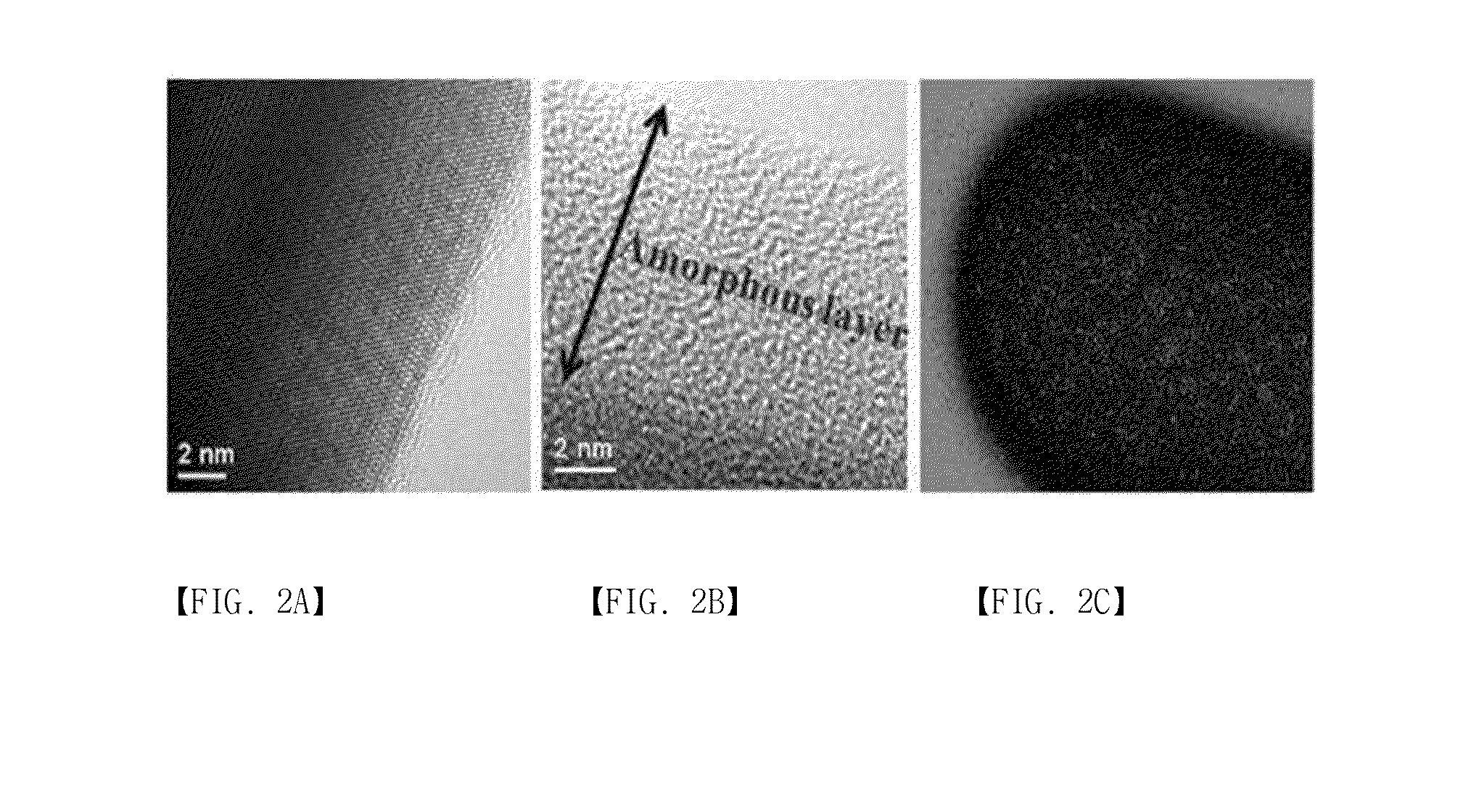

Silver nanowire conductive film and method of fabricating the same

ActiveUS20140020737A1Conductive layers on insulating-supportsSynthetic resin layered productsProtection layerSilver nanowires

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

Carbon nanotube filled polycarbonate Anti-curl back coating with improved electrical and mechanical properties

Transparent or semi-transparent, electrically conductive anti-curl back coating composite for electrophotographic imaging member comprising a carbon nanotube complex and a polycarbonate binder are described along with processes for preparing them.

Owner:XEROX CORP

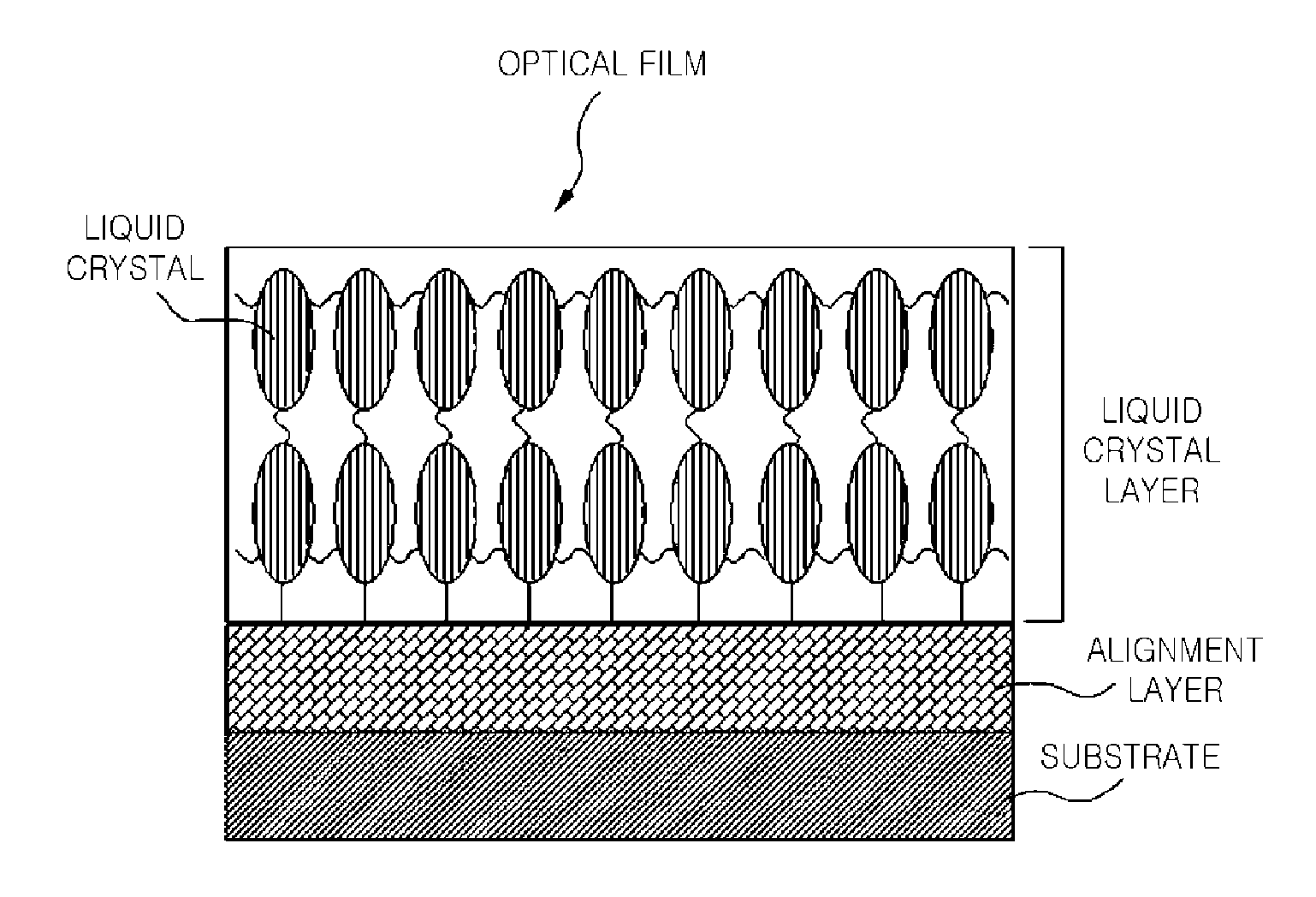

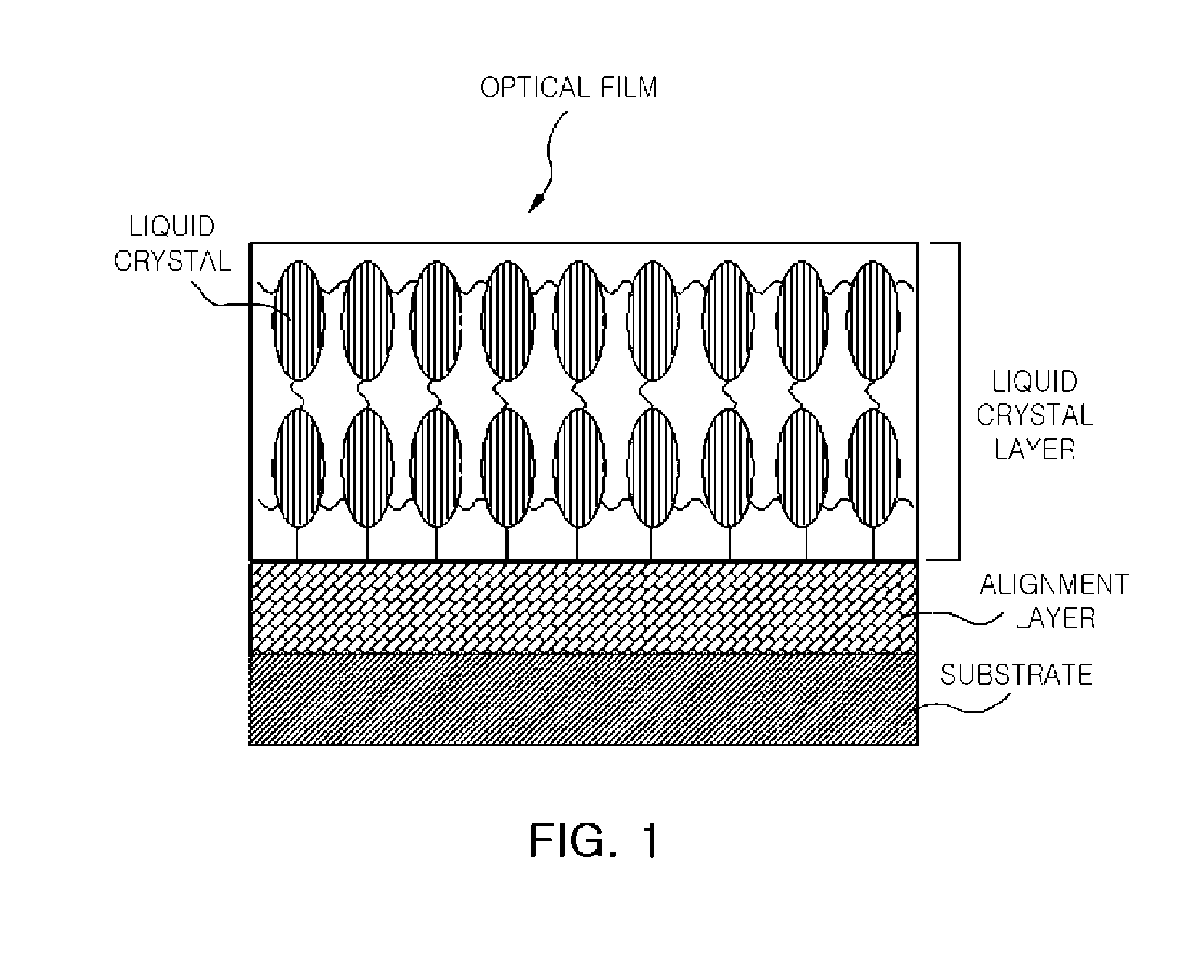

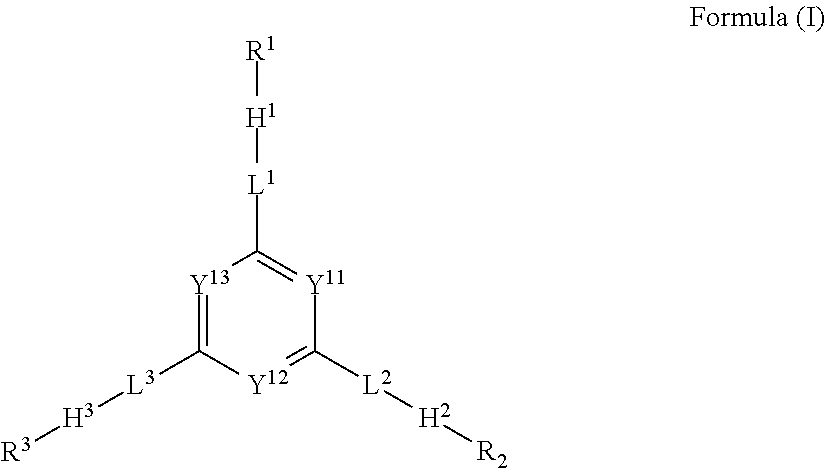

Alignment layer composition, alignment layer prepared with the same, preparation method of alignment layer, optical film containing the same, and display device including the optical film

InactiveUS20120021142A1Improve adhesionExcellent homeotropic alignmentLiquid crystal compositionsOrganic chemistryDisplay devicePolarizer

Owner:LG CHEM LTD

Corrugating linerboard, corrugated board, and methods of making the same

A method of making a corrugating linerboard includes supplying a web of coated linerboard having a first side, a second side and a thickness defined by a distance between the first side and the second side, the first side being coated with a moisture-repellant material; and impregnating the coated linerboard with a hydrophobic material from the second side such that the hydrophobic material penetrates into the thickness of the coated linerboard.

Owner:GEORGIA PACIFIC CORRUGATED

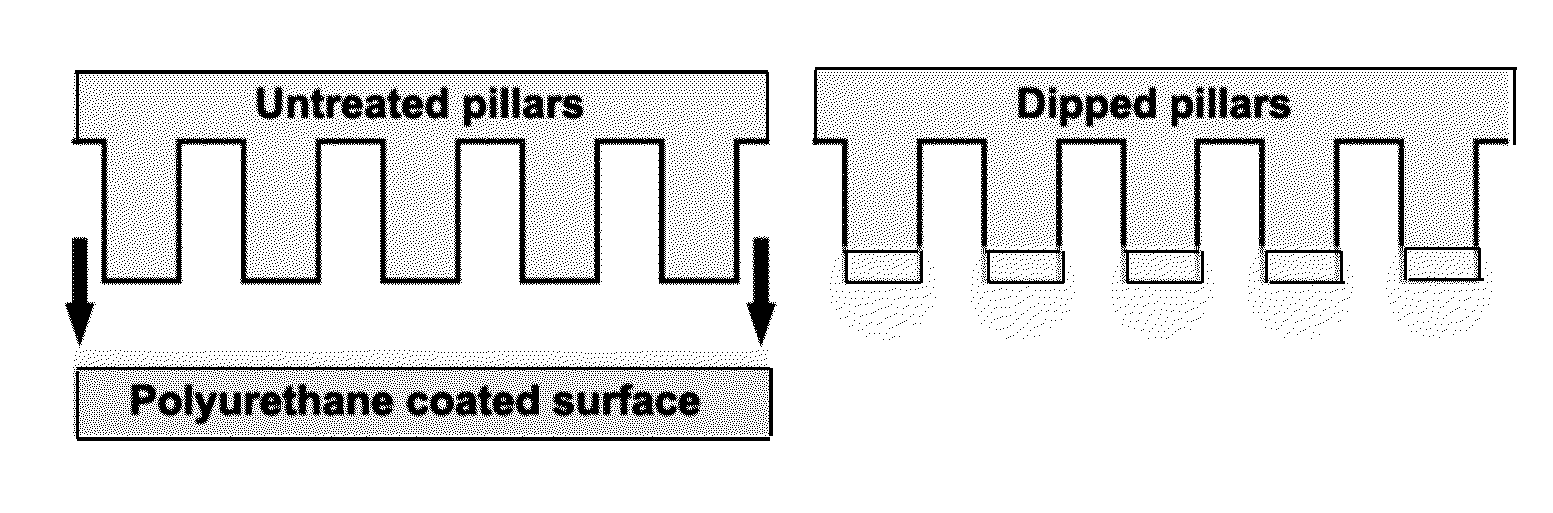

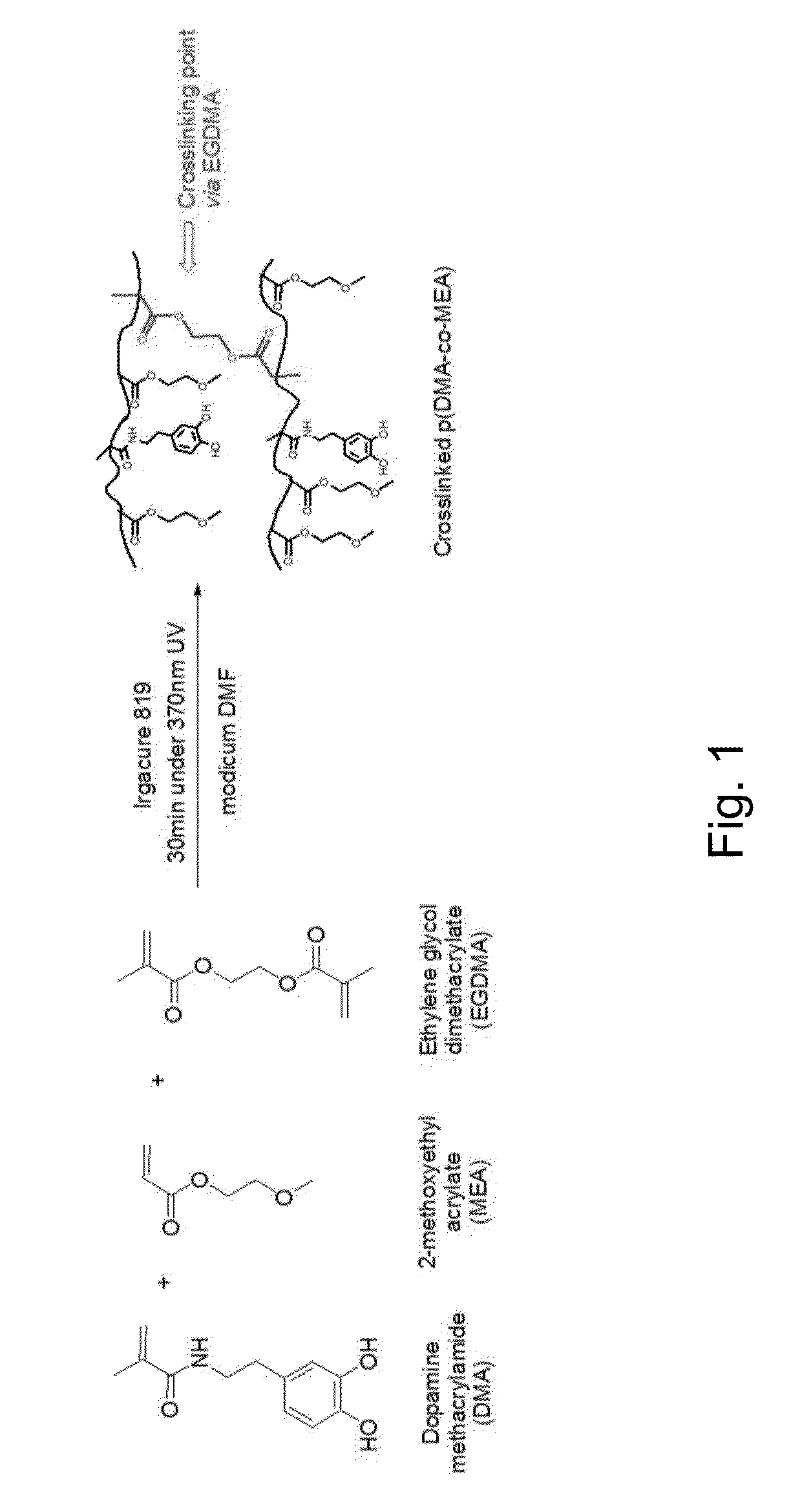

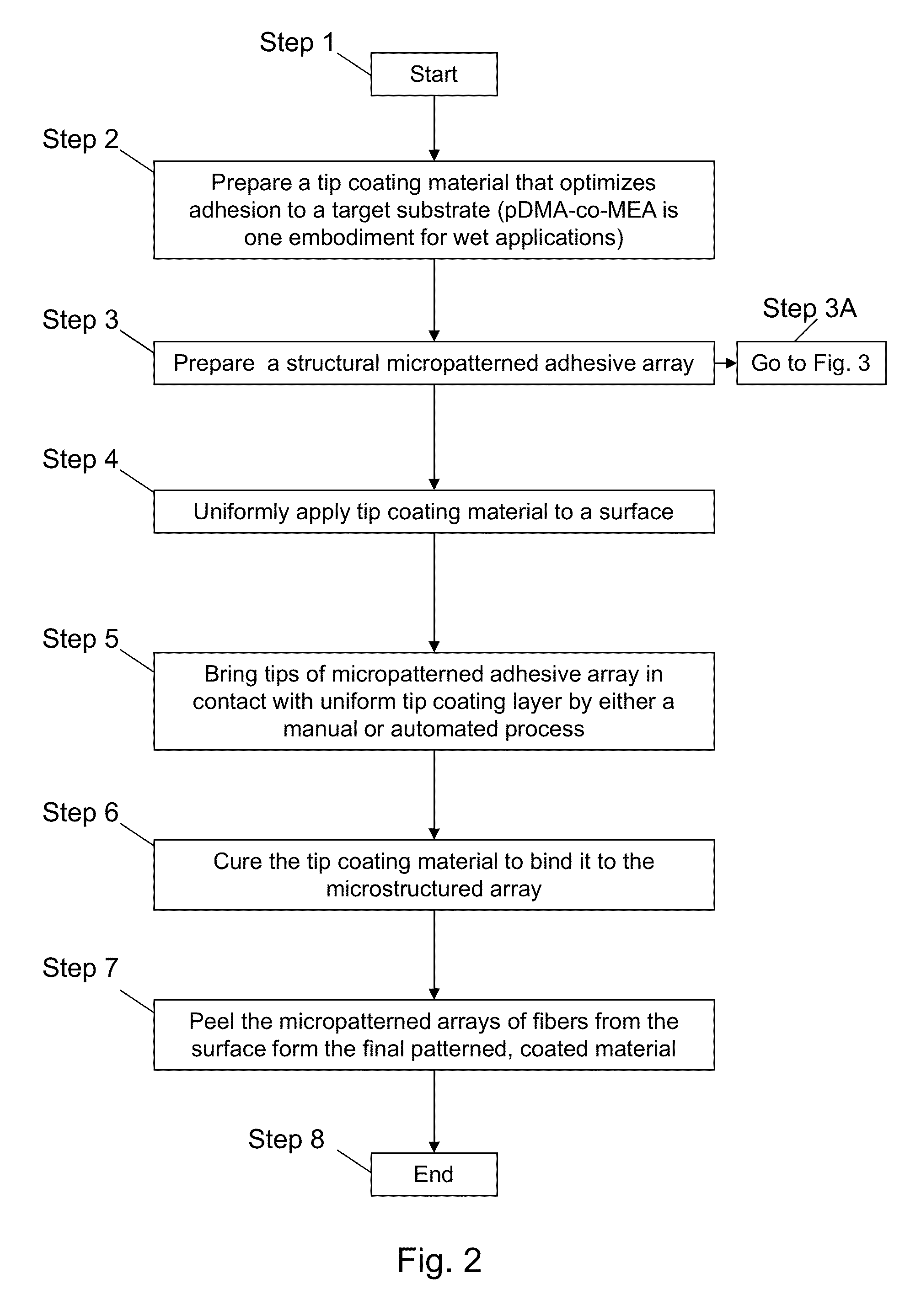

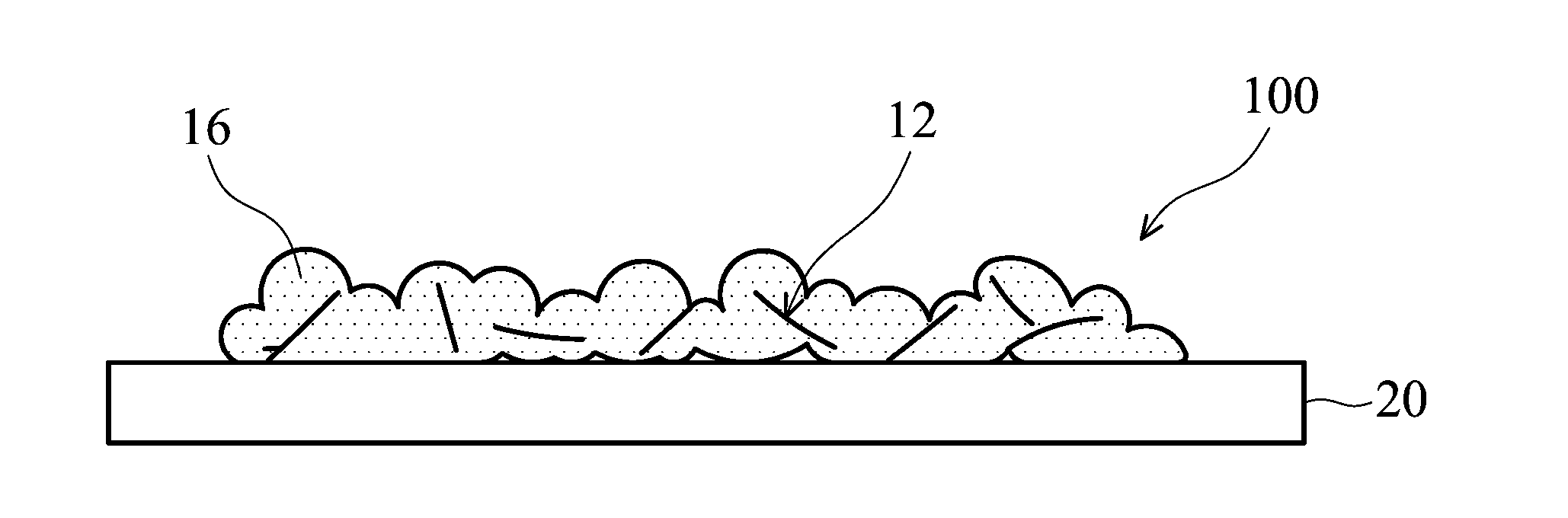

Micro-fiber arrays with tip coating and transfer method for preparing same

ActiveUS20130183481A1Performance deteriorationLayered productsPretreated surfacesMicron scaleElastomer

Owner:CARNEGIE MELLON UNIV CENT FOR TECH TRANSFER & ENTERPRISE CREATION

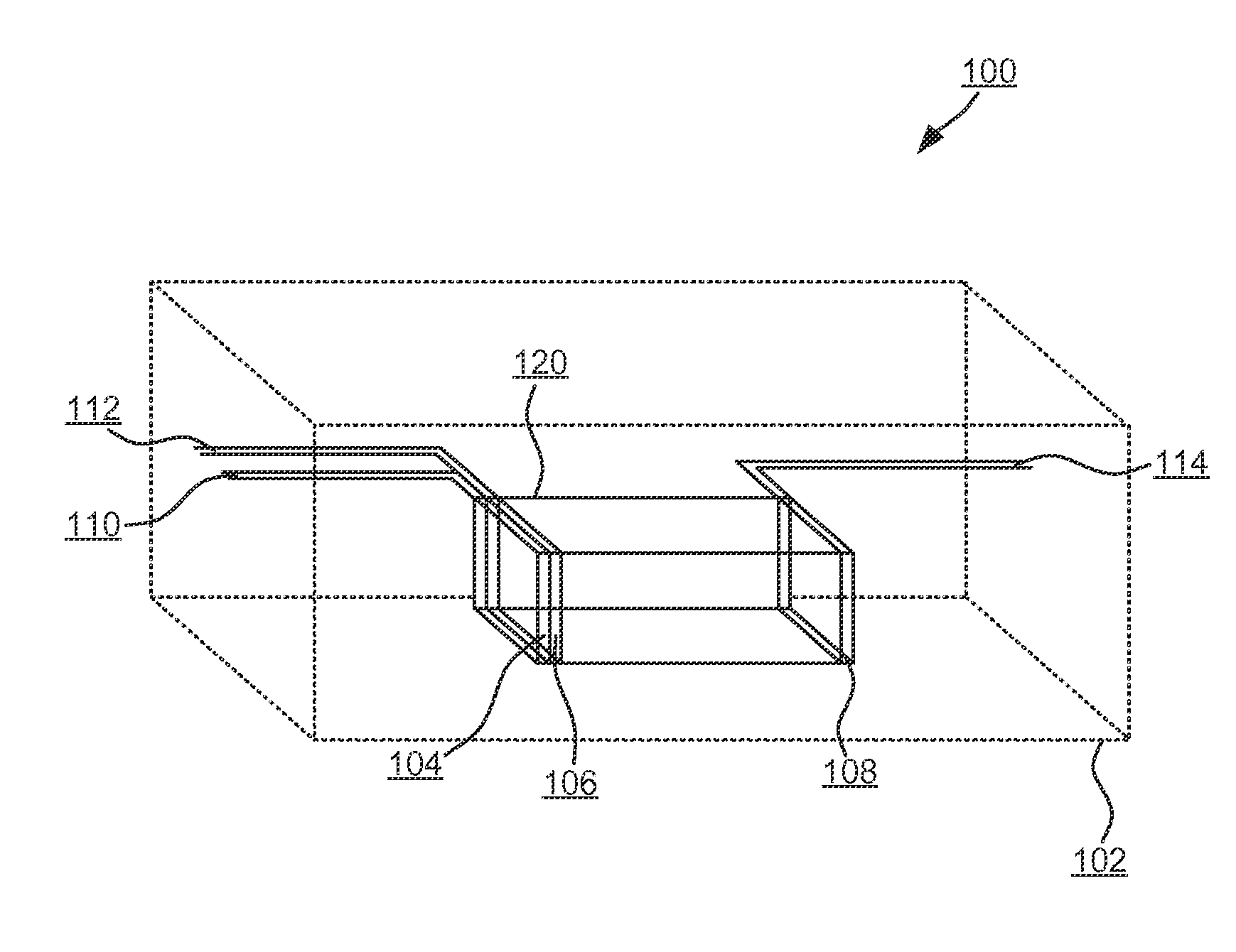

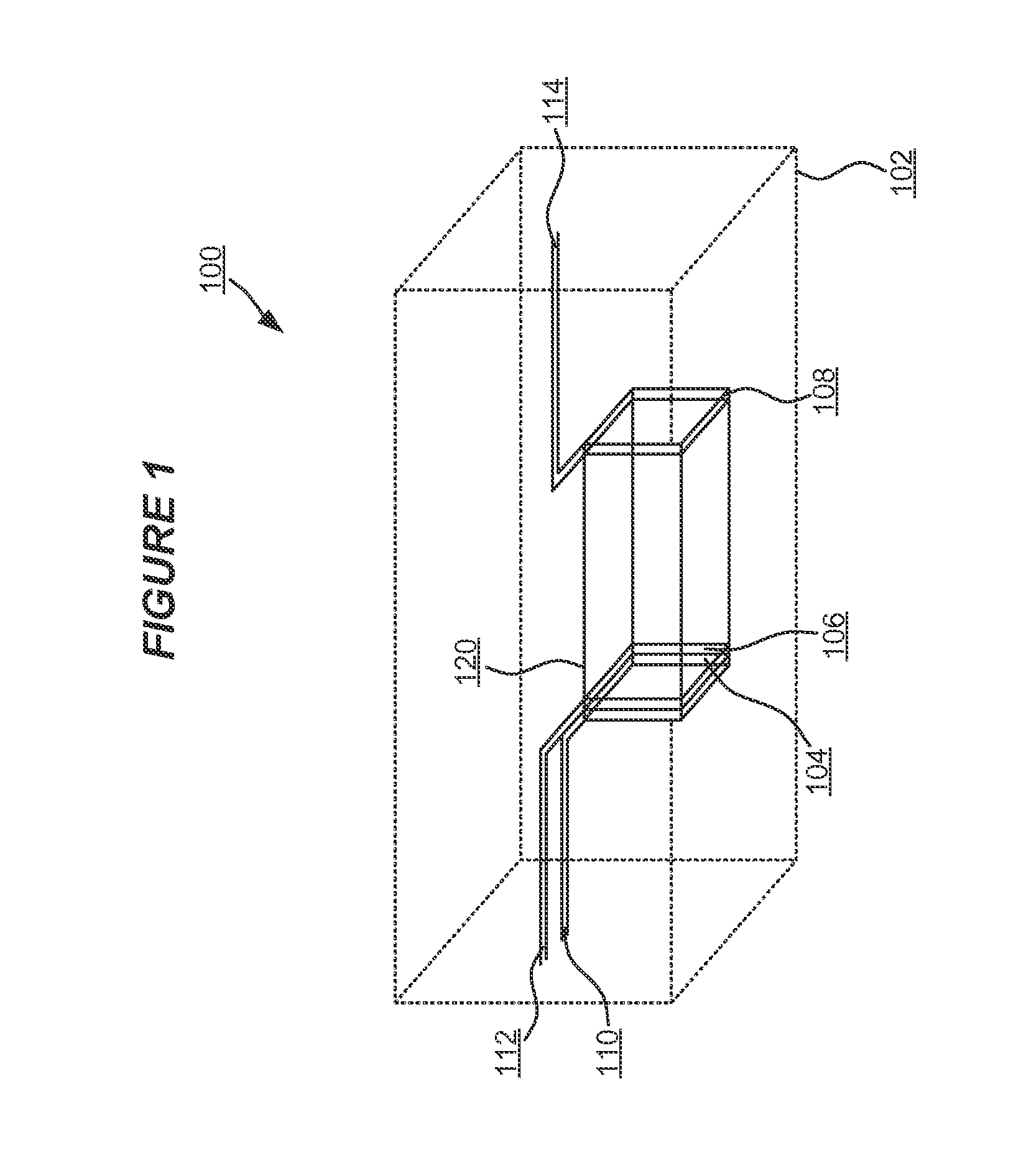

Printing superimposed layers

An apparatus and method for making a panel with superimposed layers of marking material in substantially exact registration is provided. An assembly includes a stencil layer sandwiched between a substrate and a transparent coating. The stencil includes a release surface. The coating tends to secure the stencil layer to the substrate, e.g., for storage and / or transport, and may protect the stencil layer from marking materials that might otherwise penetrate the stencil layer. A design and background layers are then printed onto the coating. A force is then applied to remove the background layer, design layer, and coating that are disposed on the stencil layer, leaving the remainder of the background layer, design layer, and coating adhered to the substrate in substantially exact registration within portions of the substrate that are devoid of the stencil layer. The design layer is right-reading visible through the substrates.

Owner:CONTRA VISION

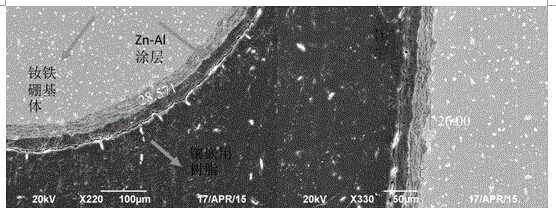

Zinc-aluminum coating enhanced with particles in micro-nano sizes and production method of zinc-aluminum coating

InactiveCN104984889AImprove mechanical propertiesImprove scratch resistancePretreated surfacesSpecial surfacesMicro nanoSilicon oxide

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

Method for preparing super-hydrophobic green film on magnesium alloy substrate

Owner:DALIAN UNIV OF TECH

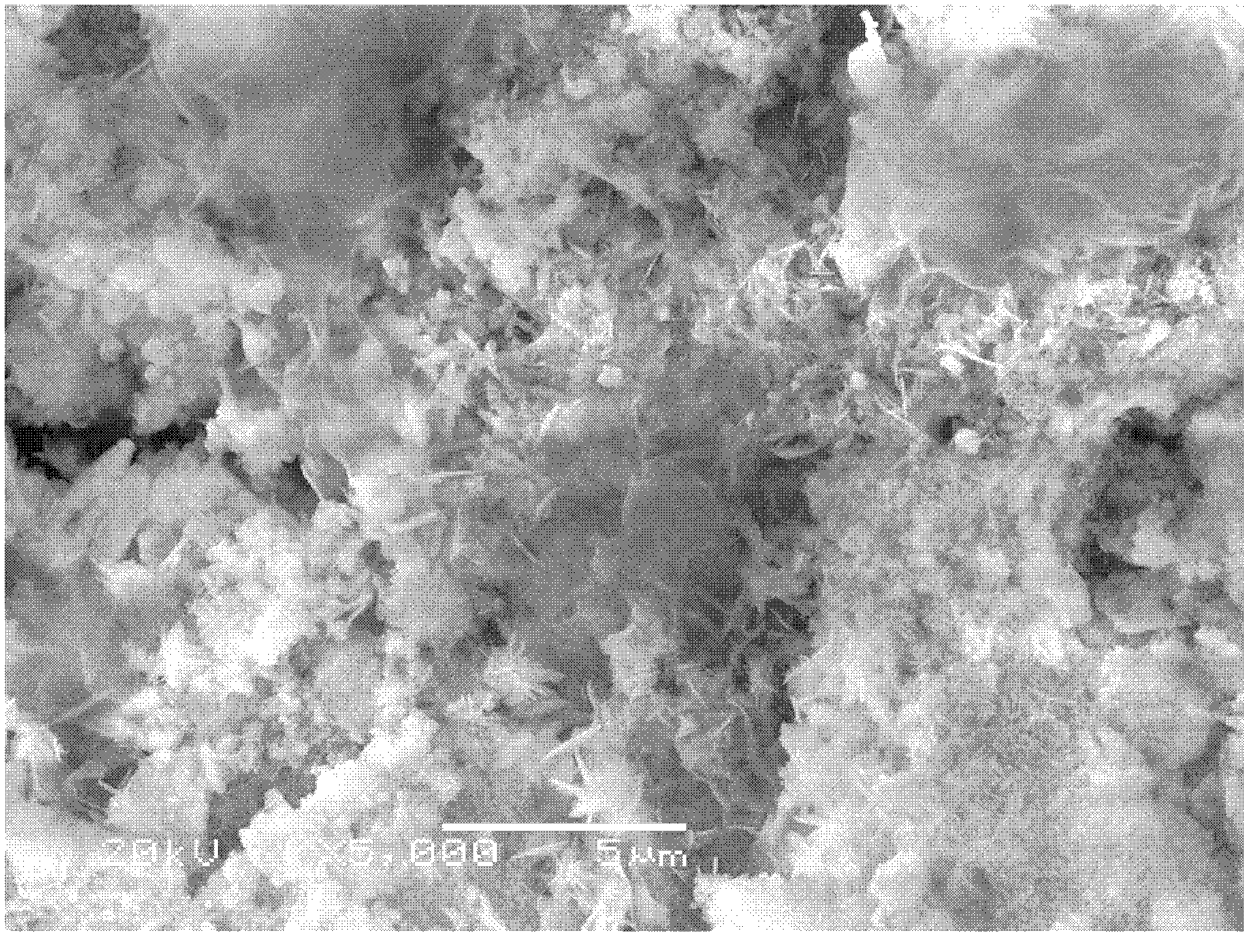

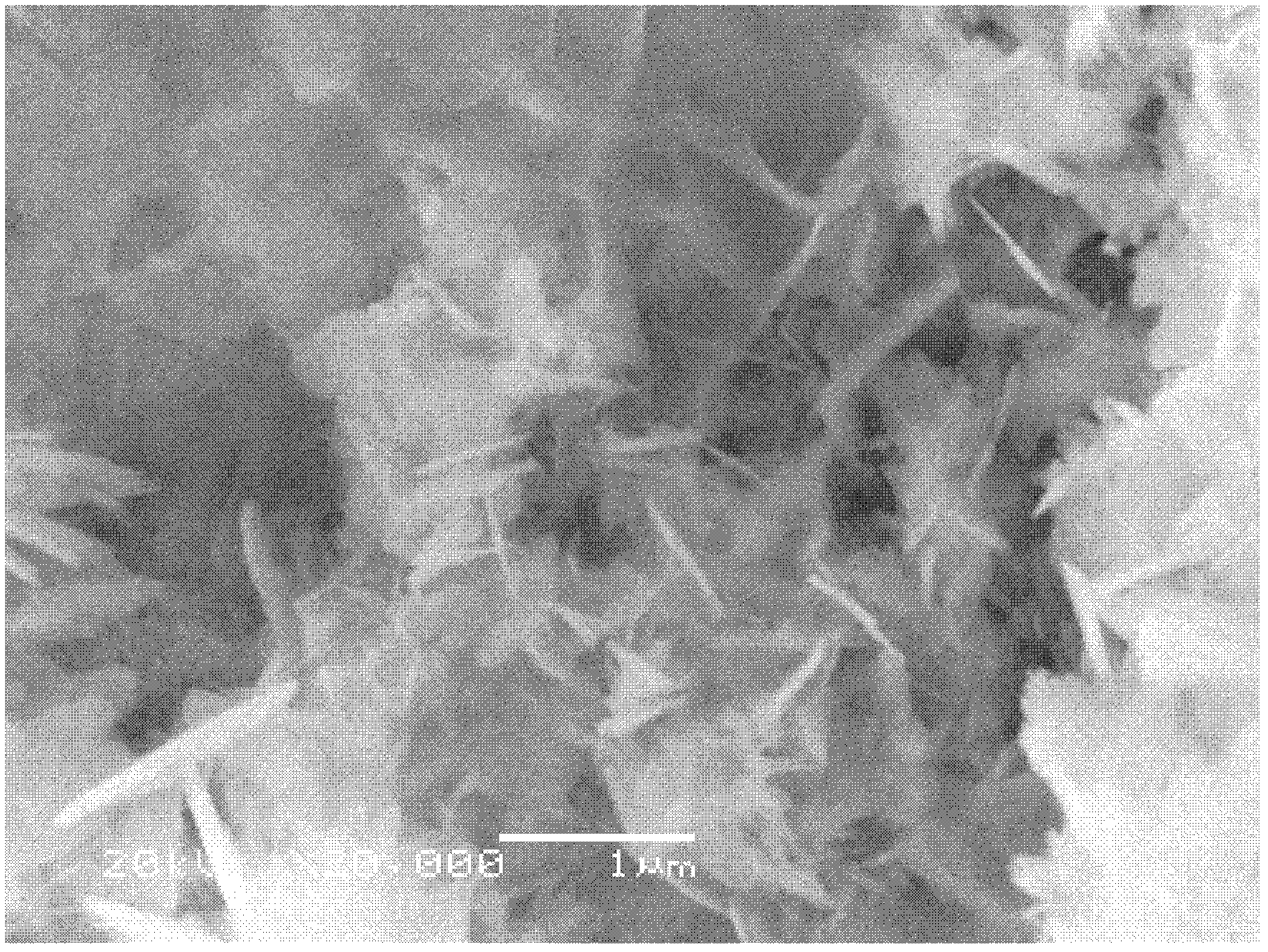

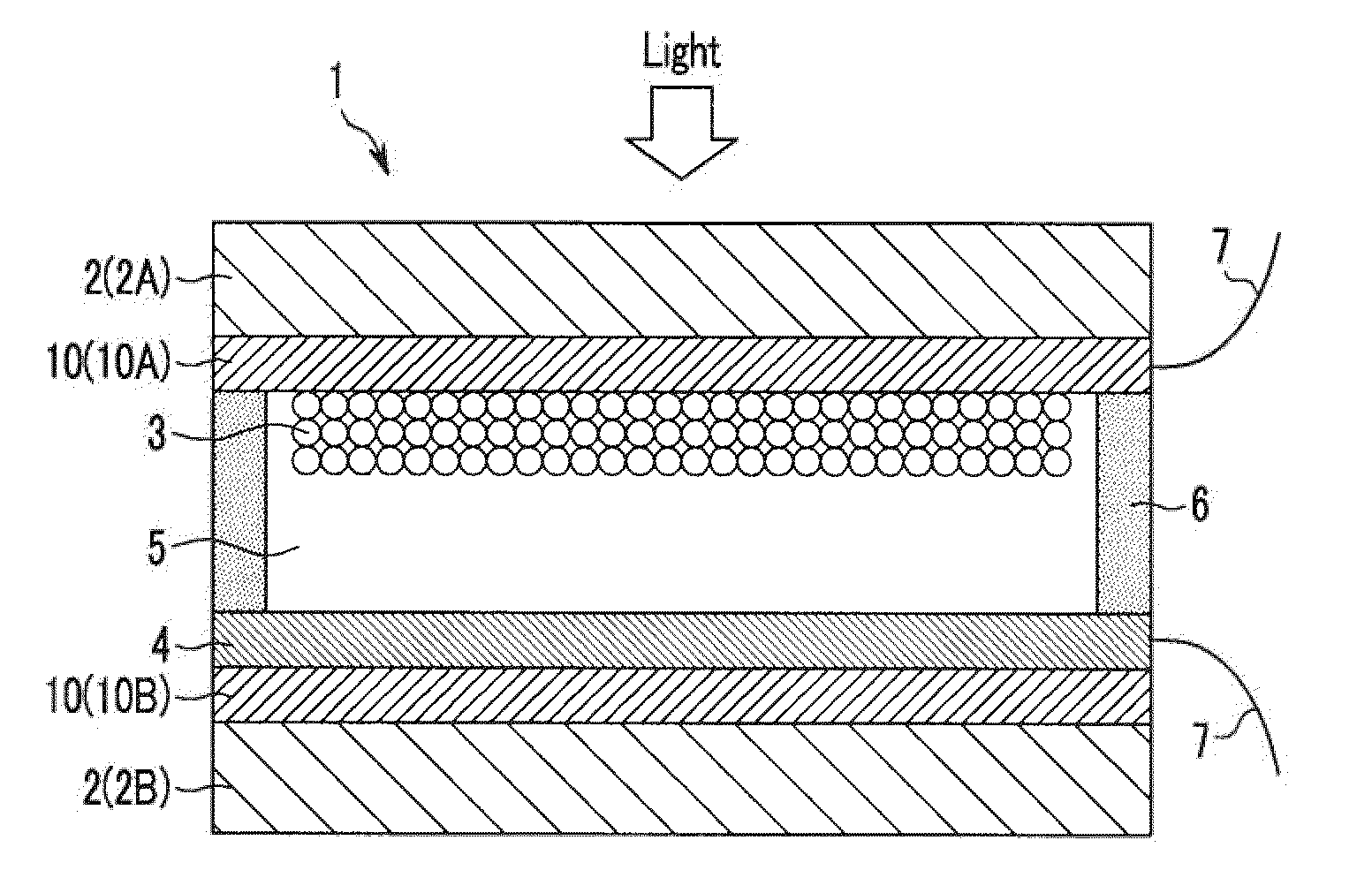

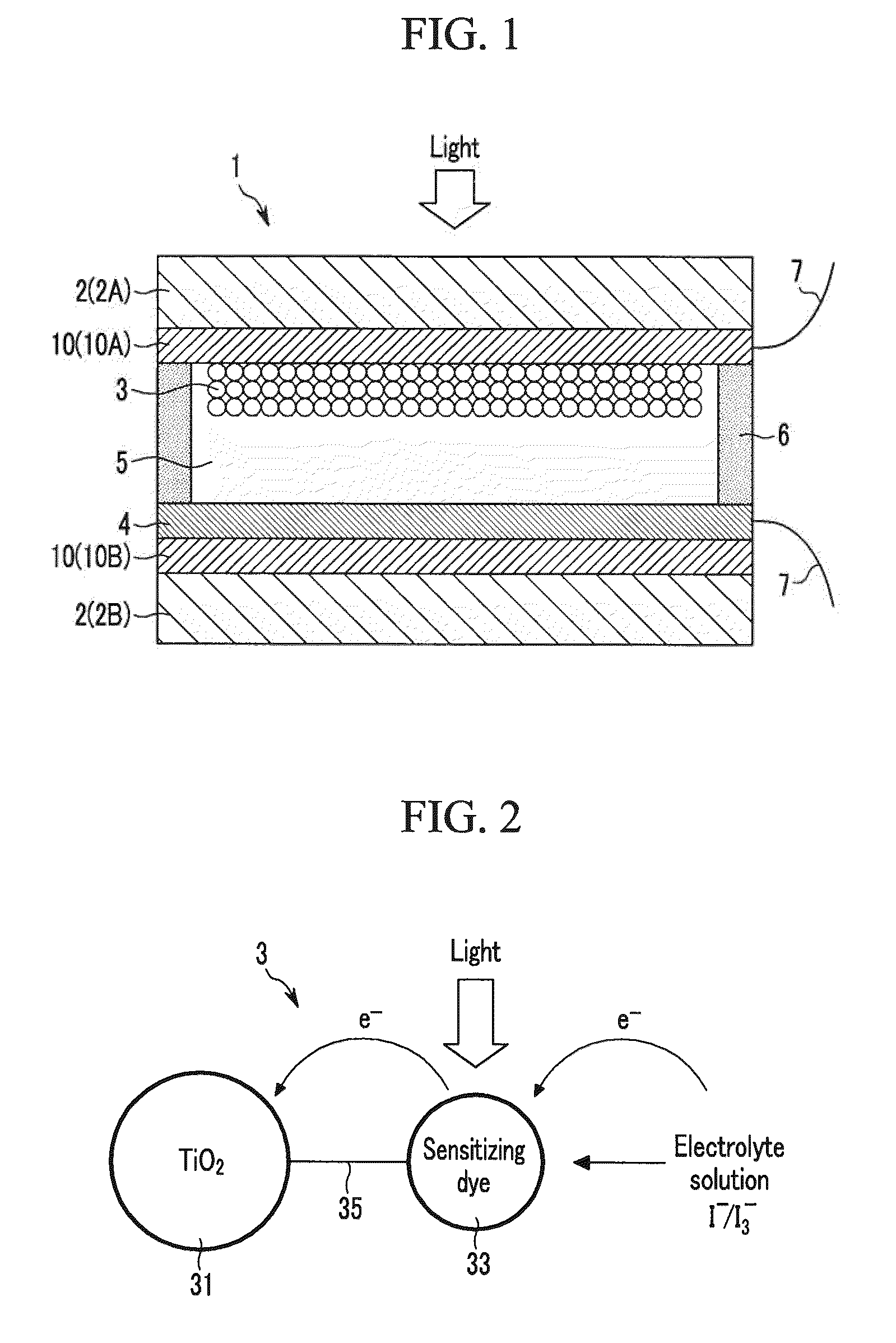

Glass paste composition, electrode substrate prepared using same, method of preparing electrode substrate, and dye sensitized solar cell including electrode substrate

InactiveUS20110088758A1Generation of cracking can be suppressed and preventedGood electrolyte solution resistanceElectrolytic capacitorsSolid-state devicesOrganic solventFrit

Owner:SAMSUNG SDI CO LTD

Preparation method for durable aluminum and aluminum alloy superhydrophobic surface coating

InactiveCN102527619AExtended service lifeGood antifoulingSpecial surfacesCoatingsSuperhydrophobic coatingPolypropylene

Owner:HUNAN UNIV OF TECH

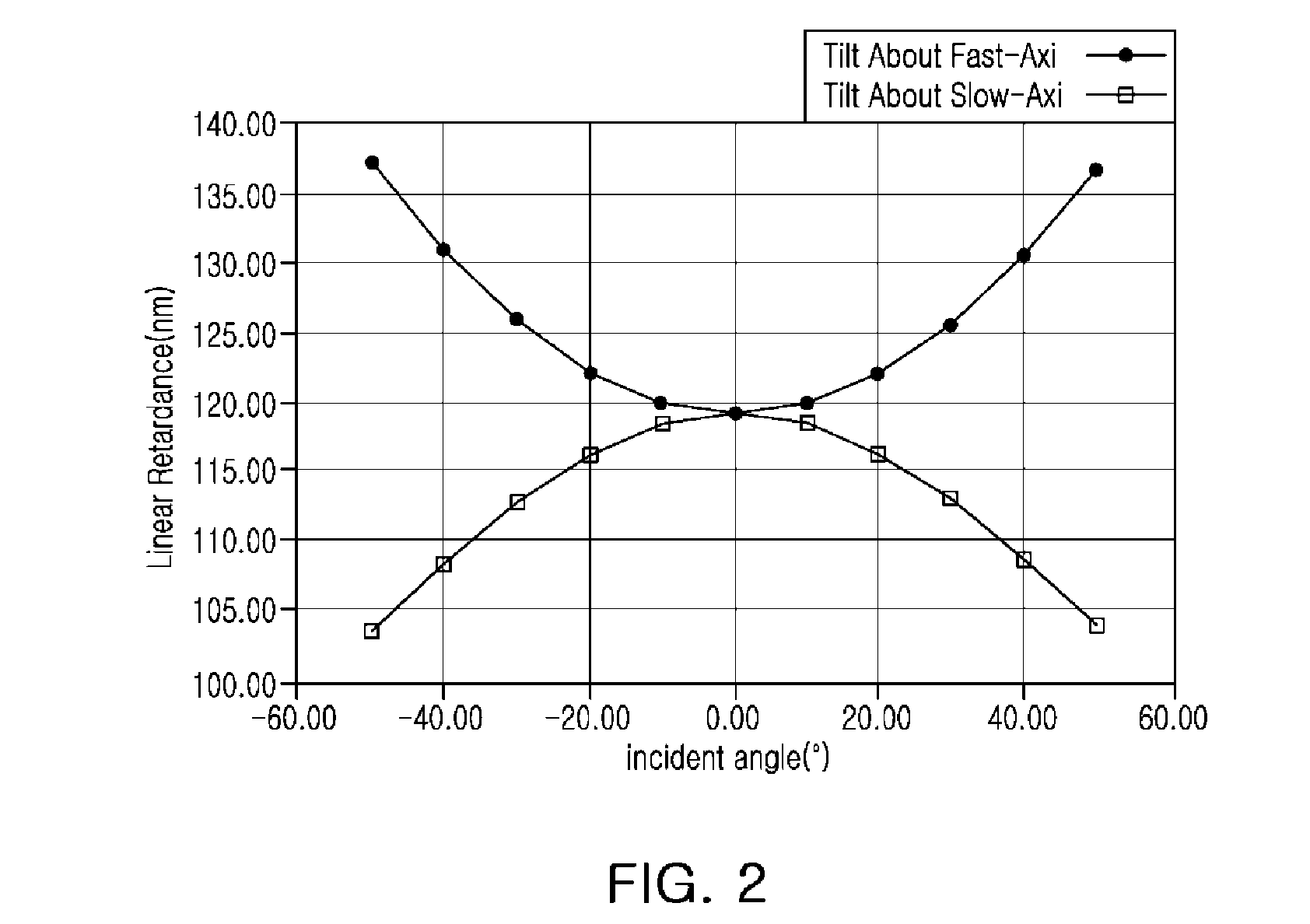

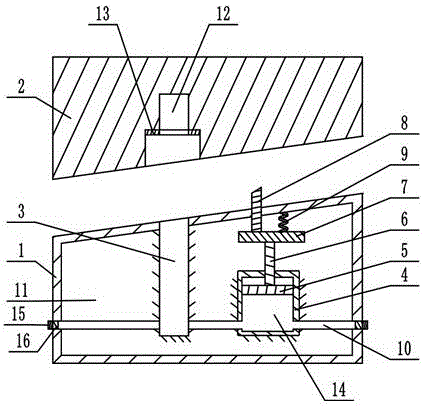

Method for manufacturing long laminated polarizing plate and long laminated polarizing plate

It is an object of the invention to provide a method for manufacturing a long laminated polarizing plate having a long polarizing coating formed by coating directly on a long retardation film and to provide such a long laminated polarizing plate. The present invention relates to a method for manufacturing a long laminated polarizing plate comprising a long retardation film having a slow axis in its longitudinal direction and a long polarizing coating placed on the retardation film and having an absorption axis or a transmission axis in an in-plane direction at an angle of 25 to 65° to the slow axis direction of the long retardation film.

Owner:NITTO DENKO CORP

Wooden sound insulation door

ActiveCN106761297AImprove sealingAchieve penetrationNoise insulation doors/windowsSealing arrangementsEngineeringPiston

Owner:重庆金华兴门业有限公司

Liquid accelerator

ActiveUS20070044686A1Underground chambersMixing operation control apparatusHydrofluoric acidAluminium sulfate

To provide a liquid accelerator which excels in accelerating effect and which also excels in storage stability at low temperature and inhibitory effect of alkali-aggregation reaction. A liquid accelerator composed of a fluoride-containing aqueous aluminum salt which is obtained through the reaction of aluminum sulfate and hydrofluoric acid, aluminum hydroxide, and one or more kinds of lithium salts selected from the group consisting of lithium hydroxides, lithium carbonates, and lithium sulfates.

Owner:CONSTR RES & TECH GMBH

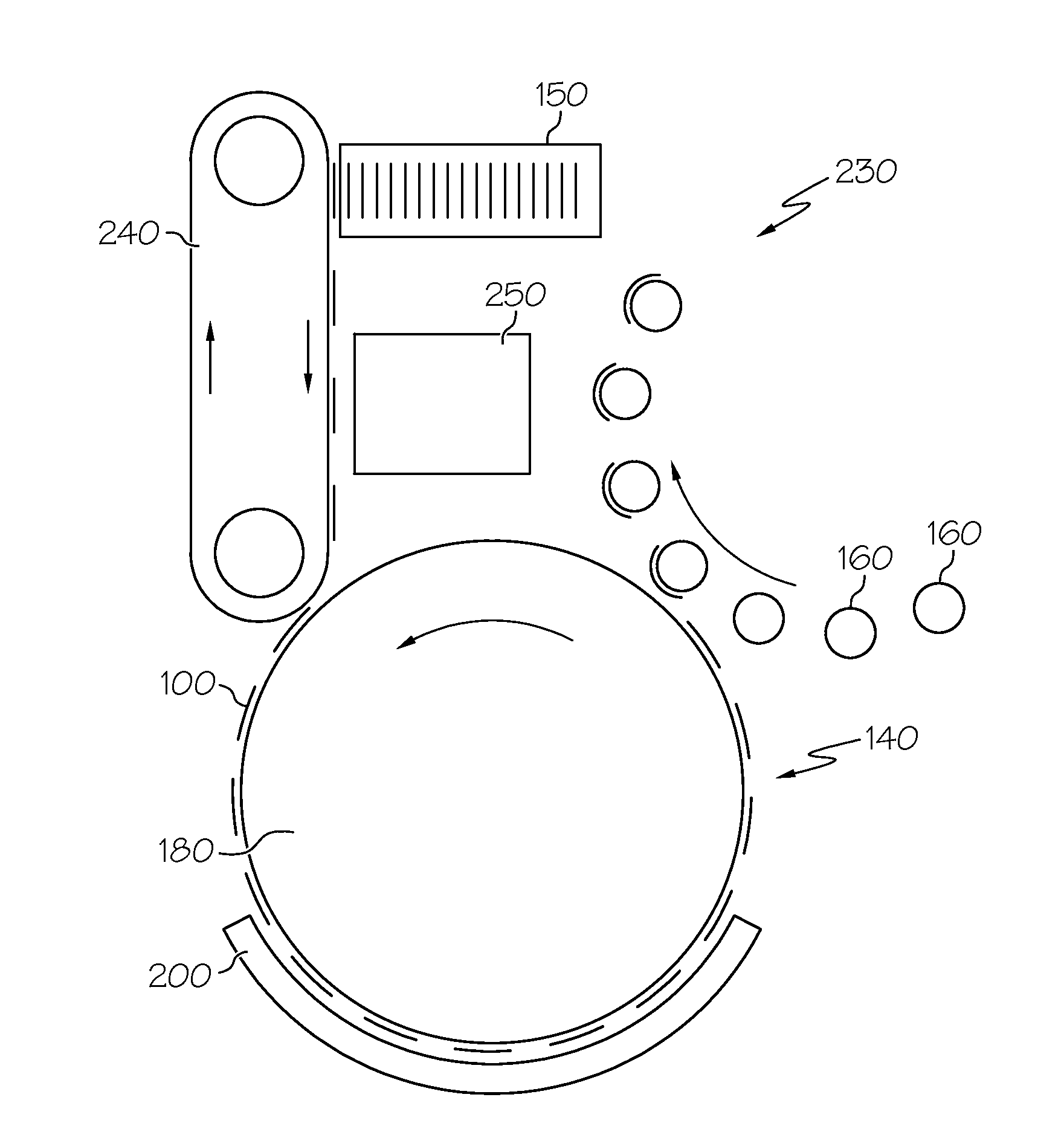

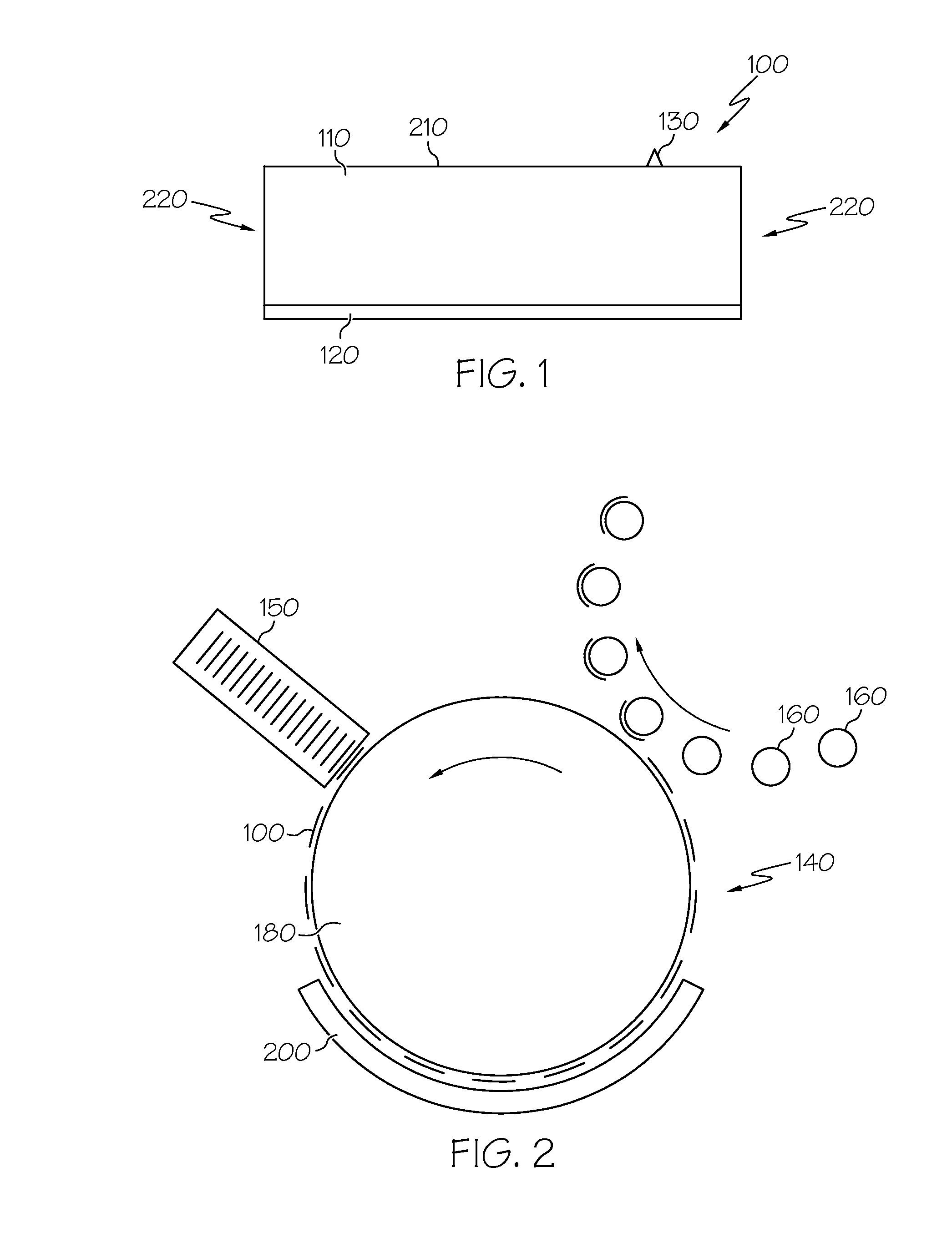

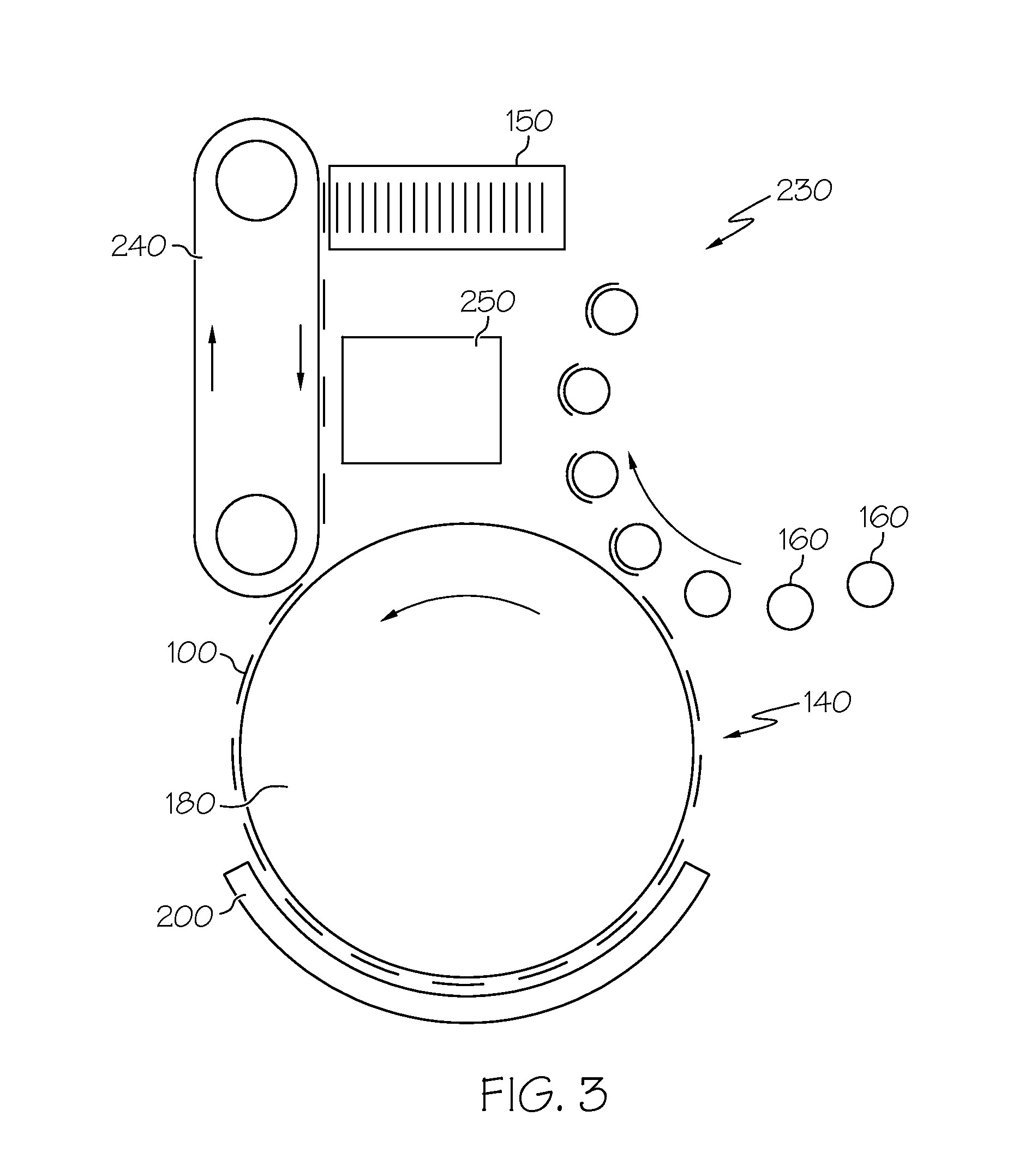

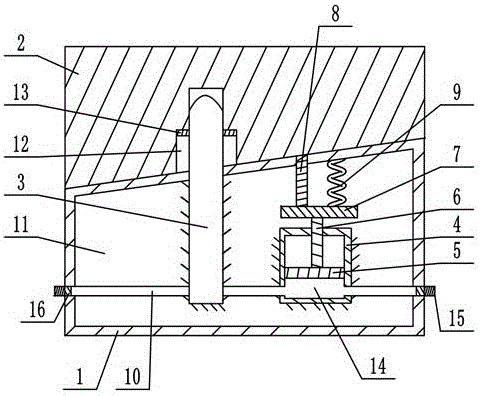

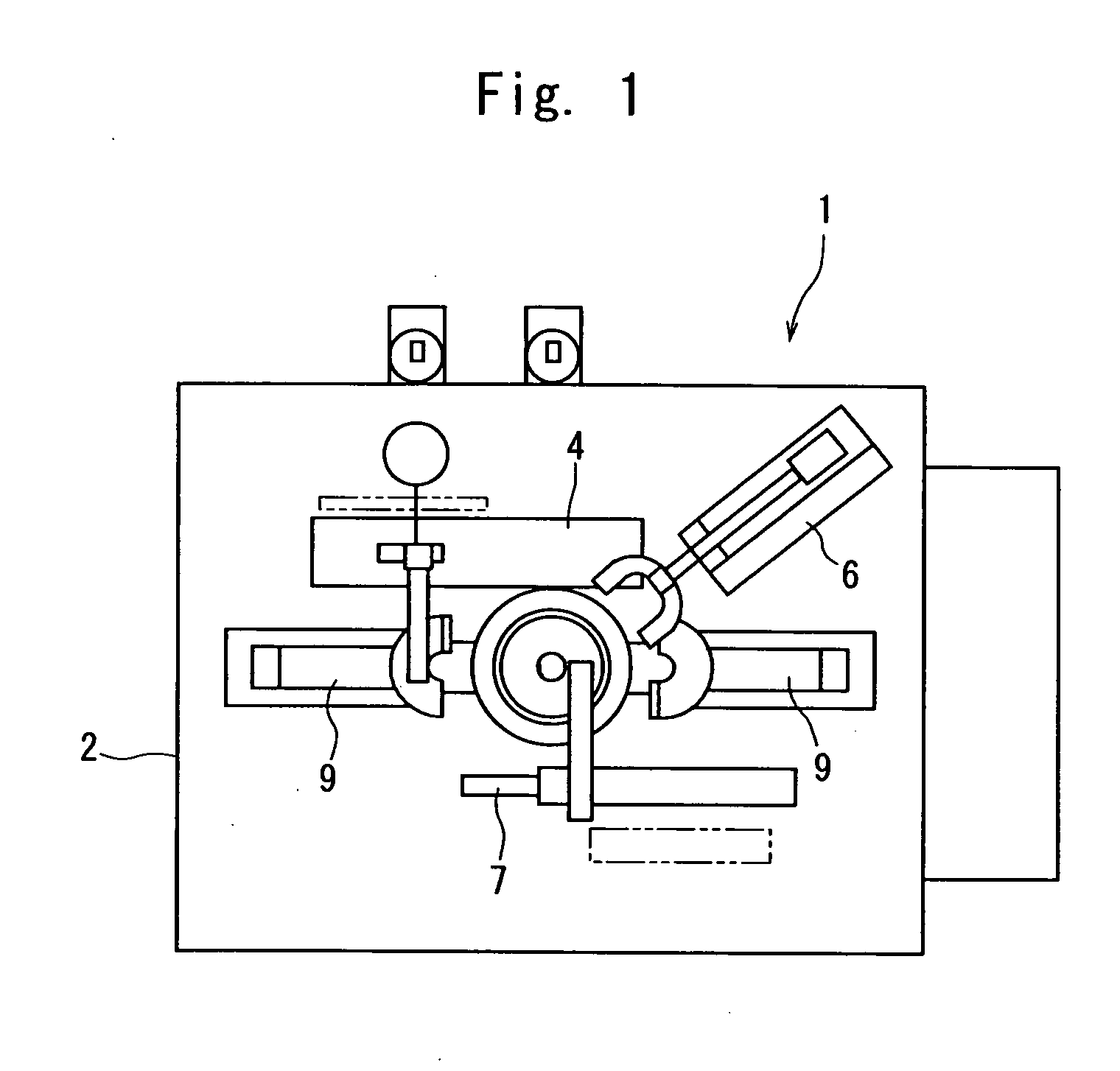

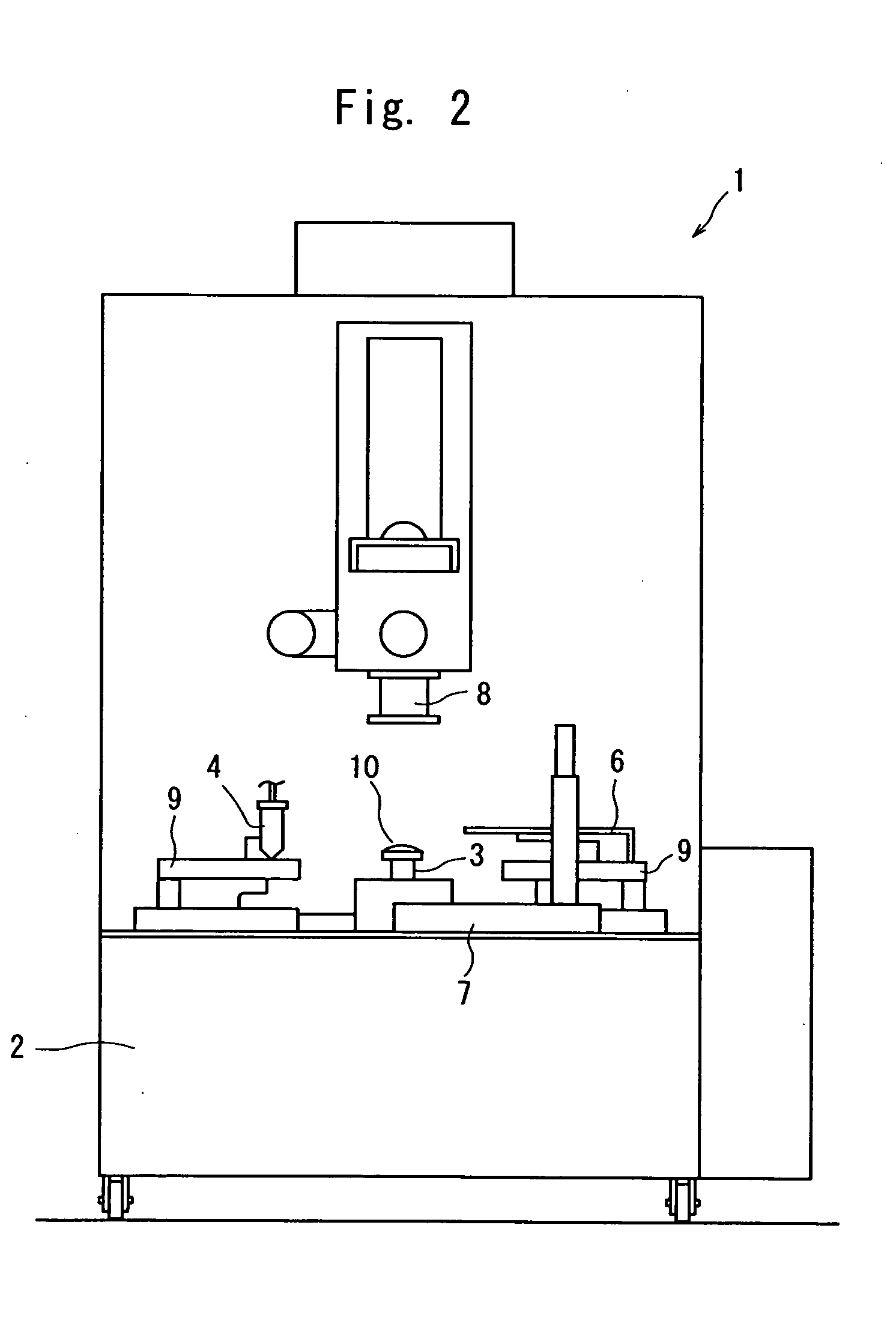

Removal Method and Removal Apparatus for Entrained Air in Coating Fluid

InactiveUS20090229465A1Prevent backflowLiquid degasification regulation/controlSpecial surfacesRotational axisAir entrainment

Owner:TOKUYAMA CORP

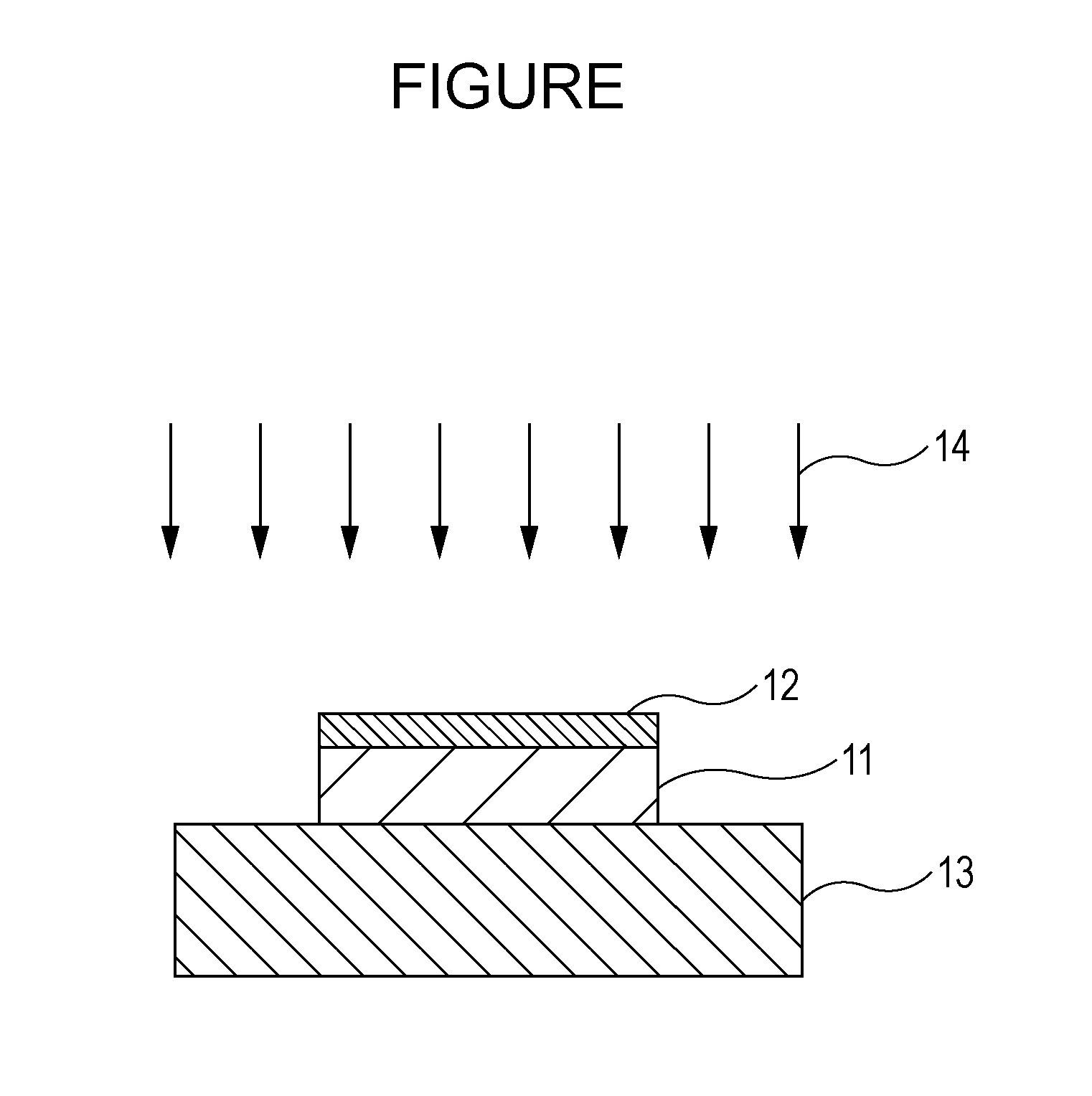

Method of producing magnesium fluoride coating, antireflection coating, and optical element

InactiveUS20110027577A1Improve anti-reflection effectLow refractive indexLayered productsRadiation applicationsMagnesium fluorideSingle bond

Owner:CANON KK

Method of manufacturing display panel

InactiveUS20080299315A1Reducing projection and depressionSimple designDuplicating/marking methodsIndication apparatusColor printingEngineering

In a method of manufacturing a display panel that includes a base and a printed layer printed on the base by inkjet printing, a color UV curable ink is deposited on a predetermined portion of the base for forming a color printed portion of the printed layer, and a transparent UV curable ink is deposited in at least one of a first depression provided by the color printed portion on a surface of the base and a second depression formed on a surface of the color printed portion for forming a transparent printed portion.

Owner:DENSO CORP

Electrically conductive composition and fabrication method thereof

ActiveUS20110101283A1Electric discharge heatingRadiation applicationsConductive polymerConductive materials

Owner:IND TECH RES INST

Strong anti-corrosion treatment technique for surface of carbon steel valve

ActiveCN105772370AImprove anti-corrosion performanceEasy to usePretreated surfacesSpecial surfacesEpoxyCross cut

Owner:浙江标盛阀门制造有限公司

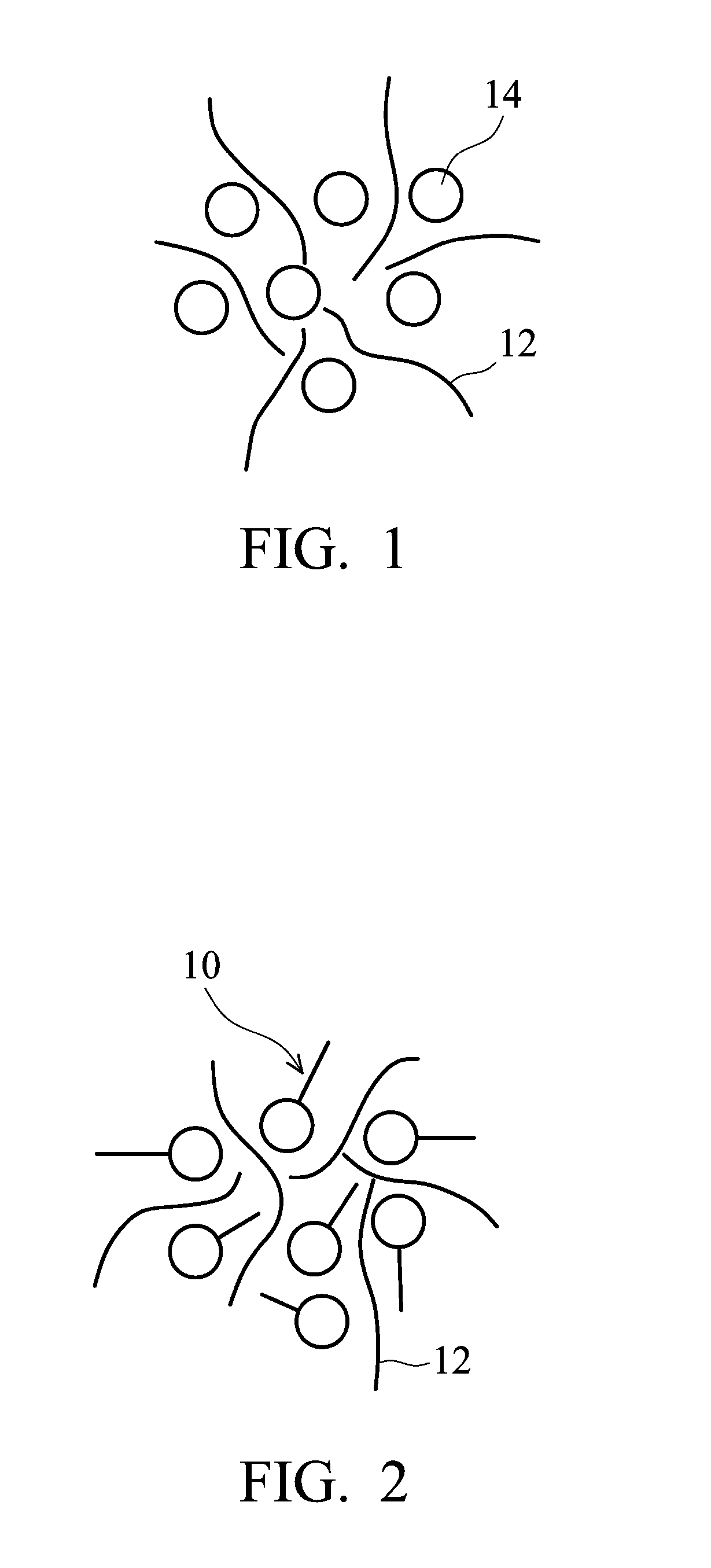

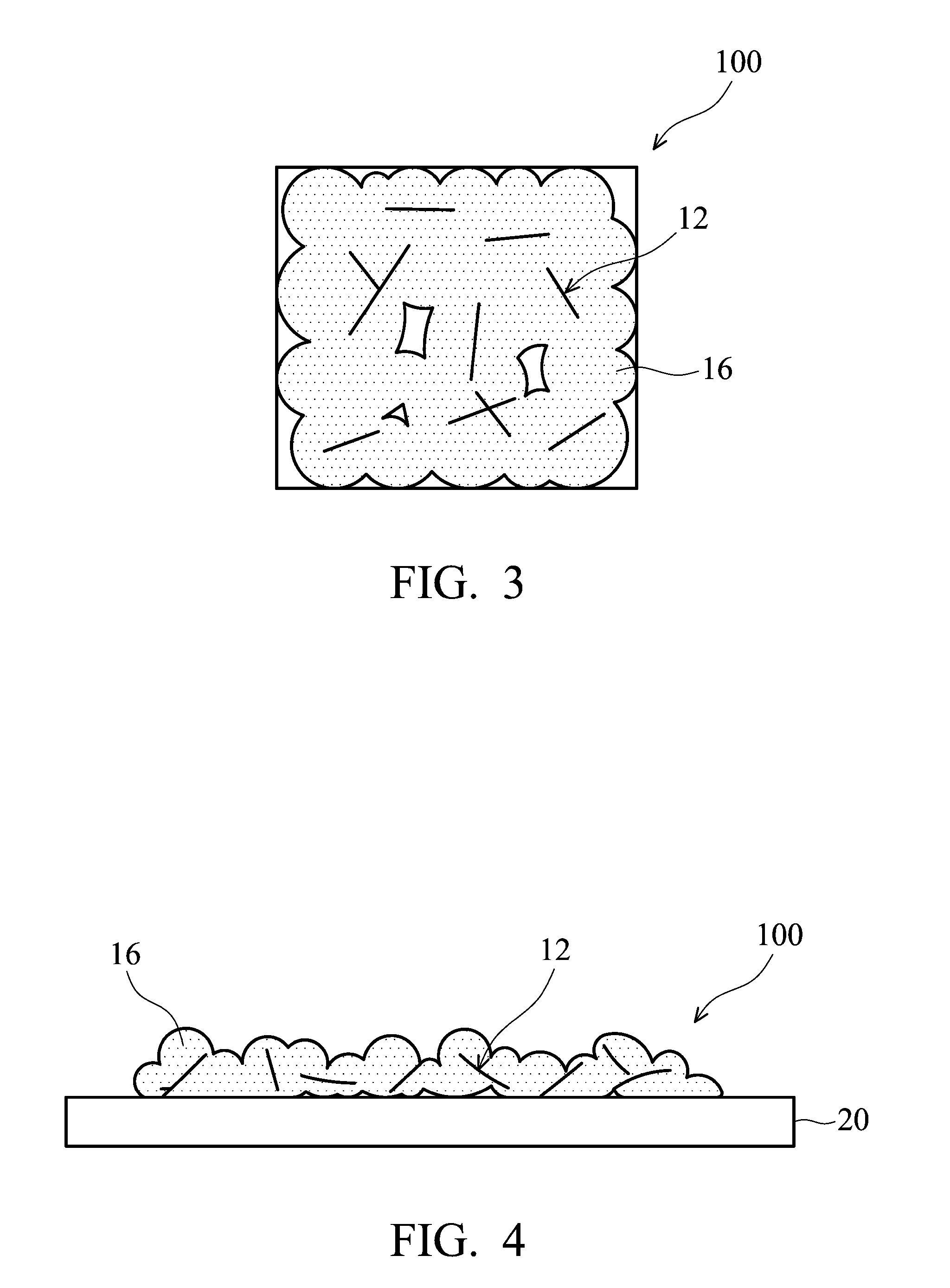

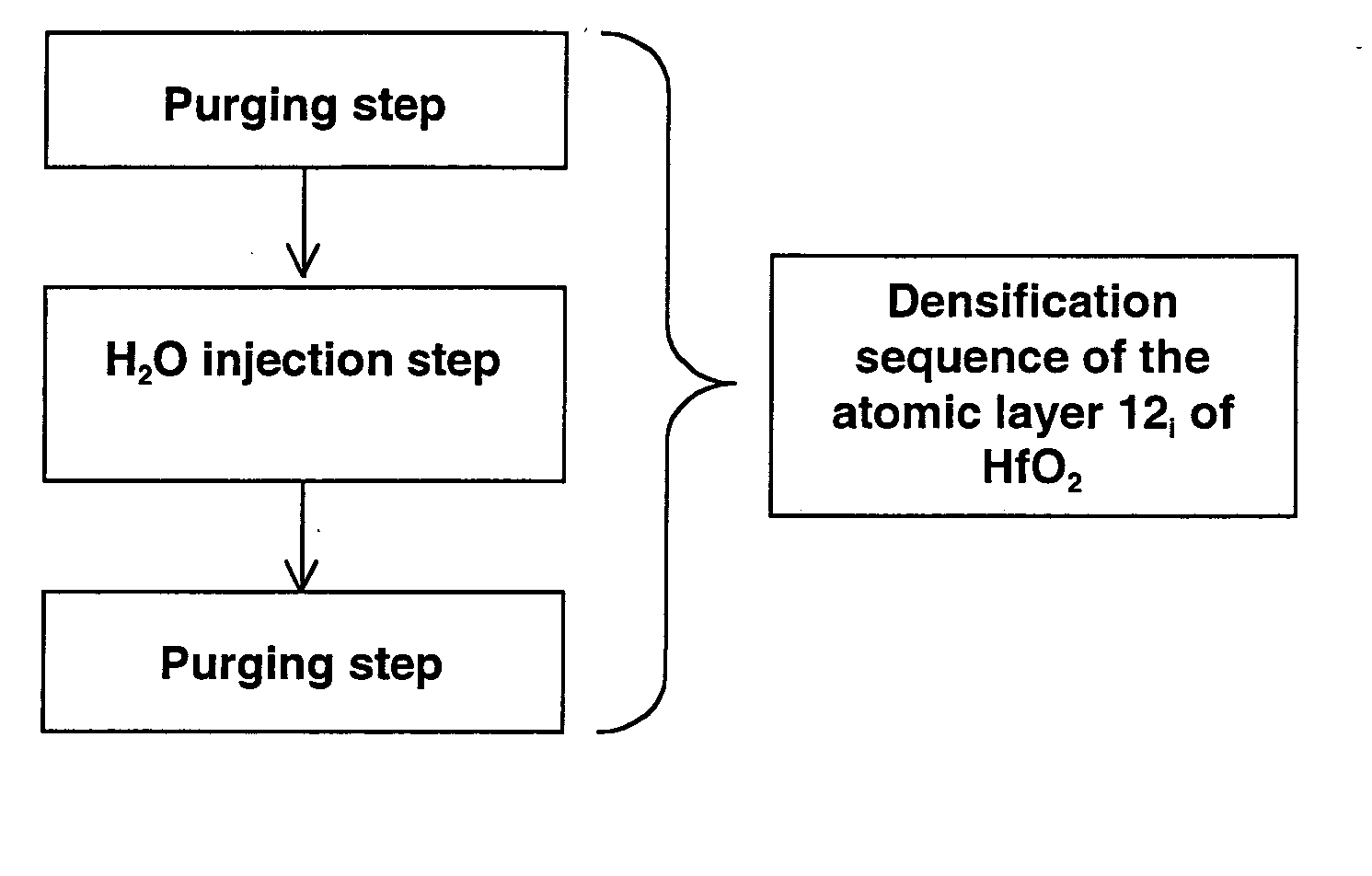

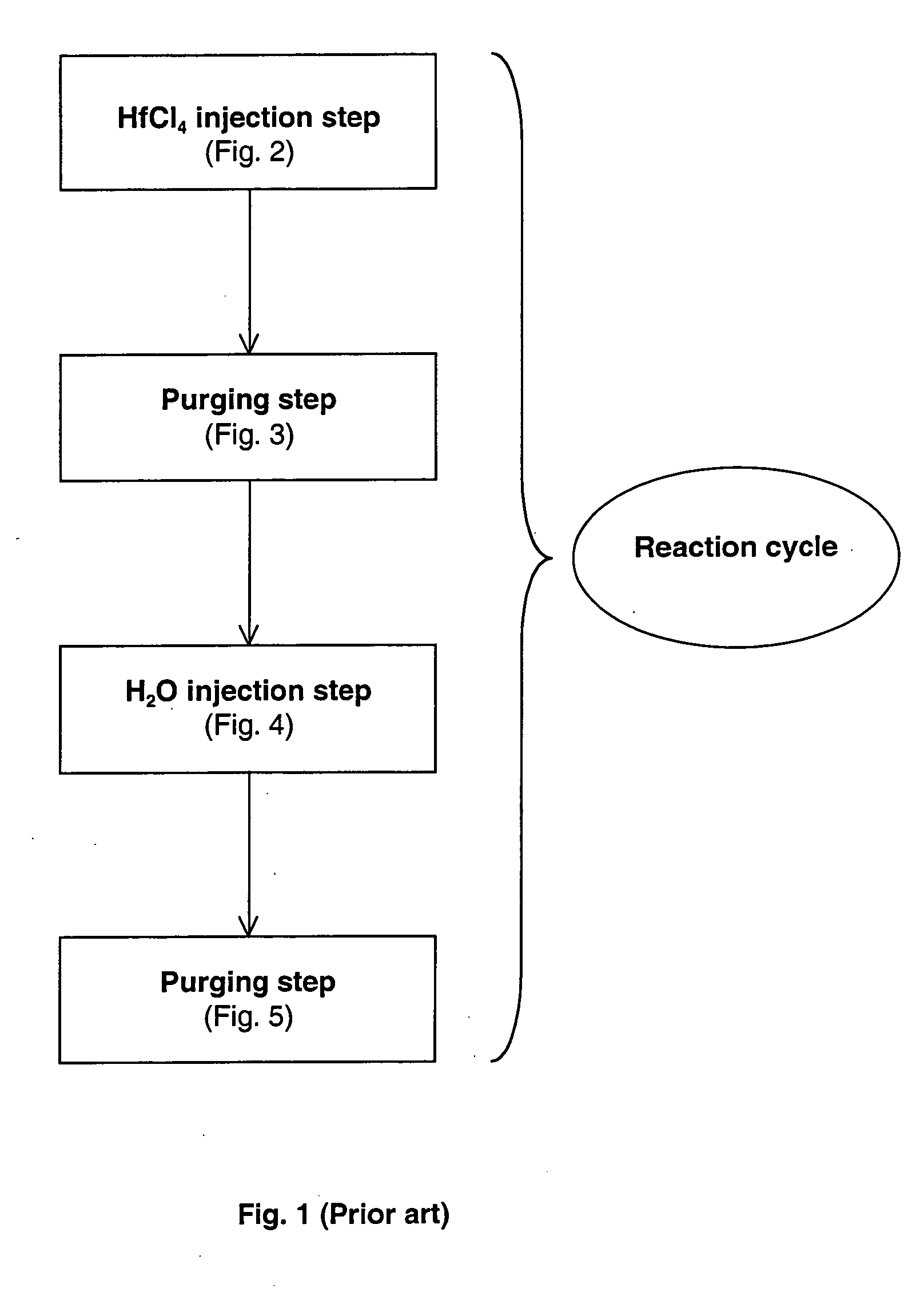

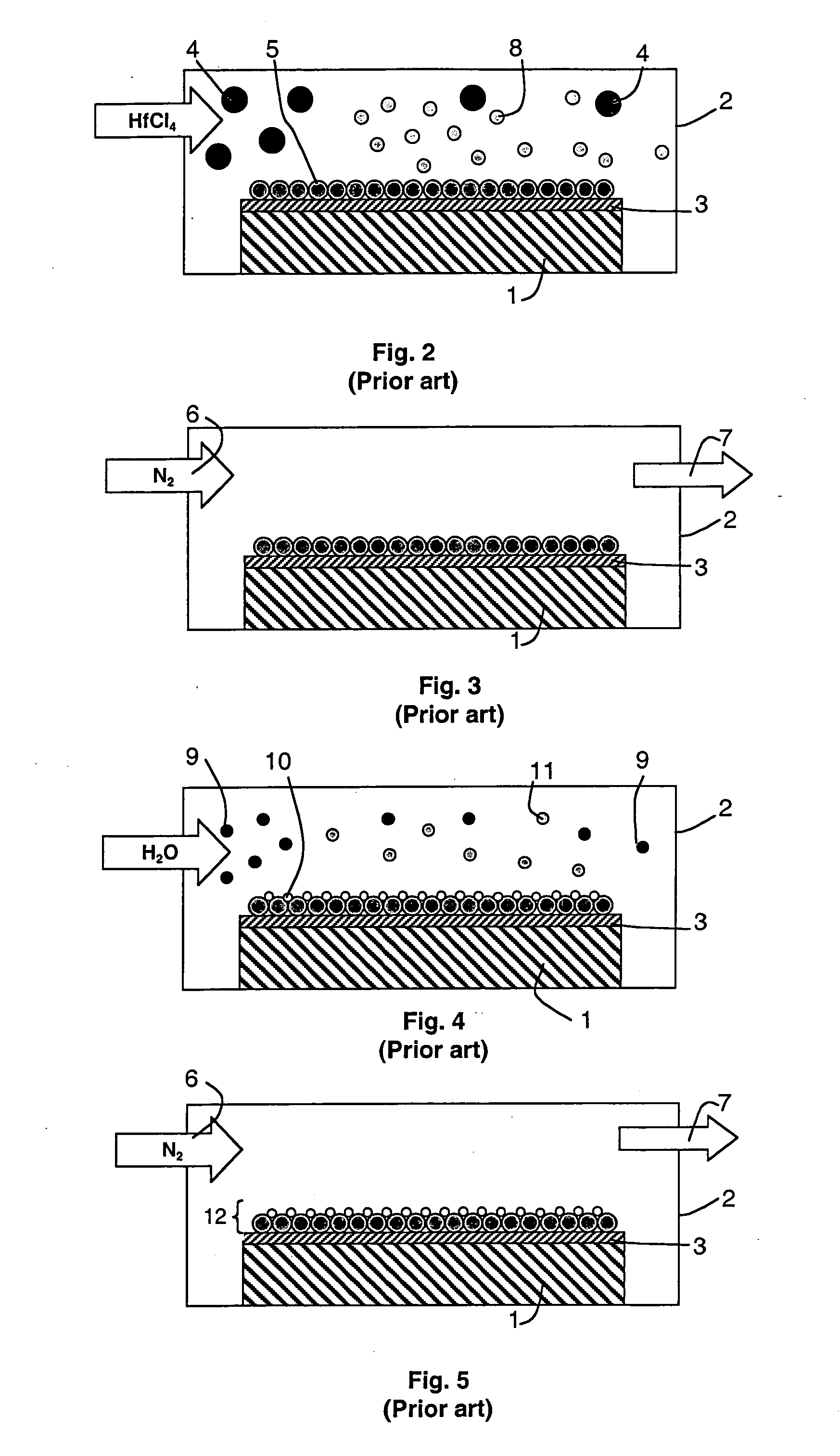

Process for deposition of a thin layer on an oxidized layer of a substrate

ActiveUS20050239298A1Effective controlSemiconductor/solid-state device manufacturingSpecial surfacesThin layerMaterials science

Owner:STMICROELECTRONICS (CROLLES 2) SAS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap