Silver nanowire conductive film and method of fabricating the same

a technology of silver nanoparticles and conductive films, which is applied in the direction of instruments, conductive layers on insulating supports, transportation and packaging, etc., can solve the problems of silver nanoparticle conductivity decreasing, and not being well oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

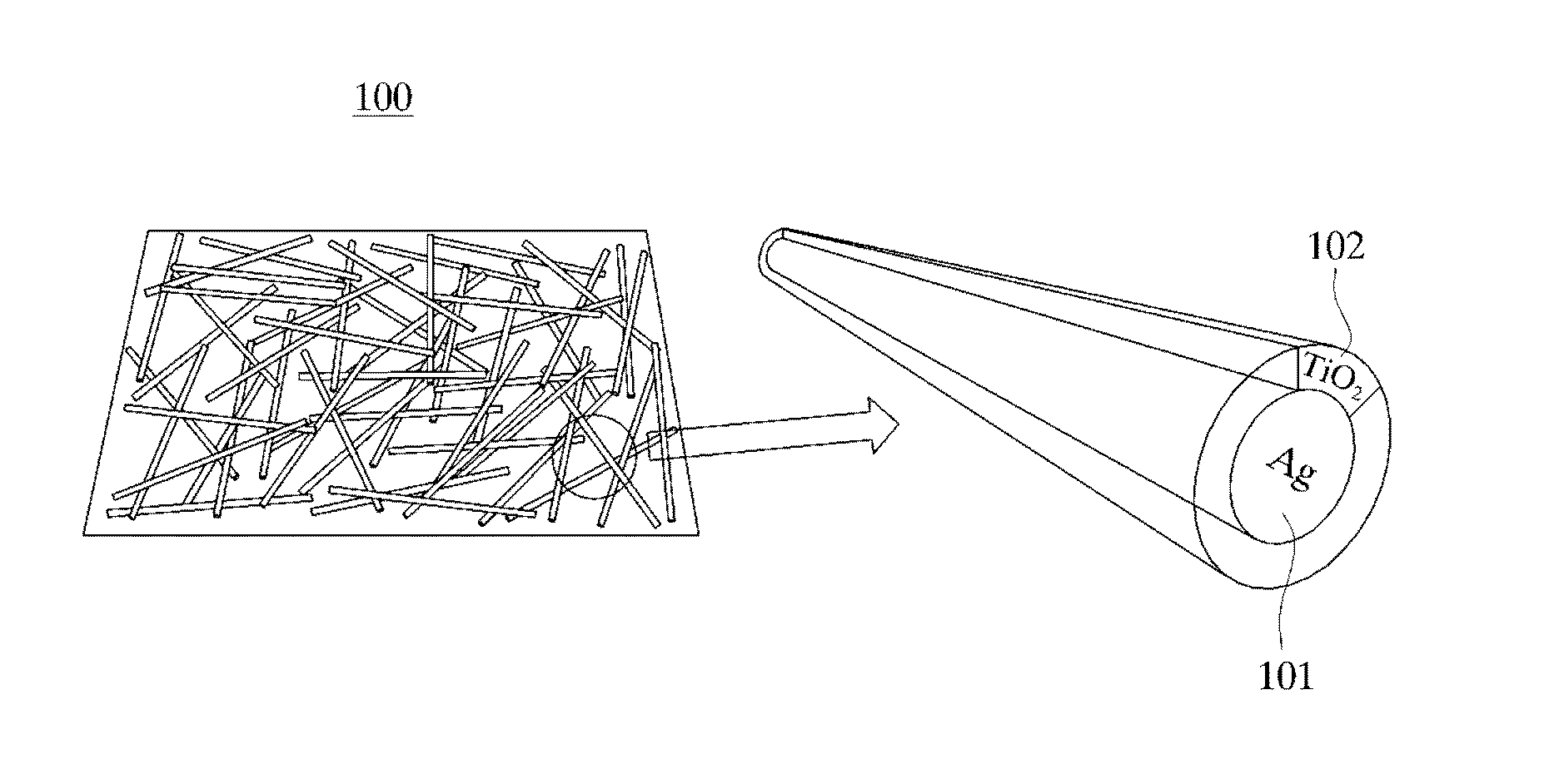

[0064]First, a PET film was prepared, and silver (Ag) nanowires were applied onto the PET film. (thickness of Ag nanowires and method of applying the naowires to the PET film, the specific PET film used, etc. may be described here). Next, a TiO2 oxide was coated on the surface of the silver nanowires using an ALD process.

[0065]TTIP (UP chemical) was used as a material for a TiO2 oxidation protection layer, and the ALD process was performed using ALD system (ForALL) equipment at a pressure of 1×10−3 torr and a temperature of 120° C. A desired number of 250-cycle (10 nm) and 500-cycle (20 nm) processes were performed according to the thickness of the TiO2 oxidation protection layer.

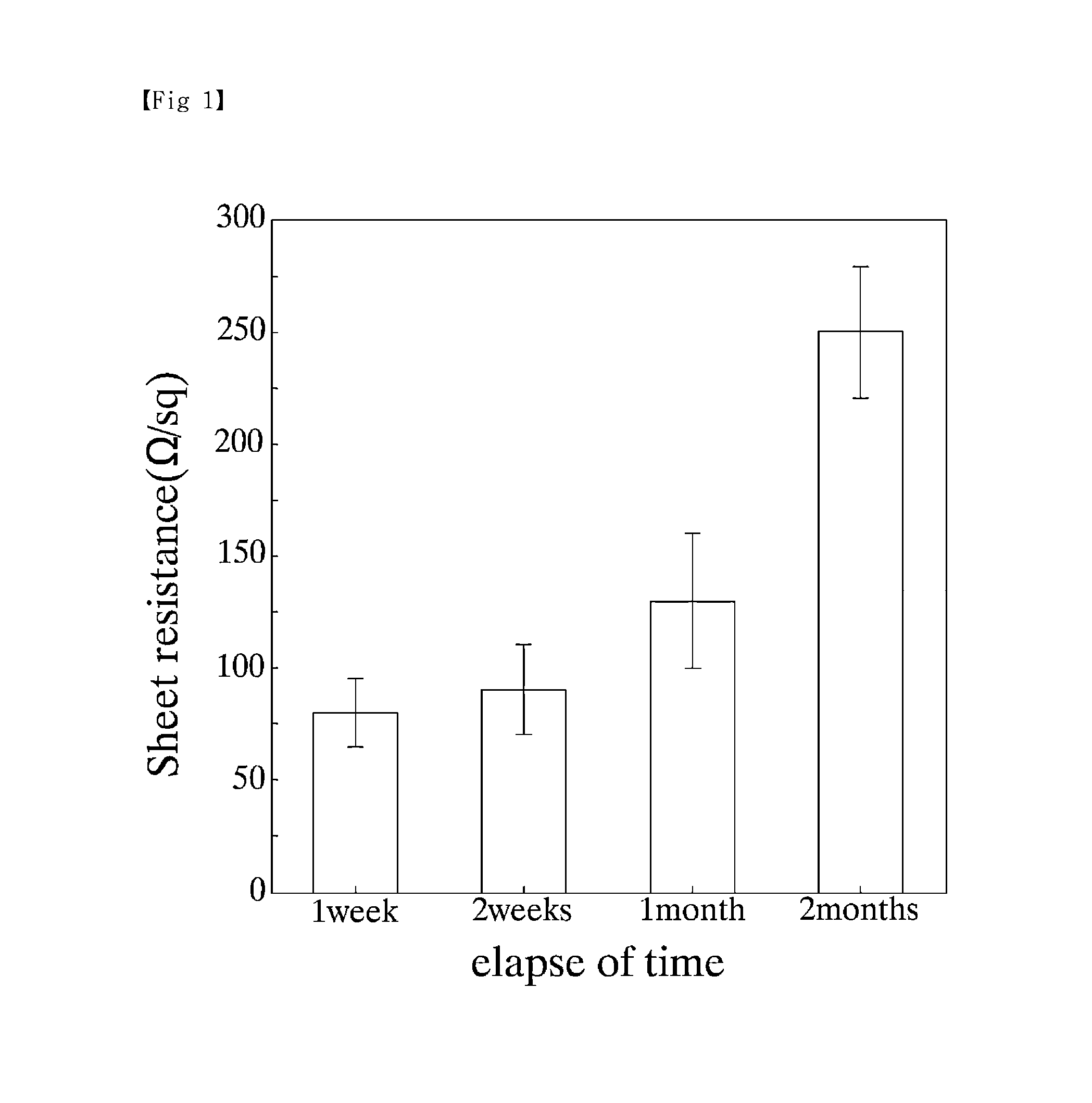

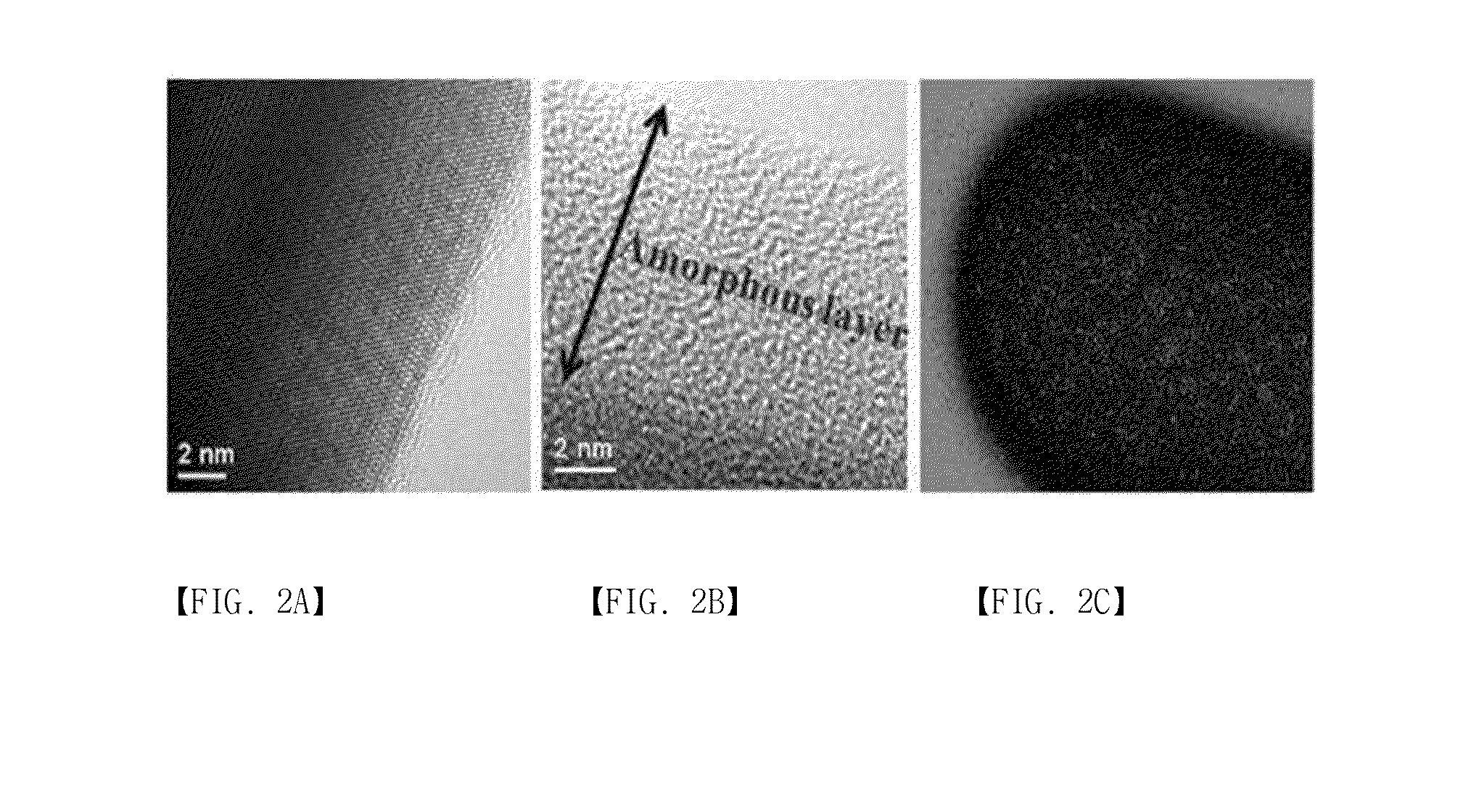

[0066]In order to compare a transparent conductive film not coated with an oxidation protection layer with a transparent conductive film coated with an oxidation protection layer, XPS was used to check oxidation of the transparent conductive film over time. In order to analyze the form of the TiO2 oxygen preve

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap