Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Protection layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Protection Layer. The Protection layer is your first line of defense against rain, snow, sleet, wind or any combination of elements that conspire to make you miserable. In this category, gear is either completely waterproof or highly water-resistant, yet breathability is not ignored to help prevent you from getting wet on the inside.

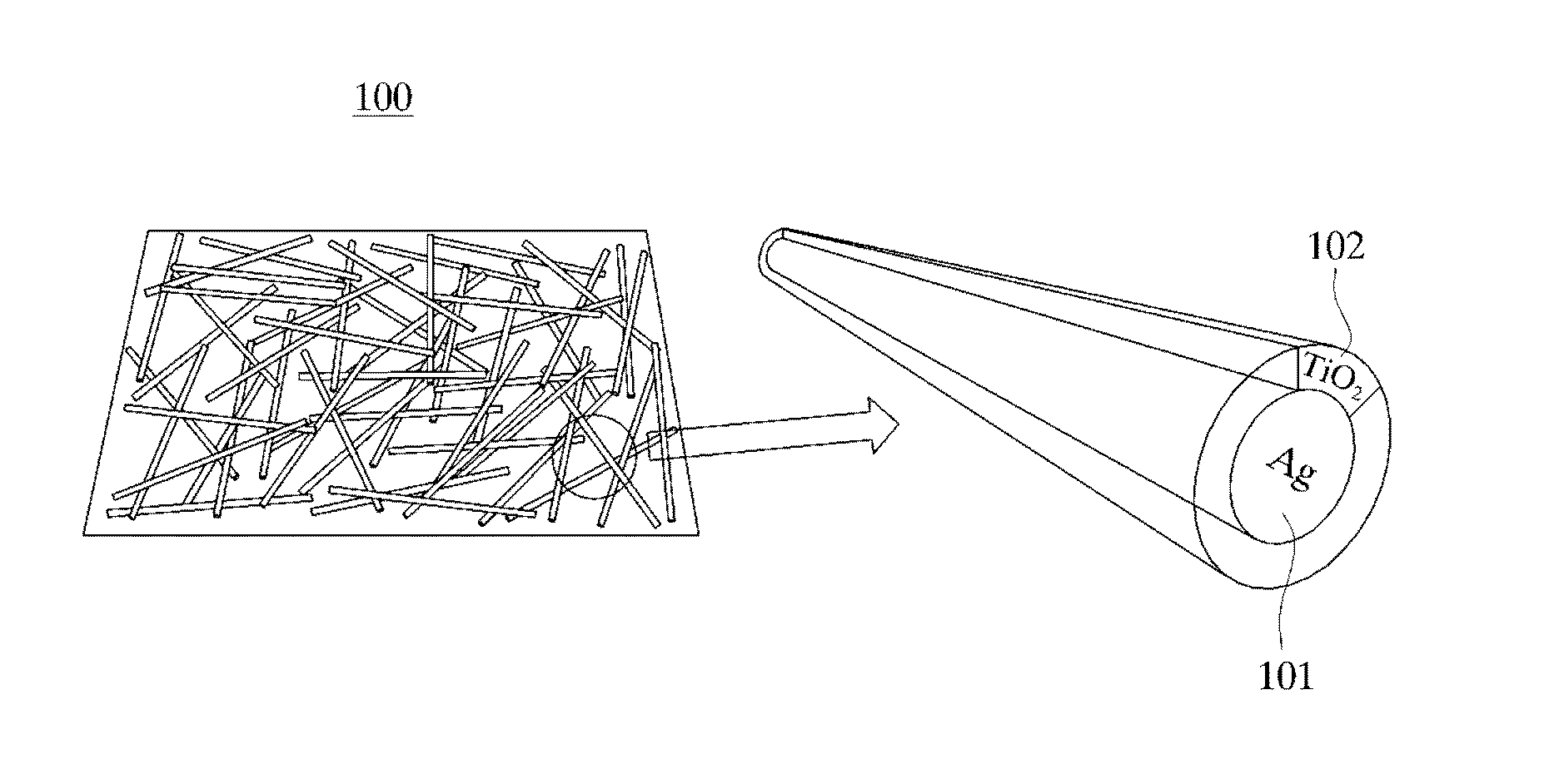

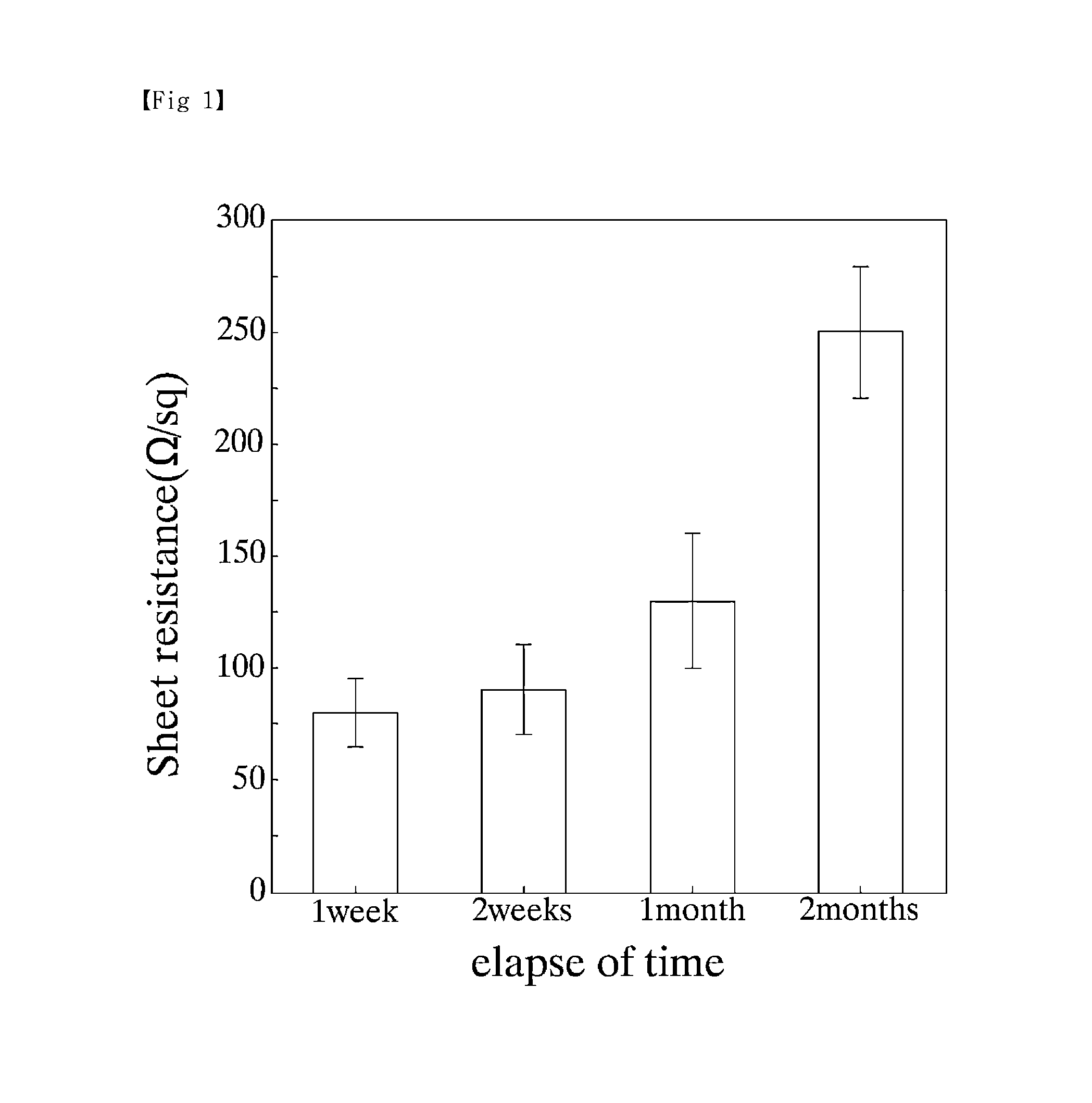

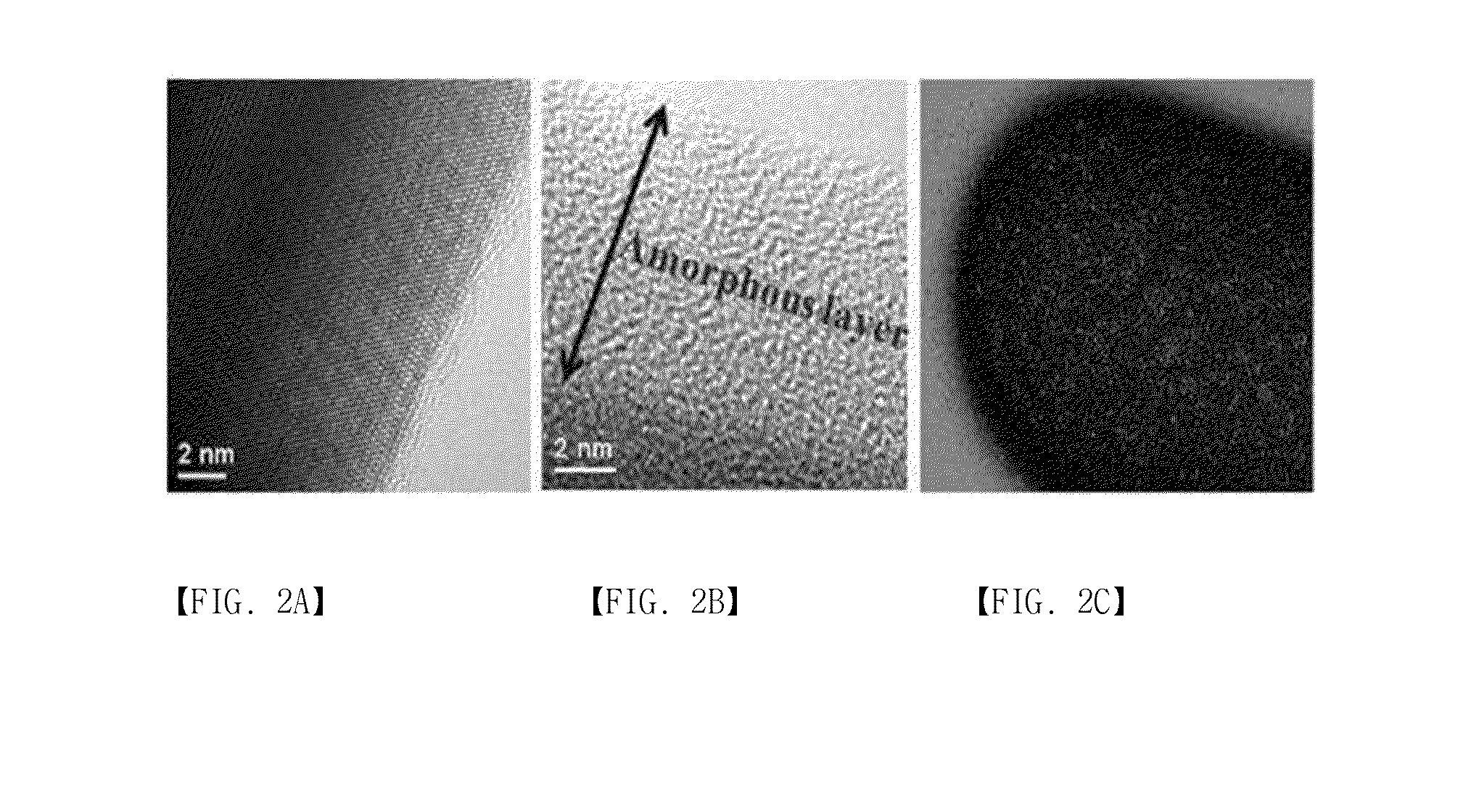

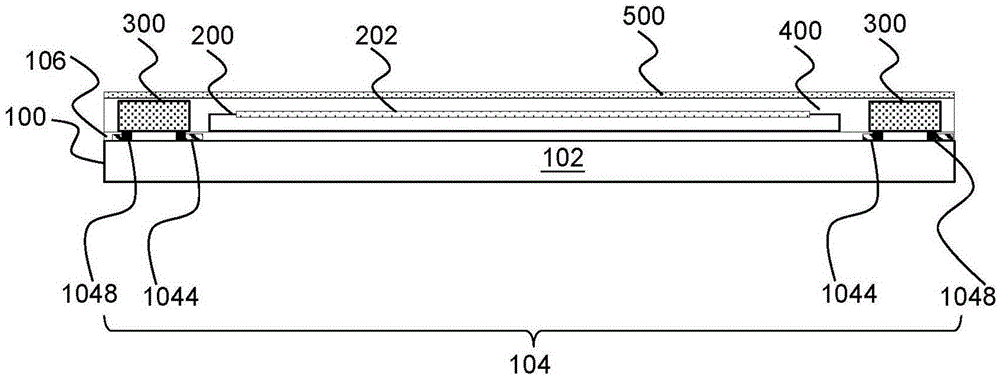

Silver nanowire conductive film and method of fabricating the same

ActiveUS20140020737A1Conductive layers on insulating-supportsSynthetic resin layered productsProtection layerSilver nanowires

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

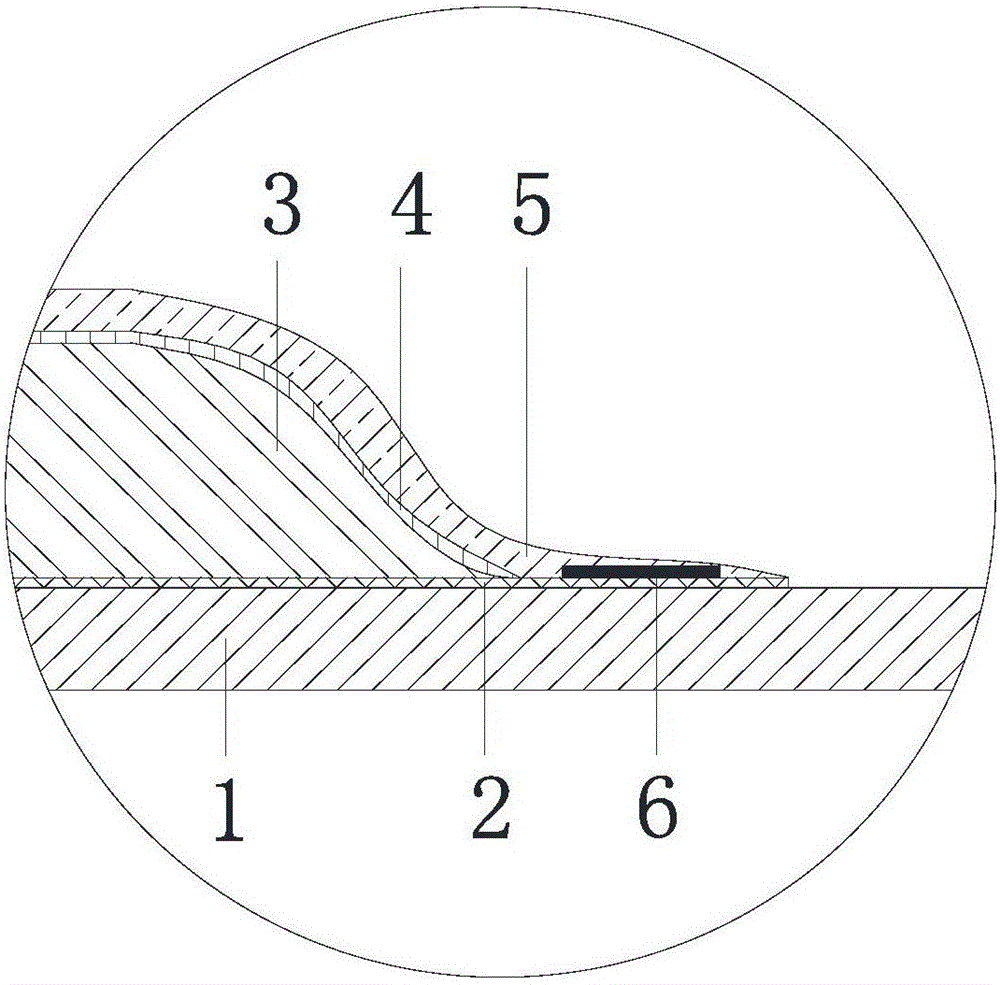

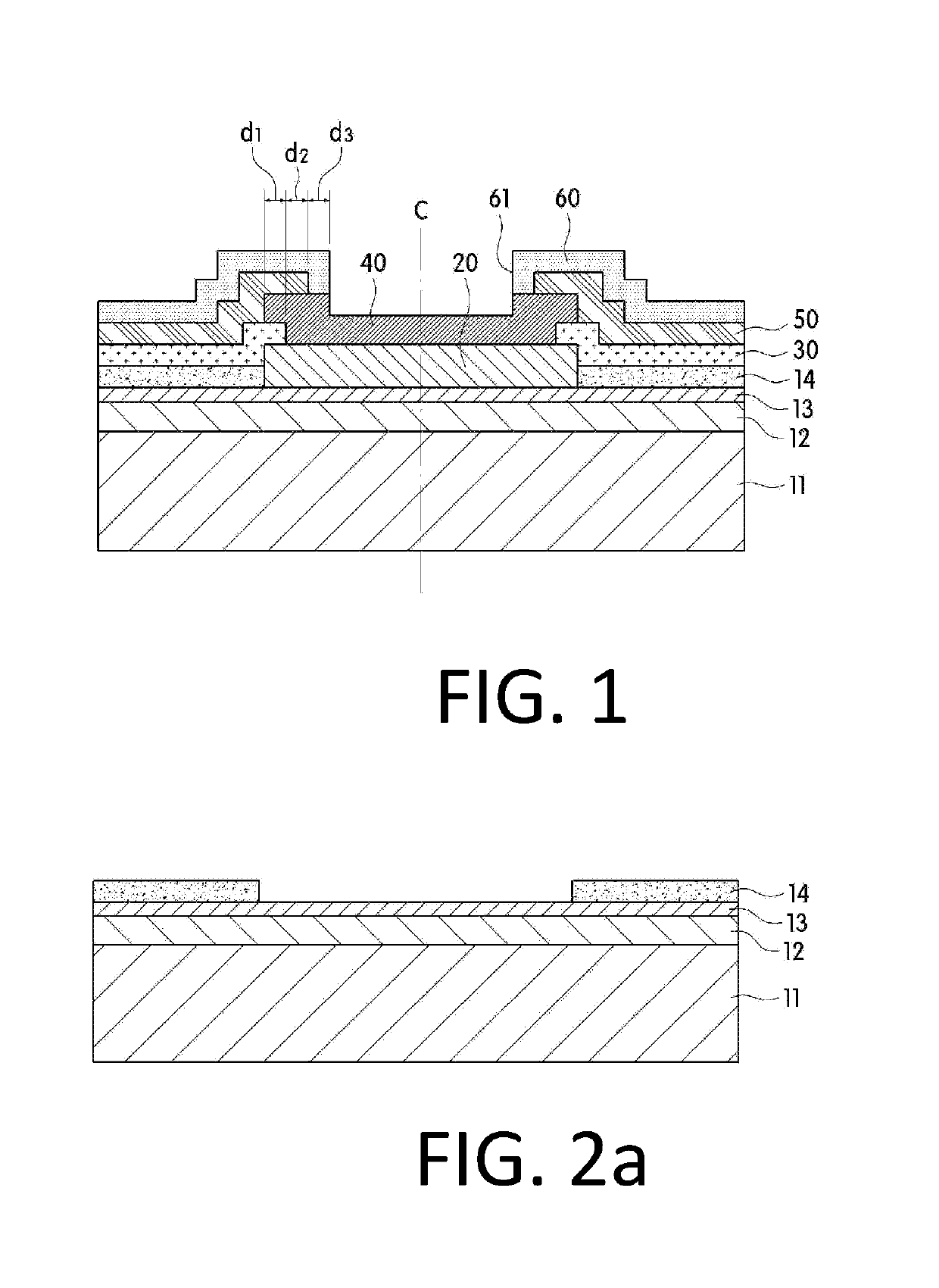

TFT array substrate manufacture method

ActiveCN105702623AReduce sizeNo short circuit problemSolid-state devicesSemiconductor/solid-state device manufacturingPixel densitySlope angle

The invention provides a TFT (Thin Film Transistor) array substrate manufacture method which comprises the following steps: coating and forming a flat layer on source electrodes and drain electrodes; instead of processing via holes, depositing and patterning a common electrode layer and a passivated protection layer; forming via holes in the passivated protection layer so as to expose the flat layer, and then ashing the flat layer so as to expose the drain electrodes. Compared with a conventional method by which the common electrode layer is deposited and patterned after the via holes are formed in the flat layer, the TFT array substrate manufacture method described in the invention is advantageous in that no electrically conductive material will be left in the via holes of the flat layer when the common electrode layer is patterned, and therefore no short circuit problem will occur in the via holes of the flat layer; the via holes are formed in the flat layer in a pixel region by a means of dry etching through ashing operation, the formed via holes are allowed to have large slope angles, and therefore the size of a TFT can be reduced to a certain extent and and pixel density can be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

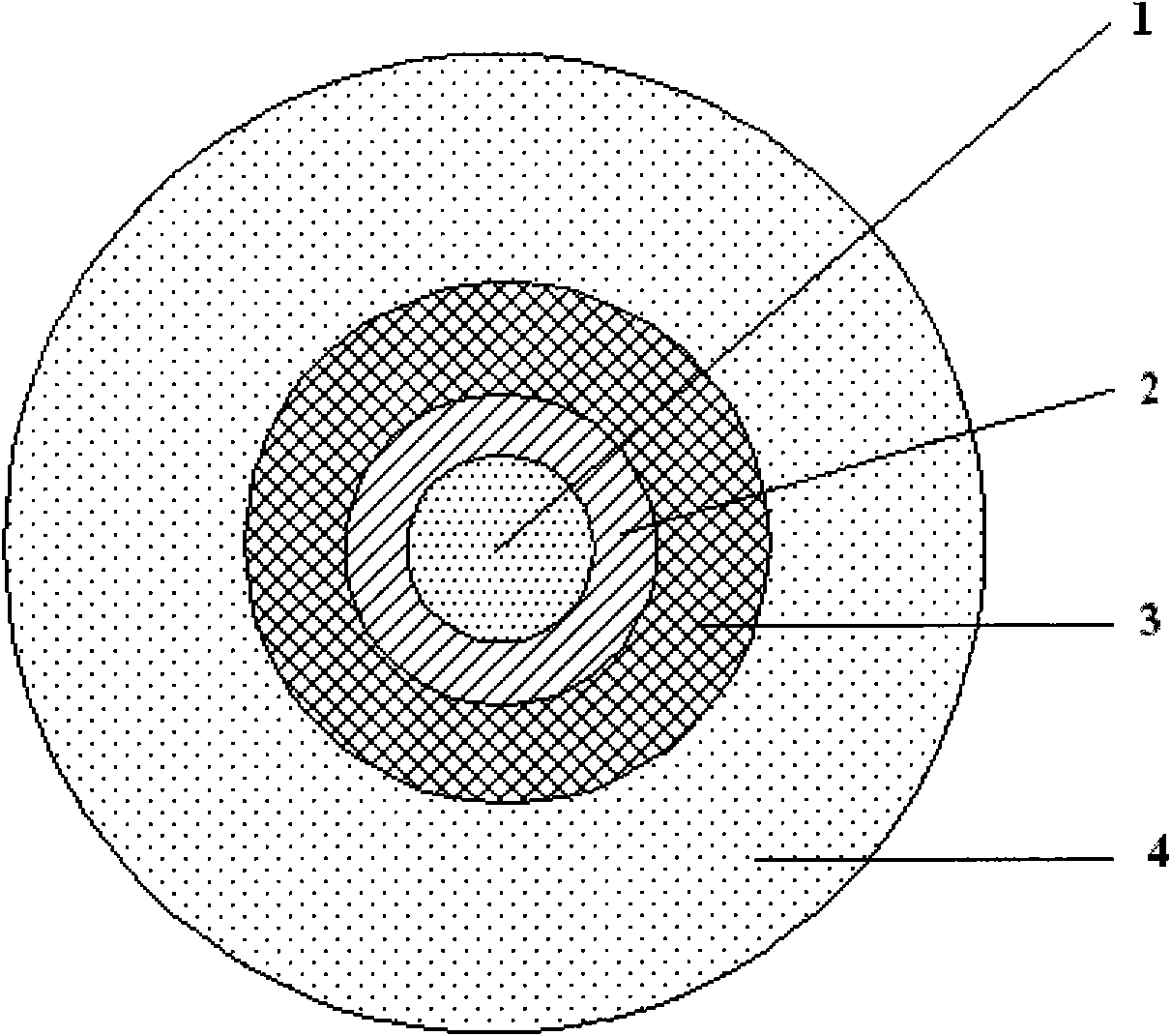

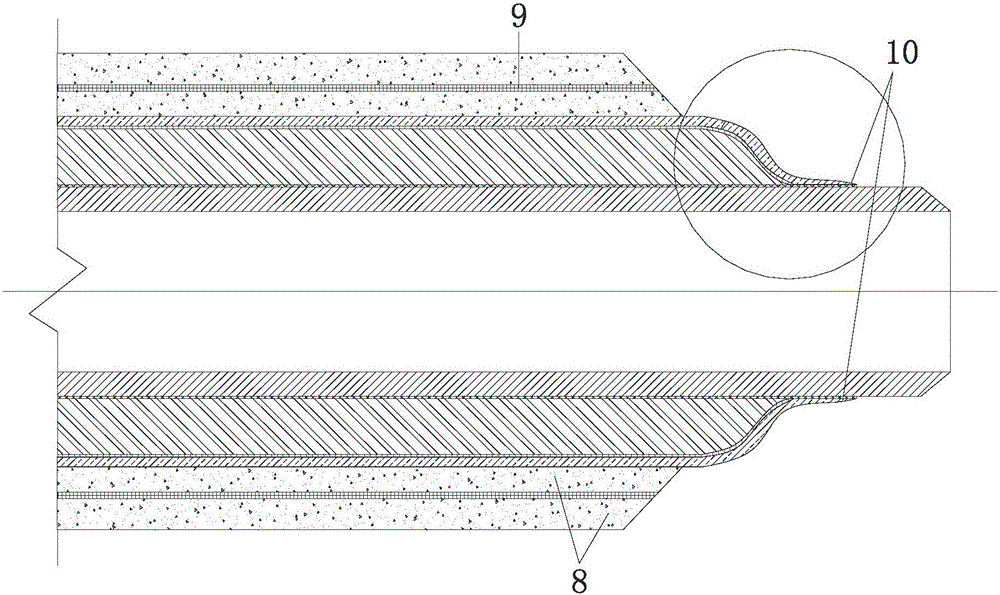

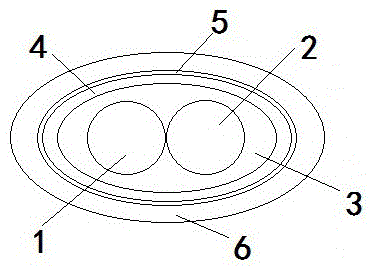

Lightning protected cable for communication base station

ActiveCN103325489ALower the resistance valueSmall short-term calorific valueCommunication cablesInsulated cablesAluminium hydroxideEngineering

The invention belongs to the technical field of cables and relates to a lightning protected cable for a communication base station. The lightning protected cable for the communication base station comprises a cable core, an inner protecting sleeve, an armor layer, an outer protecting sleeve and a ground layer. The lightning protected cable for the communication base station is characterized in that a first protecting layer is arranged outside the cable core, the inner protecting sleeve is arranged outside the first protecting layer, a second protecting layer is arranged outside the inner protecting sleeve, the ground layer is arranged outside the second protecting layer, the armor layer is arranged outside the ground layer, and the armor layer is coated with the outer protecting sleeve; the armor layer is a single-face film covering steel belt and the face, in contact with the ground layer, of the armor layer is a non-film-covering face; the first protecting layer and the second protecting layer are both mica tapes; the outer protecting sleeve comprises, by weight, the following raw materials of 71 parts of polyethylene, one part of anti-oxygen 1010, 12 parts of aluminum hydroxides, 0.5 part of HK-type antistatic agent, 3 parts of ethyl acetate, 1 part of carbon black, 10 parts of zirconium oxide and 1.5 parts of polyethylene wax. The lightning protected cable for the communication base station has the advantages of being simple in manufacturing, high in production speed, capable of enabling the electrical resisting rate of the ground layer to be low, low in maintaining cost, small in dust adsorption, pressure resistant, and good in flame resistance.

Owner:JIANGSU ZHONGLI GRP CO LTD

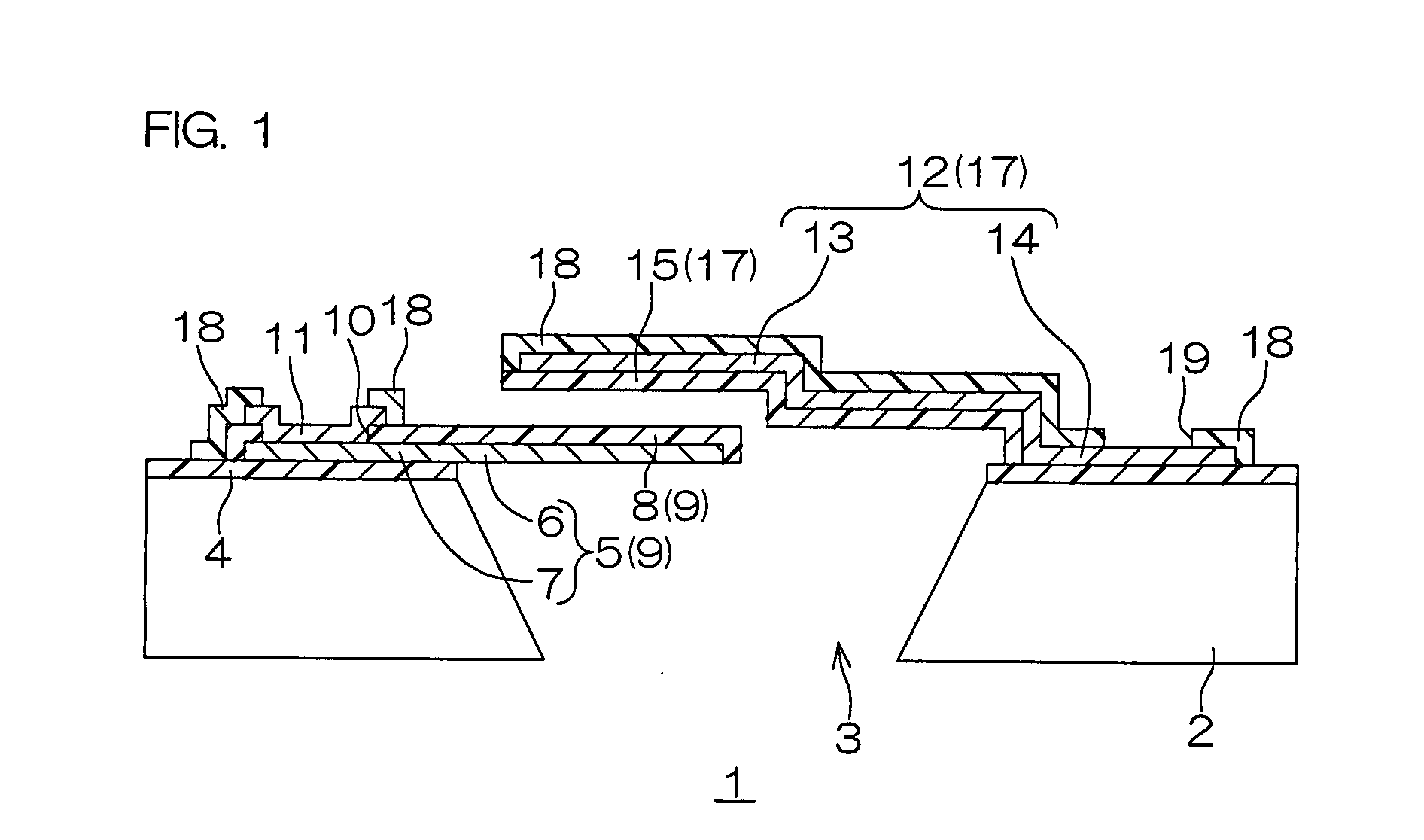

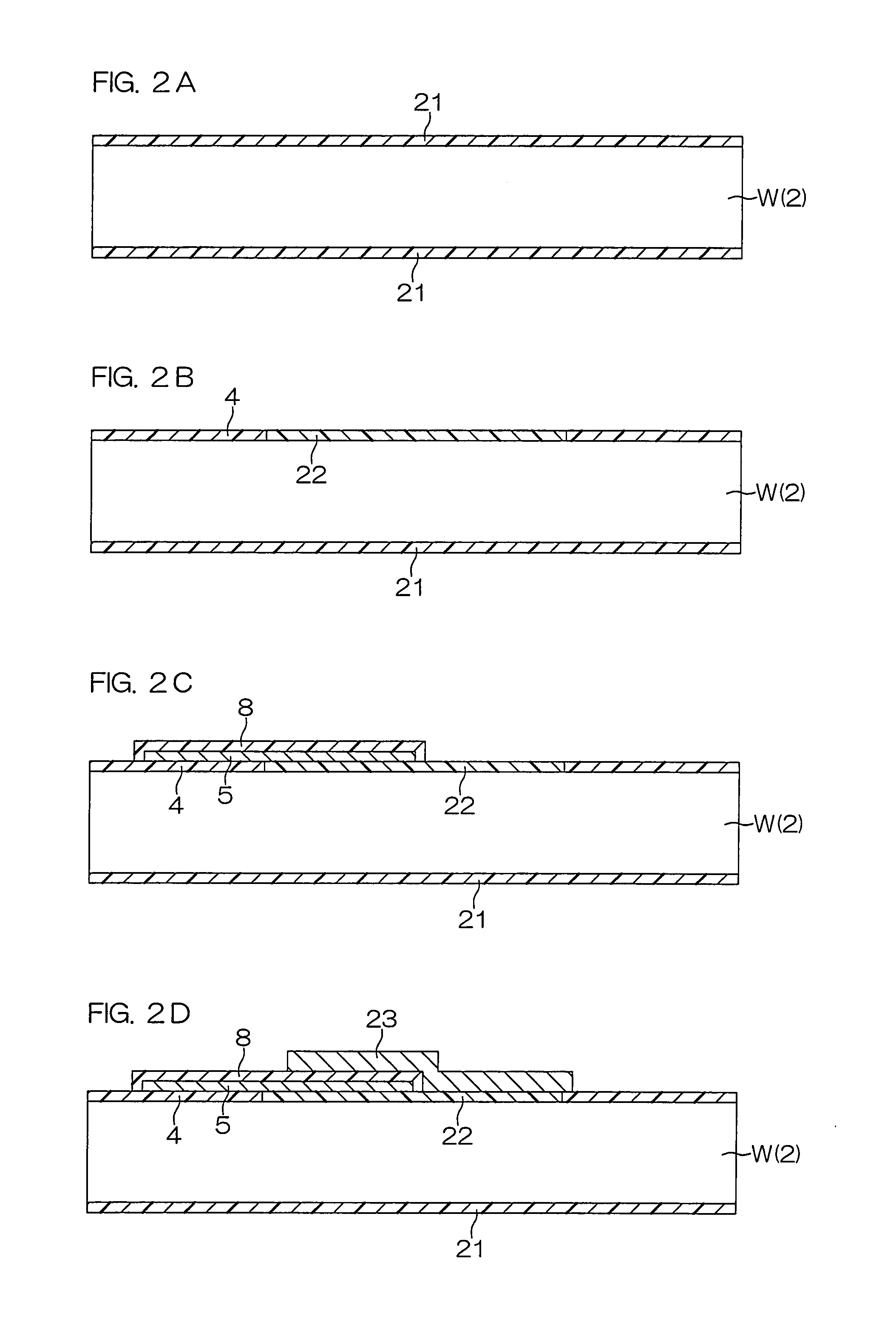

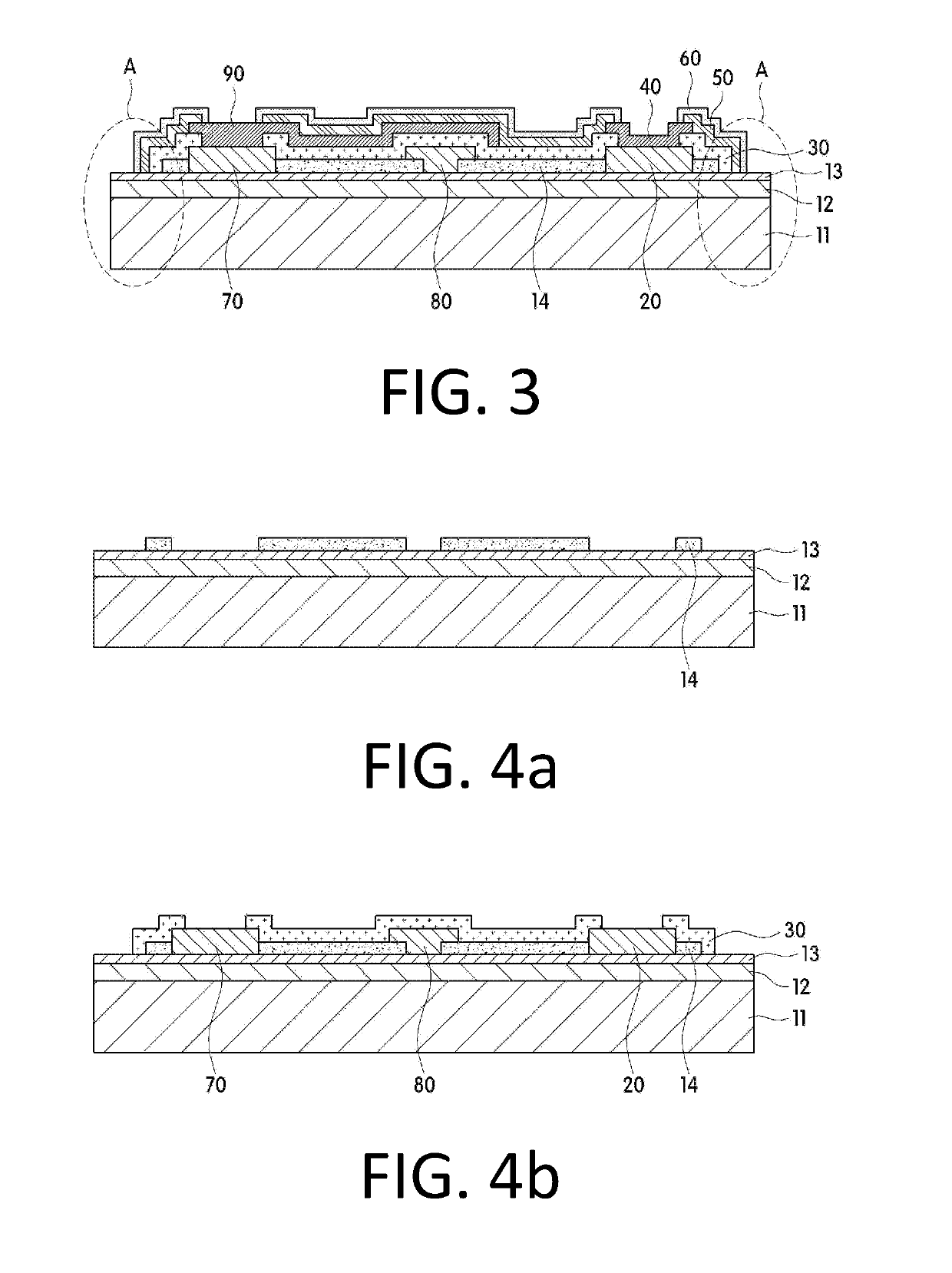

Method for manufacturing capacitive sensor, and capacitive sensor

InactiveUS20080087971A1Simple structureFirmly connectedSemiconductor/solid-state device manufacturingMicrostructural device manufactureInsulation layerCapacitive sensing

Owner:ROHM CO LTD

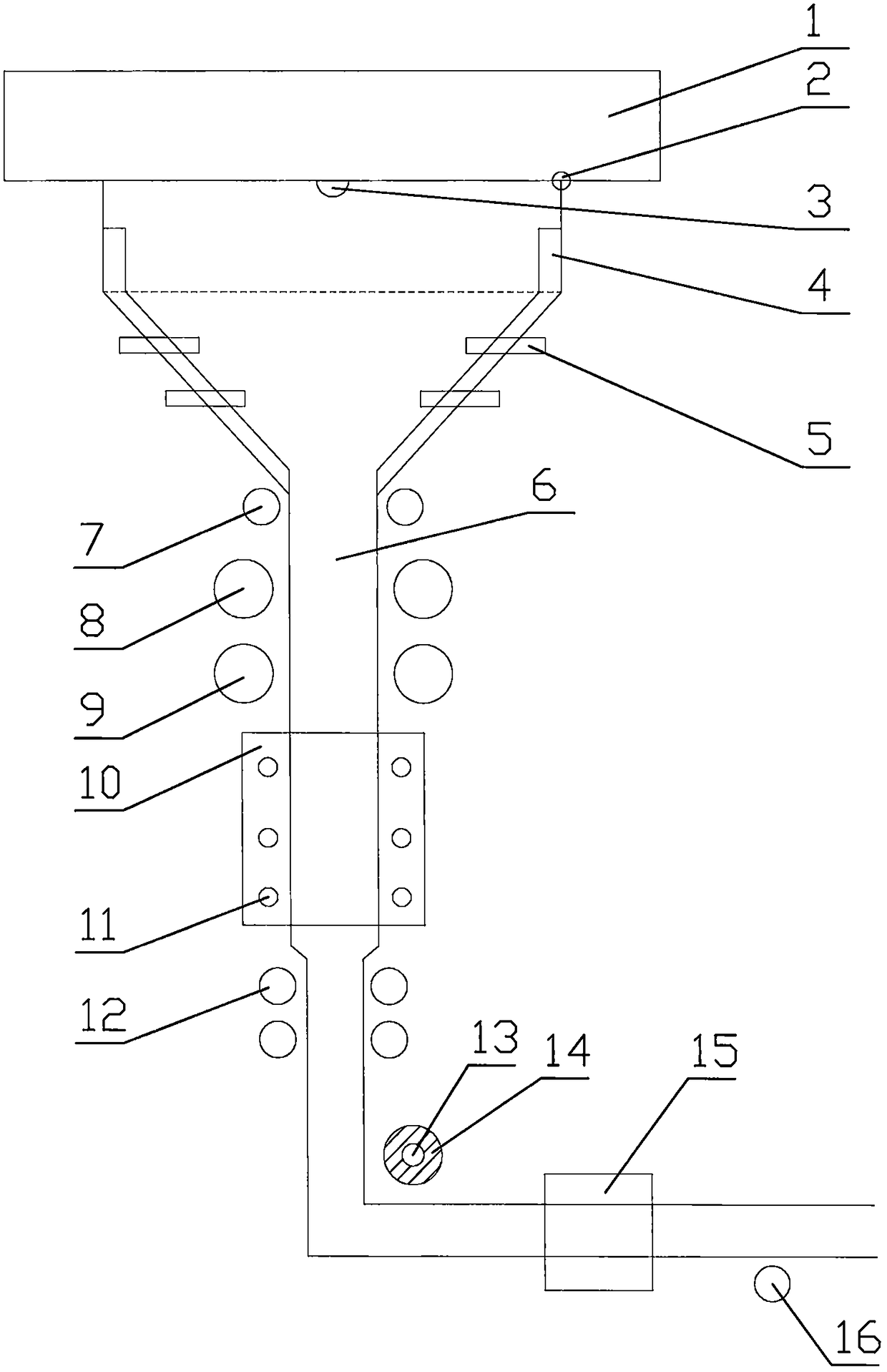

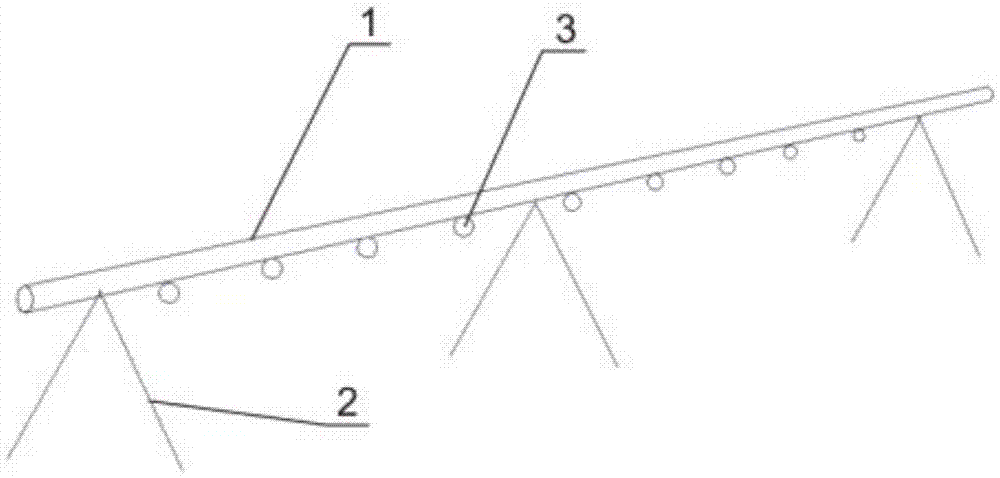

Bunchy armored optical cable and preparation method thereof

InactiveCN112198604AHigh strengthImprove tensile propertiesFibre mechanical structuresStructural engineeringProtection layer

Owner:TONGLING CITY TONGDOU SPECIAL CABLE CO LTD

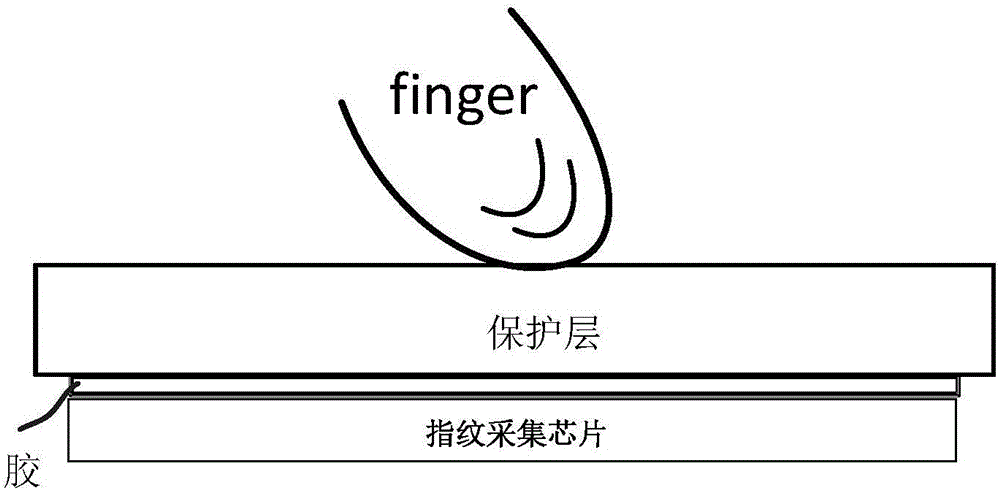

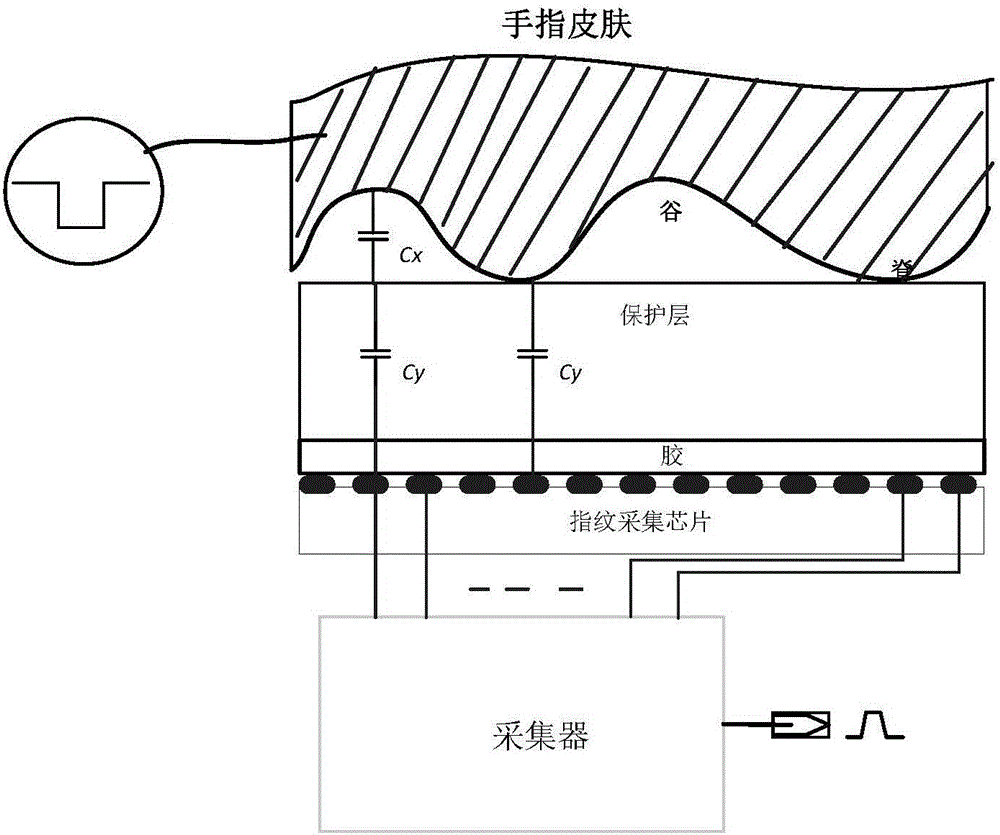

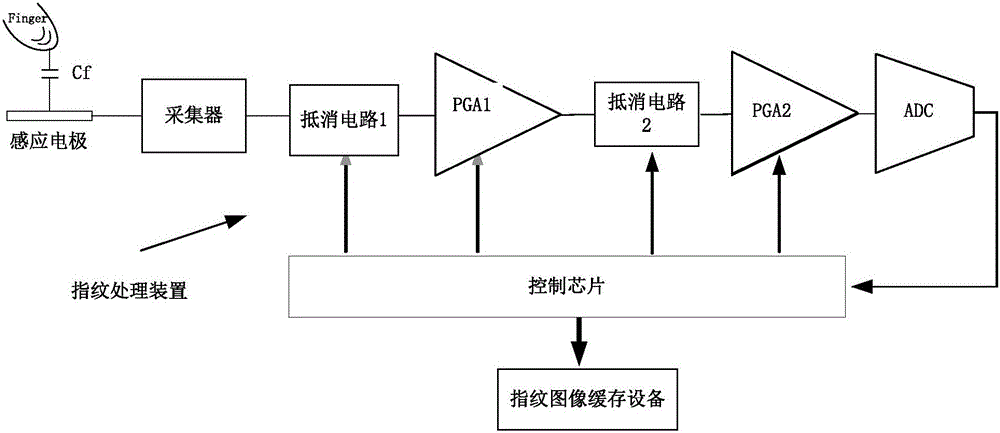

Fingerprint processing device

ActiveCN105913048AHigh-resolutionOffset Noise ImprovementPrint image acquisitionCapacitanceImage resolution

Owner:SHENZHEN BIOCOME SECURITY TECH CO LTD

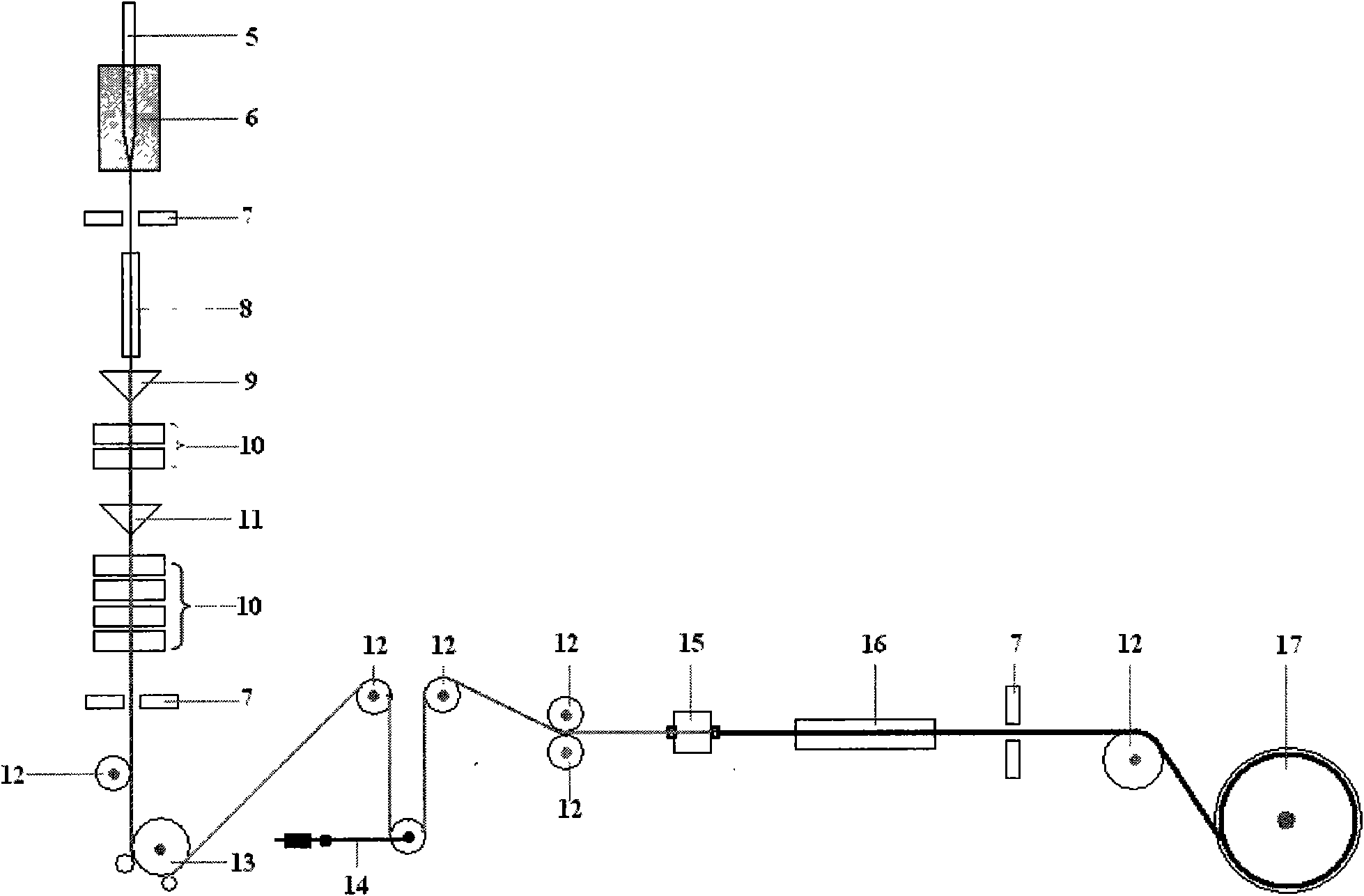

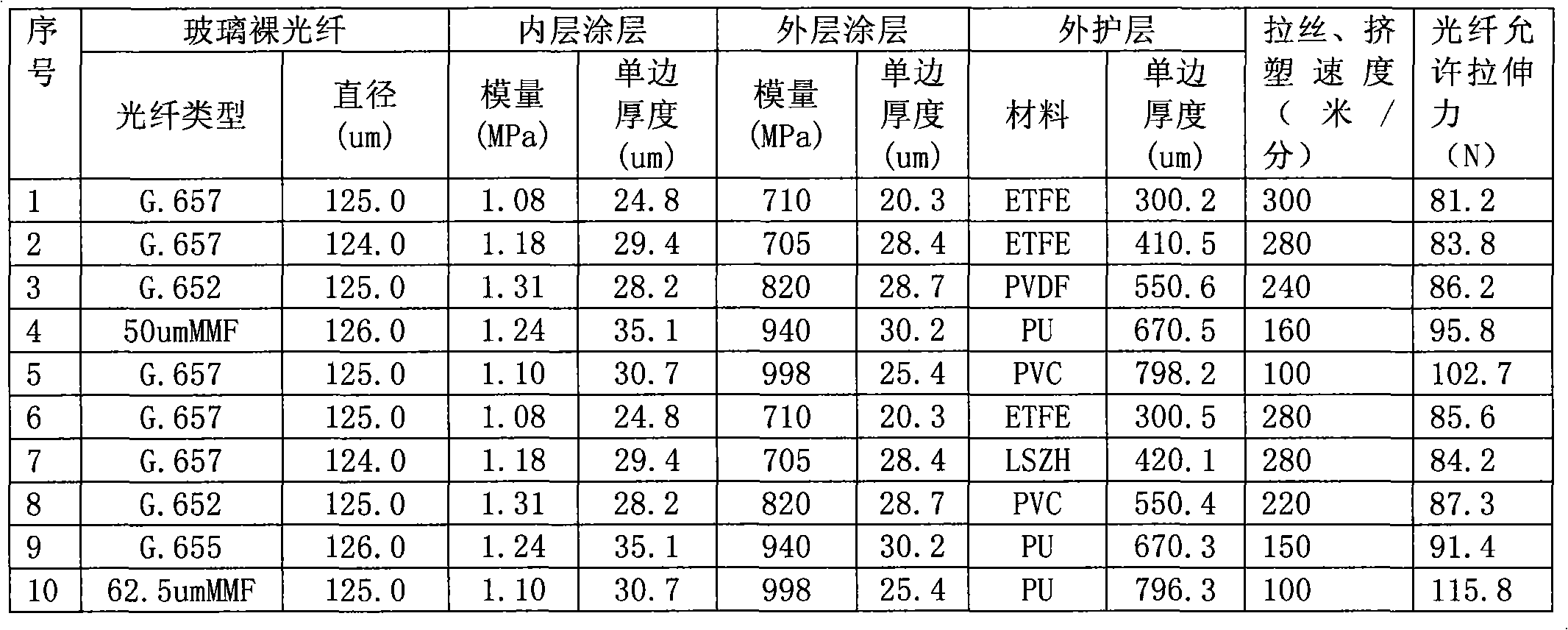

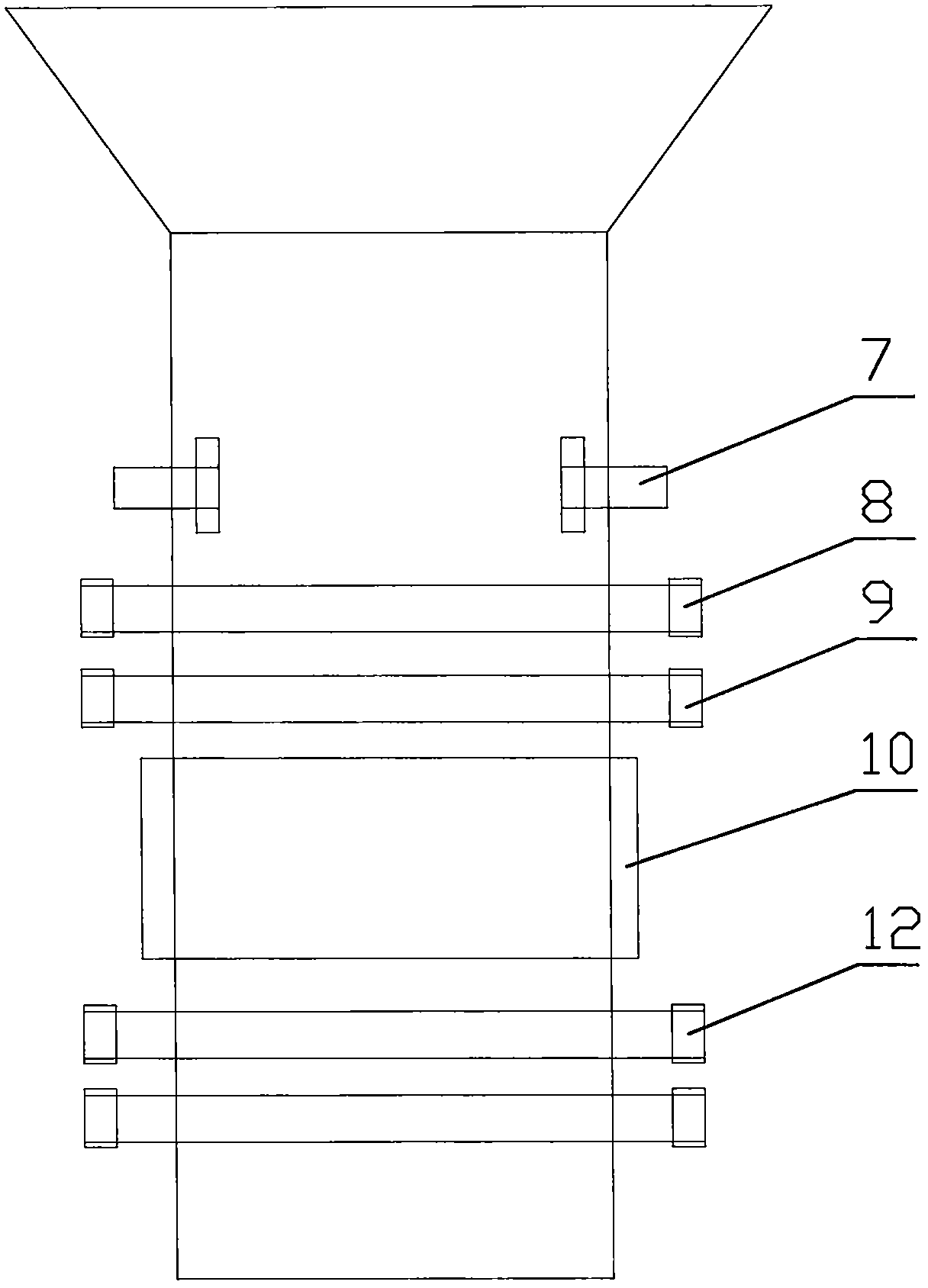

Indoor-laying optical fiber and manufacture method thereof

ActiveCN101614842AQuality improvementIncrease internal stressGlass making apparatusCladded optical fibreProduction lineProtection layer

Owner:SICHUAN LEFEI OPTOELECTRONICS TECH CO LTD +1

Equipment and method for preparing ultra-thin glass by utilizing glass fiber melting furnace discharge materials

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

Method of patterning a layer of a material

InactiveUS20060172518A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingAnti-reflective coatingProtection layer

The present invention reduces problems resulting from an incomplete removal of photoresist in a photolithographic process which are caused by a diffusion of contaminants from an anti-reflective coating into a layer of photoresist. A protective layer is formed over the anti-reflective coating, and the layer of photoresist is formed over the protective layer. The protective layer substantially prevents a diffusion of contaminants into the photoresist.

Owner:ADVANCED MICRO DEVICES INC

Metal reflector and manufacturing method thereof

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Marine polyurethane spraying prefabricated thermal insulation balance weight pipe and preparation method thereof

InactiveCN105909883AEnsure consistencyAvoid your own flawsThermal insulationPipe protection by thermal insulationPolyolefinAdhesive

Owner:CHINA NAT OFFSHORE OIL CORP +1

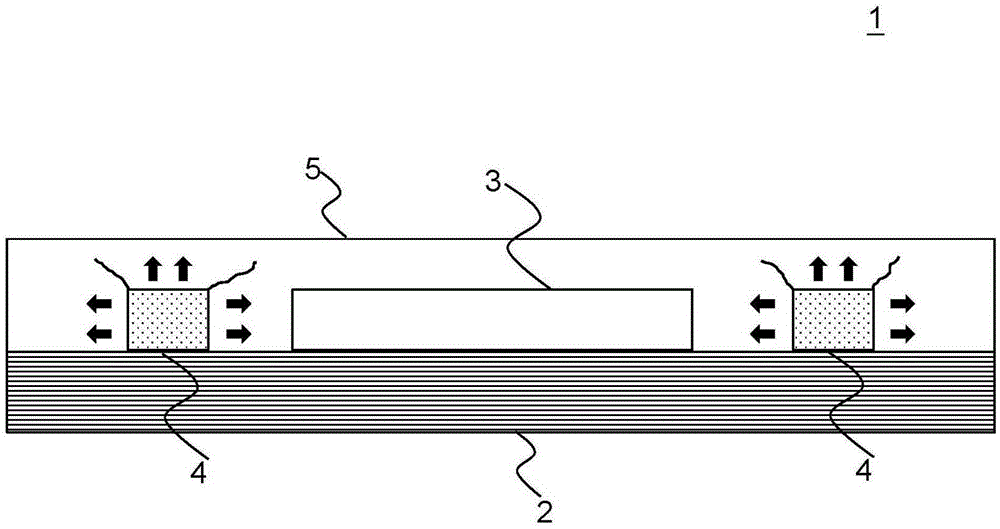

Thin film capacitor and electronic apparatus

ActiveUS20190080849A1Improve usabilityThe degree of freedom becomes largerMultiple fixed capacitorsFixed capacitor electrodesElectrical conductorElectrical connection

A plurality of first and second capacitor parts and second capacitor parts are formed on opposed main surfaces of a foil shaped conductive substrate to sandwich the conductive substrate. The first and second capacitor parts are respectively coated with insulative protection layers. Terminal electrodes are respectively formed on main surfaces of the protection layers. The terminal electrodes and conductive parts of the first and second capacitor parts are respectively electrically connected via first via conductors and the terminal electrodes and the conductive substrate 1 are electrically connected to second via conductors.

Owner:MURATA MFG CO LTD

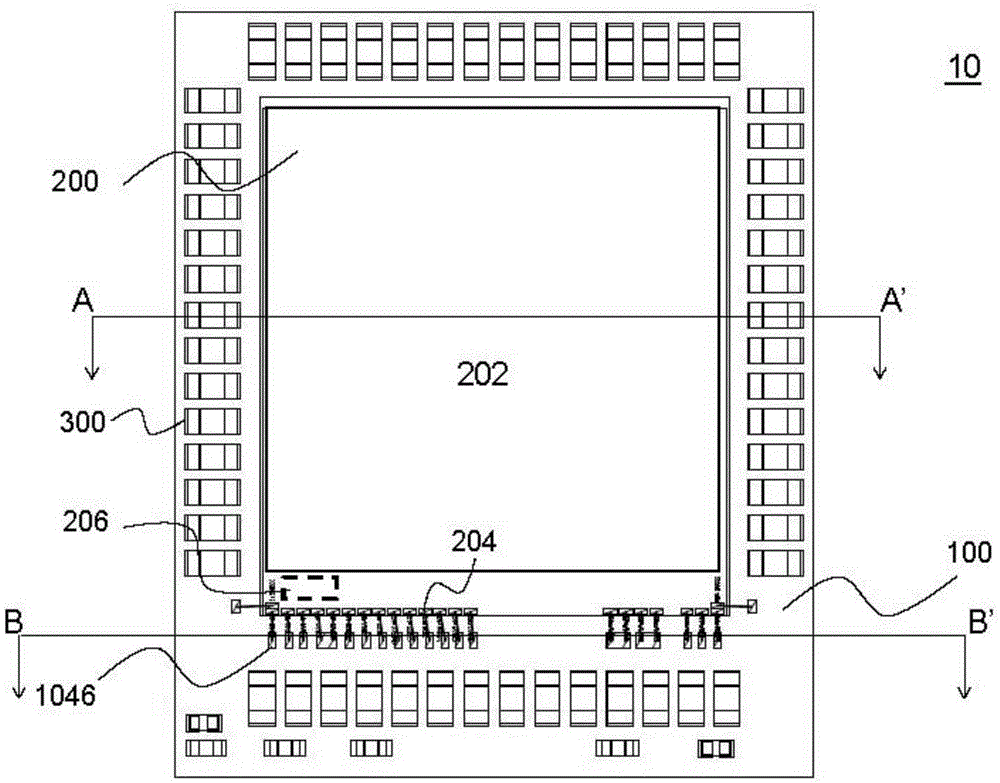

Printed circuit board element for forming enhancement mode biosensing module and fabrication method for printed circuit board element

InactiveCN106686888ALow costAvoid crackingPrint image acquisitionPrinted circuit non-printed electric components associationElectricityComputer module

Owner:SUNASIC TECH

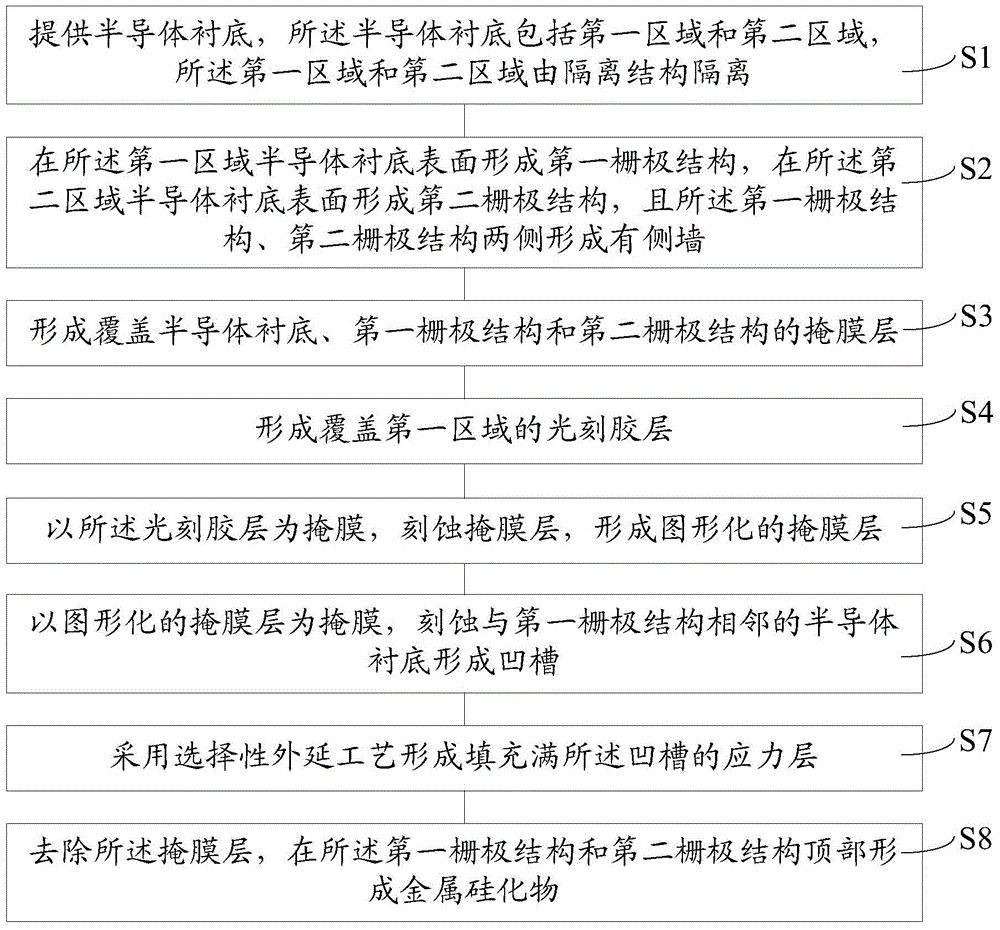

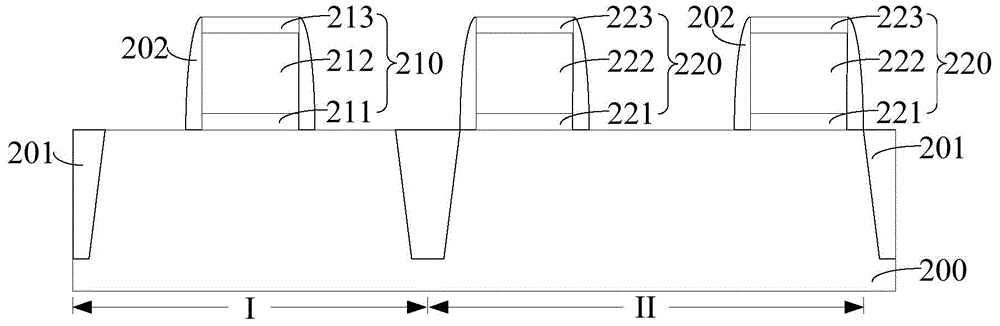

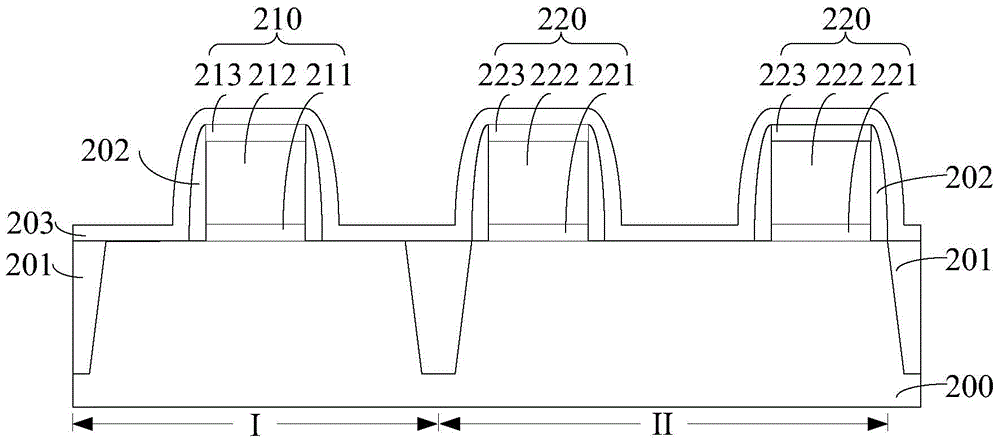

Semiconductor component forming method

ActiveCN104701166AAvoid damageGood choiceSemiconductor/solid-state device manufacturingDeposition processProtection layer

Owner:SEMICON MFG INT (SHANGHAI) CORP

Construction method of long steel bar stool cast-in-situ floor

InactiveCN105442735AControl thickness deviationEasy constructionFloorsBuilding reinforcementsFloor slabSurface level

Owner:广西华业建筑工程有限公司

Direct-current cable

Owner:秦川

Utility accessories and service hardware having luminosity for non-lighted and emergency conditions

InactiveUS20020150721A1Enhance luminescent outer surfaceEasy to observeSynthetic resin layered productsNatural mineral layered productsComposite laminatesEmergency encounter

A luminescent composite laminate structure for utility accessories and service hardware having luminosity for emergency and non-lighted conditions in which to illuminate the outer surface of such hardware and accessories. The composite laminate structure includes a plurality of layers for the protection of the luminescent outer surface of the laminated hardware or accessories. The plurality of layers include an outer first layer, an inner second layer and an inner core third layer for covering the outer surface of such hardware or accessories. The outer first layer is a plastic protective covering for resistance to wear and impact; and the outer first layer is covering the inner second layer and has an inner surface wall in contact with the inner second layer. The inner second layer is a plastic micro-thin covering having a plurality of micro-hole openings for the transfer of oxygen (O2) through the micro hole openings in order to increase visibility of the luminescent outer surface: and the inner second layer is covering the inner third layer and having an inner surface wall in contact with said inner core third layer. The inner core third layer is a luminescent material coating for providing luminosity to the outer surface of such hardware or accessories; and the inner core third layer is coating the outer surface of such hardware and accessories.

Owner:PITTS ALGEROME

Corrugated paper material arrangement table

InactiveCN103693490AEasy to tidyAvoid wear and tearPile receiversPulp and paper industryProtection layer

The invention provides a corrugated paper material arrangement table. The corrugated paper material arrangement table comprises a bracket, wherein a panel is arranged on the bracket; sliding grooves are formed in two sides of the panel; a positioning block is arranged on the panel; sliding blocks are arranged at two ends of the positioning block and are arranged in the sliding grooves; a certain clearance is formed between the positioning block and the panel; a stop block is arranged on one side of the positioning block; positioning lines are arranged on the panel; a protection layer is arranged on the positioning block; the material arrangement table is made of wood; an arc-shaped material arrangement area is arranged on one side of the panel. The corrugated paper material arrangement table has the beneficial effects that according to the size of corrugated paper which is practically produced, different pieces of corrugated paper can be positioned by adjusting the position of the positioning block through the positioning lines and fixing the positioning block through the stop block; according to the clearance between the positioning block and the panel, the surface of the panel is prevented from being abraded during movement of the positioning block; the corrugated paper which is not ordered can be arranged orderly by an operator through the arc-shaped material arrangement area, and the occupation of a workshop space is reduced. The corrugated paper material arrangement table is simple in structure and good in using effect.

Owner:ANHUI JIAXIN PACKAGING & PRINTING

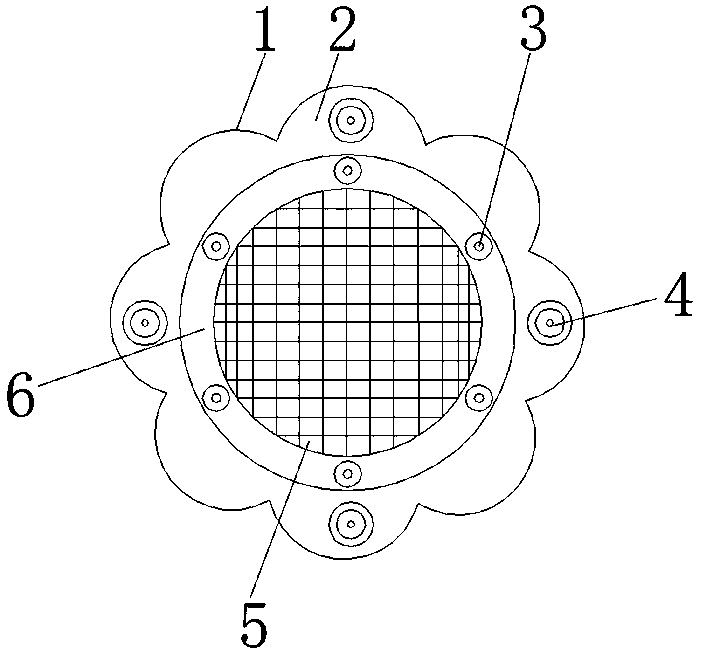

Column insulator and manufacturing method thereof

ActiveCN114496424AImprove corrosion resistanceImprove wear resistanceSupporting insulatorsOrganic insulatorsEpoxyPolyvinyl alcohol

The invention discloses a column type insulator and a manufacturing method thereof, and relates to the technical field of insulators, the column type insulator comprises an insulator base body, and a first protective layer and a second protective layer which sequentially cover the surface of the insulator base body, the first protective layer is prepared from the following raw materials: silicon carbide, polyvinyl alcohol, fraxinus mandshurica clay / glass fiber composite material, wollastonite and diatomite / nano calcium carbonate composite material; the second protective layer is prepared from the following raw materials: a modified epoxy resin / montmorillonite composite material, modified hydrophobic silicon dioxide, polyacrylate and silicone acrylic emulsion. The invention has the beneficial effects that the first protection layer and the second protection layer are formed on the surface of the insulator substrate, so that the corrosion resistance, the wear resistance, the weather resistance and the anti-pollution flashover performance of the insulator can be improved.

Owner:PINGXIANG HUACHUANG ELECTRIC CO LTD

Shouldered oil-free lining

Owner:许炎章

TRT turbine with abrasion-resistant corrosion-resistant nano coating

PendingCN107725116AIncrease power generationImprove work efficiencyMolten spray coatingEngine fuctionsCorrosion resistantStator

The invention discloses a TRT turbine with an abrasion-resistant corrosion-resistant nano coating. The TRT turbine includes a TRT turbine movable blade and a static blade. The outer surfaces of both the TRT turbine movable blade and the static blade each is provided with a nano protection layer. According to the TRT turbine with the abrasion-resistant corrosion-resistant nano coating, the surfacesof the movable blade and the static blade of the TRT turbine each are provided with the protection layer made of a nanometer material. The nano coating is a functional coating which is of a nano structure, is prepared from a nanometer ceramic composite material and is resistant to abrasion, acid-base corrosion, high temperature and cavitation, the shortcomings in the prior art are overcome, the service life is prolonged from 7-10 months to 36 months or over, and the service life and a use effect of a TRT turbine in the prior art are greatly improved. The TRT turbine can work continuously fora long time, the production cost and overhaul coat are reduced, and the working efficiency is improved.

Owner:上海英佛曼纳米科技股份有限公司

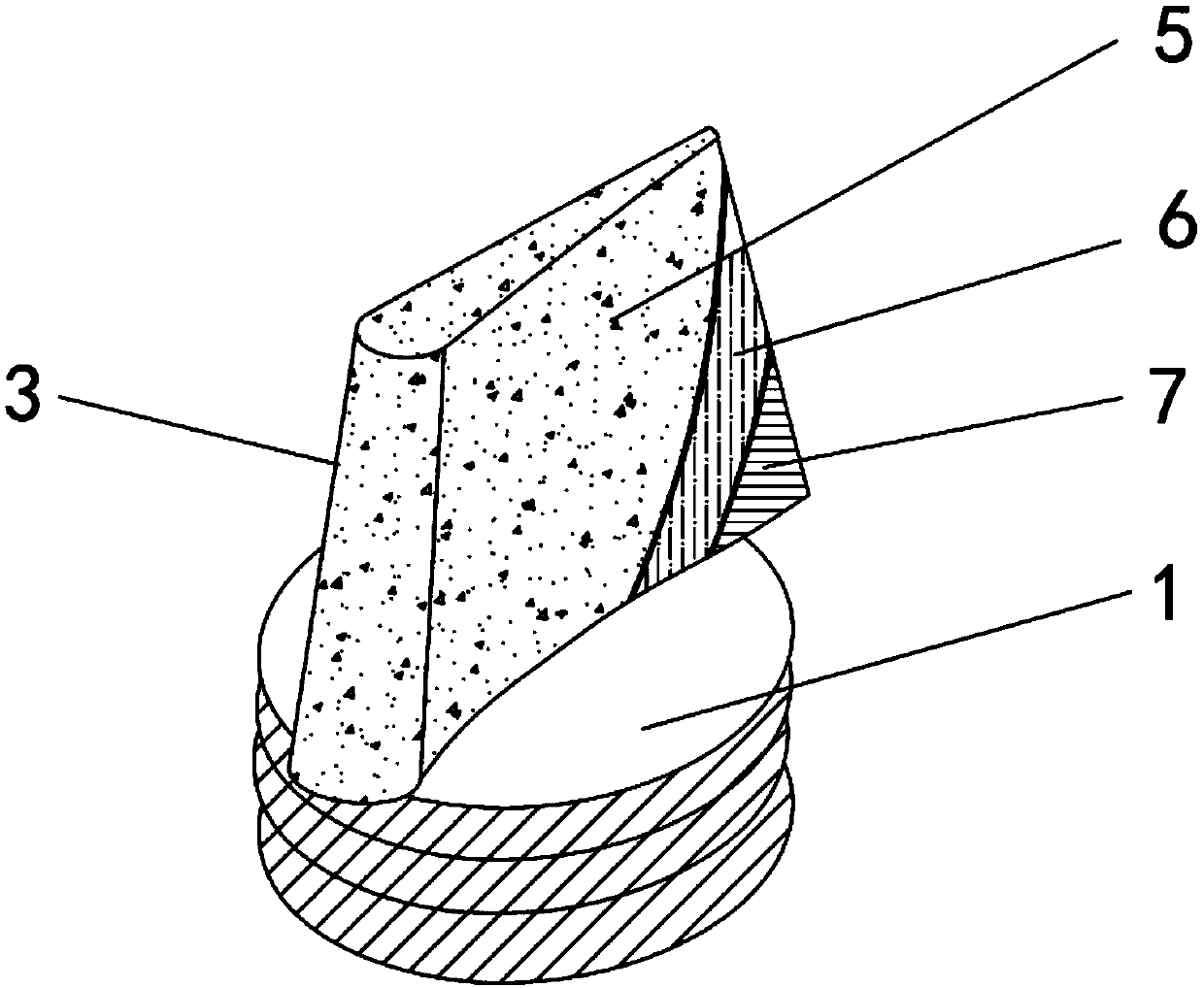

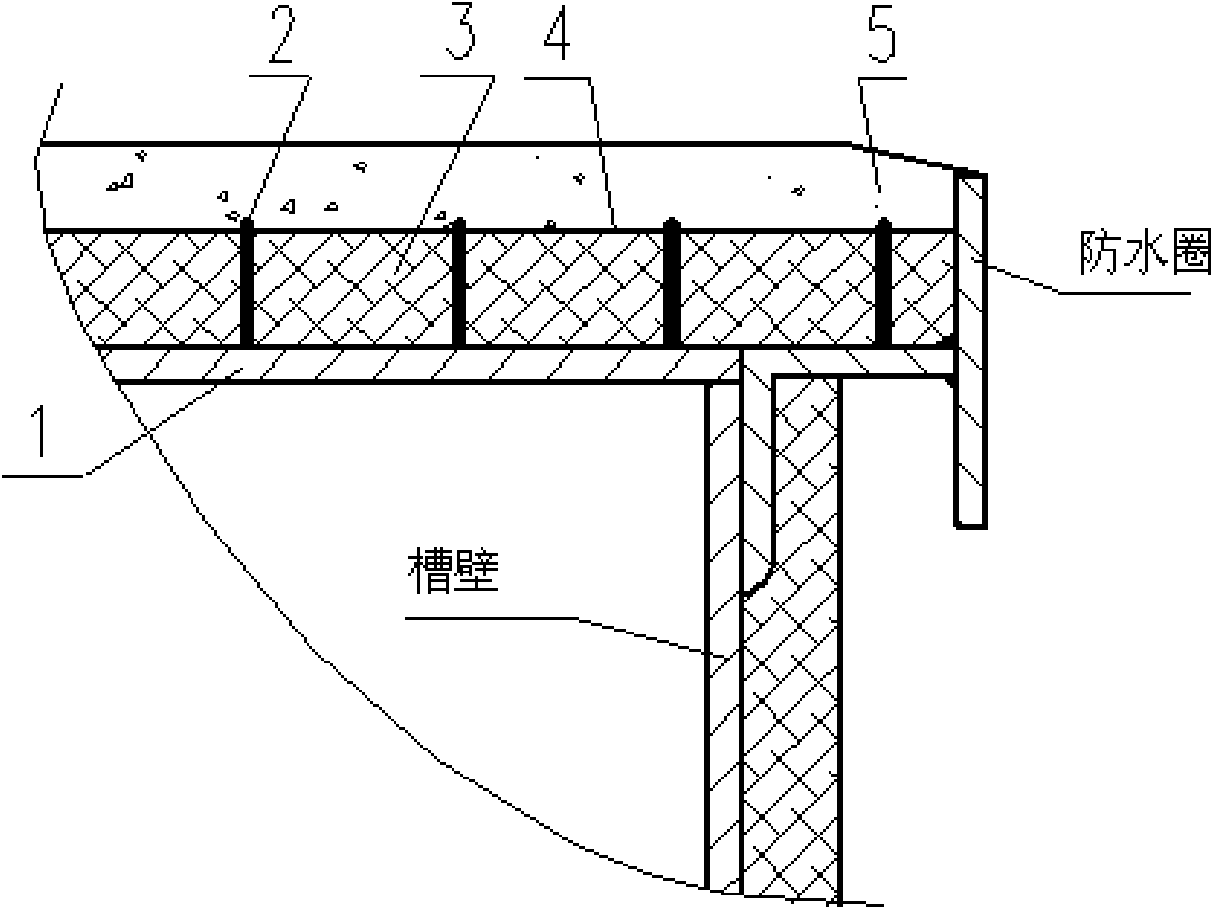

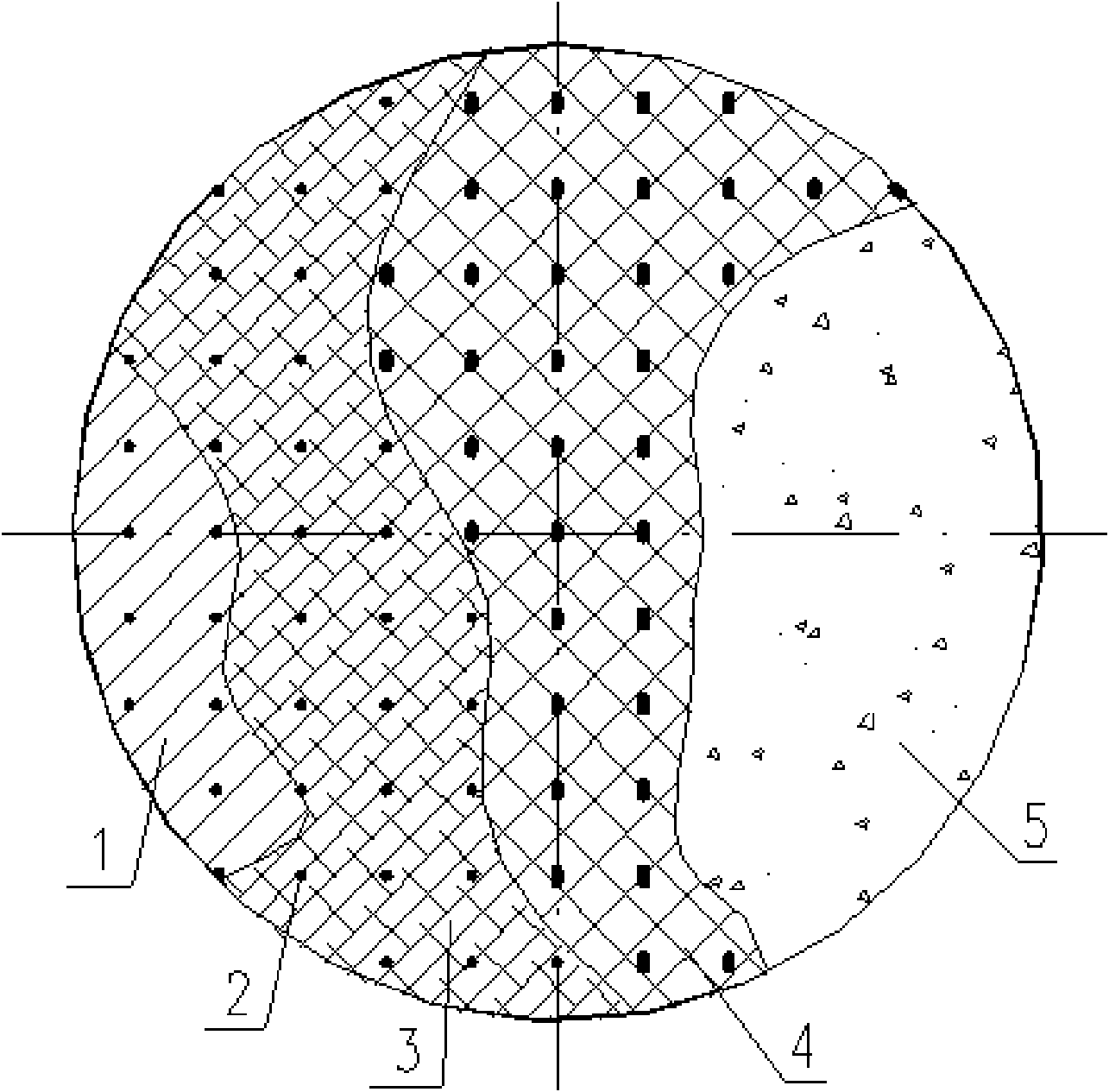

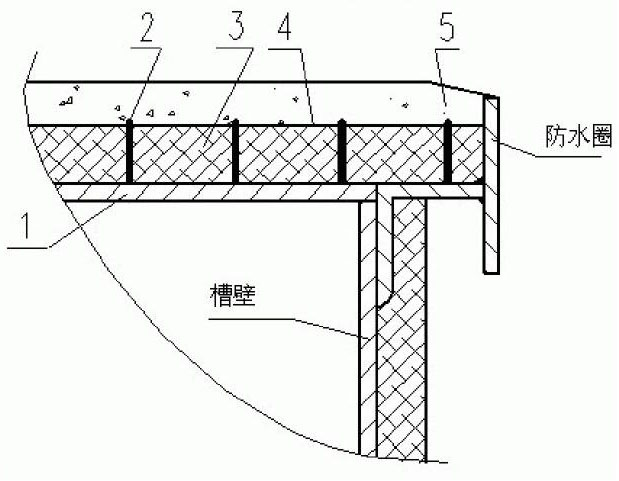

Heat-insulating structure at top of open-air atmospheric storage tank

InactiveCN101927885ANo local subsidenceWill not happenLarge containersLeaking waterVolumetric Mass Density

Owner:GUIYANG AL-MG DESIGN & RES INST

Pipeline opening repair conduction protection anticorrosion material and preparation method thereof

InactiveCN107858073AAvoid shieldingImprove conductivityAnti-corrosive paintsEpoxy resin coatingsEpoxyProtection layer

Owner:CHANGZHOU UNIV

PMMA/PC-based high-performance polaroid

InactiveCN113093323AReduce manufacturing costImprove performancePolarising elementsCoatingsGlass fiberPolymer science

Owner:SOUTHWEAT UNIV OF SCI & TECH

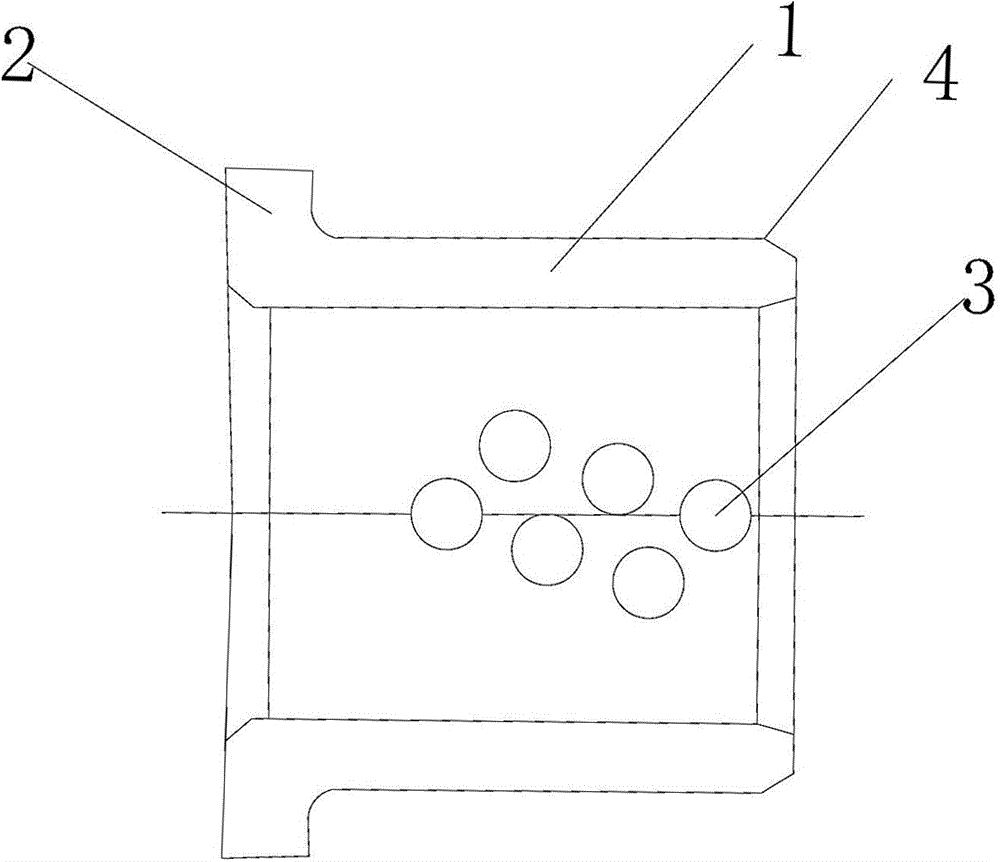

Audio/video communication guide rope for fire control

InactiveCN104575827AAccurate transmissionImprove shielding effectPower cables with screens/conductive layersInsulated cablesElectrical conductorFire control

The invention discloses an audio / video communication guide rope for fire control. The audio / video communication guide rope comprises an optical cable core. The optical cable core comprises a center stiffener located at the center, and cables and optical cables distributed in the peripheral direction of the center stiffener in a staggered mode. The cables are used for transmitting electric energy, and each cable core comprises a conductor and an insulating layer covering the conductor. The optical fibers are used for transmitting video signals and audio signals. Each optical cable core comprises a PBT loose tube and an optical fiber unit attached to the inner side of the PBT loose tube. The cable cores and the optical cable cores are stranded integrally in the circumferential direction of the center stiffener. The audio / video communication guide rope further comprises a metal shielding layer covering the optical fiber cores and a tensile high-strength protection layer covering the metal shielding layer. The tensile high-strength protection layer is made of nylon, and waterproof fillings are arranged between the cable cores and optical fiber cores and the metal shielding layer and between the PBT loose tubes and the optical fiber units.

Owner:SHANGHAI FIRE RES INST OF THE MIN OF PUBLIC SECURITY

Circuit board and preparation method thereof

PendingCN114449727AAvoid pollutionImprove rigidityConductive material removal by irradiationConductive pattern layout detailsEngineeringProtection layer

The embodiment of the invention provides a circuit board and a preparation method thereof. The preparation method comprises the steps that a conductive layer is formed on a base material, a circuit area and a peripheral area surrounding the circuit area are defined on the base material, the base material is provided with a side face connected with and surrounding the peripheral area, and the conductive layer is located on the side face, the peripheral area and the circuit area; forming a protective layer on the conductive layer, wherein the protective layer is located on the side surface and the peripheral region; the conductive layer is patterned, so that the conductive layer located in the circuit area is patterned to form a circuit layer, and the conductive layer located on the side face and the peripheral area is not patterned due to being covered by the protective layer and still remains on the base material to form a strengthening layer; wherein the step of patterning the conductive layer comprises the steps of pressing a dry film, exposing, developing, etching and removing the dry film, and the protective layer is removed in the step of removing the dry film.

Owner:礼鼎半导体科技秦皇岛有限公司 +1

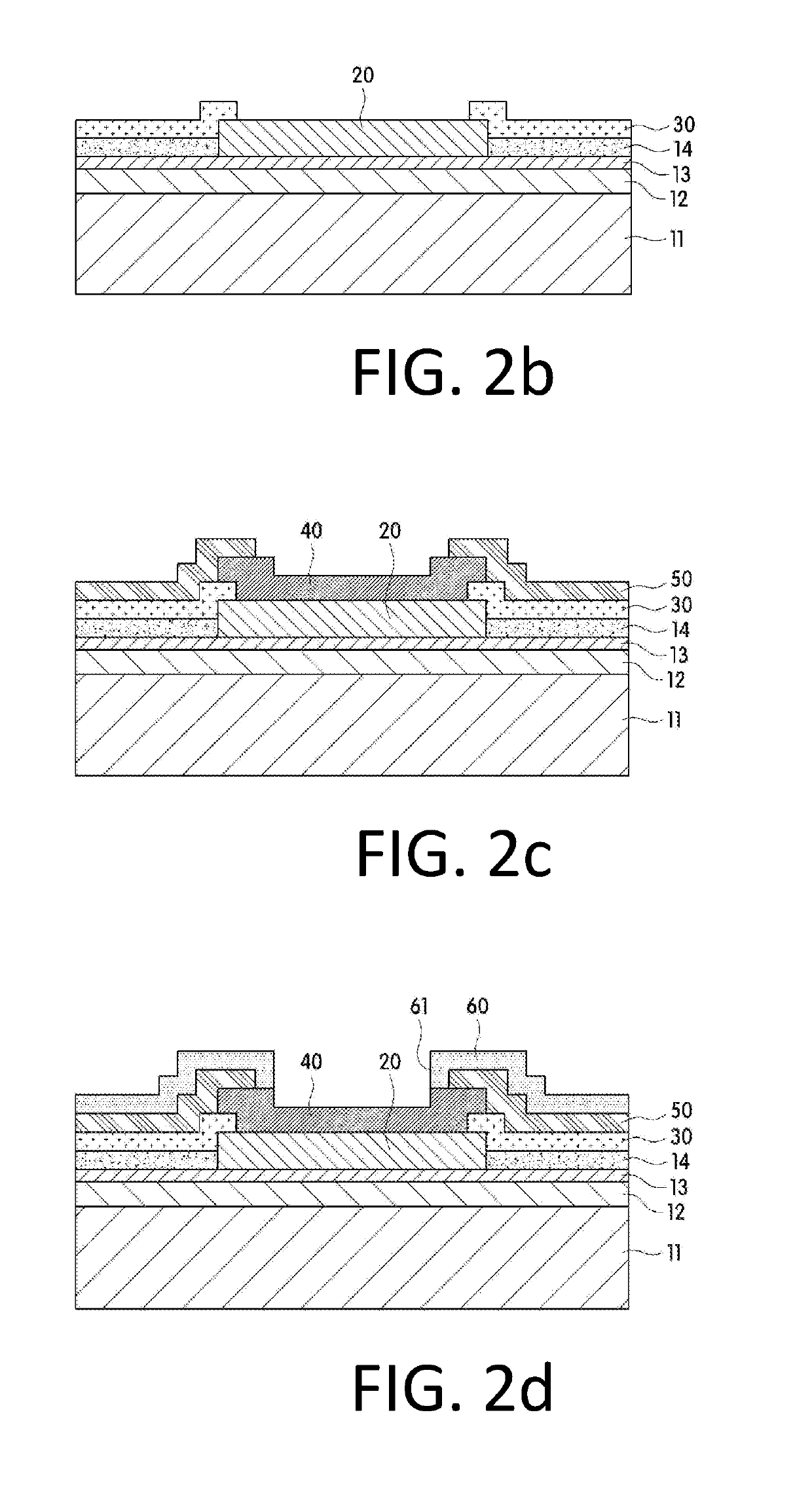

Nitride-based electronic device and method for manufacturing same

ActiveUS20190295962A1Improve moisture resistanceExpand the number of processesSemiconductor/solid-state device detailsSolid-state devicesEngineeringProtection layer

Owner:WAVICE INC

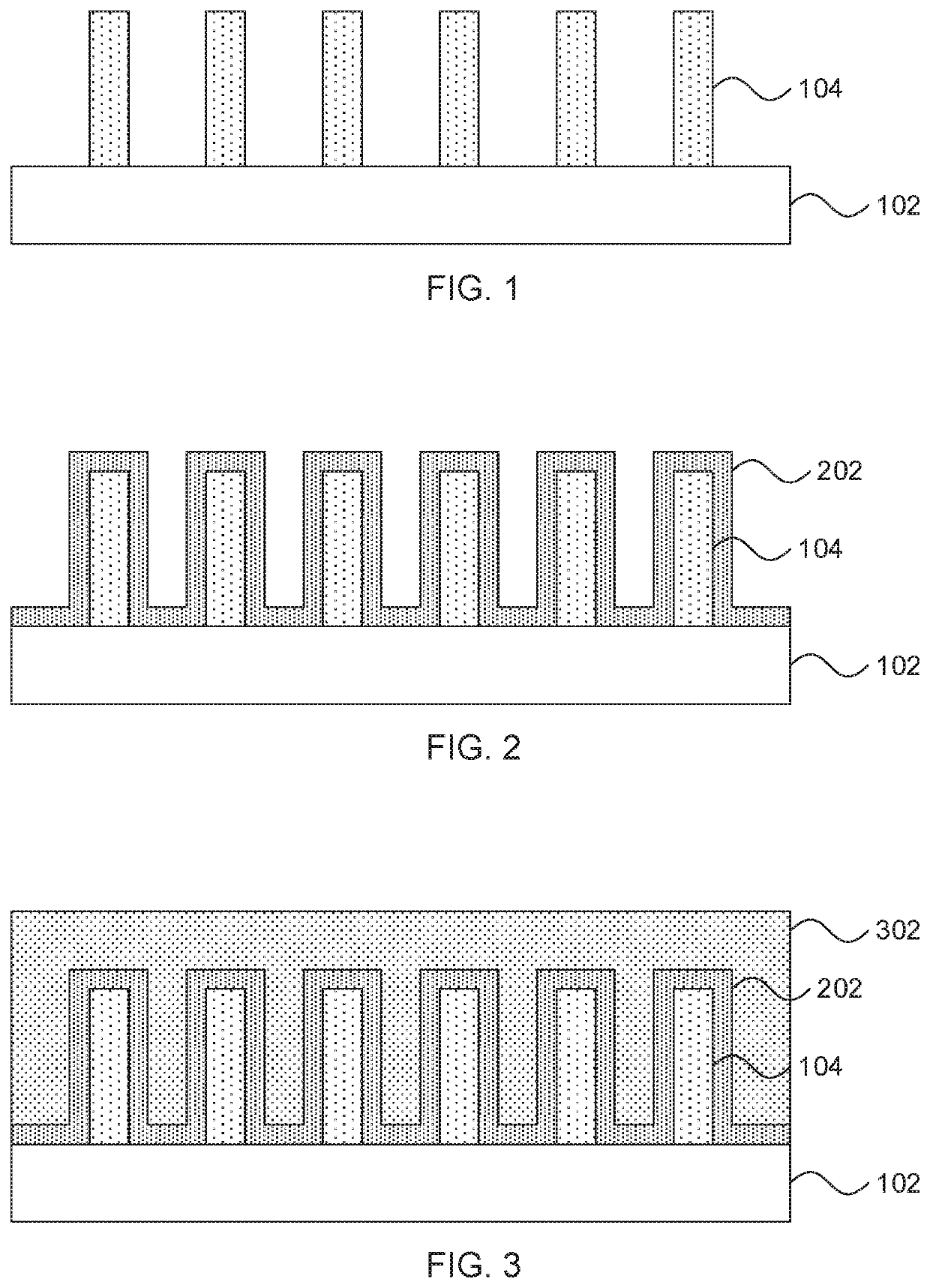

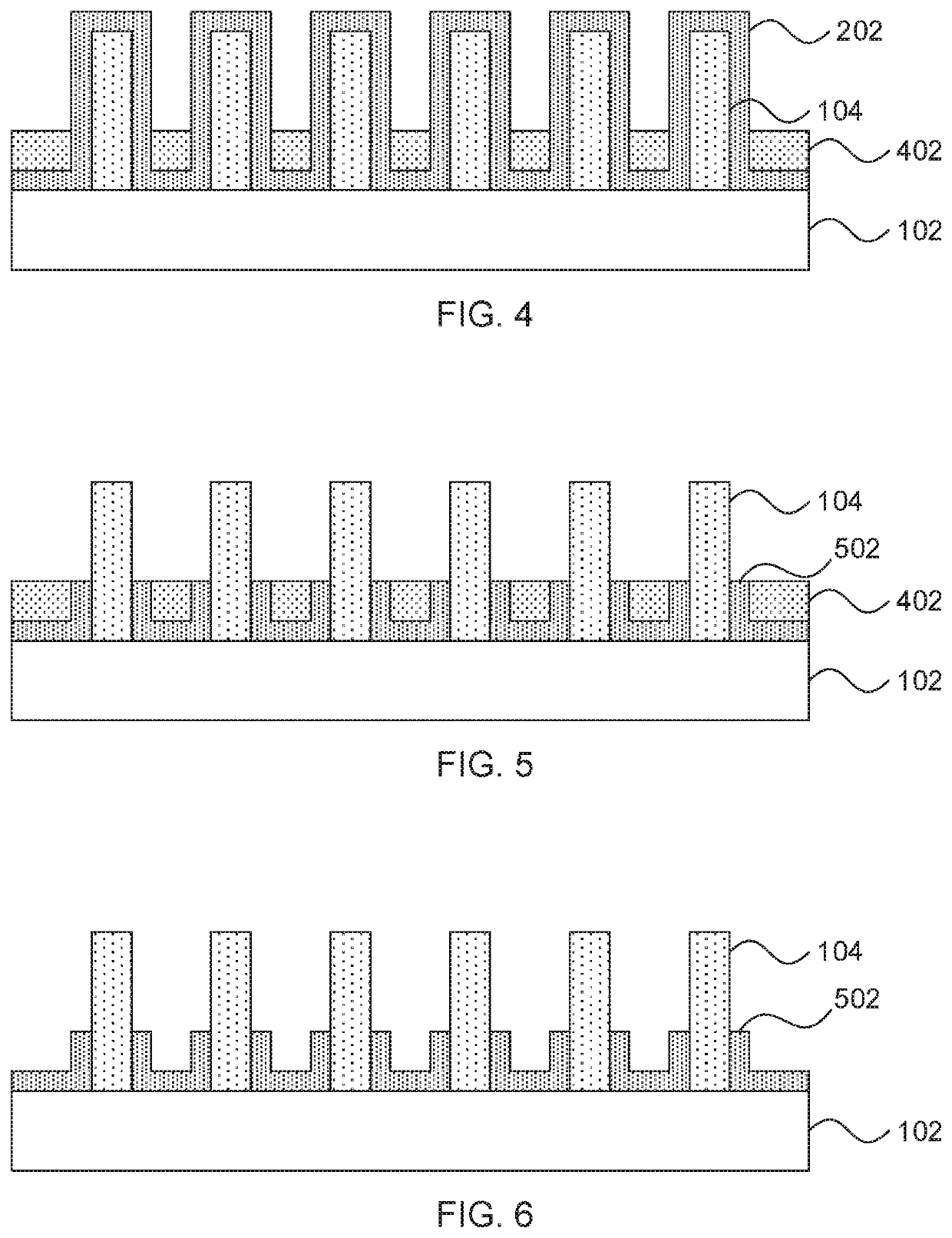

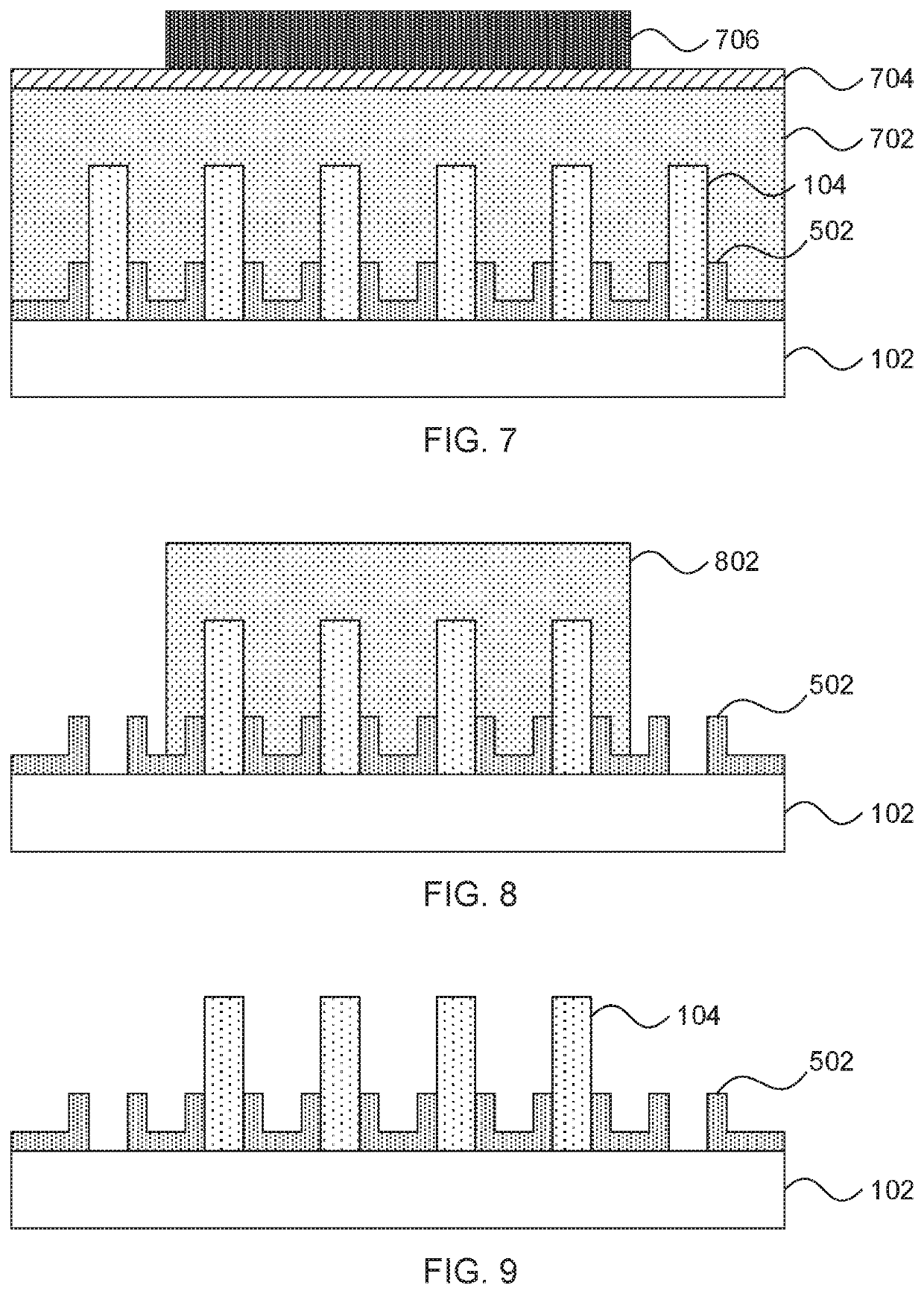

Fin cut profile using fin base liner

ActiveUS20200135484A1Semiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorProtection layer

Owner:IBM CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap