Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about "Floors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

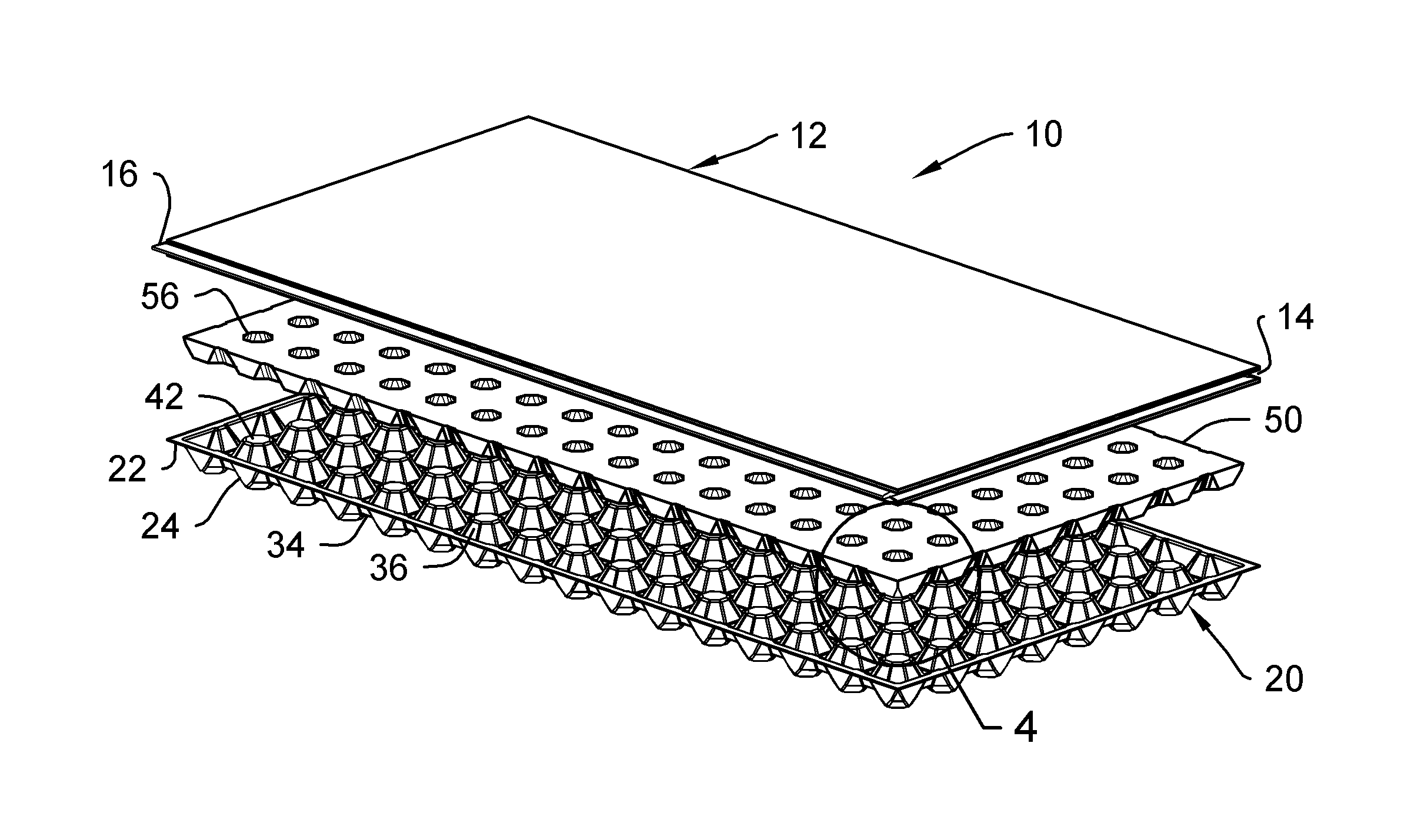

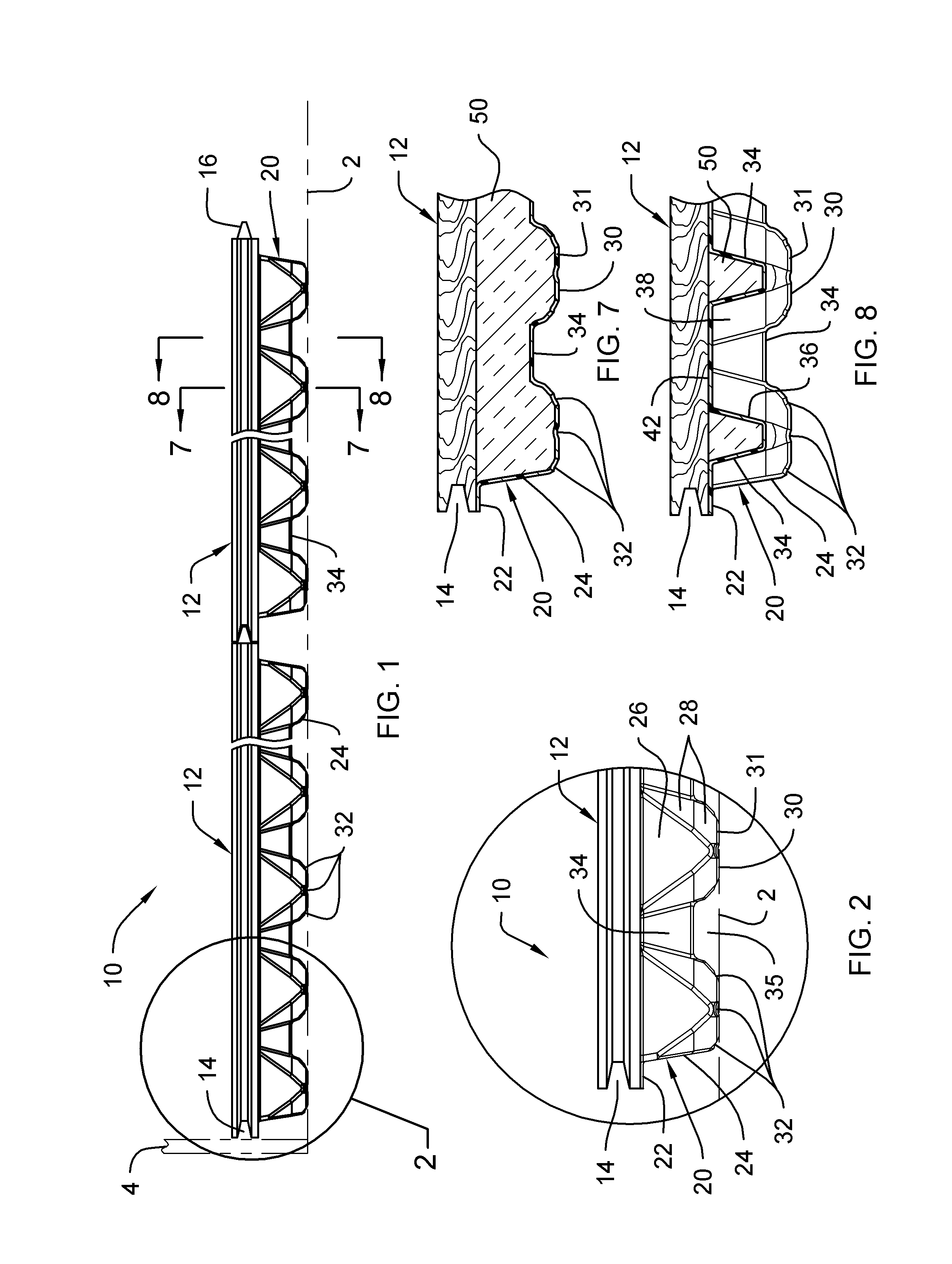

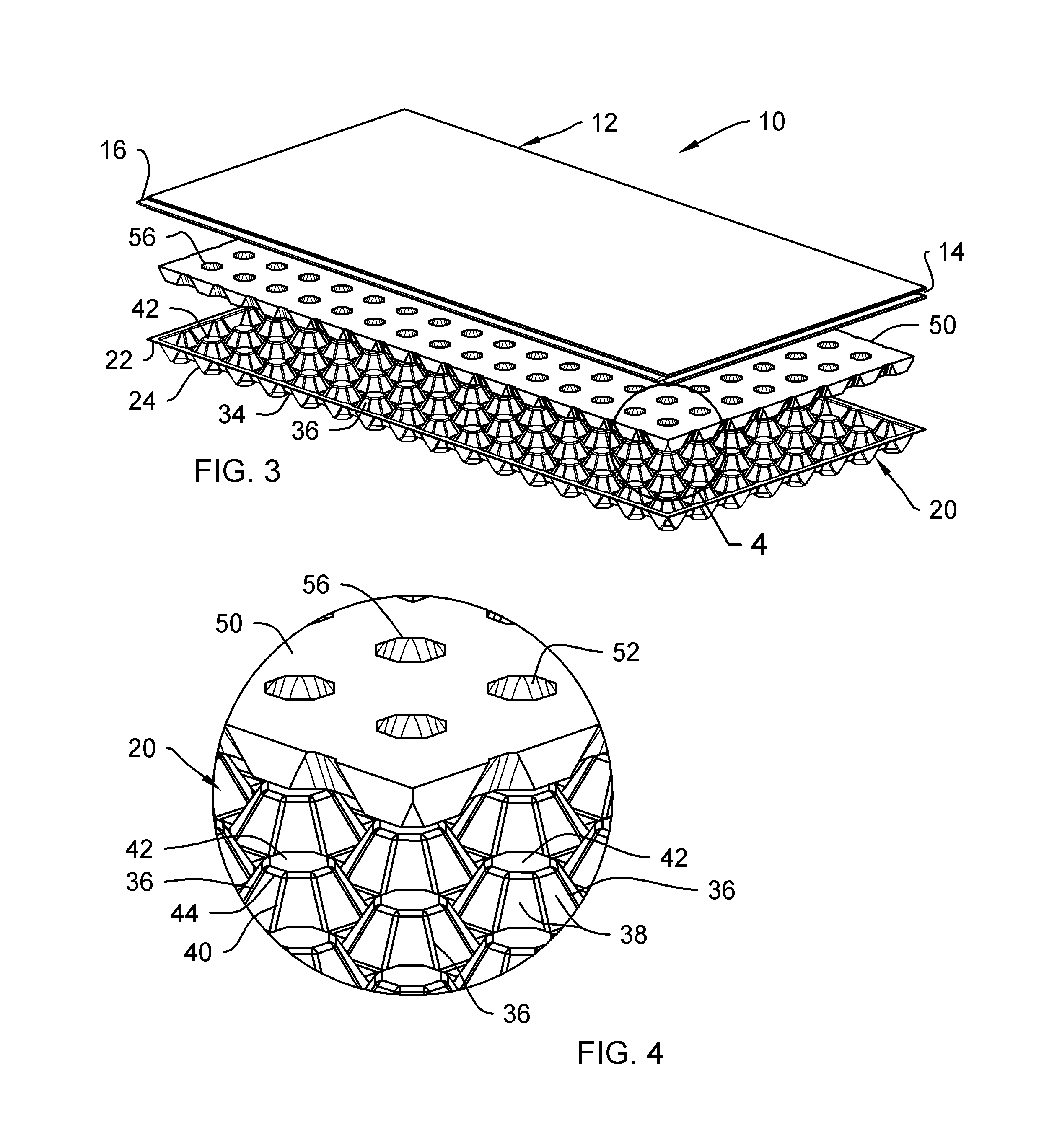

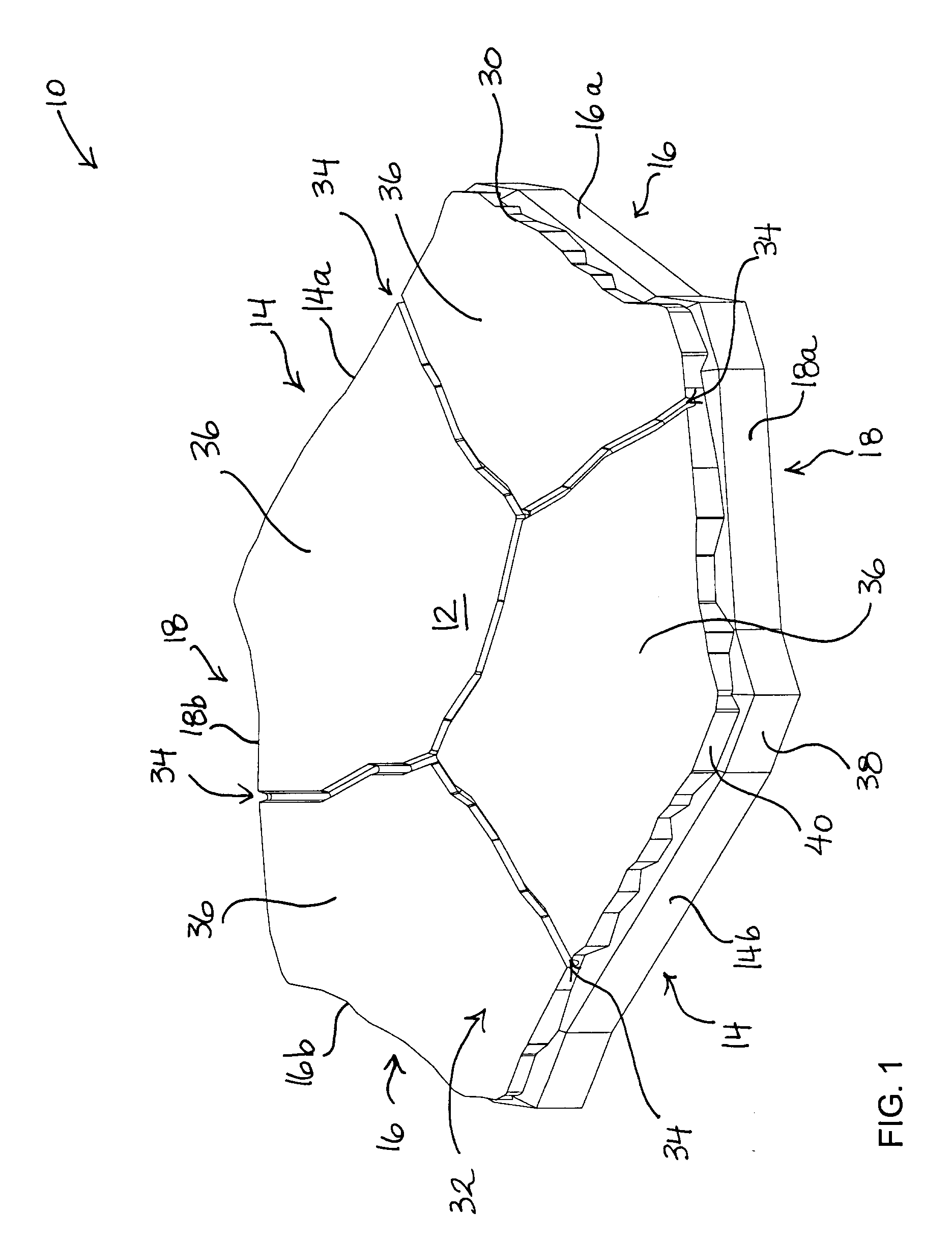

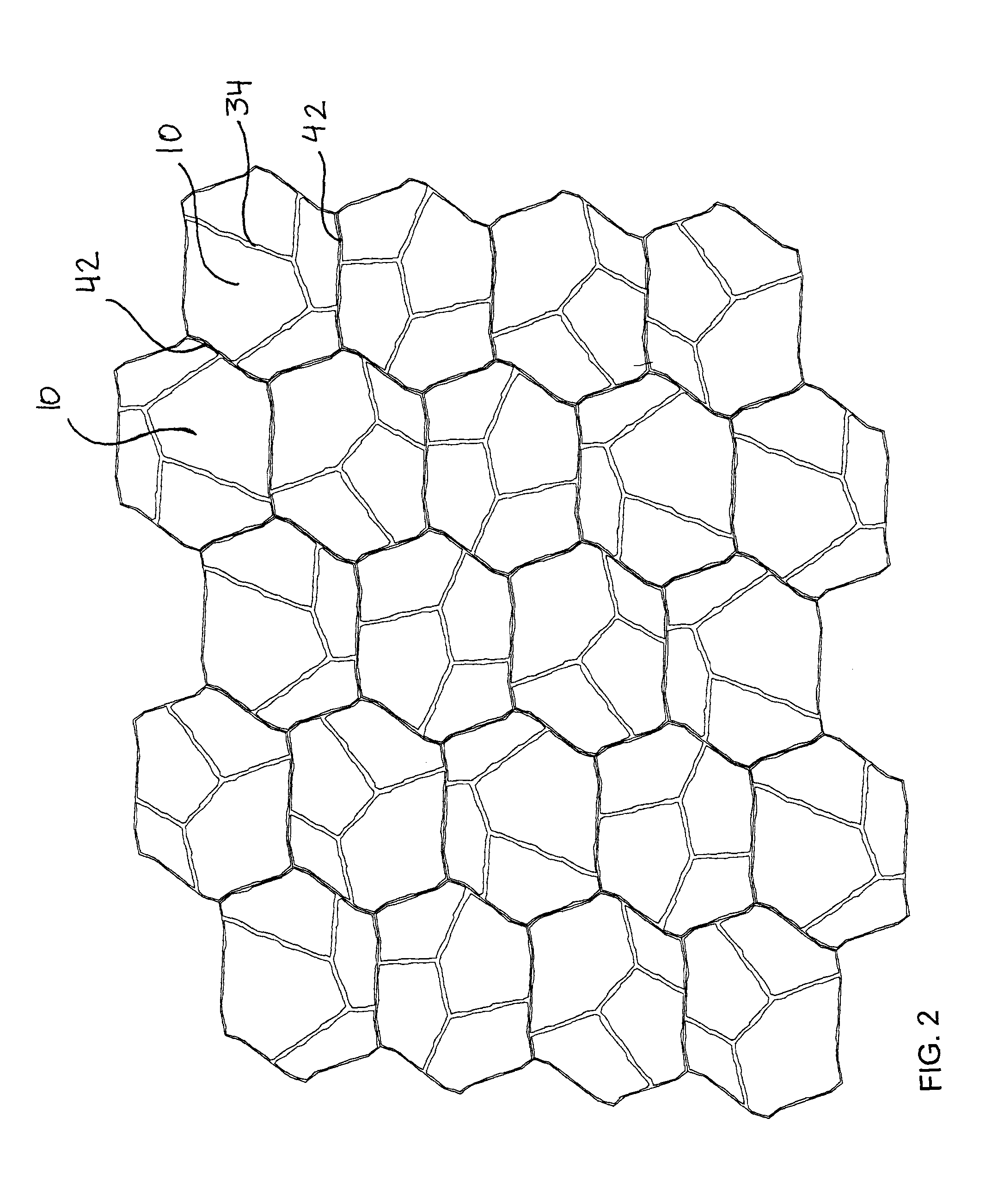

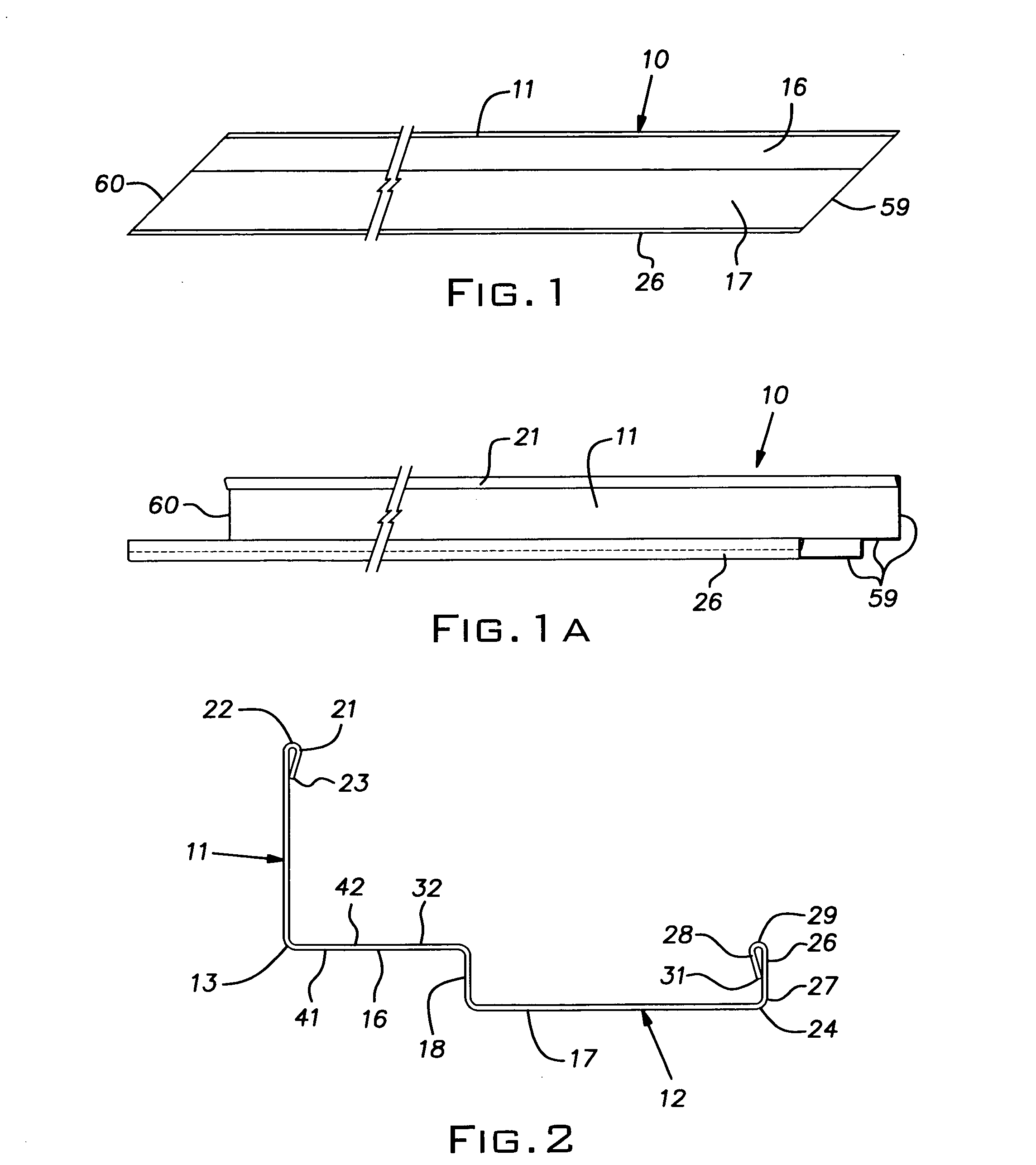

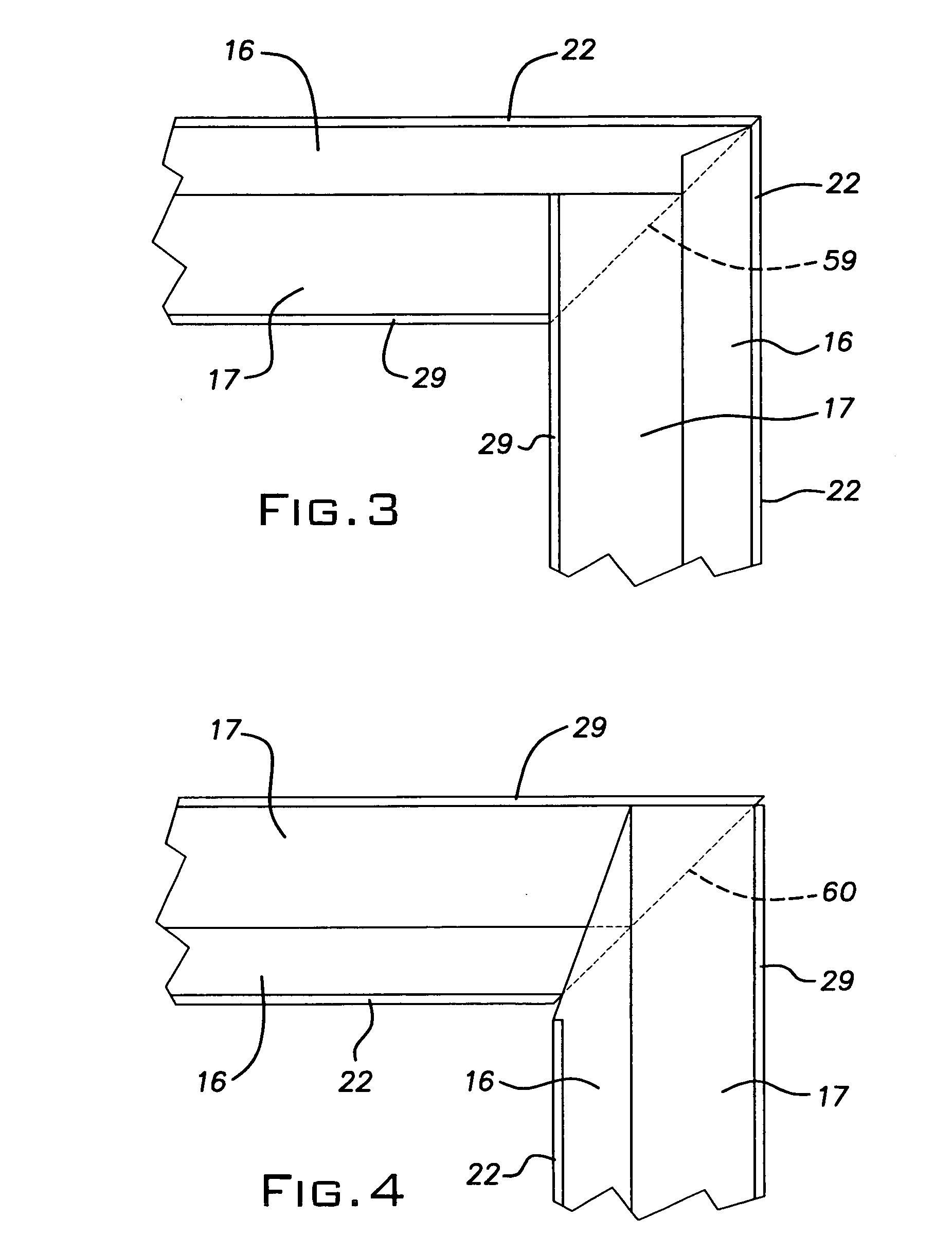

Subfloor drainage panel

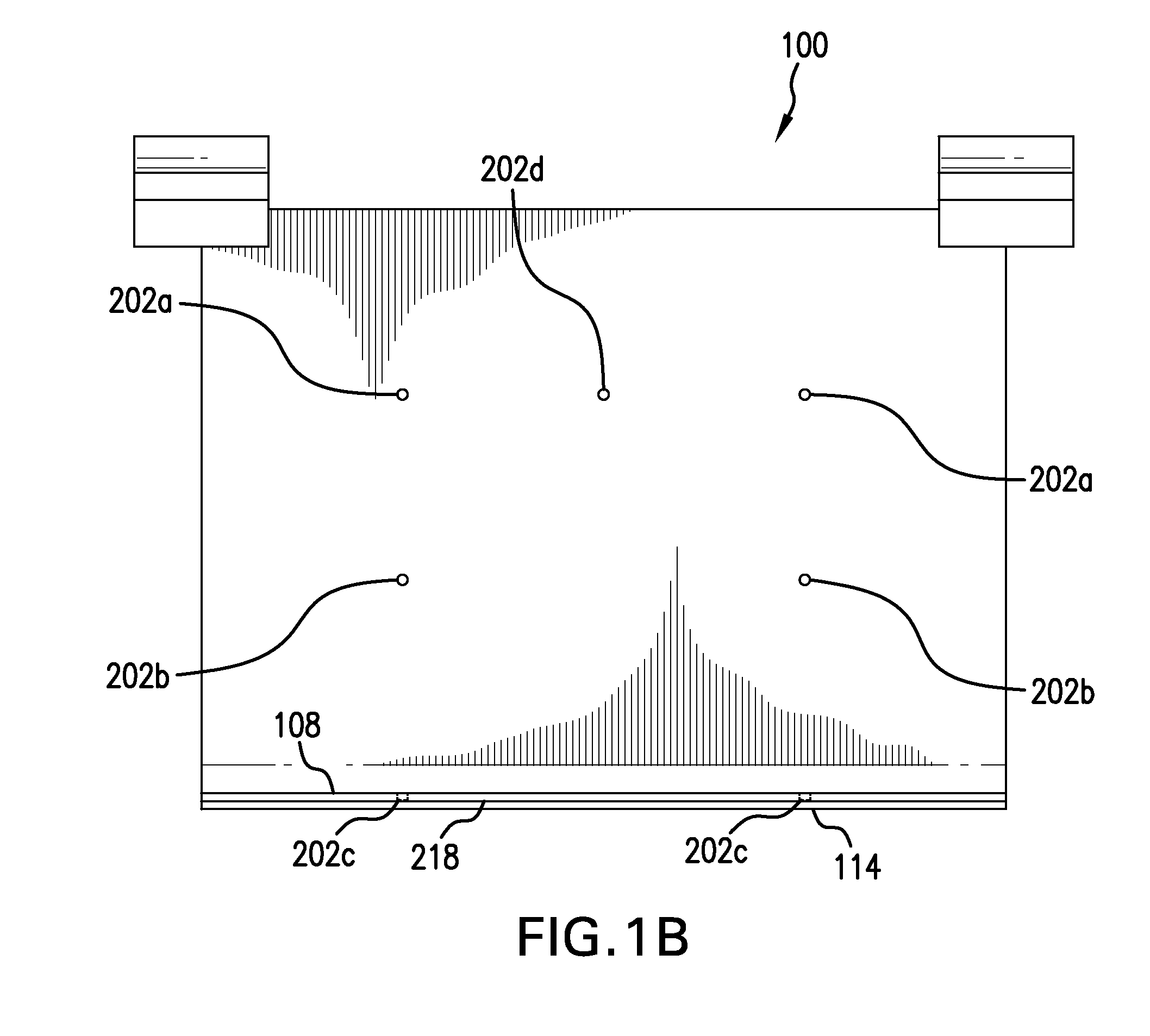

ActiveUS8955278B1Easy and efficient to manufactureLower sales priceLighting and heating apparatusFloorsEngineeringMoisture

Owner:MILLS HILTON R

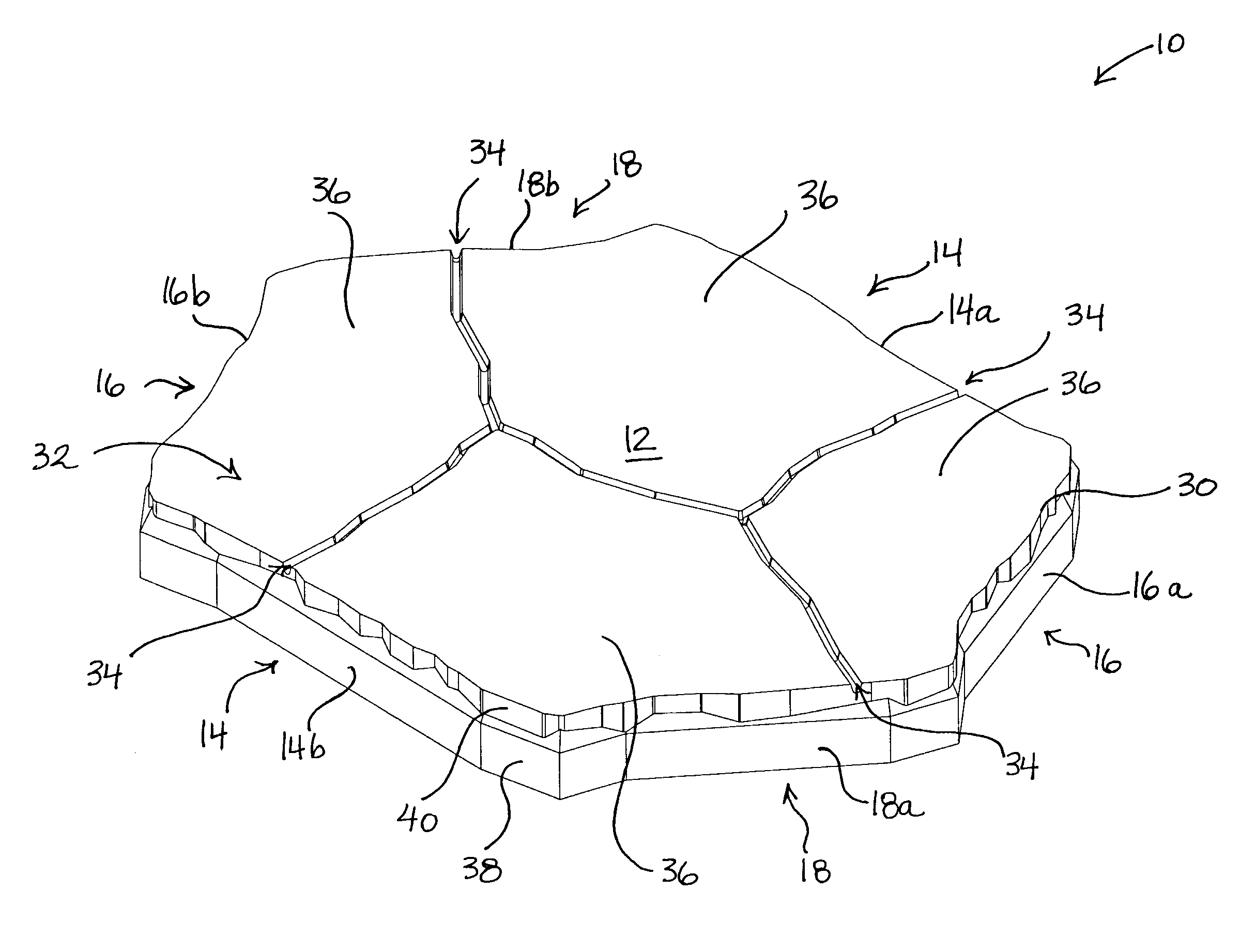

Covering Unit

Owner:OLDCASTLE BUILDING PROD CANADA INC

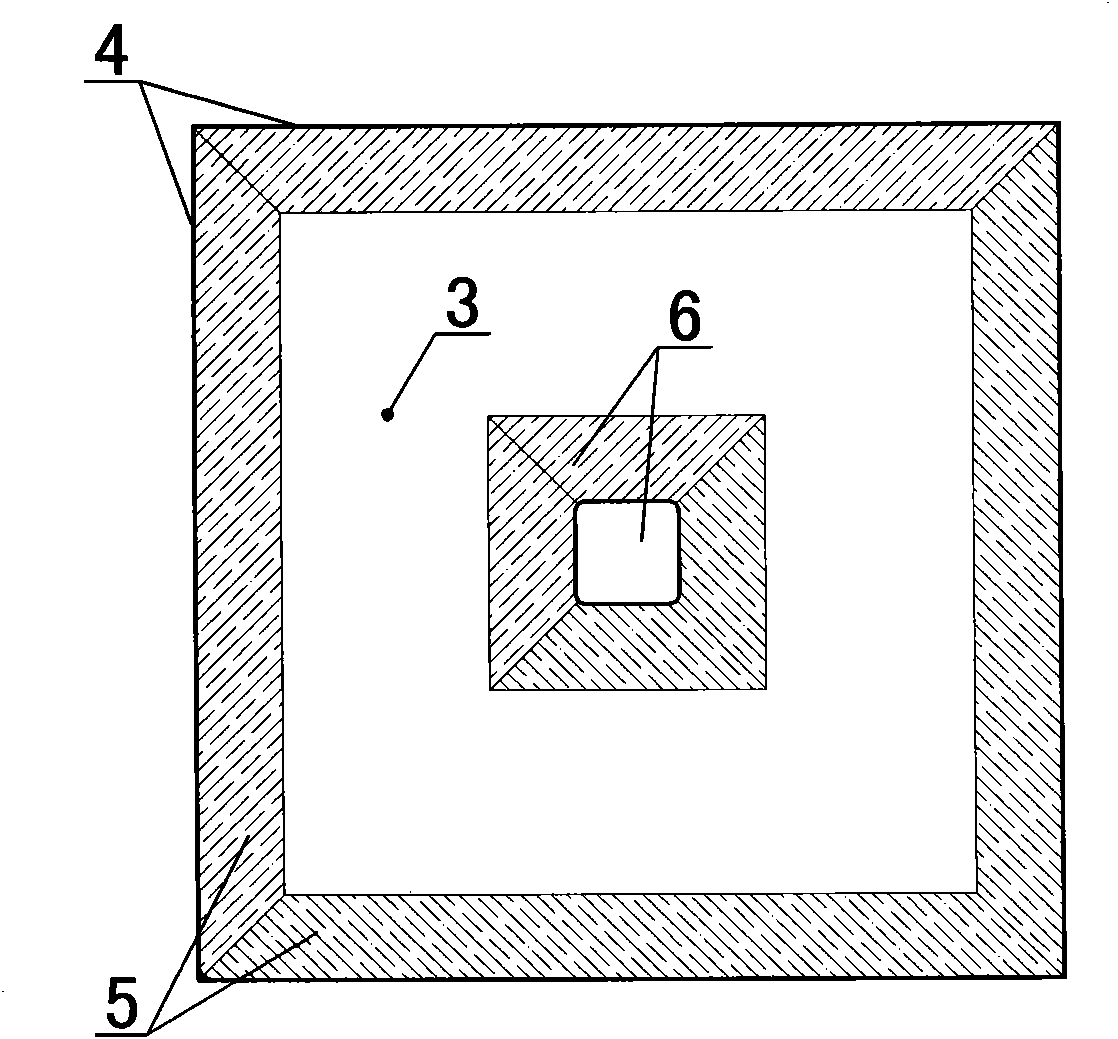

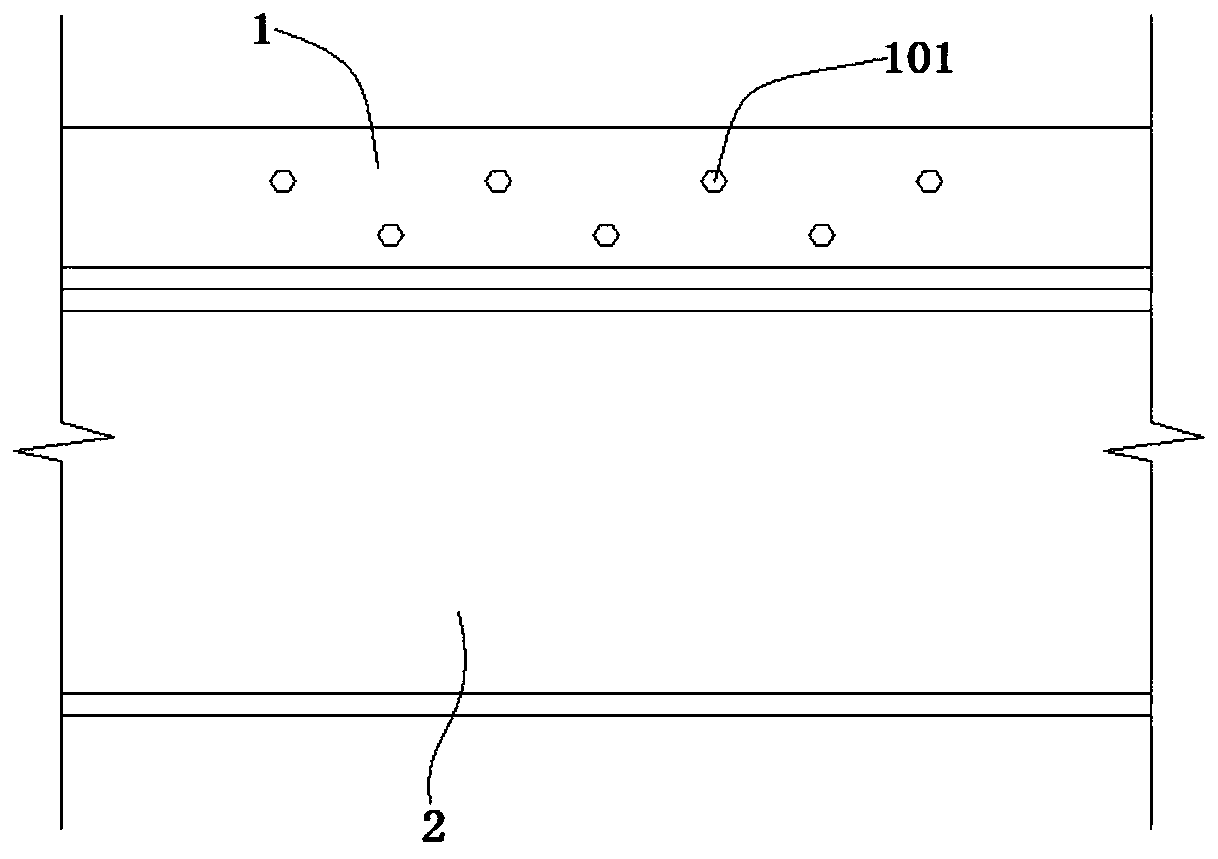

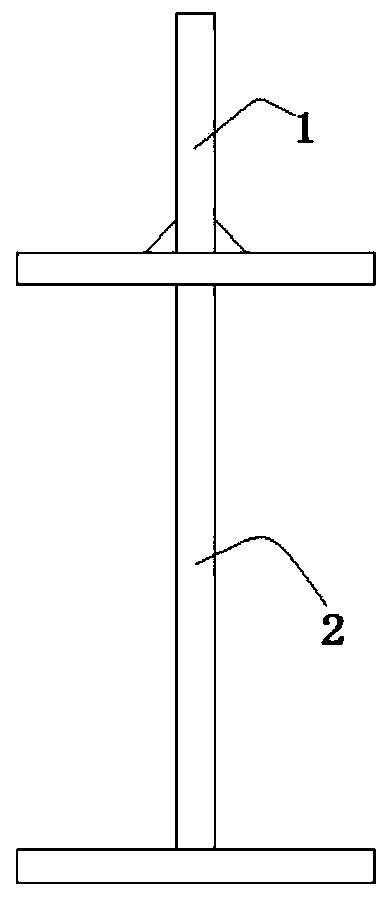

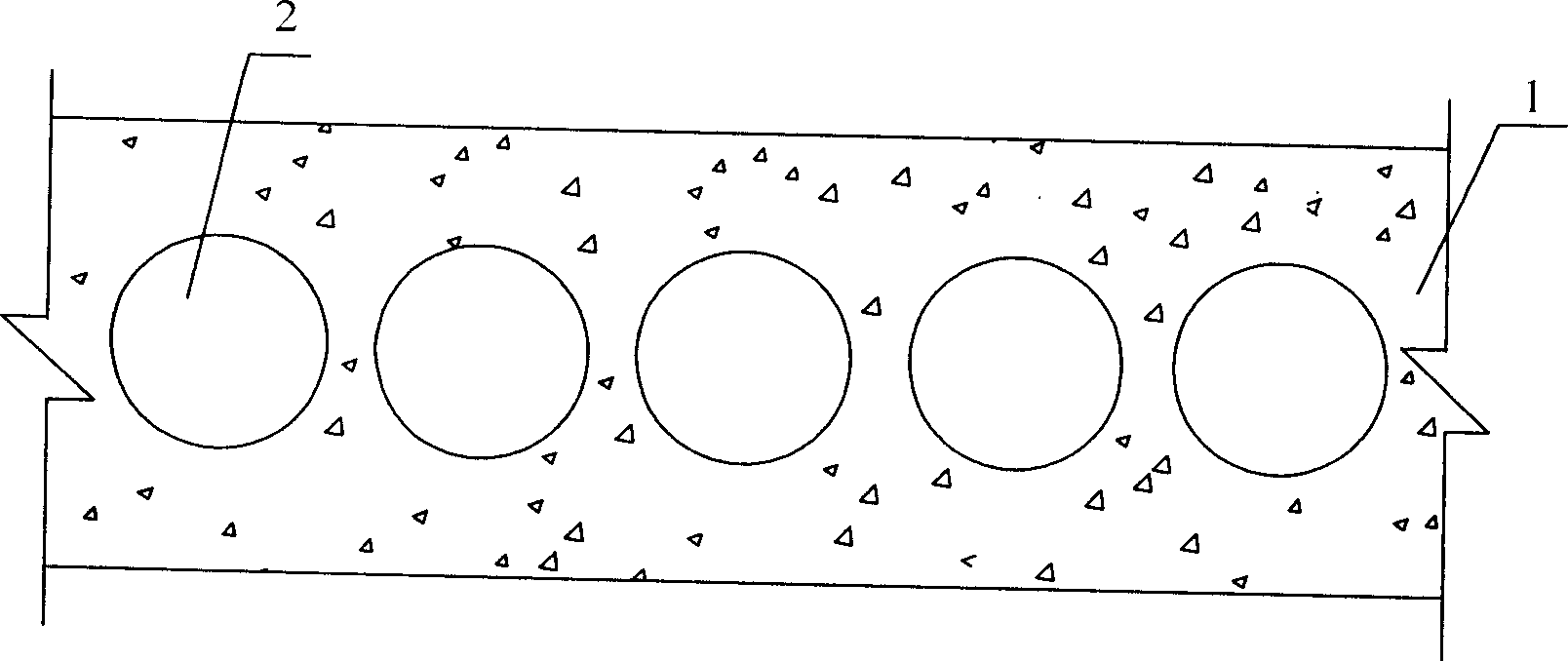

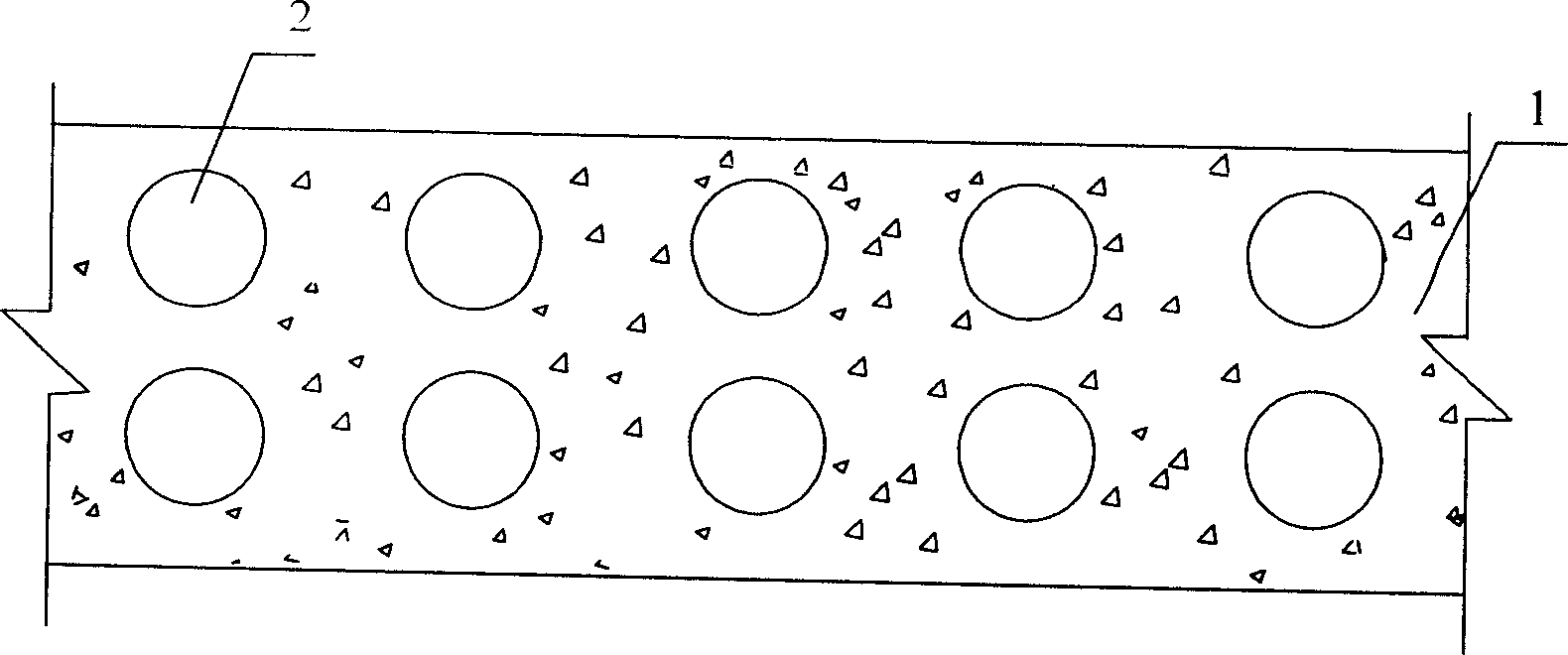

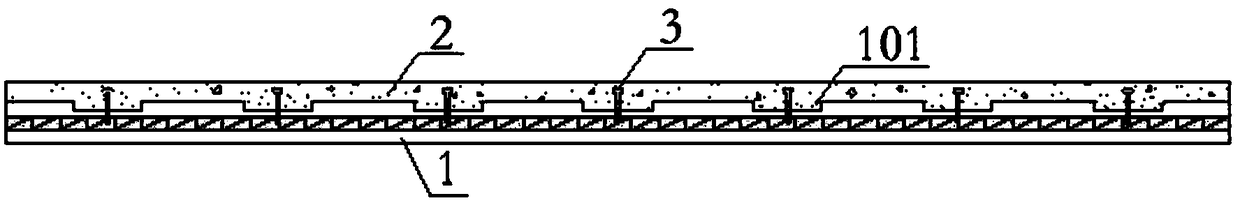

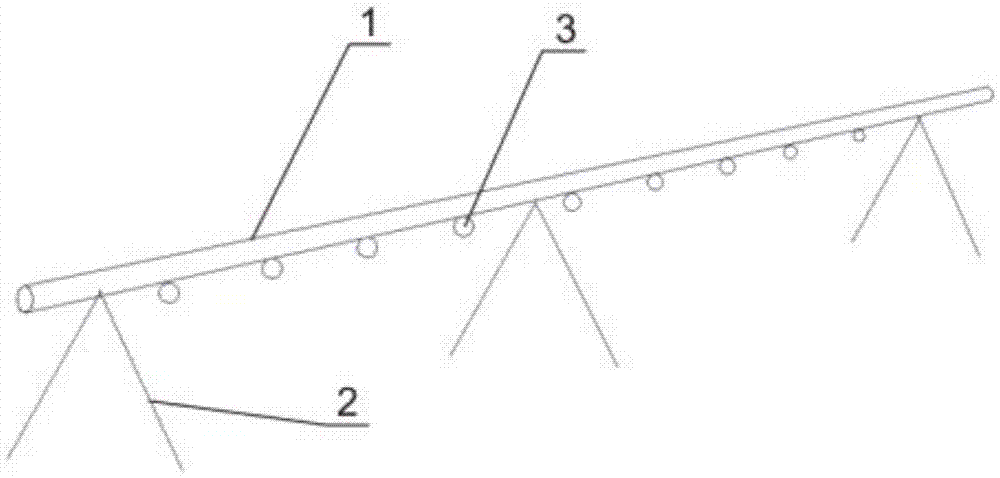

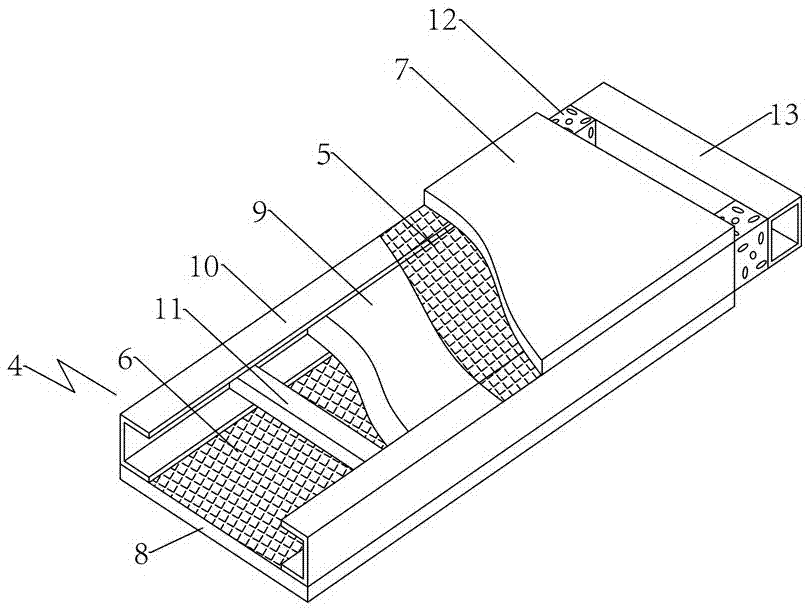

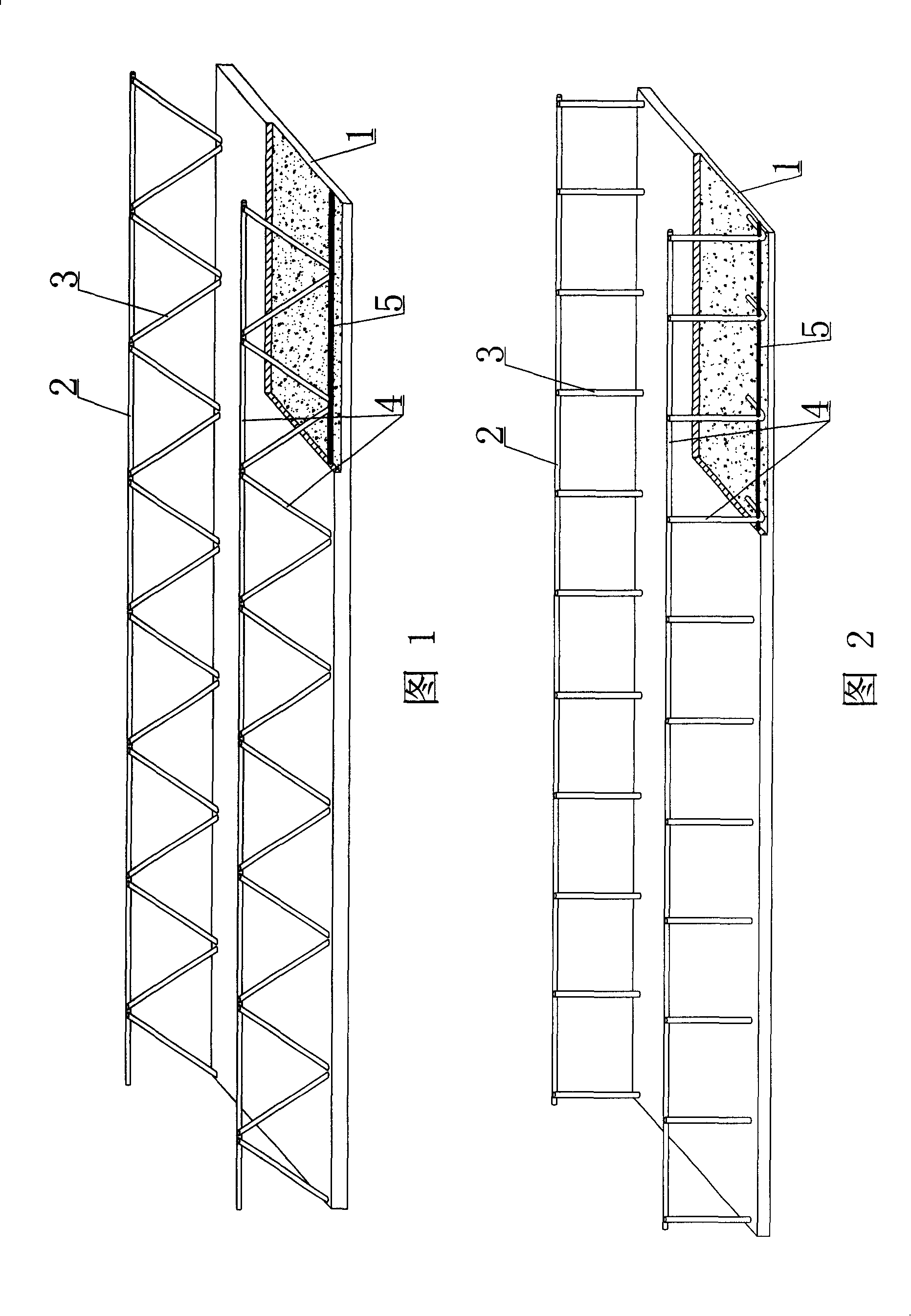

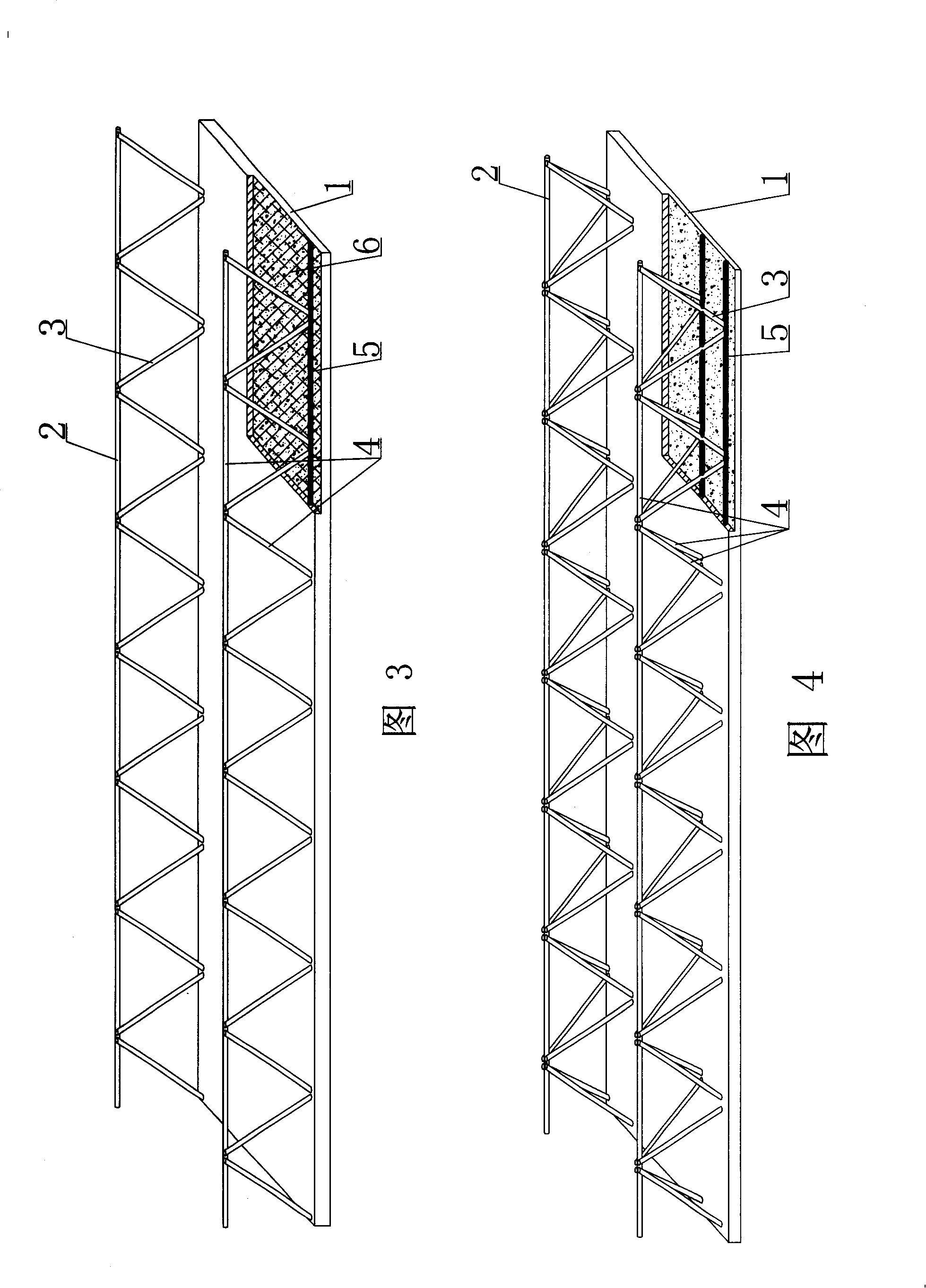

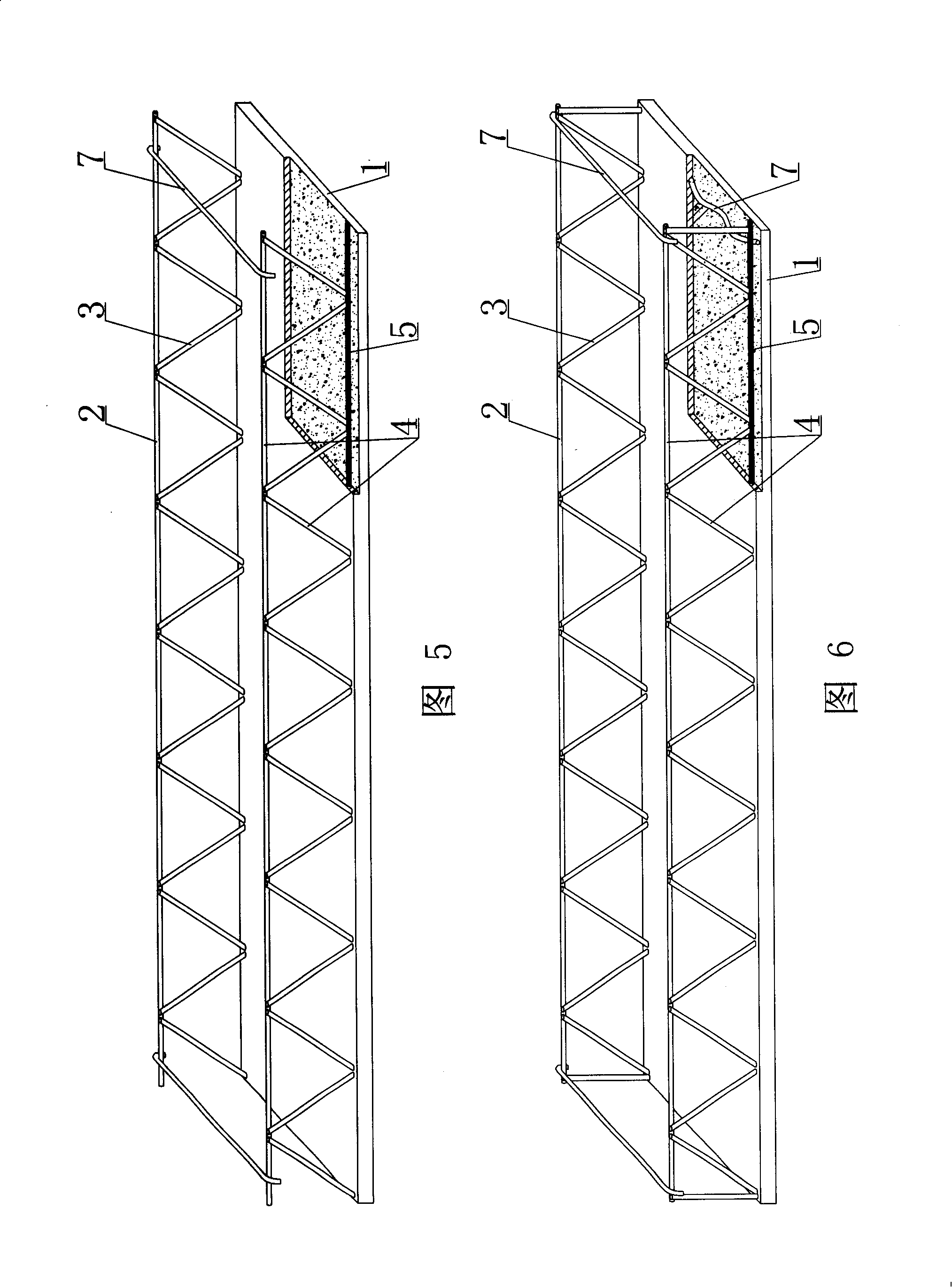

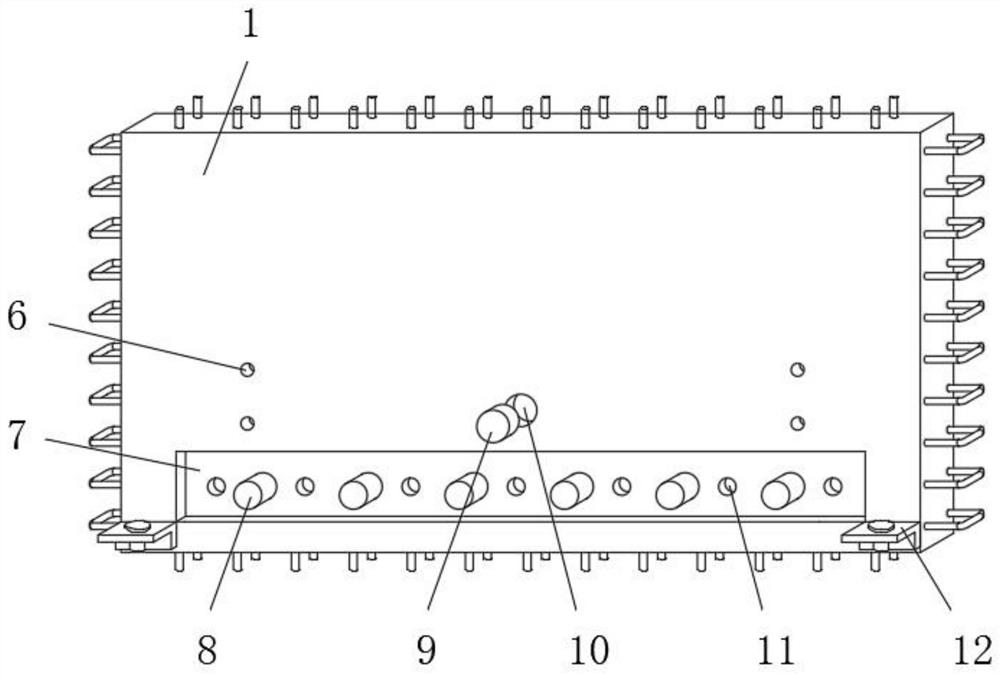

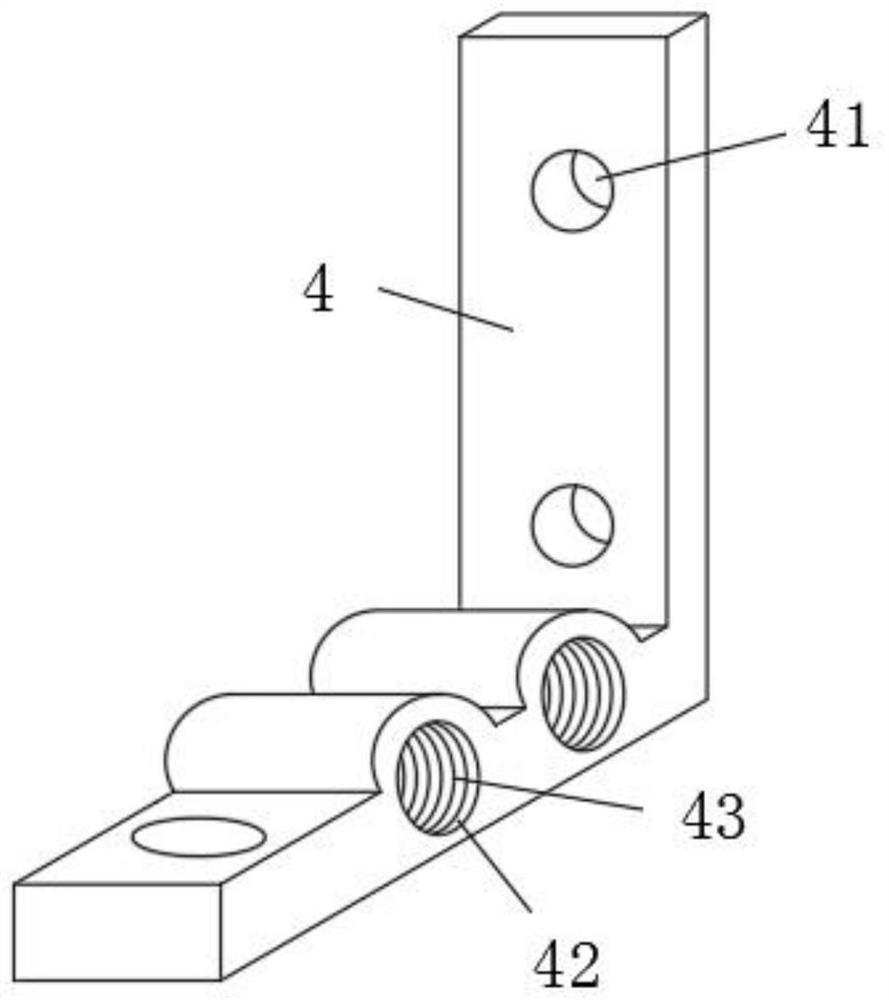

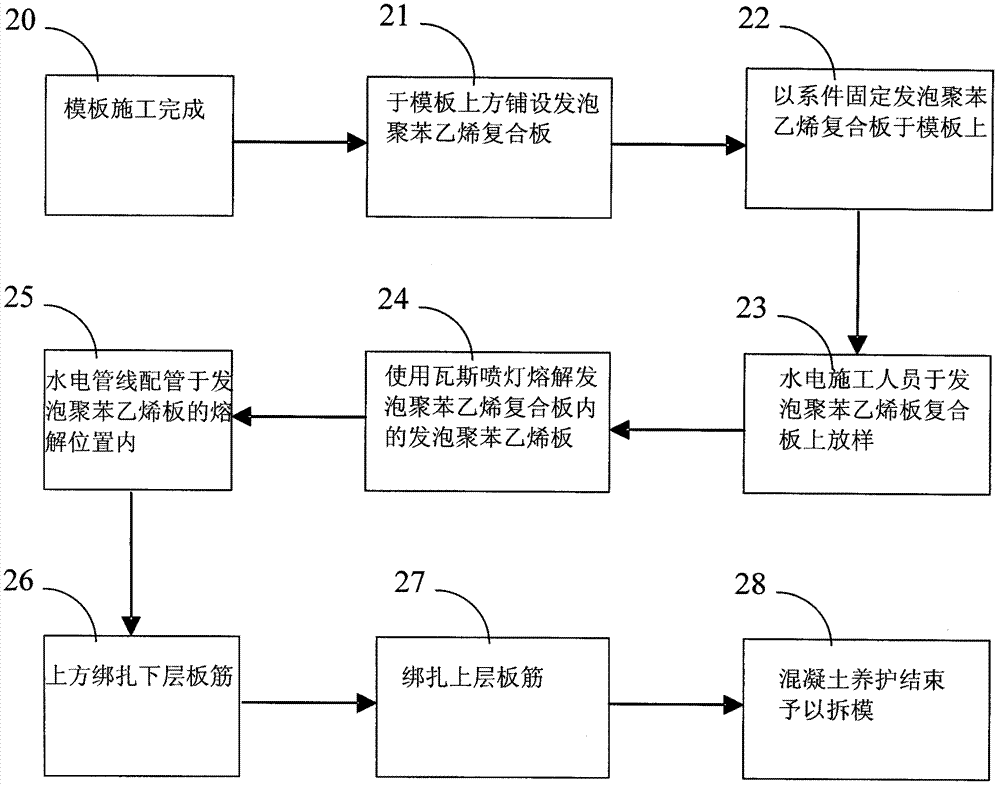

Hollow floor system filled with an air-filling bag and construction method thereof

InactiveCN101793070ALight shock and vibration resistanceGood shock and vibration resistanceFloorsEarthquake resistanceCrack resistance

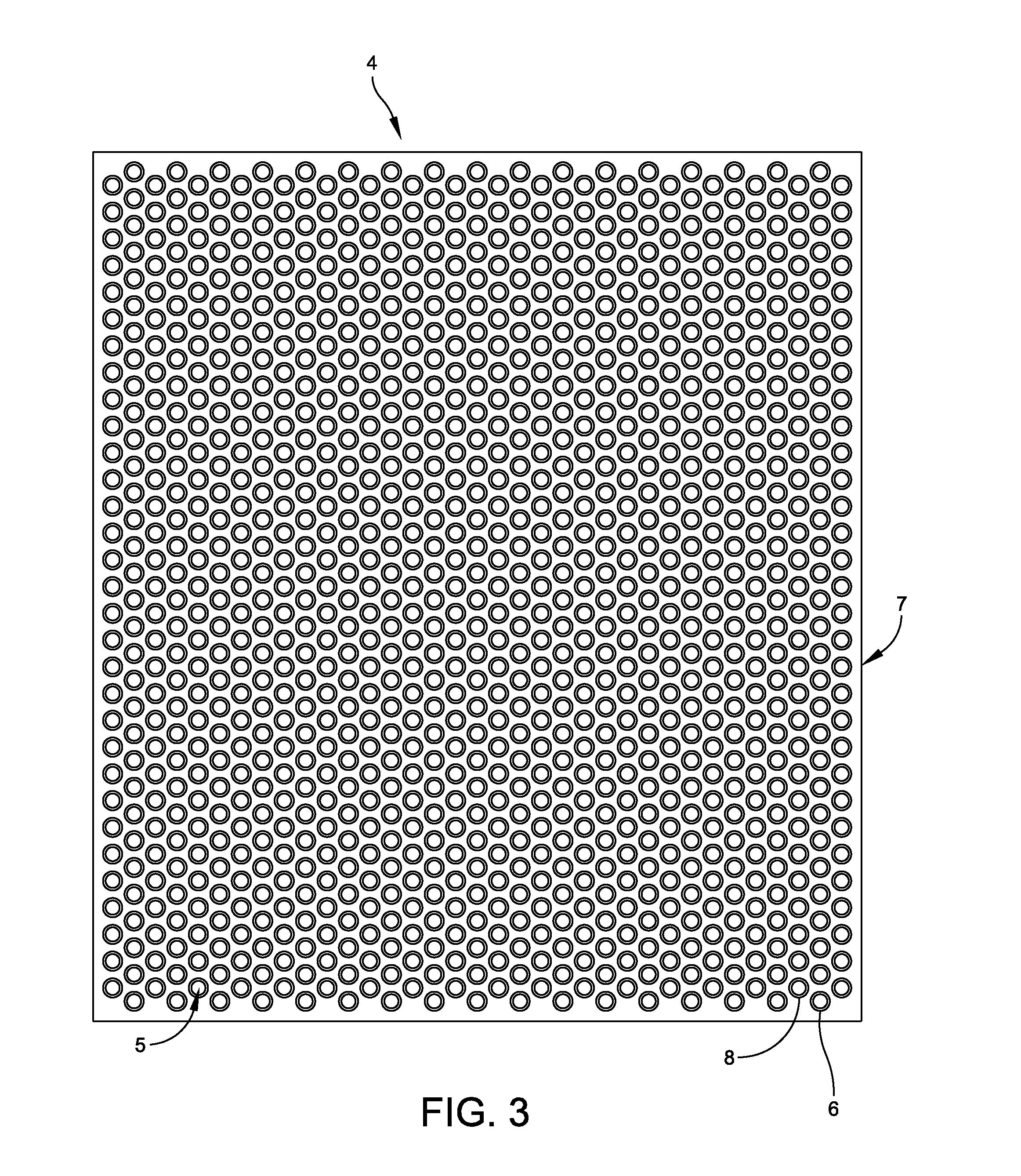

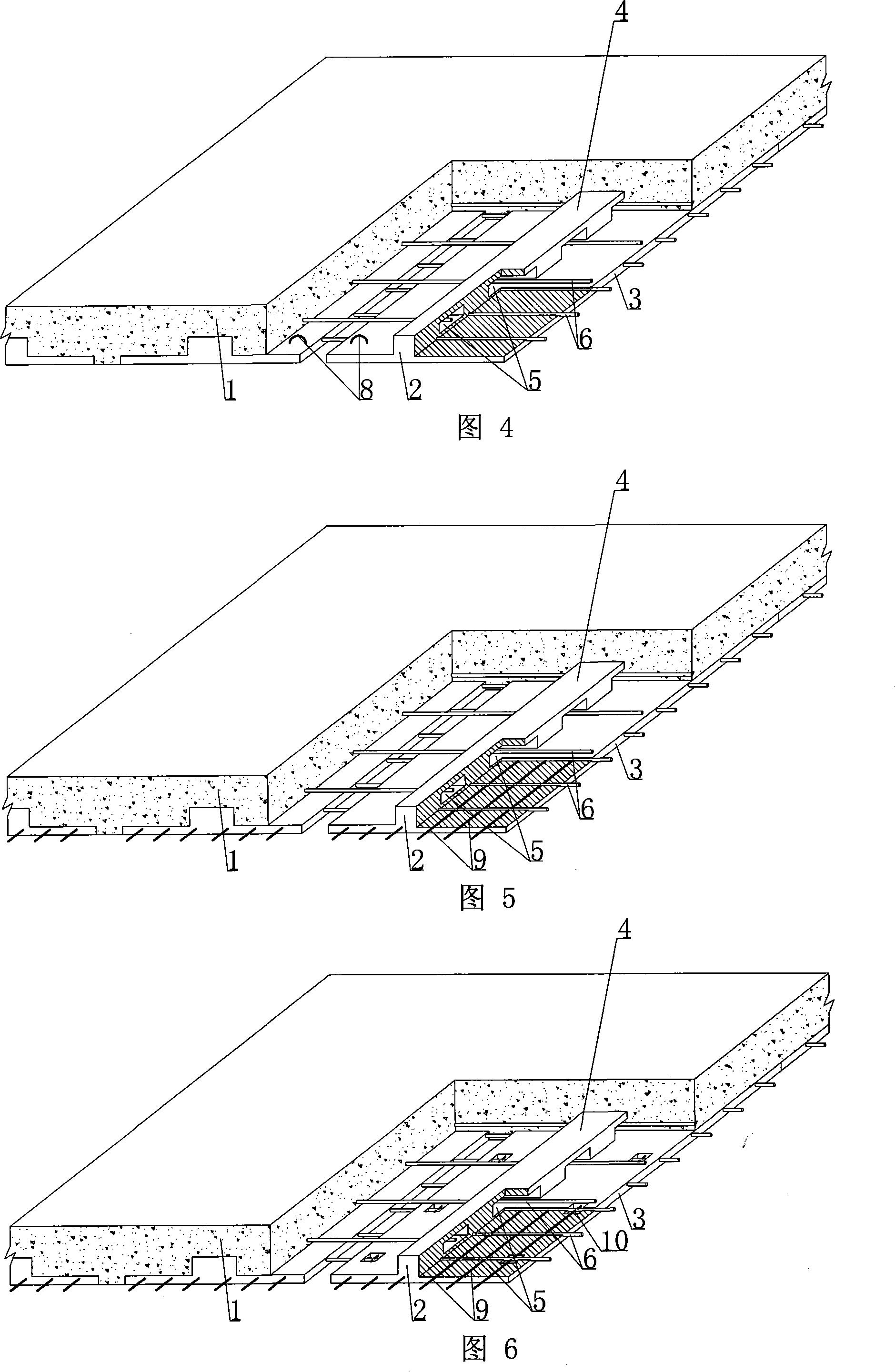

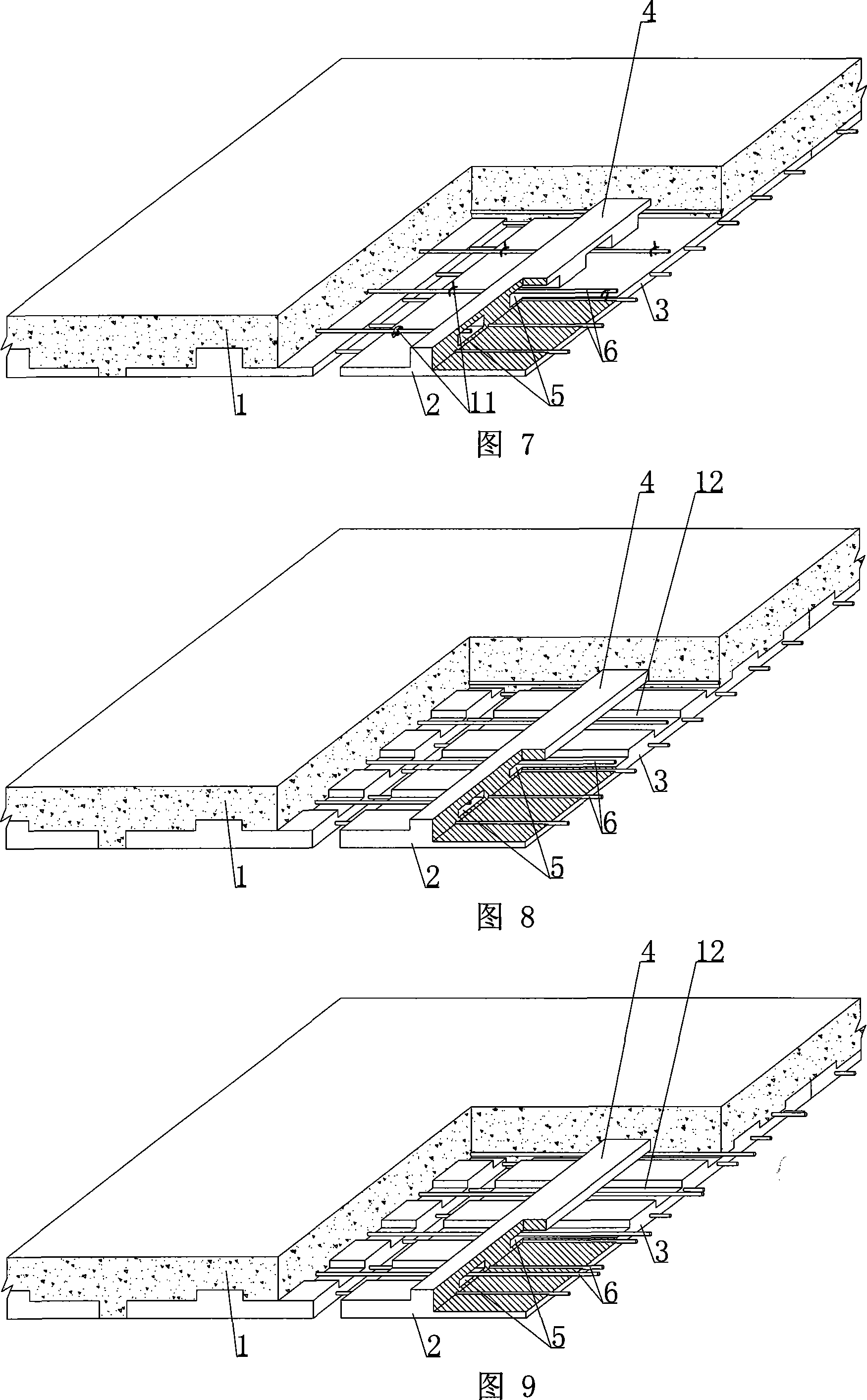

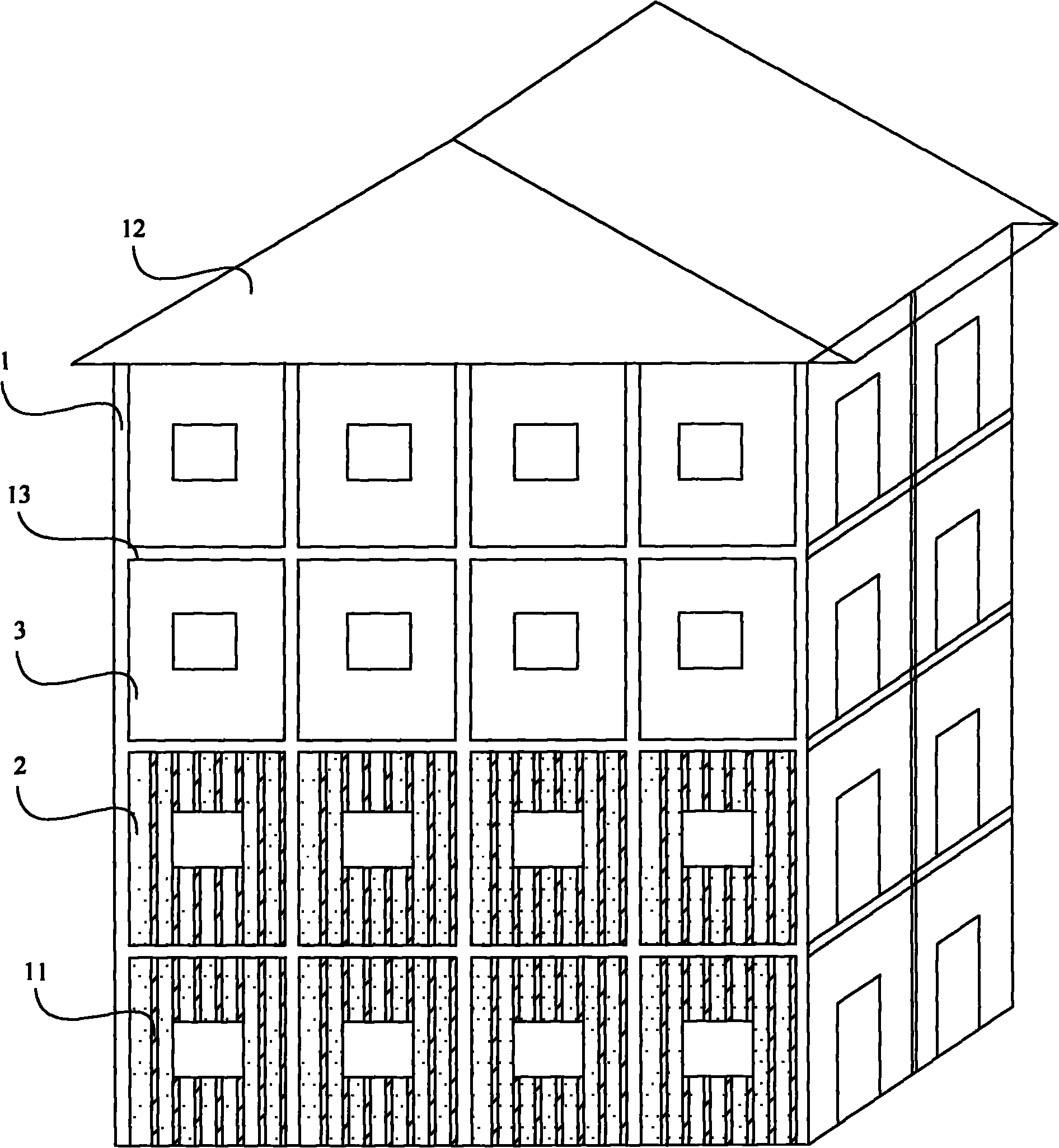

The invention relates to a hollow floor system filled with an air-filling bag and a construction method thereof, belonging to the field of the structure of the common building. The hollow floor system consists of the air-filling bag (1), upper steel bars (2), lower steel bars (3), hidden girder steel bars (4) and concrete (5), wherein the air-filling bag (1) is positioned among the upper steel bars (2), the lower steel bars (3) and the hidden girder steel bars (4); a bag wall (8) of the air-filling bag (1) consists of four side walls (9), an upper wall (10) and a lower wall (11); the shapes of at least two side walls (9) adjacent to the hidden girder steel bars (4) in the air-filling bag (1) are planes; the shapes of the upper wall (10) and the lower wall (11) are heaved-outward arc surfaces; and positioning pieces (12) are arranged among the inner sides of the side walls (9) so as to ensure that the two side walls (9) are parallel mutually. The hollow floor system has large span, better reliability, earthquake resistance and crack resistance, and good economy and applicability.

Owner:徐焱

Seismic shadow mold

Owner:USG INTERIORS LLC

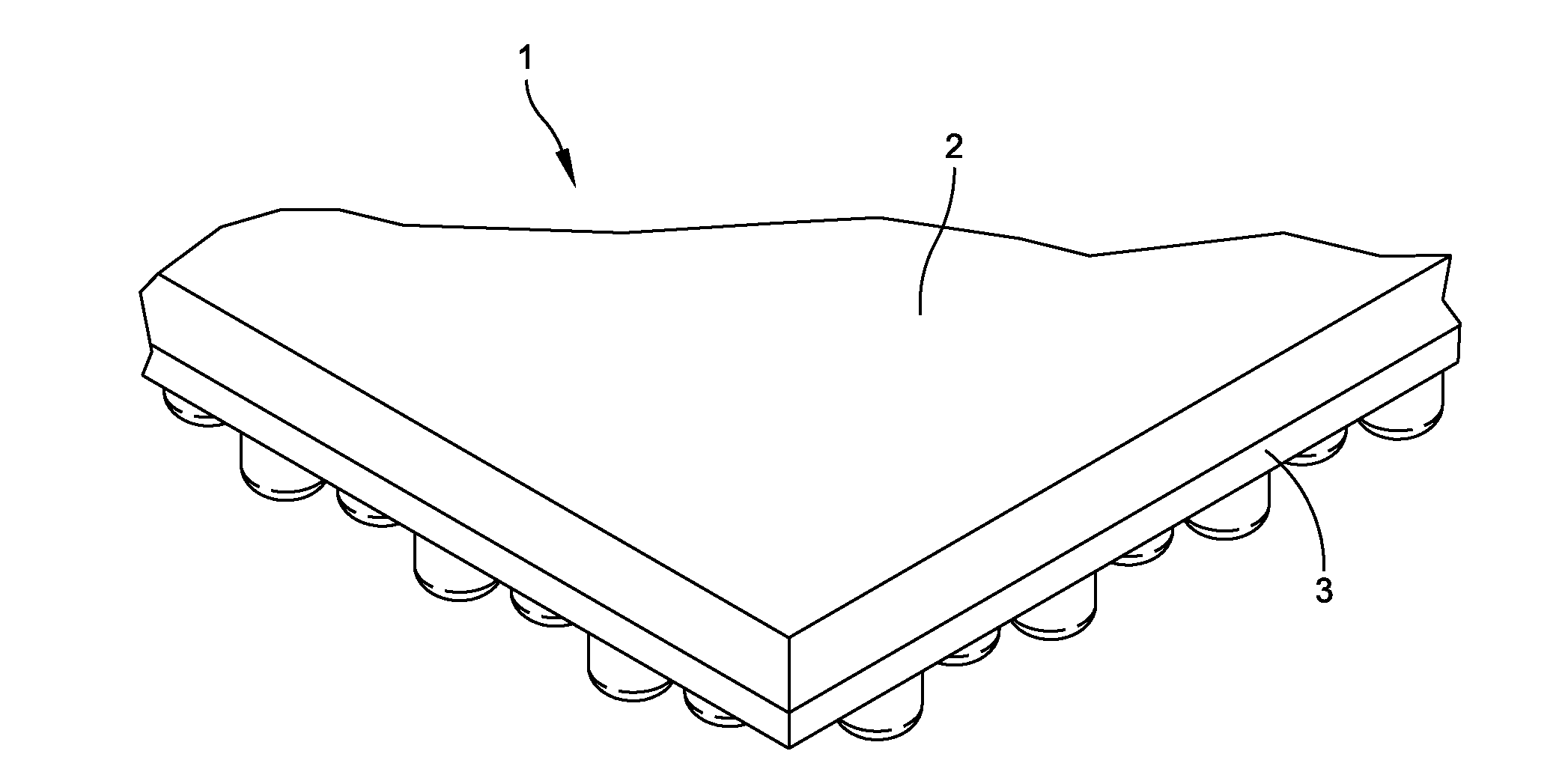

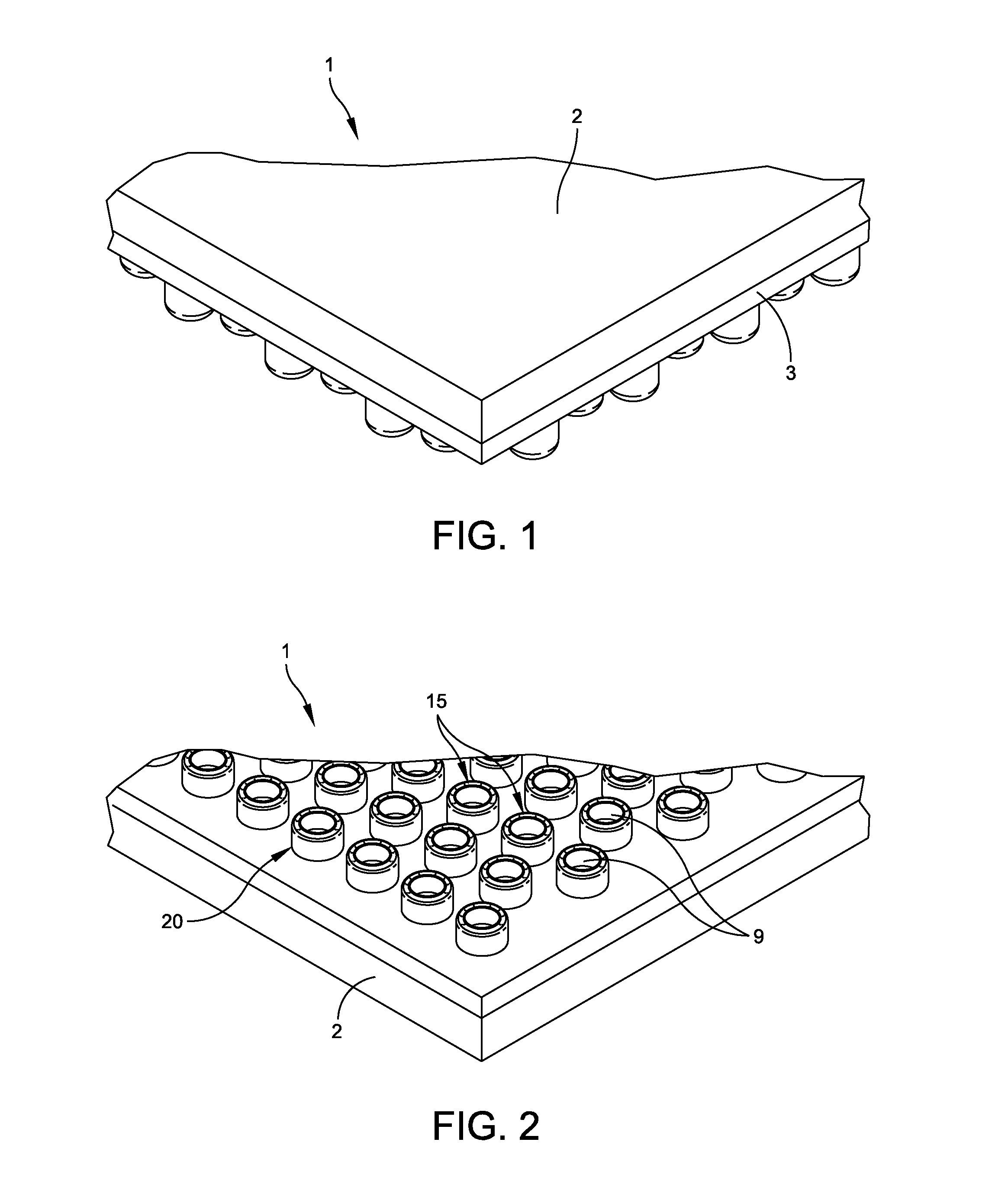

Adhesiveless decorative floor tile

InactiveUS20120324805A1Increase frictional resistanceFloorsFoundation engineeringAdhesiveSurface cover

Owner:GROWLIFE INC

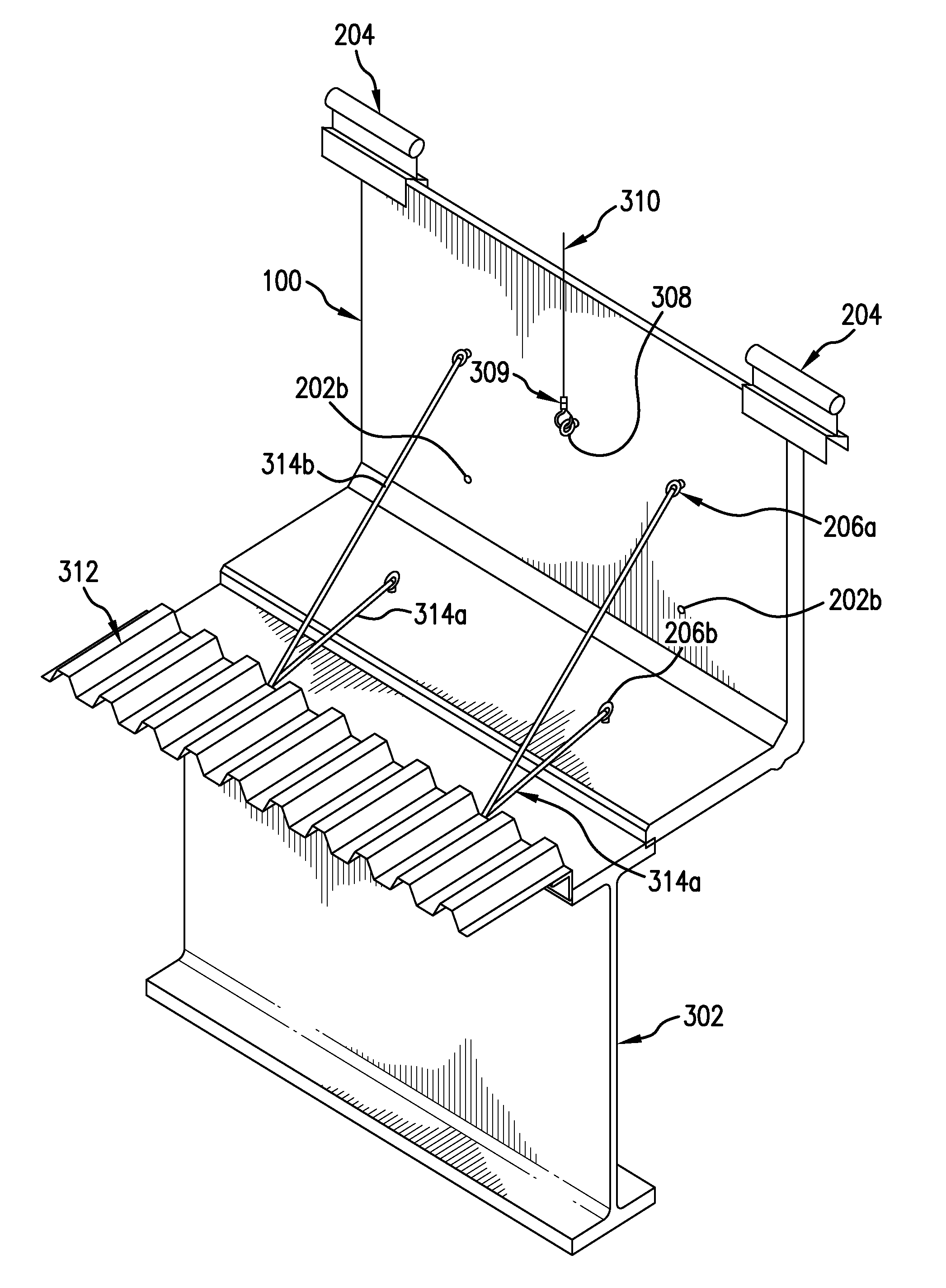

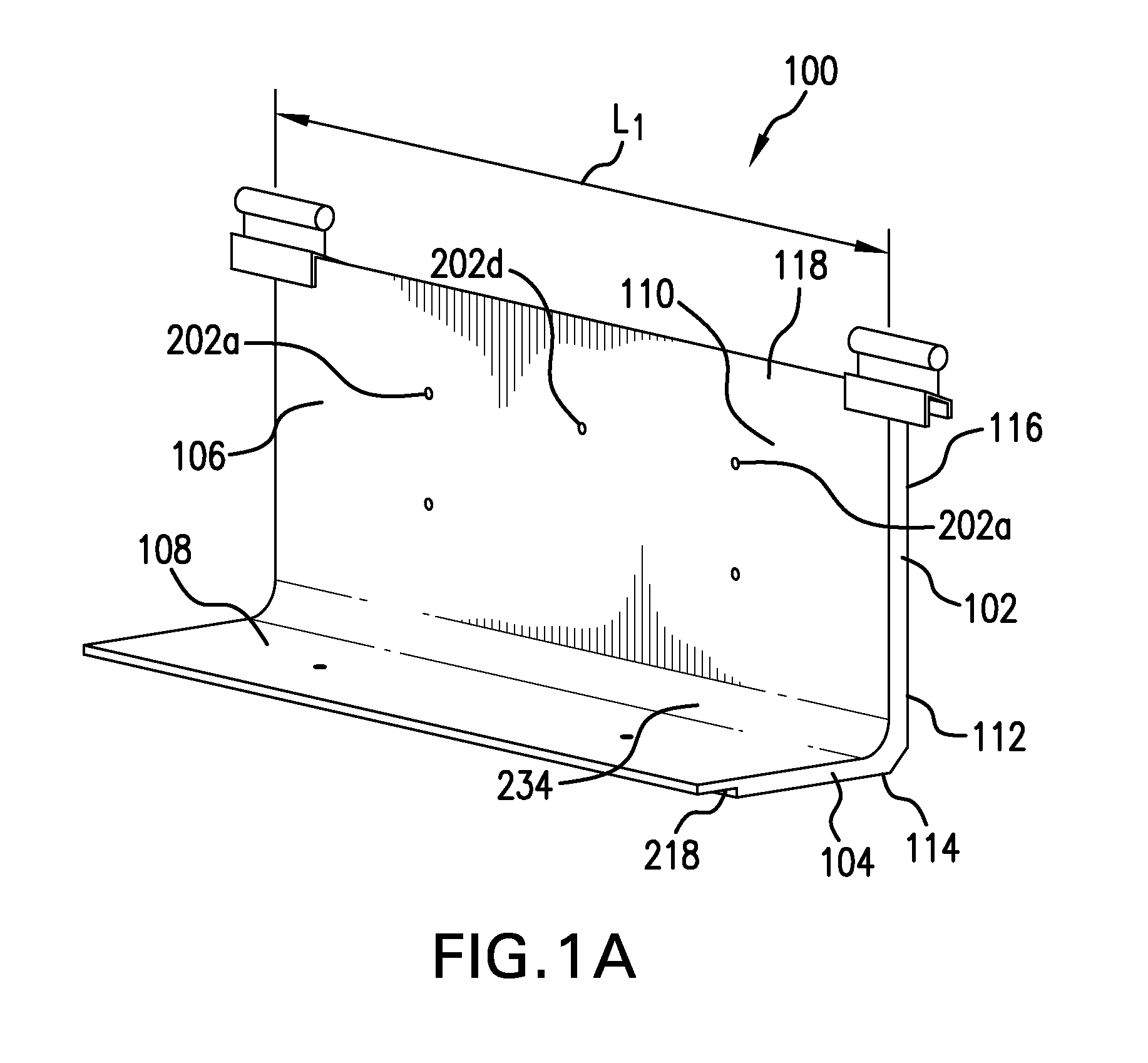

Wind resistant concrete roof component and system and method for forming same

A roof system includes a roof panel formed of concrete and an architectural surface such as a corrugated surface. A first layer of reinforcing material is disposed along and spaced inwardly from a first surface of the roof panel, and an optional second layer of reinforcing material is disposed along and spaced inwardly from a second surface of the roof panel. The first layer of reinforcing material is spaced from the second layer of reinforcing material. The reinforcing material may be formed of fiber-reinforced polymer mesh, made with carbon fibers or glass fibers. FRP rebar may be used in conjunction with FRP mesh to provide added structural strength. The roof panel may include one or more elongated ribs having a thickness greater than adjacent portions of the roof panel. In other aspects, concrete structures with reinforcing material may be used for either roof panels or wall applications.

Owner:FLORIDA INTERNATIONAL UNIVERSITY

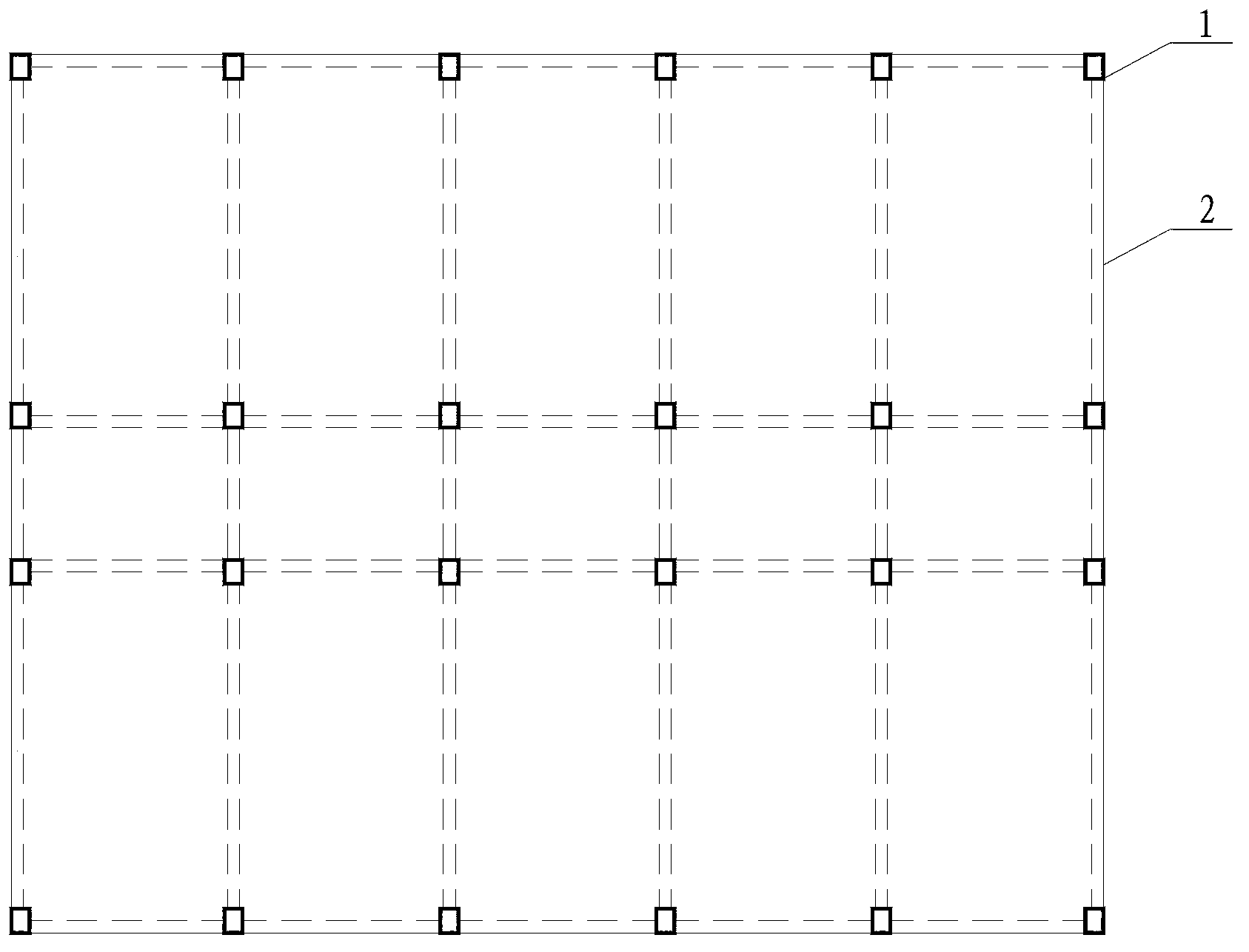

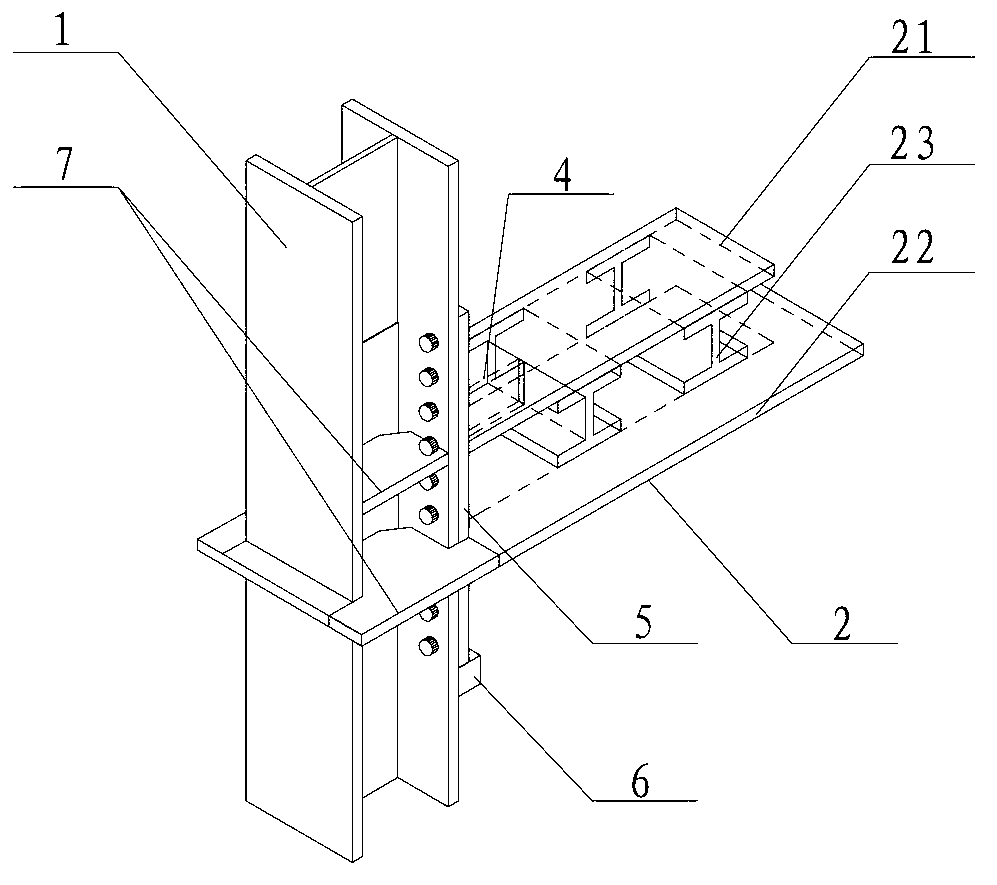

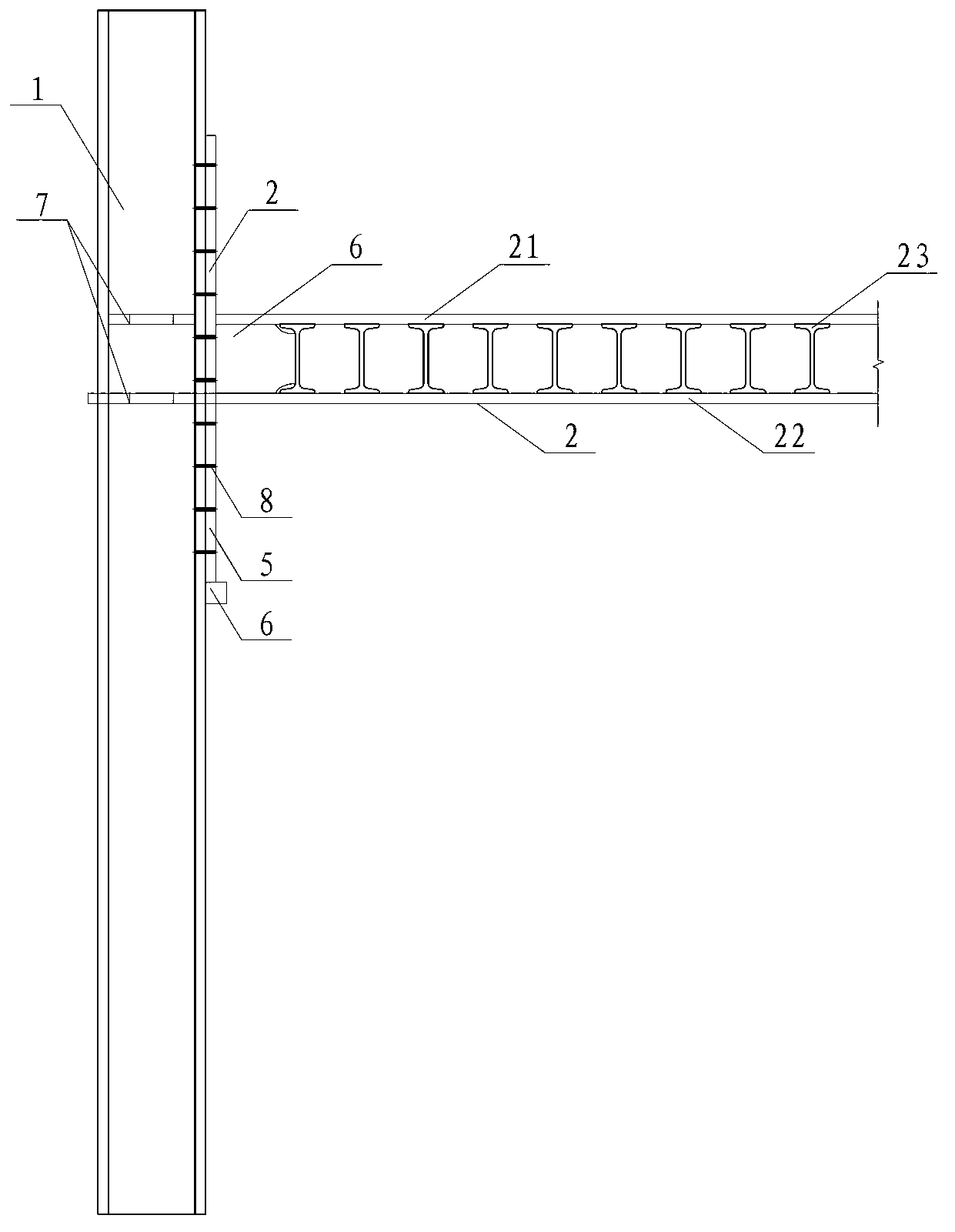

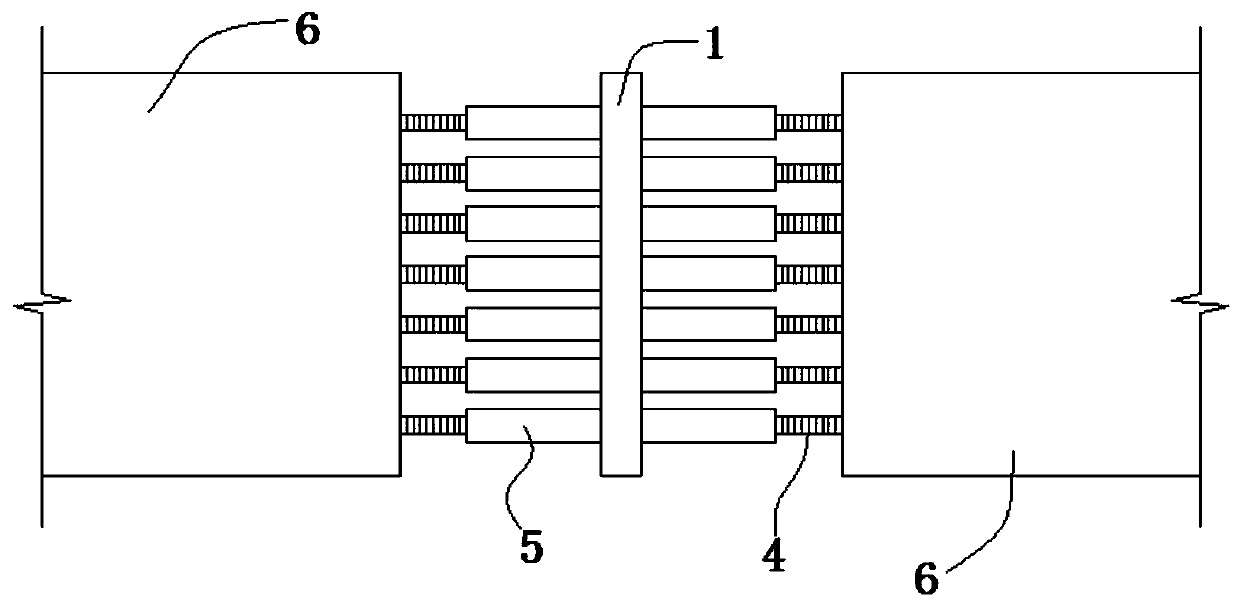

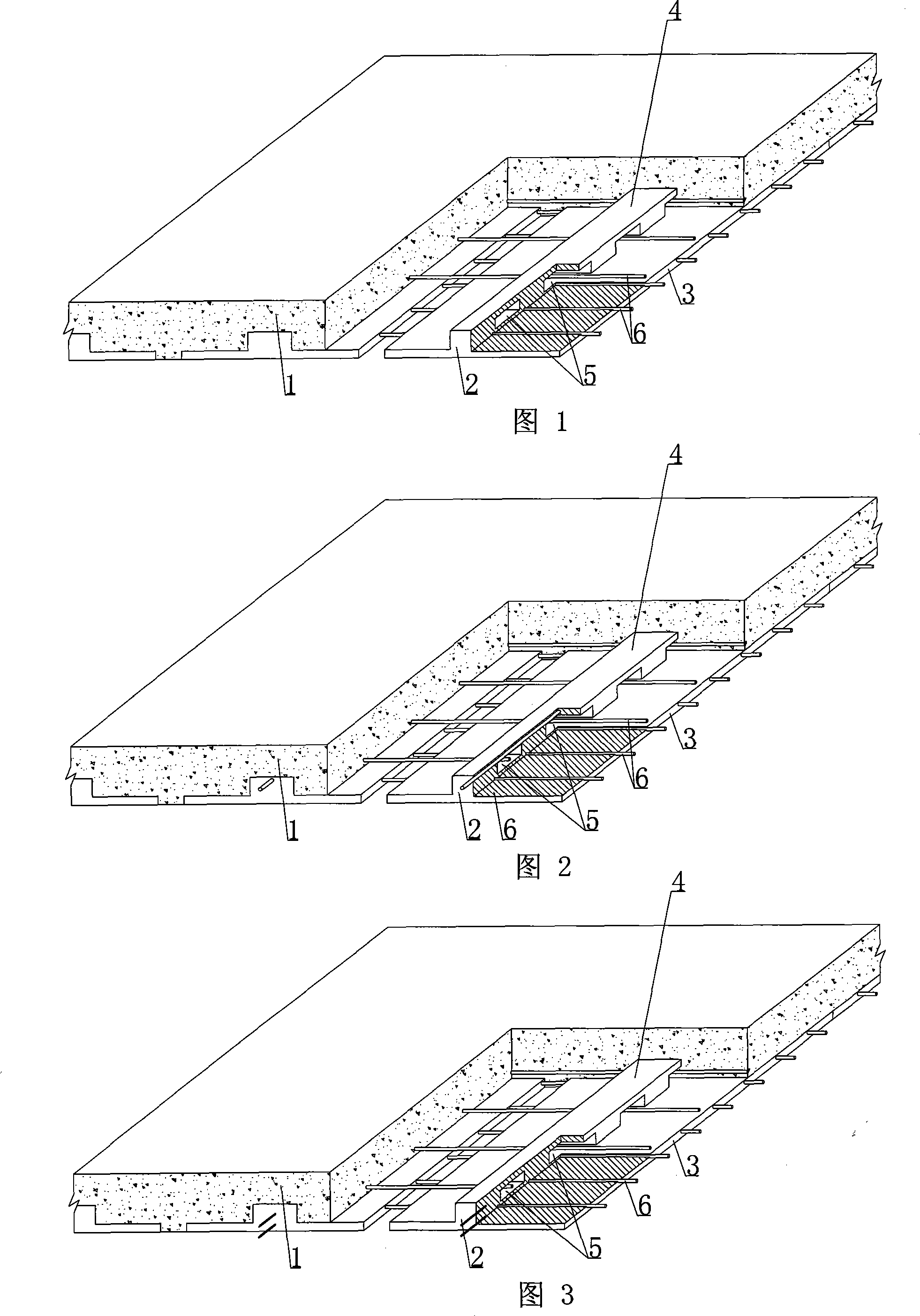

Steel-concrete slab-column structure system

ActiveCN103276795AReasonable structureConvenient on-site operationFloorsSteel columnsPrecast concrete

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

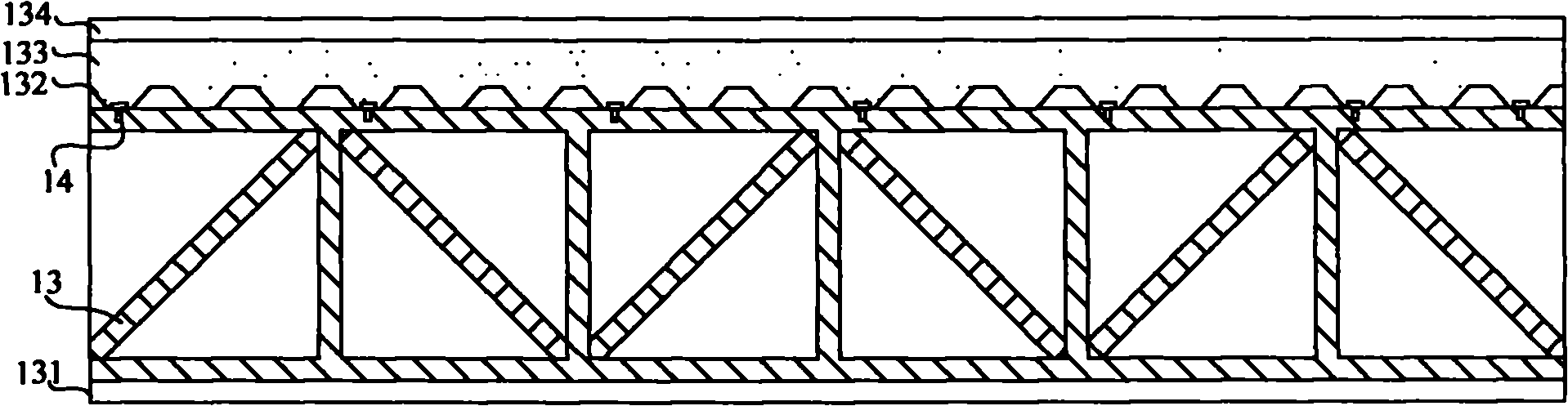

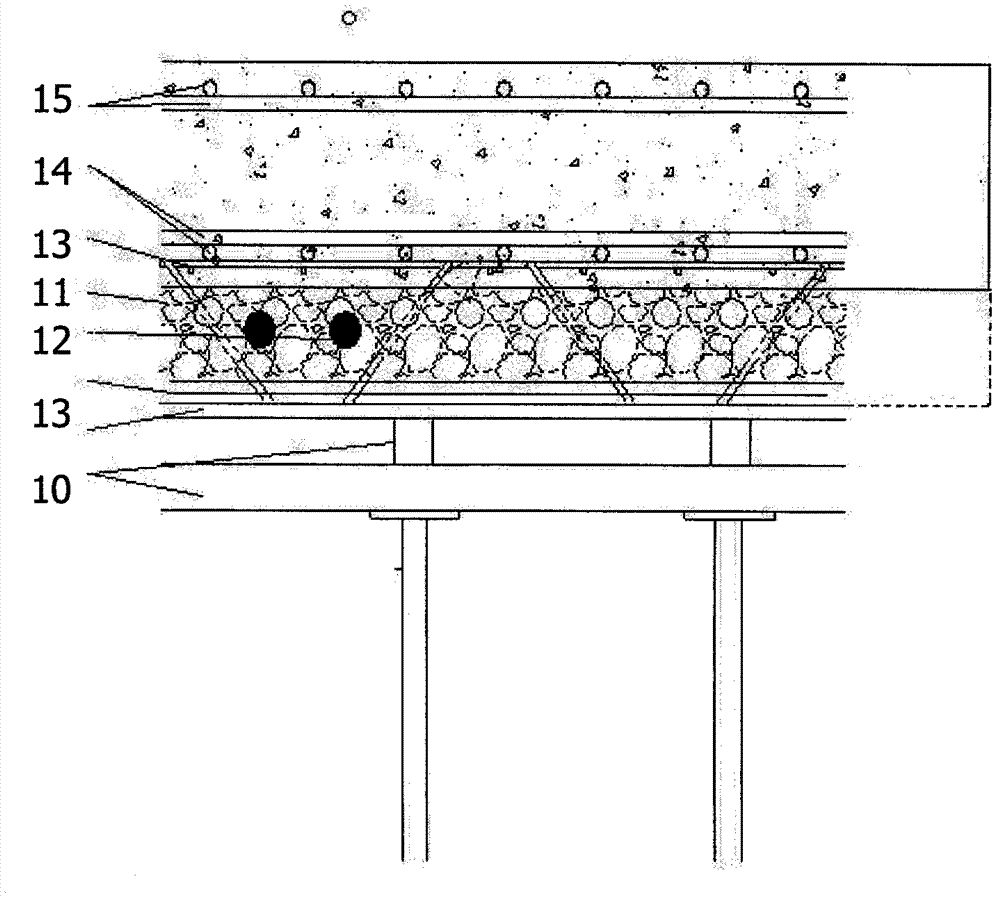

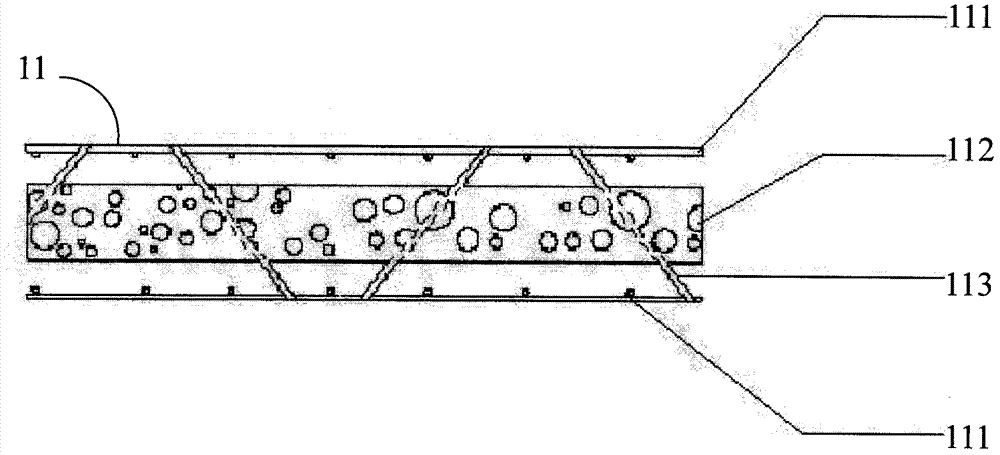

Hollow composite floor slab and construction method thereof

InactiveCN104612300AImprove construction efficiencyEasy to transportFloorsReinforced concreteCrack resistance

The invention discloses a hollow composite floor slab and a construction method of the hollow composite floor slab. The hollow composite floor slab comprises a prefabricated hollow bottom plate and an upper cast-in-place slab, continuous fully-closed preformed holes and semi-closed preformed holes are distributed in the prefabricated hollow bottom plate at intervals, or the continuous fully-closed preformed holes and plate ribs are distributed on the prefabricated hollow bottom plate at intervals, bottom plate rebars are distributed on the prefabricated hollow bottom plate at intervals in the longitudinal direction and the transverse direction, prestress rebars or prestress rebars and non-prestress rebars distributed at intervals are adopted as the bottom plate rebars, and the rebars penetrate through the semi-closed preformed holes or plate rib preformed holes. Concrete is poured on the prefabricated hollow bottom plate to form the upper cast-in-place slab, multiple sets of top rebars are distributed on the cast-in-place slab in the longitudinal and the transverse directions parallel to the bottom plate at intervals, and reinforced concrete is integrally poured on the bottom plate to form the hollow composite floor slab. Only the prefabricated bottom plate needs to be produced and transported, transportation and installation are convenient and fast, formworks are not needed, the crack resistance and the integrity are good, and the construction efficiency is high.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

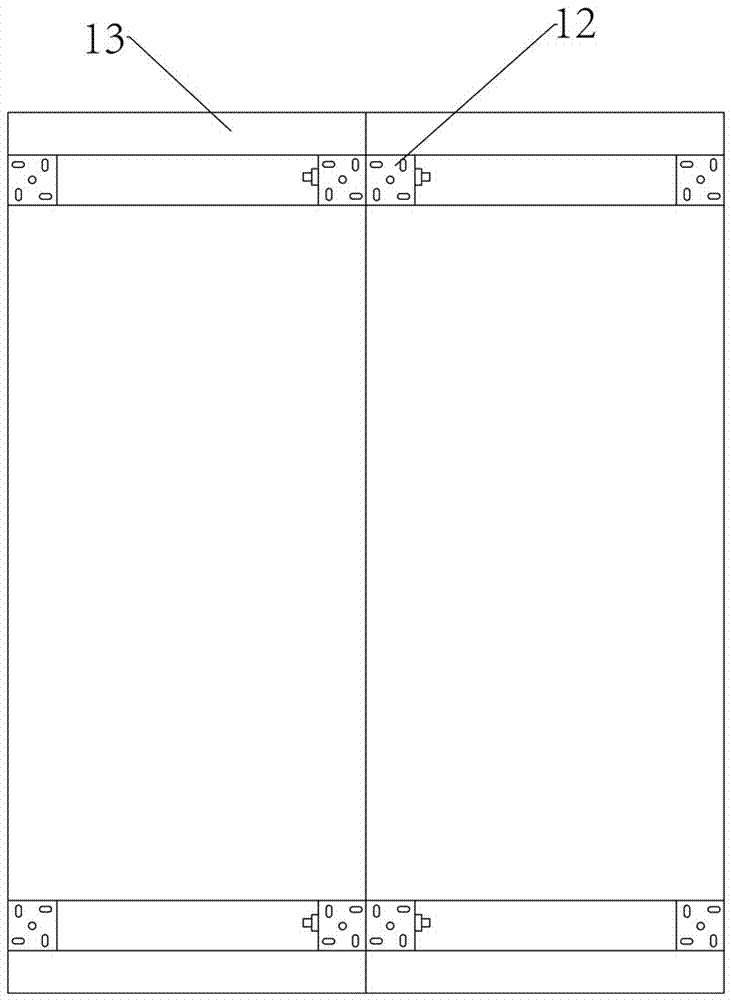

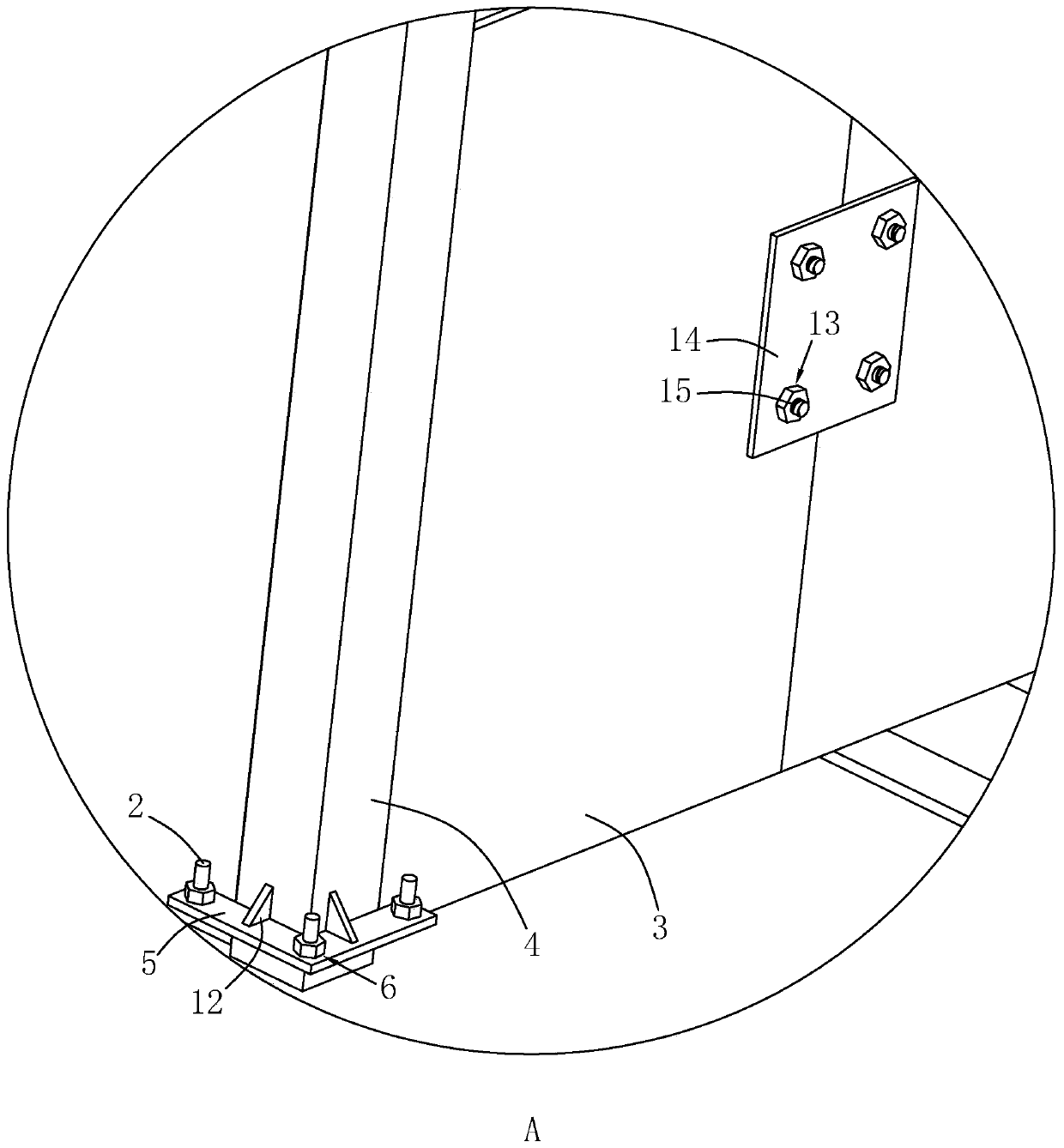

Assembled prefabricated floor connecting system and construction method thereof

PendingCN110761462AEasy to operateFast constructionFloorsBuilding reinforcementsFloor slabArchitectural engineering

Owner:CHONGQING UNIV

Energy storage type air regulating floorslab

InactiveCN1904282AEnables radiant heating/coolingImprove thermal comfortClimate change adaptationFloorsFloor slabEngineering

Owner:CHINA ACAD OF BUILDING RES

Novel combined type floor slab and construction method thereof

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD +1

Laminated slab

Owner:邱则有

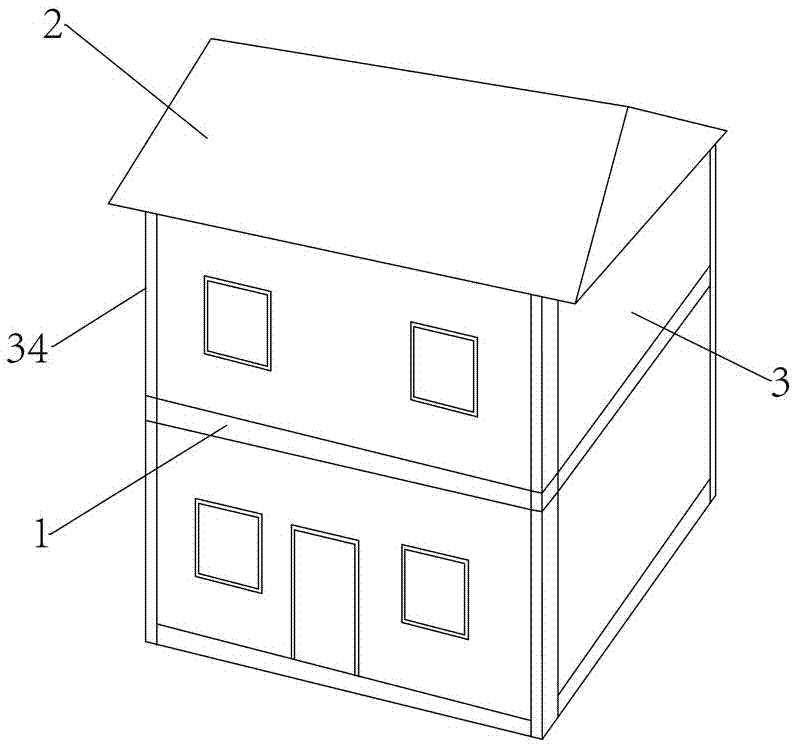

Building structure combining foaming cement and lightweight steel

InactiveCN102011431AIncreased load-bearing capacityImprove seismic performanceWallsFloorsMaterials scienceCement

Owner:魏宝良

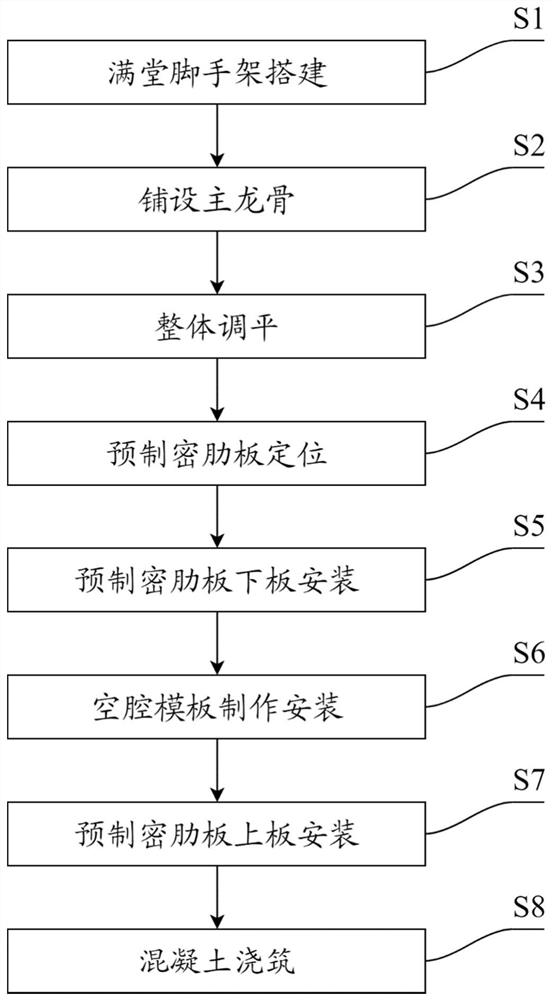

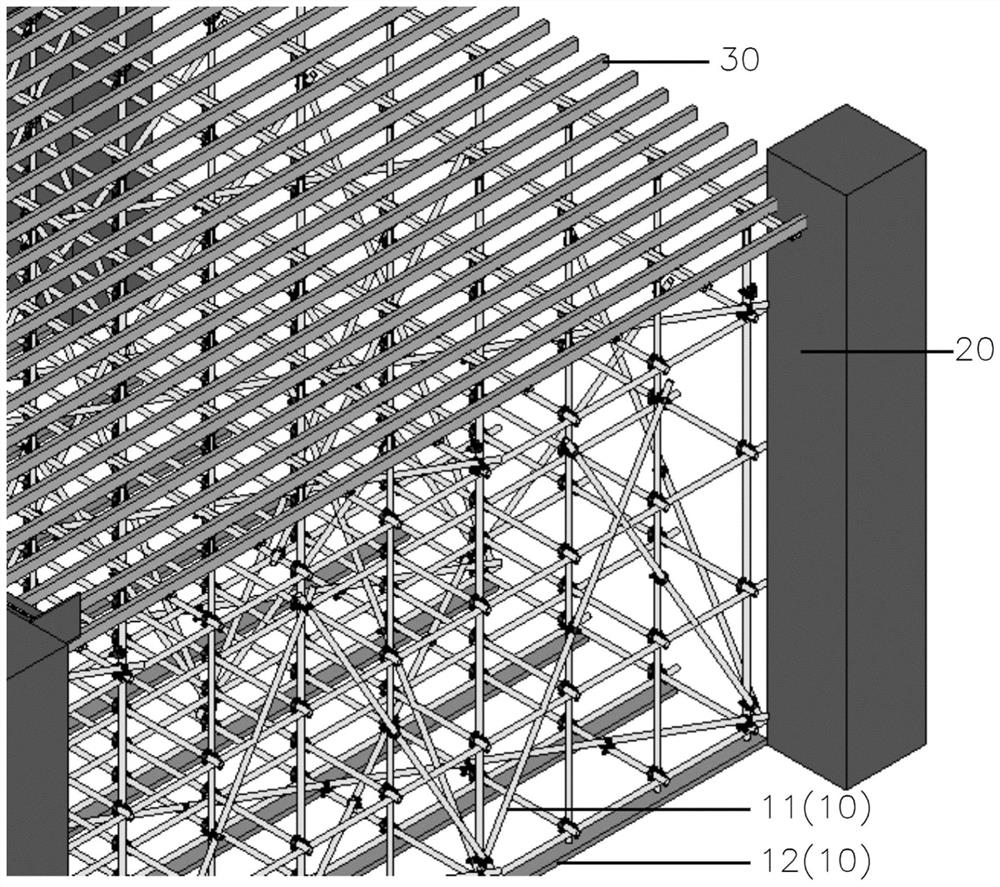

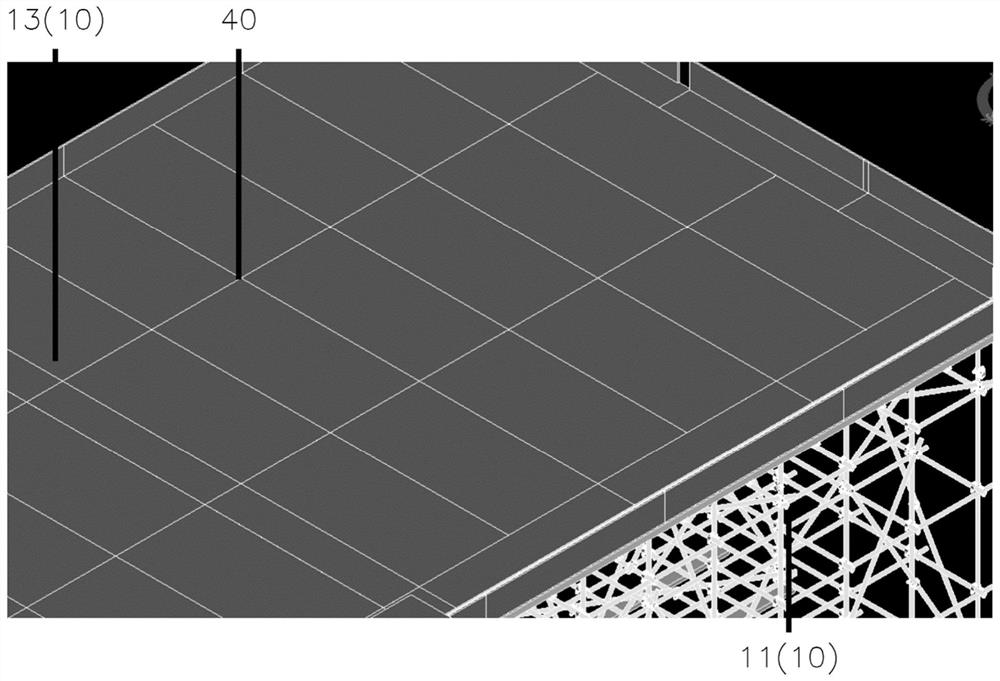

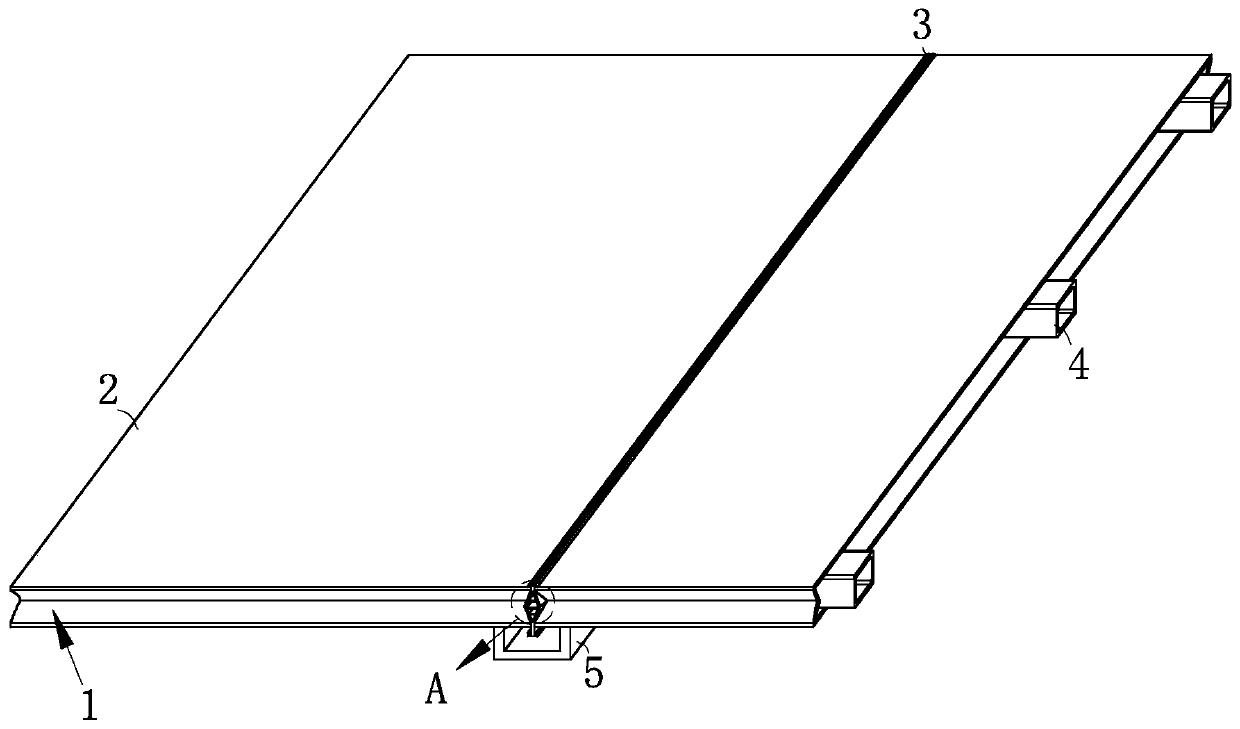

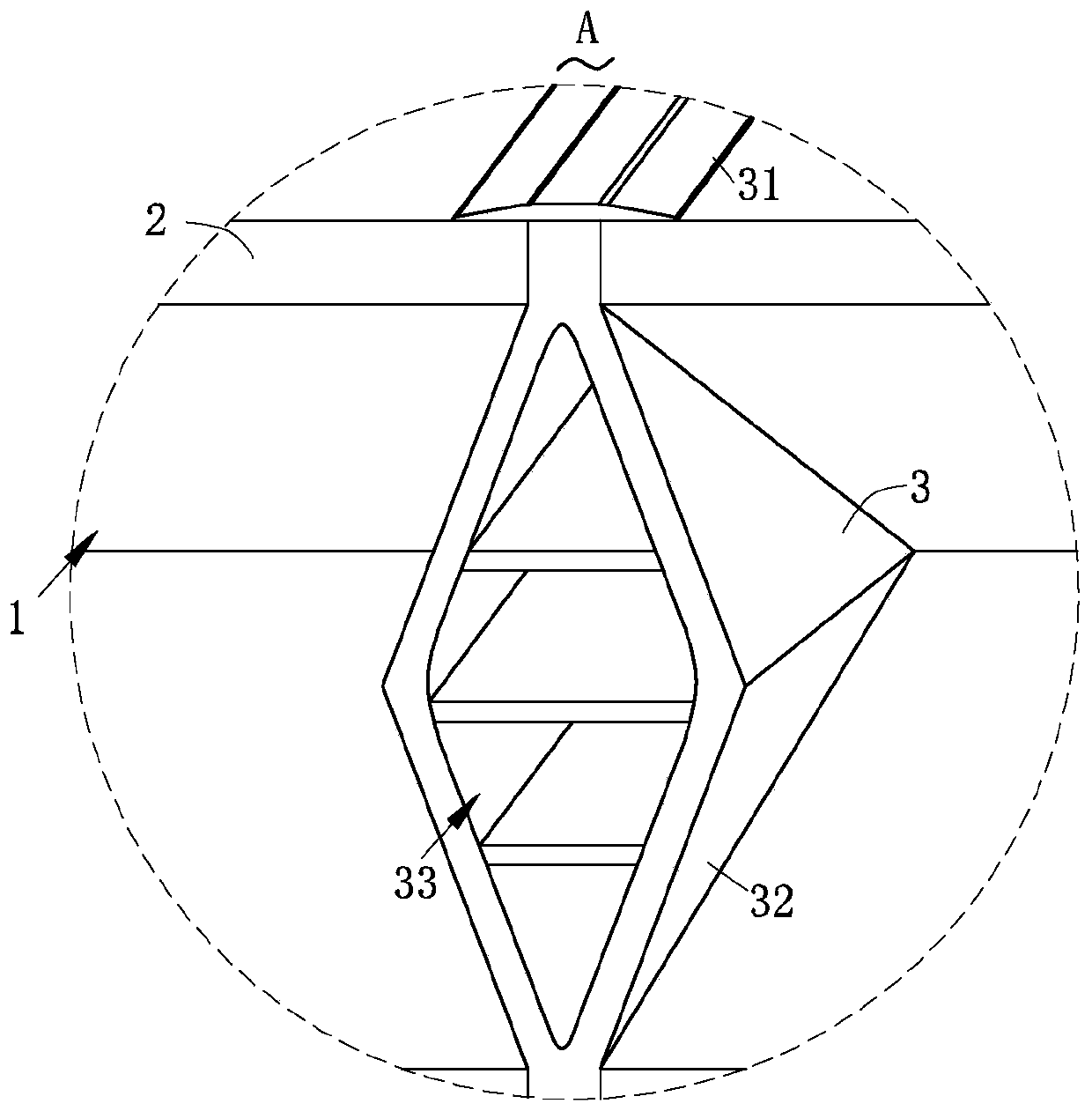

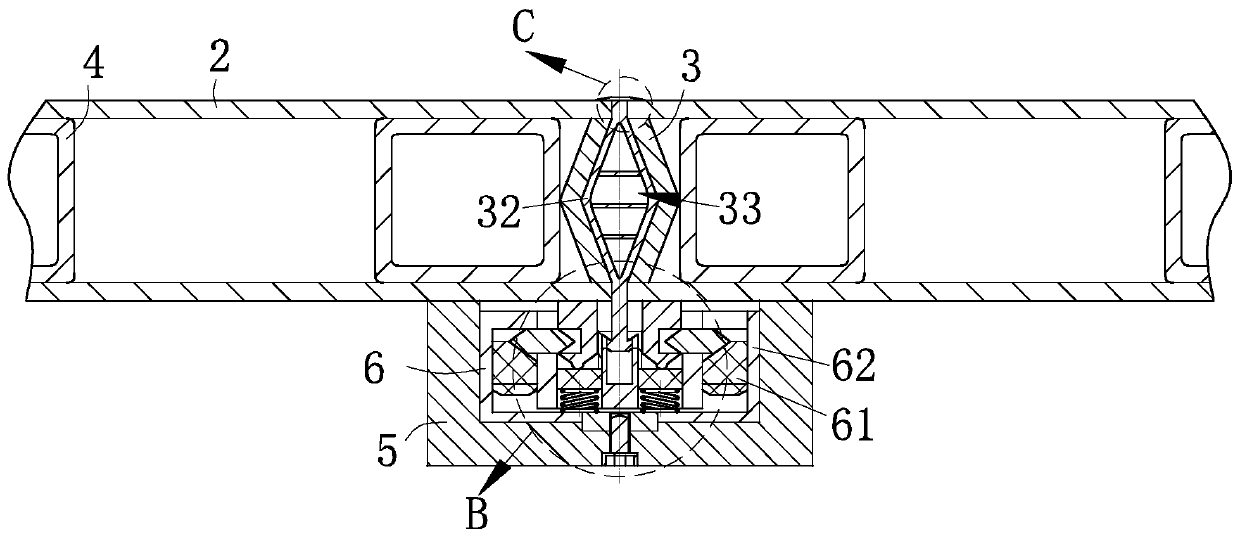

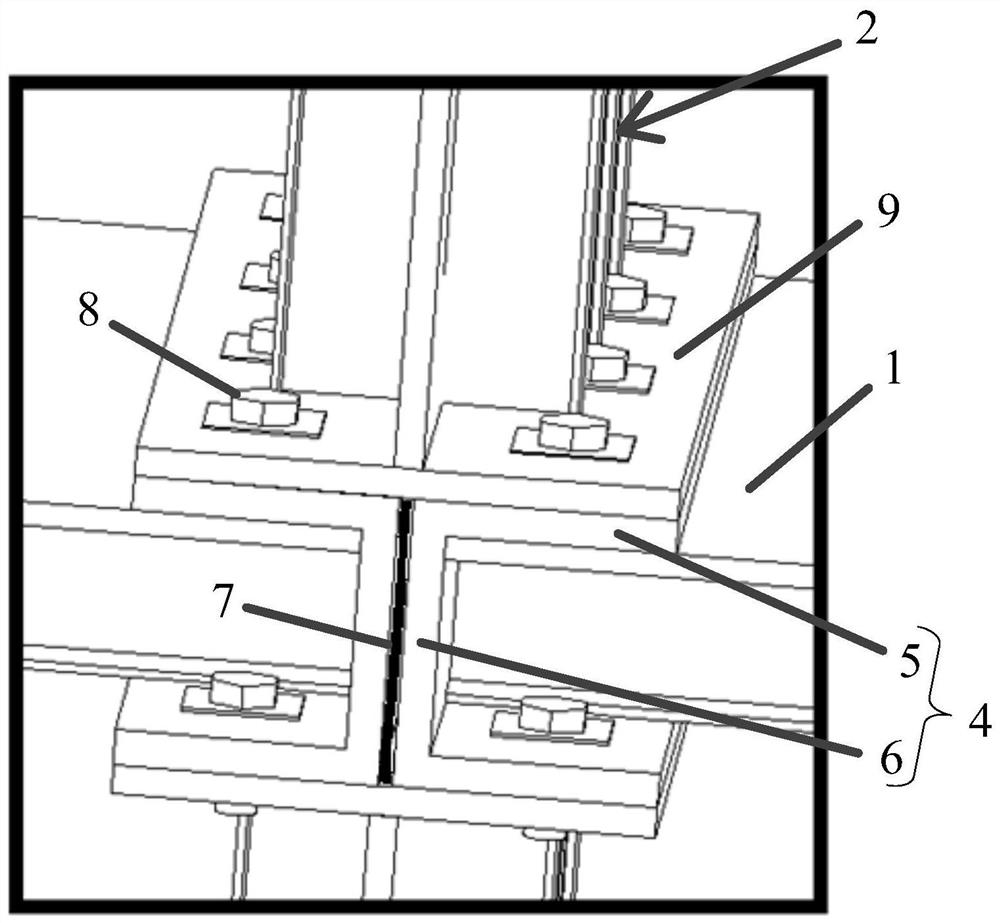

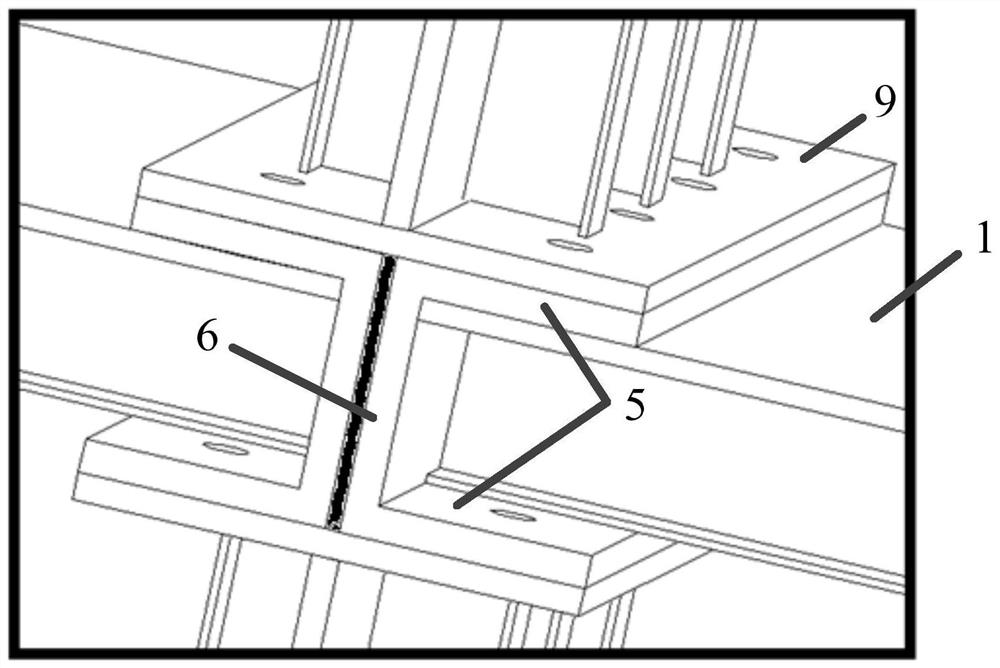

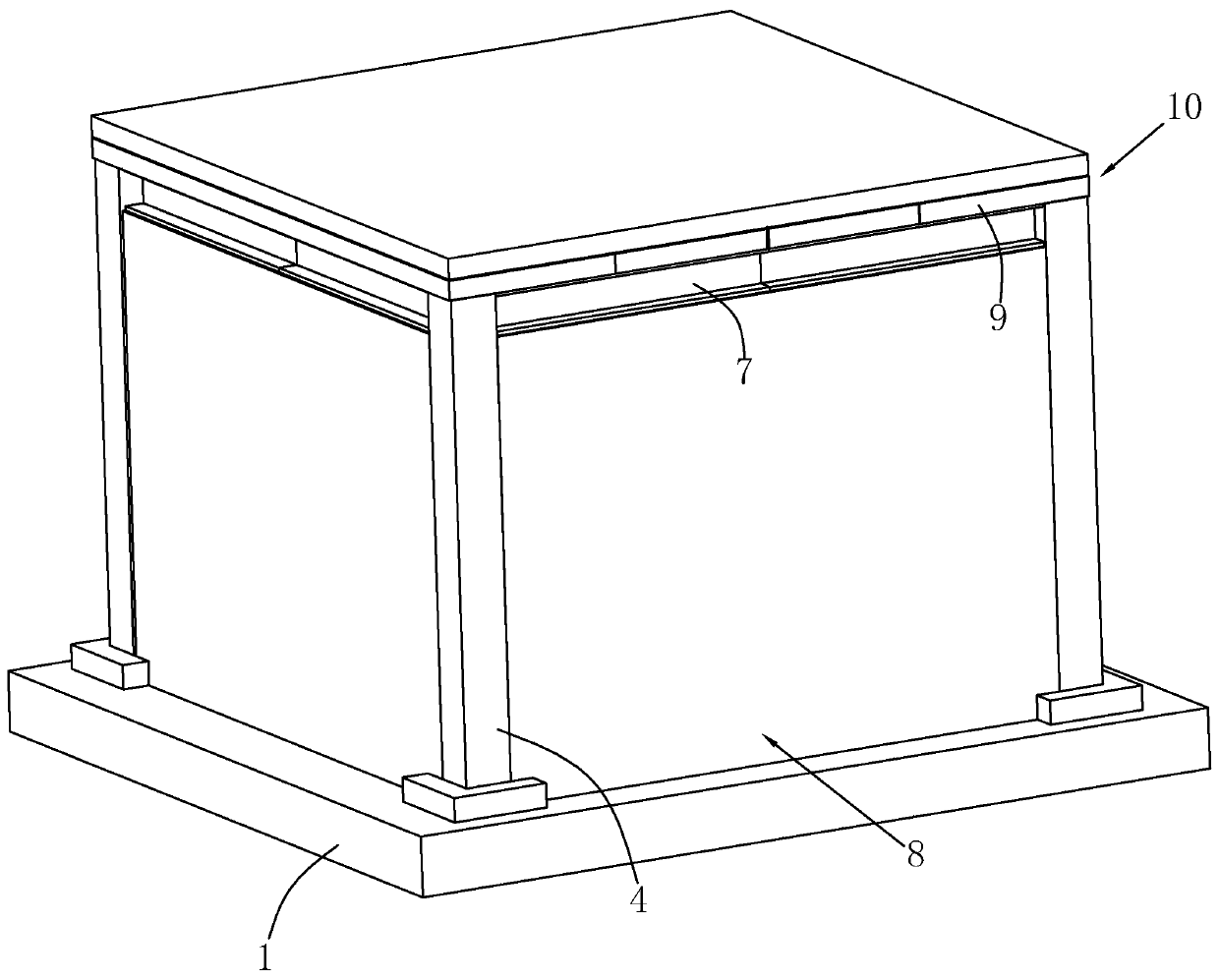

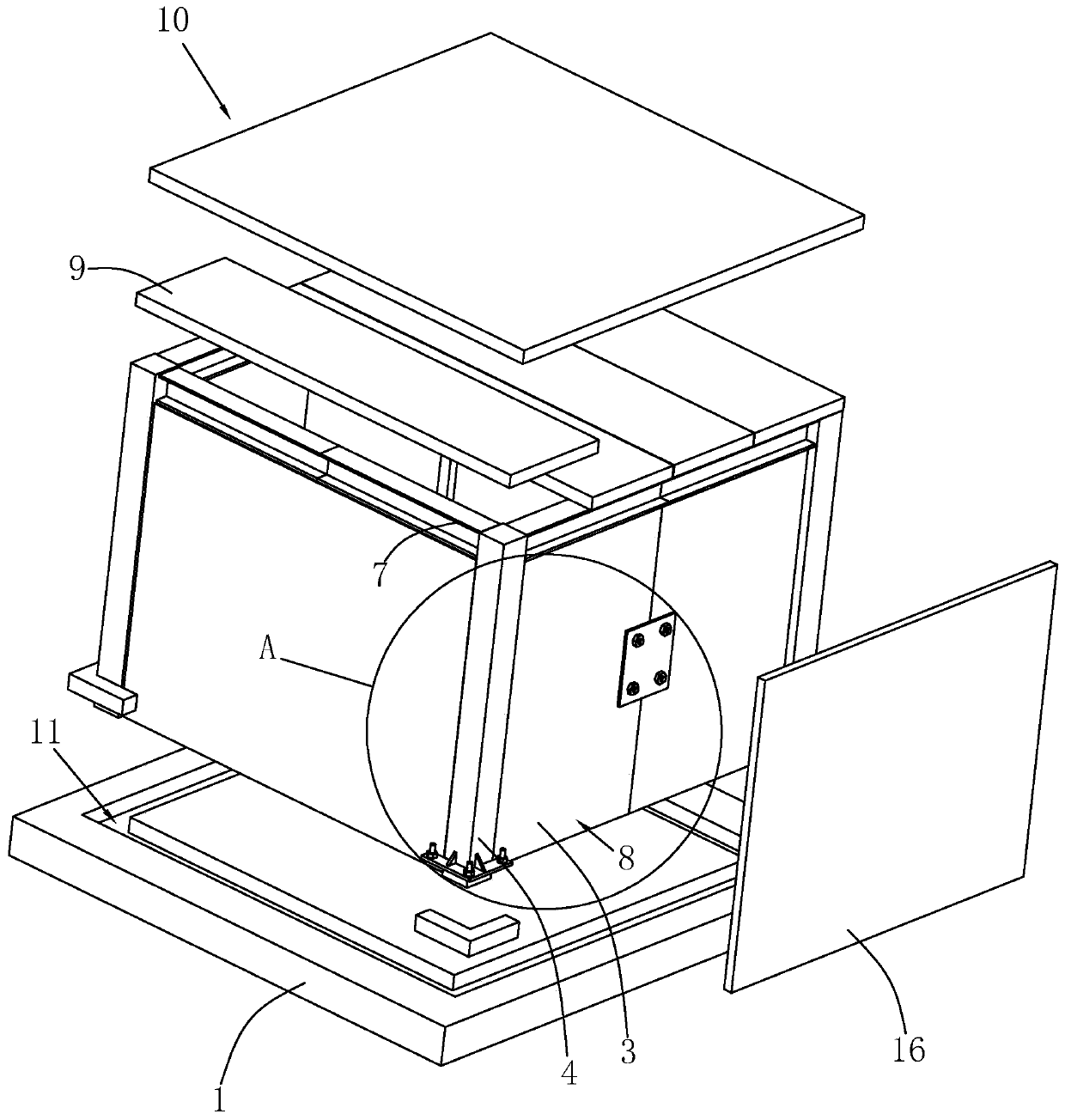

Construction method of prefabricated multi-ribbed cavity floor

The invention provides a construction method of a prefabricated multi-ribbed cavity floor, and belongs to the technical field of prefabricated multi-ribbed plate construction. The construction method of the prefabricated multi-ribbed cavity floor comprises the steps of full-hall scaffold building, main keel laying, overall leveling and the like. The construction method comprises the steps that S1, full-hall scaffold building is conducted, specifically, when a full-hall scaffold is built, vertical rods on the upper layer and the lower layer are required to be aligned, the vertical rods are uniformly arranged from the two sides of a cast-in-place ribbed beam, the vertical rods are arranged at the intersection positions of floor elastic bidirectional lines, and scaffold boards are laid under the vertical rods; S2, main keels are laid, specifically, when the main keels are installed, the main keels are required to be arranged in order and not to be inclined, and the two vertical rods at the intersection positions must abut against the main keels; and S3, overall leveling is conducted, specifically, after the main keels are laid, overall leveling is conducted according to control lines, and full-hall scaffold formworks are hoisted on the main keels. The cavity formworks are supported by placing the modularized cavity formworks which are machined and formed in a factory-like mode, and accurate and rapid installation of an upper plate of the prefabricated multi-ribbed plate is achieved by installing limiting square pipes.

Owner:中建八局发展建设有限公司

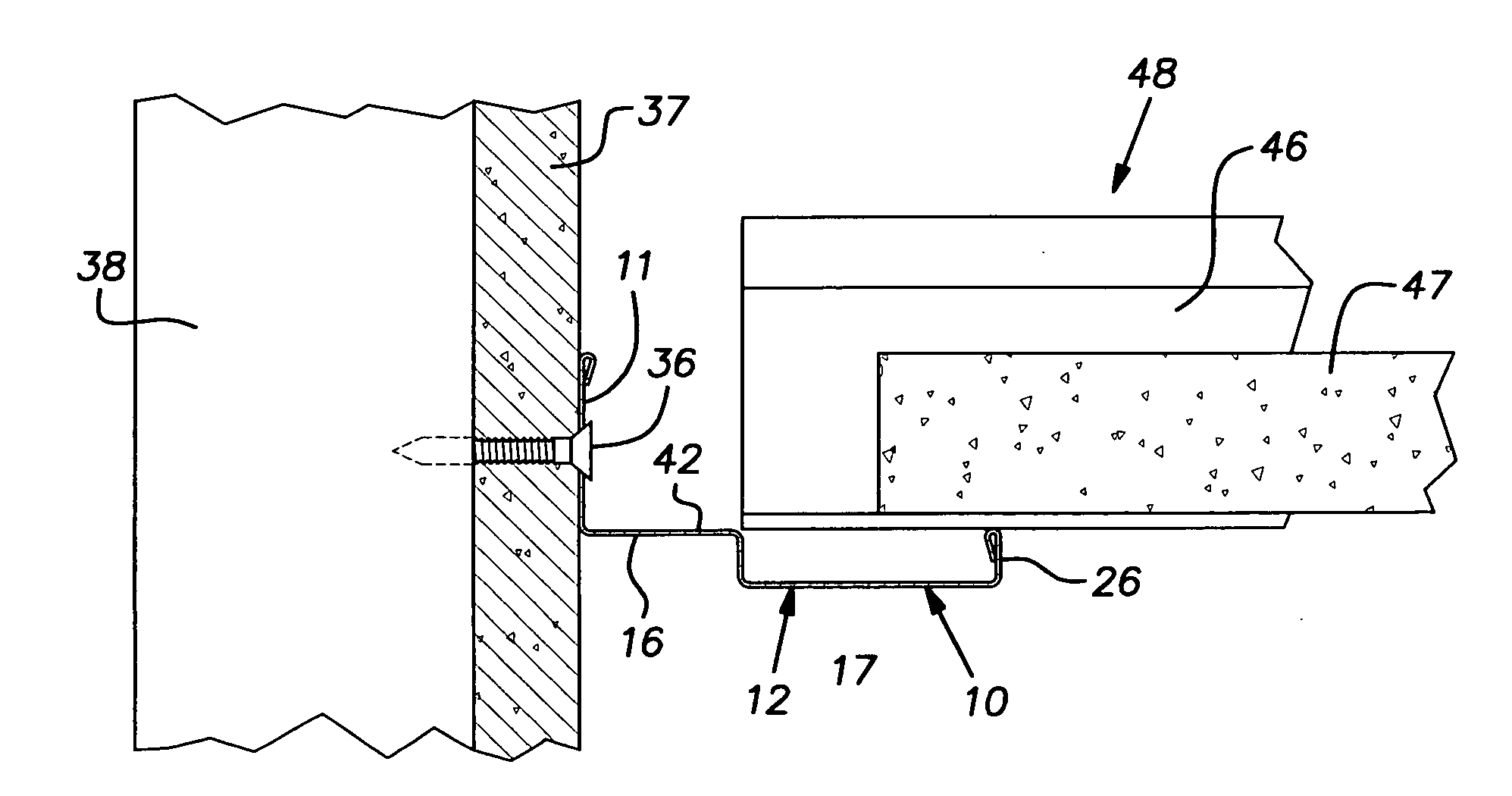

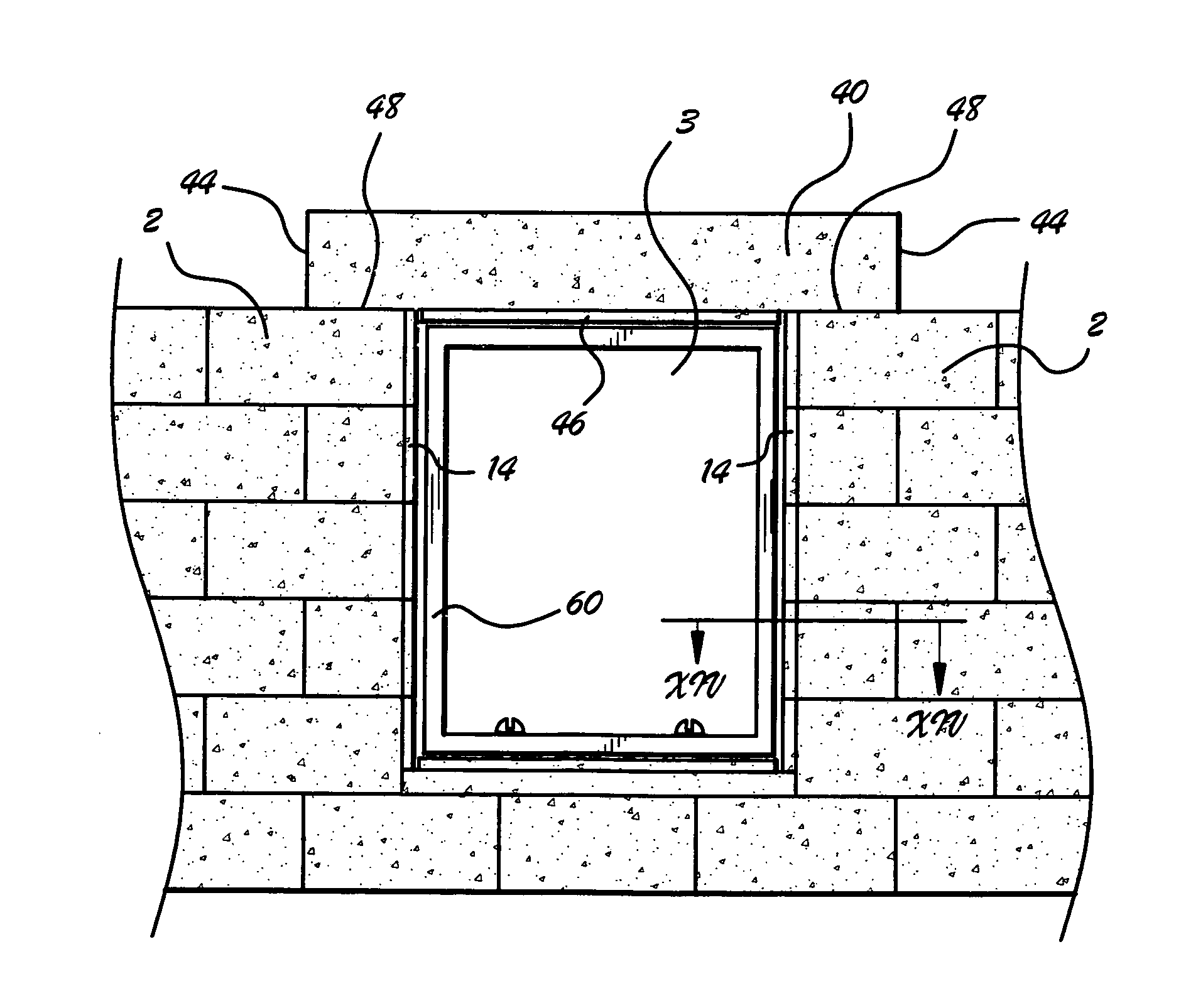

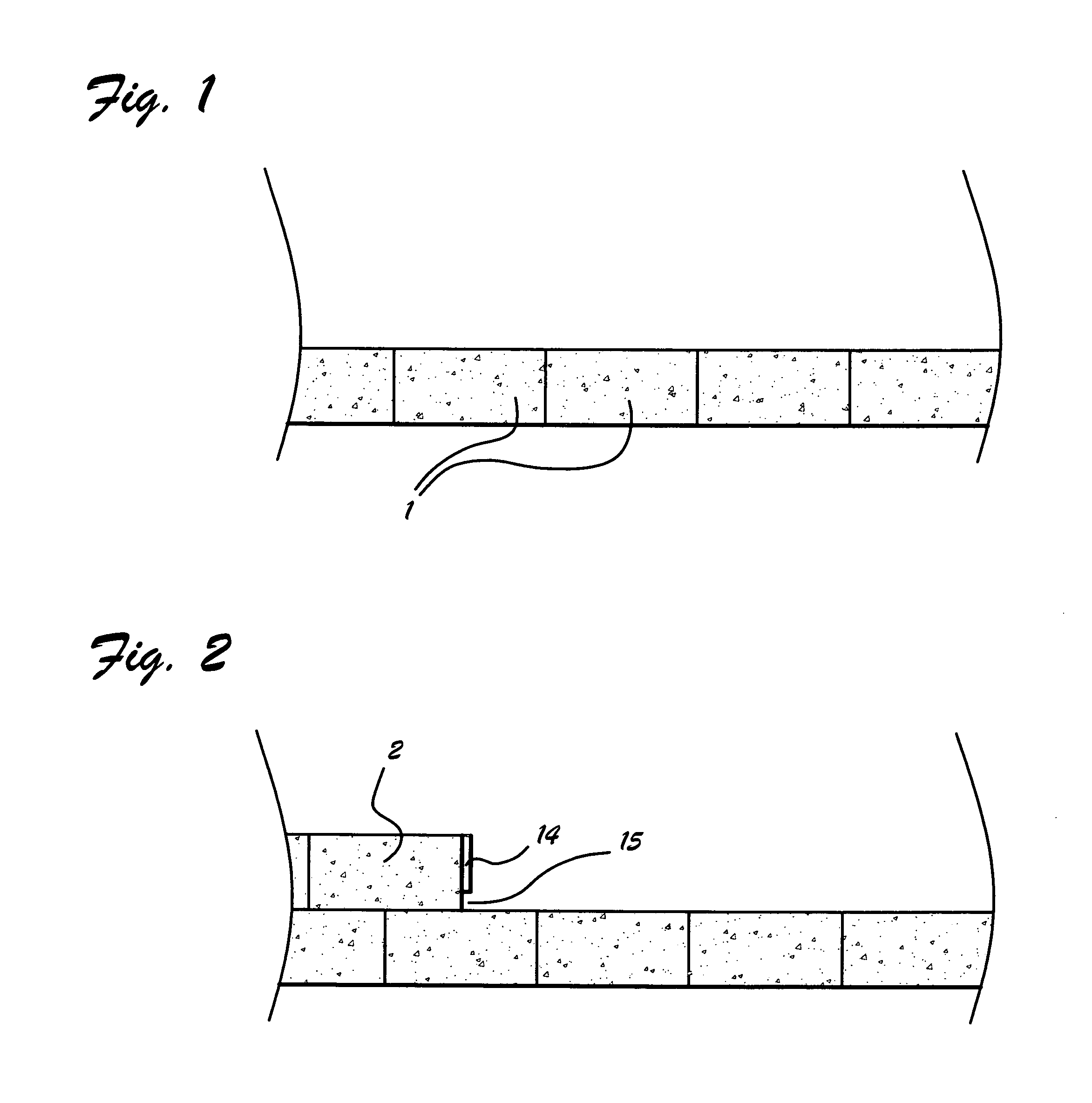

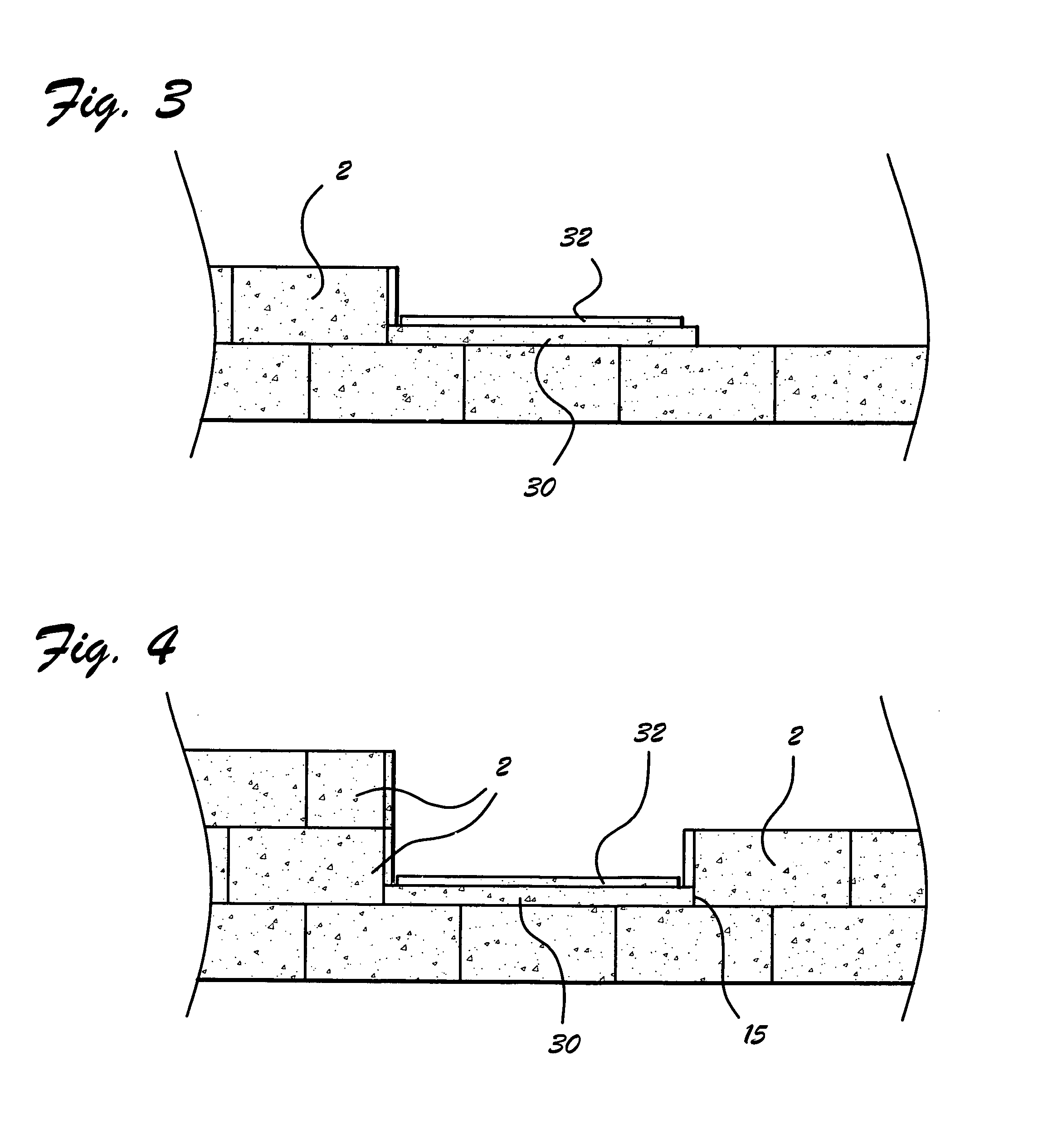

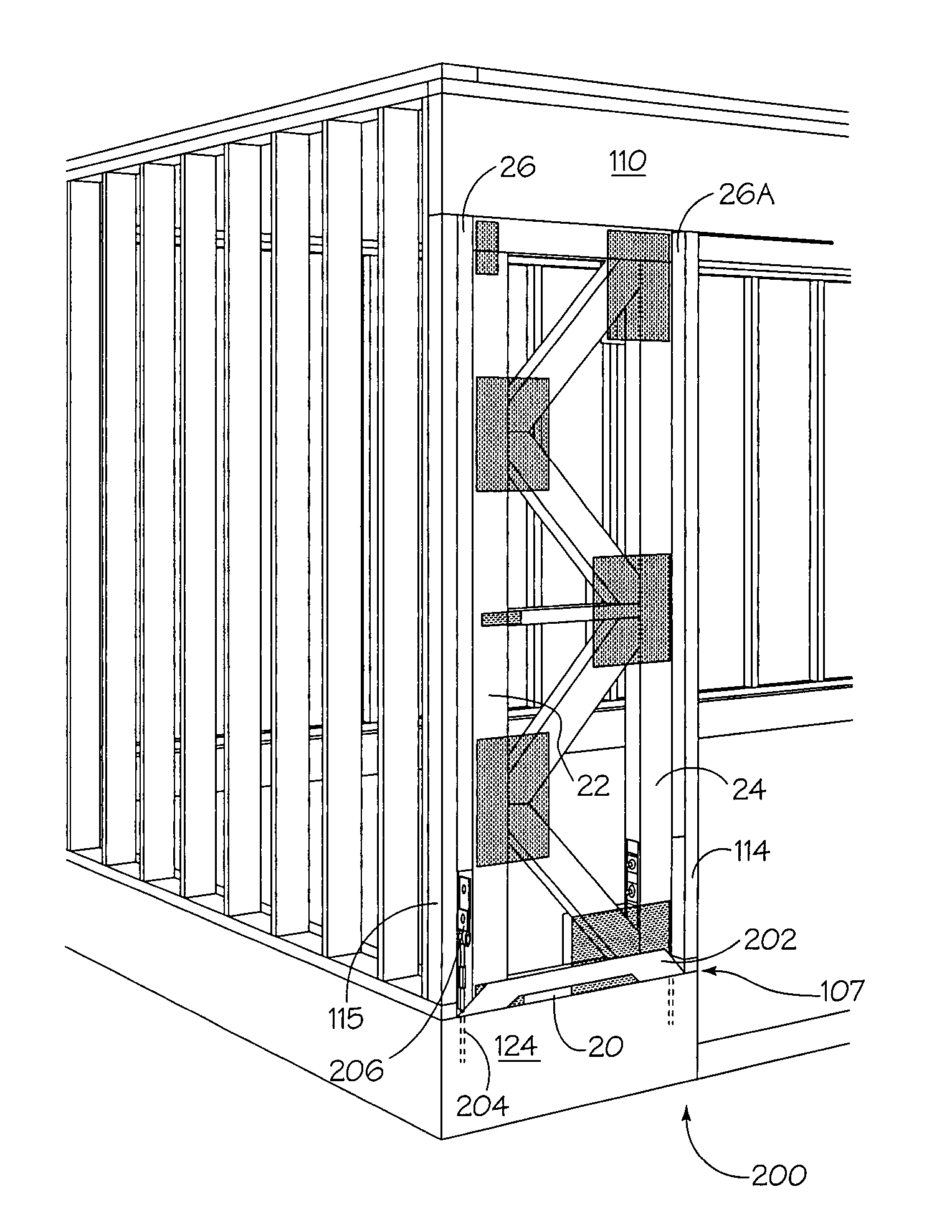

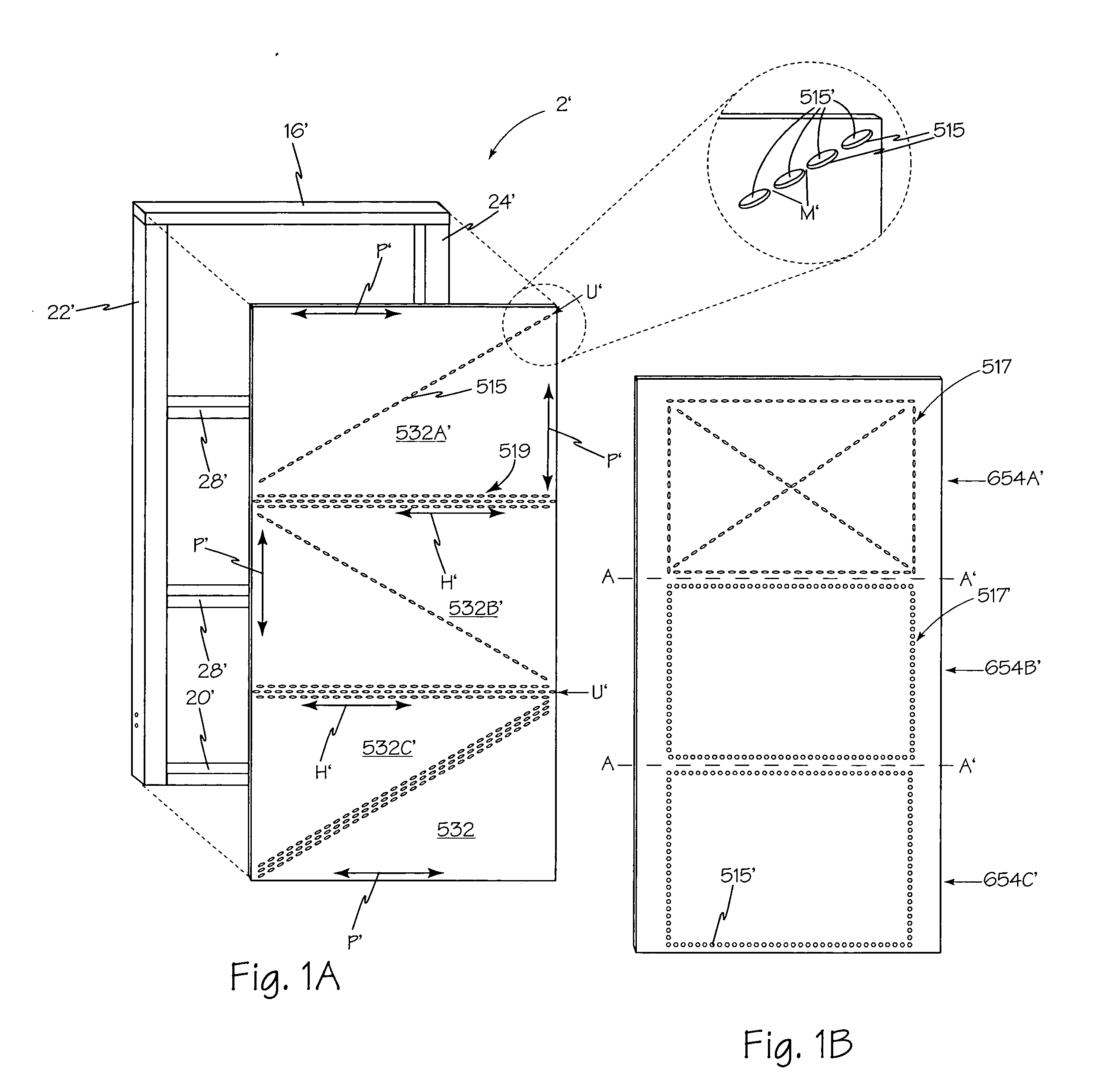

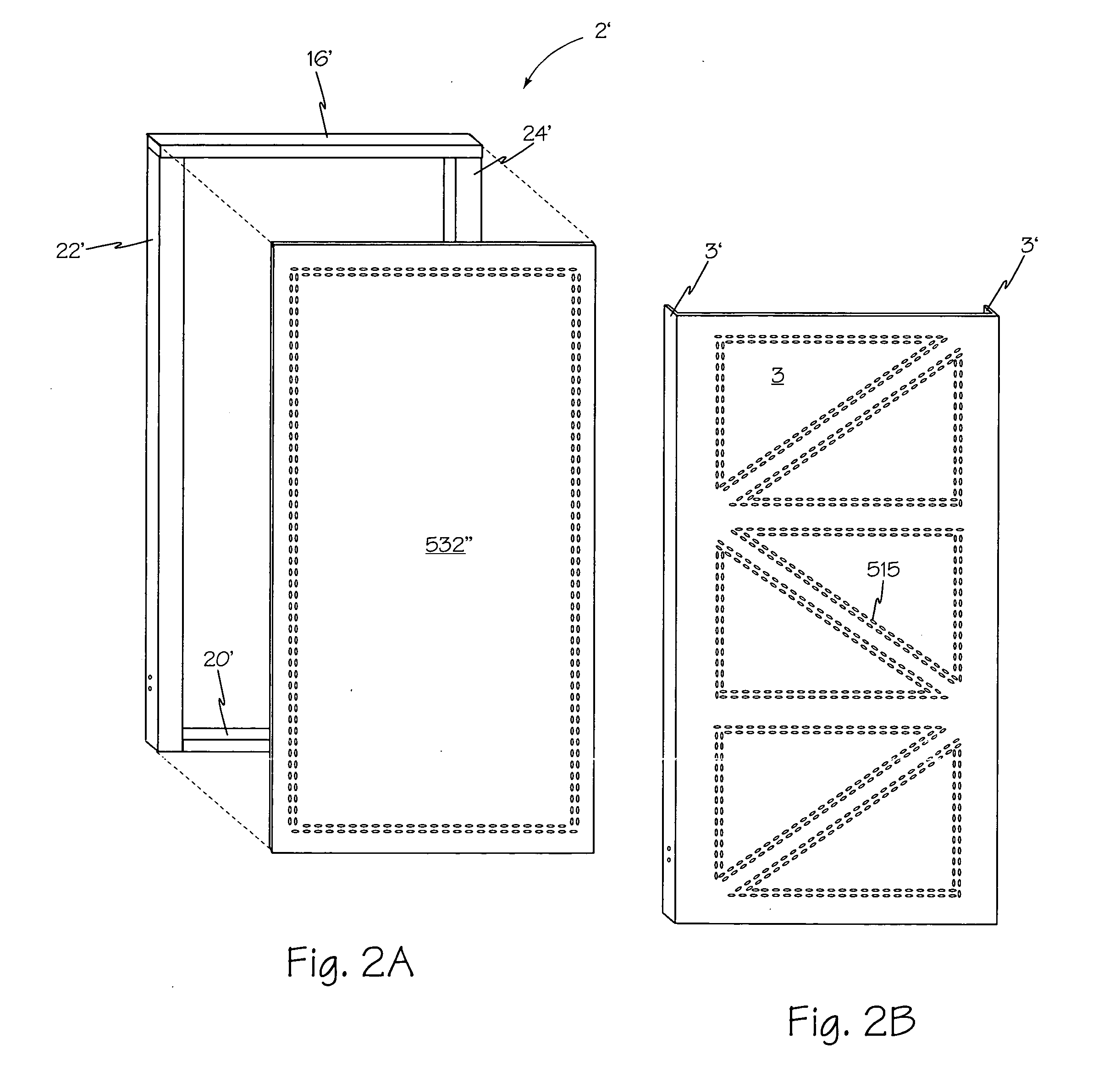

Apparatus and method for framing windows and doors

Owner:KOMETAS ATHAS N

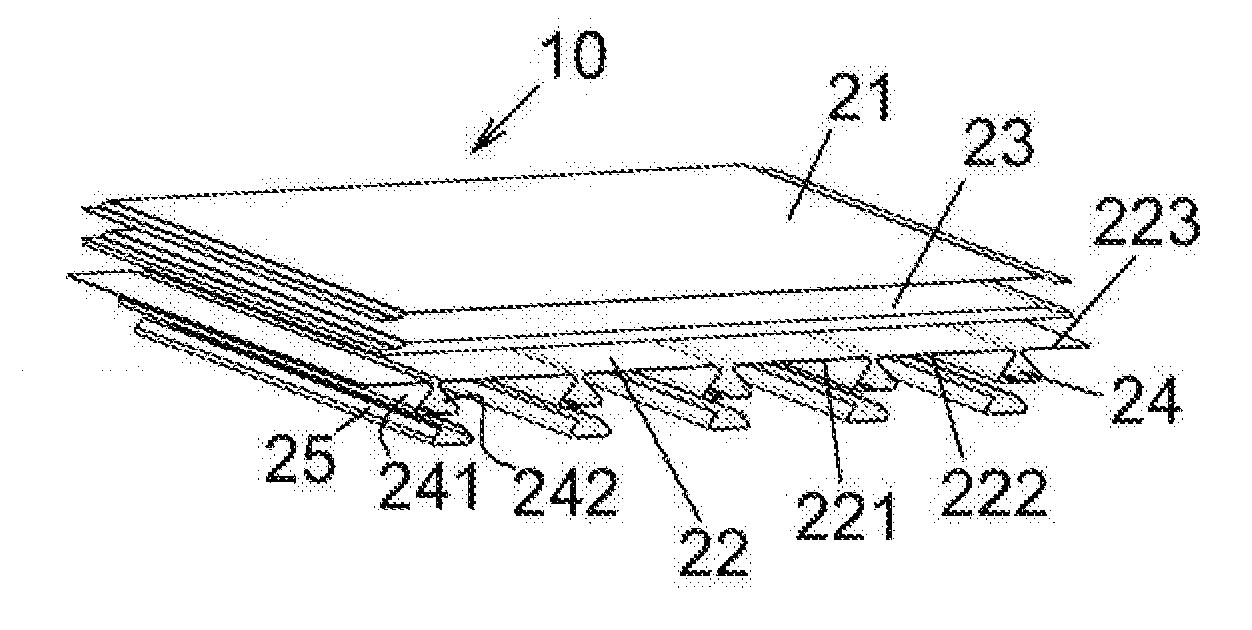

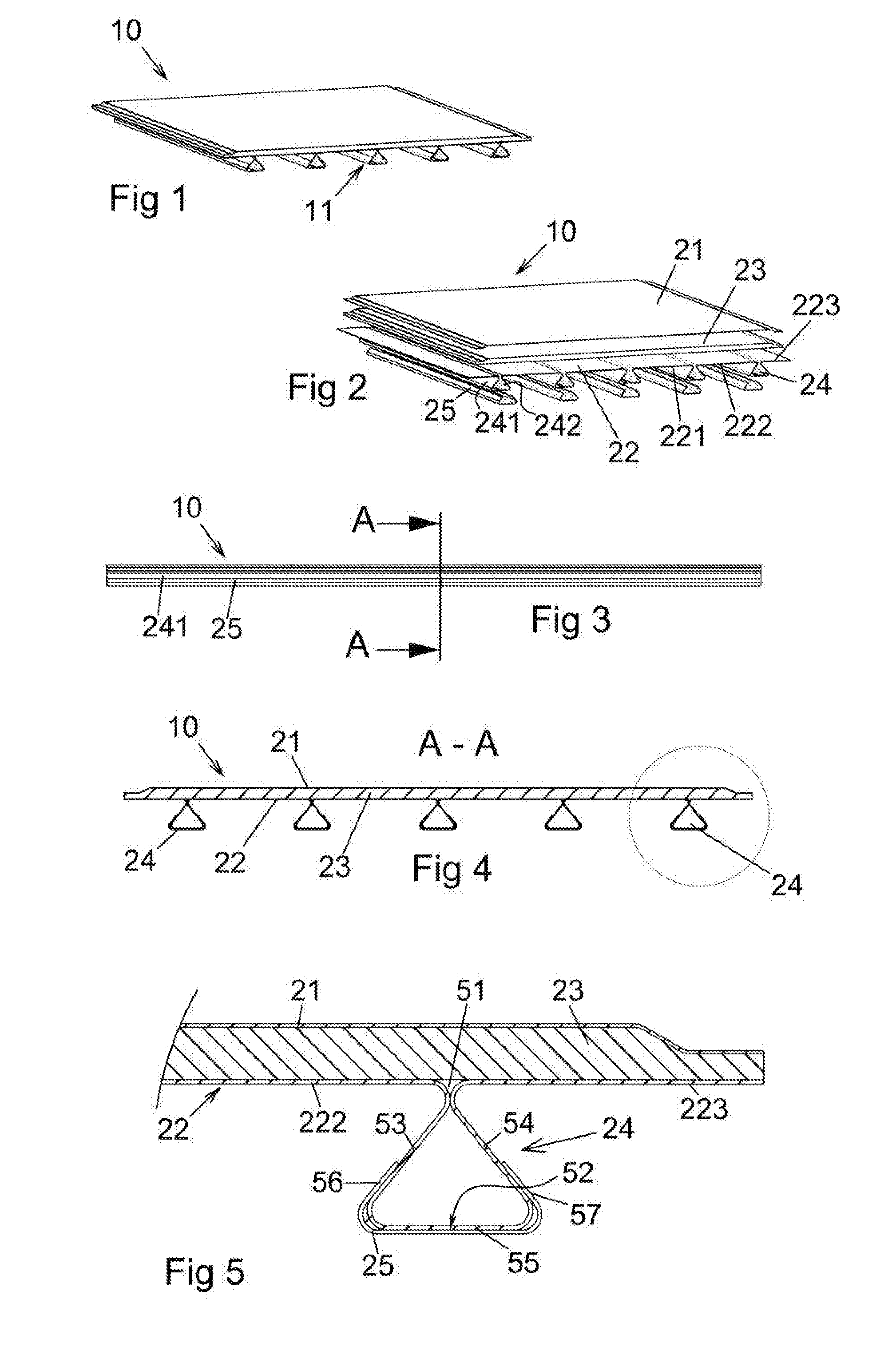

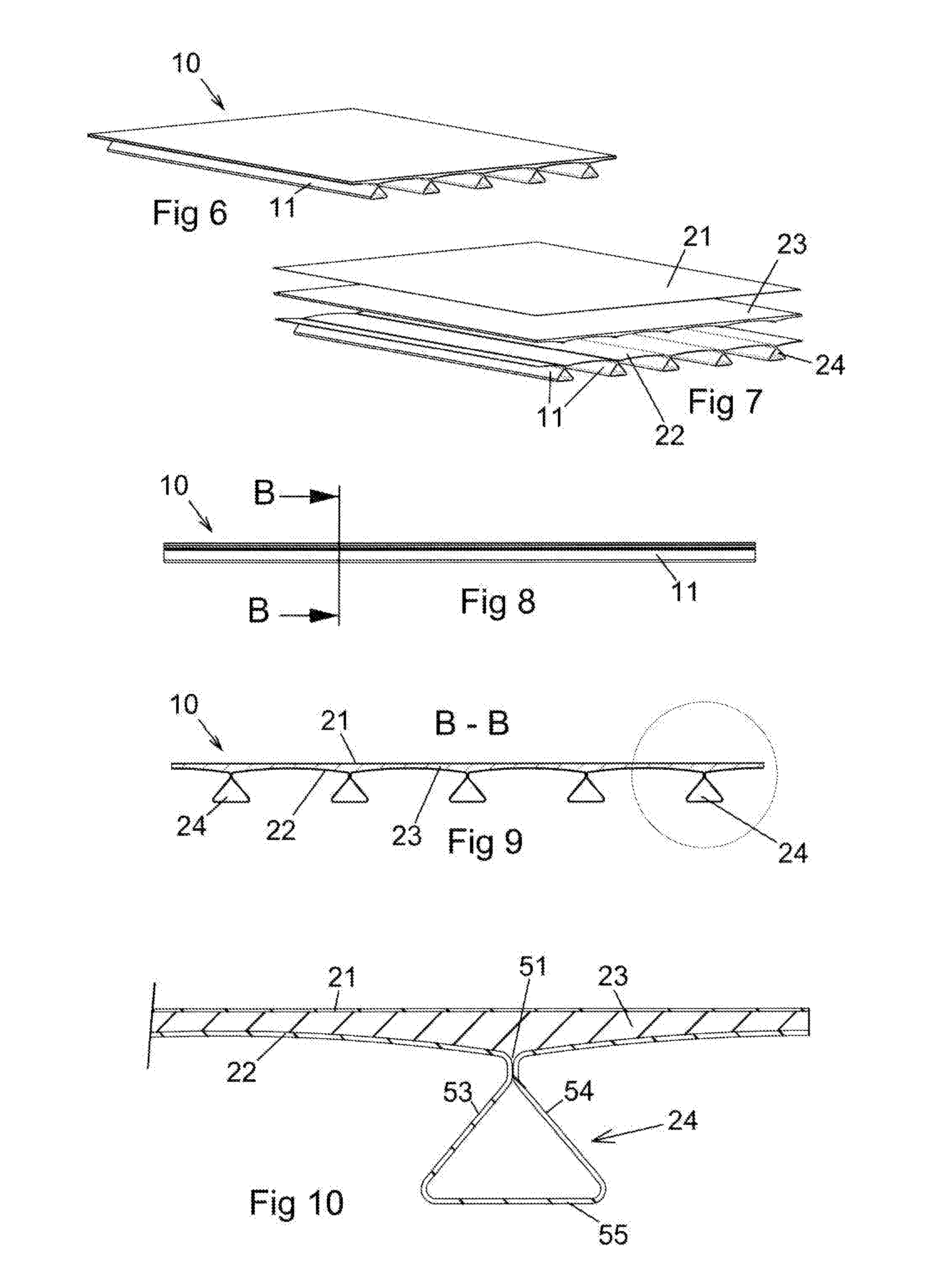

Sandwich element and a load floor made as such an element

Owner:SSAB TECH

Construction method of long steel bar stool cast-in-situ floor

InactiveCN105442735AControl thickness deviationEasy constructionFloorsBuilding reinforcementsFloor slabSurface level

Owner:广西华业建筑工程有限公司

Lateral force resisting system

Owner:TIMMERMAN TIMOTHY L +1

Assembly type composite floor slab

Owner:易县易新装配式建筑科技有限公司

Quick positioning and connecting structure for steel plate shear wall in fabricated building

Owner:杨玮军

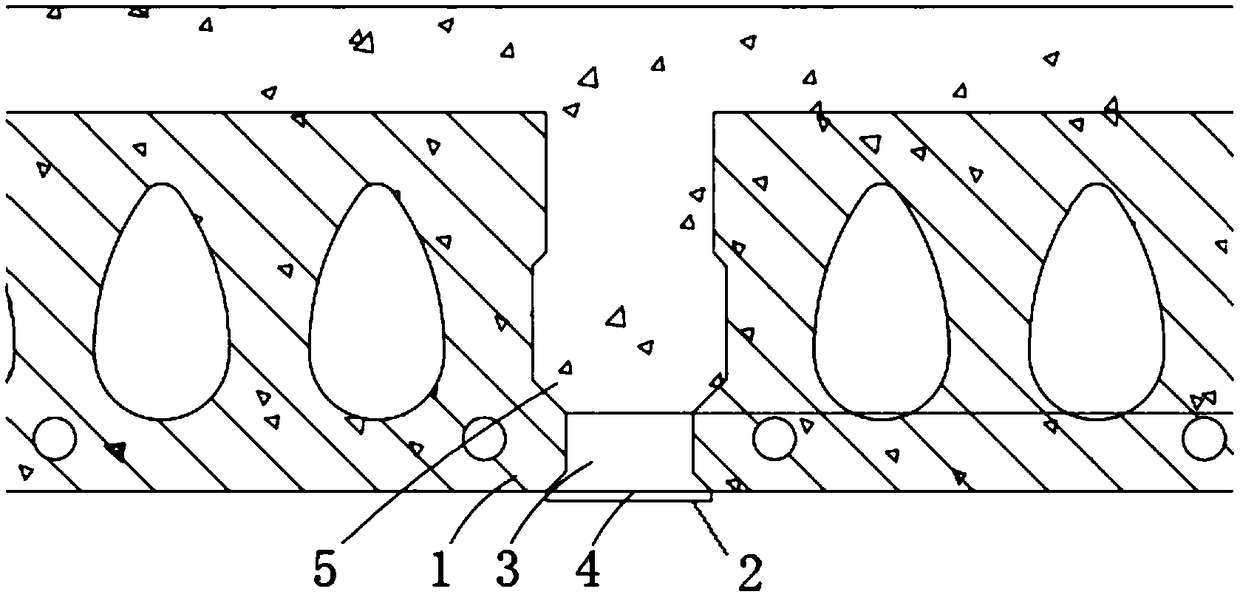

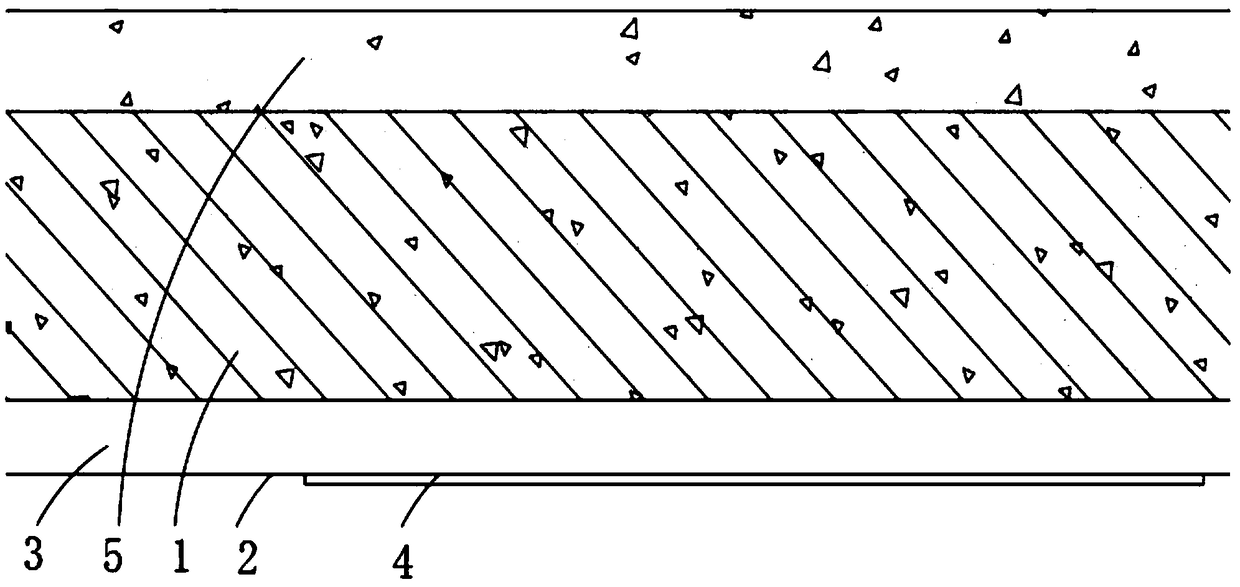

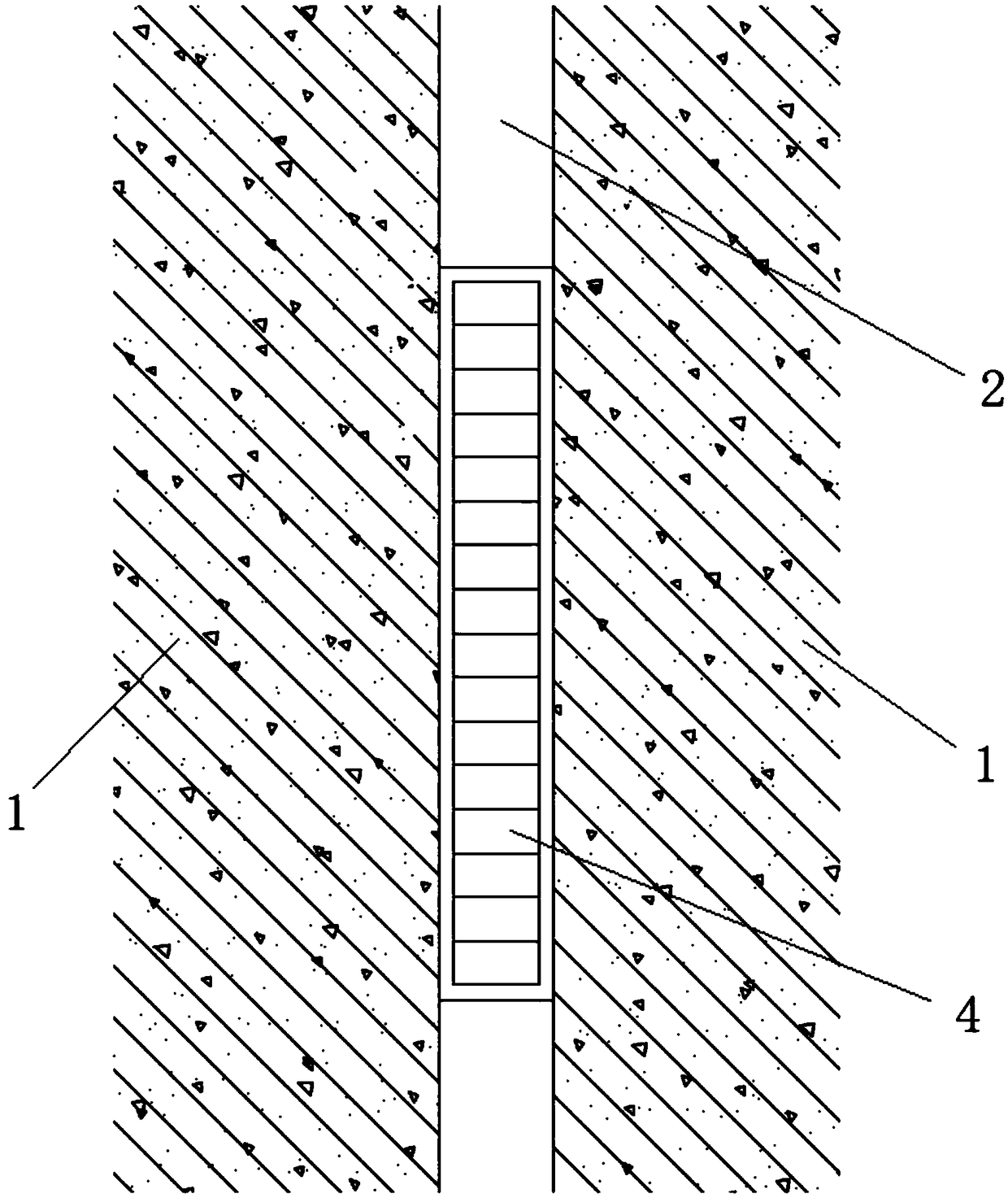

Water and electric pipe arrangement in the same layer and mute insulation wall structure in building

InactiveCN102817475ADoes not affect strengthImprove seismic performanceWallsFloorsArchitectural engineeringExpanded polystyrene

Owner:徐志成

Floor split joint ventilating pipe structure and ventilating structure

Owner:SANY CONSTR TECH CO LTD

Vibration reduction connecting structure of boxboard type building, boxboard type steel structure building and construction method of boxboard type steel structure building

Owner:TIANJIN DAYIN BUILDING MATERIAL CO LTD

Assembly type concrete component mounting method

InactiveCN111456453ASimplify the production and construction processEasy to installWallsFloorsReinforced concreteShaped beam

Owner:豫通工程管理有限公司

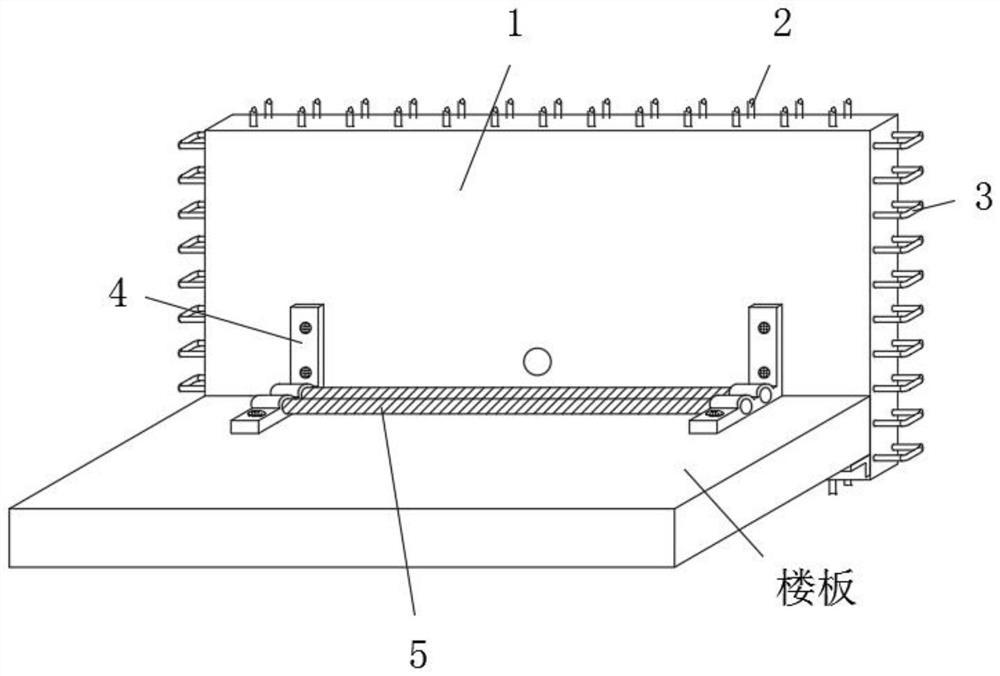

Filling and off-loading box component cast-in-situ reinforced concrete slab

The invention belongs to the field of a cast-in-situ slab used for building, and more particularly relates to a site cast steel reinforced concrete slab filled with off-loading box components. The site cast steel reinforced concrete slab has fine stress section as well as convenient transportation and flexible arrangement of the off-loading components of the site cast steel reinforced concrete slab, and comprises a single body filled with an off-loading box, reinforcing steel bars and concrete, wherein, the single body filled with the off-loading box is an opening box comprising a box crest slab and a box side wall plate which are integrated into a whole, the edge around the bottom of the box side wall plate is a convex edge, the single body is placed with a downward opening, and the convex edge is at the same plane together with the lower surface of the slab. The site cast steel reinforced concrete slab filled with the off-loading box components can combine and distribute the single bodies of the box according to different stress requirements; furthermore, the single bodies of the box are convenient for combination and distribution, and the combination modes are flexible and diverse. Meanwhile, the single body filled with the off-loading box adopts an integral structure, can be sheathed, is convenient for transportation, has lighter weight and further saves the transportation cost.

Owner:王军艇

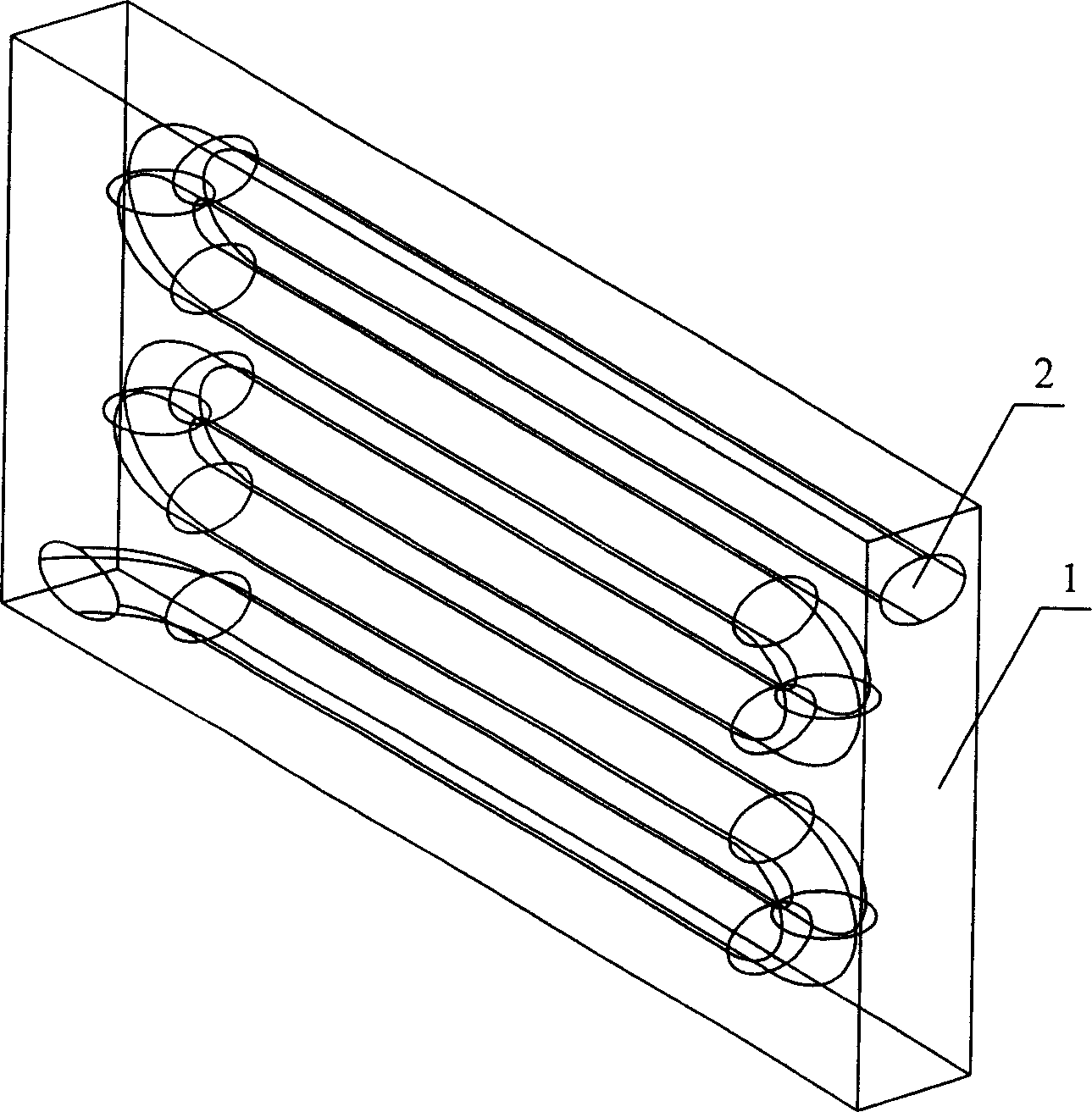

Component for cast-in-place concrete

InactiveCN1869361ARich varietyEasy to chooseFloorsForms/shuttering/falseworksSteel barMaterials science

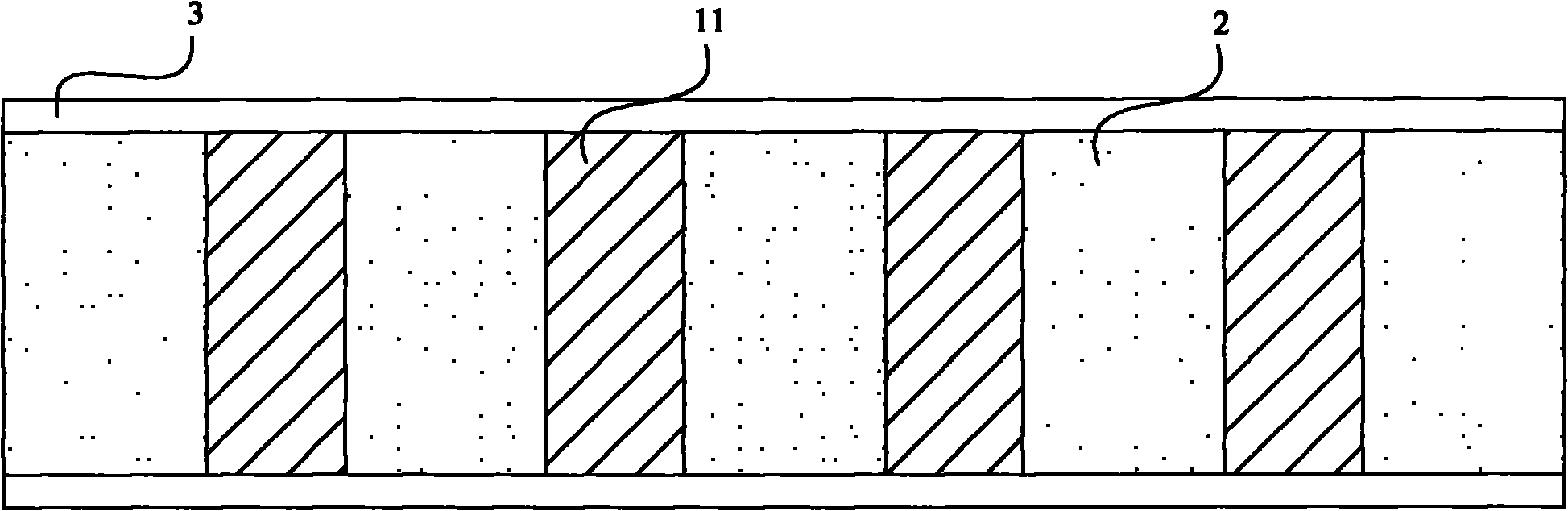

The invention relates to a one side section for combining present casting steel bar concrete component. The feature is that: joining section is setting on the one side section or / and baffle and setting at least a baffle along the portrait. While the two one side sections buckling and forming a present casting steel bar concrete component by the joining component, the baffle would seal the end section of the component. It could be suitable for casting hollow roof, roof, basic bottom board, wall and hollow bridge.

Owner:HUNAN QIUZEYOUZHUANLIZHANLVE PLANNING CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap