Subfloor drainage panel

a drainage panel and subfloor technology, applied in ventilation systems, lighting and heating apparatus, heating types, etc., can solve the problems of subfloor drainage panel moisture present, etc., and achieve the effects of low manufacturing cost, low price of sale, and easy and efficient manufacturing and marketing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

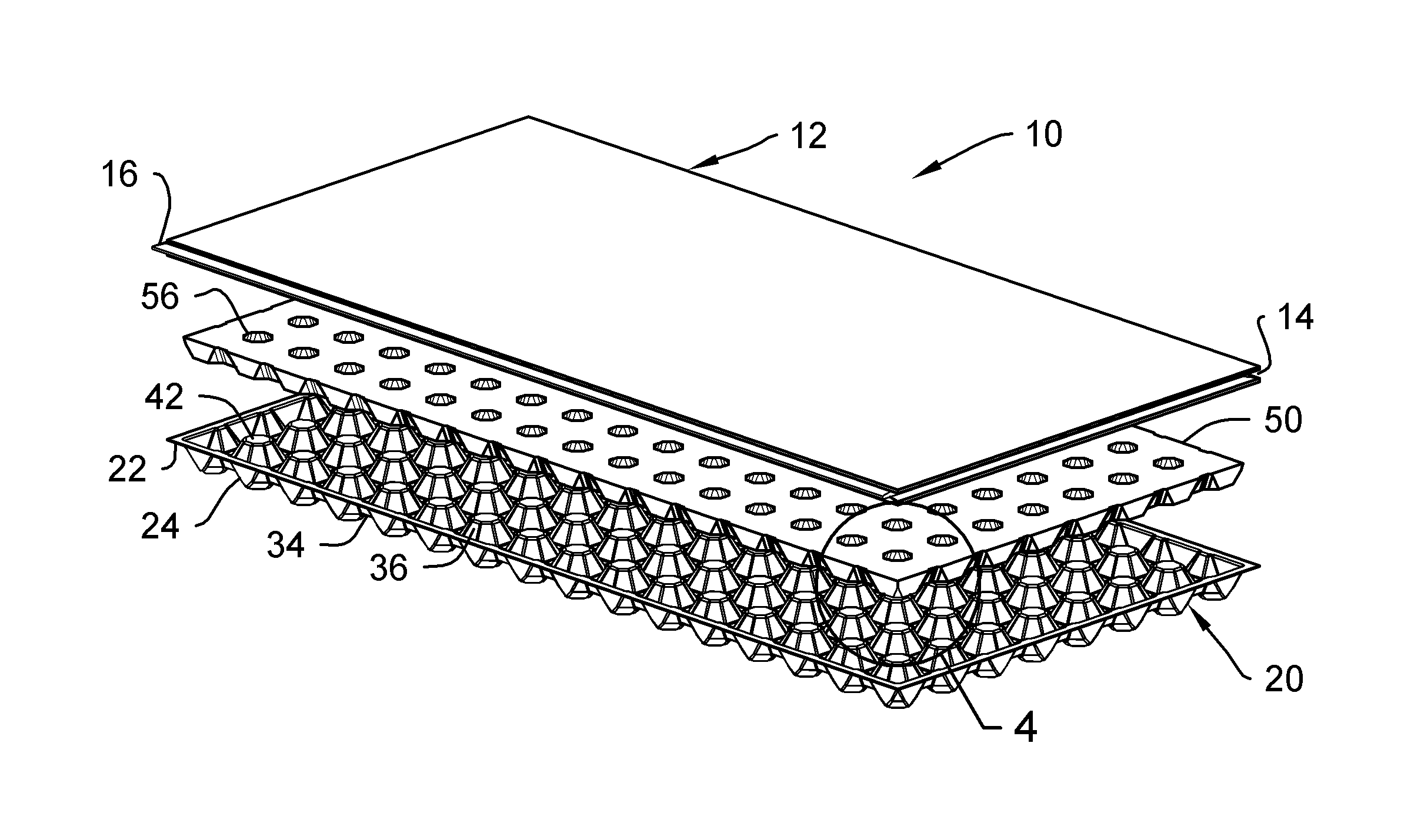

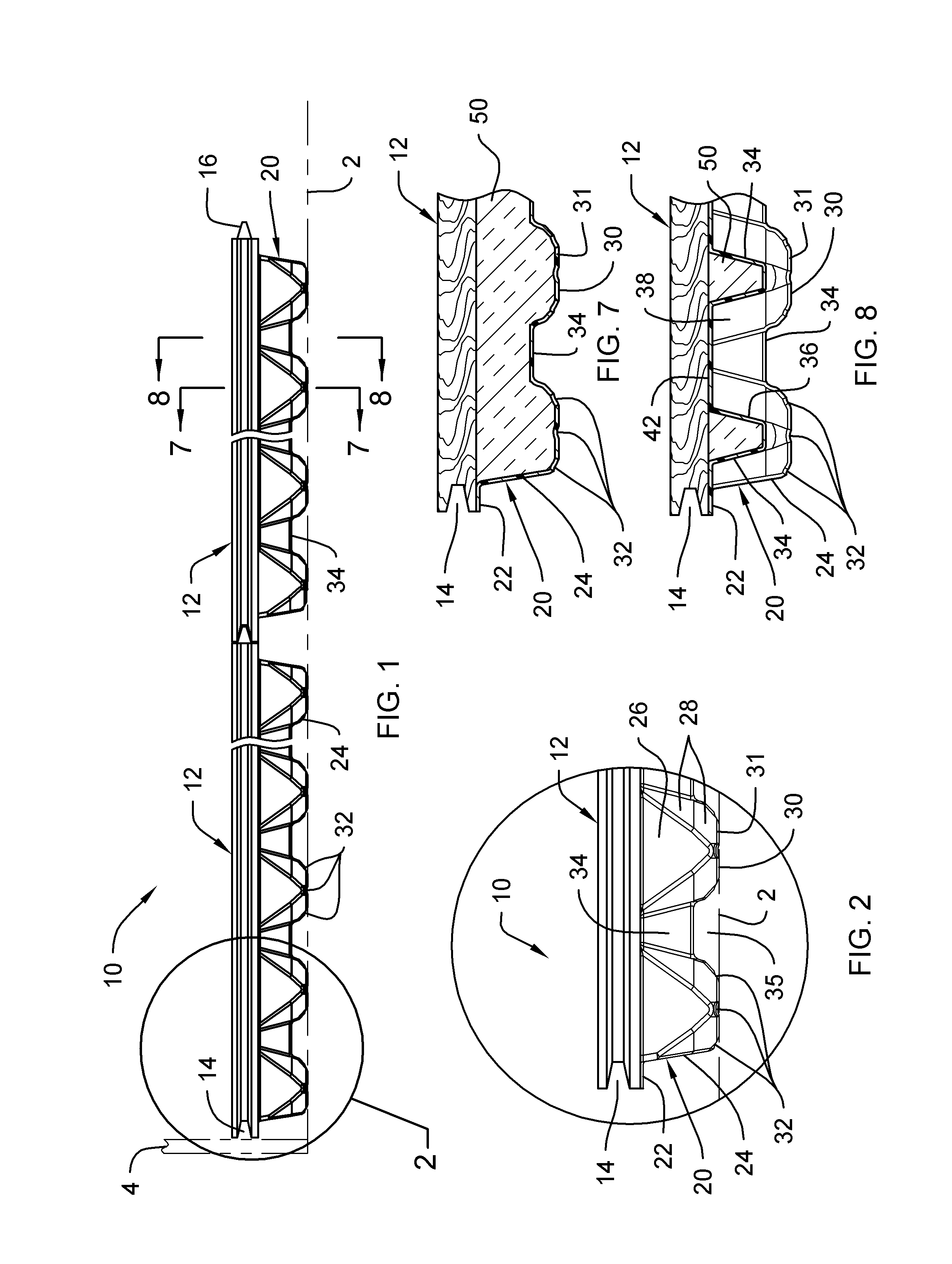

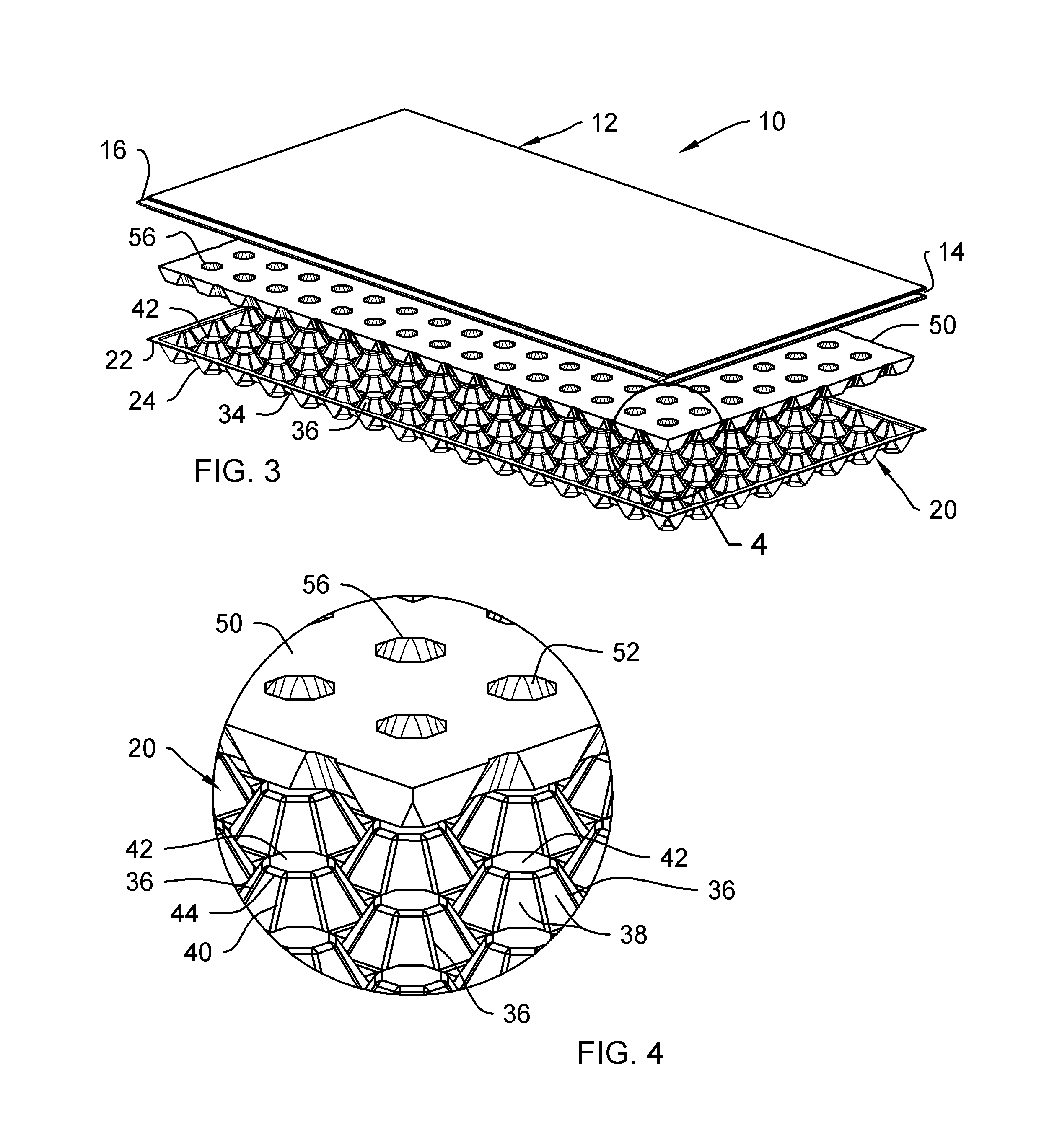

[0036]Referring now to the drawings, and particularly to FIGS. 1-11, an embodiment of the subfloor drainage panel of the present invention is shown and generally designated by the reference numeral 10.

[0037]In FIGS. 1 and 2, a new and improved subfloor drainage panel 10 of the present invention for draining moisture from a floor using a multi-component subfloor is illustrated and will be described. More particularly, the subfloor drainage panel 10 has an upper member 12 and a lower member 20. The lower member 20 is attached to the upper member 12. The subfloor drainage panel 10 rests on a surface 2, and its edges can abut against a wall or stud 4, or additional subfloor drainage panels 10. The surface 2 may be, but not limited to, a pre-existing floor, foundation or substructure. The subfloor drainage panel 10 may be used on any floor a building or vehicle, in a basement, in the bilge of a marine vessel, in an aircraft, or in any area where potential flooding or moisture damage can occ

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap