Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about "Building material handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

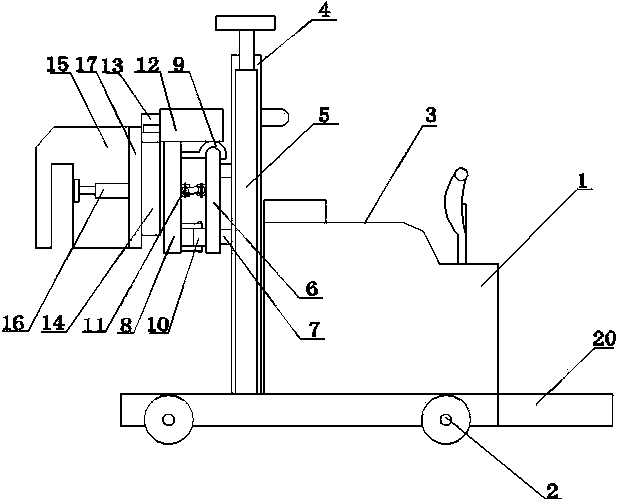

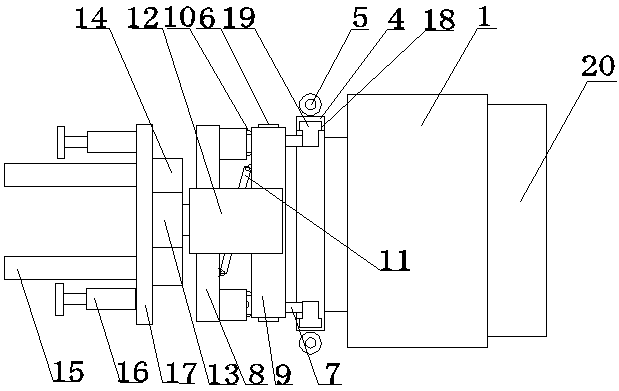

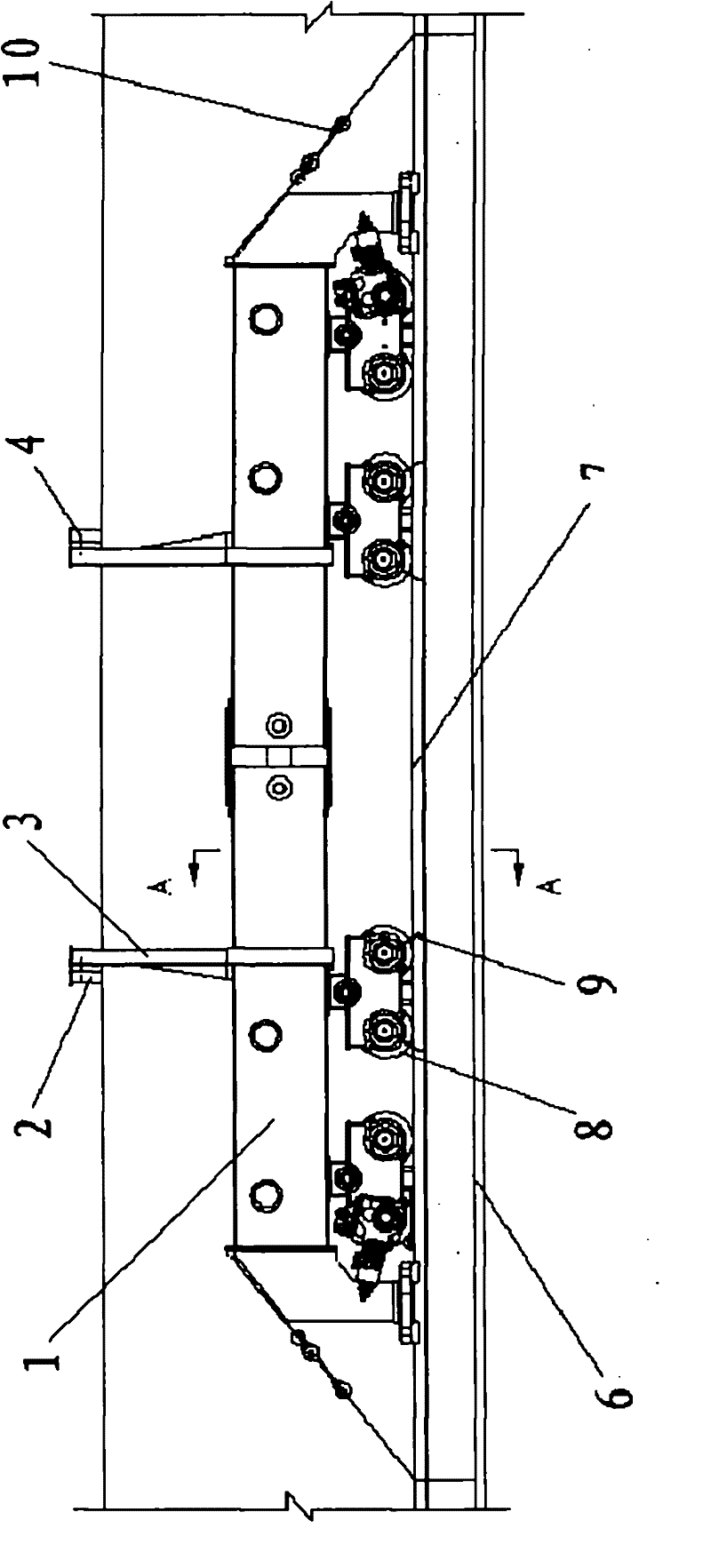

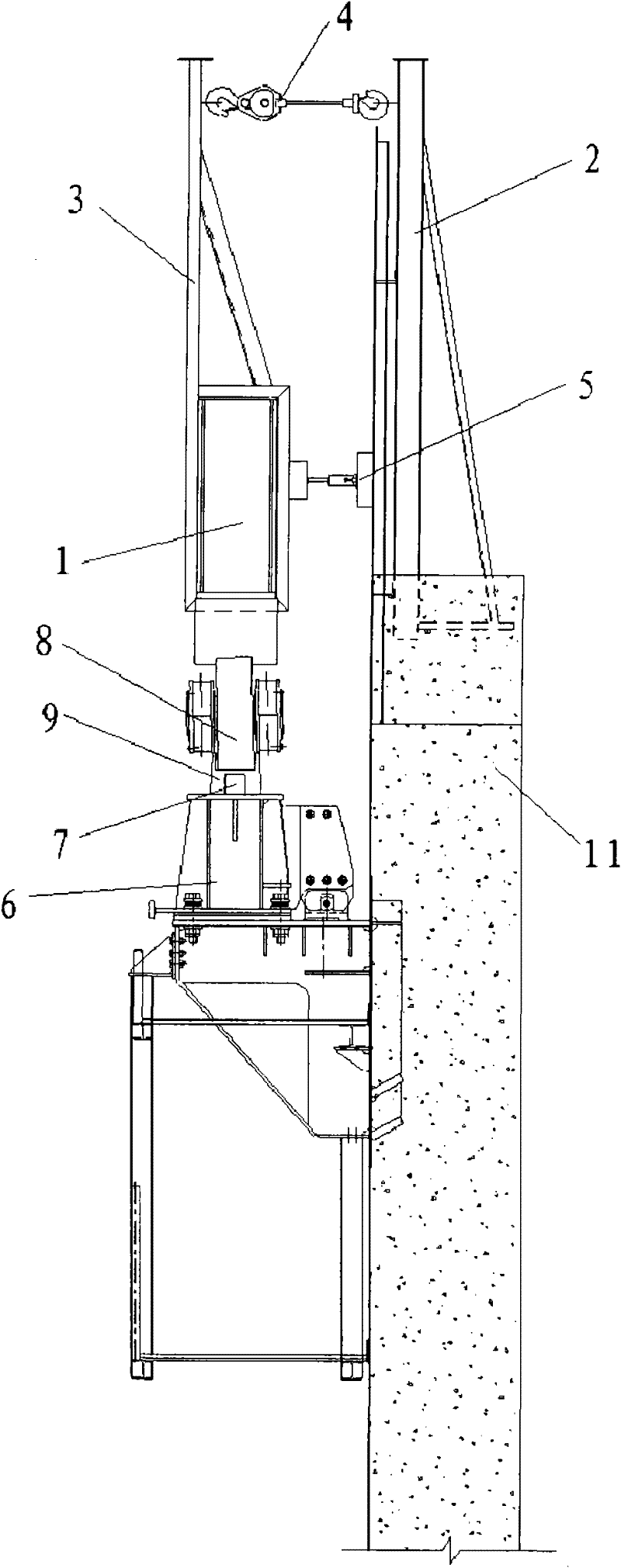

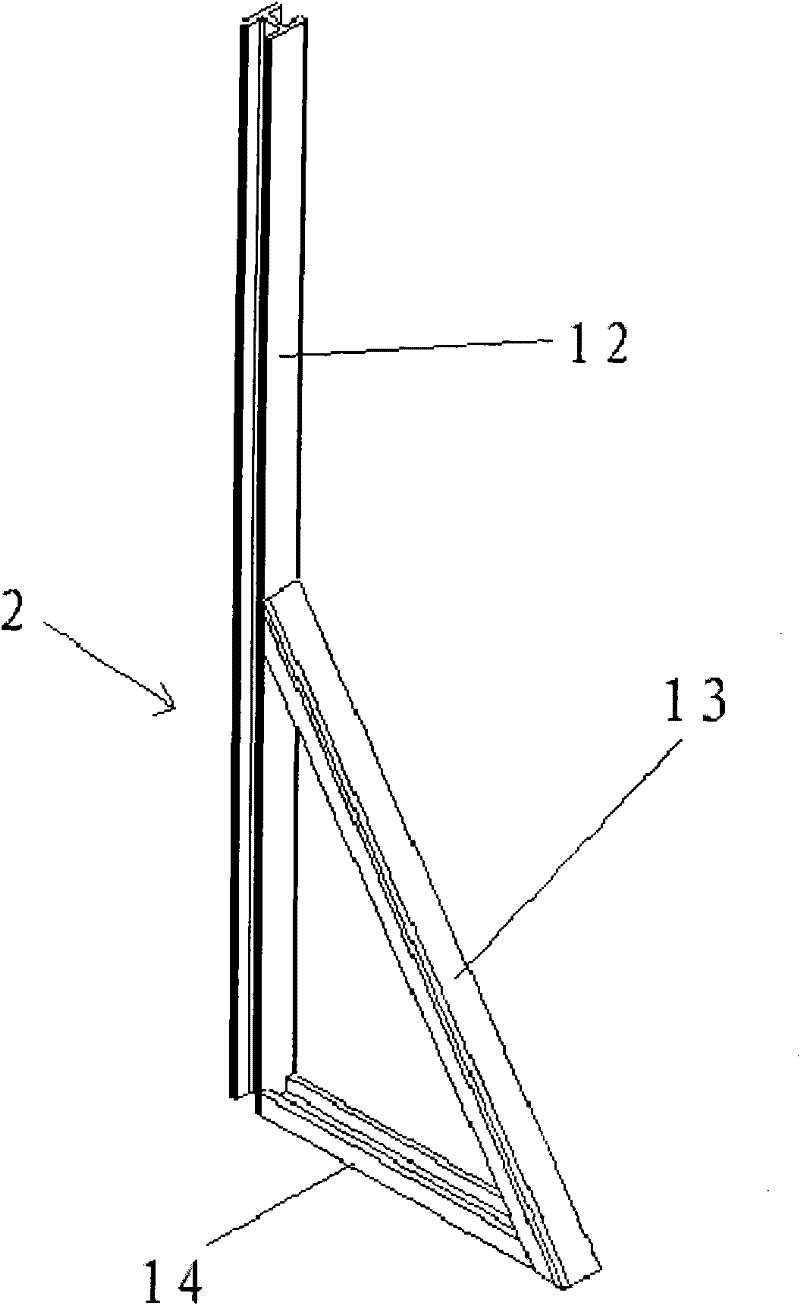

Bricklaying device and bricklaying robot

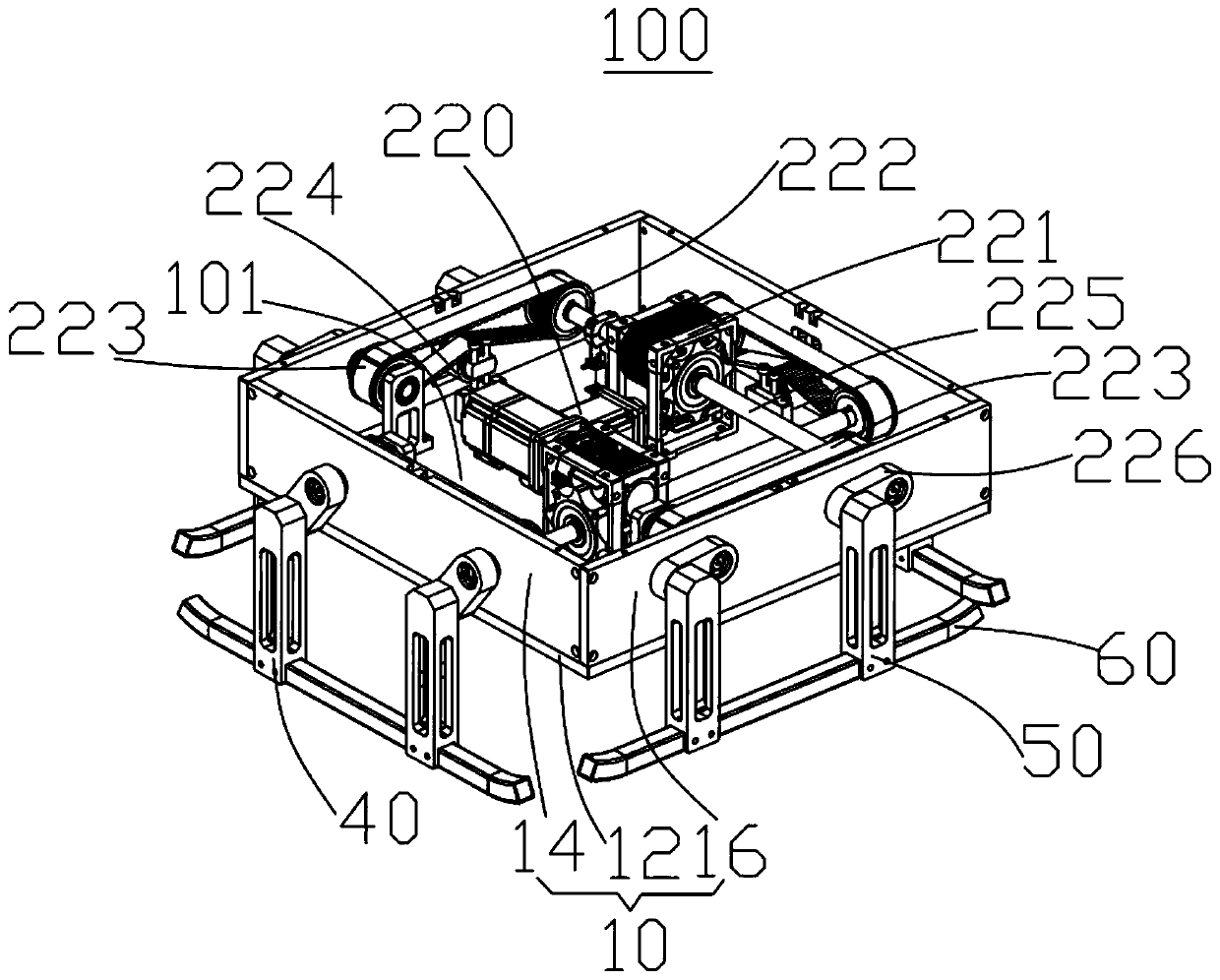

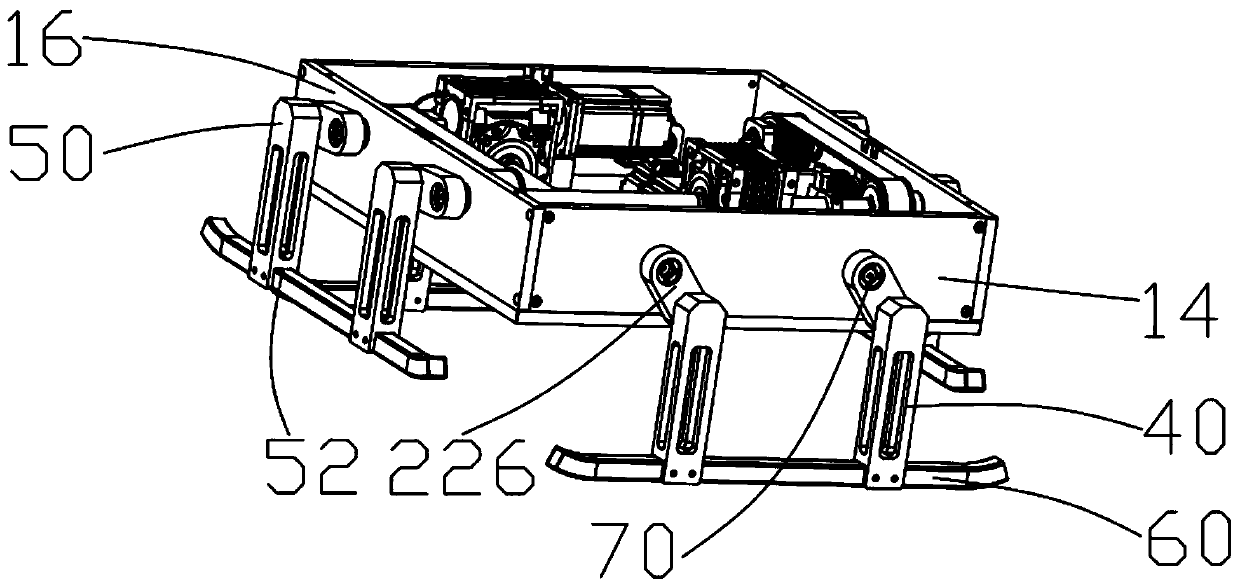

The invention discloses a bricklaying device and a bricklaying robot. The bricklaying device comprises a base, a brick transfer assembly, a brick feeding assembly and a plastering assembly. The bricktransfer assembly comprises a mechanical arm and a grabbing part. The mechanical arm is connected with the grabbing part to transfer bricks. The mechanical arm is movably arranged on the base and cando up-down lifting motion relative to the base. The brick feeding assembly comprises a bearing platform. The bearing platform is suitable for bearing the bricks. The bearing platform can do up-down lifting motion relative to the base, and the highest distance of the bearing platform relative to the base can be adjusted, so that the bricks are located within the grabbing range of the grabbing partall the time. The plastering assembly is arranged on the base and comprises a plastering head. The plastering head is used for plastering the bricks. The bricklaying device provided by the embodimentof the invention integrates brick transferring, brick plastering and bricklaying, can automatically complete the multiple working procedures, liberates manpower and accelerates the bricklaying progress; and shorter time required for brick taking is consumed, plastering and bricklaying can be quickly carried out after brick taking, the whole working procedure time is short, and the bricklaying efficiency is high.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Wall surface leveling system and leveling method

Owner:ZHEJIANG YASHA DECORATION

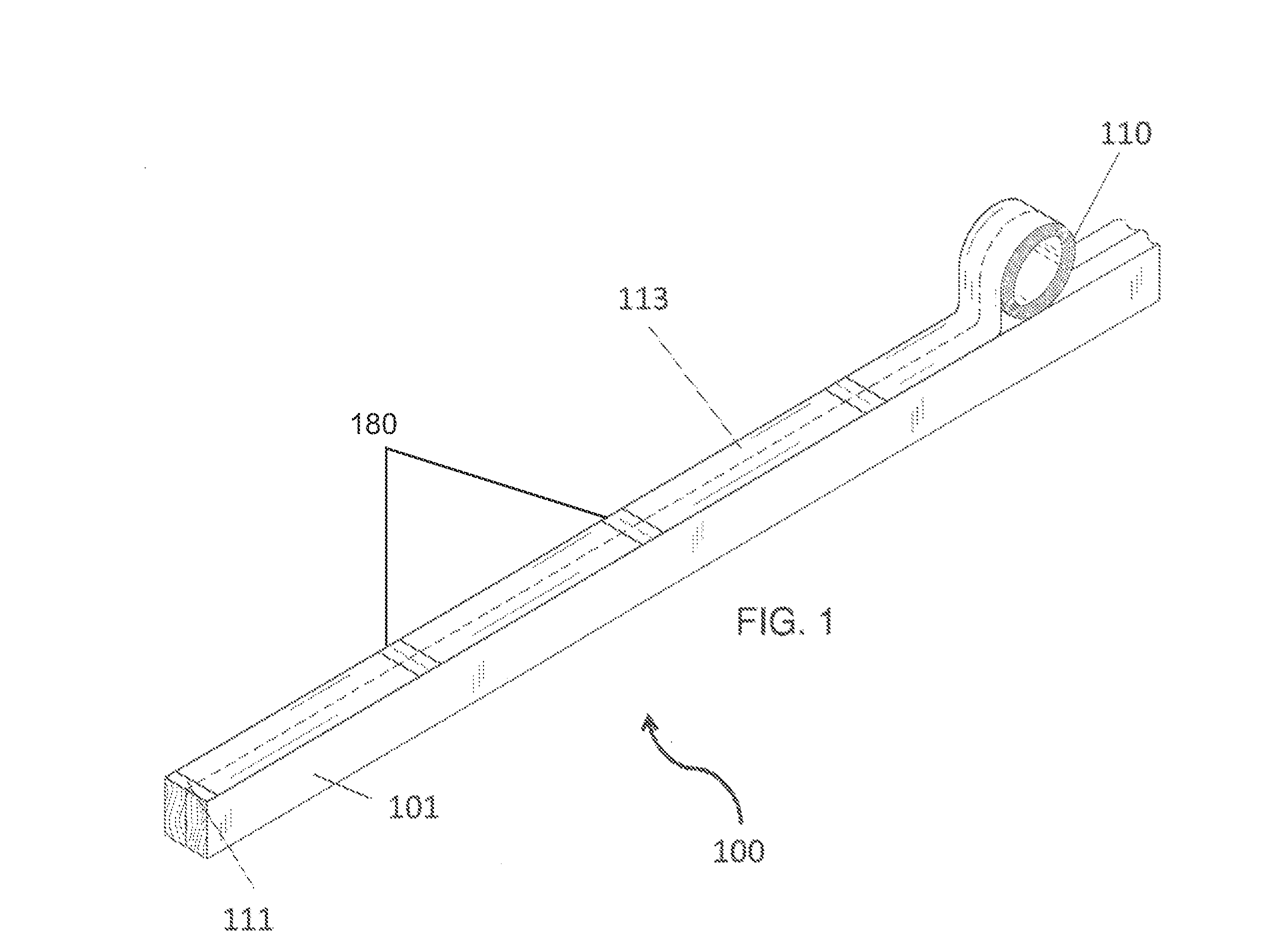

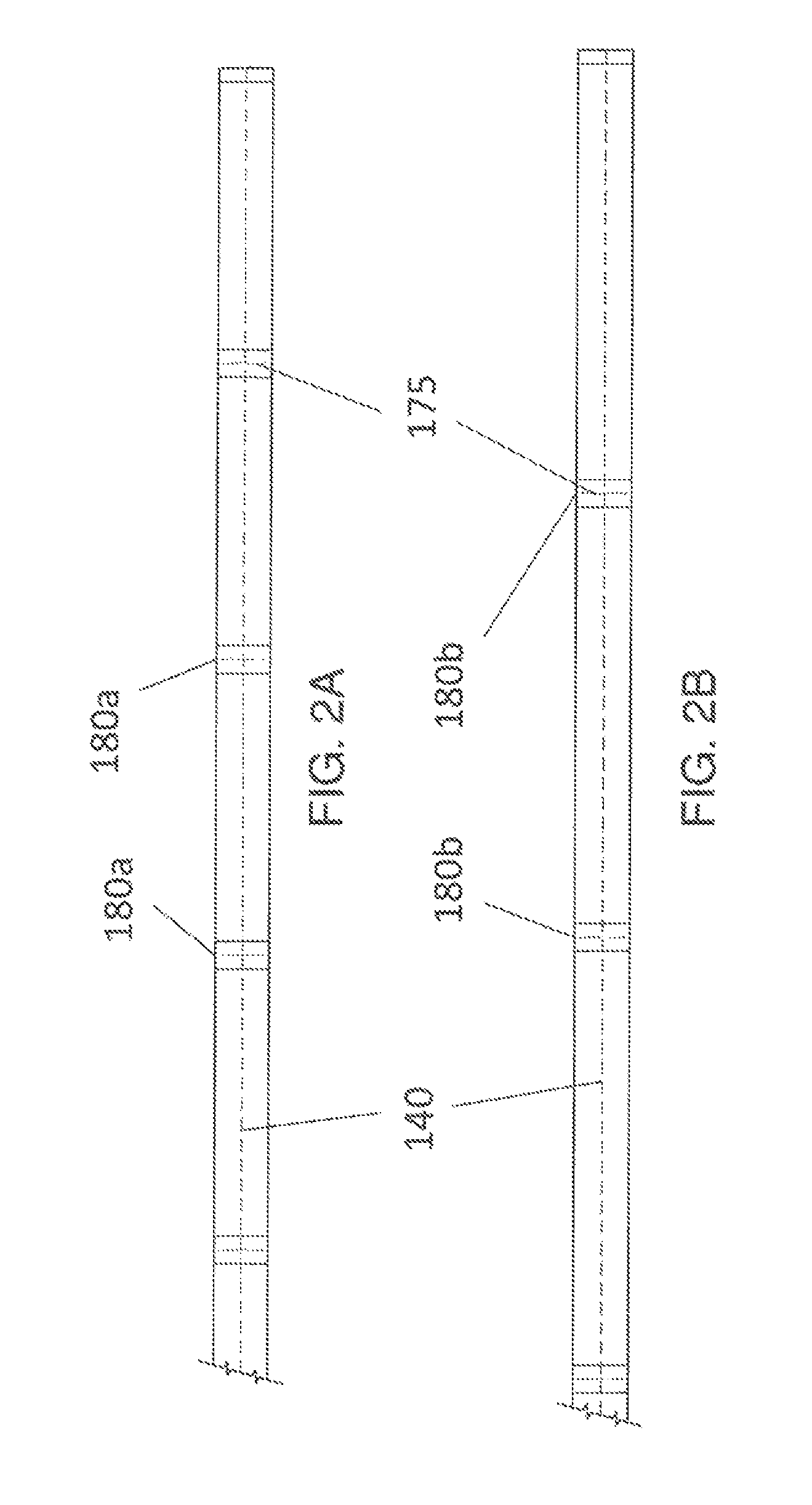

Tape system for framing

Owner:MOONEY DARRELL R

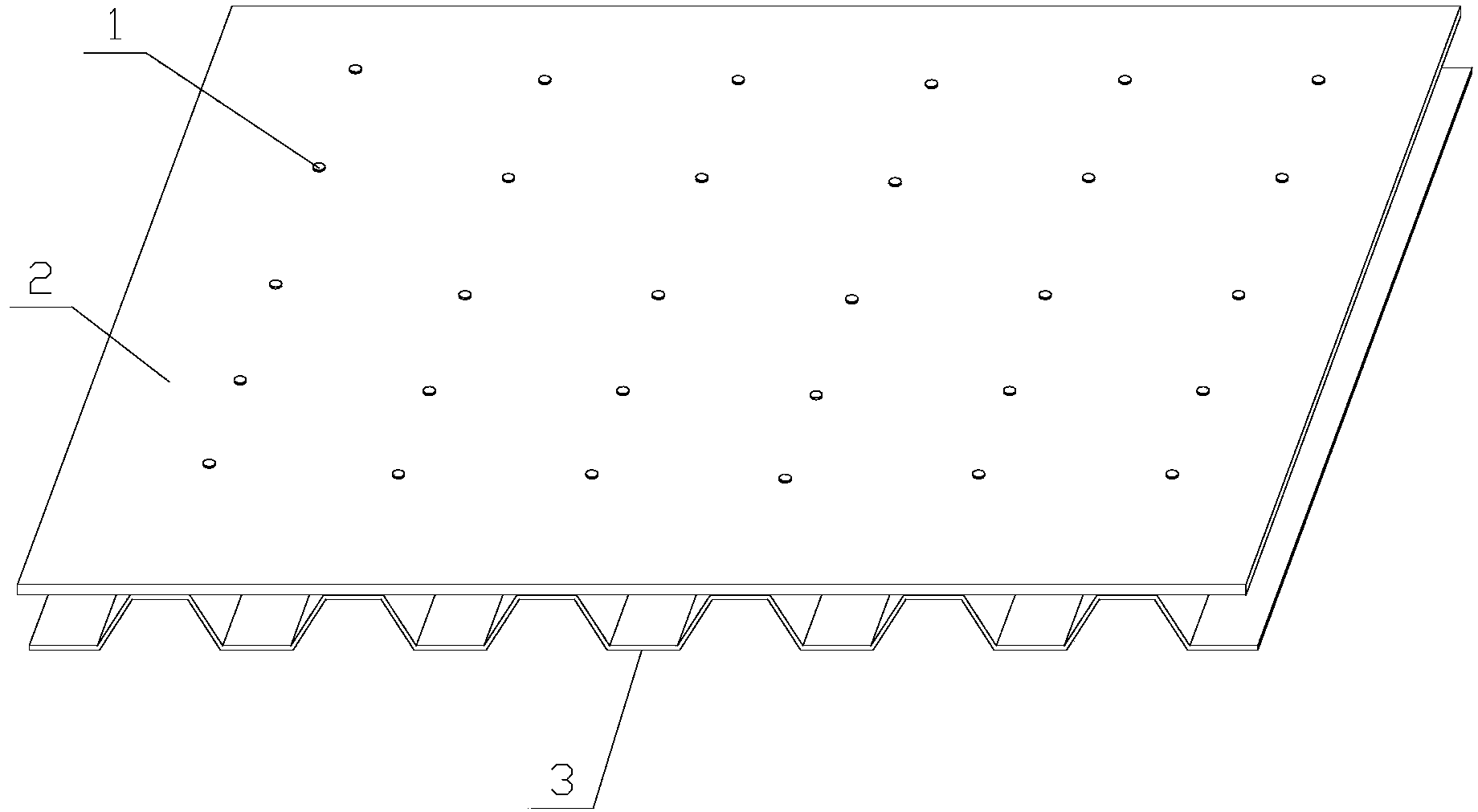

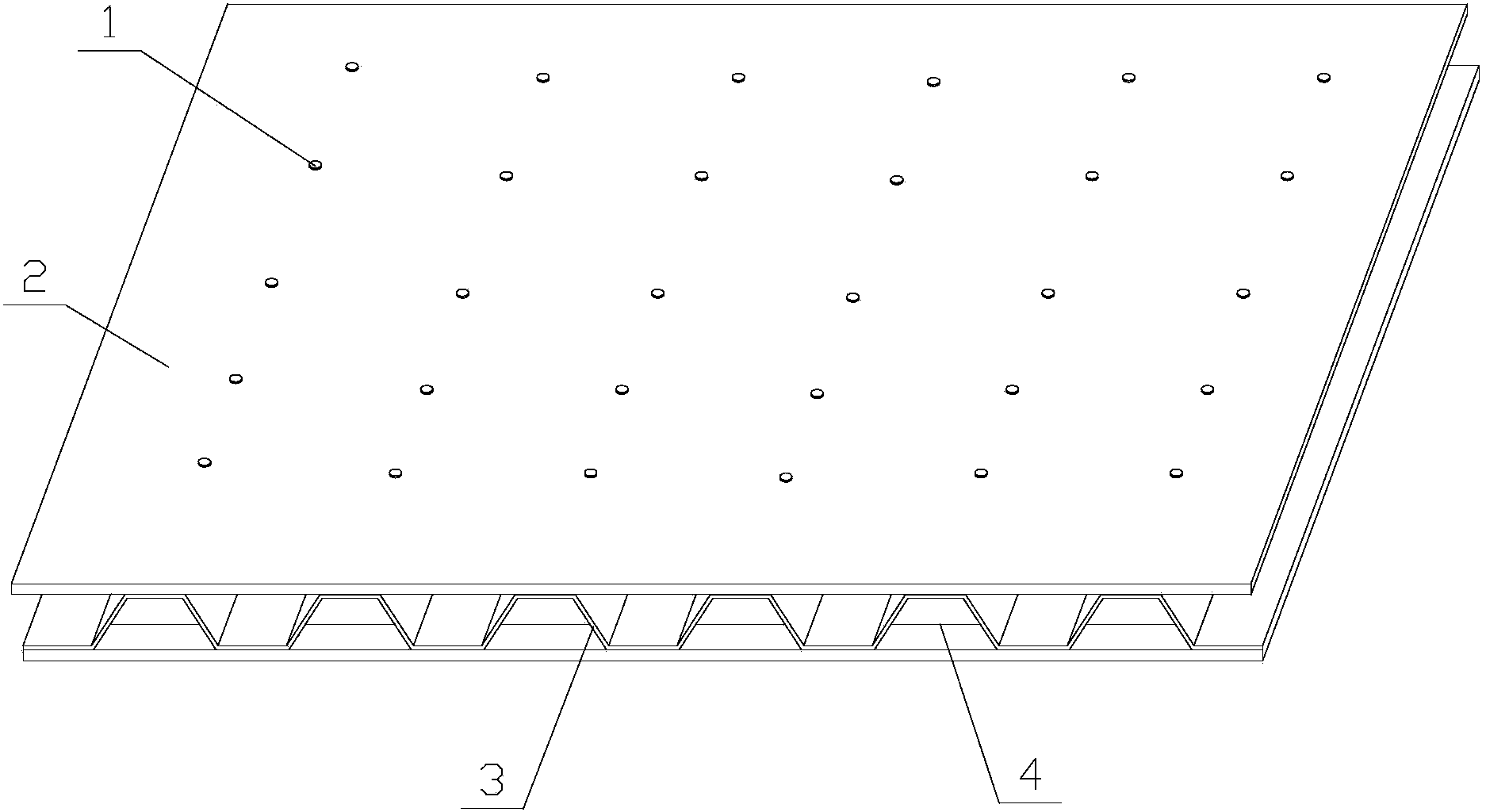

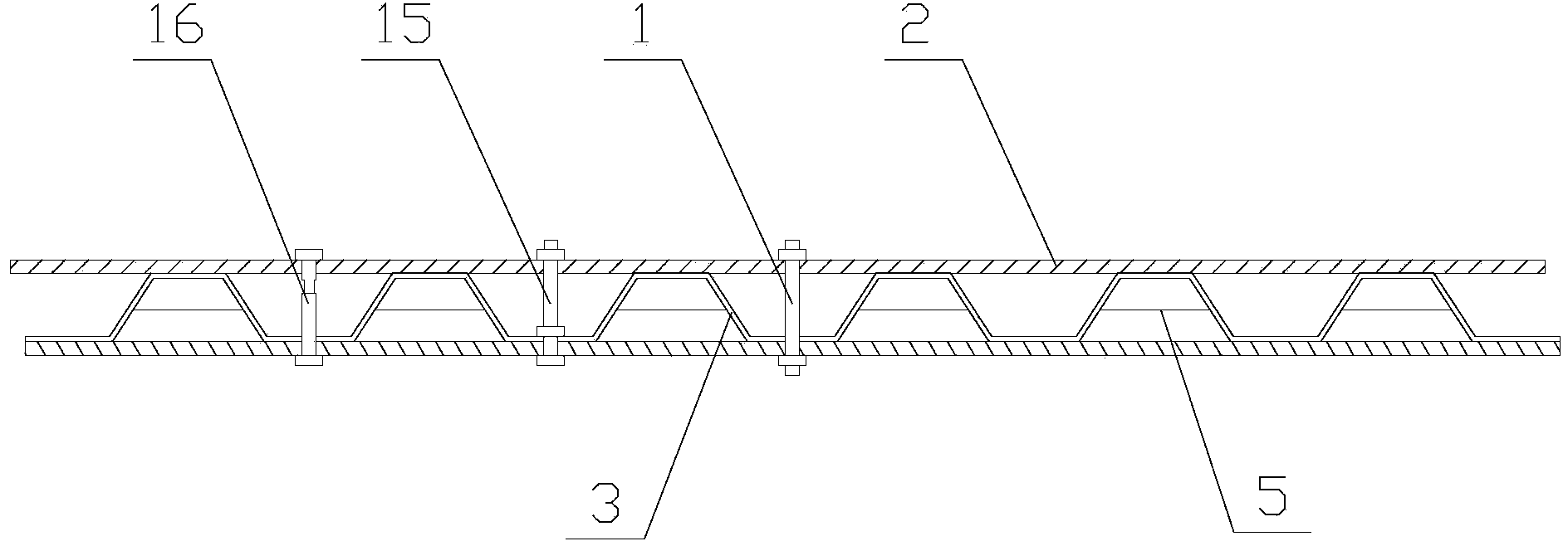

Wind resistant concrete roof component and system and method for forming same

A roof system includes a roof panel formed of concrete and an architectural surface such as a corrugated surface. A first layer of reinforcing material is disposed along and spaced inwardly from a first surface of the roof panel, and an optional second layer of reinforcing material is disposed along and spaced inwardly from a second surface of the roof panel. The first layer of reinforcing material is spaced from the second layer of reinforcing material. The reinforcing material may be formed of fiber-reinforced polymer mesh, made with carbon fibers or glass fibers. FRP rebar may be used in conjunction with FRP mesh to provide added structural strength. The roof panel may include one or more elongated ribs having a thickness greater than adjacent portions of the roof panel. In other aspects, concrete structures with reinforcing material may be used for either roof panels or wall applications.

Owner:FLORIDA INTERNATIONAL UNIVERSITY

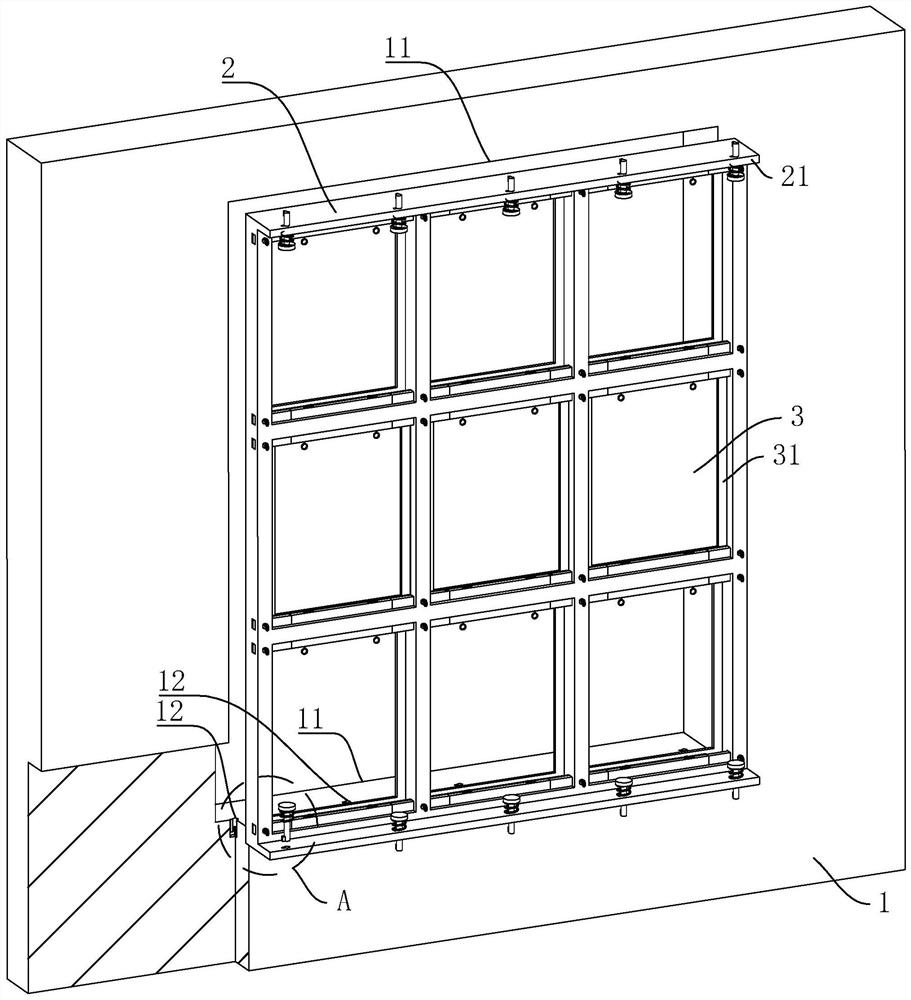

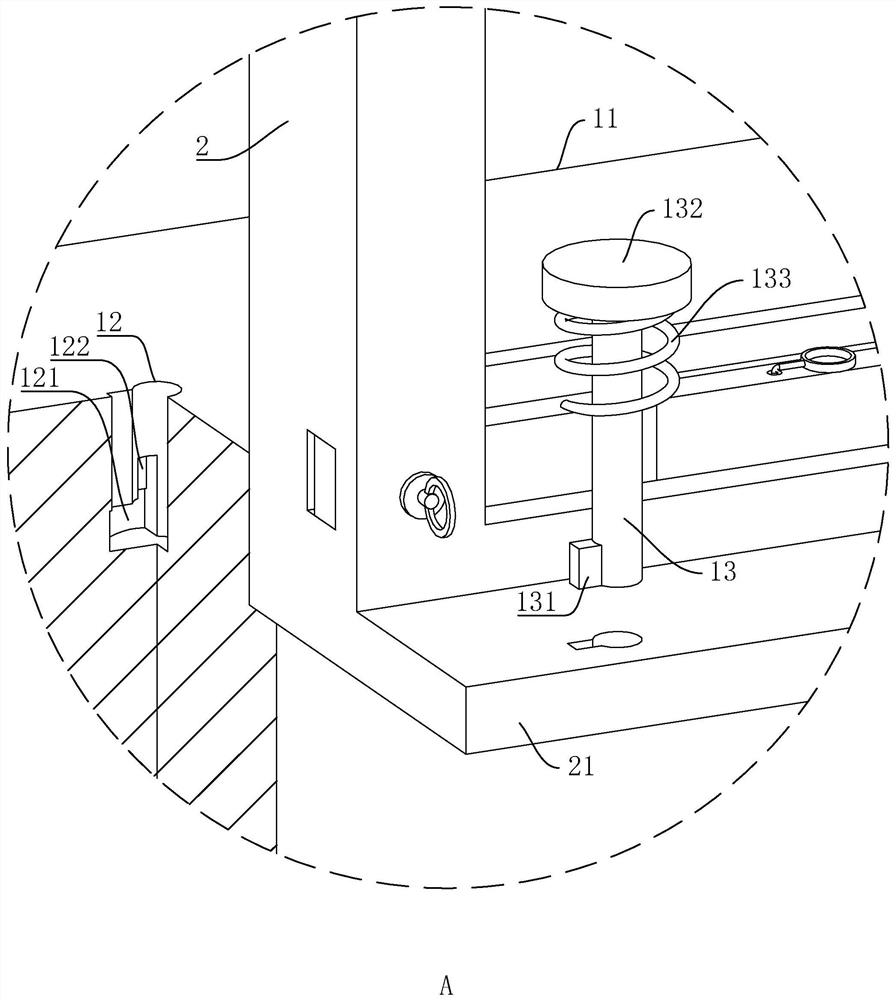

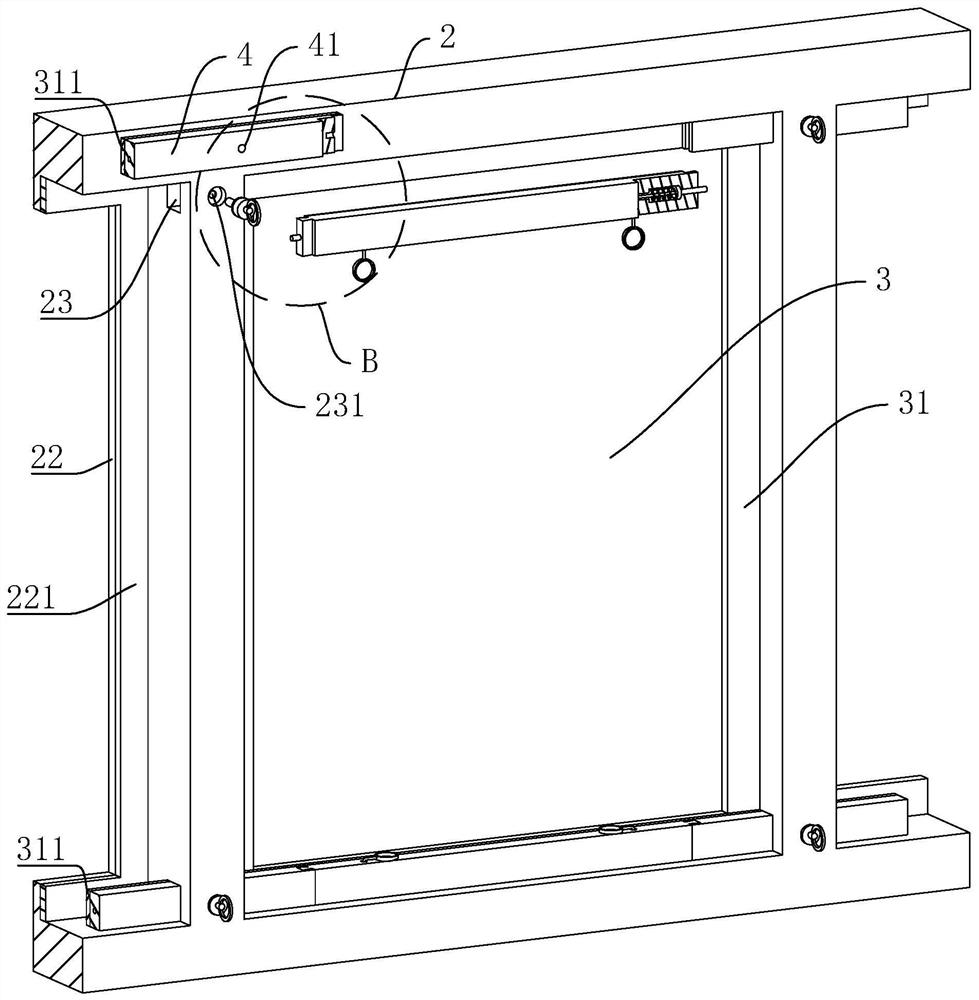

Automatic wallboard installation device

Owner:SHANDONG TIANYI MACHINERY

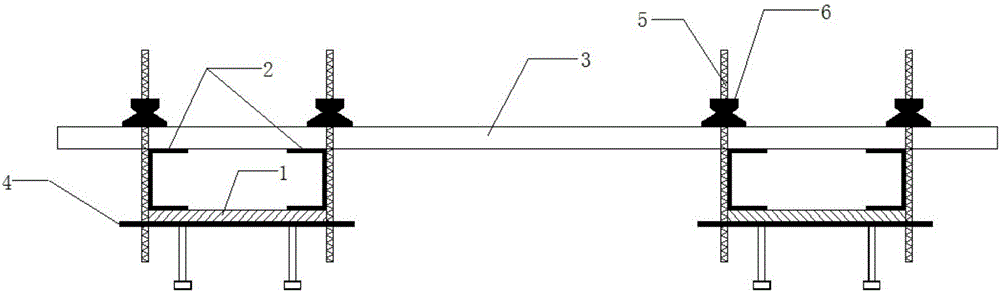

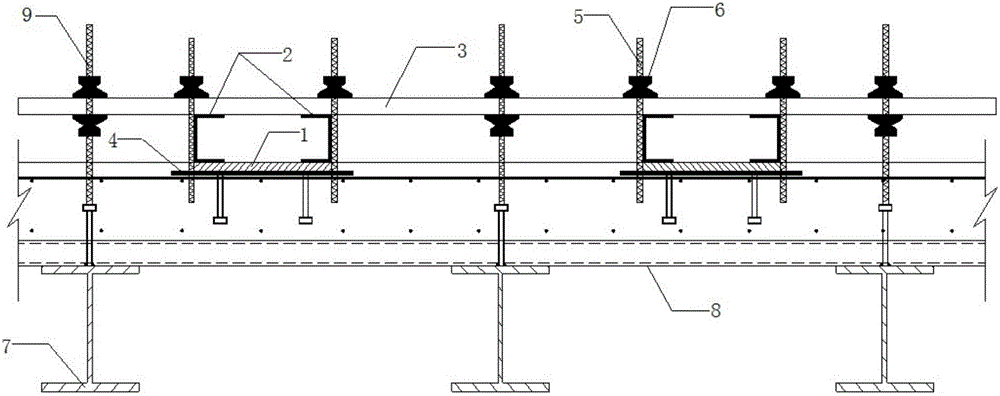

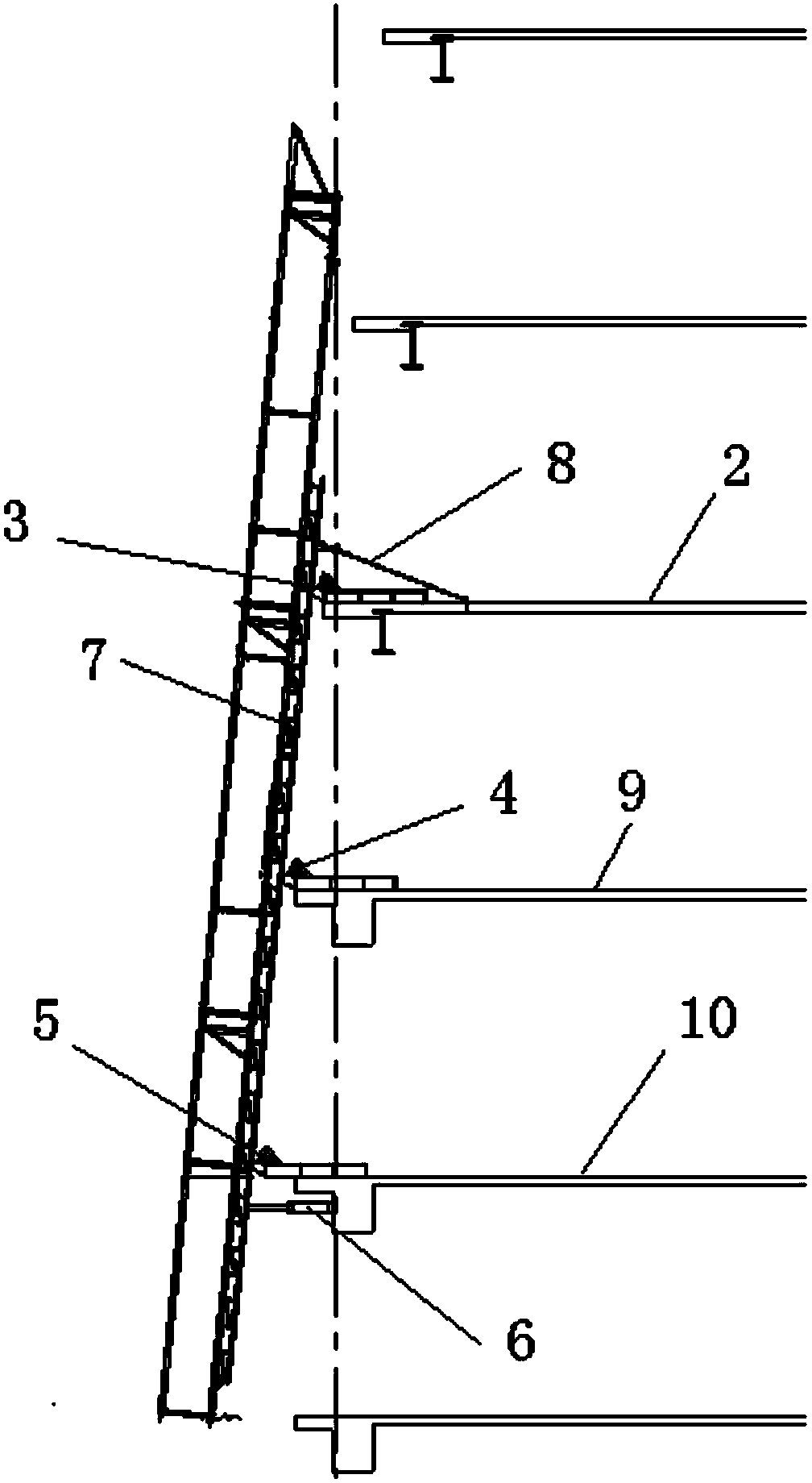

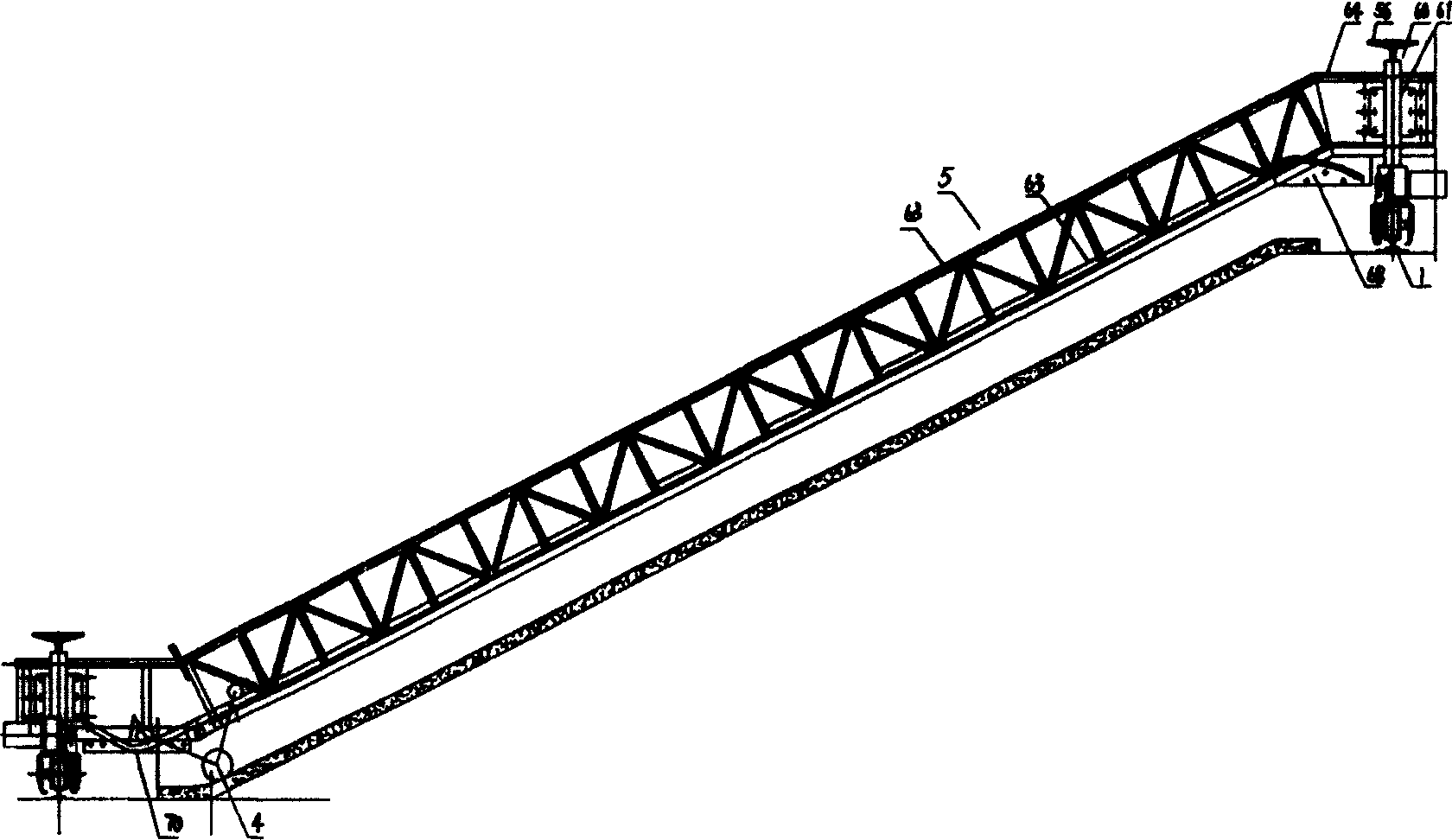

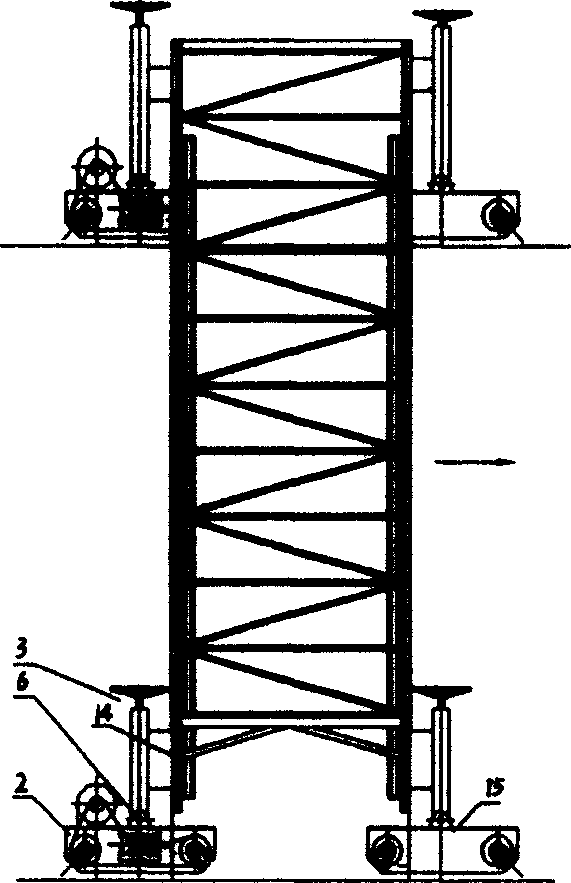

Self-stable suspension type unloading platform and construction process thereof

PendingCN107965147AShorten the installation and dismantling periodSimple installation and disassemblyBuilding material handlingSocial benefitsArchitectural engineering

The invention discloses a self-stable suspension type unloading platform and a construction process thereof. The unloading platform comprises main beams. Auxiliary beams are arranged between the mainbeams. Platform embossing steel plates are arranged among the main beams and the auxiliary beams. Vertical beams are arranged on the upper sides of the main beams. A rebar pull rod upper support is arranged among the vertical beams. A rebar pull rod lower support parallel to the rebar pull rod upper support is arranged at the bottom ends of the main beams. Rebar pull rods are arranged between therebar pull rod upper support and the rebar pull rod lower support. Upper floor system edge beams are arranged at the top ends of the vertical beams. A feed channel plate is arranged at the upper endsof lower floor system edge beams and the platform embossing steel plates. Compared with a traditional steel overhung unloading platform, embedded steel wire rope ring hanging, profile steel support ring anchoring, ending anchoring ring hole blocking and hanging ring rebar cutting treatment are not needed, and a passenger channel can be laid along a floor; construction installation and detachment operation is simple, safe and convenient, the installation and detaching construction period is shortened, embedded pieces and labor cost are greatly saved, the platform has remarkable economic and social benefits and meets the efficient, energy-saving and green construction requirements.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

Grout sleeve for connecting prefabricated member steel bars and construction method of grout sleeve

Owner:SHENYANG JIANZHU UNIVERSITY

Concrete hole wall scrabbling device

Owner:江苏金城建设有限公司

Glass curtain wall structure convenient for quick installation and installation process thereof

Owner:江苏中南建设装饰集团有限公司

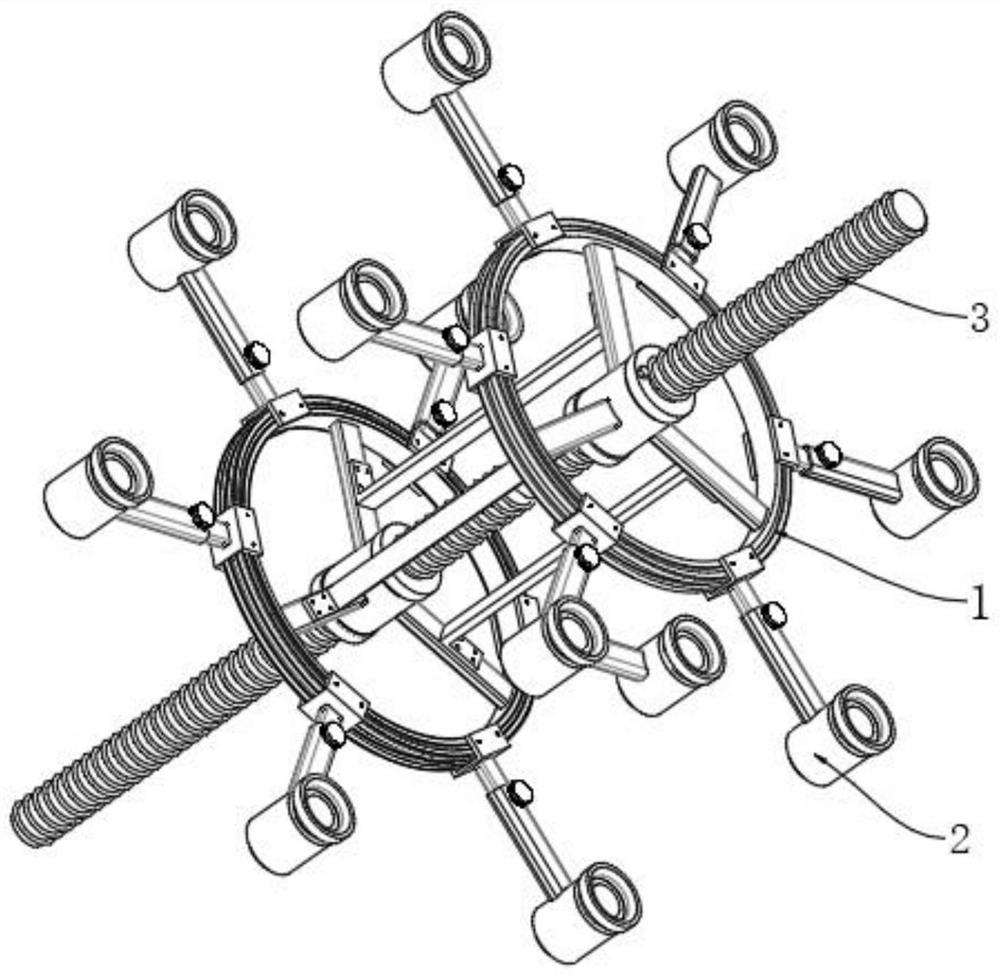

Wind turbine tower

Owner:SIEMENS AG

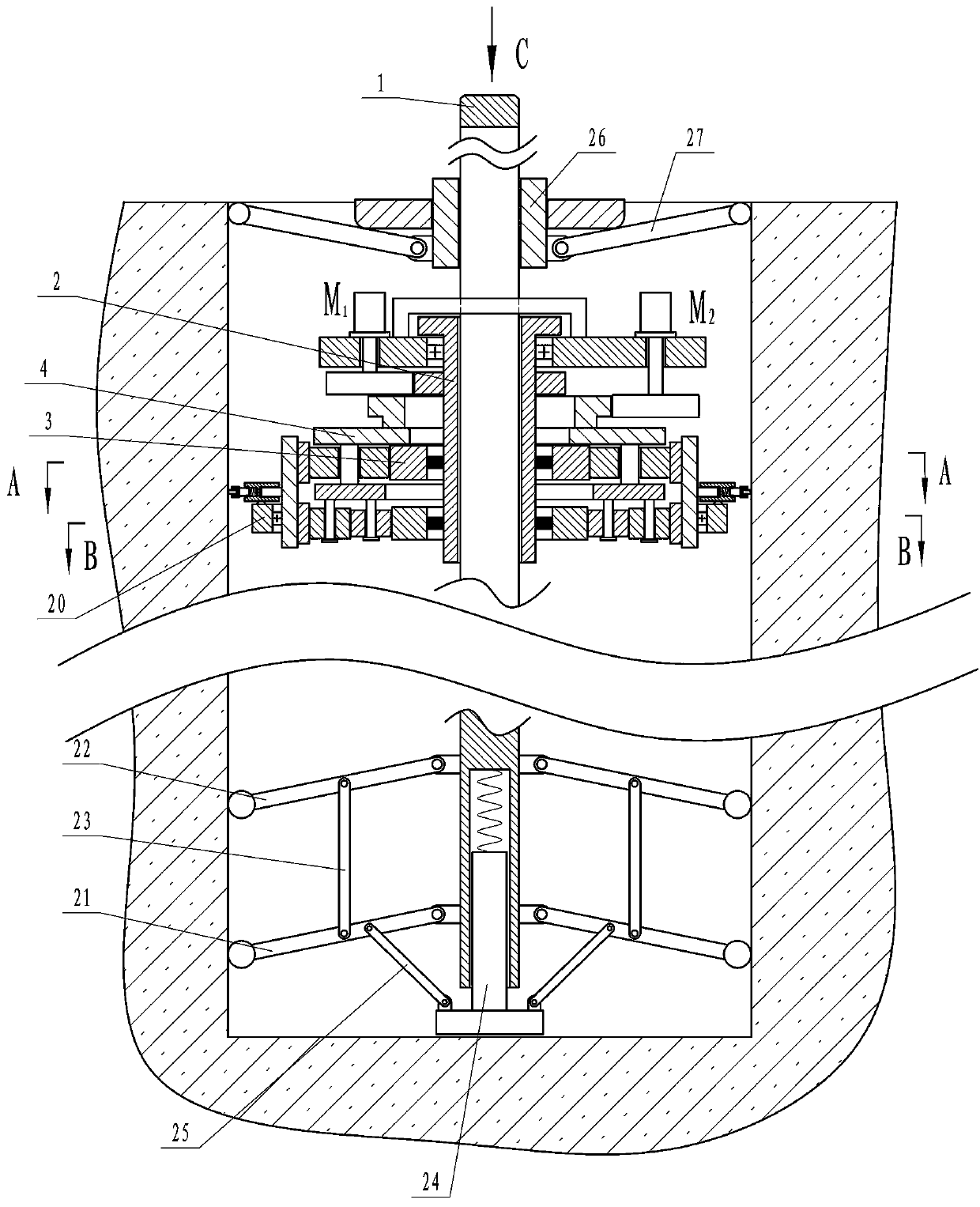

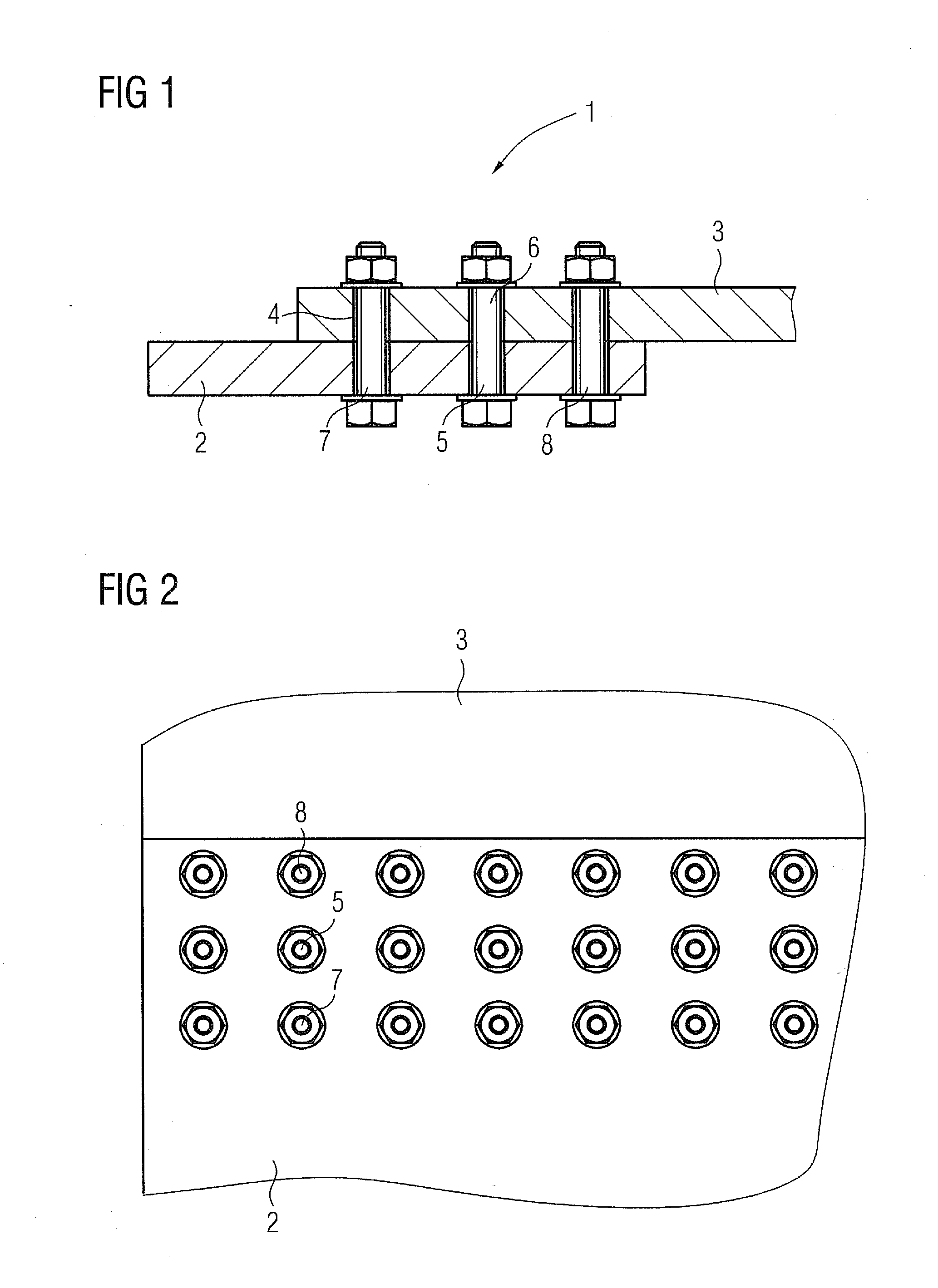

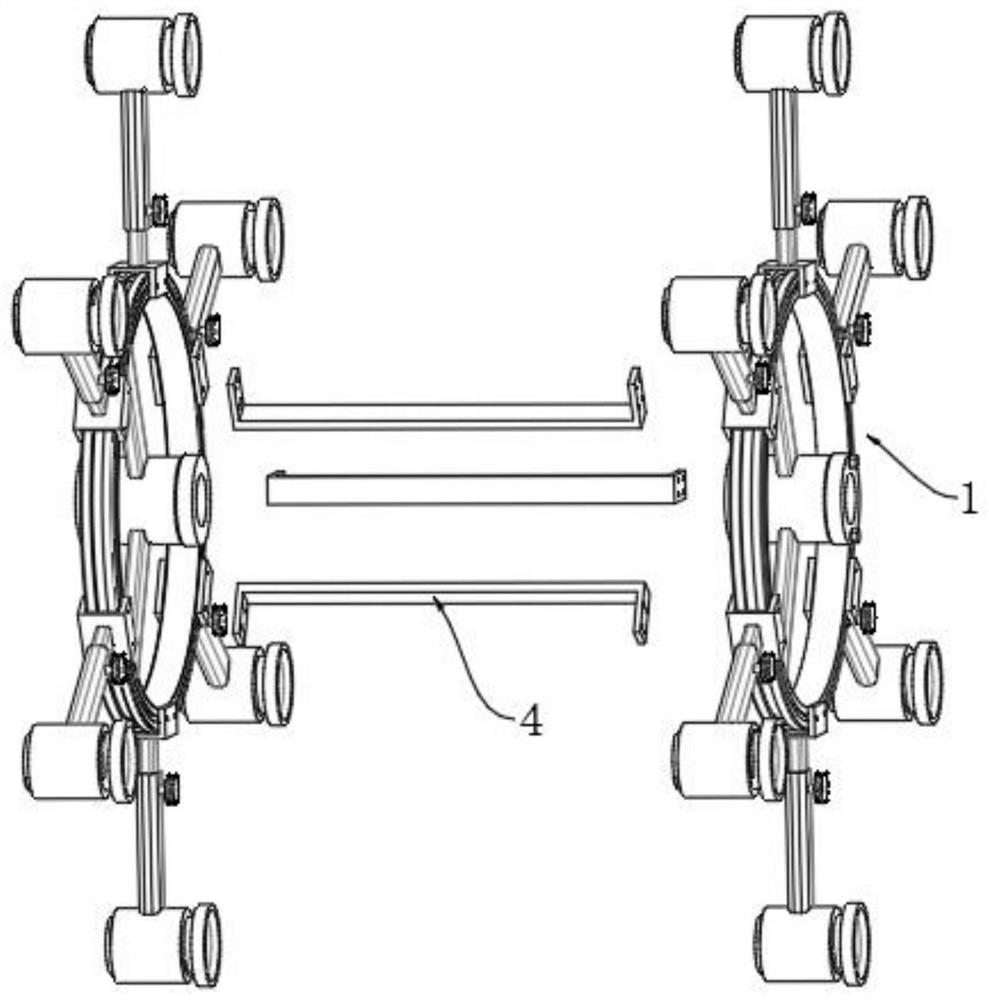

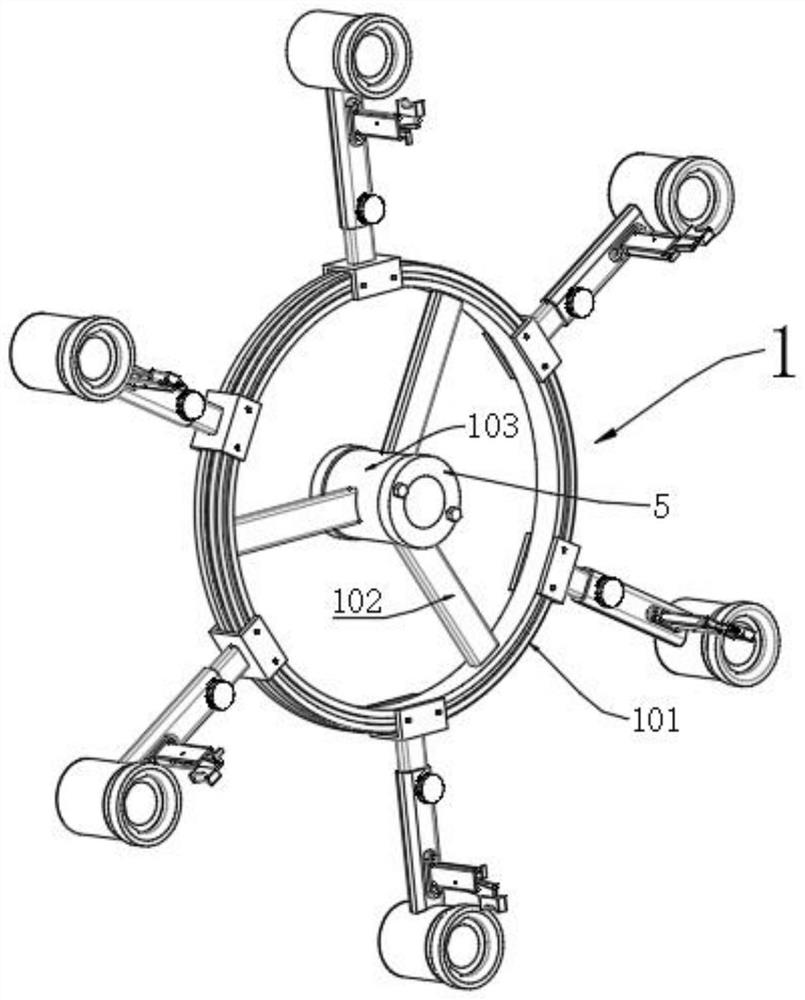

Hanger for large-span arc-shaped suspended ceiling, suspended ceiling system and construction method of suspended ceiling system

InactiveCN104989023AStable structureFast installationCeilingsBuilding material handlingEngineeringDropped ceiling

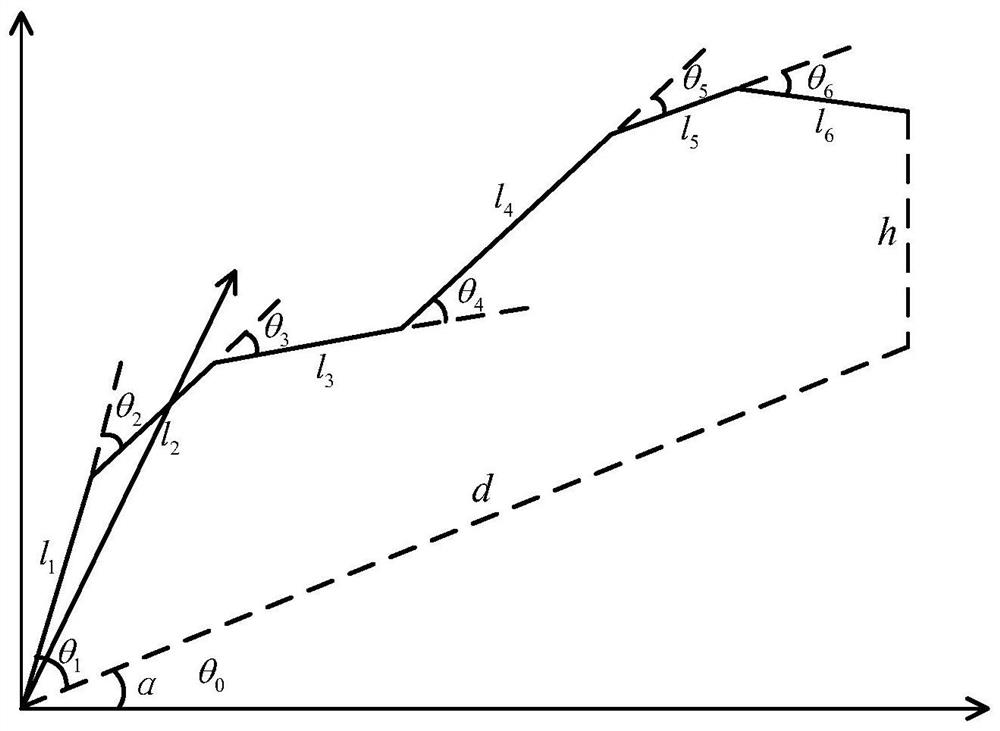

The invention discloses a hanger for a large-span arc-shaped suspended ceiling, a suspended ceiling system and a construction method of the suspended ceiling system. The hanger comprises a cross-shaped claw piece, wherein the cross-shaped claw piece comprises a base body, four connecting plates and an adaptor, a base body connecting hole is formed in the base body, a first connecting plate through hole and a second connecting plate through hole are formed in each connecting plate, one end of each connecting plate is fixedly connected with the base body, and the four connecting plates are arranged into a cross shape; a first connecting hole and a second connecting hole are sequentially formed along the adaptor, the first connecting hole is connected with the first connecting plate through hole through a bolt, the second connecting hole is an arc-shaped hole, the arc-shaped hole and the first connecting hole share the same circle center, and the second connecting hole is connected with the second connecting plate through hole through a bolt. The included angle between each connecting plate and the adaptor of the cross-shaped claw piece can be formed by locking the relative positions of the second connecting hole and the second connecting plate through hole through adjustment of the corresponding bolt, so that designing and manufacturing of the arc-shaped suspended ceiling are made possible.

Owner:DECORATION CO LTD OF CHINA CONSTR 3RD ENG BUREAU

Building embedded part device for shaping, positioning and adjusting

ActiveCN112709338AGuaranteed limit effectQuick alignment insertionBuilding reinforcementsBuilding material handlingArchitectural engineeringRebar

Owner:安徽华盛建设集团有限公司

High-precision embedded part reinforcing and mounting device and method and purpose

Owner:CHINA NUCLEAR IND 24 CONSTR

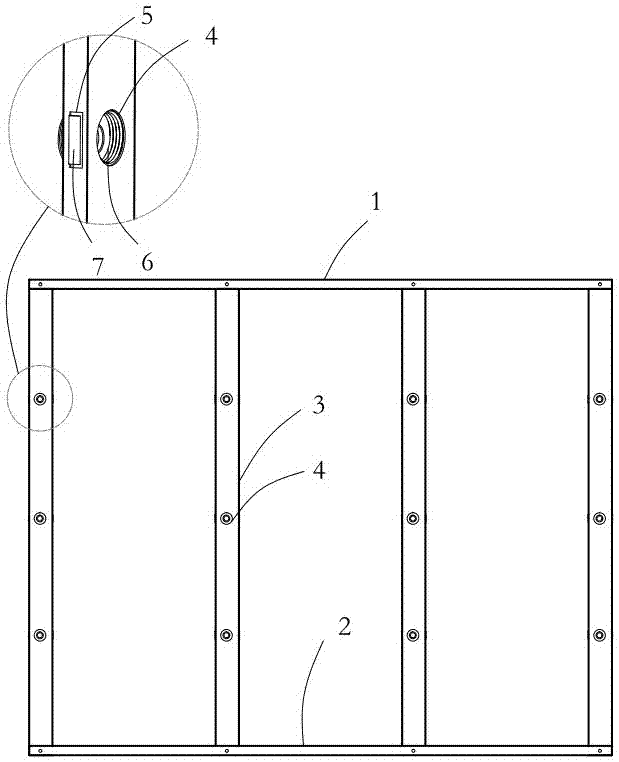

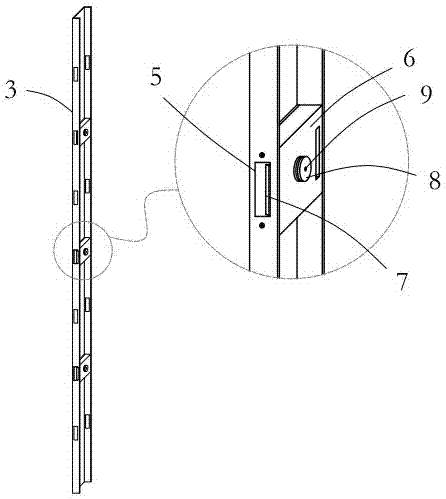

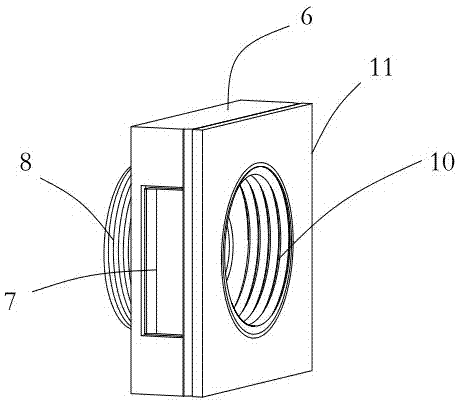

Fabricated wallboard with positioning device and mounting method thereof

Owner:广州市创搏装饰工程有限公司

Angle regulating device and angle regulating method in integrated frame lifting process

Owner:中铁十六局集团城市建设发展有限公司

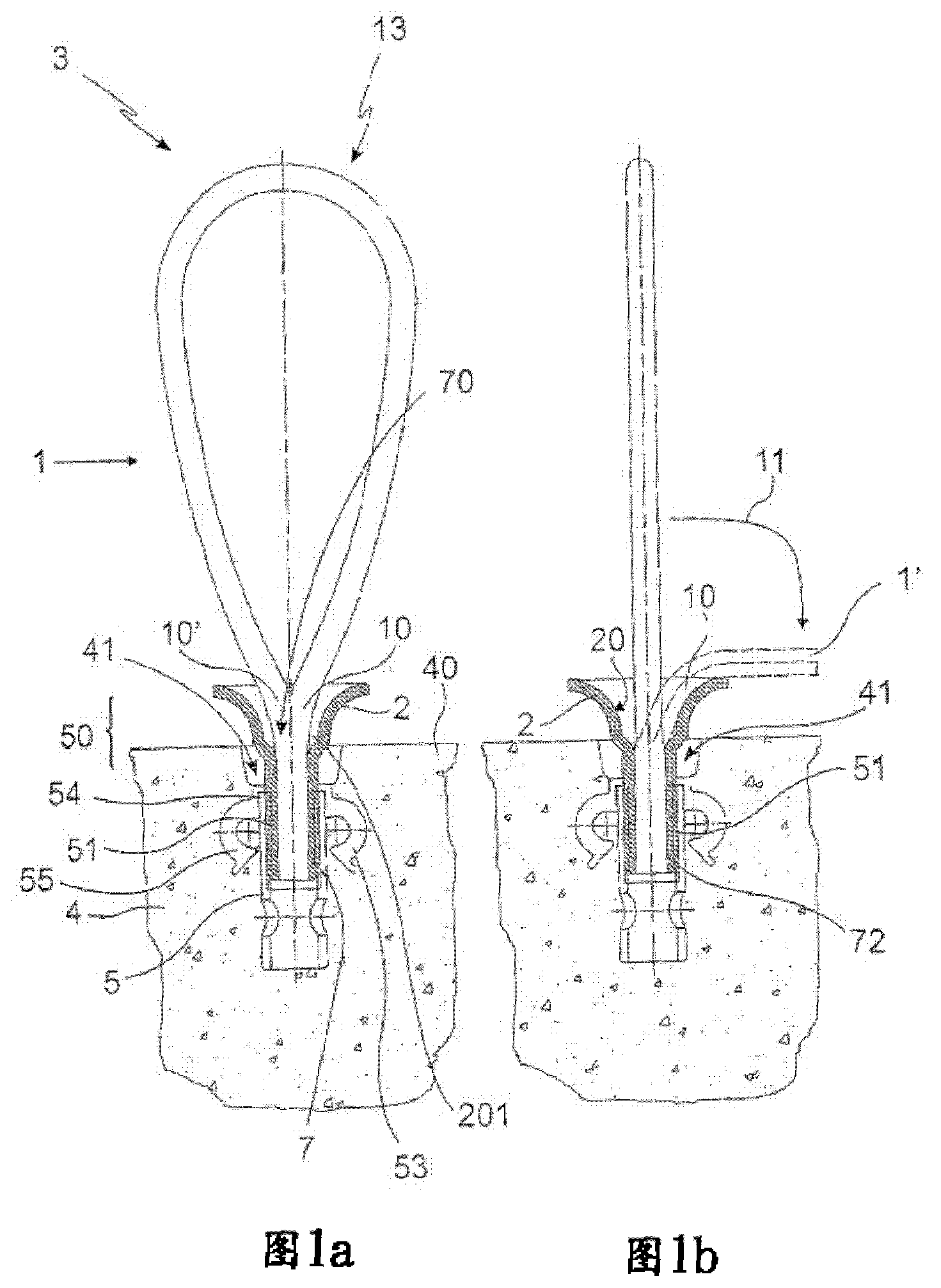

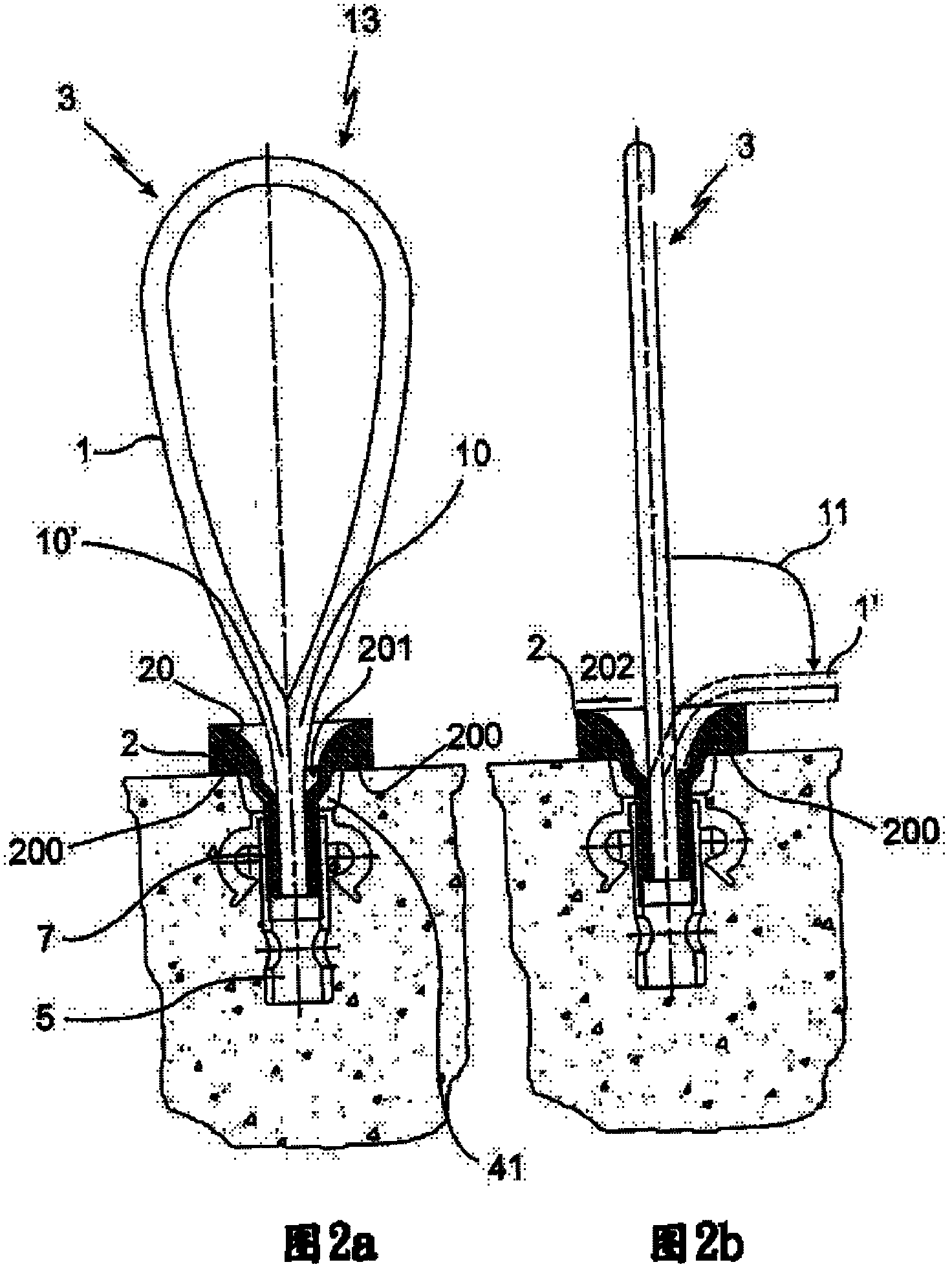

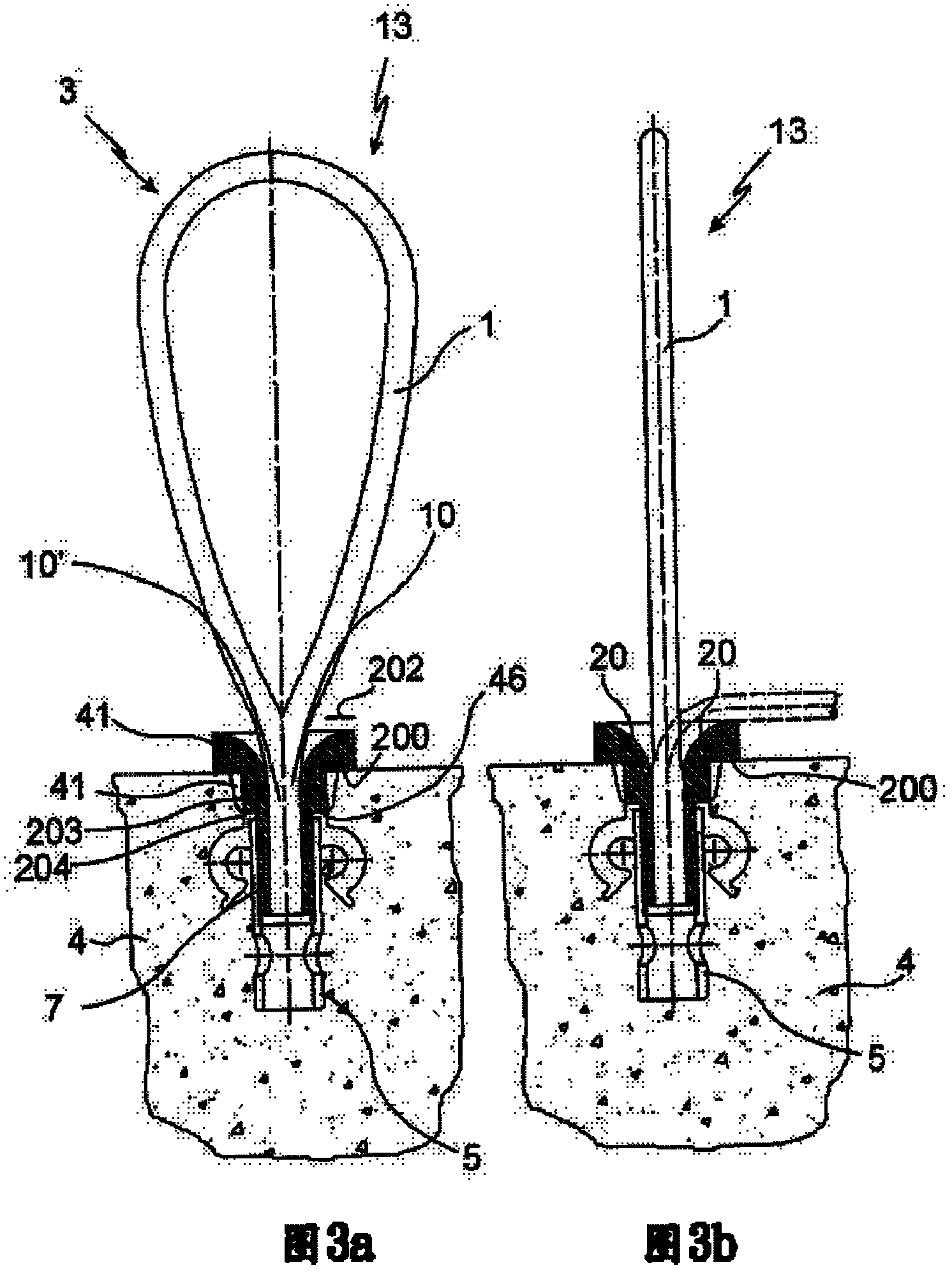

Load receiving means

ActiveCN102388194ACeramic shaping apparatusBuilding material handlingStructural engineeringArchitectural engineering

Owner:PFEIFER SEIL & HEBETECHNIK GMBH & CO

Construction method of roof waterproof engineering

InactiveCN109441113AGuaranteed waterproof effectSmooth bondBuilding material handlingBuilding constructionCivil engineering

The invention provides a construction method of roof waterproof engineering, and belongs to the field of building construction. The construction method of roof waterproof engineering adopts rubber coiled materials, and comprises the following steps that S1, the roof surface is cleaned; S2, a connecting structure protruding from the roof surface is pre-treated; and S3, the rubber coiled materials are paved and bonded. In the step S2, the pretreatment means that chamfering is performed between the connecting structure and the roof surface. During construction, by arranging a chamfer at the connecting structure protruding from the roof, a smooth transition between the connecting structure and the roof surface can be achieved, so that the rubber coiled materials can be smoothly bonded in the vicinity of the connecting structure to ensure the waterproof effect.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP SAIDE CONSTR CO LTD

Electric-cylinder concrete lining apparatus

Owner:耿福明 +2

Method for mounting nuclear island end beam of nuclear power station

Owner:CHINA NUCLEAR IND 23 CONSTR

Separating device for pouring different strengths of concrete for beam and column joints

PendingCN111173285AGood separation effectNo flow problemsBuilding material handlingClassical mechanicsStructural engineering

Owner:CHINA RAILWAY CONSTR ENG GROUP

Device and method for adjusting size of top die system hanging rack

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

Process for adopting fair-faced concrete pouring during building construction

The invention discloses a process for adopting fair-faced concrete pouring during building construction. According to the process, concrete mixing is strictly measured according to a mixing ratio, a pump is used for transportation, and a concrete pump should be placed on a solid ground; vibration time of the concrete is mastered, and vibration is not stopped until the surface of the concrete has uniform cement paste represented and does not have obvious sinking and a large number of risen air bubbles; after the concrete is cooled to <+>5 DEG C, and the difference value between the concrete surface temperature and the ambient temperature is greater than 15 DEG C after form removal, coverage and maintenance should be carried out on the surface of the concrete, so that the concrete is cooledslowly; the form removal is carried out on the concrete when the strength of test pieces under the same conditions reaches 3 MPa or 4 MPa, and in-time maintenance should be carried out after the formremoval to reduce the phenomena of chromatic aberration, shrinkage cracks and the like on the surface of the concrete, fair-faced concrete often adopts the method of combining plastic film or flame retardant mat coverage and watering maintenance, watering should be carried out before the form removal and during maintenance respectively to keep wet, and the maintenance time is not less than 7d. Theprocess for adopting fair-faced concrete pouring during the building construction can ensure that the fair-faced concrete meets the requirements after pouring and the service life of the concrete islonger.

Owner:成都美吉房地产营销策划有限公司

Hybrid core construction

Owner:FABER SHAUN +3

Leveling member for prefabricated wall structure and prefabricated wall structure

Owner:CHENGDE GREEN BUILDING ENERGY SAVING TECH CO LTD

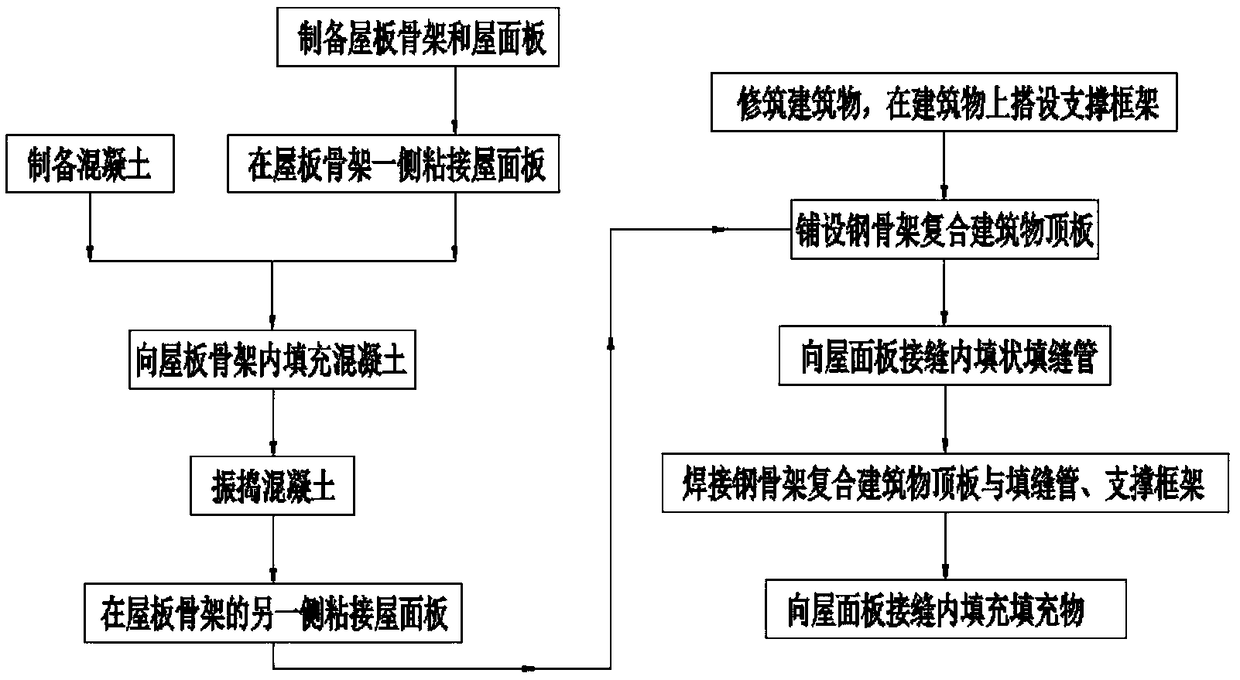

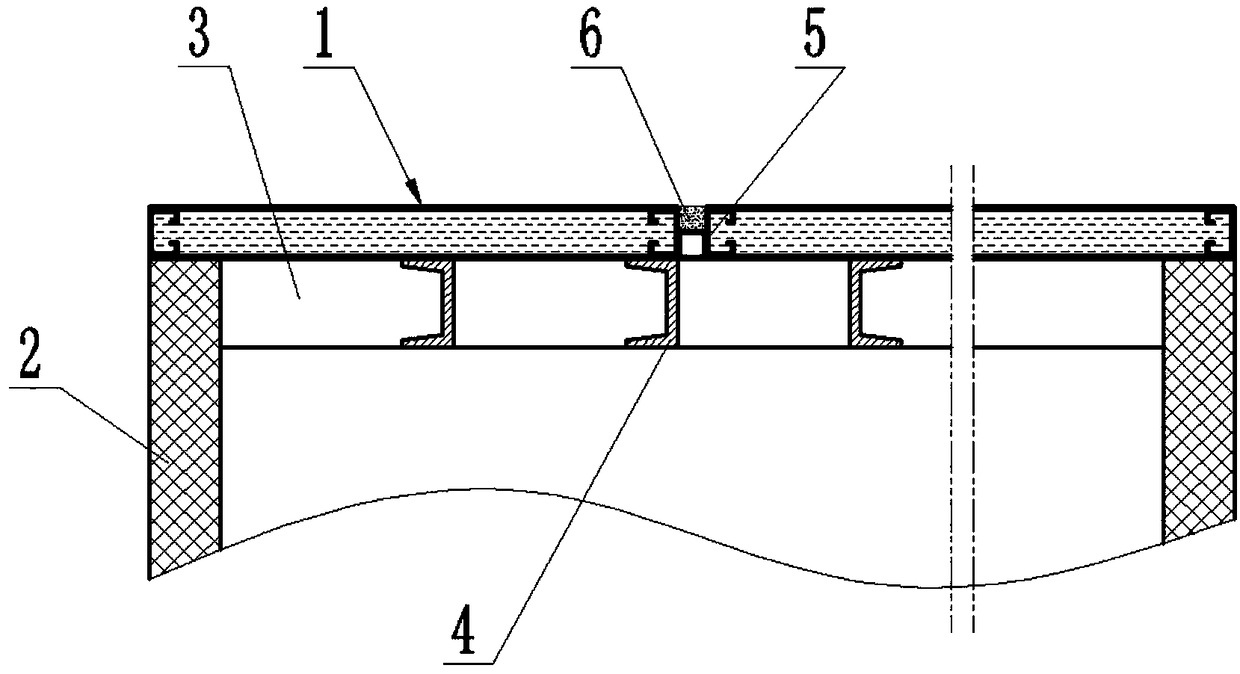

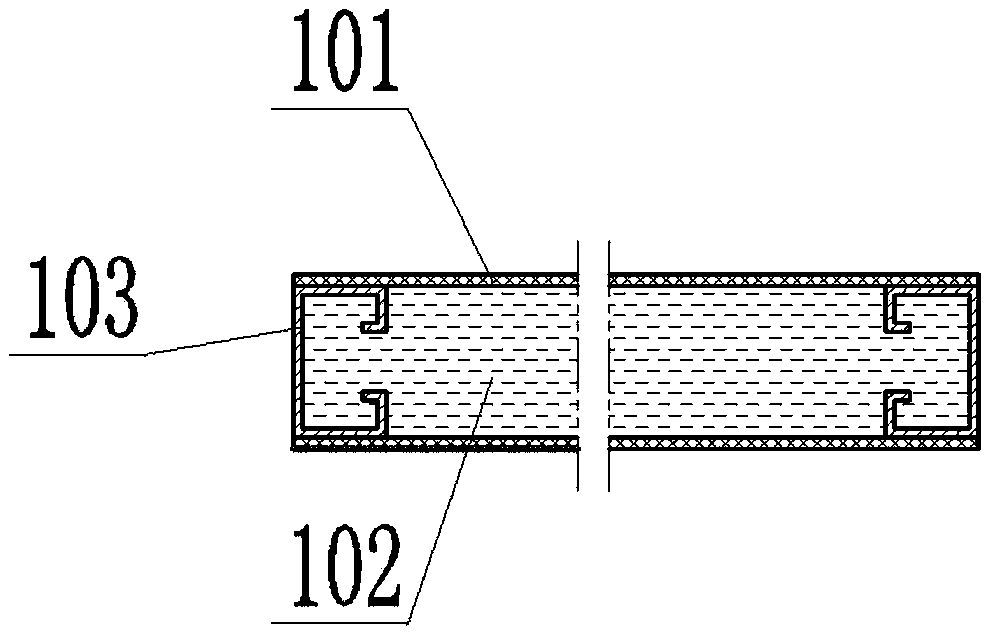

Paving construction process for roofs of steel framework composite building

ActiveCN108824810AUniform and consistent expansionSame expansion rateBuilding material handlingBraced frameArchitectural engineering

Owner:NO 1 CONSTR ENG CO LTD OF GUIZHOU CONSTR & ENG GRP

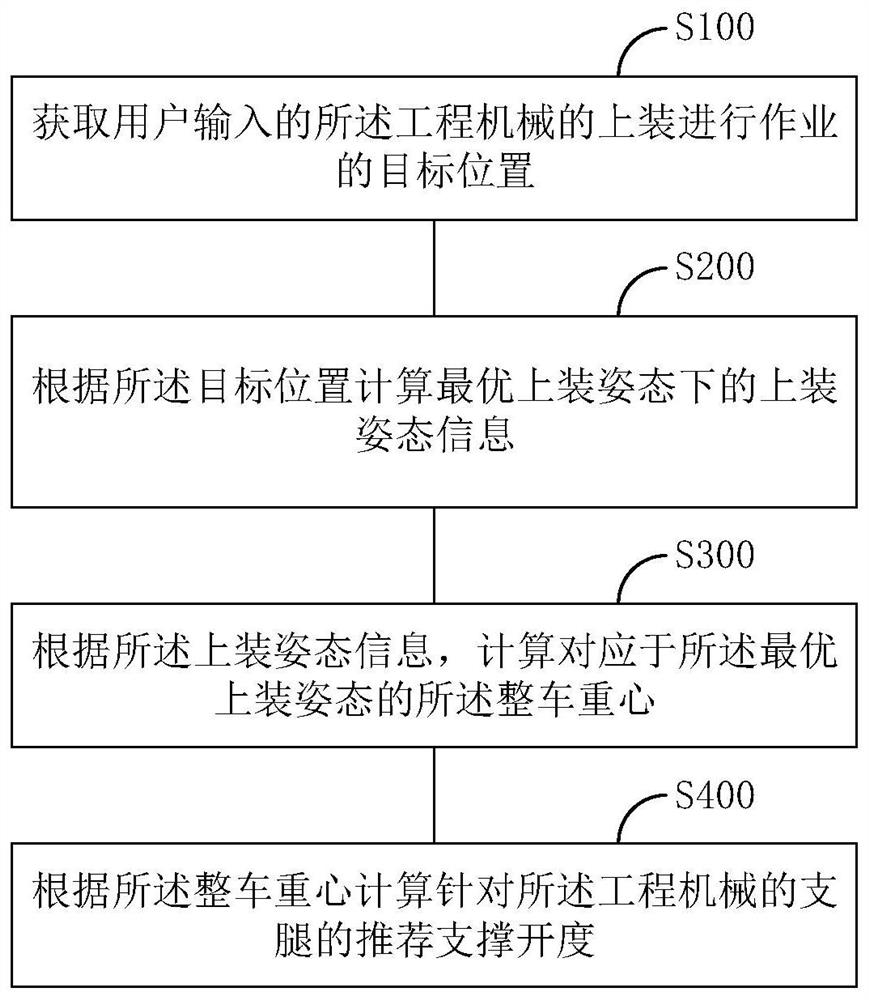

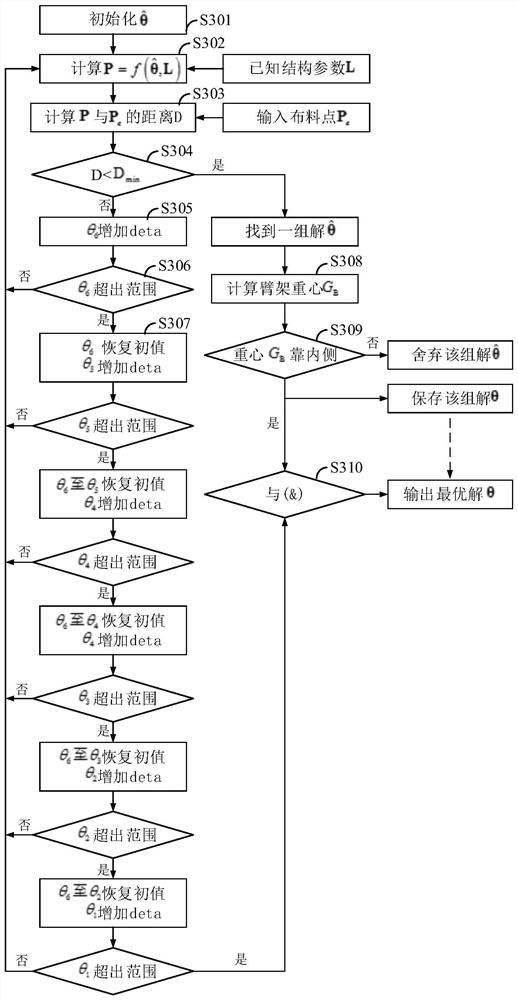

Engineering machinery, supporting control method, device and system thereof and medium

Owner:ZOOMLION HEAVY IND CO LTD

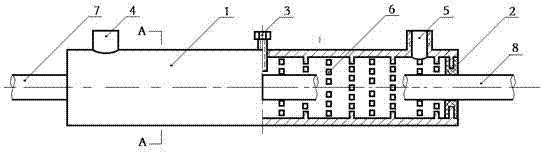

Concrete vibrating device and vibrating method thereof

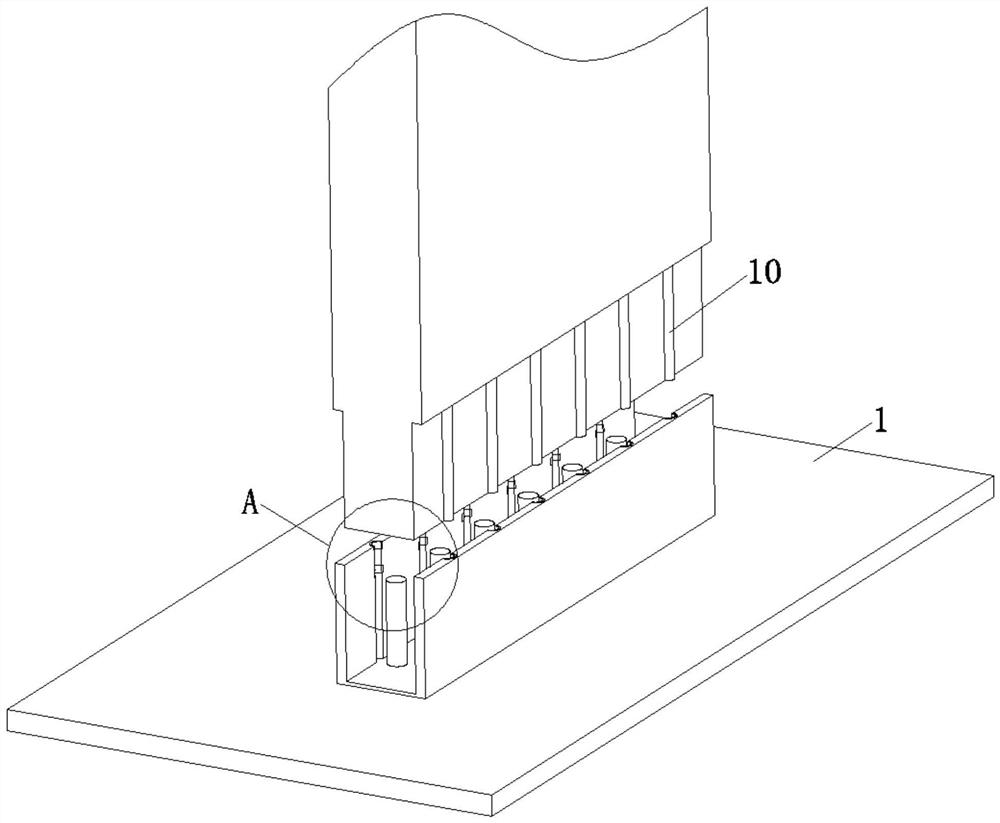

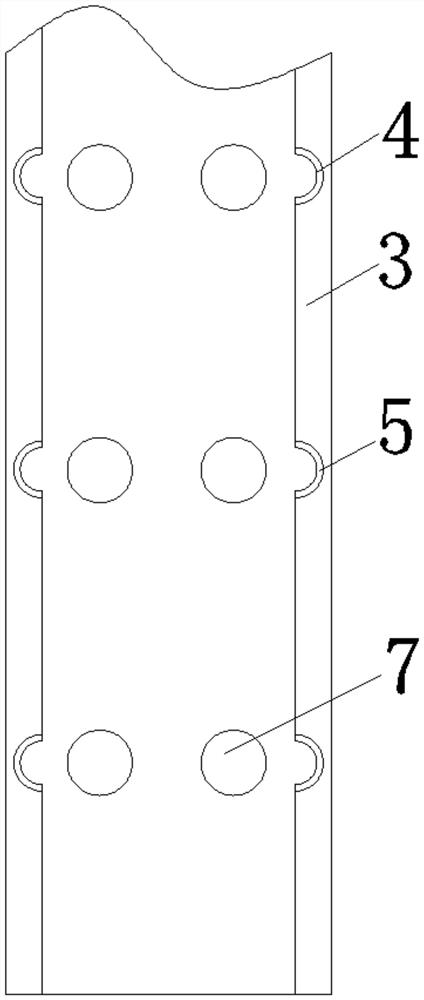

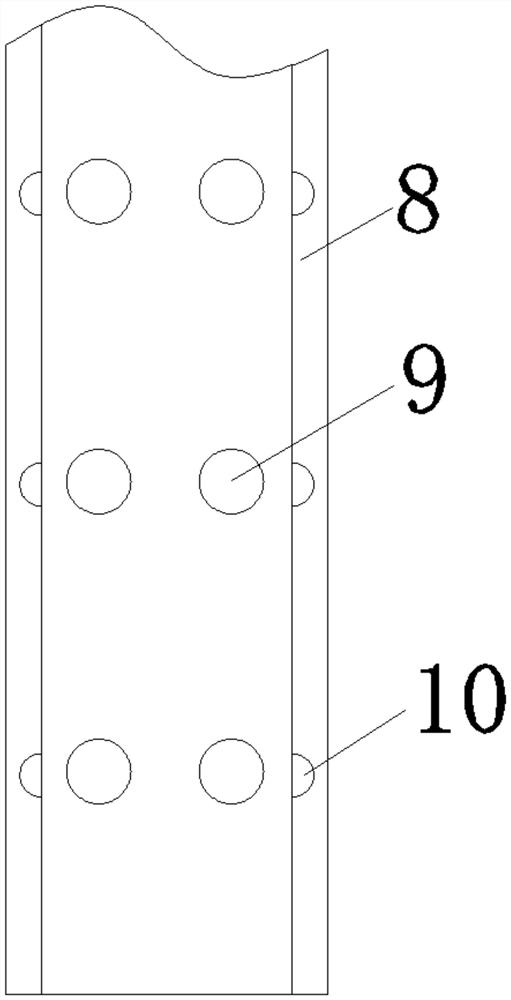

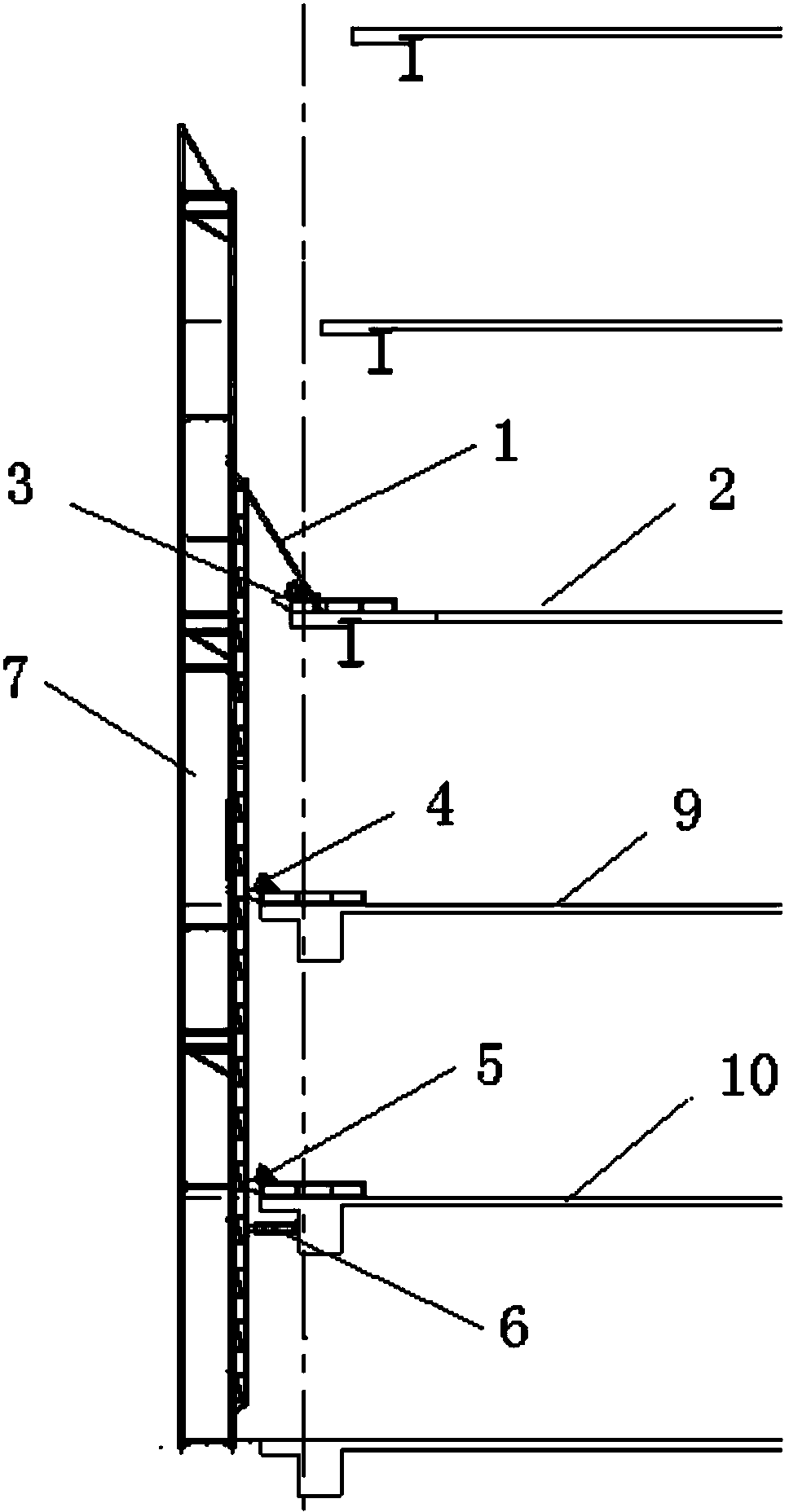

The invention relates to a concrete vibrating device and a vibrating method thereof. The concrete vibrating device comprises a vertically arranged fixing plate; a driving adjusting assembly which is mounted on the fixing plate; and a vibrating rod which is in driving connection with the driving adjusting assembly and is vertically arranged, and the vibrating rod is driven by the driving adjusting assembly to vertically move. According to the vibrating rod, continuous and long-time vibrating construction can be achieved without holding the vibrating rod by hand, and the construction efficiency is improved.

Owner:ZHONG GUO JIAN ZHU TU MU JIAN SHE YOU XIAN GONG SI

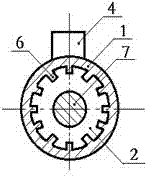

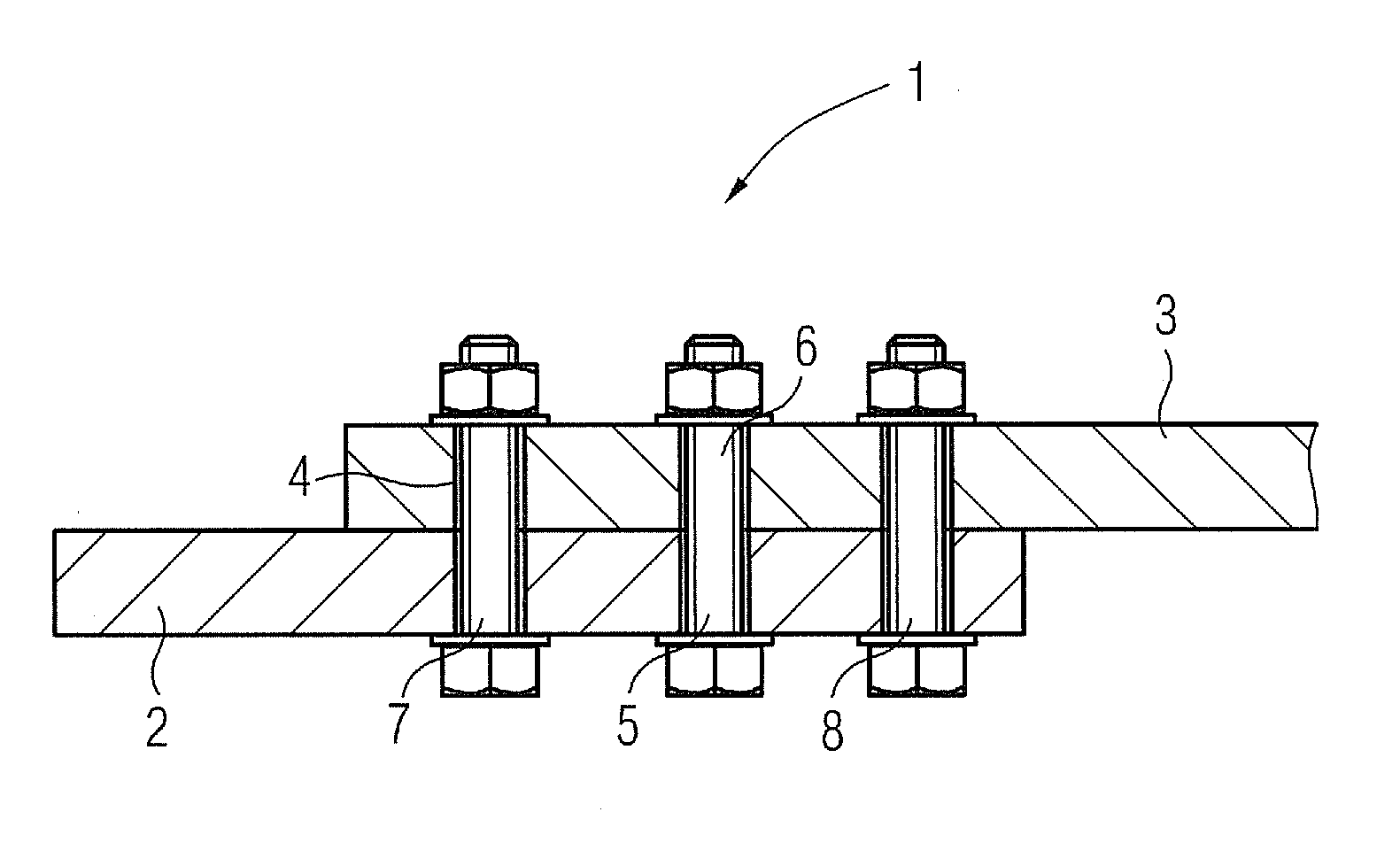

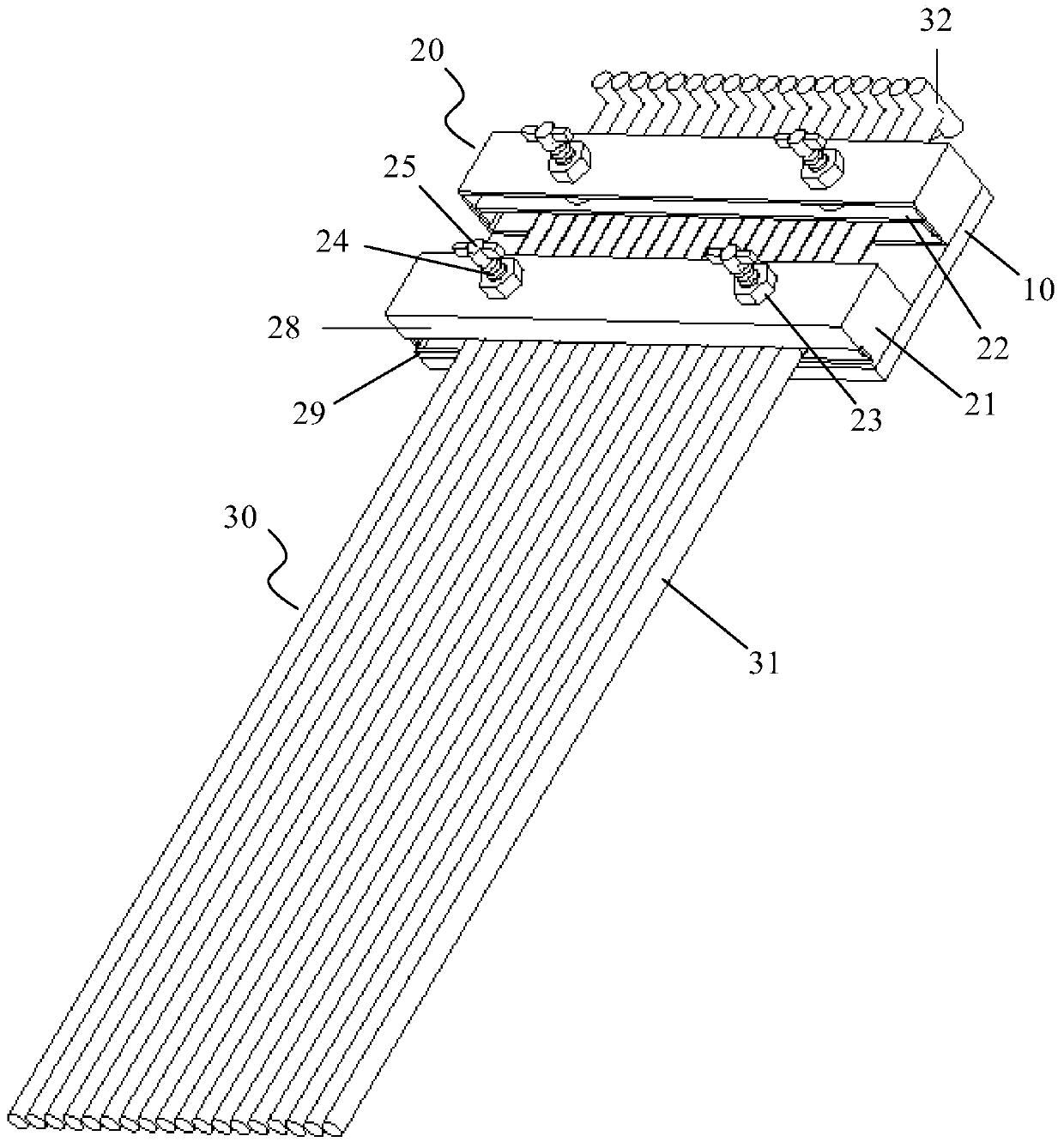

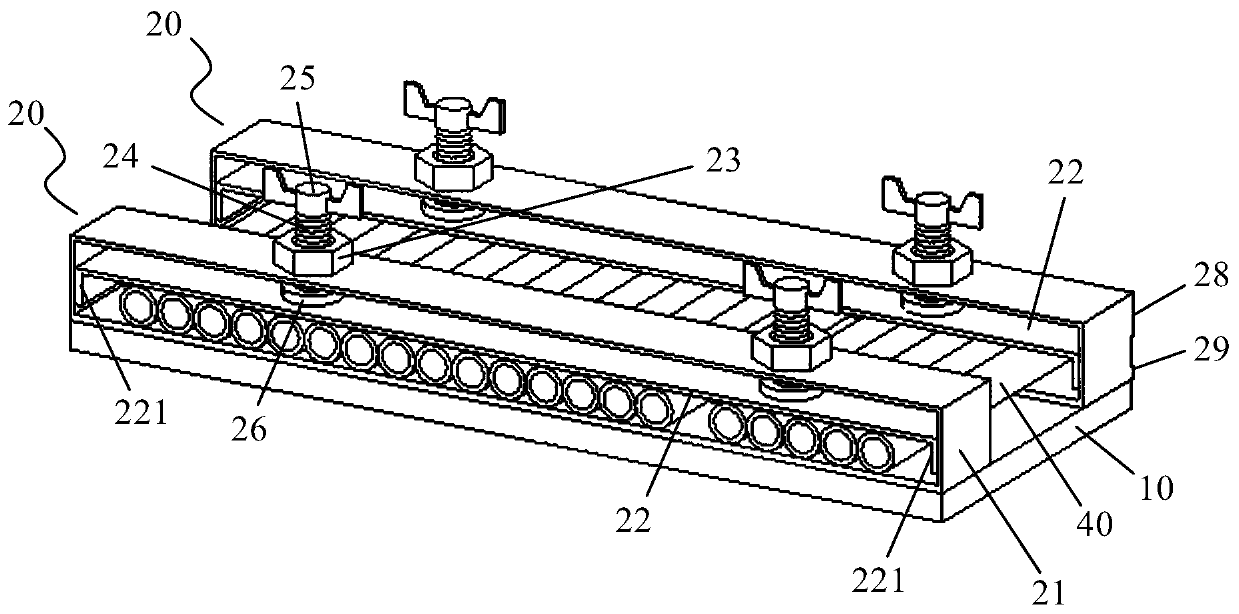

Steel bar connecting sleeve for concrete construction and construction process of steel bar connecting sleeve

ActiveCN105714985ASpeed up the installation processGuarantee the construction progressBuilding reinforcementsBuilding material handlingRebarScrew thread

The invention relates to a steel bar connecting sleeve for concrete construction and a construction process of the steel bar connecting sleeve. The steel bar connecting sleeve for concrete construction comprises a first steel bar body and a second steel bar body. A thread female head connecting sleeve of the first steel bar body is in threaded fit with a thread male head connecting sleeve of the second steel bar body. The steel bar connecting sleeve has the advantages that the construction process of the steel bar connecting sleeve for concrete construction is adopted, after the thread male head connecting sleeve of the second steel bar body is connected with the thread female head connecting sleeve of the first steel bar body through straight threads, the steel bar installing progress is accelerated, and the influence of joint bar installation on formworks is avoided; large turnup steel formworks can be used for a first-stage concrete structure, the construction progress of the first-stage concrete structure is effectively guaranteed, mutual interference of construction of the first-stage concrete structure and a second-stage concrete structure is relieved, the construction progress of the first-stage concrete structure and the second-stage concrete structure is greatly increased, and meanwhile the construction quality of the concrete structures is guaranteed.

Owner:SINOHYDRO BUREAU 11 CO LTD

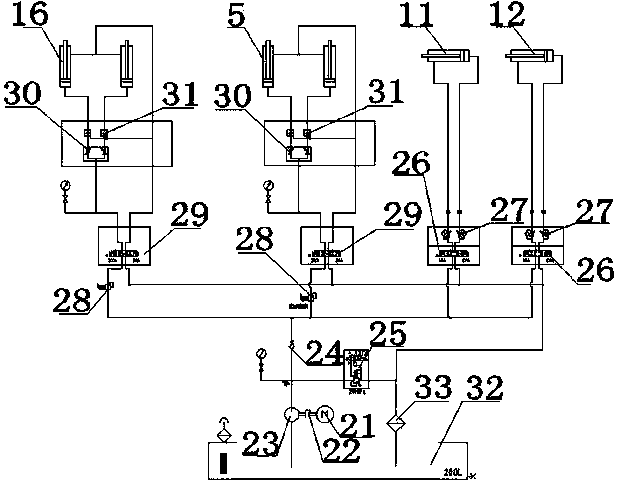

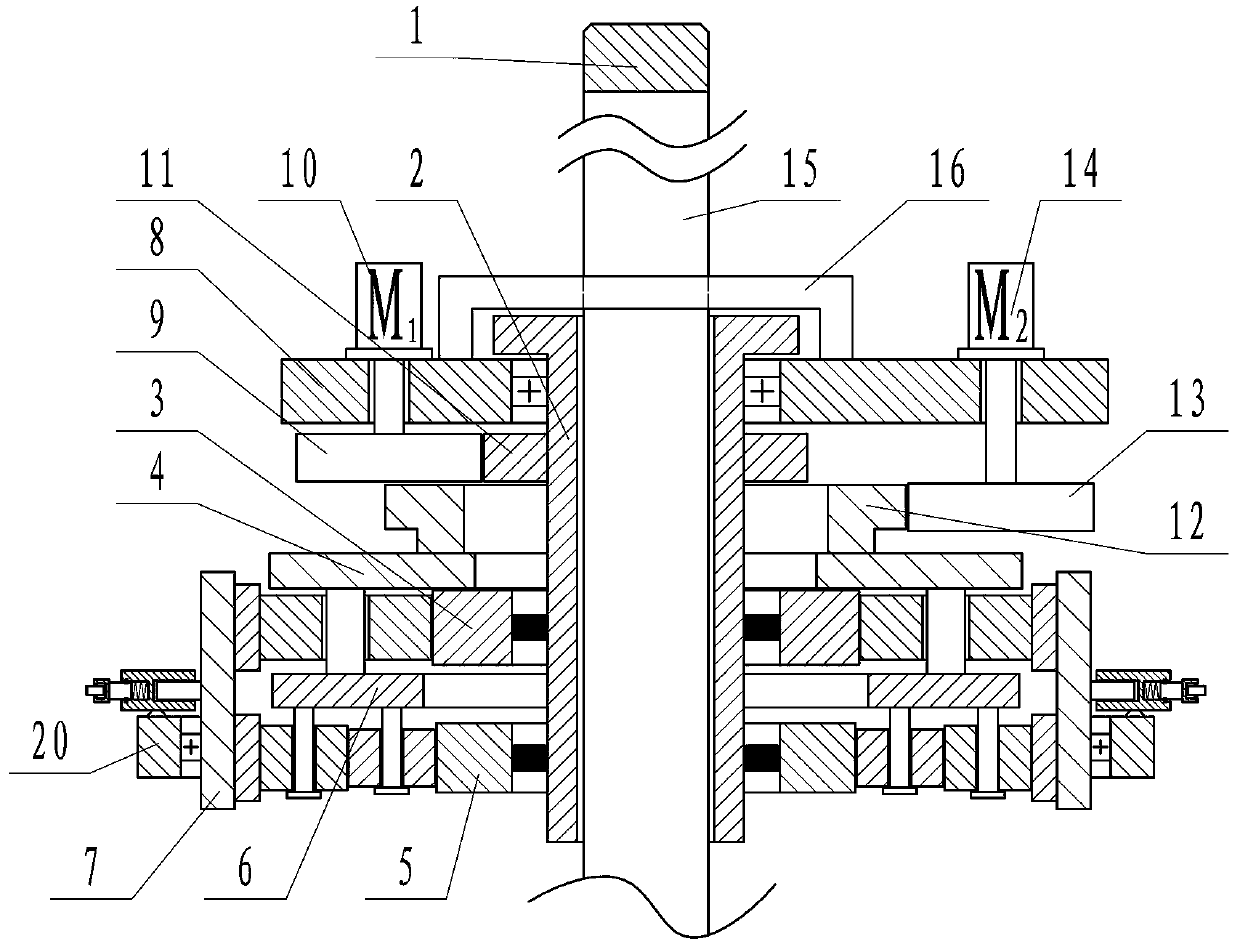

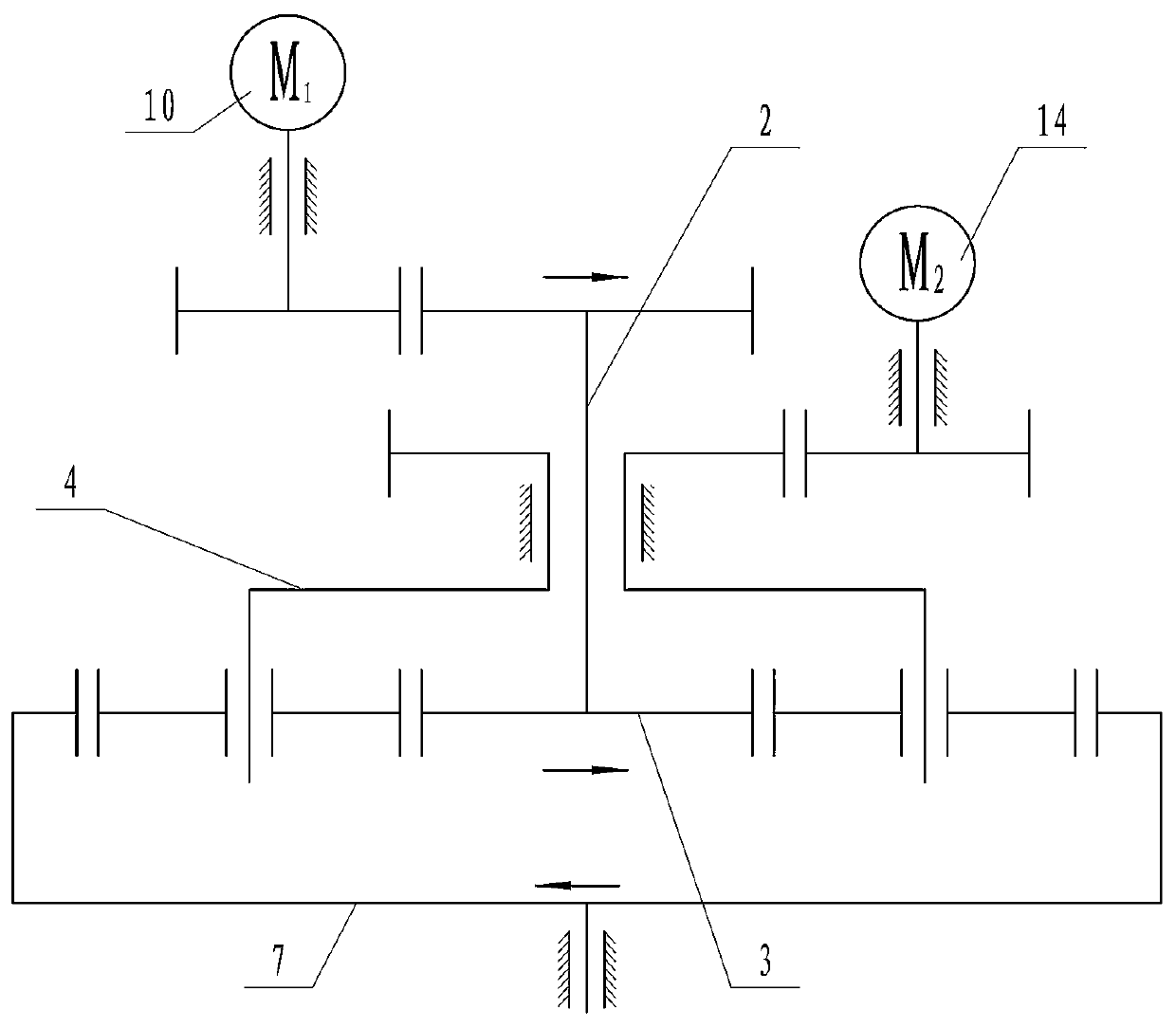

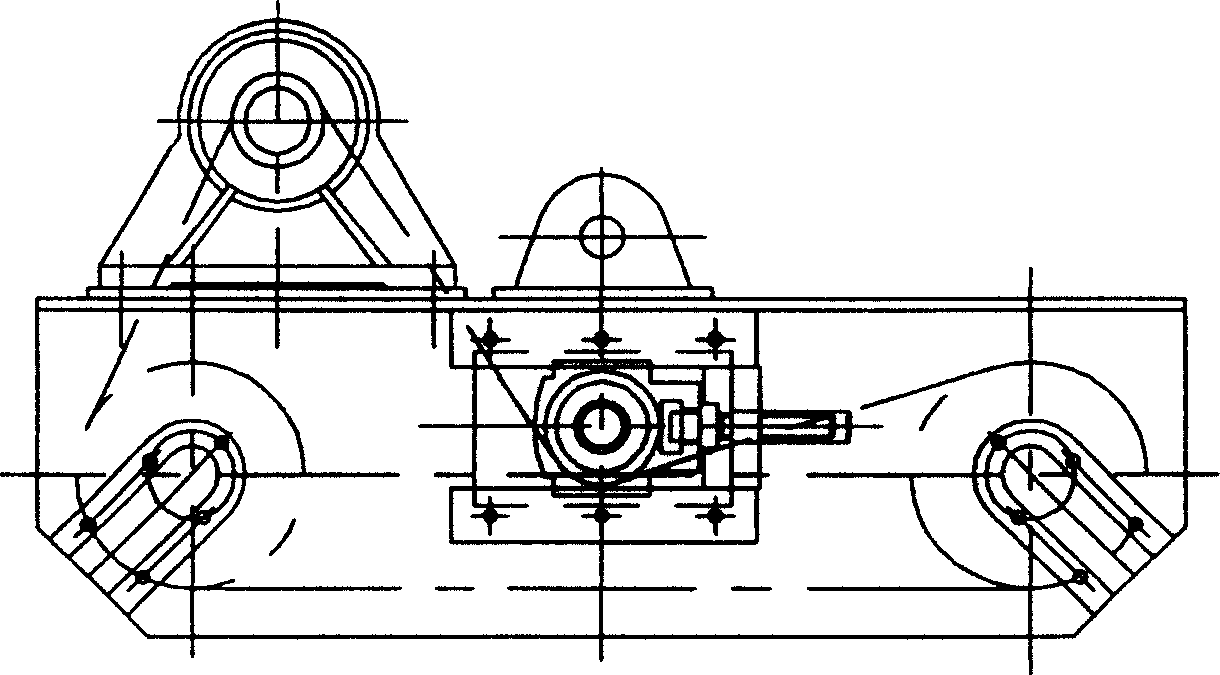

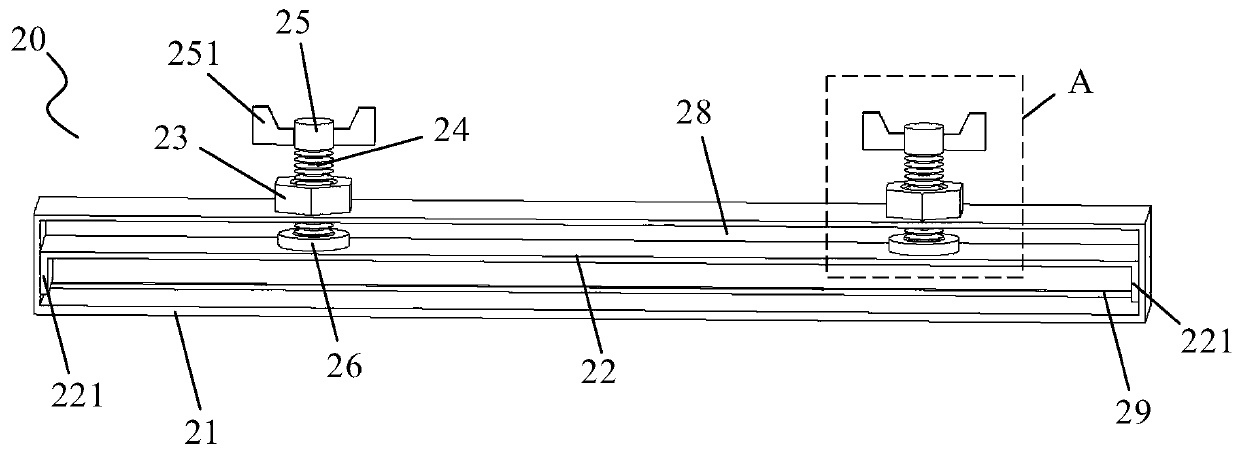

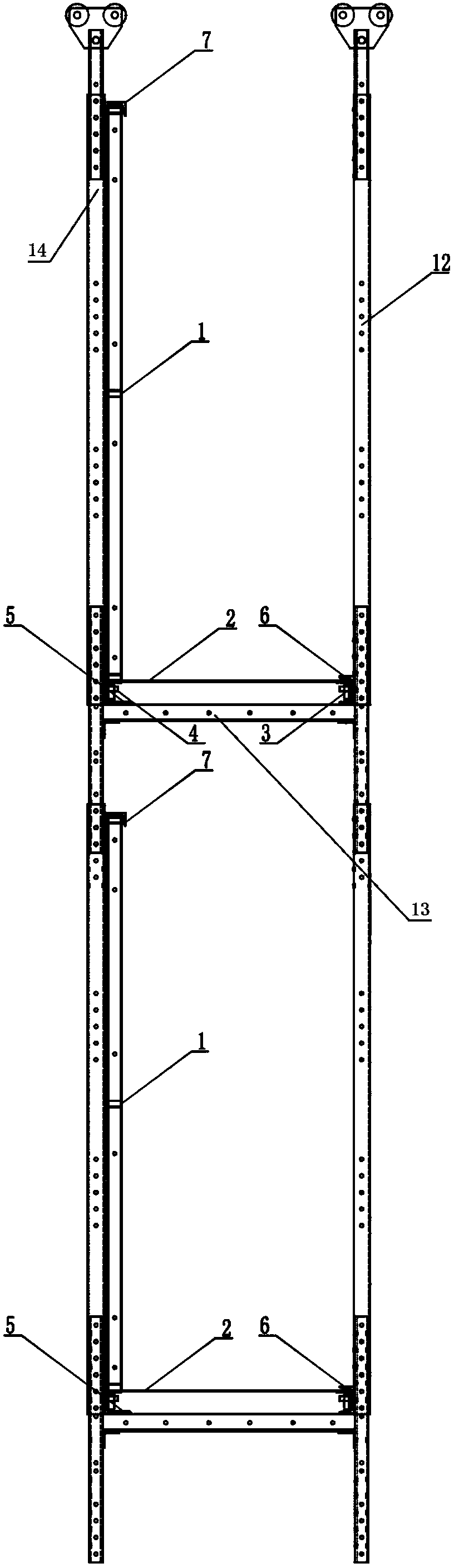

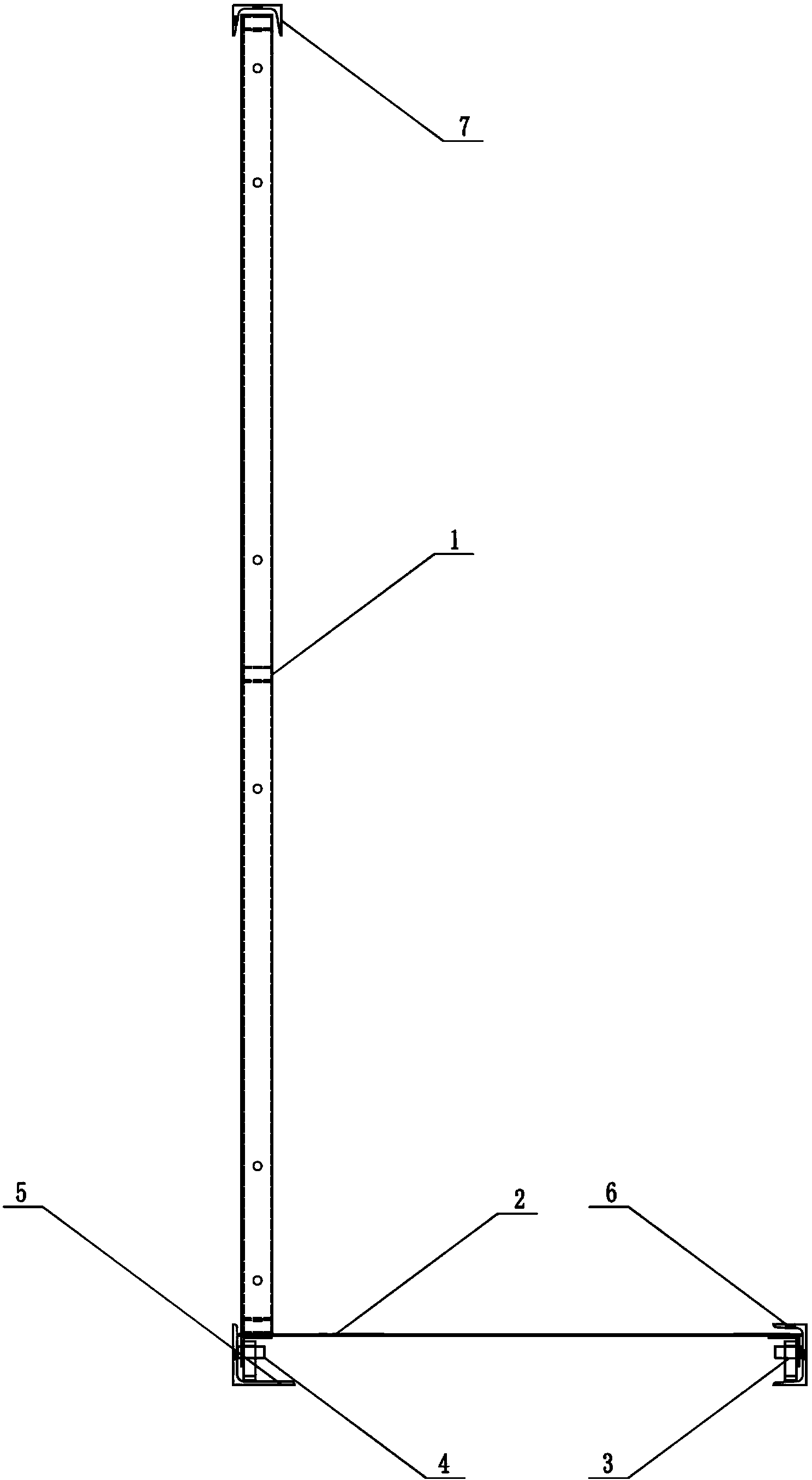

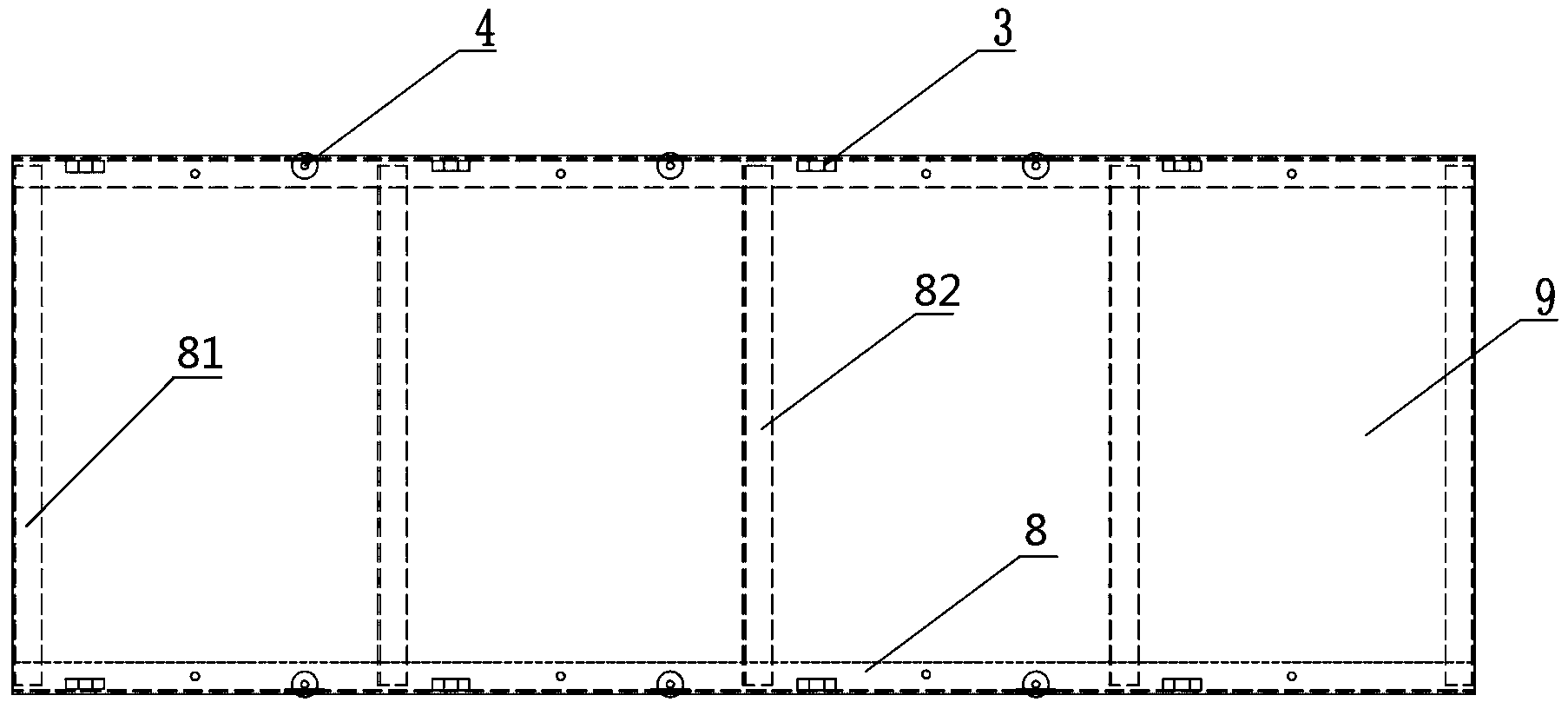

Two-dimensional travelling mechanism

PendingCN111519907ASimple structureImprove reliabilityBuilding material handlingVehiclesEngineeringMachine

Owner:中物智建(武汉)科技有限公司

Bolting component for corrugated steel plate and plain steel plate and manufacturing process

ActiveCN103437429AVirtual thickness thickIncrease stiffnessSheet joiningBuilding material handlingEngineeringSteel plates

Owner:ZHEJIANG CTB WAVEFORM STEEL WEB

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap