Concrete hole wall scrabbling device

A technology of concrete and hole wall, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve the problems that cannot be well adapted to the site construction requirements, it is difficult to control the chisel strength, and the chisel density cannot be adjusted, etc., to achieve Reduce the amount of manual labor, facilitate the construction quality, and have the effect of ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

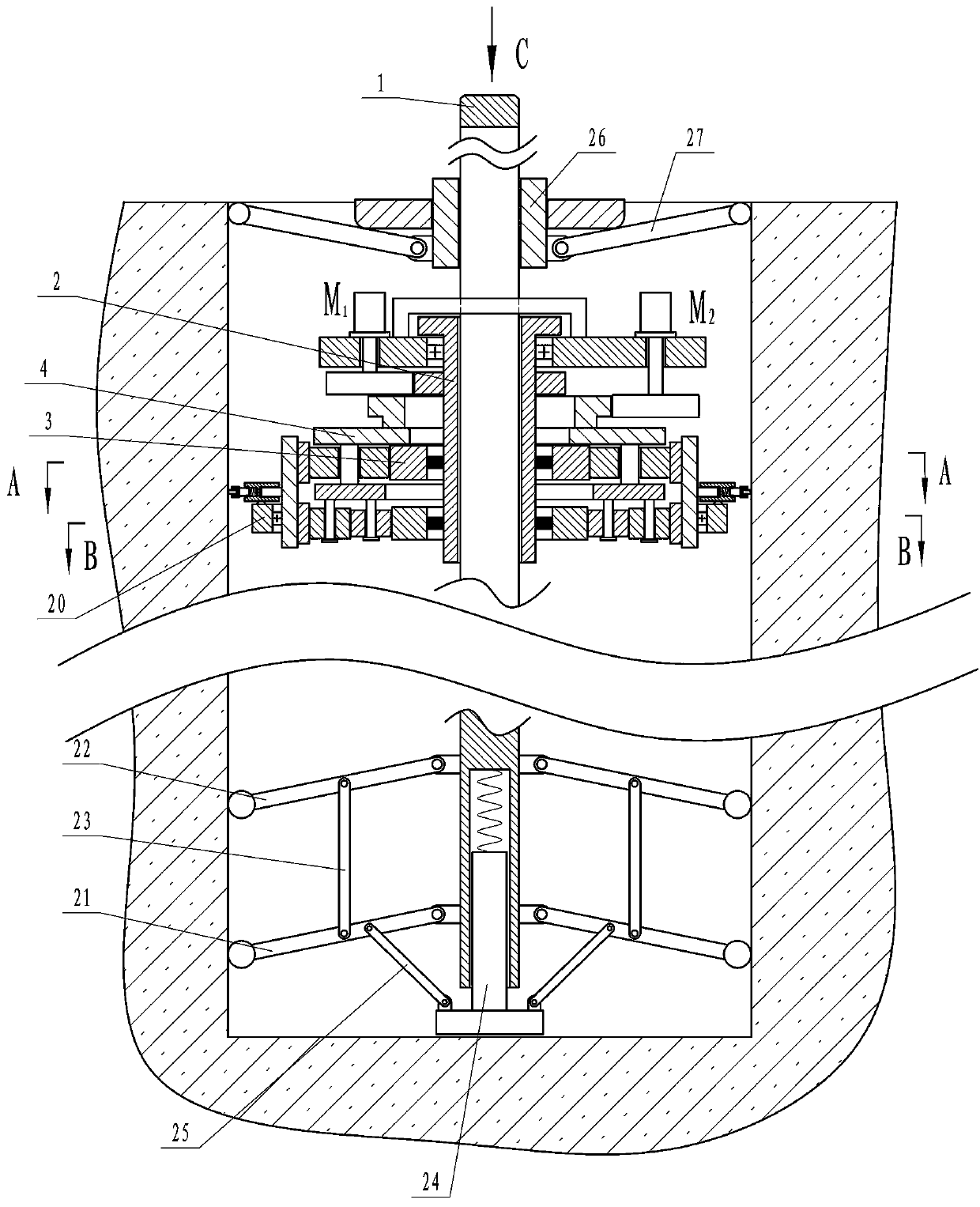

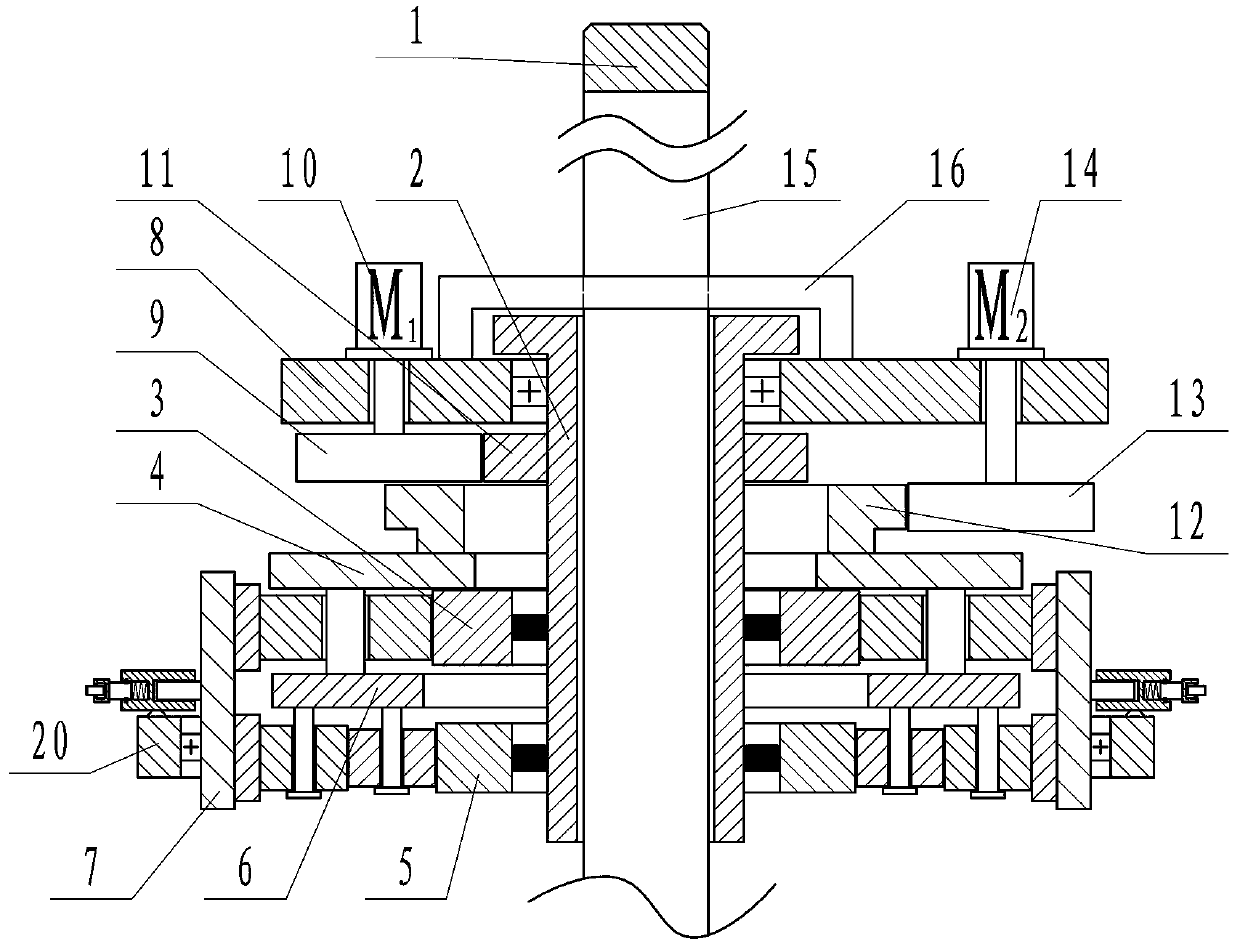

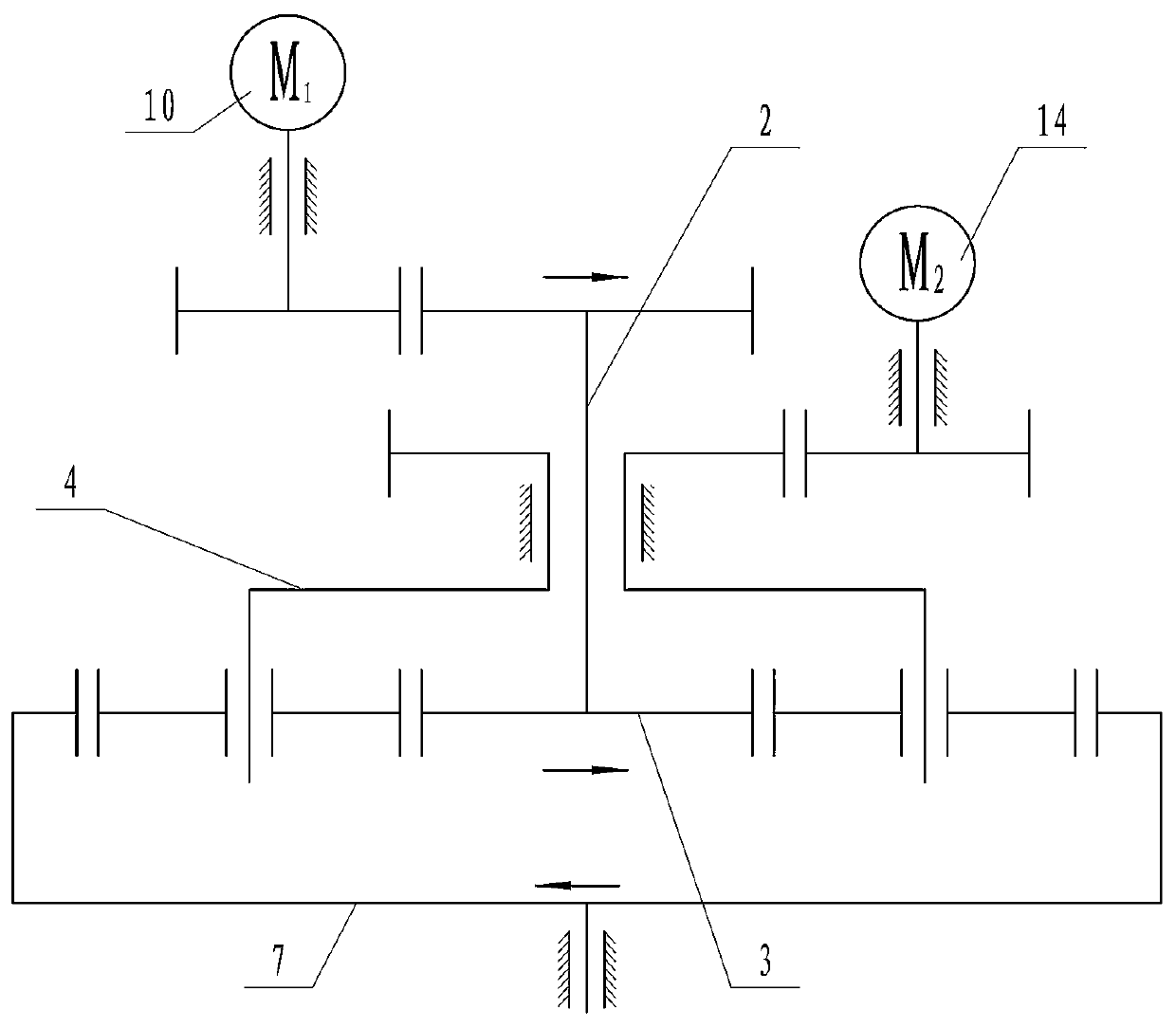

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] Depend on Figure 1 to Figure 10 Given, the present invention includes a vertical and non-rotatable screw 1, the screw 1 is placed in the concrete reserved hole and coaxial with it, the screw 1 is sleeved with a threaded tube 2 that can actively rotate, and the threaded tube 2 and the screw 1 Through screw connection, the lower end of the threaded pipe 2 is equipped with a first planetary gear train, wherein the first sun gear 3 in the first planetary gear train is set on the lower end of the threaded pipe 2, and the threaded pipe 2 can drive the first sun gear 3 only when it rotates forward Rotation, the first planetary carrier 4 in the first planetary gear train can actively rotate, the first sun gear 3 in the first planetary gear train is opposite to the rotation direction of the first ring gear; there is a second

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap