Novel rice screening machine

A screening machine, rice technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of inconvenient power cord winding and fixing, inconvenient rice isolation, inconvenient rice cleaning, etc., to achieve the effect of preventing rust damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

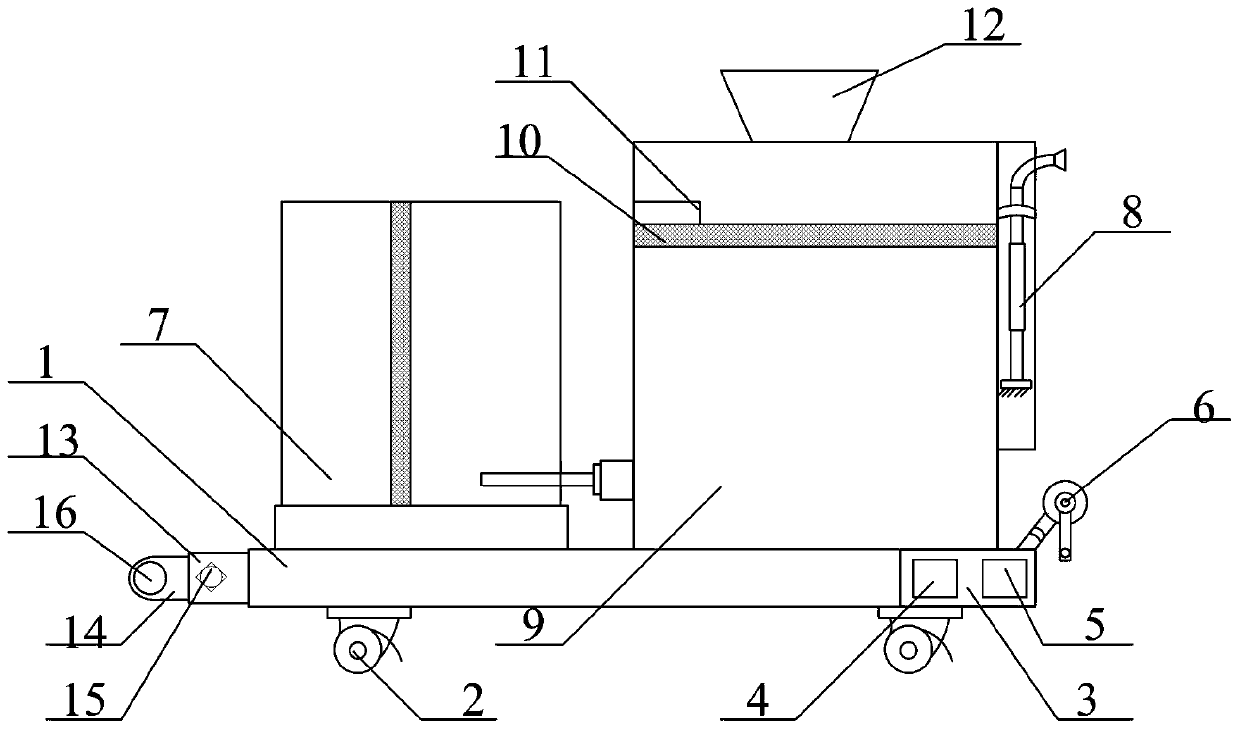

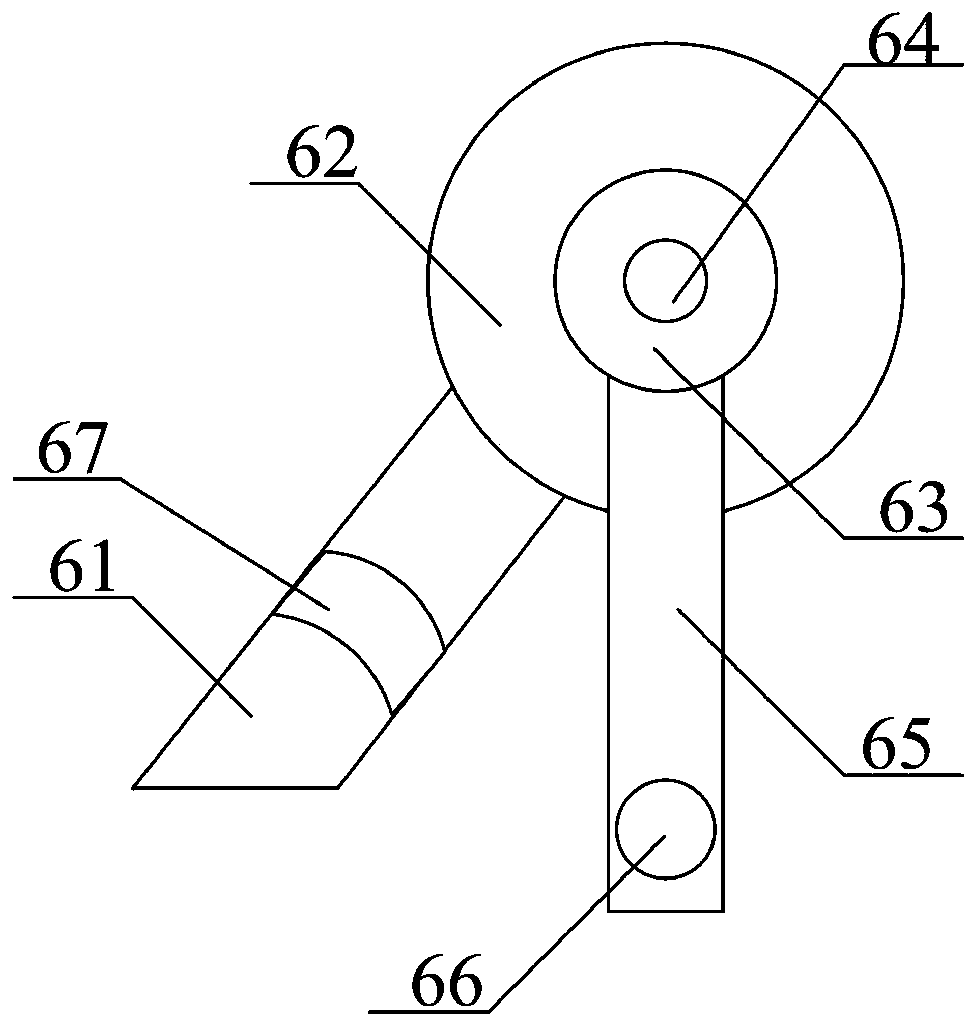

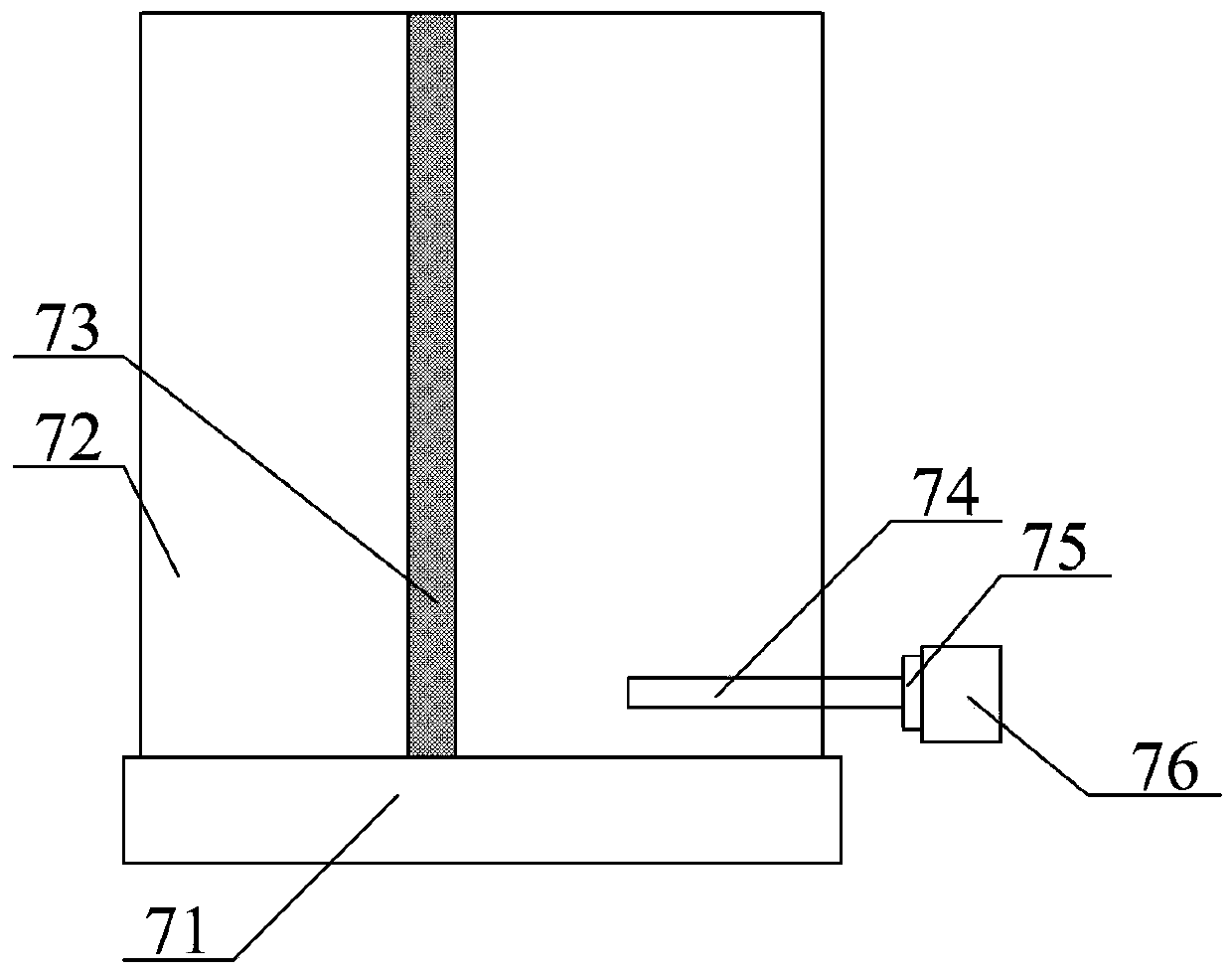

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a new type of rice screening machine includes a base plate 1, a moving wheel 2, a mounting piece 3, a vibration control switch 4, a material suction control switch 5, a fixed and protective power cord winding frame structure 6, and an isolation and protection rice isolation box structure 7 , cleaning protection rice cleaning rack structure 8, protection box 9, protection net 10, vibrating motor 11, feed hopper 12, installation pipe 13, plug-in rod 14, adjustment bolt 15 and protection hole 16, described moving wheel 2 respectively The bolts are connected to the four corners of the bottom of the bottom plate 1; the mounting piece 3 is bolted to the right side of the front surface of the bottom plate 1; the vibration control switch 4 and the suction control switch 5 are embedded in the mounting piece 3 in sequence from left to rig

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap