Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

135 results about "Rebar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rebar (short for reinforcing bar), known when massed as reinforcing steel or reinforcement steel, is a steel bar or mesh of steel wires used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has weak tensile strength. Rebar significantly increases the tensile strength of the structure. Rebar's surface is often deformed to promote a better bond with the concrete.

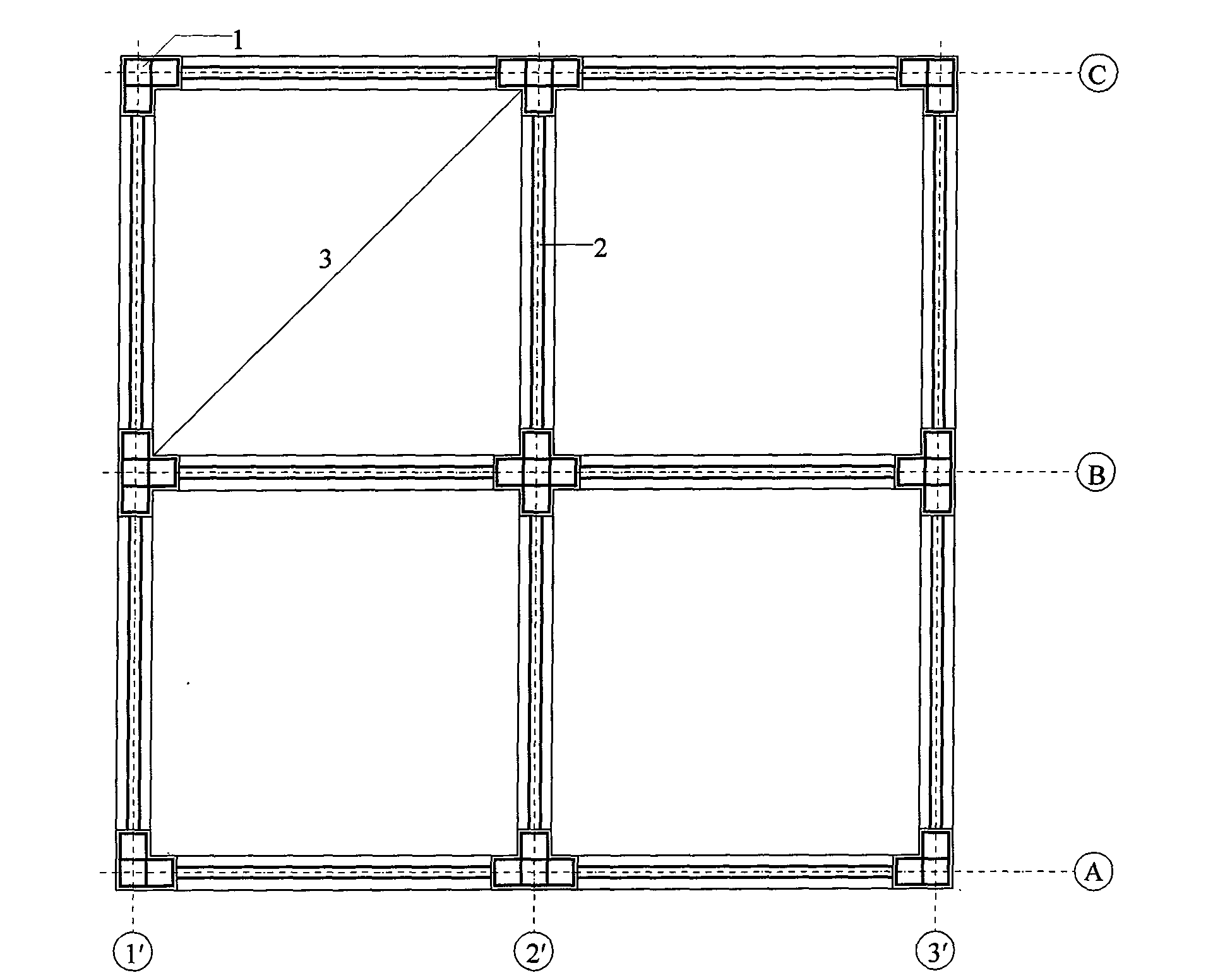

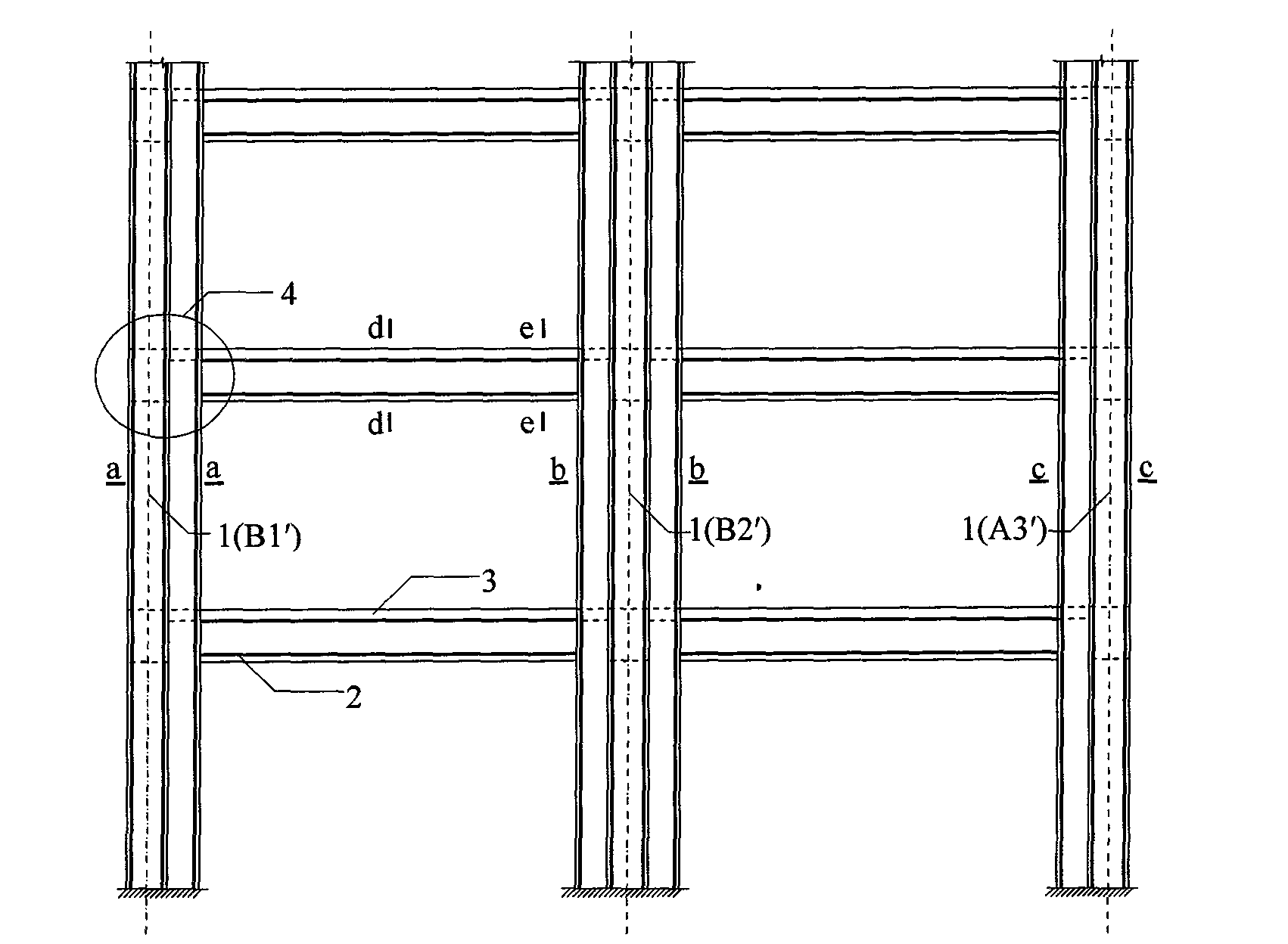

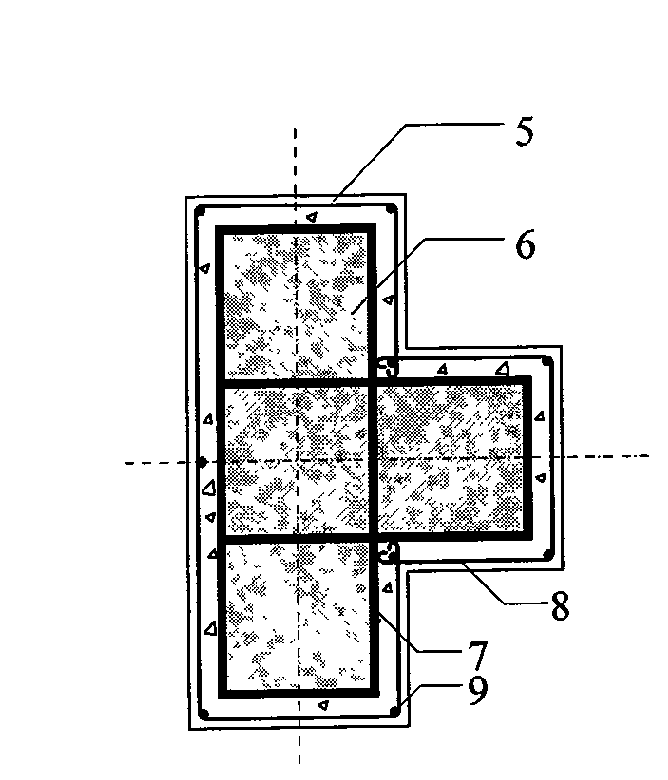

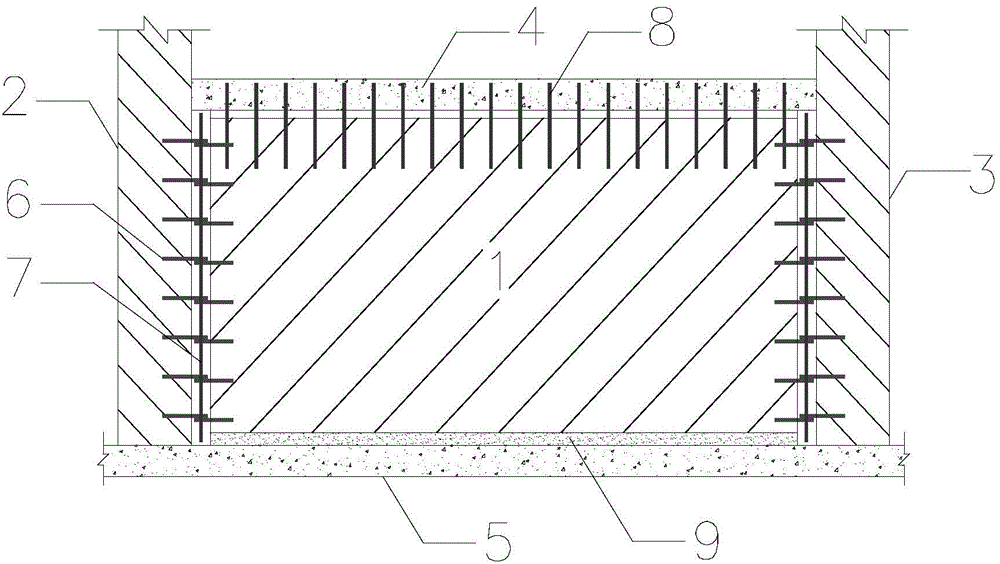

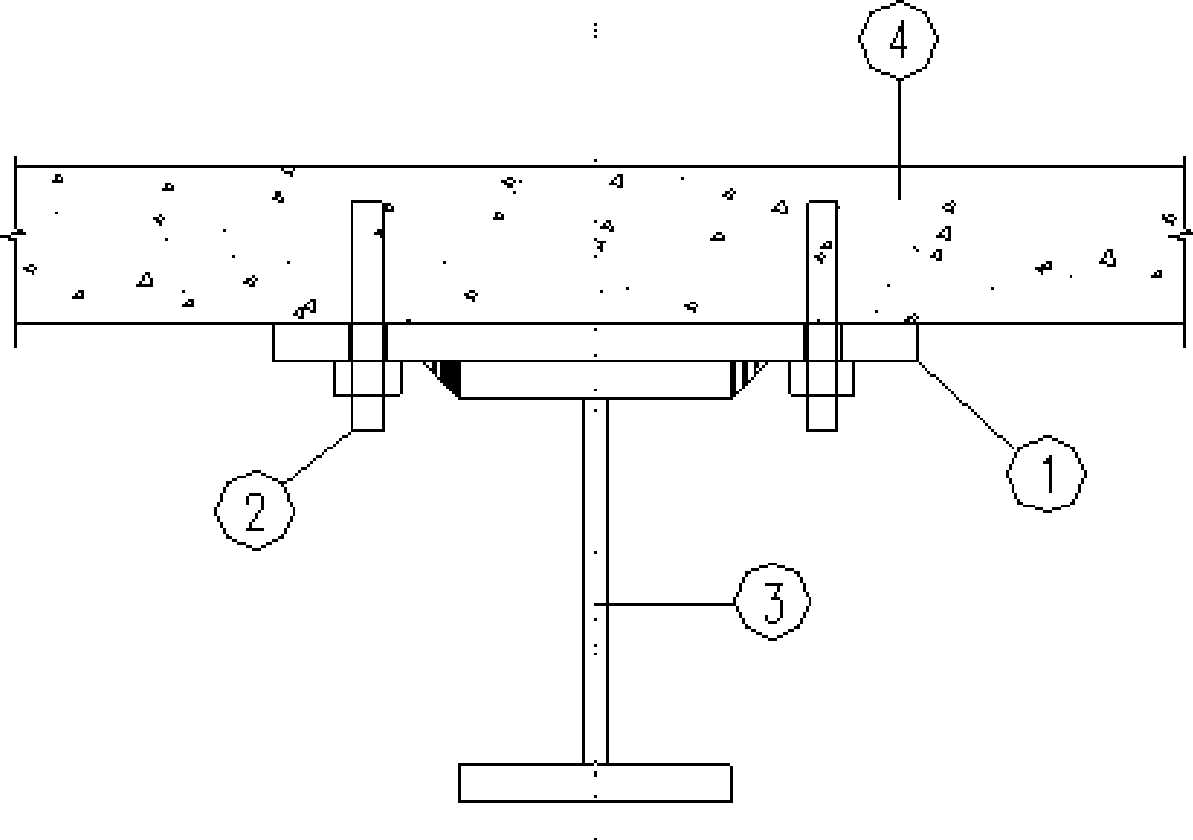

Mixed steel-concrete composite frame structure

ActiveCN101581115AEfficient use ofImprove structural fire resistanceBuilding constructionsFloor slabReinforced concrete

Owner:TSINGHUA UNIV

Production process of high-ductility cold-rolled ribbed steel bars

Owner:ANYANG HELI CHUANGKE METALLURGY NEW TECH RES & DEV

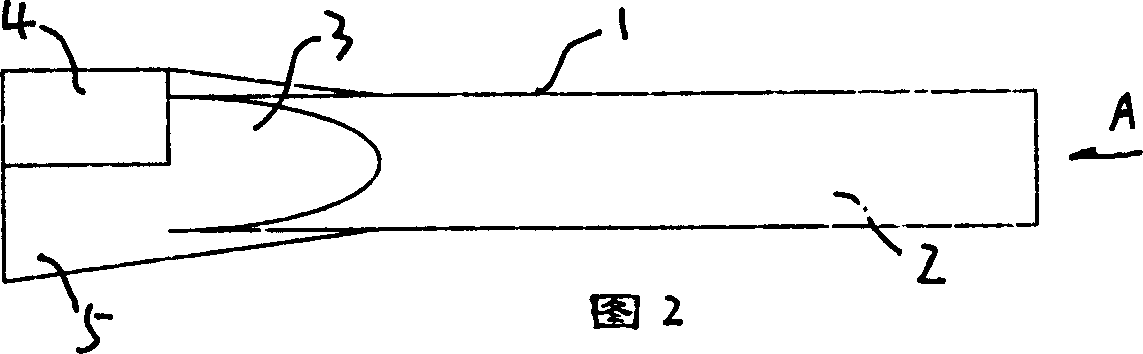

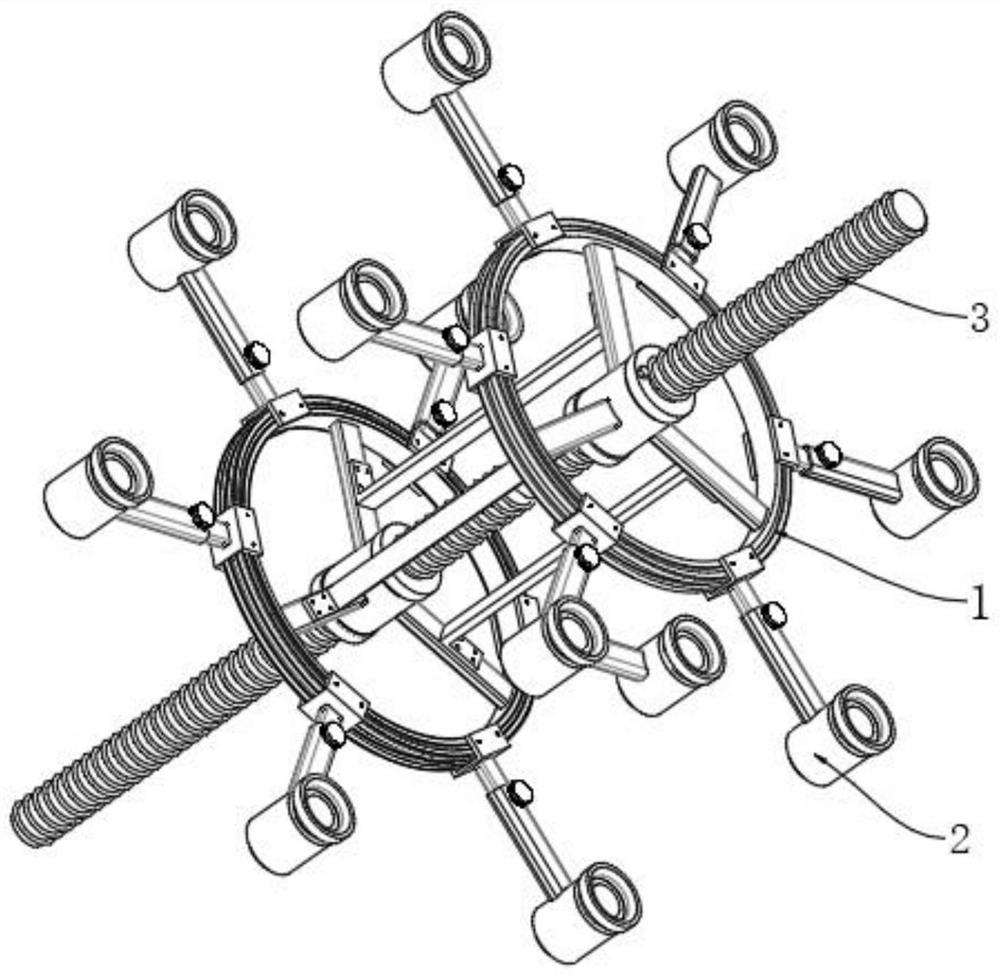

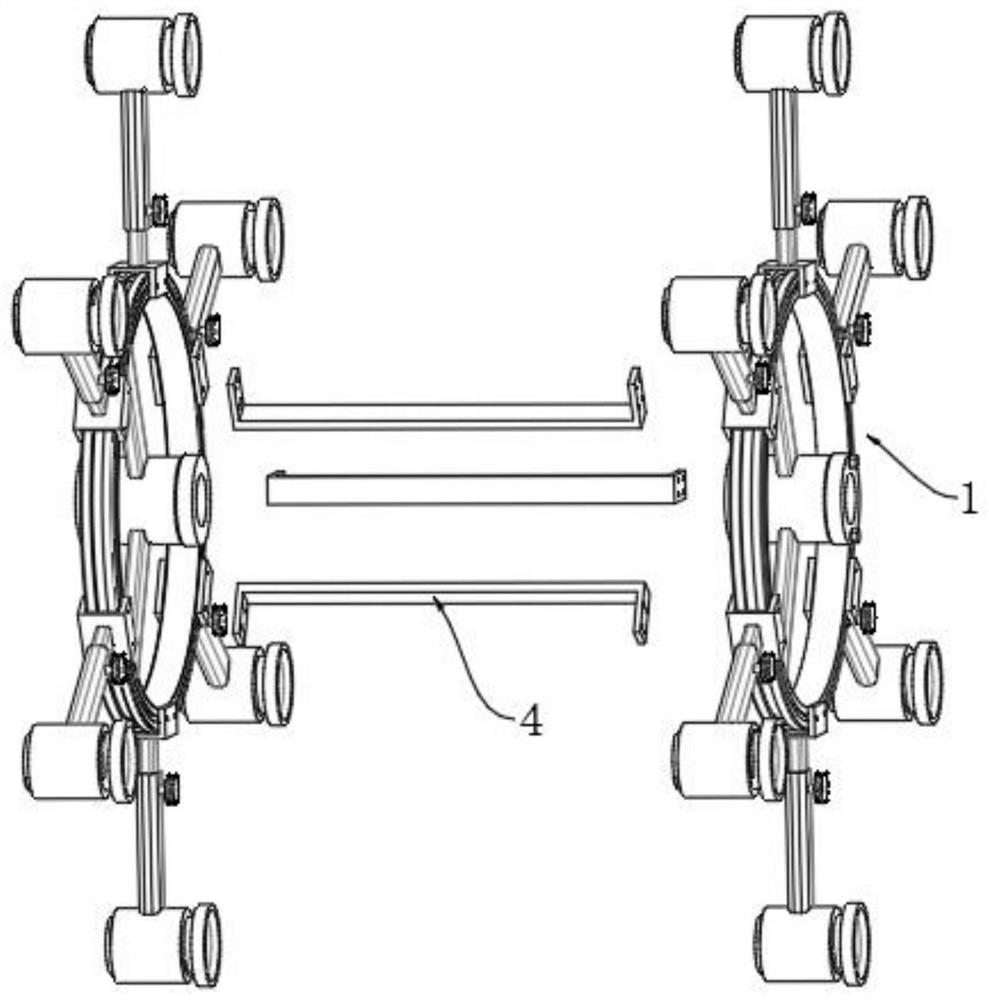

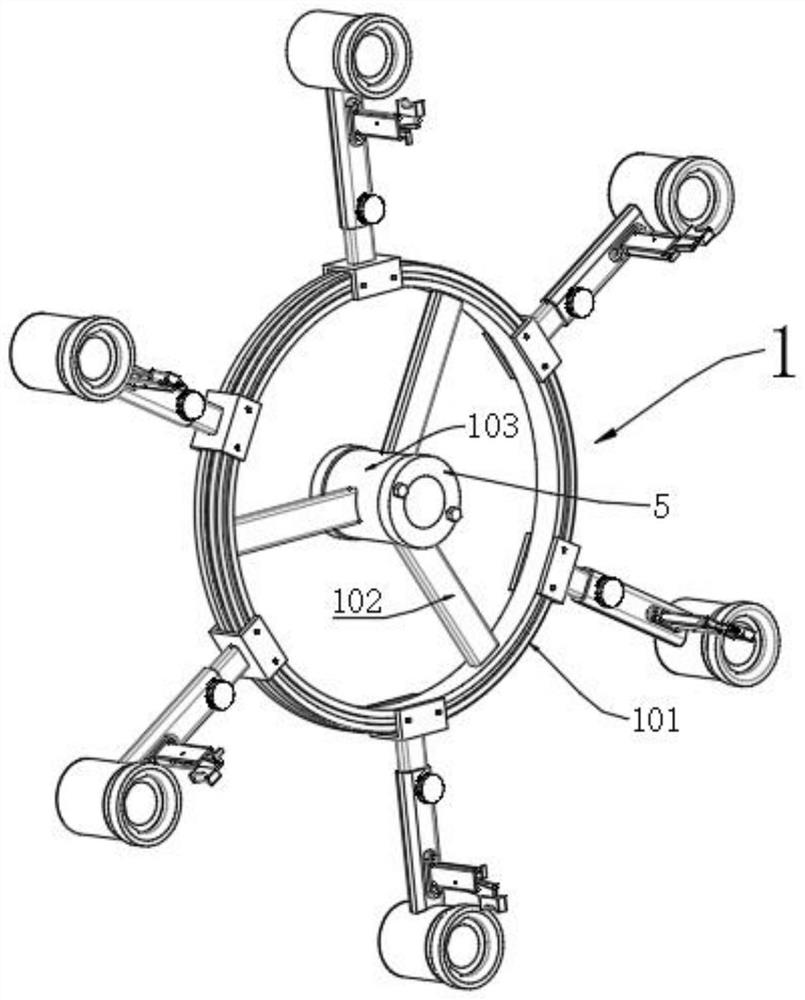

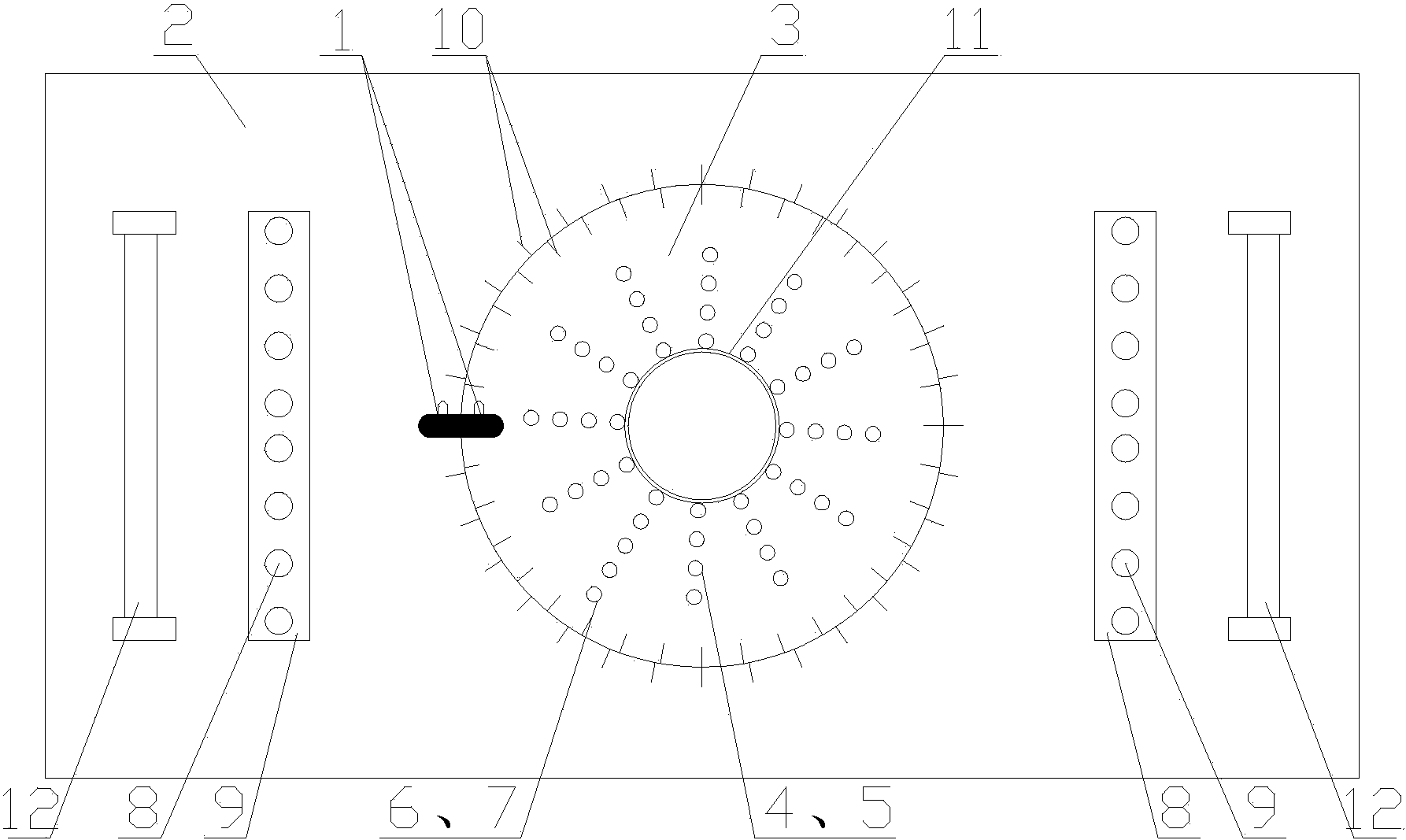

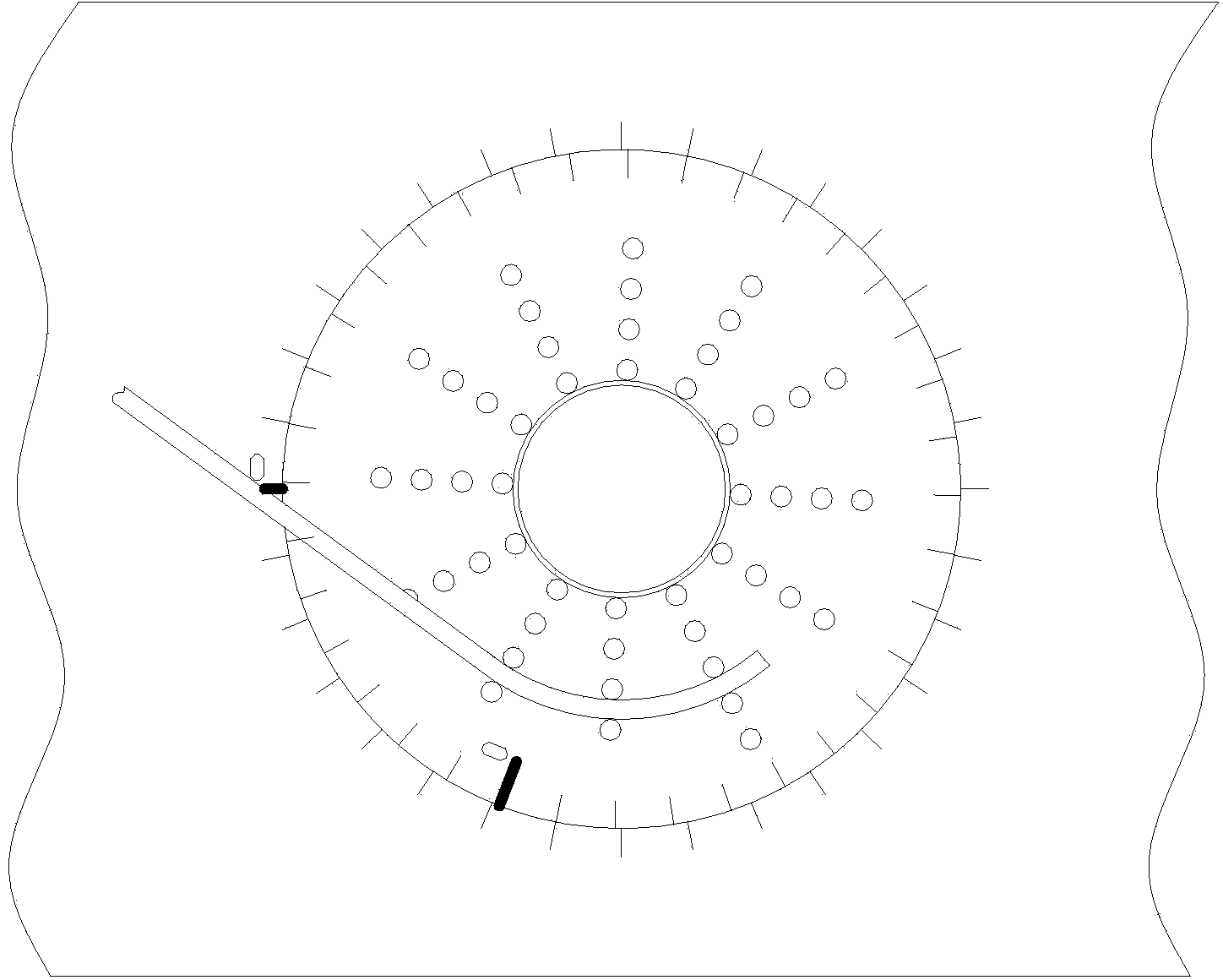

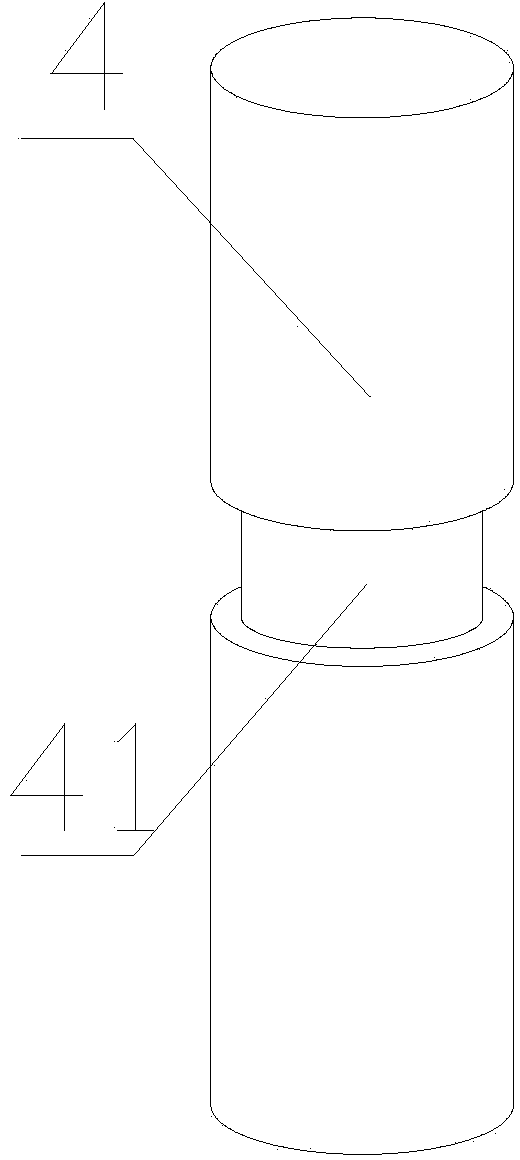

Openable skirt type steel reinforcement cage of reamed pile

The invention discloses an openable skirt type steel reinforcement cage of a reamed pile and belongs to piling building materials. According to the openable skirt type steel reinforcement cage, a reaming section of a pedestal pile has a horizontal expansion function, the reinforced concrete structure forms of the existing rotary expanding piles are changed, and the load capacity of the rotary expanding piles is increased; the steel reinforcement cage is unfolded at the bottom of a hole through a plurality of link mechanisms, the appearance of the unfolded steel reinforcement cage is basically similar to the contour of the reamed hole, the link mechanisms are simultaneously opened and are connected with an existing steel reinforcement cage through steel stranded wires, then, concrete is cast, the link mechanisms serve as steel reinforcement members, and thus, the strength of concrete members of rotary expanding pile bodies is enhanced.

Owner:XUZHOU LEHMAN MASCH TECH CO LTD

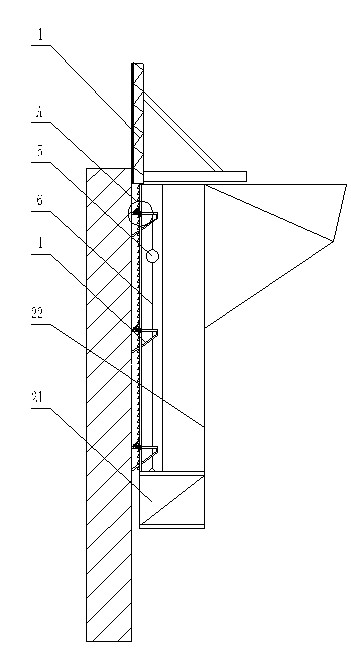

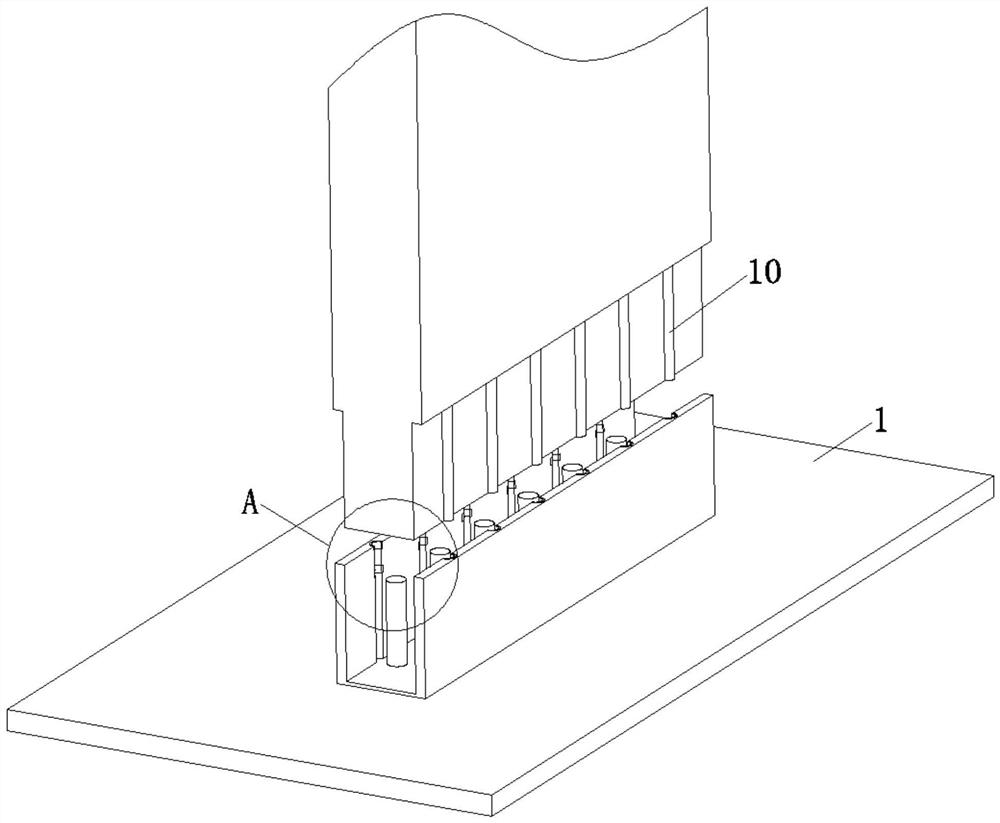

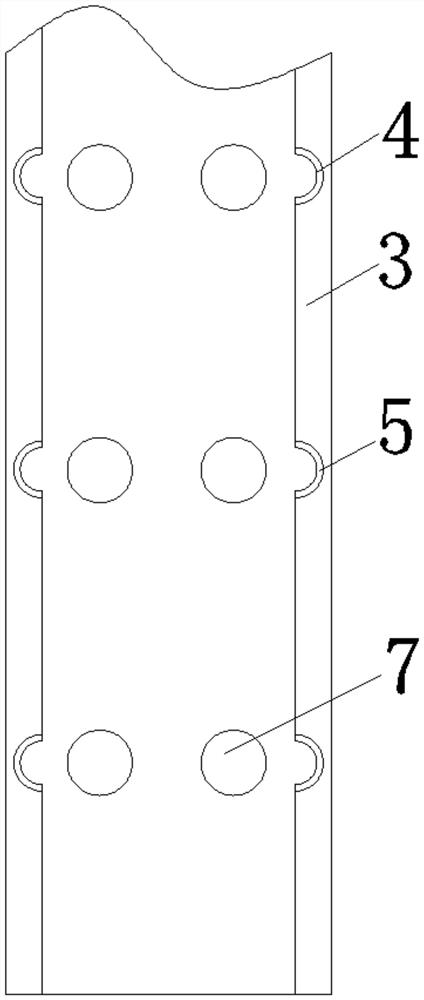

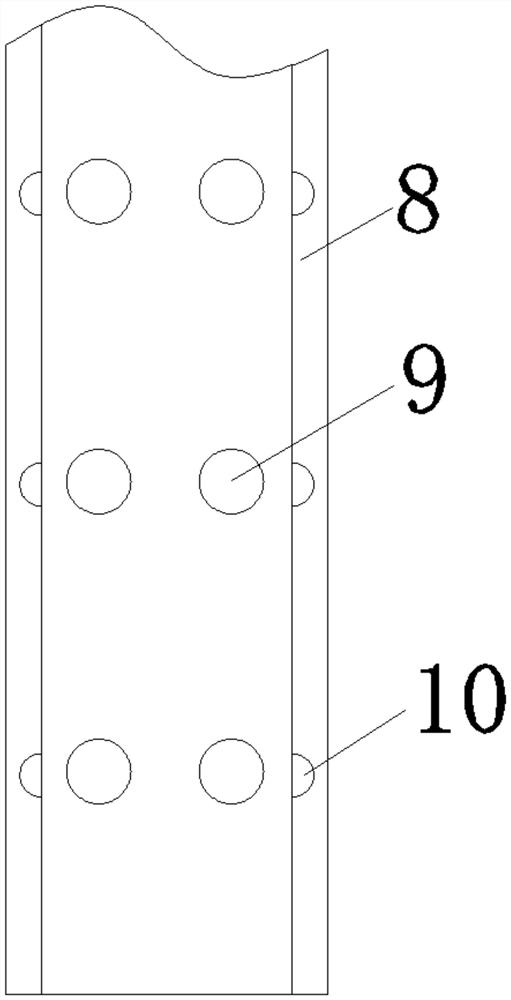

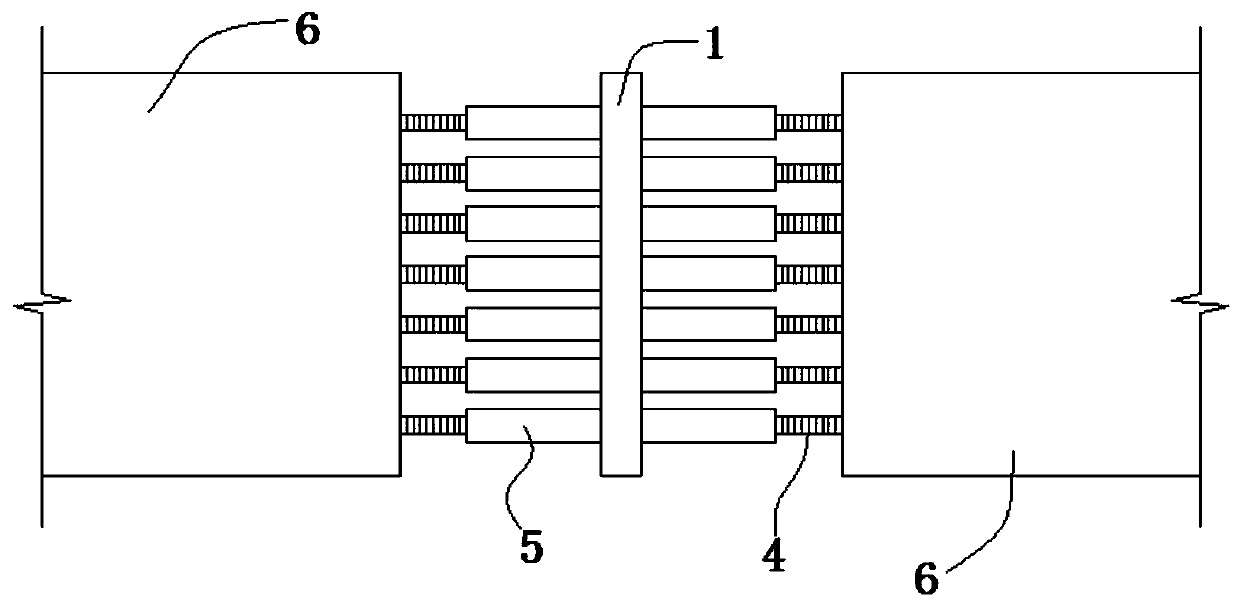

Hanging flexible connection of precast concrete infill wall

InactiveCN103556749AEnhanced horizontal and out-of-plane stiffnessPrevent out-of-plane collapseWallsShock proofingRebarEngineering

The invention discloses a hanging flexible connection of a precast concrete infill wall. The hanging flexible connection of the precast concrete infill wall comprises precast concrete infill wall, frame columns / shear walls on both sides of the infill wall, a top beam / plate on the top of the infill wall and a bottom beam / plate at the bottom of the infill wall, wherein the precast concrete infill wall is connected with the frame columns / shear walls on both sides of the infill wall through snapping flexible pull rings, the precast concrete infill wall is connected with the top beam / plate of the infill wall through reserved joint bar grouting or cast-in-place of concrete, and a base slurry layer is arranged between the precast concrete infill wall and the bottom beam / plate of the infill wall. Vertical reinforcing steel bars are inserted into the middle and rear portions of the snapping flexible pull rings. The precast concrete infill wall can be made of light walls with anti-seismic energy dissipation structure. The hanging flexible connection of the precast concrete infill wall solves the technical and theoretical problems of heavy workload of cast-in-place or masonry construction, complex collaboration with a main structure, vulnerability and lack of anti-seismic energy dissipation capacity in earthquake and the like of an existing connection of the infill wall.

Owner:NANJING UNIV OF TECH

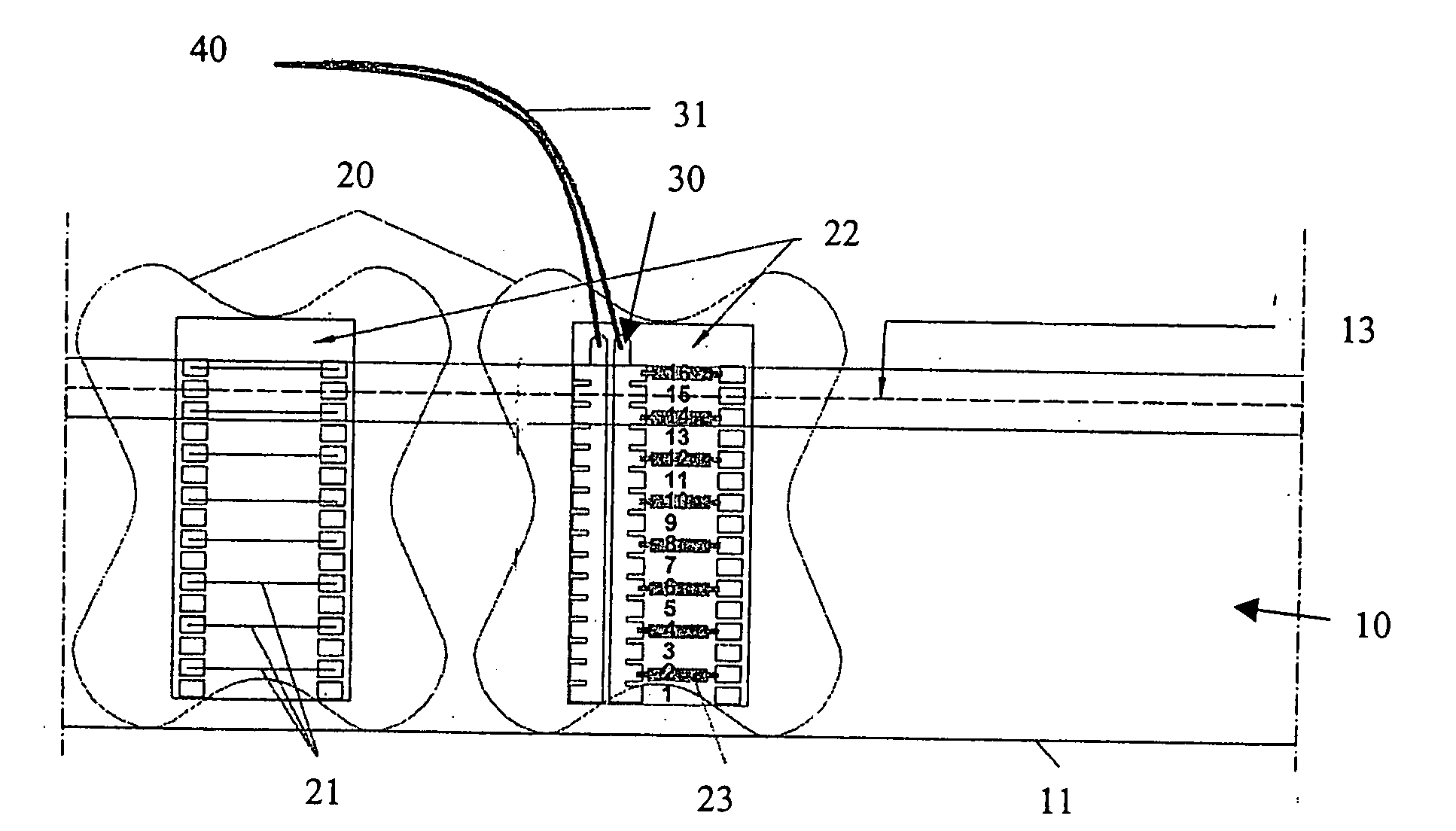

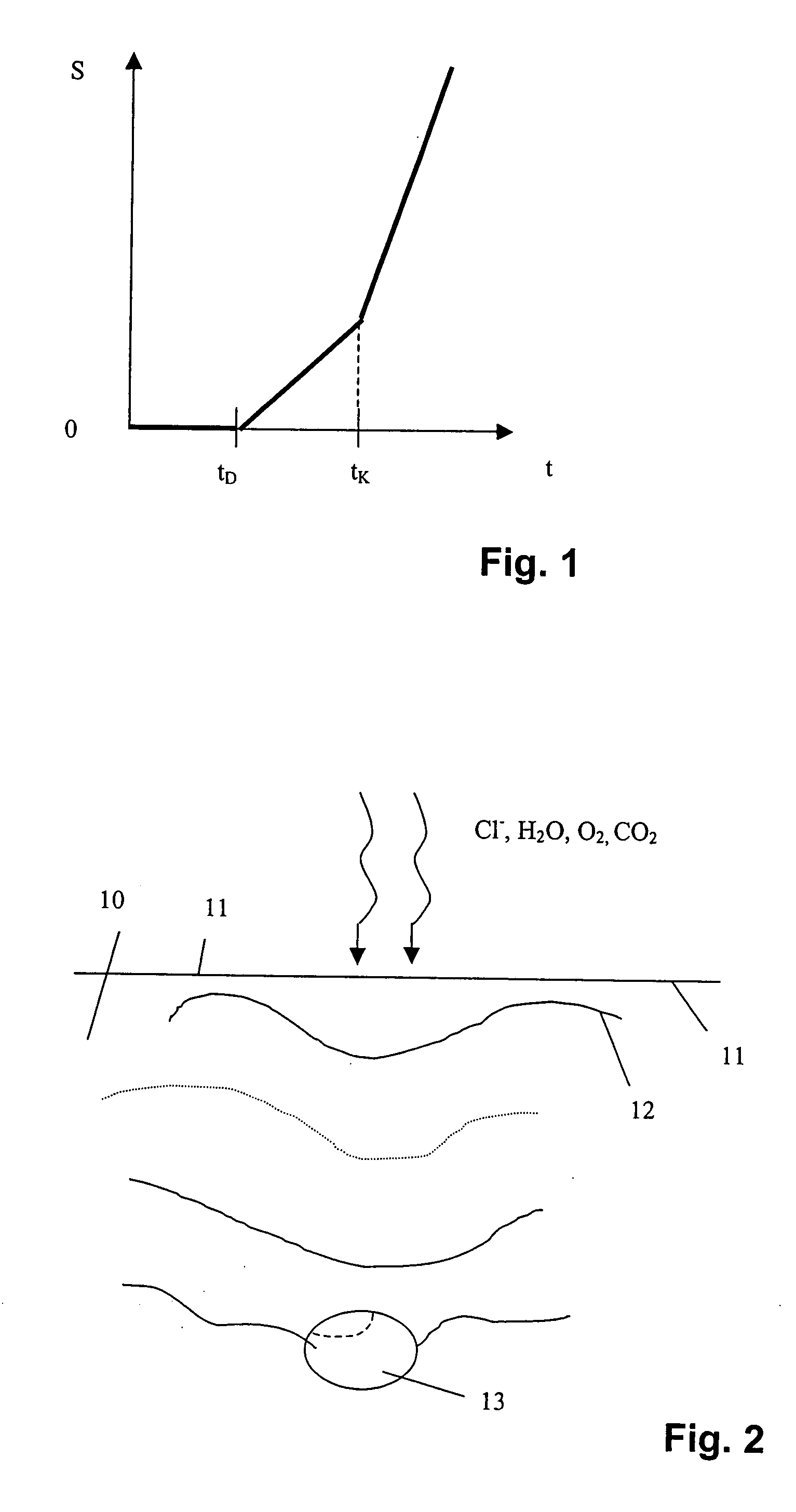

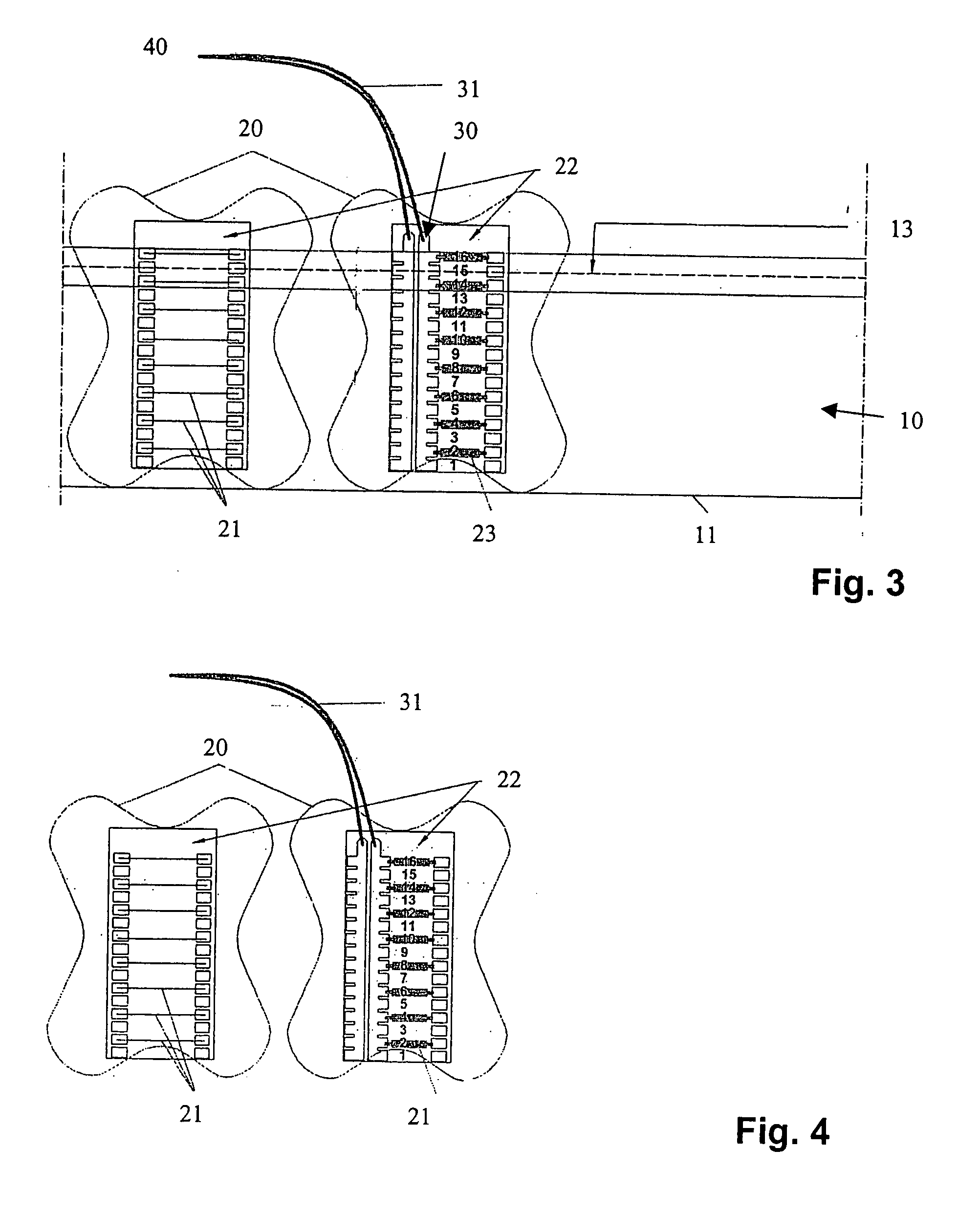

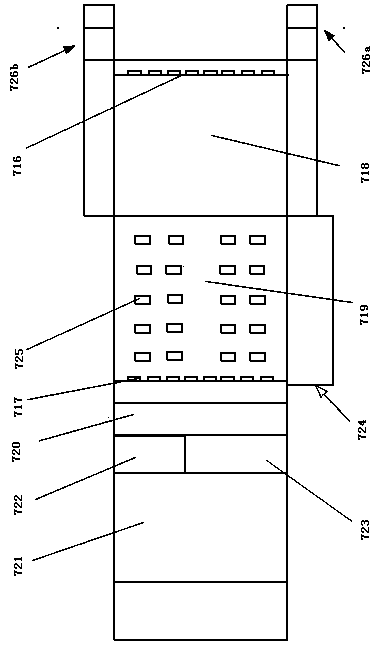

Device for detecting the state of steel-reinforced concrete construction parts

InactiveUS20080136425A1Small constructionPrecise positioningWeather/light/corrosion resistanceResistance/reactance/impedenceRebarReinforced concrete

Owner:BRAUNSCHWEIG UNIVERSITY OF TECHNOLOGY

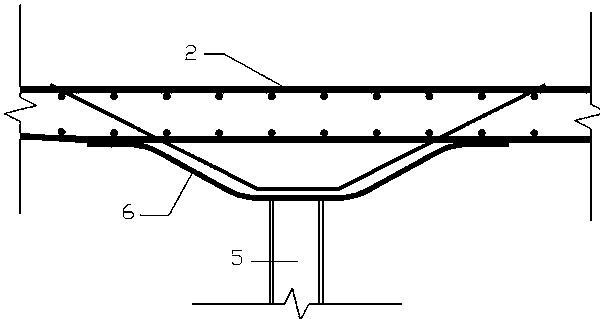

Steel-concrete combination deck plate and construction method thereof

ActiveCN106638302AReduce thicknessImprove binding structureBridge structural detailsBridge erection/assemblySheet steelRebar

The invention relates to a steel-concrete combination deck plate and a construction method thereof, wherein the steel-concrete combination deck plate comprises: bottom steel plates arranged on steel girders, wherein the bottom steel plates in the bearing regions of the steel girders are bent in shape, and the bottom steel plates are 8-10 mm in thickness; a plurality of shear plates vertically connected to the bottom steel plates; a concrete tier including reinforcement fabric penetrating through the shear plates, wherein the concrete tier is cast to the bottom steel plates, and the combination deck plate is 10-15 cm in thickness. The steel-concrete combination deck plate uses the bottom steel plates as stress-bearing parts as well as a formwork for a cast-in-place desk concrete tier, and steps of mounting and releasing concrete formwork are omitted; the shear plates serve as stiffeners for the bottom steel plates, good combination of the bottom steel plates with the concrete tier can be guaranteed, and cracking of the concrete tier is prevented; the deck thickness is controlled to 10-15 cm and is reduced, the weight is 25% and above lower than that of a composite beam deck system, dead load is reduced, crossing ability, structural strength and durability of the main structure are improved, construction input is reduced, and the efficiency of a construction method is high.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

Longitudinal short rib feeding and distributing device and method used during welding of steel bar meshes

ActiveCN110480221APreventing difficulties in the smooth supply of steel barsAccurate transferWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRebar

Owner:河南省鼎鼎实业有限公司

Civil-engineering construction monitoring system

InactiveCN106353015ARealize all-round real-time monitoringRealize reasonable choiceForce measurement by measuring optical property variationMaterial analysis by optical meansDynamic modelsRebar

The invention discloses a civil-engineering construction monitoring system, comprising optical fiber sensor group, environment acquisition module, man-machine operation module, central processing unit, prediction analysis module, expert evaluation module, establishment module of dynamics model, simulation analysis module and virtual sensor. Through the collection of such data as pressure, stress and humidity borne by the reinforcement structure of civil-engineering construction and the weather around and image data of civil-engineering construction, the system realizes all-dimensional real-time monitoring on the building,so as to obtain various evaluation results of the building with high accuracy of detection results; realizes the prediction and stimulation analysis for the follow-up situations of the building through the construction of building dynamic model, so as to found out the problems existing in the building on time, and transforms various treatment schemes into parameters in the established building dynamic model and realizes the reasonable selection for treatment scheme.

Owner:SHAANXI SCI TECH UNIV

Wind resistant concrete roof component and system and method for forming same

A roof system includes a roof panel formed of concrete and an architectural surface such as a corrugated surface. A first layer of reinforcing material is disposed along and spaced inwardly from a first surface of the roof panel, and an optional second layer of reinforcing material is disposed along and spaced inwardly from a second surface of the roof panel. The first layer of reinforcing material is spaced from the second layer of reinforcing material. The reinforcing material may be formed of fiber-reinforced polymer mesh, made with carbon fibers or glass fibers. FRP rebar may be used in conjunction with FRP mesh to provide added structural strength. The roof panel may include one or more elongated ribs having a thickness greater than adjacent portions of the roof panel. In other aspects, concrete structures with reinforcing material may be used for either roof panels or wall applications.

Owner:FLORIDA INTERNATIONAL UNIVERSITY

Piezomagnetic turbine loss type reinforced concrete strain sensor and piezomagnetic stain meter thereof

InactiveCN101806577AHigh sensitivityImprove stabilityForce measurement by measuring magnetic property varationFluid pressure measurement by electric/magnetic elementsObservational errorCantilevered beam

The invention discloses a piezomagnetic turbine loss type reinforced concrete strain sensor, and is characterized in that a piezomagnetic turbine loss effect is used as a sensing mechanism to manufacture a piezomagnetic turbine loss type reinforced concrete strain sensor and a piezomagnetic stain meter thereof for measuring surface strain, inner strain and steel bar strain. The sensor is designed with a mechanics model and a deformation structure of a combined cantilever beam or a cantilever curved beam with two elastic free ends. The invention uses a seamless connection technology of whole manufacturing and conical hole connection and a component separation signal processing method. Compared with the prior art, the invention has the characteristics of high sensitivity, good stability, small measuring error, strong reliability, simple structure, low cost and convenient use; and the invention has wide application prospect.

Owner:何思龙

Truss type steel-reinforced concrete framework side node with energy dissipation device

InactiveCN102628296AImprove energy consumptionImprove seismic performanceShock proofingViscous dampingConcrete beams

The invention relates to a truss type steel-reinforced concrete framework side node with an energy dissipation device. The steel skeleton in a beam is a truss type steel skeleton, which comprises vertical members, chord members and diagonal members. T-shaped profile steels are arranged on the upper and the lower parts of the beam to serve as the chord members, and are connected through angle irons, so that a truss type steel skeleton concrete beam member is formed. The vertical members and the chord members on the ends of the beam and in the core area of the node form a rectangular structure, the diagonal members are crossed, and are welded between the upper chord members and the lower chord members, the truss type steel skeleton extends into a column, and the length of the extending end is 0.9 times as the width of the section of the column in the direction. The ductility, equivalent viscous damping coefficient he and average energy dissipation coefficient Beta of the truss type steel-reinforced concrete framework side node with the energy dissipation device disclosed by the invention are remarkably increased in comparison with the ductility, equivalent viscous damping coefficient he and average energy dissipation coefficient Beta of reinforced concrete nodes. The truss type steel-reinforced concrete framework side node with the energy dissipation device has good structural seismic resistance and energy-dissipating capability.

Owner:GUANGXI UNIV

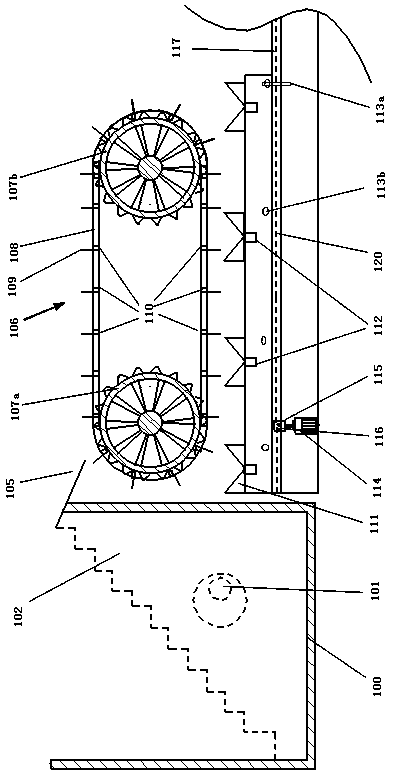

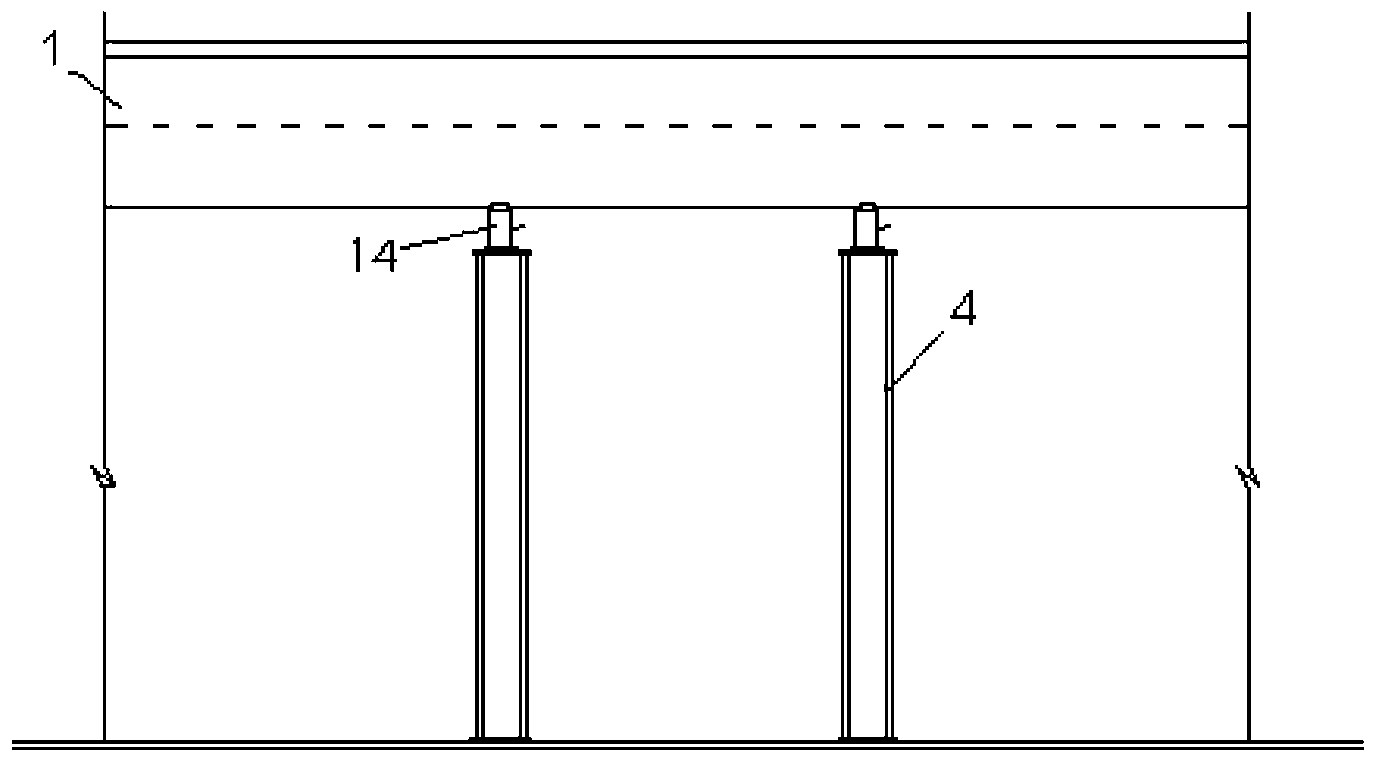

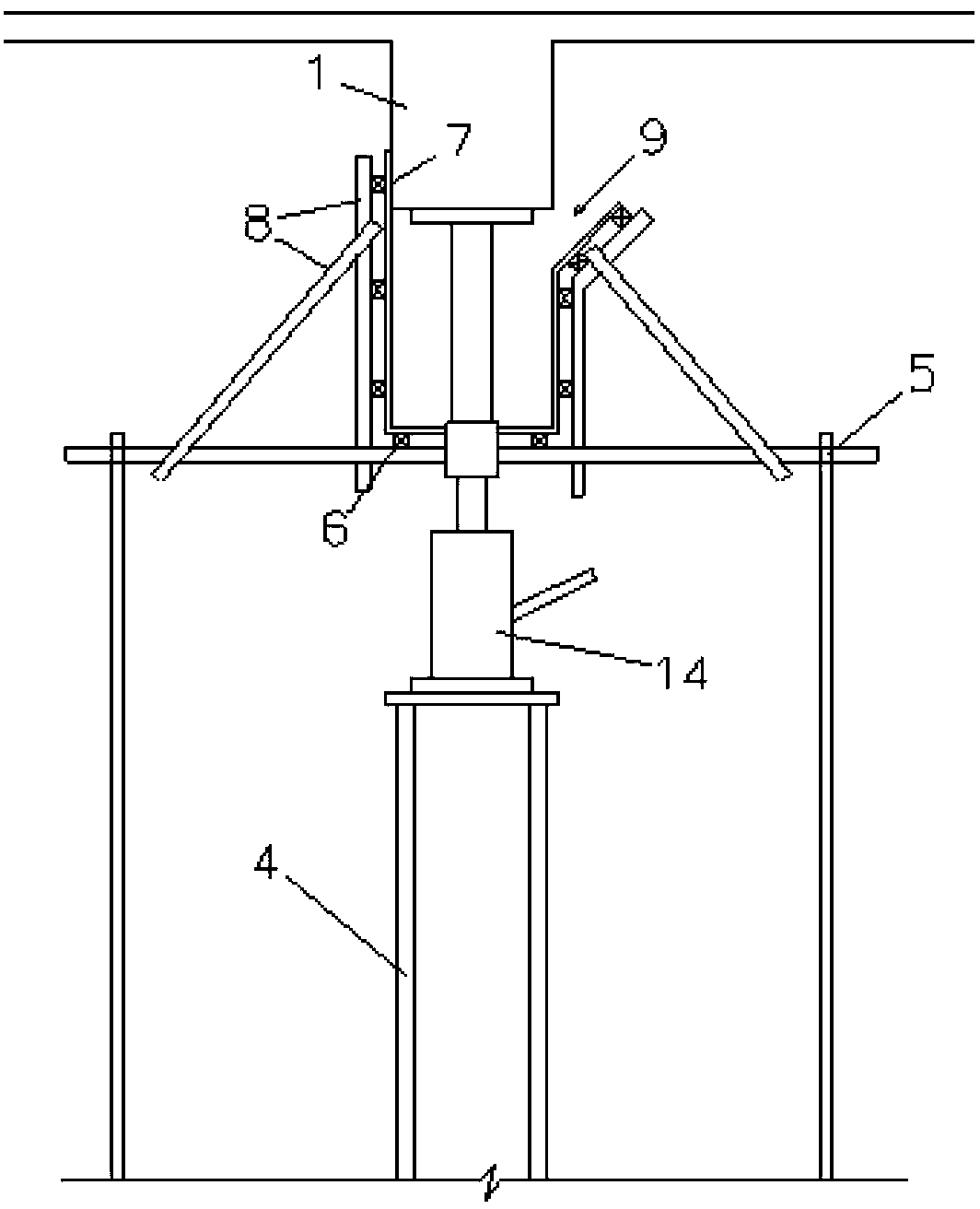

Self-stable suspension type unloading platform and construction process thereof

PendingCN107965147AShorten the installation and dismantling periodSimple installation and disassemblyBuilding material handlingSocial benefitsArchitectural engineering

The invention discloses a self-stable suspension type unloading platform and a construction process thereof. The unloading platform comprises main beams. Auxiliary beams are arranged between the mainbeams. Platform embossing steel plates are arranged among the main beams and the auxiliary beams. Vertical beams are arranged on the upper sides of the main beams. A rebar pull rod upper support is arranged among the vertical beams. A rebar pull rod lower support parallel to the rebar pull rod upper support is arranged at the bottom ends of the main beams. Rebar pull rods are arranged between therebar pull rod upper support and the rebar pull rod lower support. Upper floor system edge beams are arranged at the top ends of the vertical beams. A feed channel plate is arranged at the upper endsof lower floor system edge beams and the platform embossing steel plates. Compared with a traditional steel overhung unloading platform, embedded steel wire rope ring hanging, profile steel support ring anchoring, ending anchoring ring hole blocking and hanging ring rebar cutting treatment are not needed, and a passenger channel can be laid along a floor; construction installation and detachment operation is simple, safe and convenient, the installation and detaching construction period is shortened, embedded pieces and labor cost are greatly saved, the platform has remarkable economic and social benefits and meets the efficient, energy-saving and green construction requirements.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

Grout sleeve for connecting prefabricated member steel bars and construction method of grout sleeve

Owner:SHENYANG JIANZHU UNIVERSITY

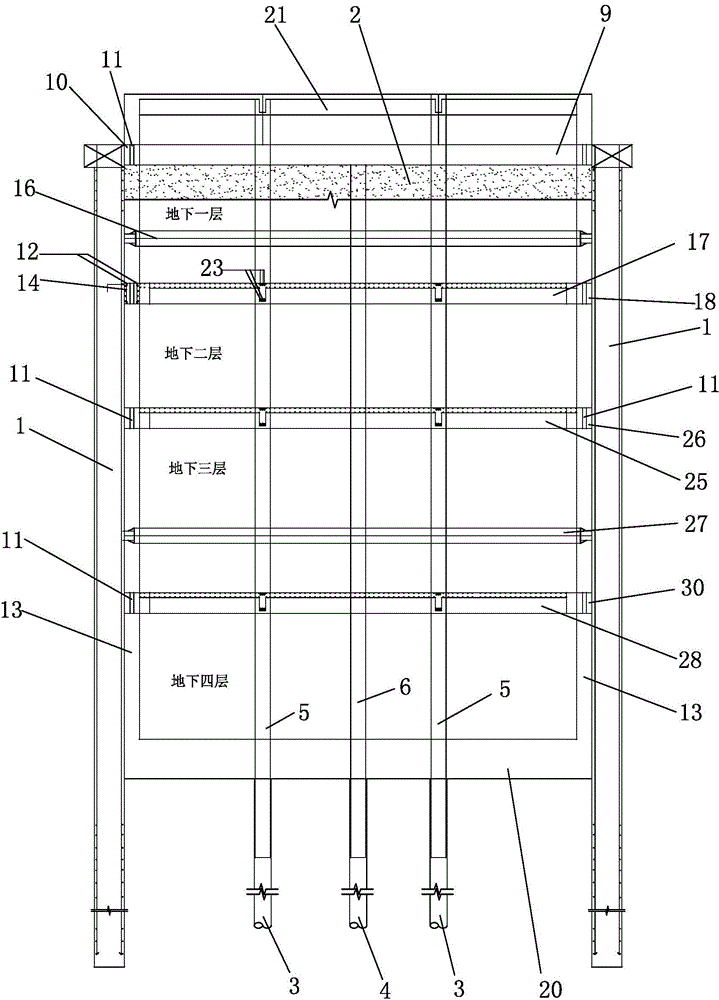

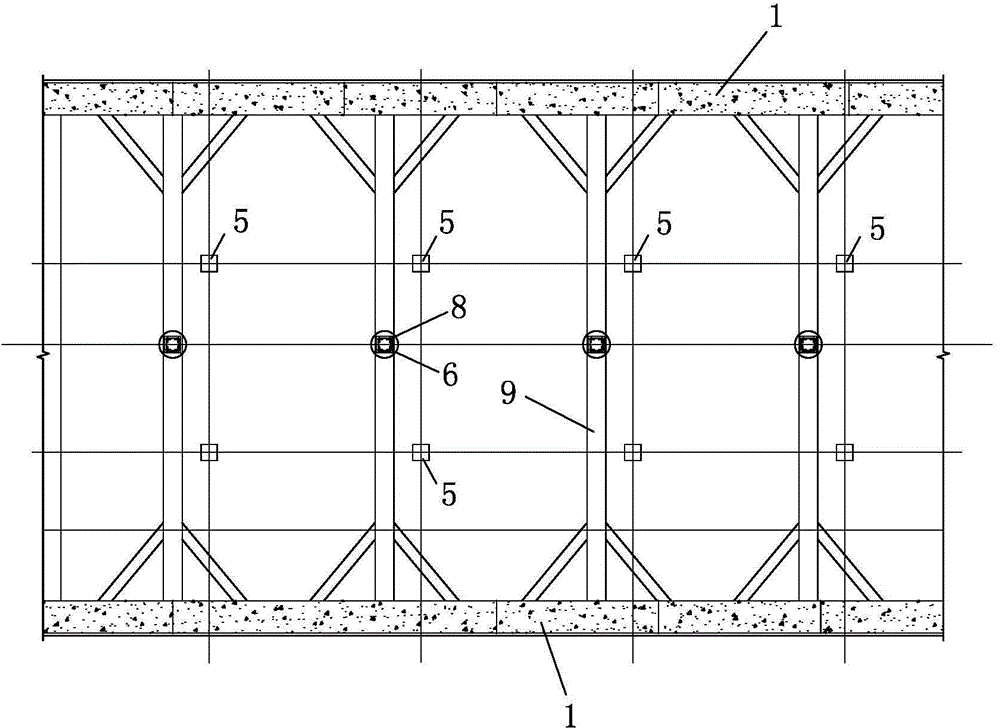

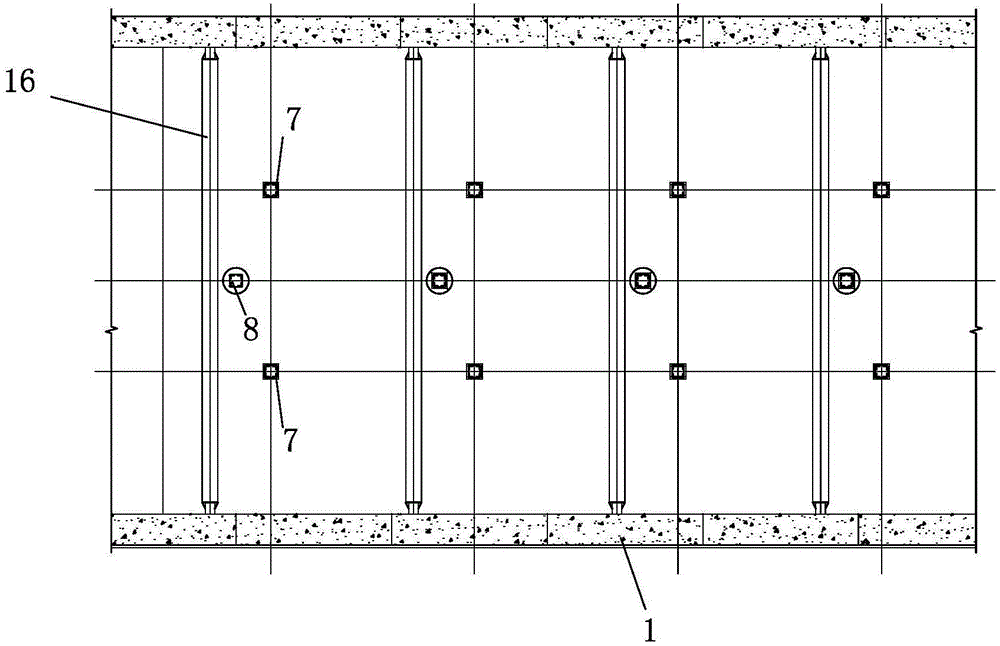

Construction method of structural system with structural floors as horizontal braces

InactiveCN104631466AControl and reduce distortionImprove securityExcavationsPurlinReinforced concrete

Owner:TIANSONG CONSTR GRP

Method for the combination of a post-increasing steel beam and a concrete slab

Owner:GUIYANG AL-MG DESIGN & RES INST

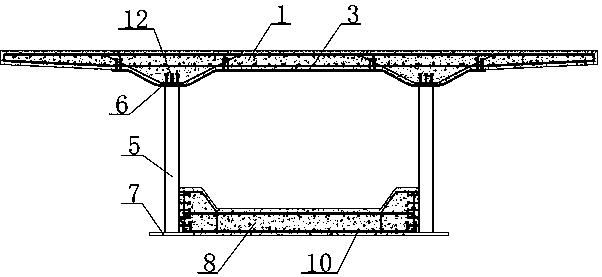

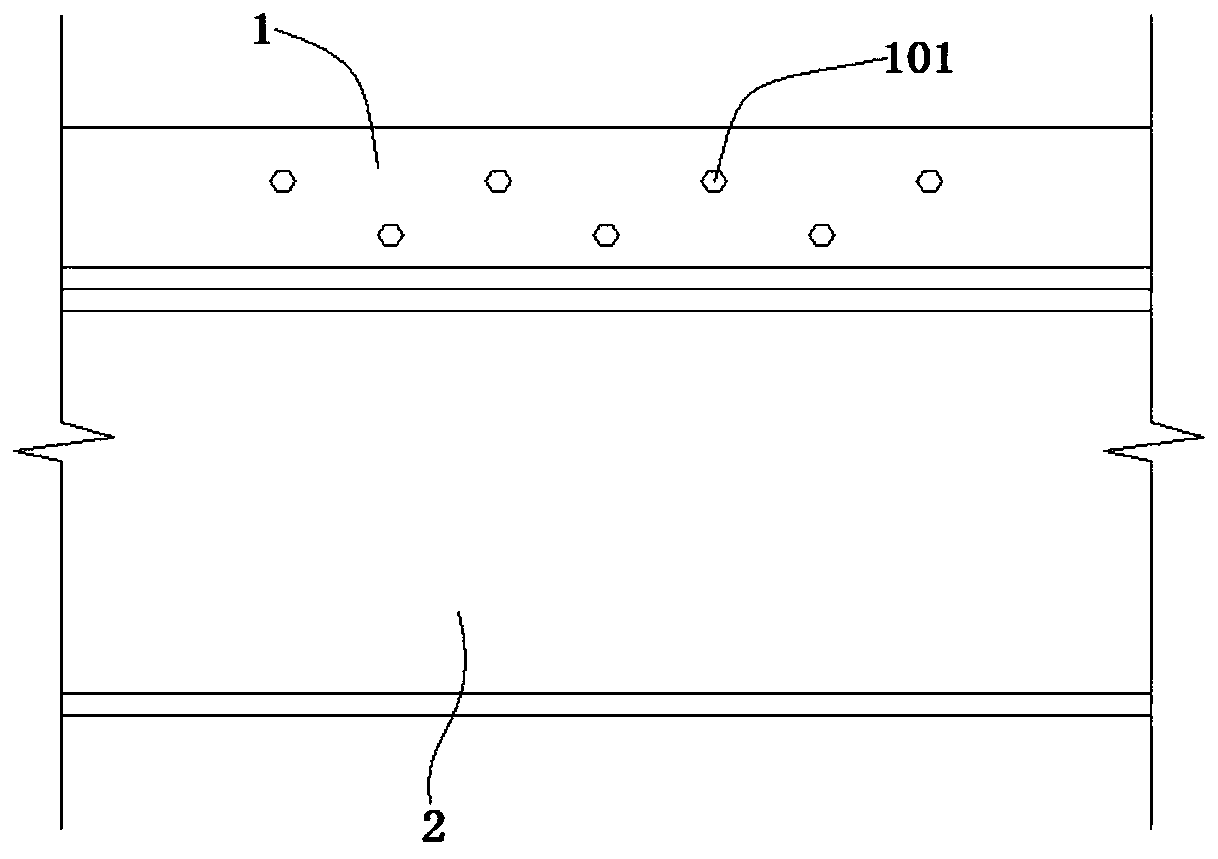

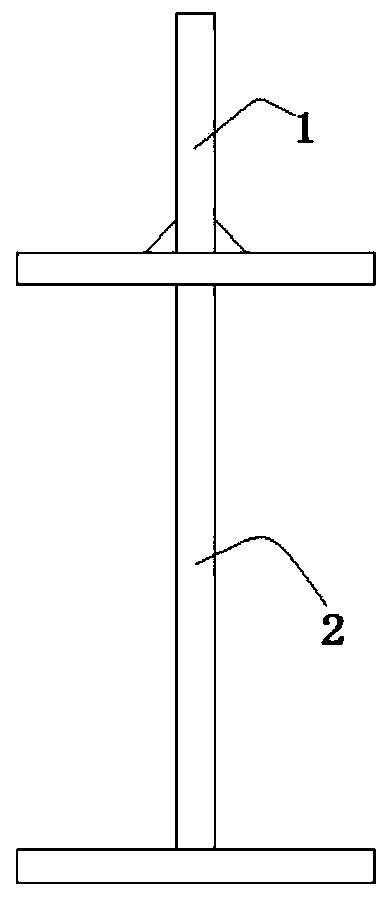

Hollow composite floor slab and construction method thereof

InactiveCN104612300AImprove construction efficiencyEasy to transportFloorsReinforced concreteCrack resistance

The invention discloses a hollow composite floor slab and a construction method of the hollow composite floor slab. The hollow composite floor slab comprises a prefabricated hollow bottom plate and an upper cast-in-place slab, continuous fully-closed preformed holes and semi-closed preformed holes are distributed in the prefabricated hollow bottom plate at intervals, or the continuous fully-closed preformed holes and plate ribs are distributed on the prefabricated hollow bottom plate at intervals, bottom plate rebars are distributed on the prefabricated hollow bottom plate at intervals in the longitudinal direction and the transverse direction, prestress rebars or prestress rebars and non-prestress rebars distributed at intervals are adopted as the bottom plate rebars, and the rebars penetrate through the semi-closed preformed holes or plate rib preformed holes. Concrete is poured on the prefabricated hollow bottom plate to form the upper cast-in-place slab, multiple sets of top rebars are distributed on the cast-in-place slab in the longitudinal and the transverse directions parallel to the bottom plate at intervals, and reinforced concrete is integrally poured on the bottom plate to form the hollow composite floor slab. Only the prefabricated bottom plate needs to be produced and transported, transportation and installation are convenient and fast, formworks are not needed, the crack resistance and the integrity are good, and the construction efficiency is high.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

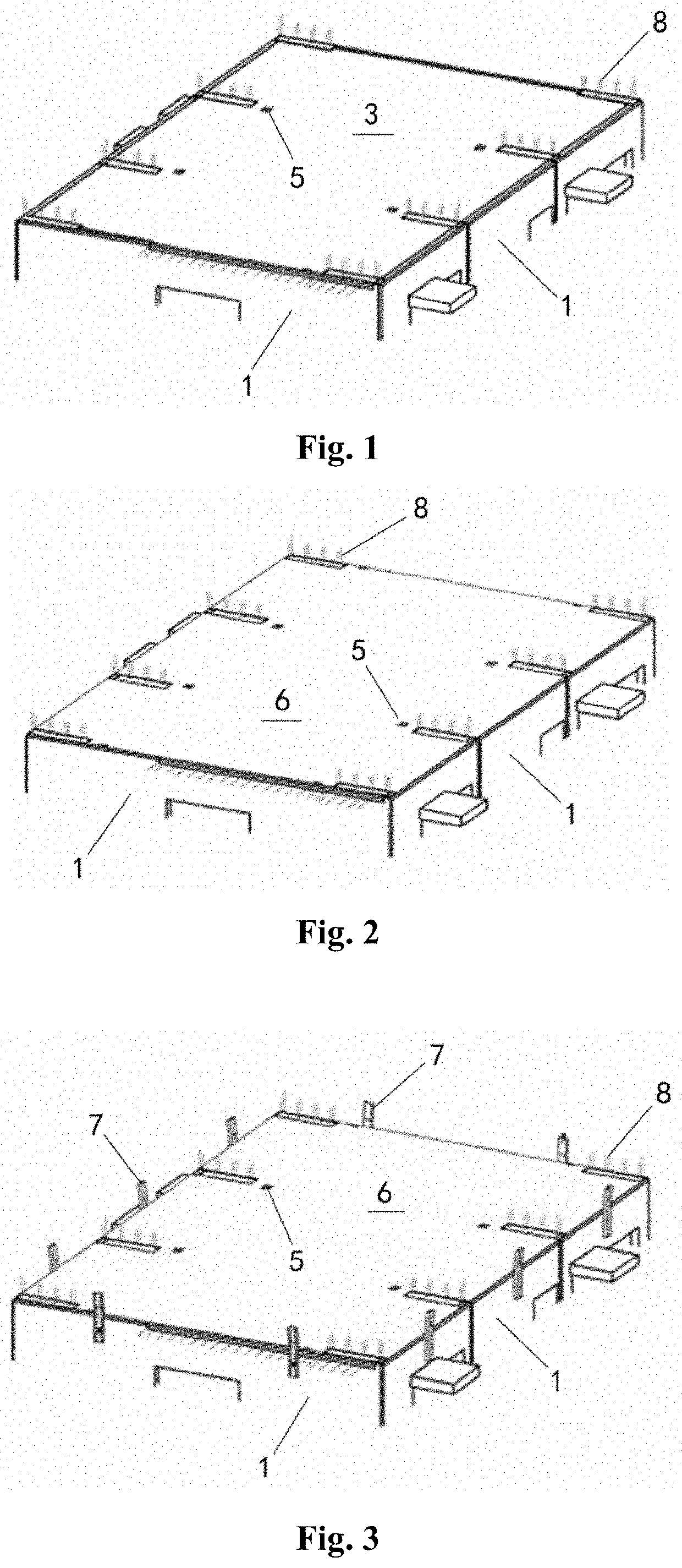

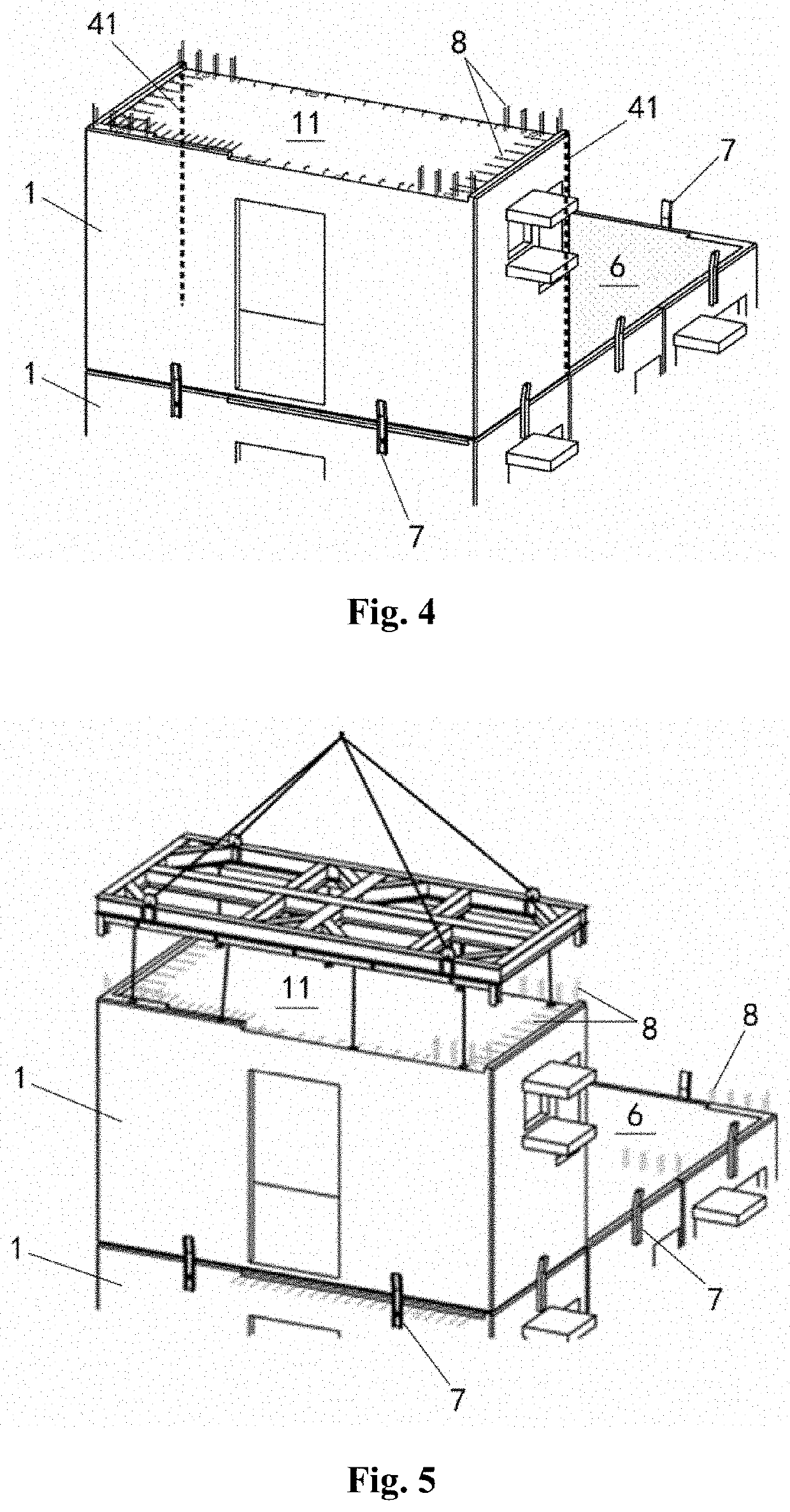

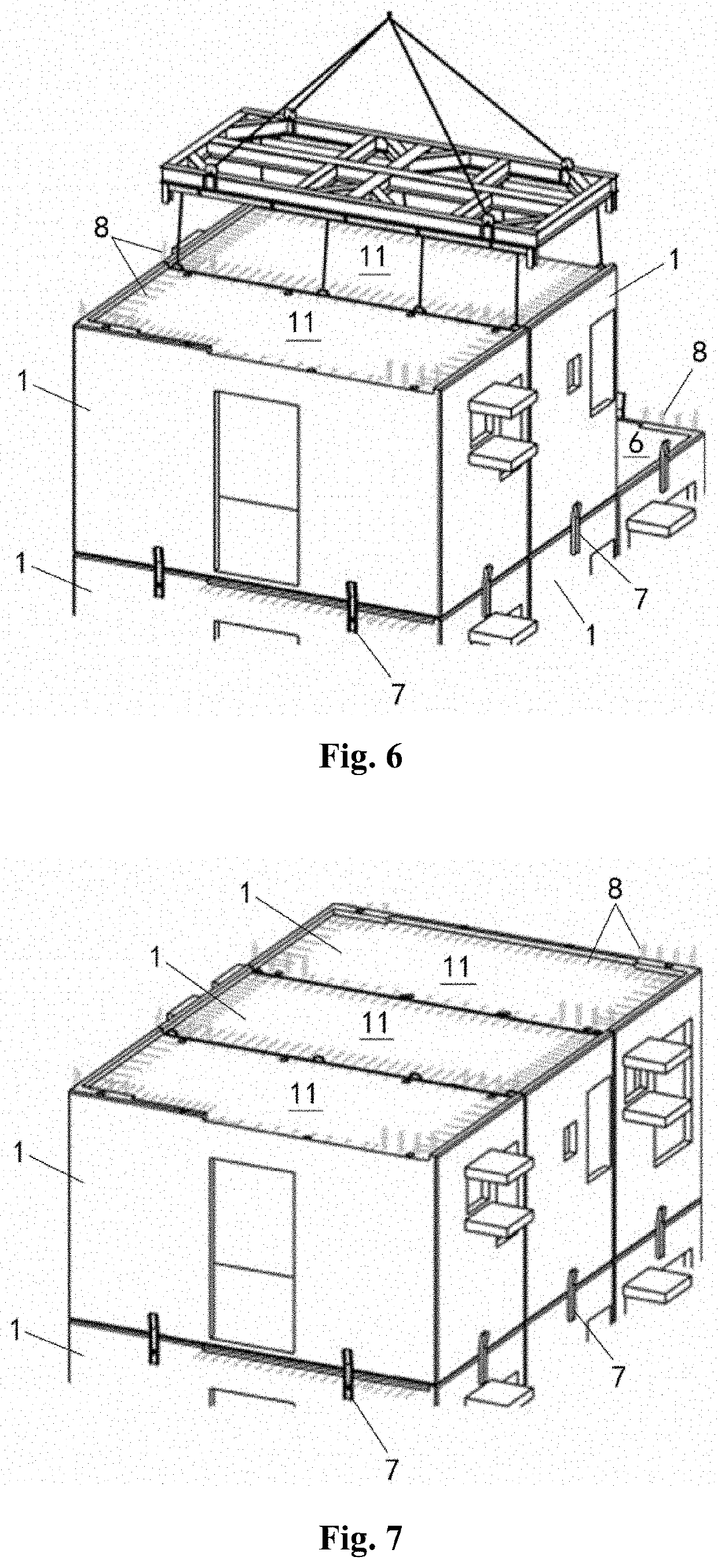

Modular Integrated Building and Construction Method Thereof

ActiveUS20200011076A1Construction is convenient and rapidShorten the overall cycleSpecial buildingBuilding constructionsArchitectural engineeringModularity

Owner:YAU LEE WAH CONCRETE PRECAST PROD SHENZHEN CO LTD

Creeping formwork platform

InactiveCN102155091AReduce weightImprove reliabilityForms/shuttering/falseworksRebarReinforced concrete

The invention relates to a cast-in-place reinforced concrete template, in particular to a creeping formwork platform. The platform comprises a template body, a creeping formwork, a guide rail and an anti-falling and anti-inclining supporting seat, wherein the template body is arranged at the upper part of the creeping formwork, the guide rail is vertically fixed on the creeping formwork, and the anti-falling and an-inclining supporting seat is arranged on a building and is matched with the guide rail; the creeping formwork platform is characterized in that an electric block is arranged below the anti-falling and anti-inclining supporting seat and is connected with the bottom of the creeping frame through a chain; the framework body of the creeping formwork platform adopting the technical scheme is light and has high reliability; moreover, the cost is relatively lower.

Owner:NORNOVA GRP

Reinforced concrete windowsill coping adverse construction method

The invention relates to a reinforced concrete windowsill coping adverse construction method comprising the following steps: (1) making pre-cast reinforced concrete building blocks; (2) removing a form; (3) maintaining the pre-cast reinforced concrete building blocks; (4) laying a masonry; (5) burying the pre-cast reinforced concrete building blocks; (6) welding windowsill coping reinforcing steel bars with reinforcing steel bars reserved for the reinforced concrete building blocks; (7) making a template; and (8) processing the joint of the template and the wall. The reinforced concrete windowsill coping adverse construction method can ensure that the reinforced concrete windowsill coping construction is not restricted by the length of the windowsill coping, guarantee the compact construction joint and greatly improve the windowsill coping construction progress and the windowsill coping construction quality. In addition, the reinforced concrete windowsill coping adverse construction method is simple and is convenient to operate. Moreover, the reinforced concrete windowsill coping adverse construction method uses the filed concrete construction residual material to make the pre-cast reinforced concrete building blocks, thereby causing no pollution to the environment and saving the energy and the windowsill coping construction cost.

Owner:WENZHOU ZHONGCHENG CONSTR GRP CO LTD

Device and method for decreasing columns and reinforcing girders of reinforced concrete members

ActiveCN103452328AImprove efficiencyLow costBuilding repairsReinforced concrete columnSocial benefits

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Steel plate externally-rived stengthening method for reinforced concrete structure and its special-purpose rivet

InactiveCN1460763AImprove bearing capacityImprove reinforcementBuilding repairsBridge erection/assemblyReinforced concreteSheet steel

Owner:郑州长建工程技术开发有限公司

Web-covering-baseplate trapezoid (wave-shaped) steel plate combined box girder and construction method thereof

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST +1

Building embedded part device for shaping, positioning and adjusting

ActiveCN112709338AGuaranteed limit effectQuick alignment insertionBuilding reinforcementsBuilding material handlingArchitectural engineeringRebar

Owner:安徽华盛建设集团有限公司

Fabricated wallboard with positioning device and mounting method thereof

Owner:广州市创搏装饰工程有限公司

Assembled prefabricated floor connecting system and construction method thereof

PendingCN110761462AEasy to operateFast constructionFloorsBuilding reinforcementsFloor slabArchitectural engineering

Owner:CHONGQING UNIV

Laying head front nip and feed technique for producing wire roll with high speed under low temperature

InactiveCN101015839AReduce weldingReduce transportationRare end control deviceTemperature control deviceCarbon steelRebar

The invention relates to a spinneret front clamping technique for high-speed producing steel coil bar at low temperature under 750Deg. C as general carbon steel 400MPa, 500MPa or the like without micro elements (Nb, V, and Ti), wherein the rib steel bar spinning temperature is lower than 750Deg. C, the gas pressure of clamping roller gas source is higher than 7bar, the clamping force of the clamping roller is 4.5-7.0bar, therefore, the invention can stably produce high-strength rib steel coil bar without additive micro elements (Nb, V, and Ti), with uniform grains, energy saving and low cost.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

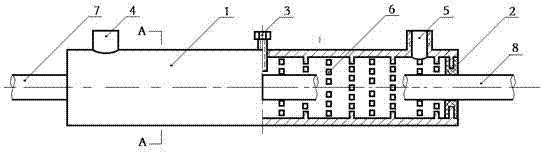

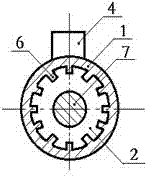

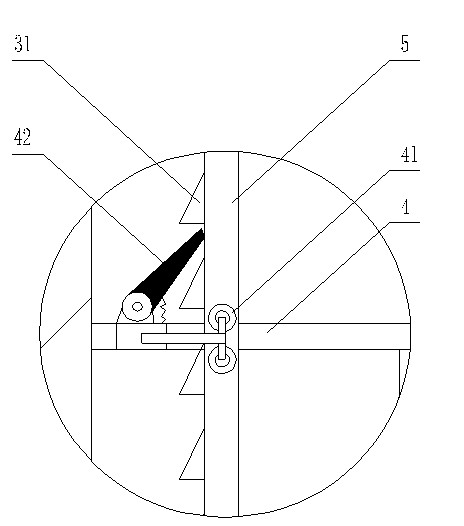

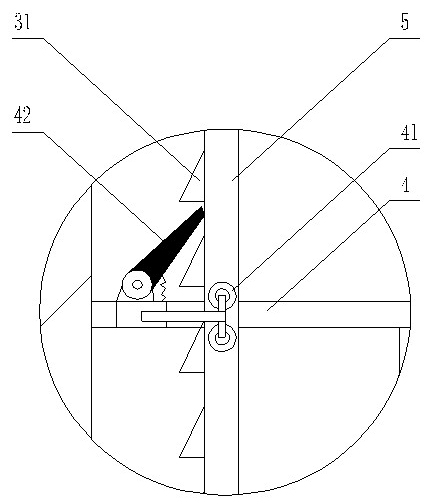

Steel bar and angle iron truss welding device and construction method thereof

ActiveCN108500492AGuaranteed dimensional accuracyReduce welding costsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRebar

The invention relates to steel bar and angle iron welding construction in a novel steel plate combined shear wall structure, is mainly applied to steel bar and angle iron welding construction in the novel steel plate combined shear wall structure, and belongs to the field of steel structures. A steel bar and angle iron truss is included and internally provided with a pneumatic clamping assembly, arotary positioning assembly and a steel bar guiding and positioning assembly, wherein the rotary positioning assembly is arranged on the left side of the pneumatic clamping assembly, and the steel bar guiding and positioning assembly is arranged on the right side of the pneumatic clamping assembly. According to a steel bar and angle iron truss welding device and a construction method thereof, thestructure is compact, operation is convenient, and the structure is firmer.

Owner:浙江东南网架股份有限公司

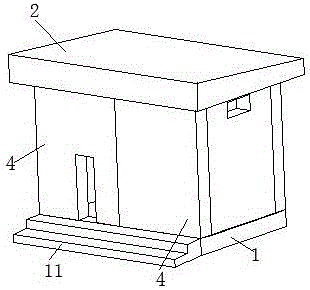

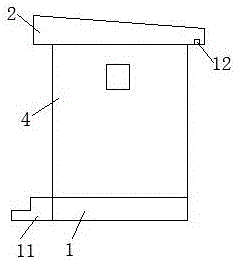

Pitched roof assembly type communication machine room

Owner:人天通信集团有限公司

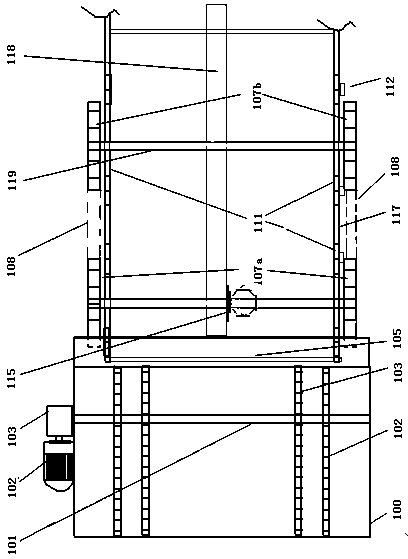

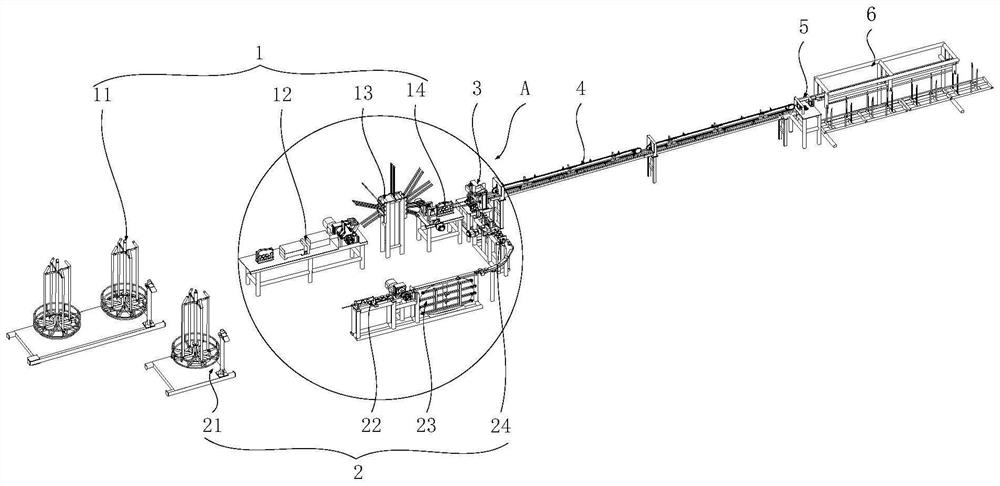

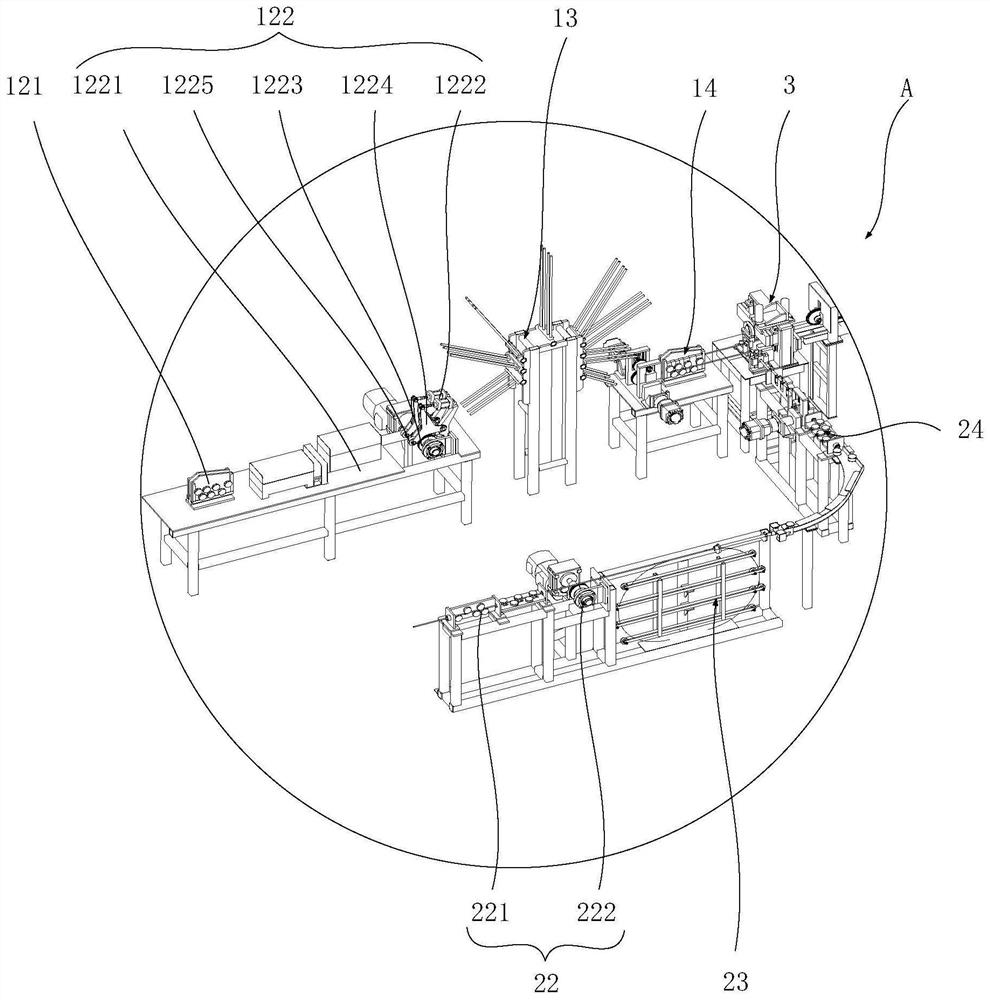

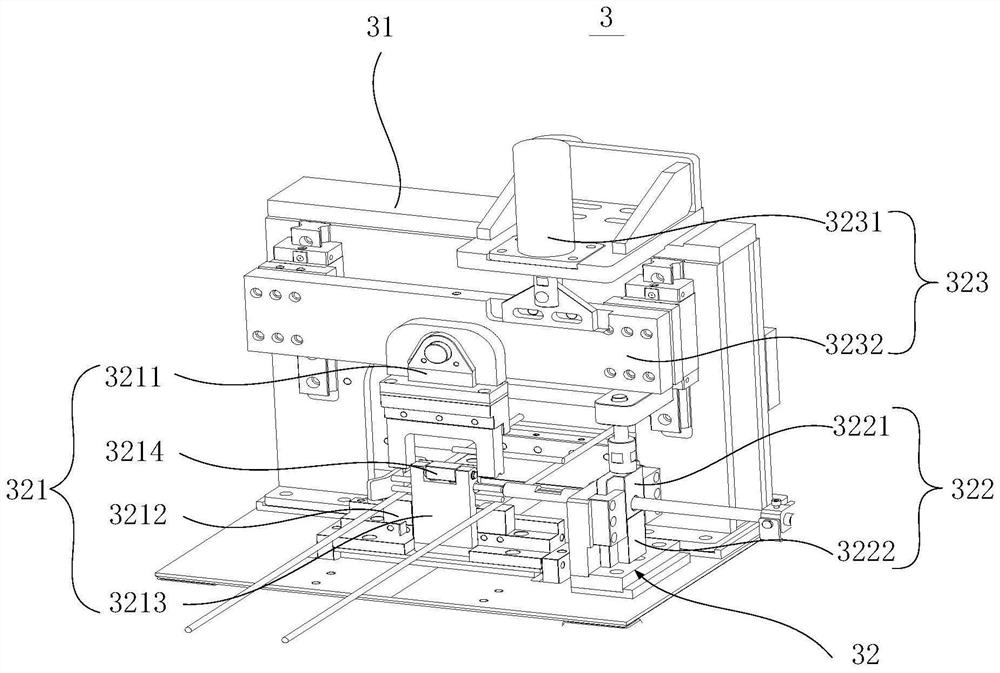

Reinforcing mesh welding production equipment

ActiveCN112045440AImprove structural strengthRealize automatic feeding processWire networkOther manufacturing equipments/toolsMesh reinforcementRebar

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

Semiautomatic steel bar bender

Owner:FUZHOU COLLEGE OF FOREIGN STUDIES & TRADE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap