Method for the combination of a post-increasing steel beam and a concrete slab

A technology for concrete slabs and steel beams, applied in the direction of joists, girders, truss beams, etc., can solve problems such as inapplicability of technical transformation projects, and achieve the effect of effective treatment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

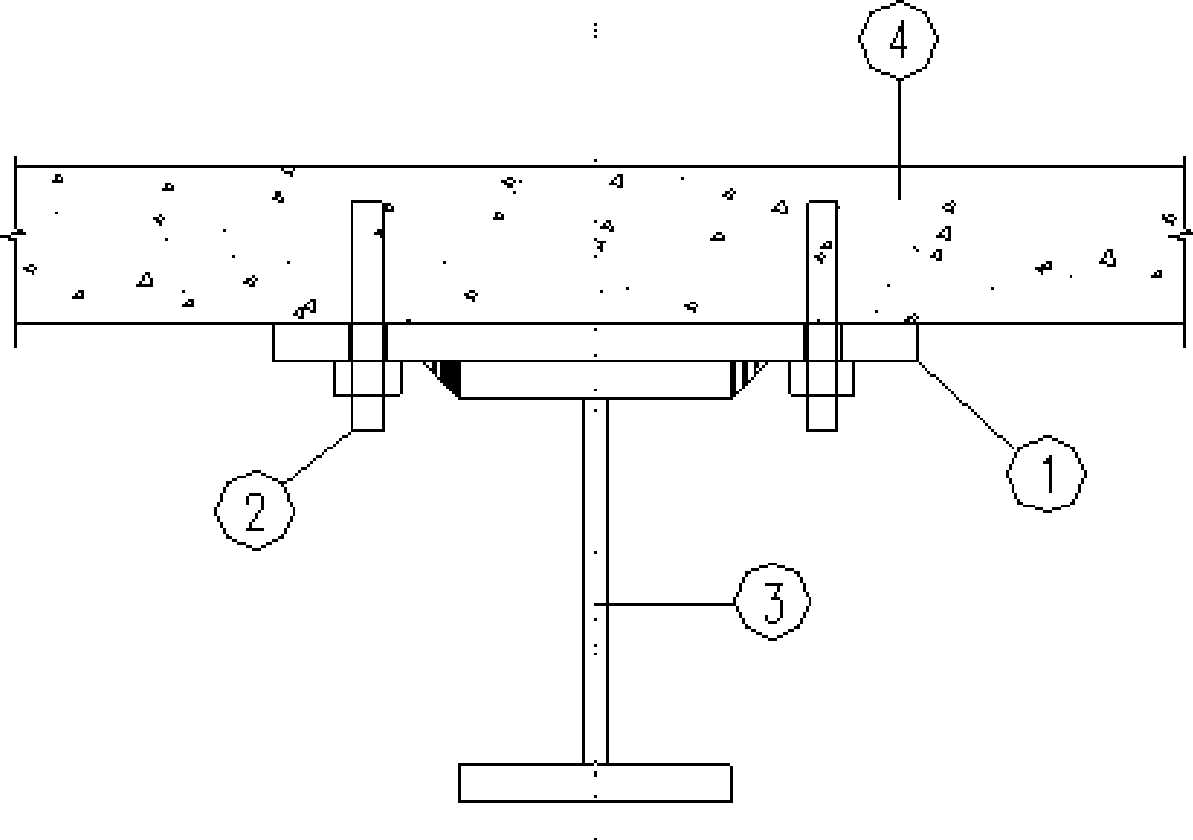

[0008] Embodiment of the present invention: make parts such as connecting steel plate 1, post-anchor building anchor bolt 2, post-reinforced steel beam 3, and carry out the combined construction of post-reinforced steel beam and concrete slab according to the diagram. Firstly, the positions of the post-increased steel beam 3 and the connecting steel plate 1 are determined on the bottom surface of the built concrete slab 4; secondly, the post-anchoring building anchor bolt 2 is anchored into the built concrete slab 4 at the position of the connecting steel plate 1; then , use post-anchoring building anchor bolts 2 to fix the connecting steel plate 1 on the bottom surface of the built concrete slab 4; finally, weld the post-increased steel beam 3 to the connecting steel plate 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap