Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16 results about "Stain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A stain is a discoloration that can be clearly distinguished from the surface, material, or medium it is found upon. They are caused by the chemical or physical interaction of two dissimilar materials. Staining is used for biochemical research, metal staining, and art (e.g., wood staining, stained glass).

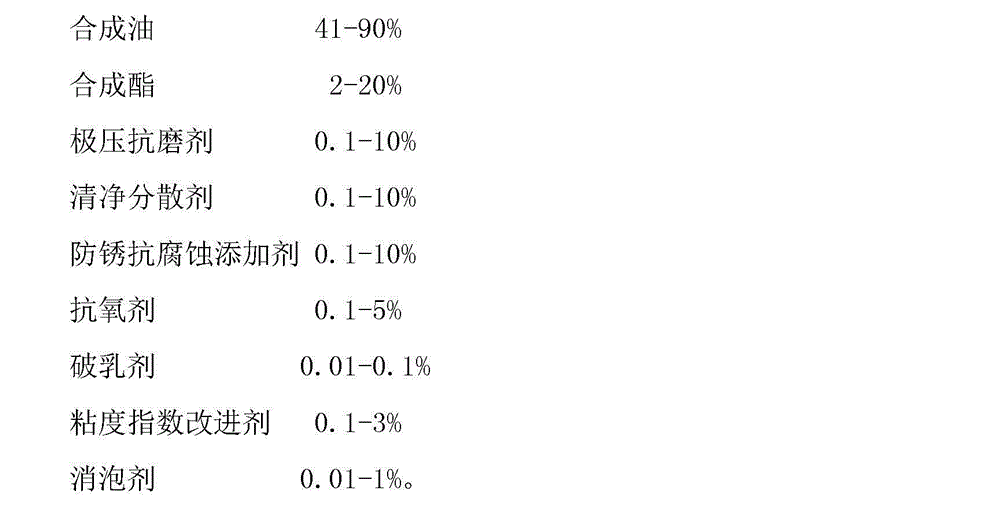

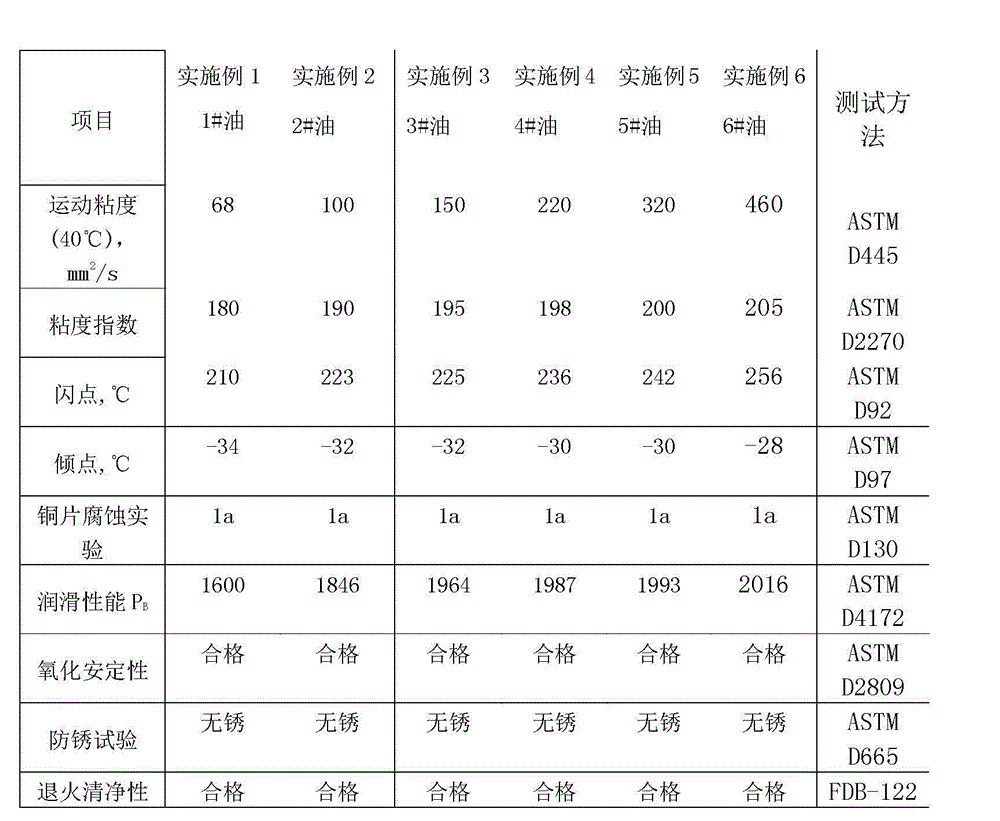

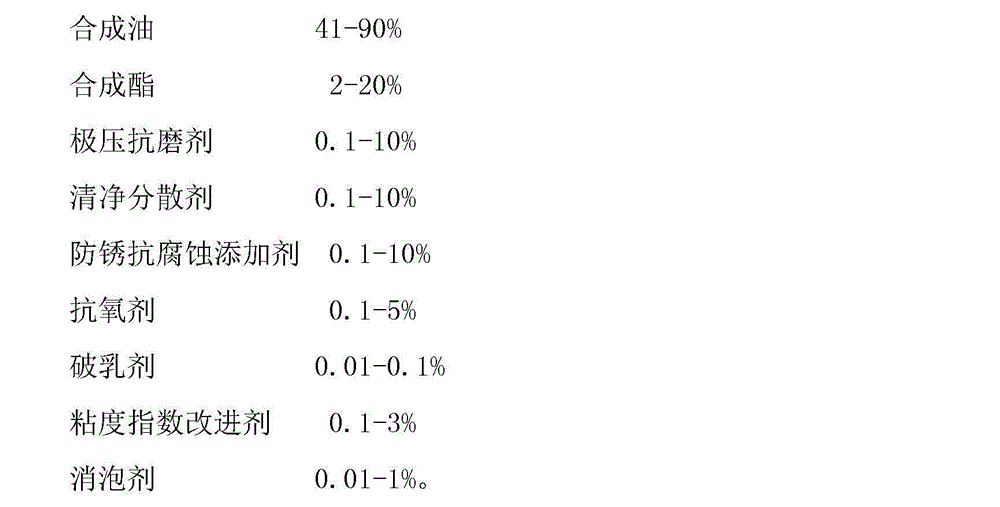

Totally synthetic non-staining bearing oil

InactiveCN102719305AReduce the temperatureImprove surface qualityLubricant compositionAntioxidantEngineering

Owner:上海福岛新材料科技有限公司

Corynebacterium glutamicum recombinant strain capable of producing high-yield L-leucine, and construction method thereof

InactiveCN109294966AEfficient synthetic pathwayLow content of by-productsBacteriaMicroorganism based processesBiotechnologyNad dependent

The invention discloses a Corynebacterium glutamicum recombinant strain capable of producing high-yield L-leucine, and a construction method thereof, and belongs to the field of genetic engineering. According to the present invention, the NADP-dependent branched-chain amino acid transaminase in Corynebacterium glutamicum is replaced with NAD-dependent leucine dehydrogenase (LeuDH) derived from B.sphaericus by using a genetic engineering method, such that the new efficient L-leucine synthesis pathway is constructed, the disadvantages of excessive accumulation of NADH in the Corynebacterium glutamicum L-leucine producing bacteria and insufficient supply of NADPH are solved, the L-leucine synthesis ability in the recombinant strain is enhanced, and the NADPH accumulation ability of the strainis improved; the shake fermentation experiment results show that the L-leucine accumulation of the recombinant strain achieves 16.7 g.L<-1> and is higher than the L-leucine accumulation of the starting stain of 13.2 g.L<-1>, and the maximum specific growth rate of the recombinant strain is 0.23 g.L<-1>.h<-1>, and is higher than the maximum specific growth rate of the recombinant strain of 0.18 g.L<-1>.h<-1>; and the L-leucine synthesis pathway in Corynebacterium glutamicum is successfully modified, the disadvantage of the intracellular cofactor imbalance is improved, and the new idea is provided for the breeding of high-yield L-leucine production bacteria.

Owner:JIANGNAN UNIV

Washing agent

ActiveCN104946417ANo harmOrganic detergent compounding agentsSurface-active detergent compositionsEngineeringStain

The invention discloses a washing agent. The washing agent comprises, by mass, 10% to 50% of emulsified detergents, 10% to 30% of penetrants and 20% to 40% of wetting agents. Compared with the prior art, the washing agent has the advantages of being environmentally friendly, efficient and capable of being used for soaking ultrasonic wave oil removing washing of various materials, having remarkable effects on various stubborn oil stains and being capable of being completely degraded and free of injuries in the human body and damage to the environment.

Owner:SHENZHEN HENGWEIXIANG SCI & TECH CO LTD

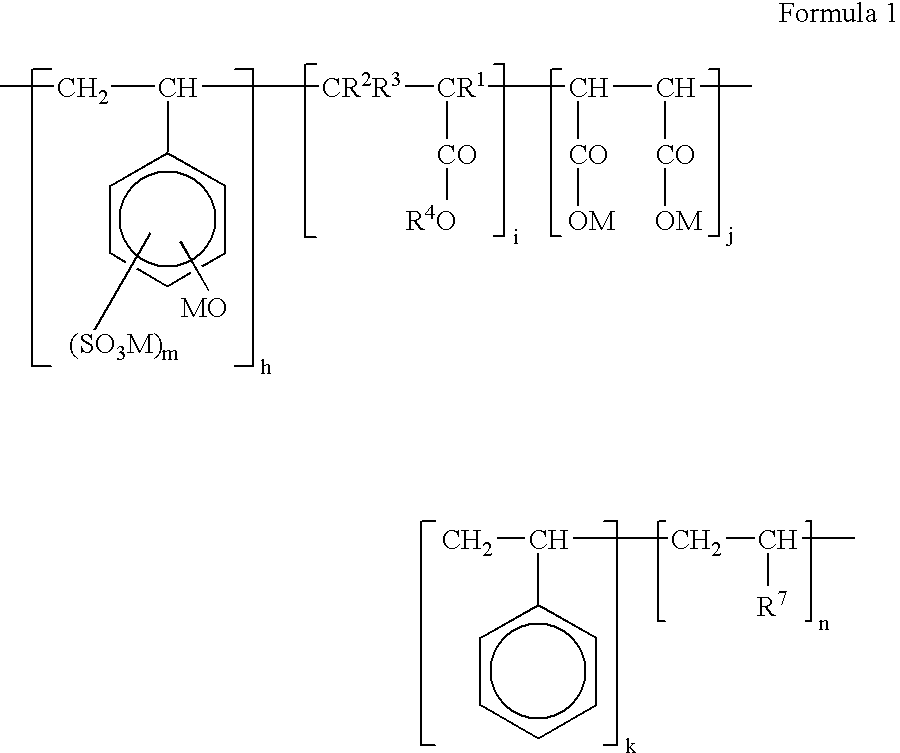

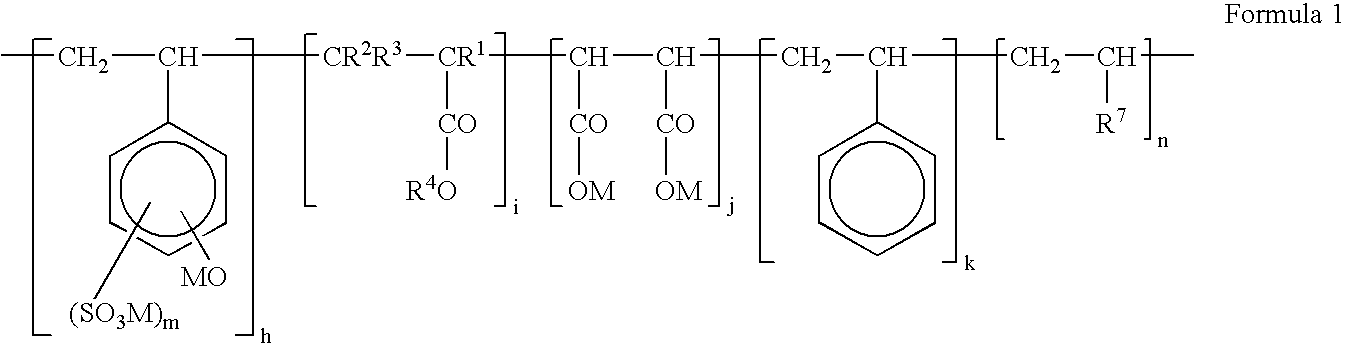

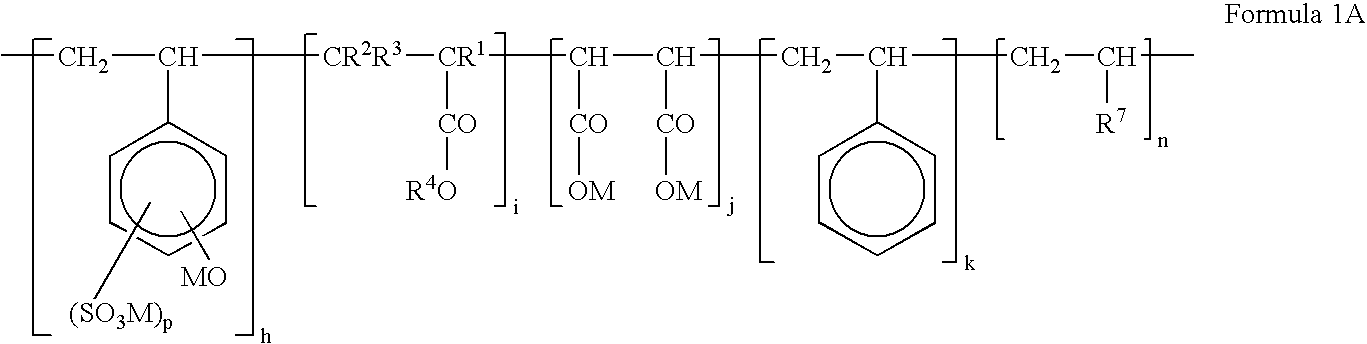

Poly(hydroxystyrene) stain resist

Owner:EI DU PONT DE NEMOURS & CO

Chromium-ion-free zinc-nickel alloy automatic electroplating process

InactiveCN106637315AGood lookingMeet environmental protection requirementsElectrochemical responseNickel alloy

The invention discloses a chromium-ion-free zinc-nickel alloy automatic electroplating process. The chromium-ion-free zinc-nickel alloy automatic electroplating process comprises the following steps: pretreatment: removing oil stain and rust on the surface of a rubber-metal composite part or a metal part to be plated in such modes as pickling, electrolytic degreasing, and high-temperature degreasing; electroplating: utilizing electrochemical reaction to enable two metal ions (zinc and nickel) to be co-deposited on the metal surface to form a plating; confining: enabling a confining liquid to infiltrate the gap of the plating to form an organic or inorganic protective layer on the surface of the plating, wherein the confining temperature is 50-80 S, and the temperature of the confining liquid is 40-50 DEG C; blow-drying; drying; and packaging. By adoption of the chromium-ion-free zinc-nickel alloy automatic electroplating process, as the surface of the electroplating does not contain chromium ions, the requirement for environmental protection is satisfied; after electroplating, passivation is not needed, the anti-corrosion performance is good, long-time use can be realized, and the chromium-ion-free zinc-nickel alloy automatic electroplating process can guarantee favorable appearance of the plating; as passivation is not needed, the operation is simple, additional treatment is not required and the production efficiency is high; and the obtained plating has no red rust under neutral salt spray for 1,000 h.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Skin-whitening functional composition and application thereof in cleaning skin care products

InactiveCN106038471APrevent overproductionInhibitory activityCosmetic preparationsToilet preparationsVitamin b6Vitamin C

Owner:TIANJIN YU MEI JING GRP

Additive-free odorless super-stain-resistant acrylate emulsion and preparation method thereof

InactiveCN111205387AEasy to wrapIntertwined closelyAntifouling/underwater paintsPaints with biocidesPolymer scienceFunctional monomer

Owner:广东巴德富新材料有限公司

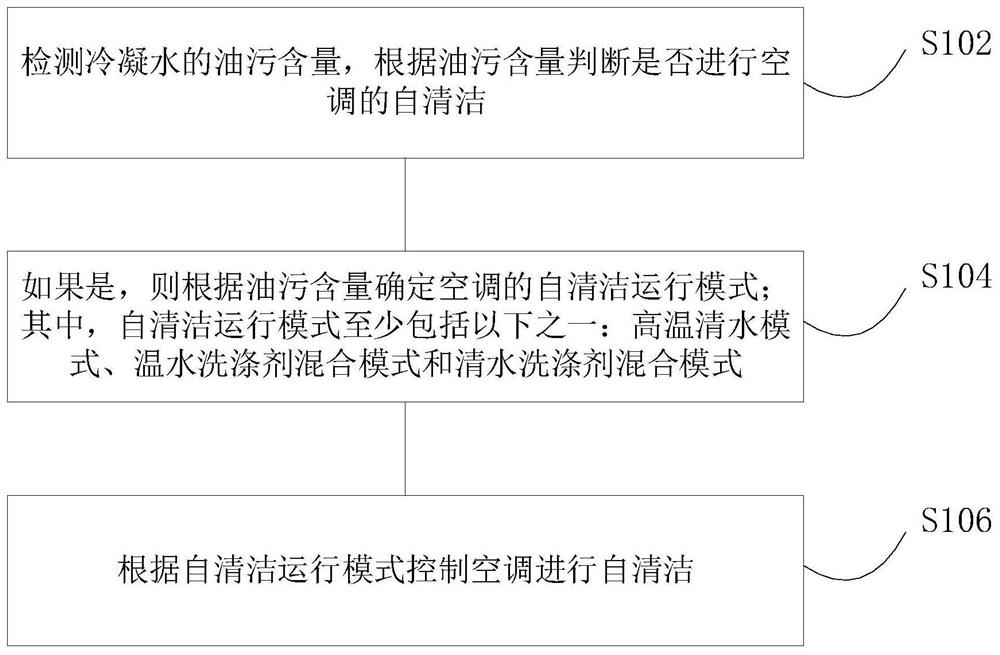

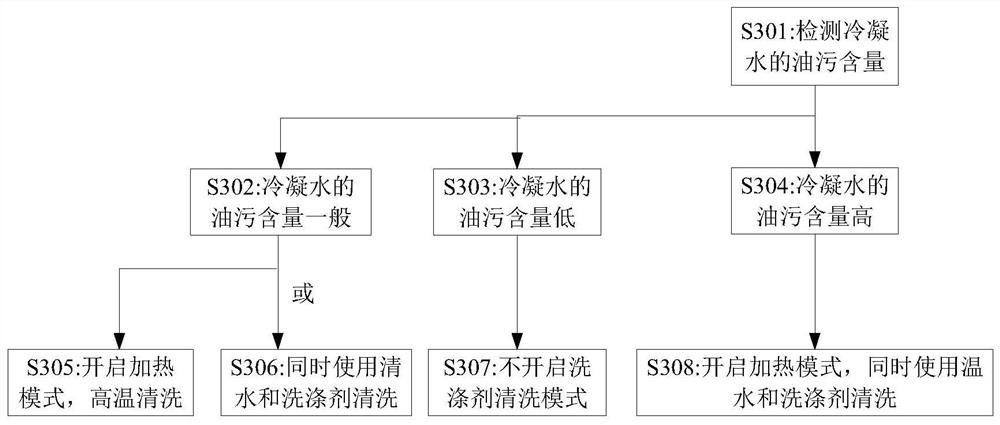

Air conditioner self-cleaning control method and device and air conditioning unit

InactiveCN111780329AImprove heat transfer efficiencyWash thoroughlyMechanical apparatusLighting and heating apparatusWarm waterProcess engineering

Owner:GREE ELECTRIC APPLIANCES INC

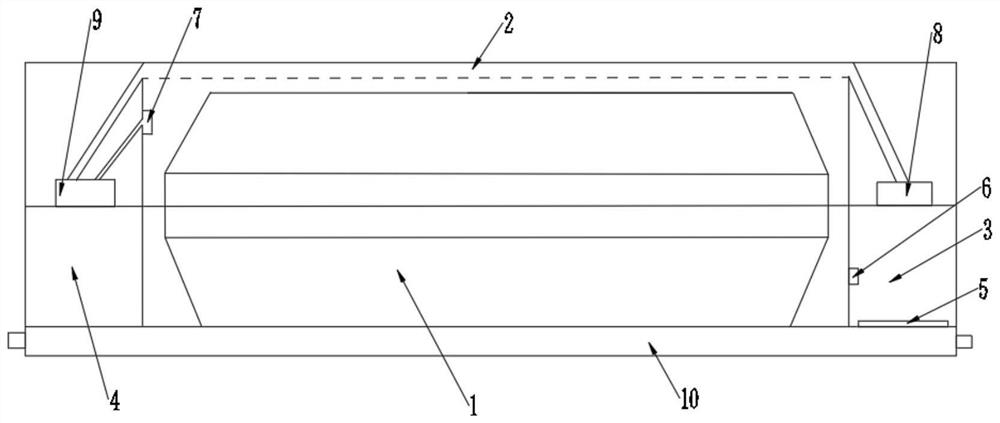

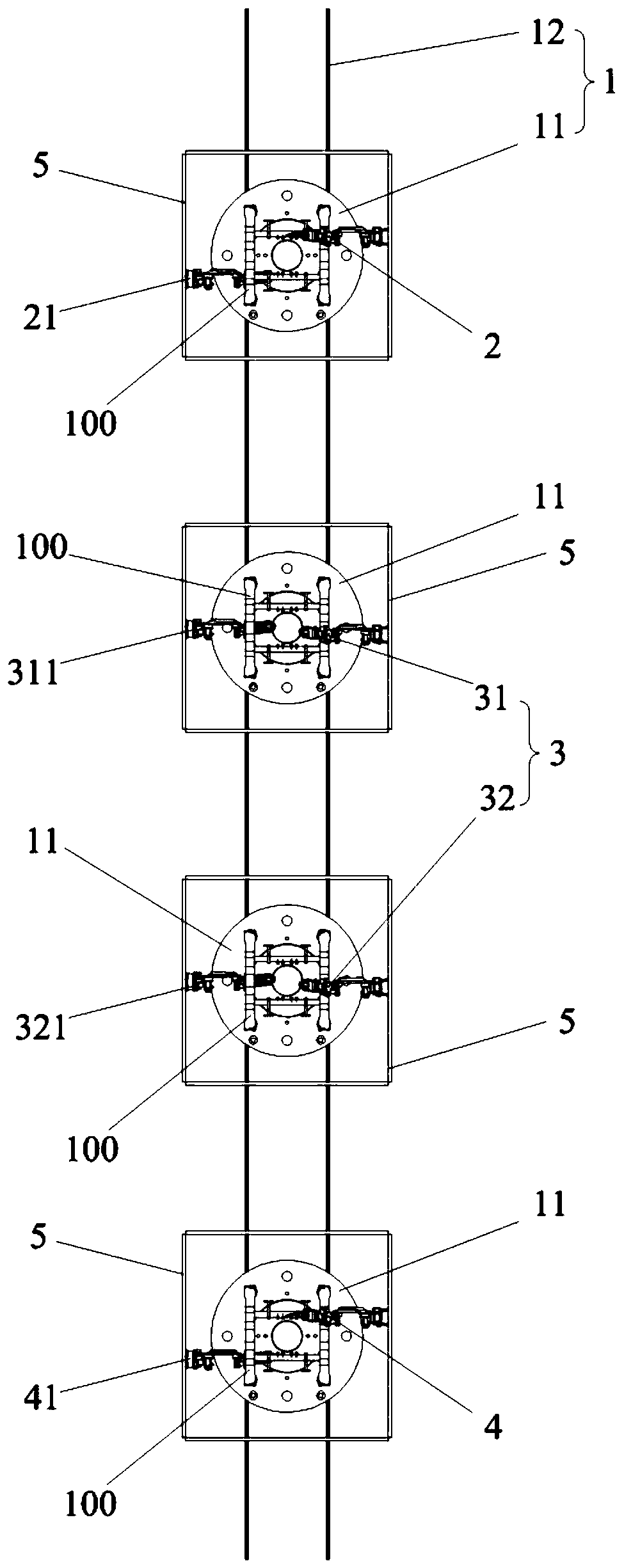

Bullet train bogie framework cleaning equipment

PendingCN111451206AEasy to cleanImprove cleaning efficiencyDrying gas arrangementsCleaning using toolsBogieStain

Owner:BEIJING RAILWAY INST OF MECHANICAL & ELECTRICAL ENG

Conductive high-temperature resistant ultraviolet curing coating and method for preparing same

InactiveCN104559372AHigh hardnessShort curing timeAnti-corrosive paintsElectrically-conductive paintsTO-18Wear resistant

Owner:HUZHOU NANXUN SHUANGLIN ZHENSEN WOOD PROCESSING FACTORY

Water paint and preparation method thereof

Owner:NANNING LAOYONGCHUN REDWOOD FURNITURE FACTORY

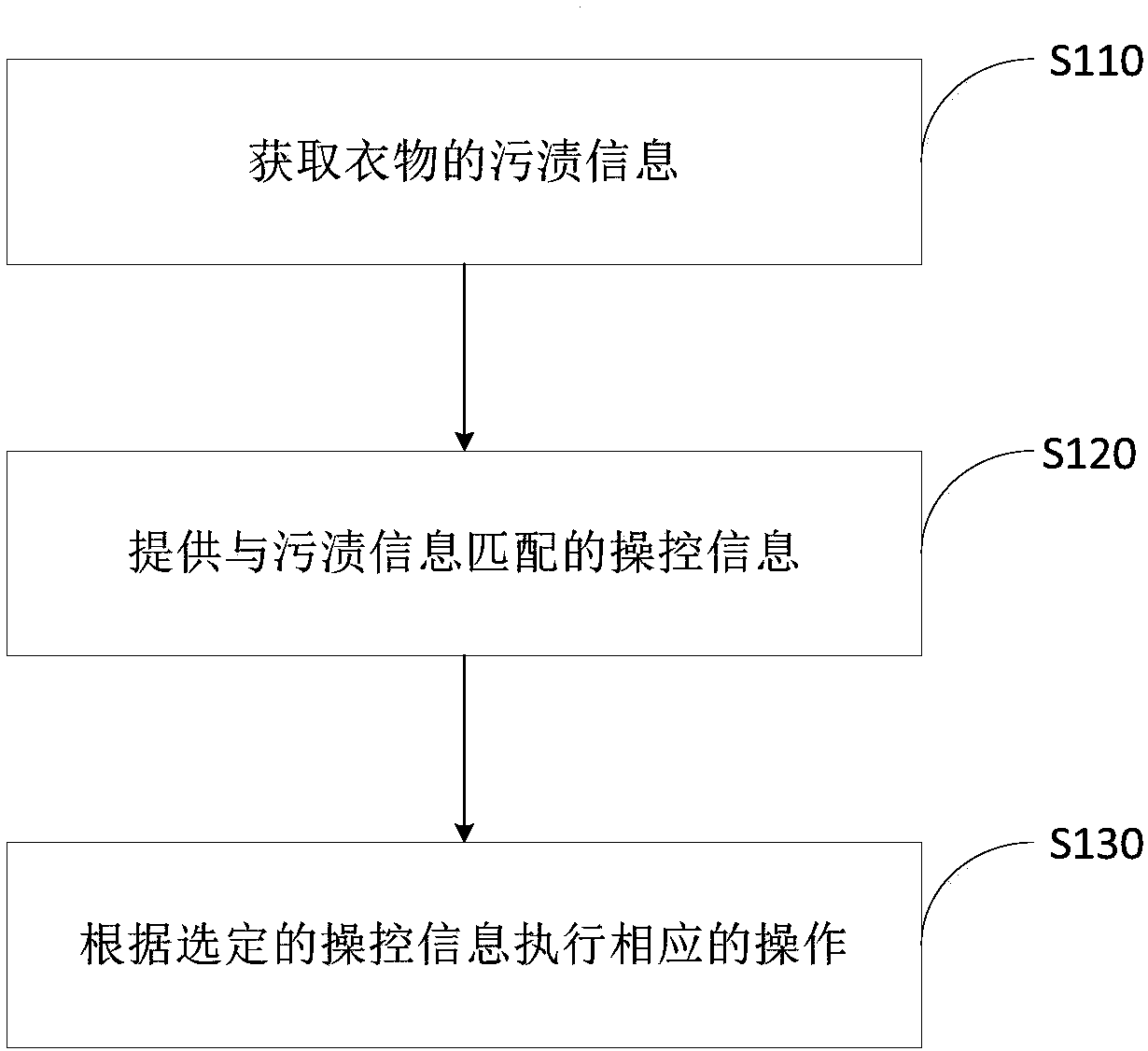

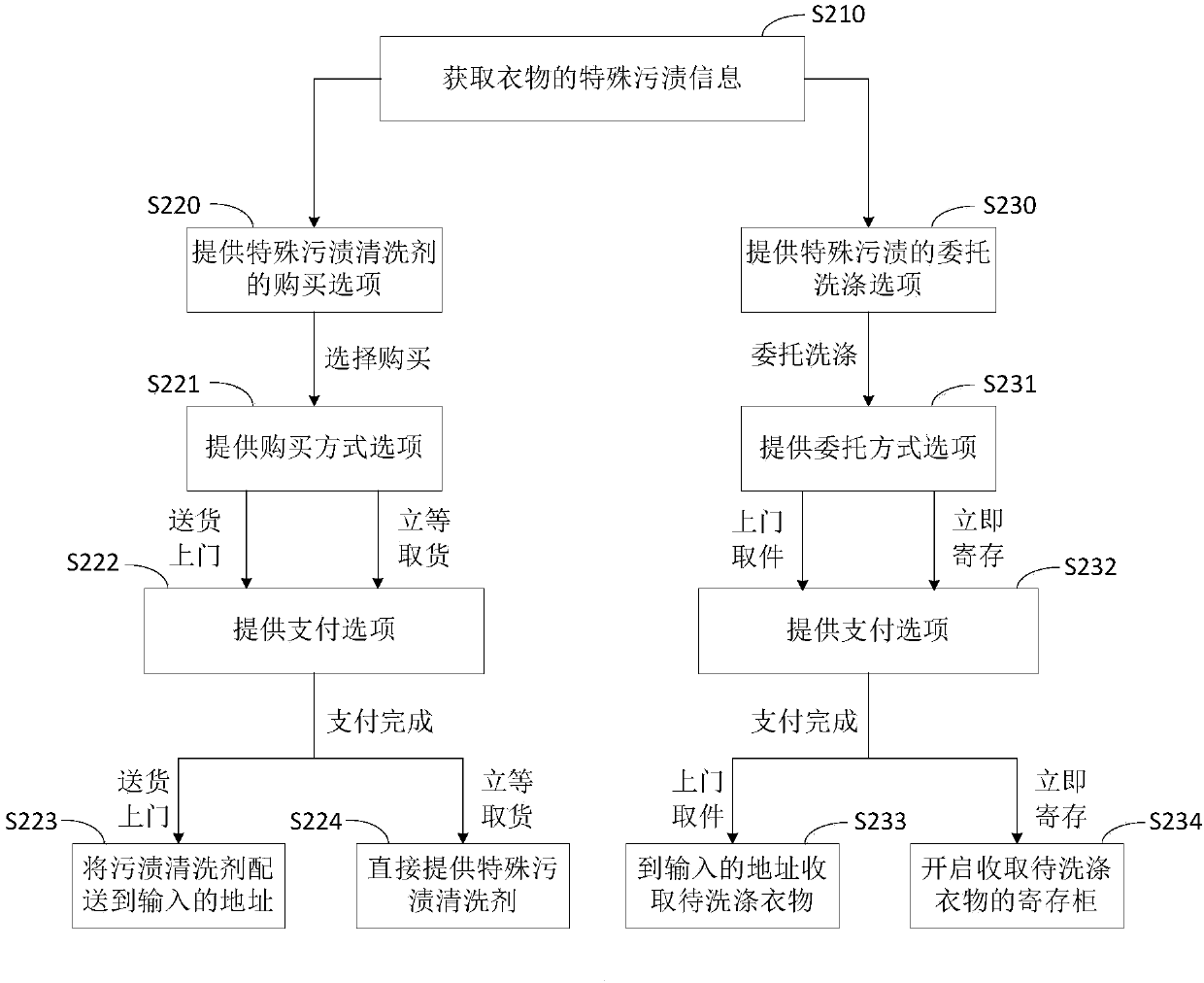

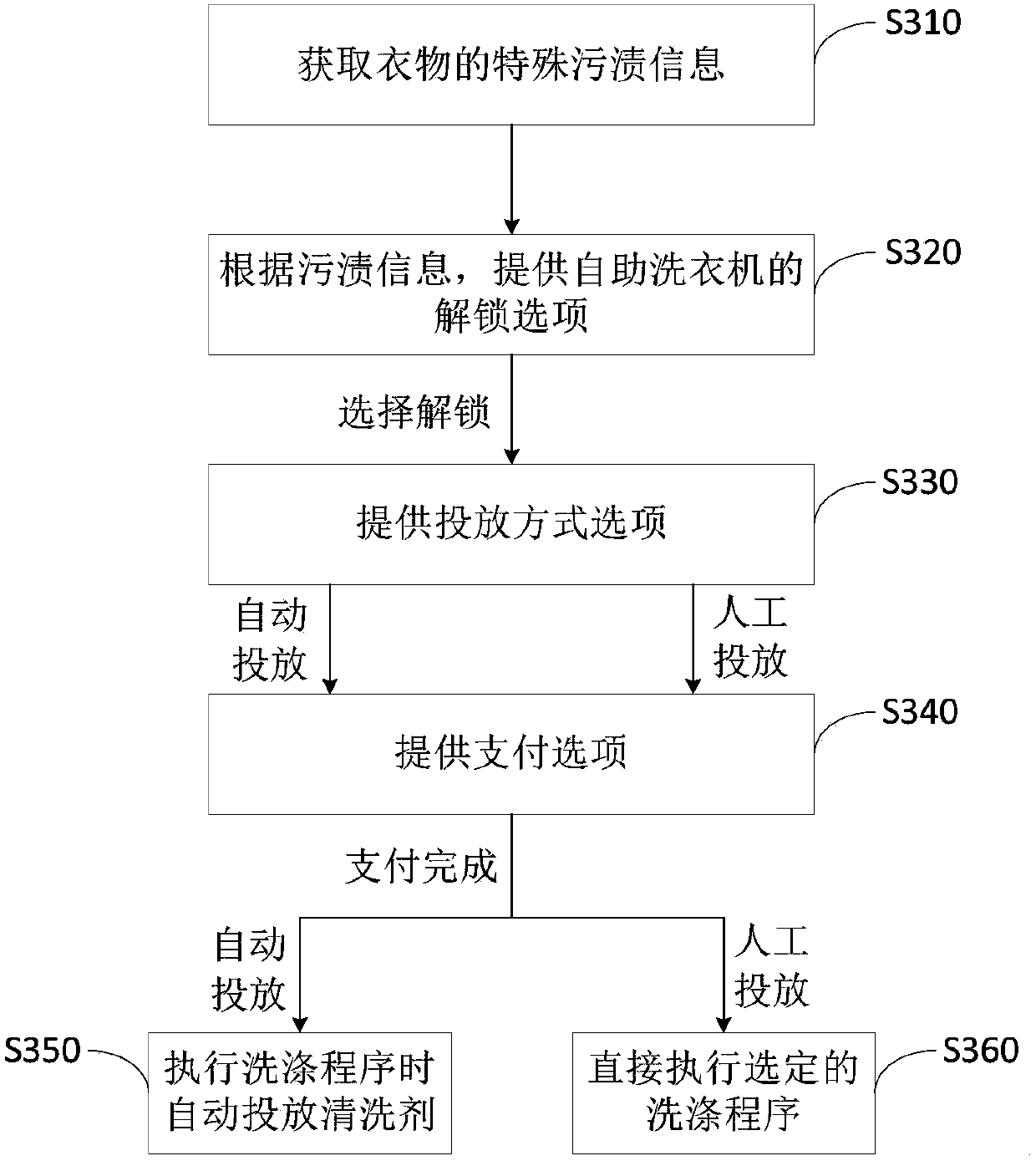

Method for treating clothing stains

ActiveCN109957912AAvoid unnecessary lossesControl devices for washing apparatusPayment architectureCleansing AgentsComputer science

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

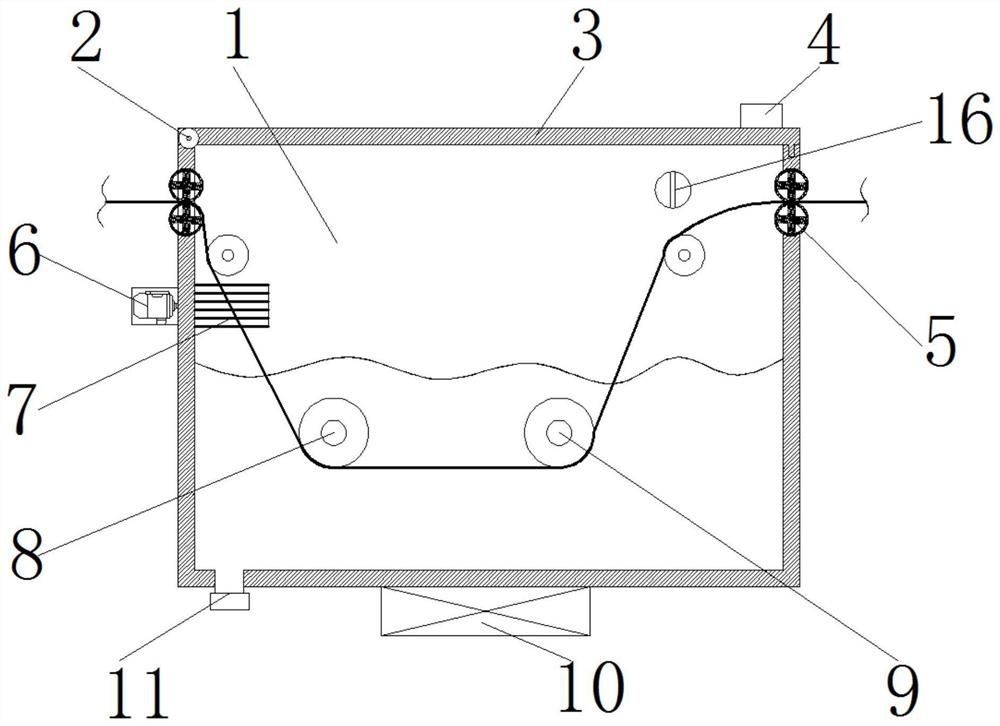

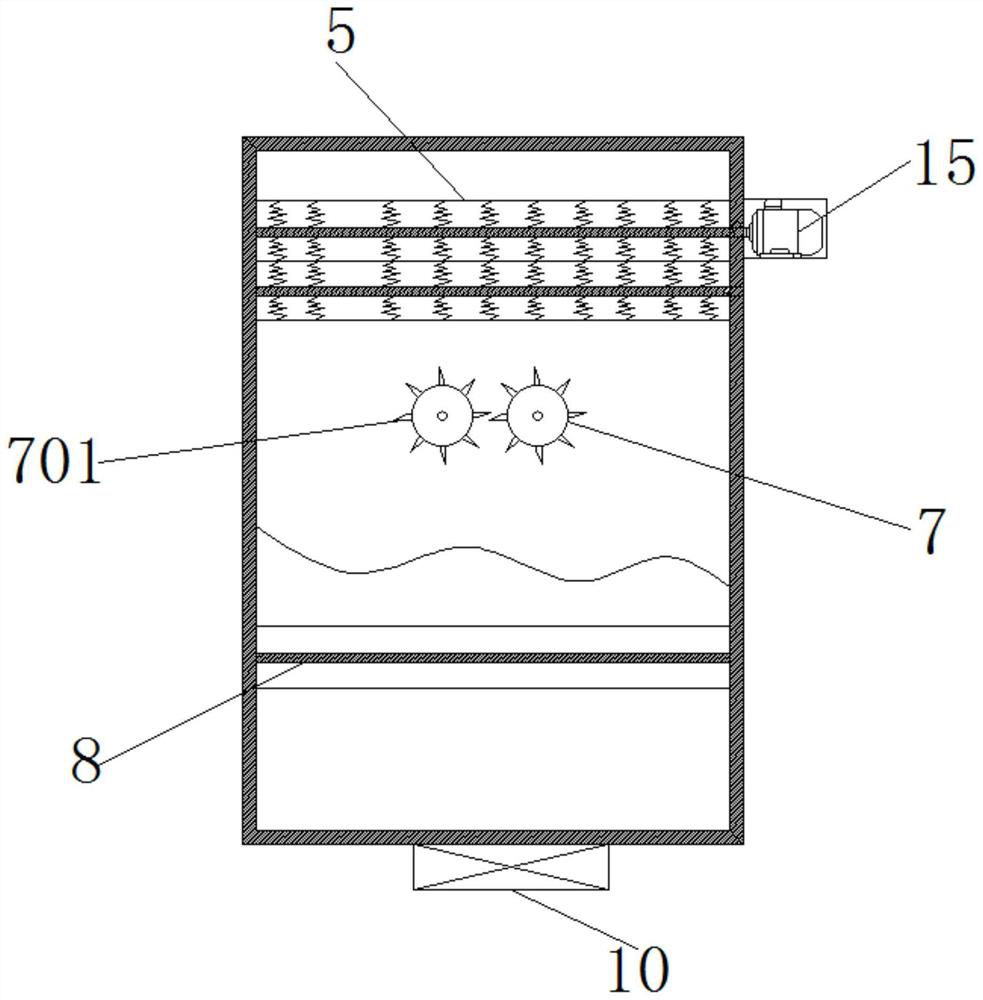

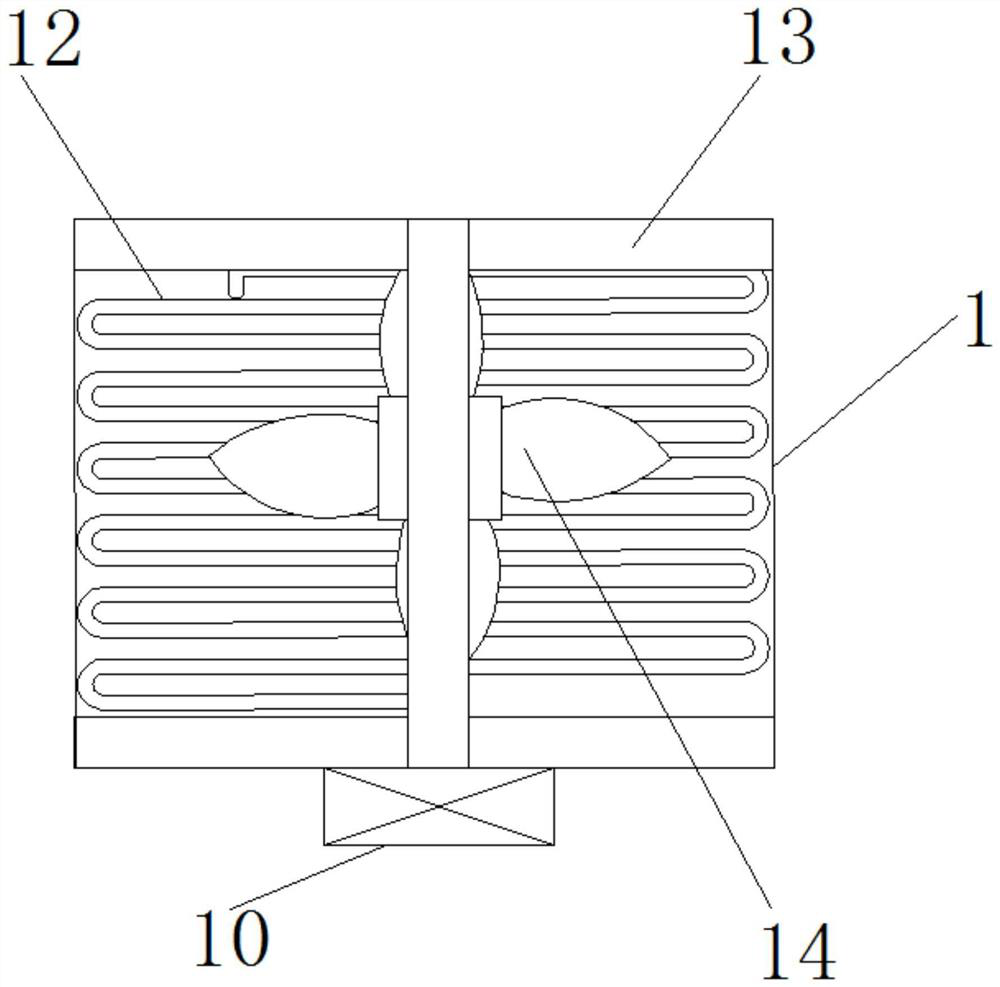

Oil stain isolation device facilitating oil stain collection and used for flat wire production

PendingCN112941764AAnnealed thoroughlyPrevent take outTextile treatment machine arrangementsLiquid/gas/vapor removal by scrapingOil canRotational axis

Owner:句容建荣汽配有限公司

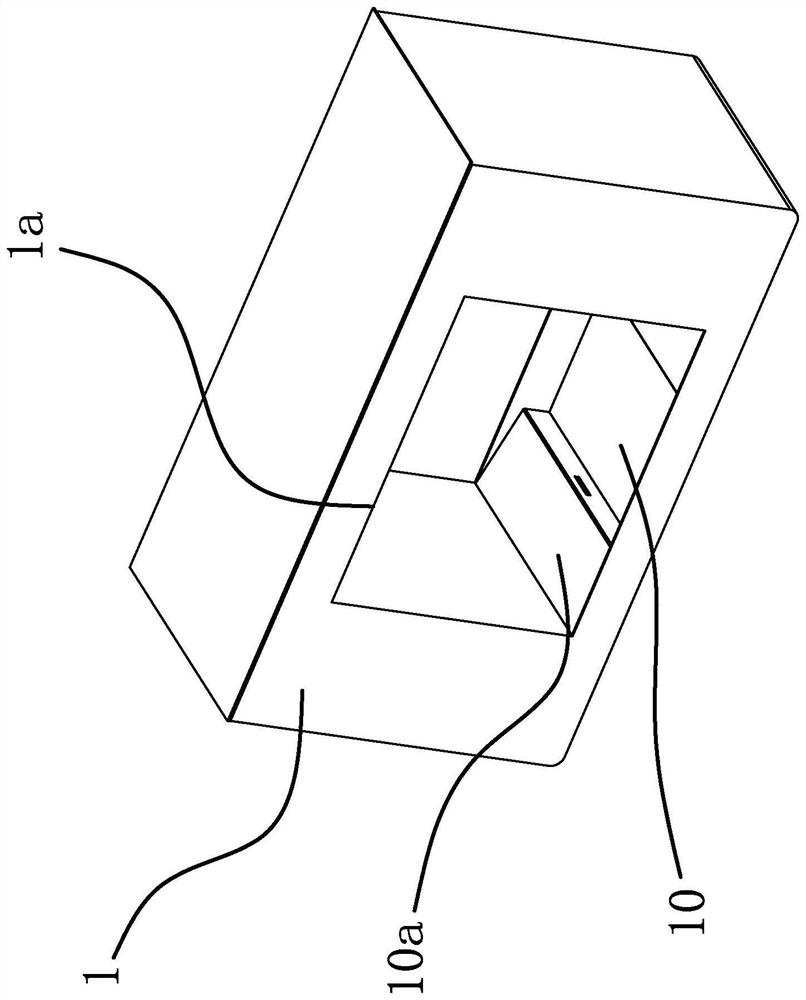

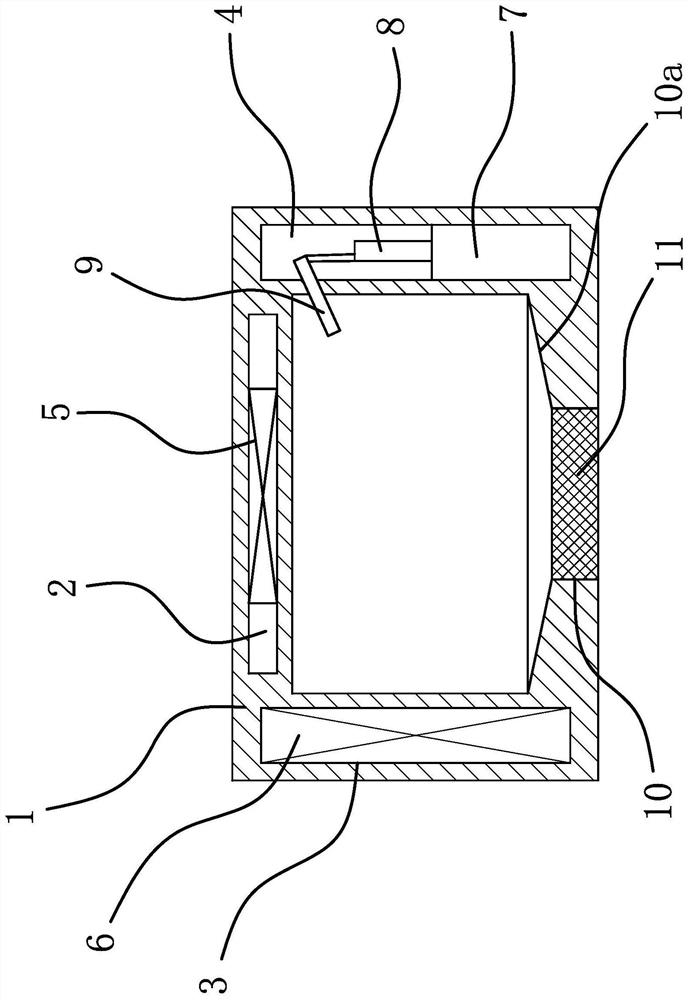

Non-contact intelligent hand washing machine

PendingCN113729528ACompact structureImprove stabilityHolders and dispensersMechanical engineeringStain

Owner:顾天尧

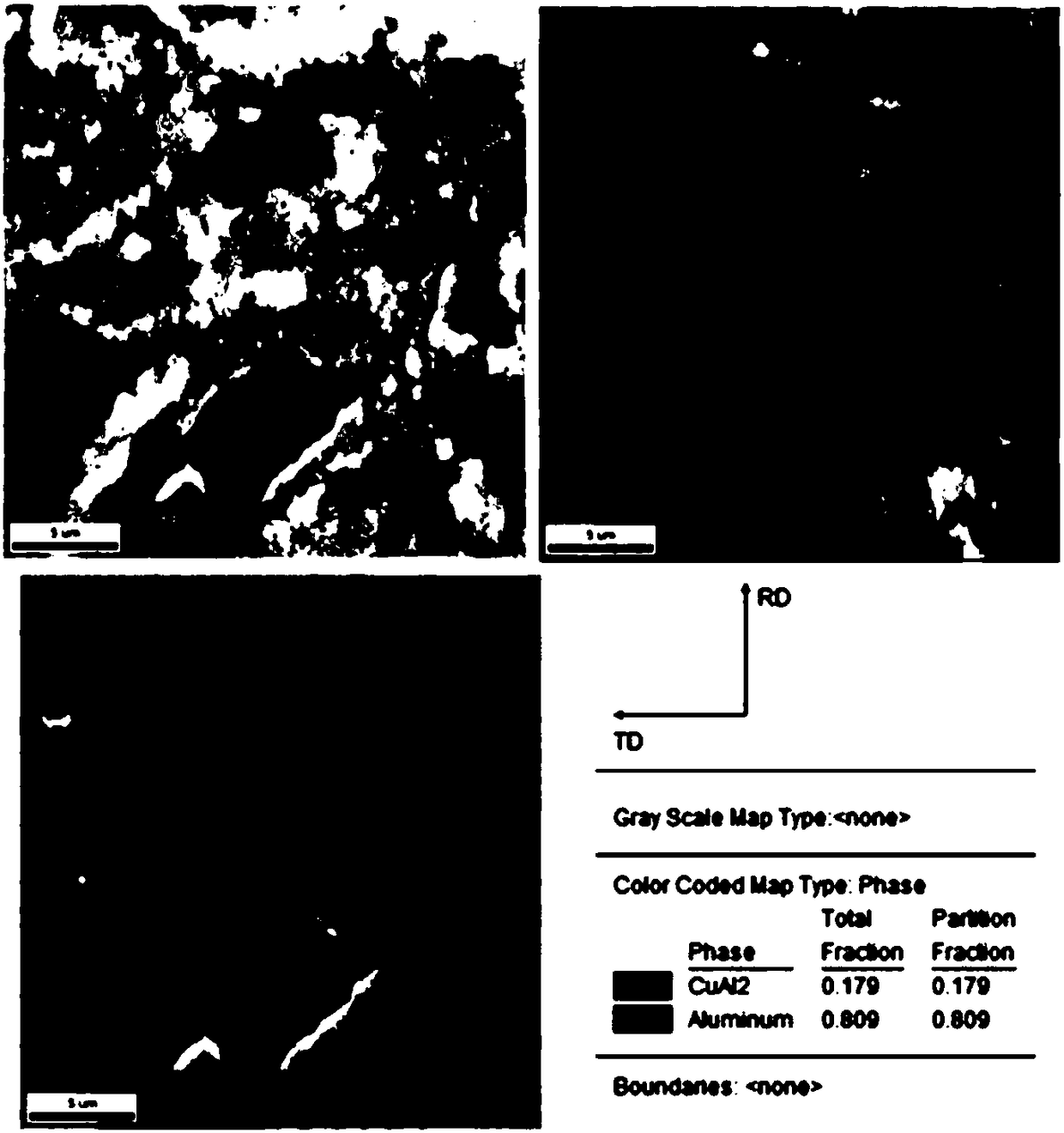

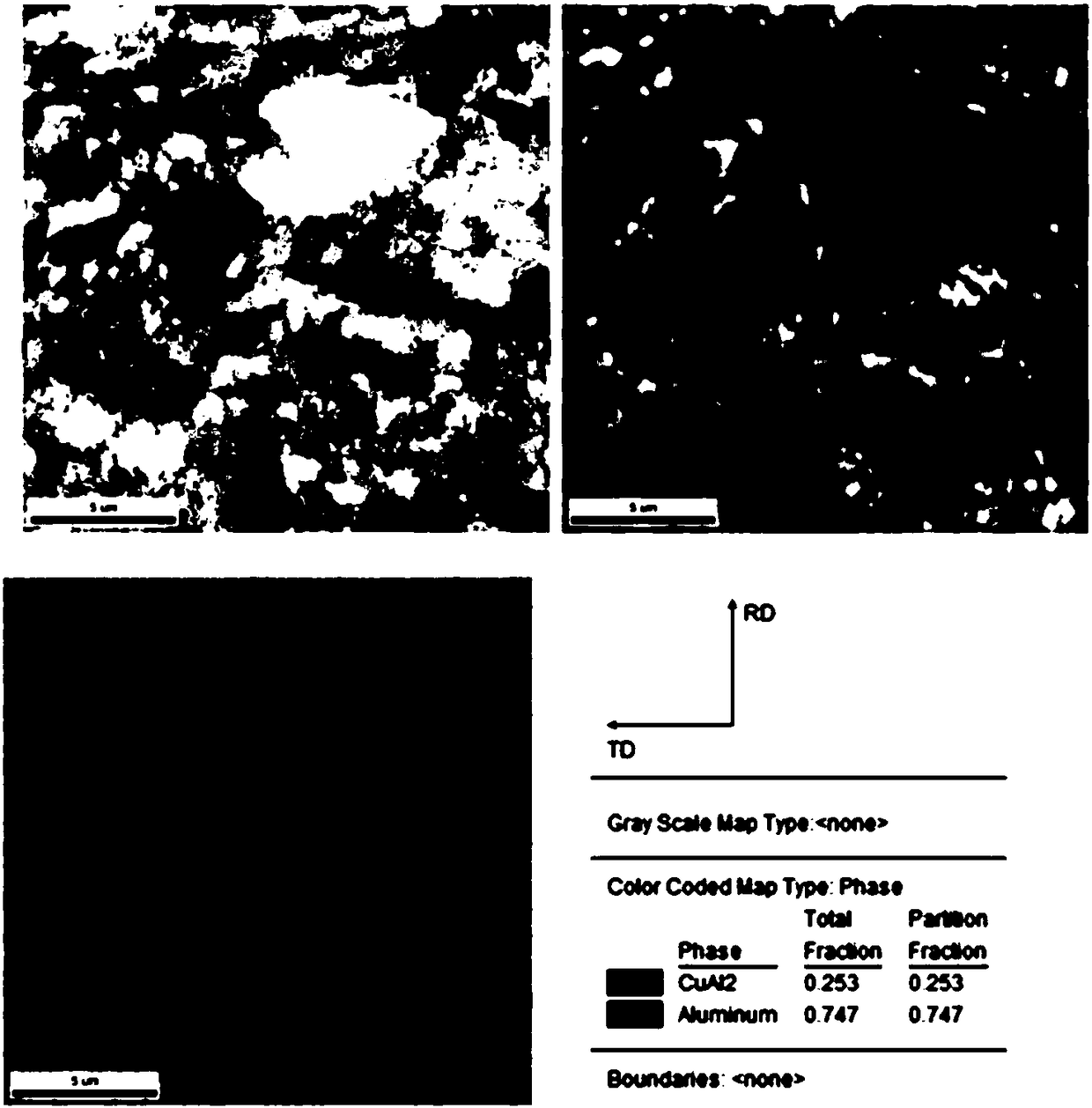

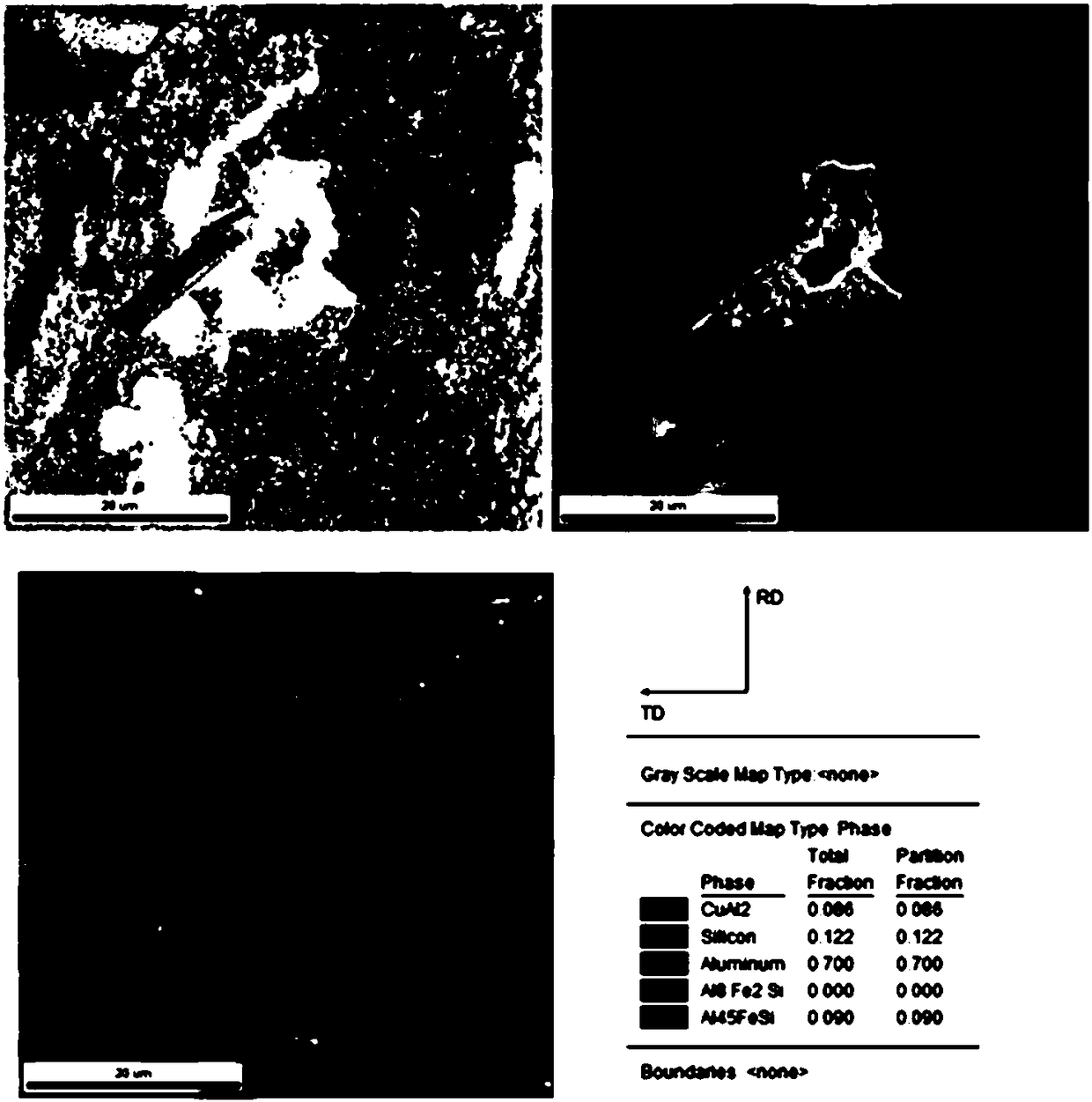

Aluminum alloy EBSD sample alkaline electrolysis polishing liquid and preparation method and electrolysis polishing method thereof

Owner:ZHEJIANG HAILI GROUP

Anti-oxidation surface treatment method for conductive bar

InactiveCN109943854AImprove adhesionMetallic material coating processesAntioxidantOxidation resistant

The invention relates to the field of conductive bar production, in particular to an anti-oxidation surface treatment method for a conductive bar. The anti-oxidation surface treatment method comprisesthe following steps of 1, soaking the conductive bar to be treated in a cleaning solution to remove oil stains and rust on the surface of the conductive bar; 2, cleaning the cleaned conductive bar with deionized water, and wiping the conductive bar with a wiping cloth; 3, placing the dried conductive bar in a solvent containing an antioxidant, heating the conductive bar to 50-200 DEG C, and carrying out sealed and pressurized reaction; and 4, after the treatment is finished, cleaning and then drying the conductive bar at a low temperature. By adopting a chemical agent blending, heating and pressurizing treatment method, the process is simple, little pollution is caused, and the process is controllable.

Owner:YANGZHOU HONGSHUN ELECTRIC CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap