Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Chemical agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

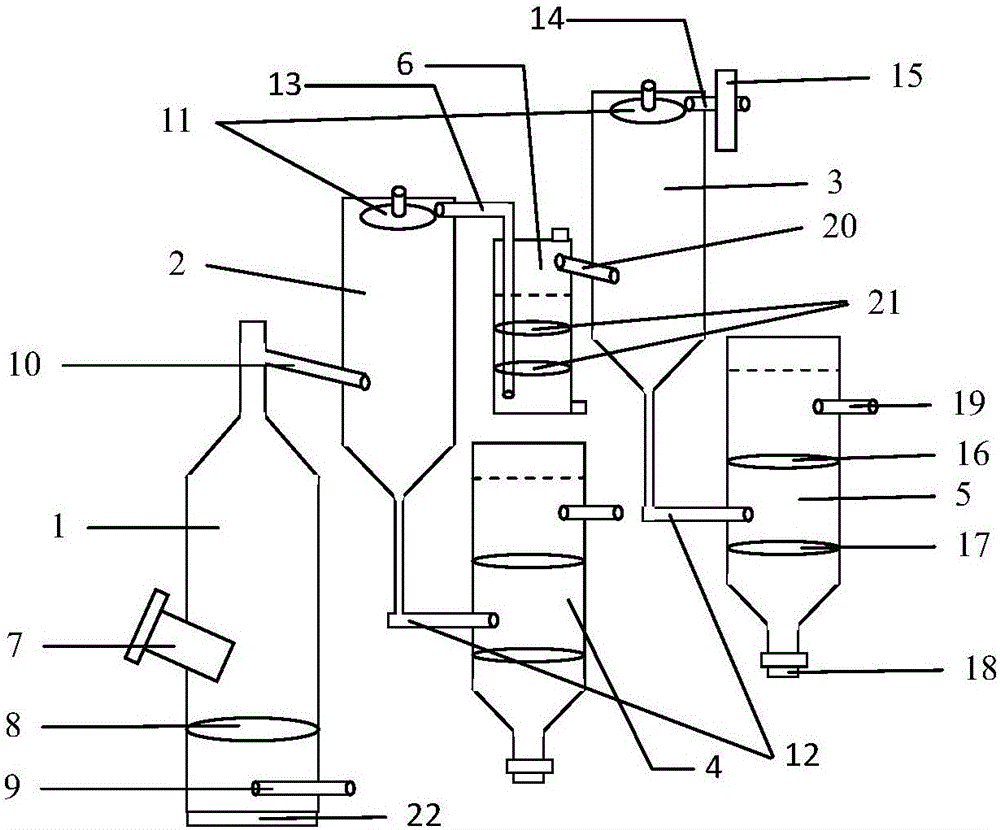

Vegetable fiber liquefied matter, and preparing method and use thereof

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

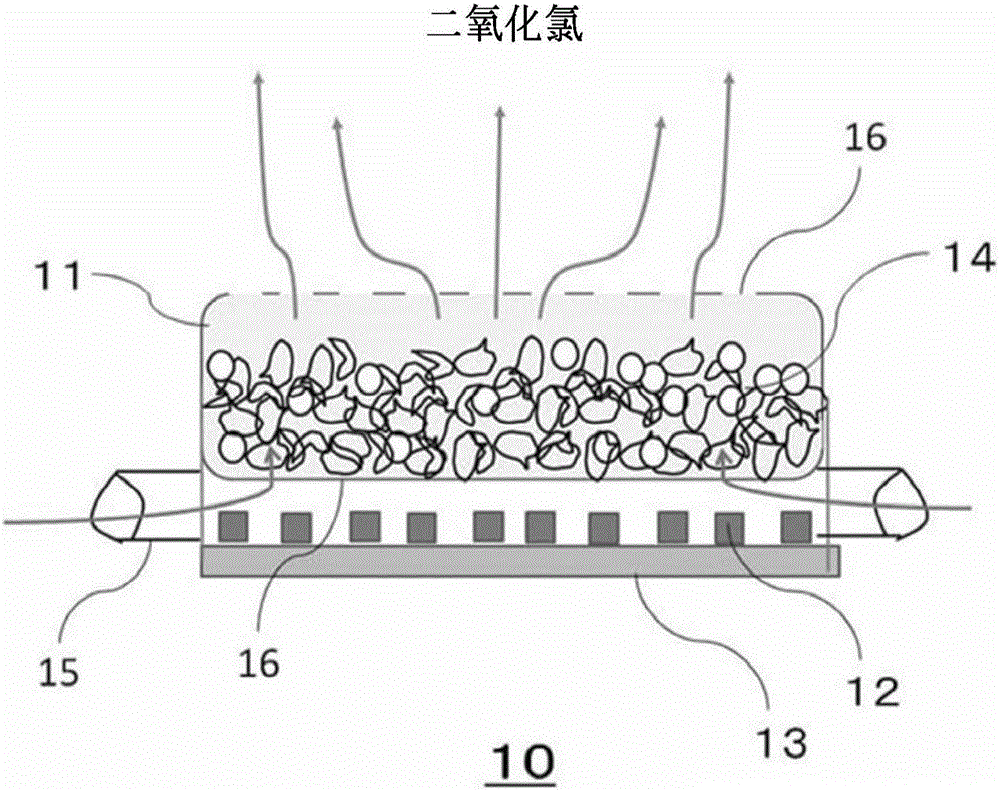

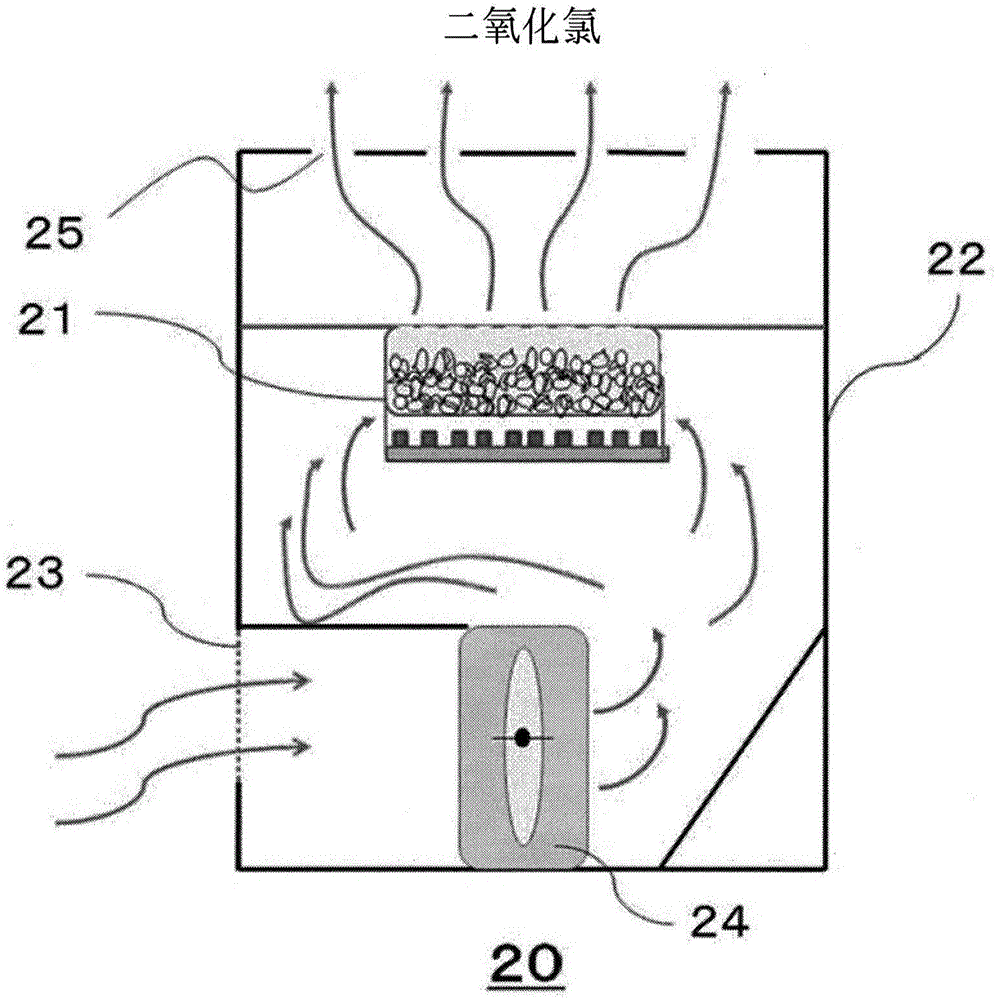

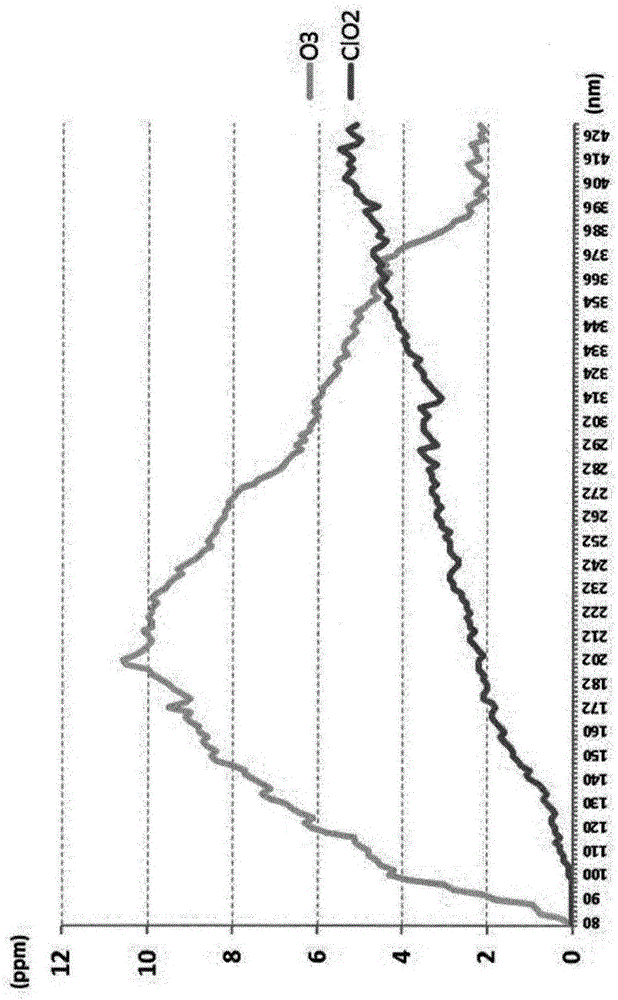

Chlorine dioxide generating unit and chlorine dioxide generating device

ActiveCN106241741AChlorine dioxideMetal/metal-oxides/metal-hydroxide catalystsChlorine dioxideLength wave

Owner:TAIKO PHARMA

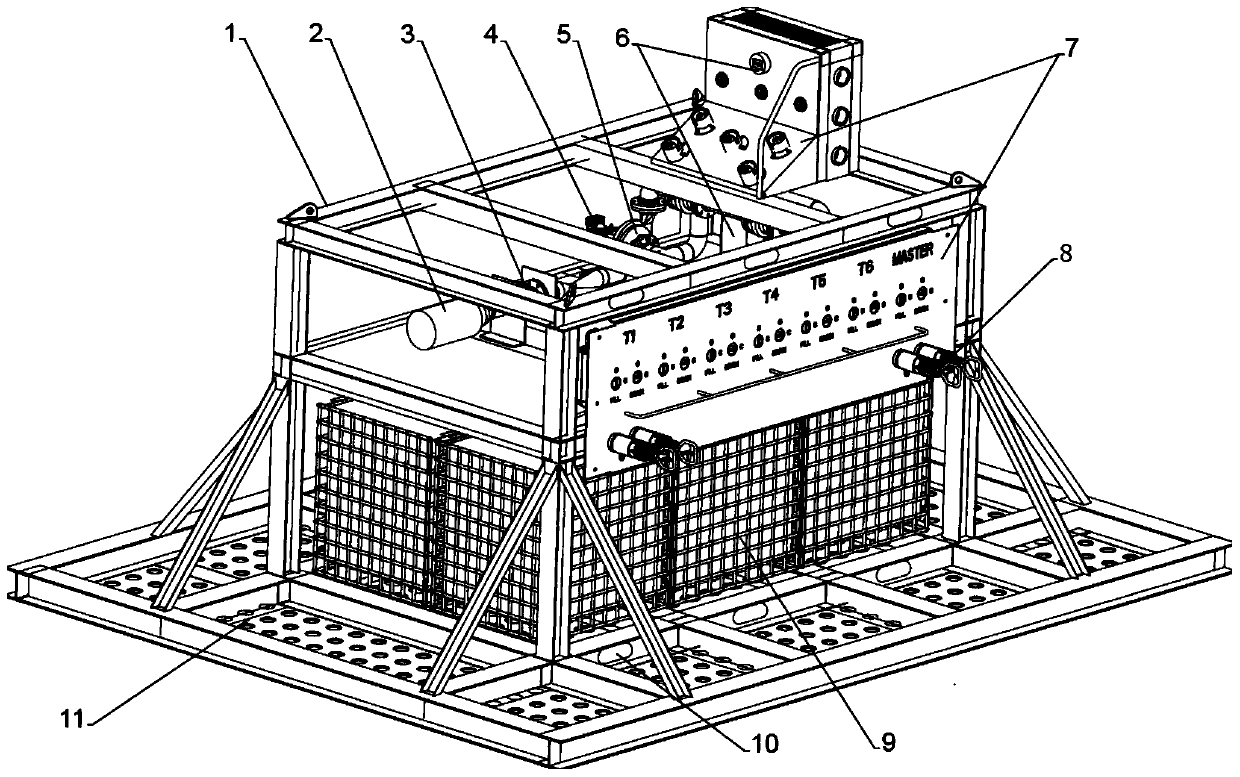

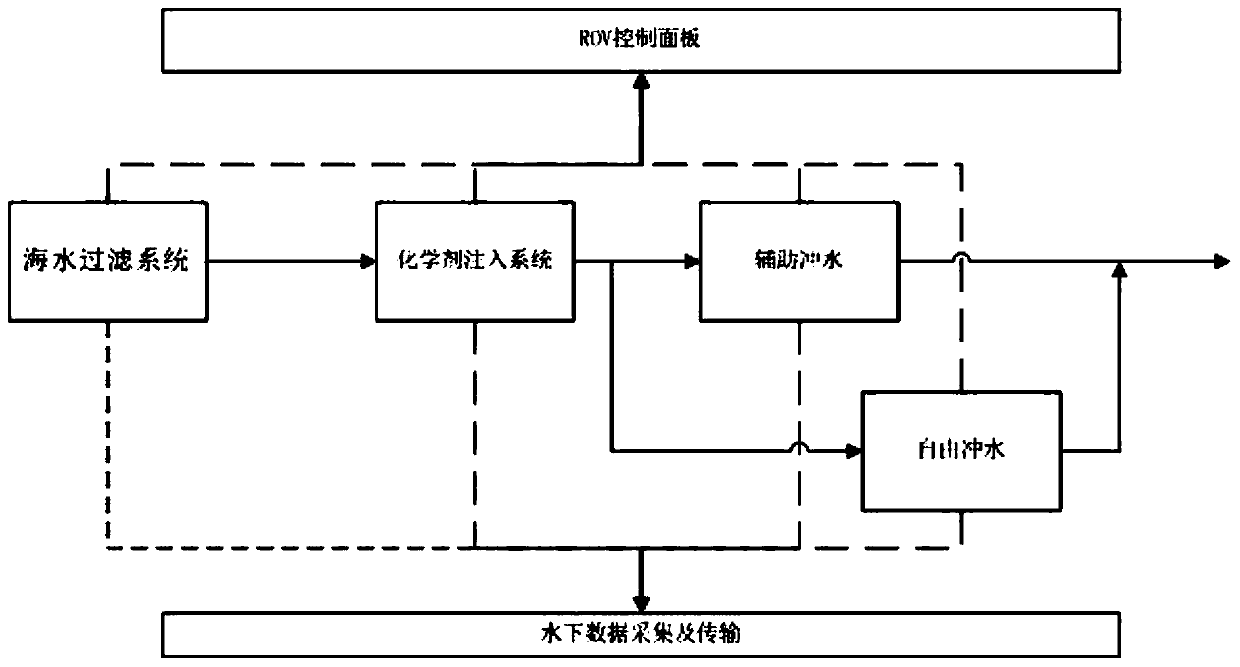

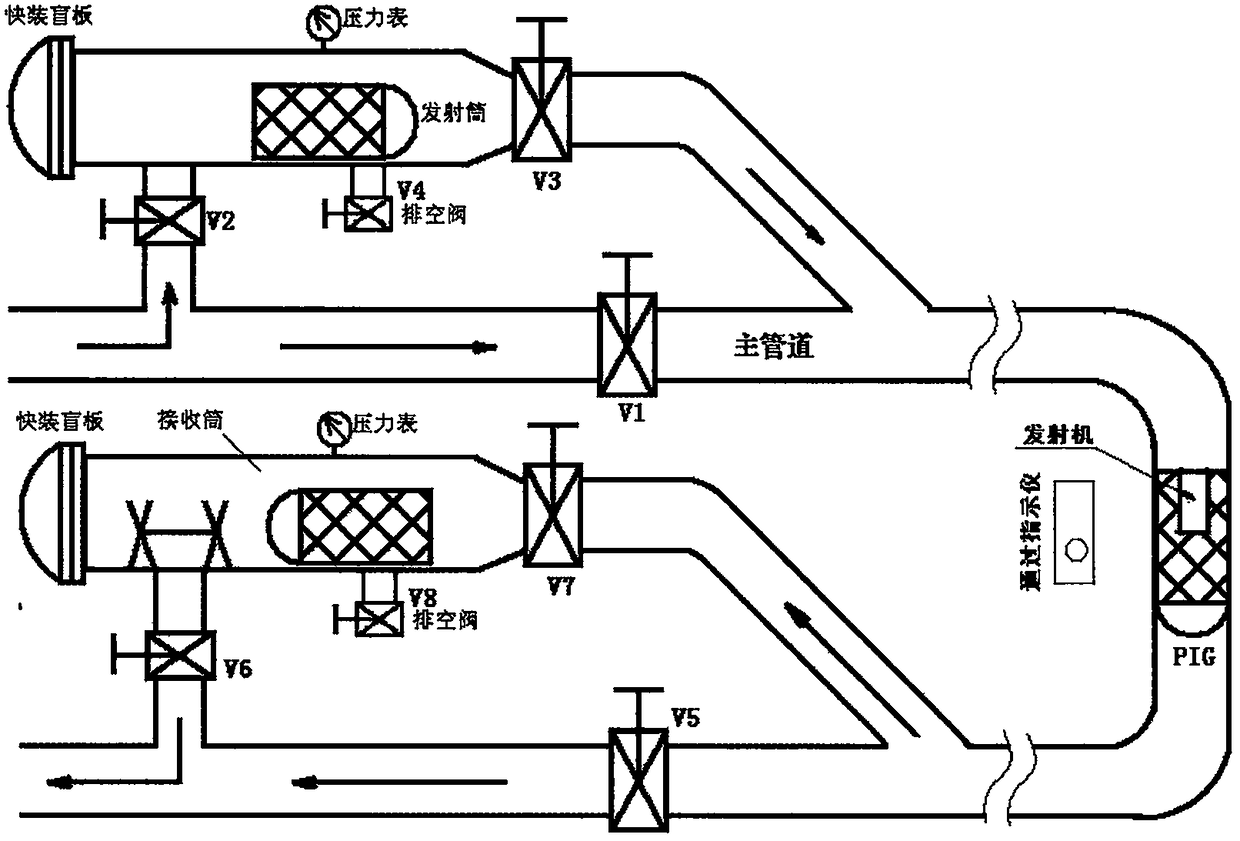

Device applicable to pipe washing work of deep sea oil and gas pipeline

InactiveCN110252750AOvercome stressOvercoming resistance along the wayHollow article cleaningPiggingPore water pressure

Owner:OFFSHORE OIL ENG +1

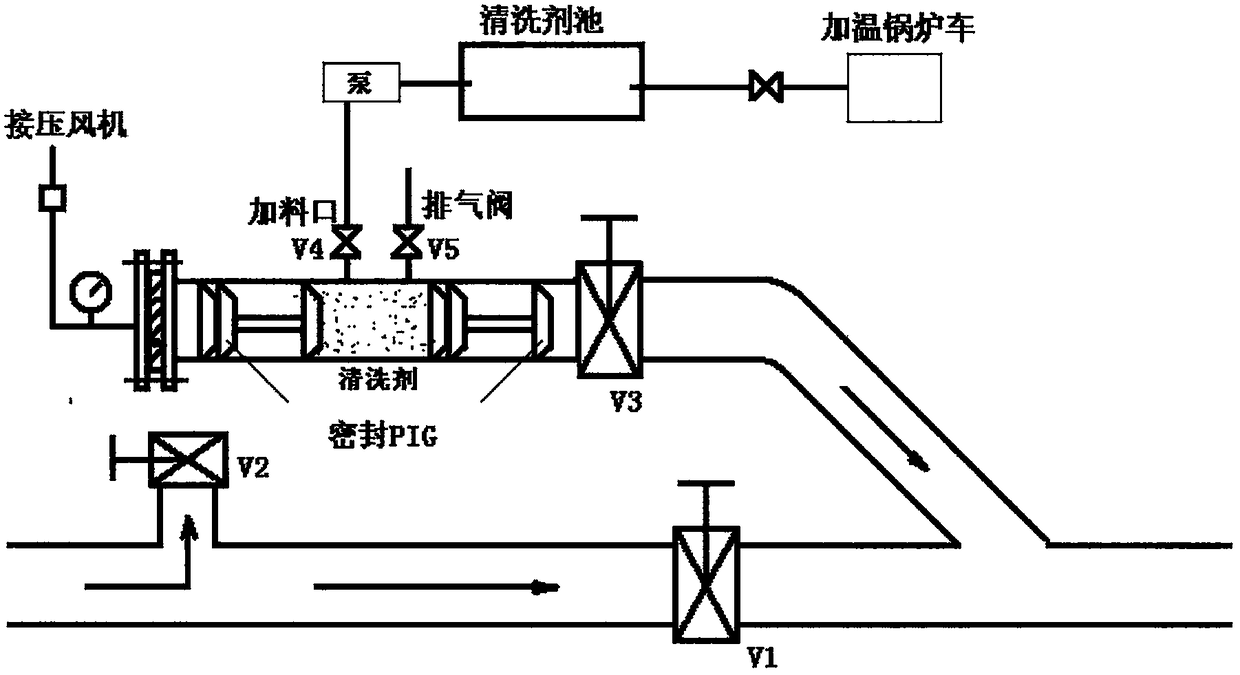

PIG high-elasticity pressurized pneumatic elastic cleaning technology

InactiveCN109013583AWide adaptabilitySimple cleaning processHollow article cleaningRinse waterEngineering

Owner:金德林

Combustion furnace

InactiveCN106765254AThe production of purificationEliminate hazardsCombination devicesLighting and heating apparatusSludgeSmoke Emission

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

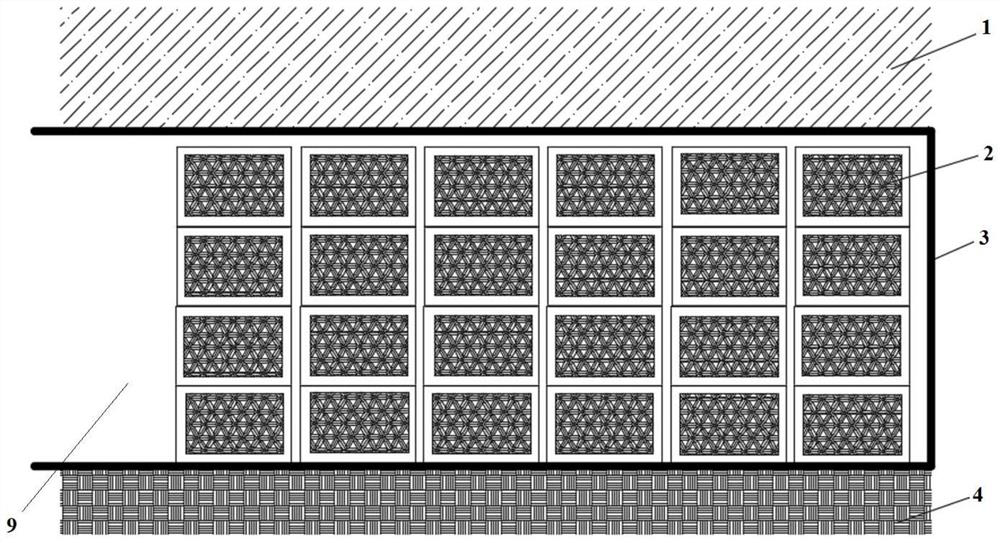

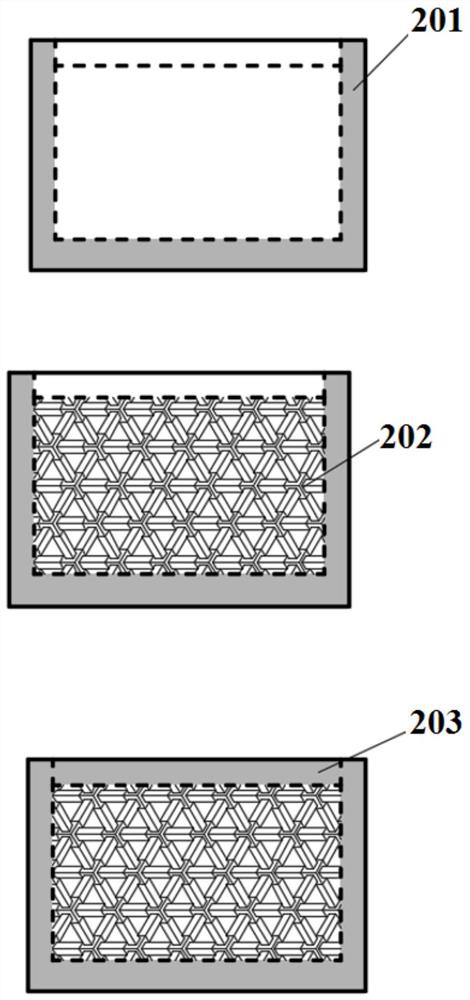

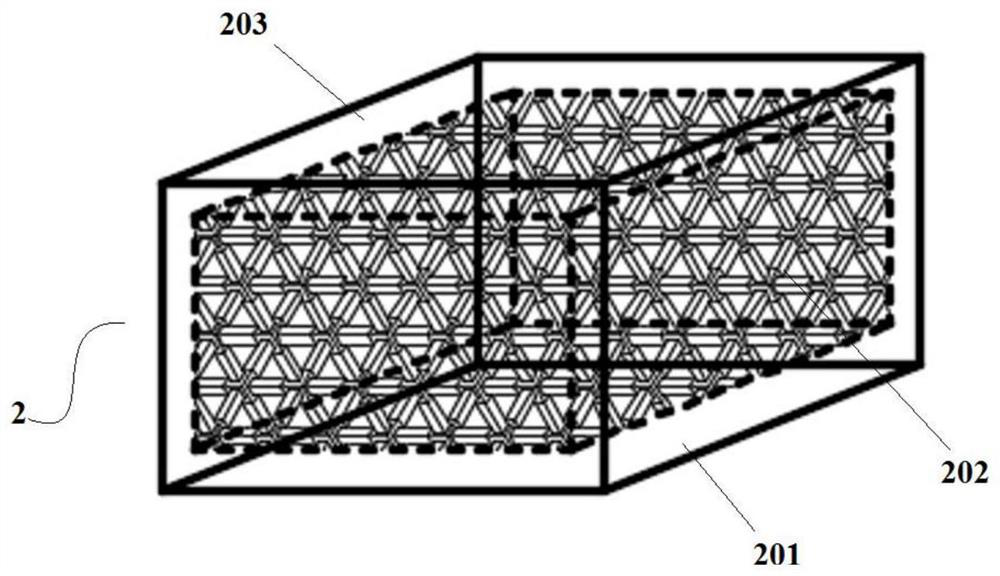

Method and structure for co-processing waste incineration fly ash underground in mine

ActiveCN114160542AAlleviate resource constraintsAlleviating the Nowhere to Dispose ProblemSolid waste disposalTransportation and packagingEnvironmental engineeringCement mortar

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

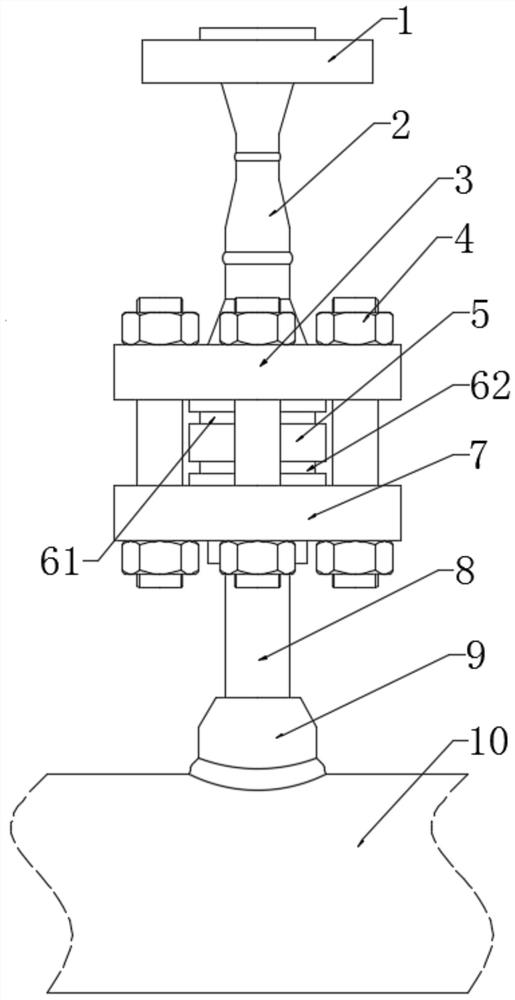

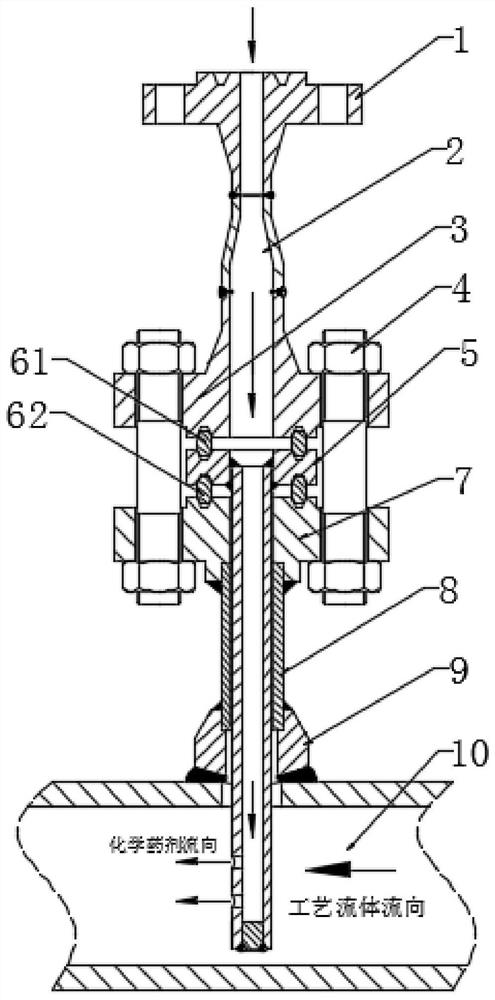

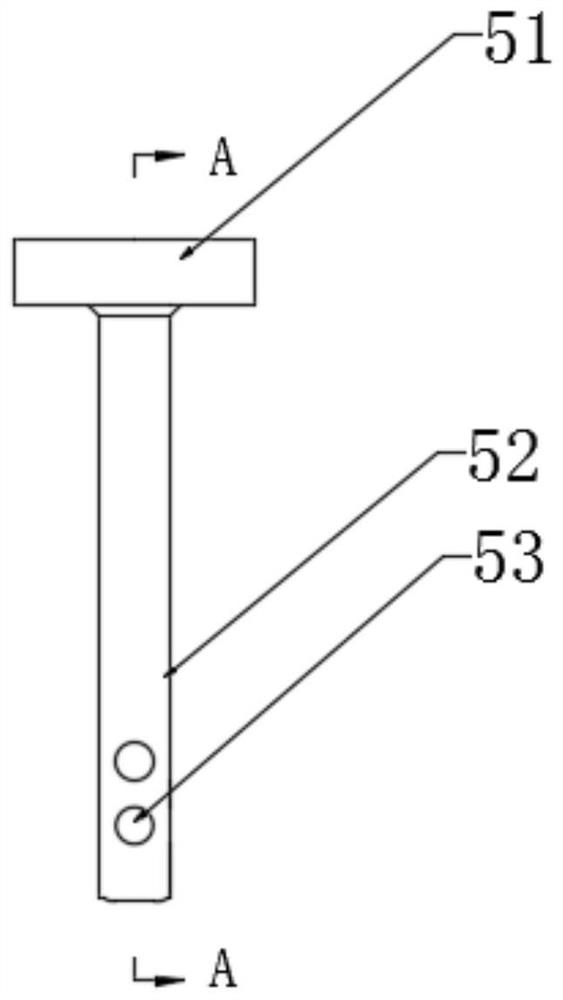

Novel chemical agent injection device

PendingCN111677894ARealize interchangeabilityRealize the realization of interchangeable universalFlanged jointsSlide valveEngineeringMechanical engineering

Owner:CNOOC ENERGY TECH & SERVICES +1

Anti-oxidation surface treatment method for conductive bar

InactiveCN109943854AImprove adhesionMetallic material coating processesAntioxidantOxidation resistant

The invention relates to the field of conductive bar production, in particular to an anti-oxidation surface treatment method for a conductive bar. The anti-oxidation surface treatment method comprisesthe following steps of 1, soaking the conductive bar to be treated in a cleaning solution to remove oil stains and rust on the surface of the conductive bar; 2, cleaning the cleaned conductive bar with deionized water, and wiping the conductive bar with a wiping cloth; 3, placing the dried conductive bar in a solvent containing an antioxidant, heating the conductive bar to 50-200 DEG C, and carrying out sealed and pressurized reaction; and 4, after the treatment is finished, cleaning and then drying the conductive bar at a low temperature. By adopting a chemical agent blending, heating and pressurizing treatment method, the process is simple, little pollution is caused, and the process is controllable.

Owner:YANGZHOU HONGSHUN ELECTRIC CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap