PIG high-elasticity pressurized pneumatic elastic cleaning technology

A highly flexible and technical technology, applied in the field of pipeline cleaning, can solve the problems of high cost and incomplete removal, and achieve the effect of economical saving, saving medicine and equipment, high efficiency and low cost cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

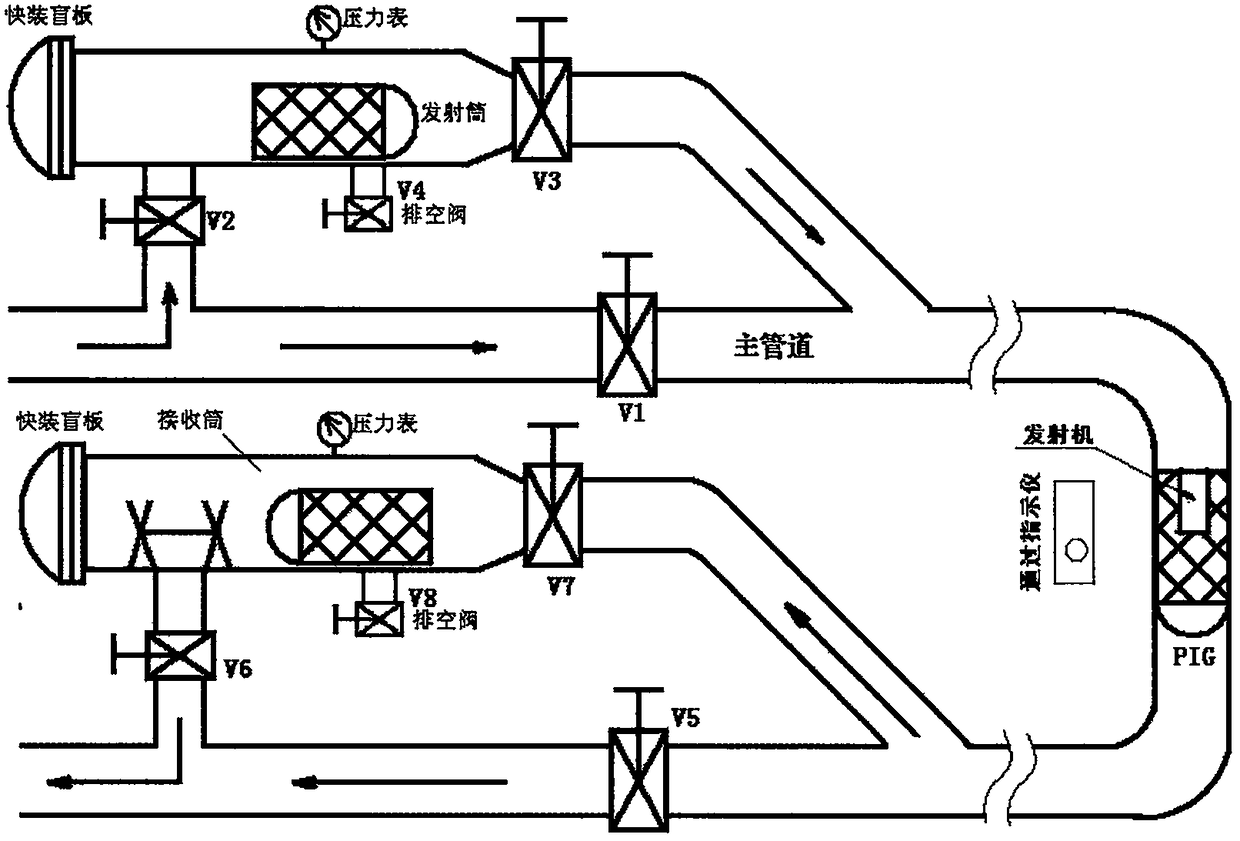

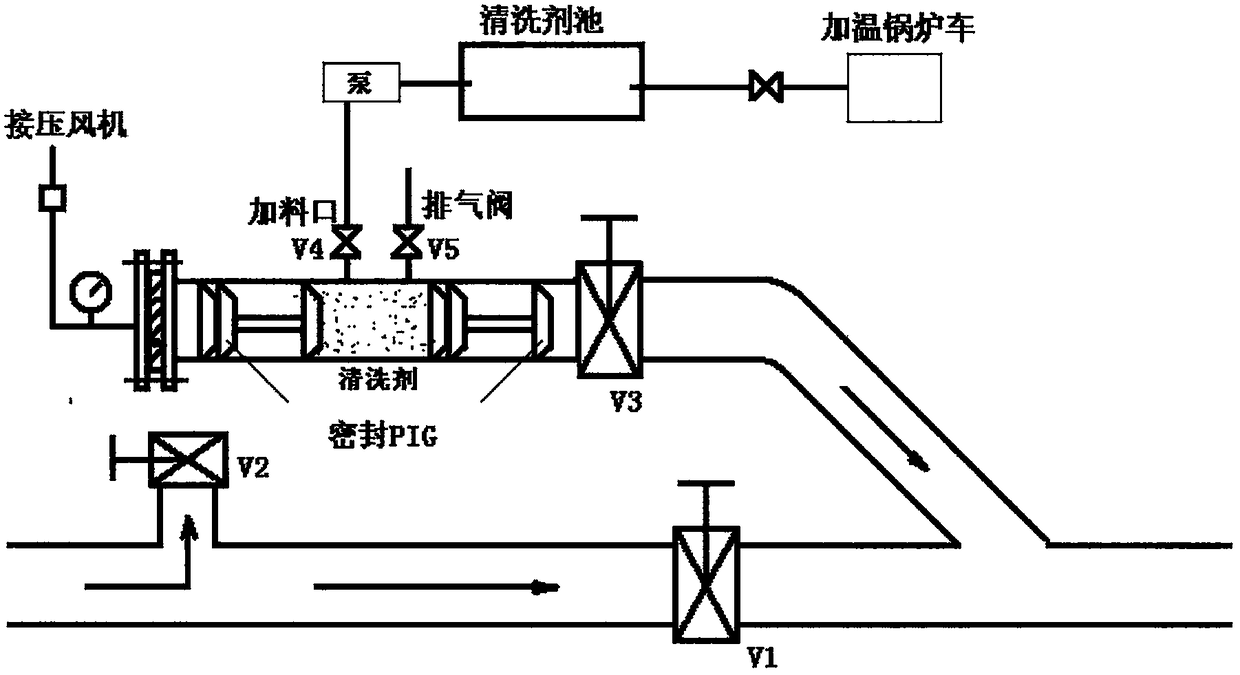

[0028] Such as figure 1 and figure 2 As shown, a PIG high-elastic pressurized pneumatic cleaning technology combines PIG cleaning and chemical cleaning, and the pipeline to be cleaned is sequentially PIG cleaning and chemical cleaning. The specific process steps are as follows:

[0029] (1) PIG cleaning

[0030] (1) Detect the direction and position of the pipeline, the type and position of the elbow, and investigate whether there is a reduction in diameter, deformation and in-line bend complexity;

[0031] (2) Use the operating medium of the original pipeline as the back power of the PIG to promote the operation of the PIG to realize non-stop cleaning. Before cleaning, close all branch line valves, close the outlet valve V3, inlet valve V2 and discharge valve V4 on the launch tube, and the main line The valve V1 is open, and the pipeline is running normally to supply water;

[0032] (3) Open the quick-install blind plate of the launch tube, put in the PIG, and close the quic

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap