Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93 results about "Metallurgy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are called alloys. Metallurgy is used to separate metals from their ore. Metallurgy is also the technology of metals: the way in which science is applied to the production of metals, and the engineering of metal components for usage in products for consumers and manufacturers. The production of metals involves the processing of ores to extract the metal they contain, and the mixture of metals, sometimes with other elements, to produce alloys. Metallurgy is distinguished from the craft of metalworking, although metalworking relies on metallurgy, as medicine relies on medical science, for technical advancement. The science of metallurgy is subdivided into chemical metallurgy and physical metallurgy.

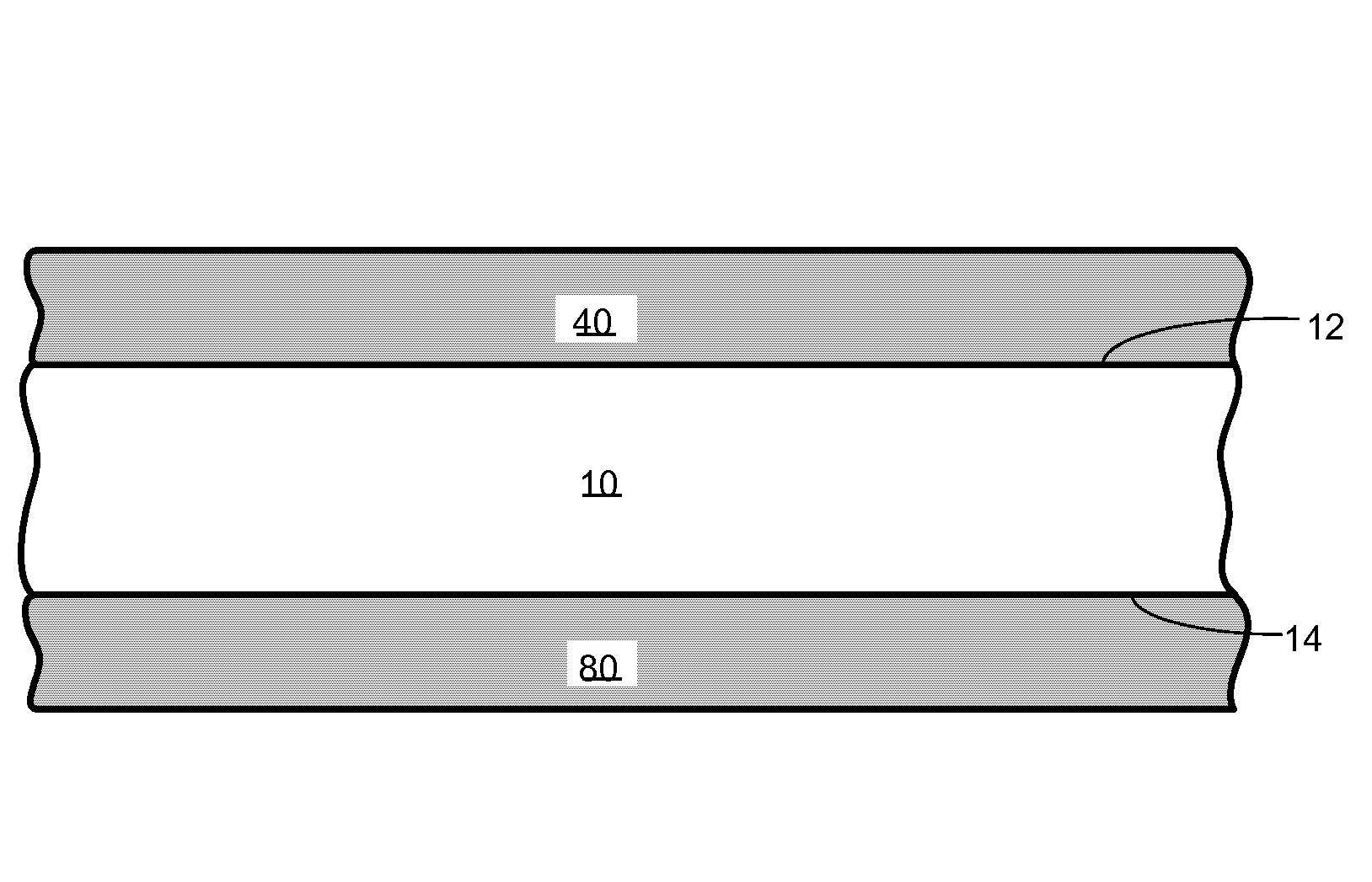

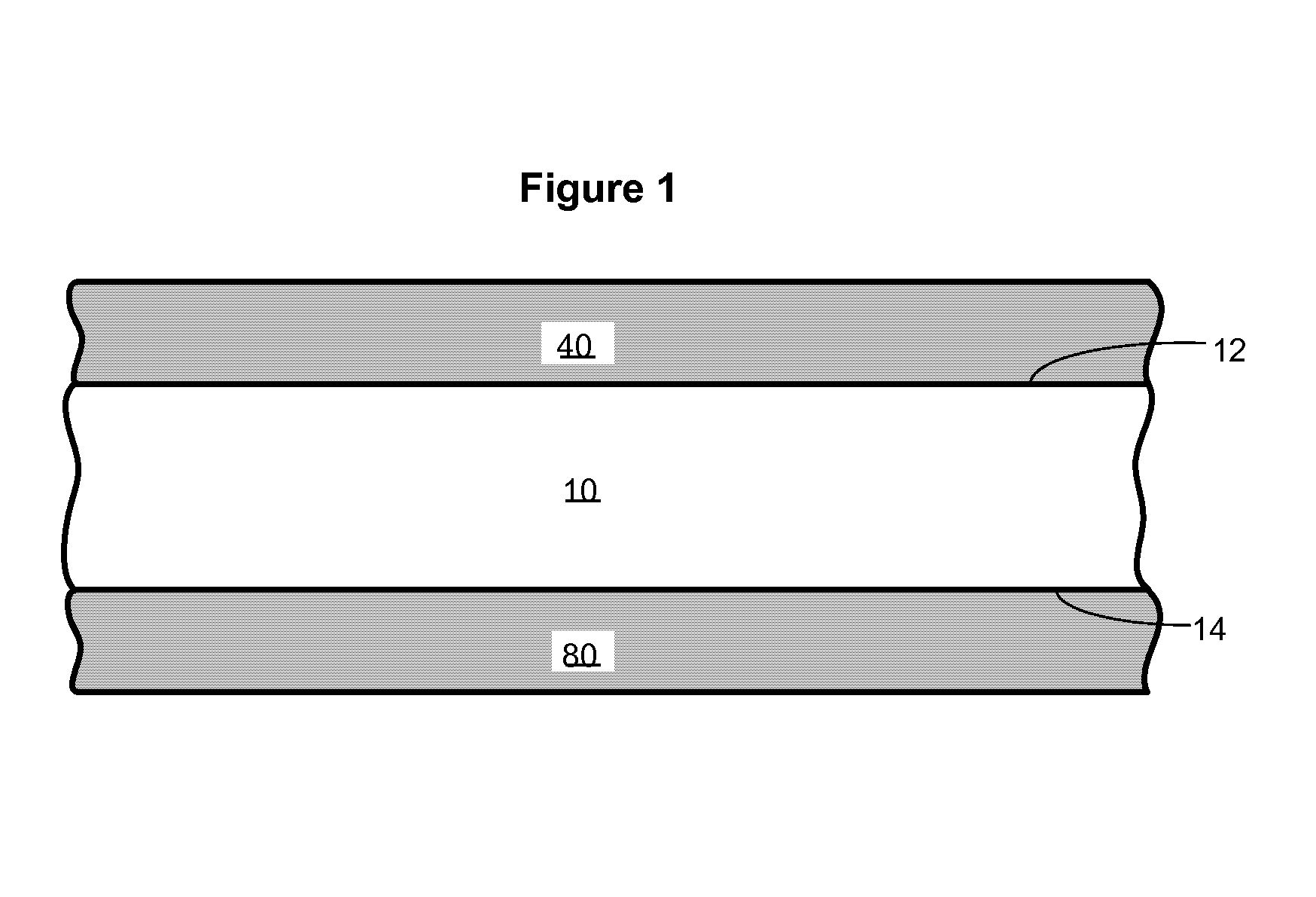

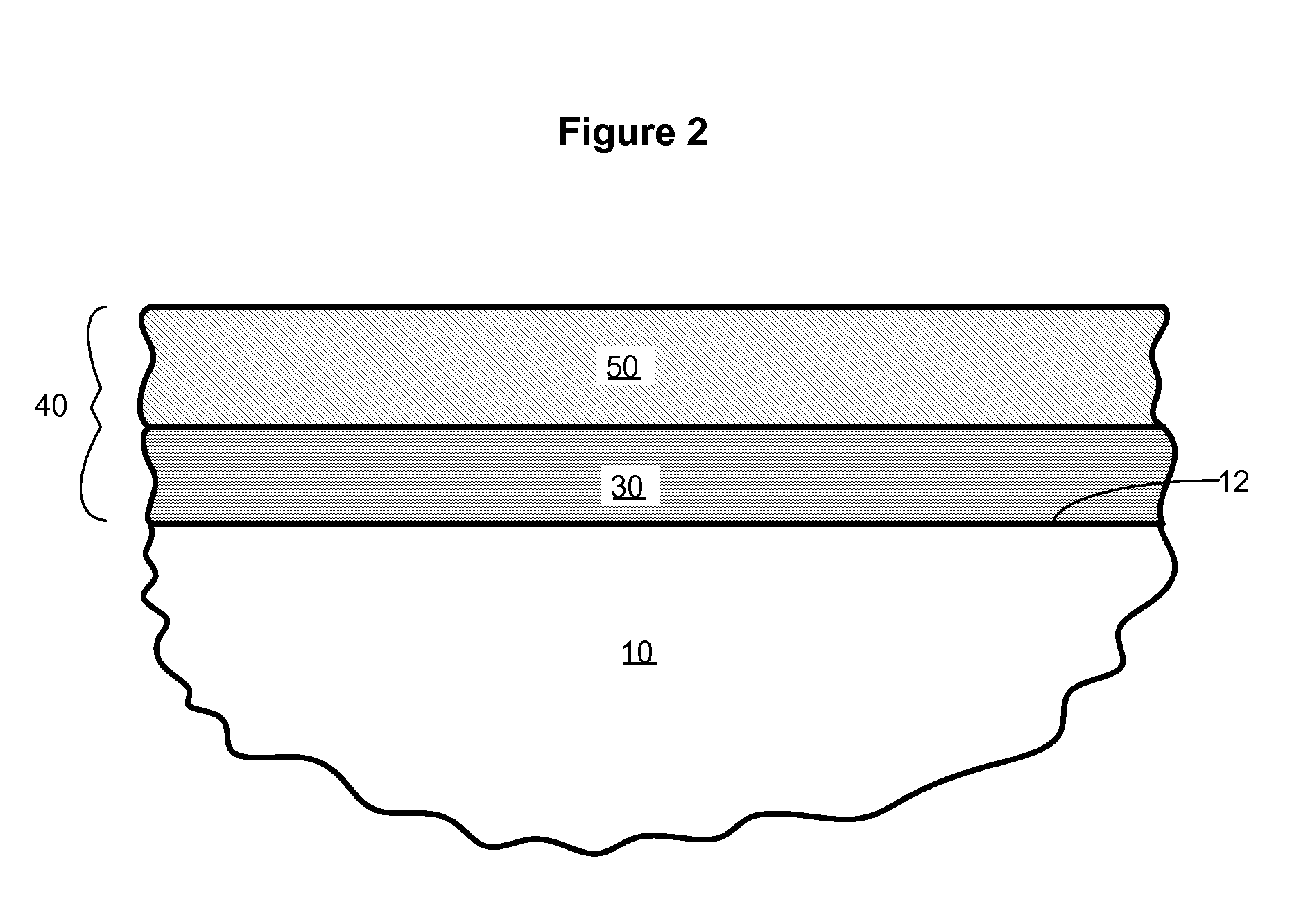

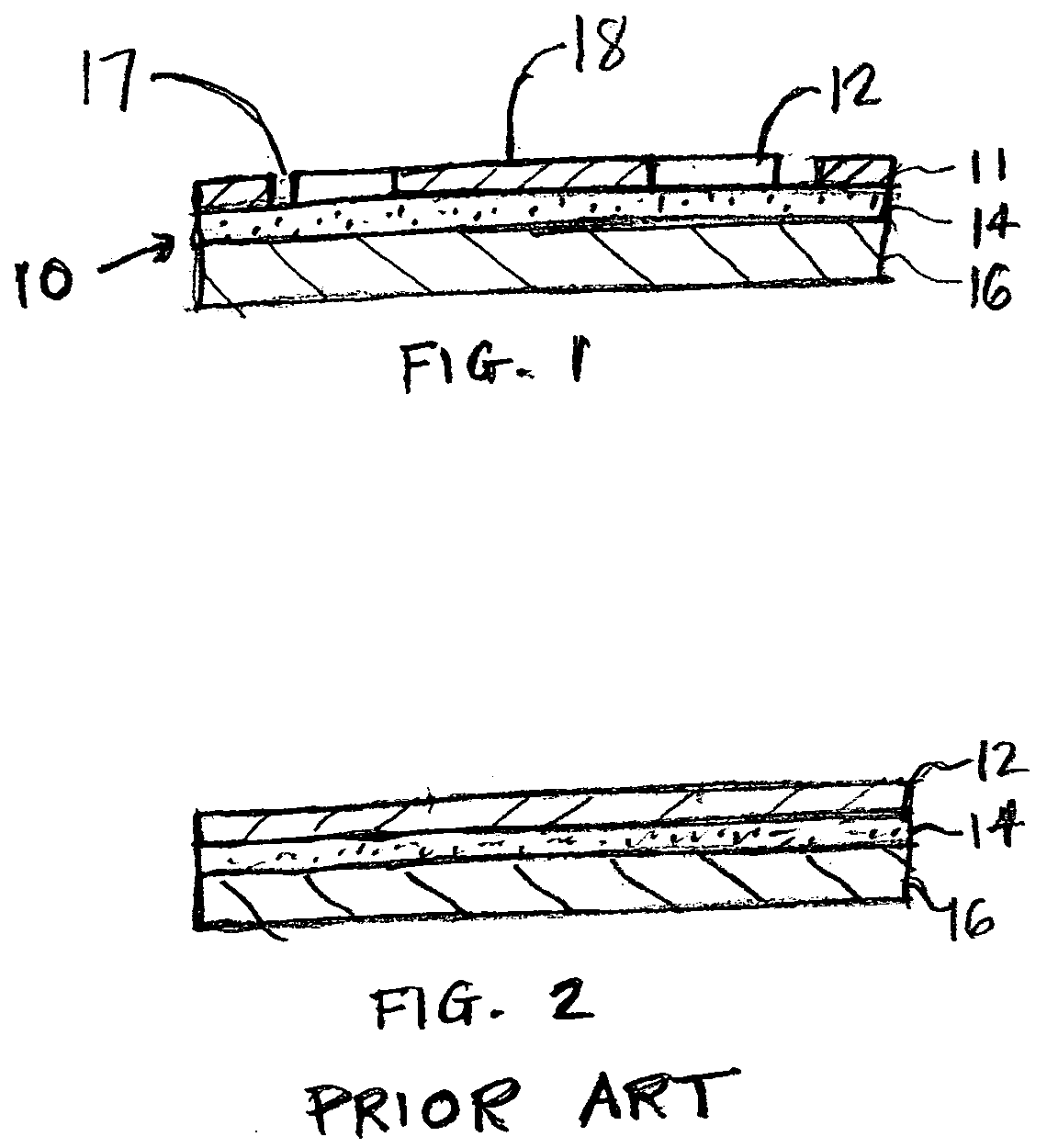

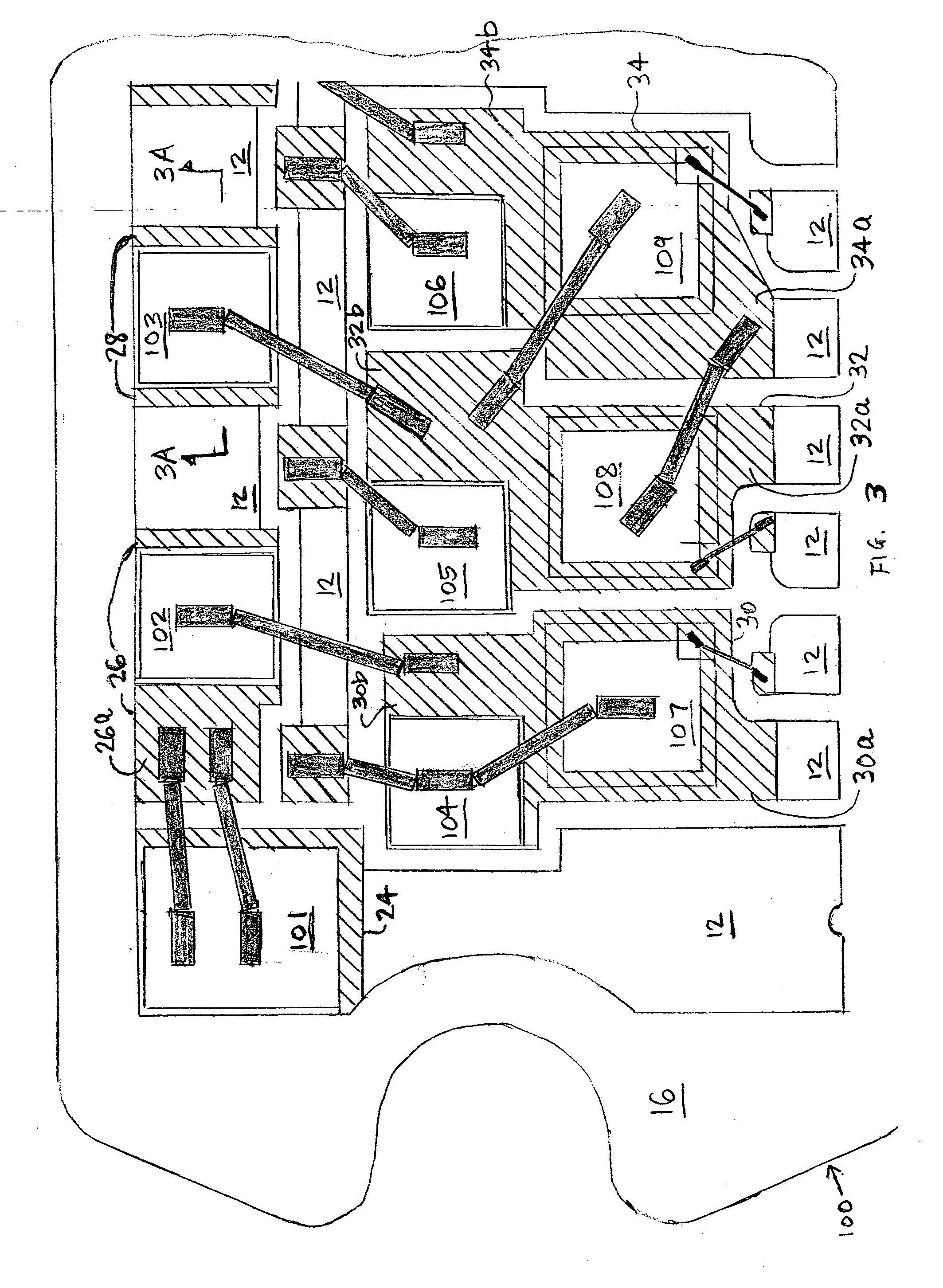

Opposed functional coatings having comparable single surface reflectances

ActiveUS20070248756A1Low-emissivity coatingLiquid surface applicatorsDoors/windowsLow emissivityMetallurgy

Owner:CARDINAL CG

Steel for enamel and production method thereof

The invention discloses a steel for enamel, and is characterized by comprising the following chemical elements by mass: not more than 0.020% of C, not more than 0.05% of Si, 0.10-0.50% of Mn, not more than 0.03% of P, 0.003-0.050% of S, 0.001-0.03% of Al, 0.001-0.015% of N, 0.005-0.050% of O, not more than 0.005% of Ca, not more than 0.005% of Mg, not more than 0.10% of Cu, not more than 0.10% of Cr, not more than 0.10% of Ni, not more than 0.10% of Mo, at least one of 0.0005-0.003% of B, not more than 0.01% of Nb, not more than 0.02% of V, and 0.001-0.05% of Ti, and the balance of Fe and other inevitable impurities, wherein N(%)*Ti(%) is not more than 3*10<-4>. Correspondingly, the invention further discloses a production method of the steel for enamel. The steel for enamel has excellent comprehensive performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Vegetable fiber liquefied matter, and preparing method and use thereof

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

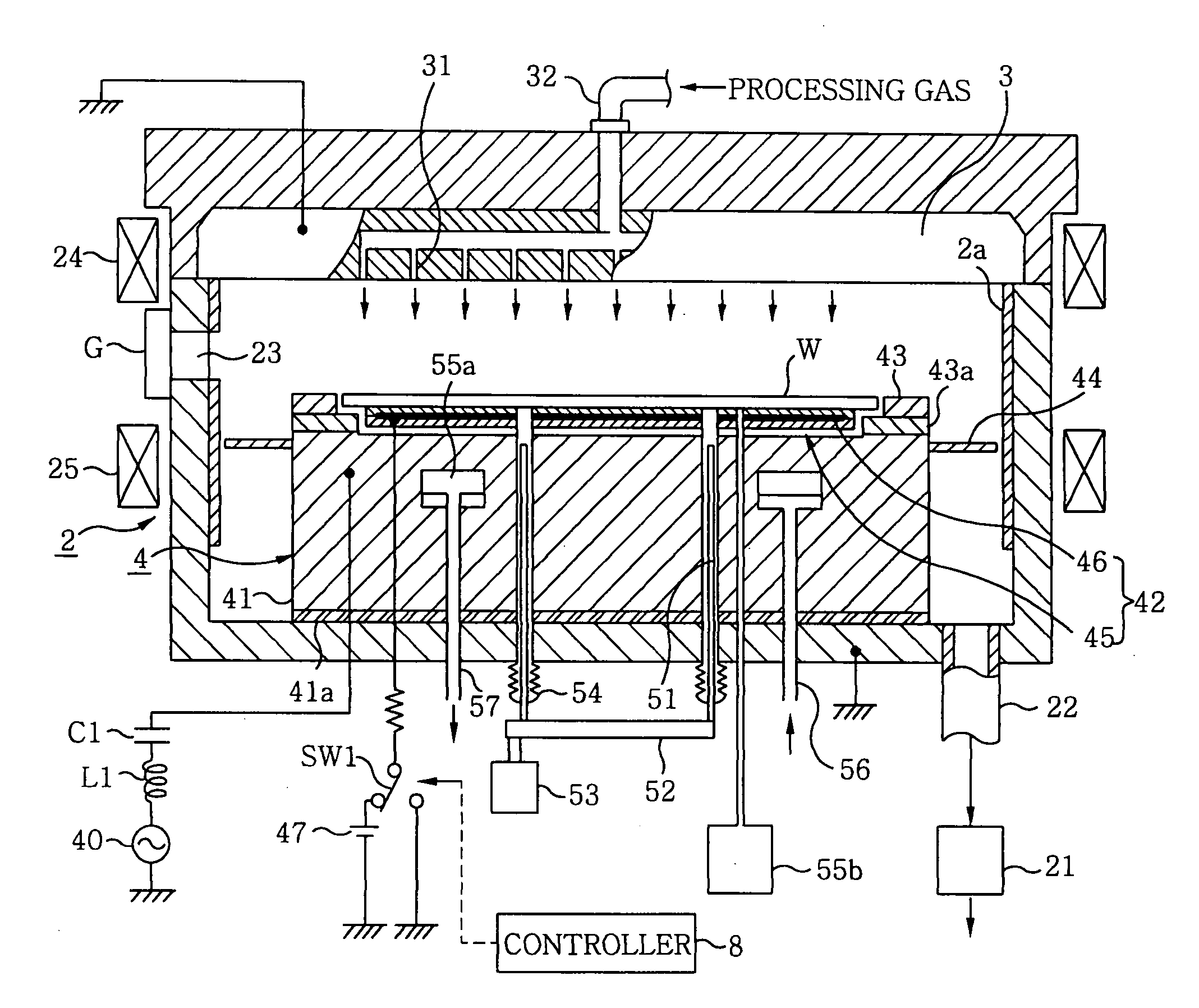

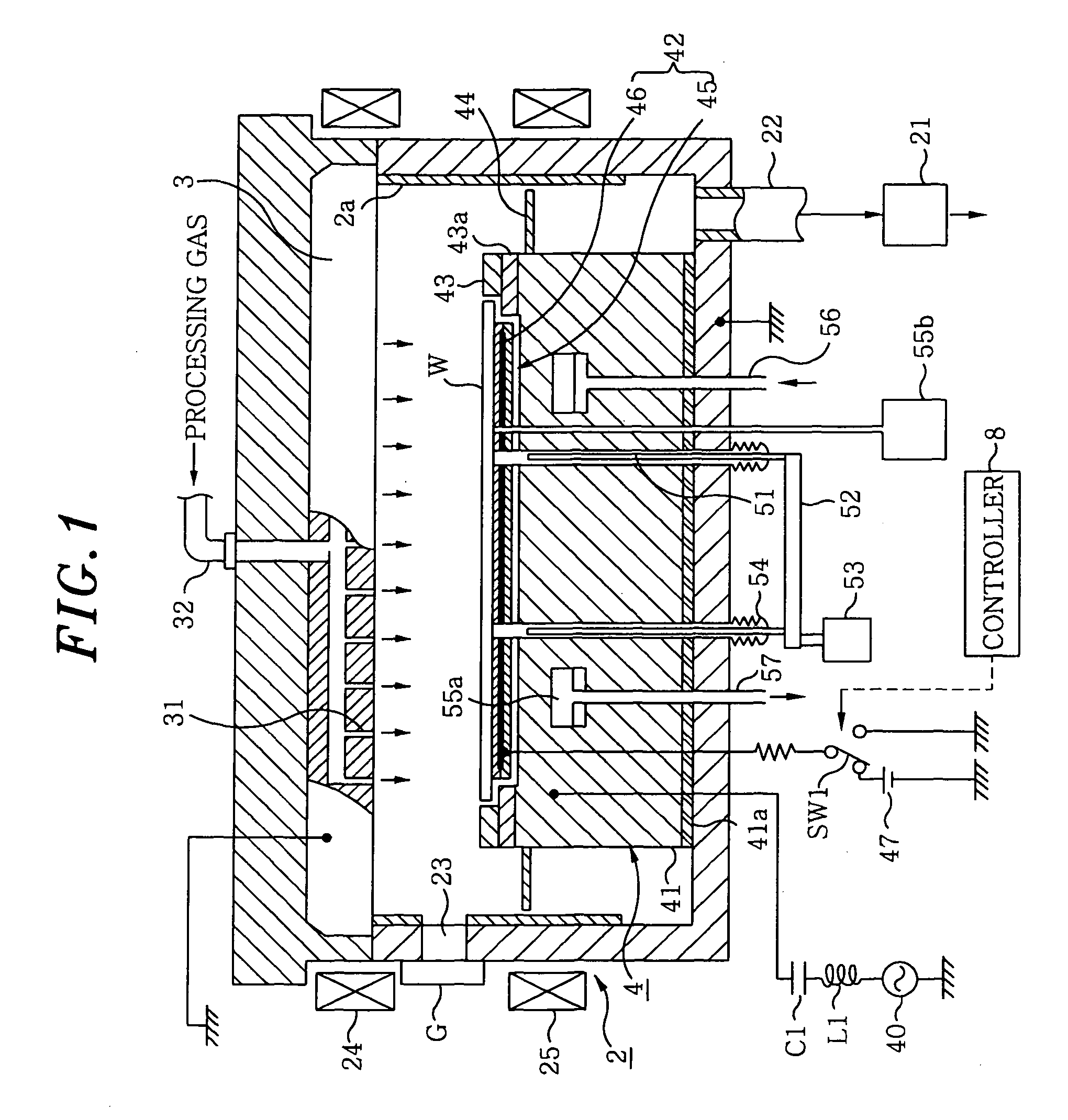

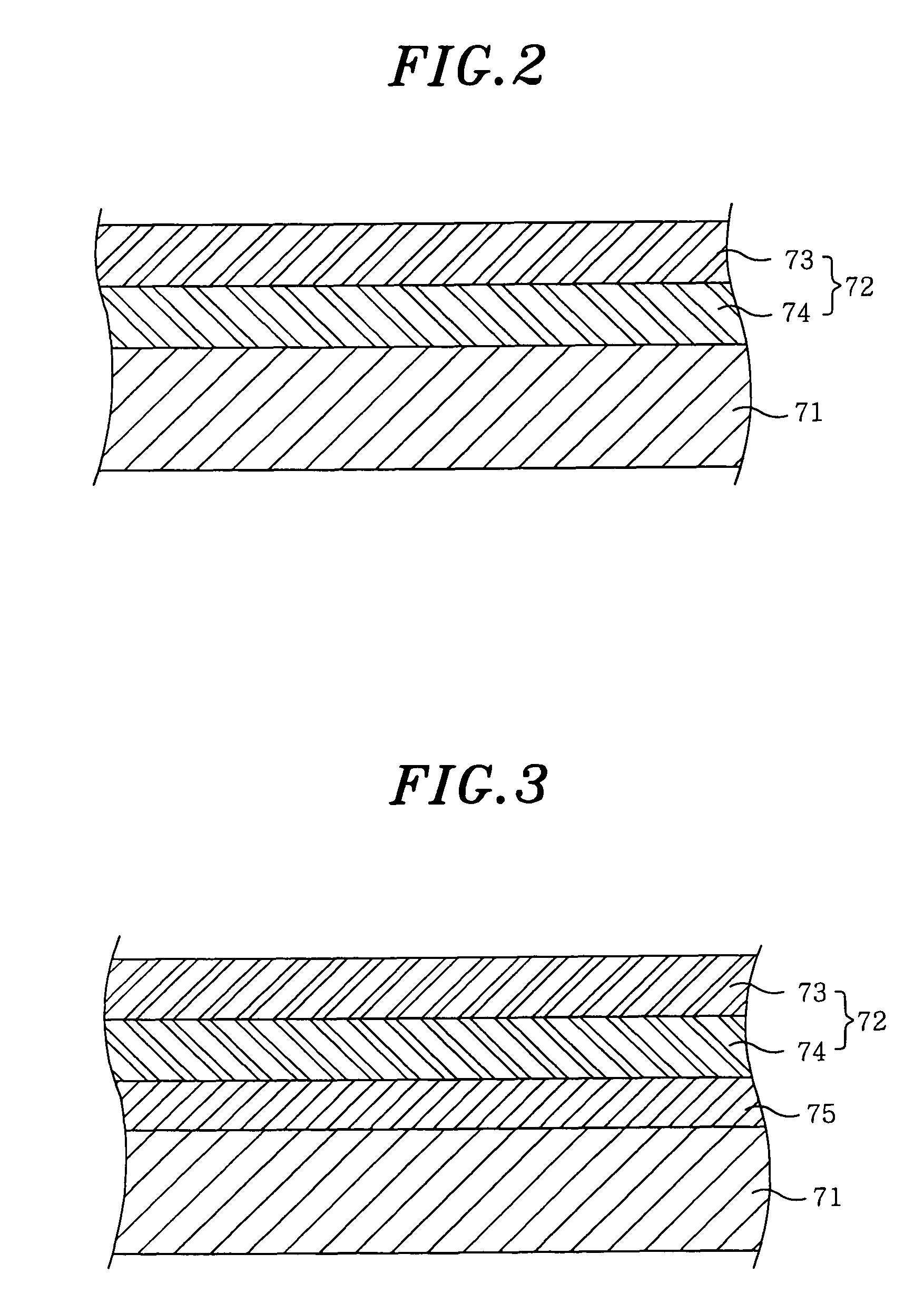

Internal member of a plasma processing vessel

ActiveUS7780786B2Prevent peelingLiquid surface applicatorsMolten spray coatingThermal sprayingMetallurgy

Owner:TOKYO ELECTRON LTD

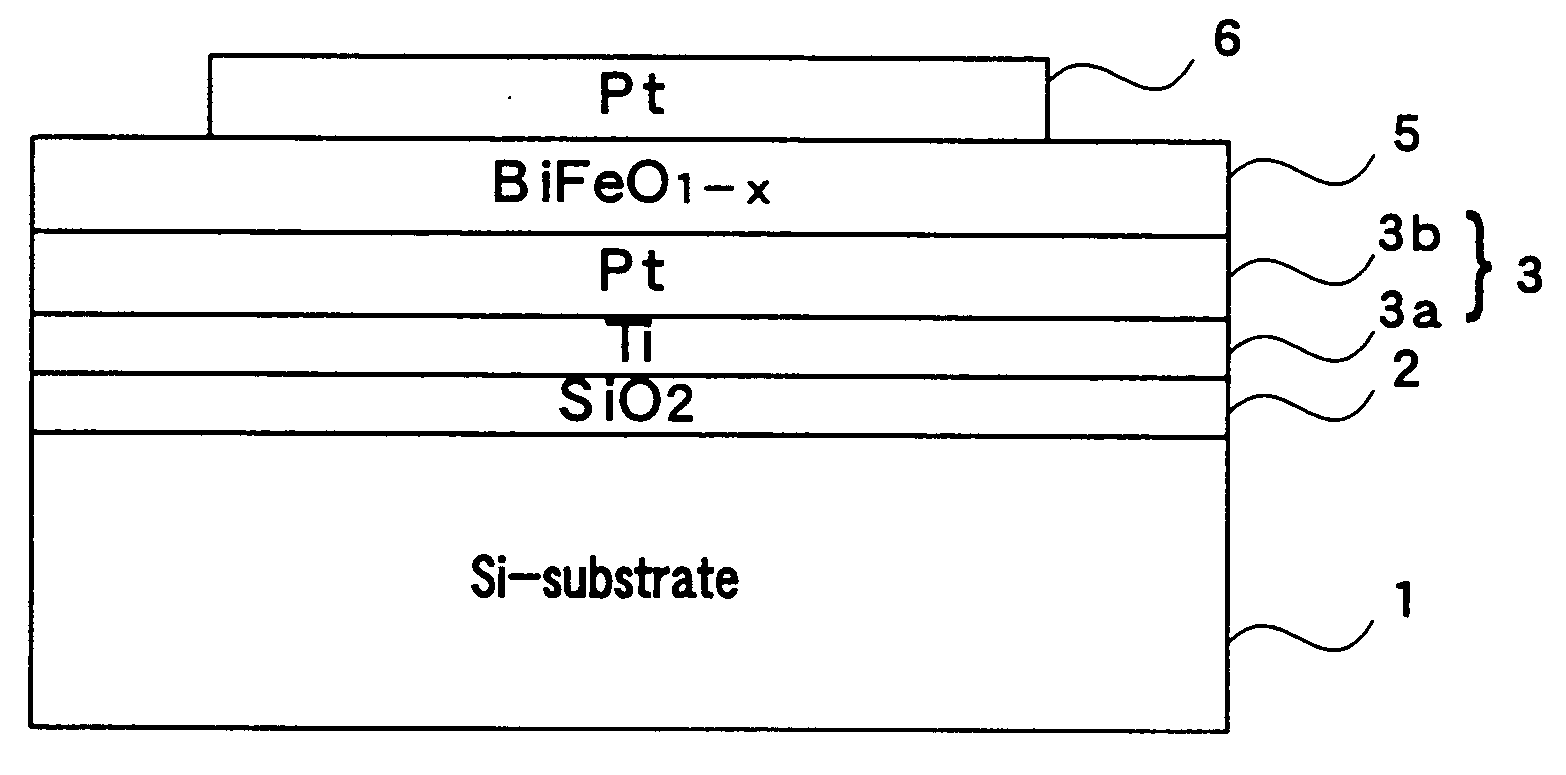

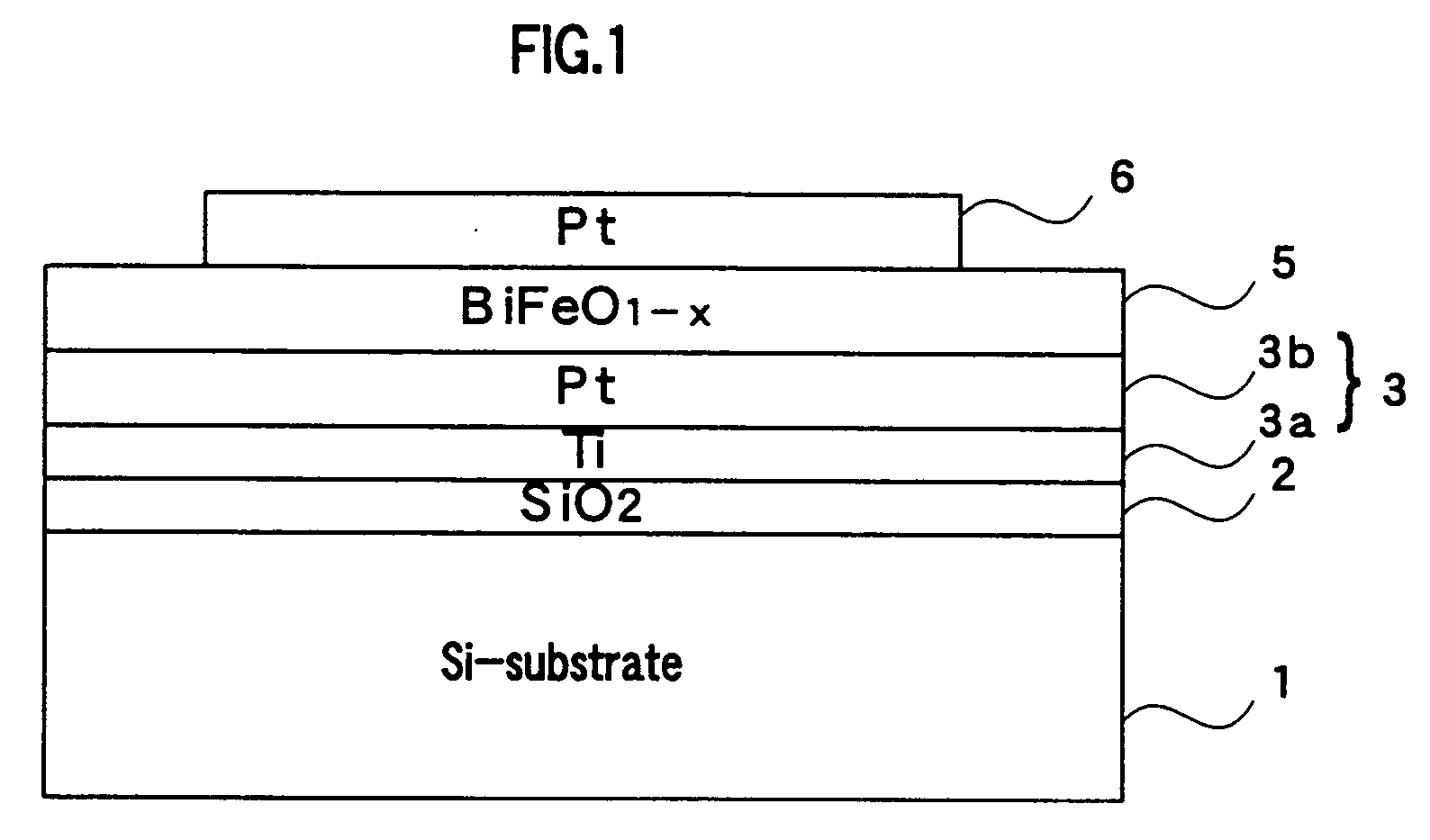

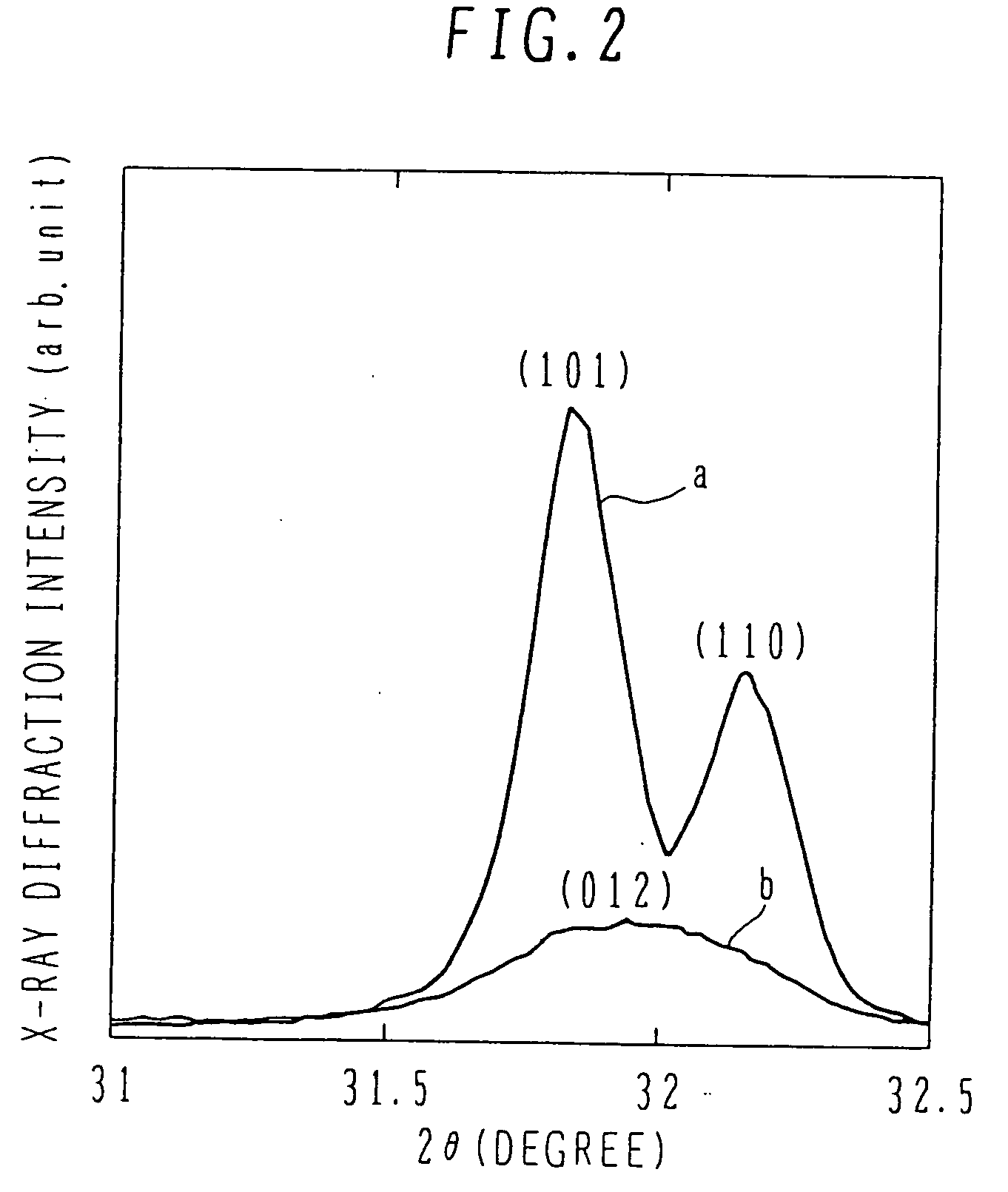

Ferroelectric material, its manufacture method and ferroelectric memory

InactiveUS20060131627A1Large remanent polarizationTransistorCeramicsTetragonal crystal systemMetallurgy

Owner:FUJITSU LTD +1

Solid Electrolytic Capacitor Containing a Poly(3,4-Ethylenedioxythiophene) Quaternary Onium Salt

ActiveUS20120147529A1Highly solubleEasily and cost-effectively formedMaterial nanotechnologyHybrid capacitor electrolytesDielectricElectrolysis

A solid electrolytic capacitor a solid electrolytic capacitor that includes an anode body, a dielectric overlying the anode body, and a solid electrolyte overlying the dielectric is provided. The capacitor also comprises a conductive polymer coating that overlies the solid electrolyte and includes nanoparticles formed from a poly(3,4-ethylenedioxythiophene) quaternary onium salt.

Owner:CENT FOR ORGANIC CHEM +1

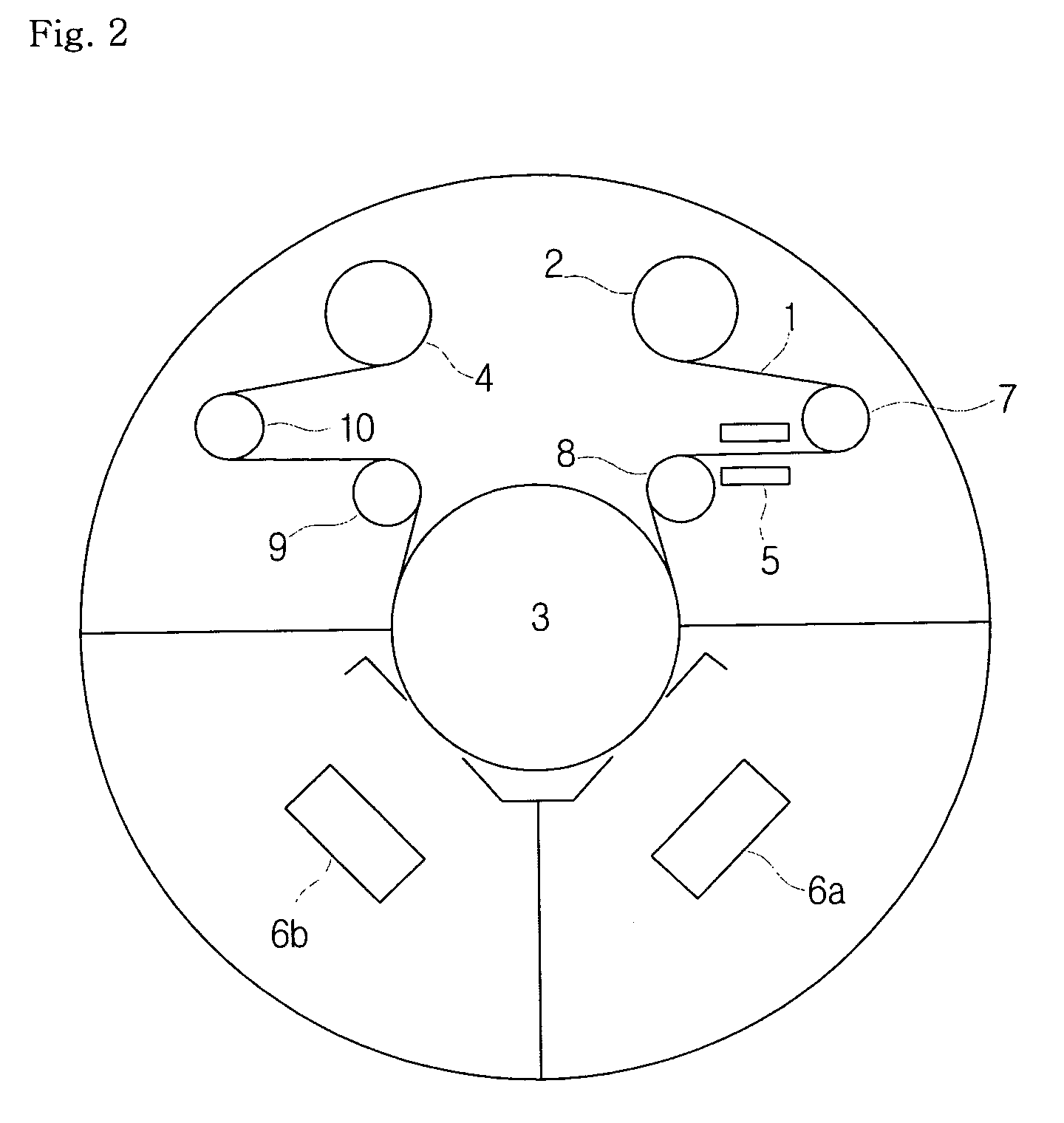

Method for casting rotary axis casts of aerogenerators

ActiveCN101618425AImprove yieldReduce manufacturing costFoundry mouldsFoundry coresMetallurgyBlock effect

The invention discloses a method for casting rotary axis casts of aerogenerators, which comprises the steps of mould manufacture, the manufacture of sand moulds and moulding by casting. In the step b of the manufacture of sand moulds, a top sprue (1) is used as an inlet of iron liquor, and is alternately communicated with runners; a bottom runner is communicated with an ingate communicated with a cast mould cavity; the runners are designed into a first runner (3), a second runner (4) and a circular runner (5); the ingate is designed into a plurality of radial runners (6) for communicating the circular runner (5) and the cast mould cavity; filtering apparatuses are arranged on the first runner (3) and the second runner (4), and are also arranged between each radial runner (6) and the circular runner (5); and in the step c of moulding by casting, the casting temperature is controlled from 1310 DEG C to 1350DEG C; and finally, a cast (2) is obtained. The method for casting rotary axis cast of aerogenerator has the advantages of good residue blocking effect and low production cost.

Owner:RIYUE HEAVY IND

Zn-Sr series zinc alloy as well as preparation method and application of Zn-Sr series zinc alloy

Owner:PEKING UNIV

Coated powder, coating composition, and coated article

InactiveUS20050208303A1Accurate particle sizeInorganic pigment treatmentSynthetic resin layered productsMetallurgyLength wave

Owner:NITTETABU MINING CORP +1

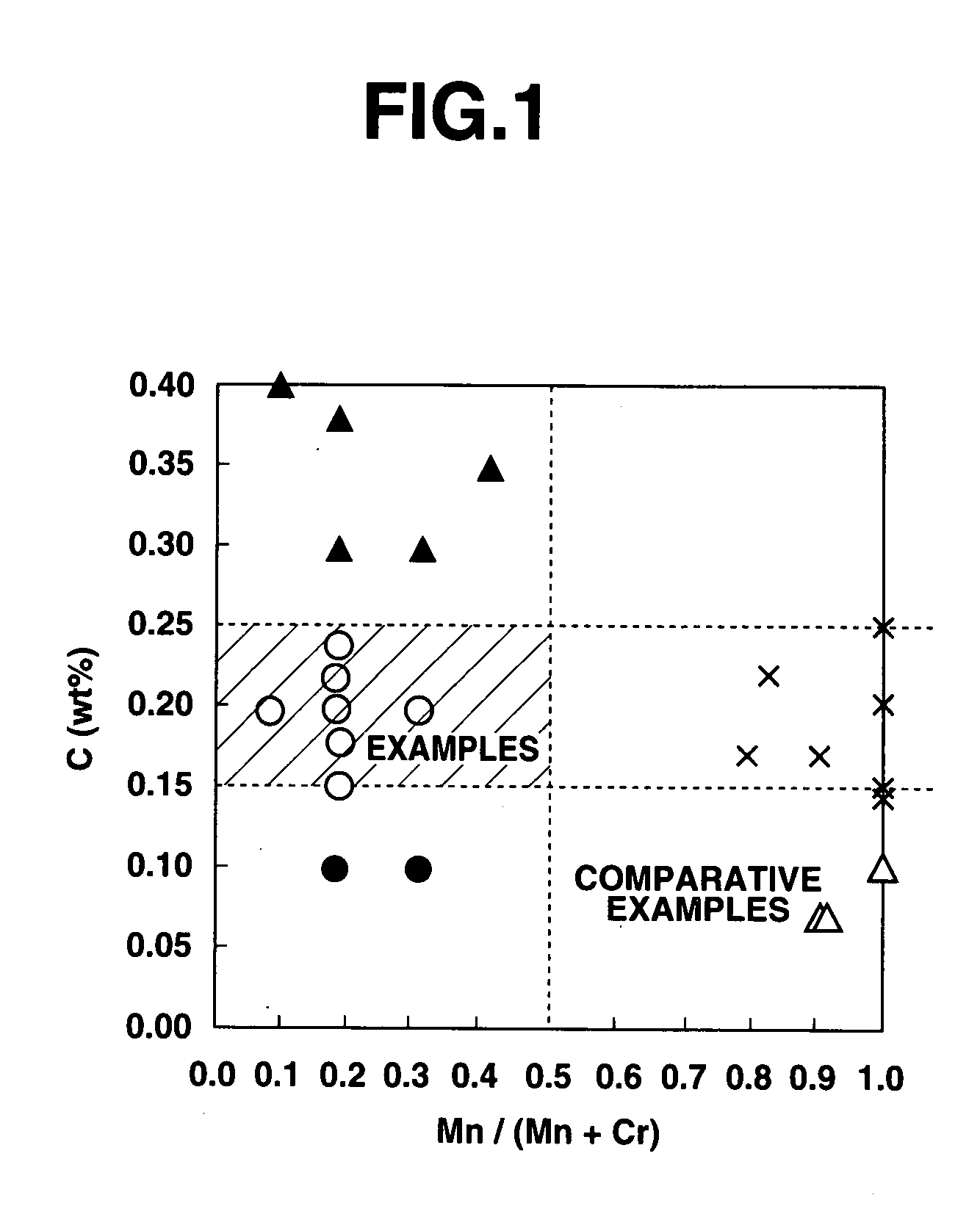

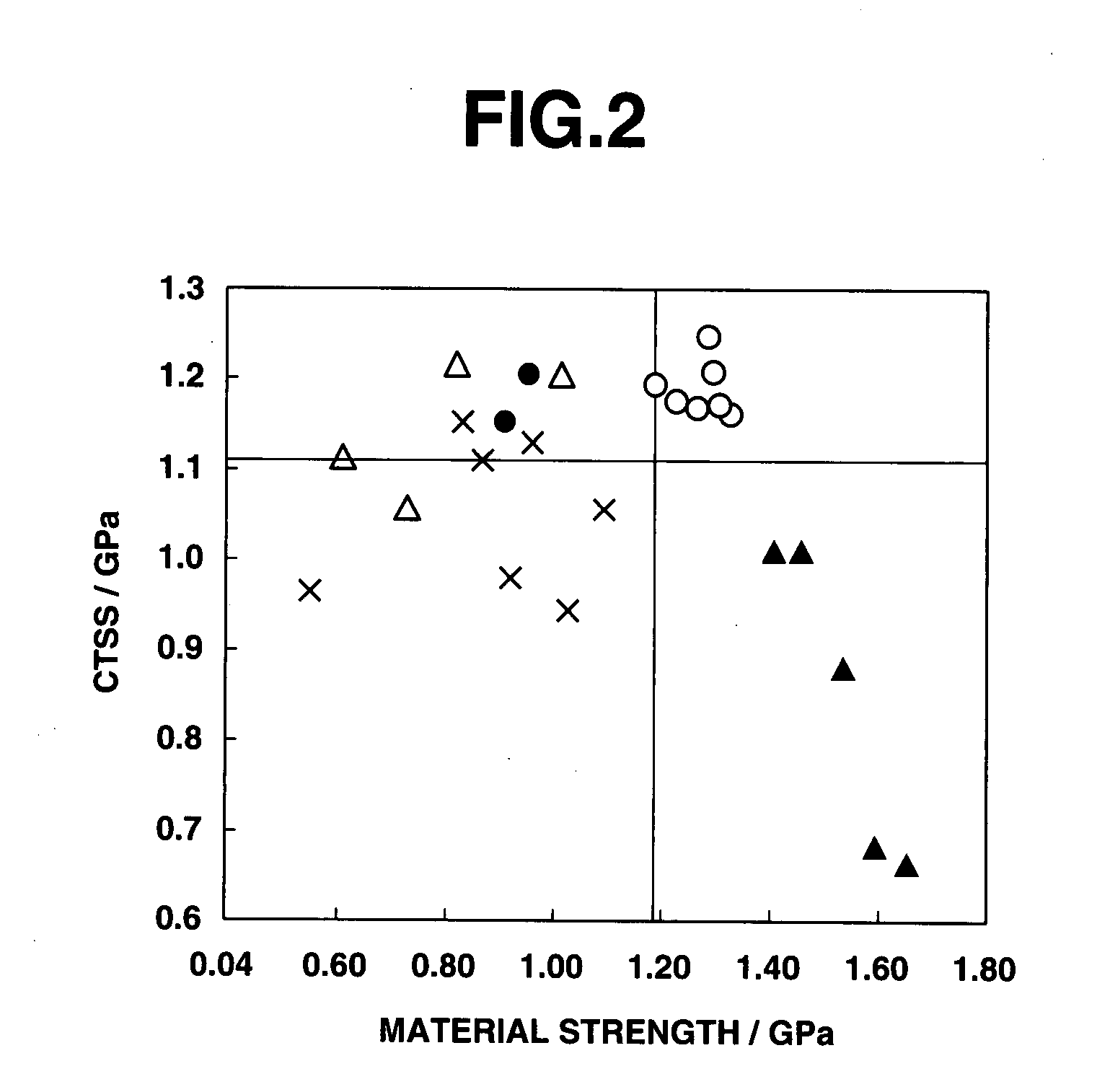

High-tensile steel sheet, steel sheet joining process and high-strength automotive part

InactiveUS20070269678A1No deterioration in resistance welding strengthDeteriorating hardenabilityFurnace typesThin material handlingMetallurgyHigh intensity

Owner:NISSAN MOTOR CO LTD

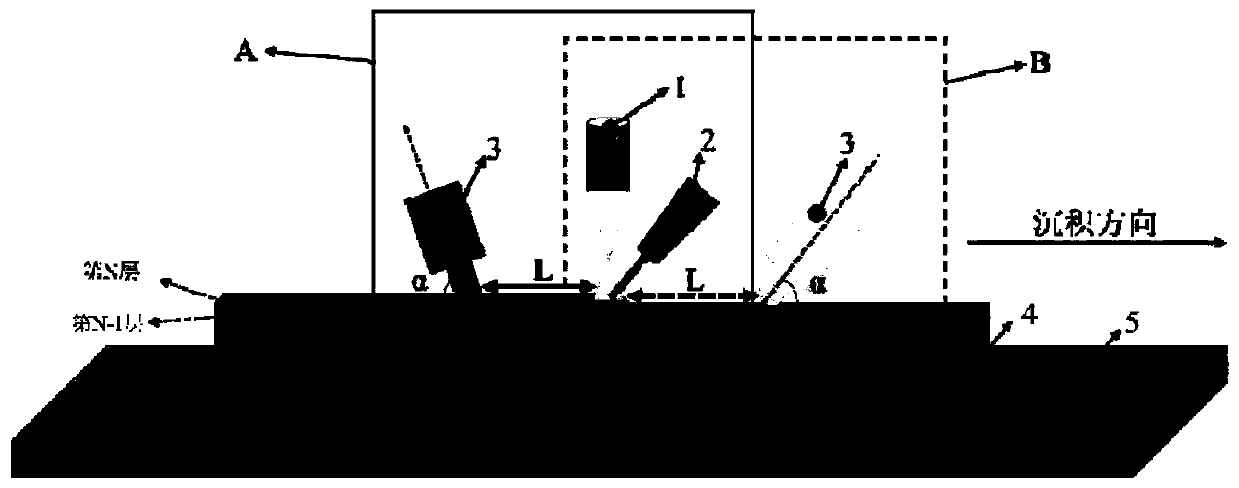

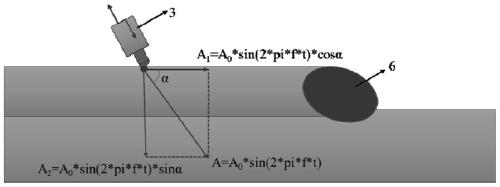

Laser wire fusing additive manufacturing titanium alloy component structure refining and isometric crystal converting method

ActiveCN111451504AEffectively compatibleRelease residual stressAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyMetallurgy

Owner:HARBIN ENG UNIV

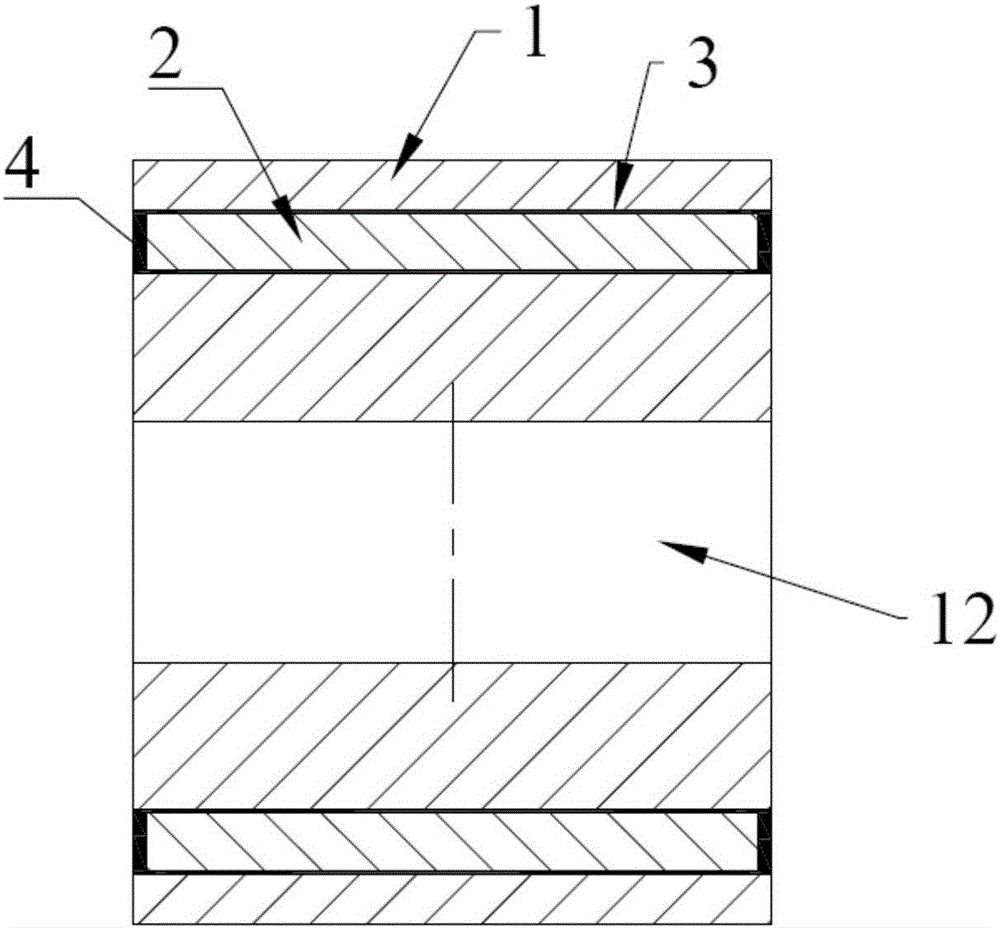

Compact, method for producing compact, reactor, converter, and power conversion device

InactiveUS20130322135A1Efficient productionTotal current dropTransportation and packagingInorganic material magnetismMetallurgyIrradiation

A low-loss compact and a method for producing the compact are provided.A method for producing a compact by using coated soft magnetic powder that includes coated soft magnetic particles constituted by soft magnetic particles and insulating coatings coating outer peripheries of the soft magnetic particles includes a raw material preparation step and an irradiation step. In the raw material preparation step, a raw compact is prepared by press-forming coated soft magnetic powder. In the irradiation step, part of a surface of the raw compact is irradiated with a laser. Irradiating a part of a surface of a raw compact with laser increases the number of disrupted portions of conductive portions where constituent materials of the soft magnetic particles at the surface of the raw compact have become conductive to each other, and the loss of the compact can be decreased.

Owner:SUMITOMO ELECTRIC IND LTD +1

Method for forming ultrathin-wall porous metal pipe fitting

Owner:UNIV OF SCI & TECH BEIJING

Method for producing permanent ferrite and permanent ferrite

InactiveCN101492288AGood for mechanical biteHigh densitySolid waste disposalInorganic material magnetismMetallurgyMagnet

Owner:四川川西磁业有限责任公司

Ceramic electronic component and method of manufacturing the same

A ceramic electronic component and a method of manufacturing the same are provided. The ceramic electronic component includes a ceramic body; internal electrodes disposed in the ceramic body; external electrodes disposed on outer surfaces of the ceramic body and electrically connected to the internal electrodes; and tin plating layers disposed on the external electrodes.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Method for producing continuous casting round billet of wind power tower cylinder flange steel

The invention discloses a method for producing a continuous casting round billet of wind power tower cylinder flange steel. The method comprises the steps that the degree of superheat of continuous casting liquid steel is controlled within the range from 21 DEG C to 25 DEG C in the continuous casting process; air water atomizing cooling serves as the cooling mode in a secondary cooling area, the specific water flow is controlled within the range from 0.15 L / kg to 0.18 L / kg, the casting speed is controlled within the range from 0.30 m / min to 0.34 m / min, the current of electromagnetic stirring of a crystallizer is controlled within the range from 200 A to 300 A, the frequency of electromagnetic stirring of the crystallizer is controlled within the range from 2.0 Hz to 3.0 Hz, the current of electromagnetic stirring of the tail end of solidification is controlled within the range from 350 A to 400 A, and the frequency electromagnetic stirring of the tail end of solidification is controlled within the range from 8 Hz to 12 Hz. According to the method, the surface quality and interior quality of the continuous casting round billet of wind power tower cylinder flange steel can be effectively improved by setting and optimizing technological parameters. In addition, a finished wind power tower cylinder flange machined through the round billet obtained according to the method can completely meet the quality requirement of the wind power tower cylinder flange steel after ultrasonic flaw detection.

Owner:LAIWU IRON & STEEL GRP

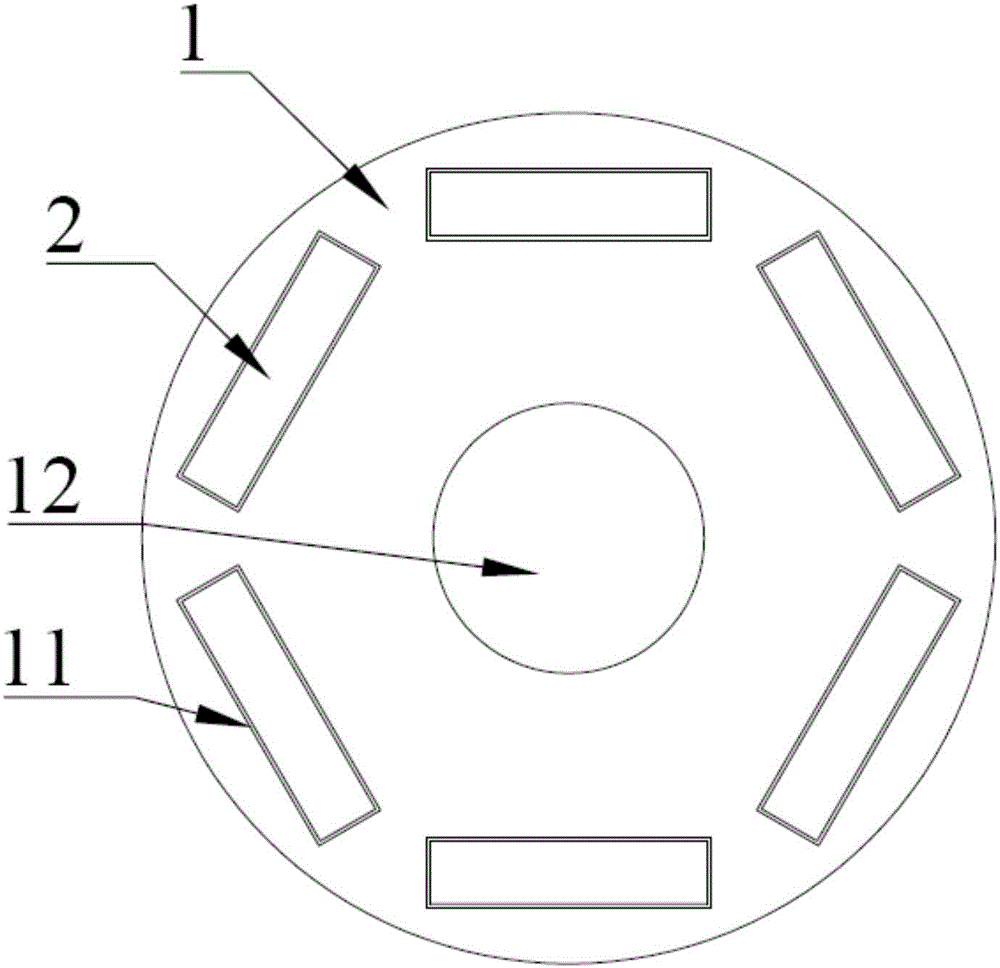

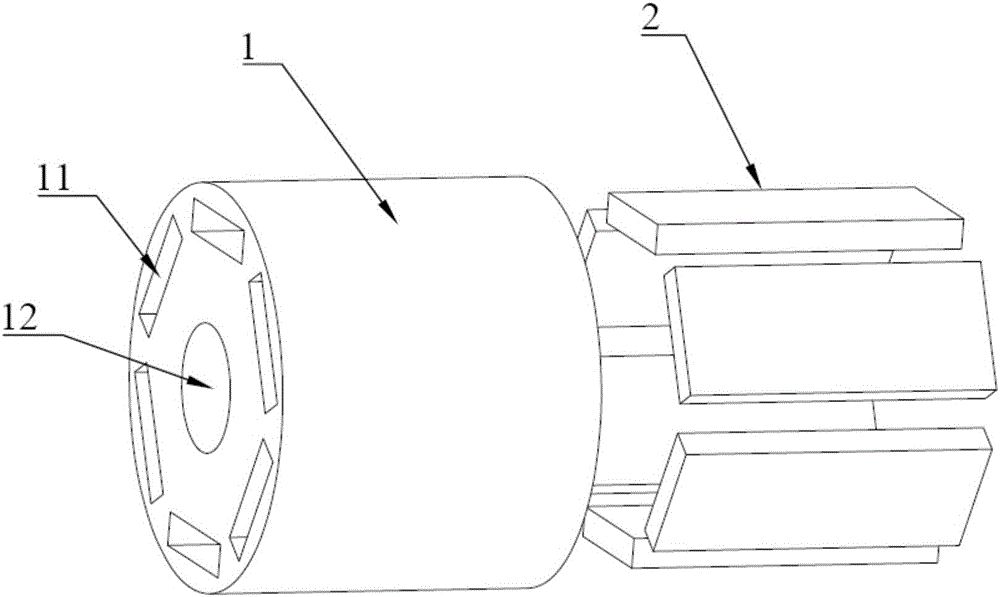

Fixing method of magnetic steel, rotor assembly and motor

ActiveCN106487171AShort curing timeFixed fastMagnetic circuit rotating partsManufacturing stator/rotor bodiesMetallurgyAdhesive

Owner:GREE ELECTRIC APPLIANCES INC +1

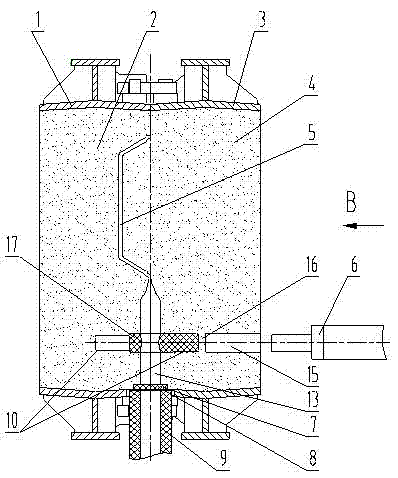

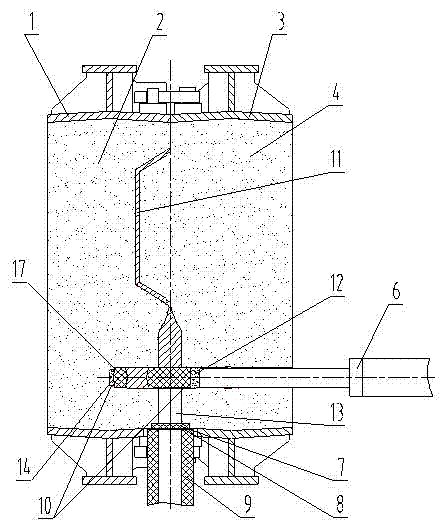

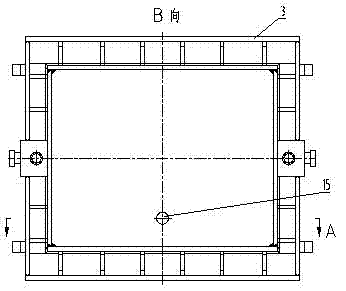

Sprue plugging device for casting sand mold at low pressure and method for casting sand mold at low pressure

Owner:JINAN CASTING FORGING MACHINERY INST

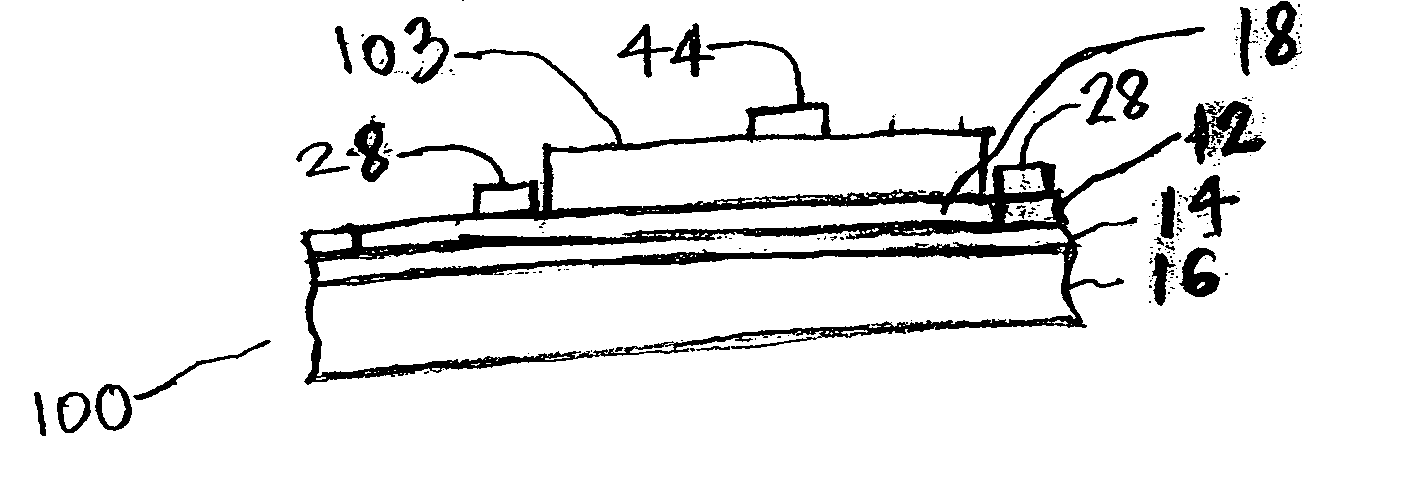

Solder flow stops for semiconductor die substrates

InactiveUS20050253258A1Prevent rotationAvoid flowPrinted circuit assemblingSemiconductor/solid-state device detailsNon wettingMetallurgy

Owner:INTERNATIONAL RECTIFIER COEP

Nanostructuring process for ingot surface, wafer manufacturing method, and wafer using the same

InactiveUS20120193764A1Improve surface strengthReduce generationMaterial nanotechnologyPolycrystalline material growthWaferingMetallurgy

The instant disclosure relates to a nanostructuring process for an ingot surface prior to the slicing operation. A surface treatment step is performed for at least one surface of the ingot in forming a nanostructure layer thereon. The nanostructure layer is capable of enhancing the mechanical strength of the ingot surface to reduce the chipping ratio of the wafer during slicing.

Owner:SINO AMERICAN SILICON PROD

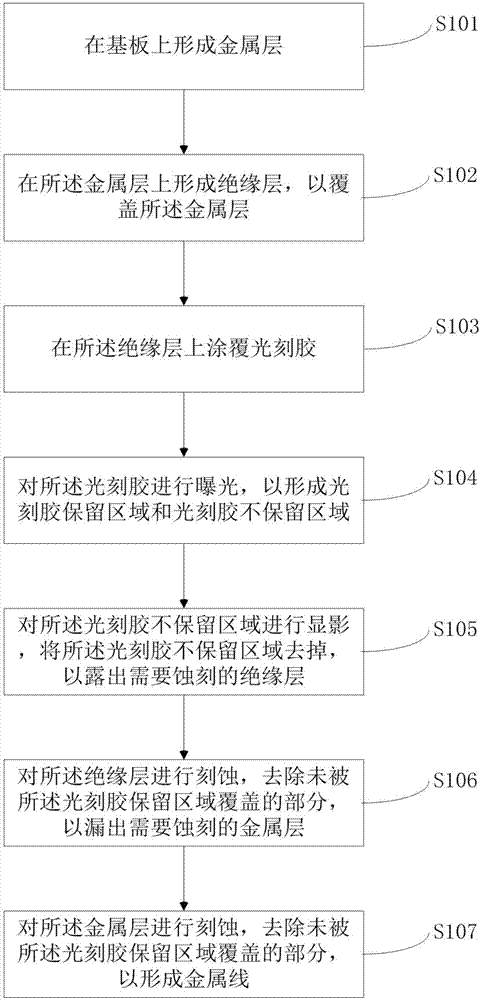

Manufacturing method of metal line and array substrate and array substrate

InactiveCN107359138AAvoid disconnectionReduce line widthSolid-state devicesSemiconductor/solid-state device manufacturingMetallurgyPhotoresist

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

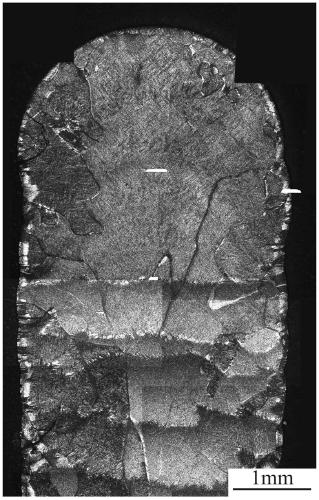

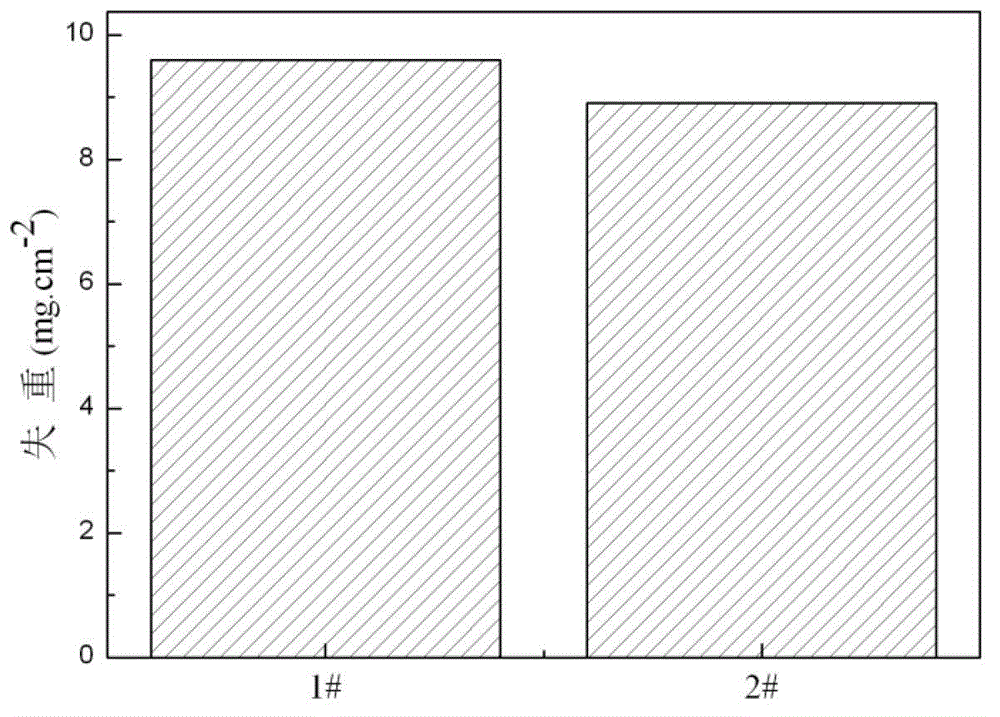

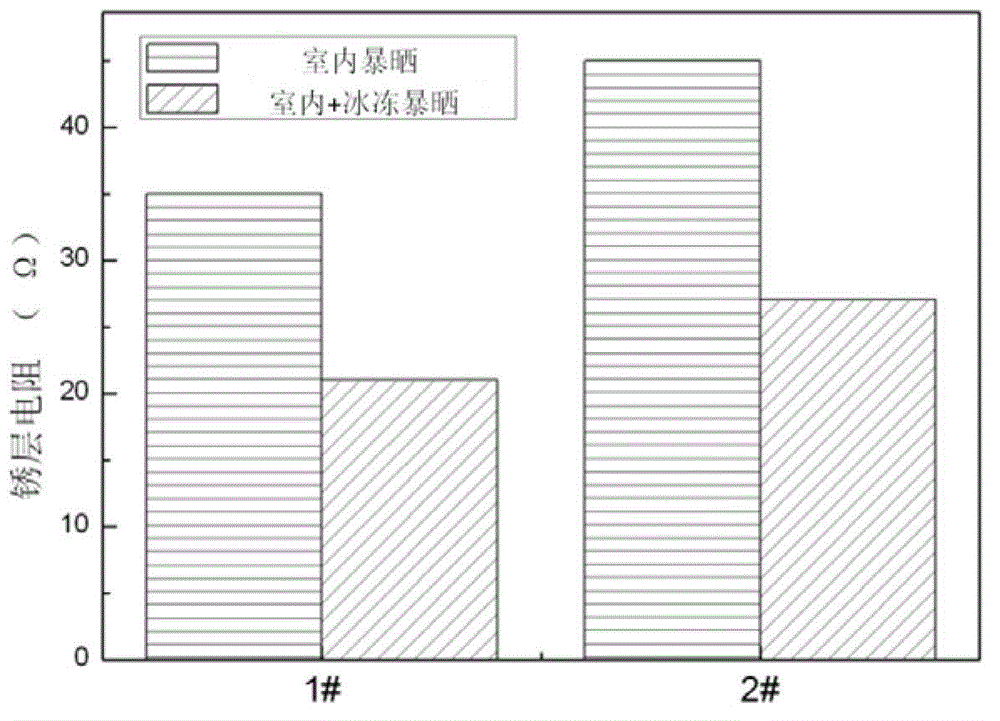

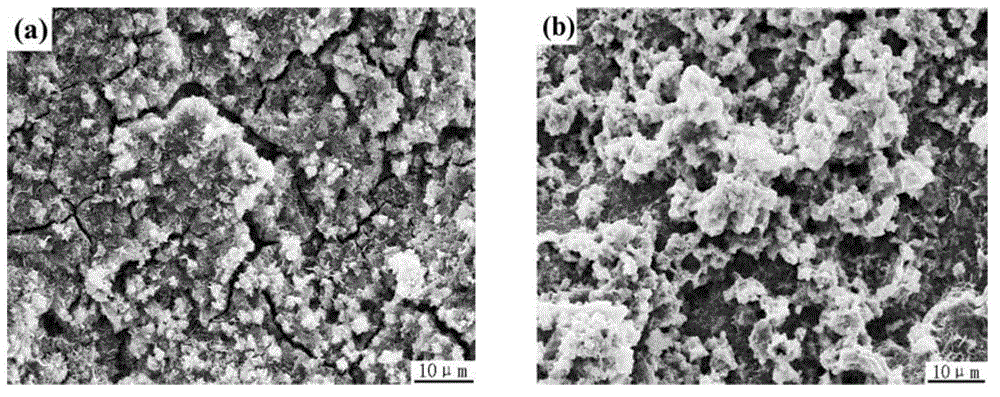

Method for evaluating protective capability of weathering steel rust layers based on freezing-unfreezing treatment

InactiveCN102866104AWeather/light/corrosion resistancePreparing sample for investigationFrostMetallurgy

The invention provides a method for evaluating the protective capability of weathering steel rust layers based on freezing-unfreezing treatment. The method comprises the following steps of: (1) collecting various weathering steel samples to be measured and with rust layers; (2) performing freezing-unfreezing treatment on the weathering steel samples; (3) analyzing influence of the freezing-unfreezing treatment on change of fissures of the rust layer of each weathering steel sample; (4) analyzing influence of the freezing-unfreezing treatment on change of the alternating-current impedance fitting resistance value of the rust layer of each weathering steel sample; and (5) evaluating the protective capability of the rust layers of the weathering steel samples, determining that the protective capability of the weathering steel samples is high if the increment of the fissures of the rust layers and the change of the alternating-current impedance fitting resistance values of the rust layers of the weathering steel samples are low, and determining that the protective capability of the weathering steel samples is low if the increment of the fissures of the rust layers and the change of the alternating-current impedance fitting resistance values of the rust layers of the weathering steel samples are high. According to the method, destructiveness conditions of the outside are considered, particularly the capability of the rust layers resisting a frost environment in a northern cold region, the compactness of the weathering steel rust layers is judged from a brand-new angle, the protective capability of the weathering steel rust layers can be reflected really, and accordingly a judgment result is real and reliable.

Owner:UNIV OF SCI & TECH BEIJING

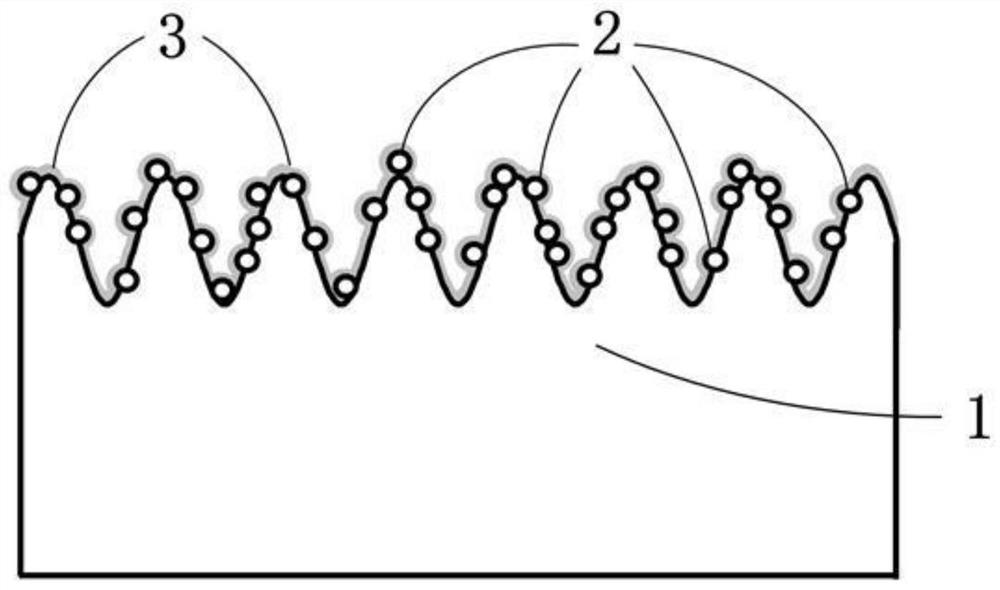

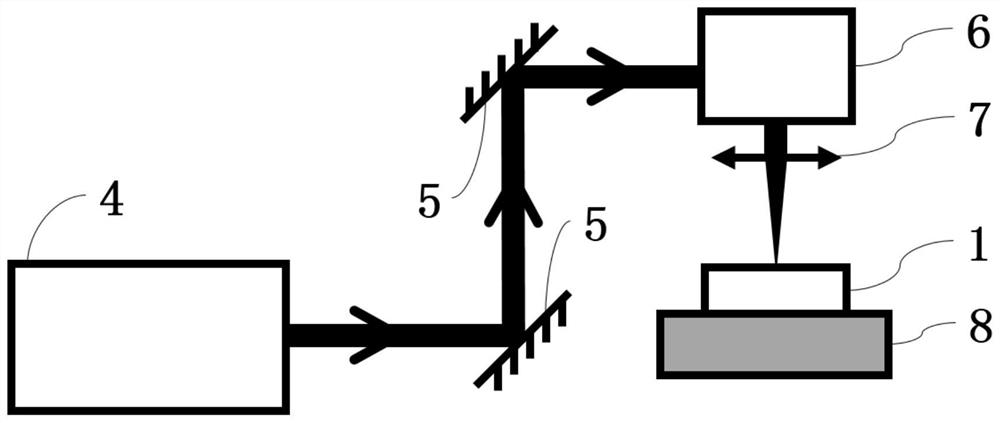

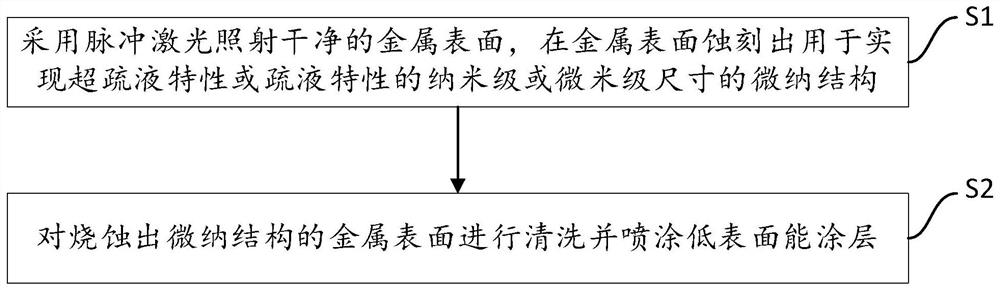

Non-stick metal surface and preparation method thereof

PendingCN113634909AWith characteristicsLong-lasting non-stick performanceSpecial surfacesCoatingsMicron scaleNano structuring

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

SiALONC ceramic with hydrogen silicone oil and Al powder and production thereof

Owner:HARBIN INST OF TECH

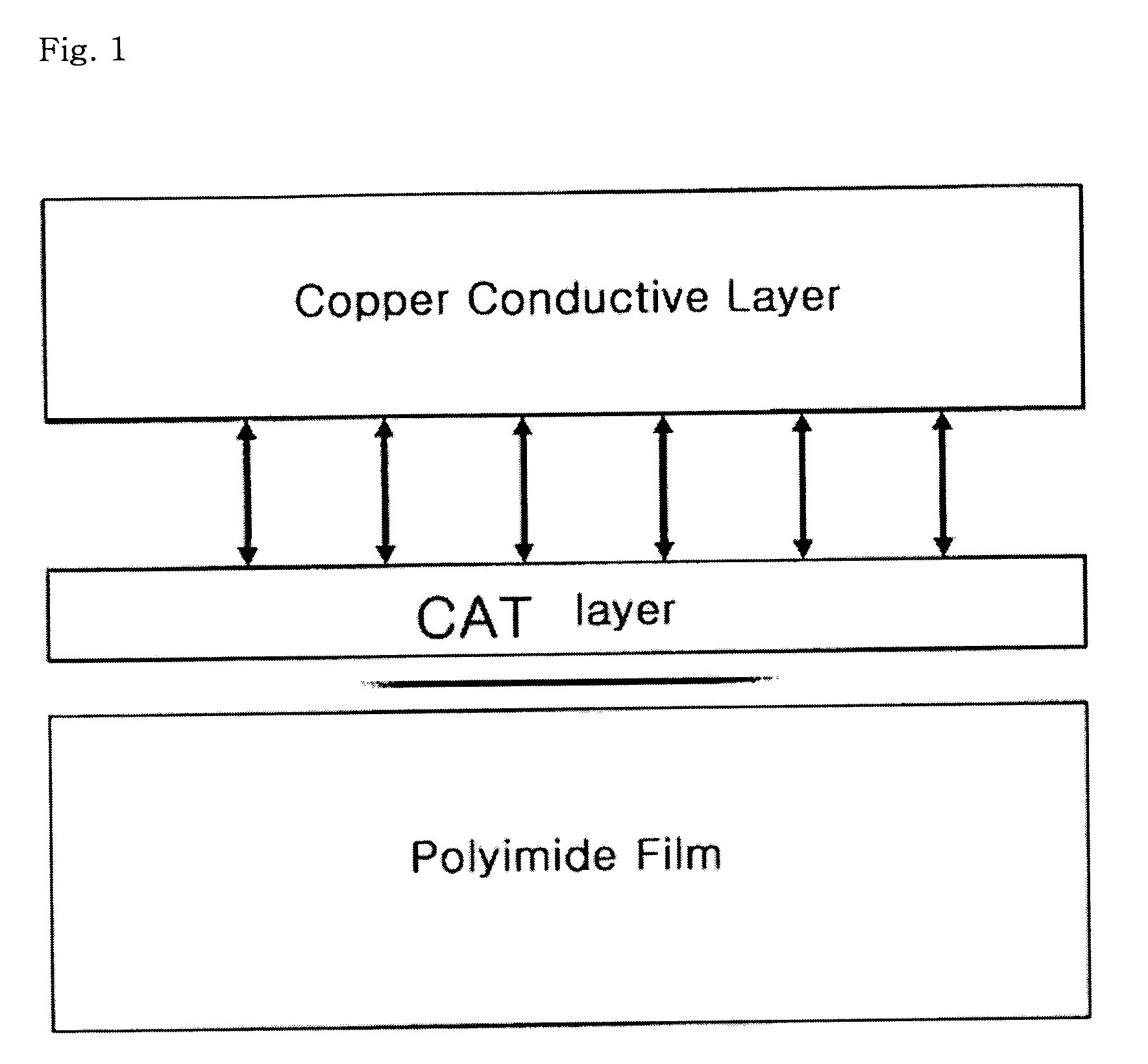

Laminate for flexible printed circuit board comprising tie layer of ternary copper alloy

InactiveUS20060029819A1Improve adhesion strengthGood chemical resistanceInsulating substrate metal adhesion improvementCircuit susbtrate materialsMetallurgyFlexible electronics

Owner:TORAY SAEHAN

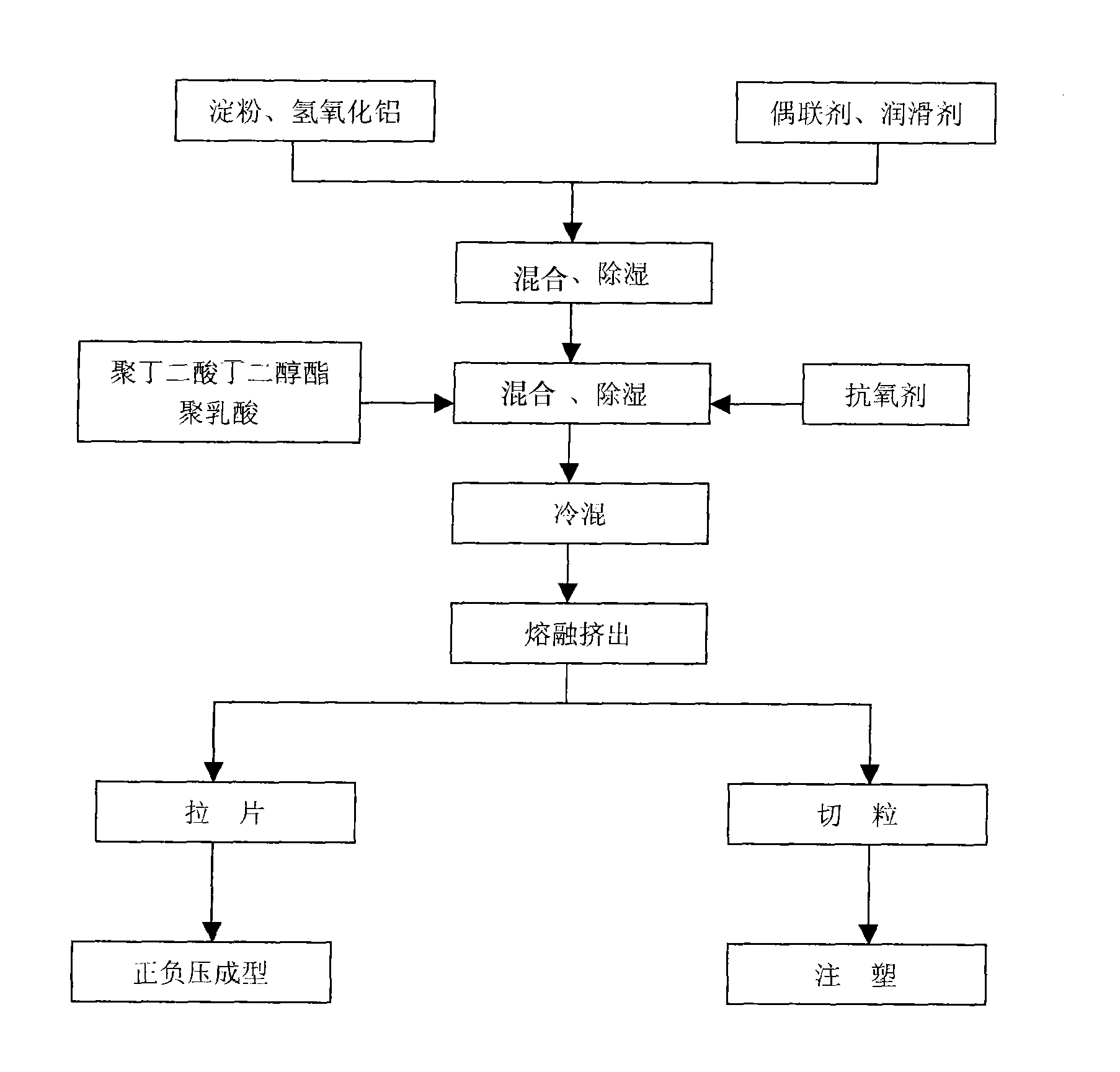

Hydroted alumina-poly-succinic acid butanediol ester composite degradation material and preparation technique

Owner:浙江华发生态科技有限公司

Heat-storage warm-keeping chinlon 6 short fiber and preparation method thereof

ActiveCN109402765AImprove dispersion uniformityLow viscosityMonocomponent polyamides artificial filamentArtifical filament manufactureFiberEmissivity

The invention relates to a heat-storage warm-keeping chinlon 6 short fiber and a preparation method thereof. The method includes: spinning a heat-storage warm-keeping chinlon 6 melt to prepare a heat-storage warm-keeping chinlon 6 short fiber, wherein the chinlon 6 is prepared from a mixture of caprolactam, a heat-storage powder coated with a catalyst, and water, and successively through a heat-storage powder surface chain growth reaction, a ring-opening pre-polycondensation reaction and a final-polycondensation reaction; wherein the heat-storage powder surface chain growth reaction is a reaction that the caprolactam on the surface of the heat-storage powder is polymerized to form a linear molecular chain under effect of the catalyst. A fabric, being 200-250 g / m<2> in gram weight and prepared from the fiber, is not less than 0.944 m<2>*K / W in thermal resistance, not less than 6.09 in Clo value, not less than 91.4% in warm-keeping rate, not less than 0.90 in far-infrared emissivity andnot less than 1.5 DEG C in far-infrared radiation temperature increasing value. The heat-storage warm-keeping chinlon 6 short fiber has good dispersion uniformity of the heat-storage powder and has excellent heat-storage and warm-keeping function.

Owner:WUXI MINGTE CHEM FIBER CO LTD

Soft solder for SnAgCuNiGe alloy solder paste

InactiveCN101176957AWeldablePrintableWelding/cutting media/materialsSoldering mediaActive agentMetallurgy

Owner:东莞市特尔佳电子有限公司

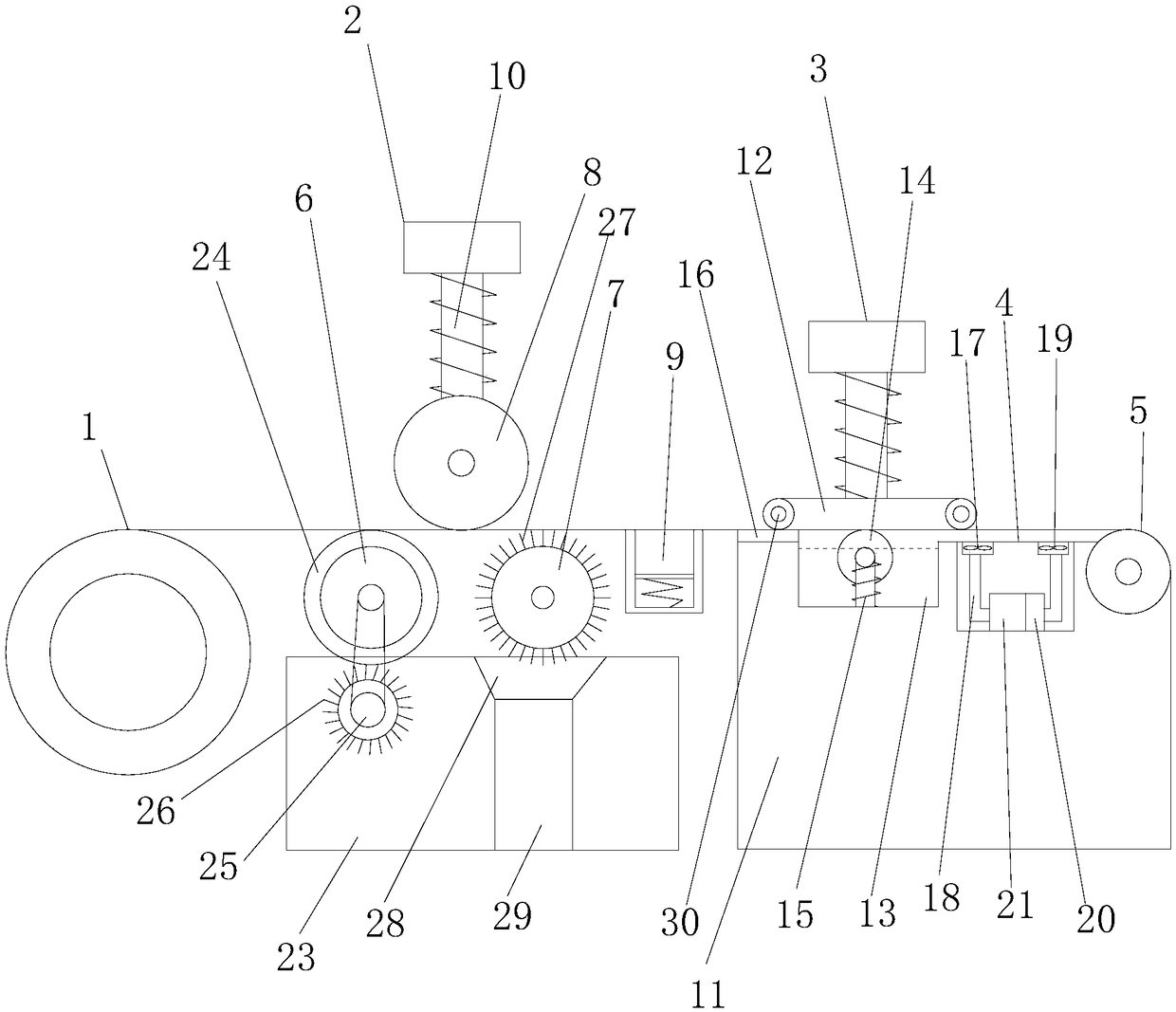

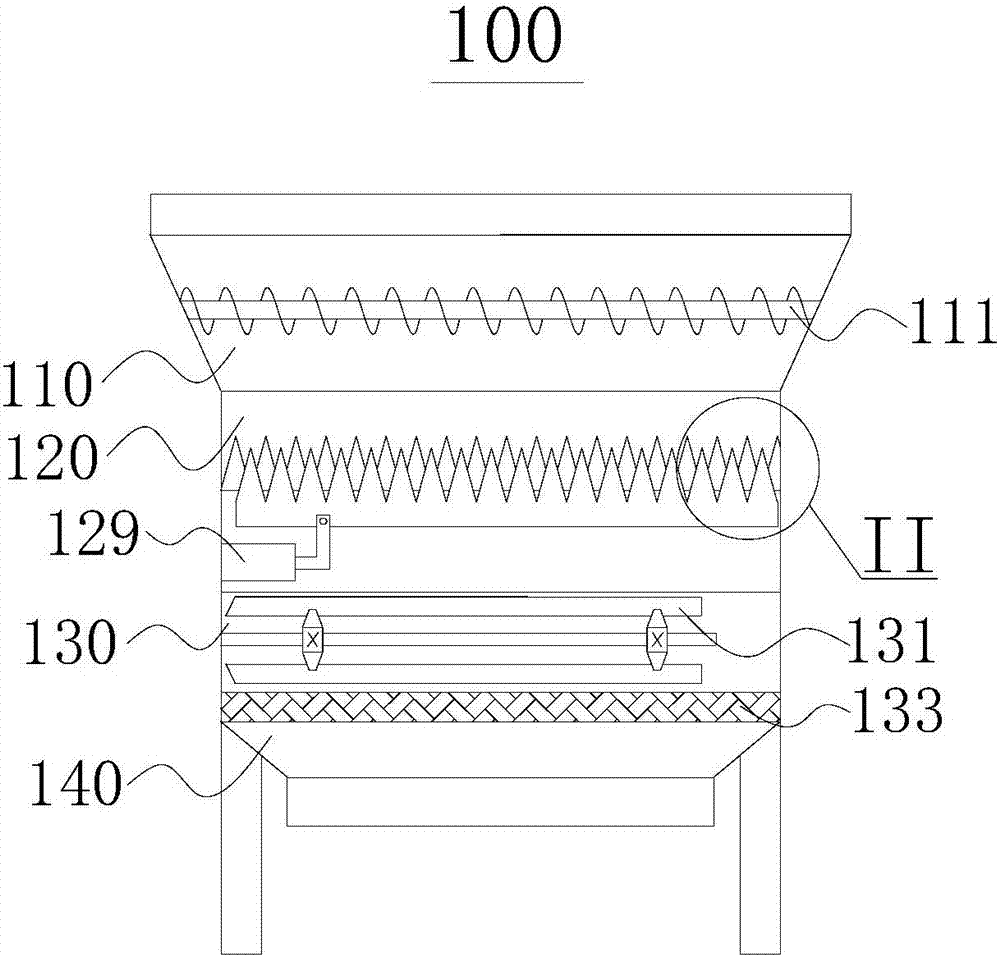

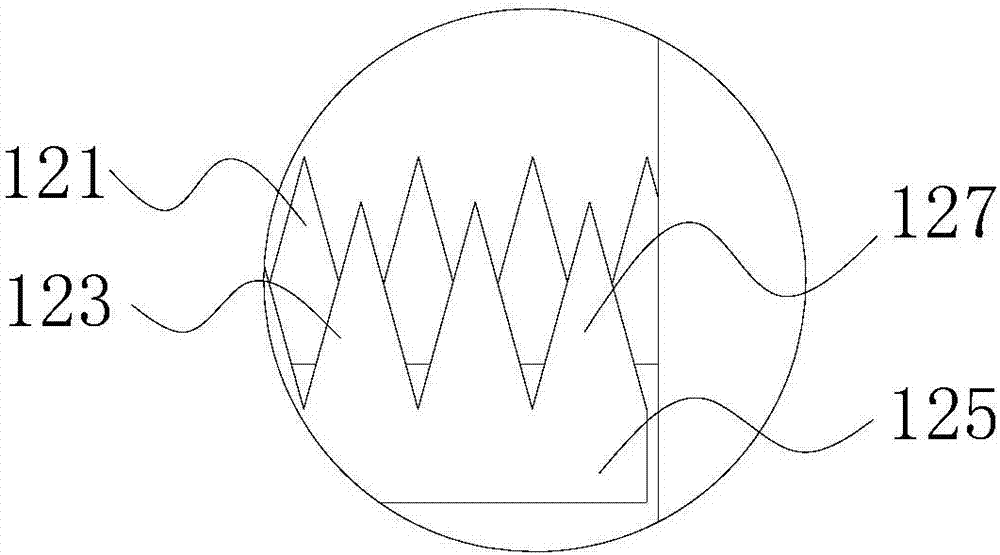

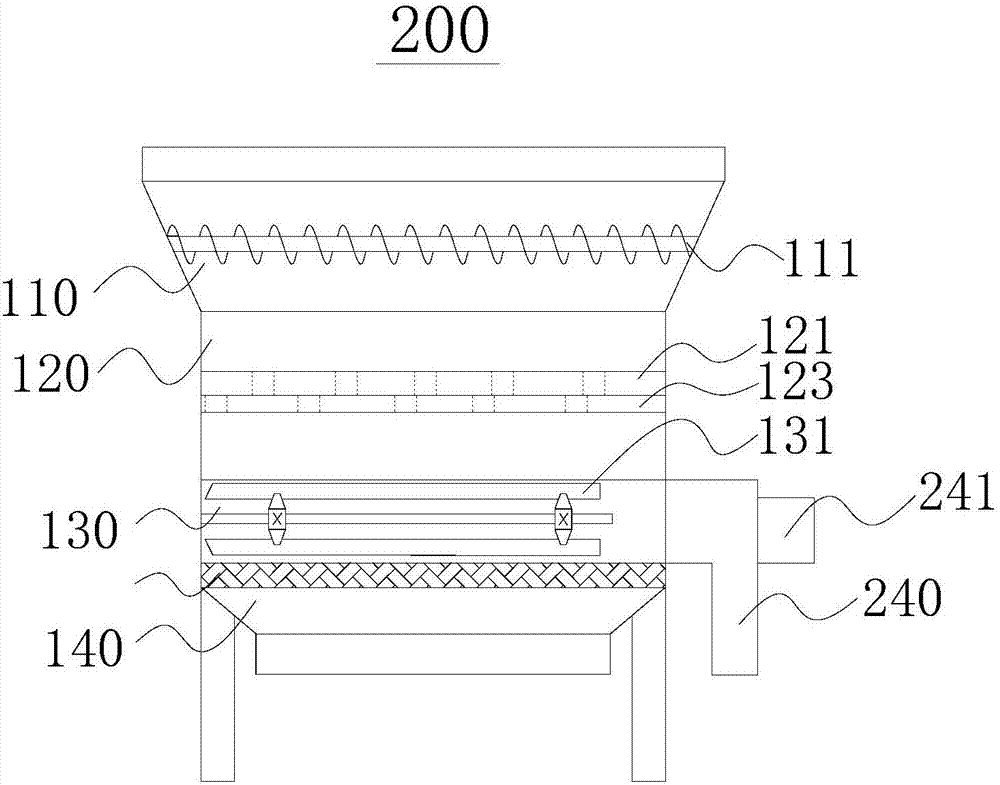

Powder sifter and silent powder sifter

InactiveCN106944201ASolution can't be screened outSolve the problem of clogged screenGrain treatmentsMetallurgy

Owner:重庆市合川区鑫蘘桃片有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap