Laminate for flexible printed circuit board comprising tie layer of ternary copper alloy

a flexible printed circuit board and ternary copper alloy technology, which is applied in the direction of improving the adhesion of metals to the substrate, transportation and packaging, and processes, etc., can solve the problems of affecting the performance of the substrate, affecting the adhesion of the substrate, and affecting the dimensional stability of the substrate, etc., to achieve excellent adhesive strength, high performance, and chemical resistance. high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, a detailed description will be given of the present invention, with reference to the appended drawings.

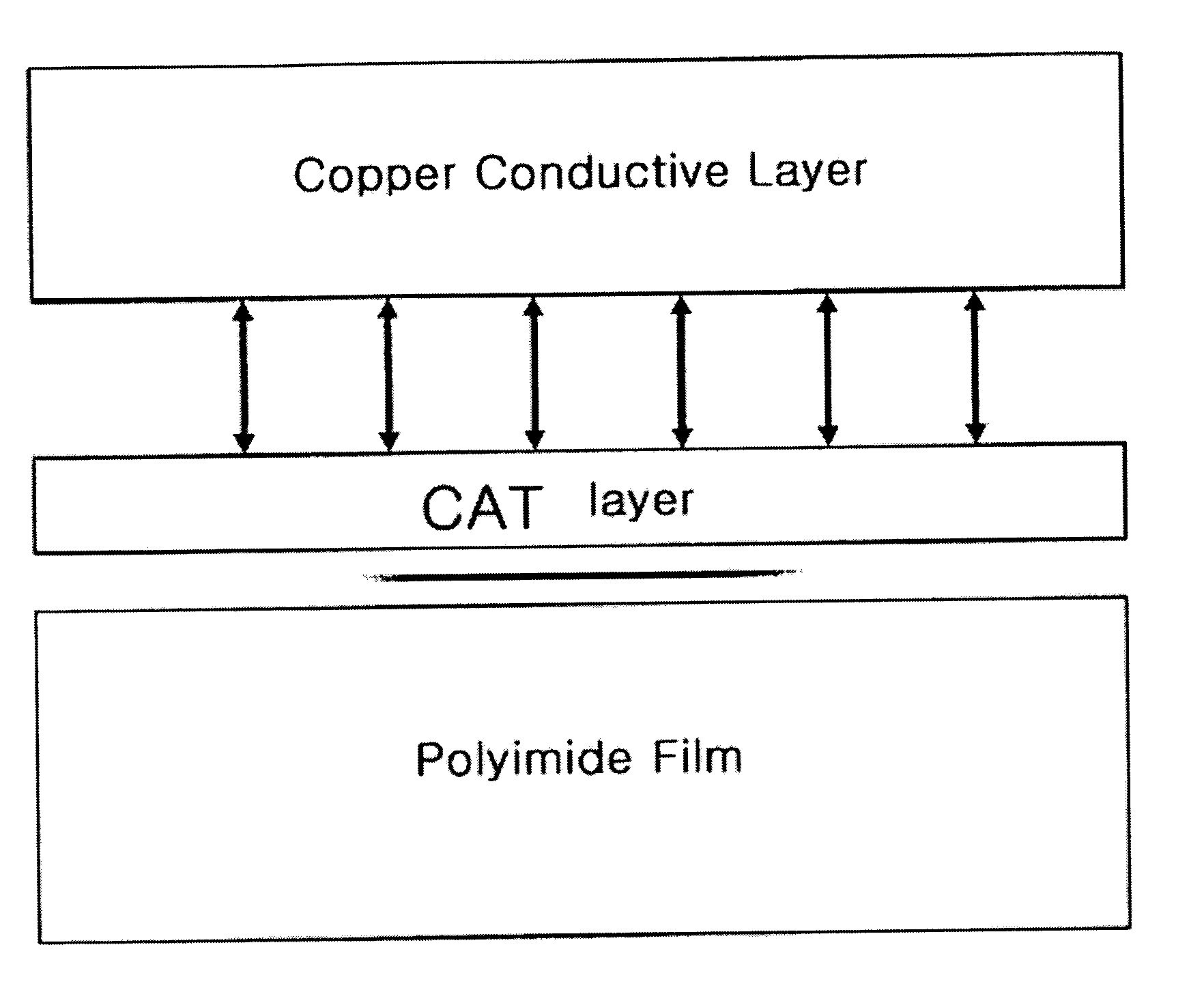

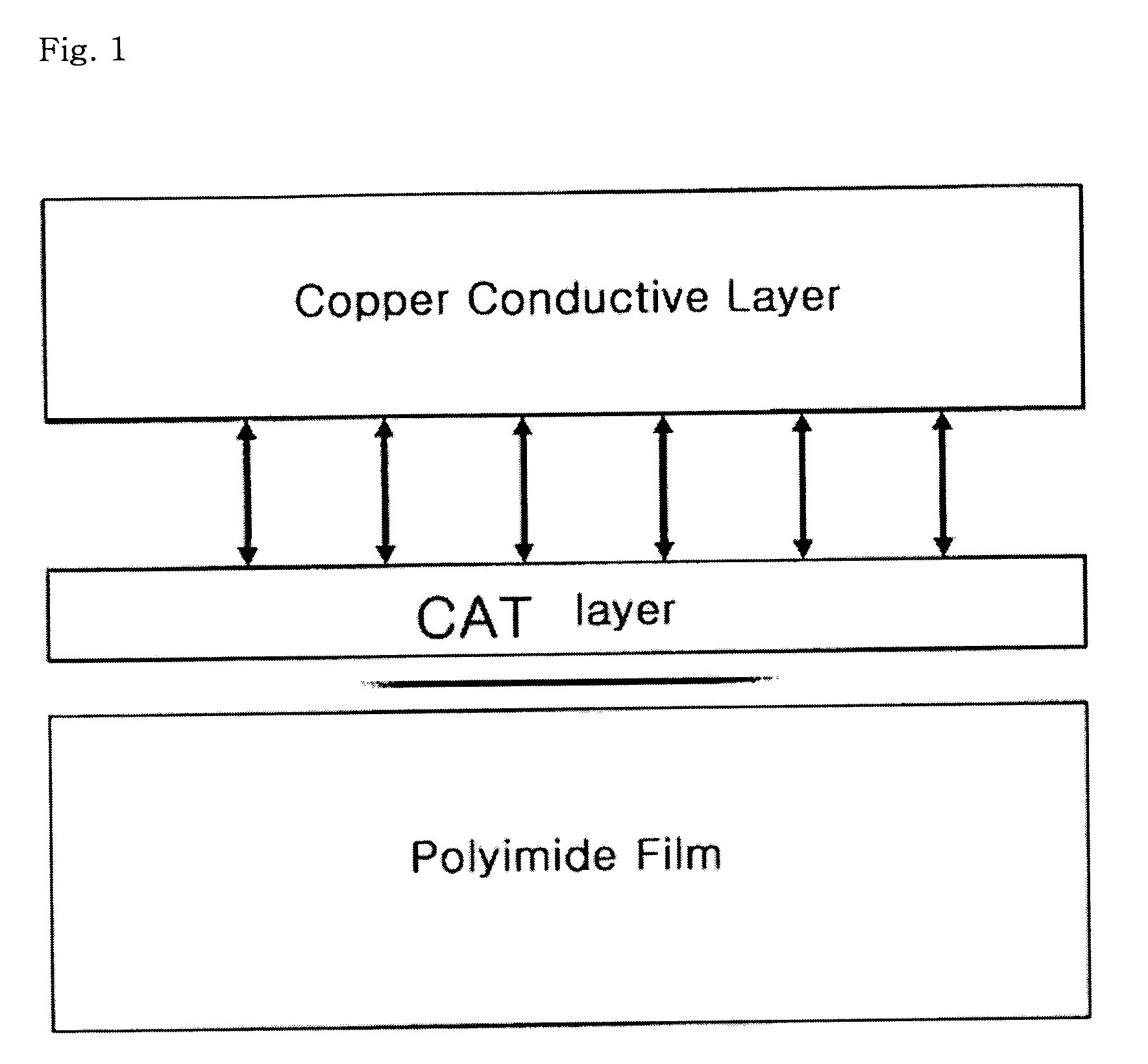

[0027]FIG. 1 is a sectional view showing a laminate for an FPCB having a tie layer formed on a polyimide film, according to the present invention. In the present invention, the tie layer is formed of a ternary copper alloy containing Zn—V or Zn—Ta. Below, a ternary copper alloy containing Zn—V is referred to as ‘CAT1’, and a ternary copper alloy containing Zn—Ta is referred to as ‘CAT2’. In FIG. 1, a CAT layer means a layer including any one of ‘CAT1’ and ‘CAT2’.

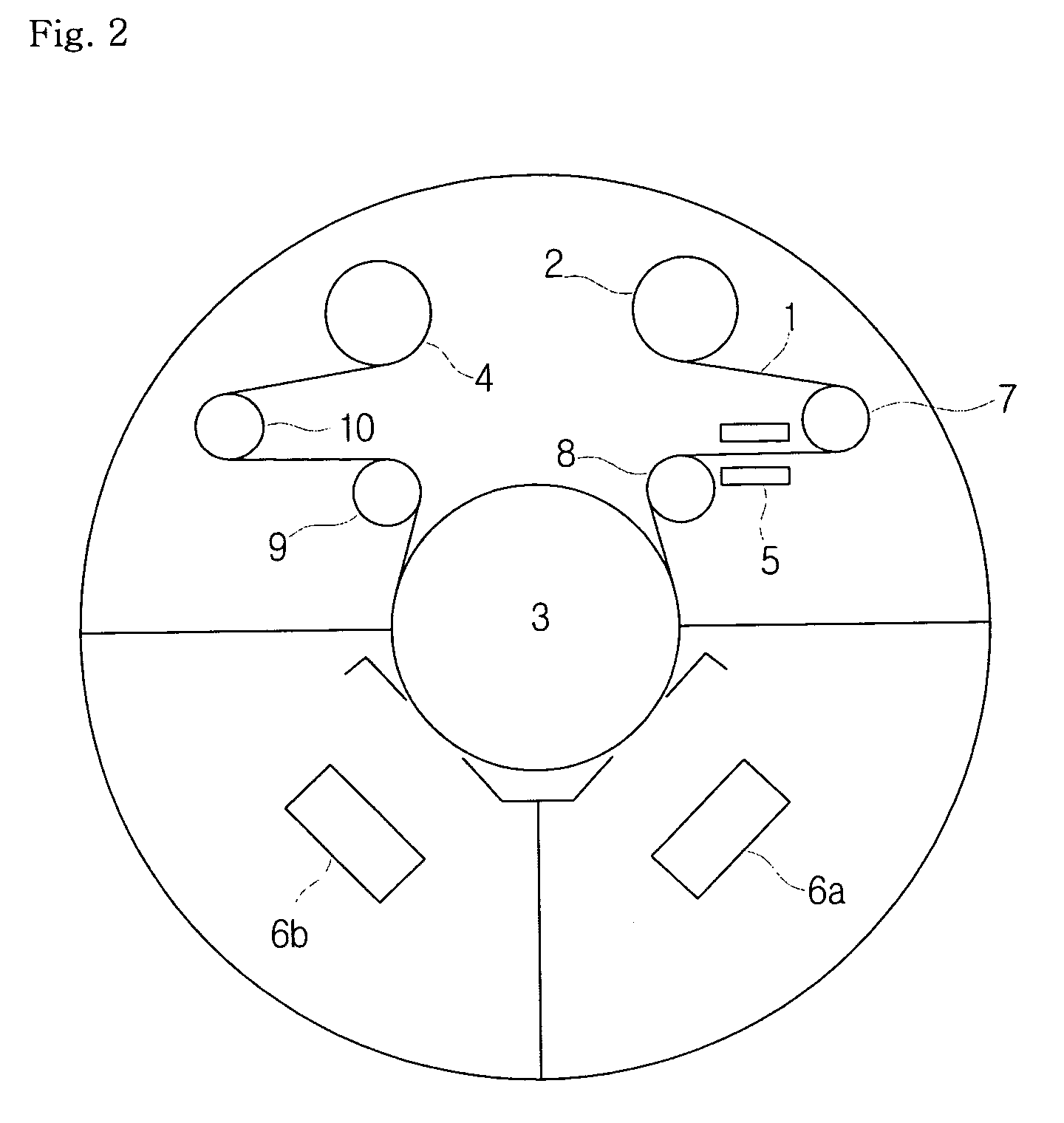

[0028] Referring to FIG. 2, a method of manufacturing the laminate for an FPCB shown in FIG. 1 is described. FIG. 2 is a schematic view showing an apparatus for manufacturing a laminate for an FPCB, according to the present invention.

[0029] The apparatus for manufacturing a laminate for an FPCB comprises a transferring system including an unwinding roller 2, a main drum 3, and a winding roller 4, all of

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap