Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about "Bearing components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

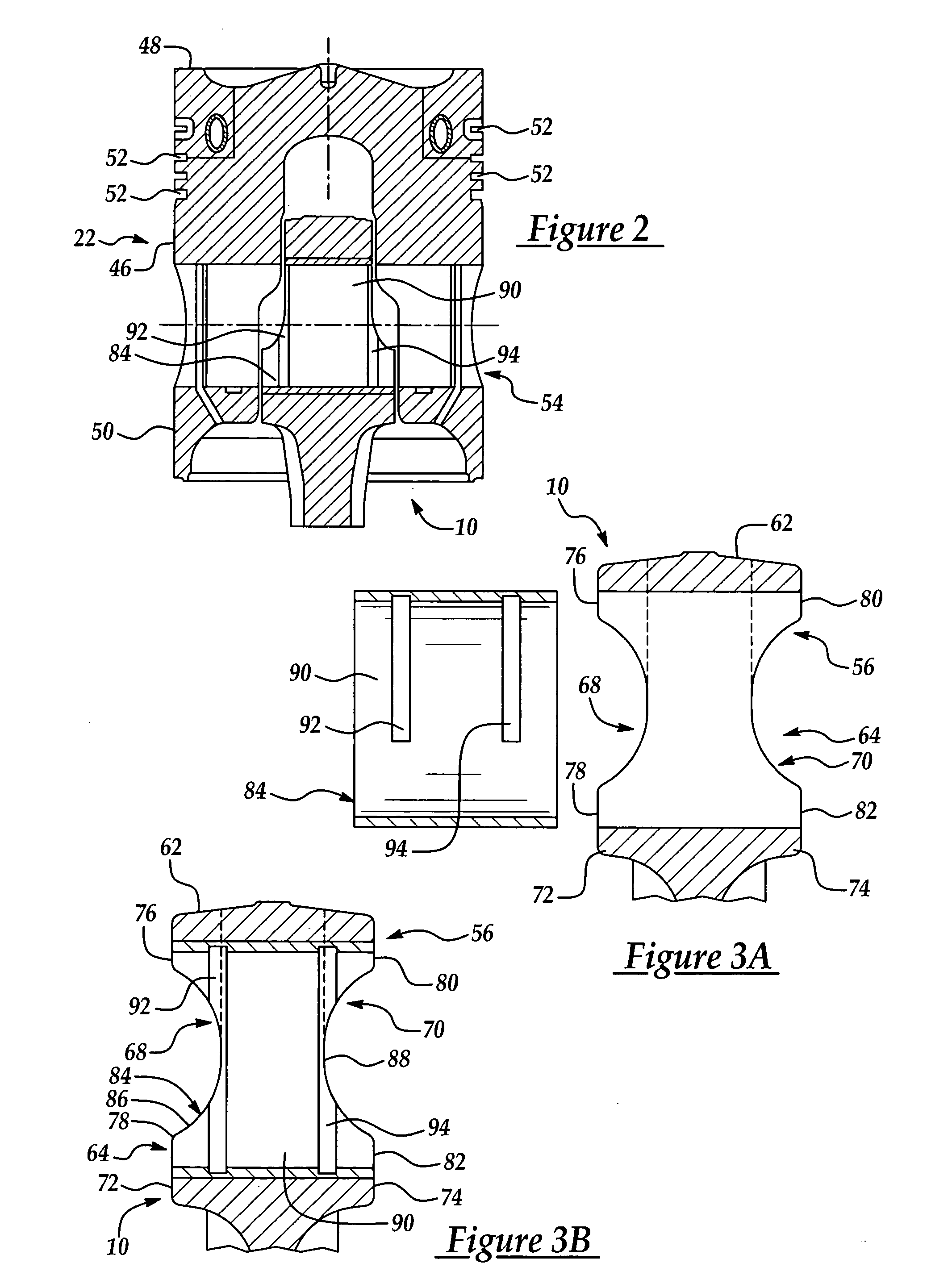

Sealing system

InactiveUS20060022411A1Improve the lubrication effectEngine sealsPiston ringsMechanical engineeringCoating

Owner:CATERPILLAR INC

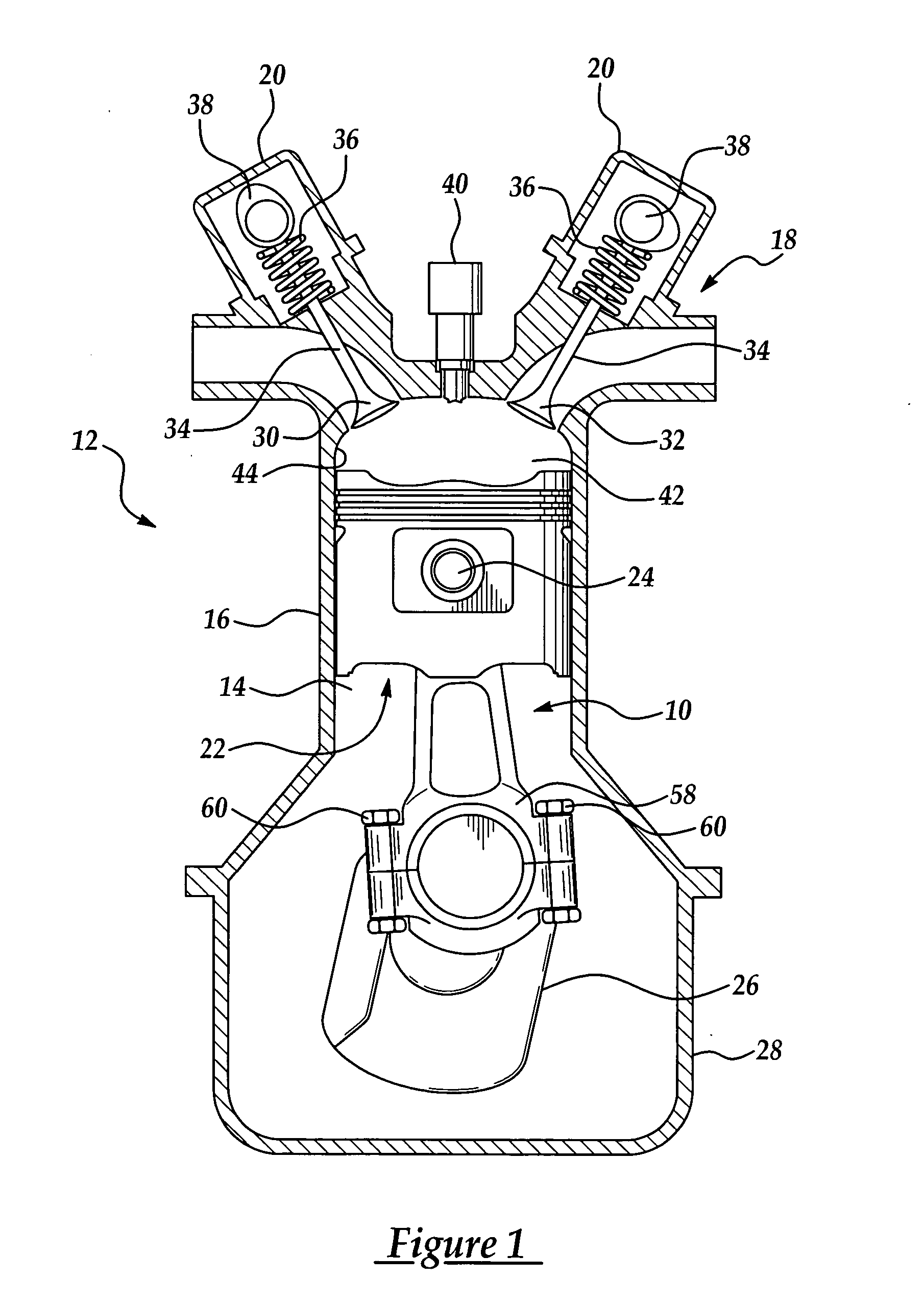

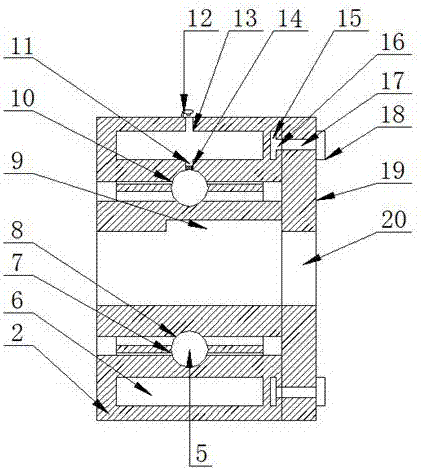

Connecting rod assembly for an internal combustion engine and method of manufacturing same

InactiveUS20060101939A1Simplify the manufacturing processReduce widthConnecting rod bearingsConnecting rodsEngineeringInternal combustion engine

Owner:MAHLE IND

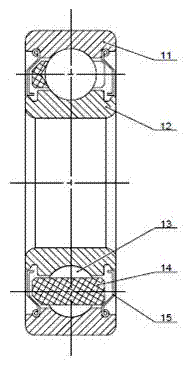

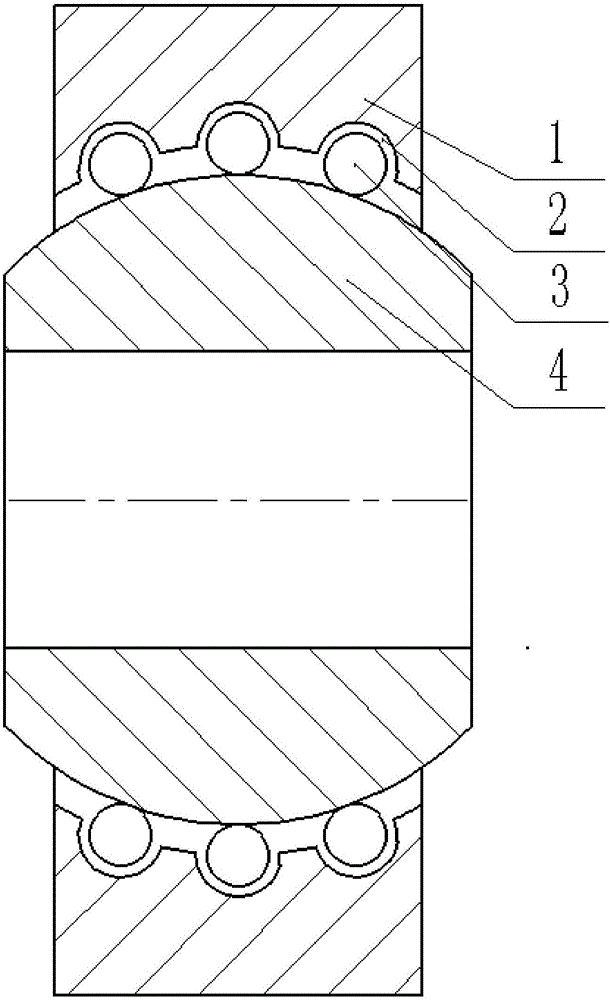

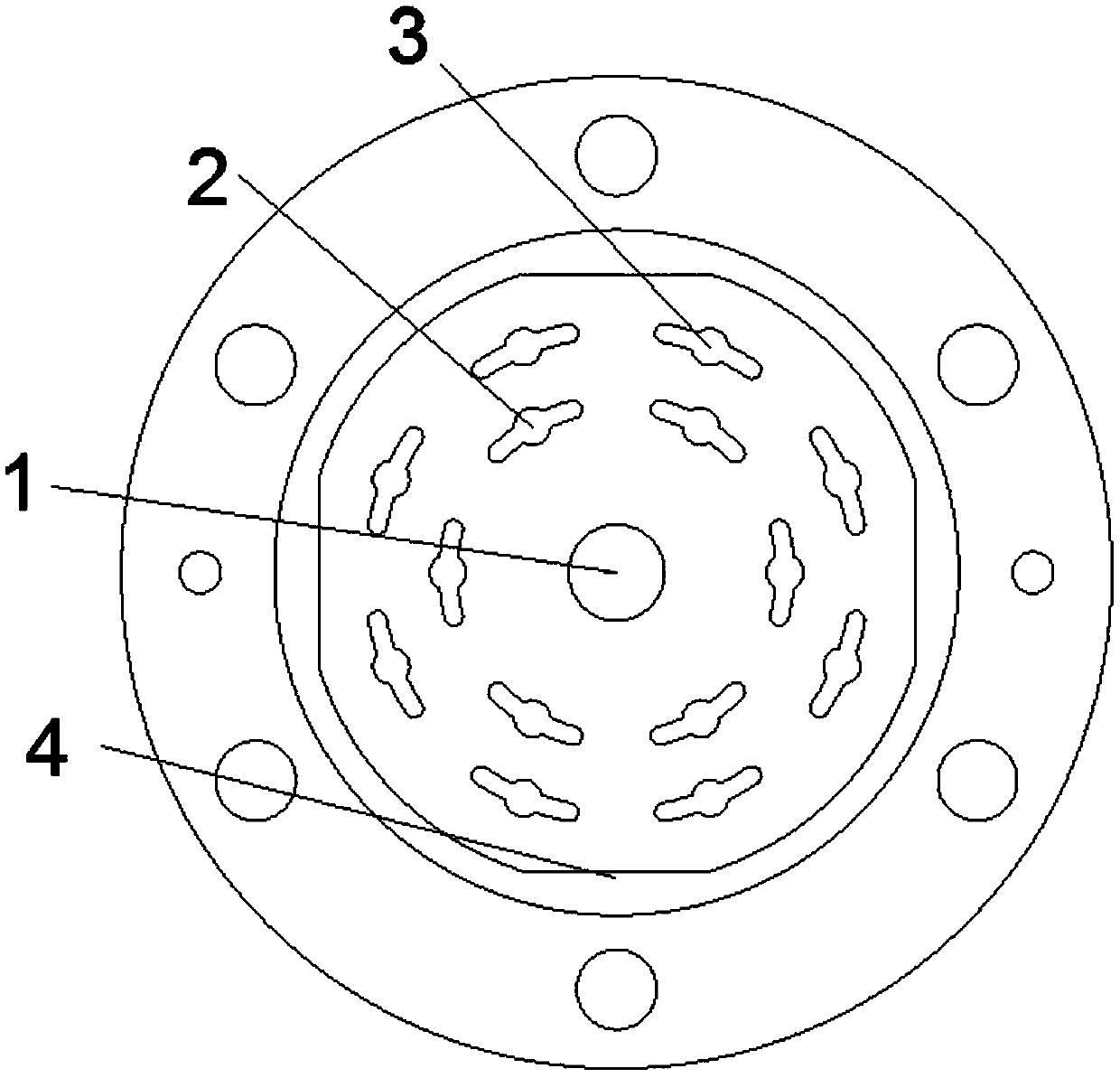

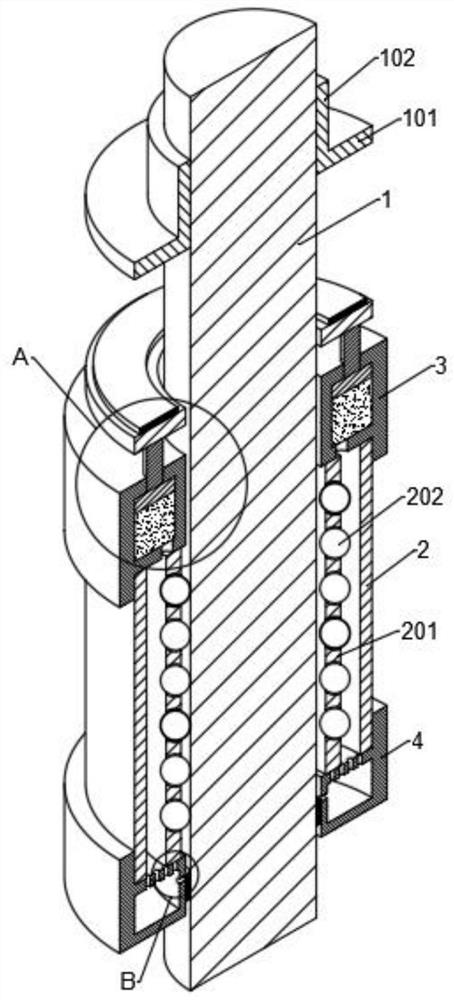

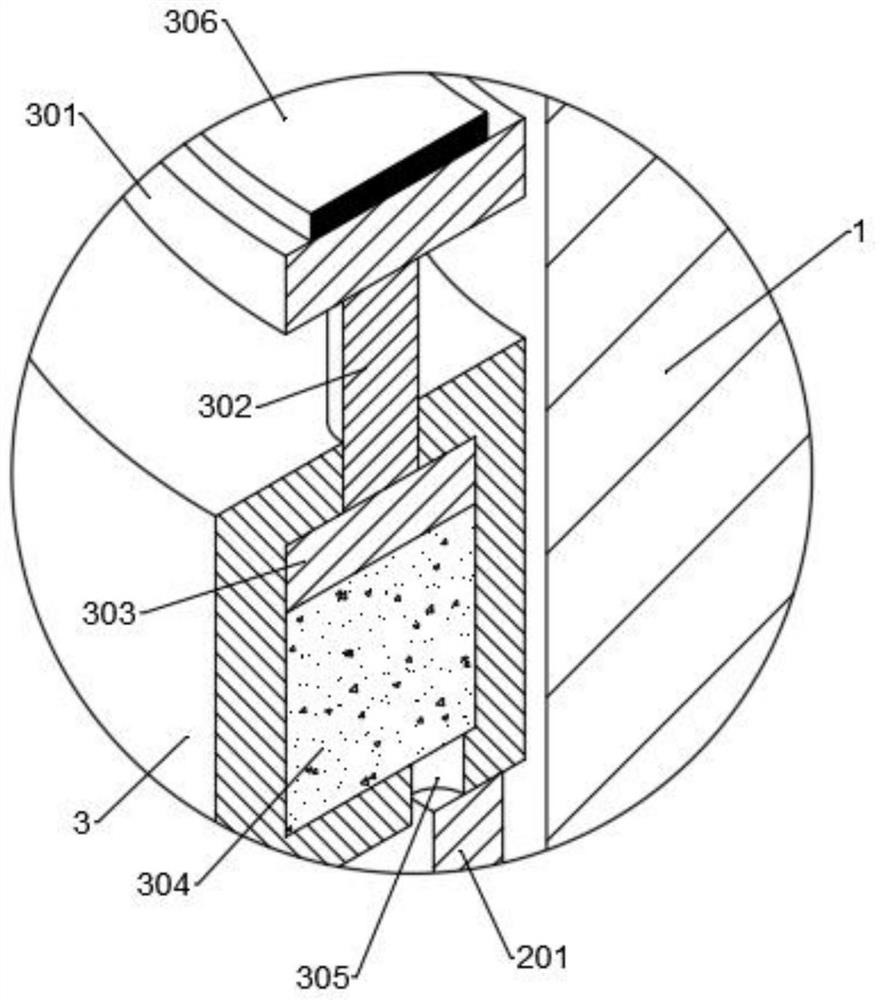

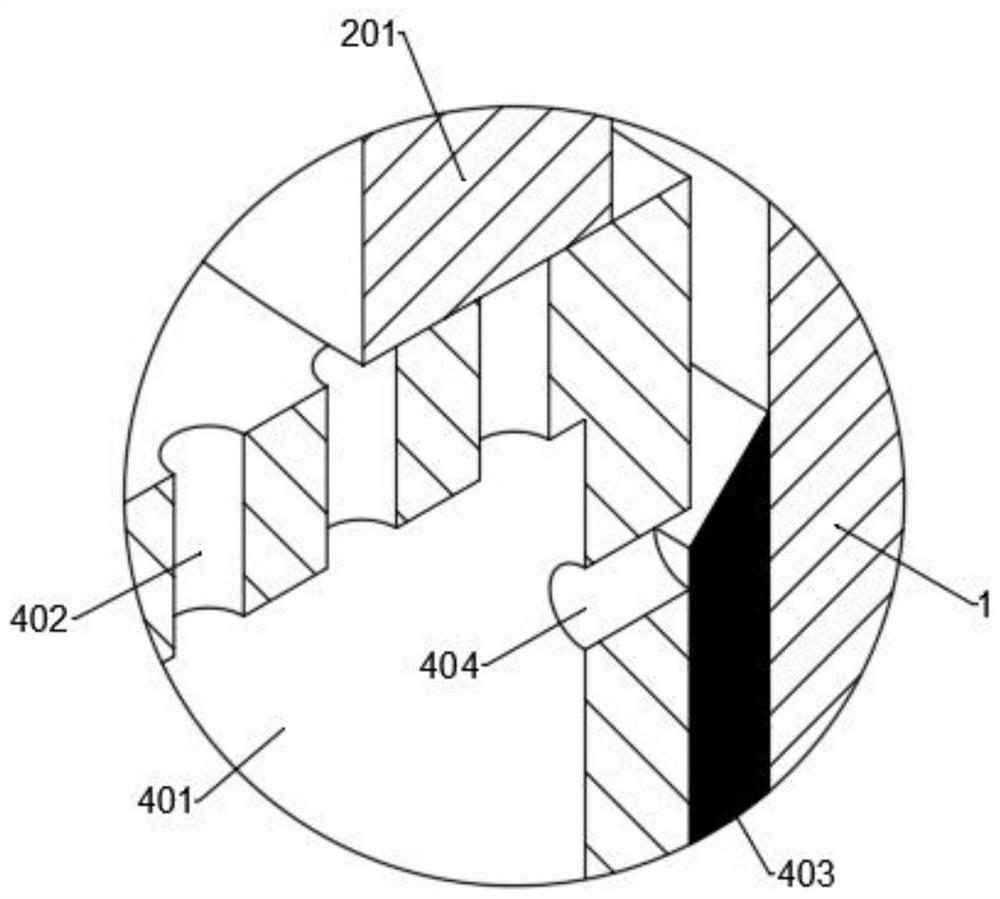

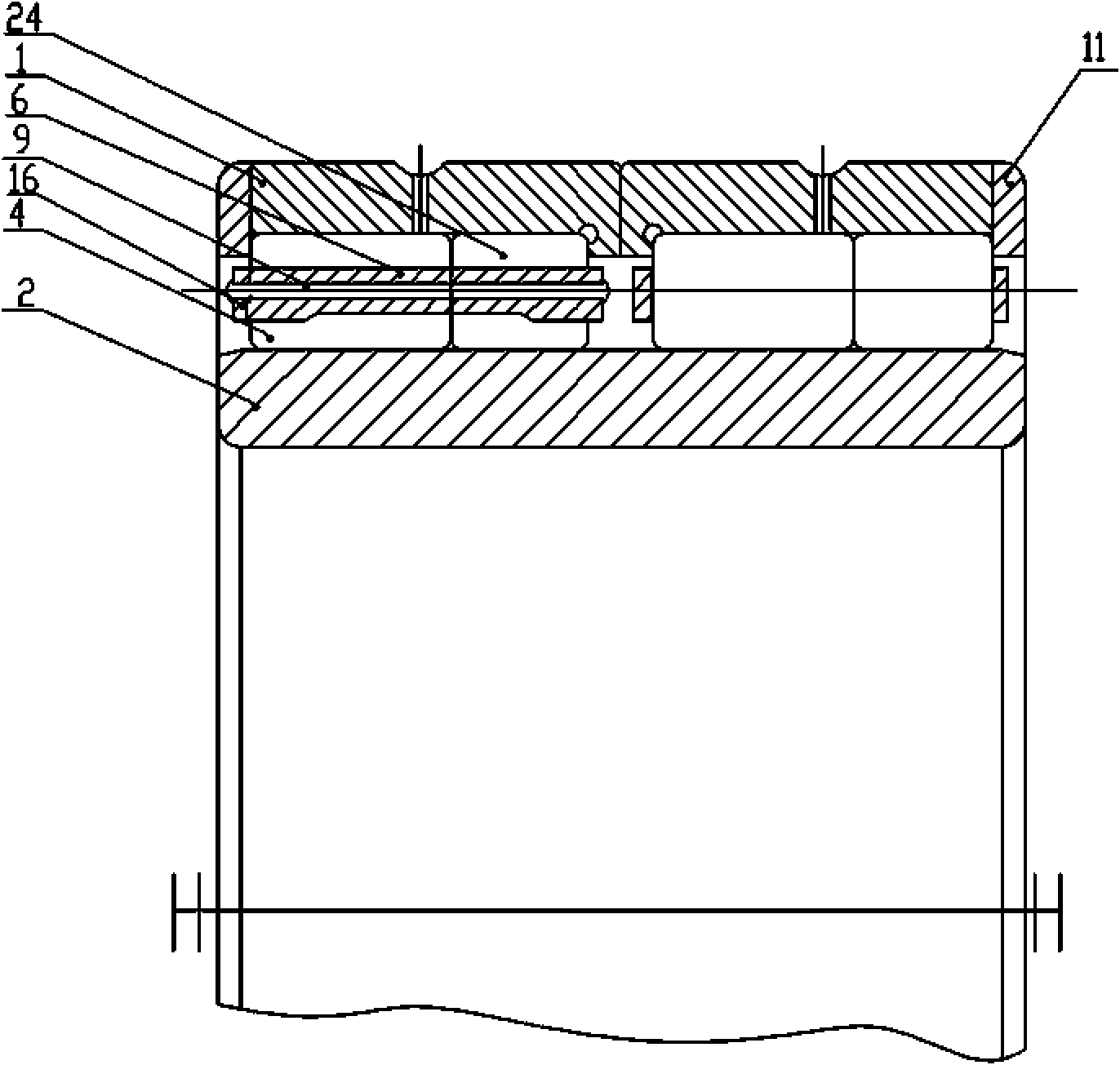

Bearing beneficial to oil injection lubrication and convenient to disassemble and assemble

InactiveCN107202066AEasy to fixEasy to disassembleBall bearingsBearing componentsLubricationH shaped

Owner:RUGAO NONSTANDARD BEARING

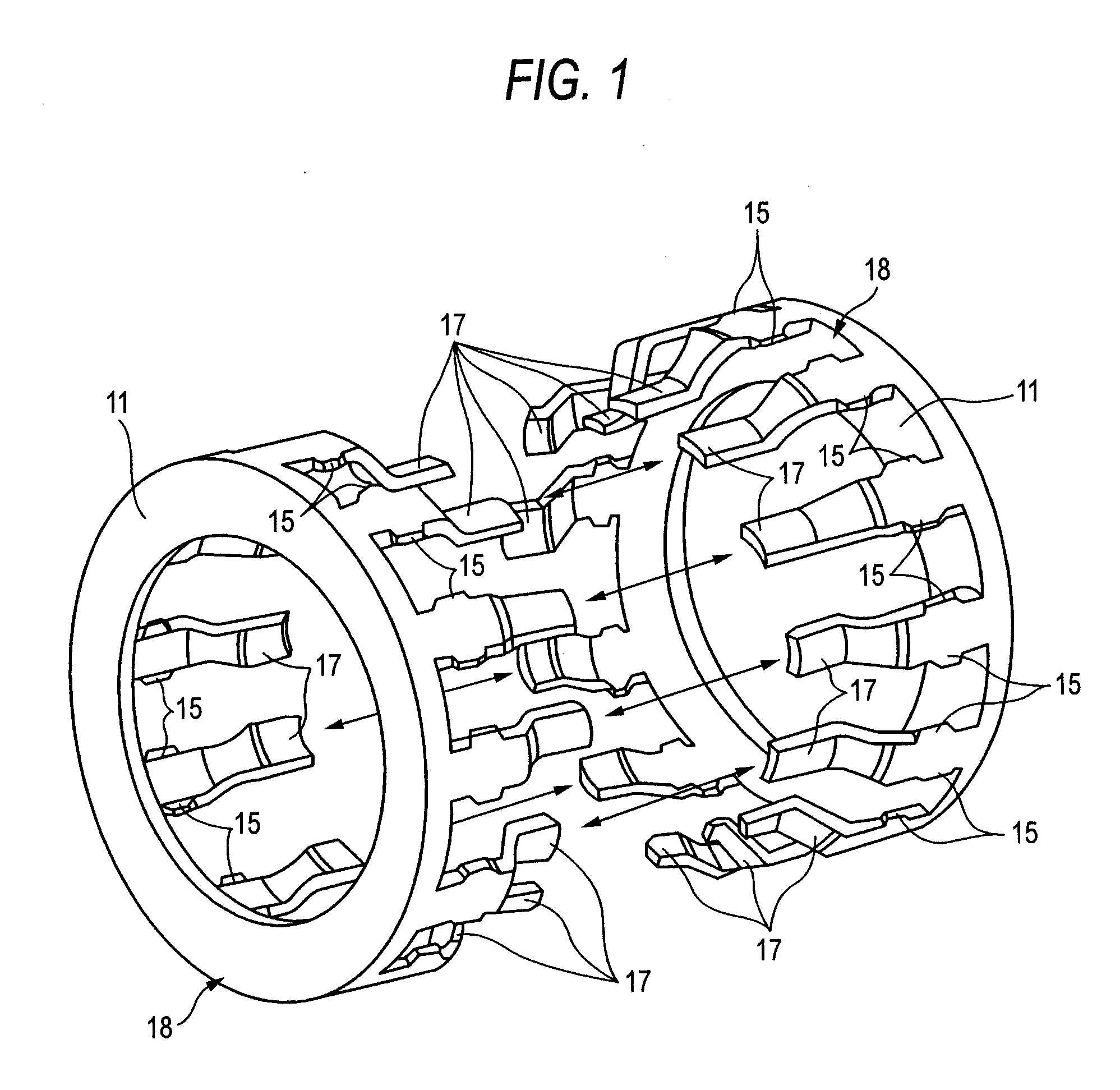

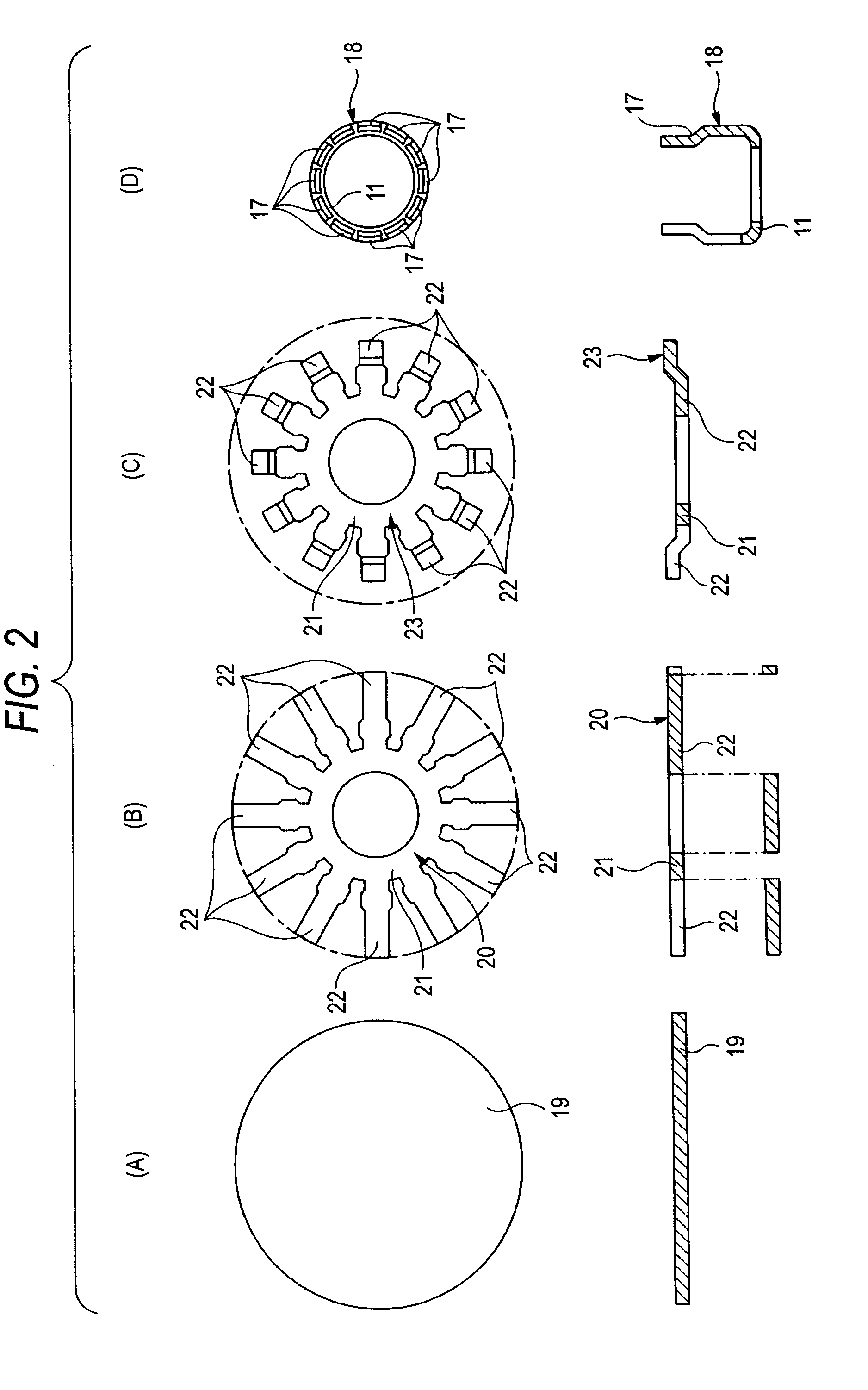

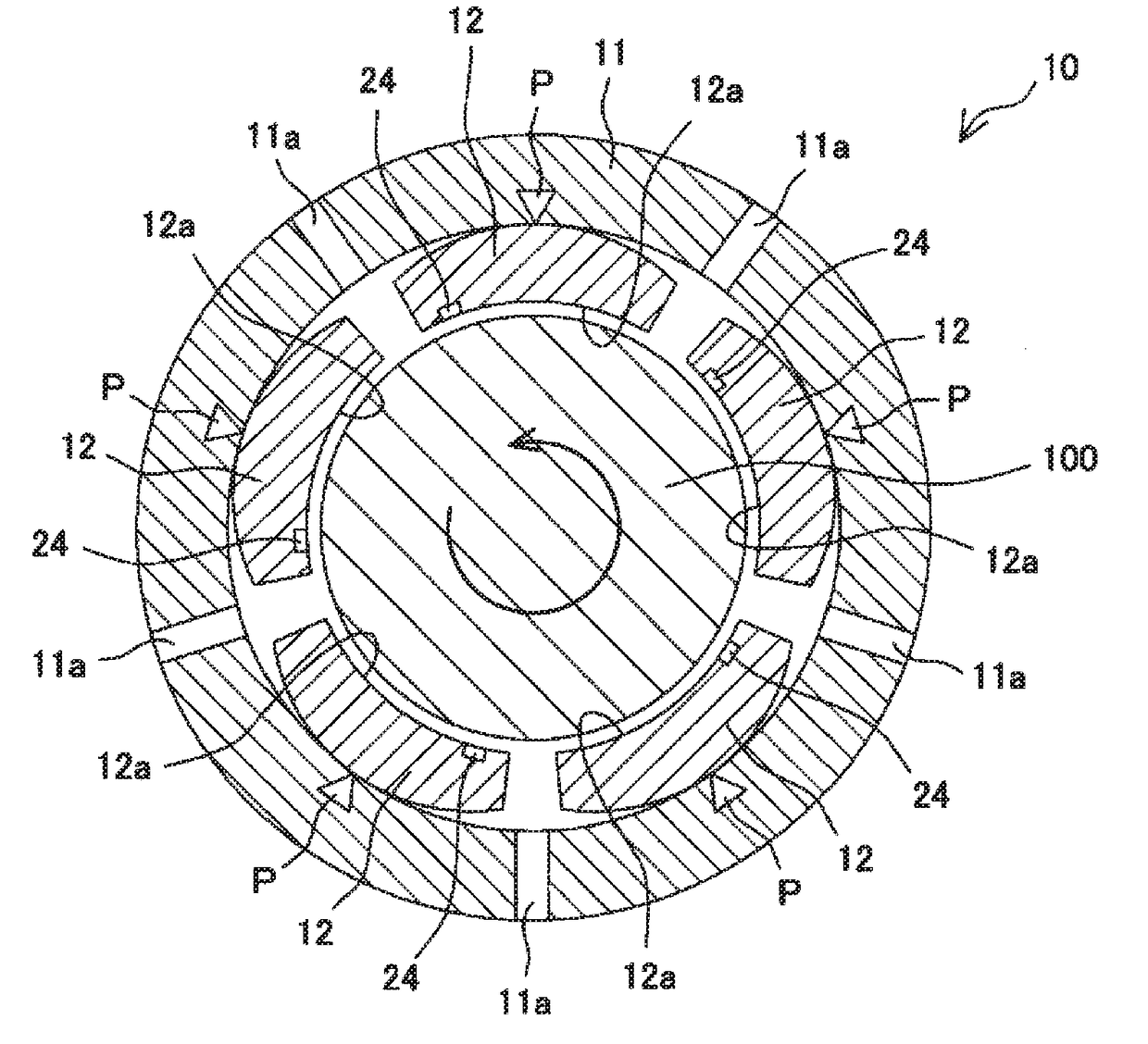

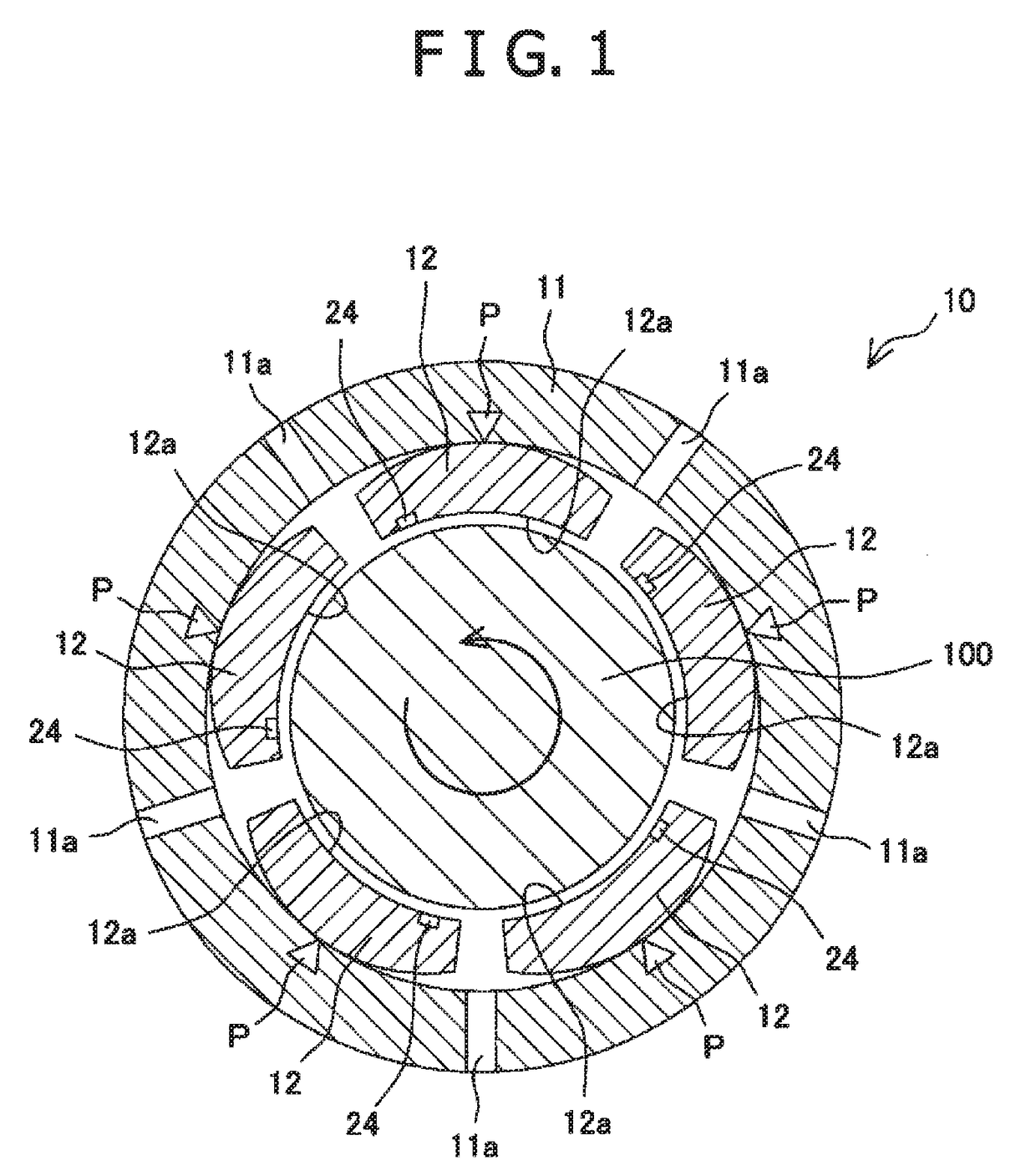

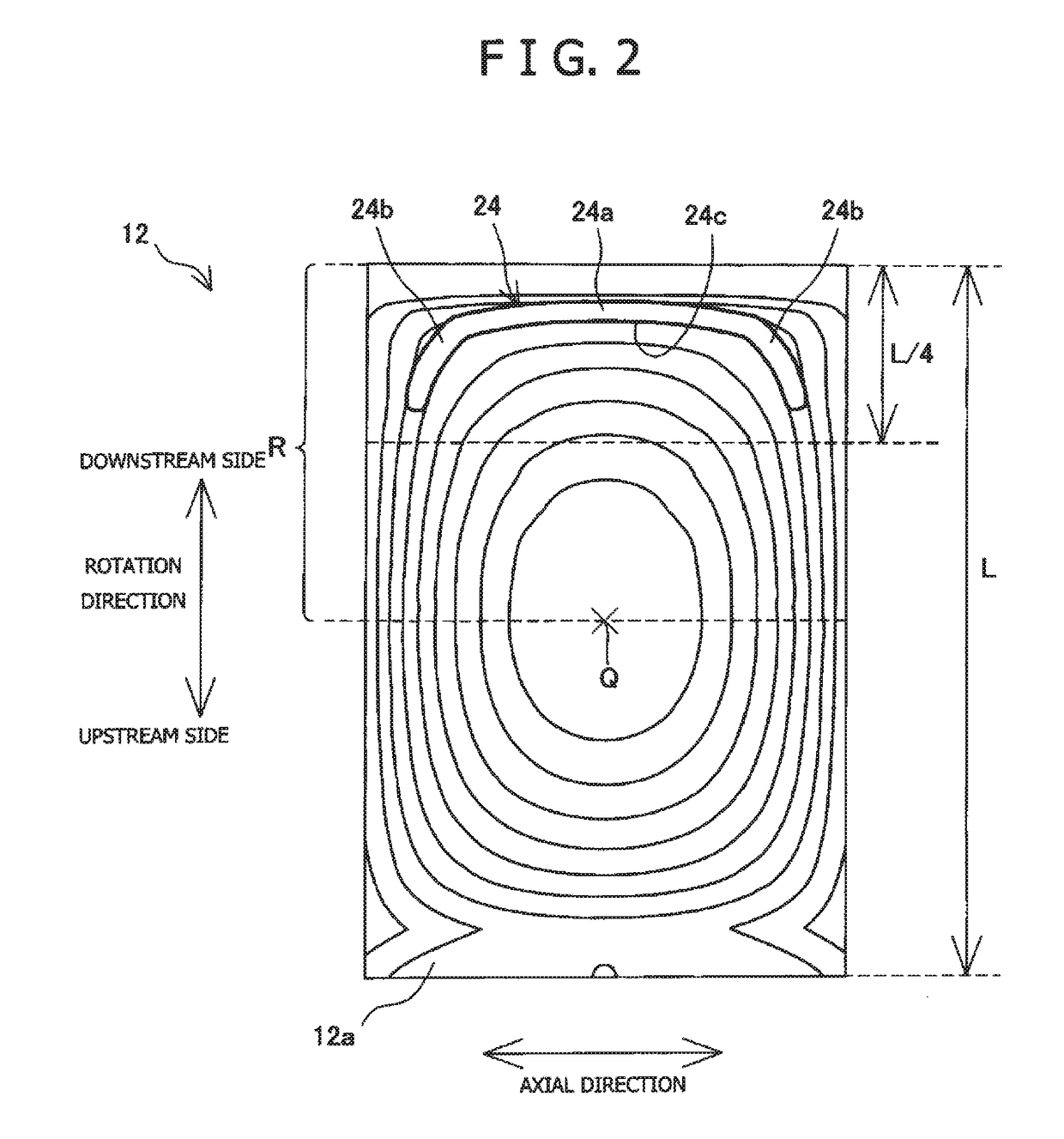

Cage for Radial Needle Bearing, Method for Manufacturing the Same and Radial Needle Bearing

Owner:NSK LTD

Carbon-graphite keeper rolling bearing used for performing protection and antifriction treatment and manufacturing method of carbon-graphite keeper rolling bearing

InactiveCN102562813ANo corrosionImprove operational reliabilityBearing componentsRolling-element bearingCarbon graphite

Owner:SHANGHAI F&S BEARING TECH

Electrically motorized pump having a submersible sleeve bearing

Owner:MINEBEA CO LTD

Grease composition

InactiveUS20120098269A1Long life-timeSuppressing bearing wearPump componentsAdditivesBase oilViscosity

Owner:IDEMITSU KOSAN CO LTD

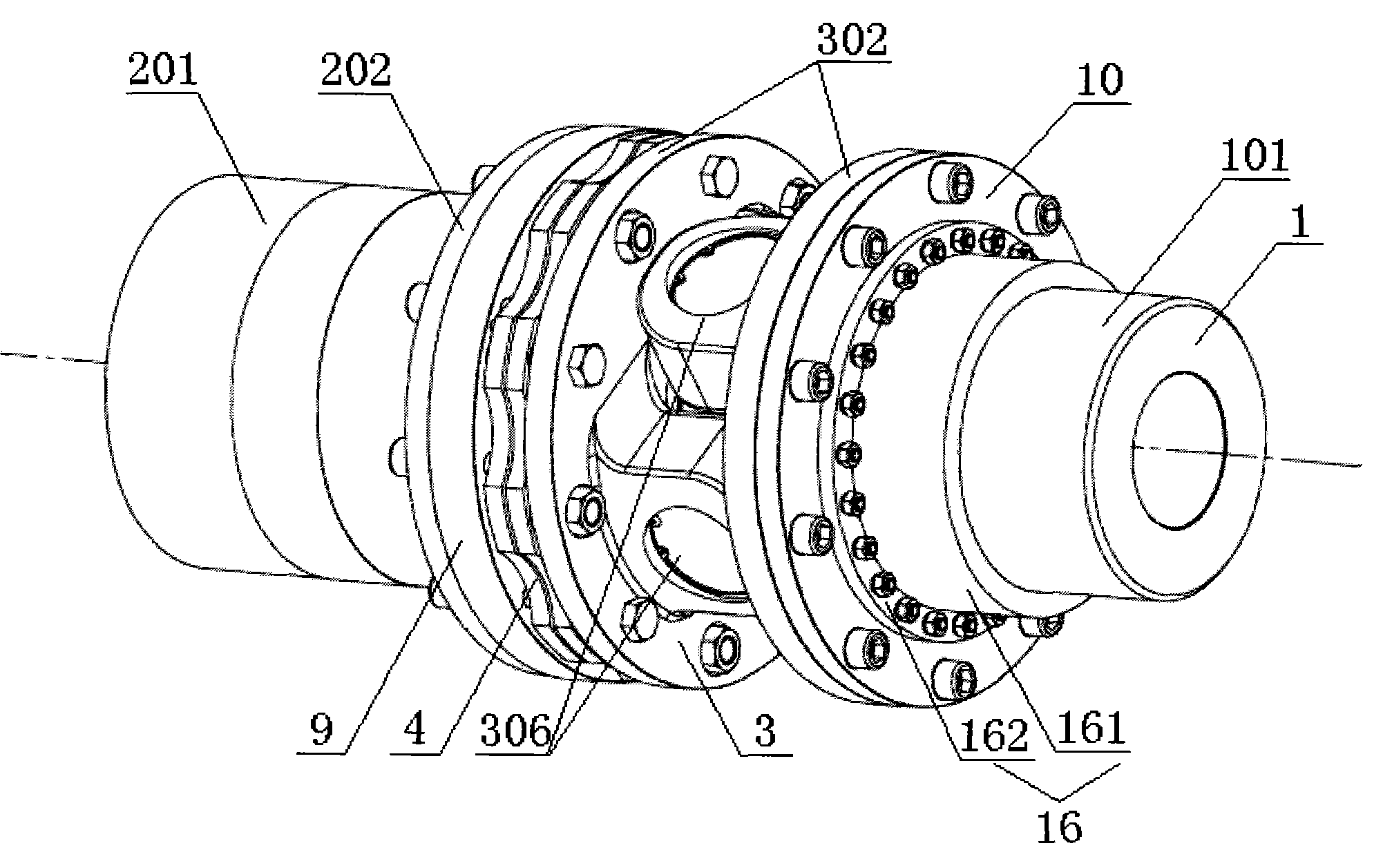

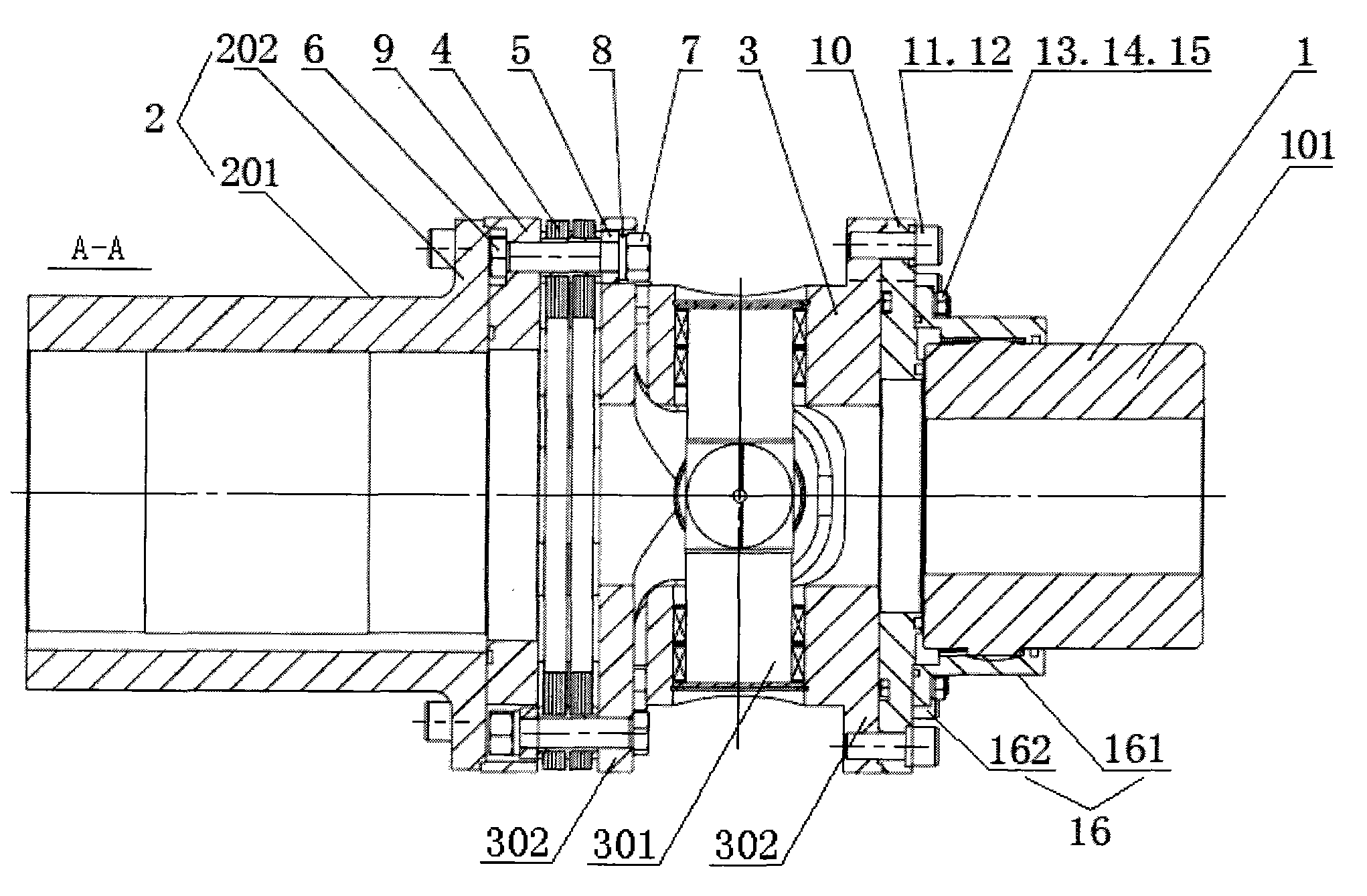

Drum-gear angular flexible coupling

InactiveCN102162491AExtended service lifeGuaranteed uptimeYielding couplingBearing componentsGear wheelCoupling

Owner:李文聪

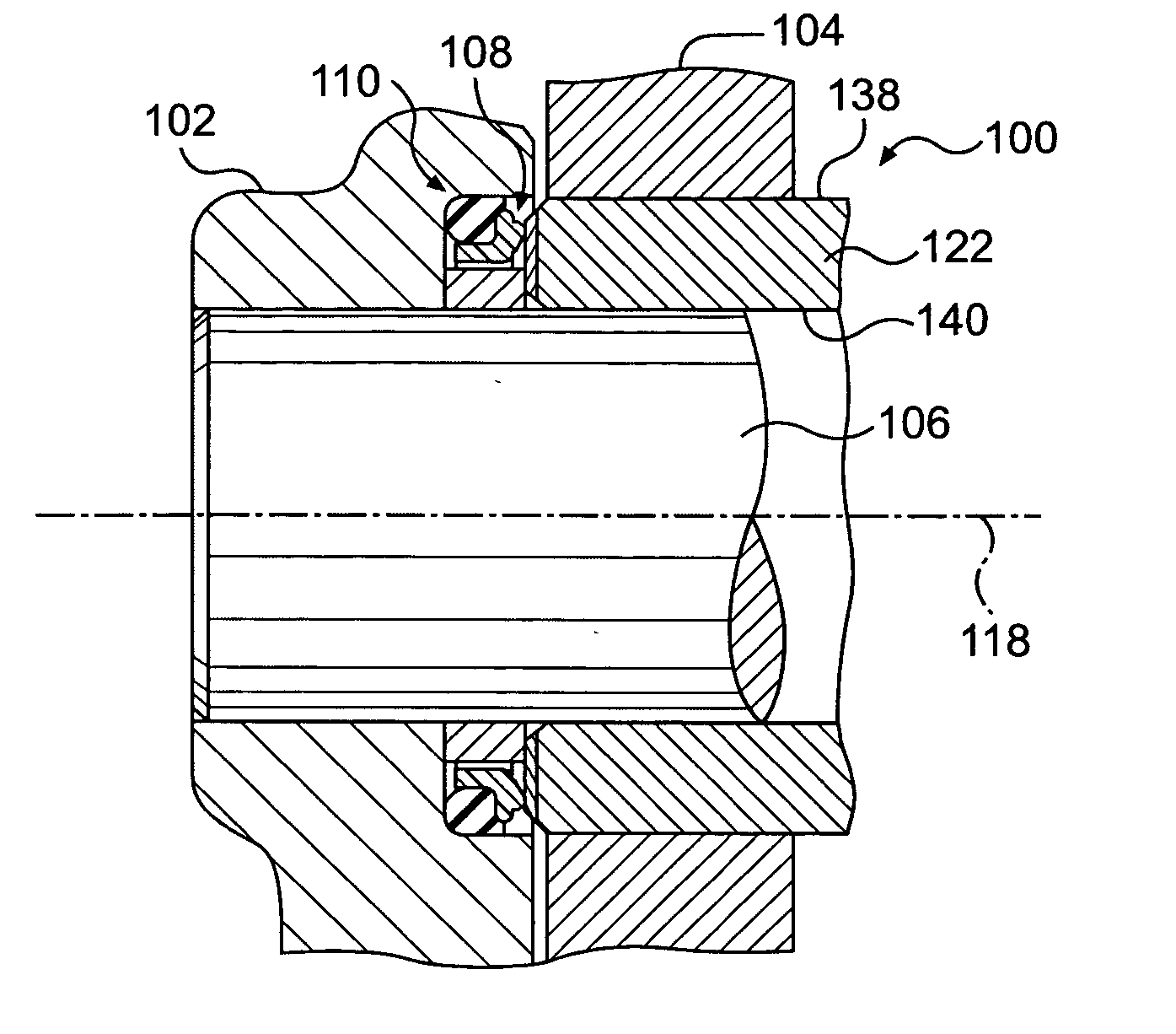

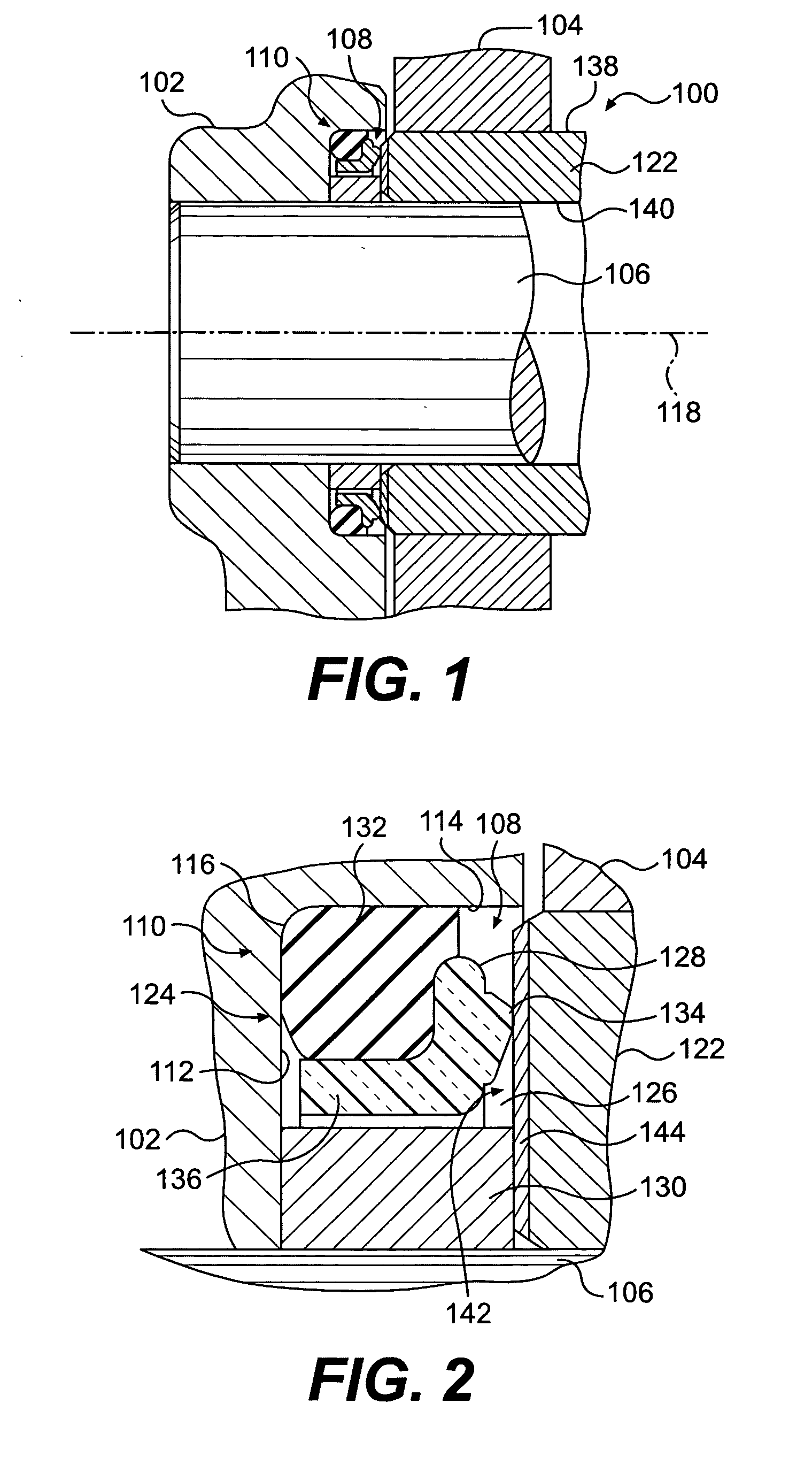

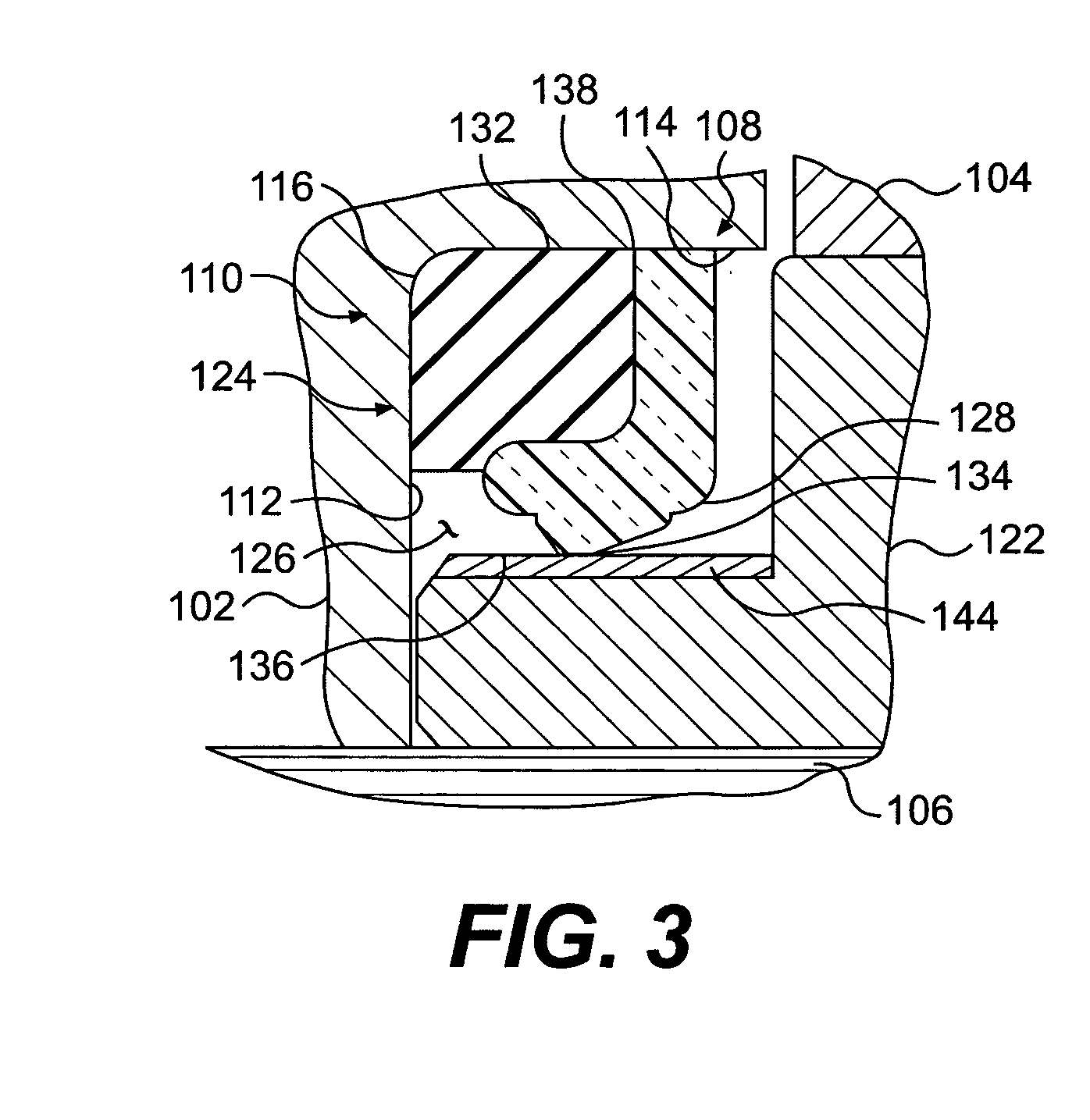

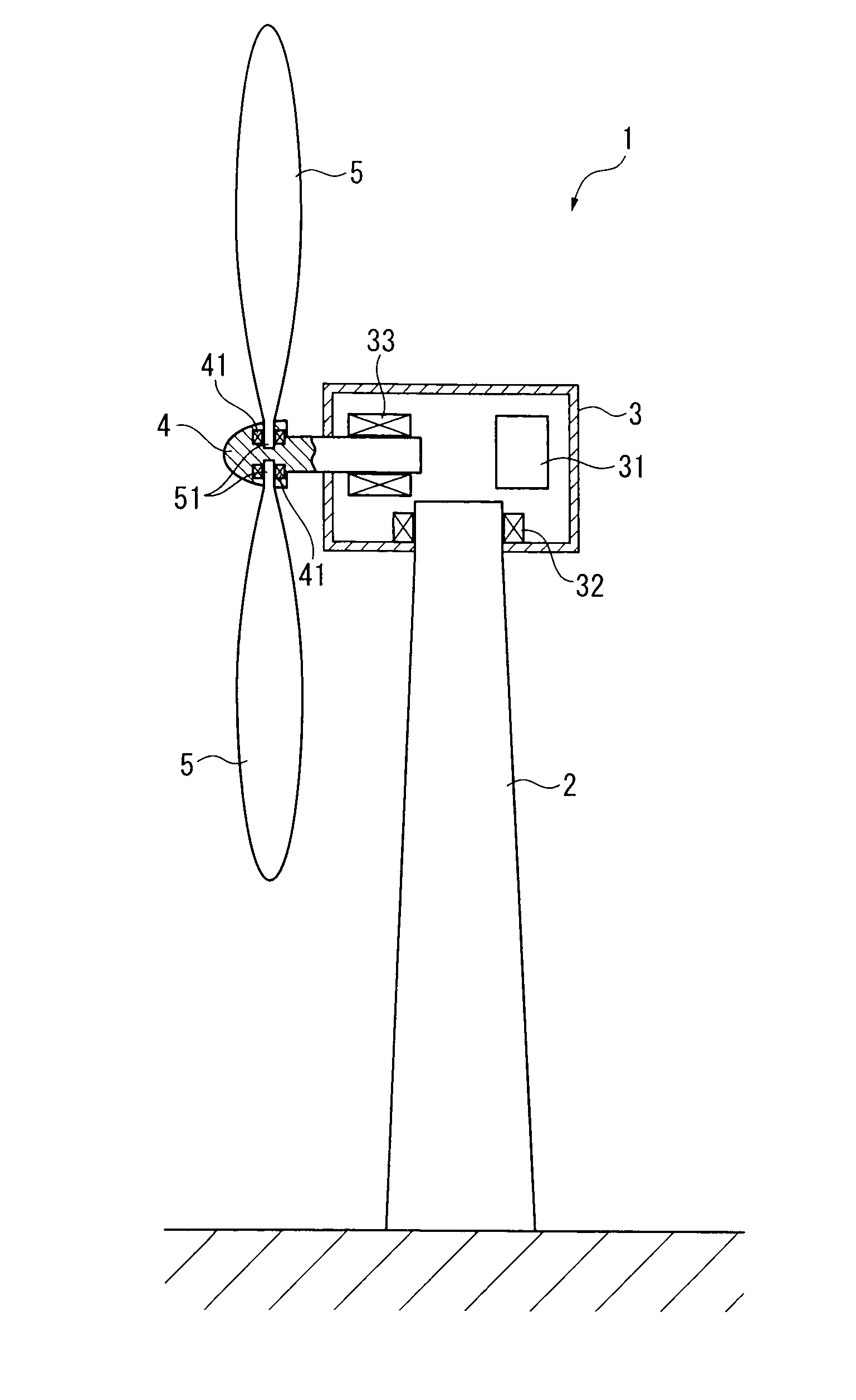

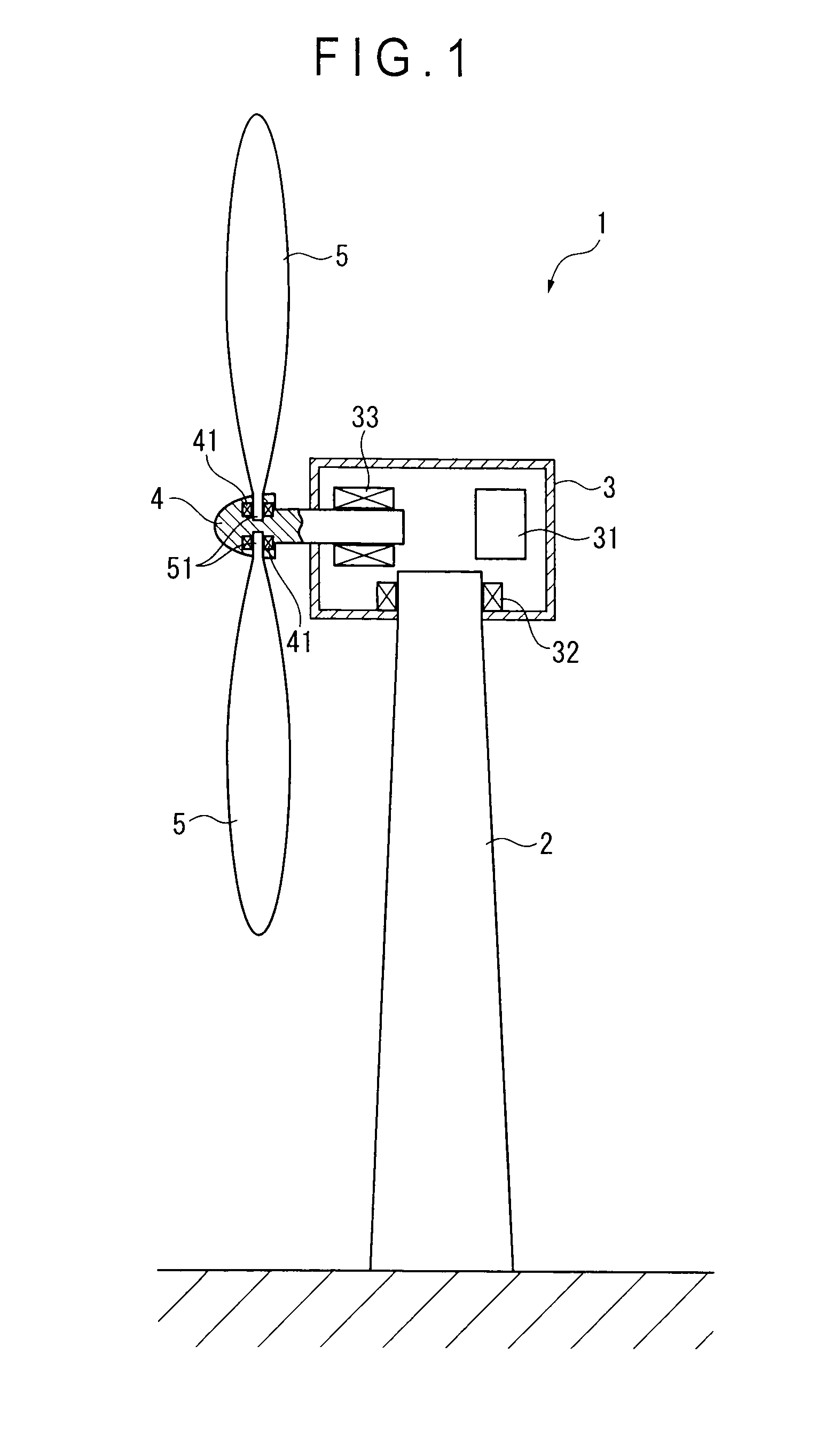

Hydrodynamic bearing device

InactiveUS20050201645A1Improve bearing rigidityImprove bearing performanceRecord information storageBearing componentsBearing surfaceWorking fluid

Owner:NIDEC CORP

Thrust bearing

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

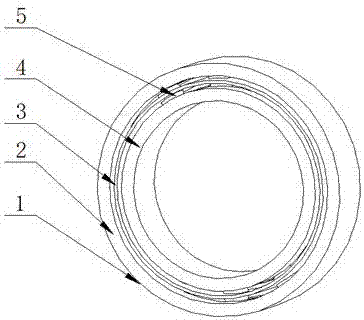

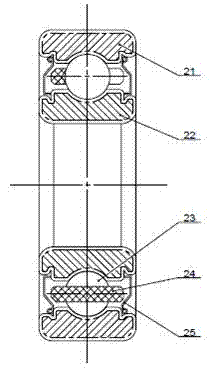

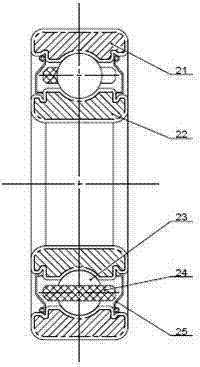

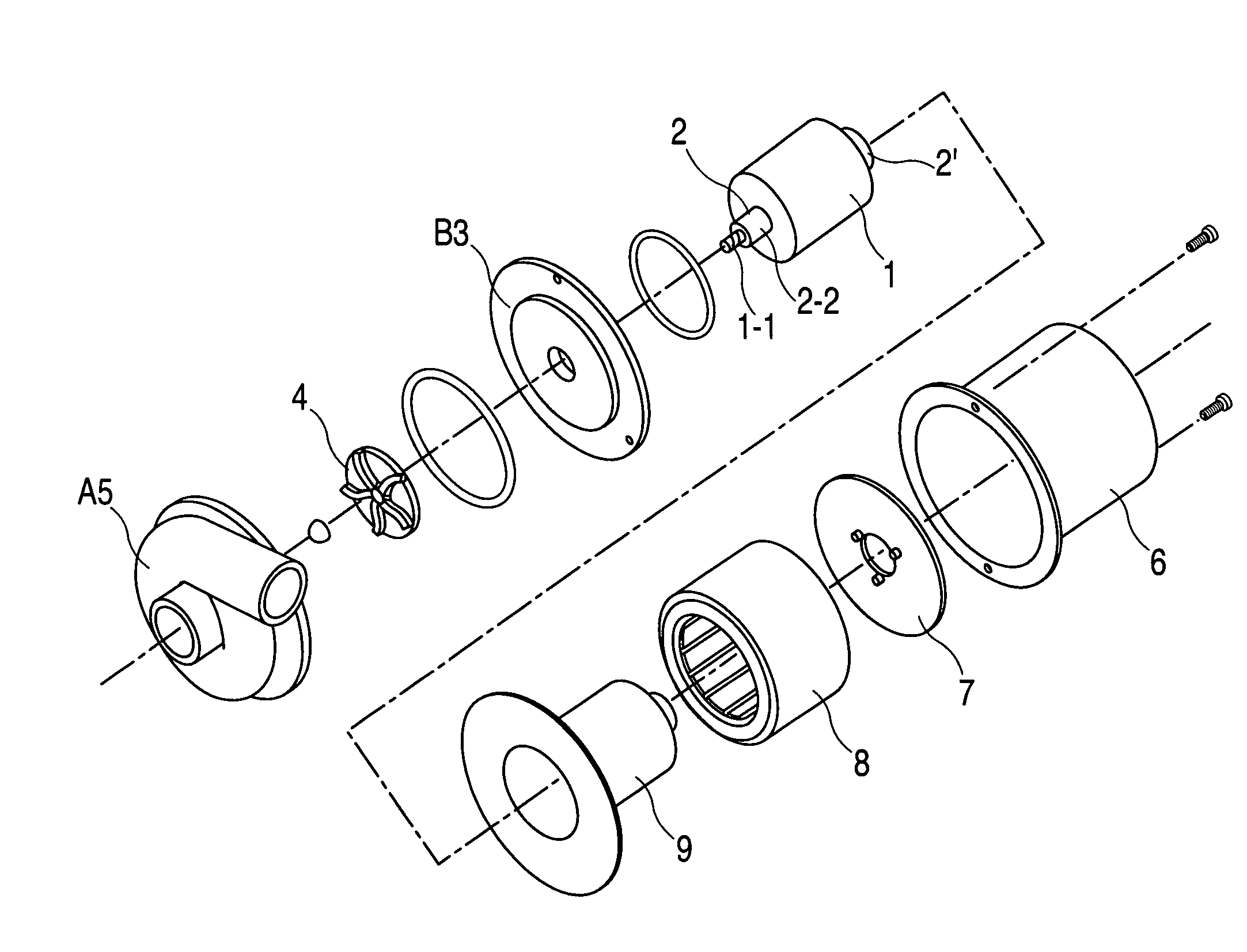

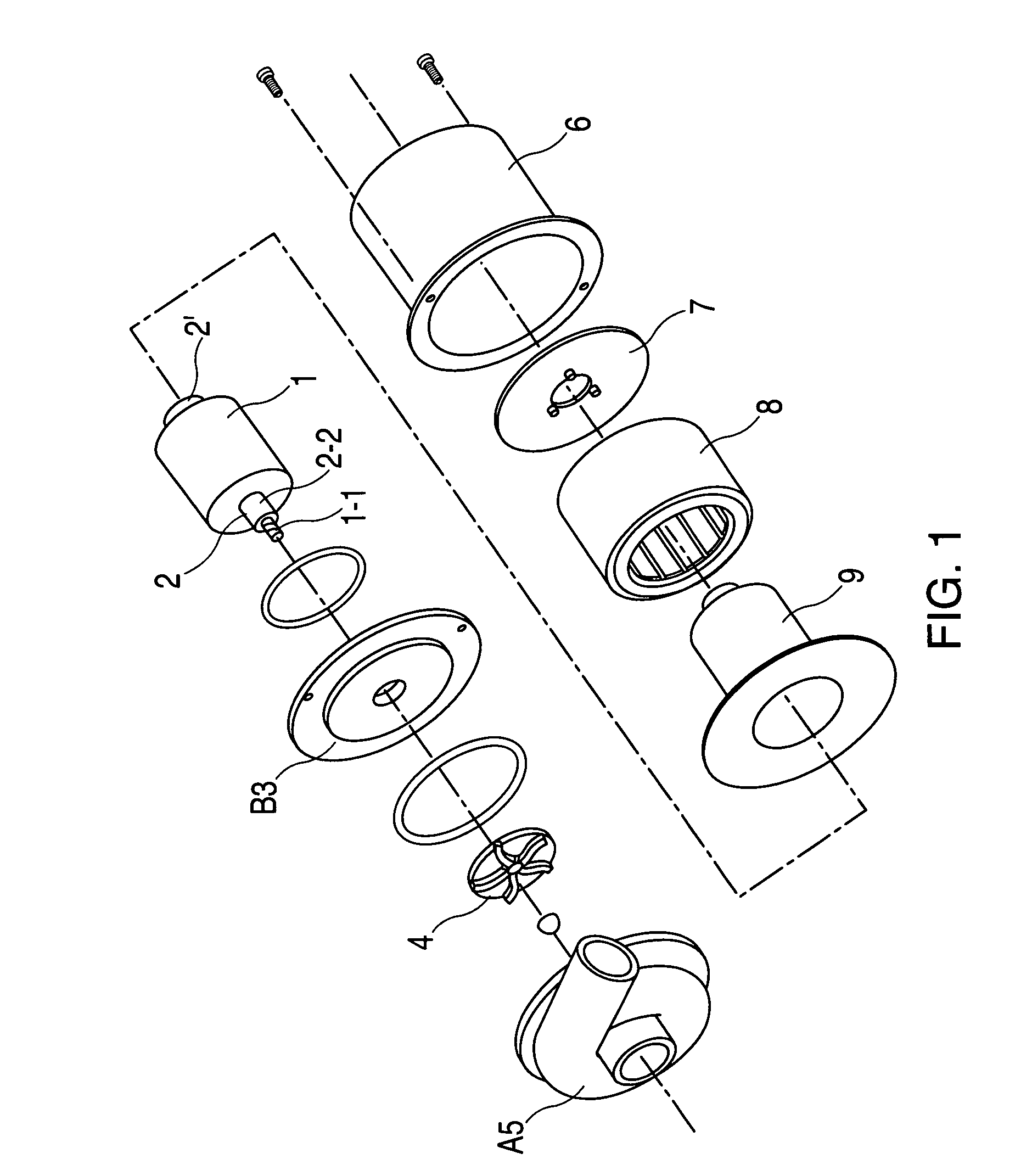

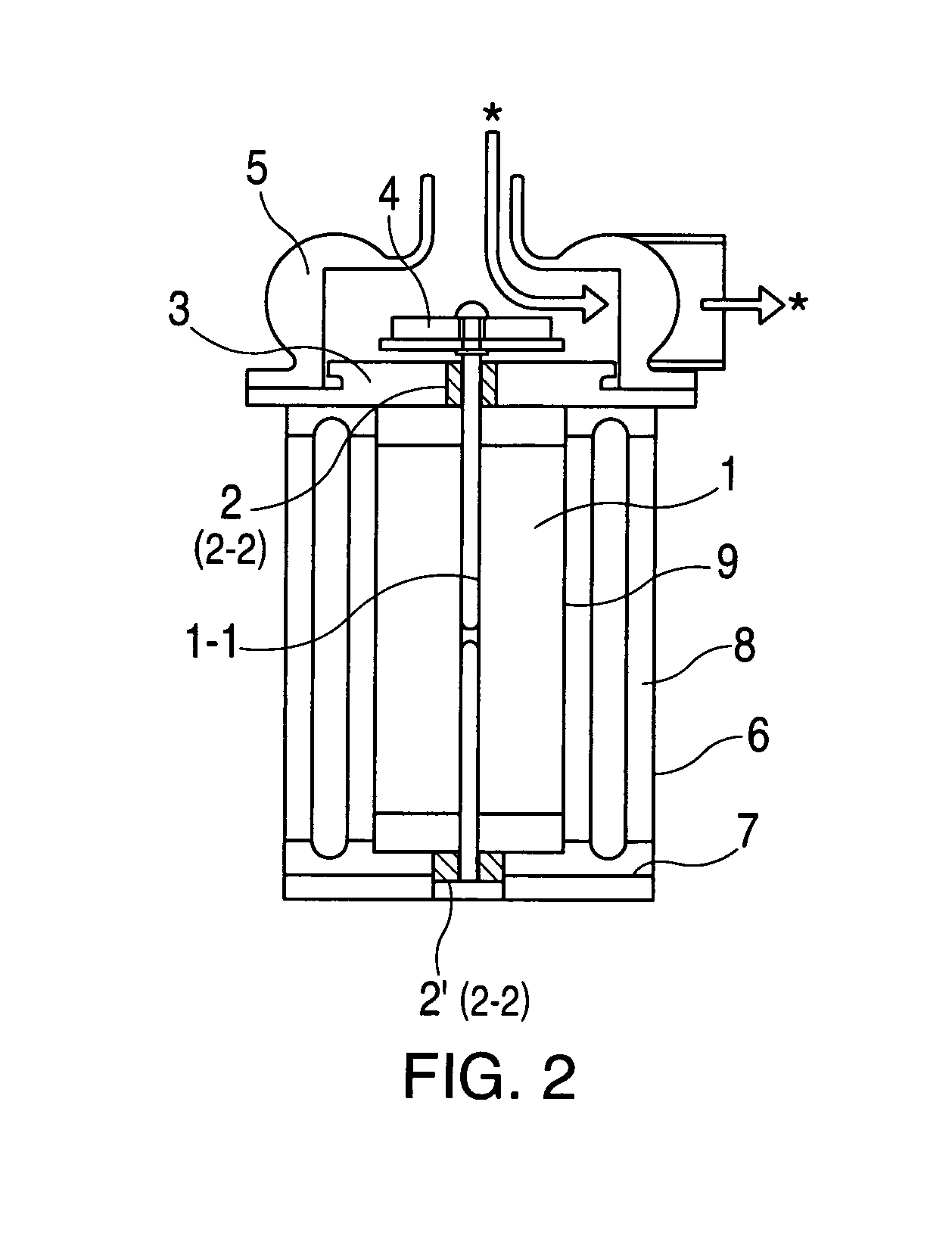

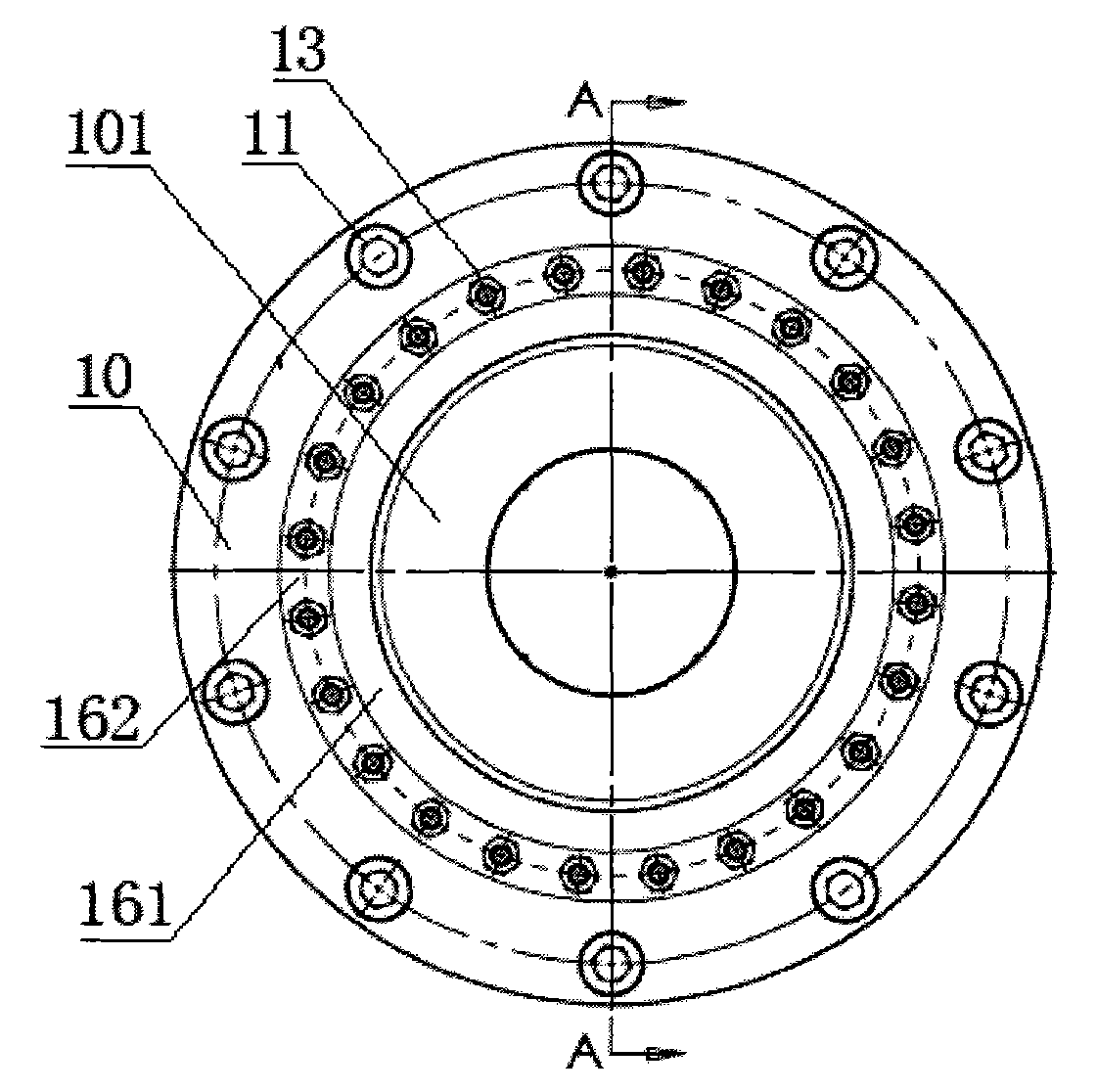

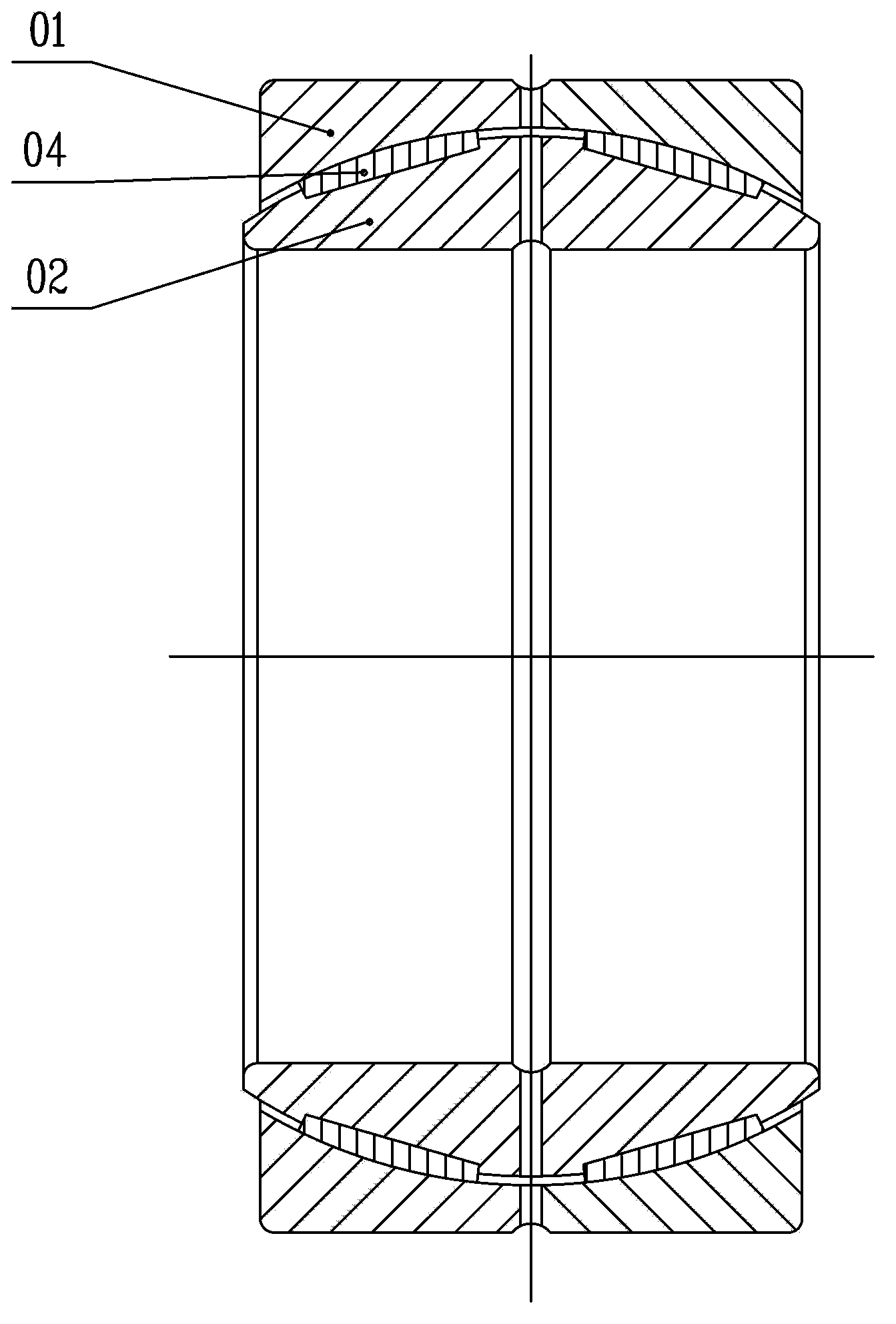

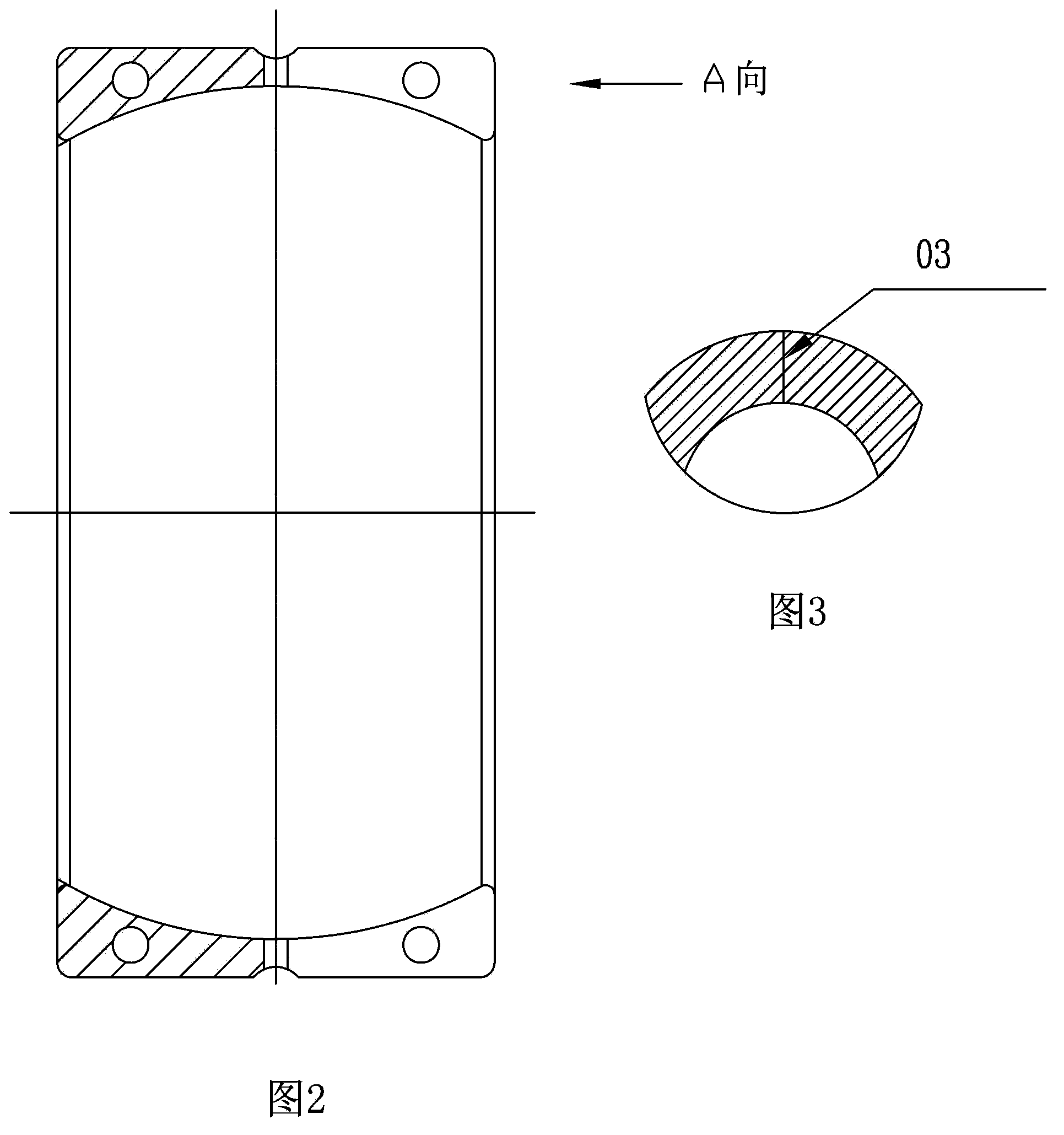

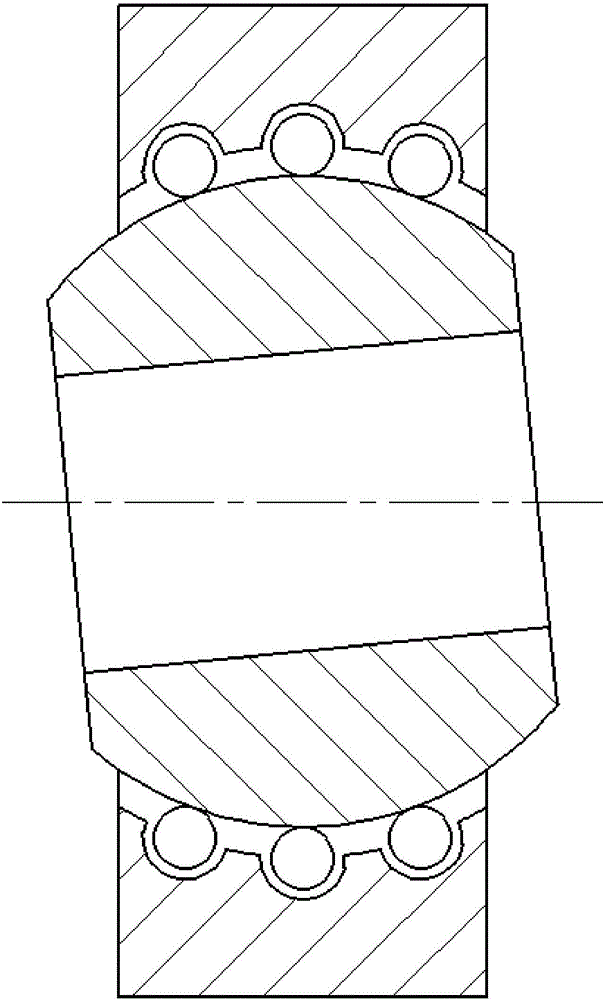

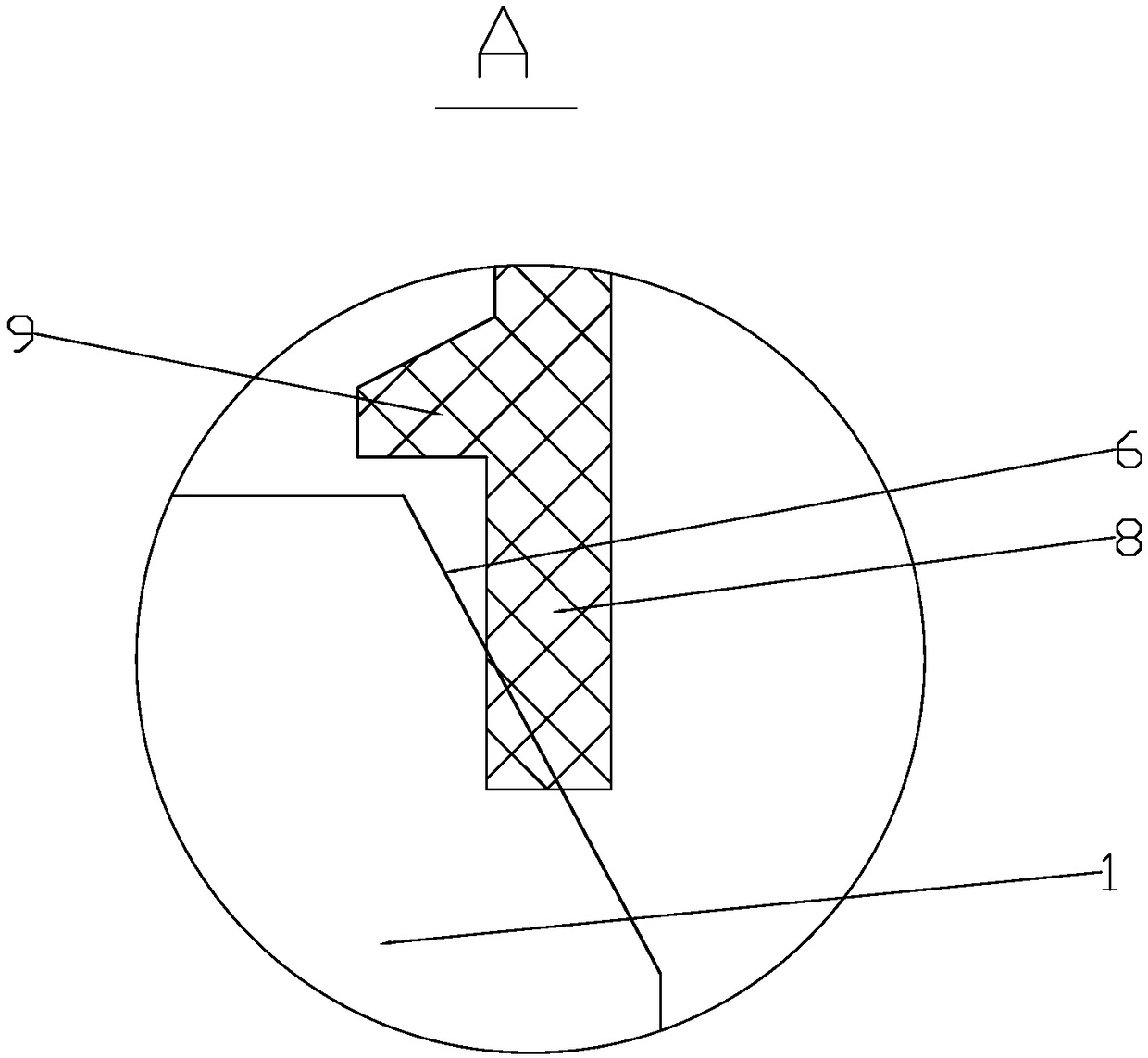

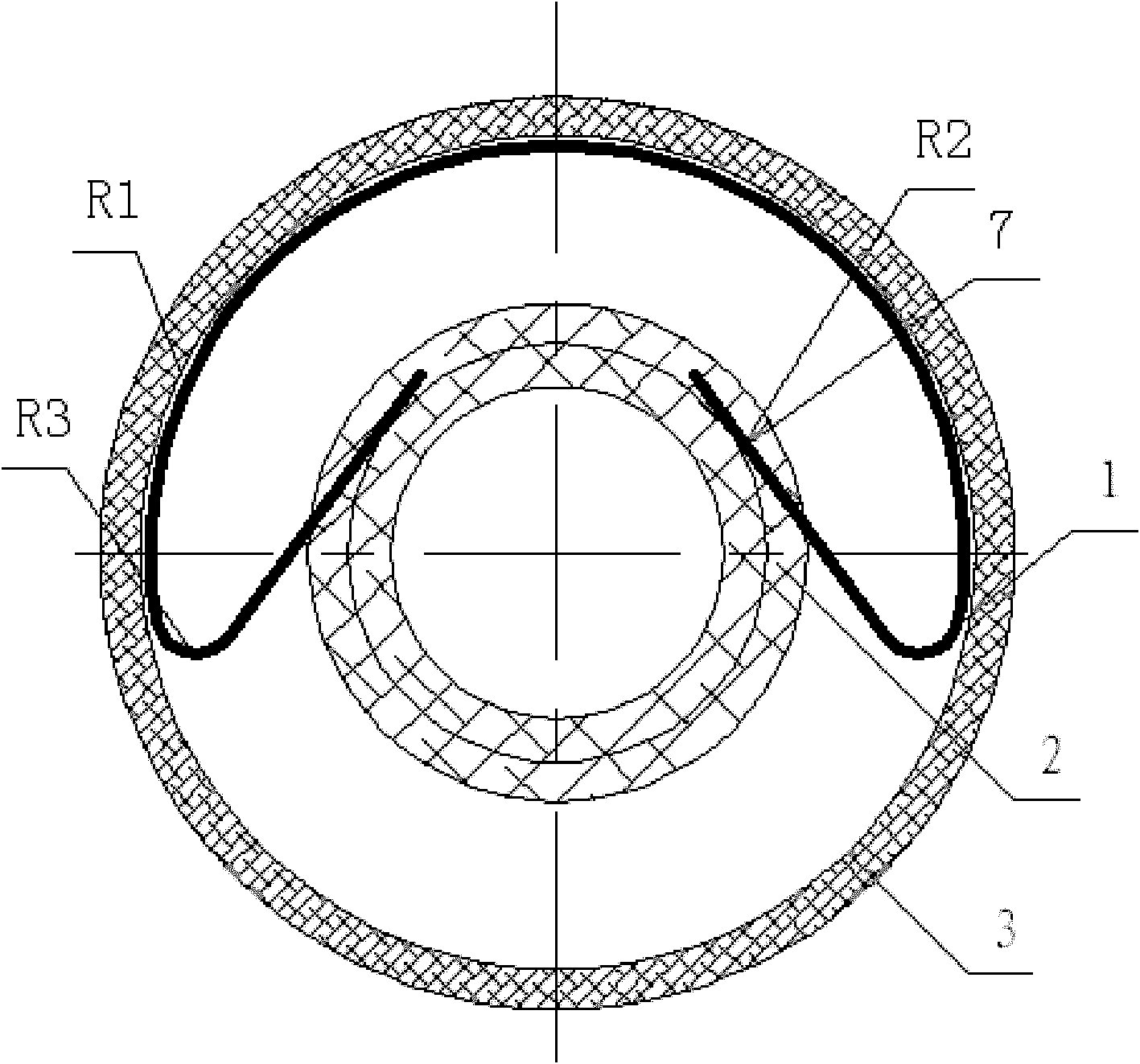

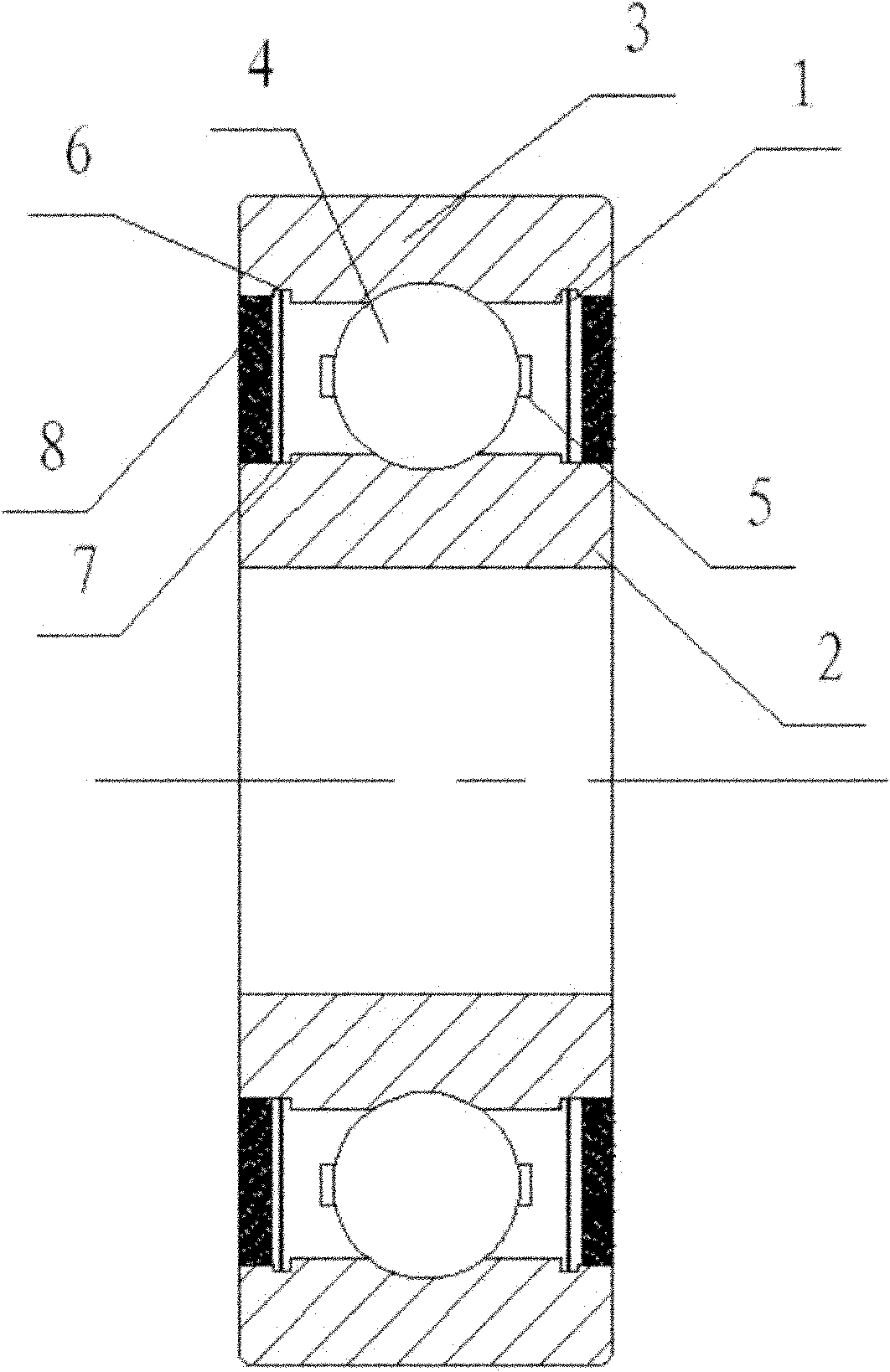

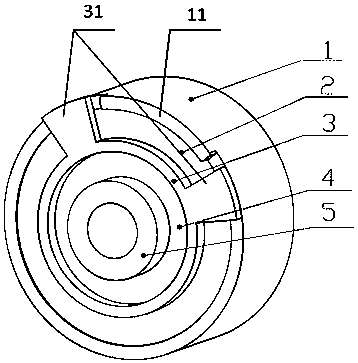

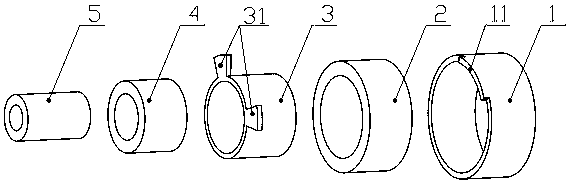

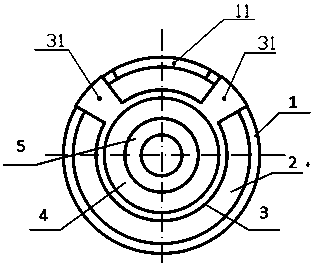

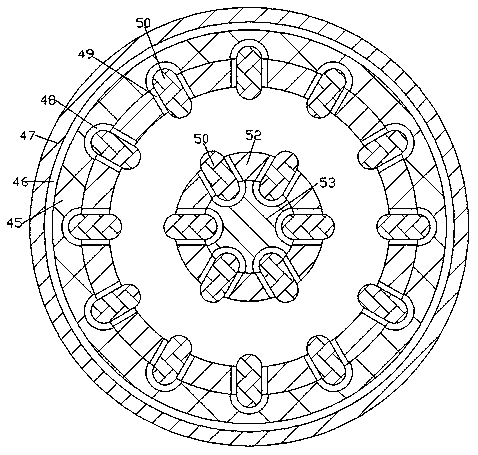

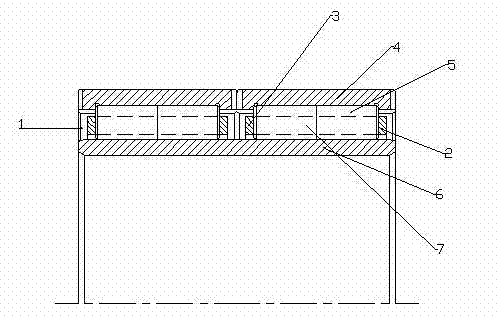

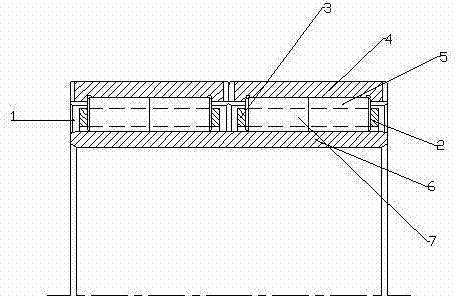

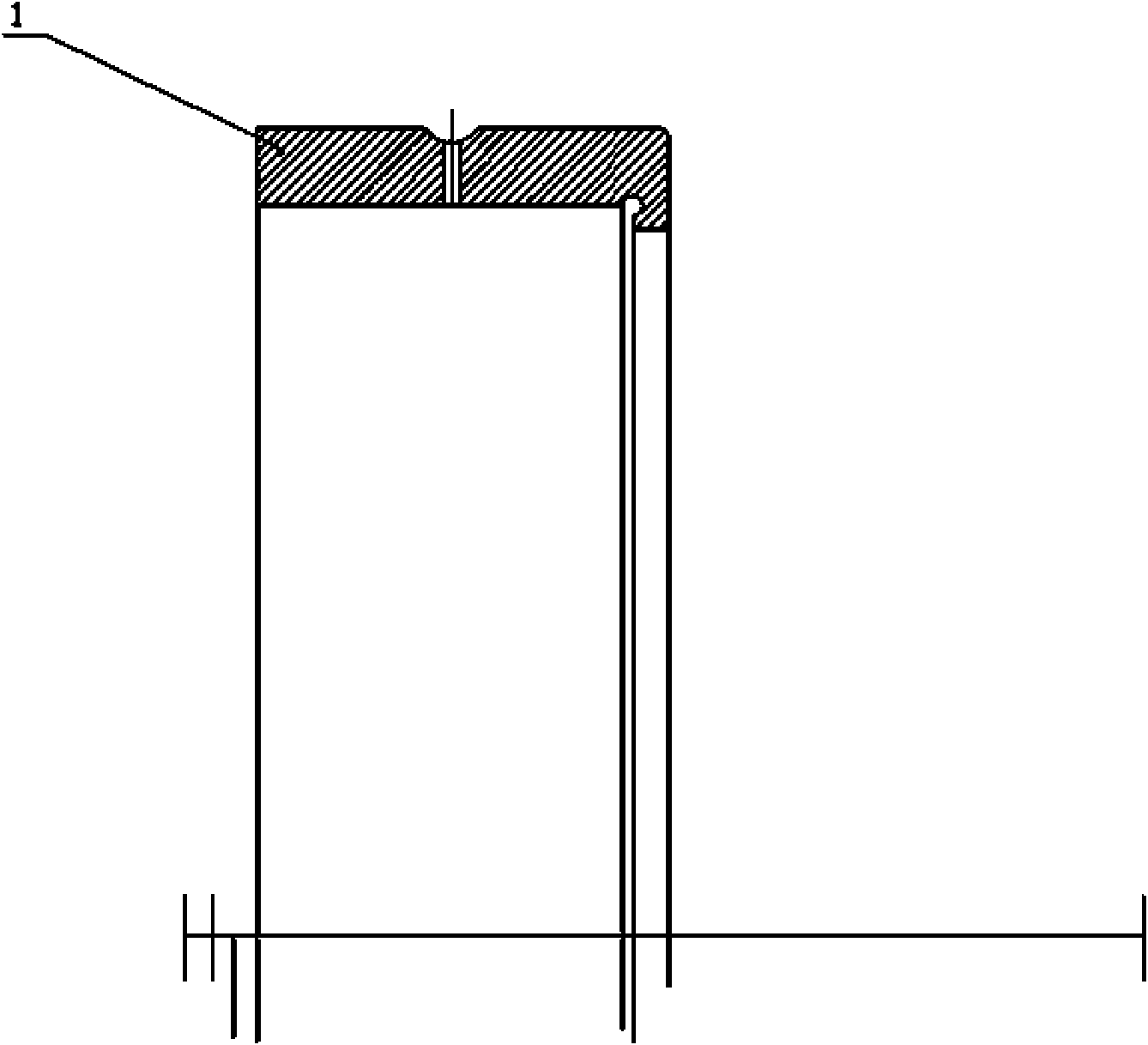

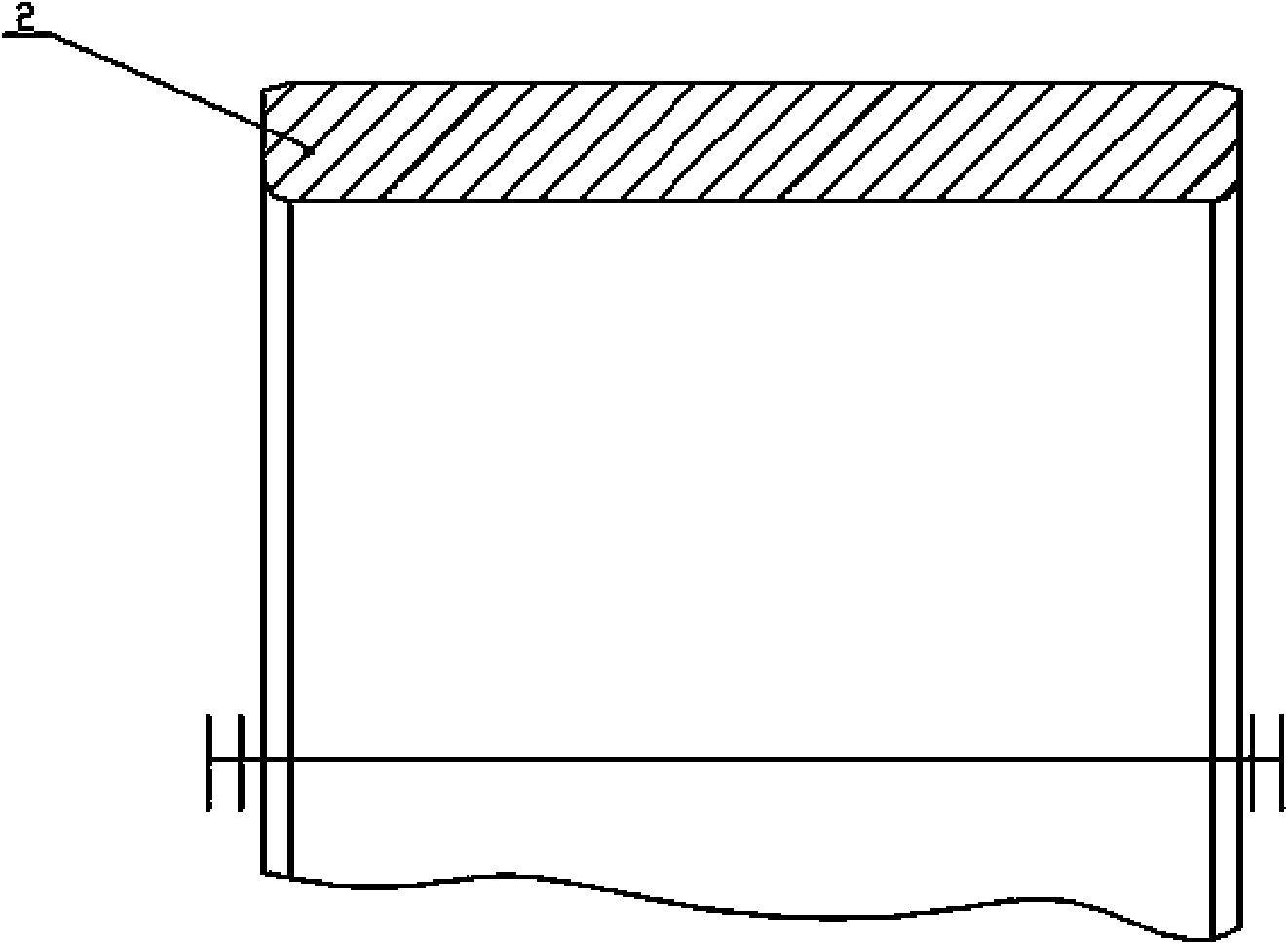

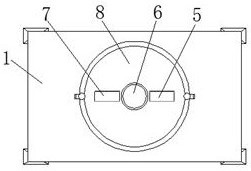

Combination bearing for disc-shaped elevator tractor

InactiveCN107299937AGuaranteed radial bearing capacityExtended service lifeBall and roller bearingsBearing componentsBall bearingEngineering

The invention relates to the field of bearings and provides a combination bearing for a disc-shaped elevator tractor. The combination bearing comprises an inner bearing ring and a first outer bearing ring and a second outer bearing ring which are located on the inner bearing ring; the first outer bearing ring and the second outer bearing ring are closely arranged along an axial direction of the inner bearing ring; a radial cylindrical roller component is arranged between the first outer bearing ring and the inner bearing ring; a ball bearing component is arranged between the second outer bearing ring and the inner bearing ring; a first sealing ring is arranged between the first outer bearing ring and the axial outer end of the inner bearing ring; a second sealing ring is arranged between the second outer bearing ring and the axial outer end of the inner bearing ring. The combination bearing is mainly designed for the machinery, such as the elevator tractor; the combination bearing can simultaneously bear the radial load and the axial load, and is especially suitable for the occasions with higher rotating speed and higher axial load; the assembling and disassembling are simple and the bearing capacity is ultrahigh; the combination bearing has an excellent sealing effect and can guarantee that the lubricating grease does not leak in the running process of the bearing.

Owner:DEQING TIANMA BEARING CO LTD

Double-half outer ring joint bearing

InactiveCN103790954AEasy to assembleEasy to assemble and disassembleBearing componentsSliding contact bearingsEngineeringSacroiliac joint

Owner:瓦房店福斯特轴承科技开发有限公司

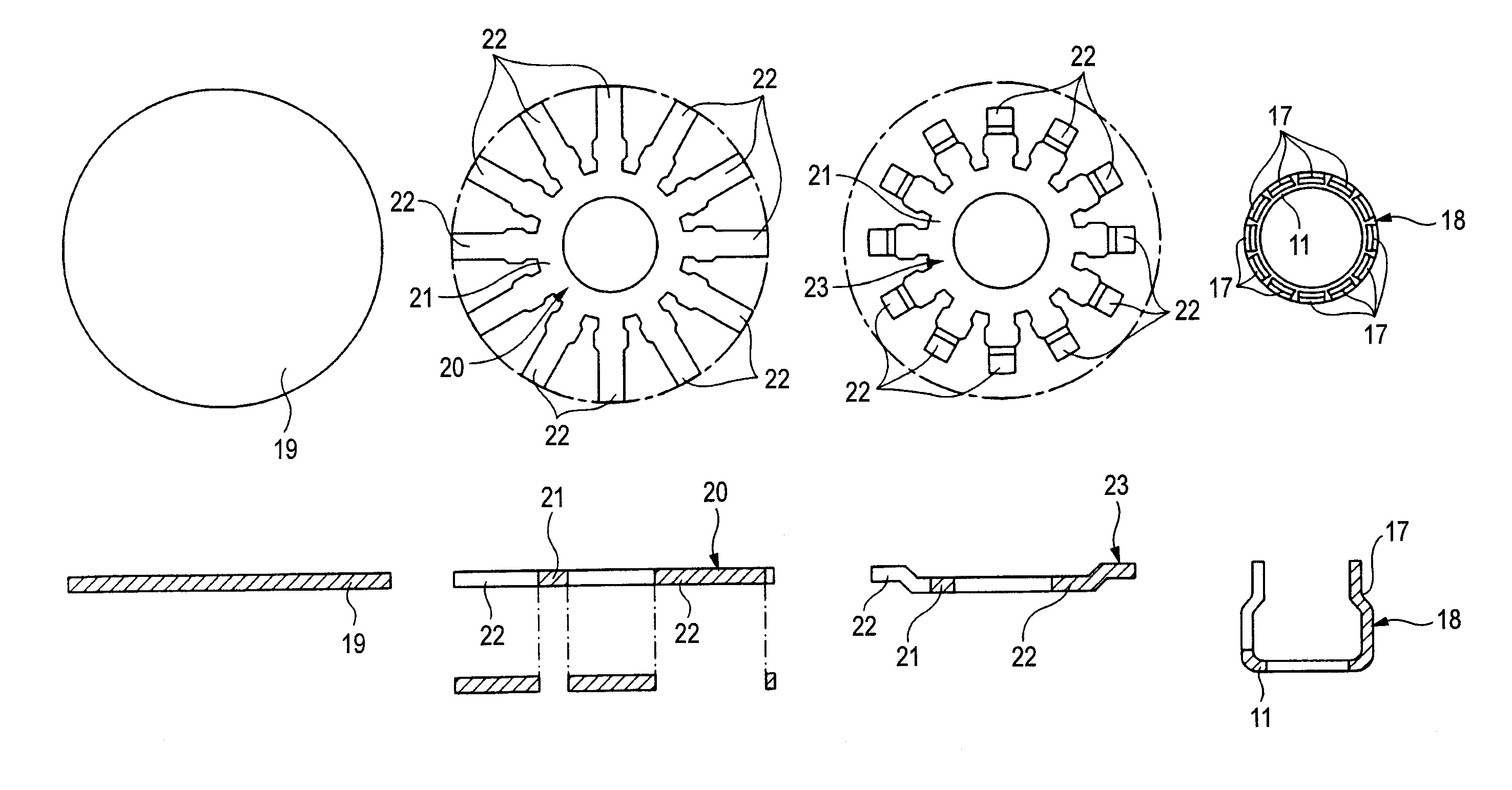

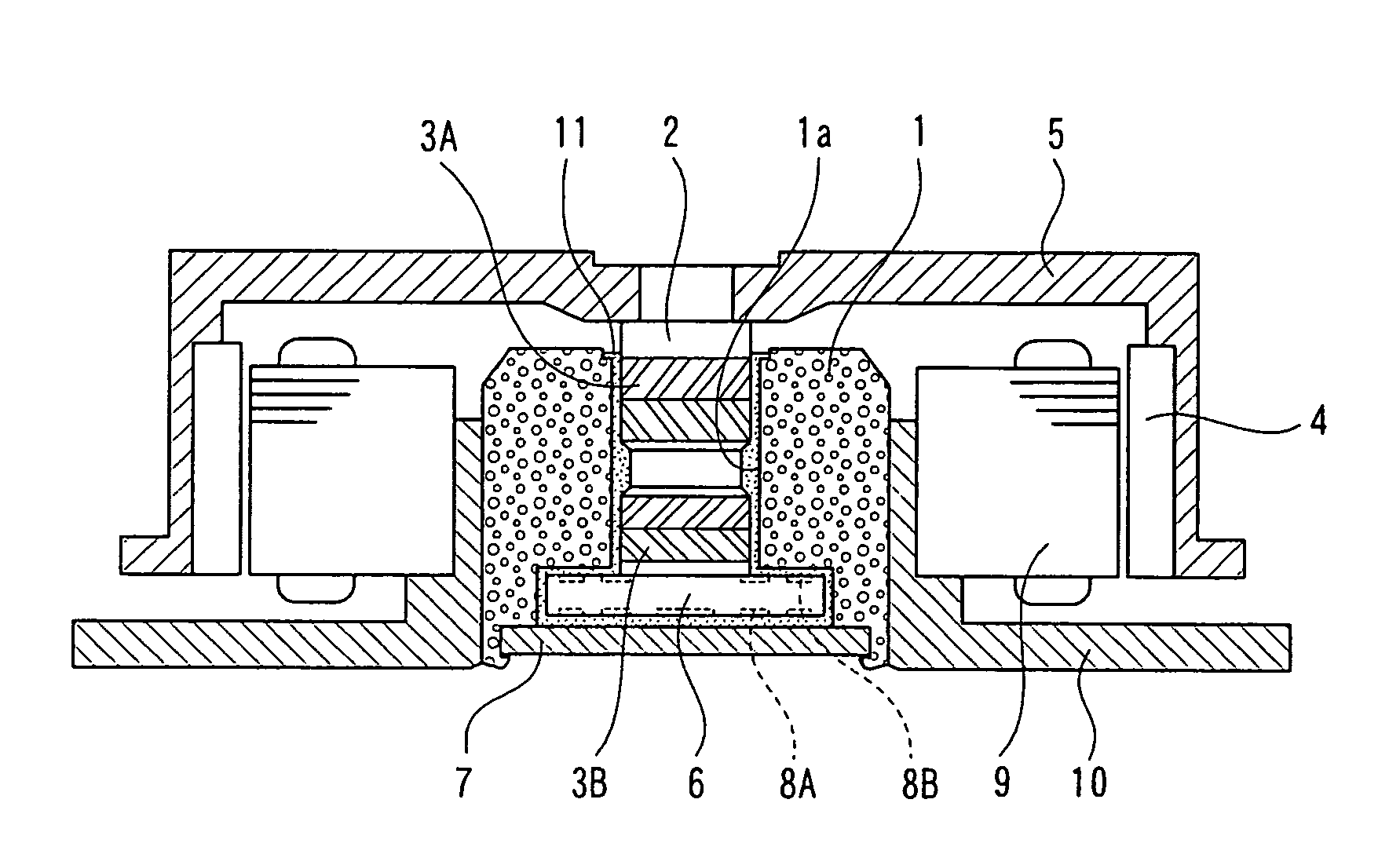

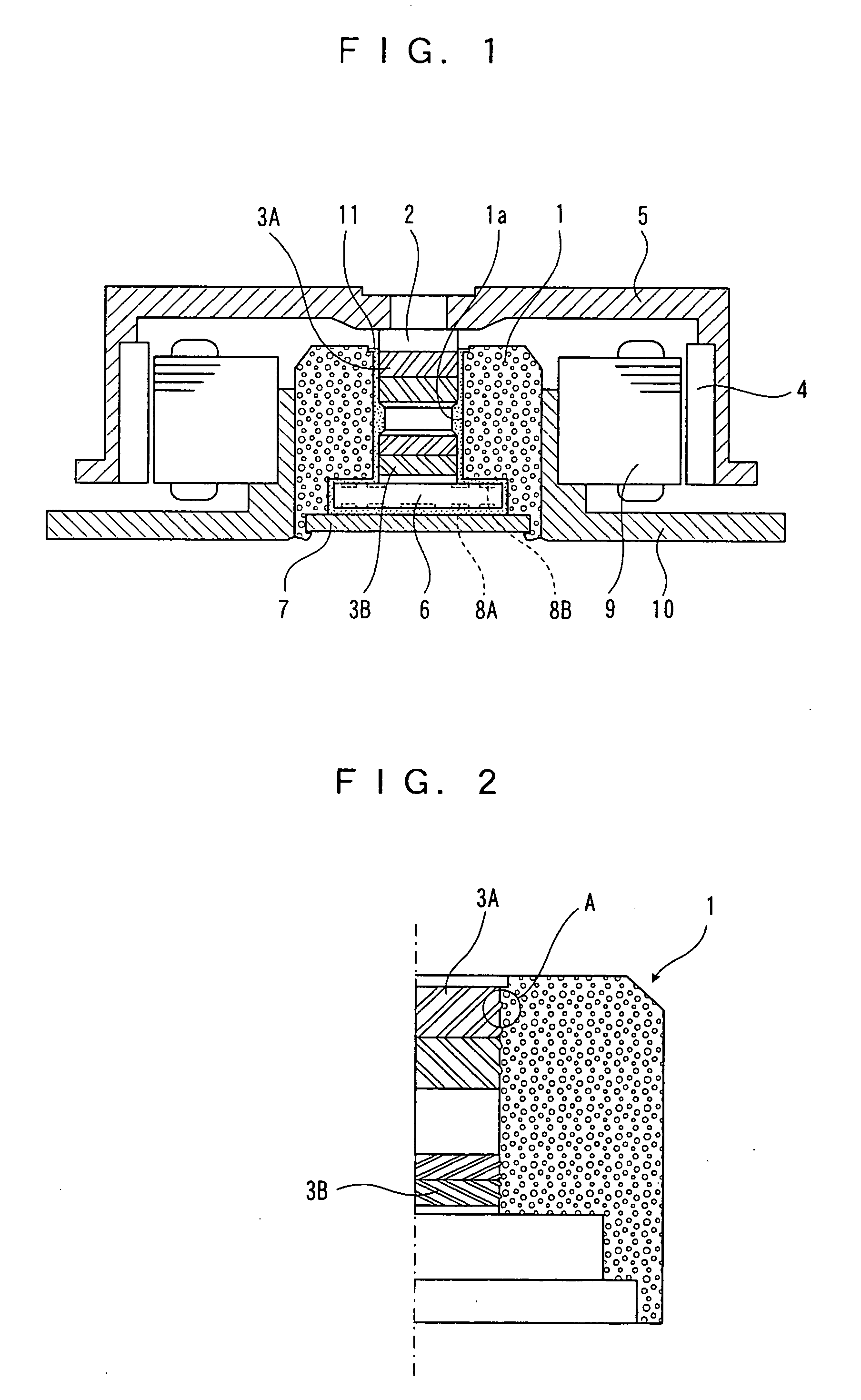

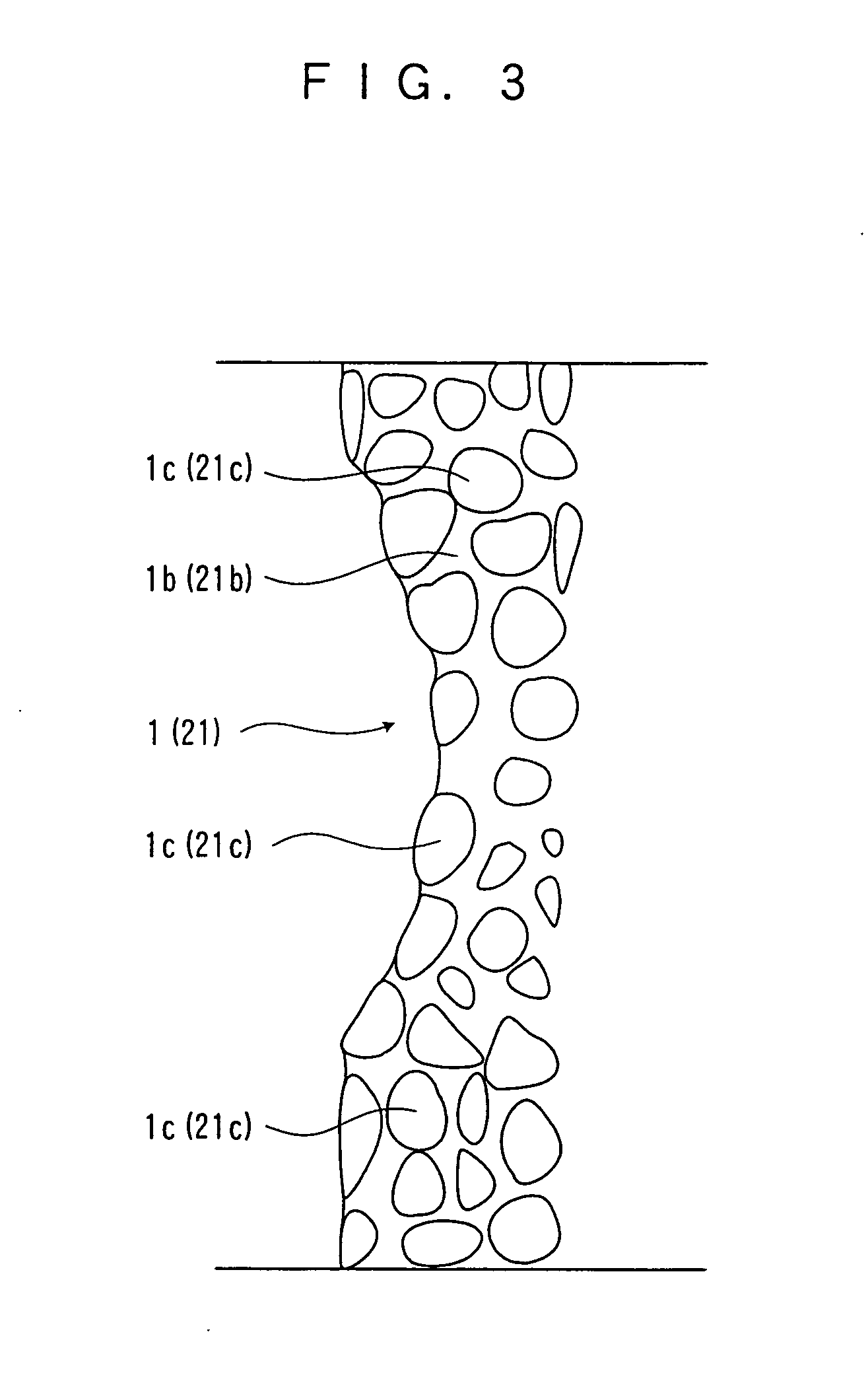

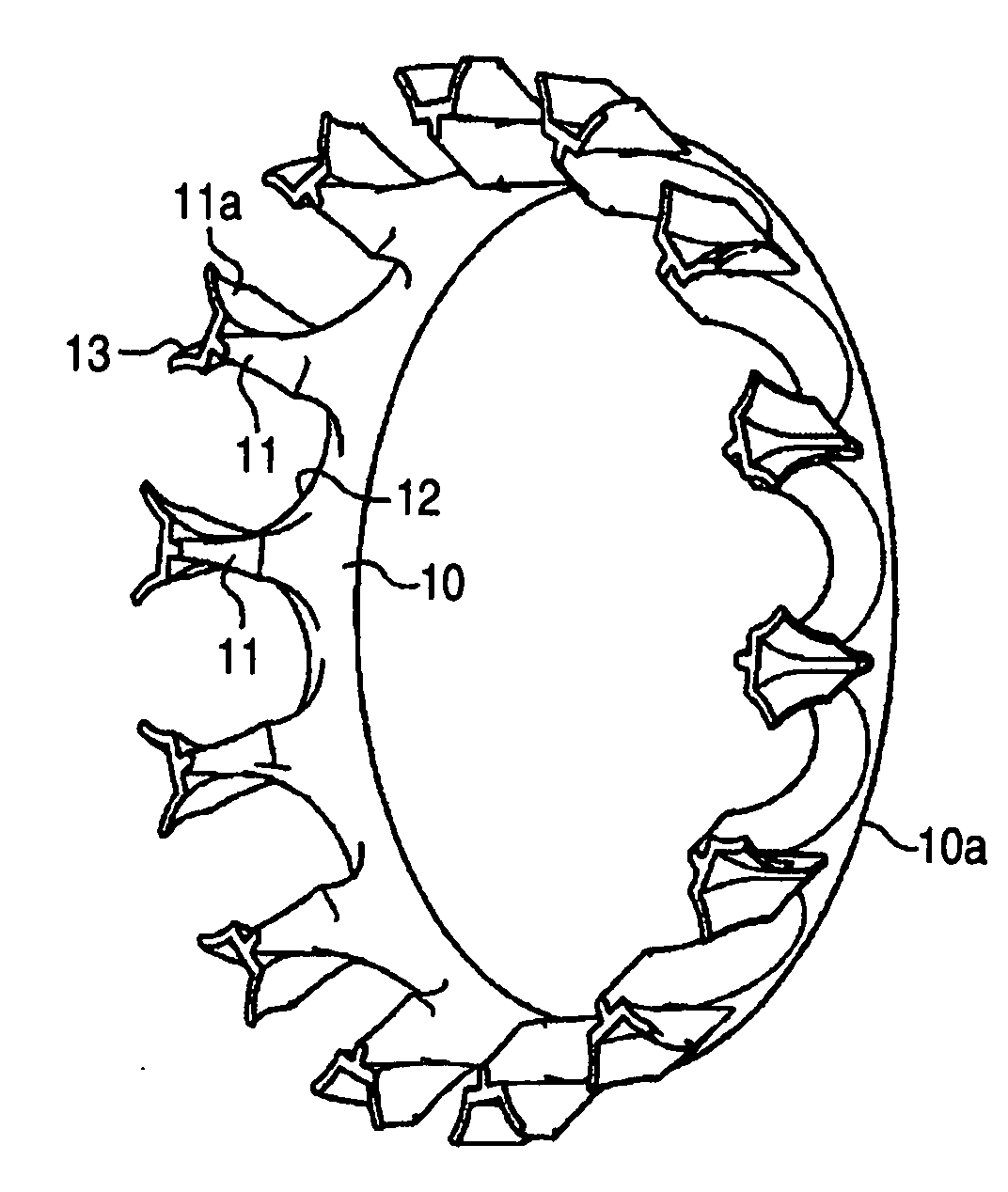

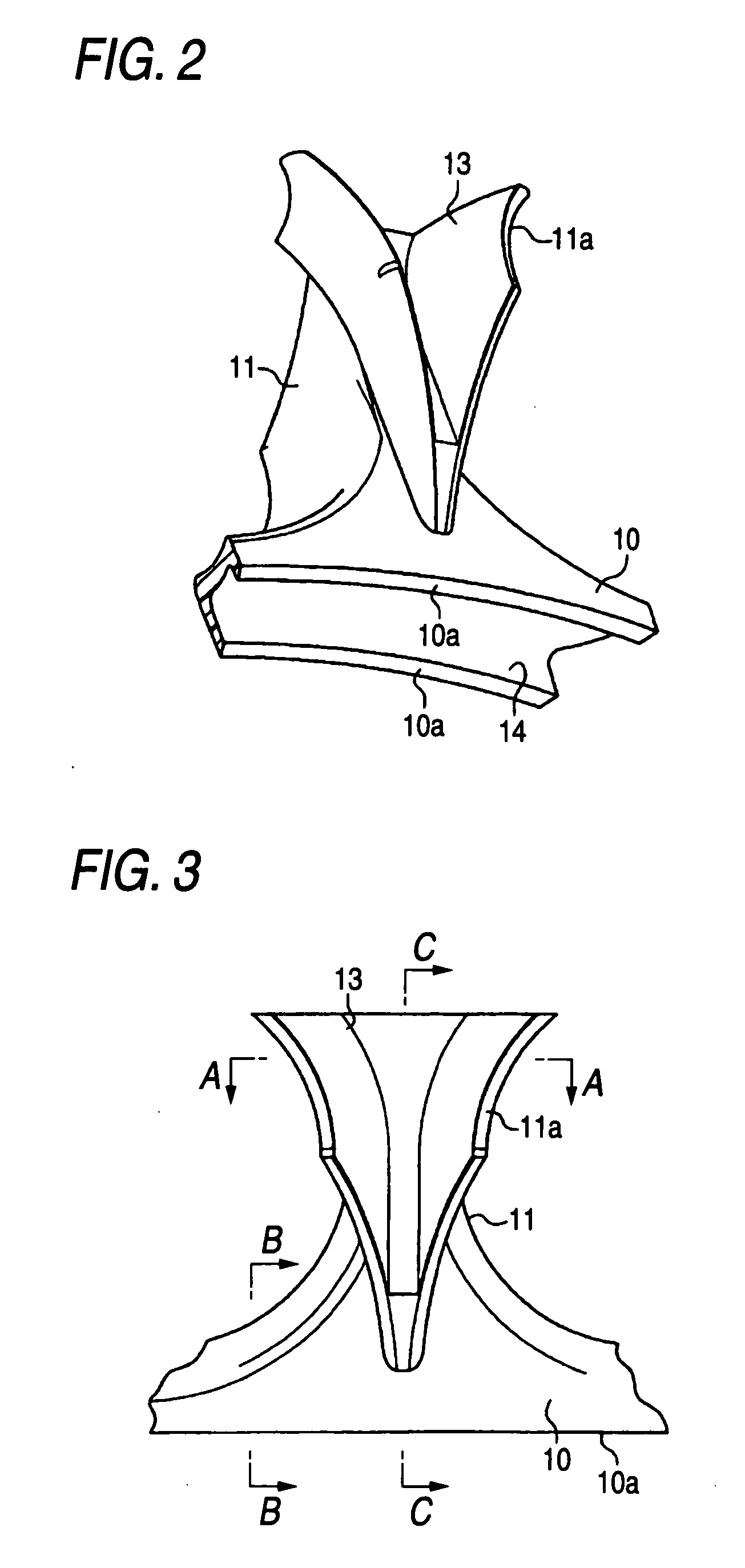

Resin cage for ball bearing

ActiveUS20090074341A1Uniform thicknessGeneration of internal stress can be suppressedRolling contact bearingsBearing componentsEngineeringMechanical engineering

Owner:JTEKT CORP

Rolling knuckle bearing

InactiveCN106015325AIncreased tolerable angular deviationReduce frictionRolling contact bearingsShaftsRolling resistanceEngineering

Owner:ZHEJIANG UNIV

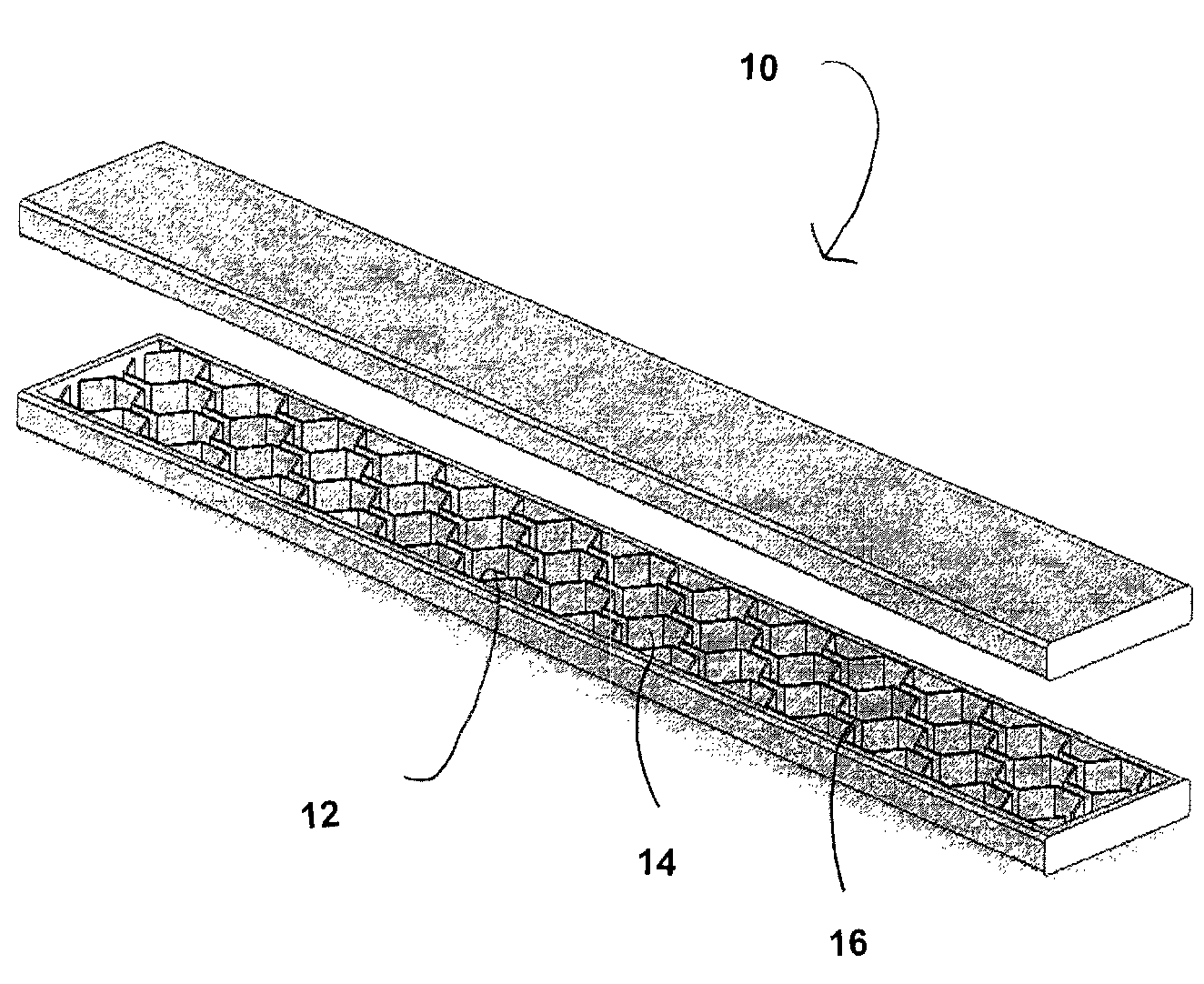

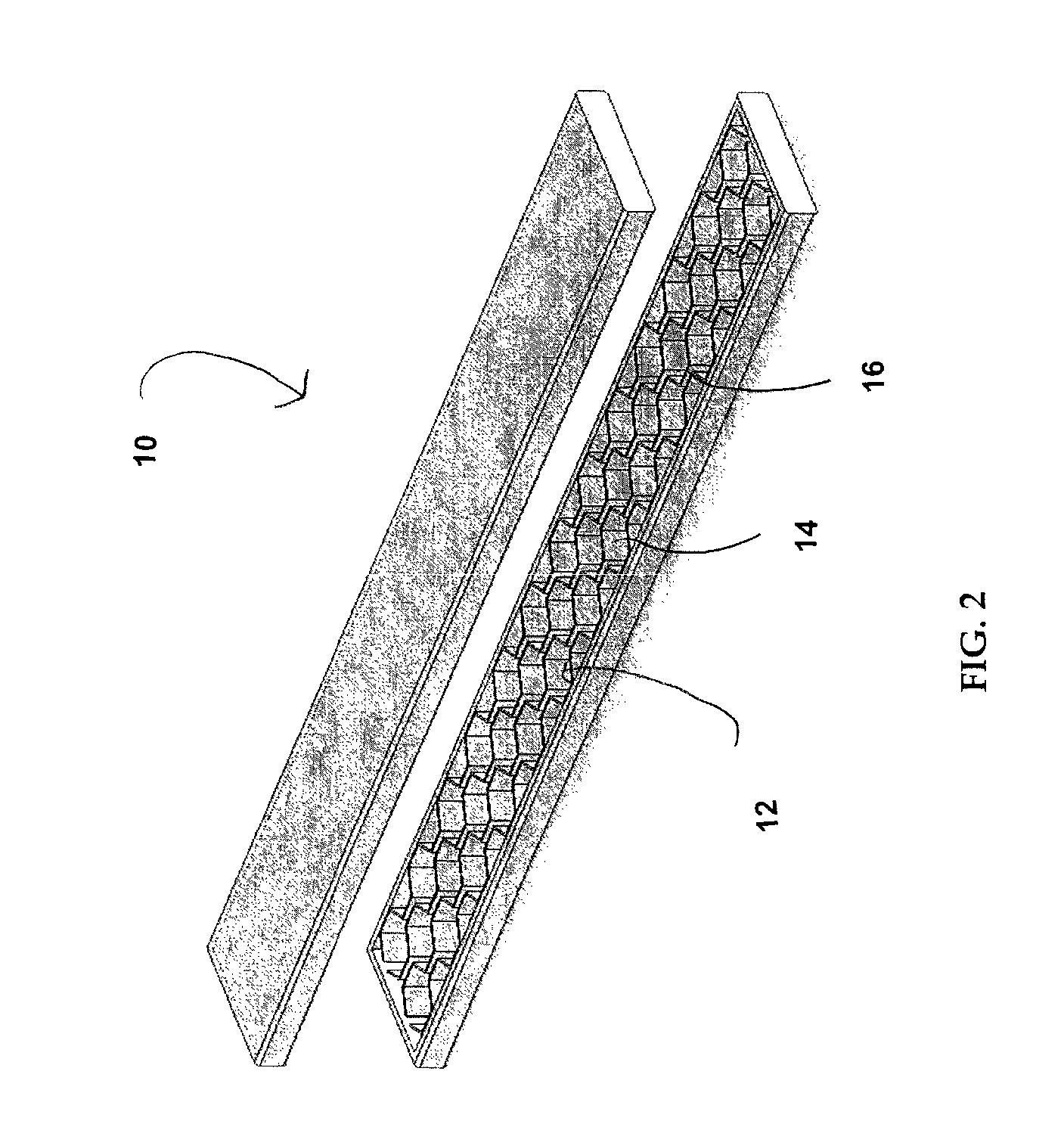

Rigid structure lubricant

InactiveUS7449433B1Increase and decrease rigidityIncrease and decrease and wear rateBearing componentsRail lubricationFiberPlastic materials

Owner:ENVIRONMENTAL LUBRICANTS MFG

Bearing sealing structure

PendingCN108223588AAvoid Sealing Gap SituationsImprove sealingBearing componentsForeign matterEngineering

Owner:WUXI CHENGSHI BEARING

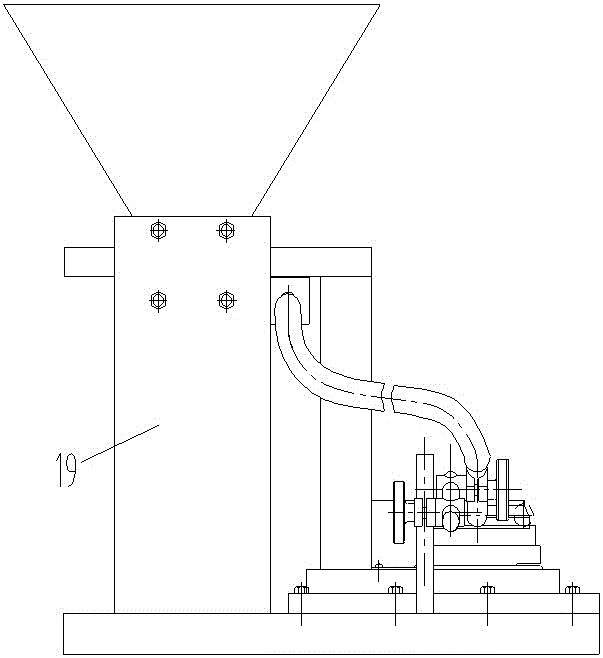

Steel ball mounting machine with bearing holding frame

Owner:江苏持华科技有限公司

Electric corrosion preventing bearing

InactiveCN102032274AExtended service lifeZero voltage differenceBearing componentsHigh volume manufacturingPotential difference

Owner:WOLONG ELECTRIC GRP CO LTD +1

Semiconductor radiator and processing method thereof

ActiveCN109531083AImprove processing strengthImprove surface roughnessBearing componentsSemiconductorMaterials science

Owner:同共(湖北)精密成形有限公司

Tilting pad journal bearing

ActiveUS20180003220A1Increase temperatureReduce pressureBearing componentsSliding contact bearingsRotational axisMechanics

Owner:KOBE STEEL LTD

Automobile suspension bushing and suspension

PendingCN110877508ABearing componentsPivoted suspension armsSuspension (vehicle)Mechanical engineering

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Bearing oiling auxiliary device

Owner:CIXI SIHAI BEARING

Anticorrosion processing method for rudder pintle bearing

Owner:GUANGXI WUZHOU YUNLONG PORT & SHIP MACHINERY MFG

Four-row cylindrical roller bearing special for steel rolling mill

InactiveCN102454697AHigh strengthDoes not reduce lubrication functionRoller bearingsBearing componentsEngineeringRolling mill

Owner:WAFANGDIAN ZHENGDA METALLURGICAL MILL BEARING

Forging technology of high-precision forklift bearing ring

Owner:CHANGSHU CHANGZHOU BEARING

Miniature ball bushing guide assembly

Owner:东莞市创宇模具配件有限公司

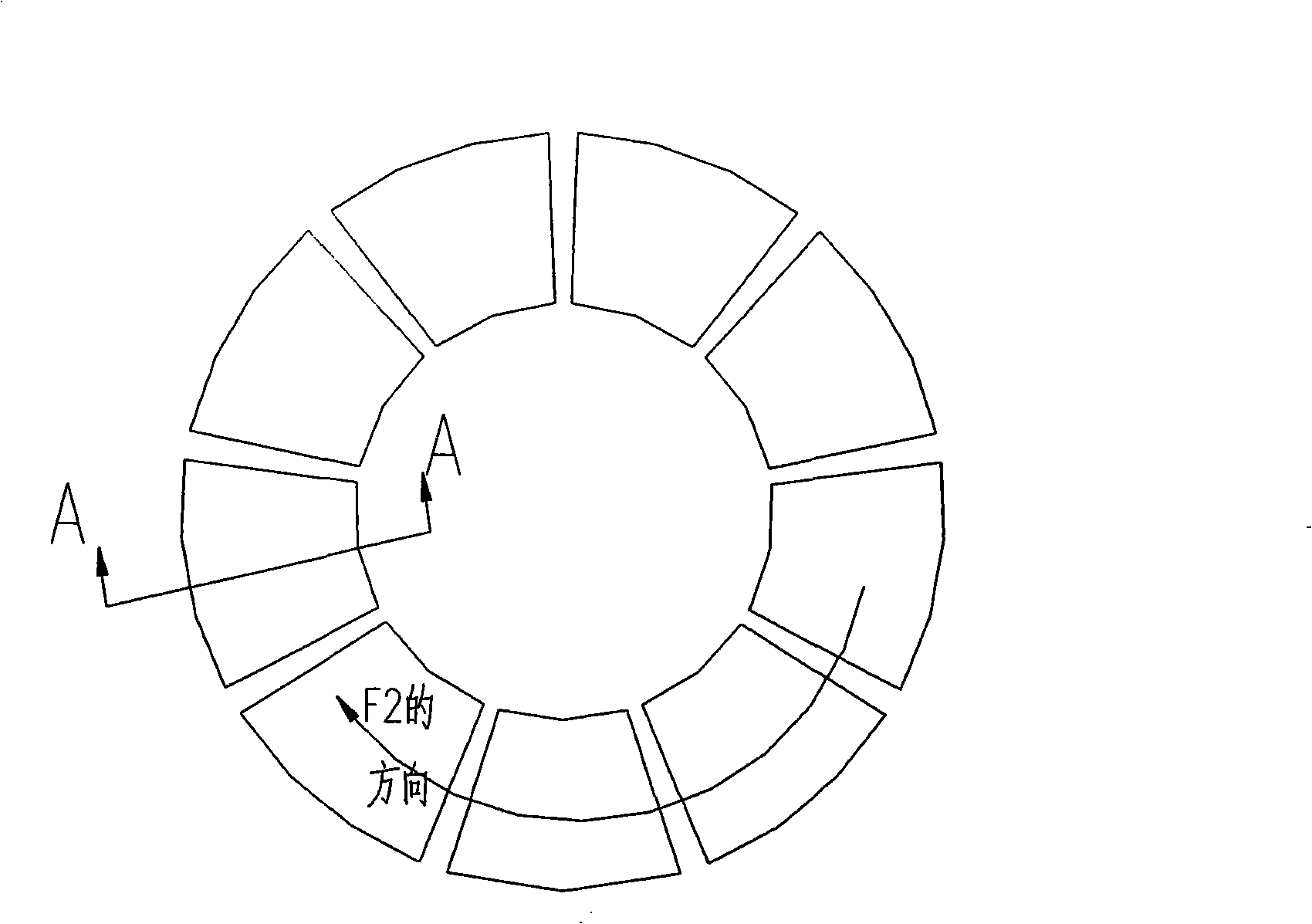

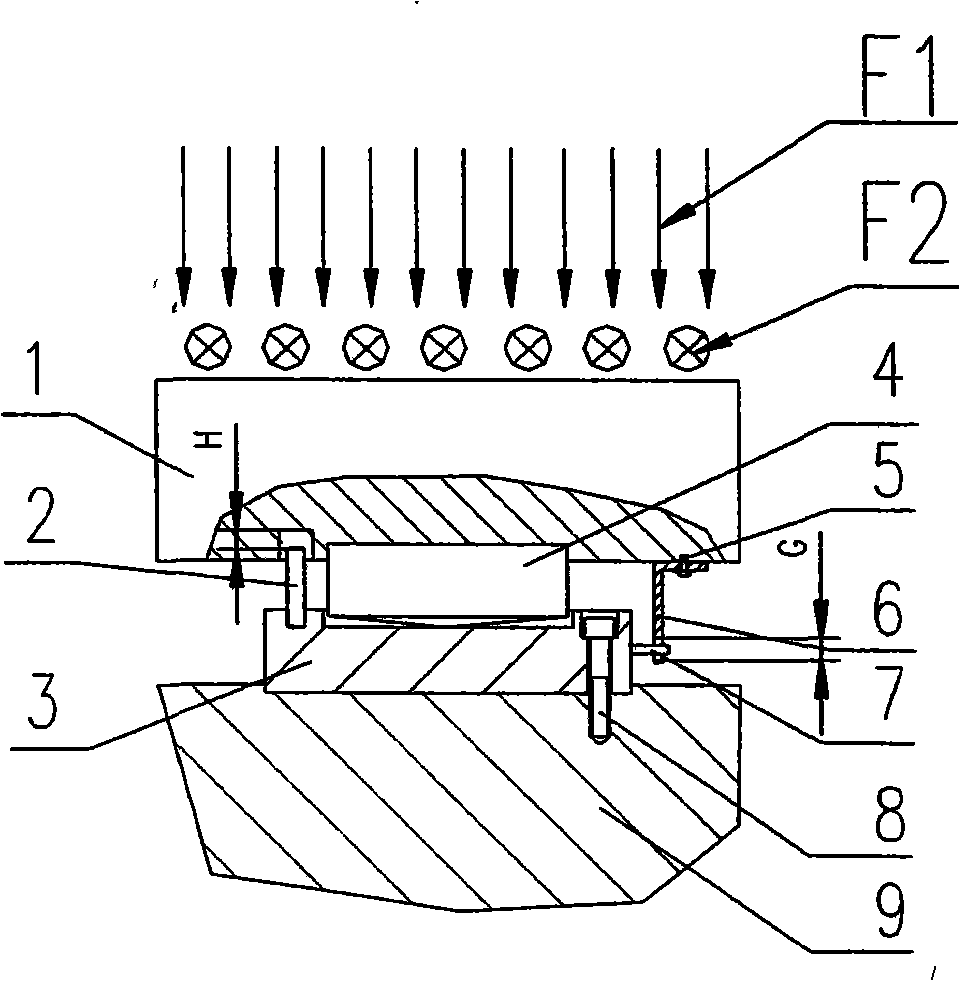

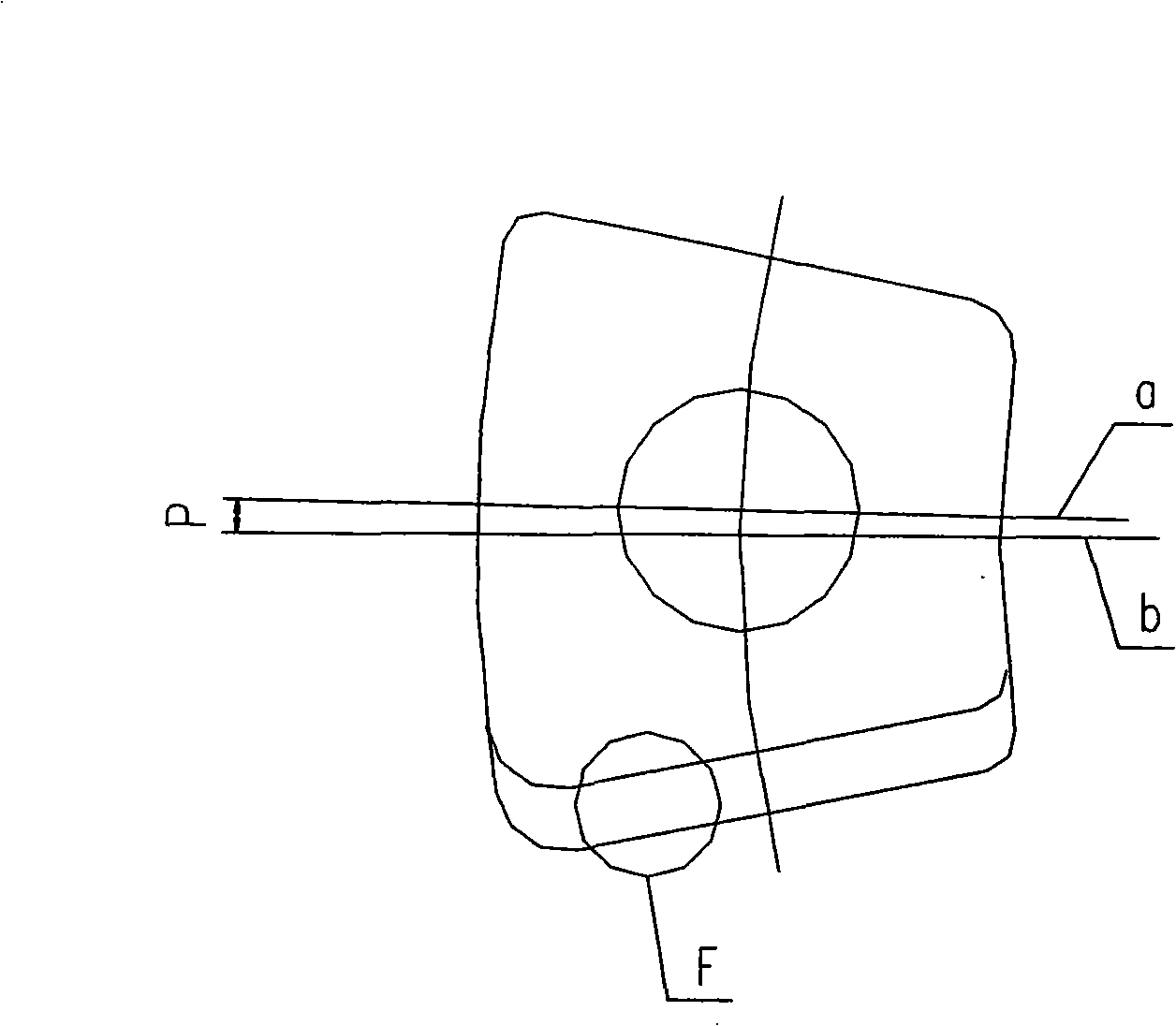

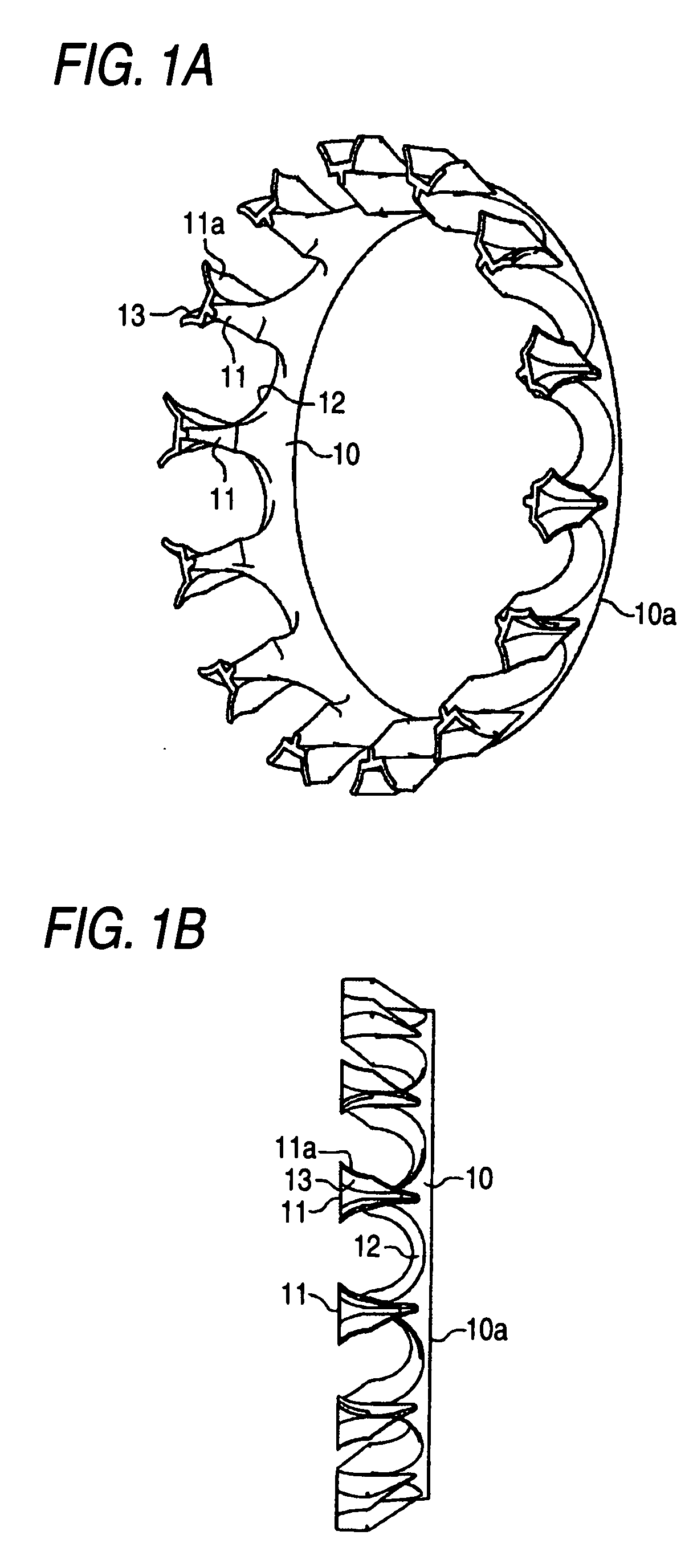

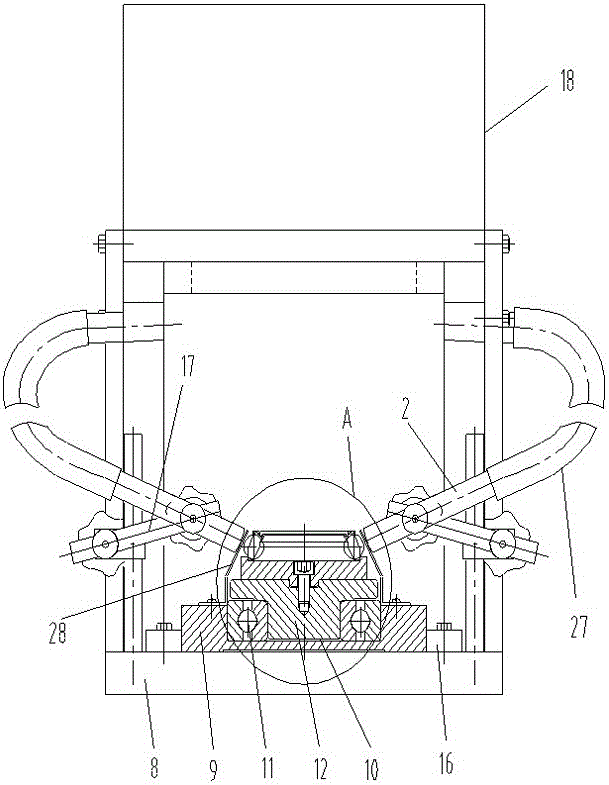

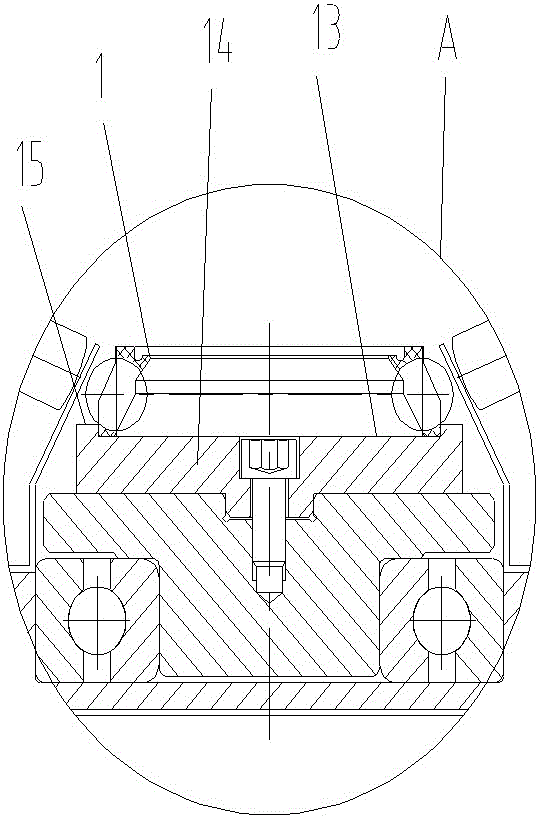

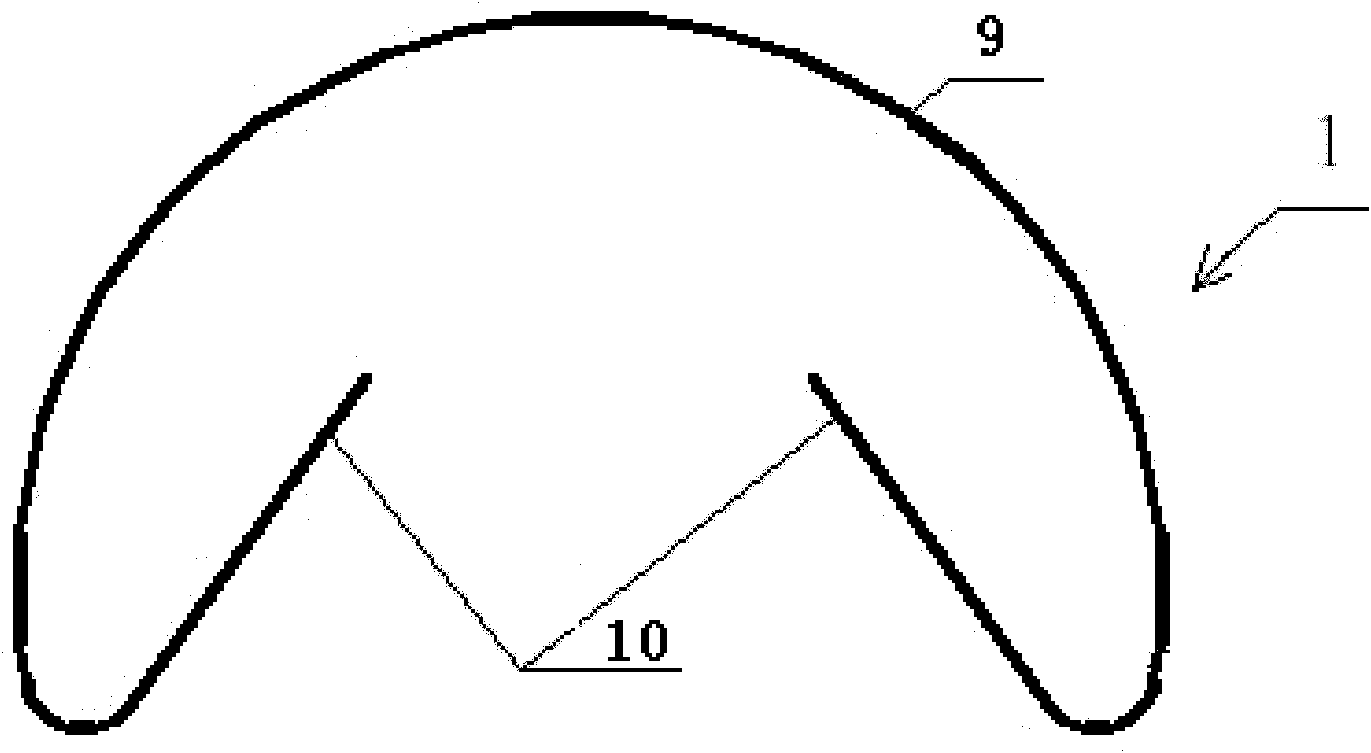

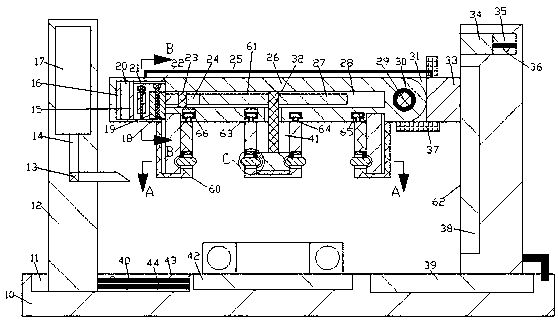

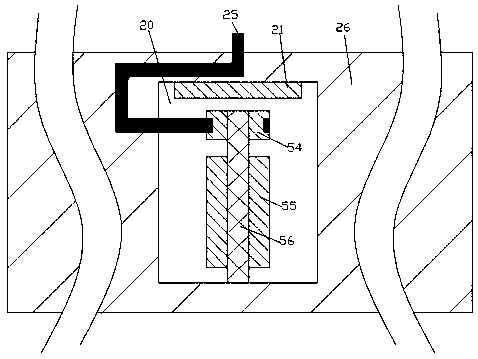

Ball socket machining device for inner ring of socket curved groove ball bearing

InactiveCN111069671AShorten the timeHigh indexing accuracyPrecision positioning equipmentShaftsBall bearingMilling cutter

The utility model discloses a ball socket machining device for an inner ring of a socket curved groove ball bearing, and belongs to the field of mechanical engineering. In order to overcome the defects of low working efficiency, large workload, incapability of effectively ensuring the precision and the like of ball socket machining of the inner ring of the socket curved groove ball bearing. The machining device comprises a base, a rapid clamping device, a set of ball socket milling devices arranged in the circumferential direction, a set of indexing precision control blocks and a feeding precision control mechanism and the like; and an air cylinder is used for independent feeding, and a motor is used for driving a spherical milling cutter to conduct independent milling. The machining device for the inner ring of the socket curved groove ball bearing has the following advantages that (1) a plurality of ball sockets can be machined at the same time at a time, and time is saved; (2) the indexing precision of the ball sockets is improved by using a movable positioning block; and (3) the feeding power of the air cylinder is flexible force, so that the impact of the milling cutter can beavoided.

Owner:NORTHWEST A & F UNIV

Load-bias free four row roller bearing for rolling mill

InactiveCN101586609AIncrease the lengthIncrease contact areaRoller bearingsBearing componentsStrip millEngineering

Owner:瓦房店第一轧机轴承制造有限公司

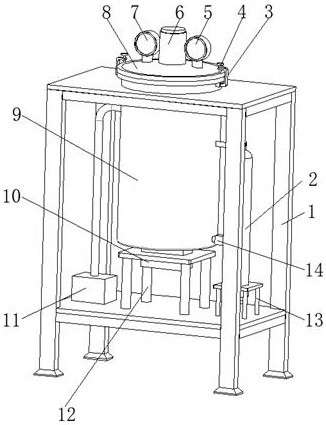

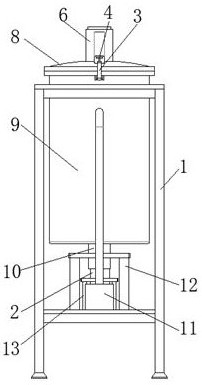

Vacuum oil injection device and method for oil bearing

PendingCN113898862AEfficient exclusionIncrease oil volumeLubricant transferBearing componentsThermodynamicsElectric machine

Owner:山东鼎益粉末冶金有限公司

Automobile bearing shell

InactiveCN104533958AImprove stress resistanceImprove toughnessBearing componentsAutomotive engineeringManufacturing engineering

The invention discloses an automobile bearing shell. The material of the automobile bearing shell is modified alloy. The material of the automobile bearing shell adopts the modified alloy, so the stress tolerance and the toughness of the automobile bearing shell are greatly improved, and are 2-3 times those of products of the same kind in the market.

Owner:LIUZHOU ERHE AUTO PART

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap