Four-row cylindrical roller bearing special for steel rolling mill

A technology of cylindrical roller bearings and cylindrical rollers, applied in the field of bearings, can solve the problems of affecting the length of rollers, reducing the service life of bearings, stress concentration, etc., and achieve the effects of improving rigidity and strength, improving overall life, and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

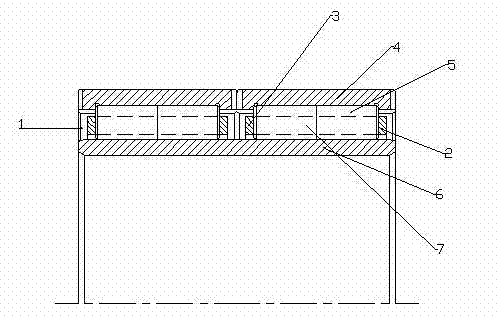

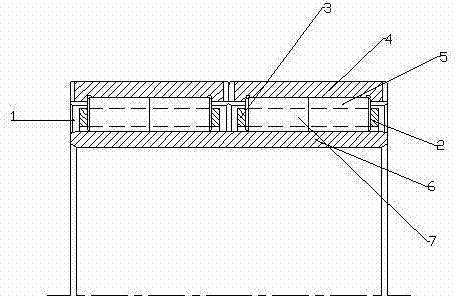

[0013] figure 1 The reference signs made are as follows: oil inlet 1, cage cover 2, cage seat 3, outer ring 4, cylindrical roller 5, inner ring 6, cage 7.

[0014] exist figure 1 In the schematic diagram of a four-row cylindrical roller bearing dedicated to a rolling mill shown, its main structure includes: an outer ring 4, a cage, a cylindrical roller 5, an inner ring 6 and an oil inlet 1; the outer ring 4 and the inner The rings 6 are respectively provided with raceways. The cylindrical rollers 5 are located between the two raceways and roll between the tracks of the outer ring 4 and the inner ring 6. A cage 7 is arranged between the inner ring 6 and the outer ring 4, and the outer ring 4 The oil inlet hole 1 is provided on the end face. The integral cage 7 is formed by the cage base 3 and the cage cover 2 through the rivets on the cage 7 and is connected into one by thermocompression. The middle of the cage base 3 and the cage cover 2 is naturally formed such as a dry pocket

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap