Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

279results about How to "High strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

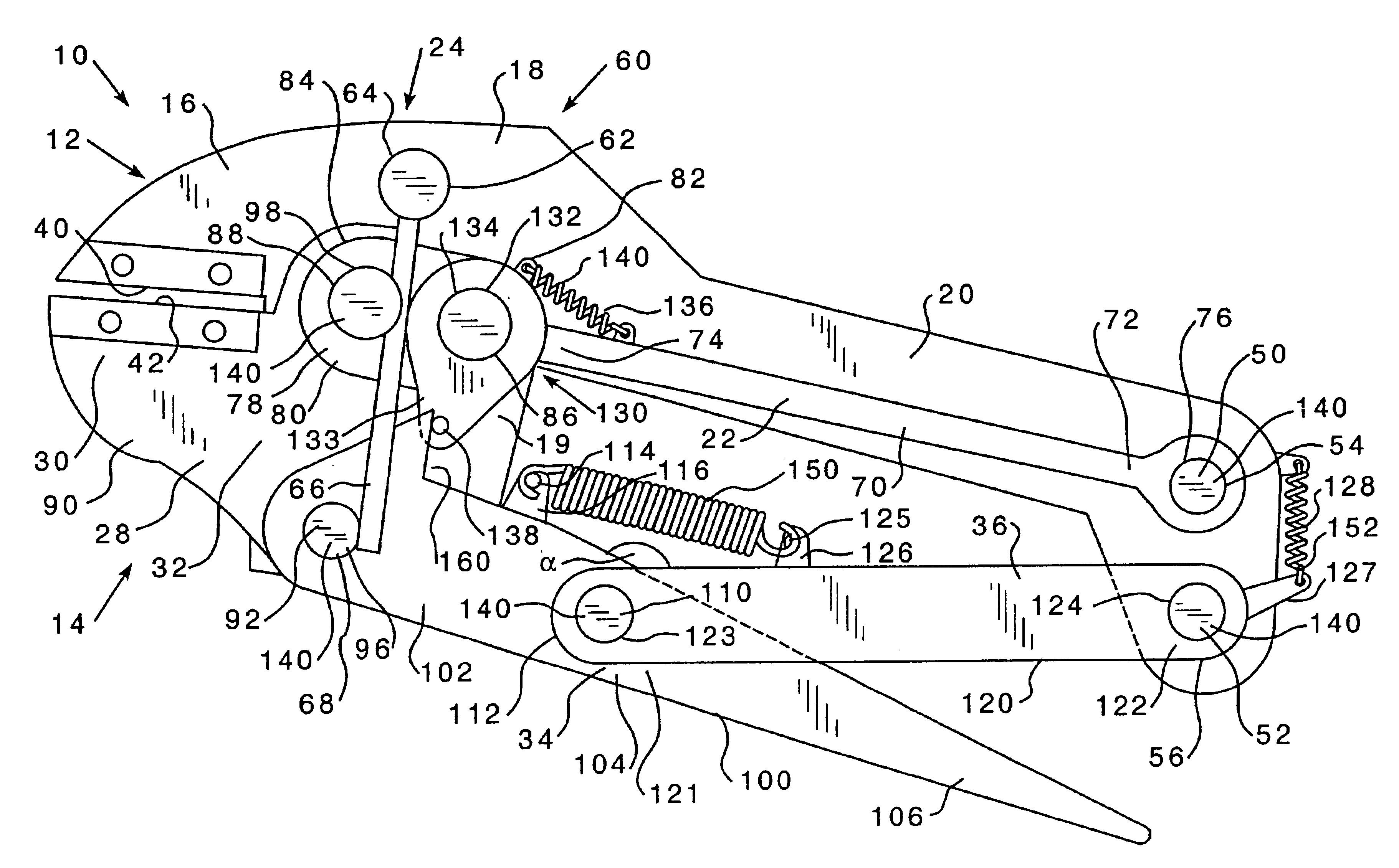

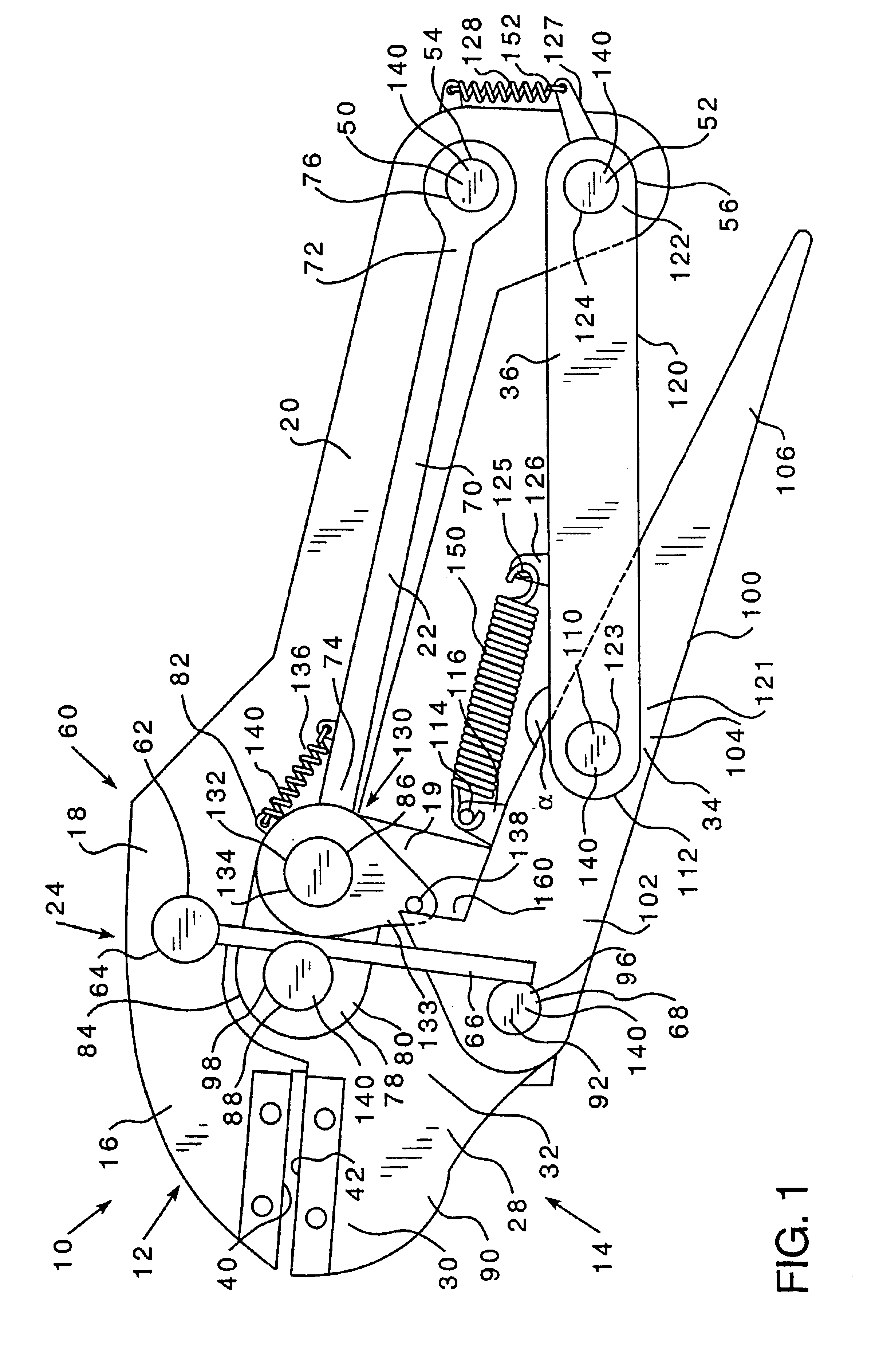

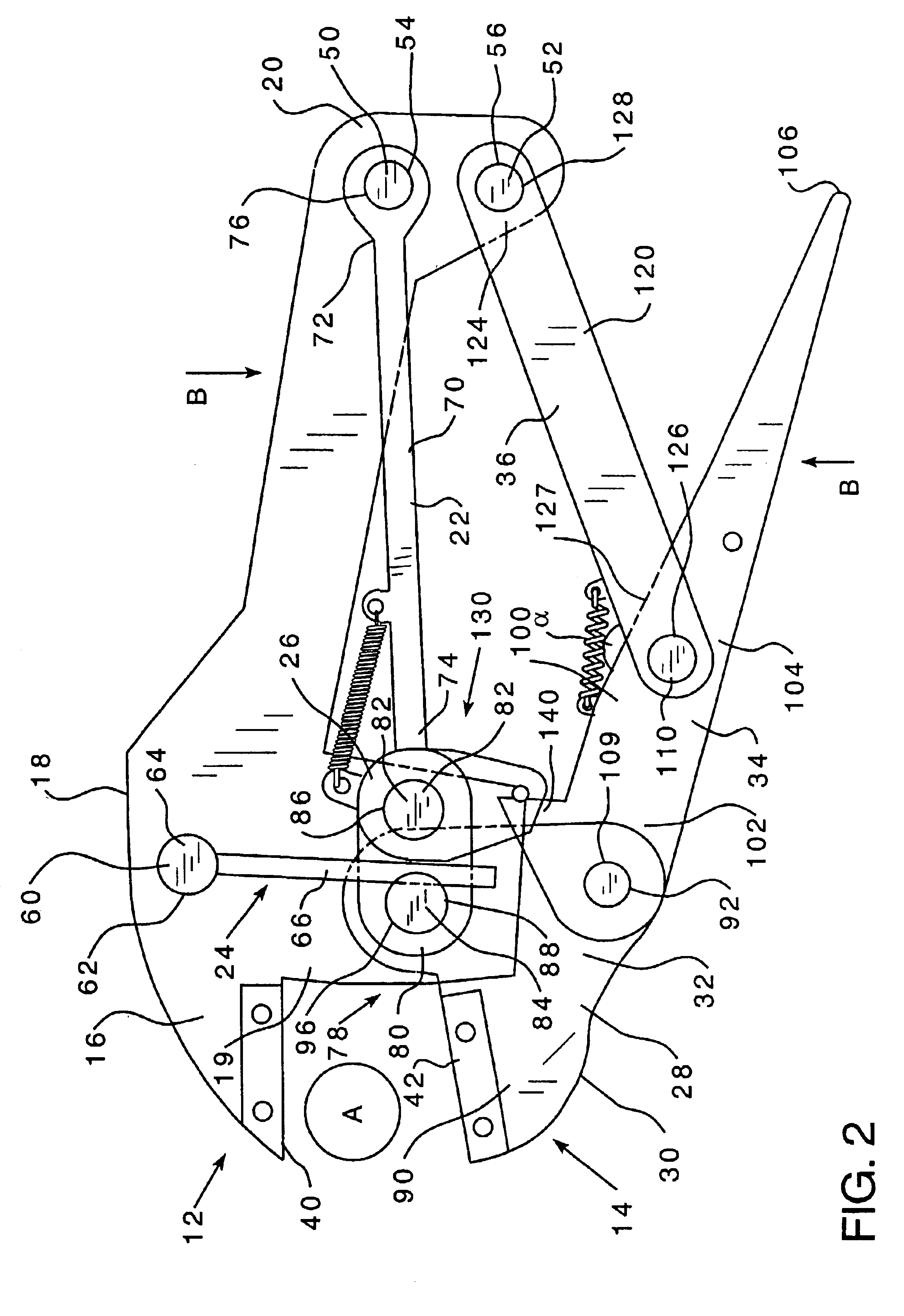

Exercise Device

InactiveUS20090112137A1Simple and inexpensive to manufactureEasy to useRoller massageTherapy exerciseMaximum diameterEngineering

An exercise device for a person, comprising at least two substantially rigid rails, each rail having an outer surface, and inner surface, and at least one peripheral edge connecting the outer surface to the inner surface. The at least one peripheral edge includes at least one axle slot formed therein. At least one substantially cylindrical axle has two ends and is adapted for rotatably and removably receiving at least one substantially cylindrical roller thereon. Each end of each axle is adapted to be captured within one of the axle slots of one of the rails. Each roller has a peripheral surface and a maximum diameter. Each axle is spaced a distance from an adjacent axle of at least the maximum diameter of the rollers, whereby each roller may rotate freely on the at least one axle. The exercise device is able to support a person lying on his back on the rollers on a flat surface.

Owner:LAMORE GEORGE

Steel for enamel and production method thereof

The invention discloses a steel for enamel, and is characterized by comprising the following chemical elements by mass: not more than 0.020% of C, not more than 0.05% of Si, 0.10-0.50% of Mn, not more than 0.03% of P, 0.003-0.050% of S, 0.001-0.03% of Al, 0.001-0.015% of N, 0.005-0.050% of O, not more than 0.005% of Ca, not more than 0.005% of Mg, not more than 0.10% of Cu, not more than 0.10% of Cr, not more than 0.10% of Ni, not more than 0.10% of Mo, at least one of 0.0005-0.003% of B, not more than 0.01% of Nb, not more than 0.02% of V, and 0.001-0.05% of Ti, and the balance of Fe and other inevitable impurities, wherein N(%)*Ti(%) is not more than 3*10<-4>. Correspondingly, the invention further discloses a production method of the steel for enamel. The steel for enamel has excellent comprehensive performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Vehicular suspension arm

InactiveUS20090295113A1High strengthStrengthTractor-trailer combinationsResilient suspensionsSingle plateStructural engineering

A vehicular suspension arm is provided in which an arm main body (1) includes a main plate (2) press-formed as a main part of the arm main body and having a short cylindrical part (EB) provided integrally with one end by flanging, and a reinforcing plate (H) superimposed on one of upper and lower faces of the main plate (2) and reinforcing the main plate (2). The reinforcing plate (H) has an eye-shaped head part (Ha) formed in an annular shape and arranged coaxially with the short cylindrical part (EB), and a tail part (Hb) extending integrally from the eye-shaped head part (Ha) along the longitudinal direction of the main plate (2), is formed from a single plate material that is thicker than the main plate (2), and has at least the tail part (Hb) welded to the main plate (2). A bush press-fit portion (P1) is formed from an inner peripheral face of the eye-shaped head part (Ha) and an inner peripheral face of the short cylindrical part (EB). This ensures that the cross-sectional shape of a transition section from the bush press-fit portion to the plate-type arm main body is adequate, thus enabling the rigidity and strength required for the transition section to be easily guaranteed and, furthermore, it becomes possible to meet a requirement for increasing the strength of the arm without specially increasing the space around the outer periphery of the bush press-fit portion.

Owner:F TECH INC +1

Method for enhancing surface of magnesium aluminium alloy by laser remelting

InactiveCN101532134AHigh strengthImprove corrosion resistanceMolten spray coatingSuperimposed coating processOxygenLaser beams

The invention relates to a method for enhancing the surface of magnesium aluminium alloy by laser remelting, aiming at enhancement processing of the surfaces of magnesium aluminium alloy plates and magnesium aluminium alloy rods by the methods of flame spraying of alloyed powder and laser remelting. The method is characterized by cleansing the surface of the magnesium aluminium alloy, carrying out oxy-acetylene flame spraying on the alloyed powder, namely aluminium nickel alloy powder, nickel-chromium-boron-silicon-iron master alloy powder and neodymium powder, carrying out remelting and curing on the surface of the magnesium aluminium alloy on a laser processor, carrying out omnibearing radiation by laser beams according to trace curves set by computer programs so that a nickel base alloy layer is melted and cured on the surface of the magnesium aluminium alloy to form the alloy layer, therefore, the hardness of the surface of magnesium aluminium alloy is greatly improved by 8-10 times as high as that before processing, the wearing resistance and corrosion resistance of the surface of magnesium aluminium alloy are greatly improved respectively by 56% and 56.4%. The method has short process flow, easy realization, safety, stability and reliability and firm solid melting layer, is not easy to fall off and can enhance the surfaces of the magnesium aluminium alloys with various profiles.

Owner:TAIYUAN UNIV OF TECH

Cement composition

InactiveUS20050016421A1High strengthImprove abilitiesOrganic fertilisersSoil conditioning compositionsPhosphateSilicic acid

To provide a novel cement which is alkalescent, capable of solidifying a wide range of soil and applicable to biological environment. That is, a cement composition comprising 100 parts by weight of magnesium oxide comprising 5 to 25% by weight of at least any one of silicic acid, alumina and iron oxide, 3 to 35 parts by weight of a phosphate, 2 to 30 parts by weight of gypsum and 0.005 to 7 parts by weight of an oxycarboxylic acid or a ketocarboxylic acid.

Owner:NAT AGRI & FOOD RES ORG +1

Self-adjusting hand tools utilizing a cam

Owner:I D L TECH TOOLS

Process for preparing precursor fiber of cellulose base carbon fiber

InactiveCN1587457AImprove thermal stabilityImprove carbonization yieldMonocomponent cellulose artificial filamentFiberCarbon fibers

The present invention relates to preparation process of precursor fiber of cellulose base carbon fiber in chemical fiber production. The preparation process includes mixing concentrated NMMO aqua and carbon black for carbon black water in the weight ratio of 20-10000, decomprssion distillation to obtain NMMO / carbon black solution with water content 24-28 wt%, adding the mixtue of sliced cellulose pulp and NMMO / carbon black solution in the weight ratio of 5-15 to 100 into dissolving reactor, swelling and stirring at 70-90 deg.c, raising the temperature to 90-120 deg.c, stirring and decomprssion distillation to eliminate water and form cellulose / NMMO / carbon black spinning liquid with water content of 12-14 wt%, and dry-wet spinning to obtain the precursor fiber. The present invention has high carbonizing yield, high mechanical performance of the carbon fiber, raised spinnability of the spinning liquid, non-toxic solvent, high solvent recovering rate and environment friendship.

Owner:DONGHUA UNIV

Endless rubber track having guide lugs with guide lug support layer, and vehicle containing such track

Owner:VEYANCE TECH

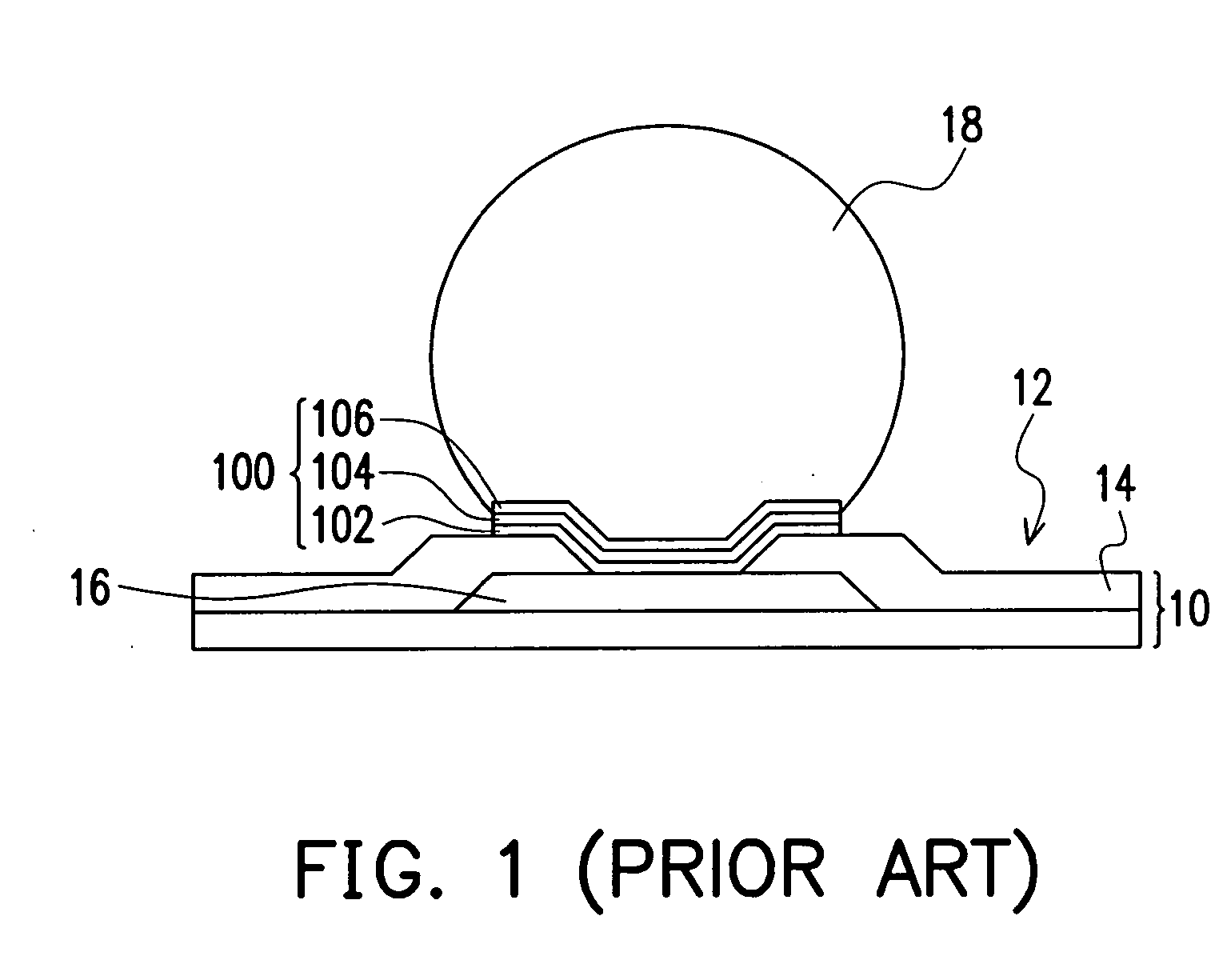

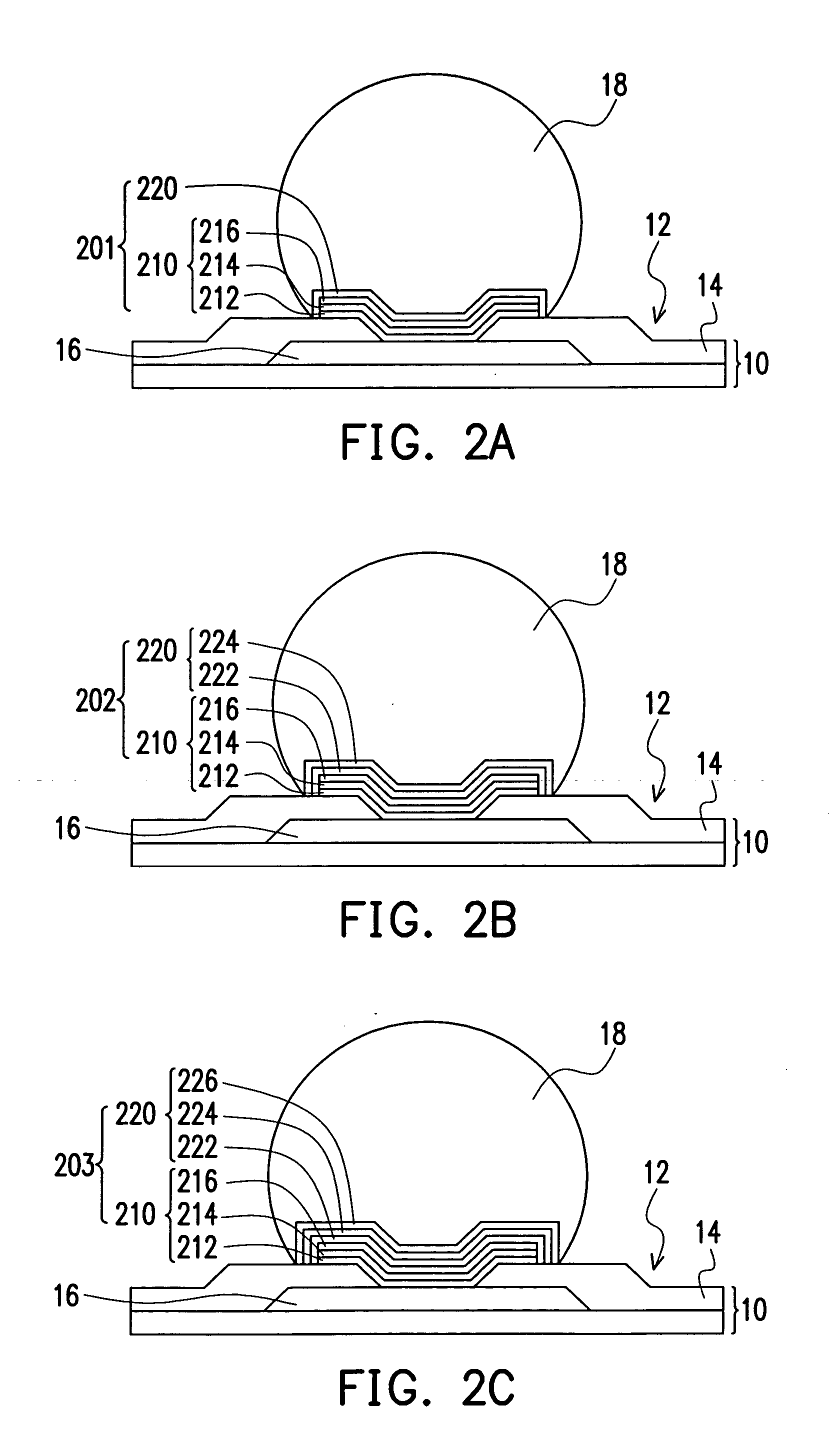

Under-bump metallugical structure

InactiveUS20050012211A1Solder bump is reducedImprove performanceSemiconductor/solid-state device detailsSolid-state devicesNickelCopper

An under-bump metallurgical structure between the bonding pad of a die or a substrate and a solder bump such that the principle constituent of the solder bump is lead-tin alloy or lead-free alloy. The under-bump metallurgical structure at least includes a metallic layer and a buffer metallic structure. The metallic layer is formed over the bonding pads of the die. Major constituents of the metallic layer include copper, aluminum, nickel, silver or gold. The buffer metallic structure between the metallic layer and the solder bump is capable of reducing the growth of inter-metallic compound due to chemical reaction between the metallic constituents of the metallic layer and tin from the solder bump.

Owner:KUNG MORISS +1

Method for desulphurizing, denitrating and decoking fire coal

The invention discloses a method for desulphurizing, denitrating and decoking fire coal. In the method, in a raw coal burning stage, a synergist is added in an amount of 0.2 to 0.3 weight percent based on the total weight of the raw coal into the fire coal, and a catalytic active agent is added in an amount of 0.002 to 0.008 weight percent based on the total weight of the raw coal into a slurry boax in a desulphurizing system at the same time. The synergist comprises 8 to 25 mass percent of calcium carbona, 5 to 15 mass percent of magnesium oxide, 5 to 10 mass percent of silicon dioxide, 5 to10 mass percent of zinc oxide, 8 to 10 mass percent of manganese dioxide, 15 to 40 mass percent of calcium oxide, 5 to 10 mass percent of barium hydroxide, 3 to 8 mass percent of aluminum oxide and 8to 15 mass percent of potassium permanganate; and the catalytic active agent comprises 0 to 40 mass percent of active calcium oxide, 20 to 30 mass percent of active carbon, 10 to 15 mass percent of calcium ammonium nitrate, 5 to 20 mass percent of ferric oxide and 2 to 10 percent of zinc oxide. Under the condition of not changing the conventional boiler equipment and process, the method can realize fire coal combustion-supporting and coal-saving functions at one time so as to perform desulphurization, denitration and decoking.

Owner:GUANGZHOU ZHONGKE GAOCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Male fixing member of hook-and loop fastener, and sheet product with the fixing member

InactiveUS20050235462A1Improve productivityEnsure durabilitySnap fastenersRopes and cables for vehicles/pulleyEngineeringSynthetic resin

A first base material having a number of male engaging elements (112) formed of synthetic resin on a surface thereof and a second base material (121) are jointed and secured each other through a column-like joint portion (131). There is provided a male fixing member for sheets, which facilitates attachment operation to clothes or suspension cloths, has a durability, never loses appearance when it is mounted on clothes and allows even an infant to engage or disengage the male fixing members easily by an engagement / disengagement function of a surface fastener.

Owner:YKK CORP

Material and method used for TA2/0Cr18Ni9Ti welded by high-entropy effect

InactiveCN102676904AImprove performanceSimple preparation stepsWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceAlloy

The invention discloses a high-entropy interlayer alloy, which comprises the following components in atomic percentage: 5-10% of Ti, 5-10% of Fe, 25-30% of Al, 15-20% of Ni, 30-35% of Cu and 5-10% of Cr. The invention also discloses a method for welding TA2 / 0Cr18Ni9Ti by the high-entropy effect, which comprises the following steps that: high-entropy interlayer alloy is placed between the two plates to be welded, the high-entropy interlayer alloy is in a foil folding structure, and the high-entropy interlayer alloy and local parent metal are subjected to heat fusing by an interface resistor ina resistance spot welding mode, so that the high performance welding of TA2 / 0Cr18Ni9Ti can be realized. According to the method and the high-entropy interlayer alloy of the method, which are disclosed by the invention, the high-entropy interlayer alloy has the advantages of favorable strength, toughness and corrosion resistance, is easy to process and form and is convenient to weld and assembly. The preparation method has the advantages of simple step and low manufacture cost and is convenient to popularize.

Owner:XIAN UNIV OF TECH

End underframe structure for rail vehicle, and rail vehicle

Owner:CRRC QINGDAO SIFANG CO LTD

Profile steel support structure based on upper-layer reinforcement protection layer of building construction protection floor slab

Owner:江铃汽车集团江西工程建设有限公司

Openable skirt type steel reinforcement cage of reamed pile

The invention discloses an openable skirt type steel reinforcement cage of a reamed pile and belongs to piling building materials. According to the openable skirt type steel reinforcement cage, a reaming section of a pedestal pile has a horizontal expansion function, the reinforced concrete structure forms of the existing rotary expanding piles are changed, and the load capacity of the rotary expanding piles is increased; the steel reinforcement cage is unfolded at the bottom of a hole through a plurality of link mechanisms, the appearance of the unfolded steel reinforcement cage is basically similar to the contour of the reamed hole, the link mechanisms are simultaneously opened and are connected with an existing steel reinforcement cage through steel stranded wires, then, concrete is cast, the link mechanisms serve as steel reinforcement members, and thus, the strength of concrete members of rotary expanding pile bodies is enhanced.

Owner:XUZHOU LEHMAN MASCH TECH CO LTD

Anti-pressure anti-torsion high-strength V-groove self-cleaning sand-proof screen pipe

The invention discloses a pressure and torsion resistance high-strength V groove self-cleaning anti-sand sieve tube which belongs to a petroleum exploitation mechanical anti-sand device. A coupling is connected with a base tube; the base tube is provided with a round through hole along the axial direction; a filter component is fixed in the round through hole on the base tube; the outer diameter of the base tube is provided with a protective tube. The filter component of the invention is welded on the base tube, and then a protective cover is welded on the filter component; next, the filter component is connected with the coupling and access to the lower end of a petroleum pipe to produce the petroleum. In the anti-sand sieve tube of the invention, the filter component with a V groove filter element consisting of a plurality of circular rings with V-shaped gaps is fixed on the tube wall of the base tube, so as to overcome the defects of low strength, high processing difficulty, high cost, etc. Fine sand can be discharged as the petroleum through elastic and vermicular filtering crack and spacing, so that the sand filtering procedure keeps self-cleaning; in this way, the gap size can mostly meet the petroleum production requirements.

Owner:詹其国

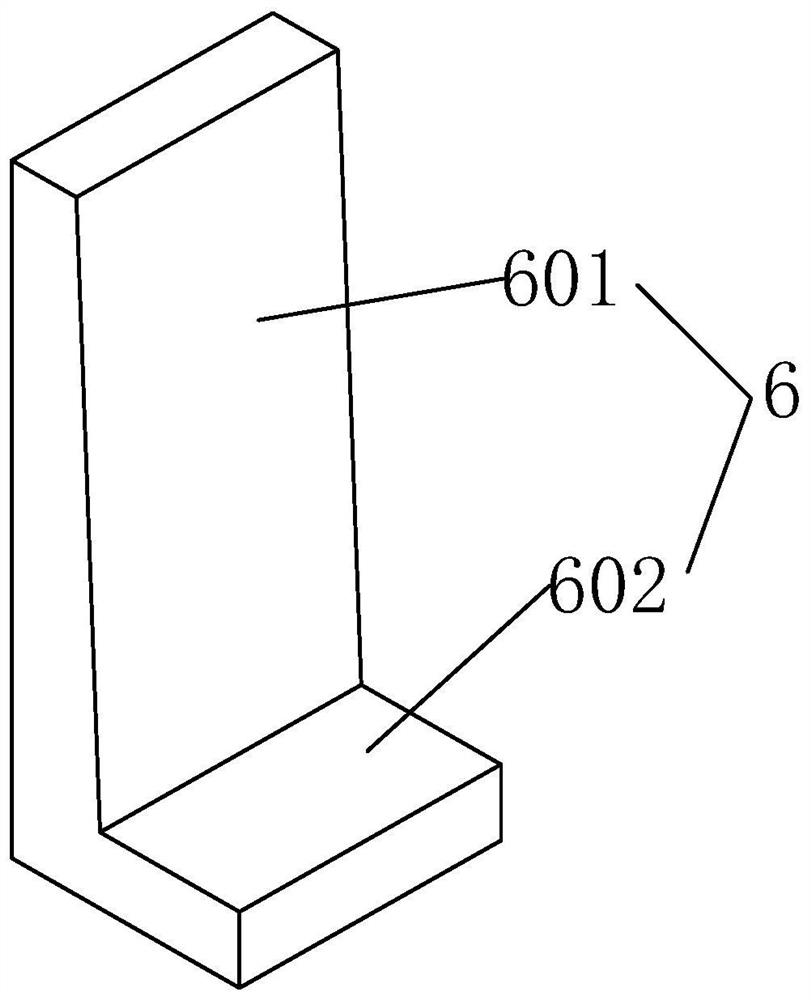

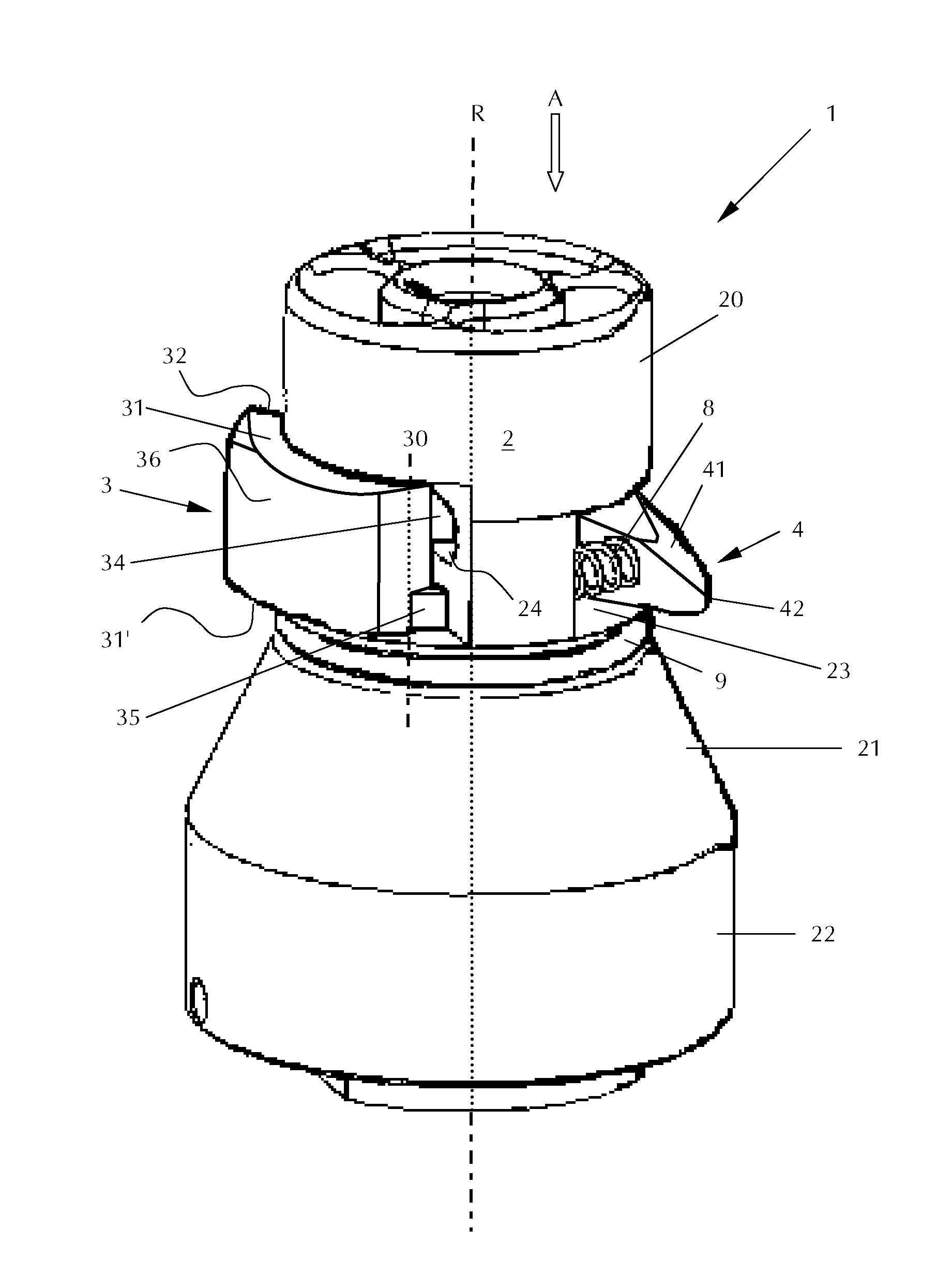

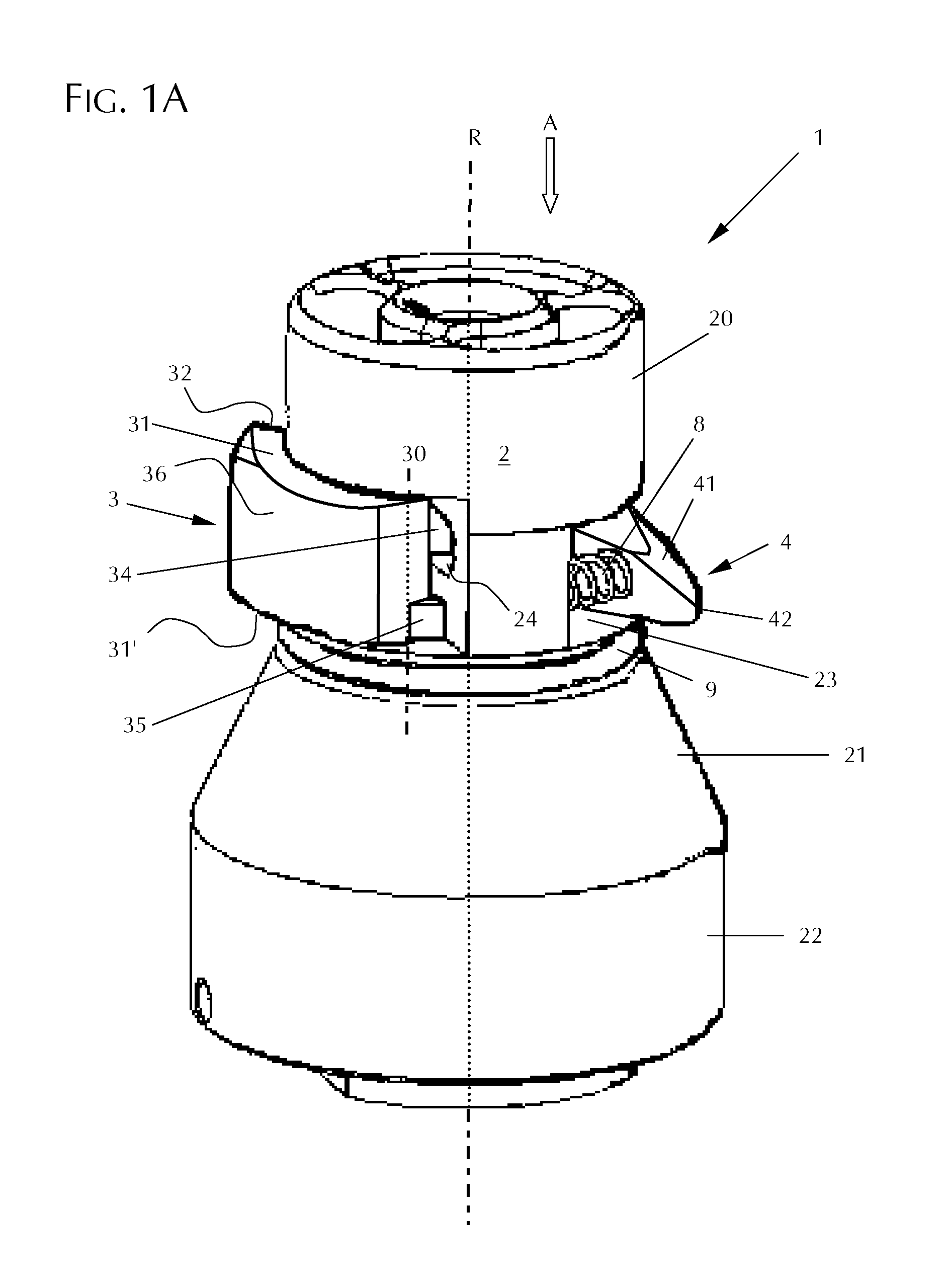

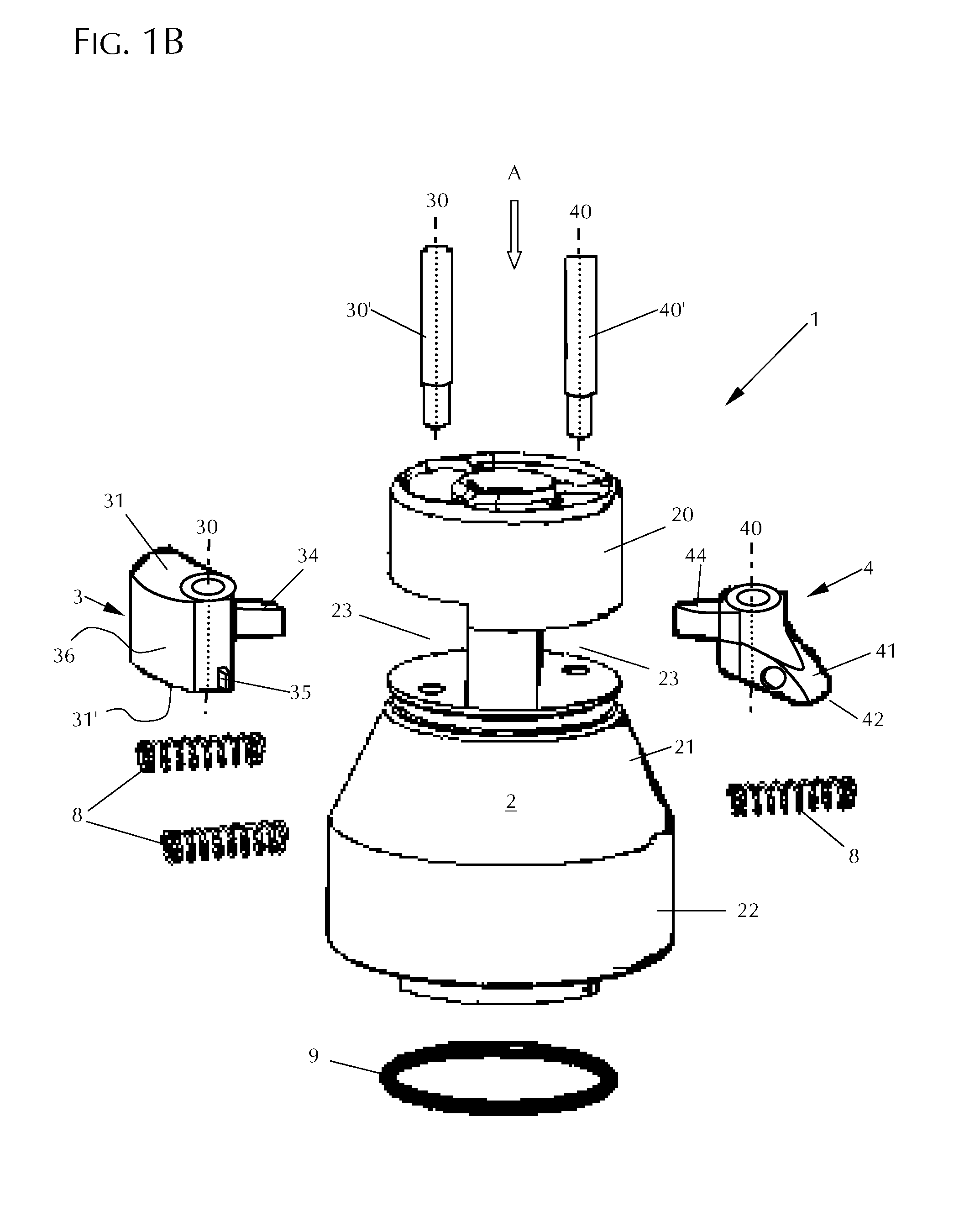

Centrifuge Drive Head For Releasably Connecting A Driving System To A Rotor Of A Centrifuge, A Set And A Centrifuge Comprising The Drive Head

ActiveUS20130331253A1High densityHigh strengthCentrifugesCouplings for rigid shaftsCentrifugeCoupling

Owner:QIAGEN

High-strength corrosion-resistant micro-alloying copper pipe and manufacturing method thereof

The invention discloses a high-strength corrosion-resistant micro-alloying copper pipe material which consists of the following components in percentage by weight: 0.005-0.04% of phosphorus, 0.2-1.0% of tin, 0-0.04% of lanthanum, 0-0.04% of cerium, 0-0.1% of nickel, 0-0.1% of zinc, 0-0.05% of cobalt, 0-0.1% of manganese, 0-0.05% of zirconium and the balance of copper. By combining phosphorus with rare earth lanthanum and / or cerium to obtain a deoxidizer of molten copper, the content of oxygen in melt is further reduced, the grain structure is refined, the recrystallization temperature is increased to prevent abnormal growth of the weld structure grain, and the ductility and thermal conductivity of copper are further improved. Through solid solution strengthening of tin and improvement of an oxide film on a surface layer, the strength and corrosion resistance of a matrix are improved. By adding trace amount of zinc, nickel and manganese subjected to solid solution into the copper matrix, the strength of the copper matrix is improved; by adding cobalt or zirconium and dispersing into the copper matrix, the strength and heat resistance of the copper matrix are improved; the combination effect is better than the performance and using effect of the existing oxygen-free copper pipe or single phosphorus deoxidization copper pipe.

Owner:NINGBO JINTIAN COPPER TUBE +1

Paper making method with pulp and product of high-surface-intensity offset printing paper

ActiveCN103526630AImprove retentionHigh strengthWater-repelling agents additionInorganic compound additionCalcium silicateFiber

The invention discloses a paper making method with pulp and a product of high-surface-intensity offset printing paper. The paper making method with the pulp comprises the steps that (1) multi-hole calcium silicate and mixed wood pulp fibers are subjected to mixing pulping, mixed pulp is obtained; (2) retention and drainage agents A, sizing agents and retention and drainage agents B are added into the mixed pulp in sequence, even stirring is carried out, papermaking pulp is obtained; (3) the papermaking pulp is subjected to papermaking, squeezing and drying, body paper is obtained; (4) surface sizing agents are used for carrying out surface sizing on the body paper, and the offset printing paper is obtained. The multi-hole calcium silicate is used as the papermaking padding, during a papermaking process, paper pulp / padding medium-high-concentration mixing pulping, CS / CPAM double-element retention and surface sizing agent formula improving and other measures are used, the padding retention rate is improved, paper intensity is effectively improved, and the waterproof performance, the oil resistance, the paper surface intensity, the tensile strength and other performance indexes of paper are obviously improved.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Formula of highly anti-fatigue automobile brake chamber rubber diaphragm material

ActiveCN101302311ASolve the blending problemImprove thermal stabilityPolytetramethylene terephthalateRubber material

The invention provides a rubber material formulation for a high fatigue resistant rubber diaphragm of an automobile brake chamber, which is mainly prepared by natural rubber (NR), styrene butadiene rubber (SBR), polybutylene terephthalate (PBT), vulcanizing agent, zinc oxides, stearic acid, anti-aging agent, dispersant, accelerant, carbon black, aromatic oil and white carbon black. The physical mechanical properties of the rubber diaphragm of the automobile brake chamber prepared by the rubber formulation all reach the novel standard drafted by the Society of Automotive Engineering (SAE) of America; the service life of a platform of the rubber diaphragm reaches over 2 million times; the platform has the advantages of high stress at definite elongation, strength and elongation property, compression fatigue resistivity, flexural deformation resistance and attrition resistance, and maintenance of small variation of the material characteristics within the wide use temperature between 55 and 100 DEG C when the material is used; and the service life of the platform is basically the same as that of an air brake assembly, and resource conservation is greatly promoted simultaneously, thereby realizing conversion of the platform from 'a wearing part' to 'a permanent part'.

Owner:GUIZHOU JINGZHONG RUBBER & PLASTIC IND CO LTD

Steel-concrete combination deck plate and construction method thereof

ActiveCN106638302AReduce thicknessImprove binding structureBridge structural detailsBridge erection/assemblySheet steelRebar

The invention relates to a steel-concrete combination deck plate and a construction method thereof, wherein the steel-concrete combination deck plate comprises: bottom steel plates arranged on steel girders, wherein the bottom steel plates in the bearing regions of the steel girders are bent in shape, and the bottom steel plates are 8-10 mm in thickness; a plurality of shear plates vertically connected to the bottom steel plates; a concrete tier including reinforcement fabric penetrating through the shear plates, wherein the concrete tier is cast to the bottom steel plates, and the combination deck plate is 10-15 cm in thickness. The steel-concrete combination deck plate uses the bottom steel plates as stress-bearing parts as well as a formwork for a cast-in-place desk concrete tier, and steps of mounting and releasing concrete formwork are omitted; the shear plates serve as stiffeners for the bottom steel plates, good combination of the bottom steel plates with the concrete tier can be guaranteed, and cracking of the concrete tier is prevented; the deck thickness is controlled to 10-15 cm and is reduced, the weight is 25% and above lower than that of a composite beam deck system, dead load is reduced, crossing ability, structural strength and durability of the main structure are improved, construction input is reduced, and the efficiency of a construction method is high.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

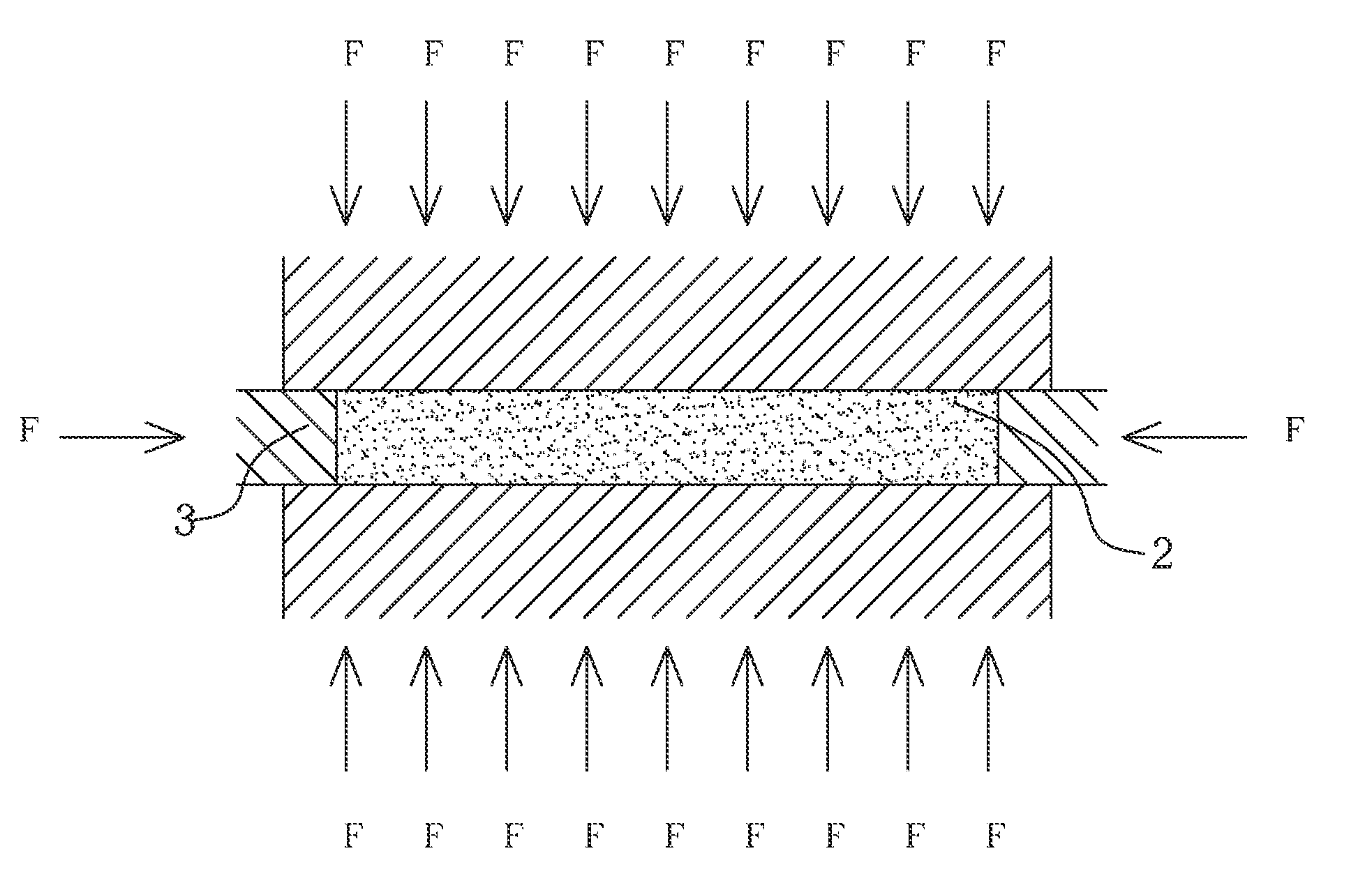

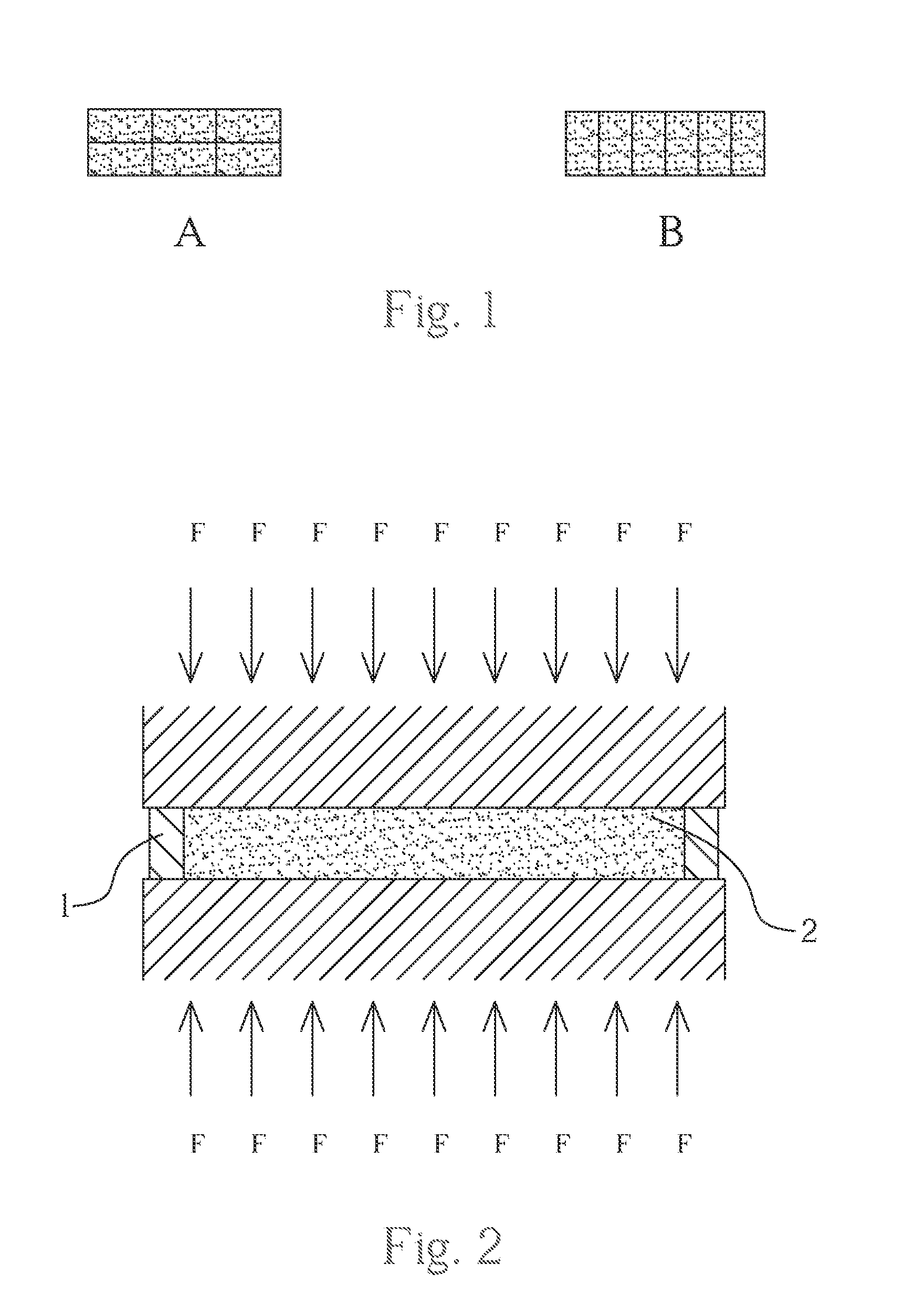

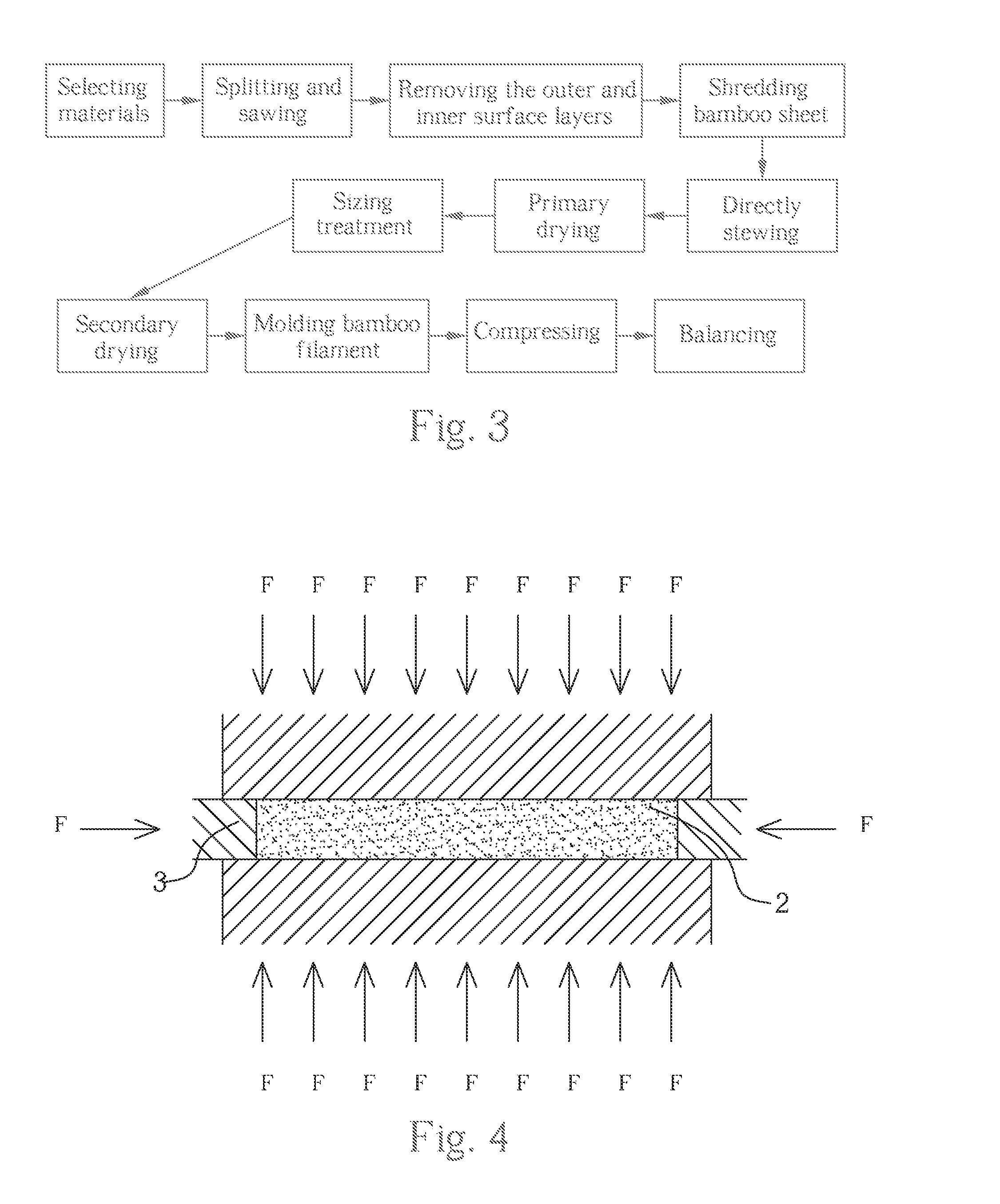

Process for Making a Bamboo Filament Slab Floor by Opposite Directional Hot Pressing

The present invention relates to bamboo manufacturing field, in particular, to a process for making a bamboo filament slab floor by opposite directional hot pressing. Aiming to overcome the defects that, while compressing, the existing bamboo filament slab floor at normal temperature under cold pressing is easy to rebound and expand, has low strength and weak resistance to abrasion and is easy to mildew while using for a long time, the present invention adopts shredding bamboo sheet, sizing treatment, moulding bamboo filament and etc. procedures, characterized in that, a secondary drying procedure should be inserted between said sizing treatment and bamboo filament moulding procedure; said sizing treatment should be implemented by soak sizing bamboo filament; said compressing includes opposite directional hot pressing of positive pressing and side pressing. The present invention adopts specific manufacturing technology, thus the floor can avoid the occurrence of holes and gaps inside bamboo filament slab floor and discharge formaldehyde and has stable quality, and will be not prone to mildew and deform while using for a long time. It can be widely used and suitable for indoor and outdoor flooring and various boards used in decoration and furniture.

Owner:WANG ZHENGFENG

Animal sanitary sand and preparation method thereof

InactiveCN109601404AHigh strengthStrong adsorption capacityAnimal housingSmooth surfaceEnvironmentally friendly

Owner:山东海沃世丰农业科技有限公司

Copper/cerium-containing antimicrobial stainless steel and preparation method thereof

The invention discloses a copper / cerium-containing antimicrobial stainless steel and a preparation method thereof. The copper / cerium-containing antimicrobial stainless steel comprises the following chemical components in percentage by weight: at most 0.08% of C, at most 1% of Si, at most 2.00% of Mn, less than 0.045% of P, less than 0.030% of S, 17.5-20.0% of Cr, 8-11% of Ni, 0.5-2.8% of Cu, 0.01-0.45% of Ce, and the balance of Fe and inevitable impurities. The stainless steel is molten in an induction furnace after smelting, and is subjected to aging high-temperature diffusion heat treatment composed of 20-minute 1180 DEG C solid solution and 1-hour 685 DEG C thermal insulation so as to precipitate the antimicrobial phase epsilon-Cu and Ce, thereby endowing the stainless steel with antimicrobial property. The steel grade has stainless steel performance and broad-spectrum antibacterial property; the corrosion resistance, wear resistance, strength, toughness, oxidation resistance and other comprehensive properties of the stainless steel are improved; and the production technique is simple, has great utilization value in industry, and is suitable for industrial production.

Owner:SHANGHAI UNIV

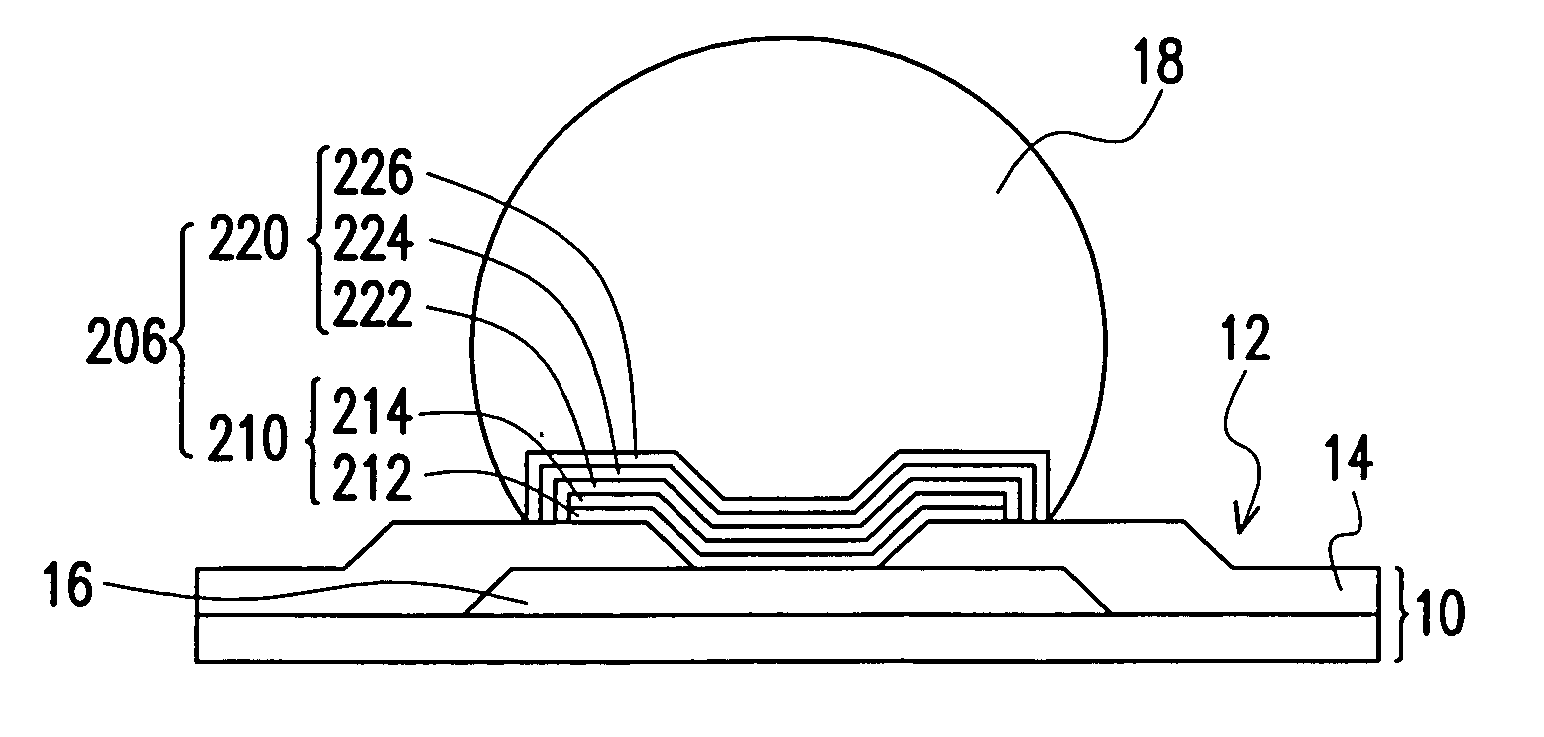

Non-contact id card and the like and method for manufacturing same

InactiveUS20060054707A1High strengthOther printing matterSemiconductor/solid-state device detailsDirect touchElectricity

A low-cost non-contact ID card having practical electrical properties and the like is disclosed. The non-contact ID card comprises an antenna circuit board wherein an antenna is formed on a substrate and an interposer board wherein an enlarged electrode is formed on a substrate that is mounted with an IC chip. The enlarged electrode is connected to an electrode of the IC chip. The antenna circuit board and the interposer board are joined in such a manner that an electrode of the antenna is in direct contact with the enlarged electrode which is a resin electrode made of a conductive resin containing a thermoplastic resin.

Owner:TORAY ENG CO LTD

HDPE(high-density polyethylene) membrane composited by high foaming of LDPE(Low-Density Polyethylene) and preparation method of HDPE membrane

ActiveCN104401076AHigh mechanical strengthImprove performanceSynthetic resin layered productsLaminationLow-density polyethyleneFoaming agent

The invention discloses an HDPE(high-density polyethylene) membrane composited by high foaming of LDPE(Low-Density Polyethylene) and a preparation method of the membrane. The HDPE membrane composited by the high foaming of the LDPE comprises the HDPE membrane, wherein a sheet layer formed by the high foaming of the LDPE is arranged on the surface of the HDPE membrane, and a PE(Poly Ethylene) bonding layer is arranged between the HDPE membrane and the sheet layer; the sheet layer consists of the following components in percentage by weight: 95% of the LDPE, 3.5% of a nucleating agent, 1.39% of a foaming agent, 0.1% of an antisbrinking agent and 0.01% of an auxiliary addition agent. Compared with the prior art, the HDPE membrane composited by the high foaming of the LDPE is a novel environmental-friendly packaging material with high buffering capacity and shock resistant capacity, the membrane has the advantages that the flexibleness and the buffering capacity are good, the heat conductivity is low, the heat-shielding performance is excellent, the membrane does not pollute the environment, and the membrane belongs to the materials capable of being recycled.

Owner:SUZHOU JIUDING

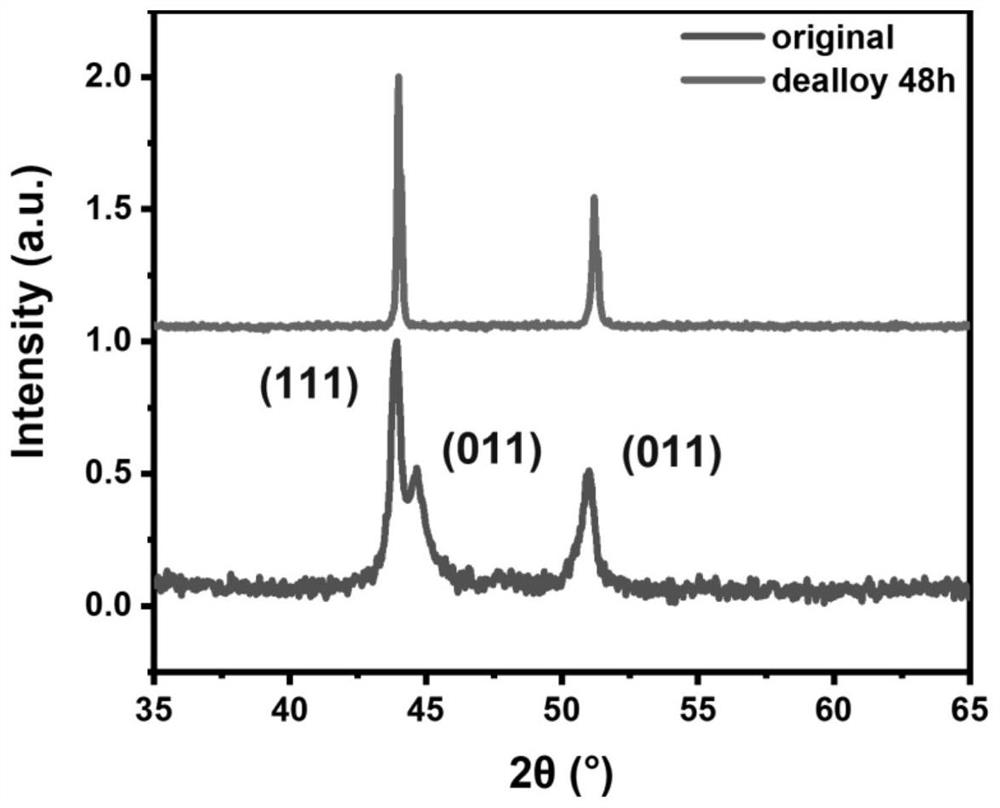

Porous high-entropy alloy self-supporting electrode for electrolyzing water and preparation method thereof

ActiveCN112725818AExcellent decomposabilityLow costNon-noble metal oxide coatingsHigh entropy alloysSurface oxidation

The invention discloses a porous high-entropy alloy self-supporting electrode for electrolyzing water and a preparation method thereof. The preparation method comprises the following steps: smelting, mixing and melting nickel powder, cobalt powder, chromium powder, iron powder, aluminum powder and tungsten powder, and conducting cooling to form a high-entropy alloy with an eutectic structure; cutting the high-entropy alloy into an alloy sheet, and conducting polishing to remove surface oxide skins; then carrying out dealloying treatment; and after dealloying treatment is completed, taking out the alloy sheet and carrying out ultrasonic treatment so as to obtain the self-supporting electrode. The invention provides a simple, efficient and controllable dealloying means for treating the high-entropy alloy sheet to obtain the sheet-shaped high-entropy alloy self-supporting catalytic electrode with a multi-scale pore structure, and the sheet-shaped high-entropy alloy self-supporting catalytic electrode is proved to have excellent electro-catalytic hydrogen evolution / oxygen evolution reaction activity and stability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

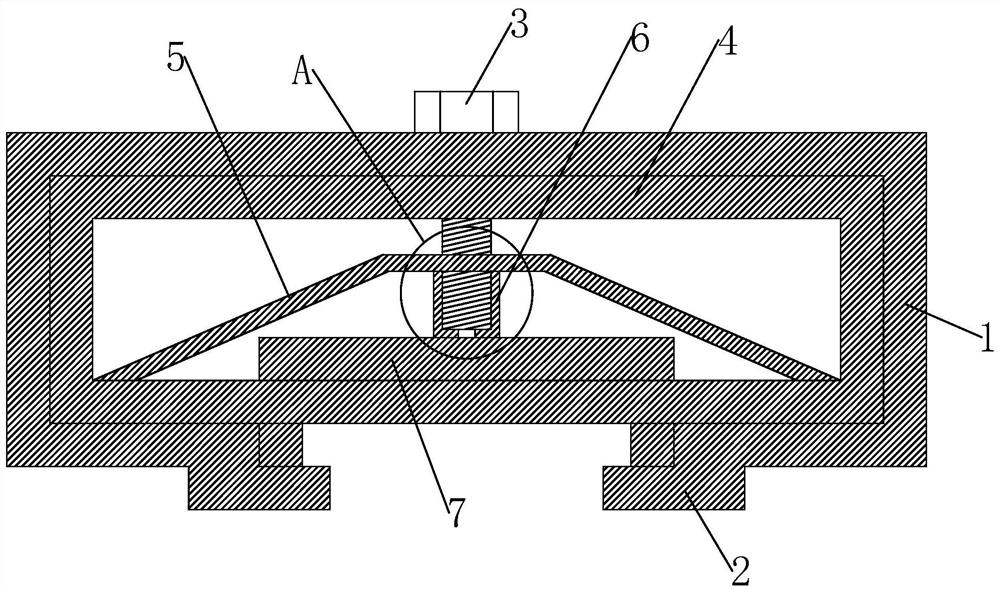

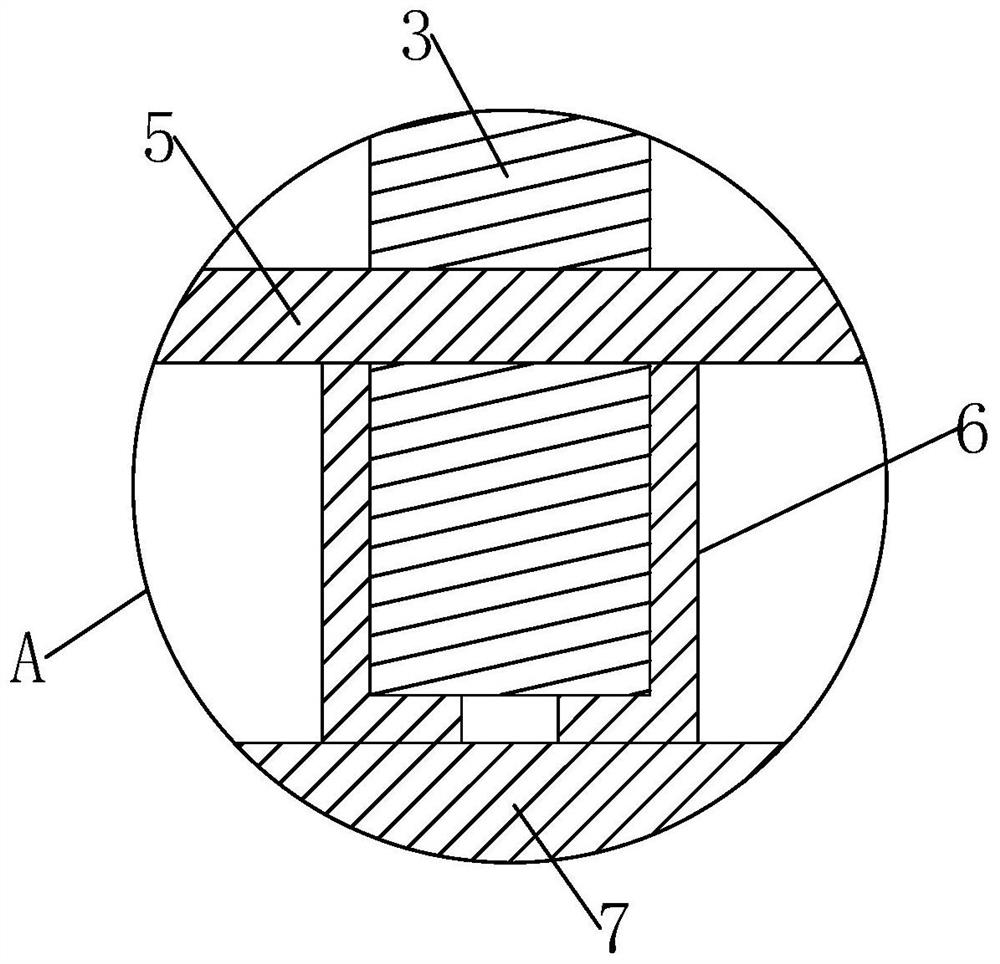

Quantum dot molecular light emitting device

InactiveCN102097564ABroad luminescence spectrumHigh strengthLaser detailsSemiconductor lasersMetal electrodesWaveguide

The invention relates to a quantum dot molecular light emitting device, which sequentially comprises the following structures from bottom to top: a lower gold germanium nickel metal electrode layer (1), a gallium arsenic substrate (2), a gallium arsenic buffer layer (3), a n-type aluminum gallium arsenic lower cladding layer (4), a gallium arsenic lower waveguide limiting layer (5), a quantum dotmolecular active area, a gallium arsenic upper waveguide limiting layer (9), a p-type aluminum gallium arsenic upper cladding layer (10), a p-type gallium arsenic ohmic contact layer (11), a dioxide silicon insulating layer (12) and an upper titanium platinum gold metal electrode layer (13), wherein the quantum dot molecular active area comprises n quantum dot molecular layers each of which comprises quantum dot molecules (6), a stress buffer layer (7) and an isolated layer (8), and n is a natural number not less than 1. According to the invention, the laterally coupled quantum dot molecules are utilized to manufacture an active area structure and corresponding light emitting devices, thereby widening the applicable scope of quantum dot and improving the performance of low dimension semiconductor device.

Owner:HUAZHONG UNIV OF SCI & TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap