Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

28 results about "Tungsten" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tungsten, or wolfram, is a chemical element with the symbol W and atomic number 74. The name tungsten comes from the former Swedish name for the tungstate mineral scheelite, tung sten or "heavy stone". Tungsten is a rare metal found naturally on Earth almost exclusively combined with other elements in chemical compounds rather than alone. It was identified as a new element in 1781 and first isolated as a metal in 1783. Its important ores include wolframite and scheelite.

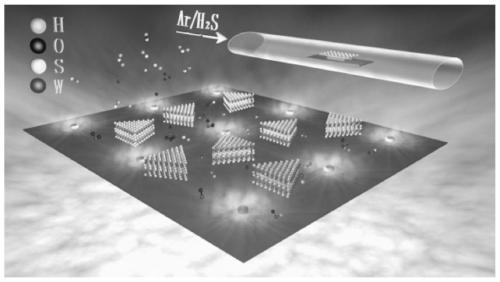

Mirror process using tungsten passivation layer for preventing metal-spiking induced mirror bridging and improving mirror curvature

InactiveUS20060037933A1Prevent metal-spiking induced mirror bridgingImprove mirror curvatureDecorative surface effectsMicroelectromechanical systemsOptoelectronicsTungsten

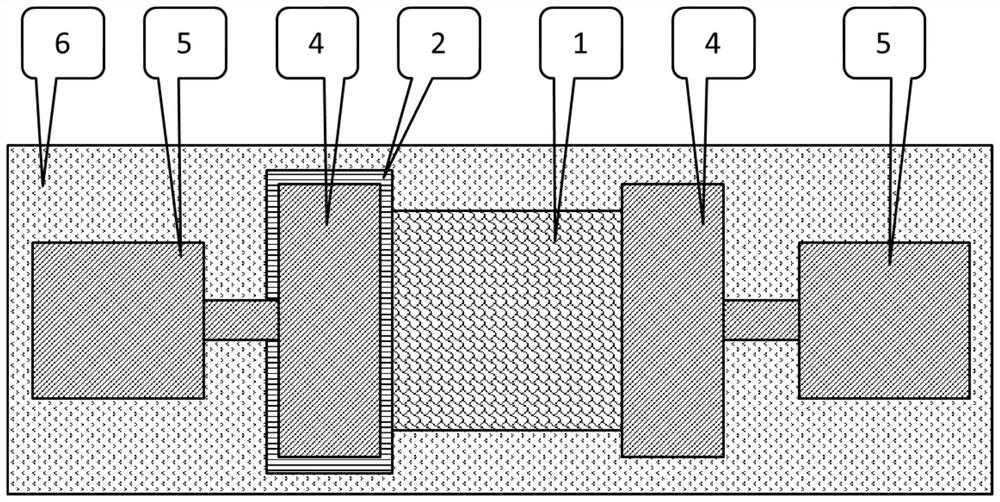

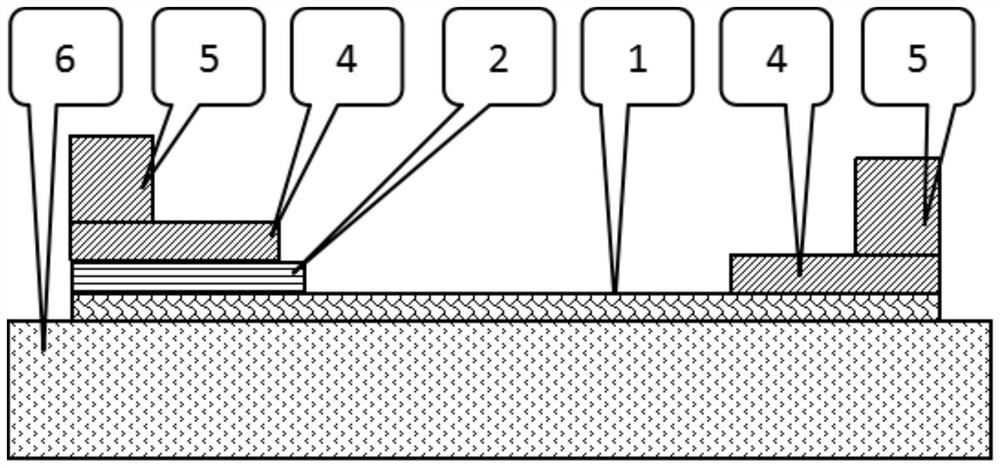

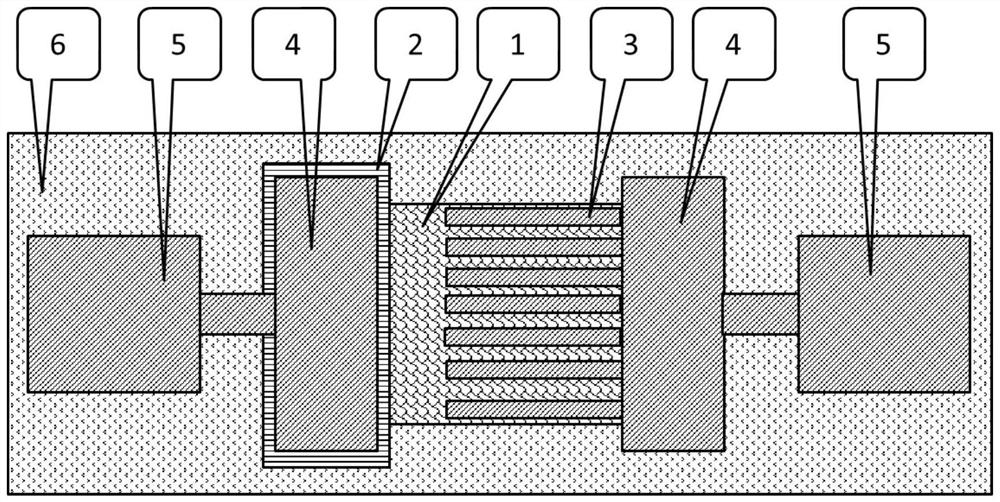

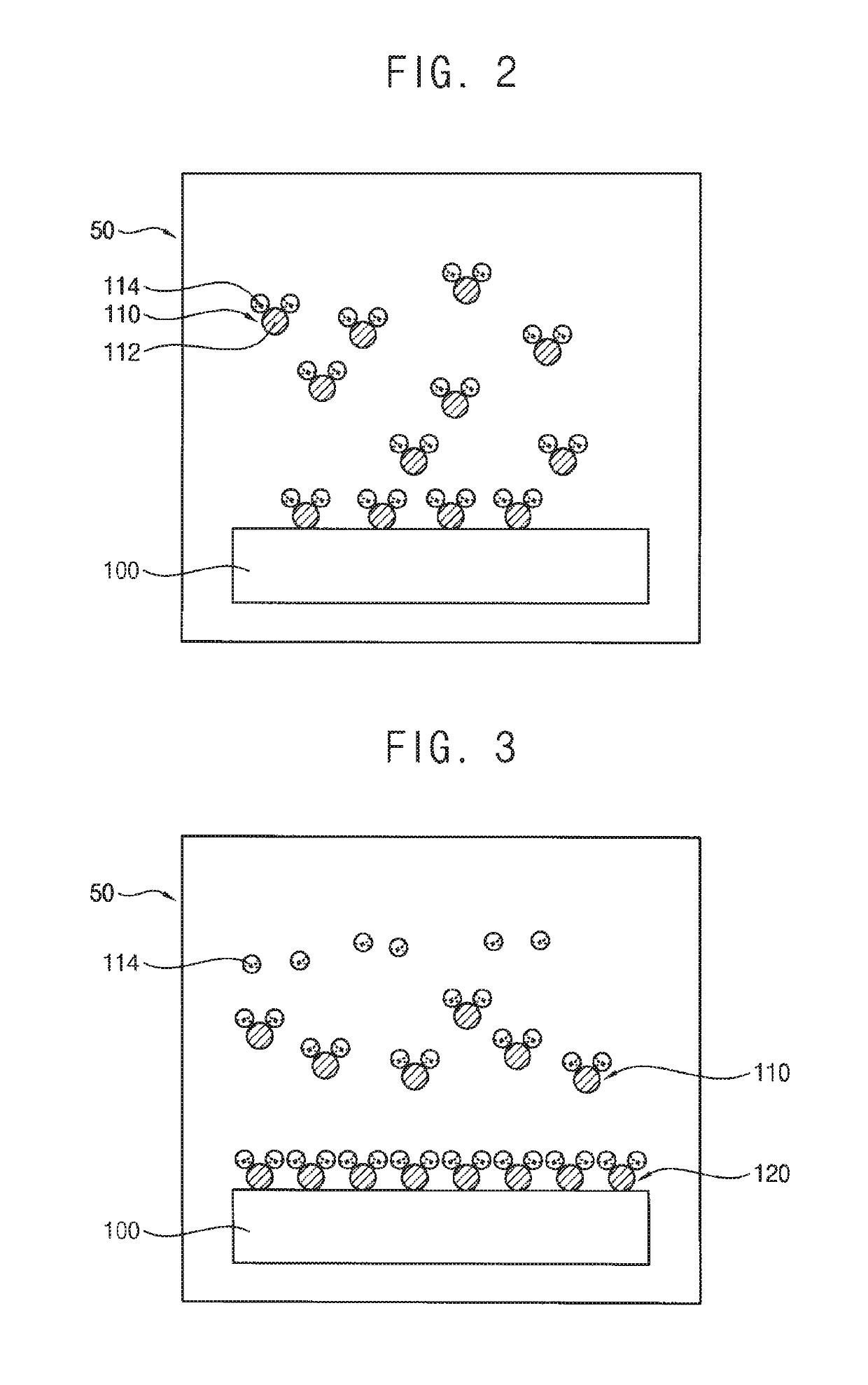

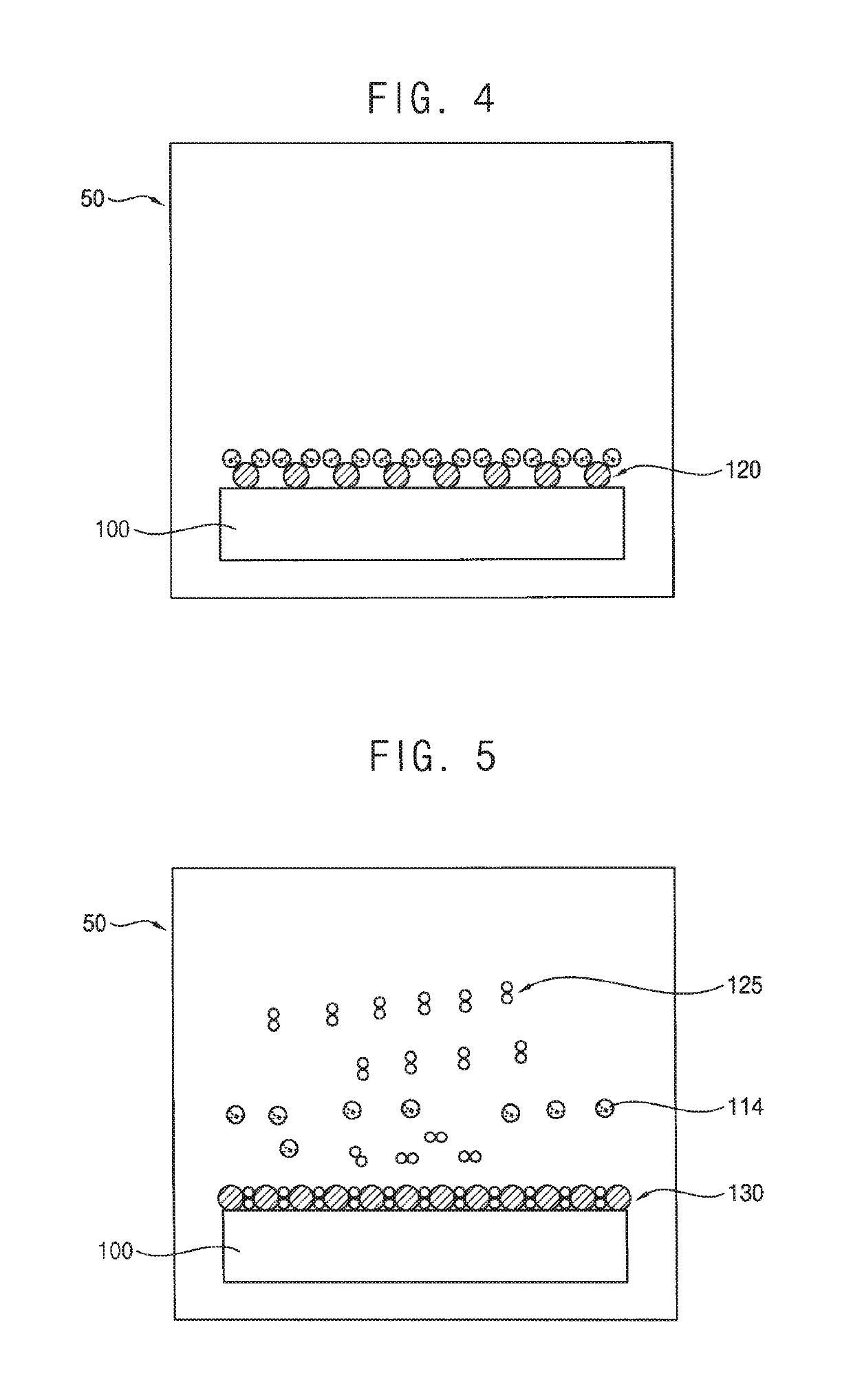

A mirror process uses a tungsten passivation layer to prevent metal-spiking induced mirror bridging and improve mirror curvature. A mirror structure is patterned on a first sacrificial layer overlying a substrate. A tungsten passivation layer is then blanket deposited to cover the top and sidewalls of the mirror structure. A second sacrificial layer is formed overlying the tungsten passivation layer. A releasing process with an etchant including XeF2 is performed to remove the second sacrificial layer, the tungsten passivation layer and the first sacrificial layer simultaneously.

Owner:TAIWAN SEMICON MFG CO LTD

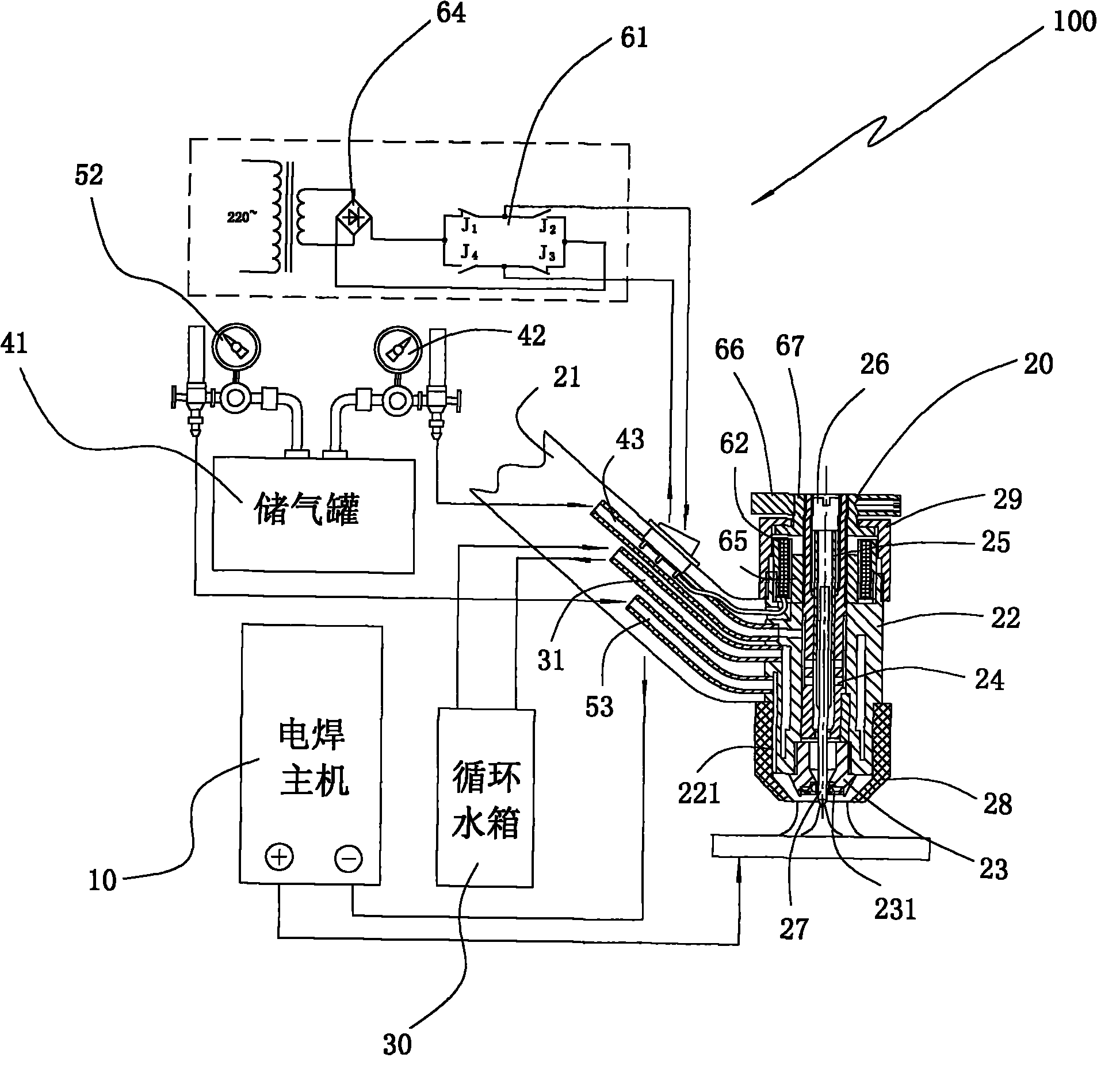

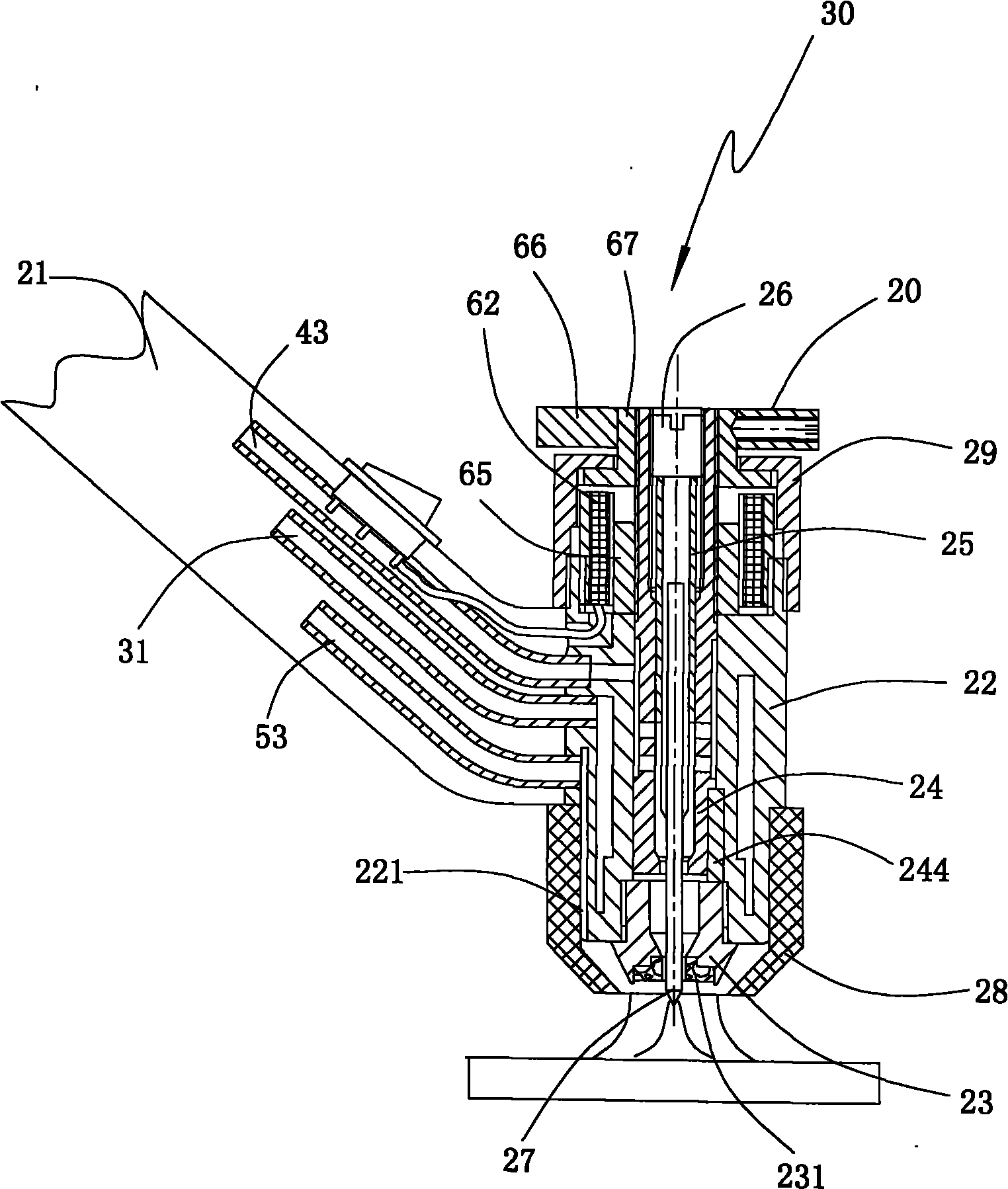

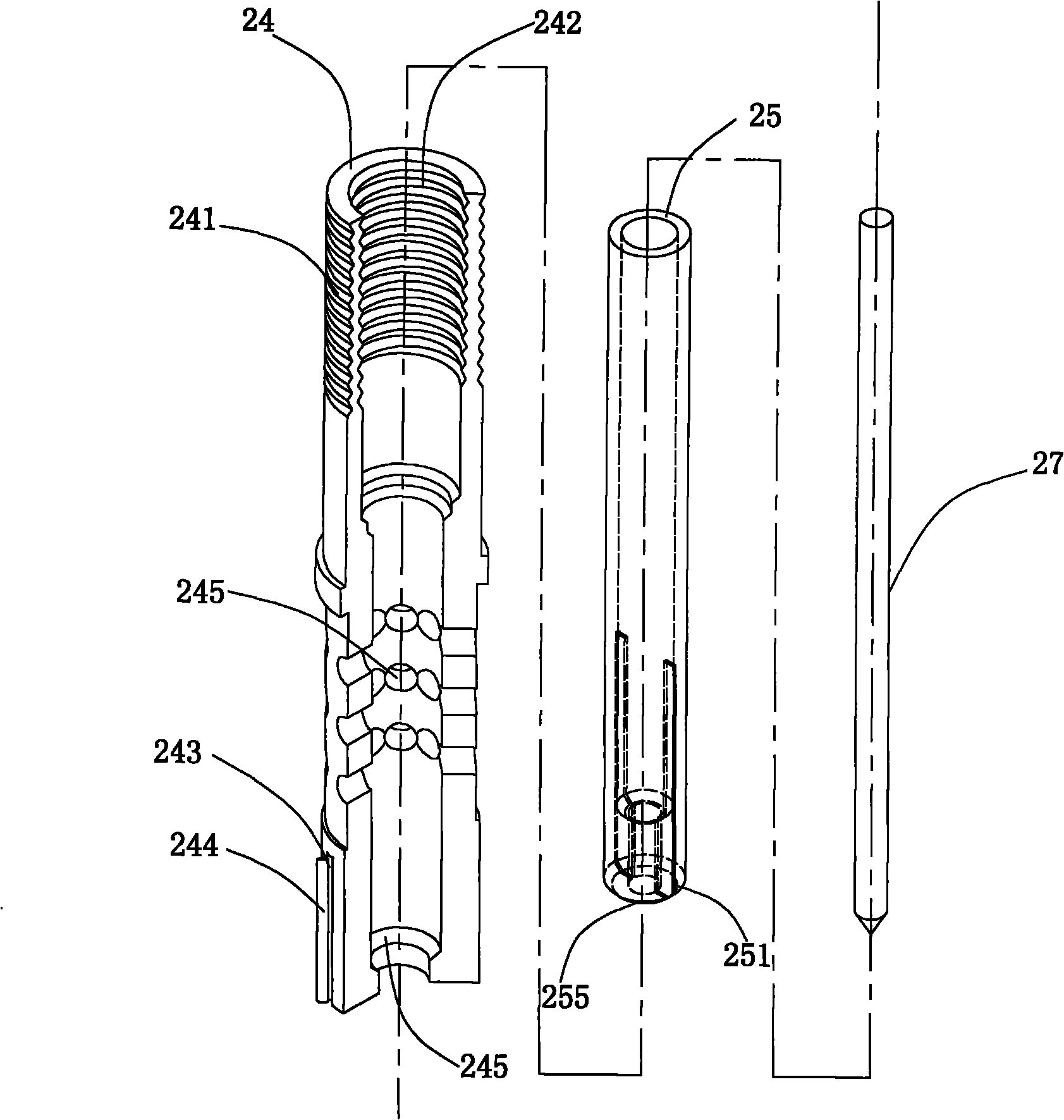

Inverter electric welding machine device with adjustable electric arc

InactiveCN101823176AImprove stabilityImprove practicalityElectrode vibration holdersShielding gasCompression screw

Owner:上海新亚电焊机有限公司

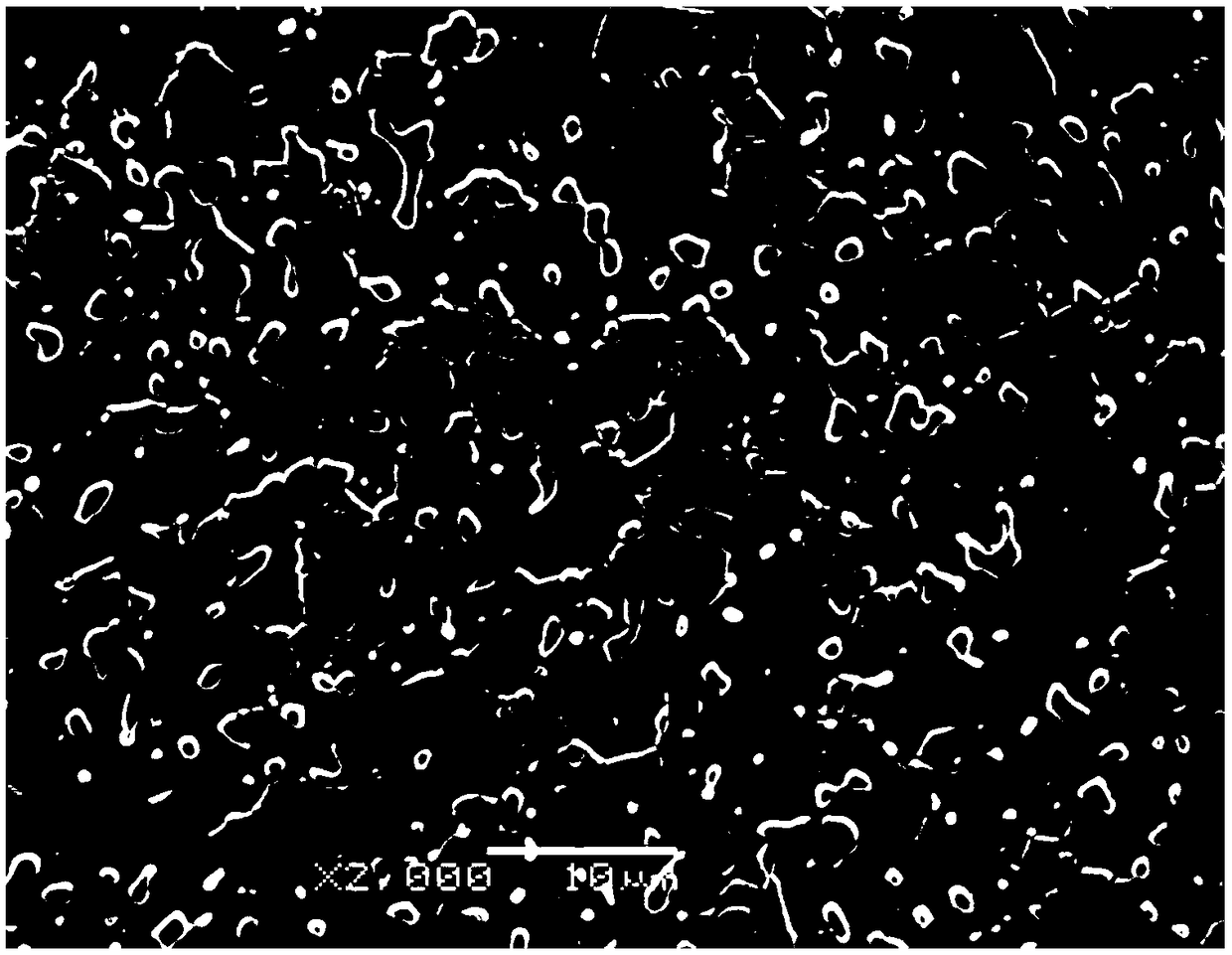

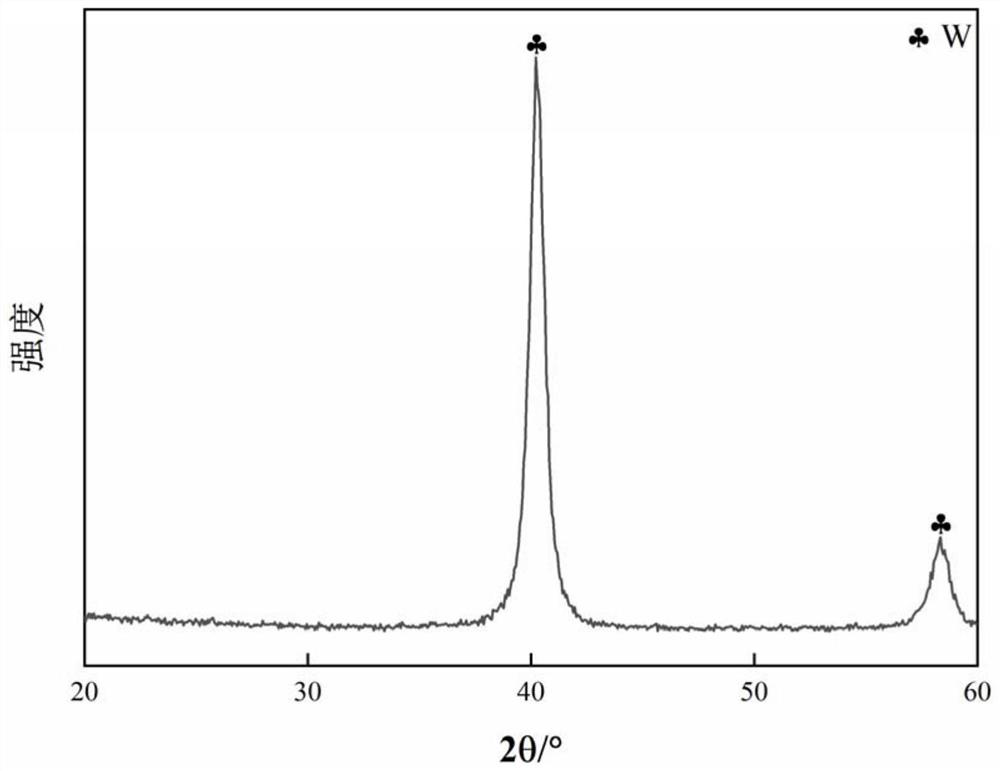

W-Mo-Re-HfC alloy material and preparation method thereof

InactiveCN108796333ATungstenMicrostructure

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

SPS connection method for tungsten and molybdenum dissimilar refractory metals

ActiveCN108262483AEfficient connectionFacilitated DiffusionRoom temperatureUltimate tensile strength

Owner:HEFEI UNIV OF TECH

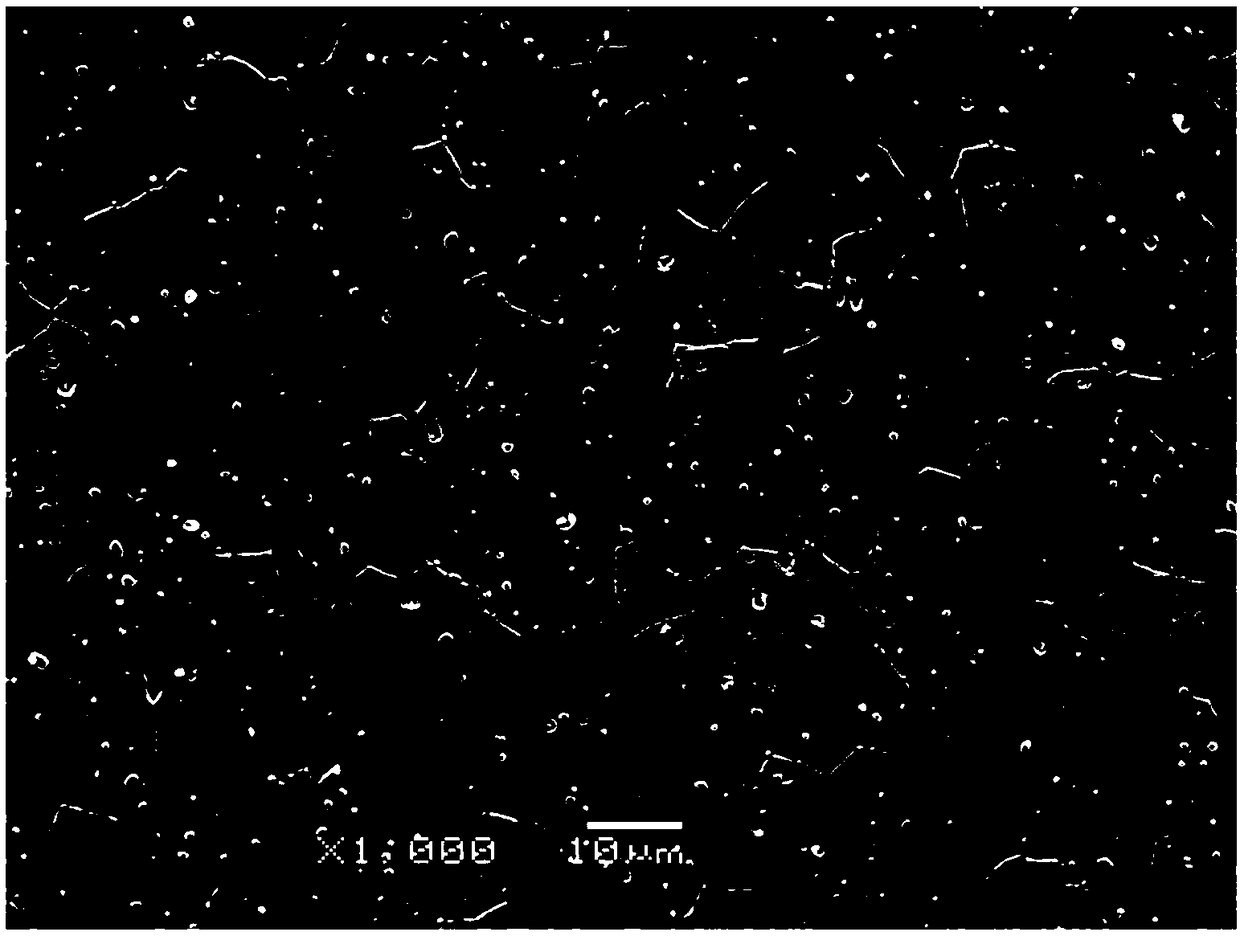

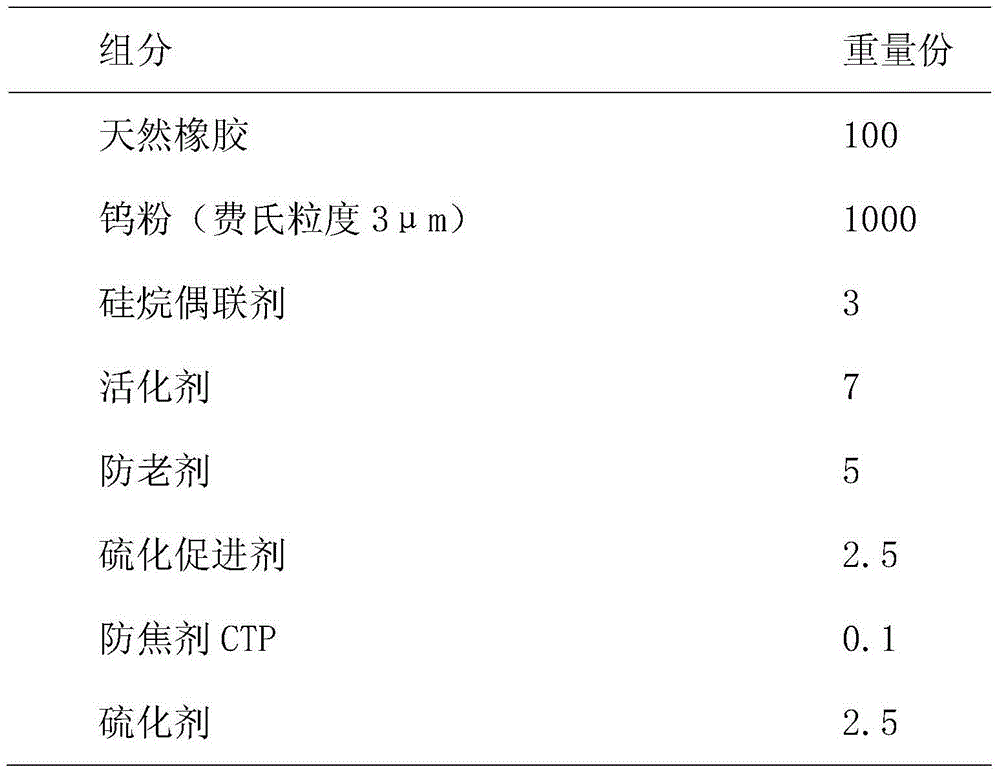

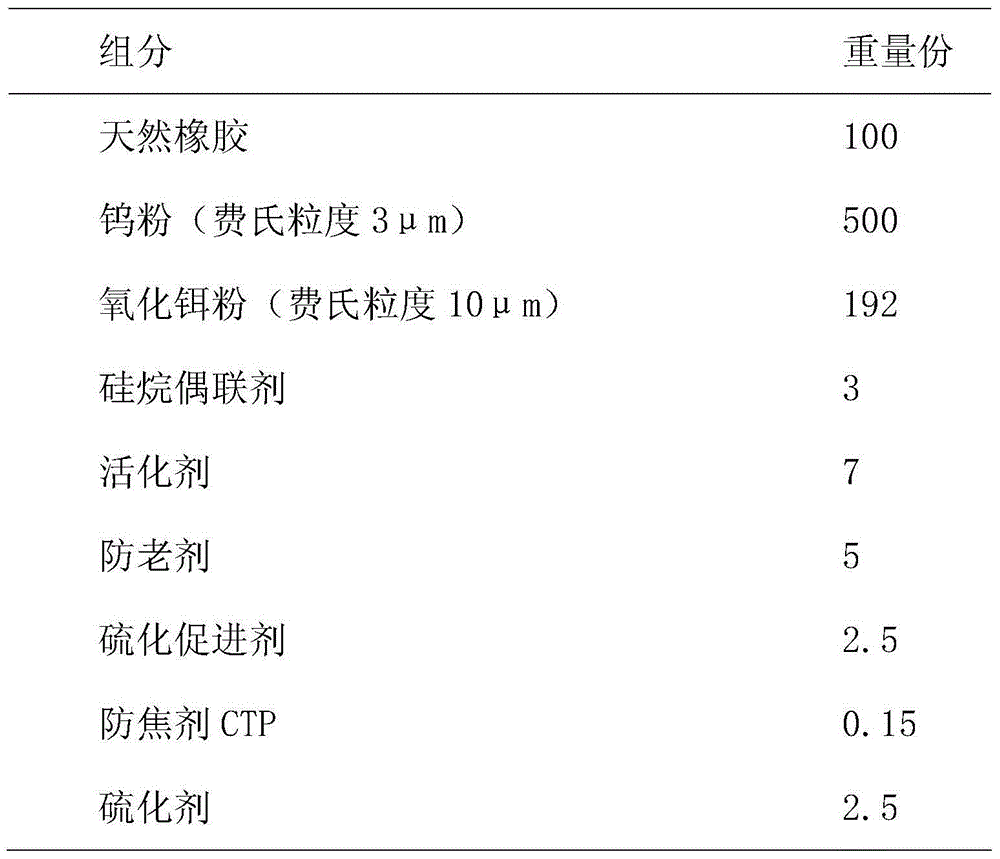

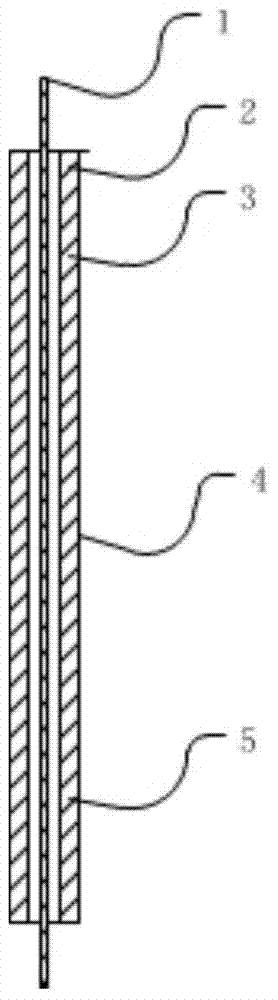

Tungsten-base composite material applied to ray shielding and preparation method thereof

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

Preparation method of micrometer-scale dispensing tungsten needle

InactiveCN104741292ASimple technical meansEasy to make raw materialsLiquid surface applicatorsCoatingsMolten stateMicrometer scale

Owner:SOUTH CHINA UNIV OF TECH

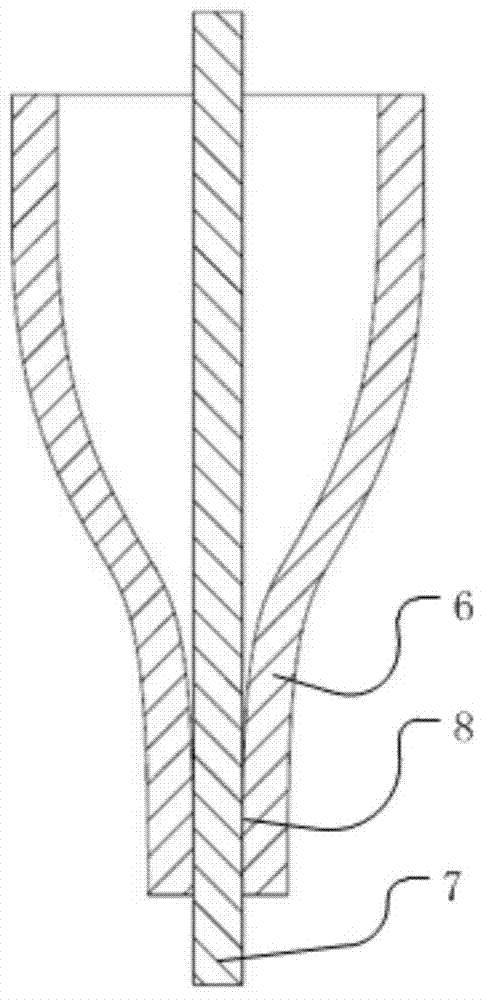

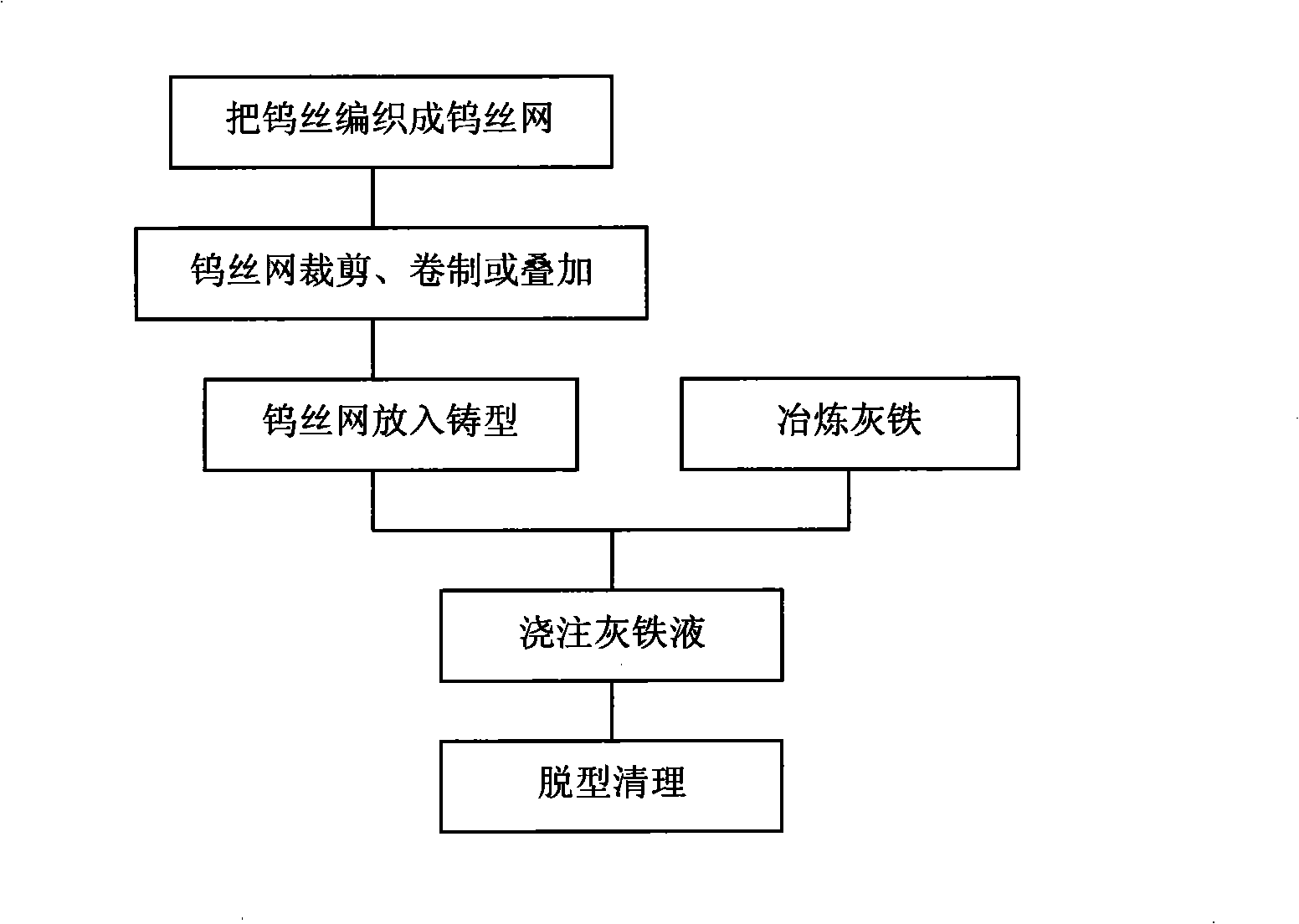

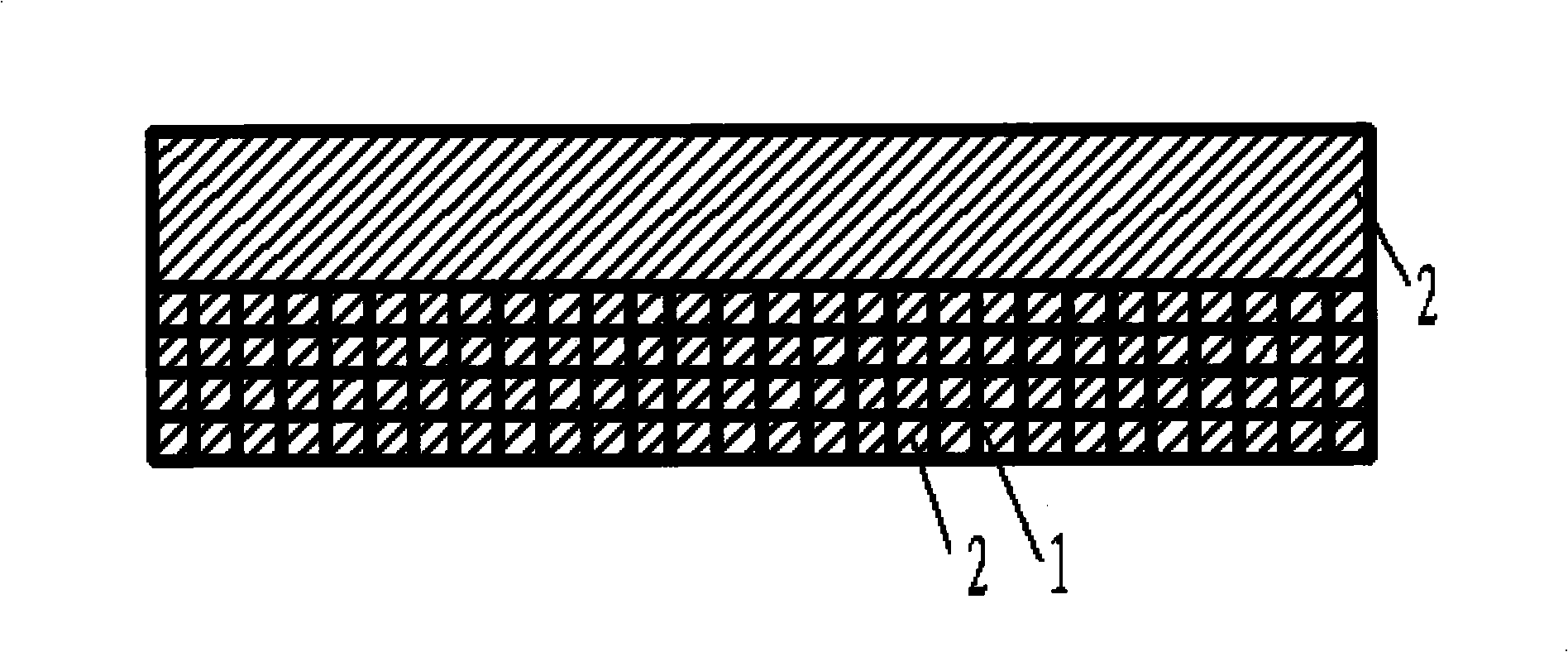

Method for preparing gray iron-base composite material for in situ production of tungsten carbide

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

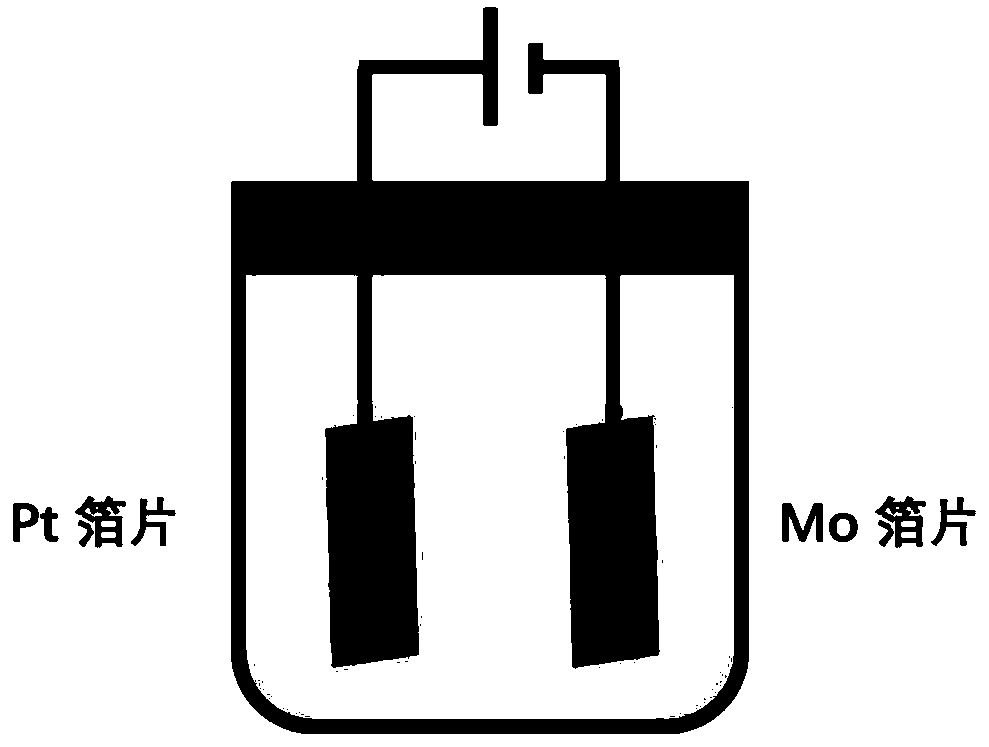

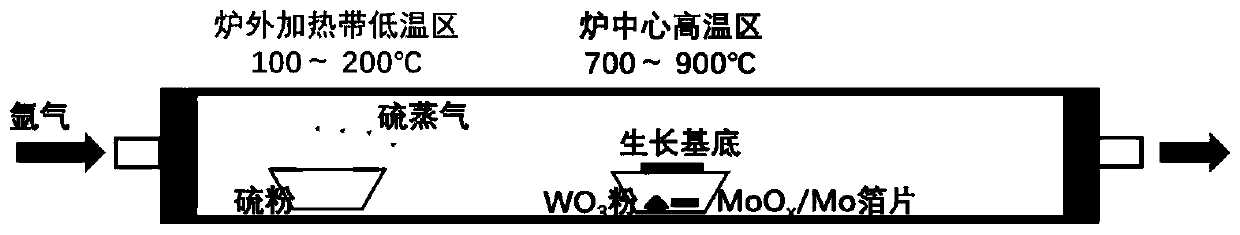

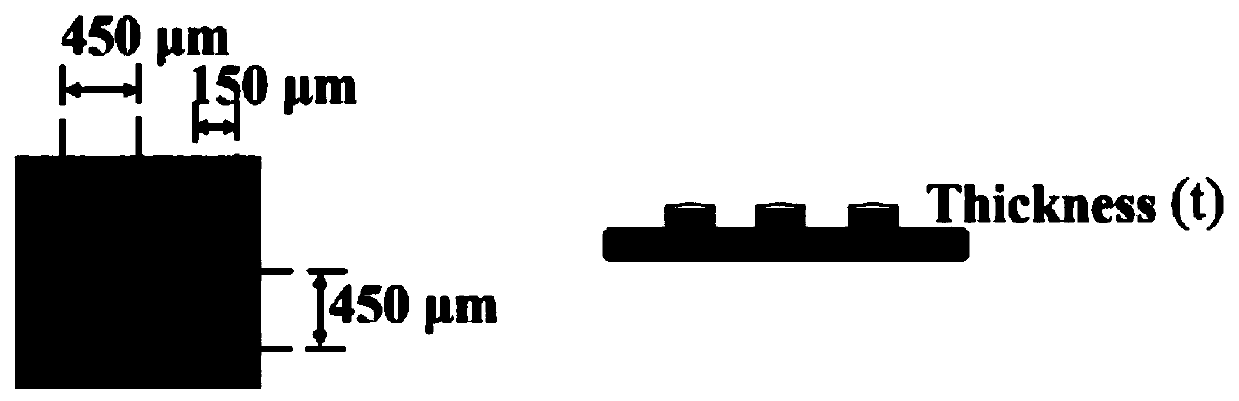

Preparation method for single-layer MoS2-WS2 transverse heterojunction

PendingCN110808281ASimple methodStrong controllabilitySemiconductor/solid-state device manufacturingSemiconductor devicesTube furnaceTungsten

The invention discloses a preparation method for a single-layer MoS2-WS2 transverse heterojunction, which belongs to the field of nano material growth. Electrochemical oxidation treatment is carried out on selected precursor sources to volatilize the precursor sources corresponding to molybdenum and tungsten at different temperatures, and the transverse heterojunction with the micron-sized clear interface is prepared in one step by a chemical vapor deposition method. According to the method of growing the transverse heterojunction, in a tubular furnace capable of accurately controlling the temperature, inert gas is used as transport gas of reaction sources (a molybdenum source, a tungsten source and a sulfur source), and different chemical vapor deposition reactions are controlled to occurto form the transverse heterojunction. The single-layer MoS2-WS2 transverse heterojunction prepared by the method has a micron-scale clear heterojunction boundary, and the transverse size can reach 100 microns or above. According to the method, the controllability of the growth process is high, a growth temperature window can be effectively widened, the growth temperature is reduced, and size andinterface controllable growth is achieved.

Owner:BEIJING UNIV OF TECH

Method of manufacturing vitreous silica diffusion reaction furnace tube

Owner:江苏宏伟石英科技有限公司

Novel thermoforming reinforcer and processing method thereof

Owner:JINGJIANG XINCHENG VEHICLE PARTS

Self-lubricating hard alloy wire drawing die and preparation method thereof

InactiveCN109226301AImprove drawing process qualityAchieve self-lubricating effectDrawing diesManufacturing technologyHigh energy

Owner:SOUTHEAST UNIV

Tungsten/molybdenum crucible for high-temperature heating furnace and manufacturing method of tungsten/molybdenum crucible

ActiveCN104534878AImprove structural strengthImprove heating effectCrucible furnacesRounded RectangleCrucible

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Preparation method of tungsten disulfide single crystal with controllable layer number

ActiveCN111472049AIncrease profitHigh repetition ratePolycrystalline material growthFrom chemically reactive gasesSingle crystalMaterials science

Owner:WENZHOU UNIVERSITY

Preparation method of tungsten-nickel alloy dielectric material with barium titanate thin film

InactiveCN108239717AIncrease internal pressureLow dielectric lossVacuum evaporation coatingSputtering coatingIn planeDielectric loss

The invention discloses a preparation method of a tungsten-nickel alloy dielectric material with a barium titanate thin film. The dielectric material prepared by adopting the preparation method can beused for solving the problems of a 'nickel pool' and holes which frequently appear in the traditional fine grain hard alloy preparation process, and a multilayer thin film structure not only can hinder migration of oxygen vacancies but also can increase in-plane compressive stress of a BaTiO3 thin film, so that the effects of reducing dielectric loss and improving dielectric constant can be realized, and the problems that leakage current and dielectric loss are increased as an existing BaTiO3 thin film produces the oxygen vacancies due to preparation and service and even the BaTiO3 thin filmis disabled are solved.

Owner:QINGDAO XIANGZHI ELECTRONICS TECH CO LTD

Asymmetric induced room-temperature high-sensitivity photoelectric detection device and preparation method thereof

PendingCN114784125AEnhanced photoresponsive currentPhotoresponsive current suppressionSemiconductor devicesMetallic electrodeSilicon oxide

Owner:HANGZHOU INST FOR ADVANCED STUDY UCAS

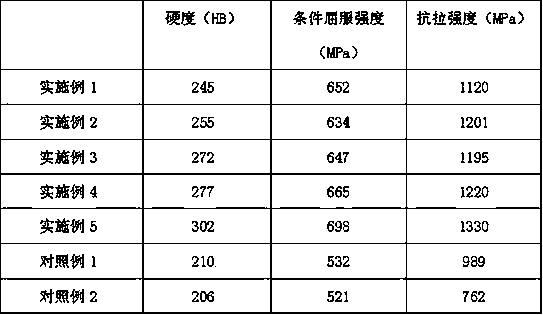

Special magnesium alloy material for vehicle crankshaft and preparation method thereof

The invention discloses a special magnesium alloy material for a vehicle crankshaft and a preparation method thereof. The special magnesium alloy material for the vehicle crankshaft comprises the following components in percentage by weight: 4.0-7.0% of silicon, 3.7-5.8% of copper, 2.5-4.0% of lithium, 0.4-0.6% of tungsten, 0.5-0.9% of chromium, 0.04-0.07% of titanium, 0.02-0.07% of boron, 0.001-0.004% of nickel, 0.001-0.003% of vitriol, 0.001-0.003% of zirconium, and the balance of magnesium. The high-performance magnesium alloy material with higher strength and hardness is prepared through selecting the specific formula, has the advantages of lightness and wear resistance, is excellent in heat dissipating capacity, and can satisfy the quality requirement of the vehicle crankshaft.

Owner:YUYAO WANZHEN HARDWARE FACTORY

Method of preparing golden yellow film-coating glass or ceramic

Owner:HUZHOU TIAHE AUTOMOBILE PART

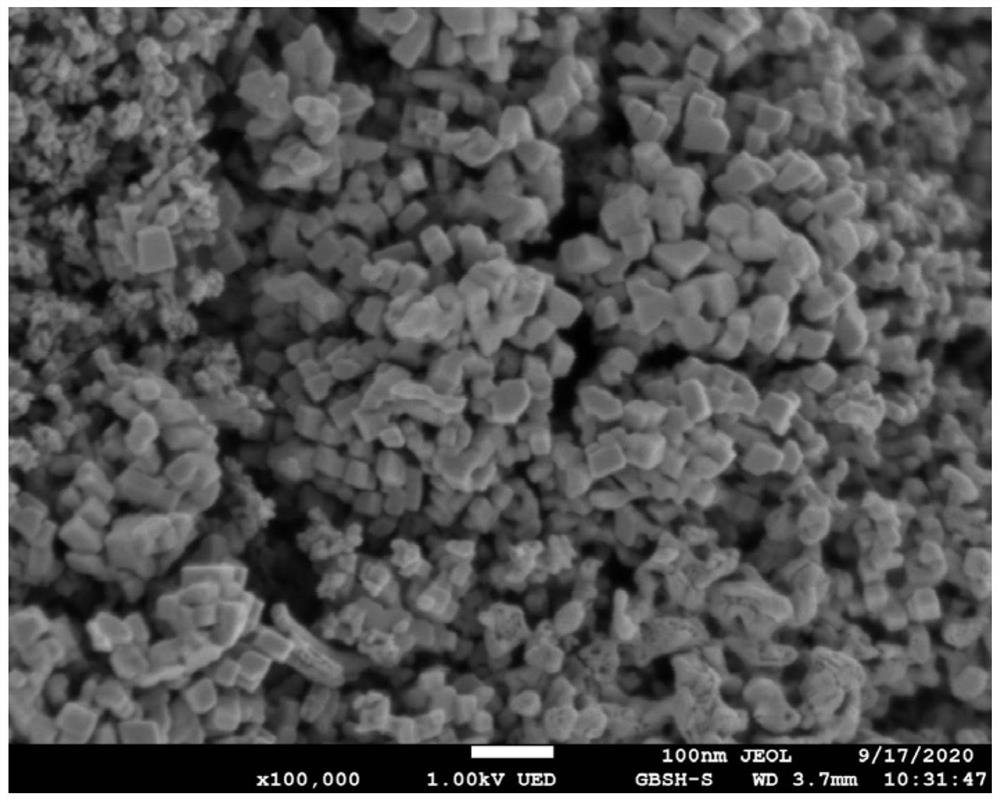

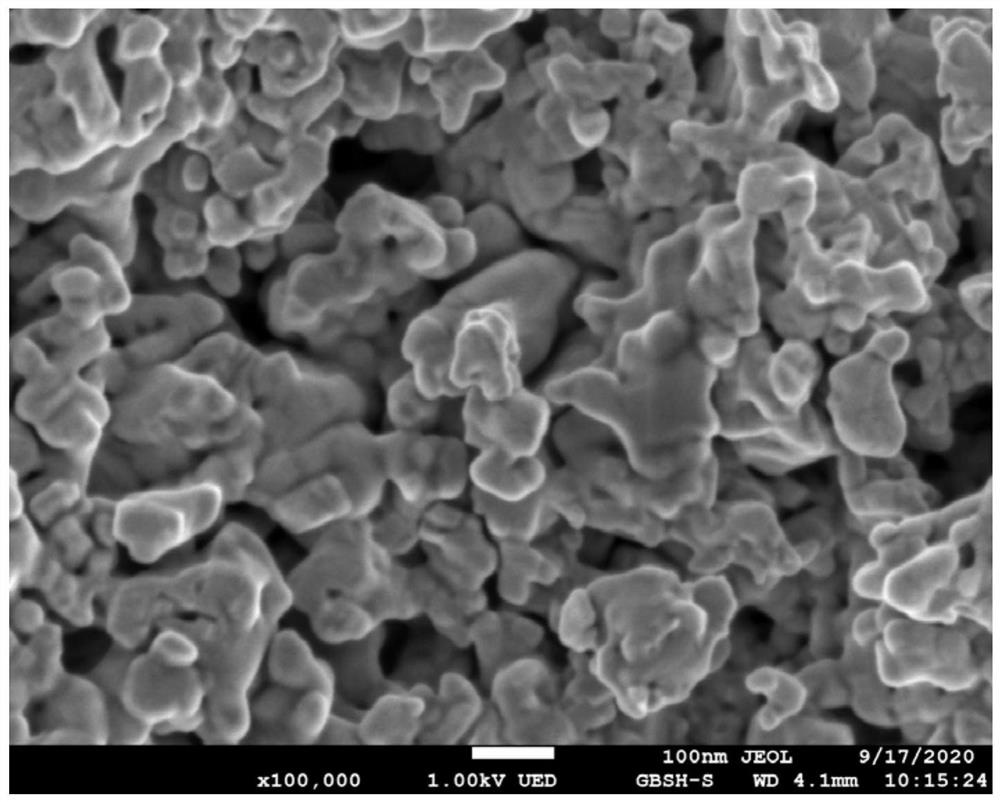

Preparation methods of high-specific-surface-area nano W powder and high-specific-surface-area nano WC powder

Owner:SICHUAN UNIV

Material formula for diamond bit

InactiveCN108746592AReduce manufacturing costHigh tensile strengthTransportation and packagingMetal-working apparatusNiobiumSilicon dioxide

Owner:如皋千骏工具有限公司

Titanium alloy used for high performance cutter

Owner:江苏天工科技股份有限公司

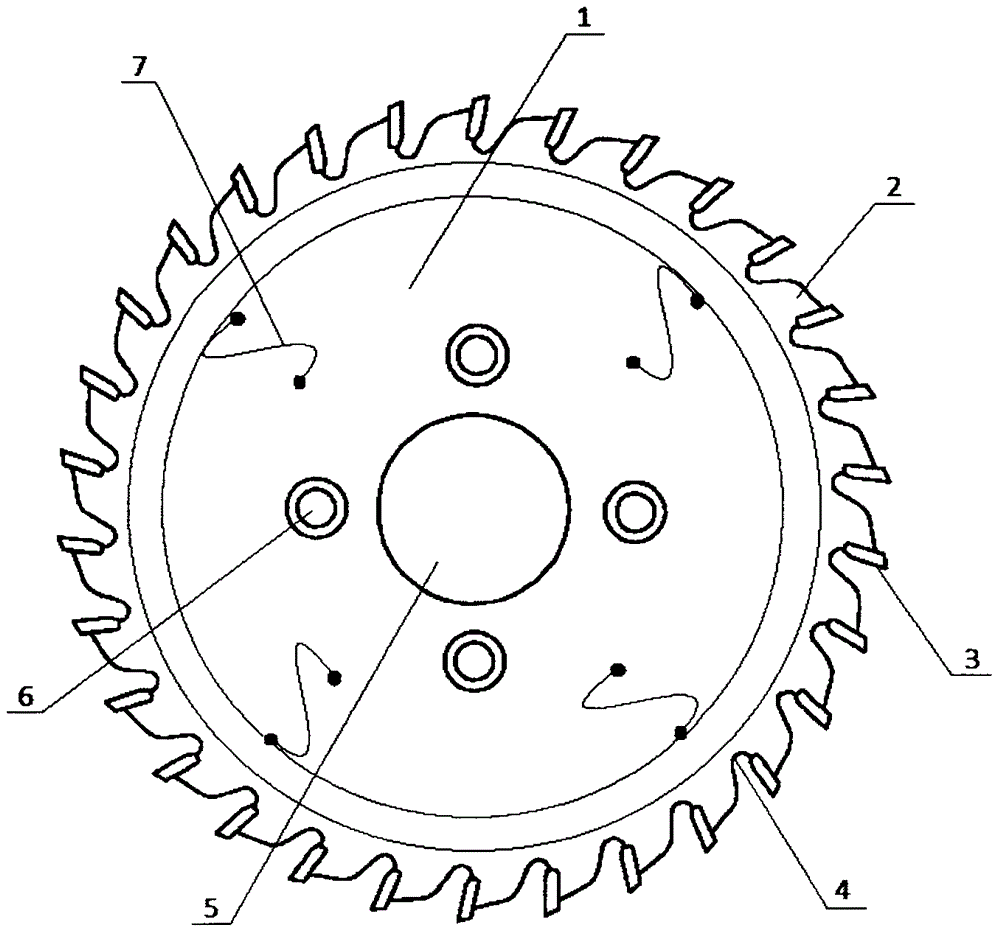

Oil manifold fish tail rapid cutting machine

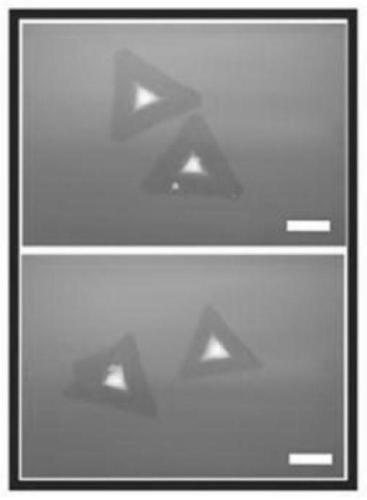

InactiveCN101324177AReduce cutting timeFast cutting speedBorehole/well accessoriesIsosceles trapezoidRight triangle

The invention relates to a fast oil pipe fish tail cutter which consists of a body and a tungsten steel cutting head and is characterized in that the body is designed to be a cylinder shape, the upper part of the body is provided with an oil pipe box, the center of the body is provided with a cutting fluid flow passage, the periphery of the lower part of the body is symmetrically provided with a right angle and acute angle triangle and isosceles trapezoid slot embedded with the tungsten steel cutting head, and a right triangle tungsten steel block and an isosceles trapezoid tungsten steel block are embedded in the slot. In the process of cutting the oil pipe fish tail, the cutter firstly cuts out a conical surface on the oil pipe fish tail and then cuts off the conical tip, thus shortening cutting time, speeding up the cutting, and gaining time for salvage and well repairing work.

Owner:刘华峰

Metal electrographite brush having high precision and good reliability and preparation method of metal electrographite brush

InactiveCN104882757AImprove density uniformityImprove conductivityRotary current collectorBrushes manufactureManganese(II) carbonateIron powder

Owner:ANHUI TIANYU ELECTROMECHANICAL

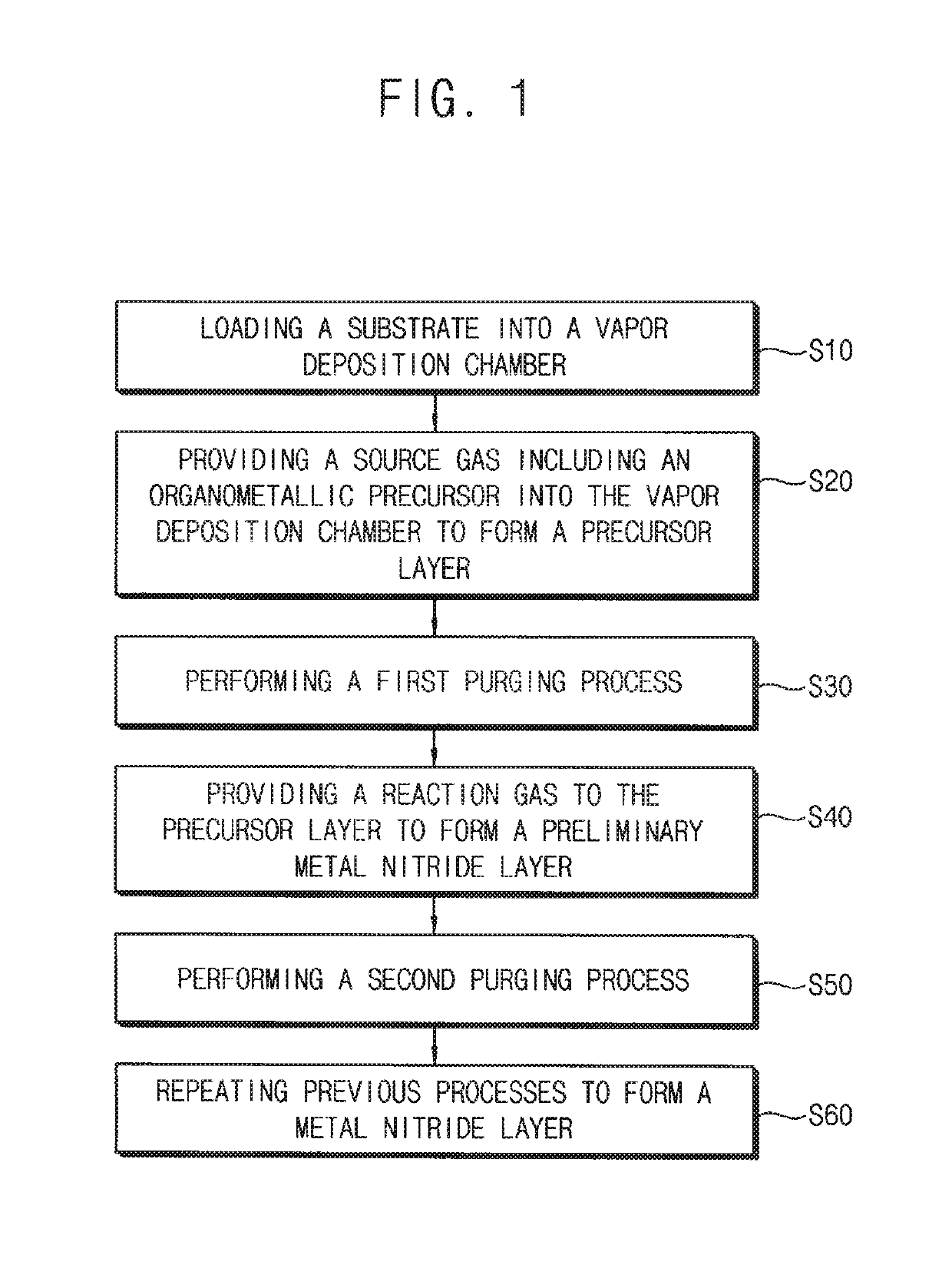

Organometallic precursors, methods of forming a layer using the same and methods of manufacturing semiconductor devices using the same

ActiveUS10361118B2Control damageSemiconductor/solid-state device manufacturingCapacitorsSilyleneSemiconductor

Owner:SAMSUNG ELECTRONICS CO LTD +1

Preparation method of catalyst for catalytic oxidation synthesizing of acrolein through propylene

InactiveCN103285913AHigh catalytic activityMolecular sieve catalystsOrganic compound preparationCatalytic oxidationManganese

Owner:陈和平

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap