Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Single crystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A single crystal or monocrystalline solid is a material in which the crystal lattice of the entire sample is continuous and unbroken to the edges of the sample, with no grain boundaries. The absence of the defects associated with grain boundaries can give monocrystals unique properties, particularly mechanical, optical and electrical, which can also be anisotropic, depending on the type of crystallographic structure. These properties, in addition to making them precious in some gems, are industrially used in technological applications, especially in optics and electronics.

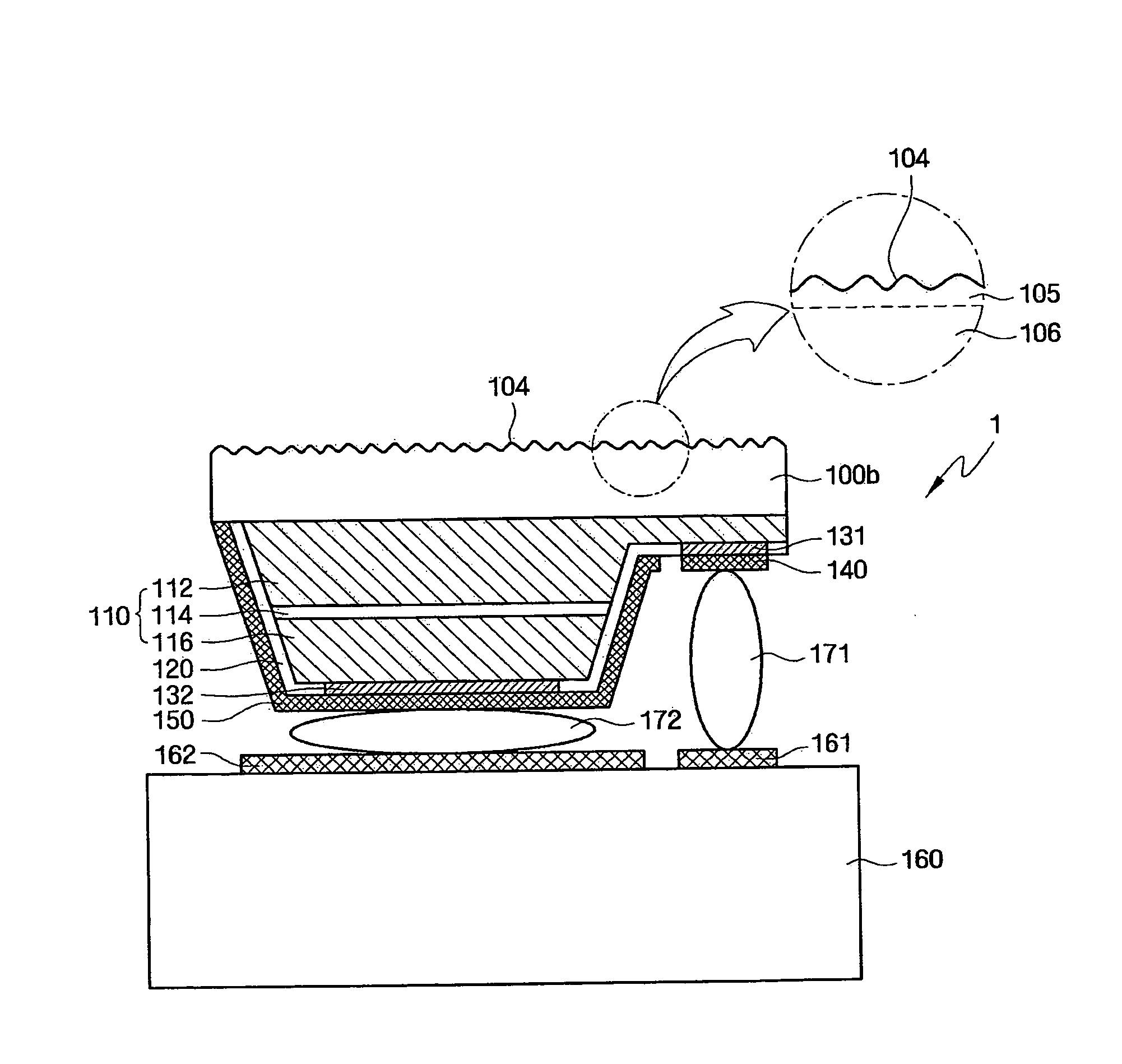

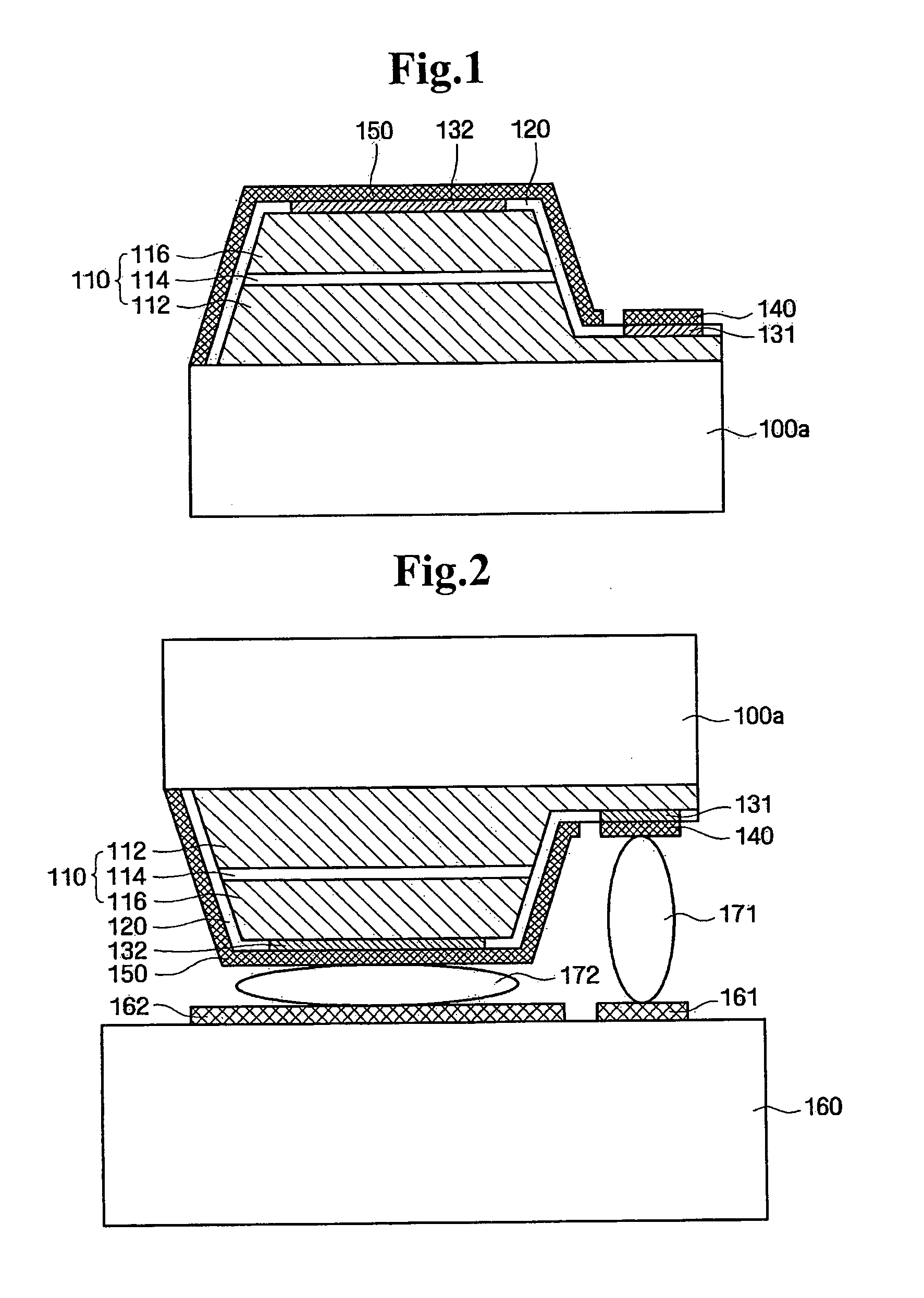

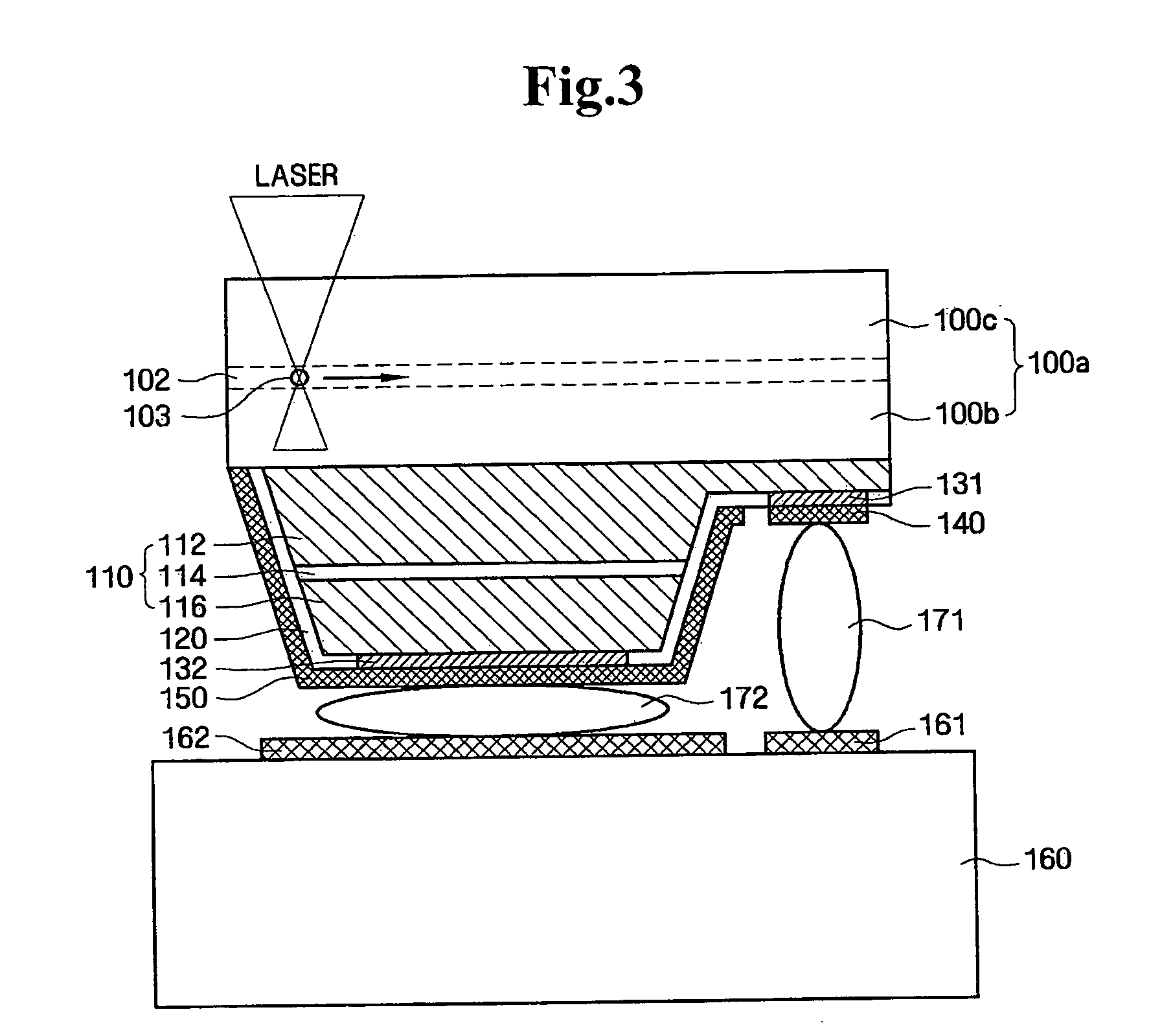

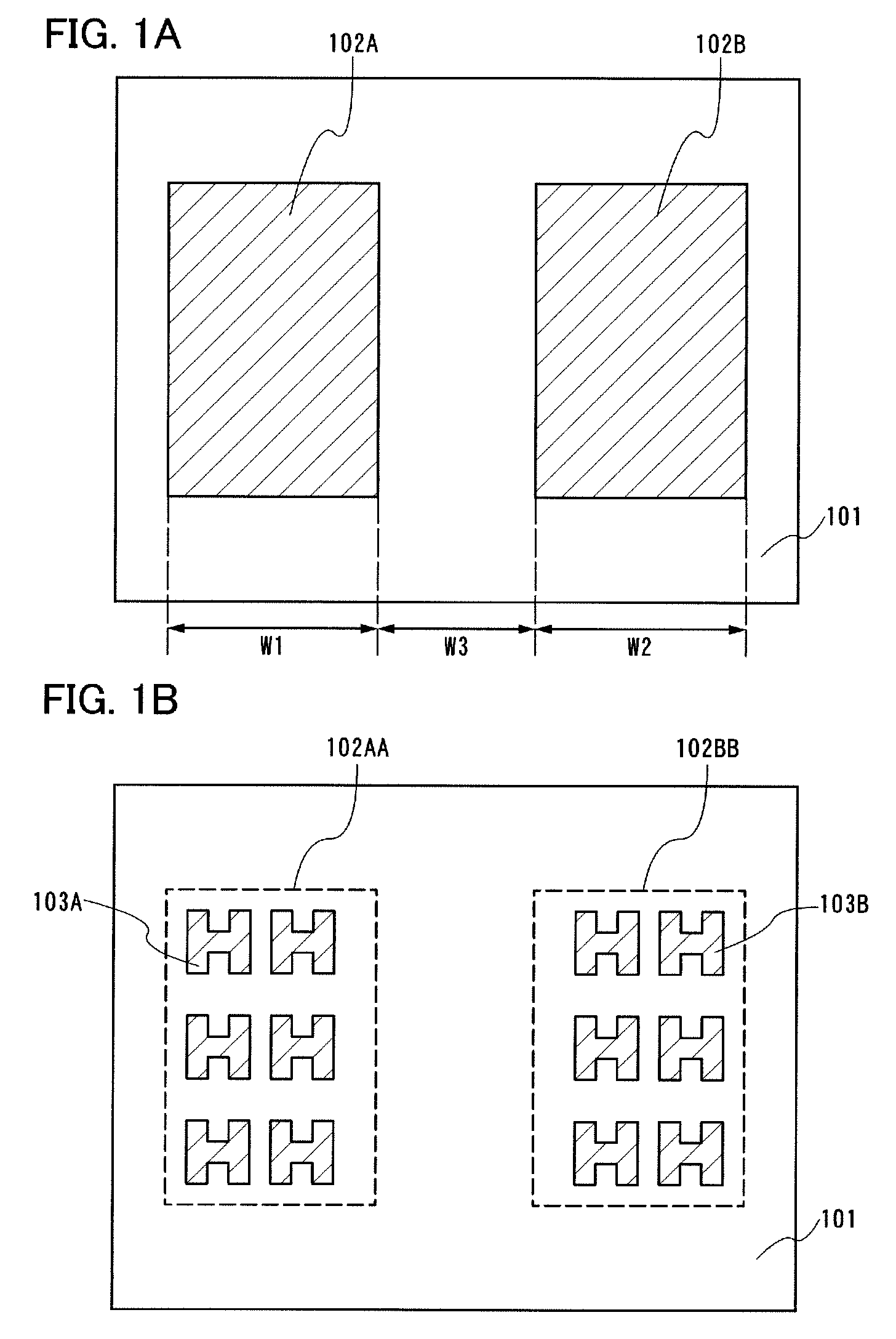

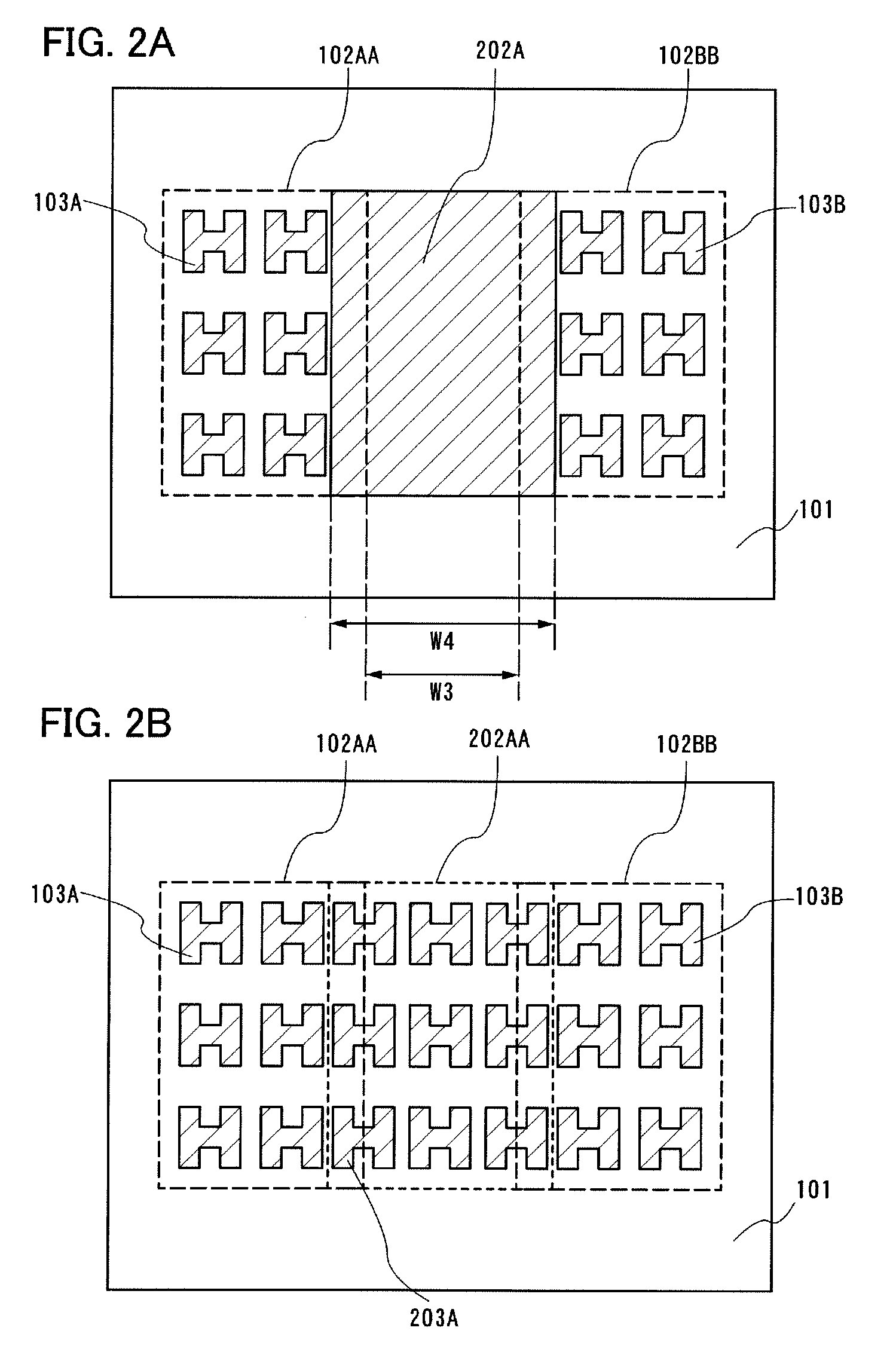

Method of fabricating light-emitting apparatus with improved light extraction efficiency and light-emitting apparatus fabricated using the method

ActiveUS20100120183A1Light extraction efficiency can be improvedSolid-state devicesSemiconductor/solid-state device manufacturingLight beamSingle crystal

Owner:SAMSUNG ELECTRONICS CO LTD

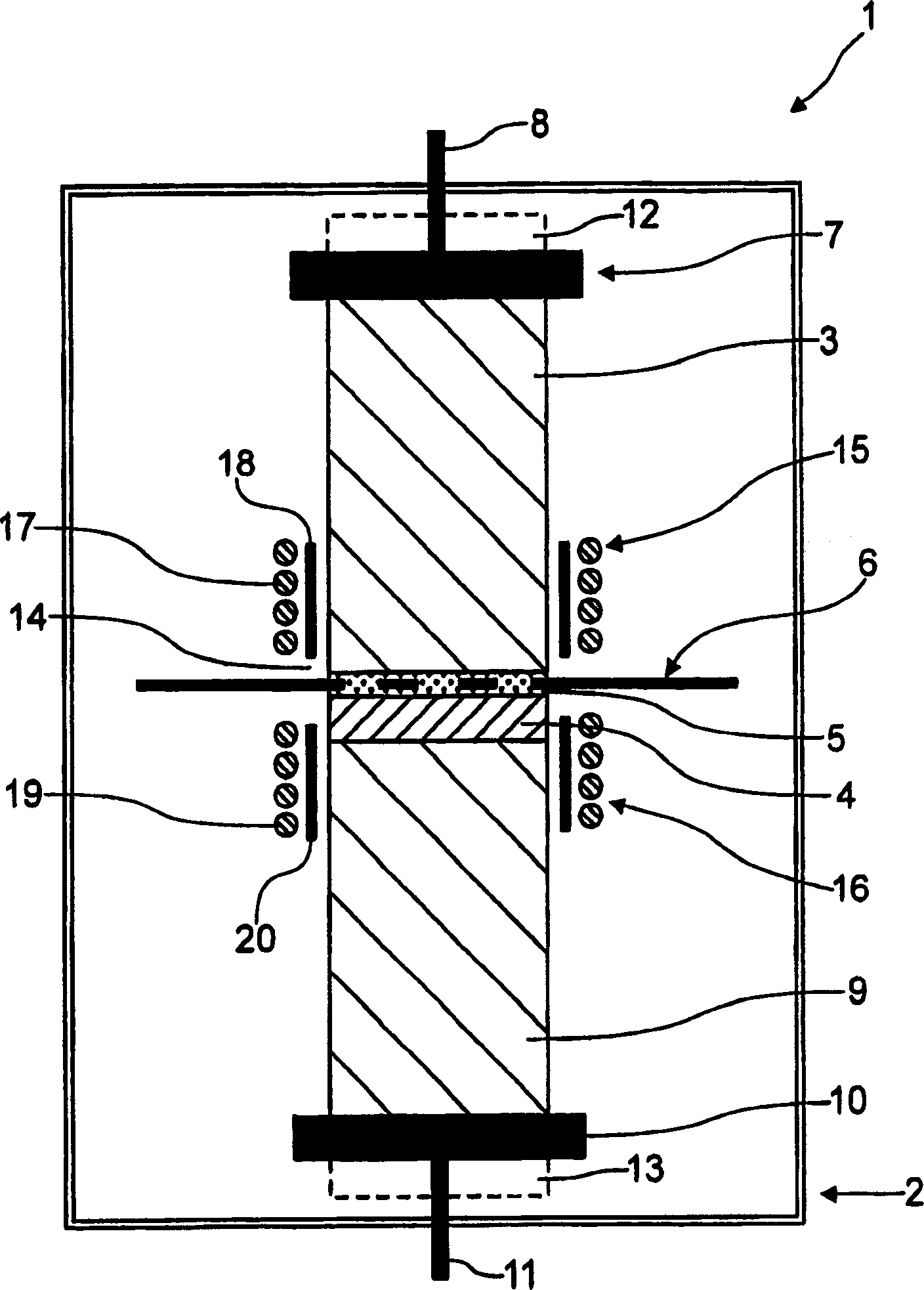

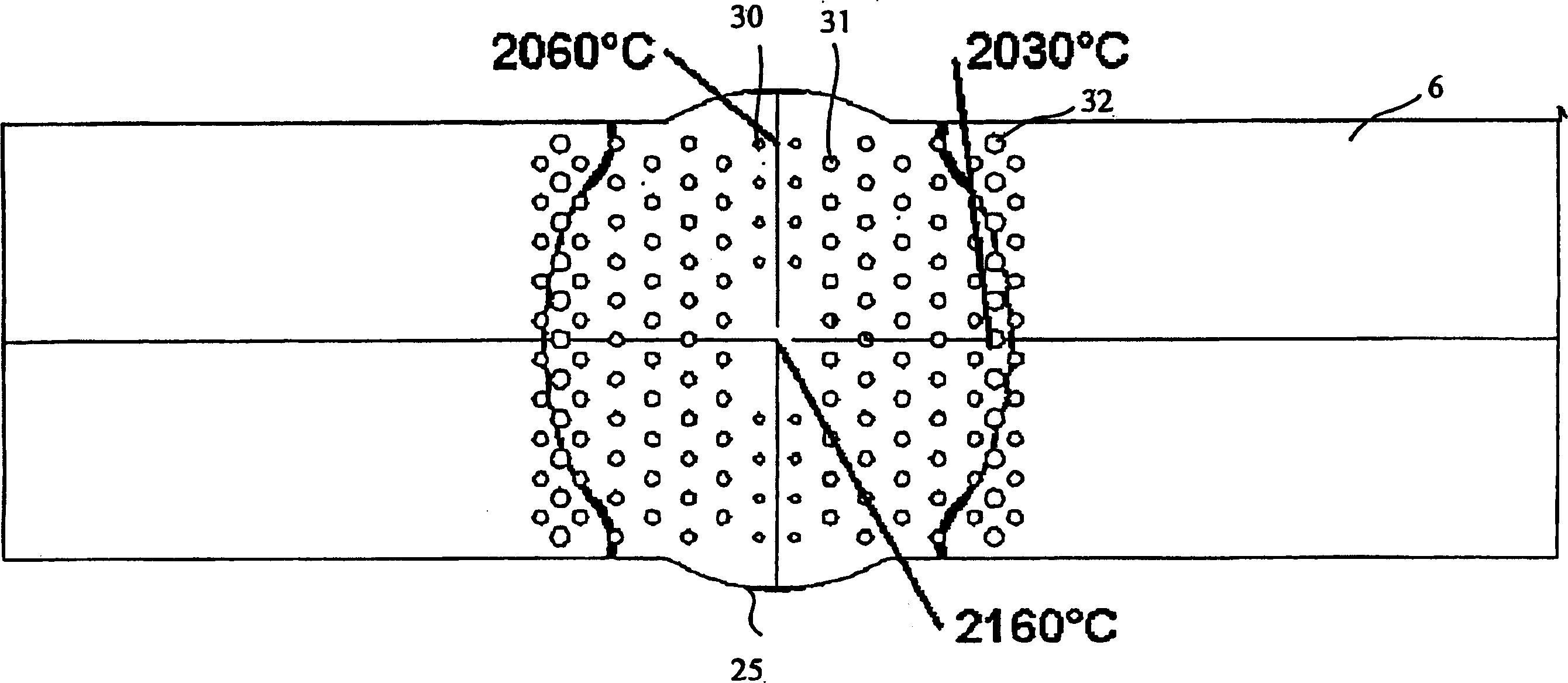

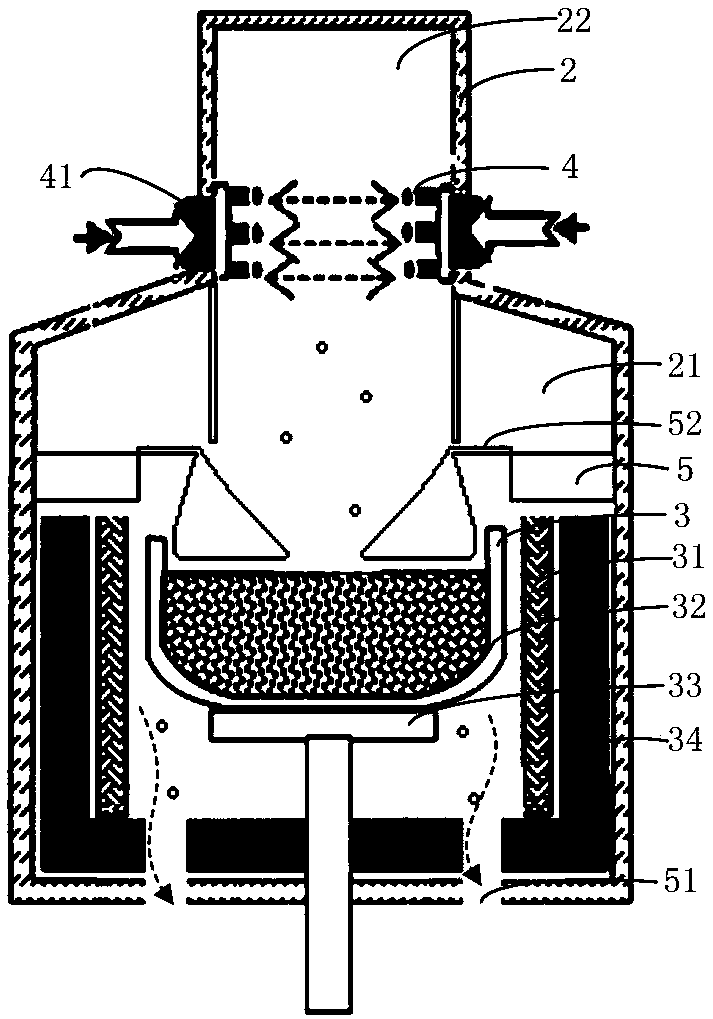

Method and apparatus for preparing major diameter single crystal

InactiveCN1847468AMake up for heat lossHigh Inductive Heat InputPolycrystalline material growthBy zone-melting liquidsSingle crystalEngineering

Owner:SCHOTT AG

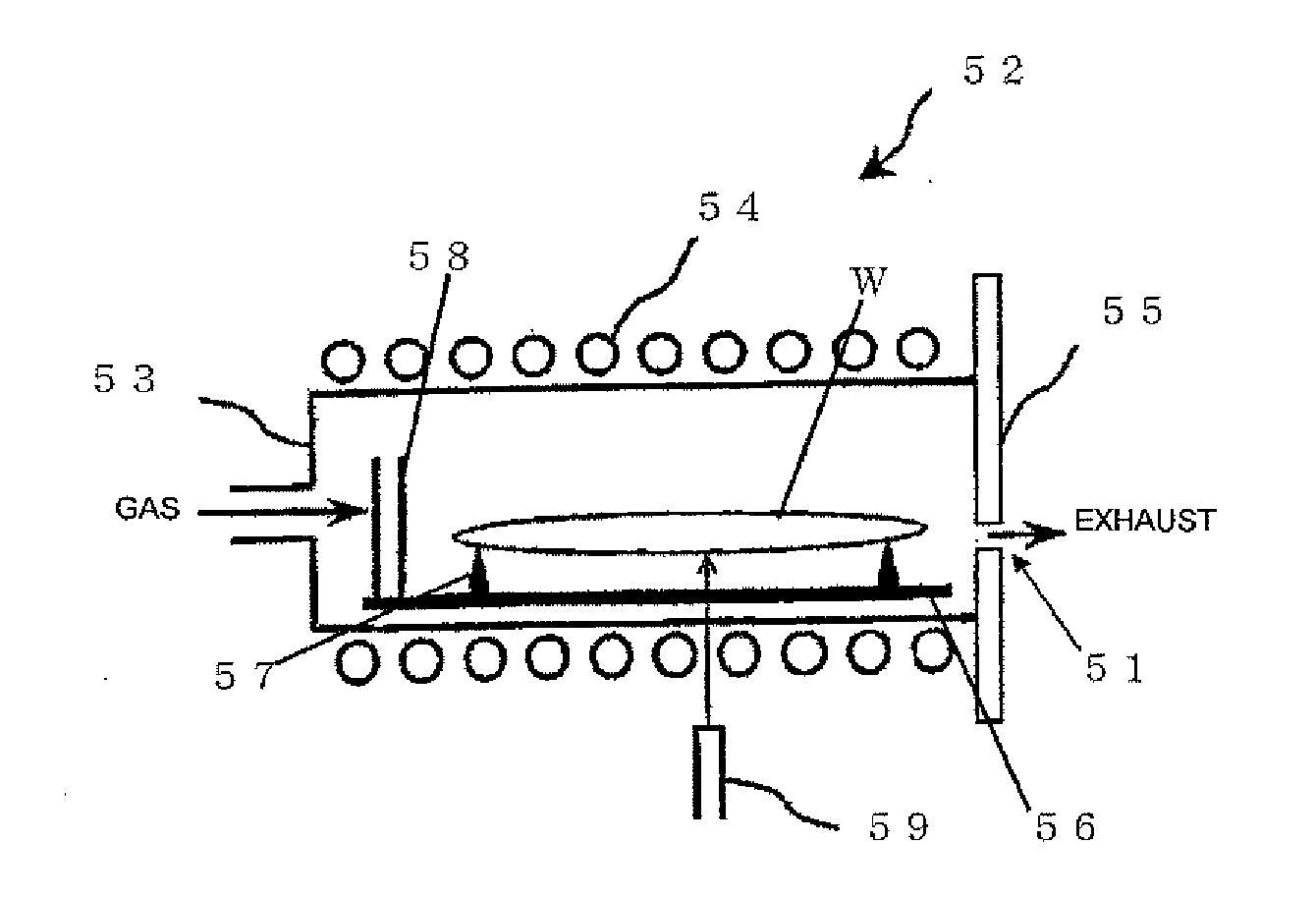

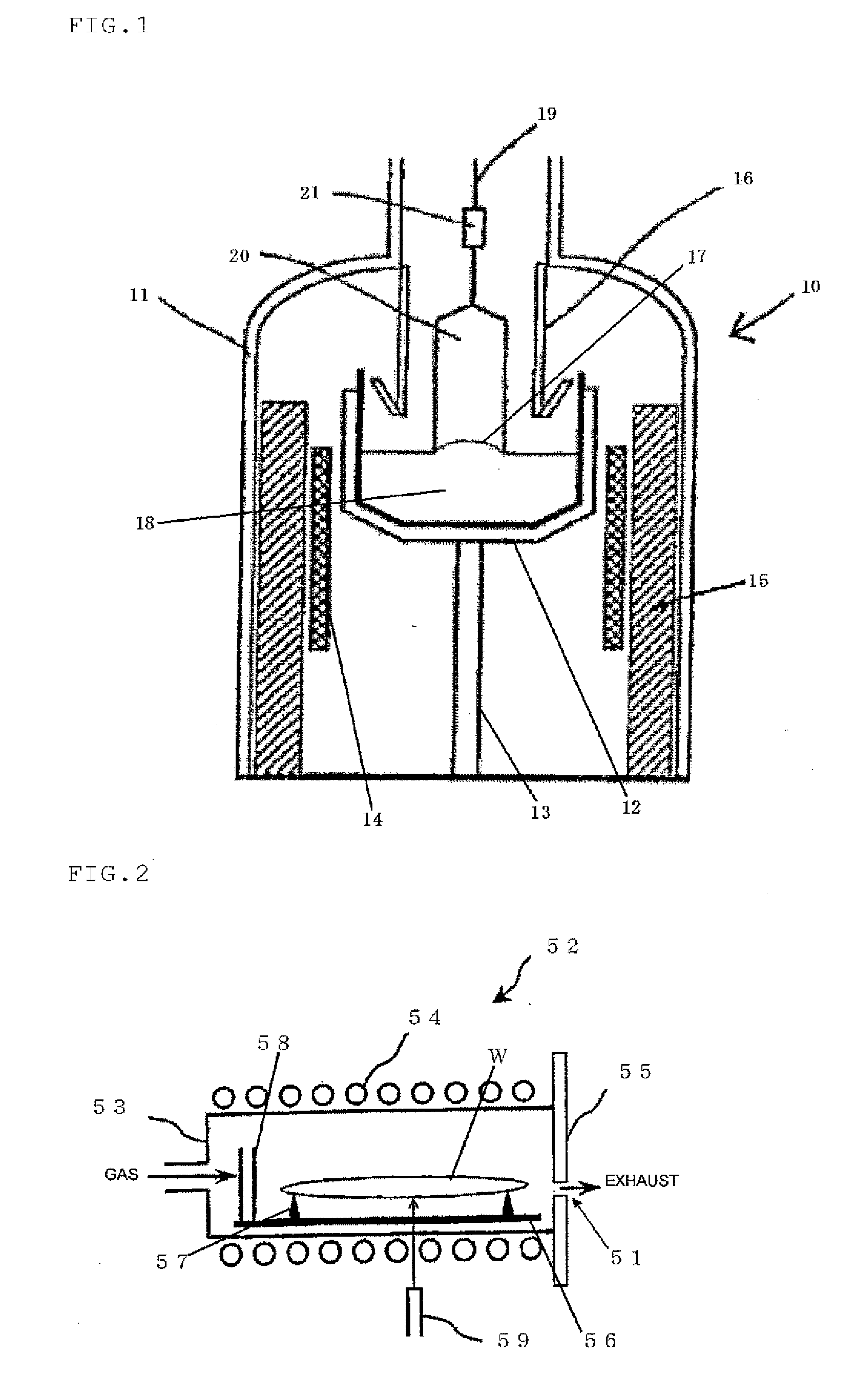

Method for manufacturing semiconductor device

InactiveUS20090001387A1Easy to operateImprove current characteristicsTransistorSolid-state devicesDevice materialSingle crystal

Owner:SEMICON ENERGY LAB CO LTD

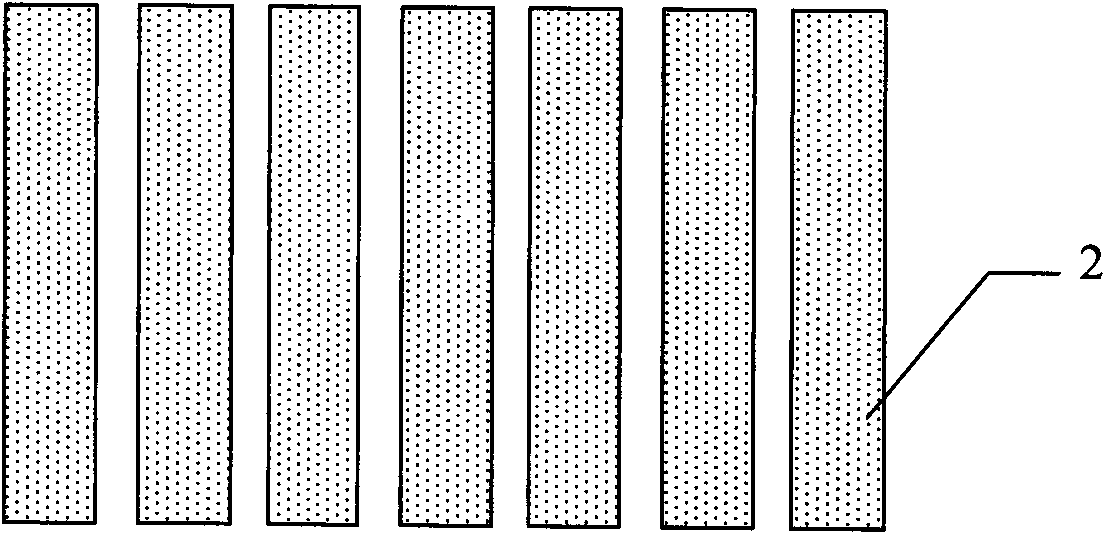

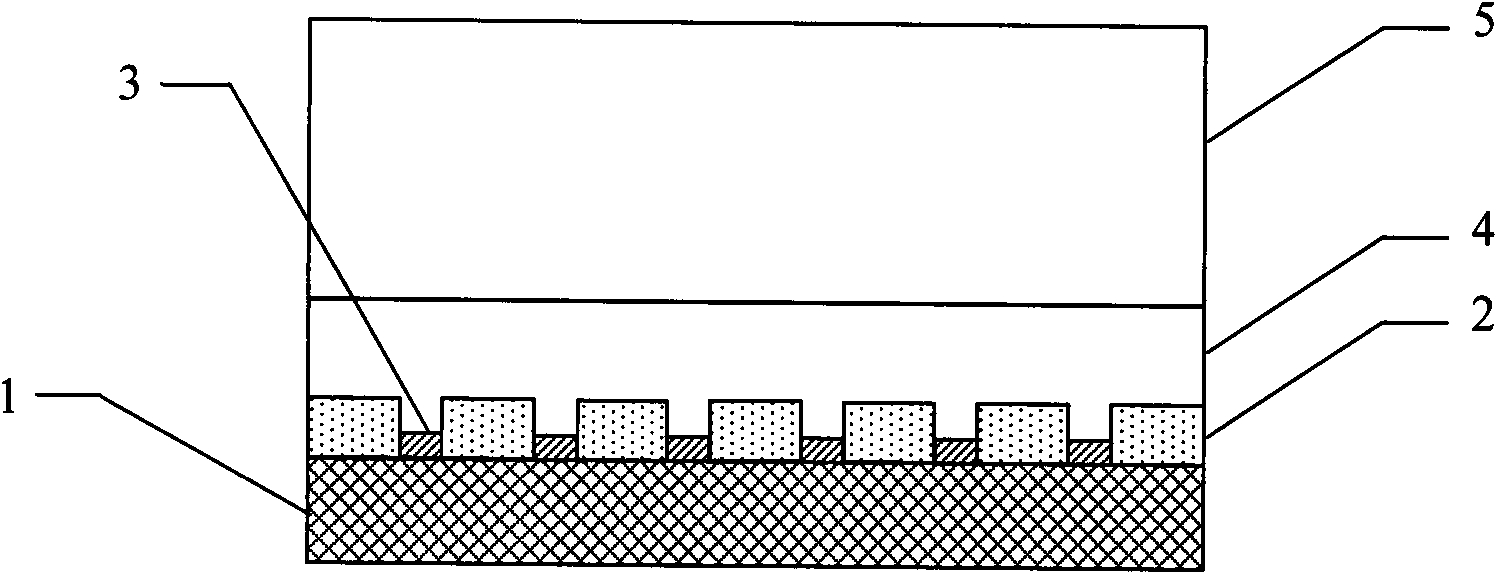

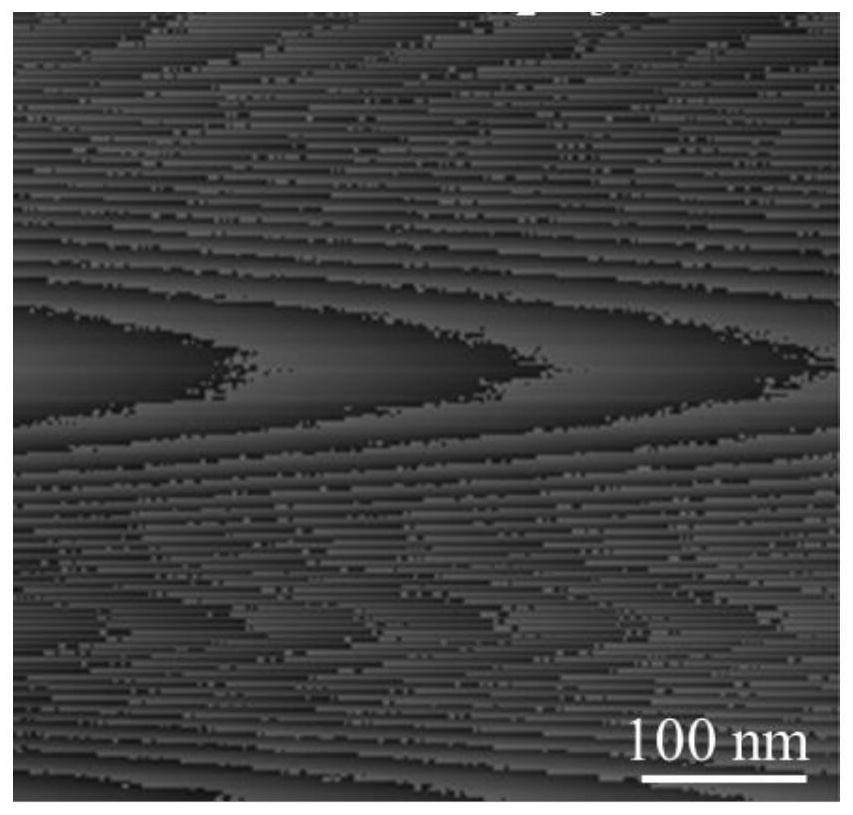

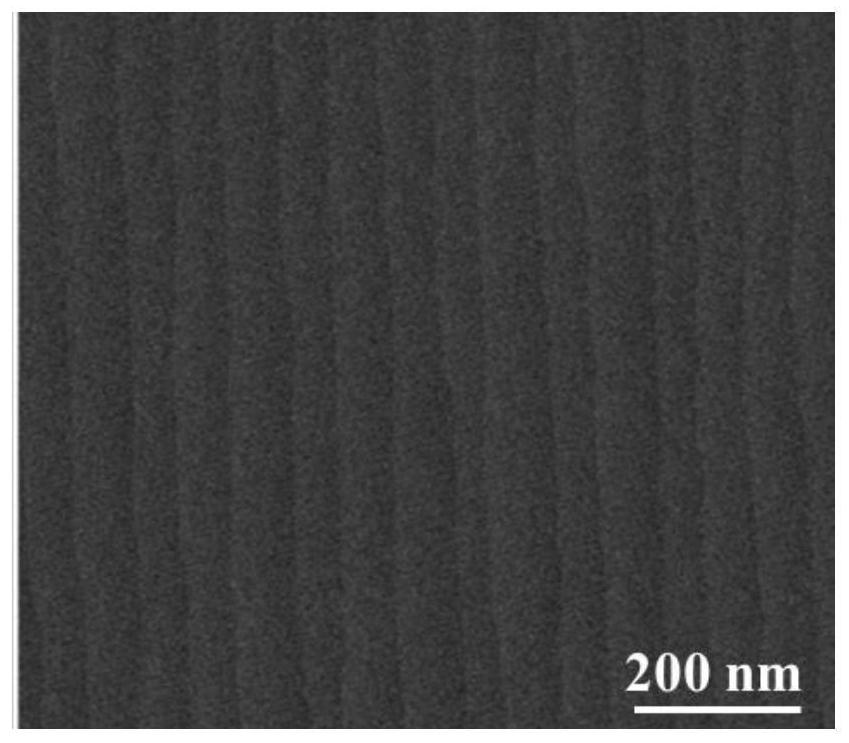

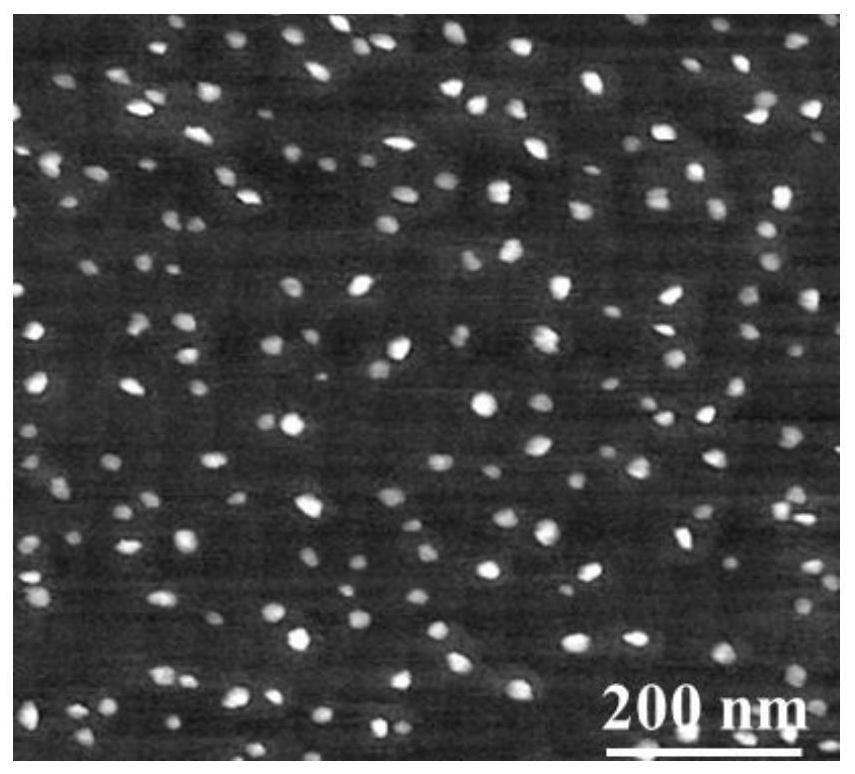

Silver nano lattice surface enhanced raman active substrate and preparation method thereof

InactiveCN102590179AUniform shapeOptimal Control StructureRaman scatteringNanotechnologyNanodotSingle crystal

The invention discloses a silver nano lattice surface enhanced raman active substrate and a preparation method thereof. According to the substrate, silicon single crystal is used as an underlay; a silver nanoparticle array structure is deposited on the silicon surface; the particle size of the silver nanoparticles is 30-90 nm; and the center distance of the particles is 99-111 nm. The silver nano lattice surface enhanced raman active substrate provided by the invention has a uniform shape and a controllable structure, and has an obvious surface raman enhancement effect on analytes of different concentrations, and an enhancement signal is uniform and stable. According to the method, the structural parameters and the shape of a silver nano lattice can be adjusted according to structural parameters of an ultra-thin aluminum oxide template, so that different influences of different metal nano lattice substrates on a raman surface enhancement effect are realized. The substrate and the method have the advantages of easiness for operation, low cost and easiness for industrial production.

Owner:SHANGHAI UNIV

Method for preparing self-supporting mono-crystal gallium nitride substrate

InactiveCN101685768AUniform stress reliefImprove yieldLaser detailsSemiconductor/solid-state device manufacturingLaser lightStress relief

Owner:PEKING UNIV

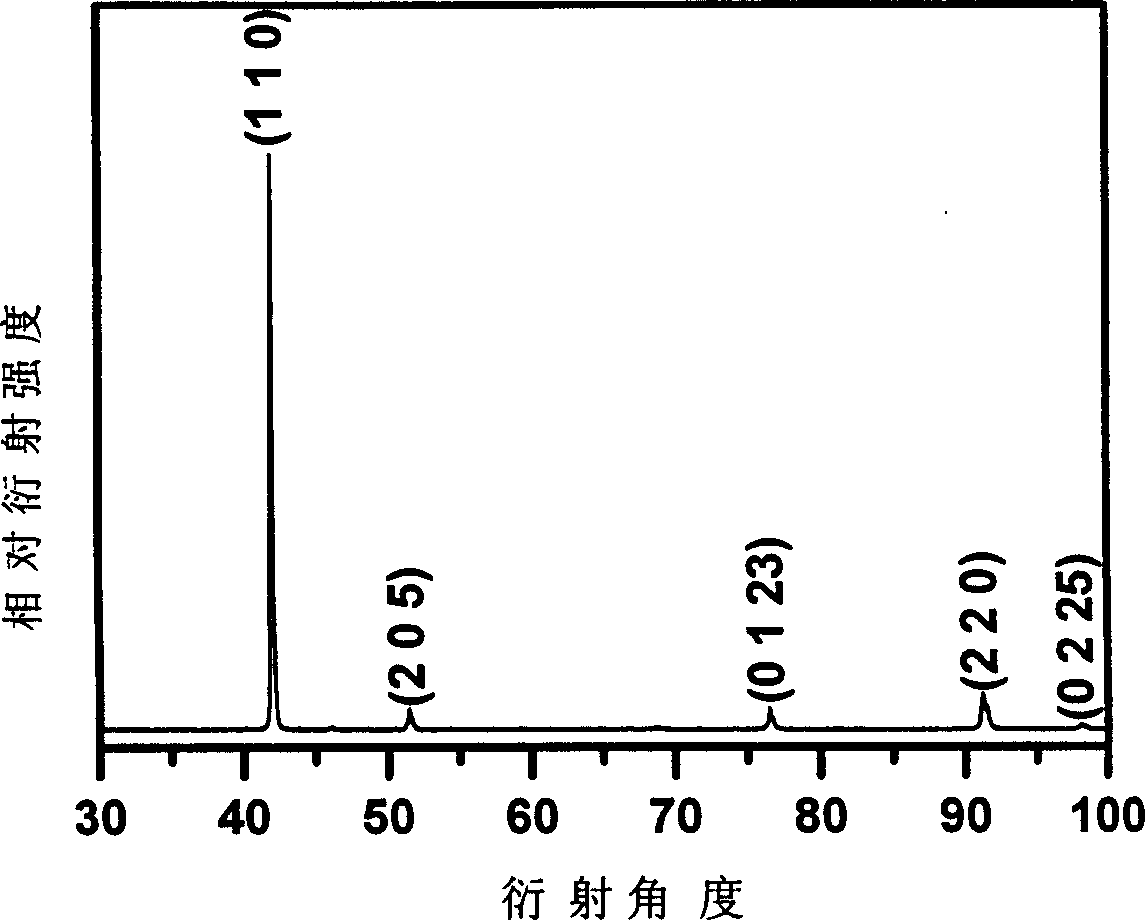

Oxygen atmosphere control preparation method for alpha-axis oriented Yt-Ba-Cu-O superconductive thick film

InactiveCN1970849APolycrystalline material growthSuperconductors/hyperconductorsSingle crystalCopper

Owner:SHANGHAI JIAO TONG UNIV

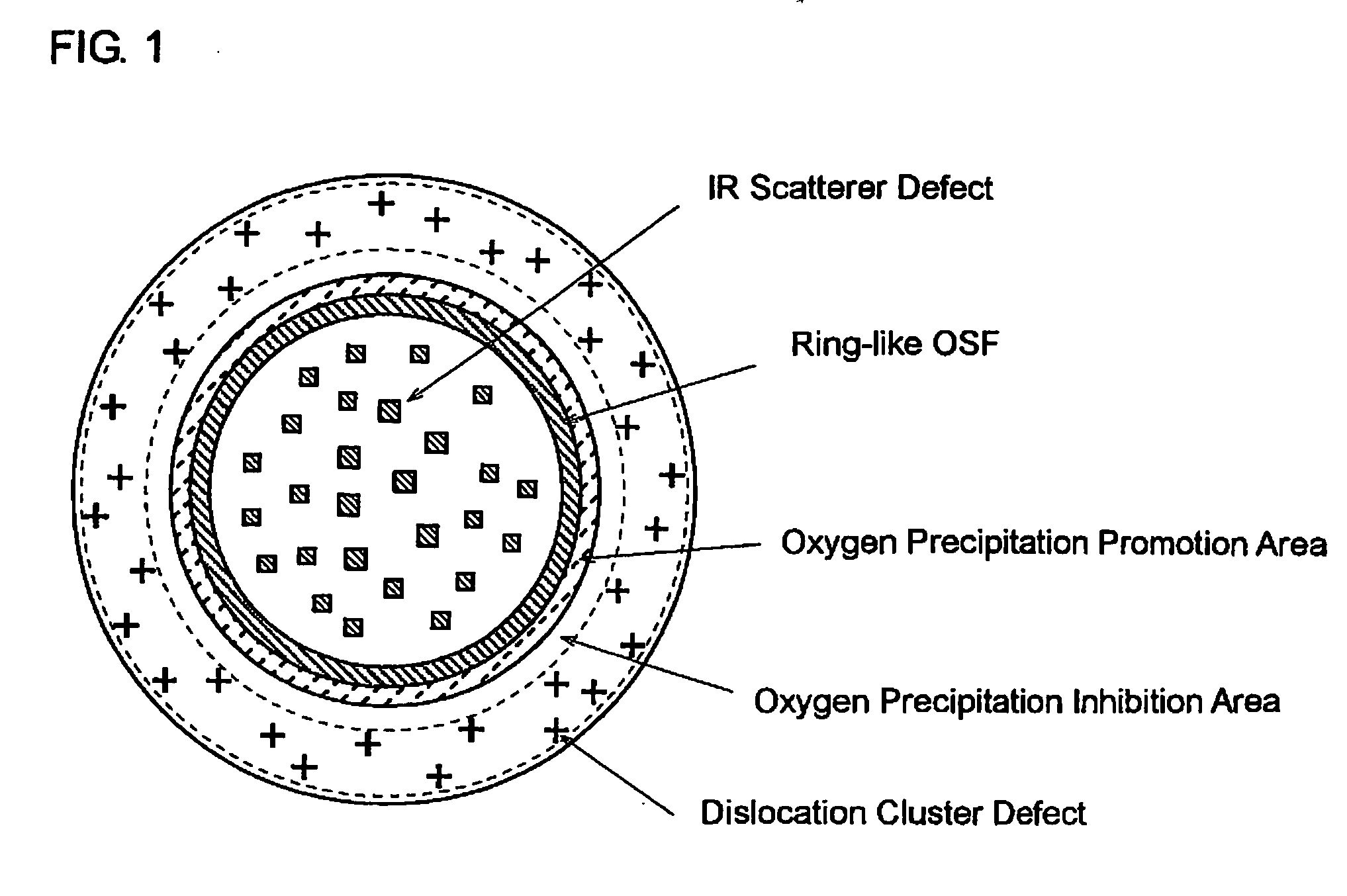

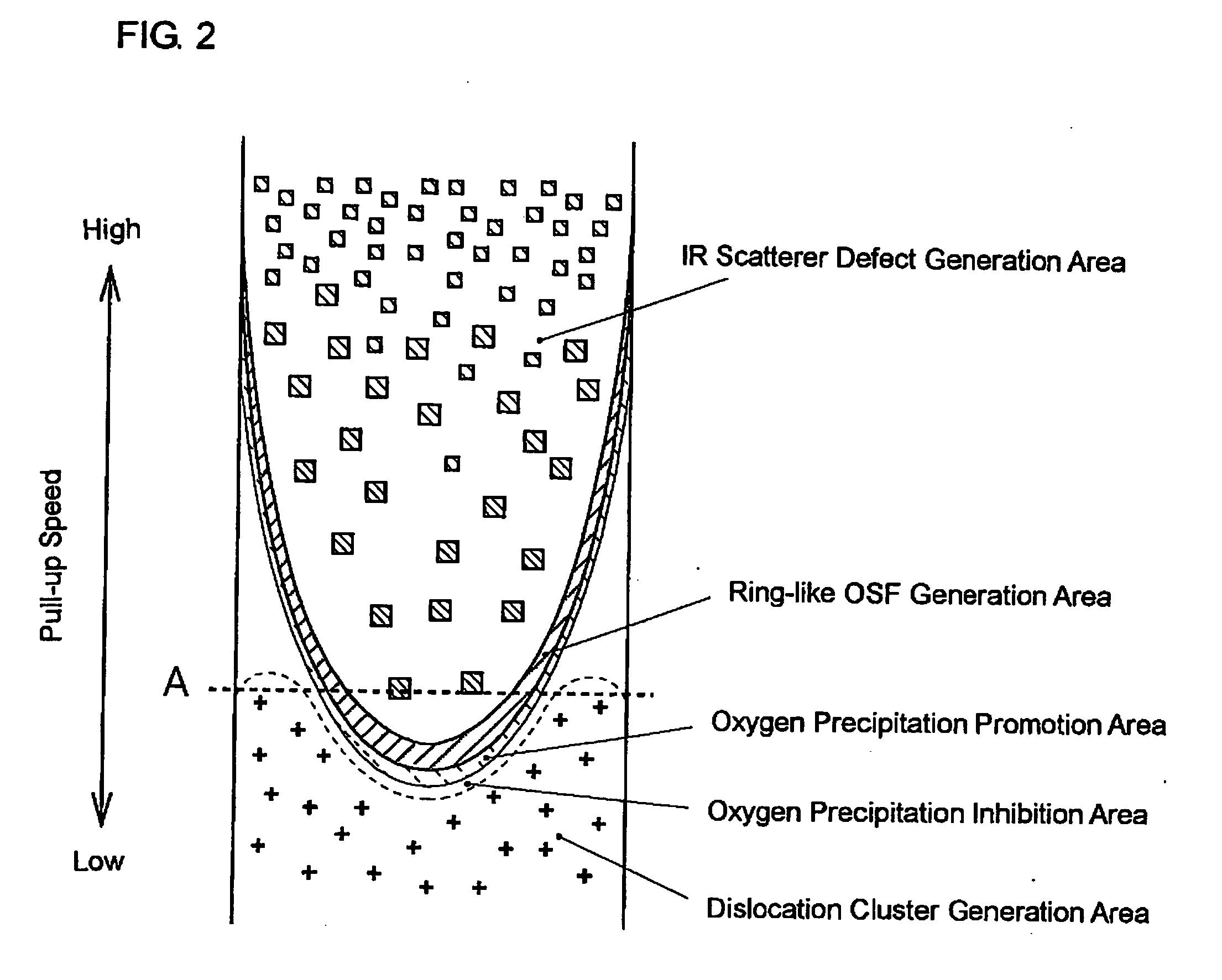

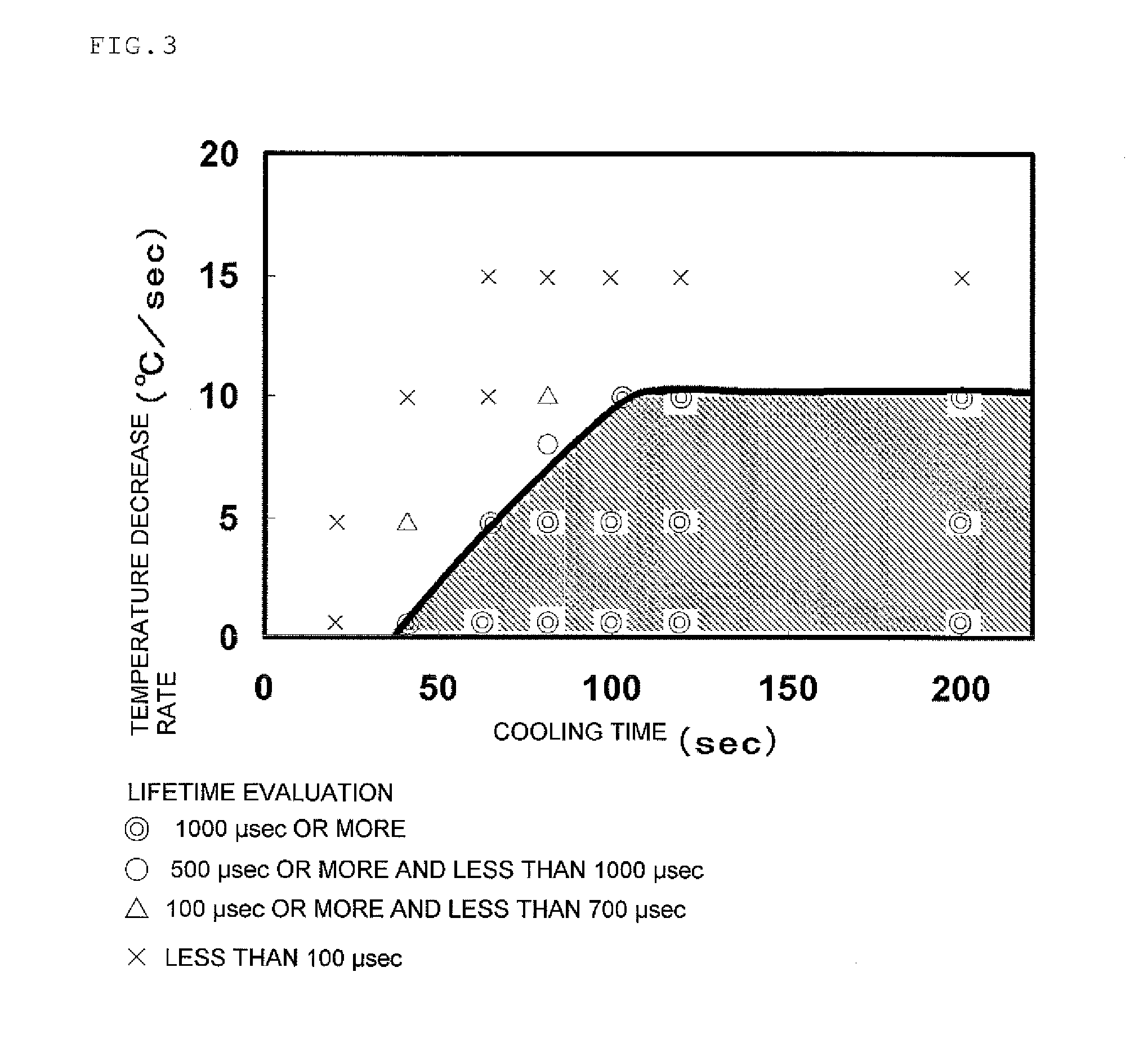

Method for growing silicon single crystal, and silicon wafer

InactiveUS20060225639A1Stable productionEasy to adaptPolycrystalline material growthBy pulling from meltHigh densityMiniaturization

Owner:SUMCO CORP

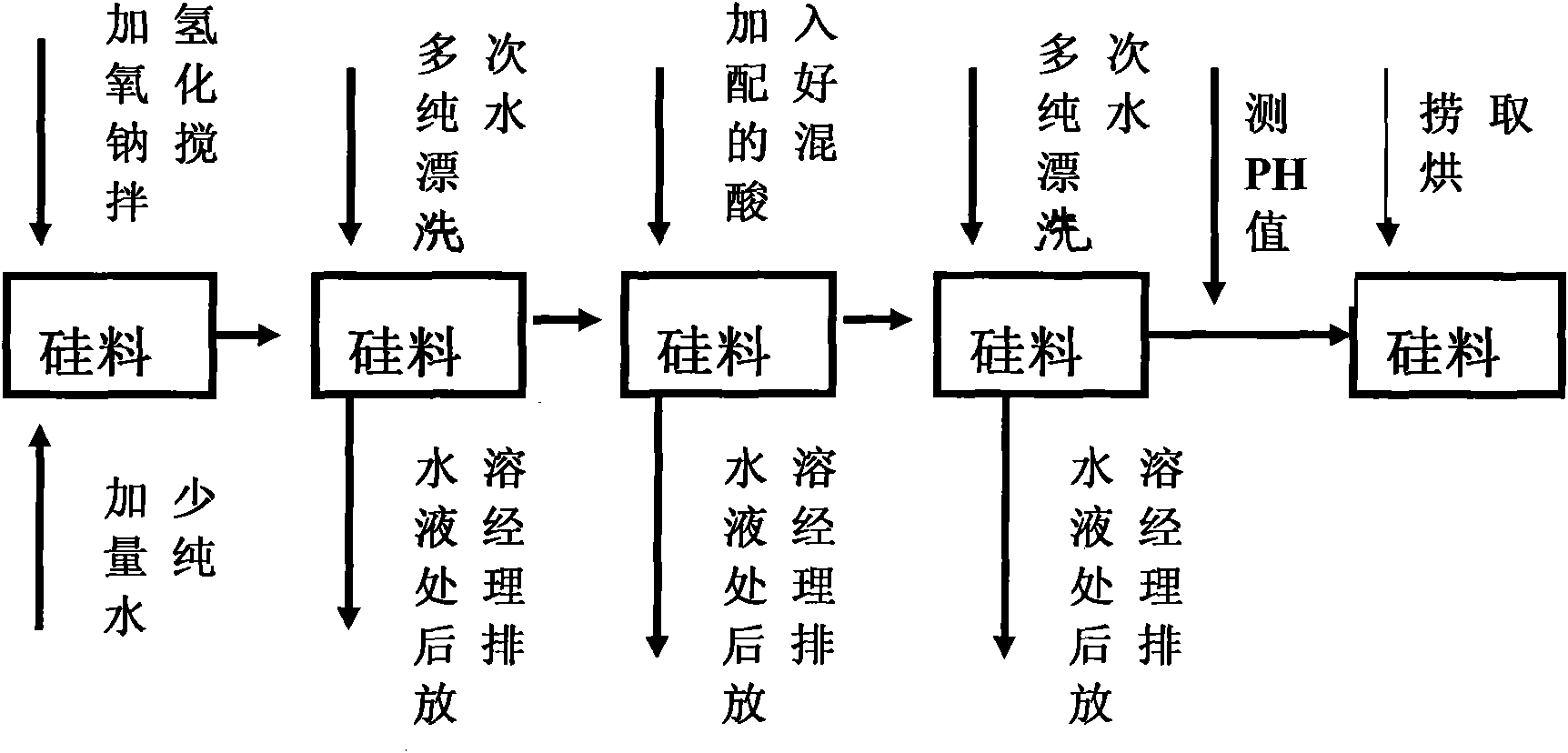

Method for cleaning graphitic silicon materials

Owner:HEFEI JINGKUN NEW ENERGY

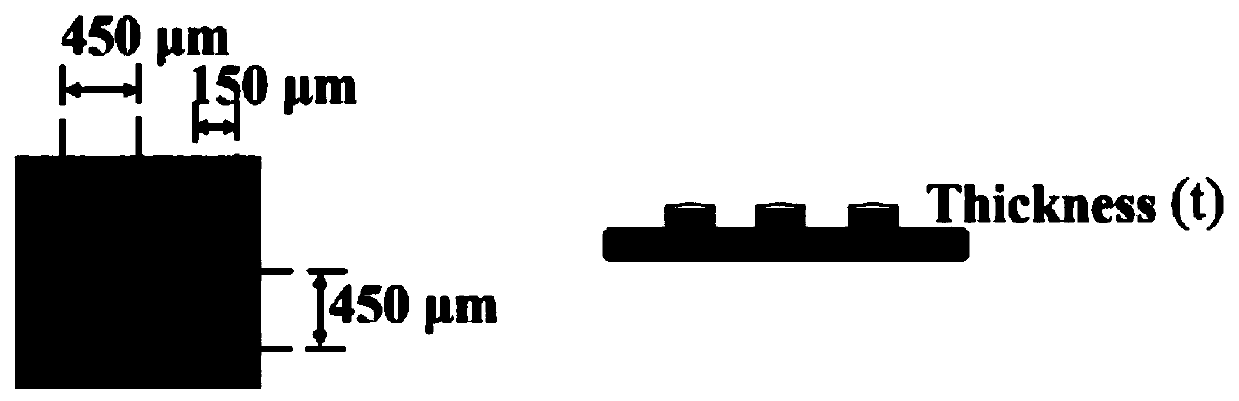

Pt Ni Al bonding layer doped with binary trace active elements and capable of being completely oxidation resisting at 1200 DEG C and preparation method thereof

ActiveCN103966615AImproved high temperature oxidation resistanceImprove high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionGas phase

The present invention discloses a Pt Ni Al bonding layer doped with binary trace active elements and capable of being completely oxidation resisting at 1200 DEG C and a preparation method thereof and belongs to the field of novel thermal barrier coatings and the preparation technologies. According to the invention, firstly, a Pt layer with the thickness of 5-10 microns is prepared on a nickel base monocrystal high temperature alloy matrix through the plating or the electron beam physical vapor deposition method, and then a NiAlHfZr coating with the thickness of 20-60 microns is deposited on the Pt layer through the electron beam physical vapor deposition method. The Pt layer reduces the interfacial holes and effectively improves the adhesion of an oxidation film; binary doping of Hf, Zr enables the NiAl coating surface to be smoother and denser and enables the oxidation film generated during the oxidation process on the coating surface to be straighter, especially with little oxidation increase, and greatly improves the oxidation resistance of the coating. The Pt Ni Al bonding layer is completely oxidation resisting at 1200 DEG C. The service life of the coating is prolonged to certain degree through doping of binary elements namely Hf and Zr and Pt modification.

Owner:BEIHANG UNIV

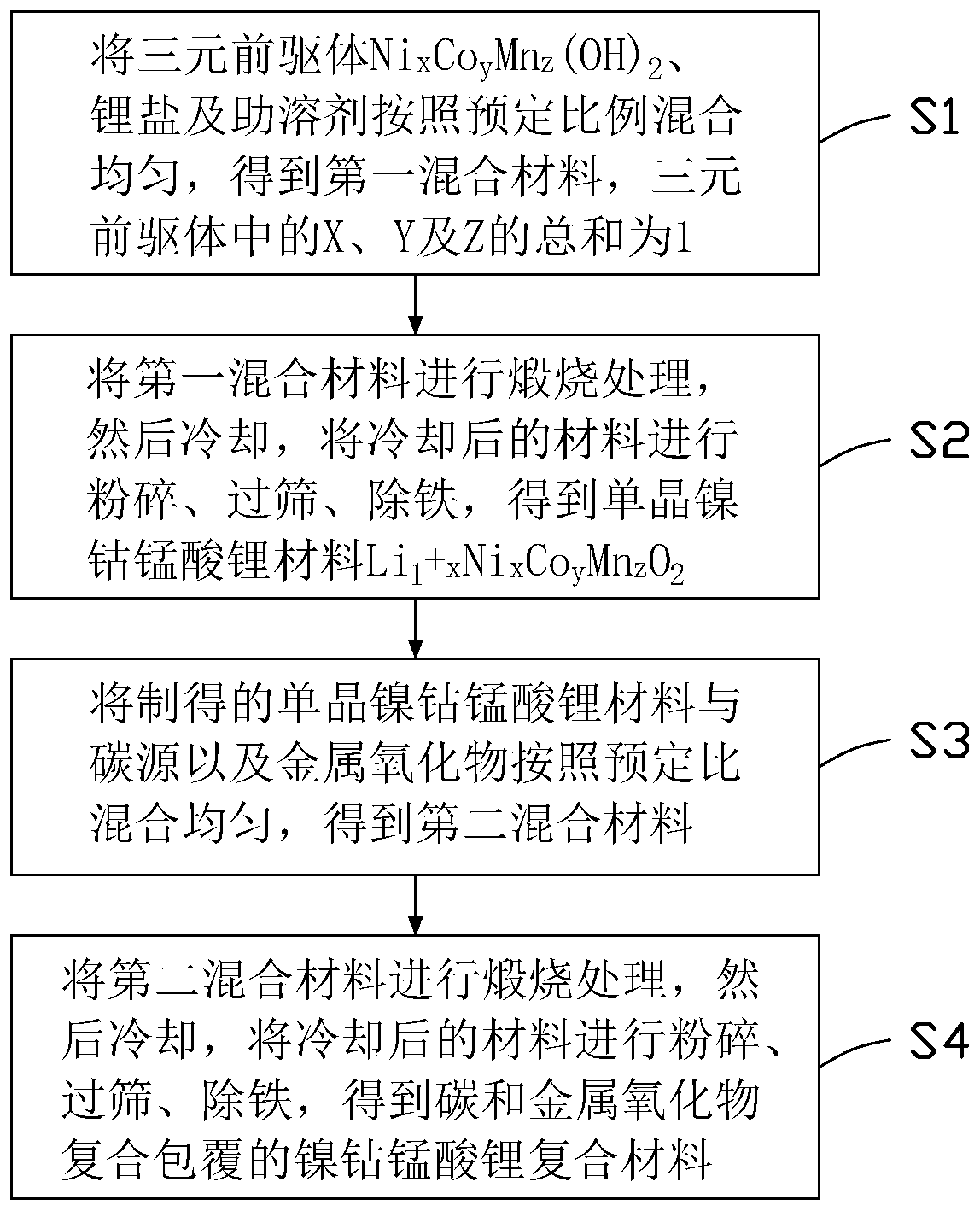

Nickel cobalt lithium manganate composite material and preparation method thereof

Owner:ZHONGTIAN EMERGING MATERIALS CO LTD

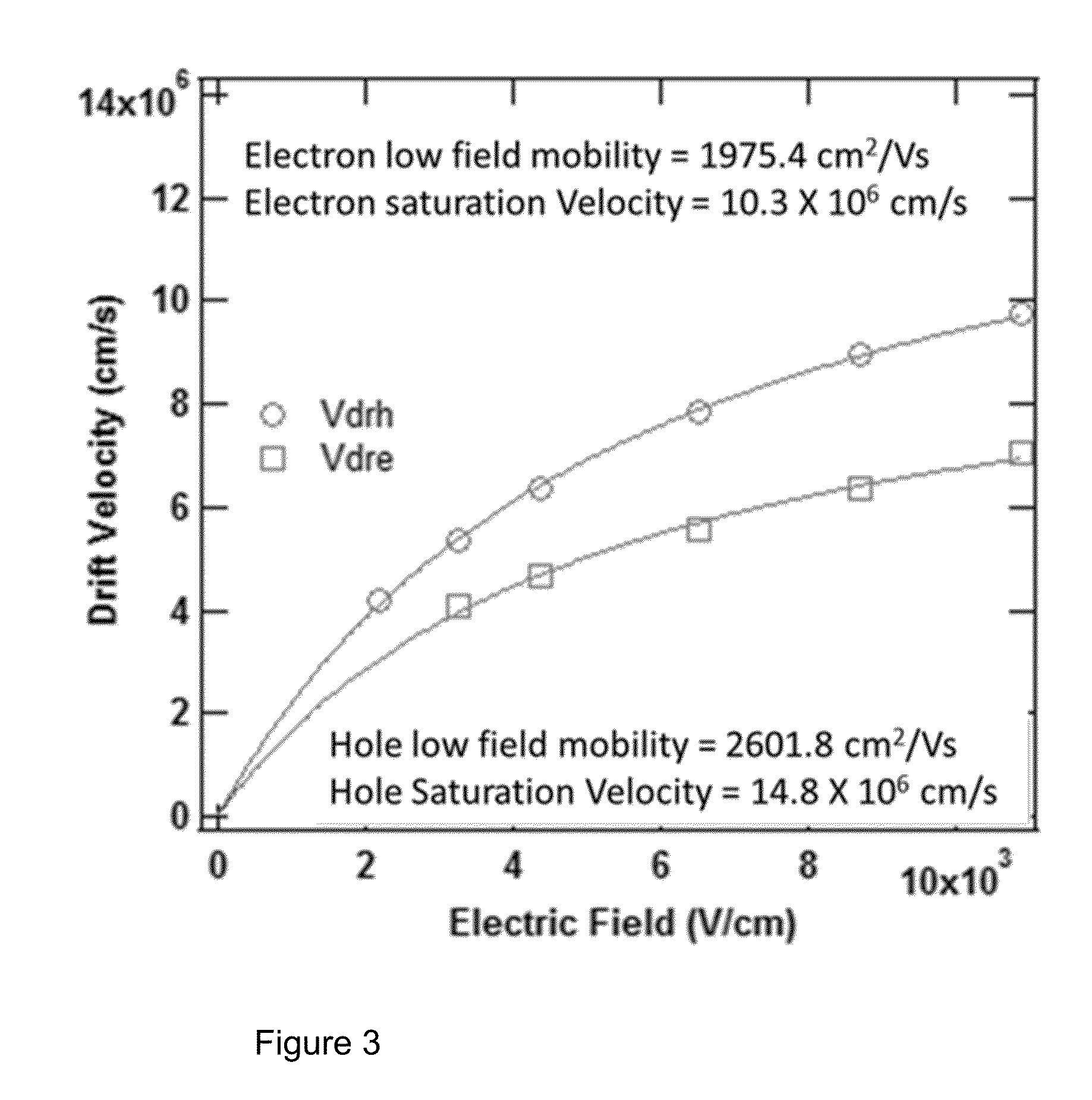

Electronic device grade single crystal diamonds and method of producing the same

ActiveUS20160201221A1Reduce crystal defect densityPolycrystalline material growthUltra-high pressure processesMicrowaveSingle crystal

Owner:IIA TECH

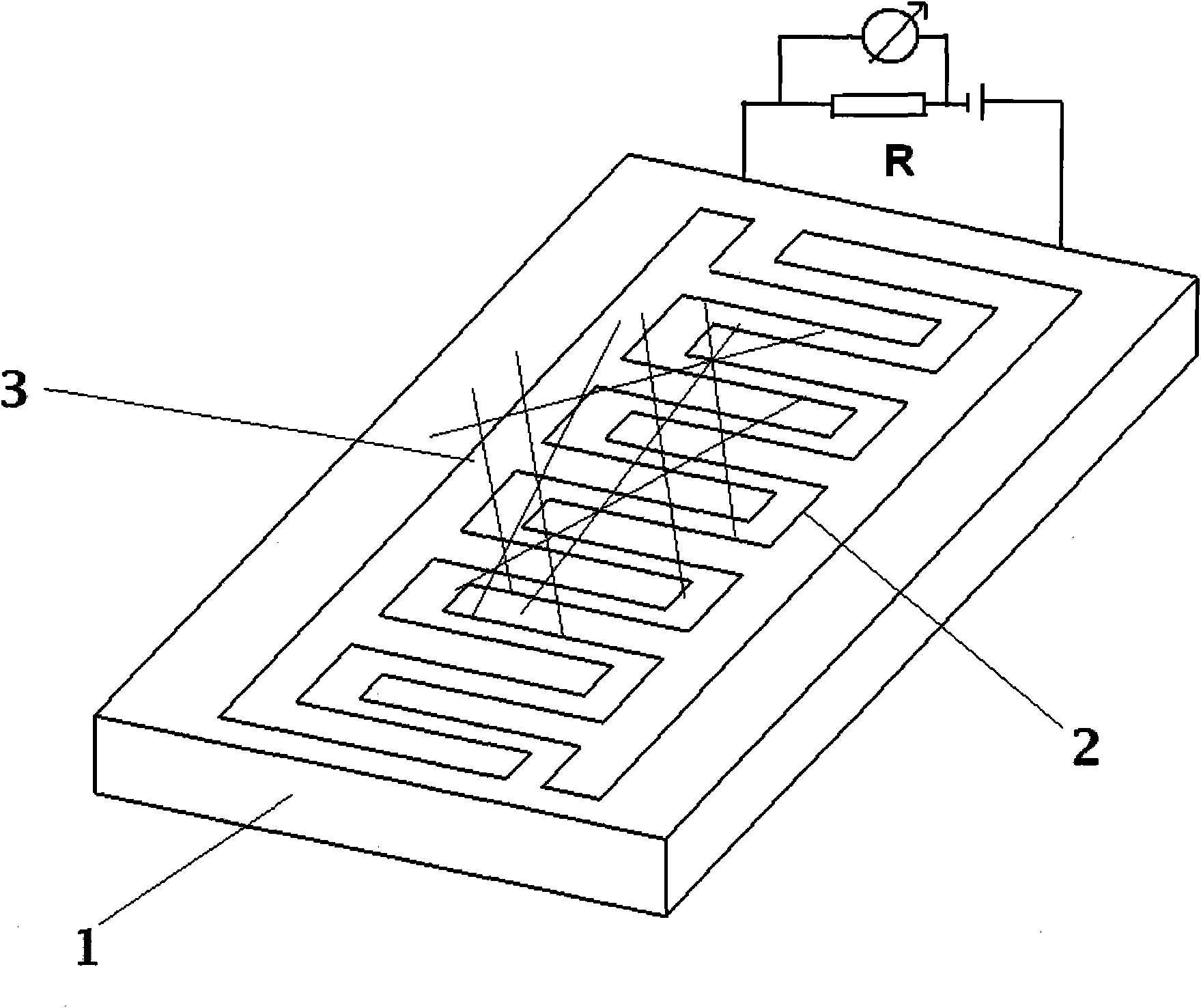

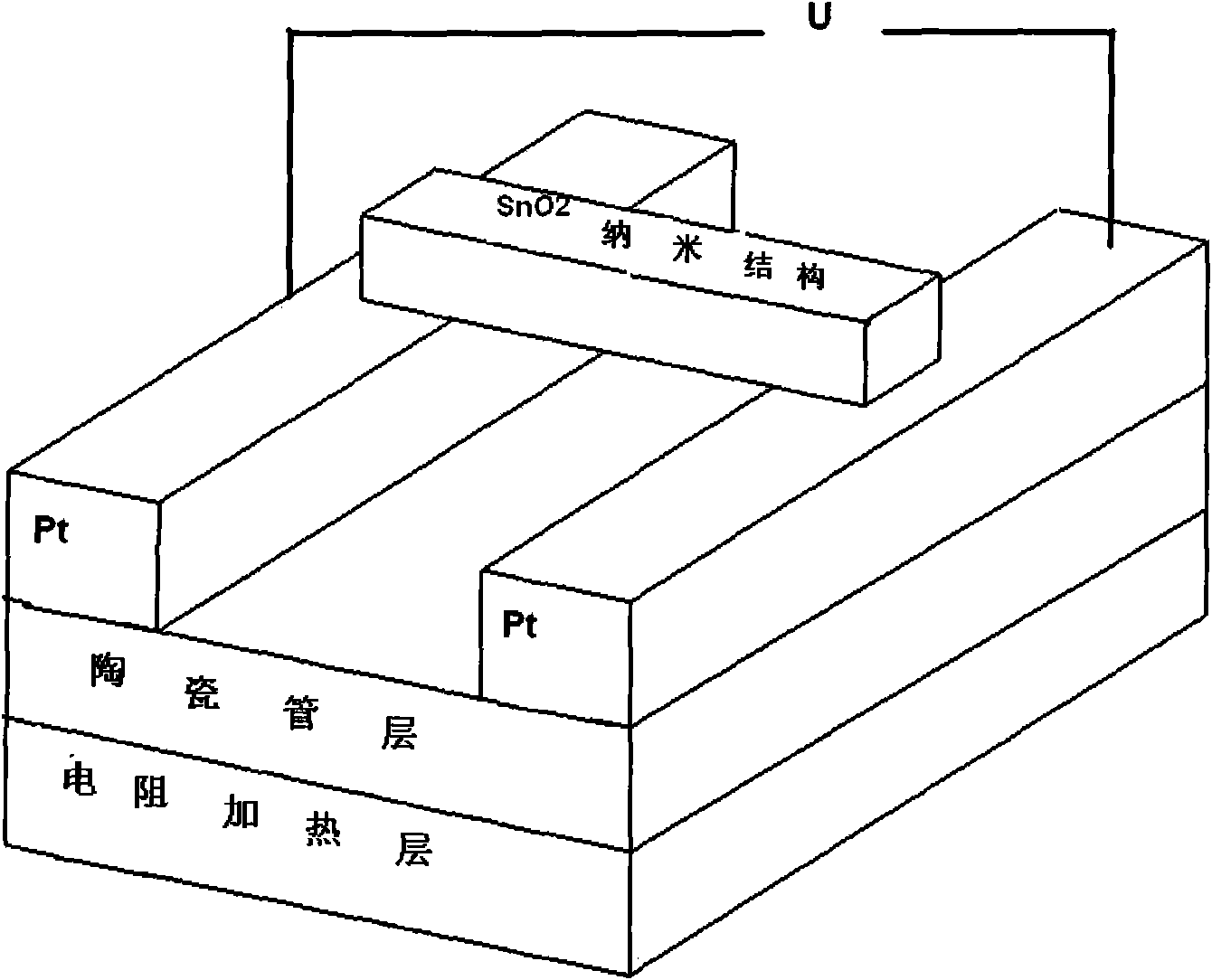

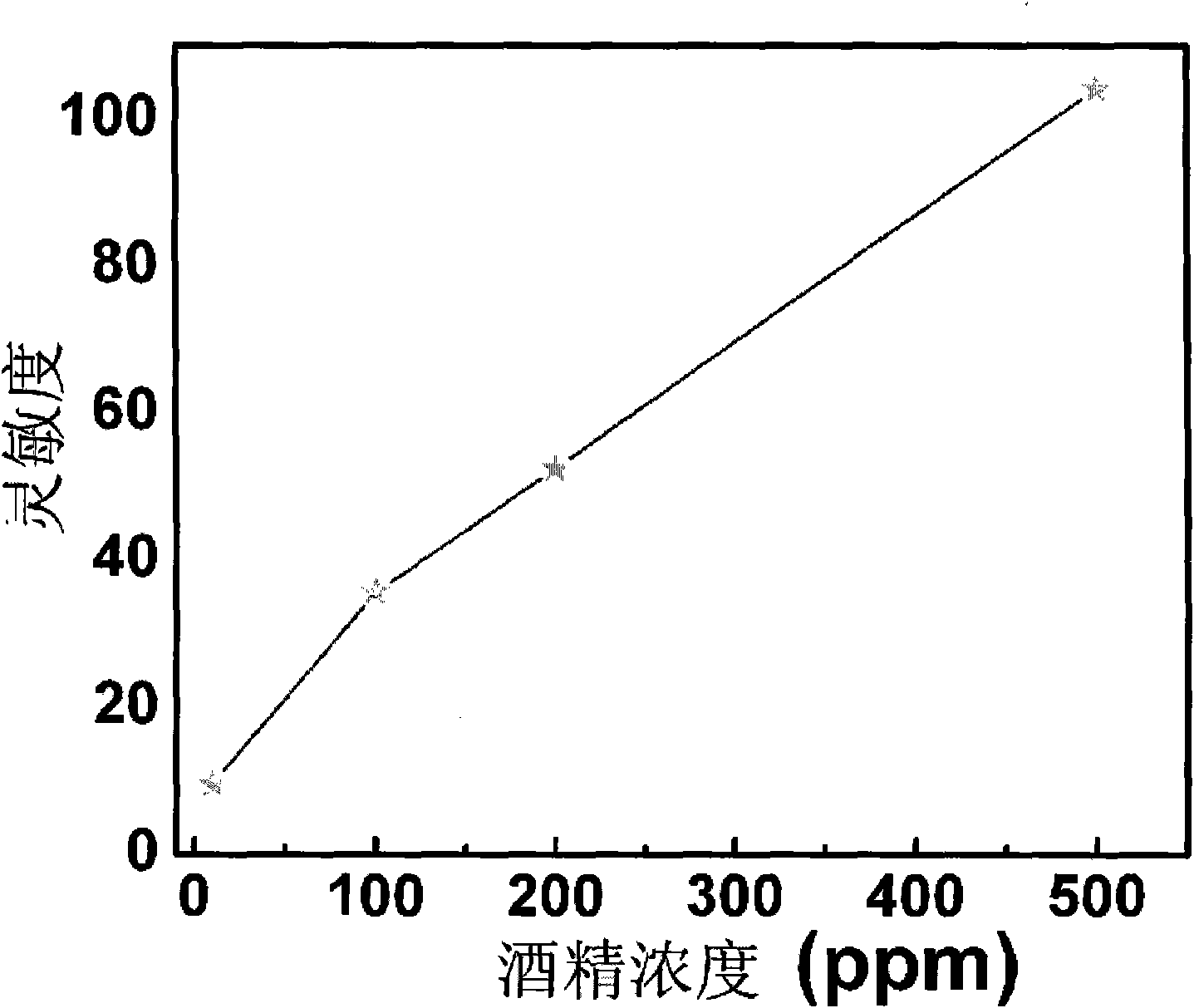

Gas sensor based on novel SnO2 nano material and manufacturing method thereof

Owner:SHANGHAI GEZHI HIGH SCHOOL

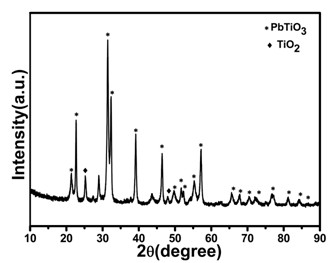

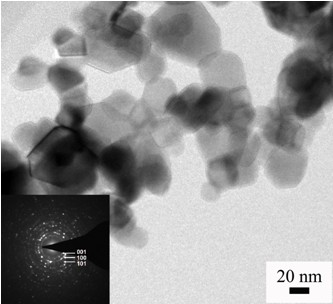

Preparation method of perovskite structure lead titanate single crystal nanoparticles

ActiveCN102677145AAchieve synthesisEasy to separatePolycrystalline material growthFrom normal temperature solutionsDispersityNanoparticle

Owner:ZHEJIANG UNIV

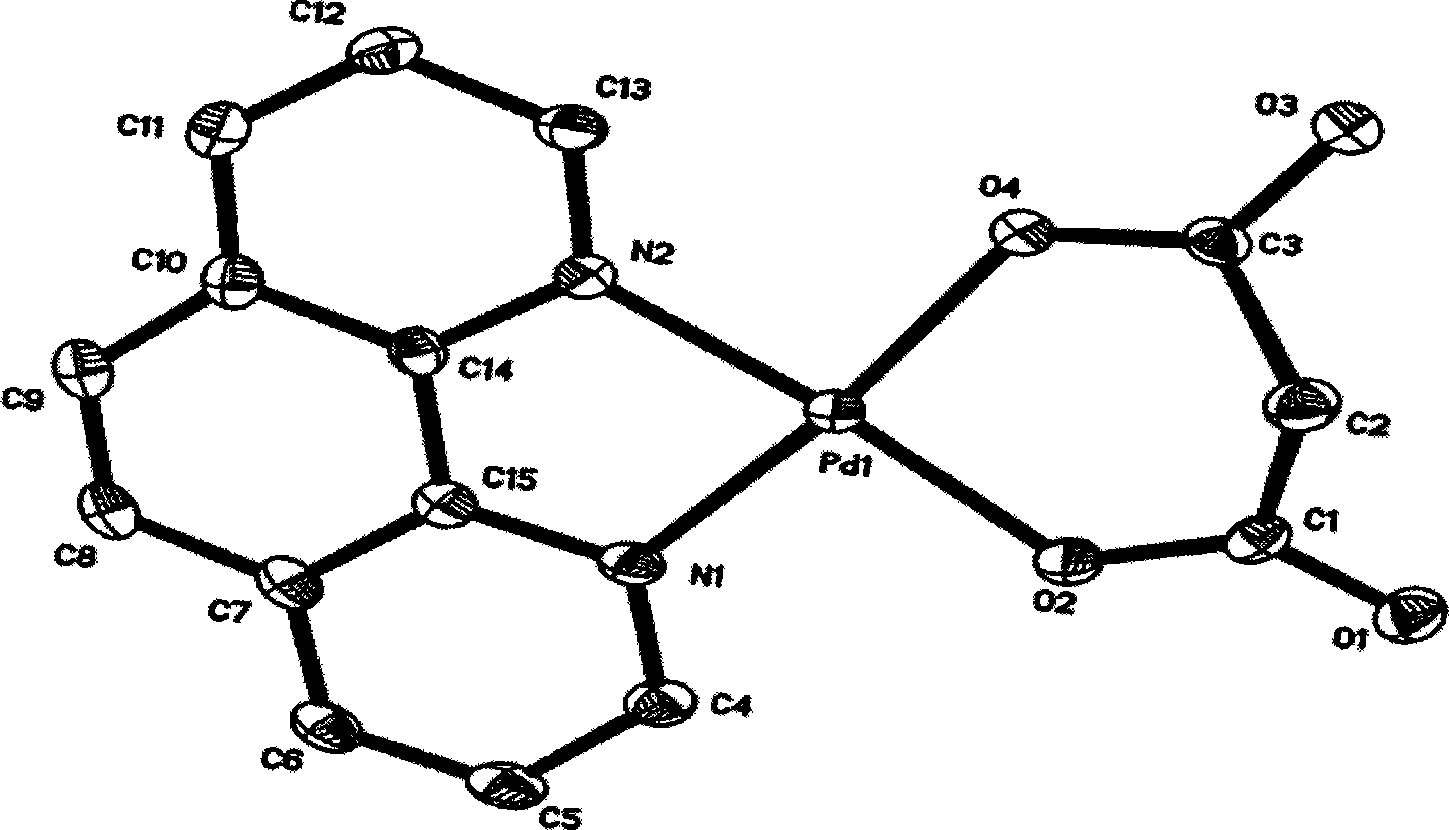

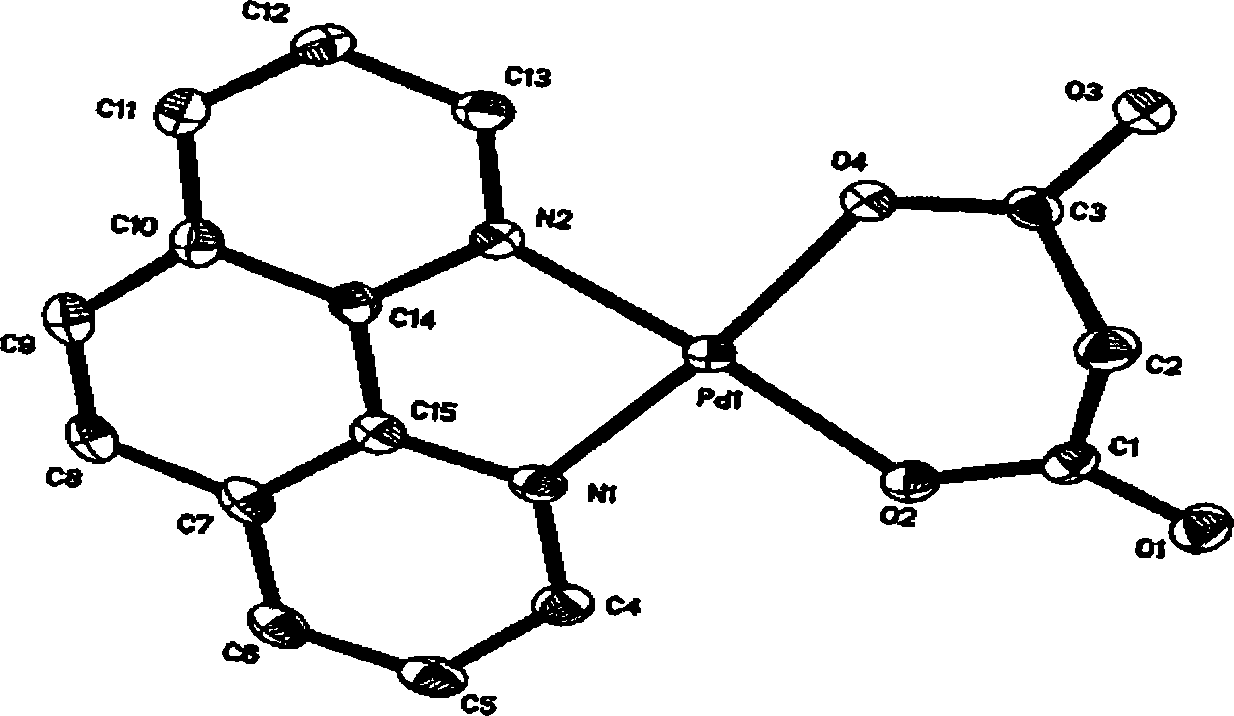

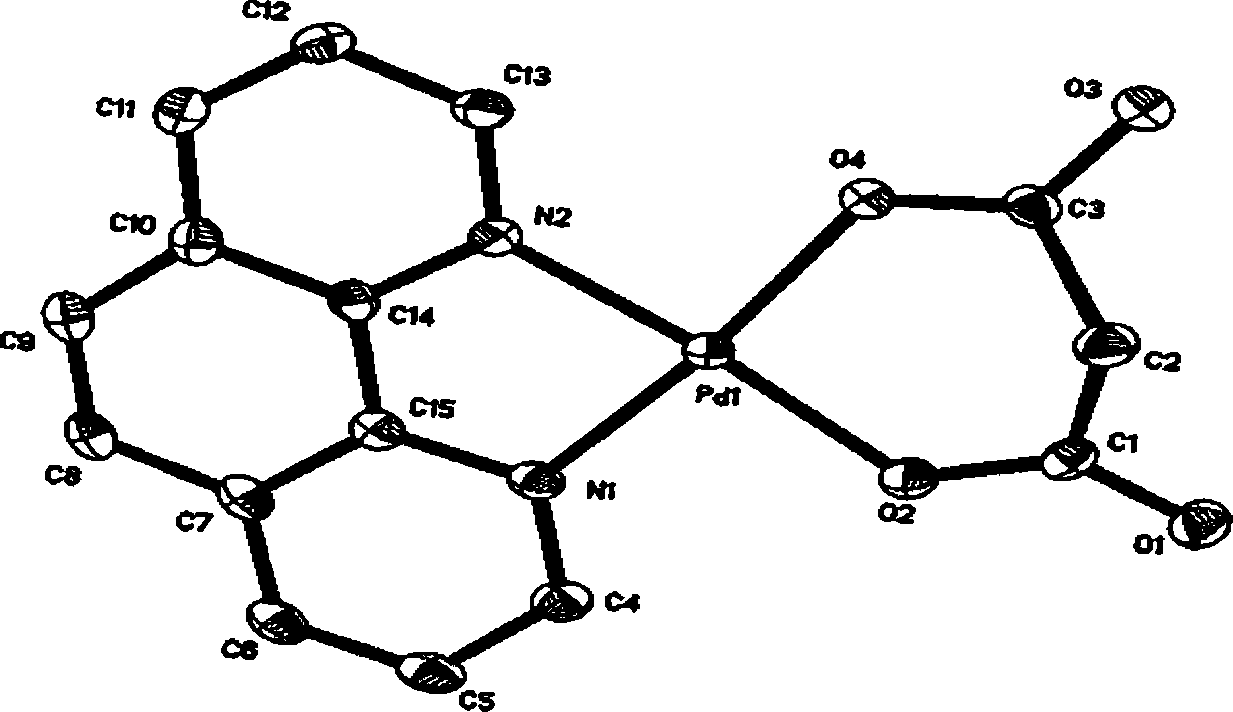

Method for preparing complex palladium malonic acid Phen mono-crystalline and structure thereof

InactiveCN101139364AClear compositionClear molecular structureGroup 8/9/10/18 element organic compoundsMalonic acidPhenanthroline

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

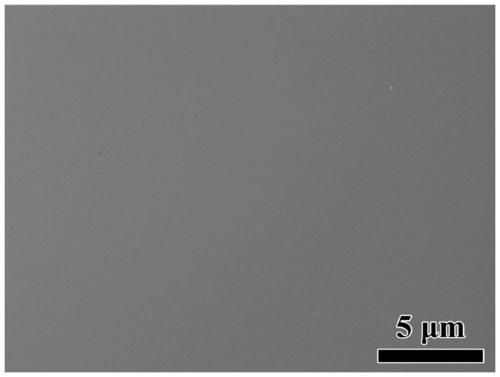

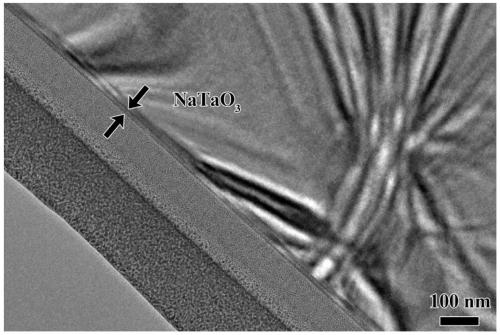

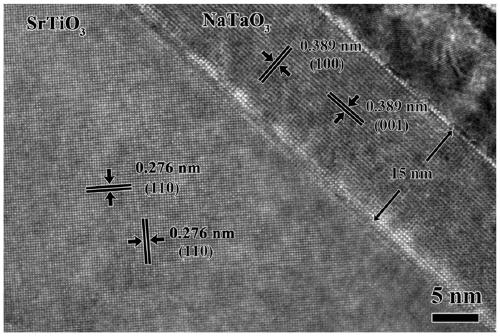

Preparation method of sodium tantalum oxide single-crystal film

InactiveCN109898137APolycrystalline material growthFrom normal temperature solutionsSpintronicsSingle crystal

Owner:ZHEJIANG UNIV

Method for manufacturing silicon substrate and silicon substrate

ActiveUS20130316139A1Polycrystalline material growthAfter-treatment detailsSingle crystalMelting point

Owner:SHIN-ETSU HANDOTAI CO LTD

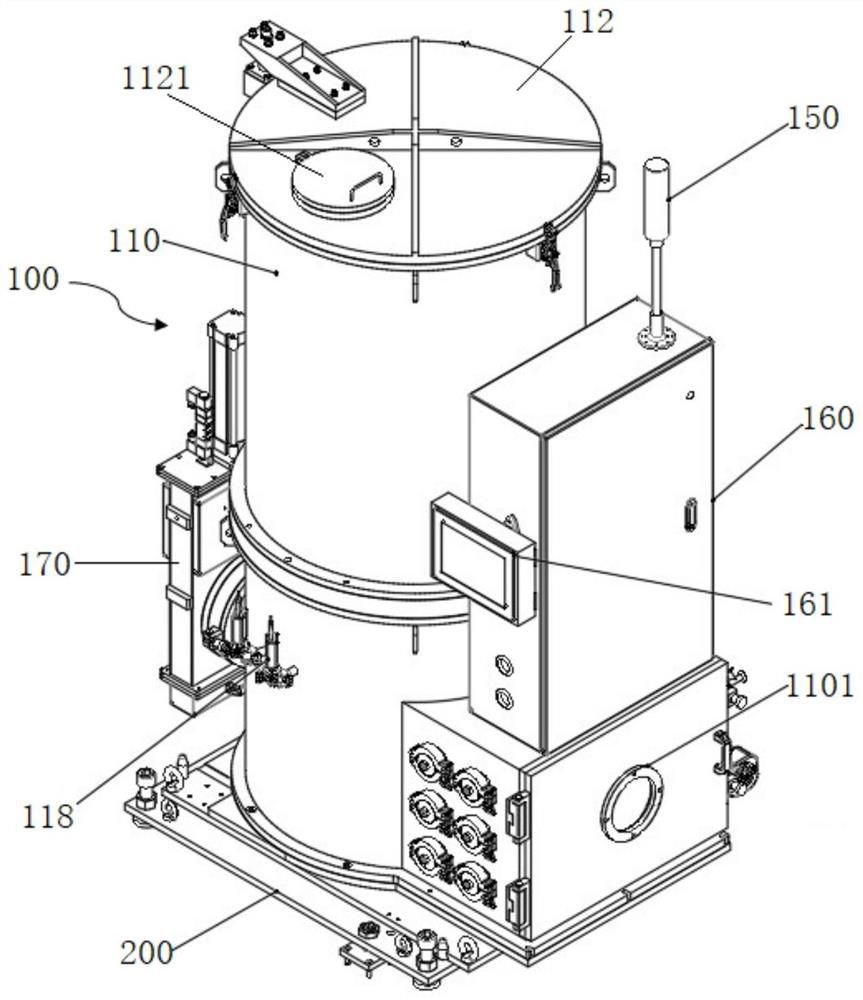

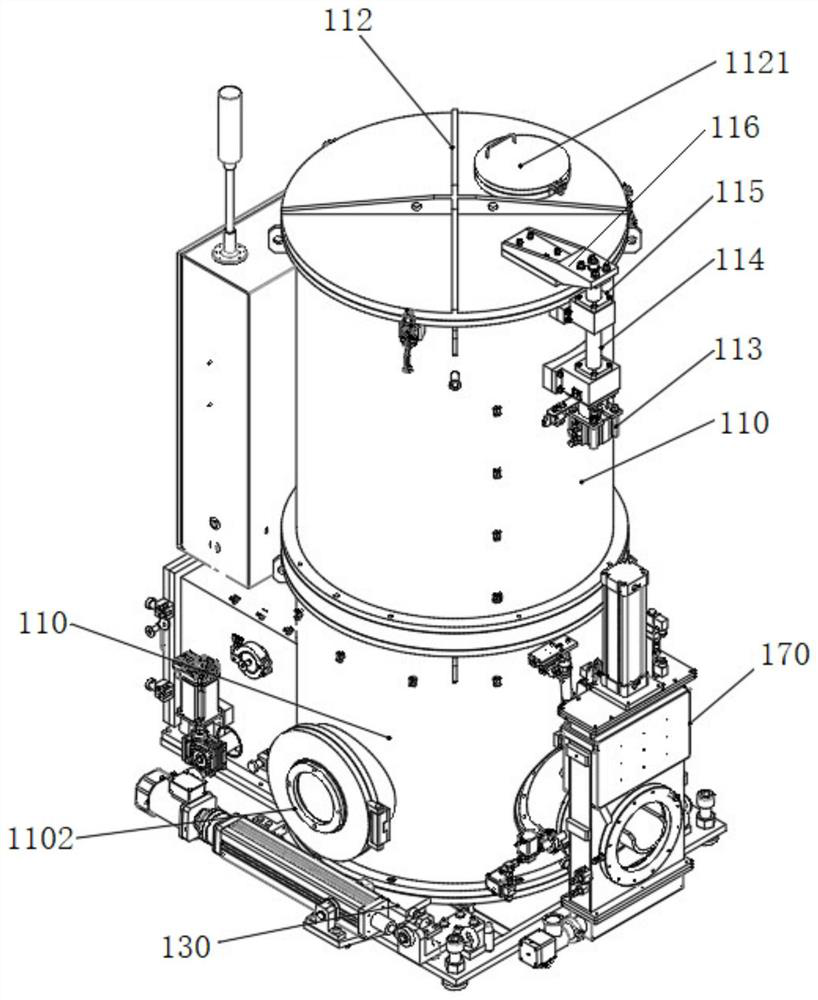

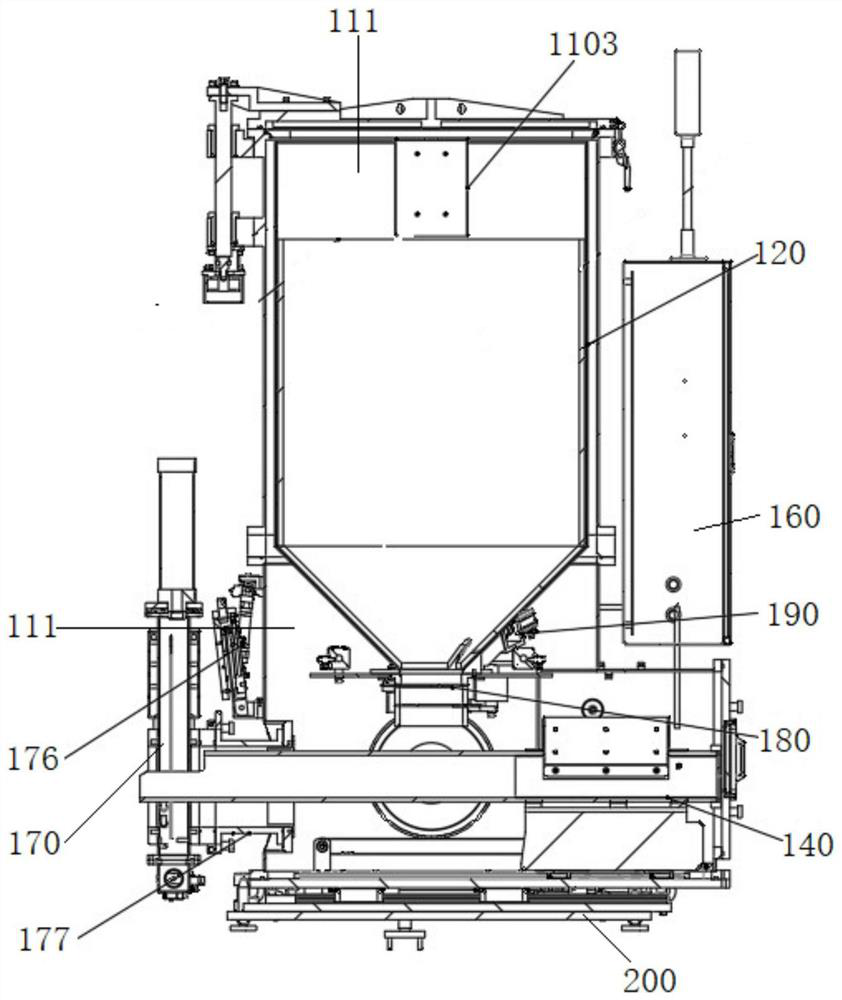

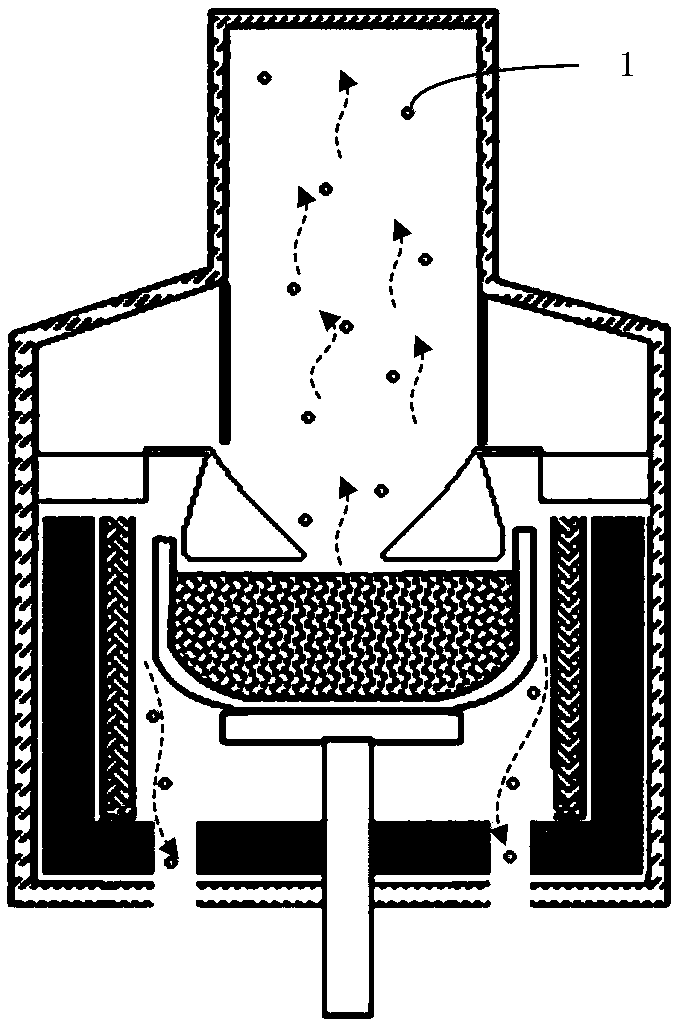

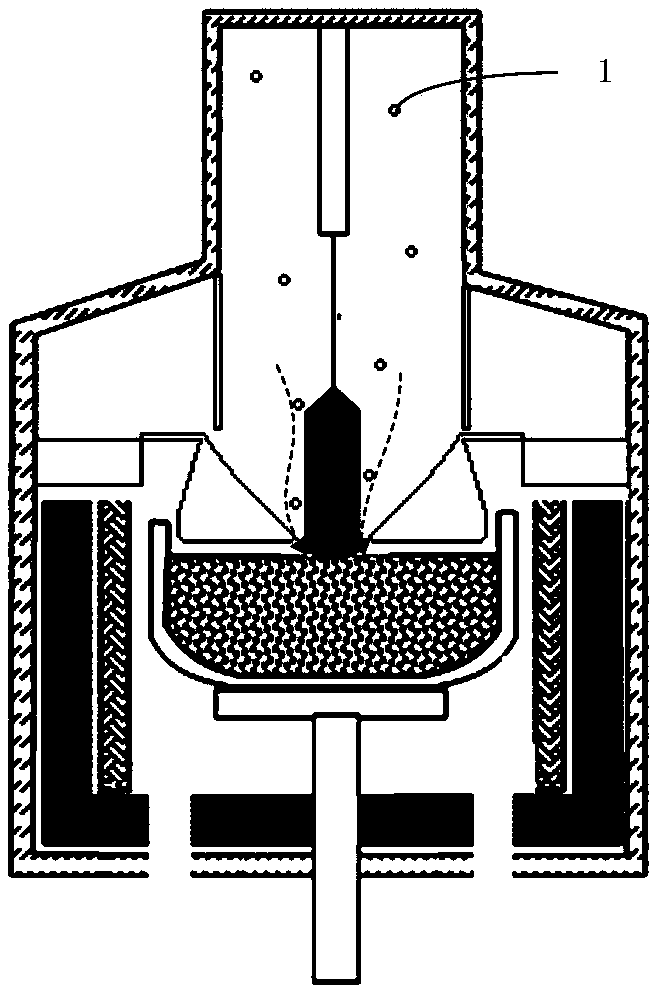

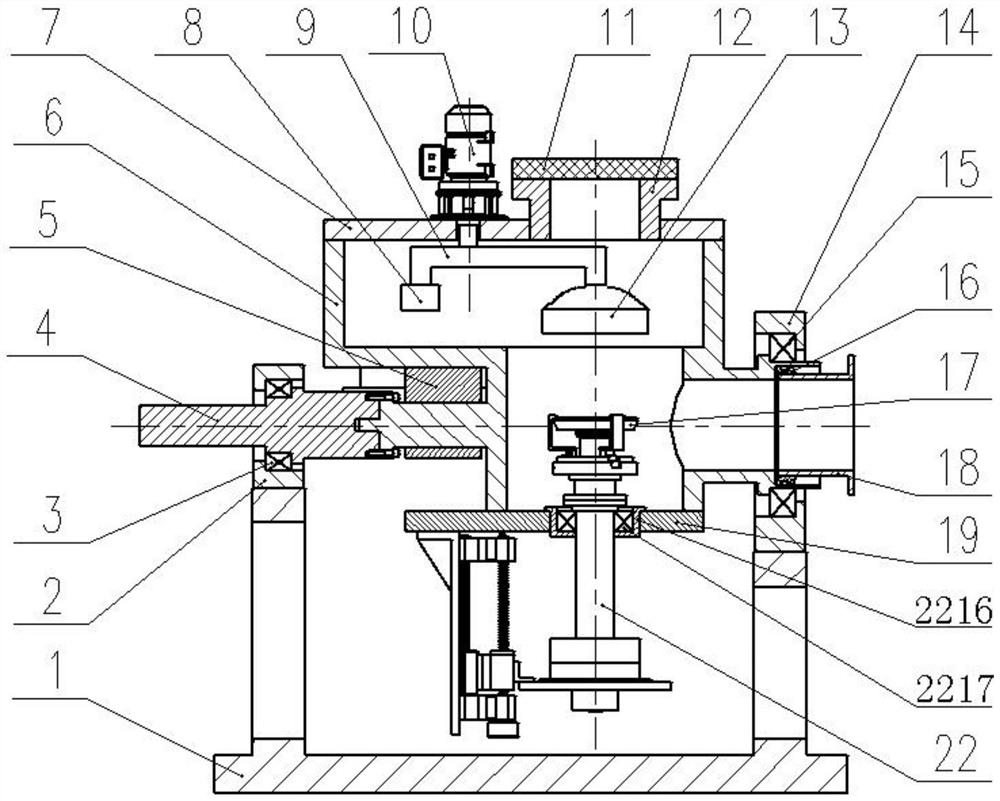

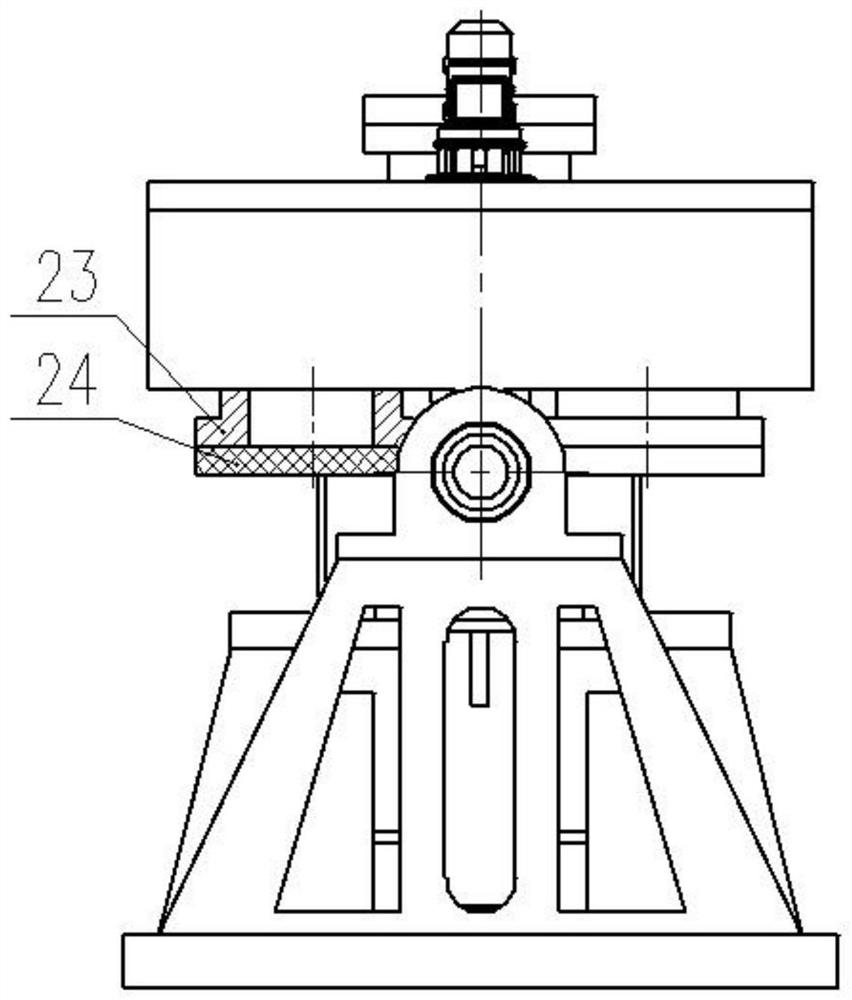

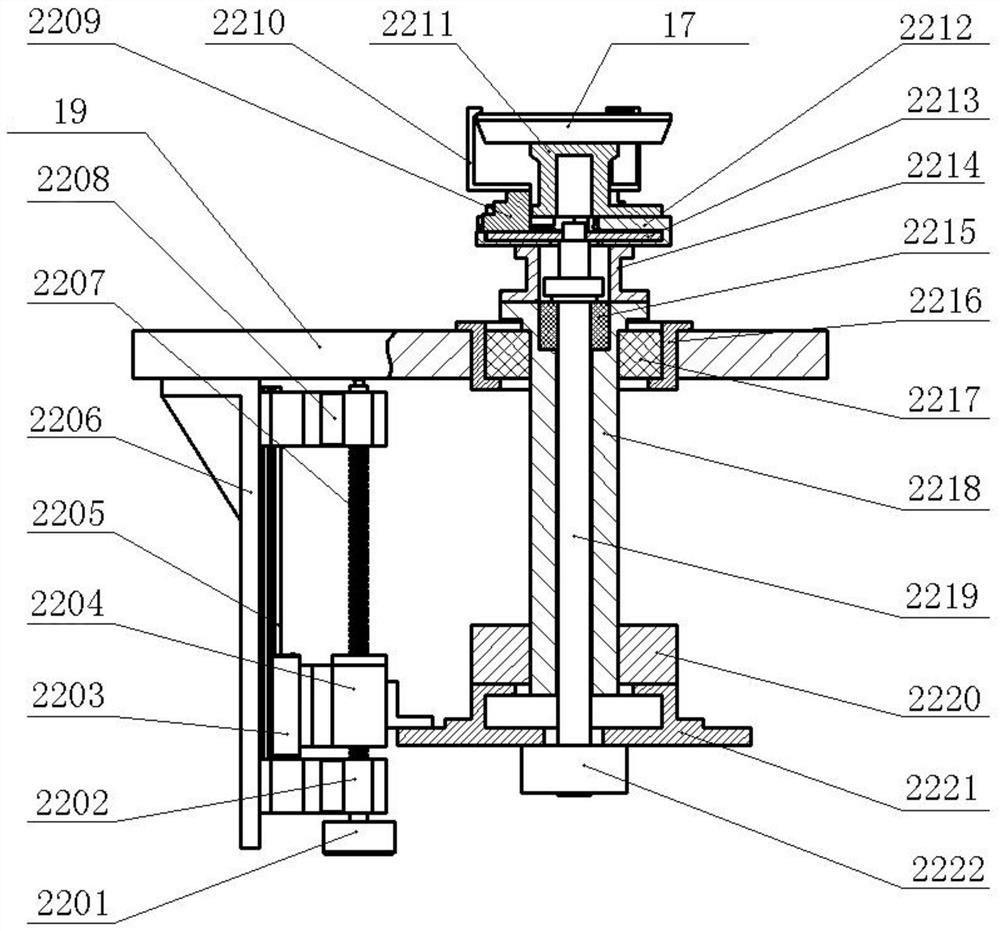

Feeding device for single crystal furnace

PendingCN114395795ASmall footprintAvoid damagePolycrystalline material growthBy pulling from meltElectrical connectionSingle crystal

Owner:晶澳(无锡)光伏科技有限公司

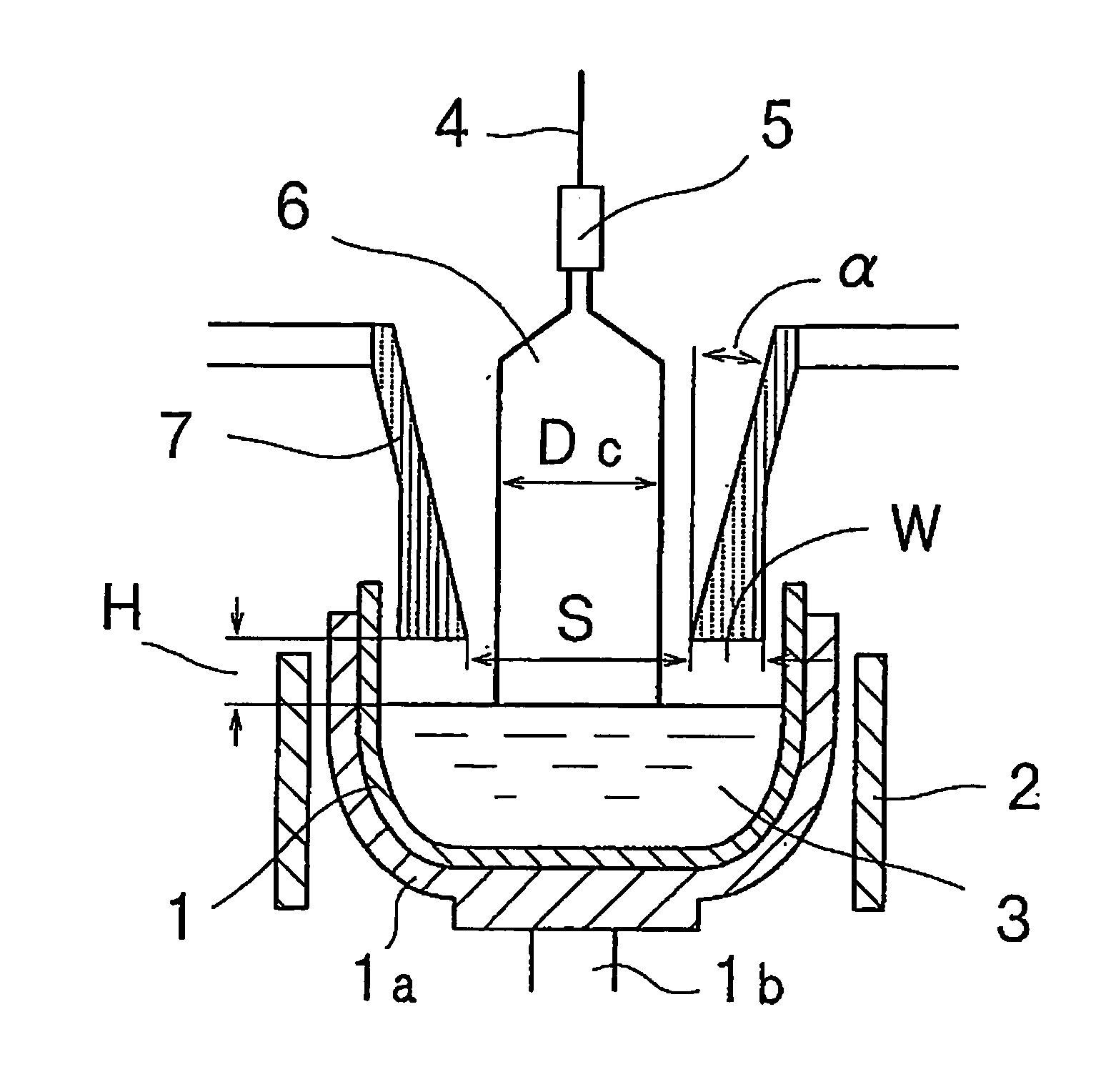

Single crystal pulling device, preparation method of single crystal silicon and single crystal silicon

InactiveCN109554756APrevent inflowReduce dislocationPolycrystalline material growthUnder a protective fluidSingle crystalEngineering

Owner:XIAN ESWIN SILICON WAFER TECH CO LTD

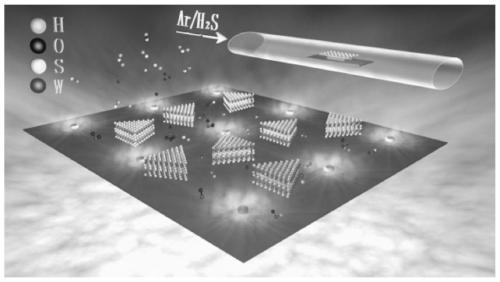

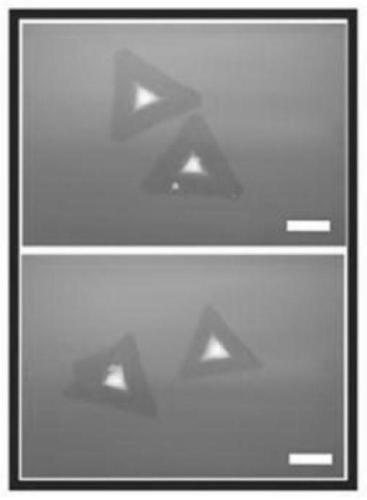

Preparation method and application of wafer-level absolute single-layer transition metal chalcogenide

ActiveCN113088922AImprove crystal qualityLarge single crystal sizeFinal product manufactureChemical vapor deposition coatingPhysical chemistrySingle crystal

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Sb2Te3 monocrystalline nanometer line ordered array and its preparation method

InactiveCN1769539ASolve easy hydrolysisAddress effectivenessPolycrystalline material growthElectrolytic organic material coatingNanowireAuxiliary electrode

Owner:UNIV OF SCI & TECH OF CHINA

Preparation method of tungsten disulfide single crystal with controllable layer number

ActiveCN111472049AIncrease profitHigh repetition ratePolycrystalline material growthFrom chemically reactive gasesSingle crystalMaterials science

Owner:WENZHOU UNIVERSITY

Method for reducing content of carbon in single crystal bar

ActiveCN109097822APrevent fallingAvoid enteringPolycrystalline material growthBy pulling from meltLower limitCrucible

The invention discloses a method for reducing content of carbon in a single crystal bar. The method specifically comprises steps as follows: (1) a thermal field below a liquid level is mounted at thelower end of a furnace tube; (2) a material block is put in a crucible by means of a hoisting procedure, material protecting cloth is uniformly spread, wherein traction wires are uniformly arranged onone surface of the material protecting cloth, all the traction wires are connected together through a traction wire guide block, the traction wire guide block is arranged in the center of the material protecting cloth, the surface without traction wires completely covers the material blocks put in the crucible, and the crucible is descended to the lower limit position in the furnace tube and located at the upper end of the thermal field below the liquid level; (3) a thermal field above the liquid level is mounted, and the furnace tube is started to be closed after mounting; (4) after the furnace tube is closed, the traction wire guide block is lifted upwards, the material protecting cloth is directly taken out, and the furnace is continuously closed; (5) after the tube is closed, the material protecting cloth is turned over in the designated position of a workshop, so that lifted graphite powder and other impurities are lifted, then, the material protecting cloth is blown clean on thewhole with a blower, and the material protecting cloth and a sucker are transported to a charging chamber.

Owner:BAOTOU MEIKE SILICON ENERGY CO LTD

Method for preparing cubic boron nitride single crystal-film homogeneous P-N junction

InactiveCN101807519AReduce processing difficultyIncrease productivitySemiconductor/solid-state device manufacturingDiffusion methodsSynthesis methods

Owner:JILIN UNIV

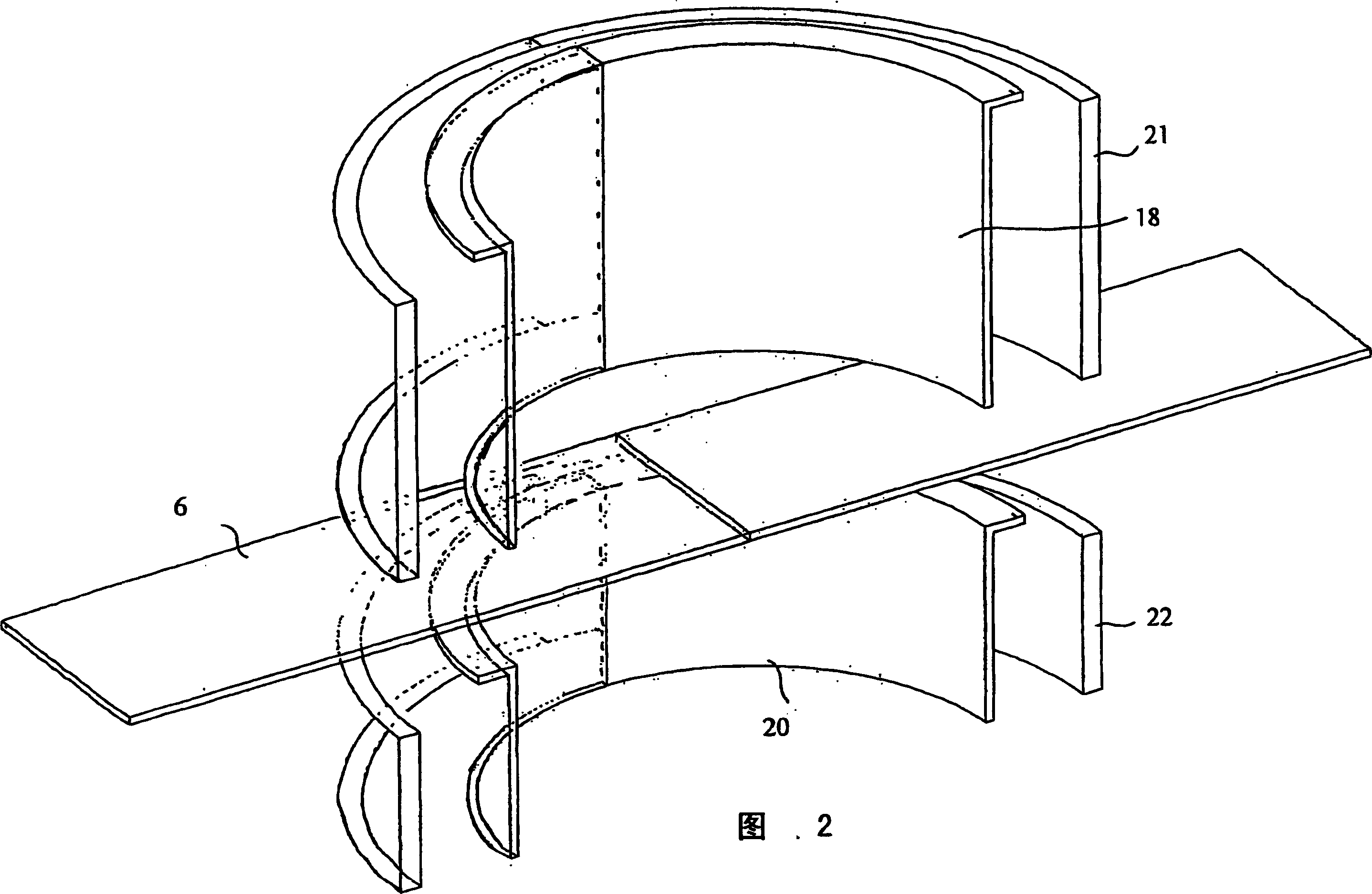

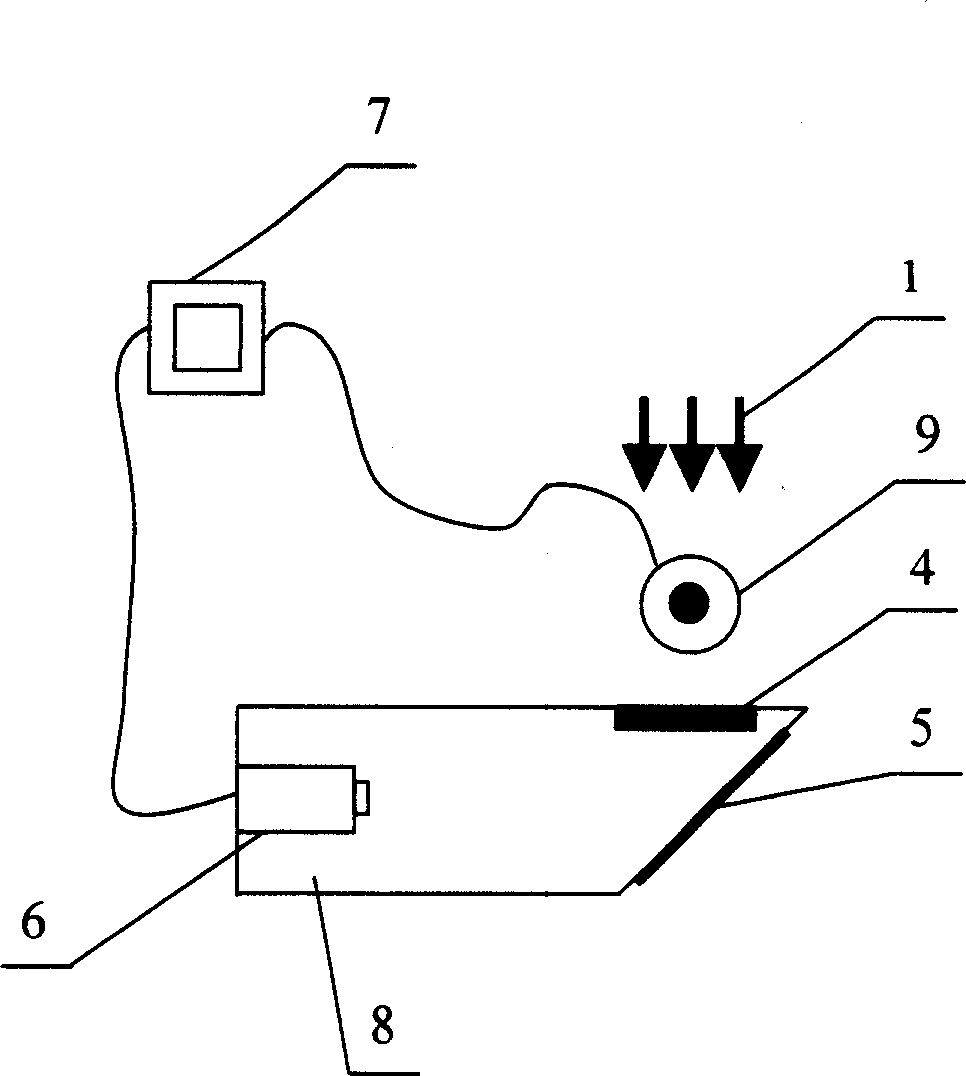

Graphite disc turnover type GaN single crystal substrate laser pre-stripping integrated cavity

PendingCN111778559AAchieve heat preservationReduced growth quality issuesPolycrystalline material growthFrom chemically reactive gasesSingle crystal substrateSingle crystal

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

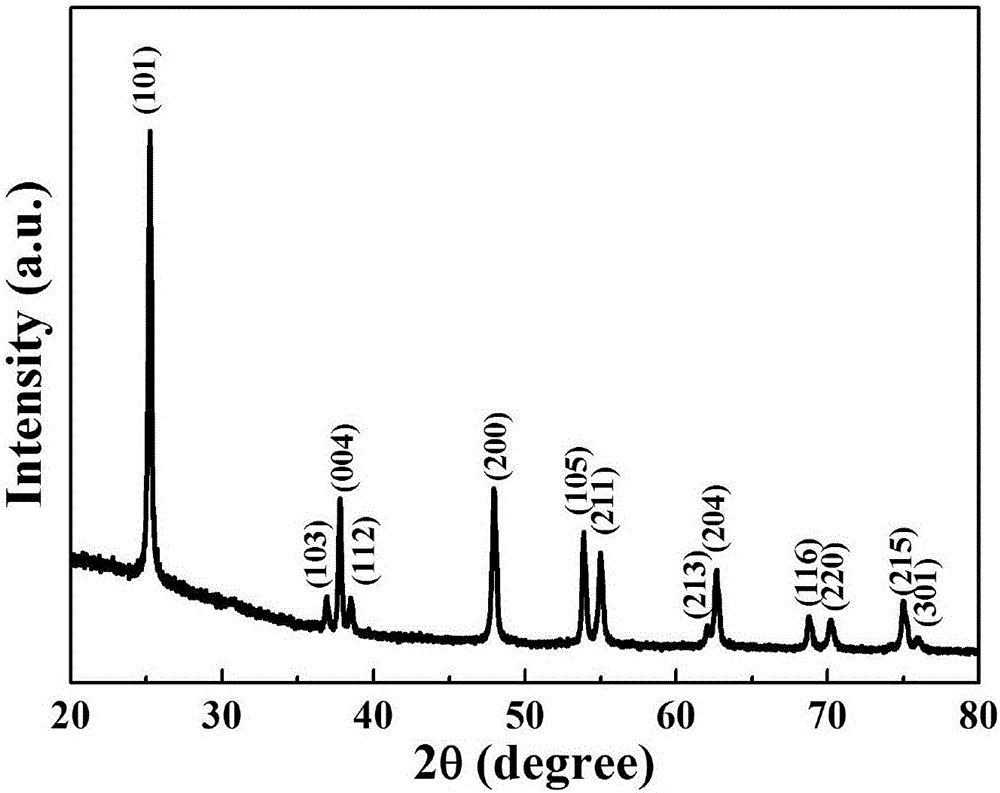

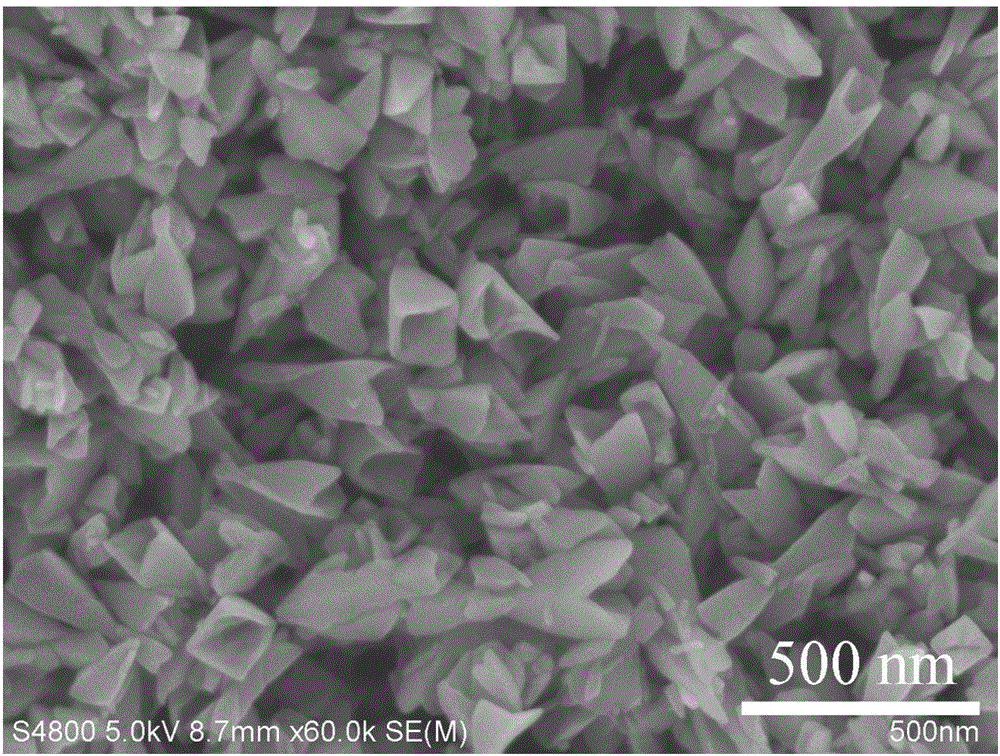

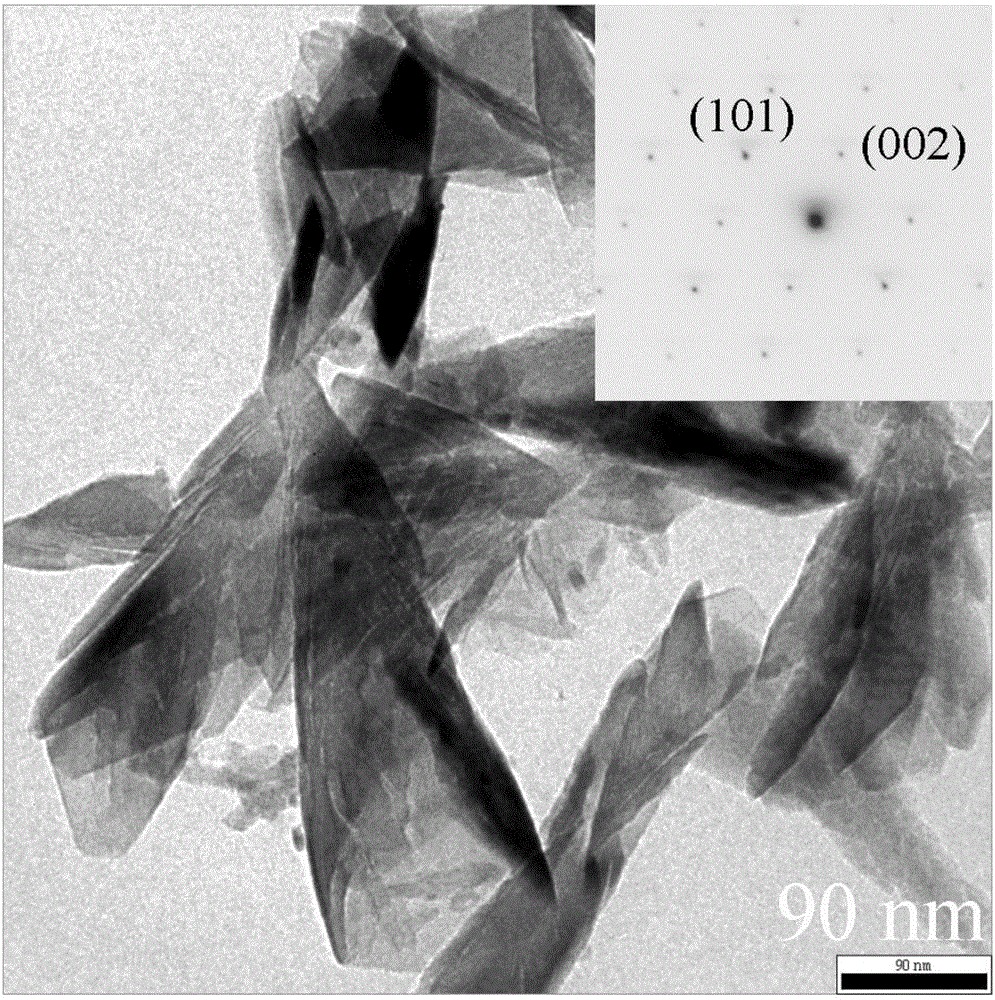

TiO2 single-crystal hollow square nanocone material and preparation method and application thereof

InactiveCN106348340ALarge specific surface areaImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationOrganic dyeSingle crystal

Owner:ANHUI NORMAL UNIV

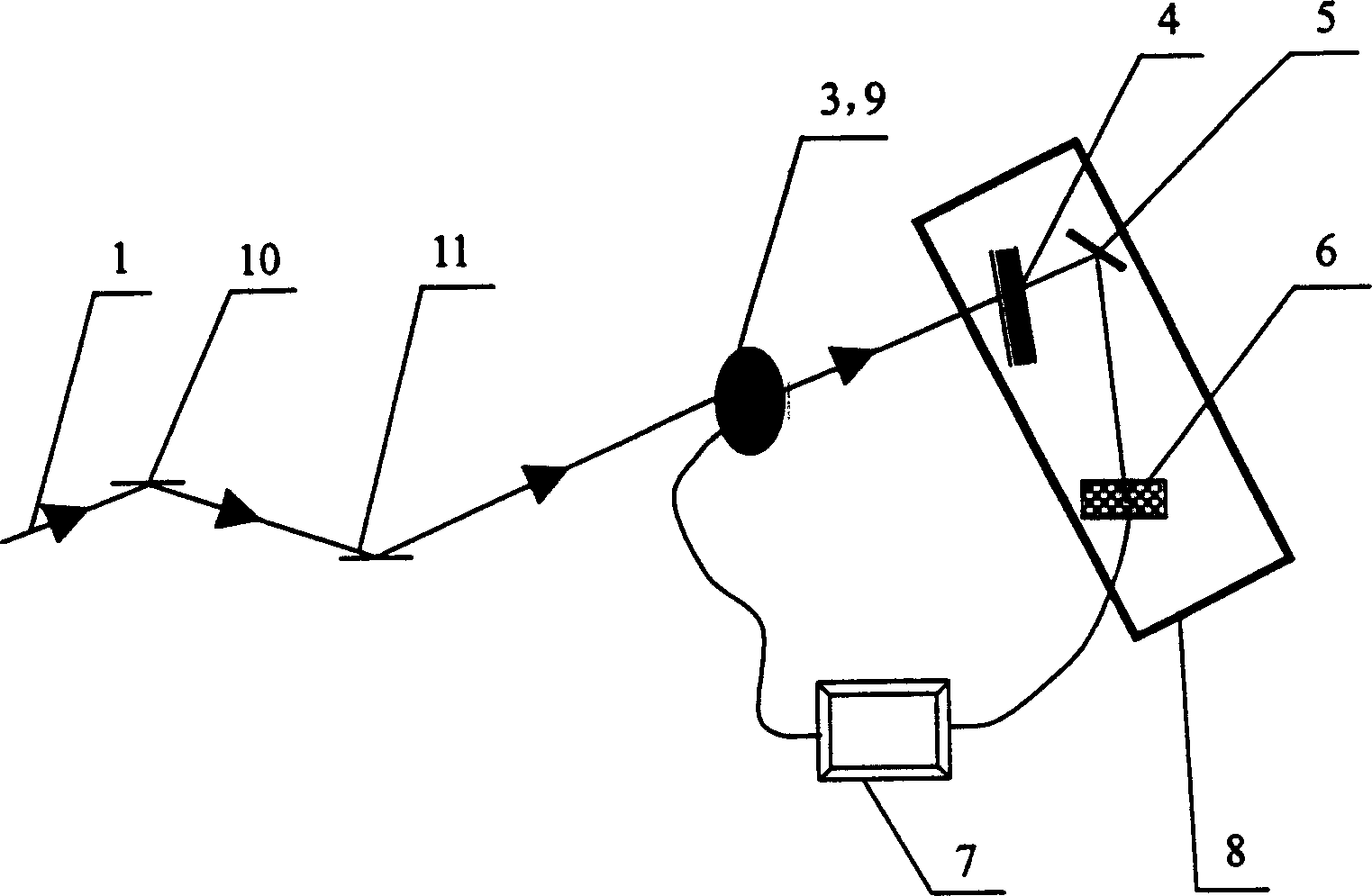

Neutron phase contrast chromatographic imaging device

InactiveCN1434291AHigh resolutionMaterial analysis using wave/particle radiationSingle crystalCcd camera

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Novel production method of 8-inch zone-melting silicon single crystal for IGBT (insulated gate bipolar transistor)

InactiveCN106011997AIncrease crystallization rateReduce manufacturing costPolycrystalline material growthBy zone-melting liquidsMicrowaveSemiconductor materials

Owner:BEIJING TIAN NENG YUN TONG CRYSTAL TECH CO LTD

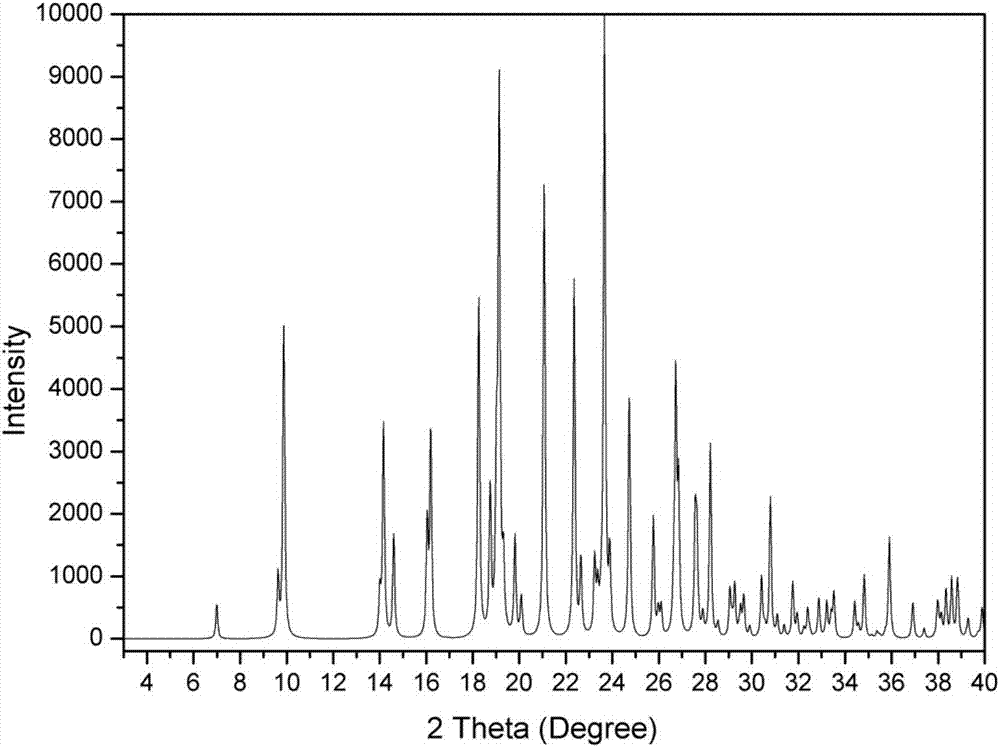

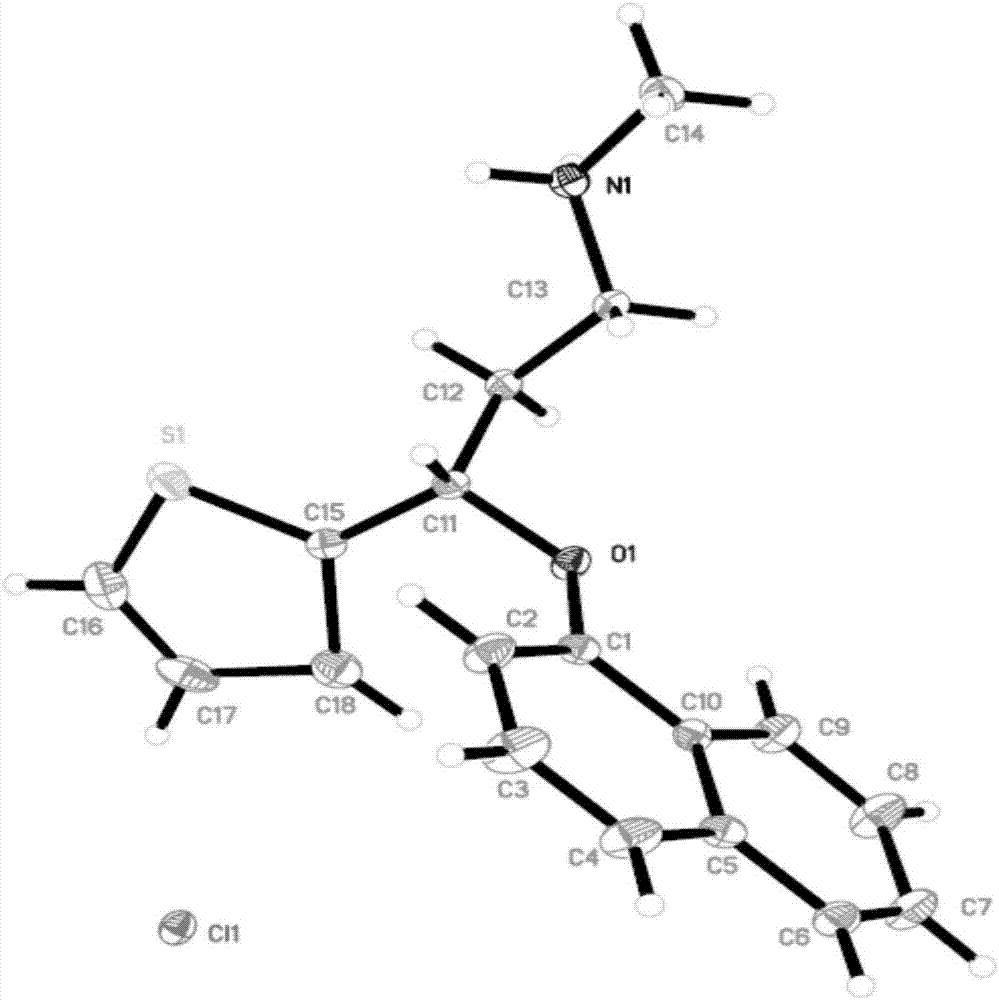

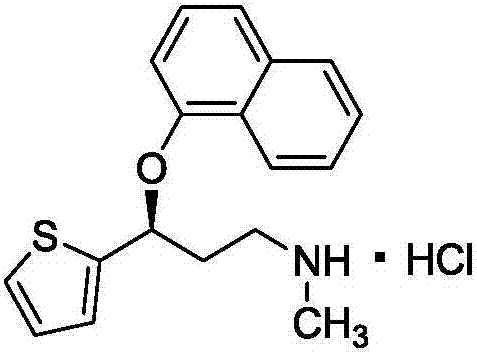

Duloxetine hydrochloride single crystal and preparation method thereof

ActiveCN107200724AReduce defectsEasy to operateOrganic chemistry methodsDiffusion methodsSingle crystal

Owner:NHWA PHARMA CORPORATION

Two-dimensional organic-inorganic hybrid double perovskite semiconductor crystal and preparation method and application thereof

ActiveCN114686987AApparent photoconductive effectPolycrystalline material growthFrom normal temperature solutionsSemiconductor materialsPhotoconductive detector

The invention relates to a two-dimensional organic-inorganic hybrid double perovskite semiconductor crystal and a preparation method and application thereof. The invention relates to an organic-inorganic hybrid double perovskite semiconductor crystal. The chemical formula of an inorganic-organic hybrid semiconductor material is (C6H5CH2NH3) 4AgBiBr8. According to the invention, the organic-inorganic hybrid double-perovskite semiconductor crystal is prepared, and the organic-inorganic hybrid double-perovskite semiconductor crystal is prepared into a planar photoconductive detector, so that high-sensitivity detection of an intrinsic absorption spectrum can be realized. Laser with the wavelength of 405 nm is used for irradiating the single crystal detector, and the photoelectric response of the single crystal detector is tested. When the power density of incident light is 50.9 mW / cm < 2 >, the crystal device shows an obvious photoconductive effect, and the ratio of light current to dark current can reach 1.8 * 10 < 3 >. The result shows that the material has potential application value when being used as a photoconductive detector.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap