Single crystal pulling device, preparation method of single crystal silicon and single crystal silicon

A pulling device and monocrystalline silicon technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as dislocation of single crystal silicon, improve crystal quality, reduce dislocation problems, clean work easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

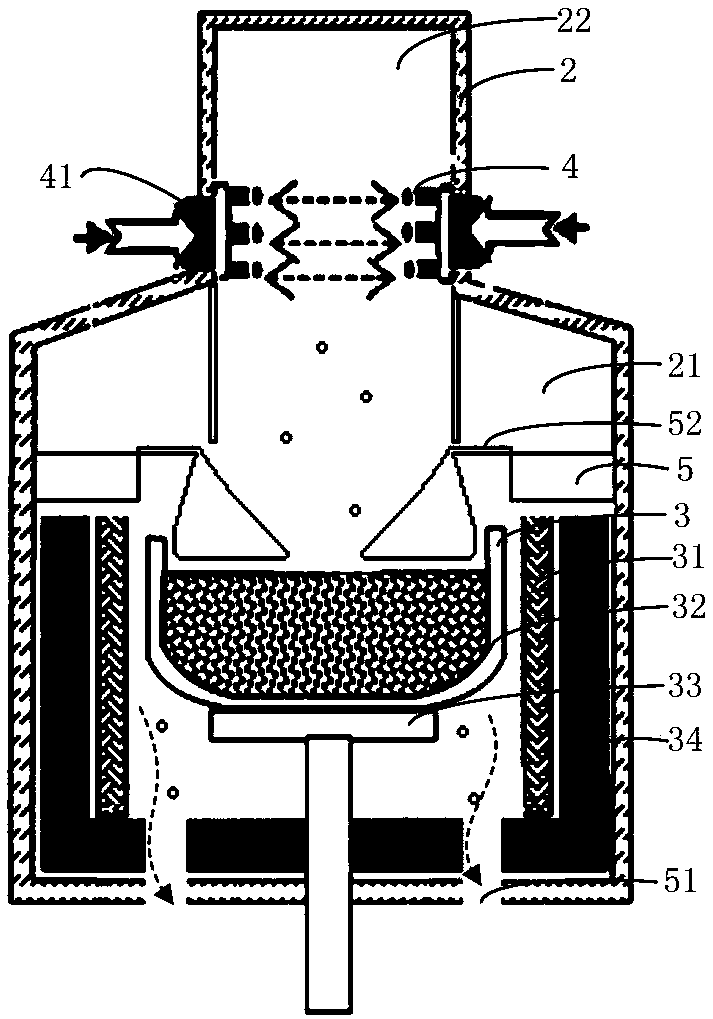

[0035] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0036] The terms "first", "second" and the like in the description and claims of the present invention are used to distinguish similar objects, and are not necessarily used to describe a specific order or sequence. It is to be understood that the data so used are interchangeable under appropriate circumstances such that the embodiments of the invention described herein are, for example, capable of practice in sequences other than those illustrated or described herein.

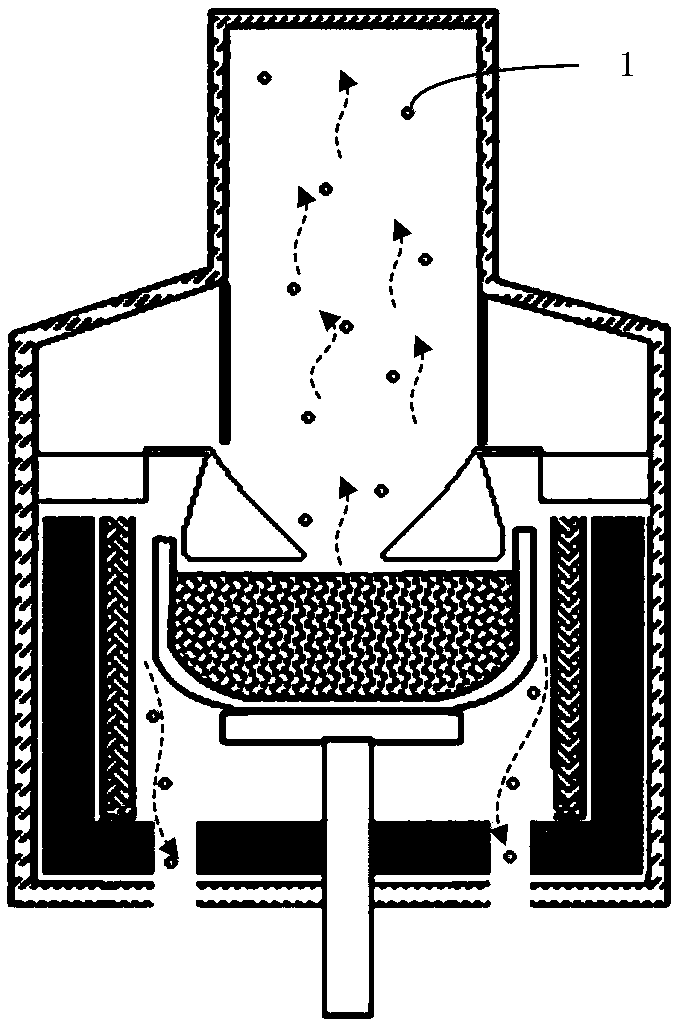

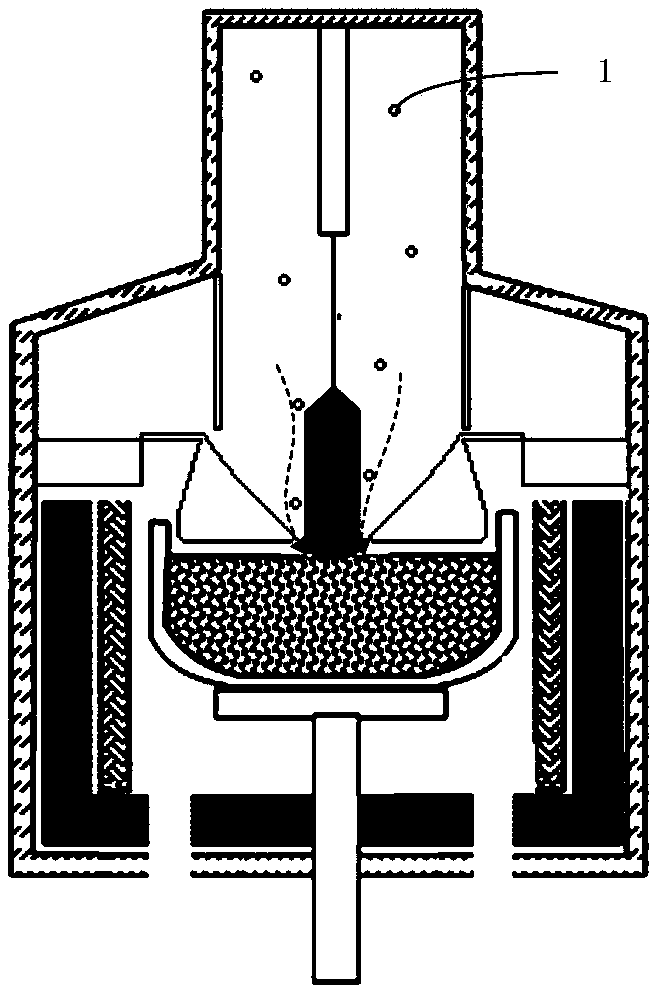

[0037] see figure 1 , in the process of manufacturing monocrystalline silicon, it is necessary to heat and melt the polysilicon placed in the crucible, and a large amount of impurities 1 (or called impurities) will be produced during the melting of polysilicon, and the impurities 1 can be ox

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap