Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Inert gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An inert gas is a gas that does not undergo chemical reactions under a set of given conditions. The noble gases often do not react with many substances and were historically referred to as the inert gases. Inert gases are used generally to avoid unwanted chemical reactions degrading a sample. These undesirable chemical reactions are often oxidation and hydrolysis reactions with the oxygen and moisture in air. The term inert gas is context-dependent because several of the noble gases can be made to react under certain conditions.

Electronic tobacco juice with baking aroma

ActiveCN104026728AImproves intrinsic suction qualityFeel the sameTobacco treatmentTobacco devicesBiotechnologyLiquid smoke

Owner:CHINA TOBACCO HUNAN INDAL CORP

Catalyst for ternary copolymerization of norbornenes, tetrafluoroethylene and pentenes and ternary copolymerization method

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

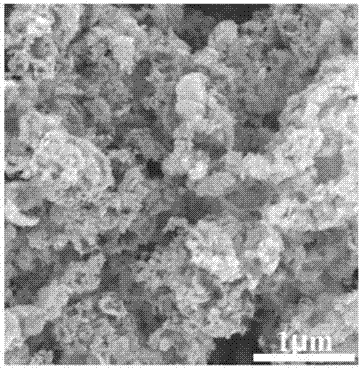

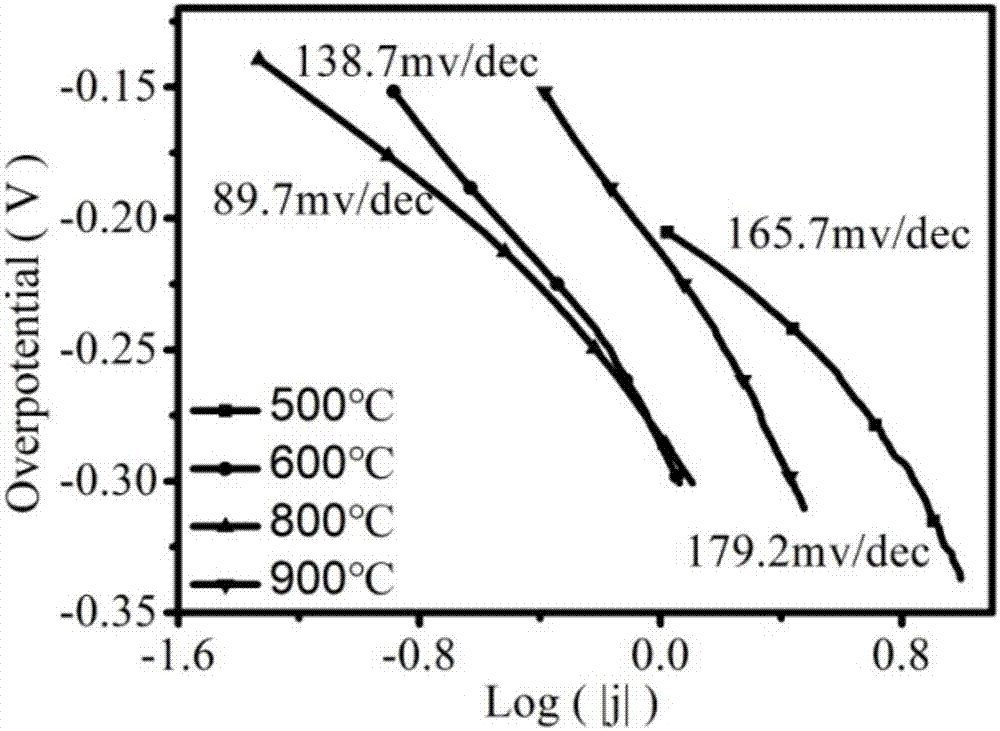

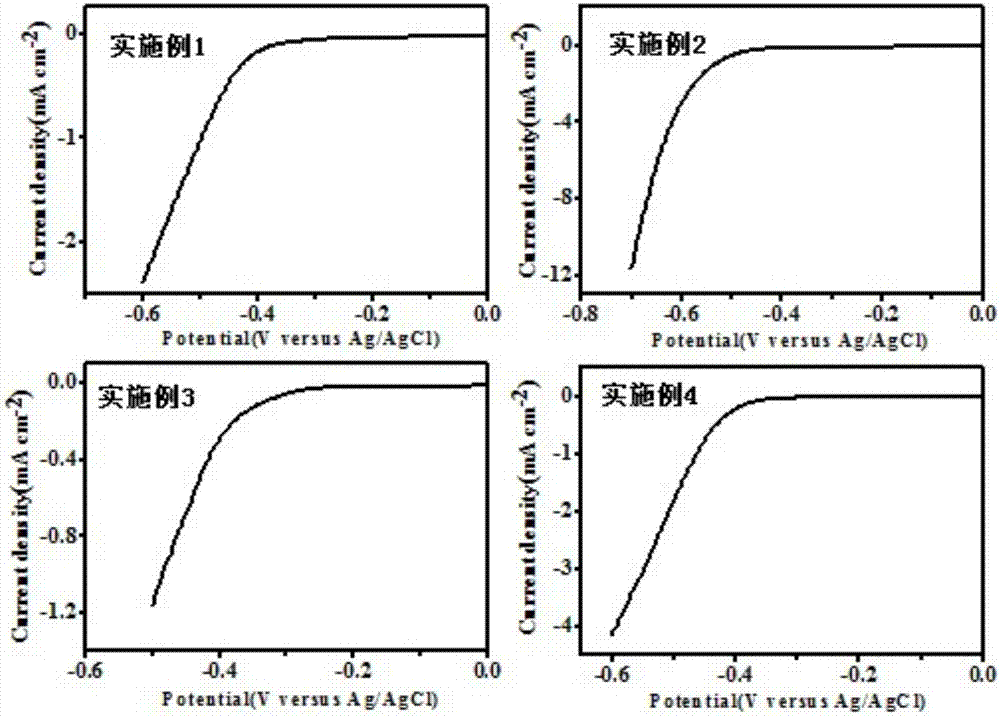

Cobalt sulfide material, preparation method and application of cobalt sulfide material

ActiveCN106865624AImprove electrocatalytic activityEffective generationPhysical/chemical process catalystsCell electrodesSodium carbamateMole ratio

Owner:WENZHOU UNIVERSITY

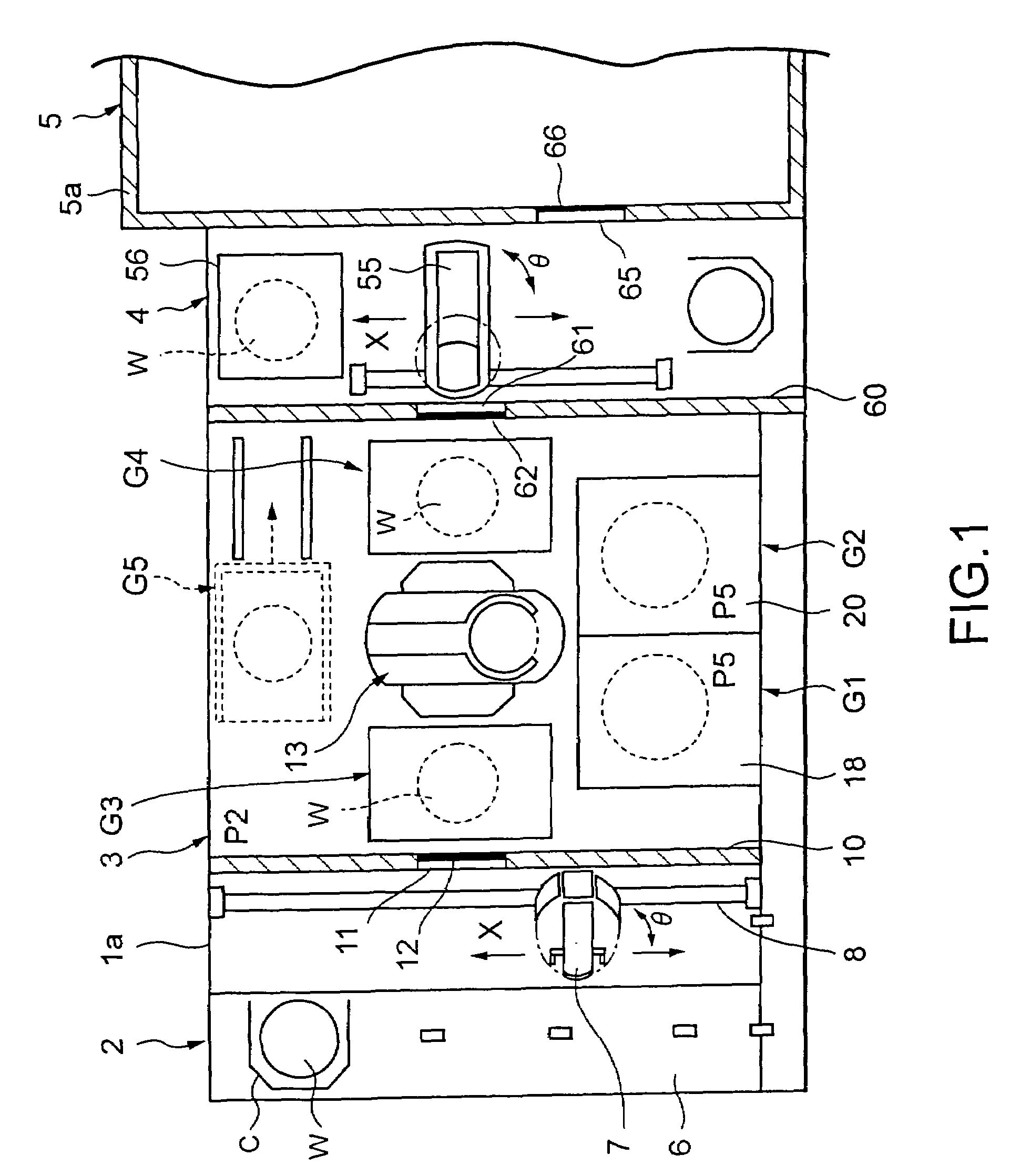

Method of Fabricating Thin Film by Microplasma Processing and Apparatus for Same

InactiveUS20120021132A1Reduce necessityLiquid surface applicatorsMolten spray coatingIonRaw material

Provided is a method of fabricating, with satisfactory adhesion, a thin film of a metal or a metallic-compound, such as a metal oxide or nitride, on a substrate made of a high-melting-point material such as silicon or ceramics by using a metal or metallic-compound target as the primary raw material so as to eliminate the necessity of using harmful gases such as organometallic gas, and by using an atmospheric-pressure plasma generated under atmospheric pressure as a reaction field and also as a heat source. Additionally provided is an apparatus for fabricating the thin film. The thin-film fabrication method by microplasma processing includes the steps of disposing a raw material for thin-film fabrication in one or more tubes (A) having a uniform inner diameter throughout, introducing an inert gas and applying a high-frequency voltage to the narrow tubes (A) to generate high-frequency plasma in the narrow tubes (A), heating / evaporating the raw material while maintaining the flow rate of the plasma gas in the narrow tubes (A) and maintaining the plasma gas temperature high, ejecting the evaporated material from the narrow tubes (A) to spray it onto the substrate, heating the substrate with the plasma, and depositing the sprayed material on the substrate under atmospheric pressure.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Loaded metallocene catalyst and preparation method thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

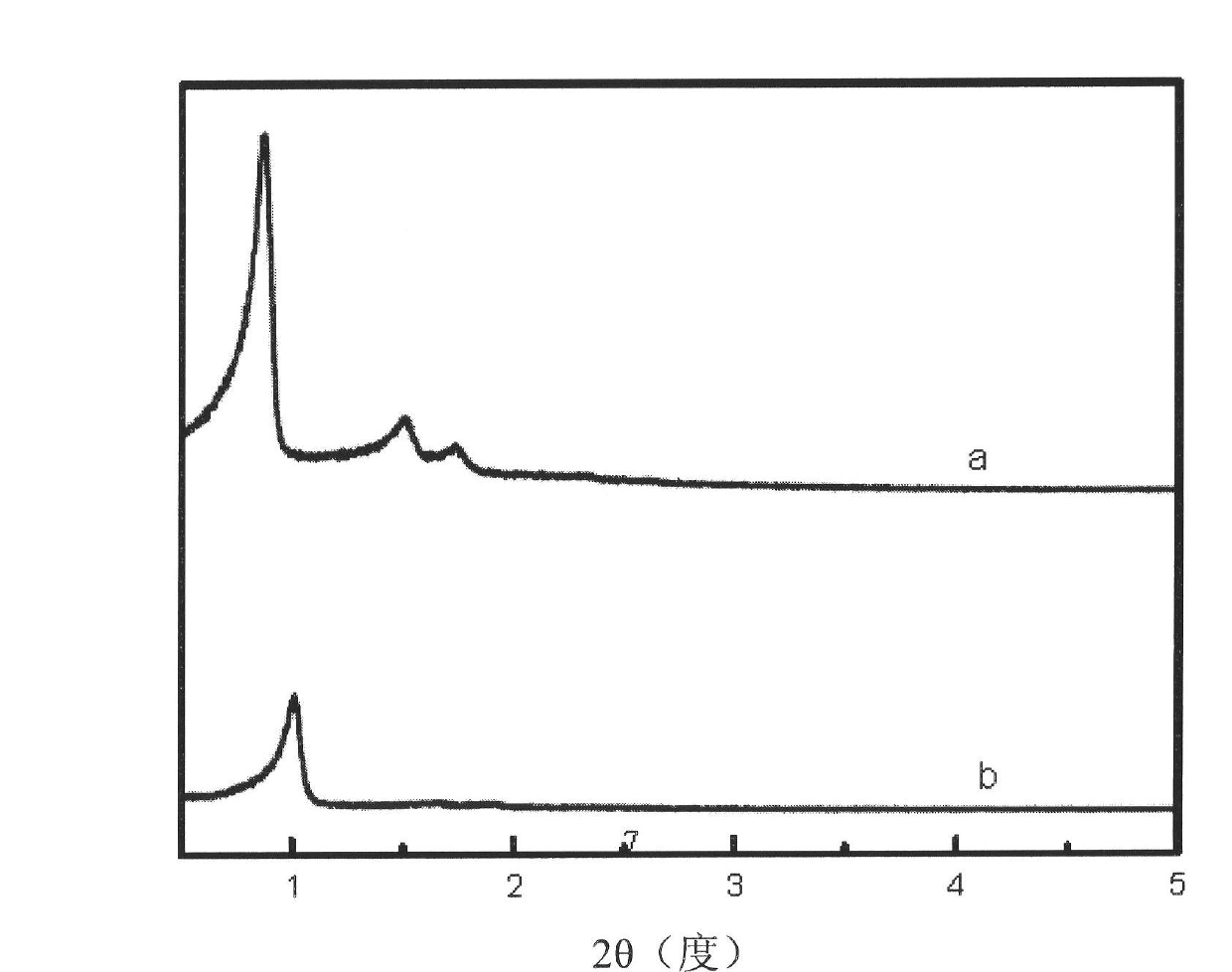

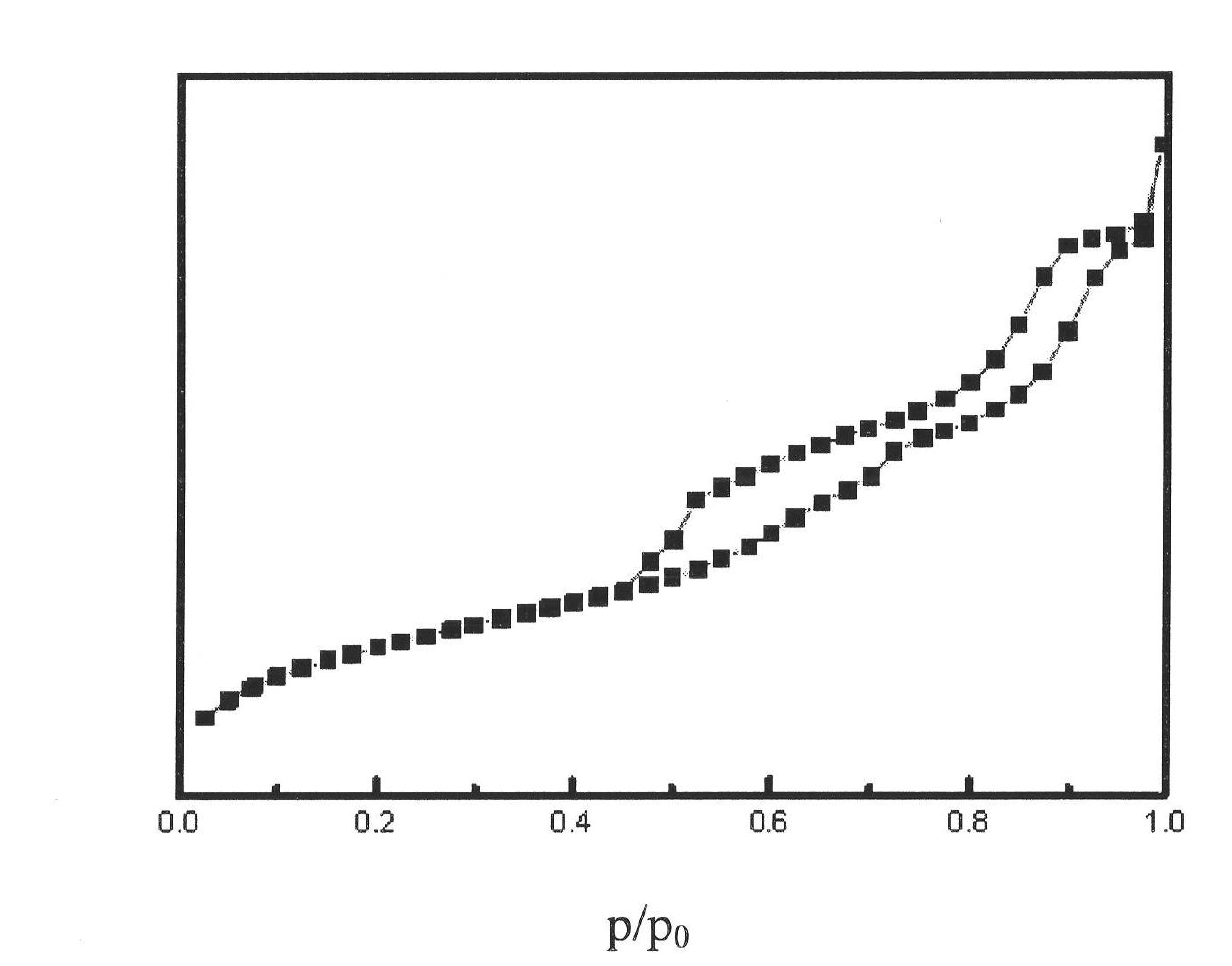

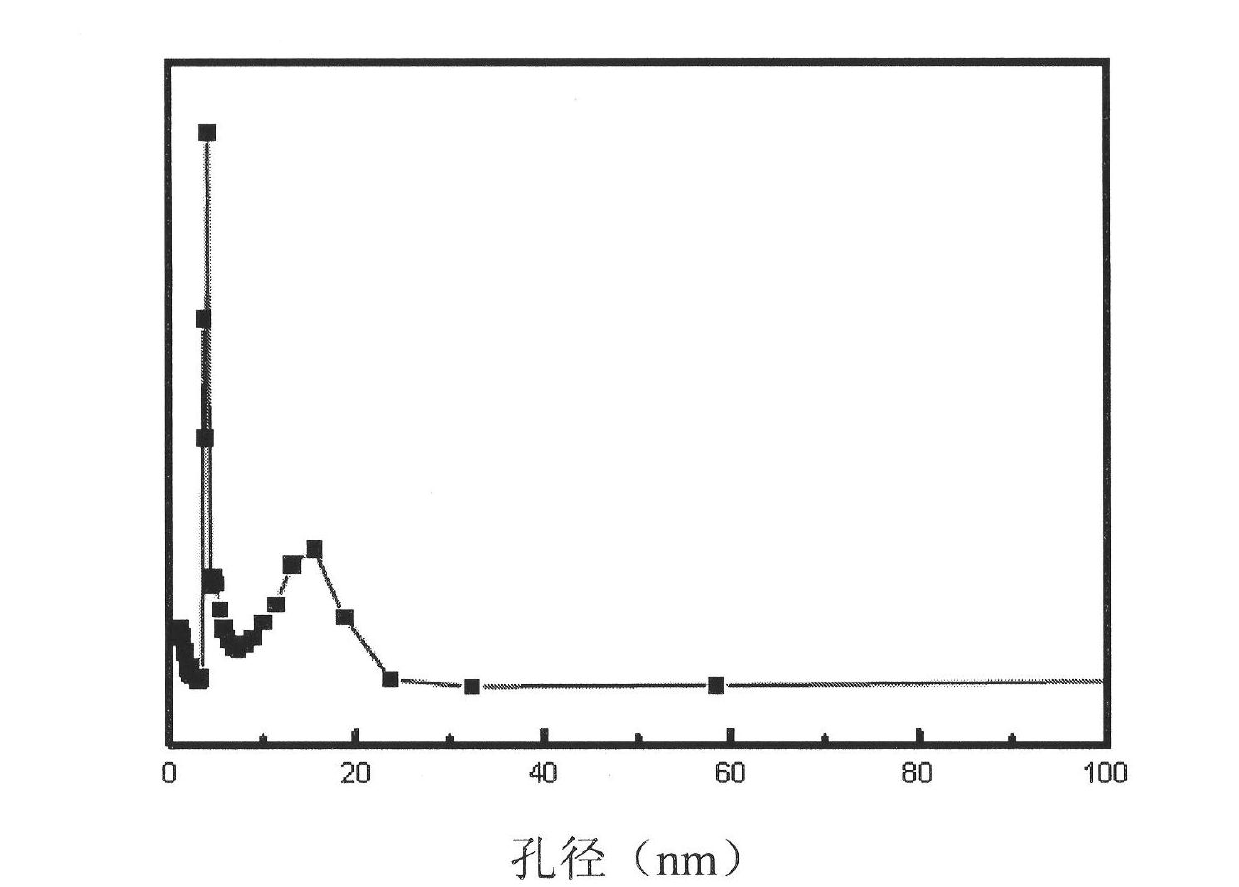

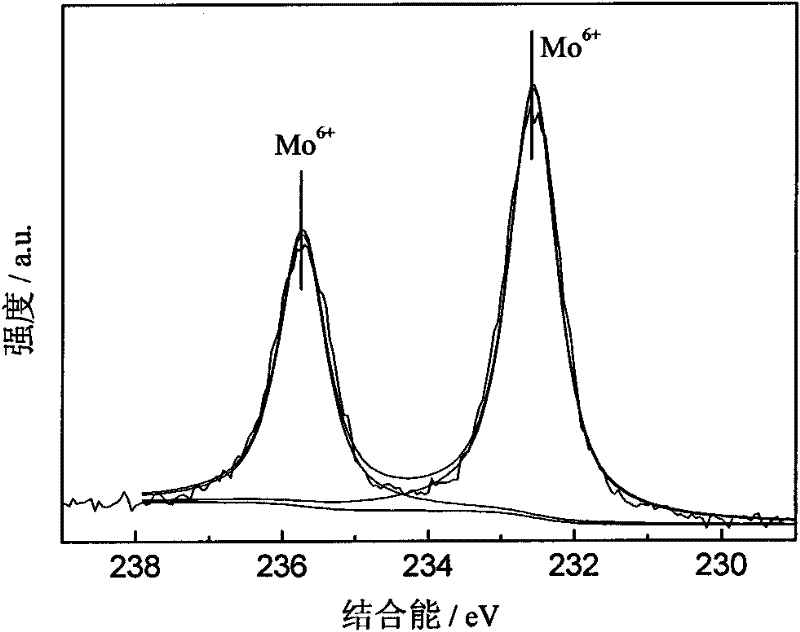

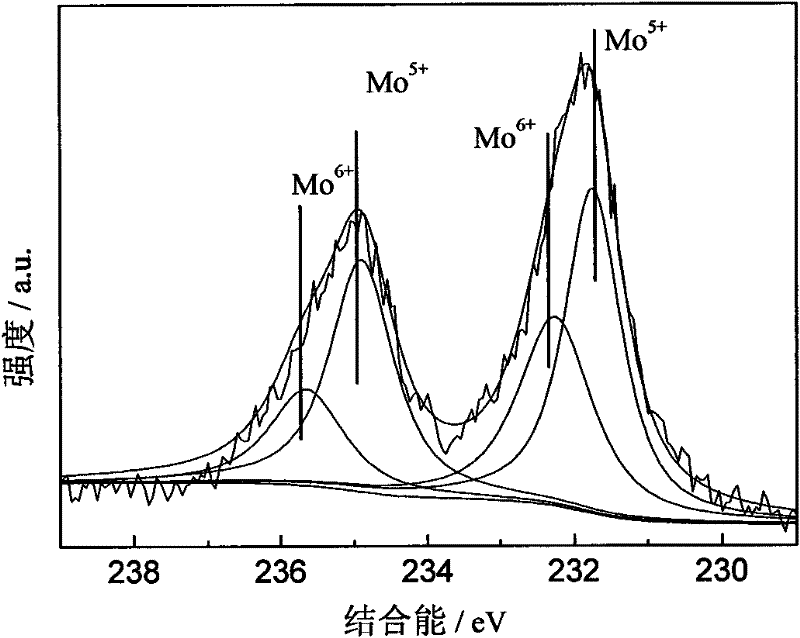

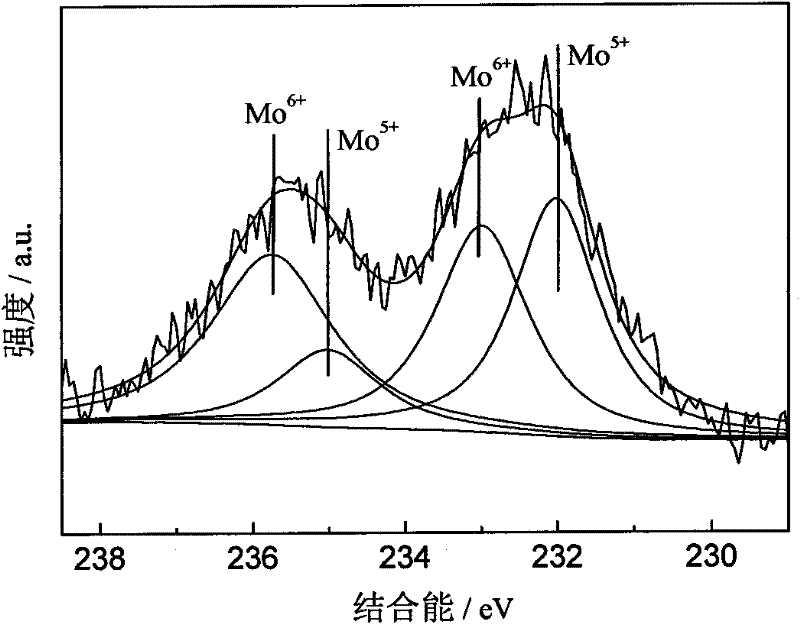

Preparation method for supported Mo-based oxidation and desulfurization catalyst

InactiveCN102294236AHigh activityRealize deep desulfurizationMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsOrganic acidPetrochemical

Owner:DALIAN UNIV OF TECH

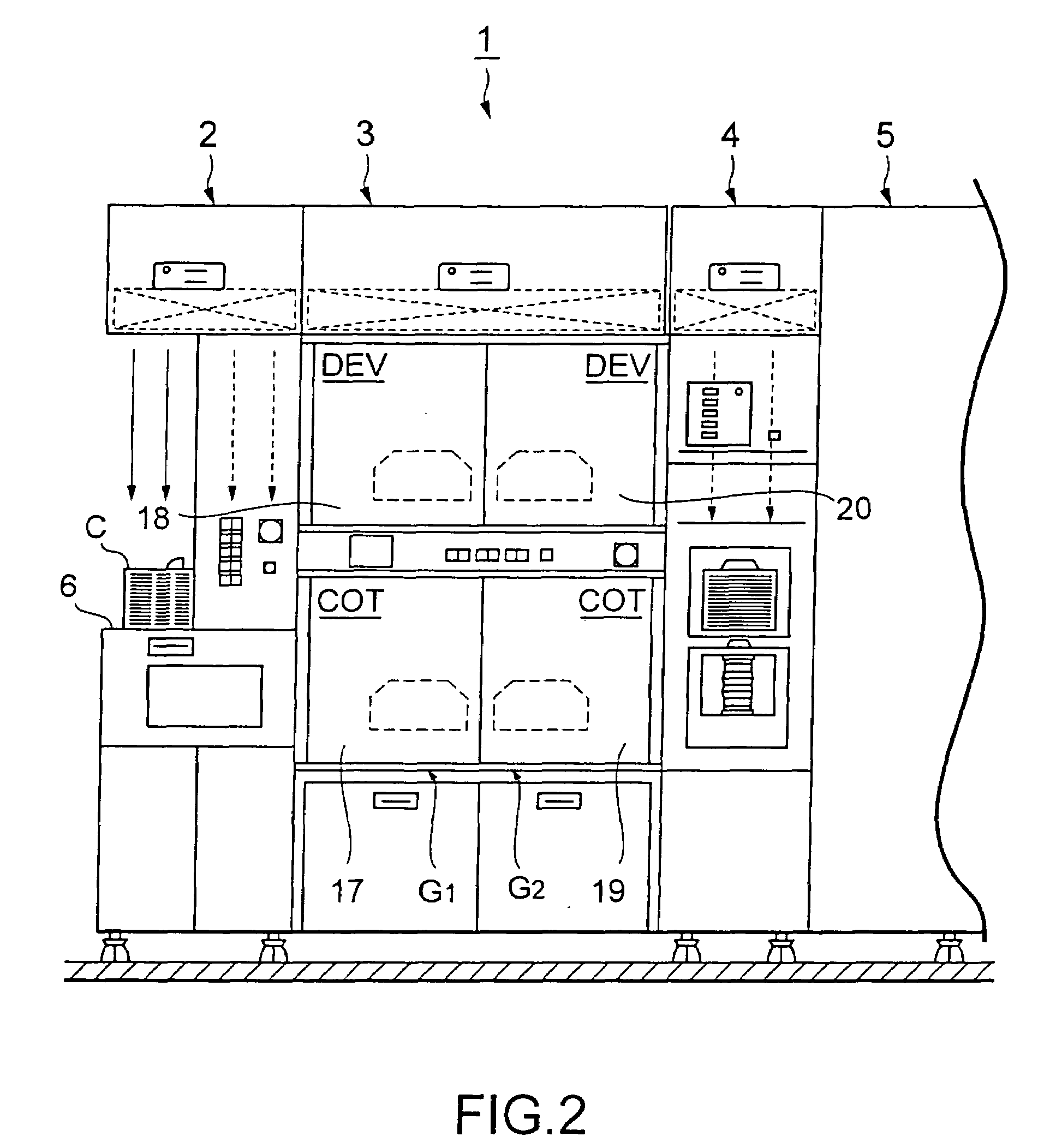

Substrate processing apparatus and substrate processing method

InactiveUS7208066B2Avoid levelingLiquid surface applicatorsPhotomechanical apparatusAtmospheric airEngineering

Owner:TOKYO ELECTRON LTD

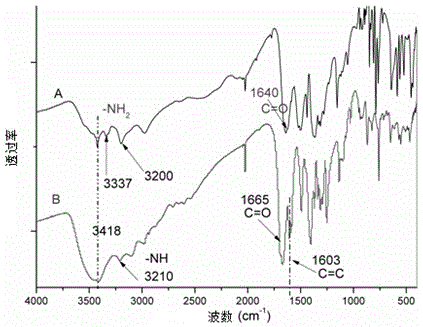

Method for preparing 2,2-dual [3-amido-4-(4-nitrophenoxy)phenyl group]-1,1,1,3,3,3-hexa-fluoropropane

InactiveCN101130502AHigh yieldHigh purityOrganic compound preparationAmino-hyroxy compound preparationOrganic solventHEXA

The invention discloses a making method of 2,2-di [3-amino-4-(4-nitrobenzeneoxy) phenyl]-1,1,1,3,3,3-hexafluoropropane, which comprises the following steps: (1) heating 2, 2-di (3-amino-4-hydroxybenzene)-1,1,1,3,3,3-hexafluoropropane and 4-halogenated nitrobenzene with molar rate at 1. 00: 2. 00-3. 00 under inert gas to reflux and do diversion reaction for 4-18h; (2) condensing the reacting liquid; cooling the reactant system; adding water; evolving solid product; filtering; washing; drying; obtaining the product. The invention simplifies the operation with high receiving rate and purity, which is easy to recycle solvent to use reciprocally to reduce three wastes for industrialized manufacturing.

Owner:DONGHUA UNIV

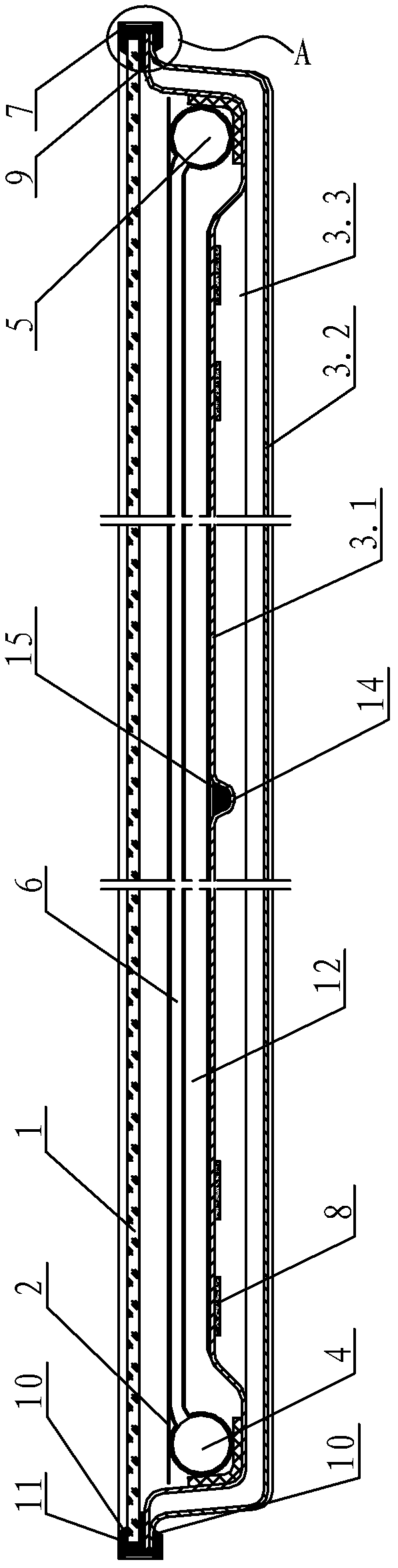

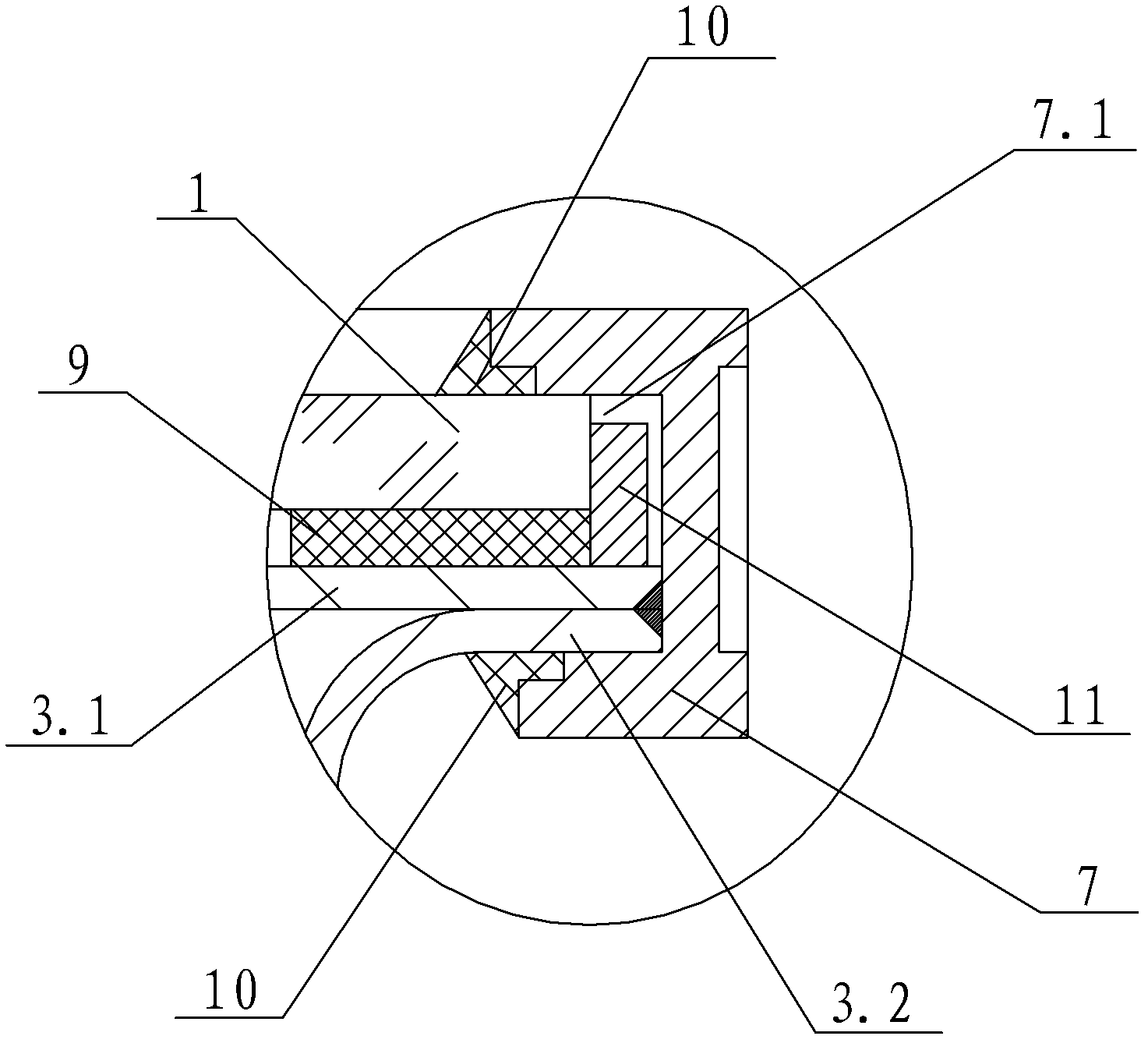

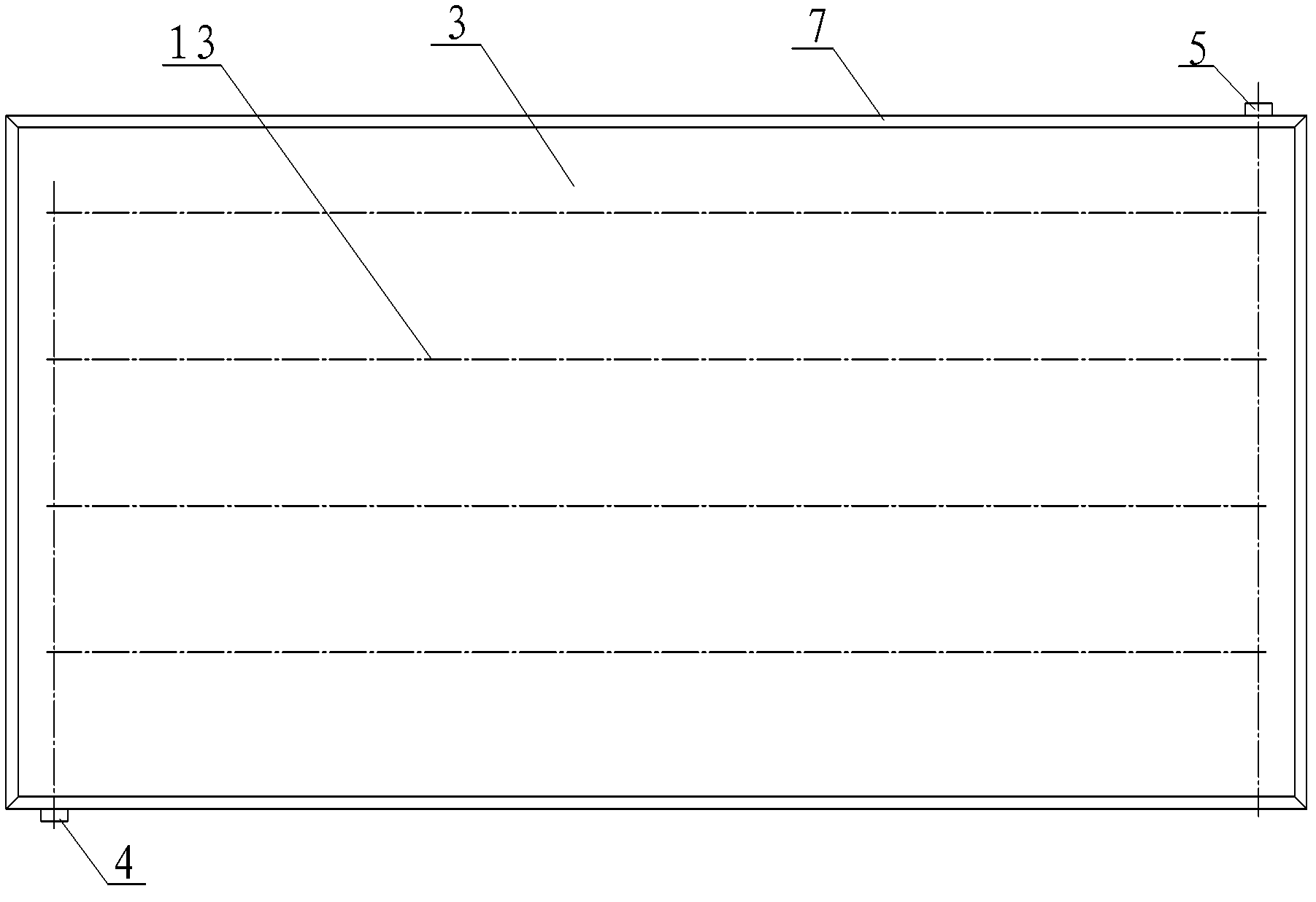

Panel solar thermal collector

InactiveCN102538235AImprove insulation effectIncrease profitSolar heating energySolar heat devicesThermal insulationCollector device

Owner:湖北贵族真空科技股份有限公司

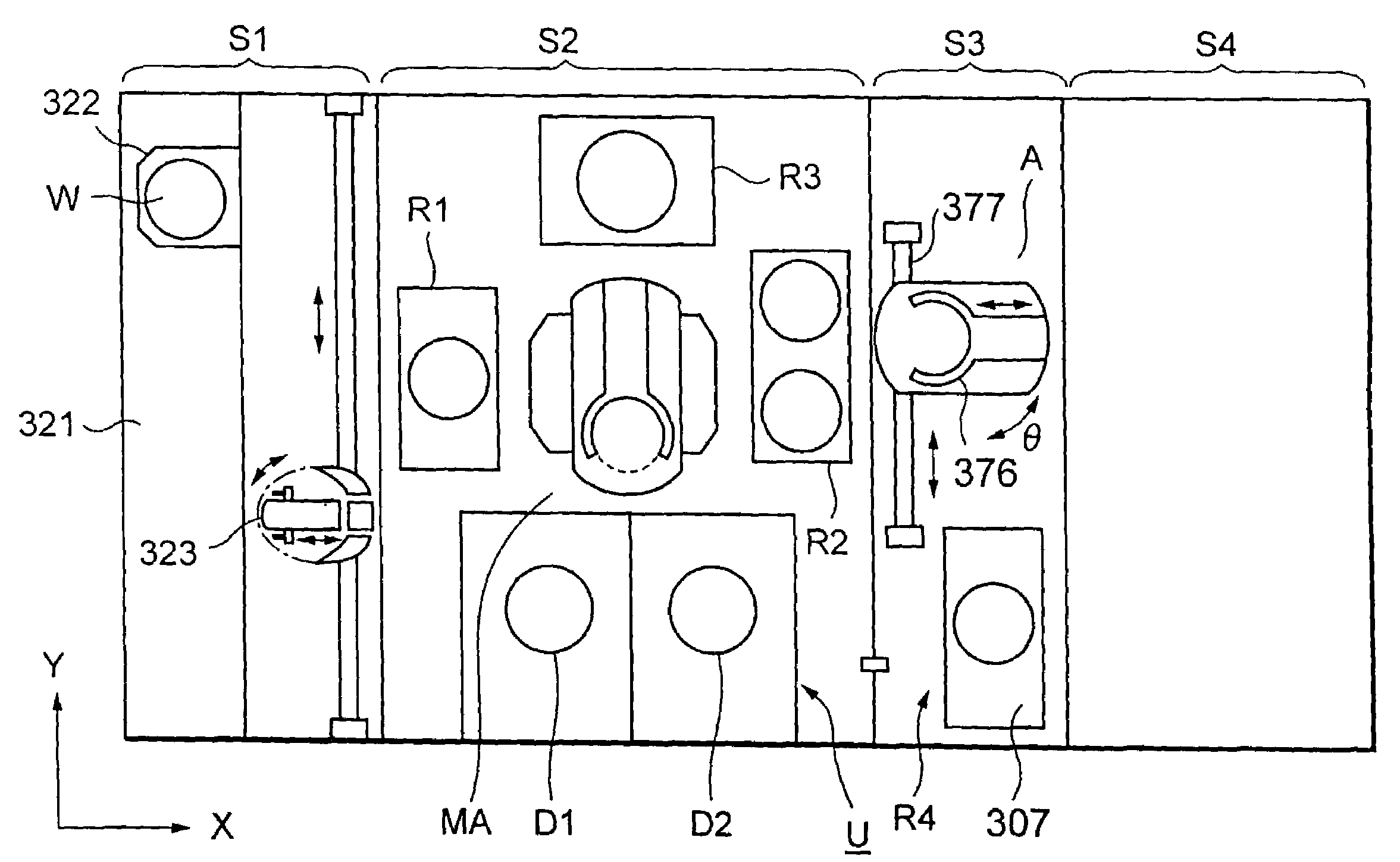

Substrate processing apparatus, substrate processing method, and storage medium storing a computer program for performing substrate processing method

ActiveUS20110220157A1Improve processing efficiencyImprove reliabilitySemiconductor/solid-state device manufacturingCleaning using liquidsCompound (substance)Product gas

A substrate processing apparatus according to the present invention comprises: a processing part configured to process a substrate; a chemical-liquid storing container configured to store a chemical liquid; a chemical-liquid supply driving part configured to supply the chemical liquid from the chemical-liquid storing container into the processing part; a circulation line configured to circulate the chemical liquid stored in the chemical-liquid storing container; and a mixture generating part provided on the circulation line. An inert-gas supply source is configured to supply an inert gas into the mixture generating part. The mixture generating part is configured to mix the chemical liquid supplied from the chemical-liquid storing container and the inert gas supplied from the inert-gas supply source with each other so as to generate a gas-liquid mixture.

Owner:TOKYO ELECTRON LTD

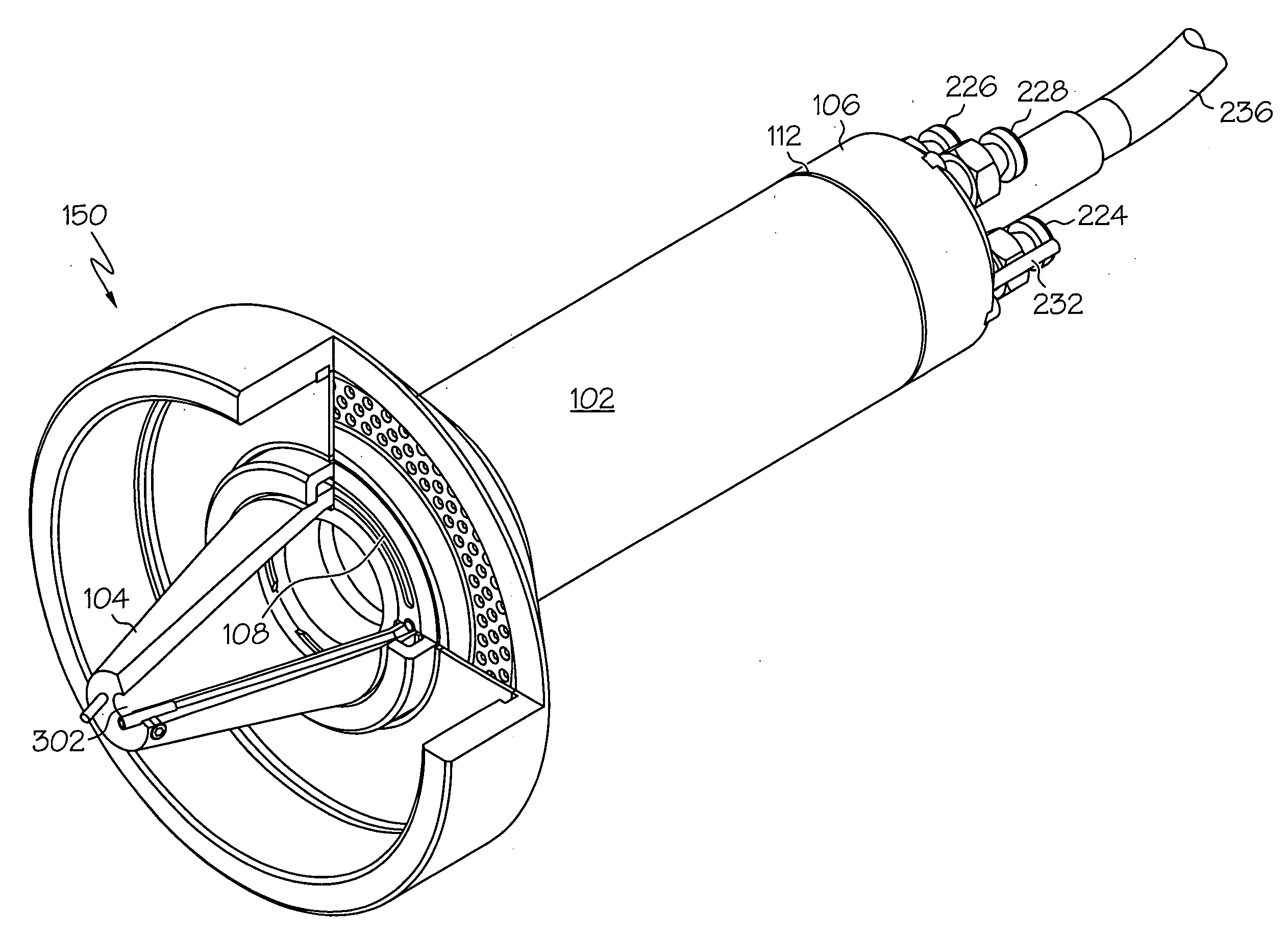

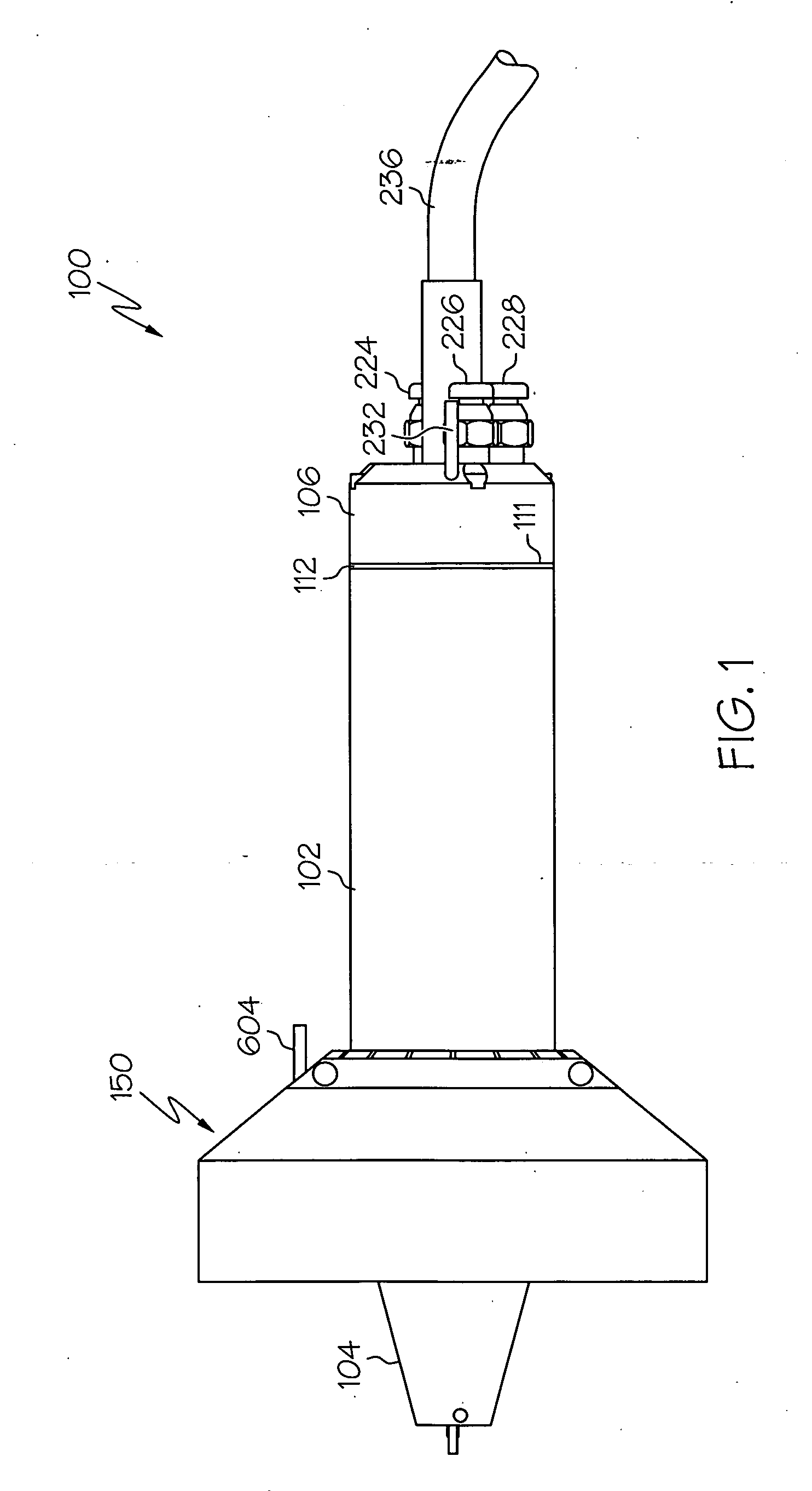

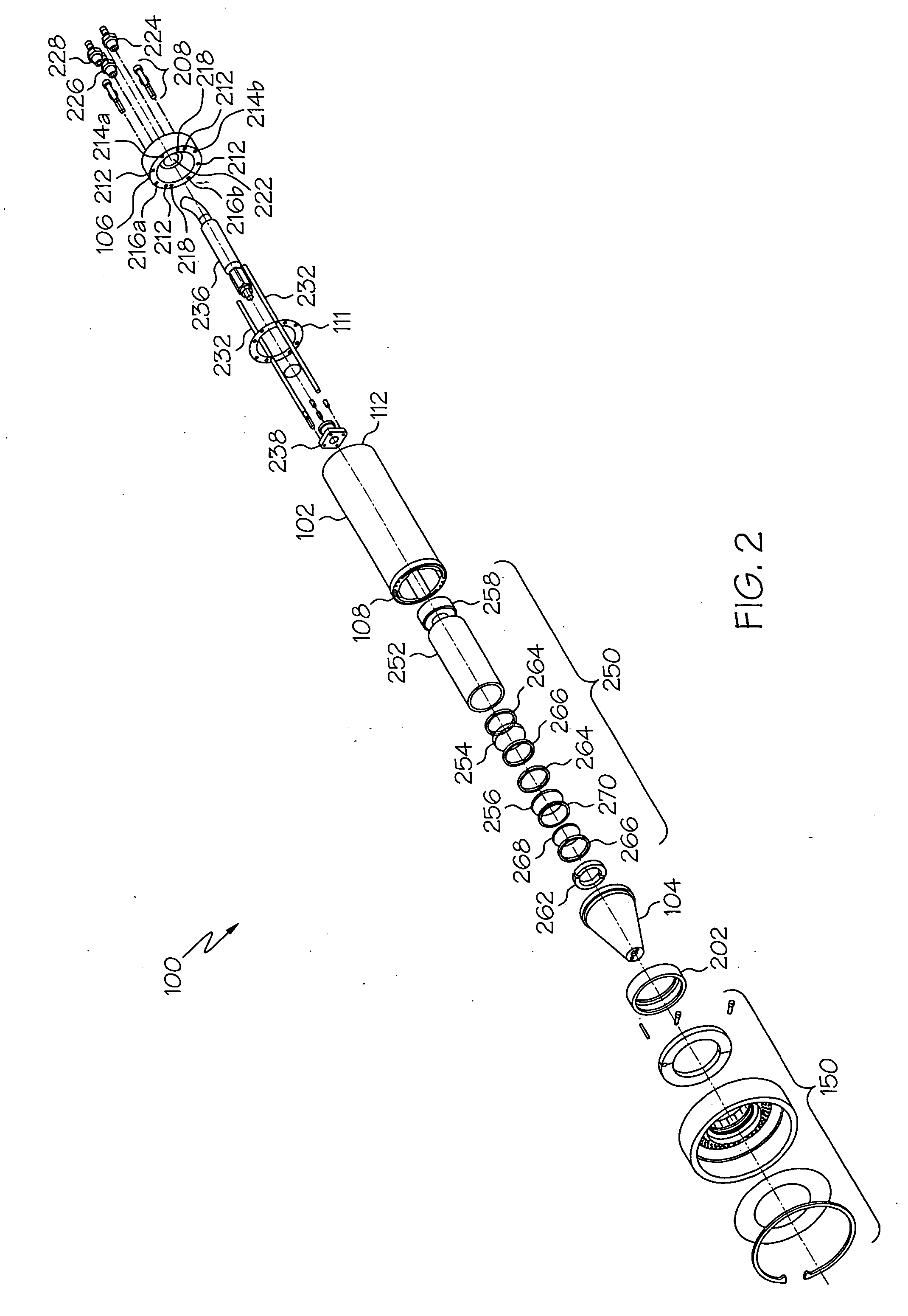

Hand-held laser welding wand gas lens

Owner:HONEYWELL INT INC

Method of manufacturing thin film transistor

InactiveUS20020072158A1Good precisionImprove directivitySolid-state devicesSemiconductor/solid-state device manufacturingMass numberEngineering

In a thin film transistor, a first insulating film on a silicon layer formed in an island on a substrate is smaller in thickness than the silicon layer so that the stepped island edges is gentle in slope to facilitate covering the island with a second insulating film. This reduces occurrence of gate leak considerably. Since the peripheral region of the stepped island is smaller in thickness than the central region above the channel, it is possible to minimize occurrence of gate electrode breakage. The silicon layer contains two or more inert gas atoms, and the atoms smaller in mass number (e.g., He) are contained in and near an interface with a silicon active layer while the atoms larger in mass number (e.g., Ar) than those smaller in mass number are contained in and near a second interface with a gate electrode.

Owner:GOLD CHARM LTD

Heat treatment method for recovering performance of K465 alloy turbine blade

ActiveCN103643188ARecovery performance (creep) effect is obviousSquare shapeFurnace typesHeat treatment furnacesTurbine bladeAlloy

The invention discloses a heat treatment method for recovering the performance of a K465 alloy turbine blade and belongs to the technical field of metallurgy. The heat treatment method comprises the following steps of 1, blade feeding, 2, furnace heating and then heat preservation: in vacuum or inert gas protective atmosphere, carrying out heat preservation at a temperature of 950-960 DEG C for 40-45min, carrying out heat preservation at a temperature of 1190-1200 DEG C for 2-2.5h and carrying out heat preservation at a temperature of 1230 DEG C for 4-4.5h, and 3, furnace cooling: (1), carrying out cooling from a temperature of 1230 DEG C to a temperature of 1000 DEG C at a cooling rate of 40+ / -25 DEG C / min by inert gas-based differential pressure cooling, and (2), feeding inert gas at a temperature of 1000 DEG C, carrying out cooling to a temperature of 300 DEG C, and opening a furnace door at a temperature below 300 DEG C and carrying out cooling. The heat treatment method can obviously recover the performance (such as creep deformation) of the K465 alloy turbine blade after a service cycle. Through the heat treatment method, transgranular gamma' polygonal or flower basket-shaped morphology is transformed into the cubical morphology so that morphology squaring is promoted.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Preparation method of ternary terbium complex monomer and copolymer luminescent material of ternary terbium complex monomer and MMA

InactiveCN105061481AImprove internal quantum efficiencyHigh color purityGroup 3/13 element organic compoundsLuminescent compositionsN dimethylformamideFluorescence

Owner:CHONGQING UNIV OF TECH

3, 3-difluoro-1, 5-hexadiene compound as well as preparation method and application thereof

ActiveCN113024349AHigh selectivityEasy to operateSugar derivativesCarboxylic acid nitrile preparationMeth-Silanes

The invention discloses a 3, 3-difluoro-1, 5-hexadiene compound as well as a preparation method and an application thereof. The preparation method comprises the following steps: in an inert gas atmosphere, sequentially adding alpha-trifluoromethyl styrene, allyltrimethylsilane, tetrabutylammonium fluoride and a solvent into a reaction tube, and magnetically stirring uniformly to obtain a mixture; performing a magnetic stirring reaction on the mixture for 12 h under the condition of a 130 DEG C oil bath, cooling the reaction mixture to the room temperature, and obtaining the 3, 3-difluoro-1, 5-hexadiene compound from the reaction mixture through rapid column chromatography separation. The compound can be used for synthesizing a precursor compound containing a CF2 organic framework. The preparation method has the advantages of high selectivity, economy, environmental protection, simple operation, cheap and easily available raw materials, and is suitable for industrial application.

Owner:NANJING TECH UNIV

Defoaming method in synthesizing process of polyamide resin

ActiveCN103028274ASimple structureReduce discolorationFoam dispersion/preventionRelative pressurePolymer science

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

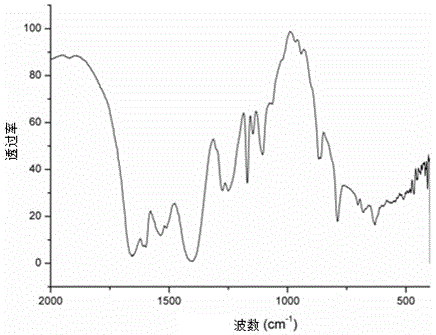

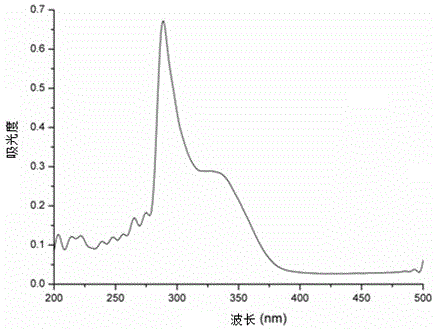

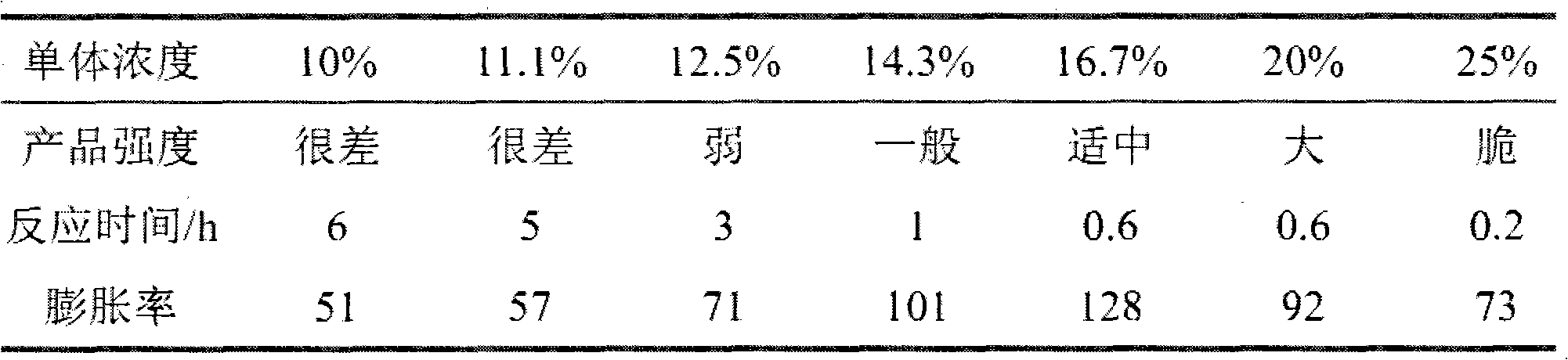

Preparation process of leak protection plugging agent along with drilling based on control of monomer concentration

InactiveCN102993357AImprove performanceIncrease productivityDrilling compositionWater bathsReaction temperature

Owner:倪蕊

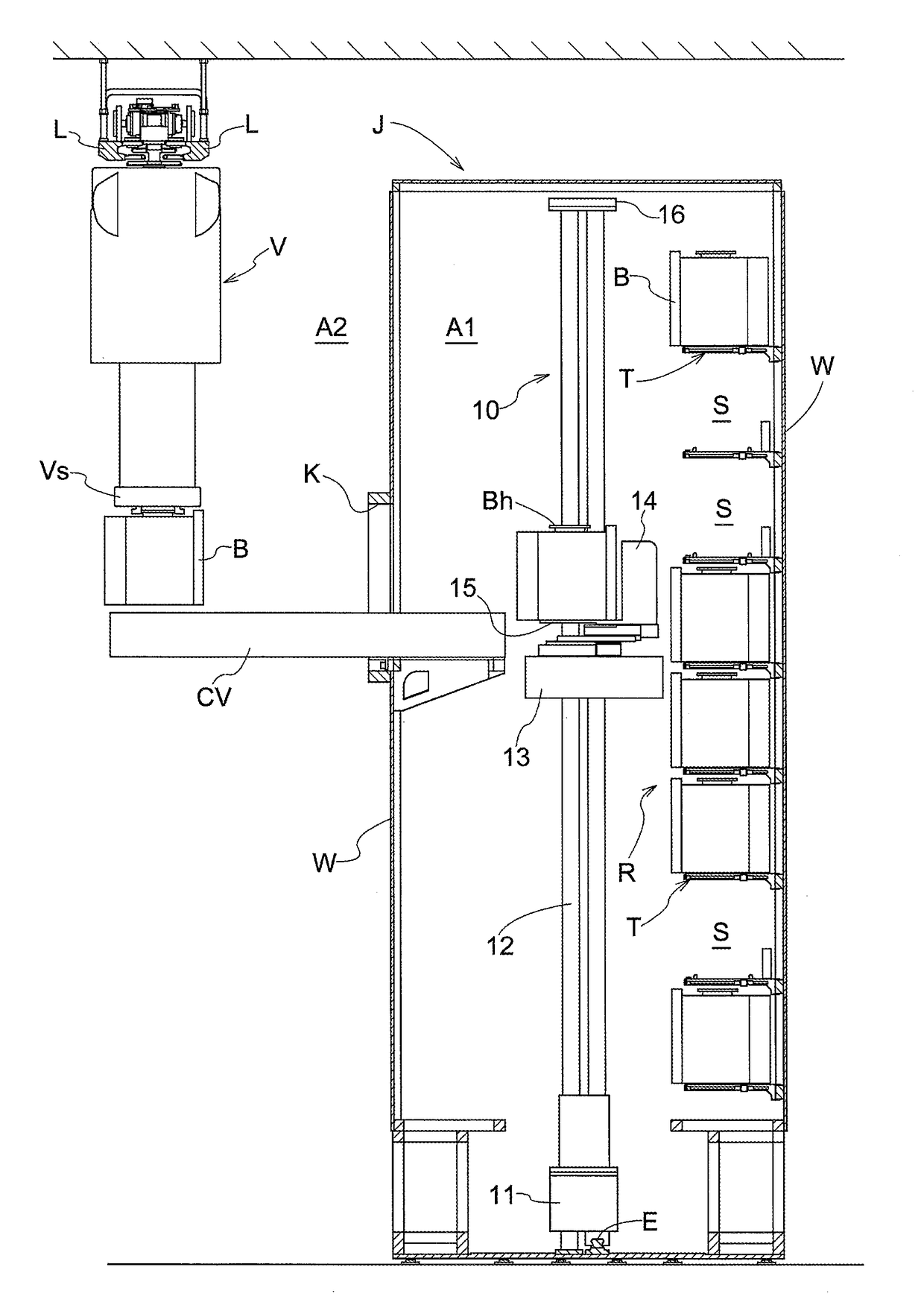

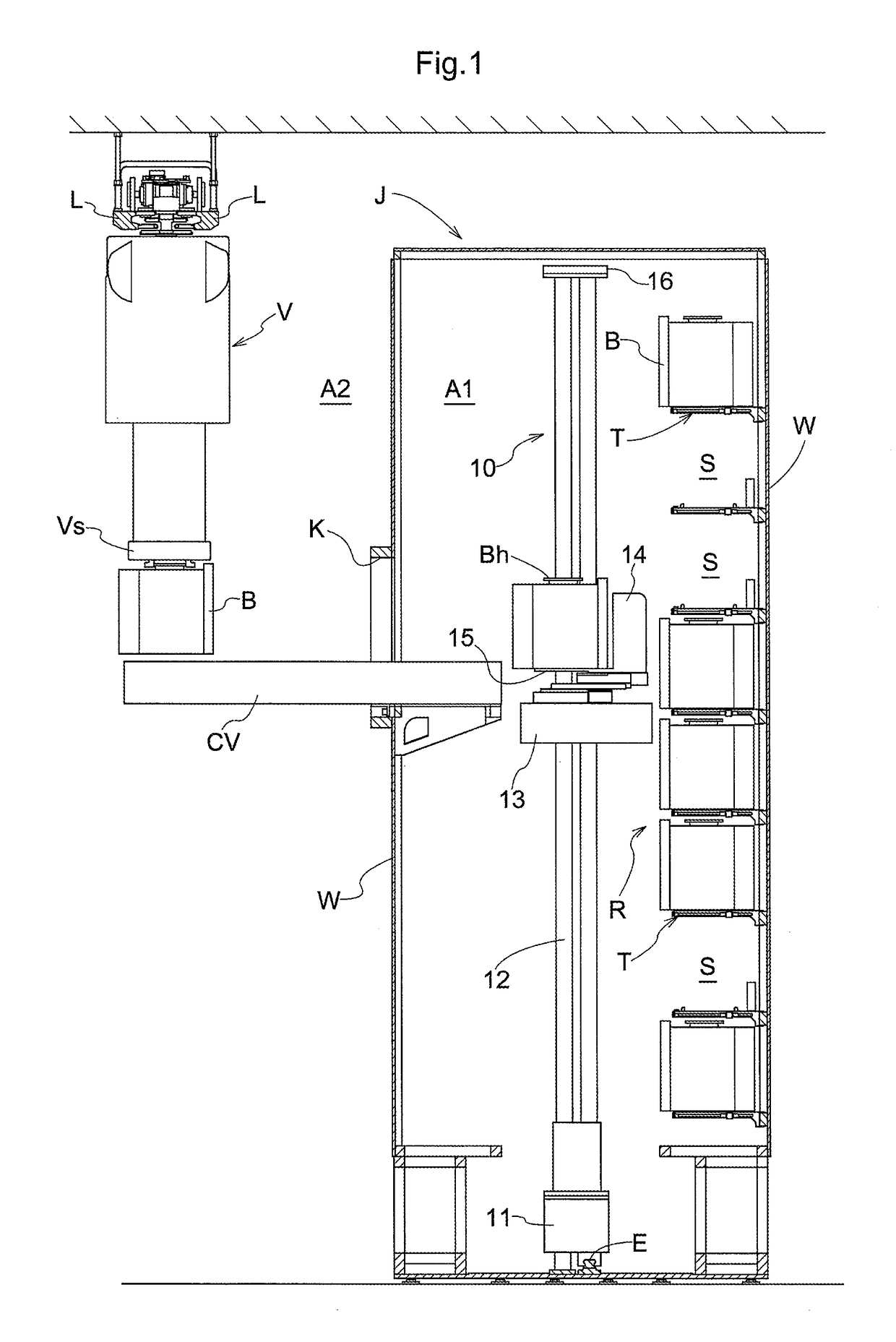

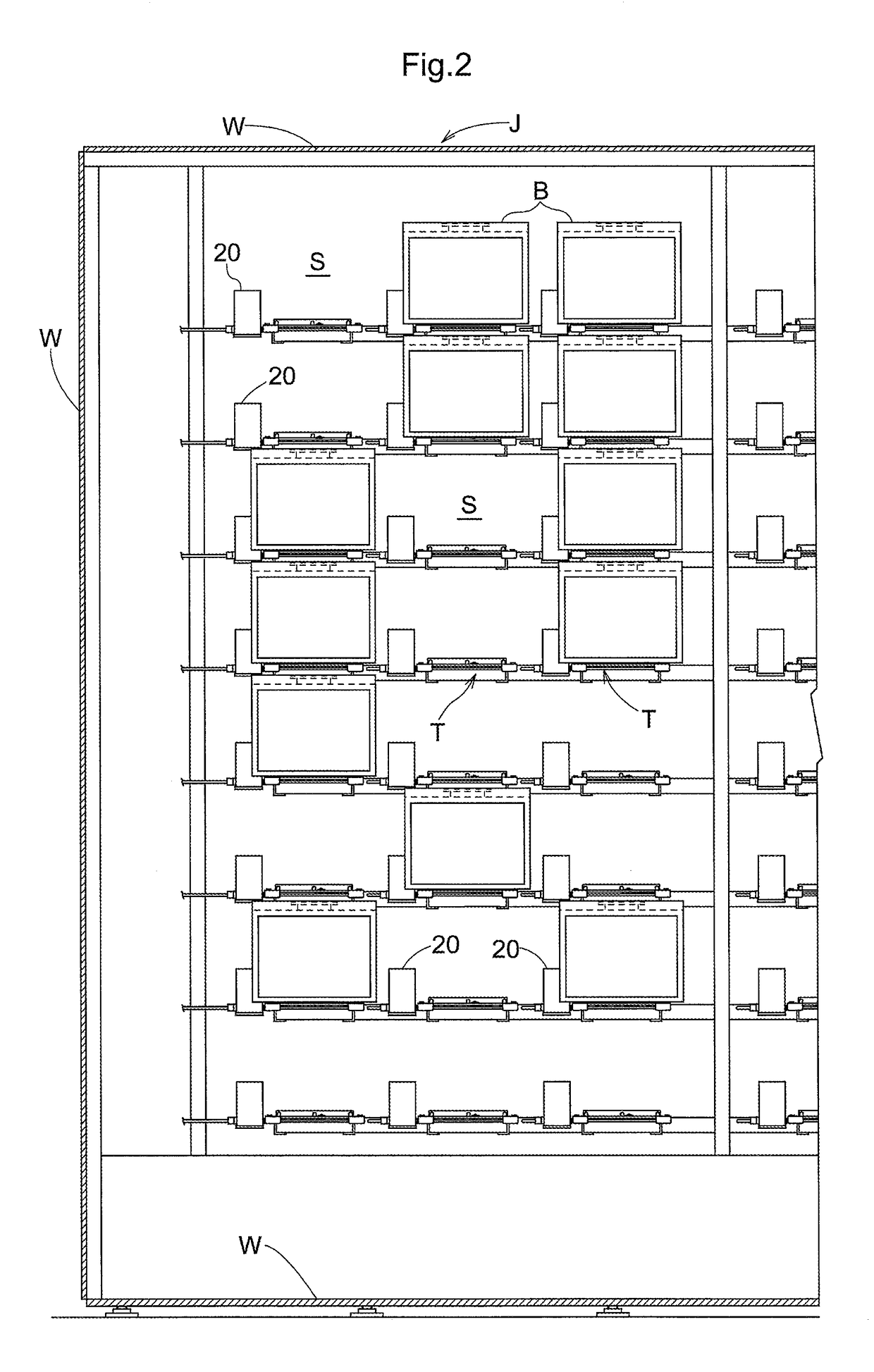

Container Storage Facility

ActiveUS20180076078A1More likelihoodSemiconductor/solid-state device manufacturingConveyor partsElectric power systemEngineering

Owner:DAIFUKU CO LTD

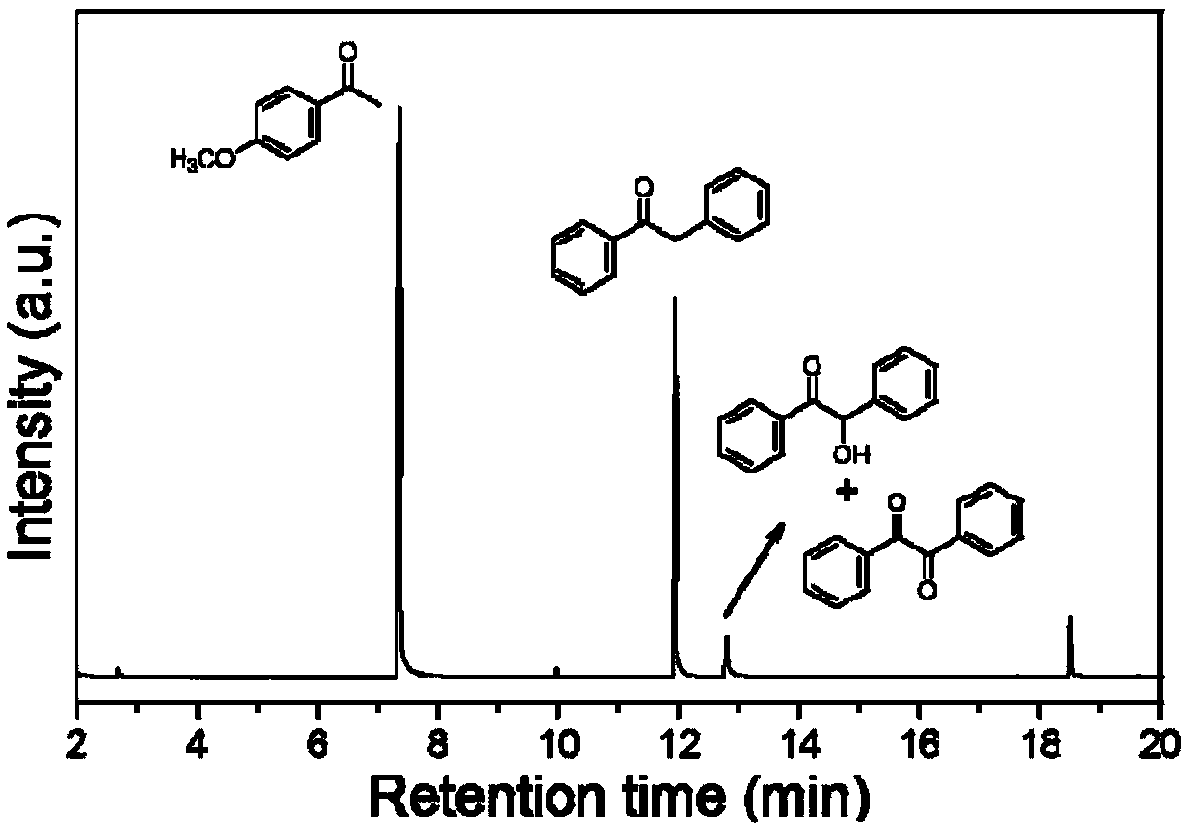

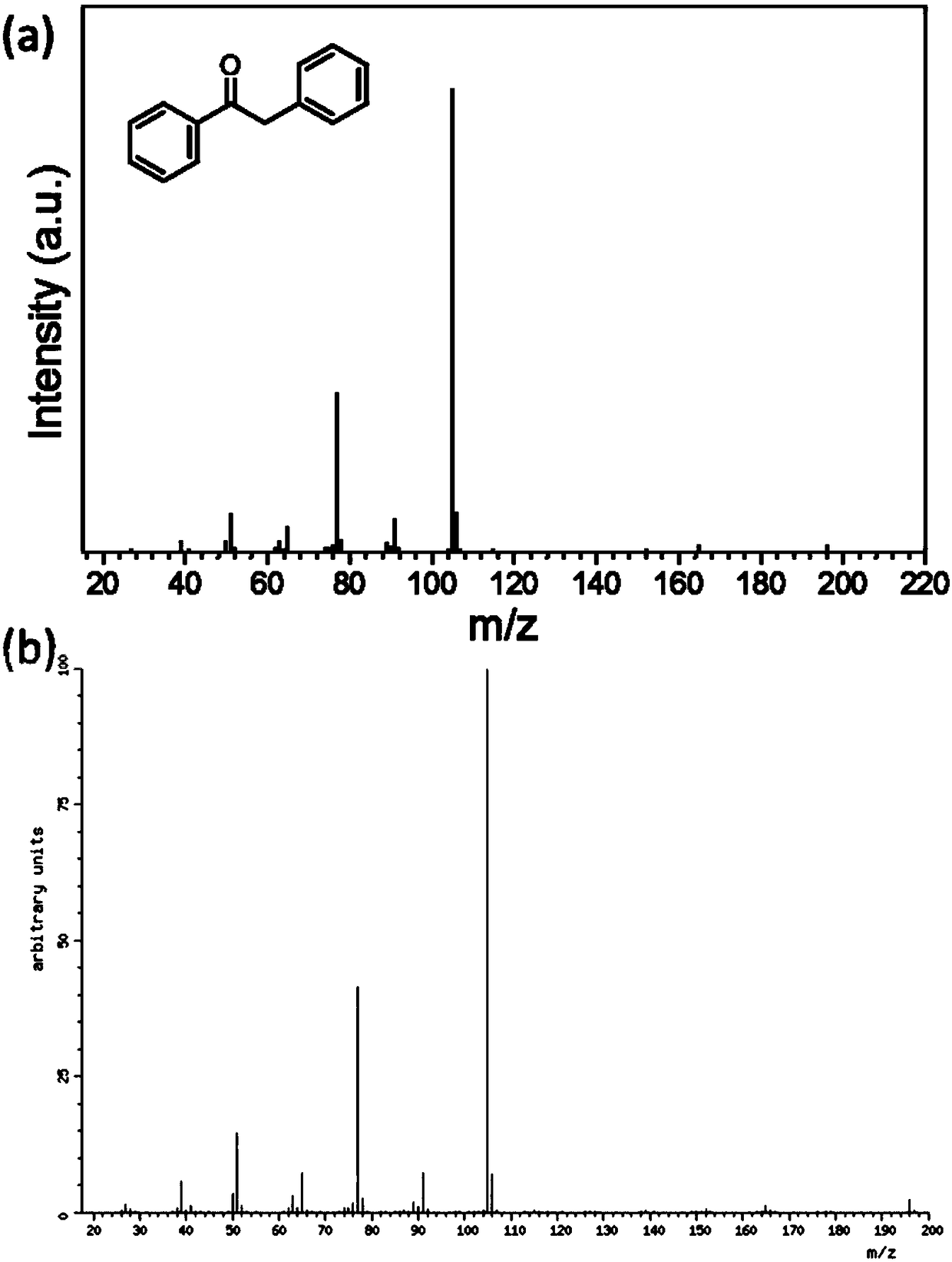

Method for preparing diphenylethanone from benzyl alcohol through photocatalytic one-step method

InactiveCN108440259ALow costAvoid dangerOrganic compound preparationHydroxy compound preparationRoom temperatureAcetonitrile

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Resin graphene composite material, preparation method and application thereof

InactiveCN108329520AImprove conductivityImprove thermal conductivityElectroconductive/antistatic filament manufactureAnti-corrosive paintsSlurryCvd graphene

The invention provides a resin graphene composite material, a preparation method and an application thereof, which belong to the technical field of the graphene composite material. The preparation method comprises the following steps: 1) mixing a metal auxiliary agent, a graphene material and water and stirring a mixture to obtain a slurry; 2) drying the slurry to obtain metal graphene; and 3) heating the metal graphene and thermoplastic resin and heating the materials under inert gas atmosphere to the temperature of 50-300 DEG C for a reaction. The preparation method composites the graphene material and the thermoplastic resin, through a Pi bond electron cloud of the graphene material, free electron transmission is carried out, the obtained resin graphene composite material has good conductivity and thermal conductivity, and can be used as a novel electric conduction and heat conduction composite material.

Owner:BEIJING NORTH GUONENG TECH CO LTD

Preparation method for zeolite-activated carbon composite adsorbent

InactiveCN107876009AIncrease the areaLarge adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesSorbentCarbonization

Owner:SHAANXI SHENGMAI PETROLEUM

Single crystal pulling device, preparation method of single crystal silicon and single crystal silicon

InactiveCN109554756APrevent inflowReduce dislocationPolycrystalline material growthUnder a protective fluidSingle crystalEngineering

Owner:XIAN ESWIN SILICON WAFER TECH CO LTD

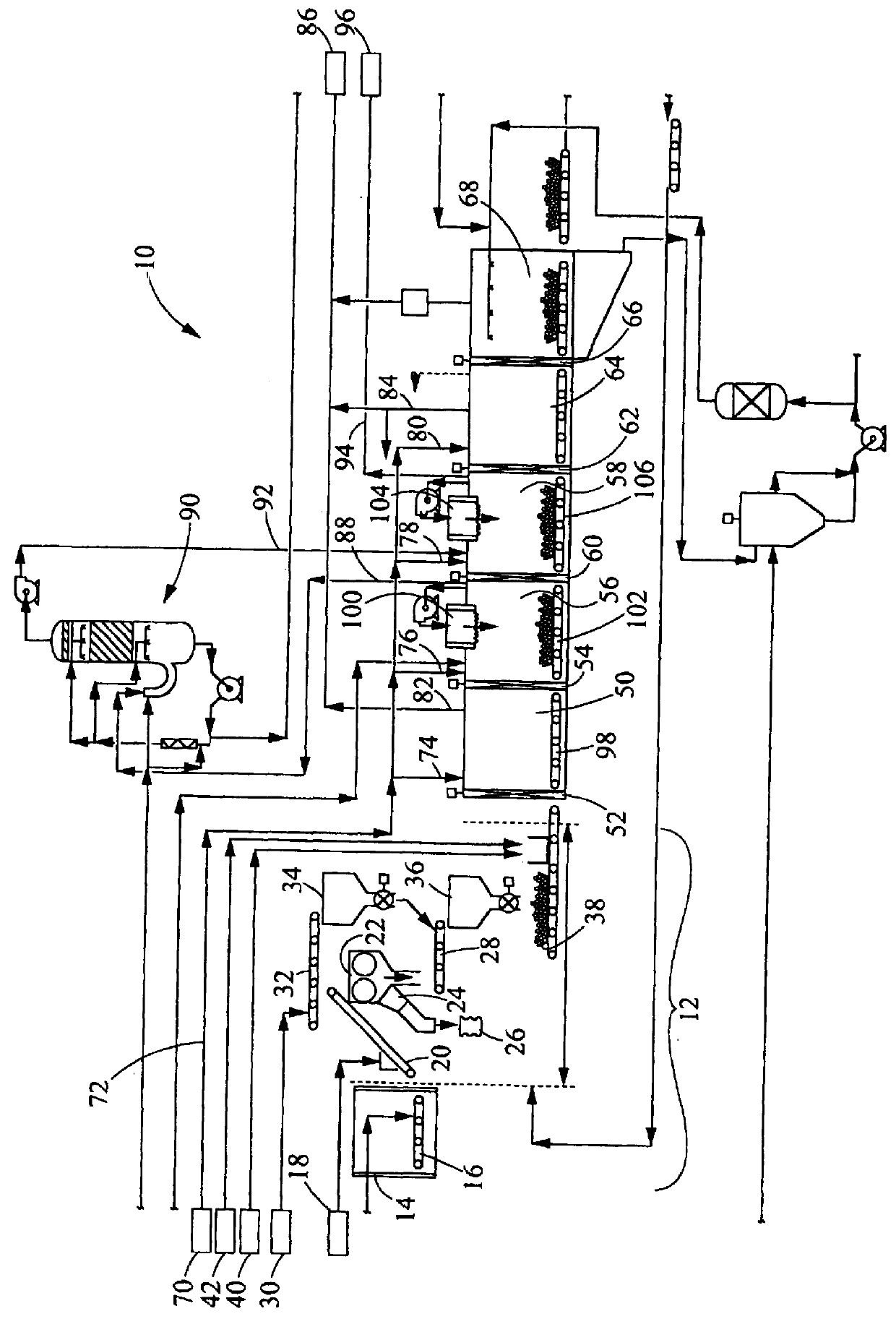

Multi-stage pyrolysis systems for treating chlorine contaminated wastes

InactiveUSH2198H1Minimize the possibilityMinimizes dioxinUsing liquid separation agentIncinerator apparatusFuranOxygen

Owner:CH2M HILL

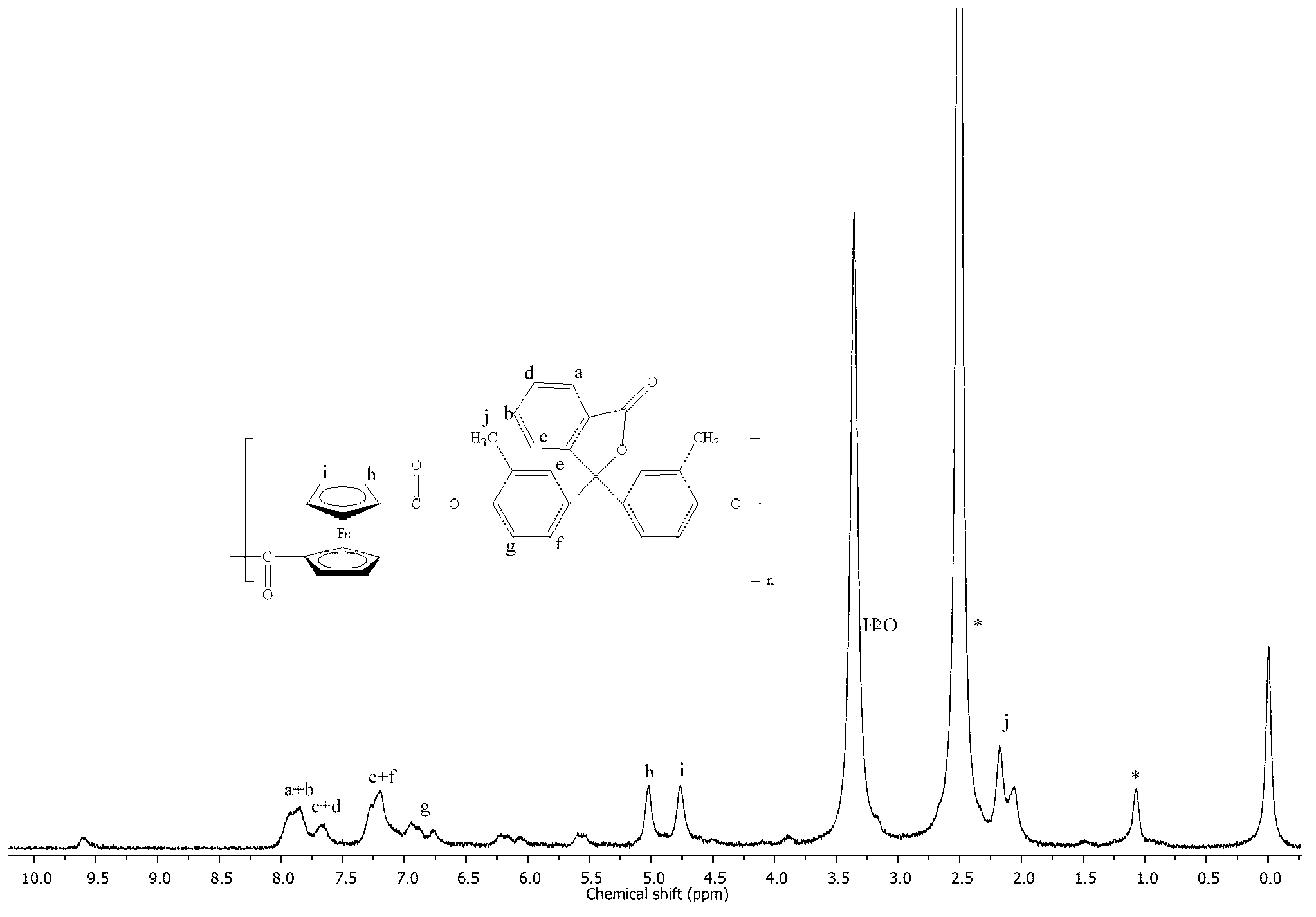

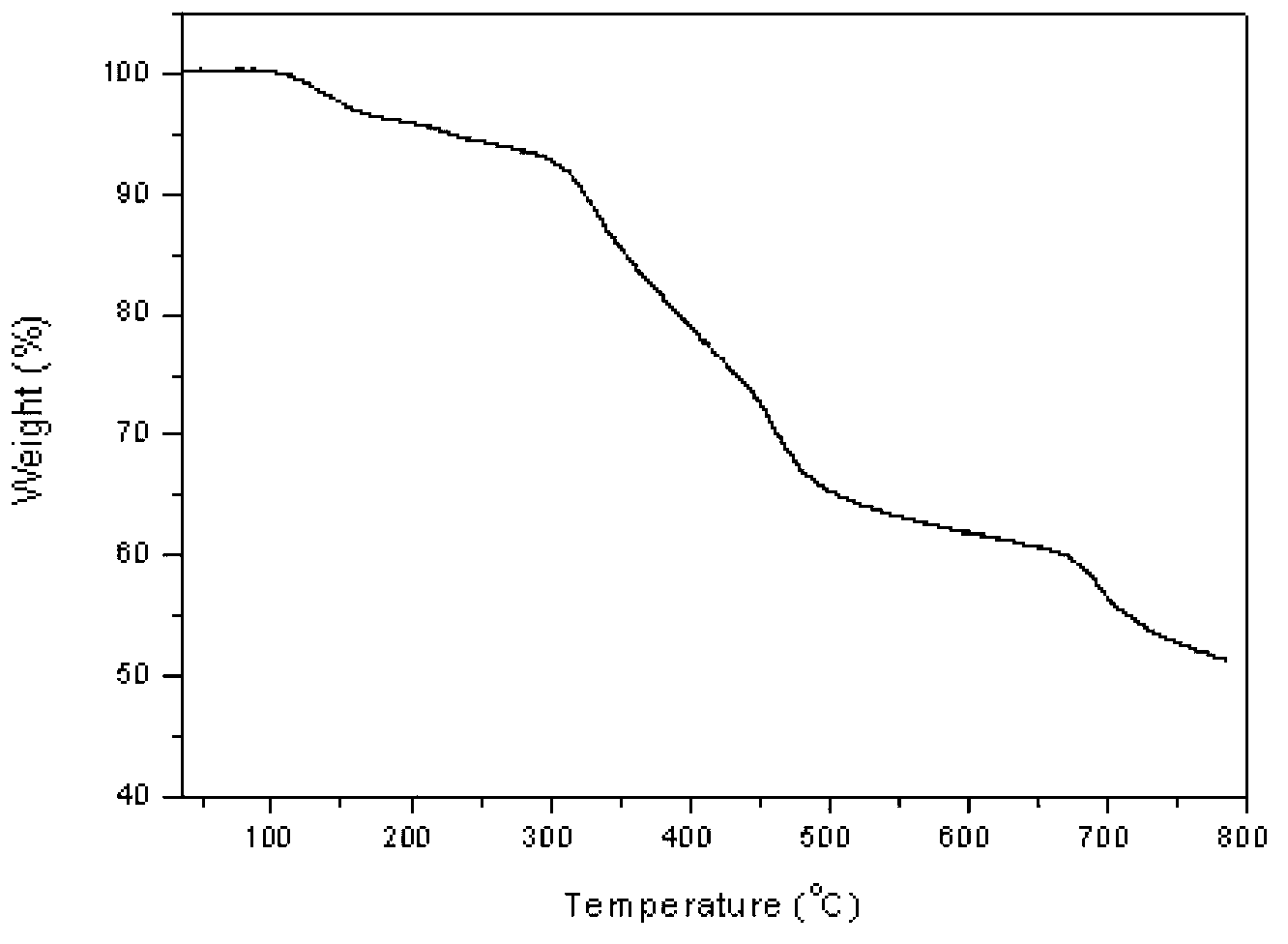

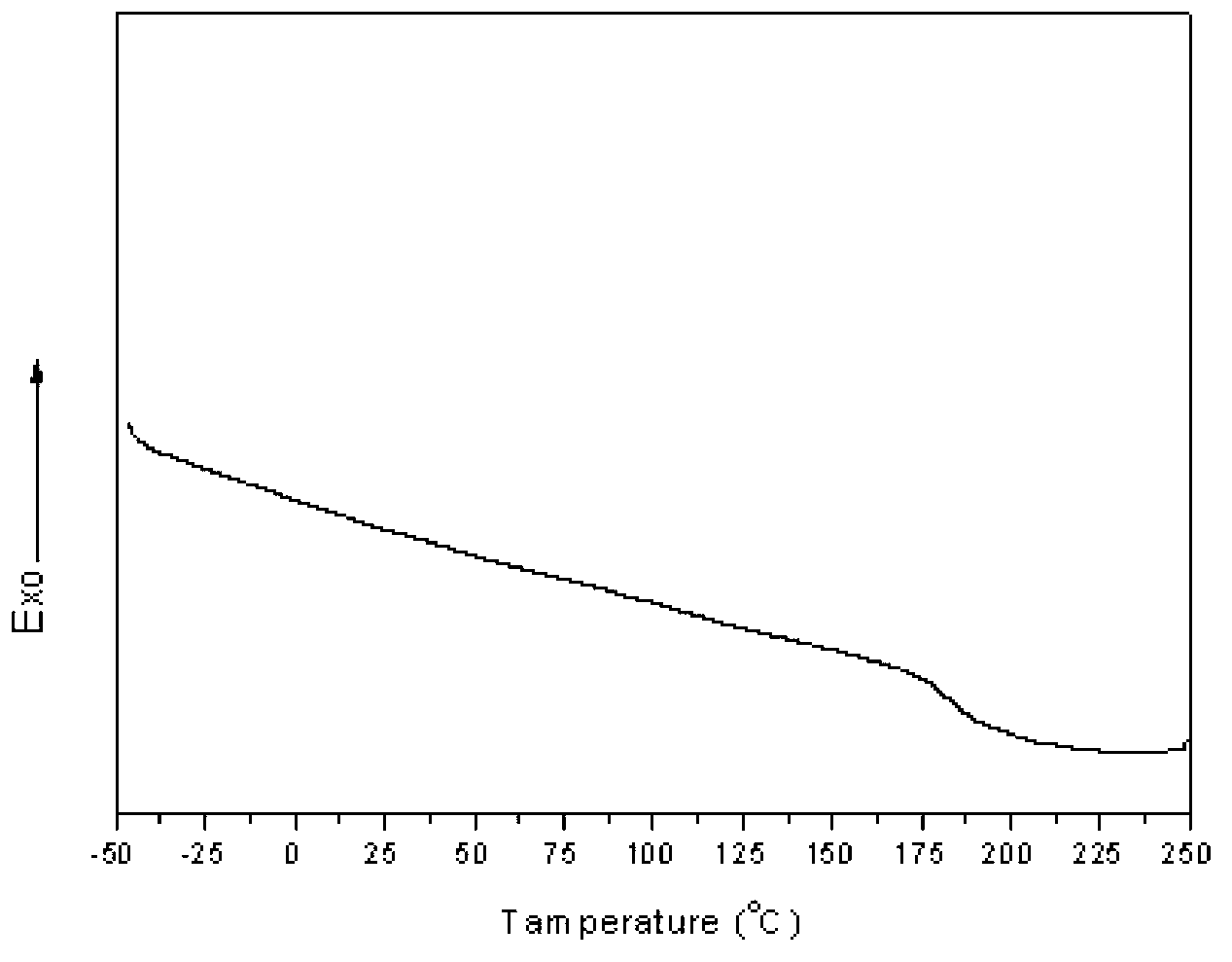

Preparation method of liquid crystal material of aromatic metal polymer of which main chain contains ferrocenyl

ActiveCN103059281ASimple processImprove thermal stabilityLiquid crystal compositionsPtru catalystDistillation

Owner:ZHEJIANG UNIV

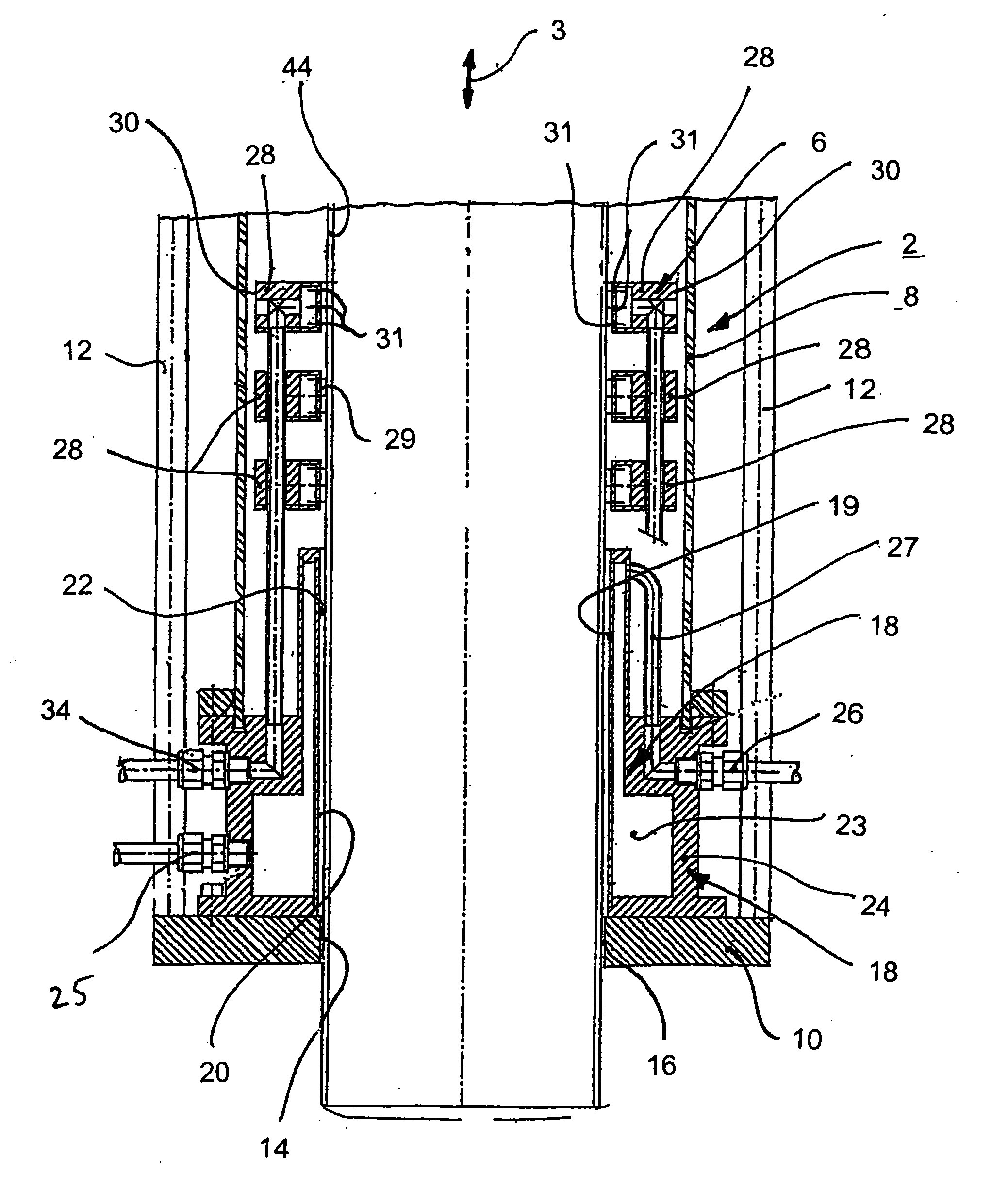

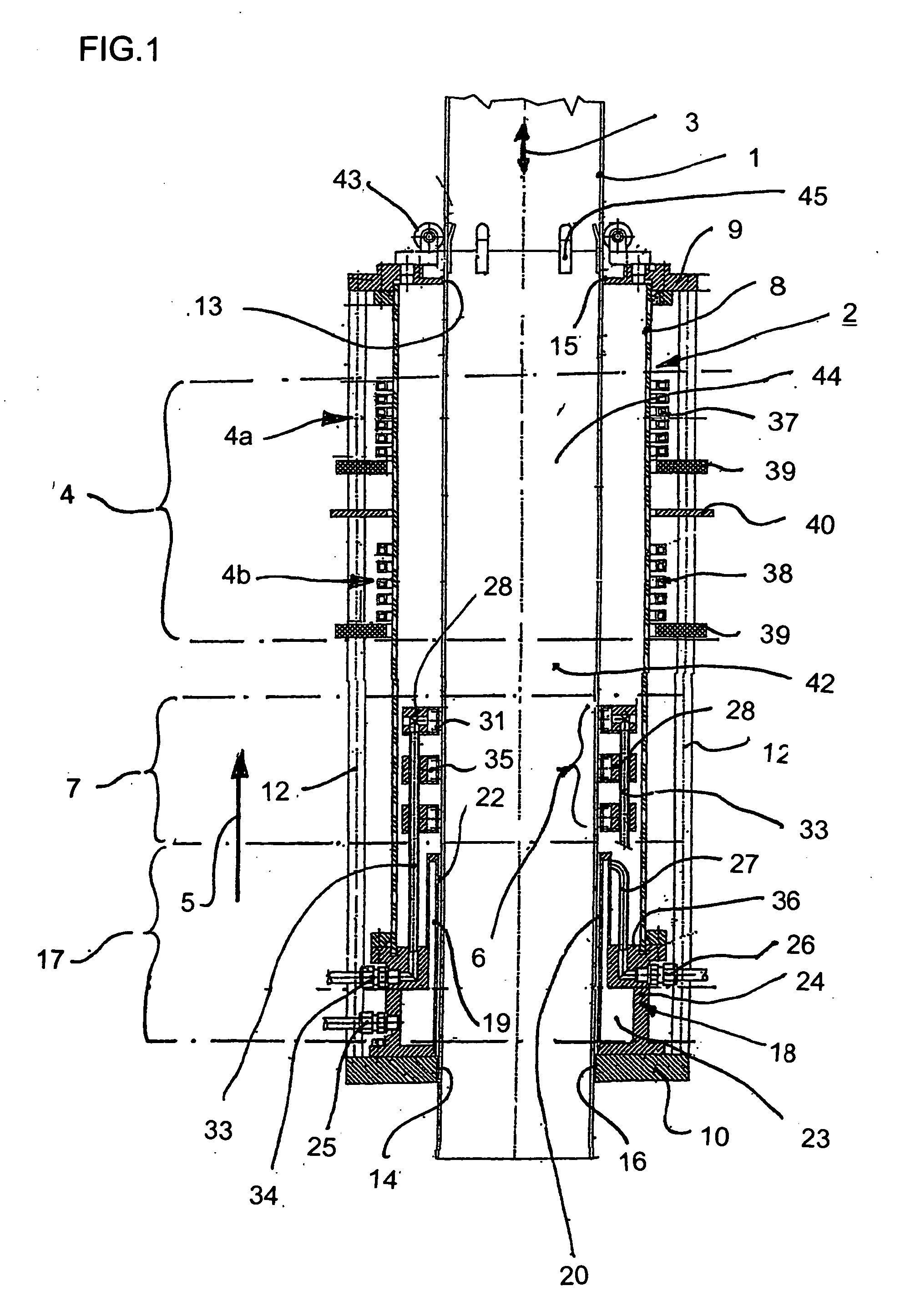

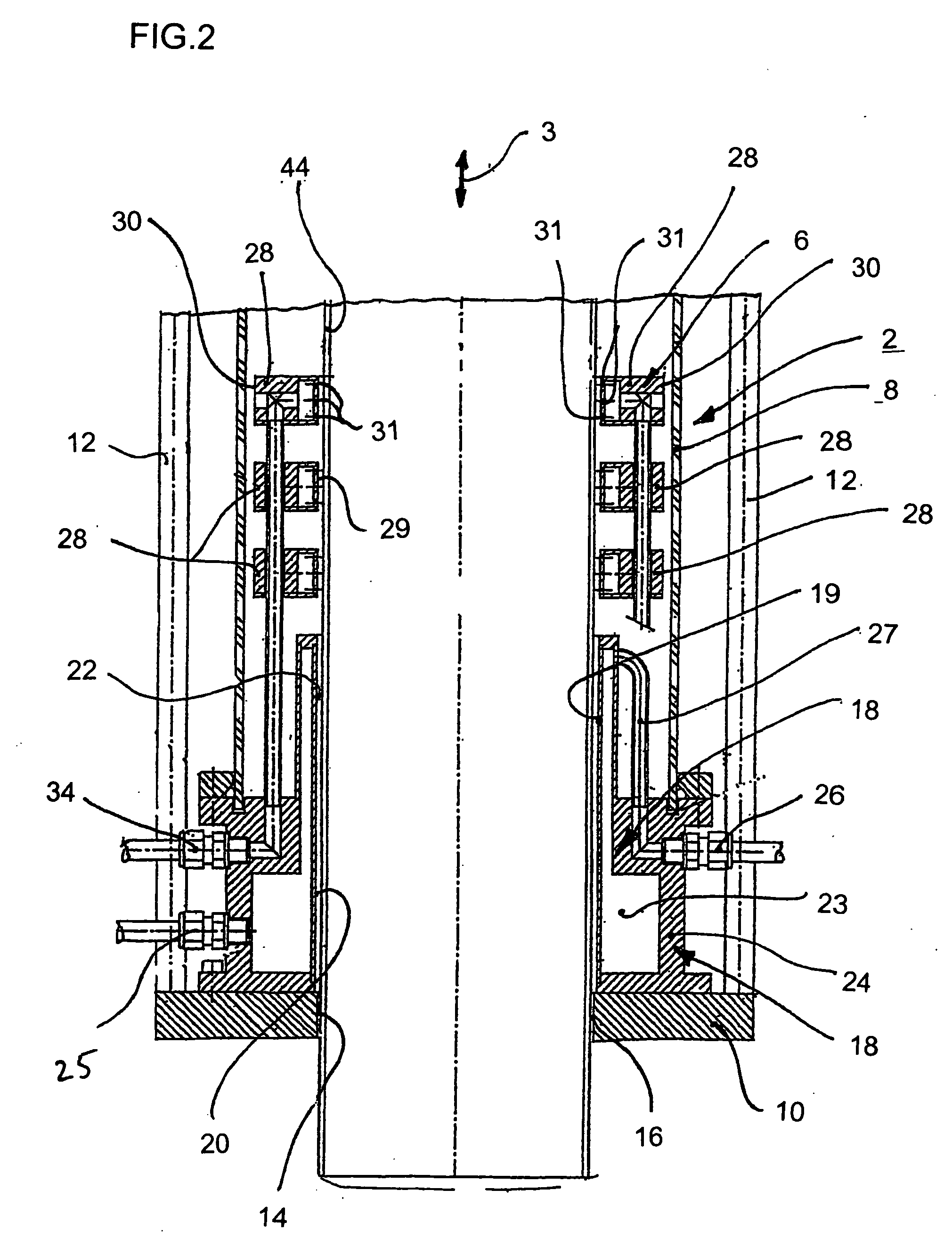

Method and apparatus for heat treating a fuel assembly channel made of a zirconium alloy

InactiveUS20070131218A1Increase variabilityEasy to controlDomestic stoves or rangesCoil arrangementsBeta phaseZirconium alloy

Owner:AREVA GMBH

Preparation method of iron-tantalum alloy powder, iron-tantalum alloy powder and application

ActiveCN112059195AHigh purityDense highTransportation and packagingMetal-working apparatusAlloyUltimate tensile strength

The invention relates to a preparation method of iron-tantalum alloy powder, the iron-tantalum alloy powder and application. The preparation method of the iron-tantalum alloy powder comprises the steps: firstly, an iron material and a tantalum material are prepared according to the target atom proportion and mixed; then a mixture is completely molten at the temperature of 1542-1600 DEG C; and thenatomization is conducted under the action of inert gas, and the iron-tantalum alloy powder is obtained. According to the preparation method, the melting temperature of the iron-tantalum mixture is controlled to be 1542-1600 DEG C, the atomization condition is optimized, the purity of the prepared iron-tantalum alloy powder is larger than or equal to 99.95%, the oxygen content is smaller than or equal to 600 ppm, and the iron-tantalum alloy powder with the particle size smaller than 150 meshes is obtained through screening; and an iron-cobalt-tantalum alloy sputtering target material with thehigh purity, high compactness, the high bending strength and the qualified magnetic flux is prepared advantageously, wherein tantalum rim charge of the tantalum target material is used as the tantalummaterial for preparation, so that waste is turned into wealth.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Medium and low temperature oil bath tempering equipment

The invention provides medium and low temperature oil bath tempering equipment. The medium and low temperature oil bath tempering equipment comprises a furnace body, a vacuumizing protective atmosphere system, a hot oil circulation system and a cold oil circulation system. The vacuumizing protective atmosphere system comprises a tee joint gas pipe, a vacuum pump communicating with an inner cavityof the furnace body through the tee joint gas pipe, and a steel cylinder for storing inert gas, and the steel cylinder is connected with the tee joint gas pipe. The hot oil circulation system comprises a hot oil tank, a first hot oil pump, a heater and a hot oil circulation pipeline with the two ends communicating with the furnace body, and the hot oil tank, the first hot oil pump and the heater are sequentially connected with the hot oil circulation pipeline. The cold oil circulation system comprises a second hot oil pump, a cold oil tank and a cold oil circulation pipeline with the two endscommunicating with the furnace body, and the second hot oil pump and the cold oil tank are both connected with the cold oil circulation pipeline. Tempering oil is heated and subjected to heat preservation under a completely sealed condition, and aging caused by oxidation when the tempering oil makes contact with air is eliminated. Meanwhile, oil fumes are eliminated, and the higher tempering temperature is obtained. After tempering is finished, the hot oil circulation pipeline is closed, the cold oil circulation pipeline is opened, cold oil is injected into the furnace body, a workpiece is cooled through the cold oil, and the recycled cold oil flows back to the cold oil tank.

Owner:HAINING XINYI MACHINERY & ELECTRICAL

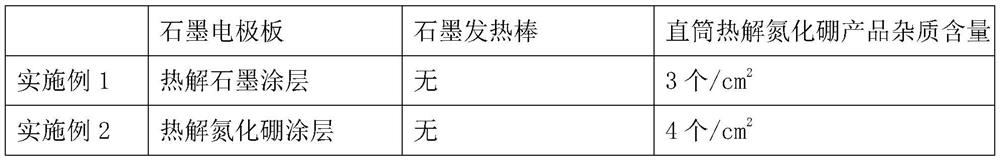

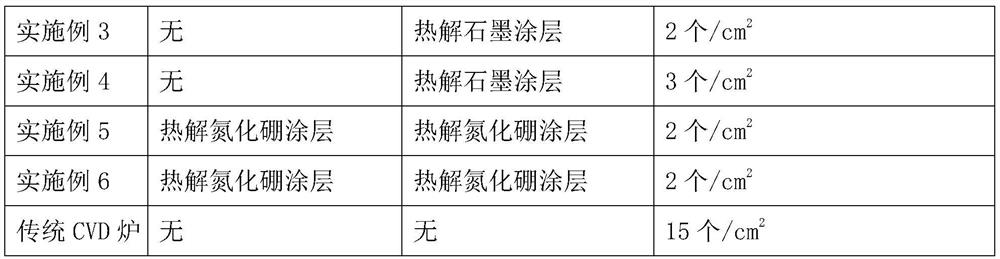

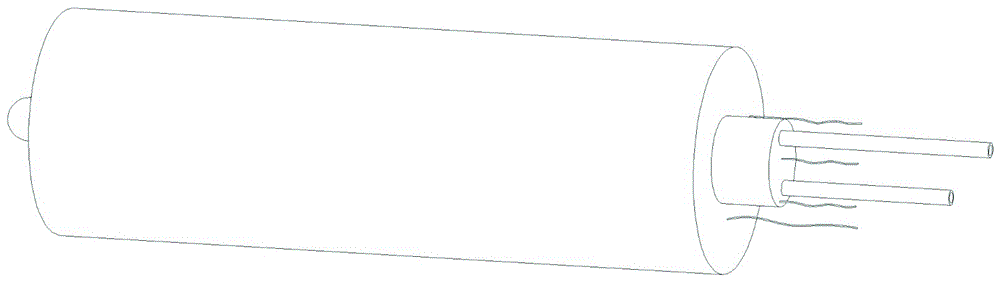

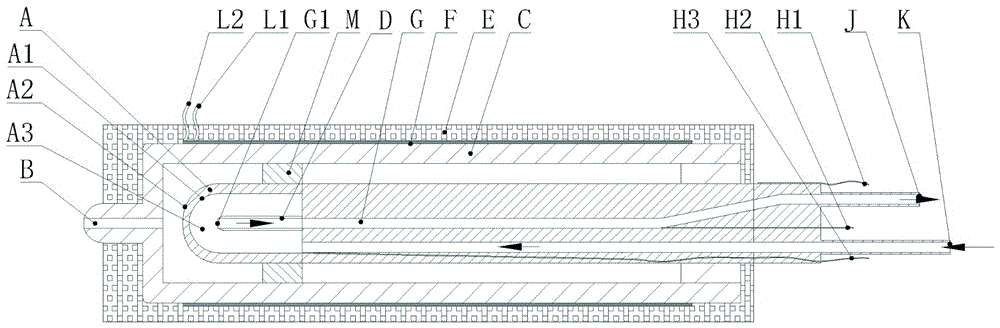

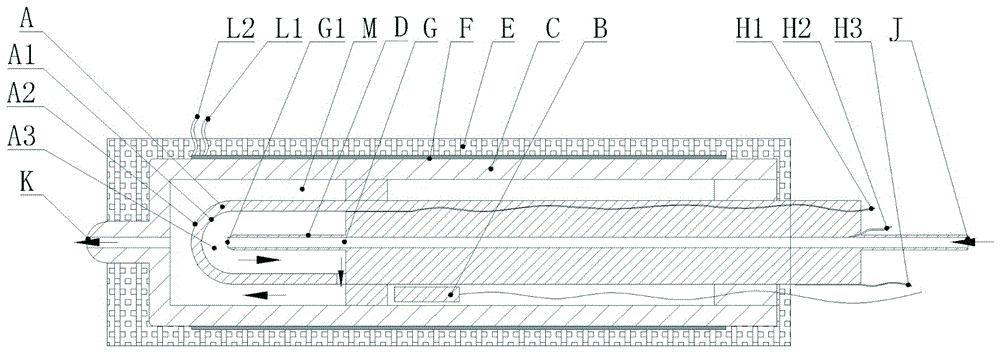

Protection method for graphite part of vacuum furnace

PendingCN111945129AExtended service lifeAvoid pollutionChemical vapor deposition coatingBoron trichlorideSurface roughness

Owner:山东国晶新材料有限公司

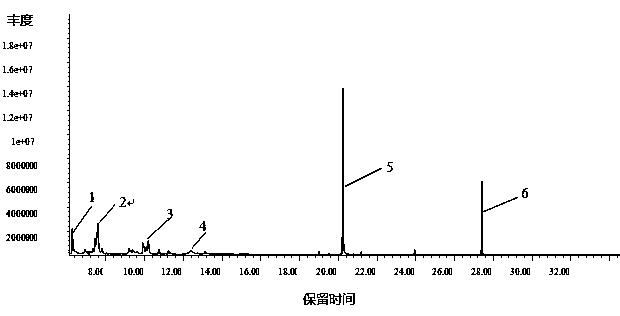

Fire ion detector

PendingCN106841445AAvoid safety hazardsSolve the big problem of difficult monitoringComponent separationChemical industryNitrogen gas

Owner:成都凯圣捷科技有限公司

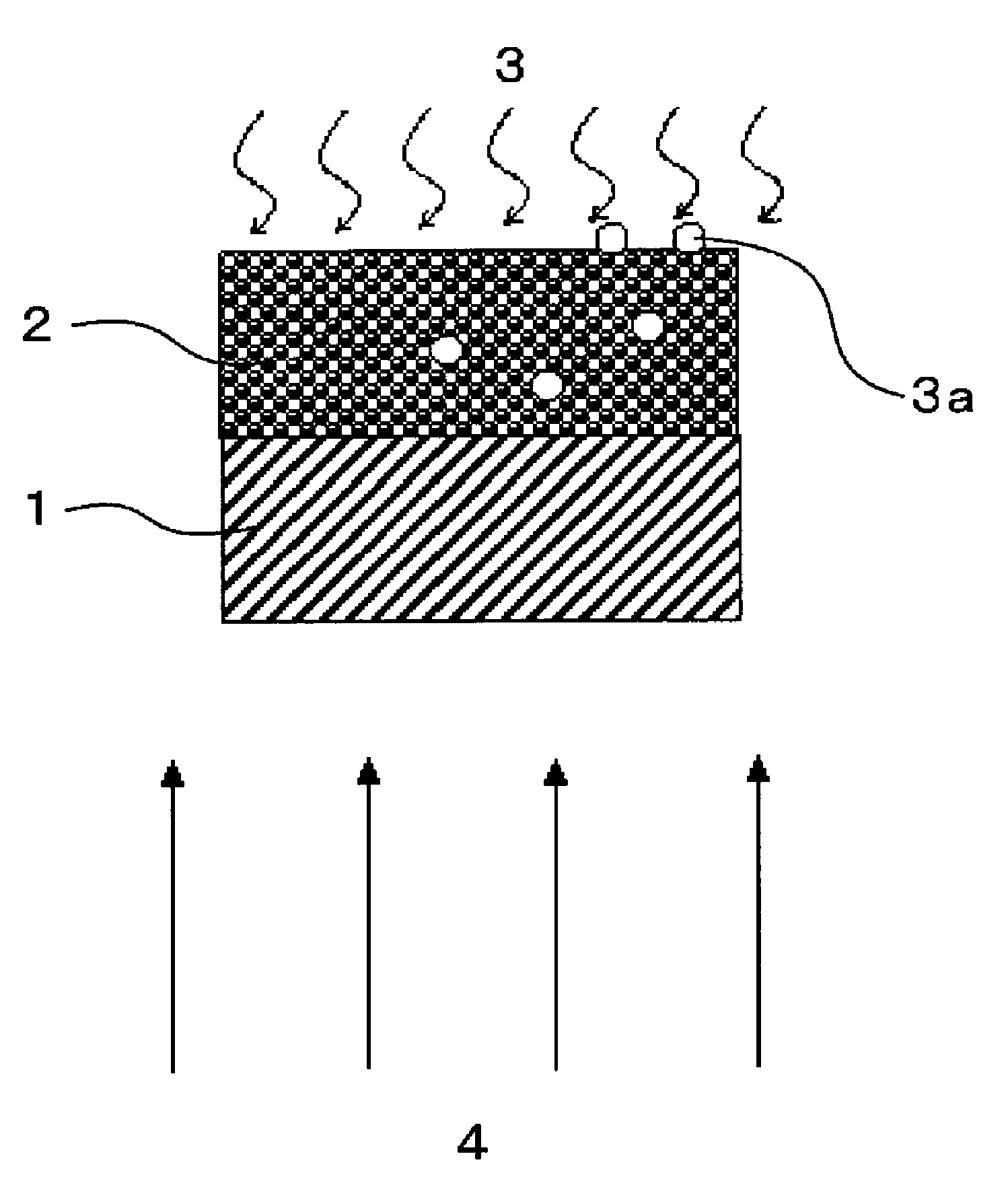

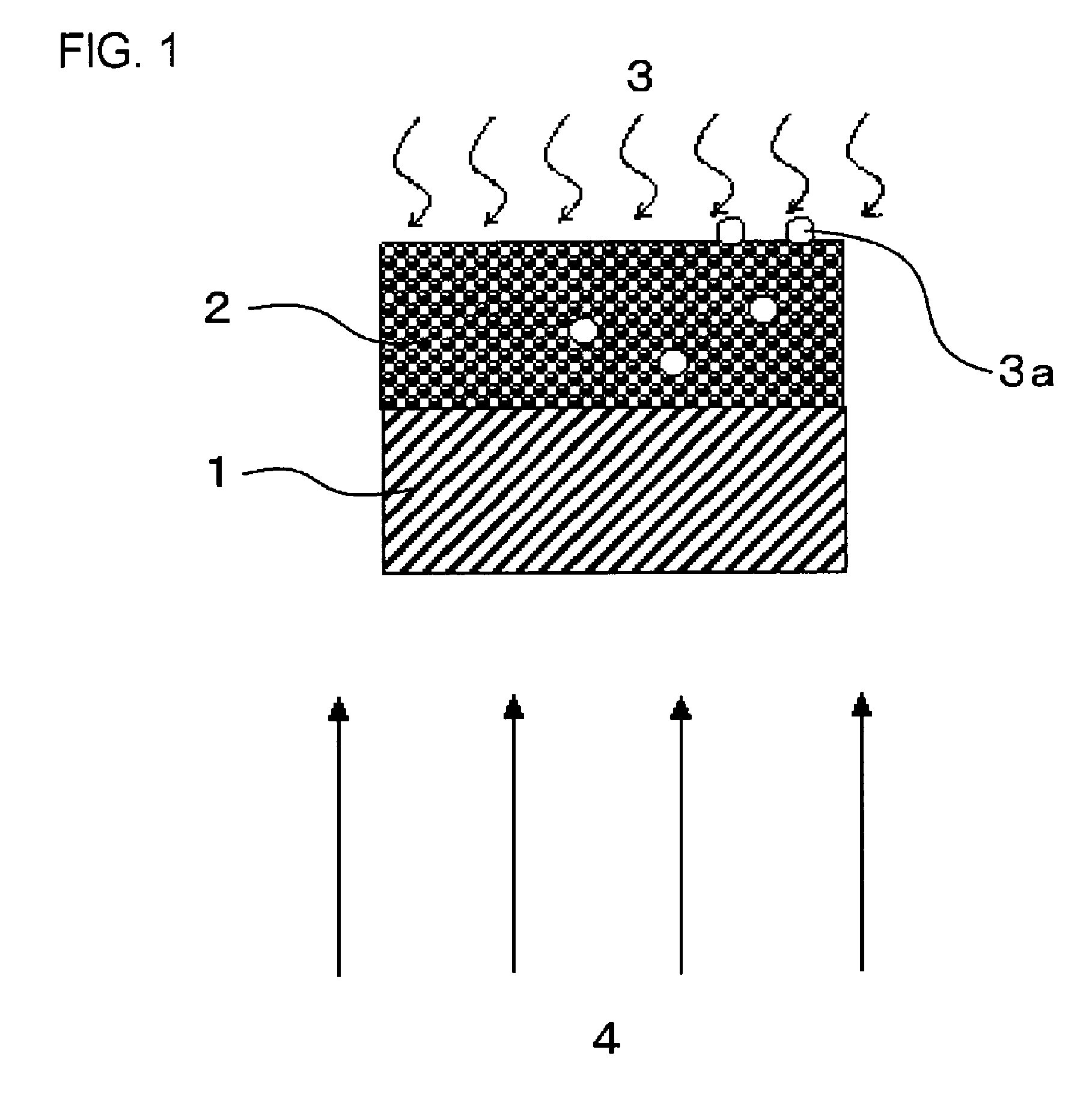

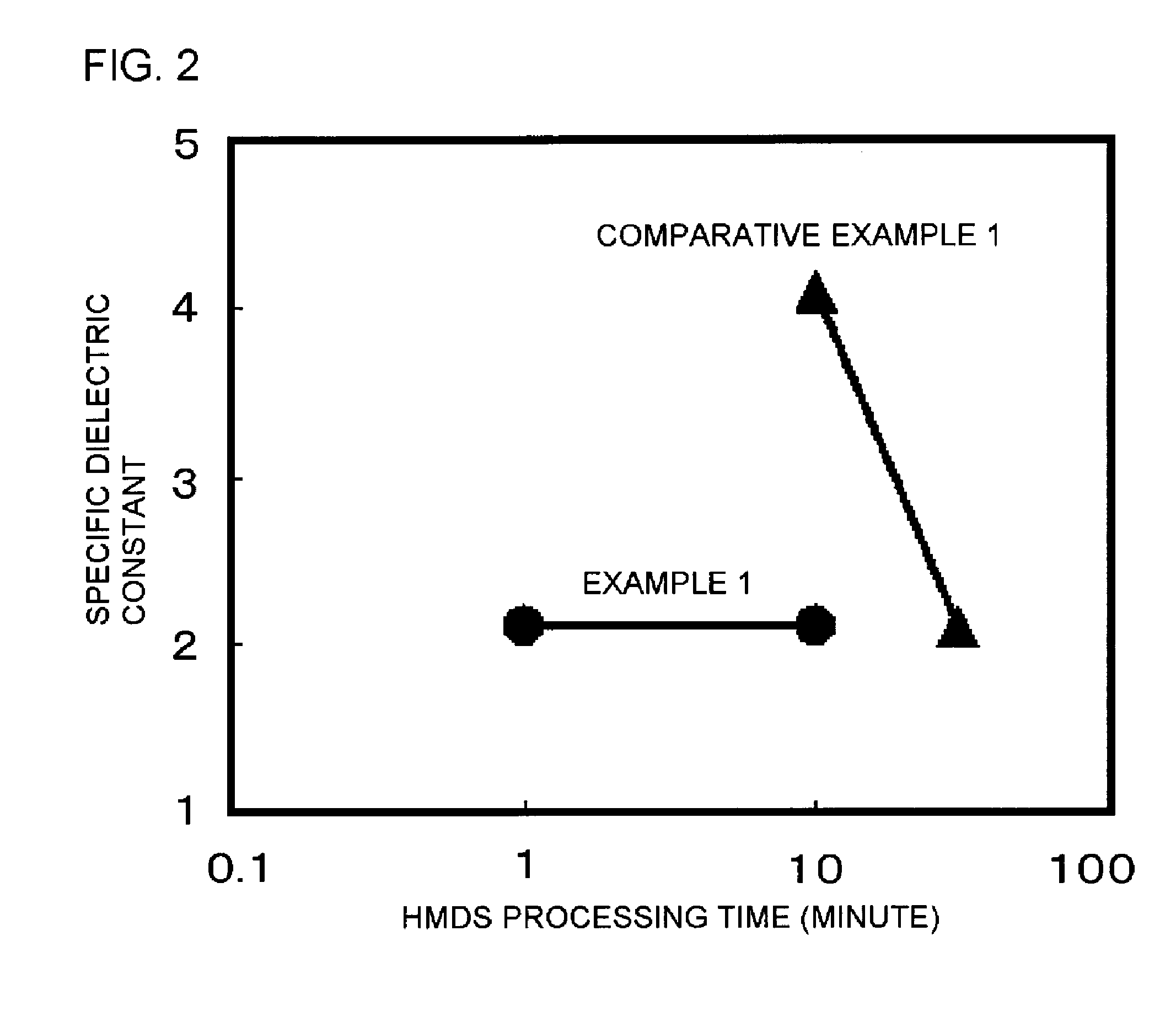

Process for manufacturing hydrophobized microporous film

ActiveUS20100221433A1Improve adsorption capacityDeteriorating elastic modulusSemiconductor/solid-state device detailsSolid-state devicesSilylationSilicon dioxide

Owner:RENESAS ELECTRONICS CORP +1

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap