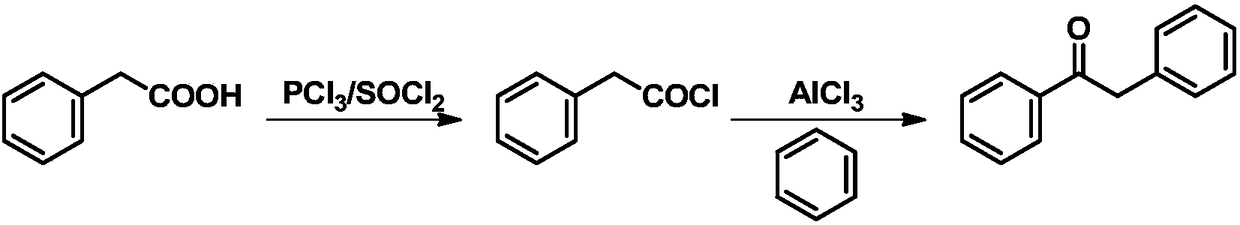

Method for preparing diphenylethanone from benzyl alcohol through photocatalytic one-step method

A technology of benzophenone and benzyl alcohol, which is applied to the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of hydroxyl compounds. It can solve problems such as long routes, high raw material costs, and environmental pollution, and achieve simple and safe operation processes. The effect of broadening the product range and making the preparation is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

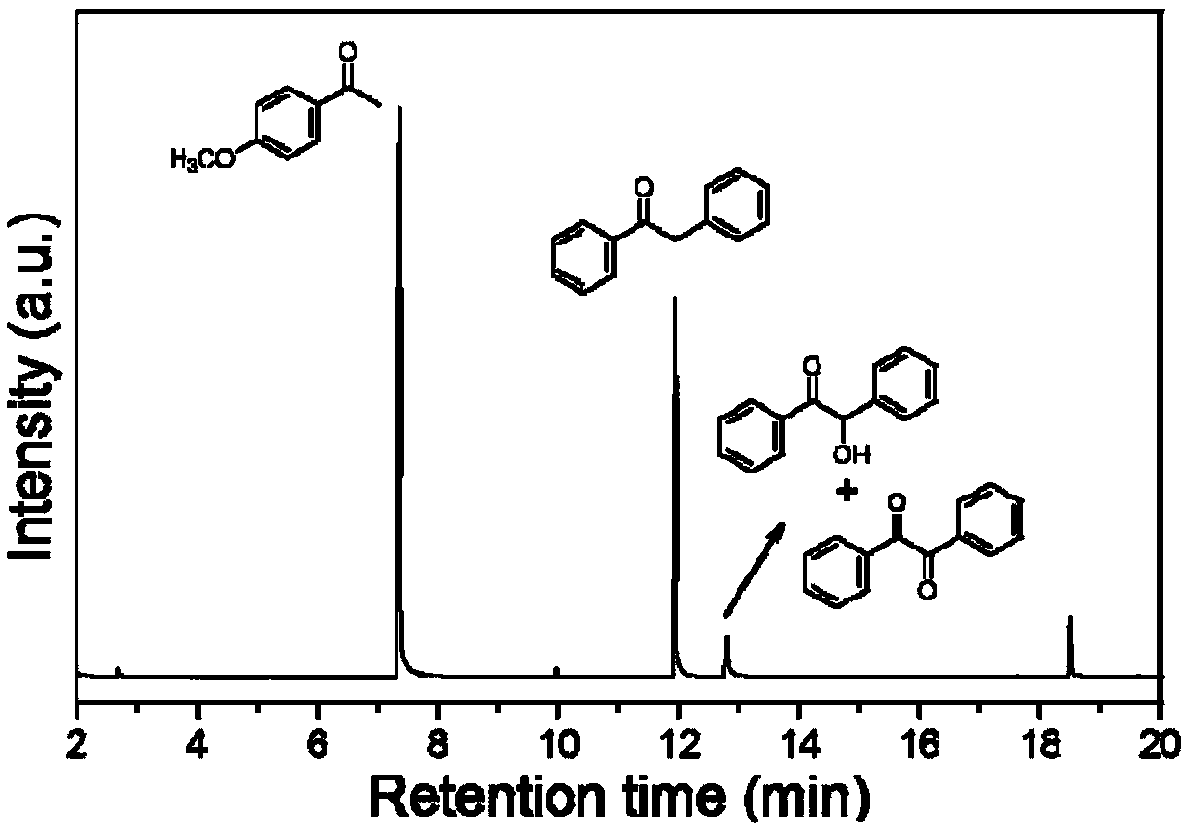

[0028] In a 5ml quartz glass reaction tube, add 0.02mmol benzyl alcohol respectively, weigh 5mg Zn 0.6 In 2 S 3.6 Catalyze the reaction, add 1.0ml of acetonitrile, replace the reaction tube with argon gas and seal it, and light it with 6W LED at room temperature for 2 hours. Figure 1 Sincerely. The yield of benzophenone was 84.9%.

Embodiment 2

[0030] In a 5ml quartz glass reaction tube, add 0.2mmol benzyl alcohol respectively, weigh 10mg Zn 0.6 In 2 S 3.6 Catalyze the reaction, add 1.0ml of acetonitrile, replace the reaction tube with argon gas and seal it, and light it with 6W LED at room temperature for 10 hours. After the reaction, the product is detected by chromatography. Figure 1 Sincerely. The yield of benzophenone was 75.1%.

Embodiment 3

[0032] In a 5ml quartz glass reaction tube, add 0.4mmol benzyl alcohol respectively, weigh 2mg Zn 0.6 In 2 S 3.6 Catalyze the reaction, add 1.0ml of acetonitrile, replace the reaction tube with argon gas and seal it, and light it with 6W LED at room temperature for 30 hours. Figure 1 Sincerely. The yield of benzophenone is 63.8%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap