Preparation process of leak protection plugging agent along with drilling based on control of monomer concentration

A technology of monomer concentration and preparation process, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of delaying drilling time, reducing drilling efficiency, and consuming a lot of time, so as to reduce production costs and increase production efficiency , Facilitate the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The invention relates to a preparation process of an anti-leakage plugging agent while drilling based on controlling the concentration of a monomer, comprising the following steps:

[0030] (a) AM and AMPS are purified for subsequent use;

[0031] (b) Weigh a certain amount of AA and hydrolyze it, and move it into a reaction vessel placed in a super constant temperature water bath;

[0032] (c) adding a certain amount of cross-linking agent;

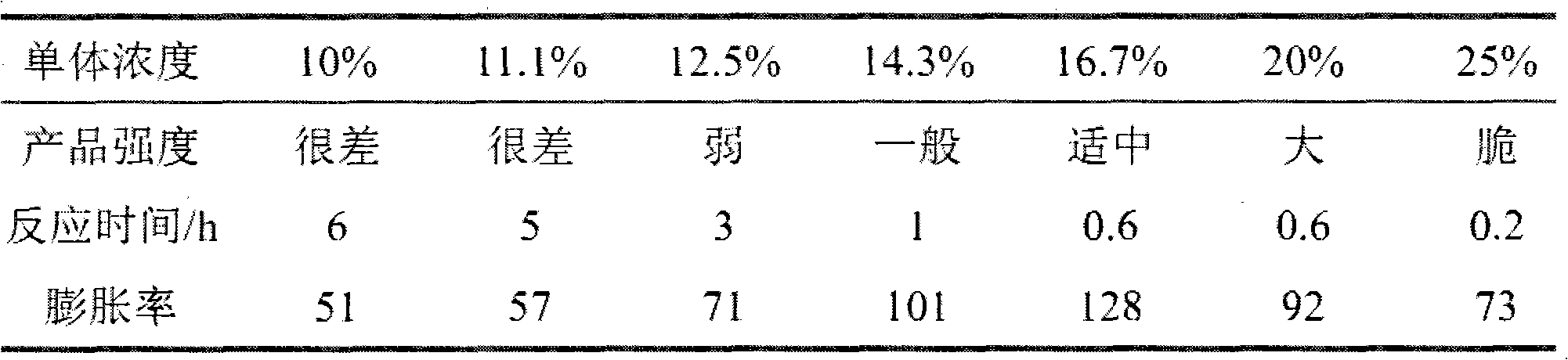

[0033] (d) adding a certain amount of AM and AMPS, and the total monomer concentration is 14.3% to 18.2% by mass, and adjusting the pH value of the reaction system to 7 with 10% sodium hydroxide solution;

[0034] (e) After exhausting oxygen with an inert gas and stirring for about a period of time, add the initiator;

[0035] (f) Adjust the temperature to the reaction temperature, and polymerize for a certain period of time to obtain the target product.

[0036] In the step (a), AM and AMPS are purified by ethanol.

[0037] In t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap