Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about "Gearing control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

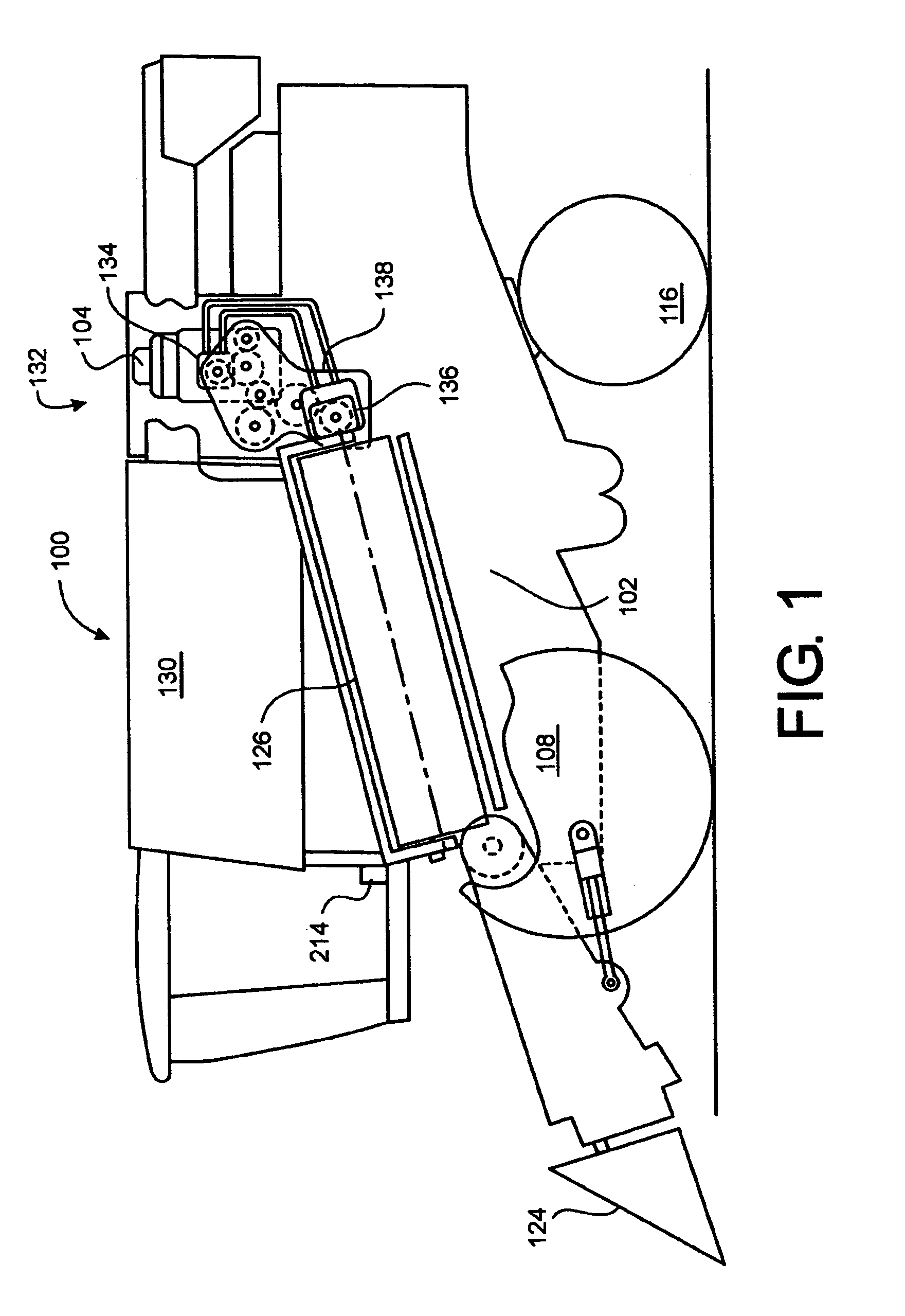

Fluid dampening chain tensioning device

In one embodiment, a chain tensioning system is provided which maintains tension on a chain and permits slow changes in chain tension while dampening sudden changes. An exemplary embodiment may permit slow changes in chain tension while dampening sudden changes through the use of a fluid dampening device. Additionally, some embodiments may permit slow changes in chain tension while dampening sudden changes in only one direction of chain tension change.

Owner:BLACKGLASS

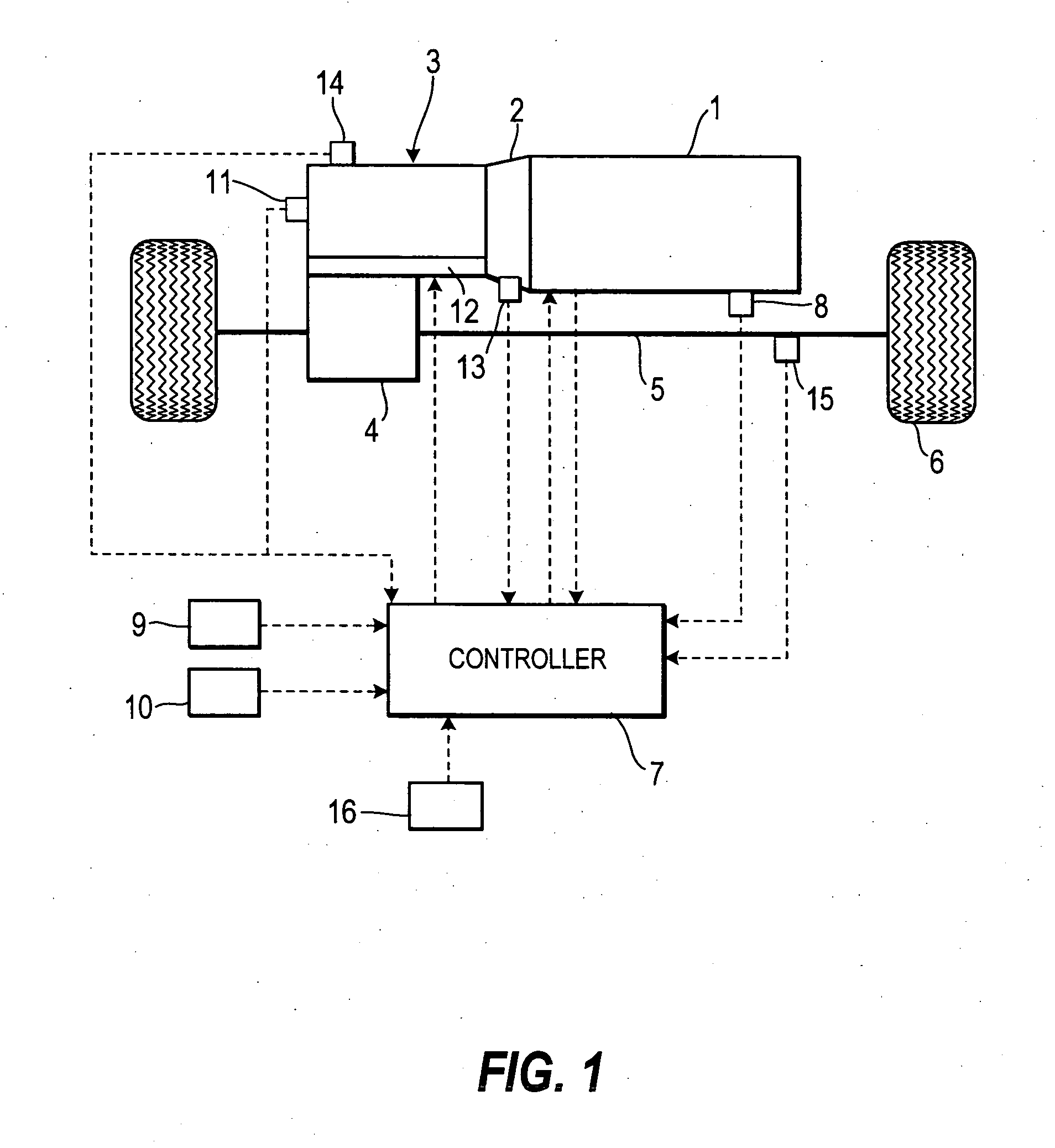

Vehicular control apparatus and method

Owner:TOYOTA JIDOSHA KK

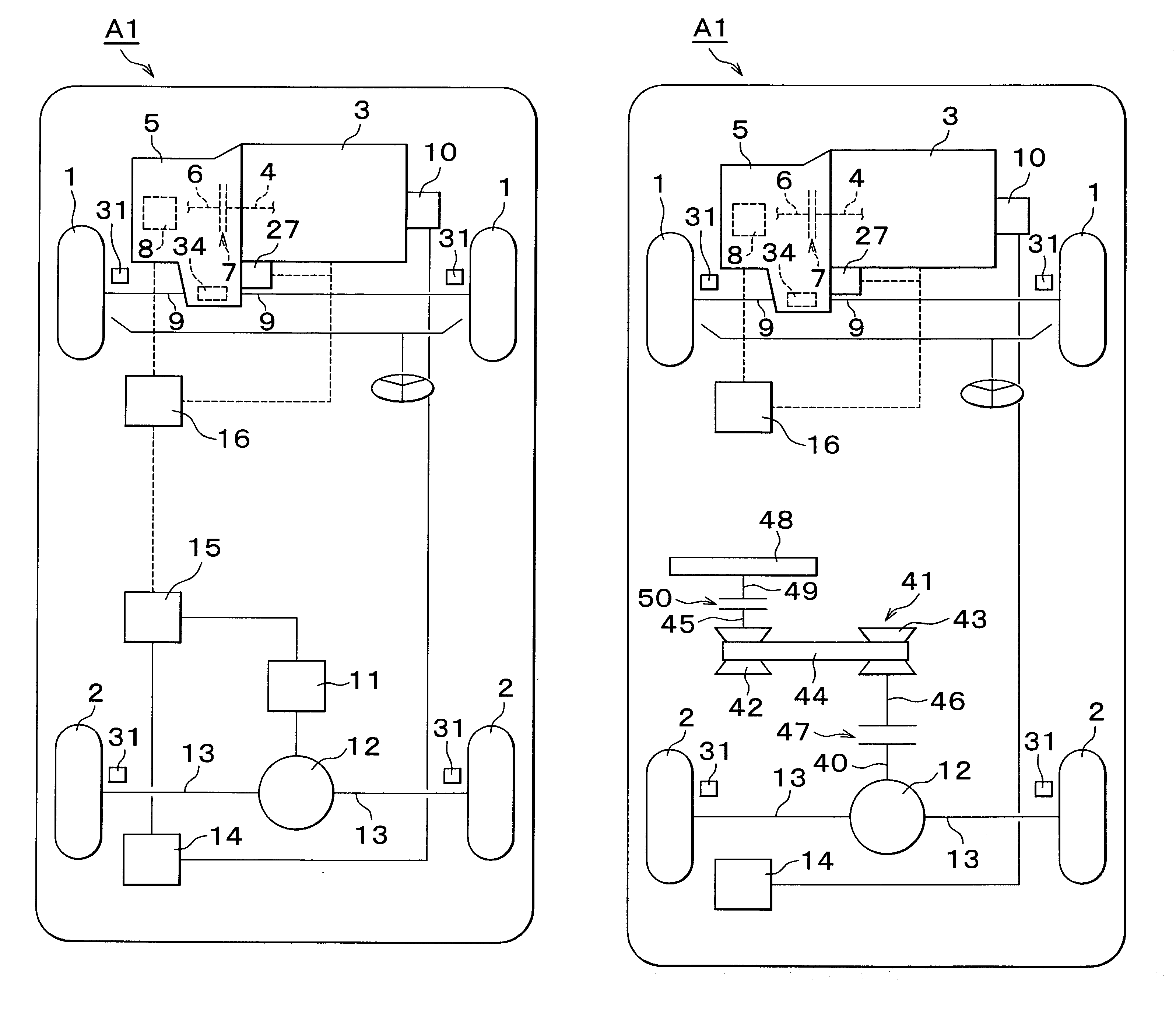

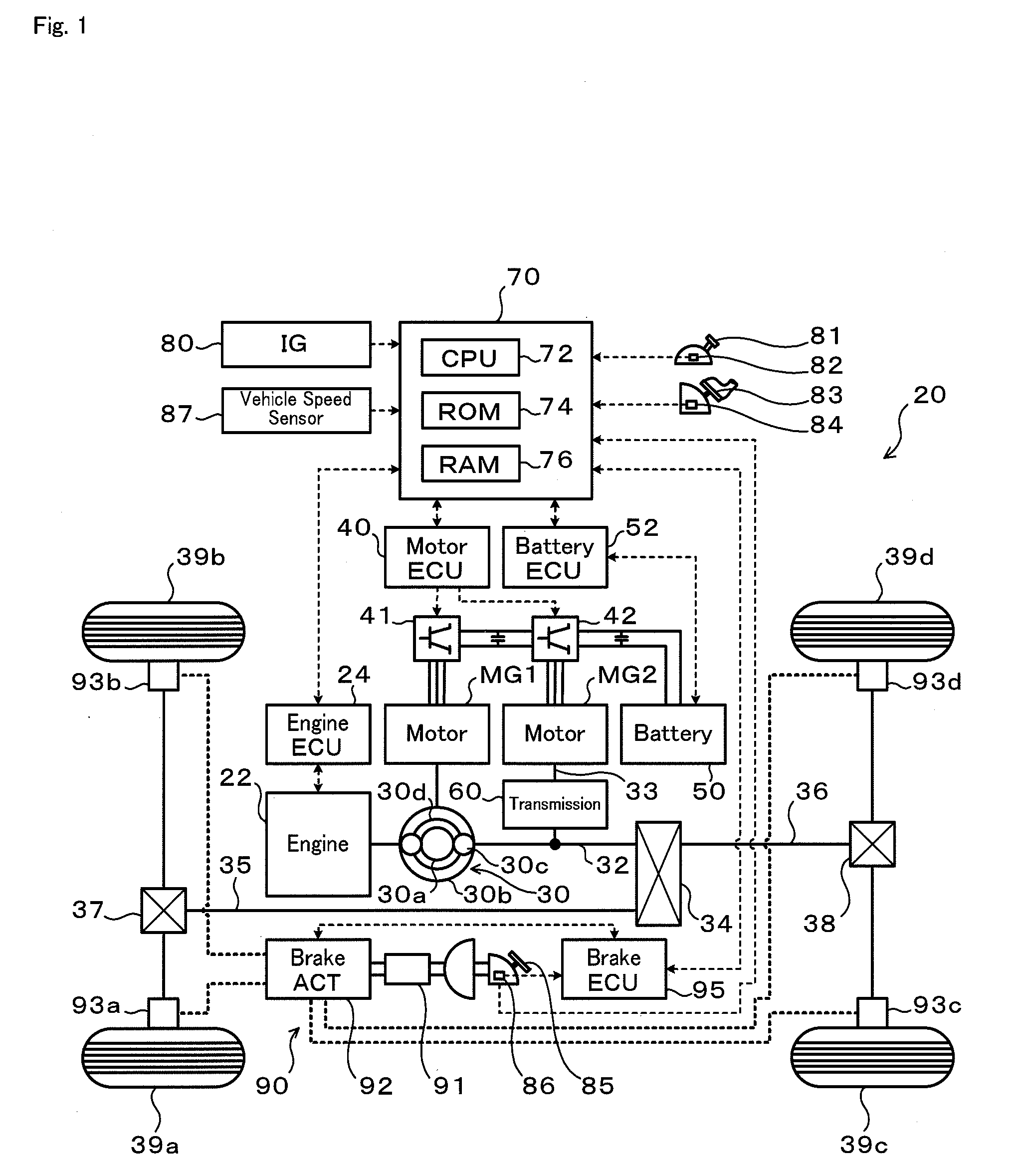

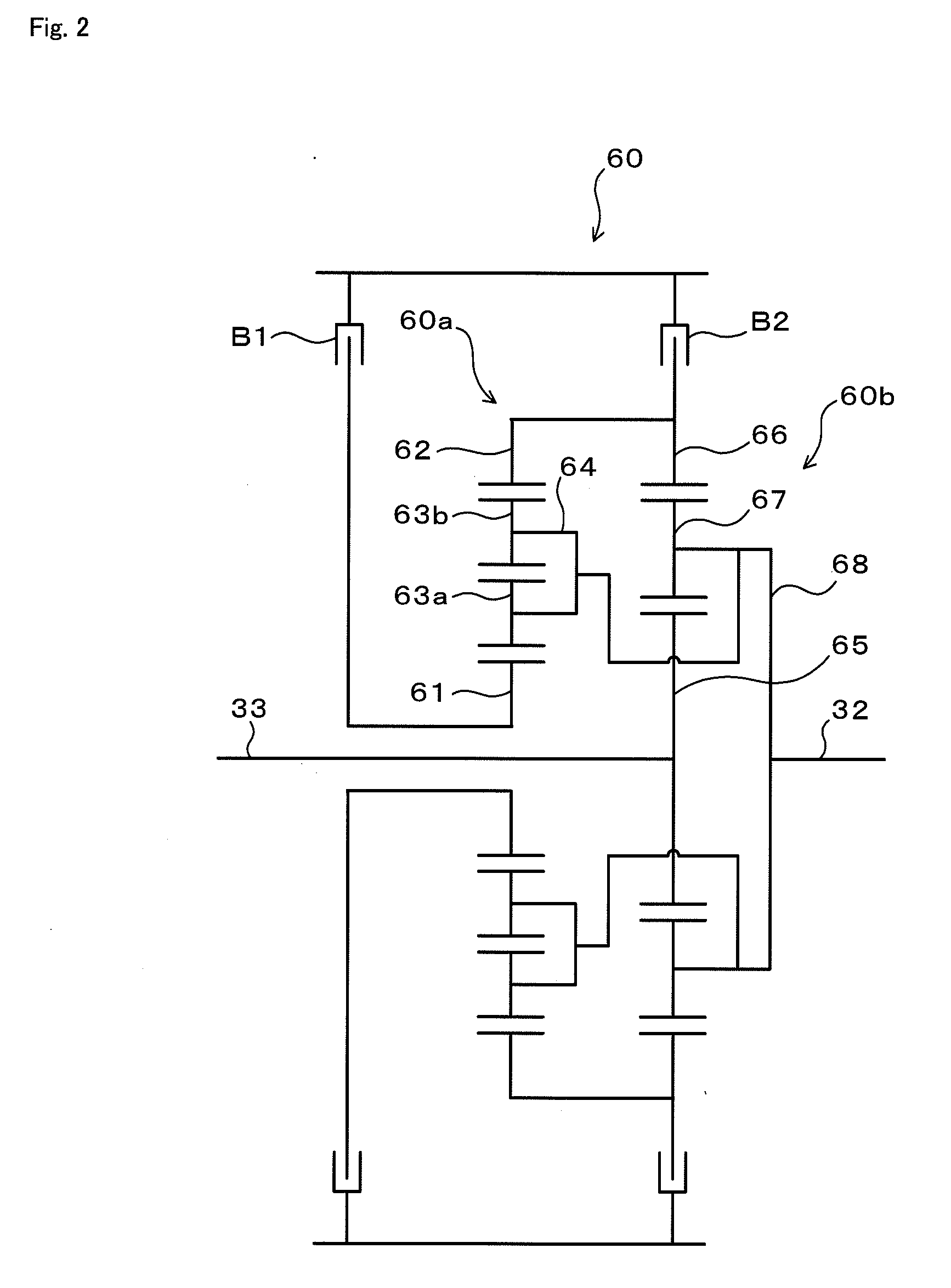

Vehicle and control method thereof, power output apparatus and control method thereof, and driving system and control method thereof

ActiveUS20080185199A1Reduce variationImprove braking effectHybrid vehiclesAnalogue computers for trafficBrake torqueRegenerative brake

Owner:TOYOTA JIDOSHA KK +1

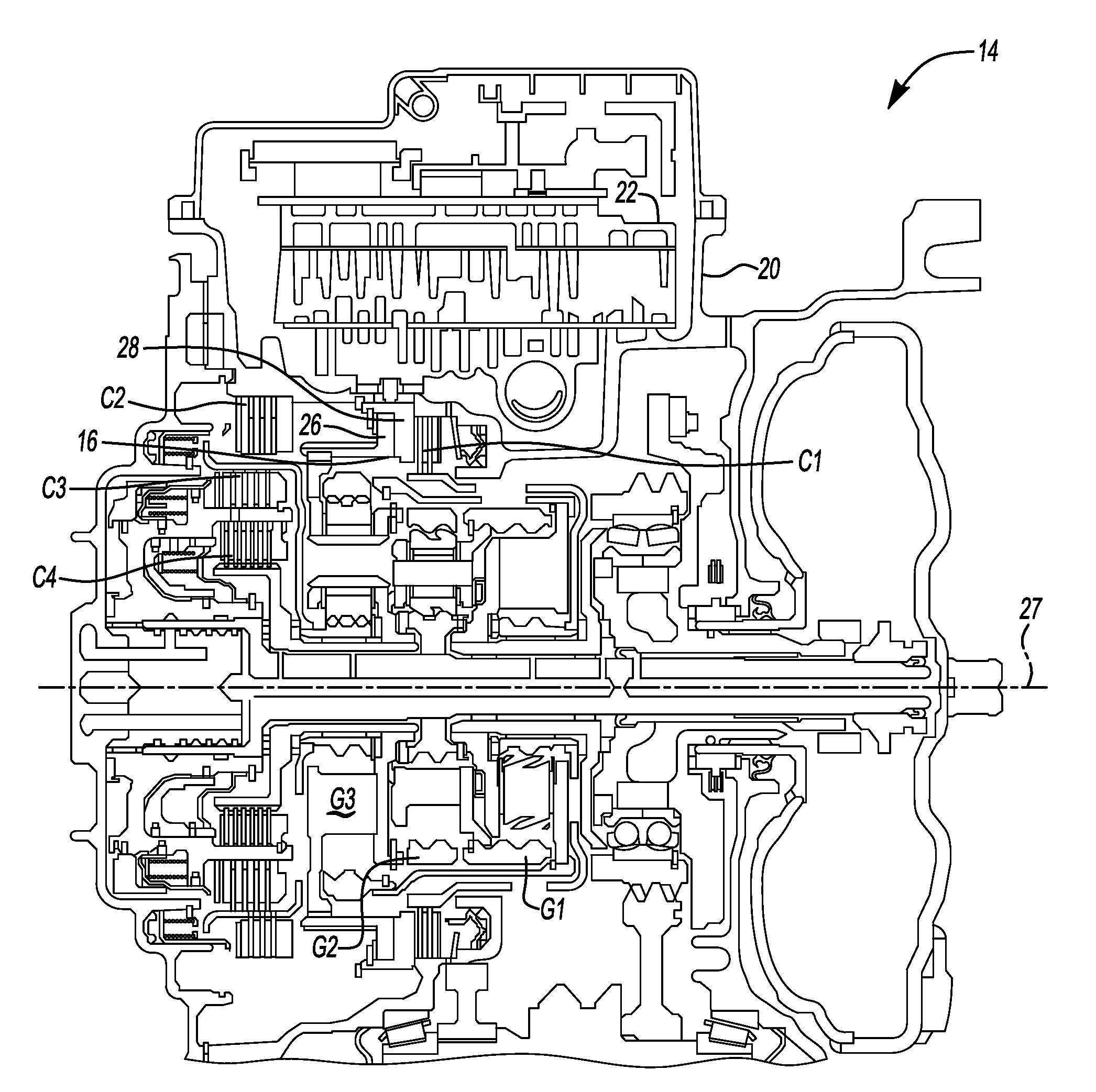

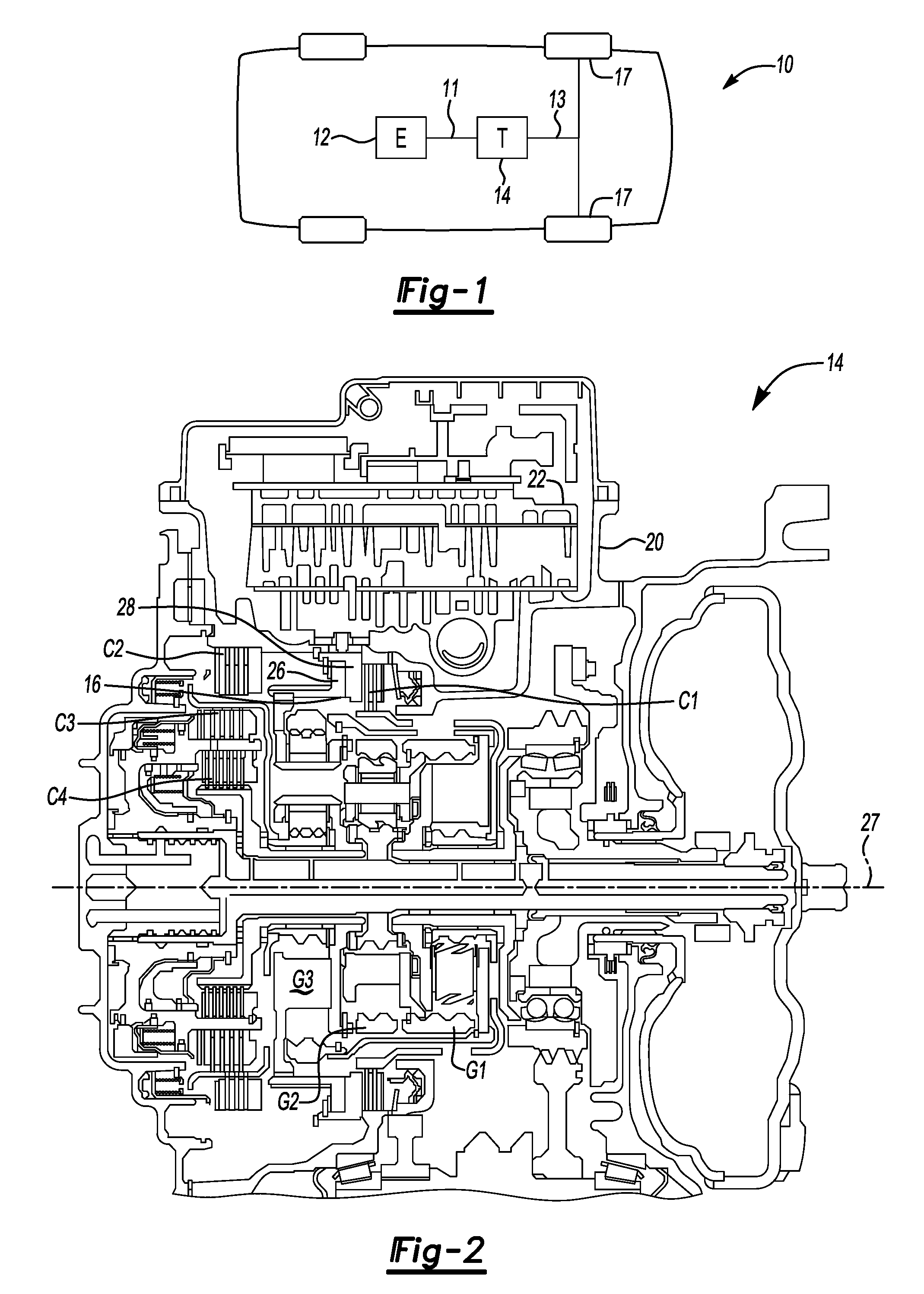

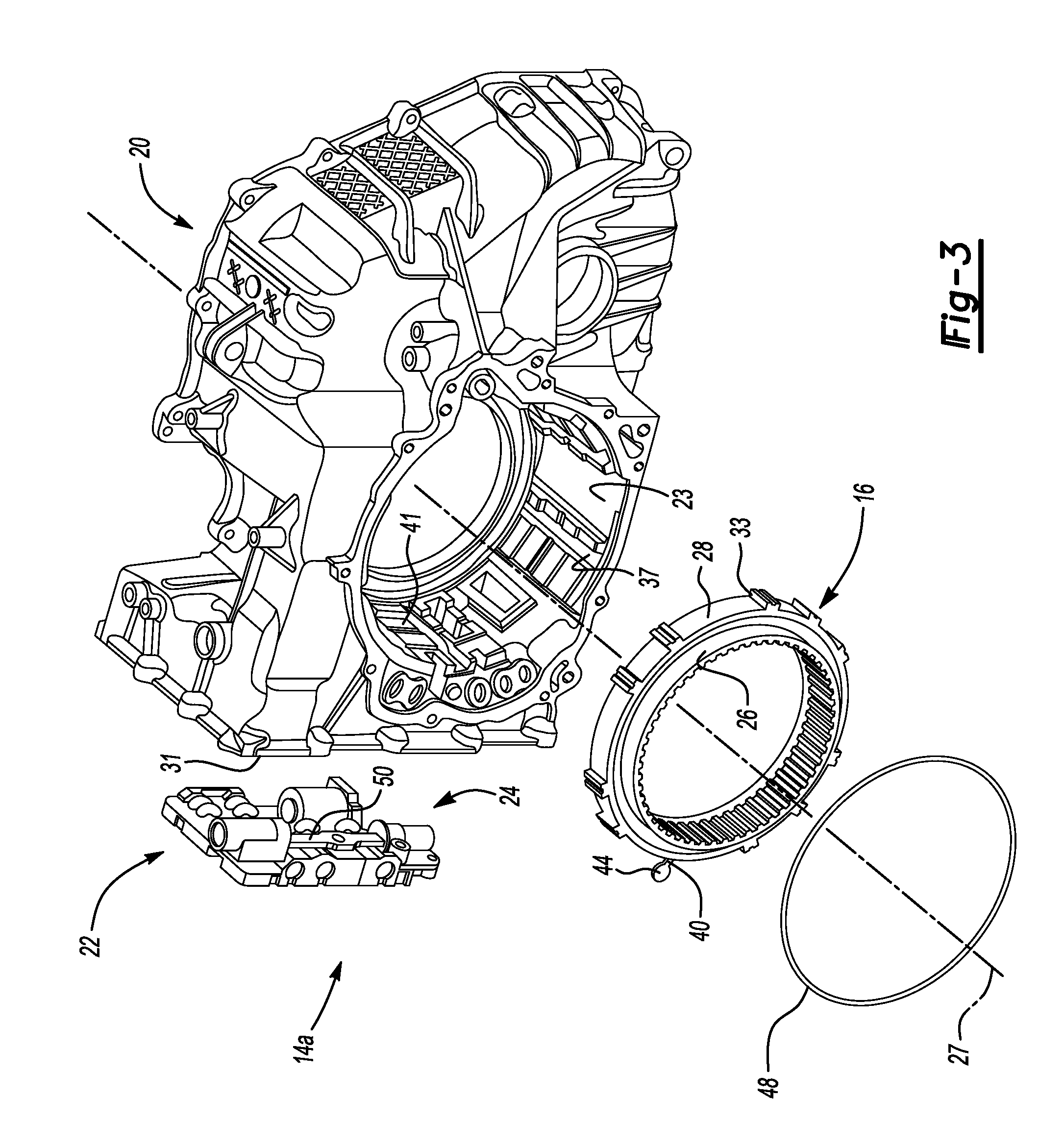

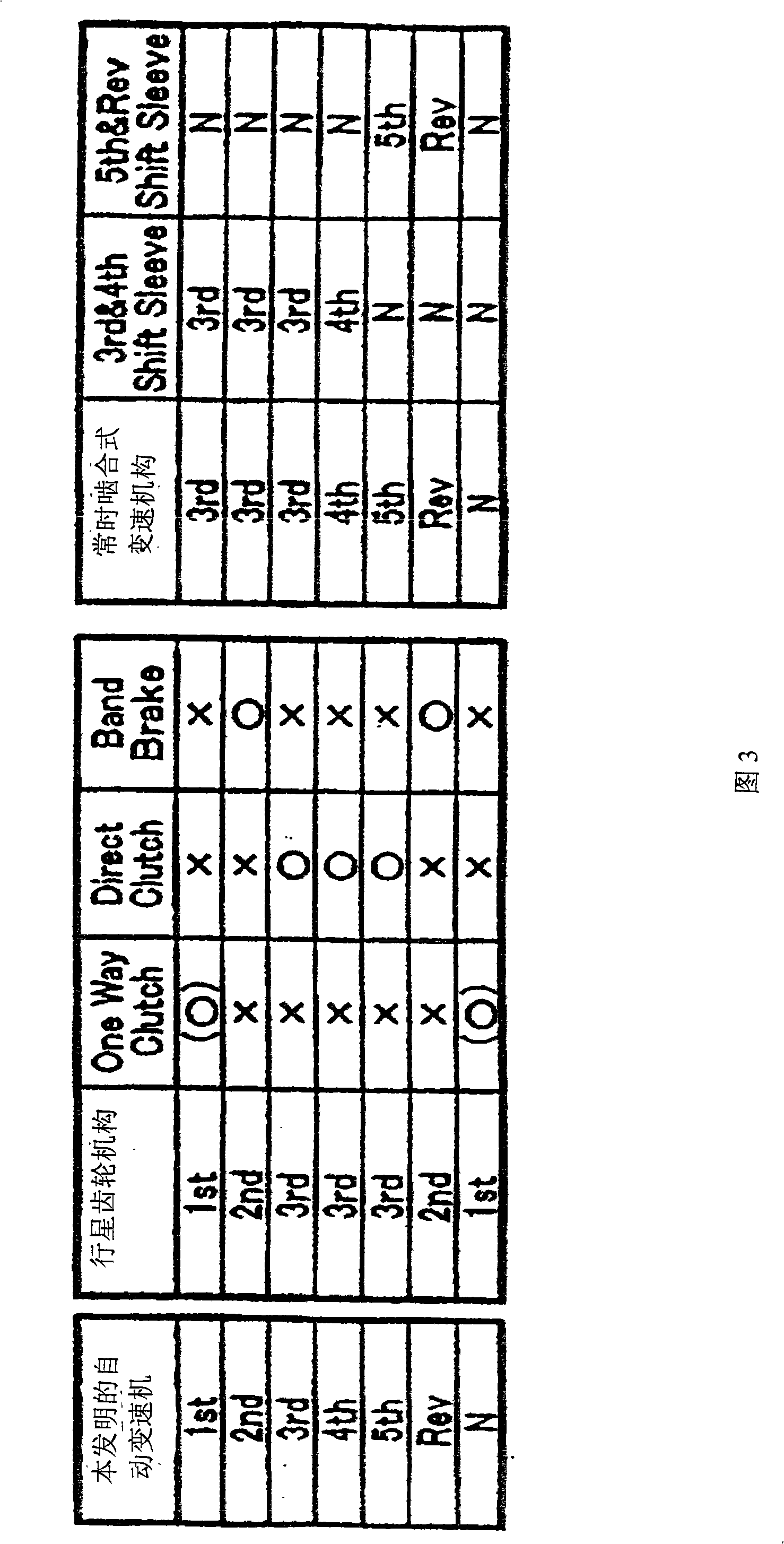

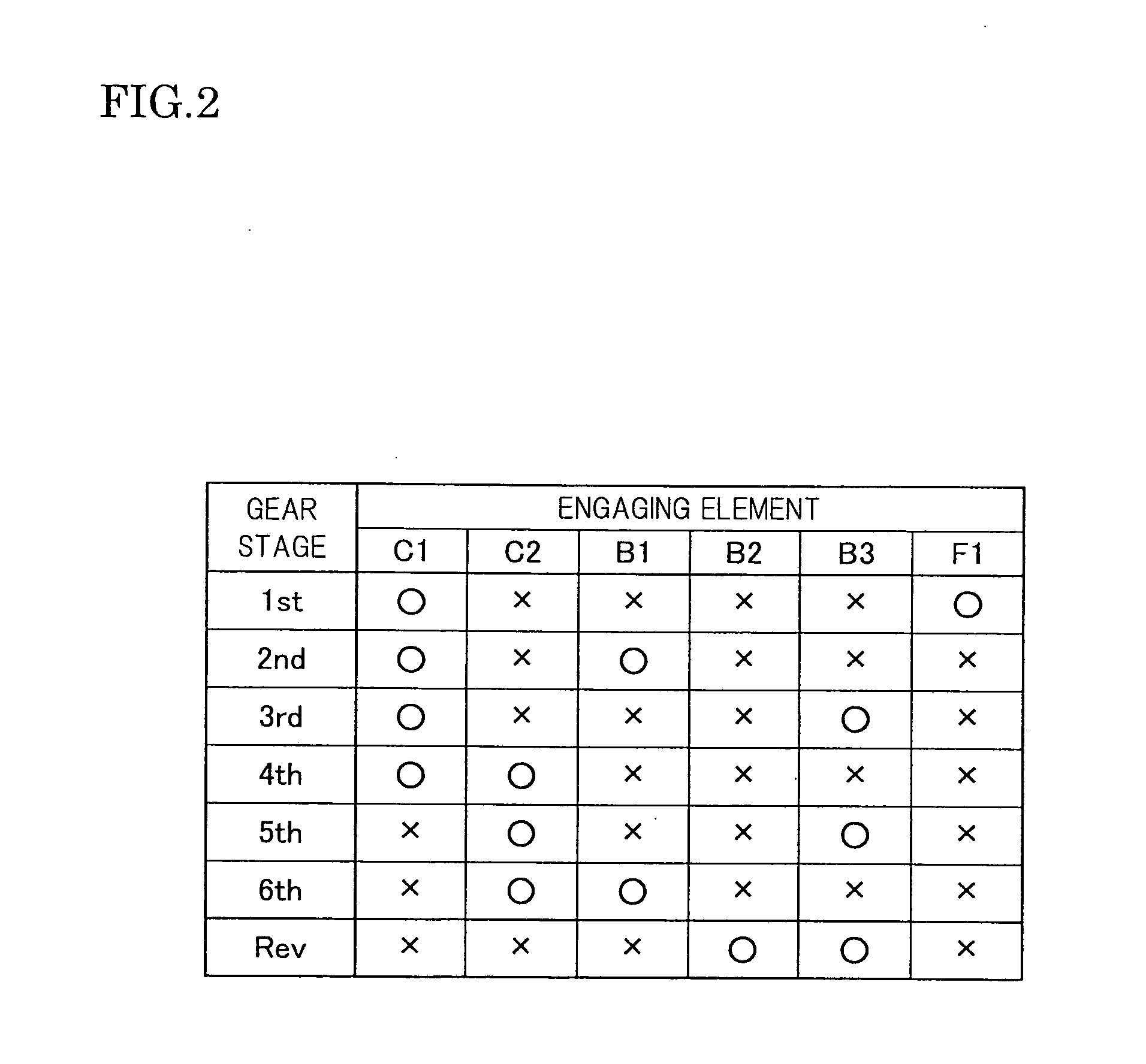

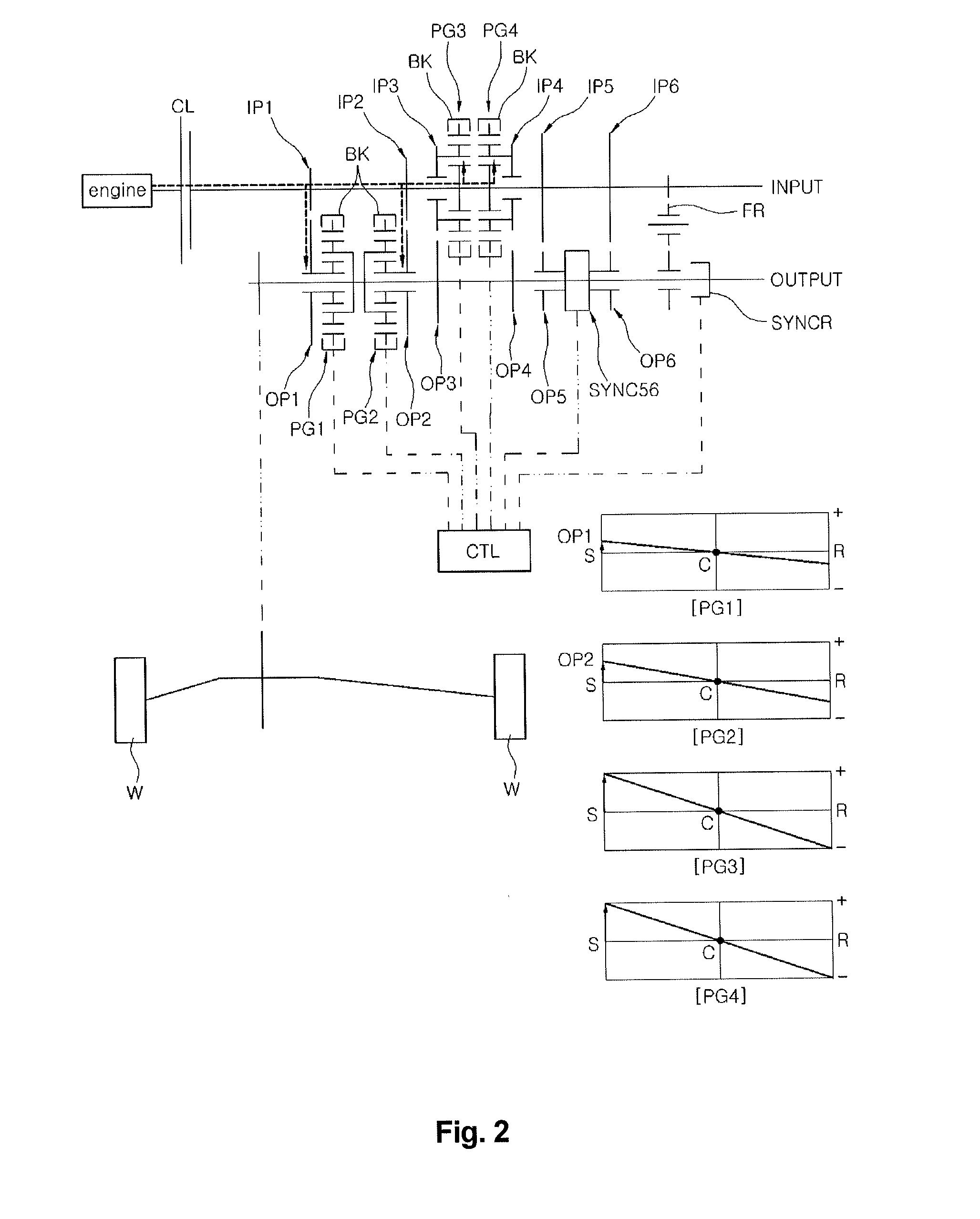

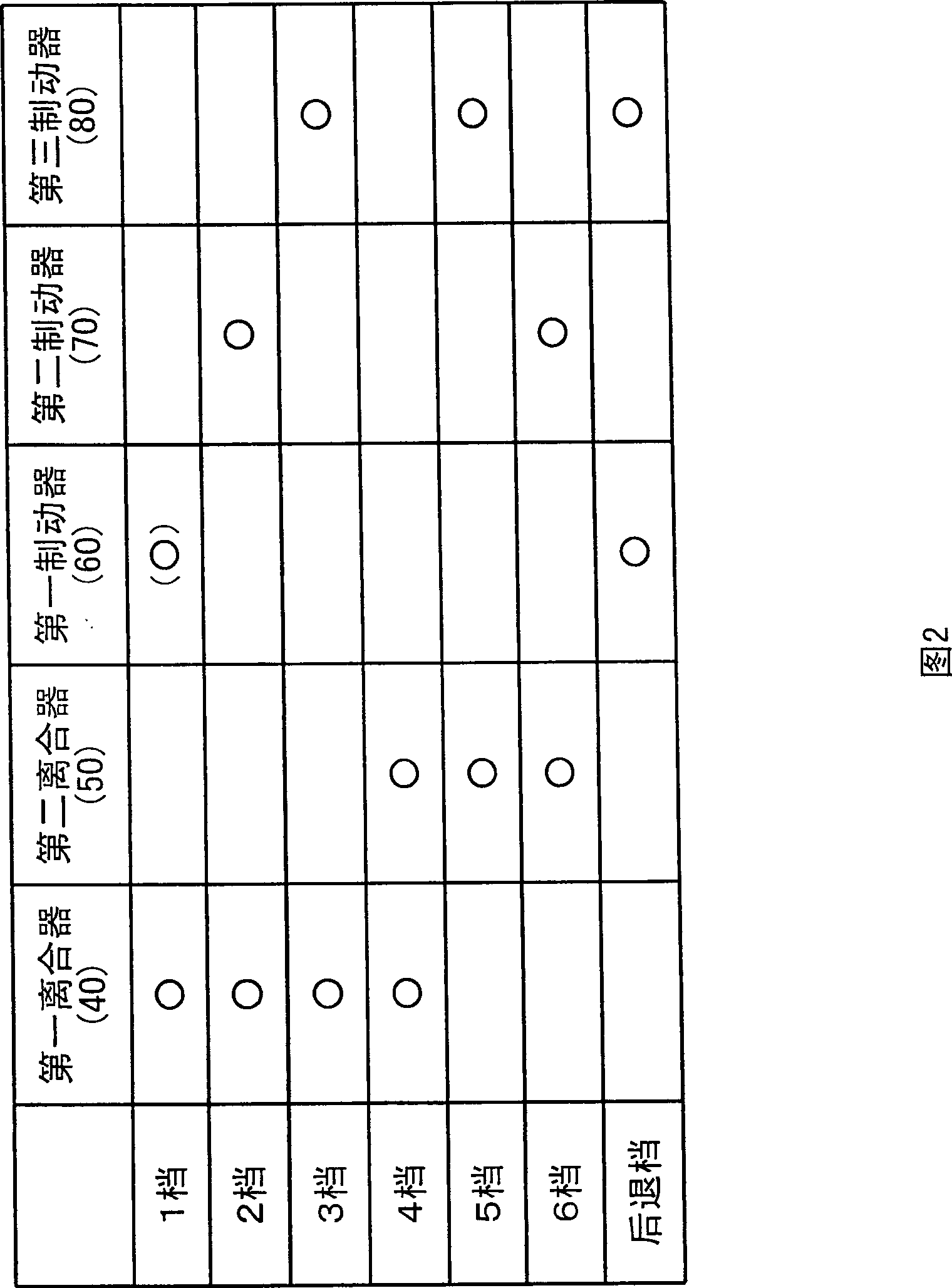

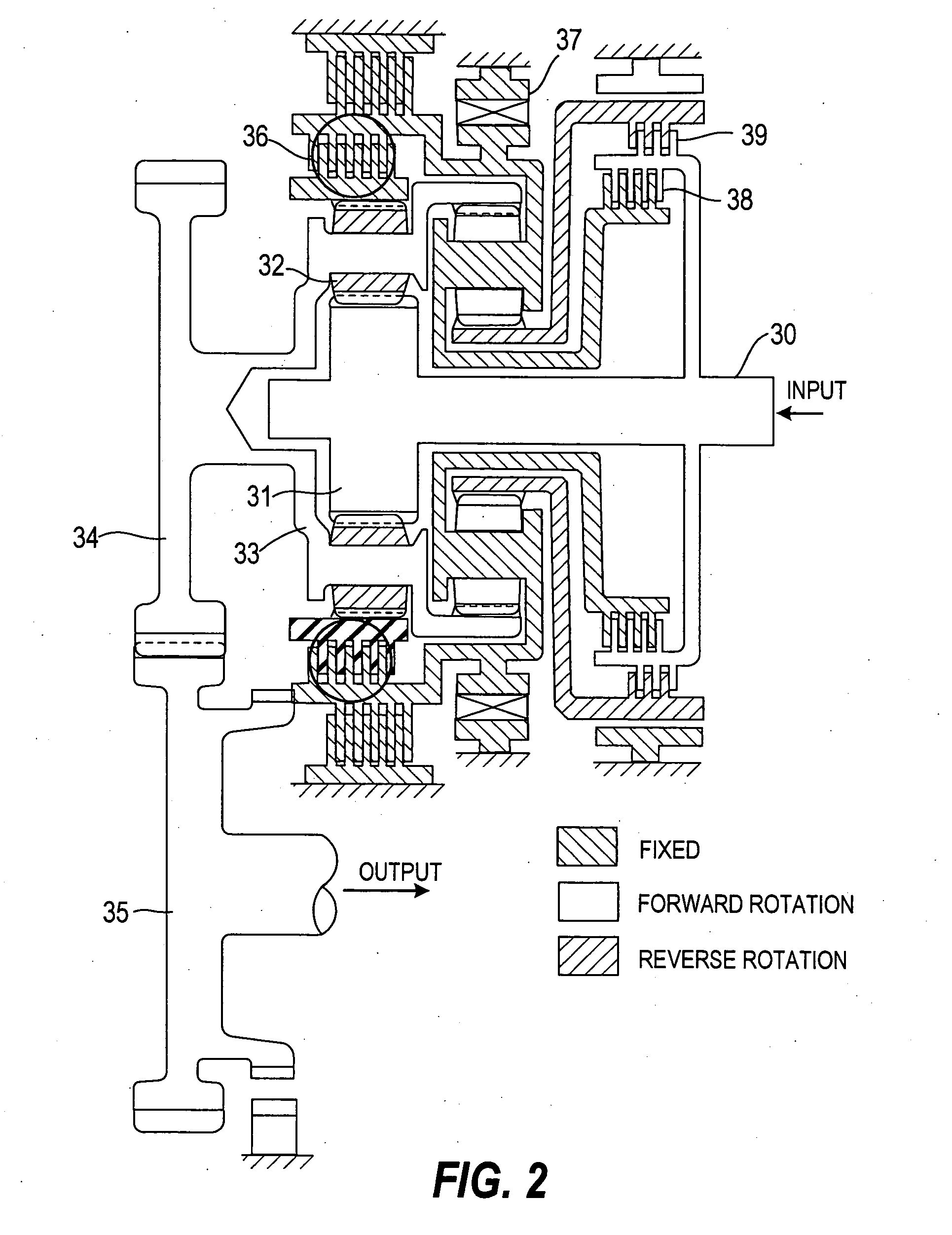

Front Wheel Drive Automatic Transmission with a Selectable One-Way Clutch

ActiveUS20100022342A1Reducing spin lossTransmission lossDigital data processing detailsToothed gearingsAutomatic transmissionOperation mode

Owner:GM GLOBAL TECH OPERATIONS LLC

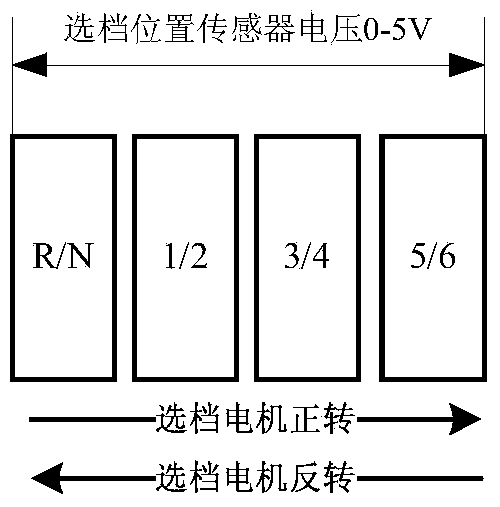

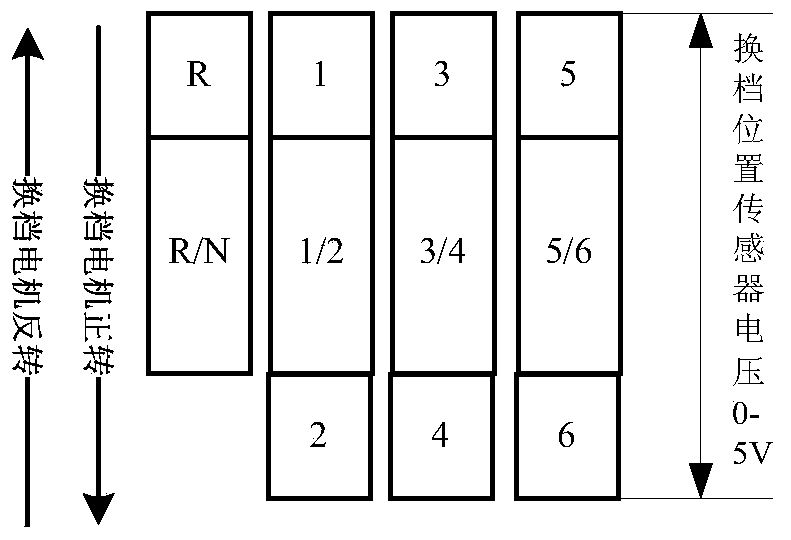

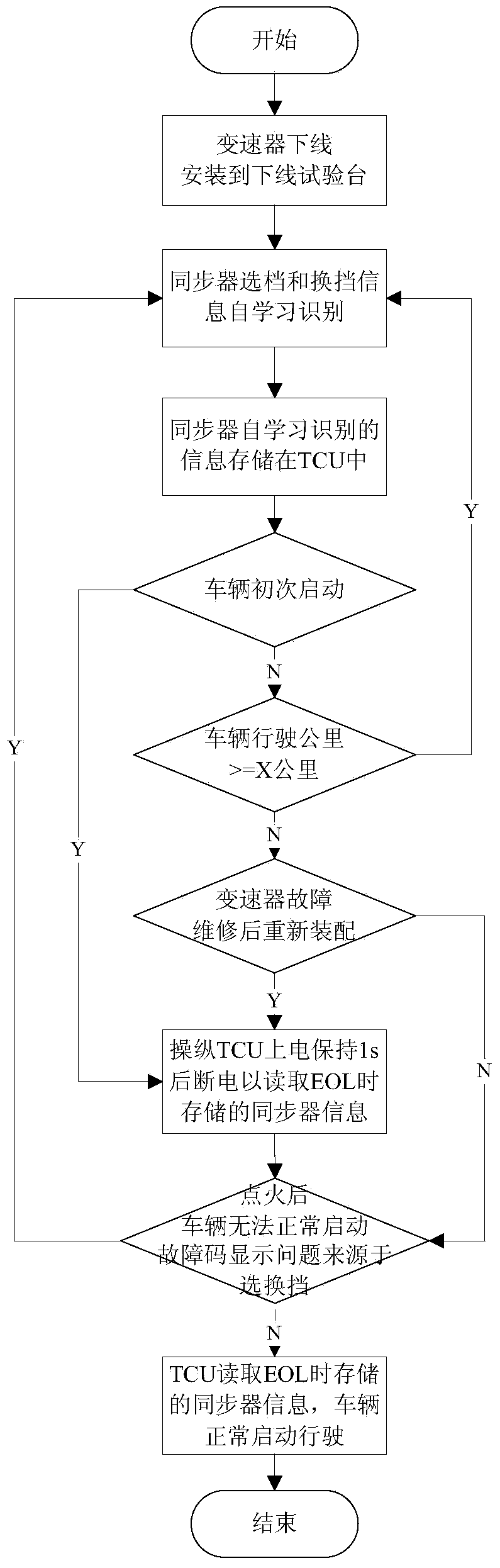

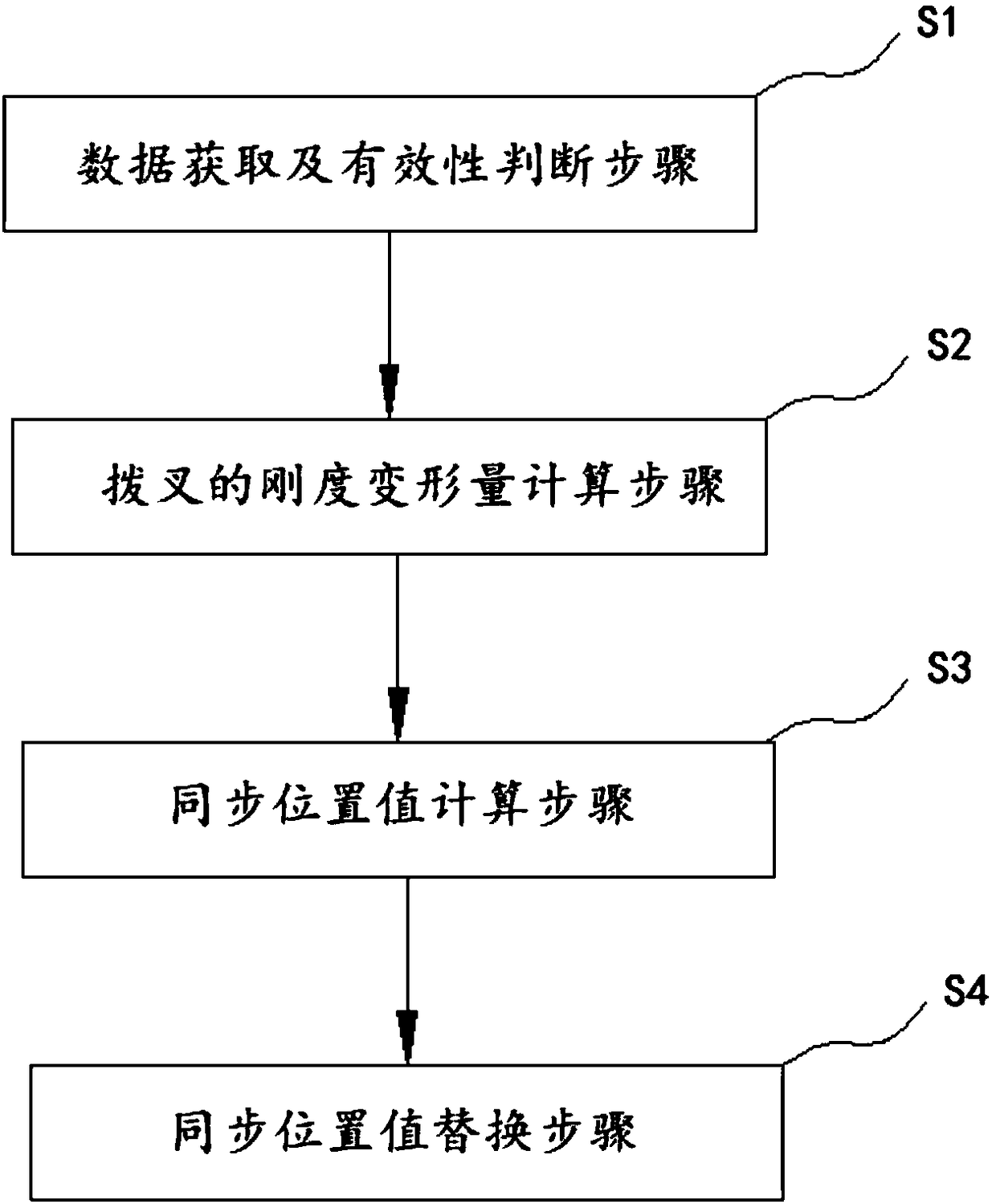

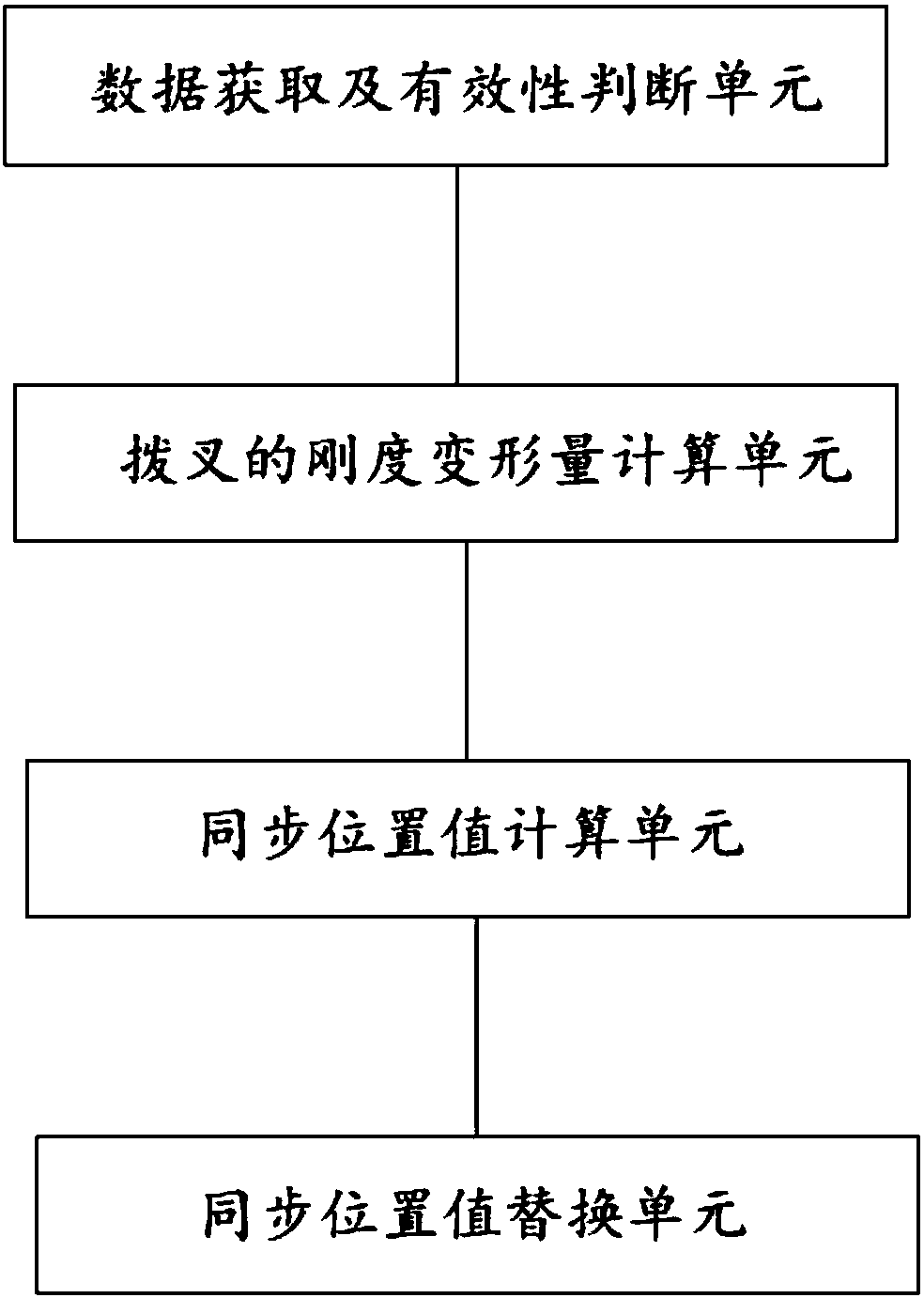

Synchronizer self-learning identification control method and position verification control method

The invention provides a synchronizer self-learning identification control method and a vehicle synchronizer position verification control method based on the synchronizer self-learning identification control method. According to the synchronizer self-learning identification control method, forward and reverse rotation of a gear selection and shifting motor are controlled, the voltage change of a gear selection and shifting position sensor is monitored so as to identify the state of a synchronizer reaching extreme positions, the voltage value of the position sensor when the synchronizer is at each extreme position is recorded, and therefore self-learning identification of gear selection information and gear shifting information of the synchronizer is realized. According to the position verification control method, when a speed changer reaches a bottom line, a vehicle runs for a certain period of time and the vehicle cannot be started normally due to gear selection and shifting, the synchronizer self-learning identification control method is adopted for learning and identification of the gear selection information and the gear shifting information. By means of the synchronizer self-learning identification control method and the position verification control method, the problem that the synchronizer is inaccurate in position because of multiple factors is effectively eliminated, gear selection and shifting of the vehicle can be based on a correct synchronizer position, and therefore the correctness of gear selection and shifting of the vehicle is guaranteed.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

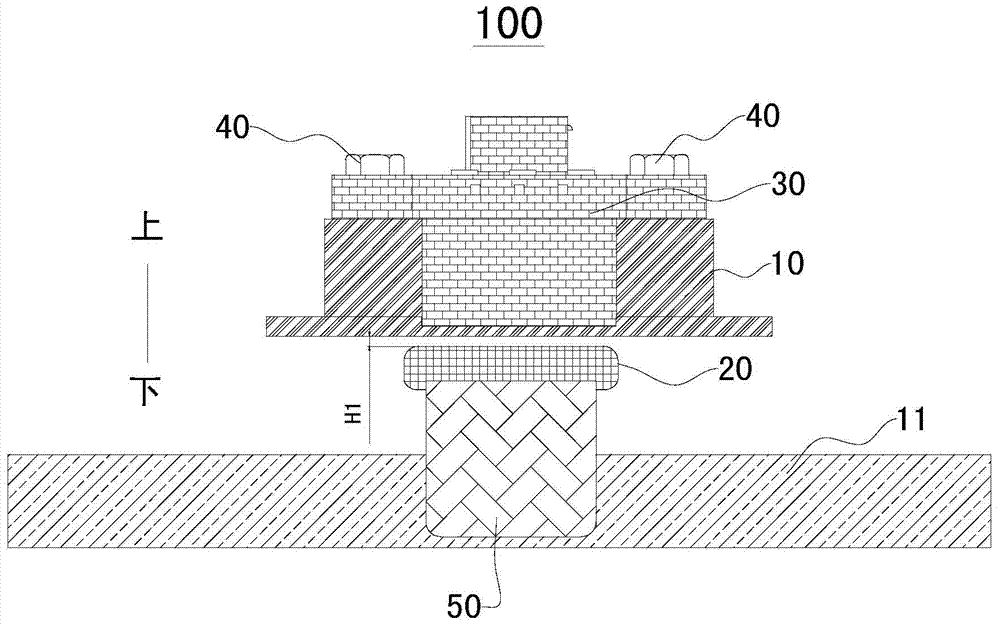

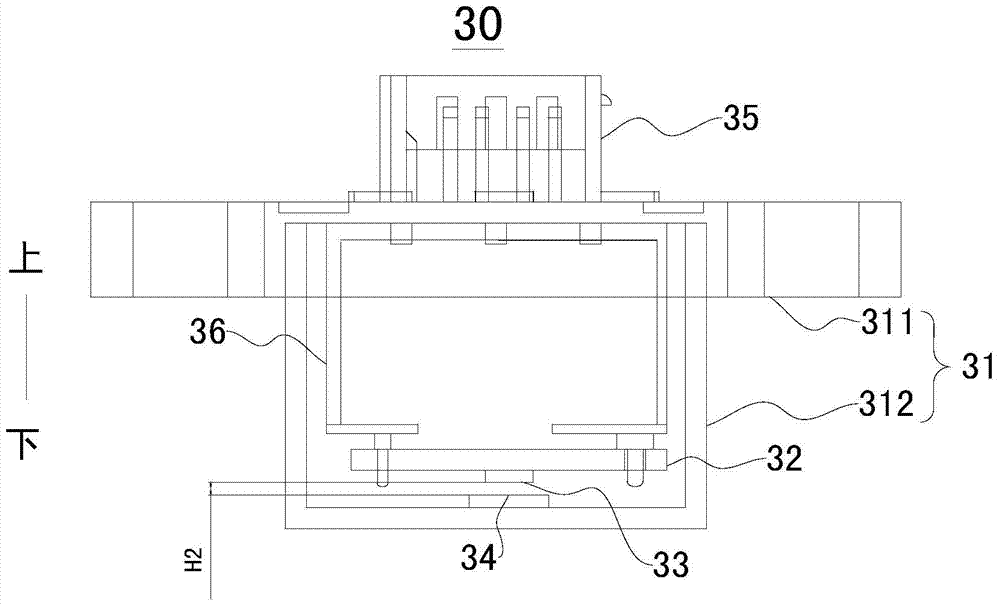

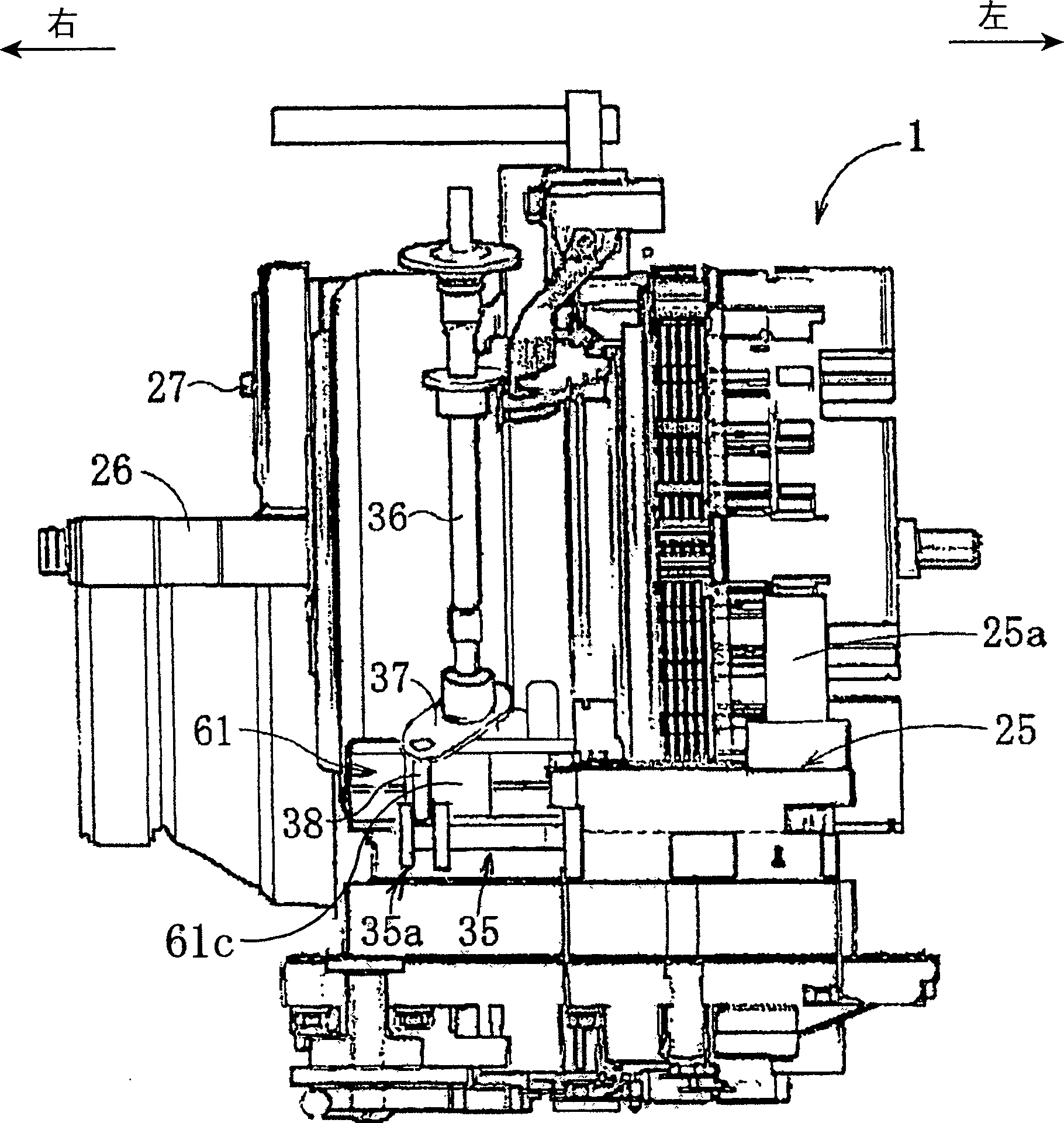

Clutch actuator structure

A clutch actuator structure provided for an internal combustion engine and a hydraulic clutch mechanism for transmitting a rotational driving force of a crankshaft of said engine includes a clutch actuator for controlling an oil pressure for engaging and disengaging the hydraulic clutch mechanism. The clutch actuator structure ensures that noises generated at the times of operation of the clutch actuator for actuating a hydraulic clutch are prevented from being transmitted to the exterior. The clutch actuator structure includes an oil sump part for reserving oil provided in the periphery of a clutch actuator. The clutch actuator is disposed in the oil sump part.

Owner:HONDA MOTOR CO LTD

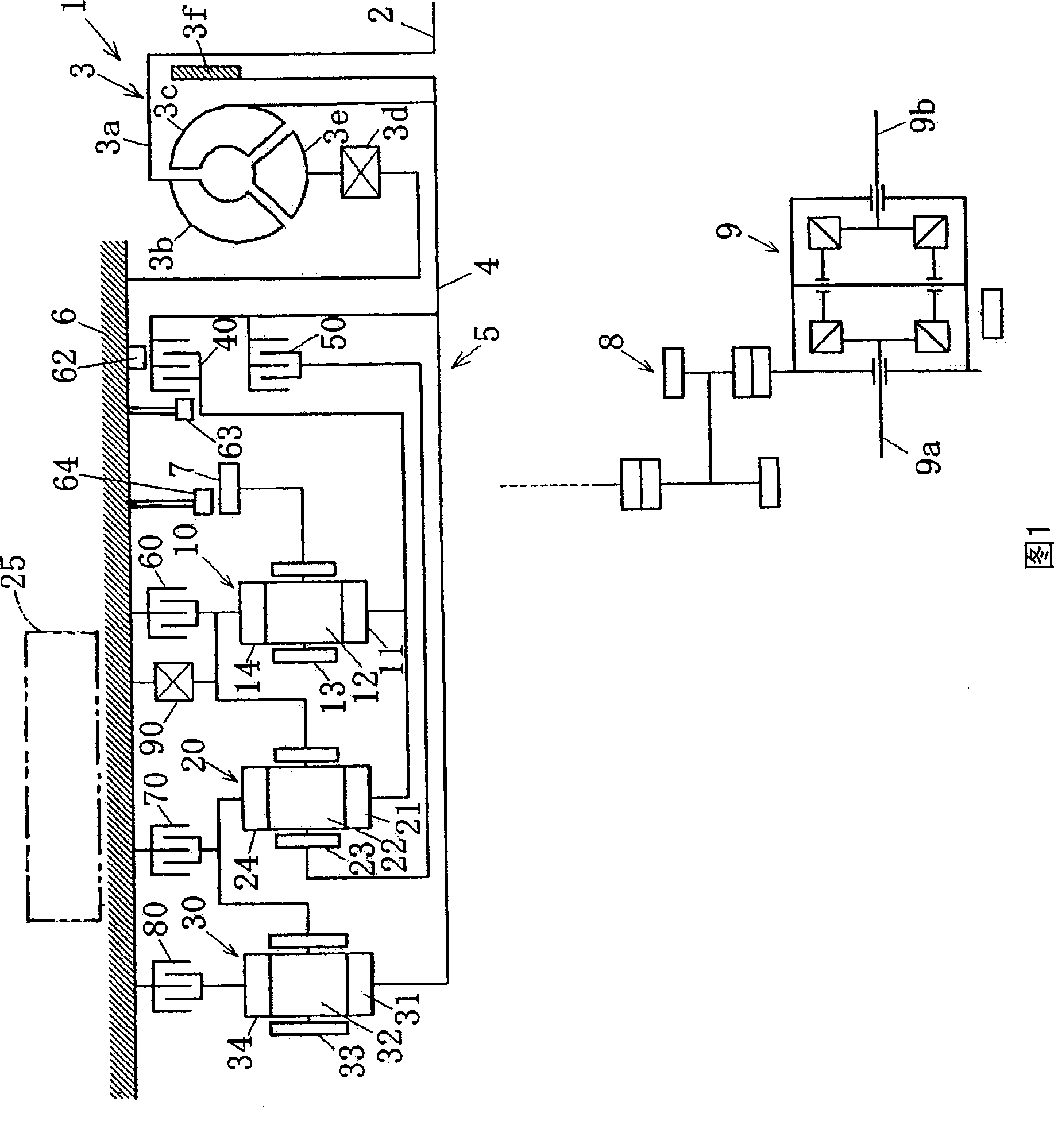

Double-motor driving device with parking brake of electric forklift

InactiveCN103522885AMeet input power requirementsBroaden the tonnage classElectric propulsion mountingGearing controlBrake torqueMotor drive

The invention relates to a double-motor driving device with a parking brake of an electric forklift. The double-motor driving device comprises a speed reducer and driving motors, wherein the speed reducer comprises an output shaft, a left input shaft and a right input shaft which are parallel to each other. An output gear is arranged on the output shaft, a left input gear is arranged on the left input shaft, a right input gear is arranged on the right input shaft, and the left input gear and the right input gear are both meshed with the output gear constantly. The extending-out end of the output shaft is connected with the input shaft of the speed reducer through a transmission shaft, the extending-out end of the left input shaft is provided with a braking drum and the parking brake respectively, the other end of the left input shaft is connected with a left driving motor through a spline, the right input shaft is connected with a right driving motor through a spline, and the left driving motor and the right driving motor are arranged side by side. According to the double-motor driving device, two small-power motors are utilized to output moment in a coupling mode, therefore, needs of input power of the finished vehicle are met, the layout is utilized reasonably, and large brake torque required by the large-tonnage forklift is achieved by means of the attached parking brake.

Owner:ANHUI HELI CO LTD

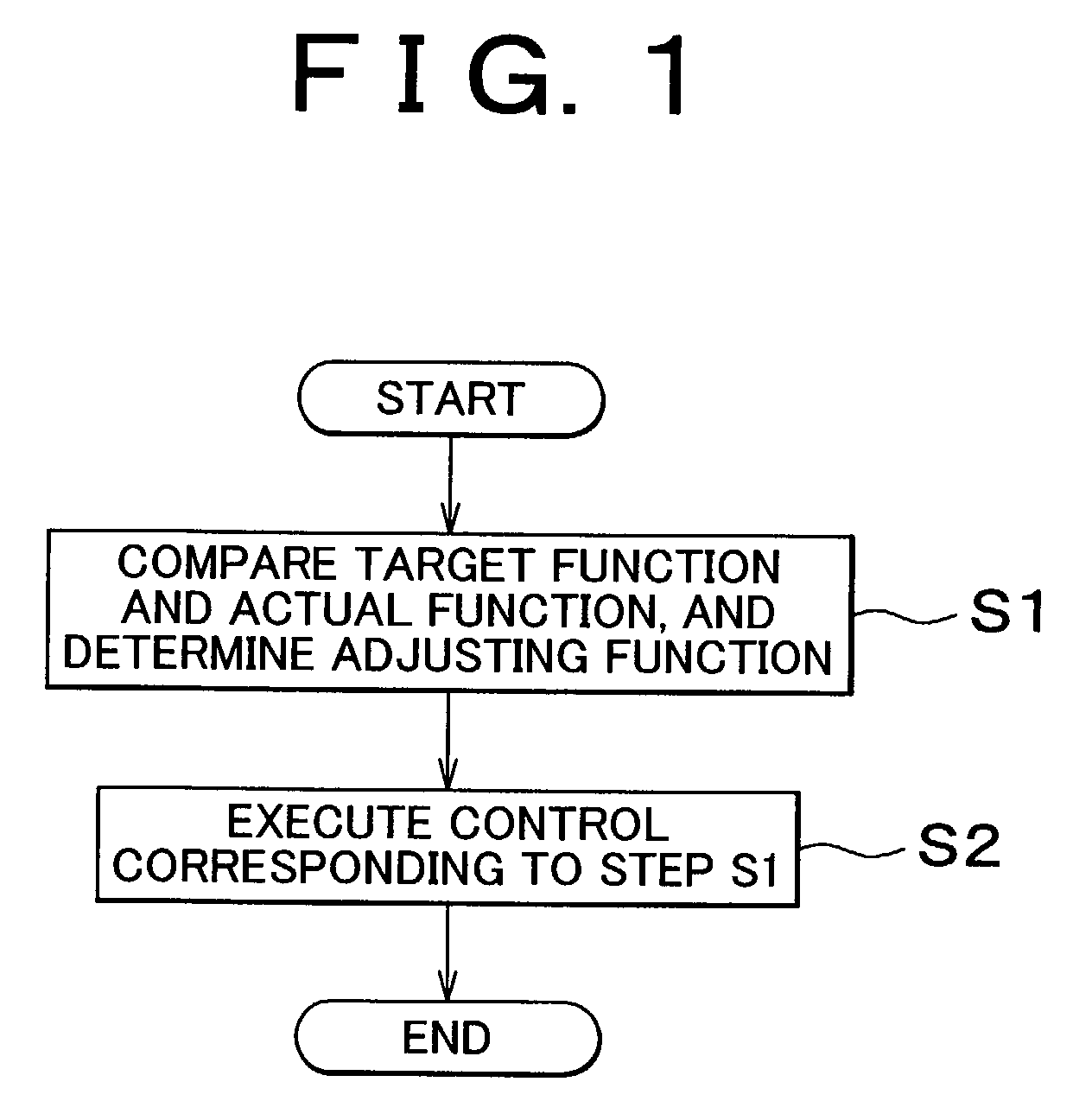

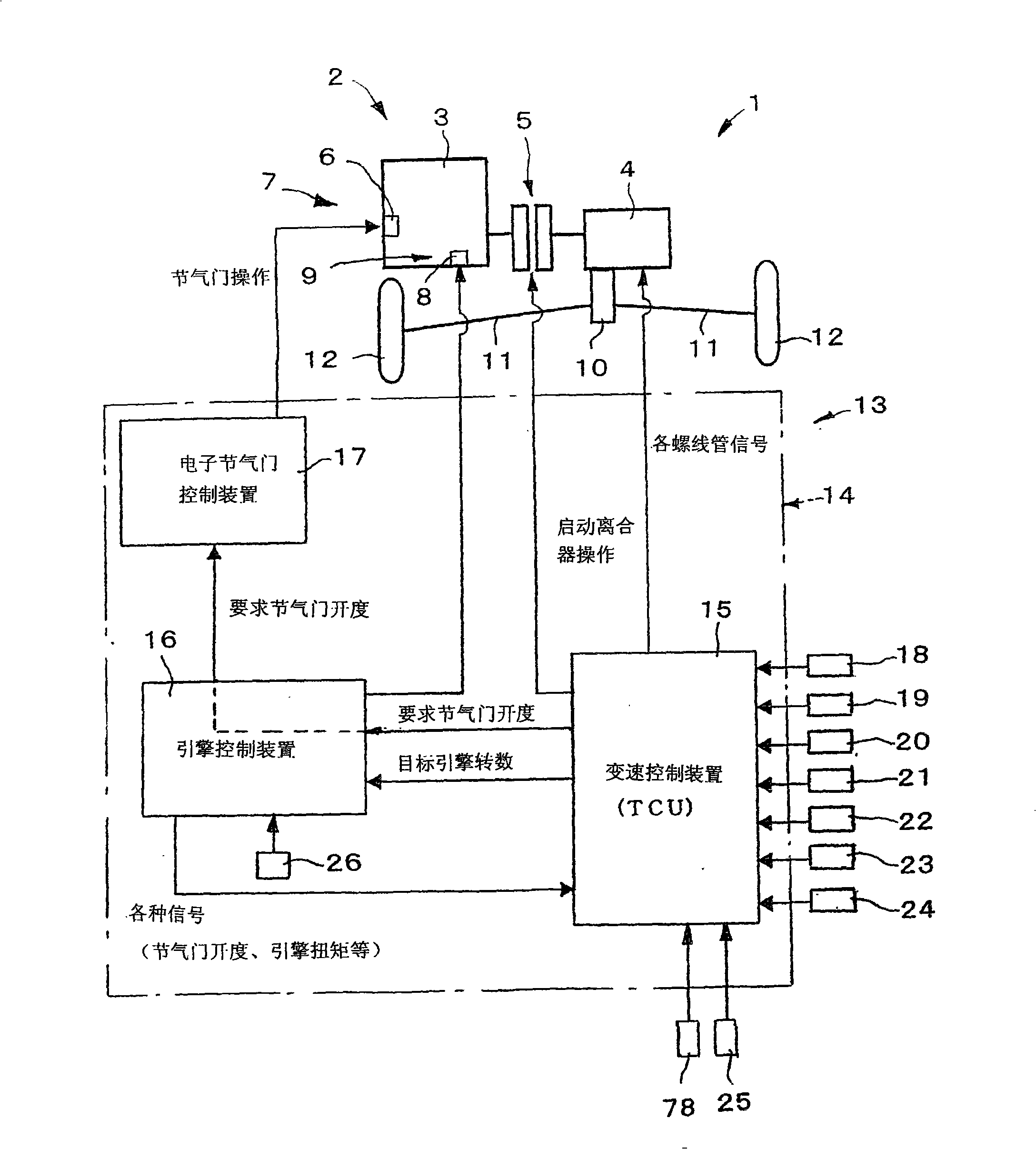

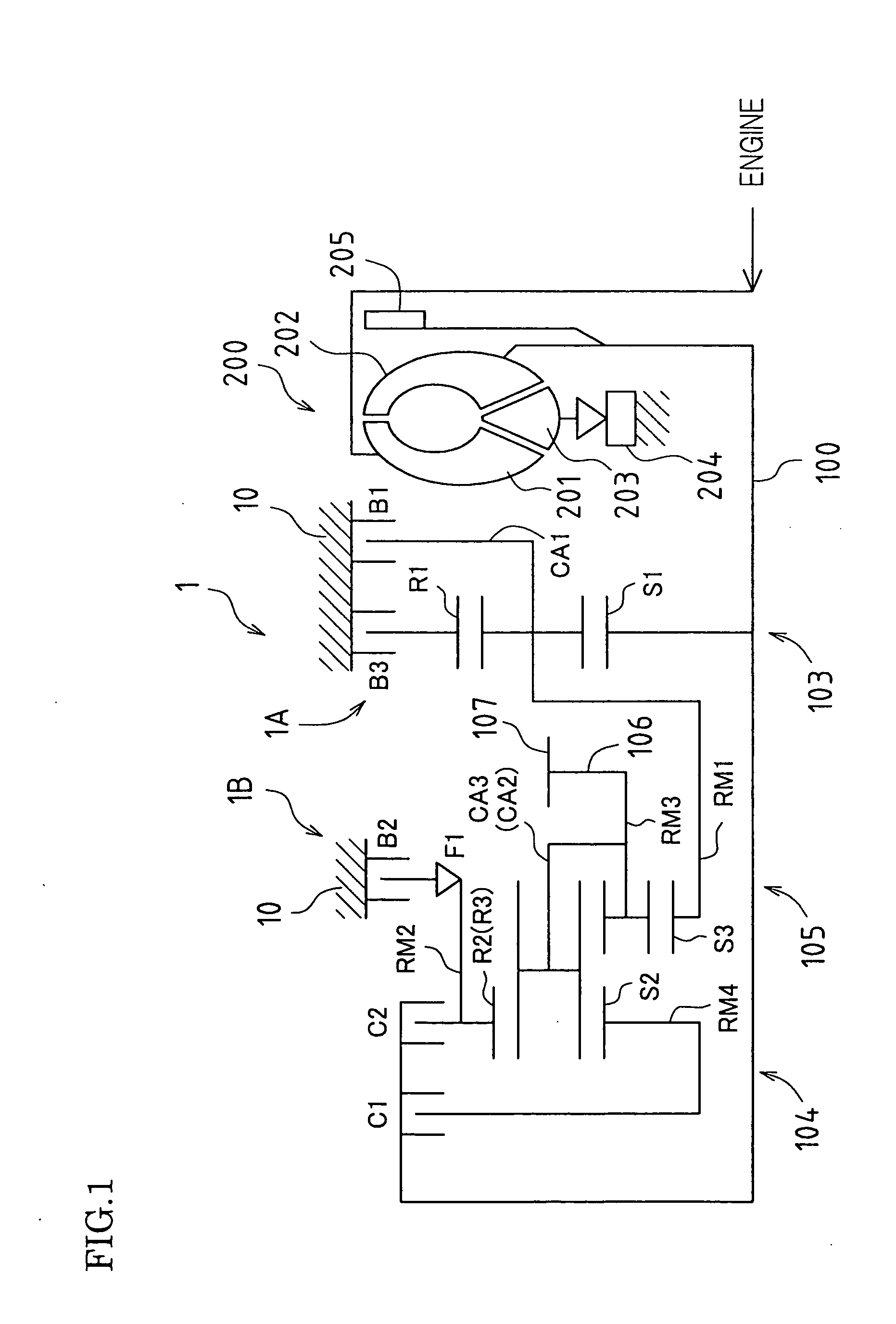

Control device and control method for powertrain, program for implementing the control method, and recording medium containing the program

InactiveUS20080153660A1Prevent change of directionReduce shockHybrid vehiclesDigital data processing detailsElectric machineExecution control

A shock caused due to a change in the direction of torque transferred to an output shaft is reduced. There is provided a control device for a powertrain including a drive power source that transfers torque to an output shaft connected to a wheel of a vehicle, and a rotary electric machine that transfers torque to the output shaft via a transmission. When electric power generation performed using the rotary electric machine is restricted, if torque that decelerates the vehicle is transferred from the drive power source to the output shaft, a control is executed so that torque that does not decelerate the vehicle is transferred from the drive power source to the output shaft, and a shift control over the transmission is executed.

Owner:TOYOTA JIDOSHA KK +1

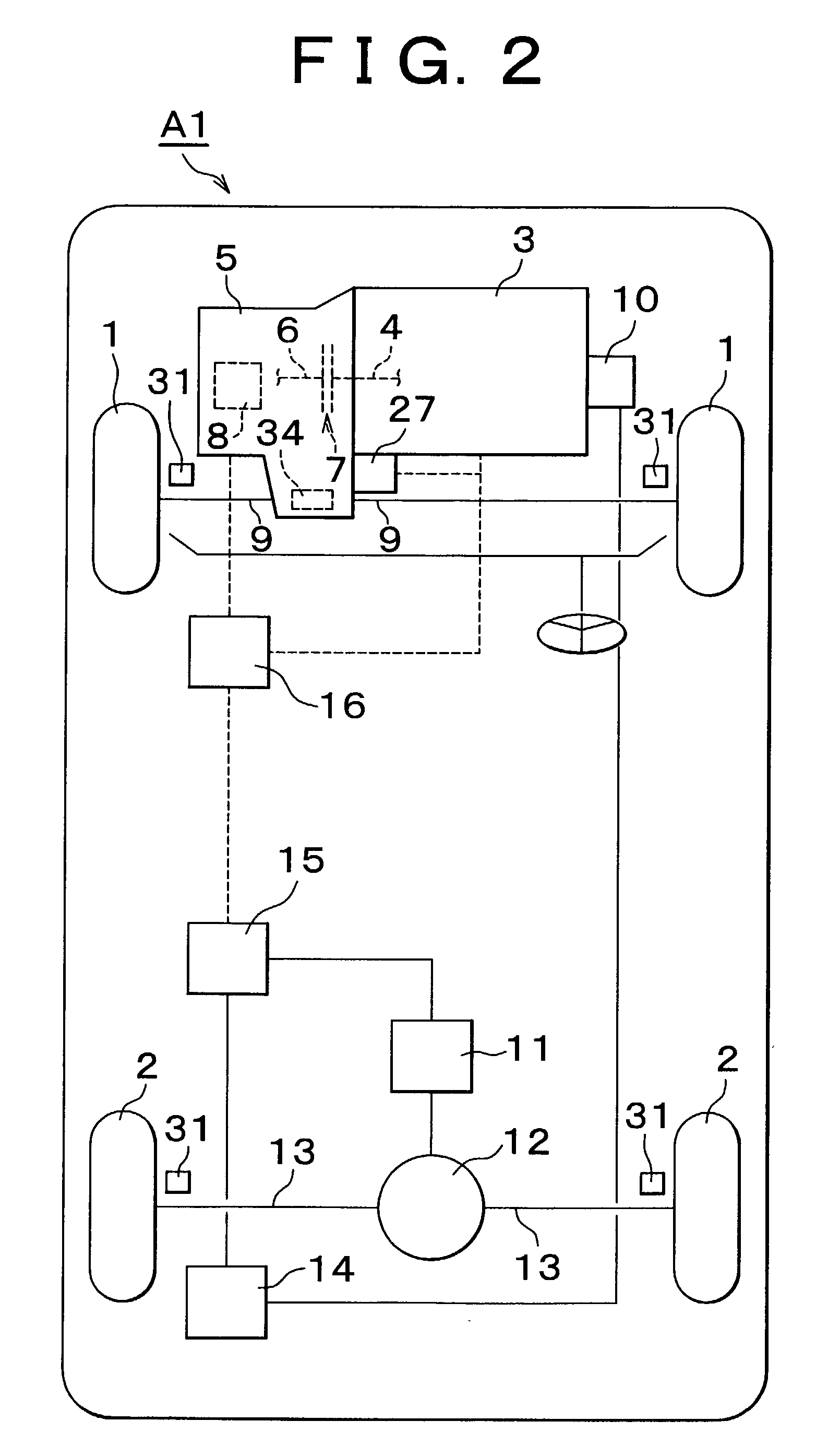

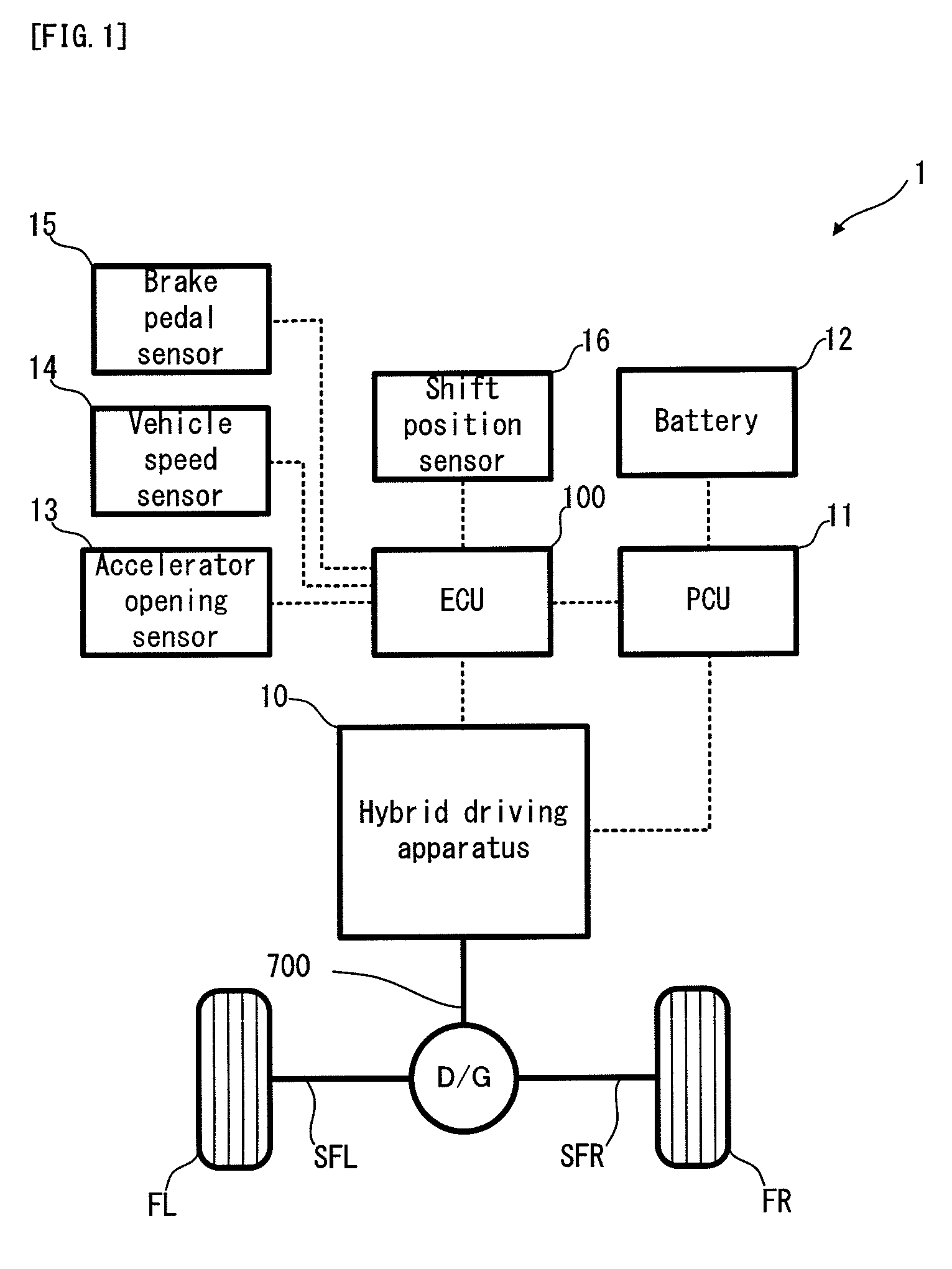

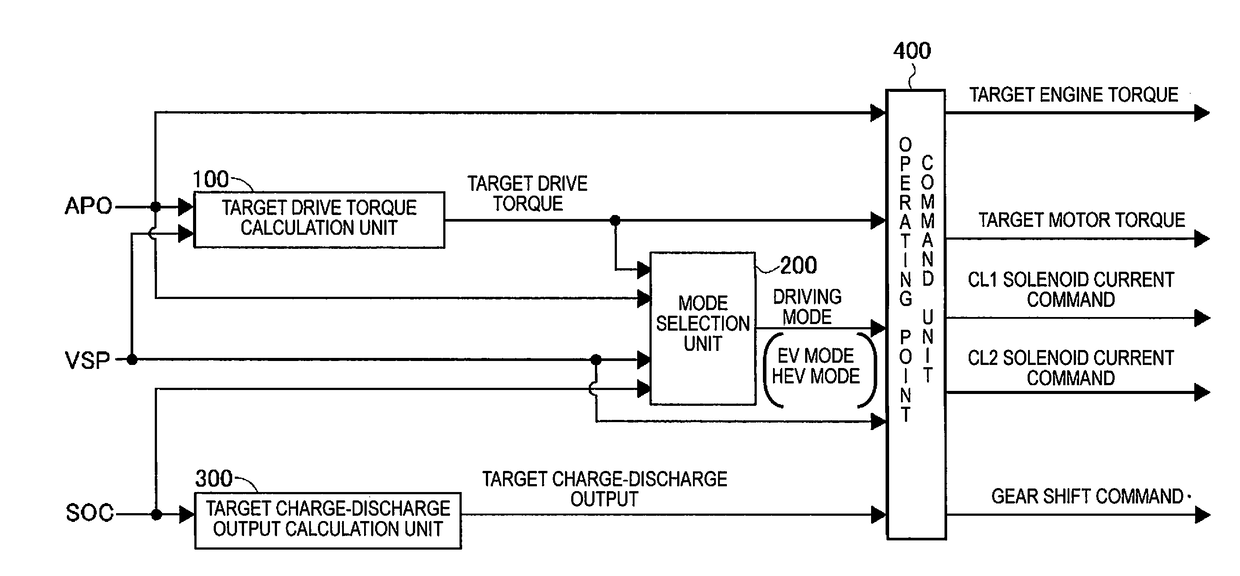

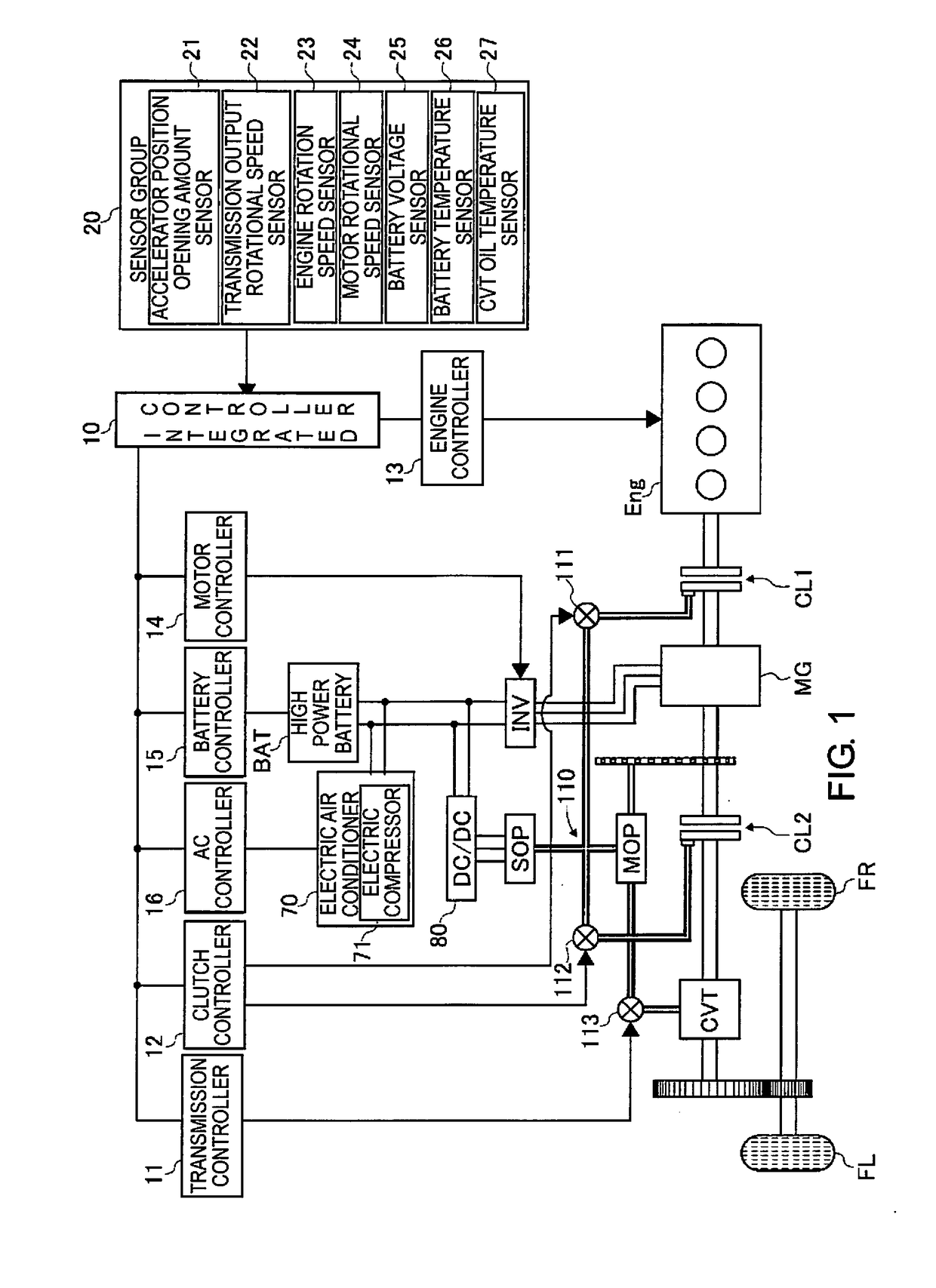

Vehicle control apparatus

ActiveUS20120053769A1Suppress sudden changesMitigate torque shockHybrid vehiclesDigital data processing detailsElectric machineryControl theory

Owner:TOYOTA JIDOSHA KK

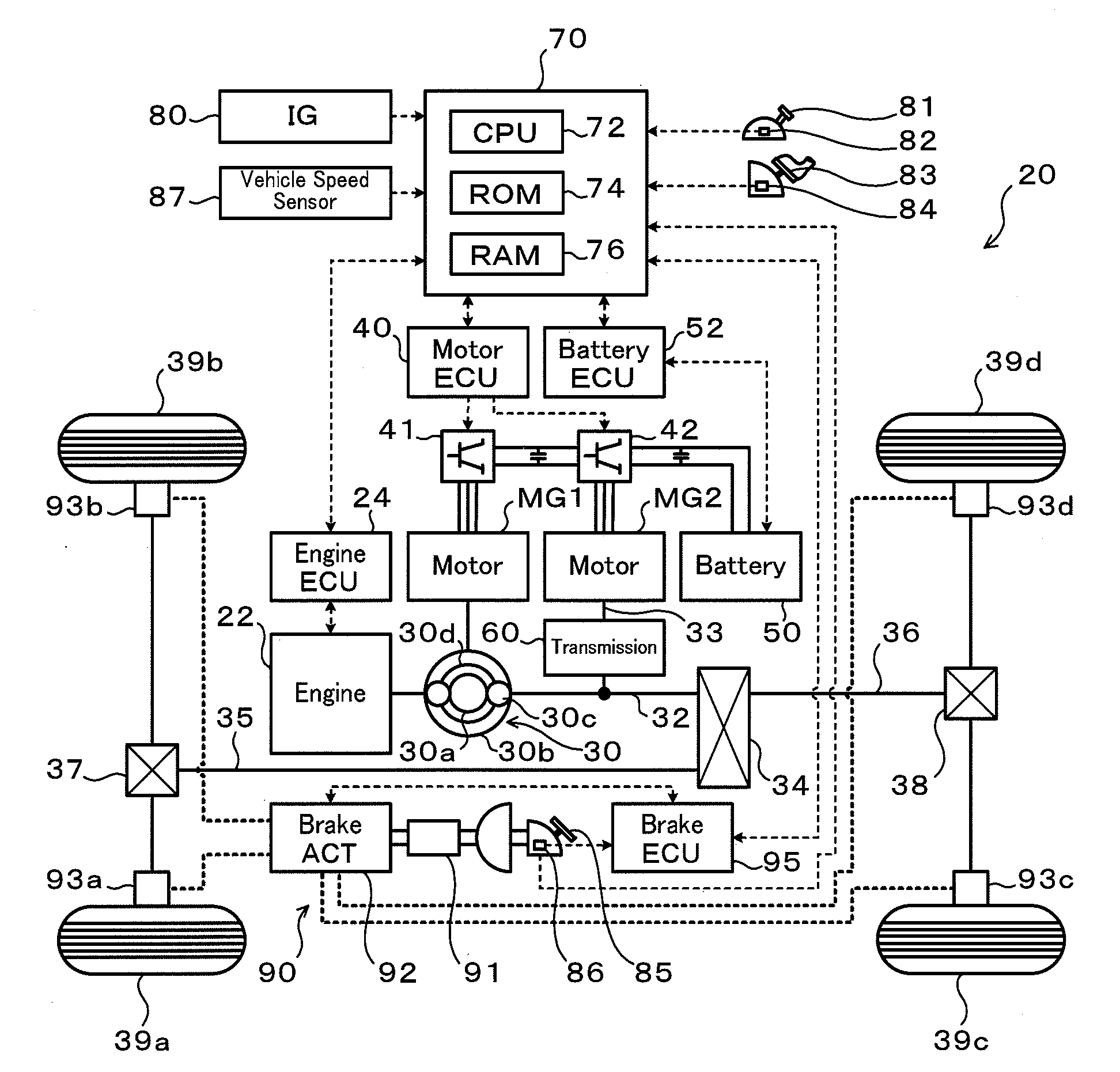

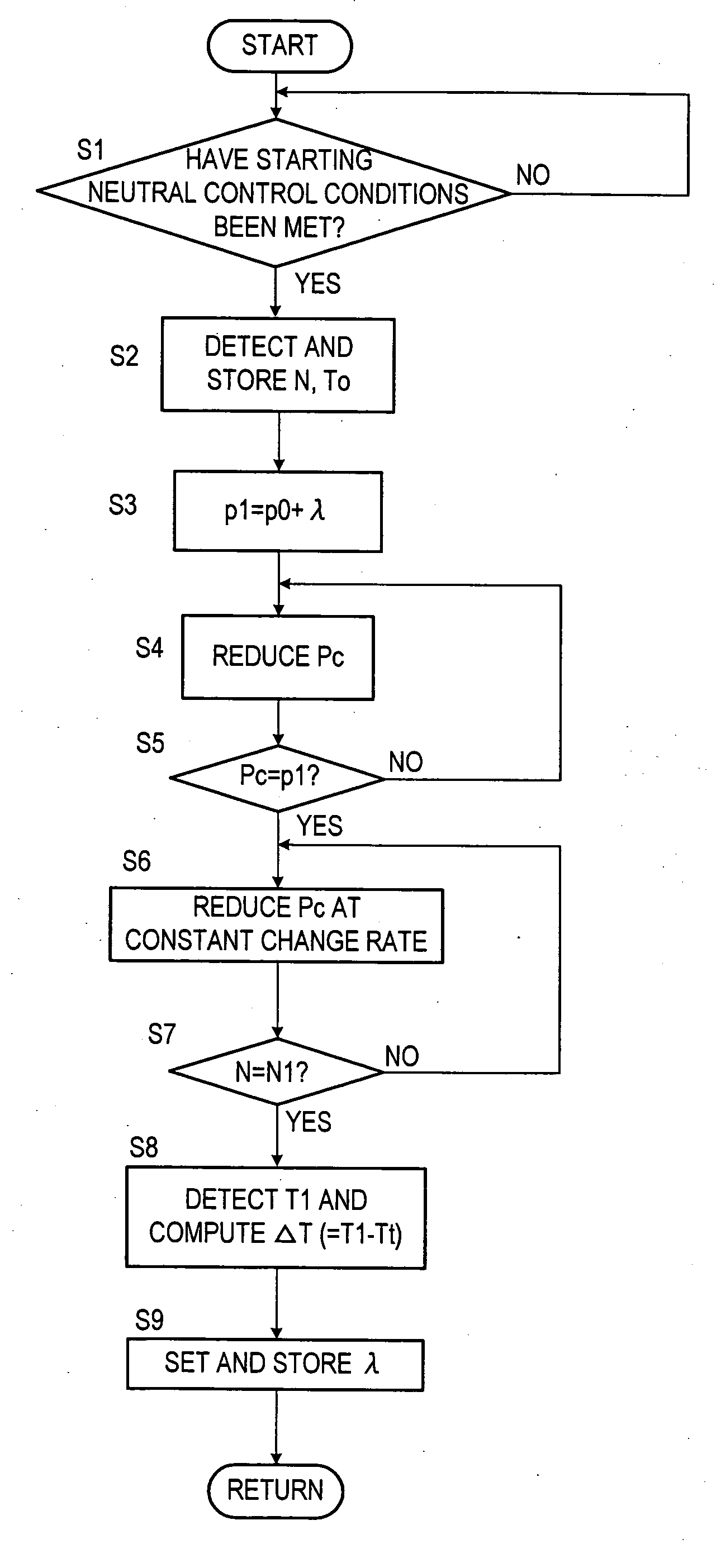

Apparatus for and method of controlling power train, and storage medium storing program for implementing the method

InactiveUS20080146413A1Reduce the shock that can occurReduce capacityDigital data processing detailsGearing controlControl powerAutomatic transmission

An ECU executes a program for implementing a method that includes: a step of performing control so that torque capacity Tch of a frictional engagement device that is brought from an engaged state by a downshift operation is gradually reduced to start an inertia phase when a power-on downshift is performed; and a step of stopping the gradual reduction of the torque capacity Tch when the rate of change in an input shaft rotation speed NI of an automatic transmission has reached a desired rate of change ΔN(1). Variation in output torque is kept small, and the shock that can occur at the time of a shift is thus reduced.

Owner:TOYOTA JIDOSHA KK

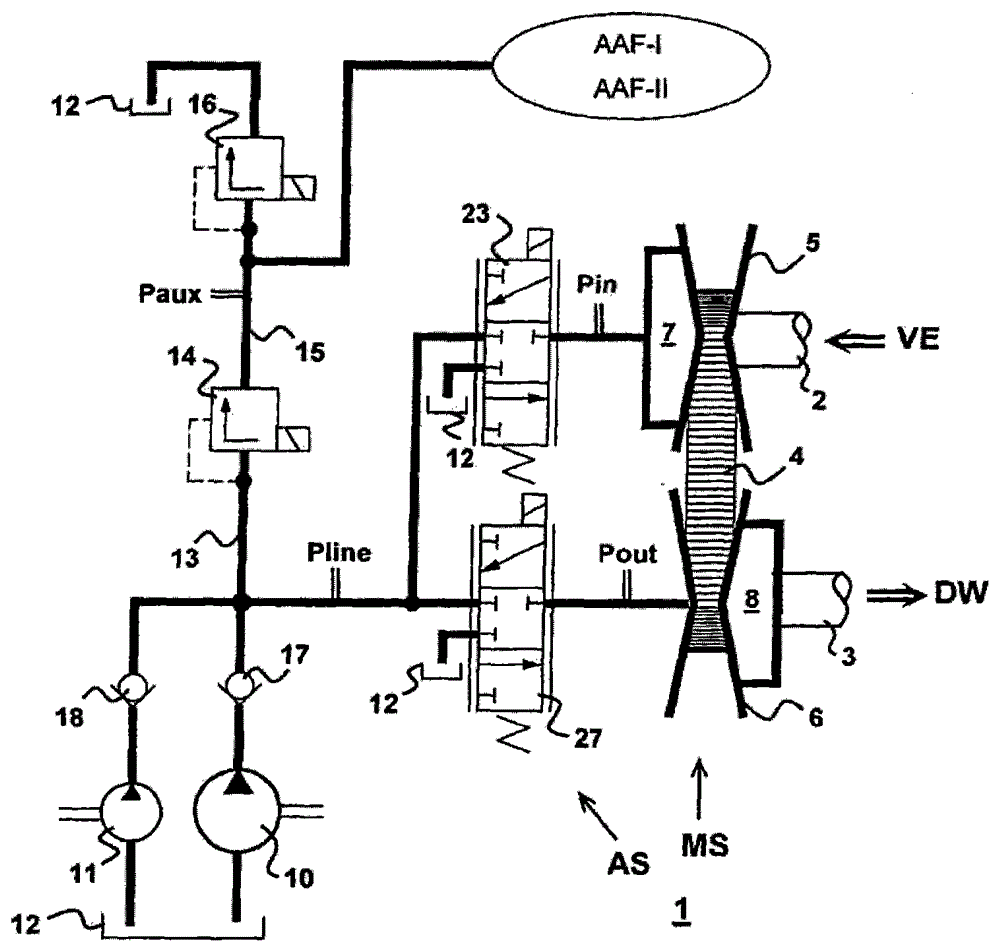

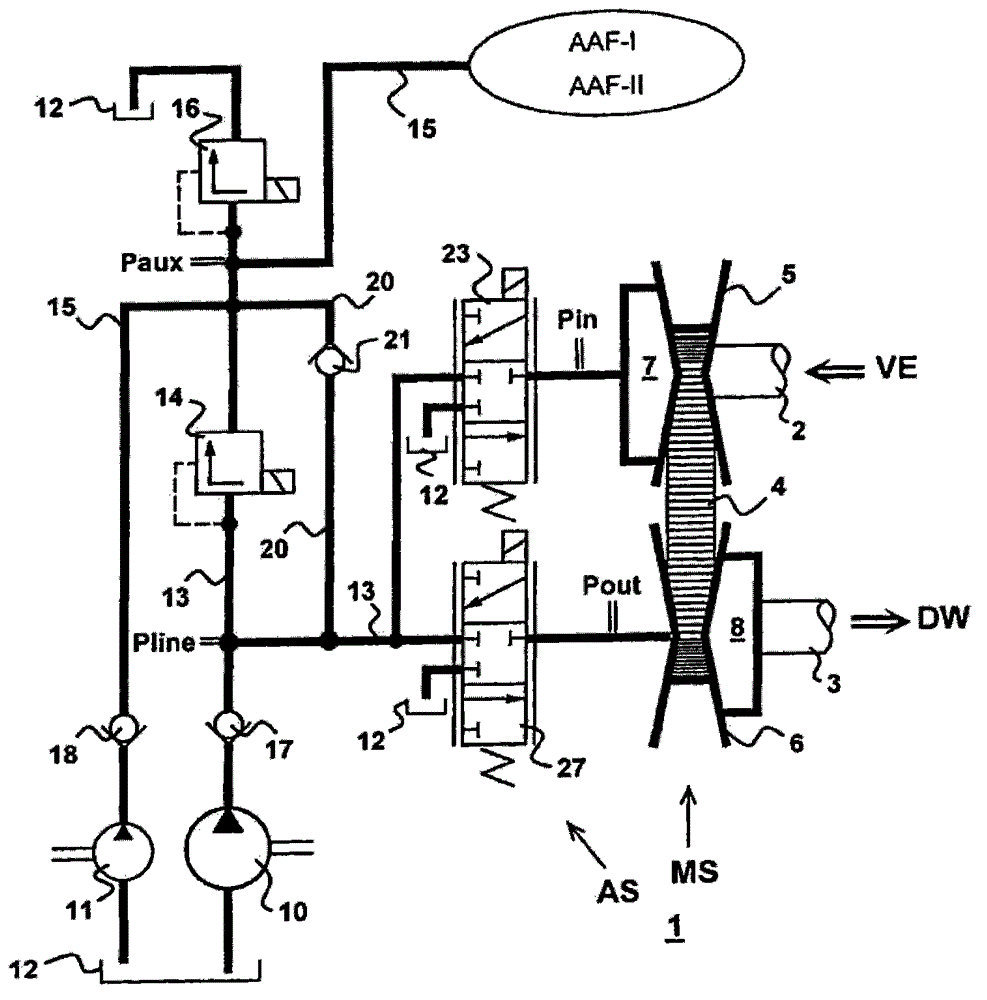

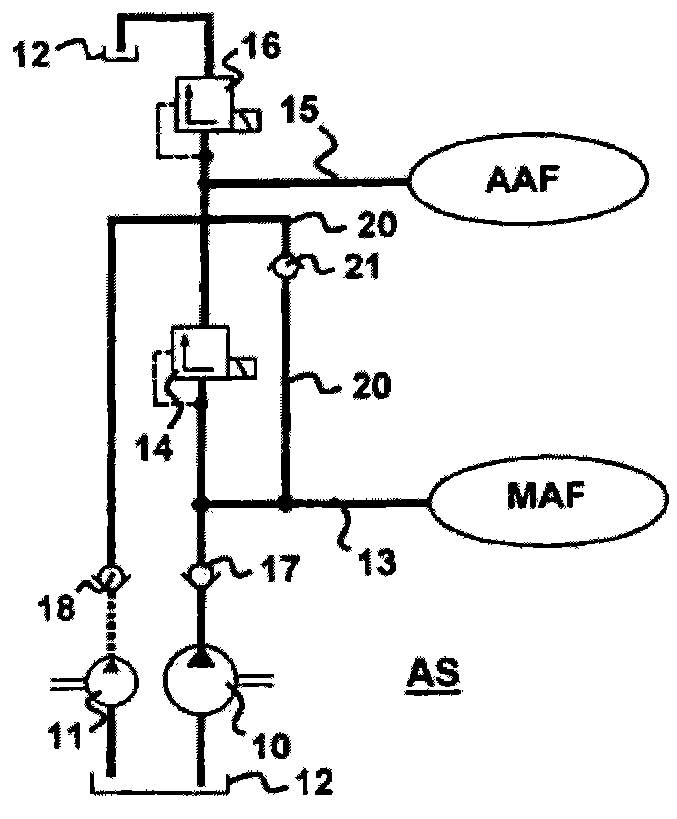

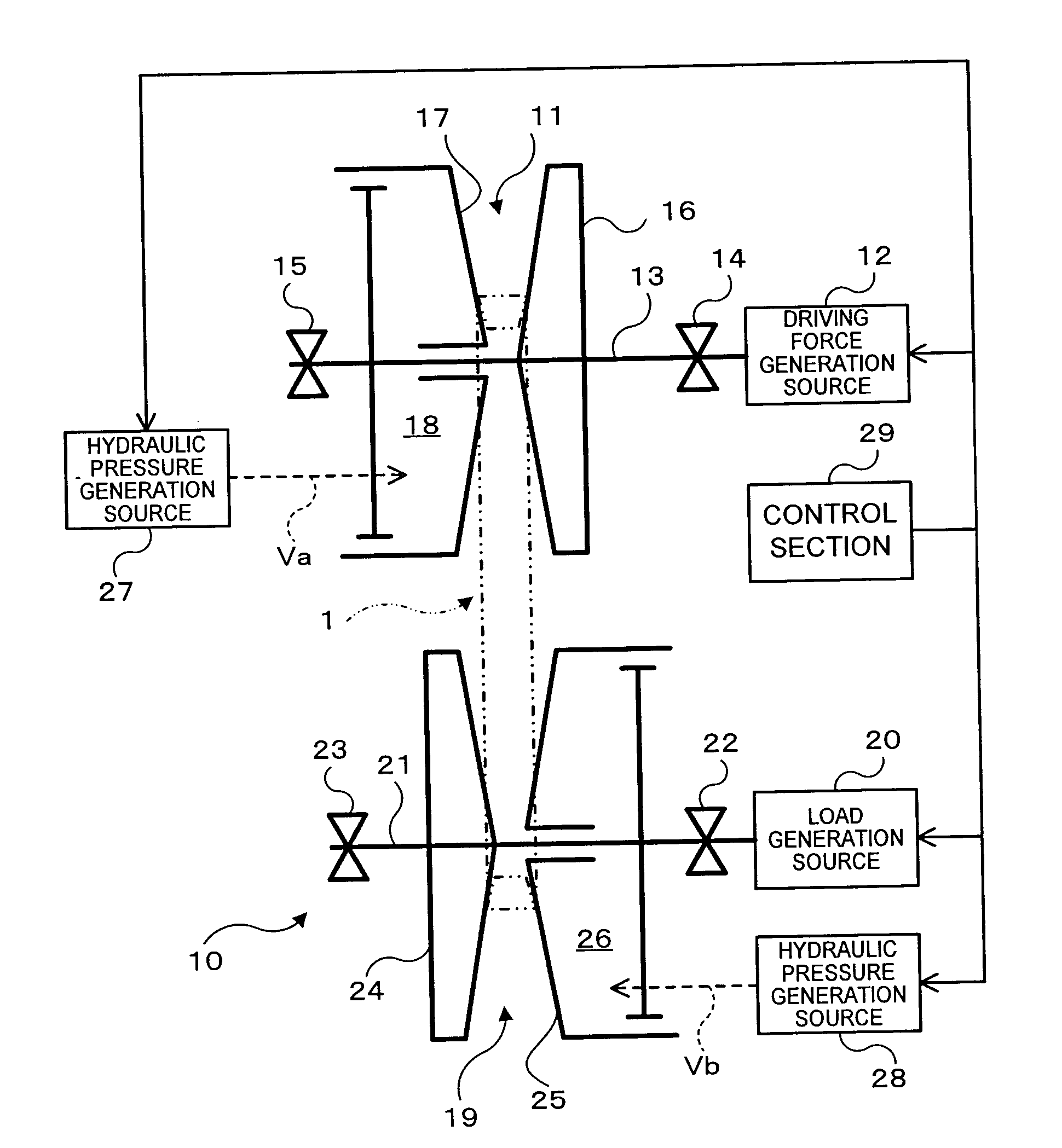

Hydraulically actuated continuously variable transmission for a vehicular drive line provided with an engine

InactiveCN104160180ASimple designImprove efficiencyGear lubrication/coolingGearing controlElectric machineHydraulic pump

Owner:ROBERT BOSCH GMBH

Vehicle speed variation time control apparatus

Owner:SUZUKI MOTOR CORP

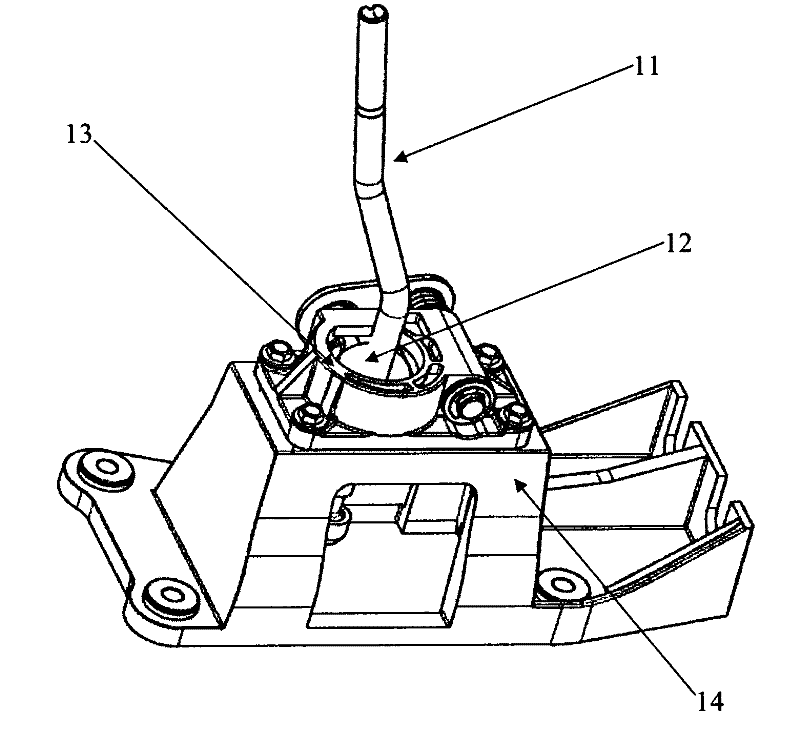

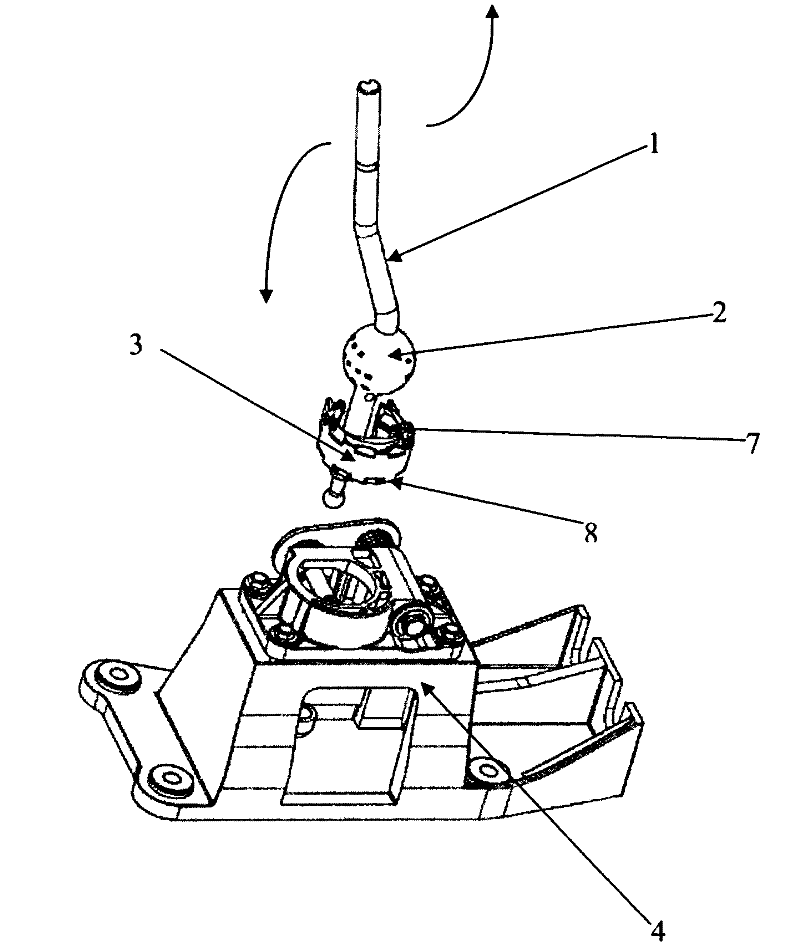

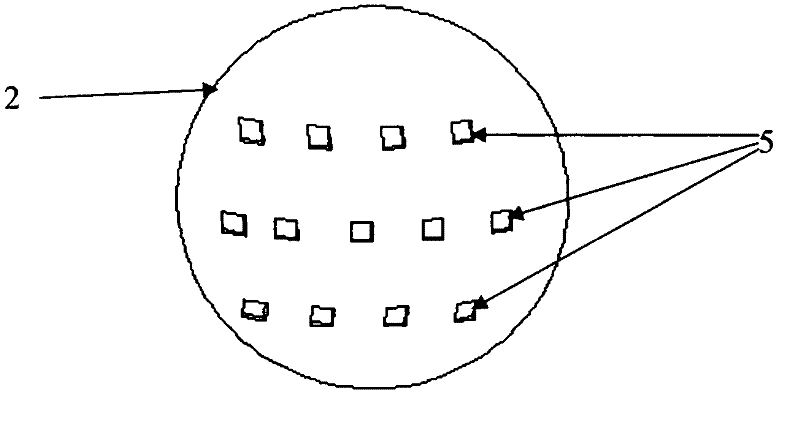

Automobile gear selecting and shifting mechanism and automobile

ActiveCN102506156AGuaranteed lubrication statusKeep lubricated for a long timeGearing controlEngine lubricationEngineeringOil storage

Owner:WUHU WANLIYANG TRANSMISSION CO LTD

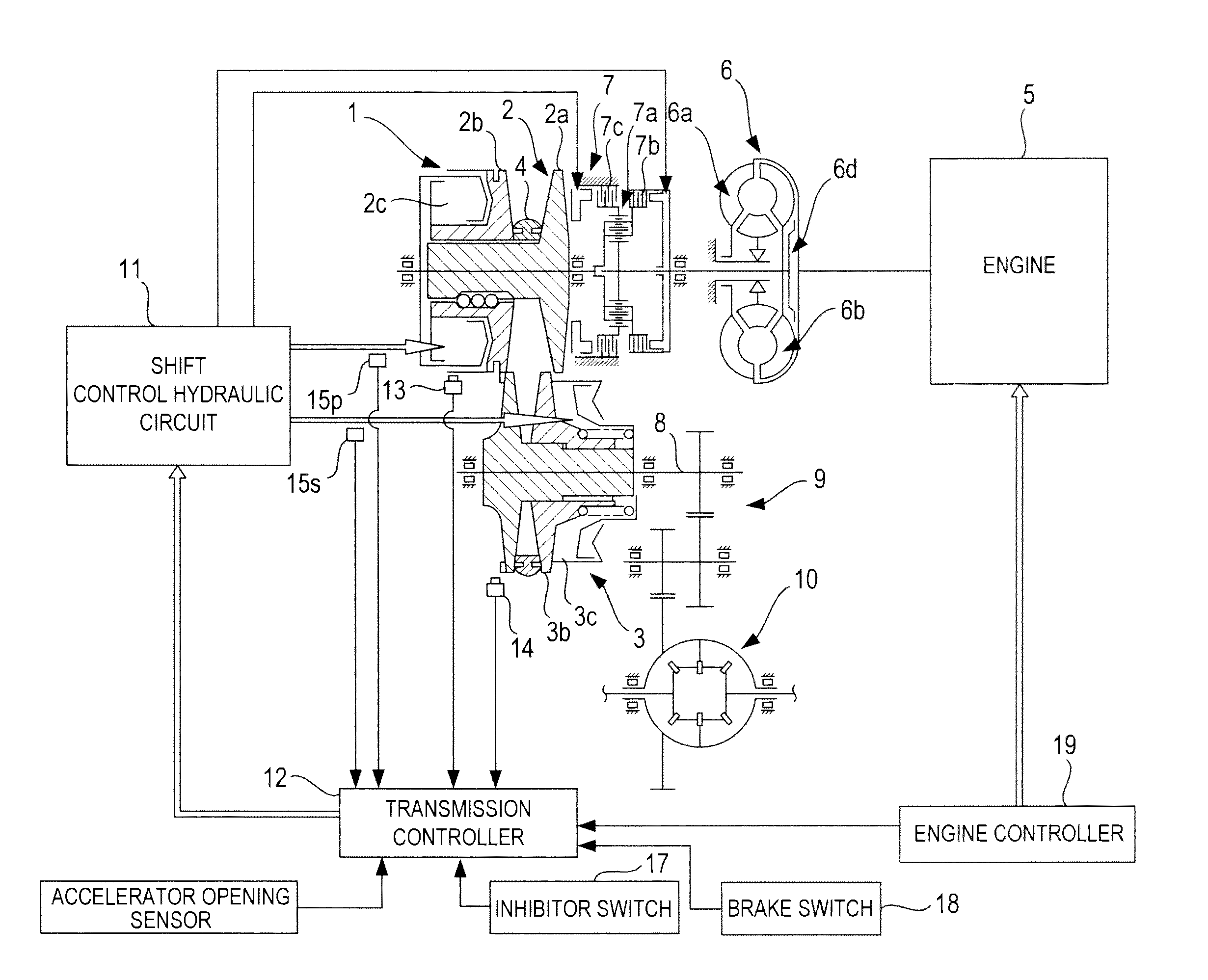

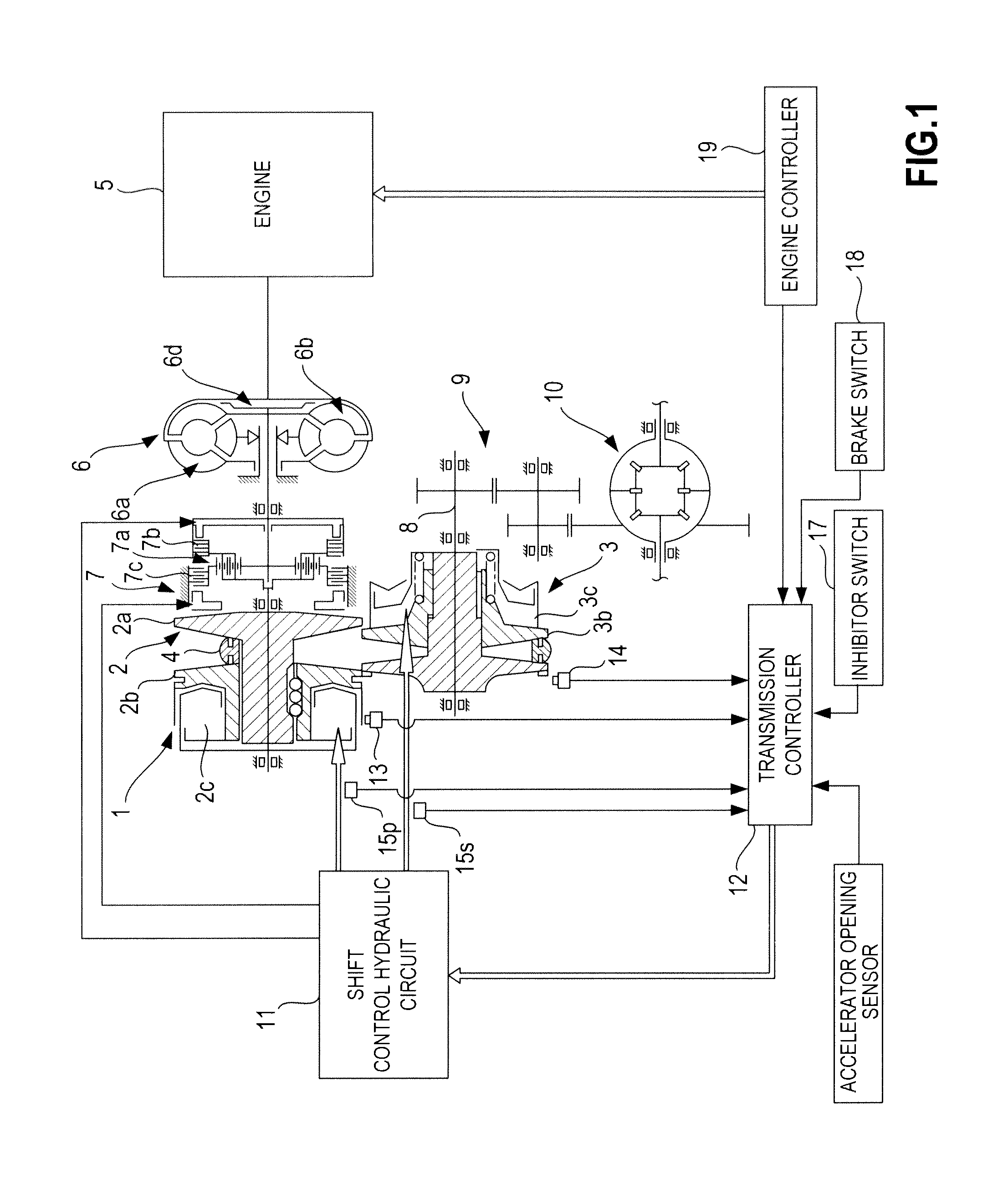

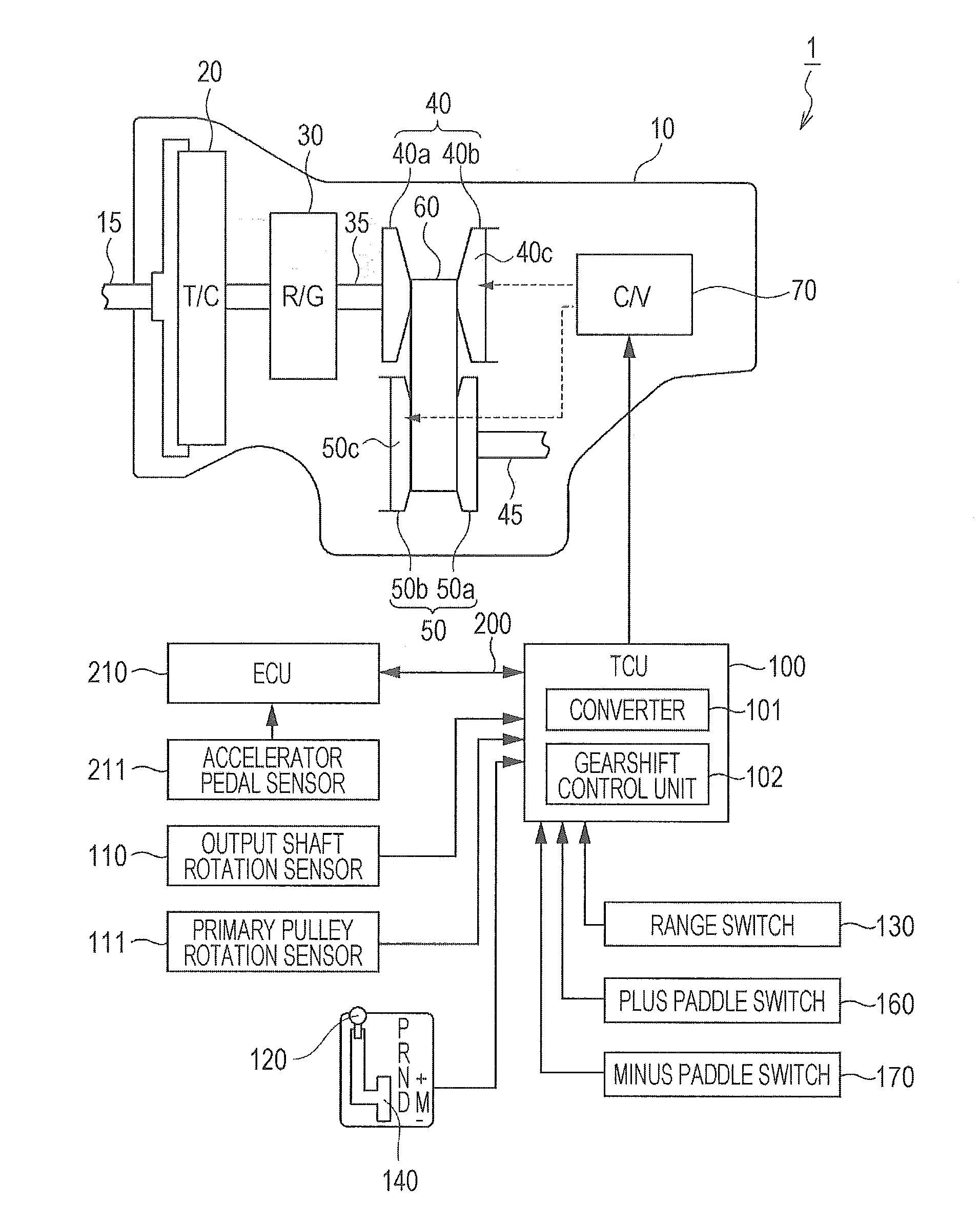

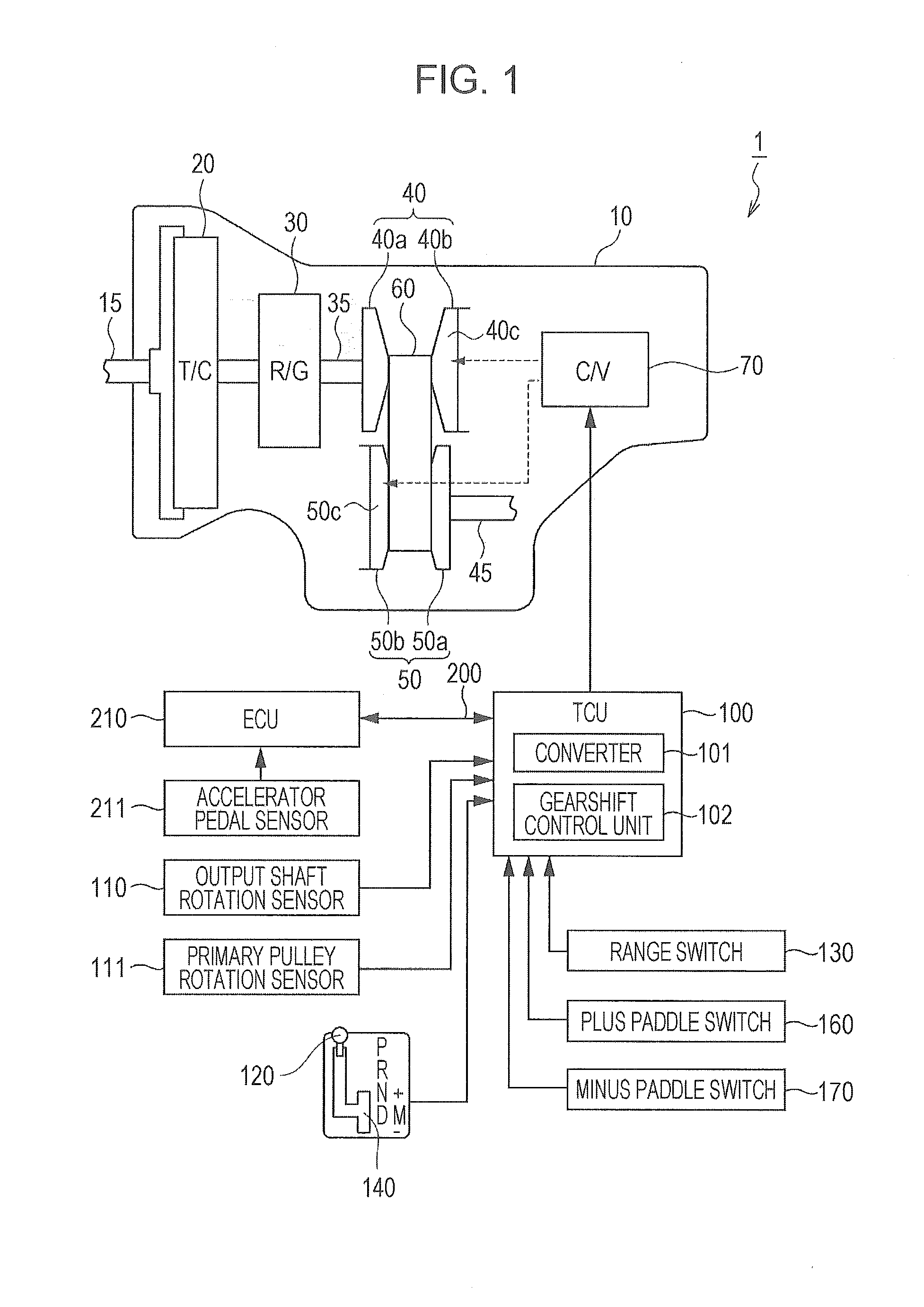

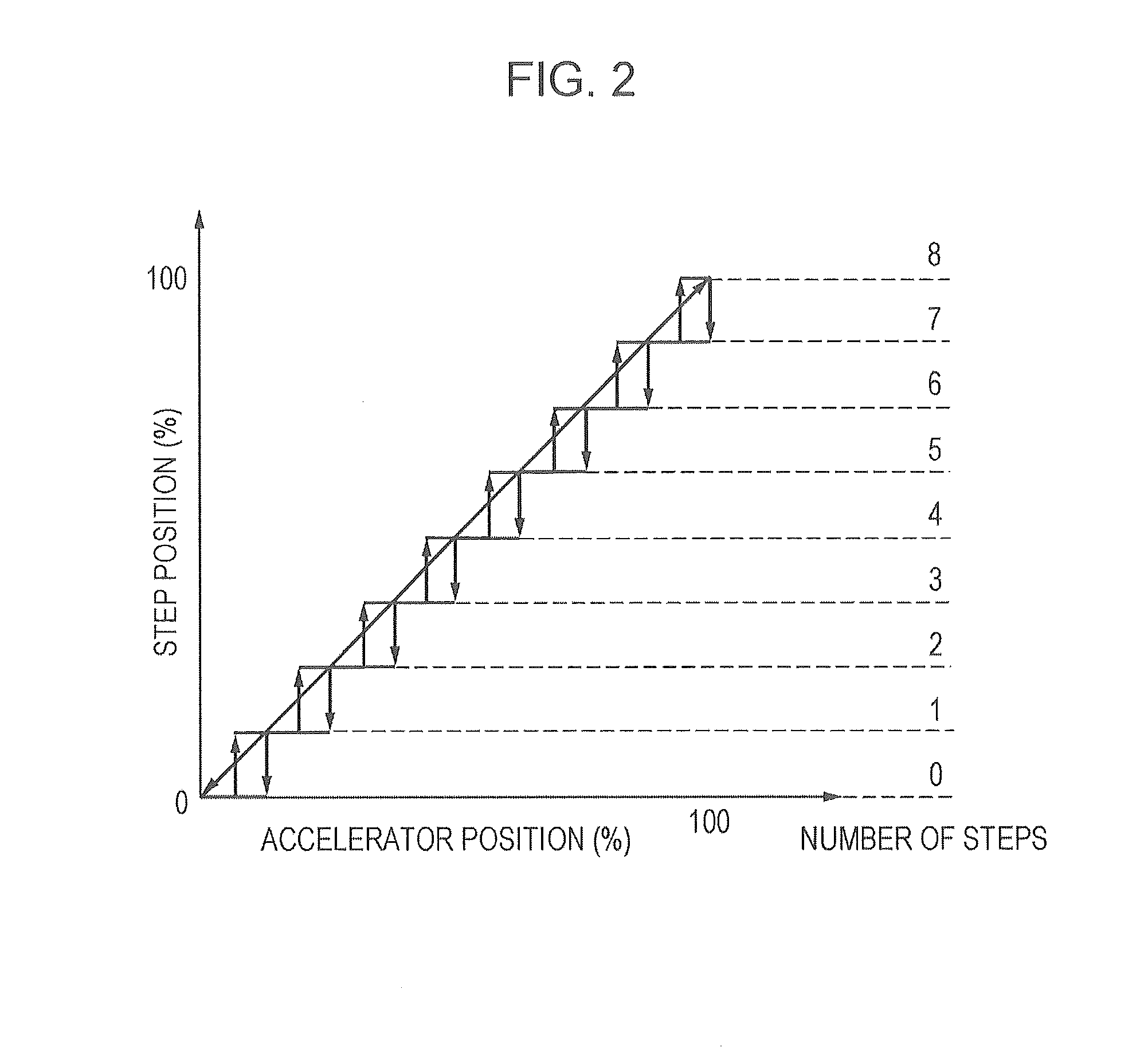

Continuously variable transmission and its hydraulic pressure control method

ActiveUS20150081181A1Improve fuel efficiencyReduced engine powerDigital data processing detailsGearing controlLower limitControl theory

Owner:JATCO LTD +1

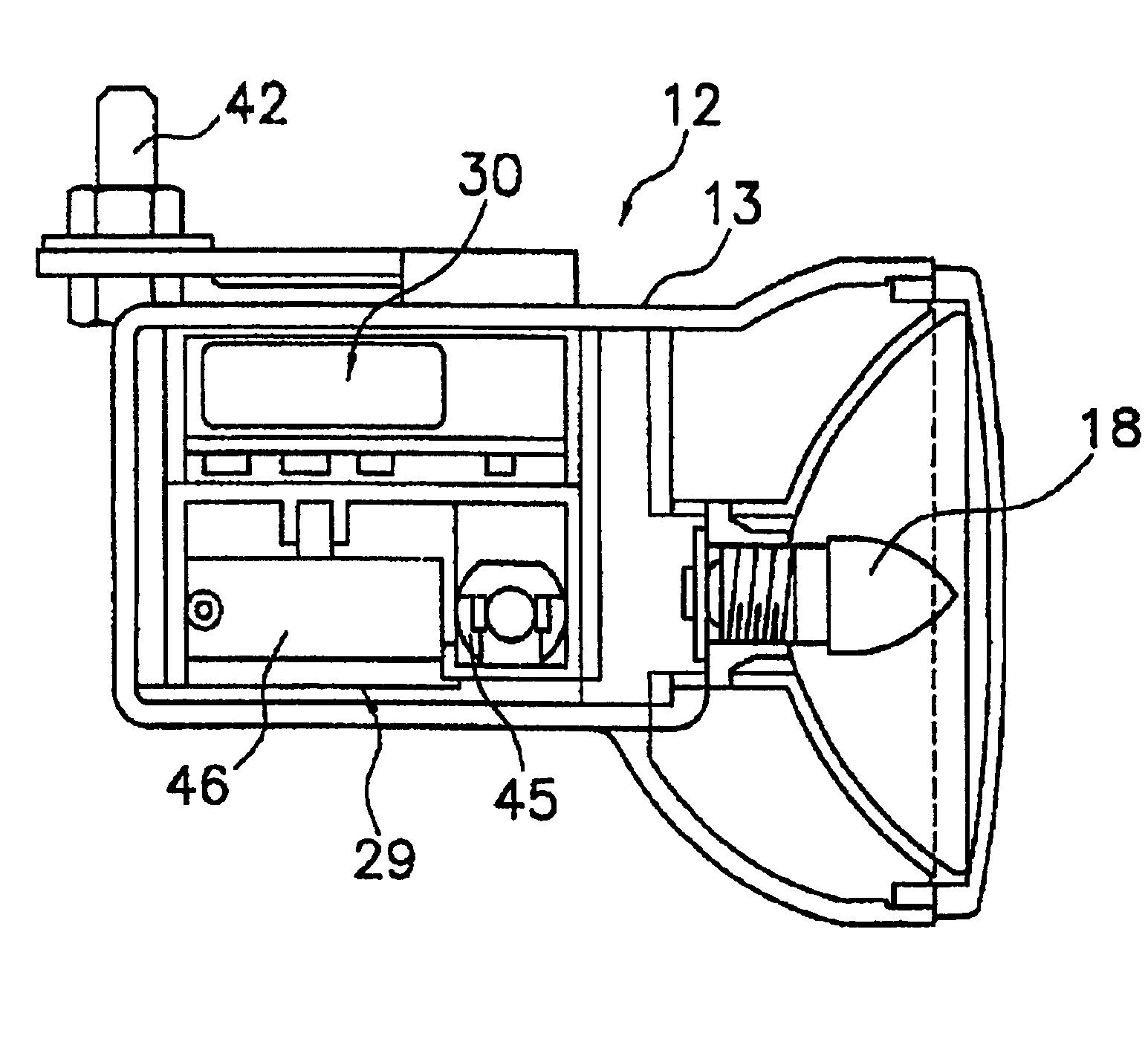

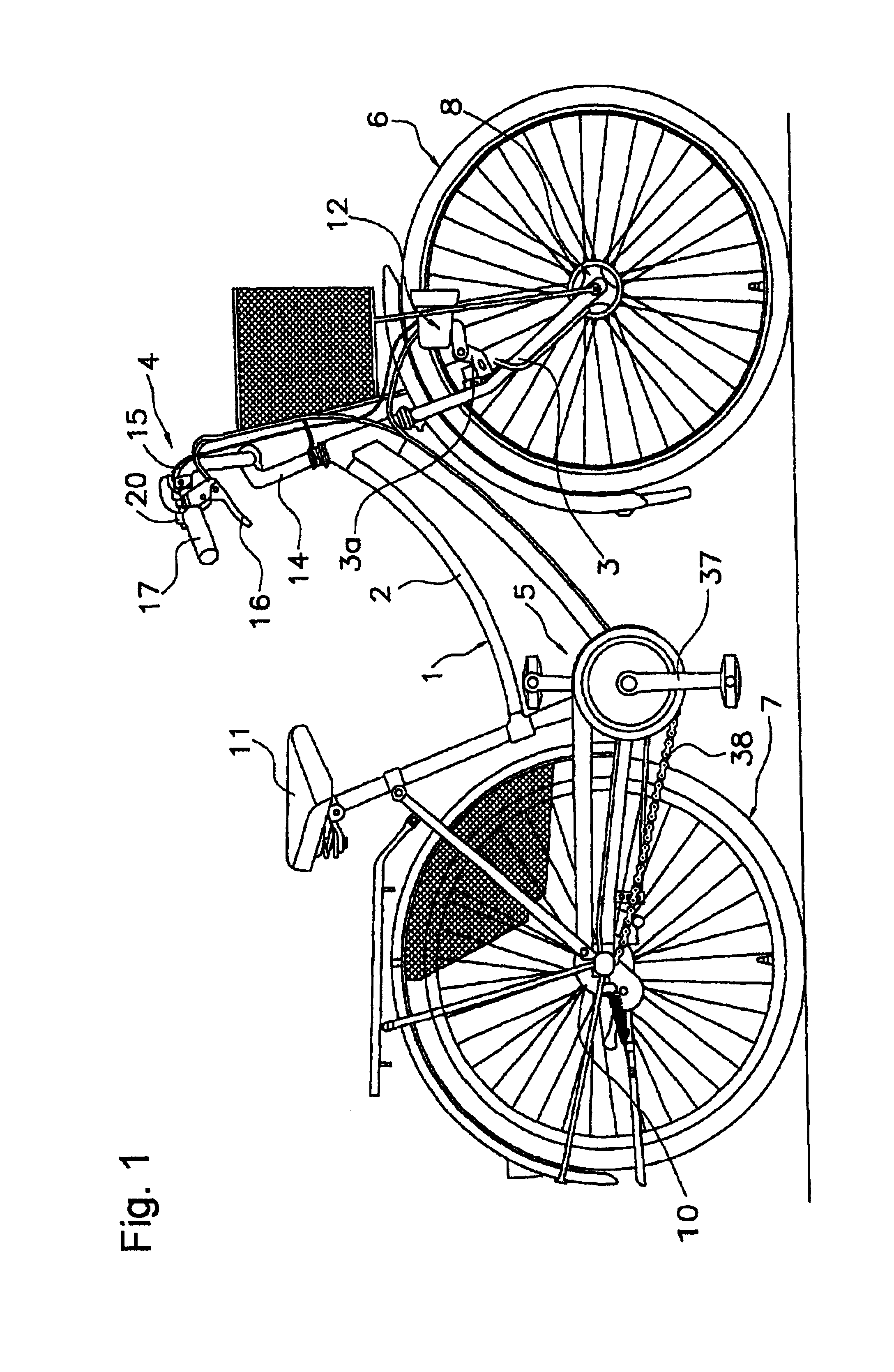

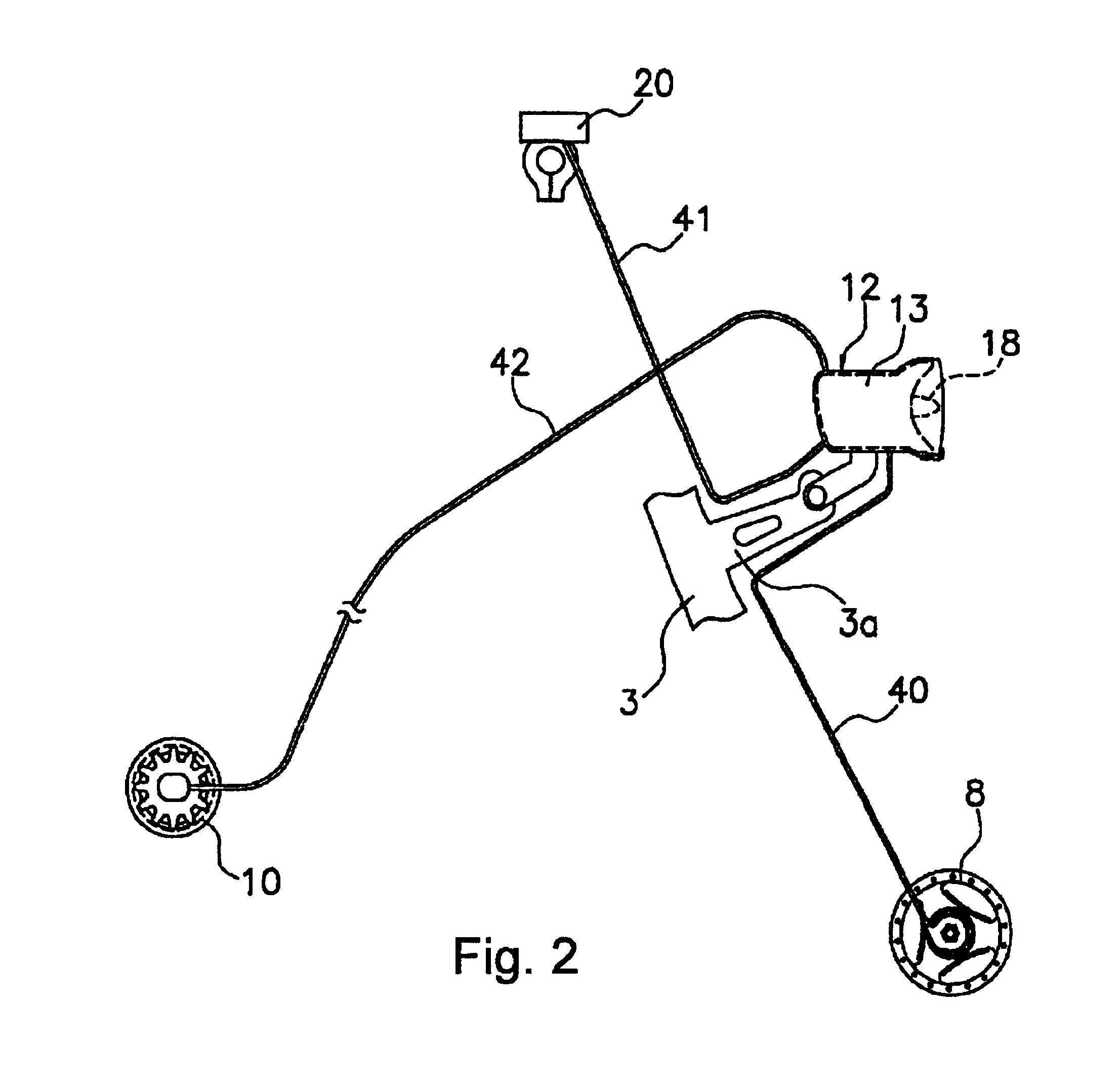

Electronic bicycle shift control device

Owner:SHIMANO INC

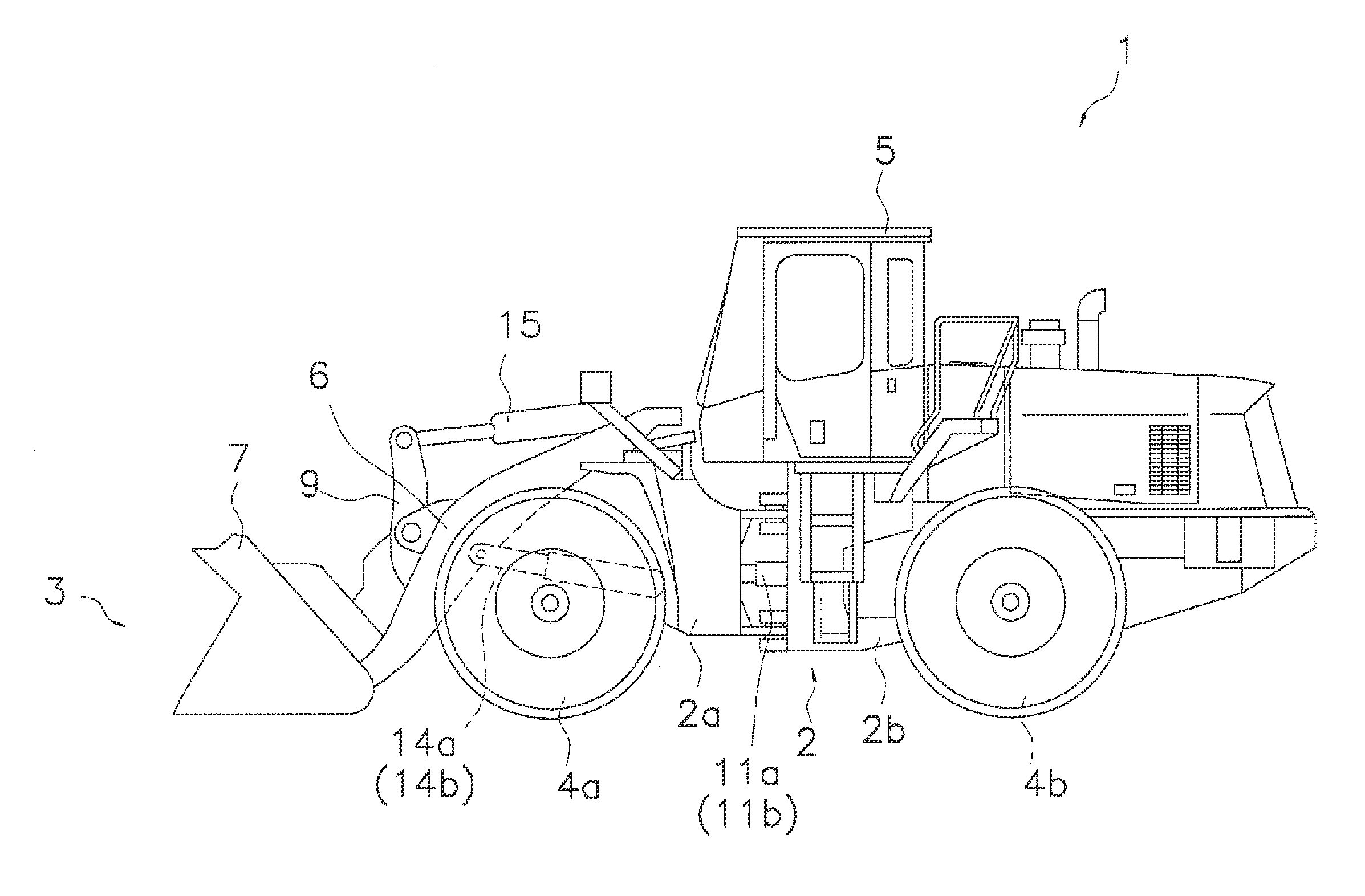

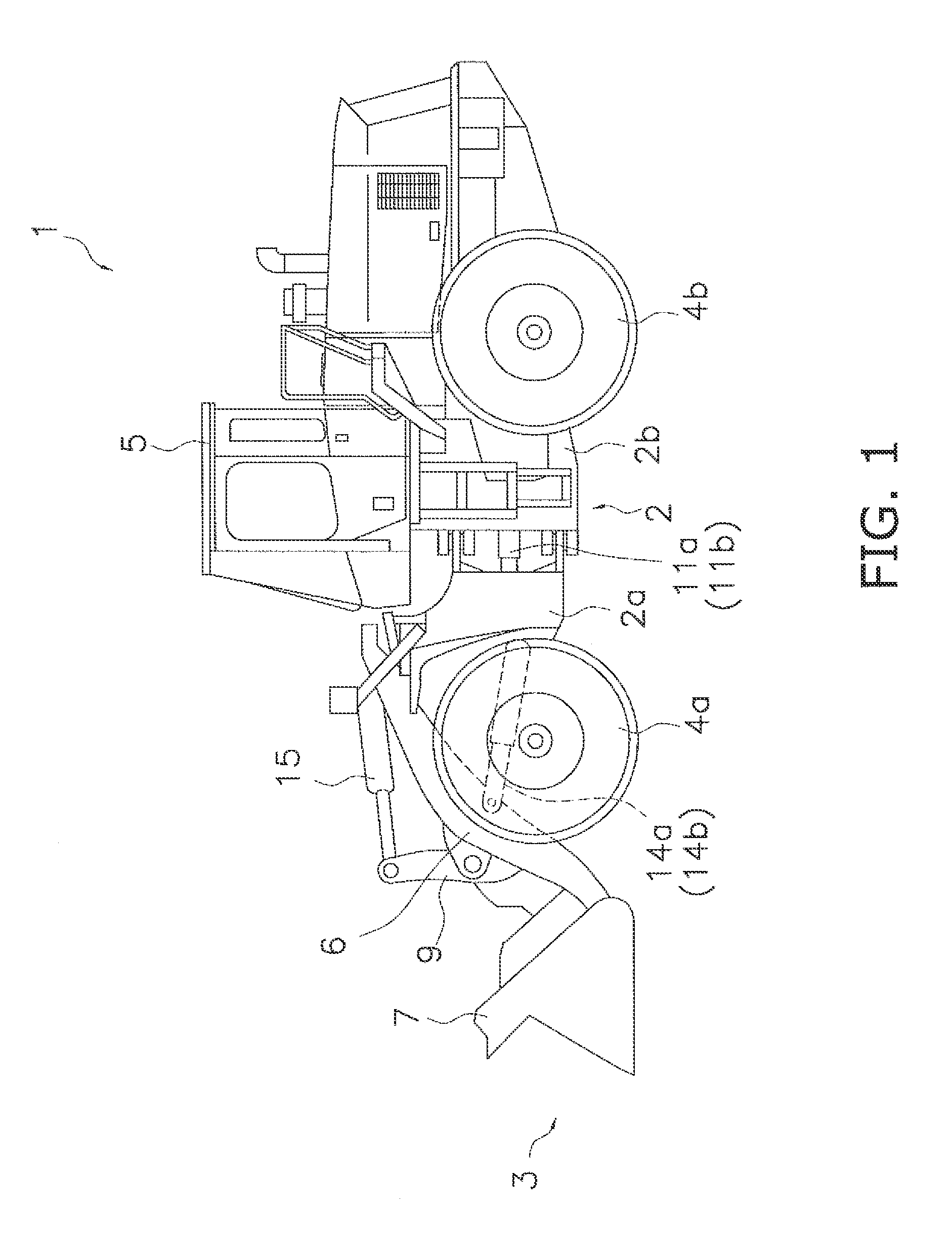

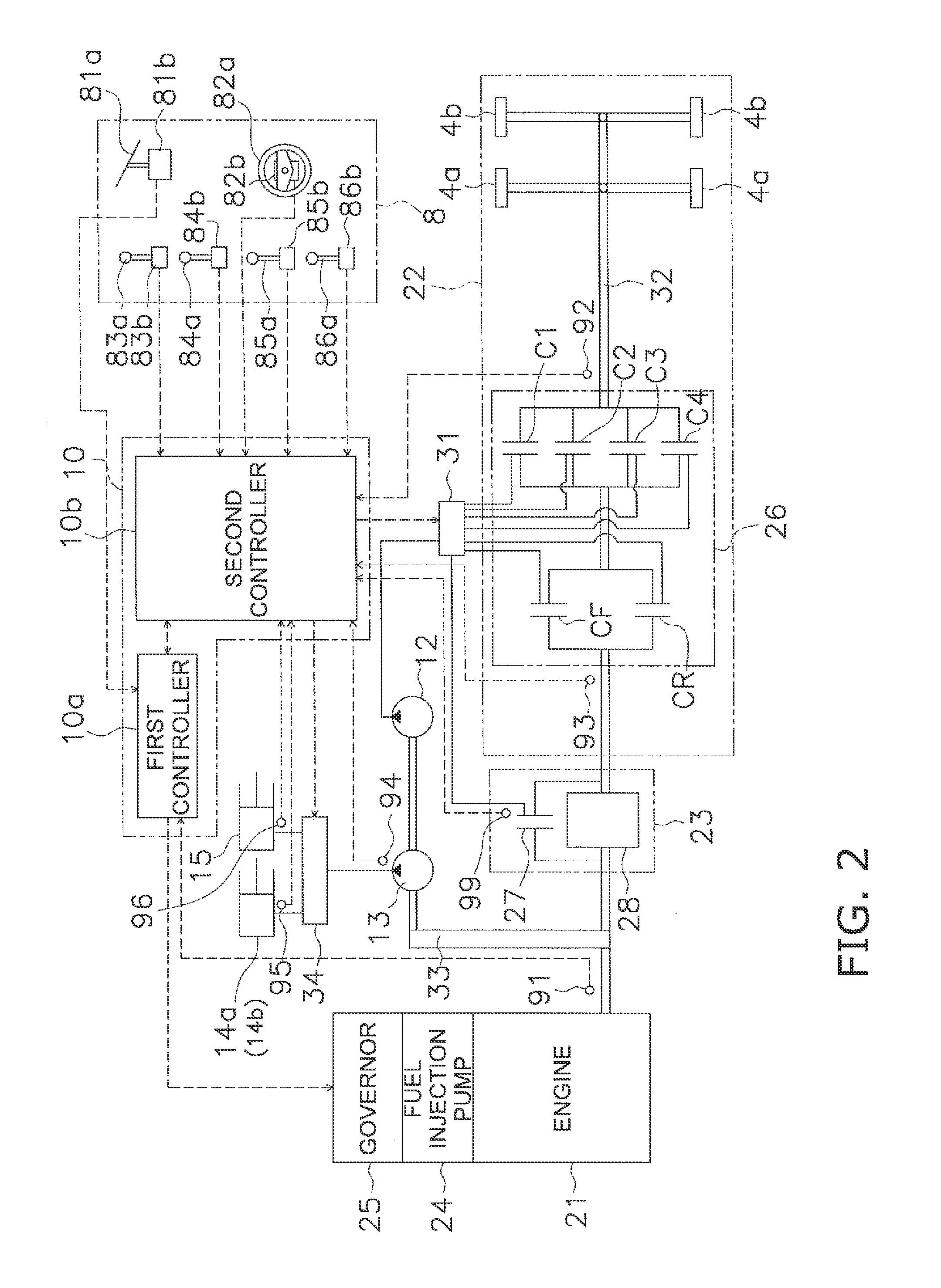

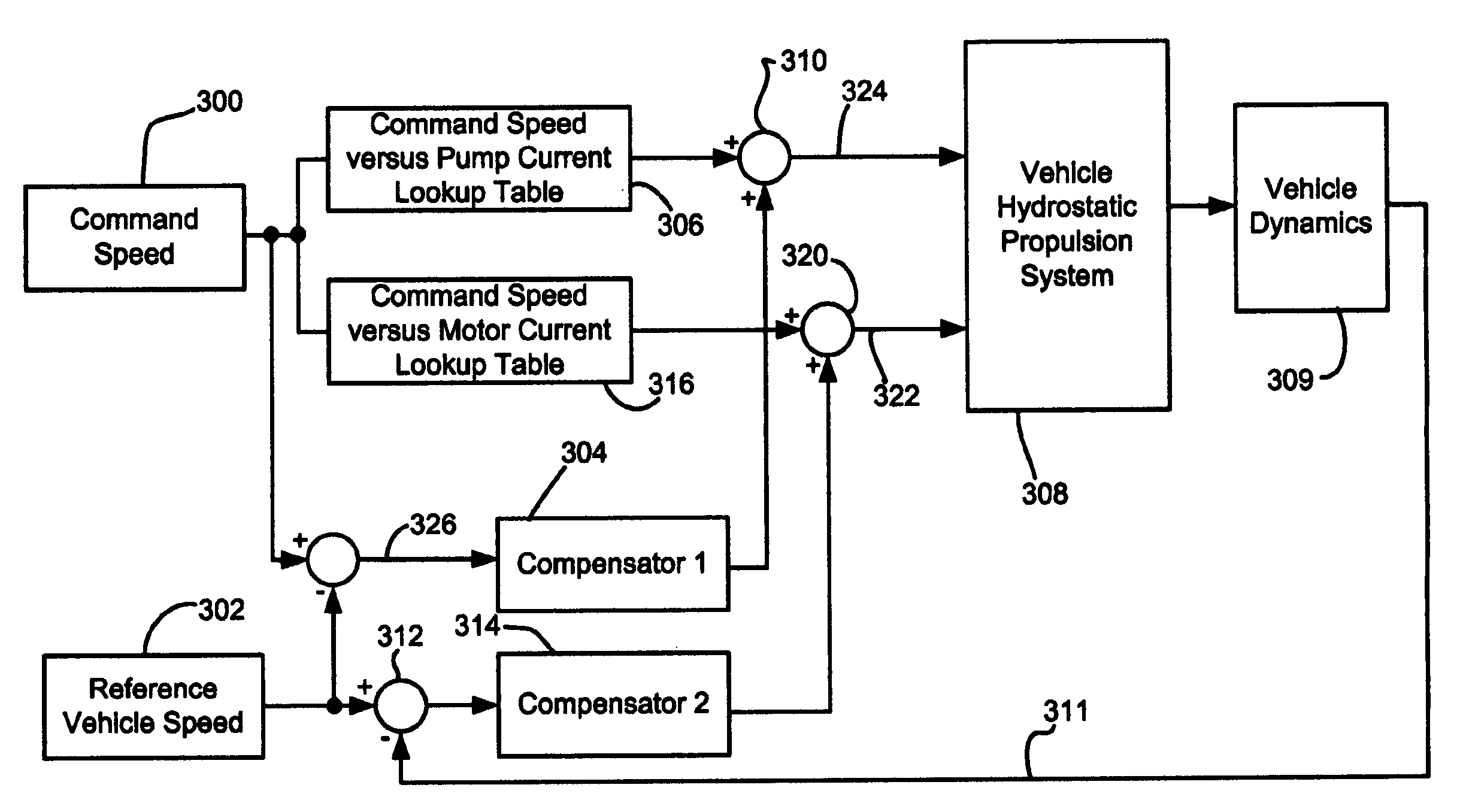

Work vehicle and method of controlling the same

ActiveUS20120245805A1Inhibit reduction in life durationImprove transmission efficiencyAnalogue computers for trafficSoil-shifting machines/dredgersInstrumentationClutch

Owner:KOMATSU LTD

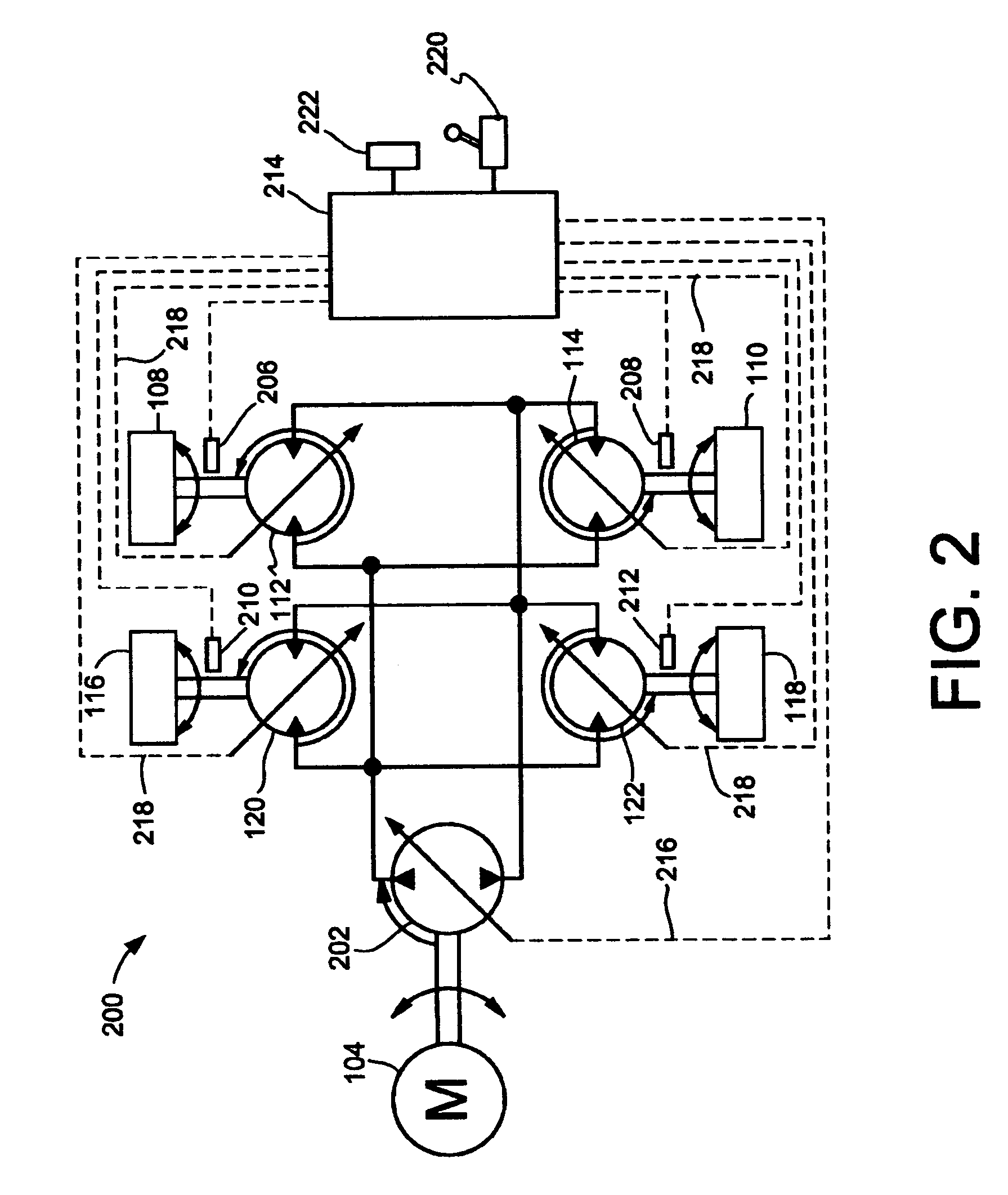

Four-wheel drive combine with slip control

Owner:BLUE LEAF I P

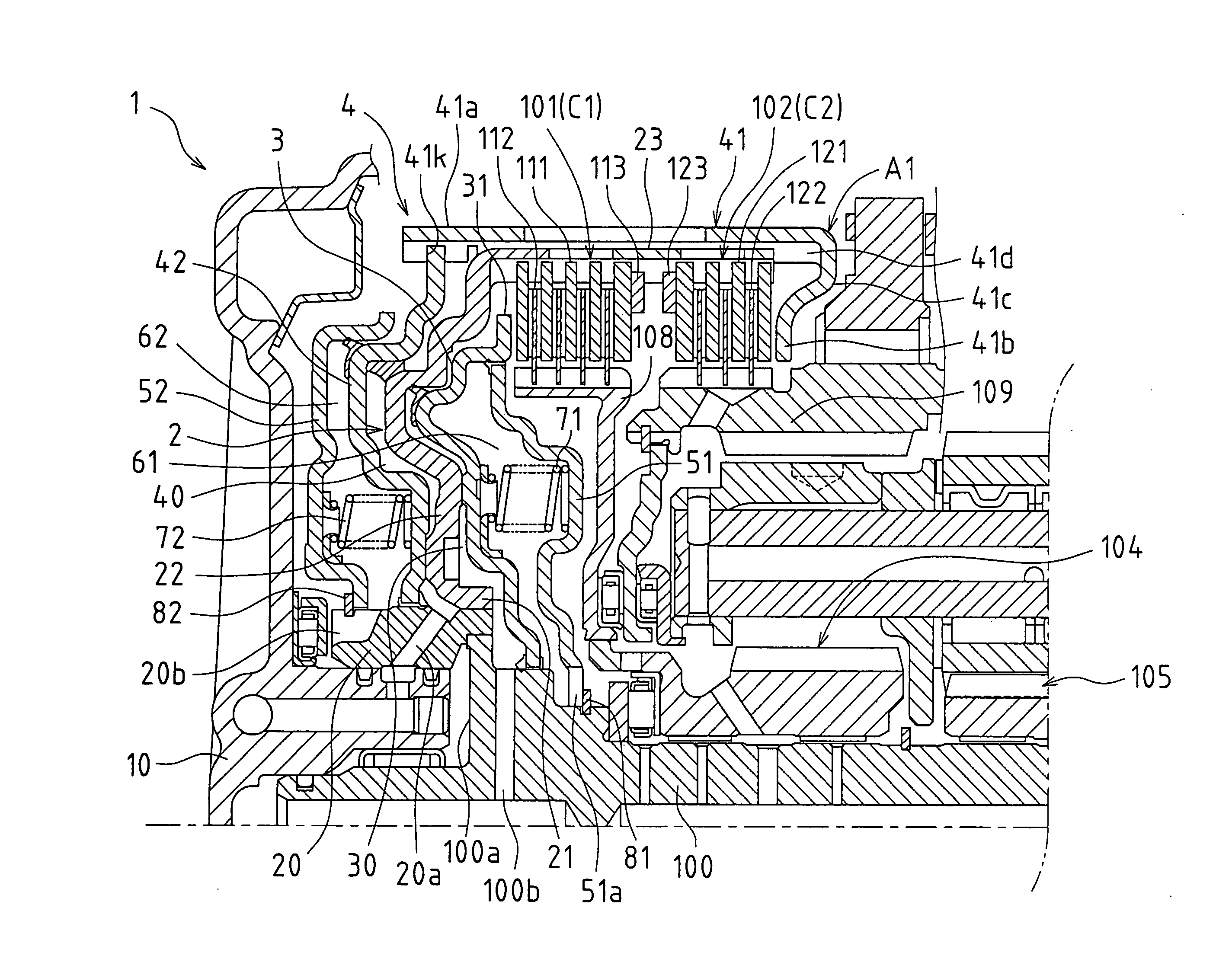

Piston apparatus of automatic transmission

InactiveUS20100140038A1Low costSmall sizeFluid actuated clutchesToothed gearingsAutomatic transmissionEngineering

Owner:TOYOTA JIDOSHA KK

Variable valve system of internal combustion engine and control method thereof

InactiveUS20060052216A1Inhibit deteriorationGearing controlEngine controllersExternal combustion engineInternal combustion engine

A valve characteristic changing mechanism is supplied with oil discharged from an electric oil pump in addition to oil discharged from a mechanical oil pump that is driven by an operation of an internal combustion engine. Driving of the electric oil pump is controlled such that a work rate of the electric oil pump increases as a temperature of the oil supplied to the valve characteristic changing mechanism increases, or as a viscosity of the oil is reduced.

Owner:TOYOTA JIDOSHA KK

Damping control device for electric vehicle

ActiveUS20180237021A1Accurate detectionPrevent false detectionHybrid vehiclesSpeed controllerElectric vehicleFeedback control

Owner:NISSAN MOTOR CO LTD

Control method and device for sliding friction torque of clutch and electronic equipment

ActiveCN113217619ASlip torque completeSave storage spaceHybrid vehiclesFluid actuated clutchesFriction torqueEngineering

The invention provides a control method and device for the sliding friction torque of a clutch and electronic equipment. The control method for the sliding friction torque of the clutch comprises the steps of expressing and storing a strong nonlinear relation between the clutch sliding friction torque and multiple influence factors through a neural network model; and acquiring clutch target sliding friction torque and the values of influence factors of the clutch target sliding friction torque, and enabling the neural network model to output corresponding clutch target pressure accordingly so as to calculate electromagnetic valve target current to control the clutch. According to the method, more complete clutch sliding friction torque characteristics are expressed by using a smaller storage space, and the storage space is greatly reduced; and online self-learning is performed on the complex torque characteristics of the clutch by using the characteristics of the neural network so as to adapt to the individual deviation of clutch assembly manufacturing and assembling and the performance change after long-term use.

Owner:TONGJI UNIV

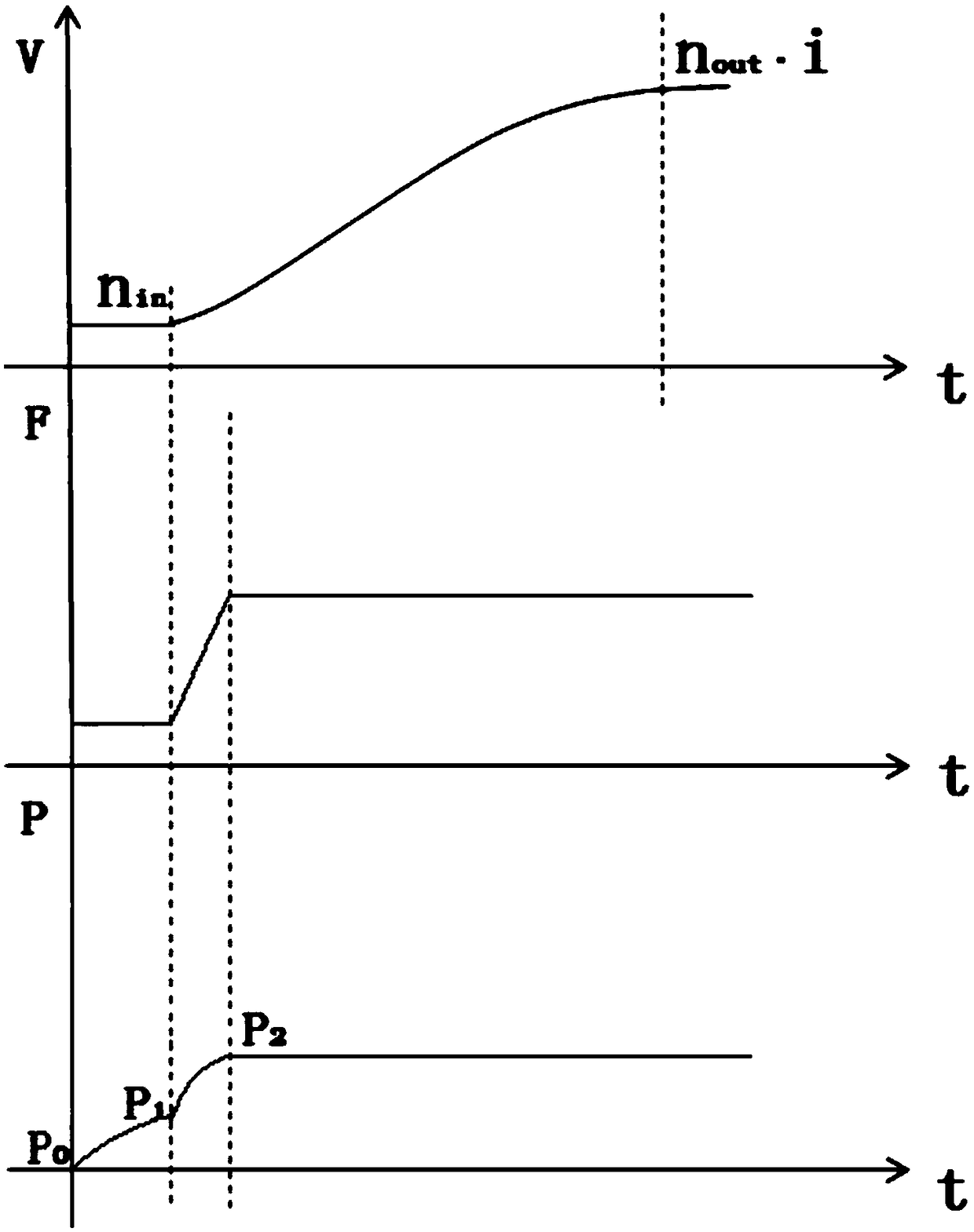

Speed changer synchronizer synchronous self-adaptation control method and system

Owner:吉泰车辆技术(苏州)有限公司

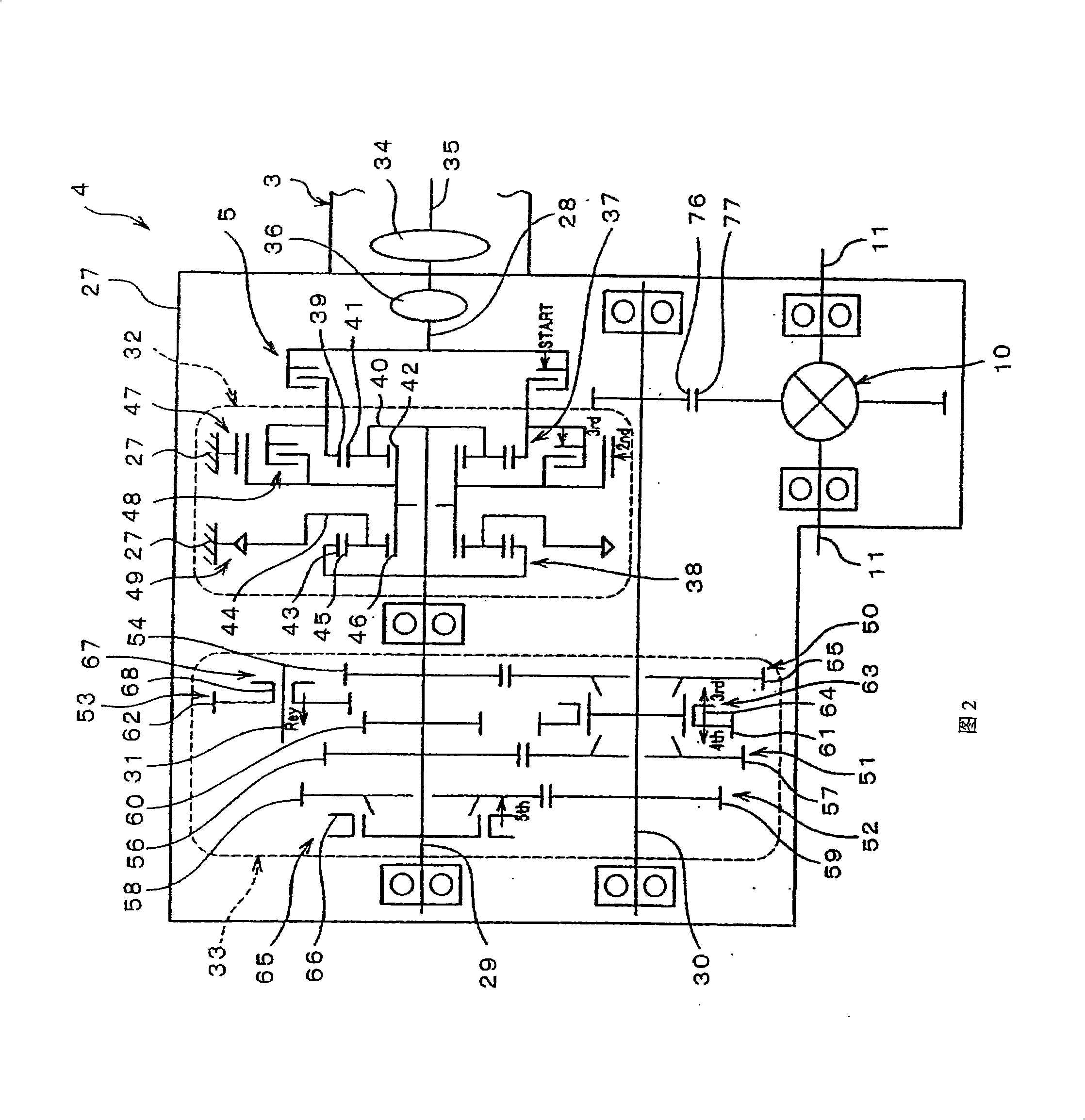

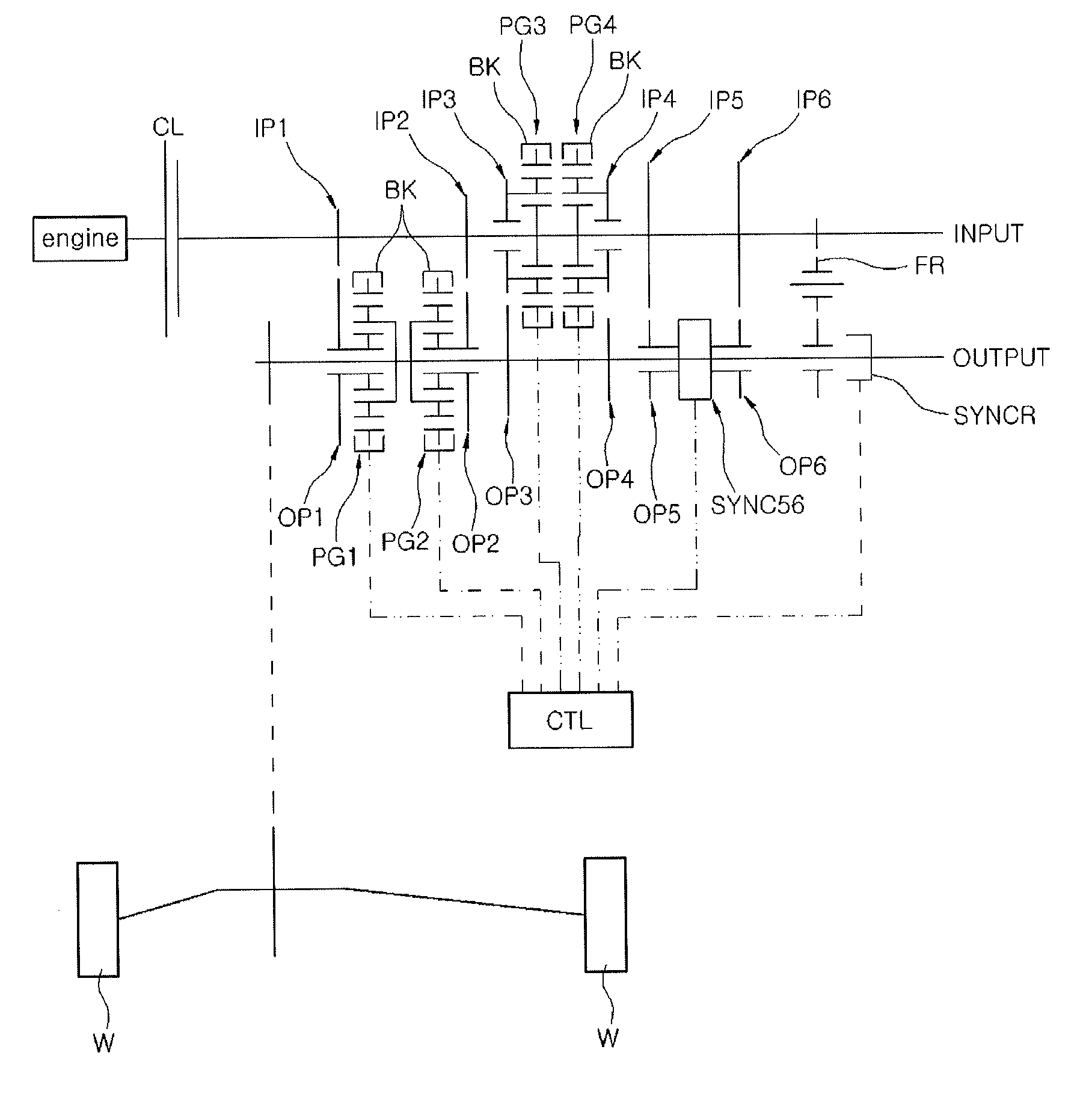

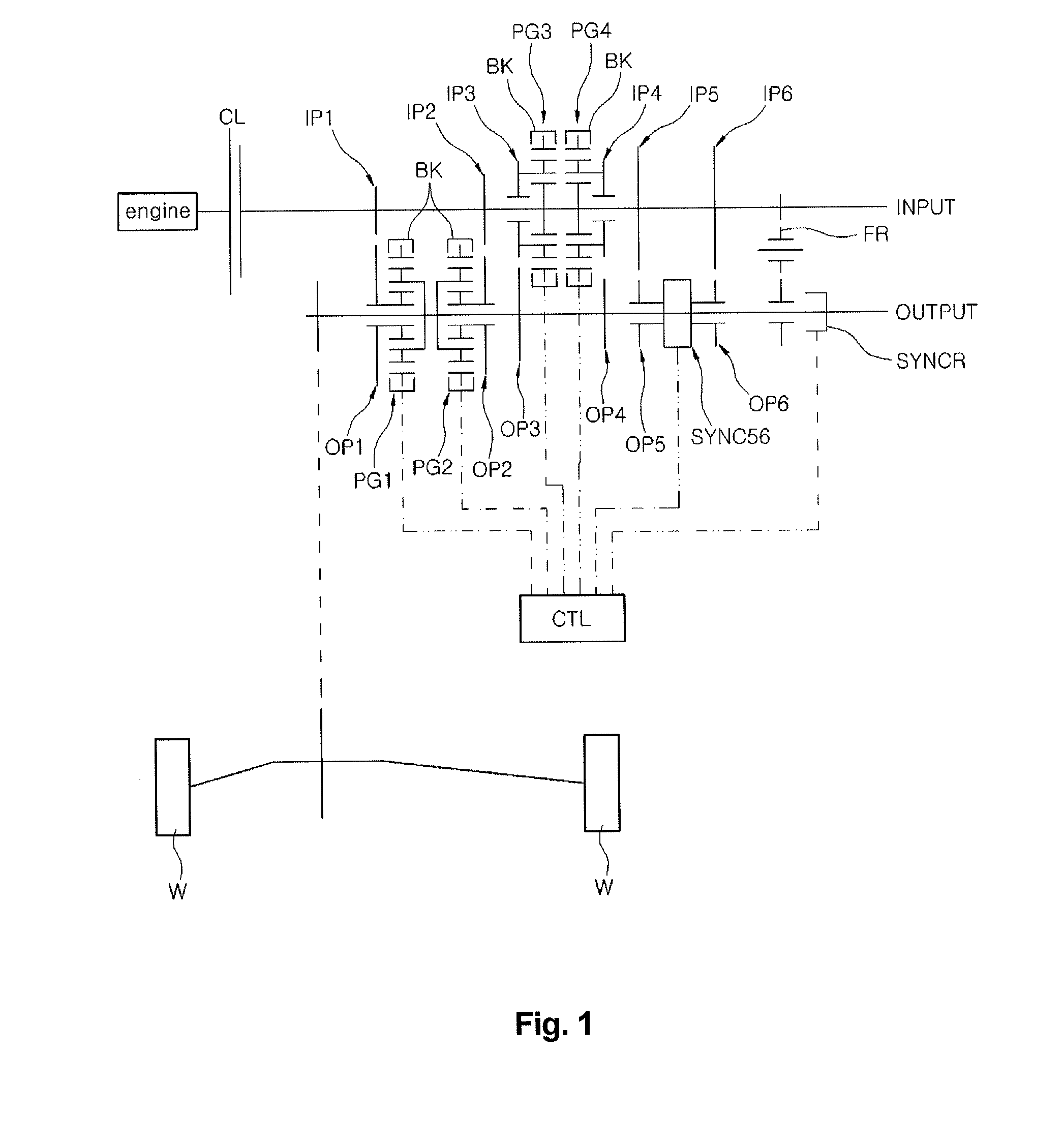

Automated manual transmission for vehicle

ActiveUS20140371022A1Smooth and reliable gear shift sensationImprove marketabilityToothed gearingsGearing controlGear wheelEngineering

Owner:HYUNDAI MOTOR CO LTD

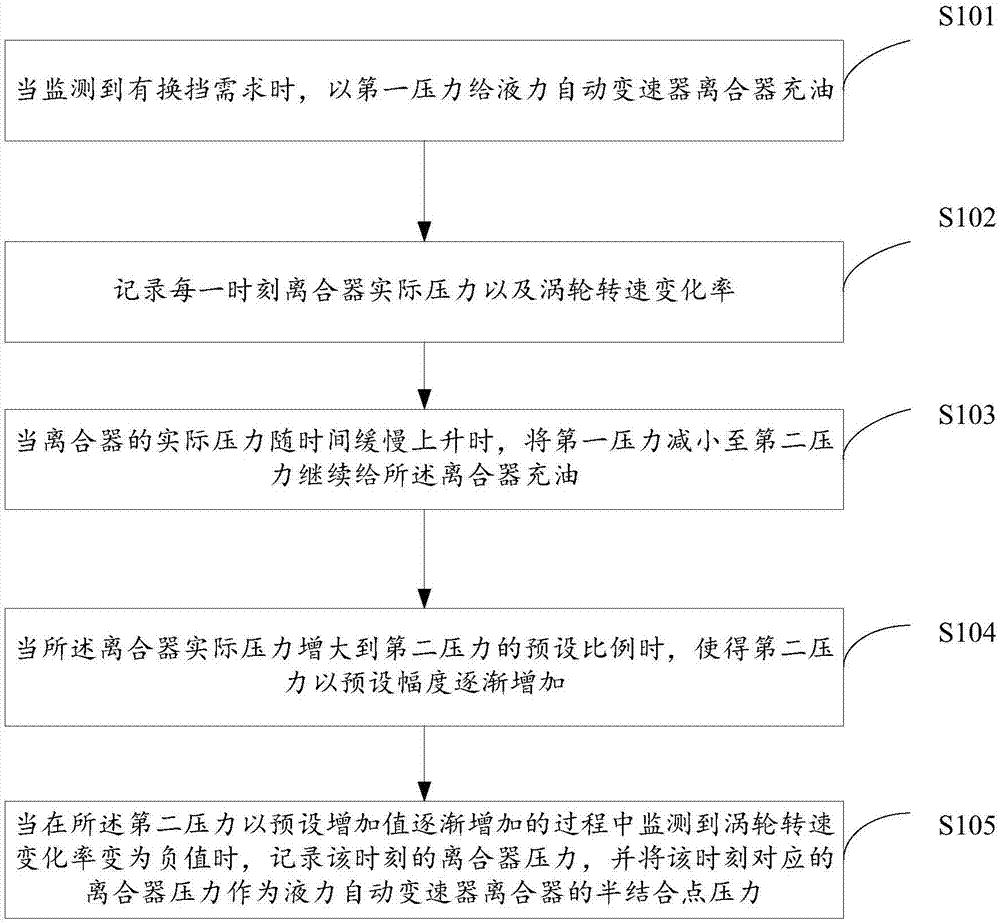

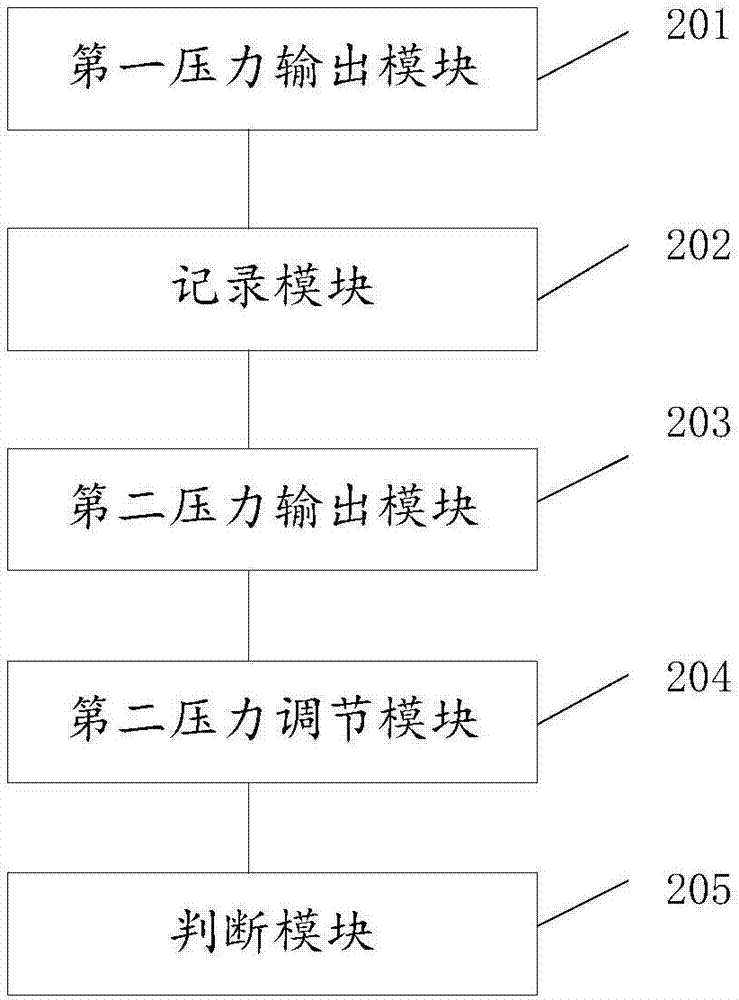

Semi joint point judgment method and system of hydraulic automatic transmission clutch

Owner:CHINA FIRST AUTOMOBILE

Position sensor assembly for manual transmission and manual transmission

Owner:GREAT WALL MOTOR CO LTD

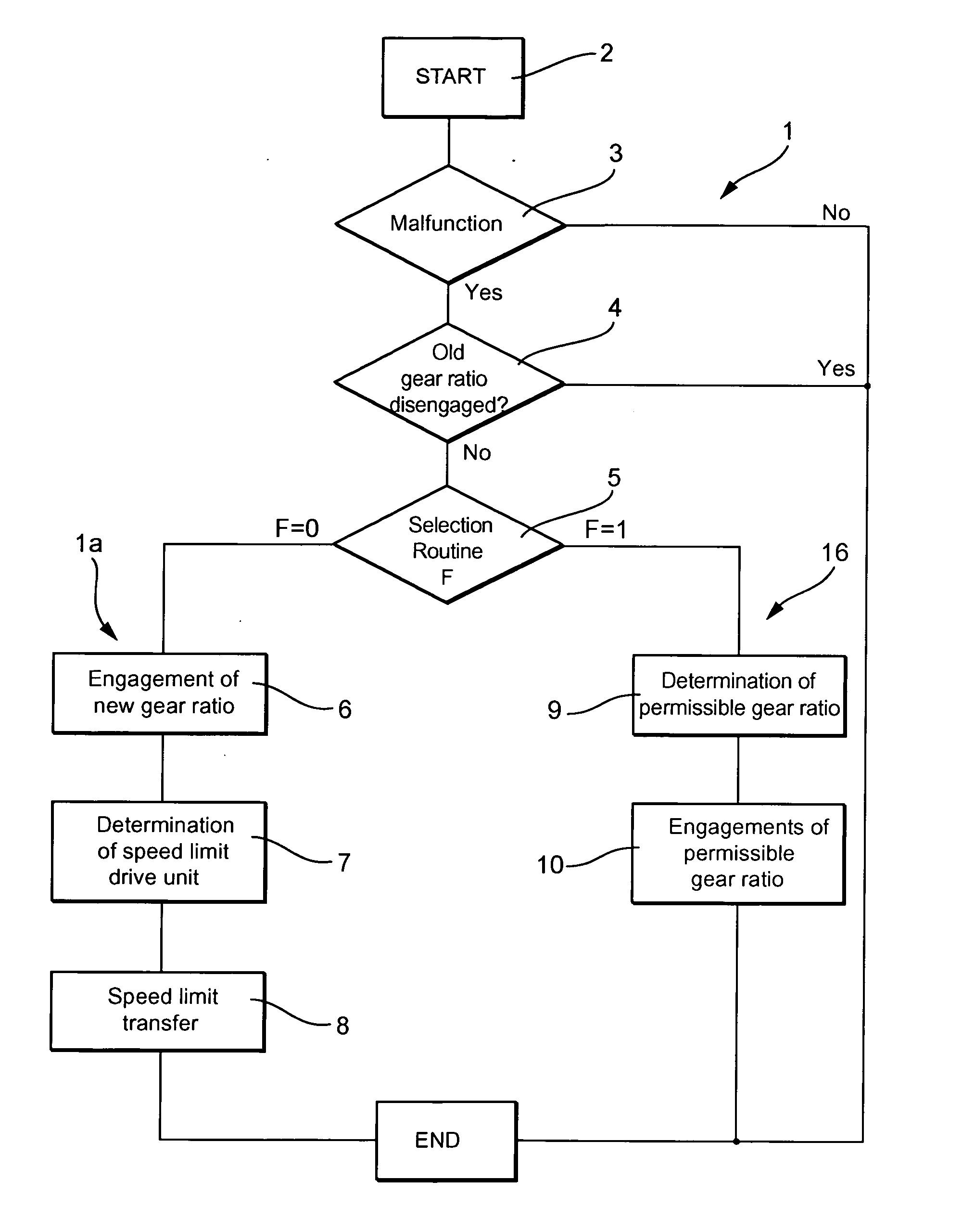

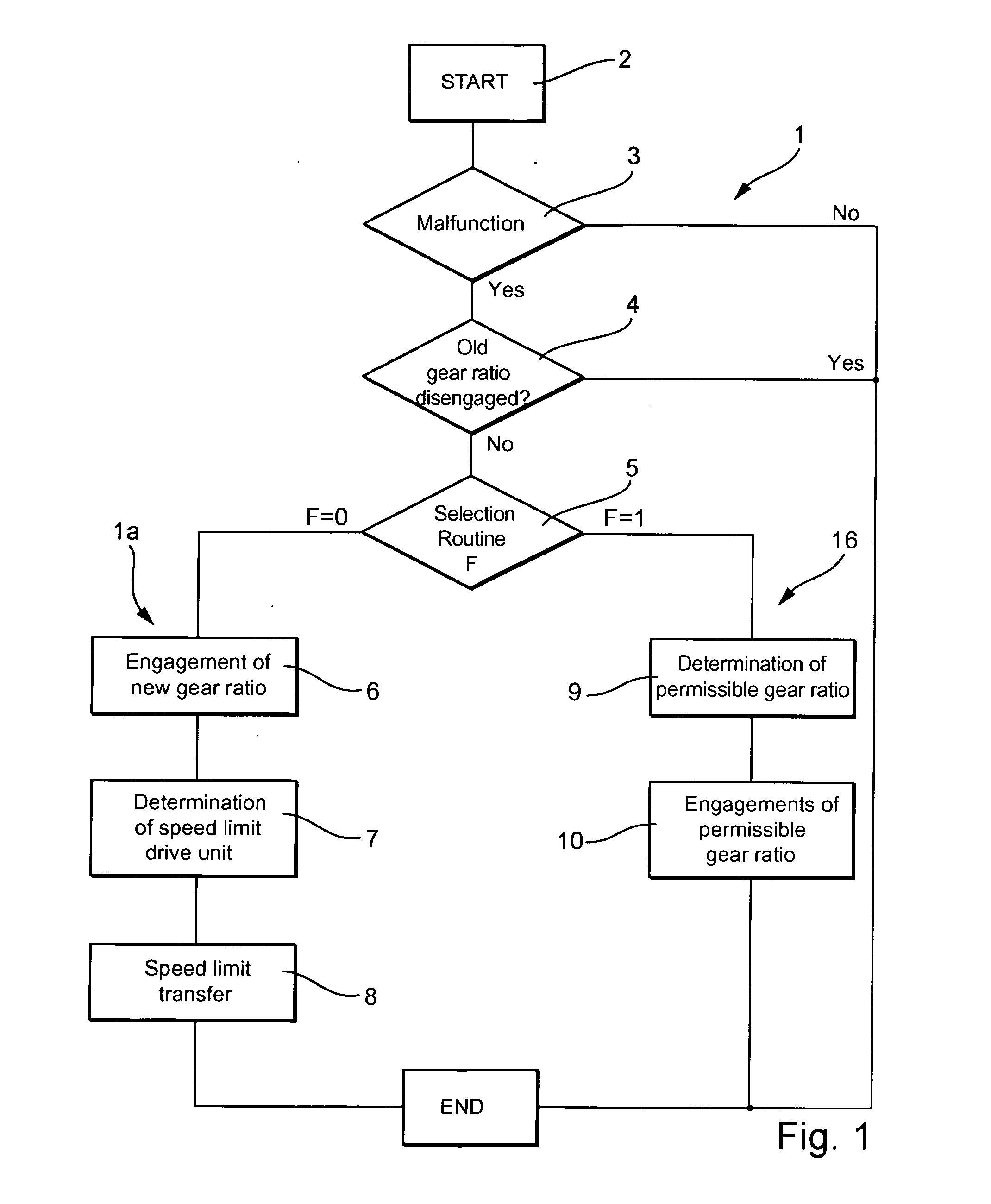

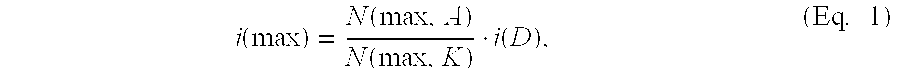

Parallel shift transmission and method for controlling it

InactiveUS20060089231A1Service life is prevented and reducedReduce and prevent situationToothed gearingsGearing controlEngineeringGear ratio

Owner:SCHAEFFLER TECH AG & CO KG

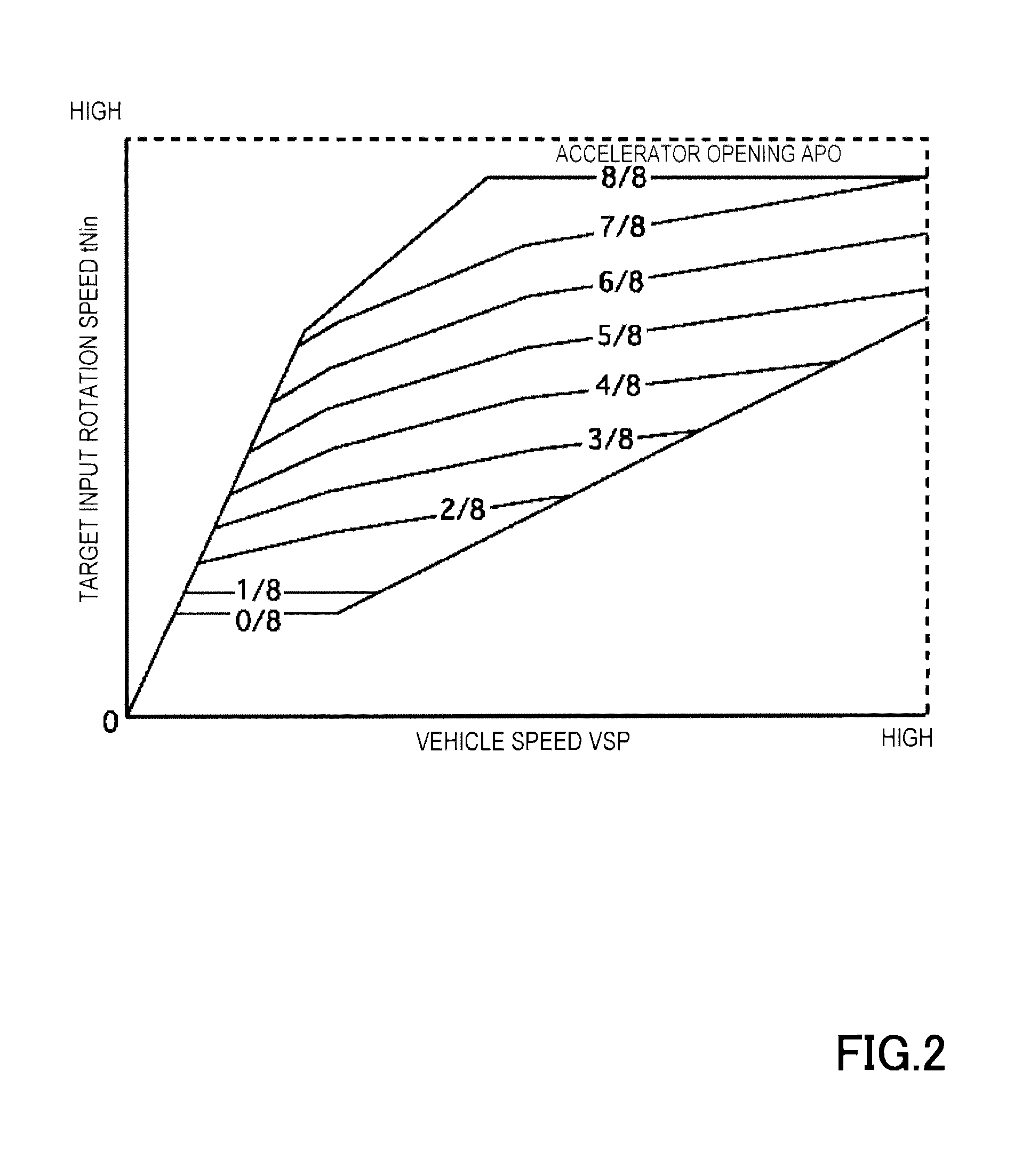

Shift control device for continuously variable transmission

Owner:SUBARU CORP

Control device for automatic transmission

InactiveCN101398073AReduced durabilityShorten the lengthGearboxesGearing controlAutomatic transmissionEngineering

Owner:MAZDA MOTOR CORP

Vehicle transmission control system

Owner:JATCO LTD

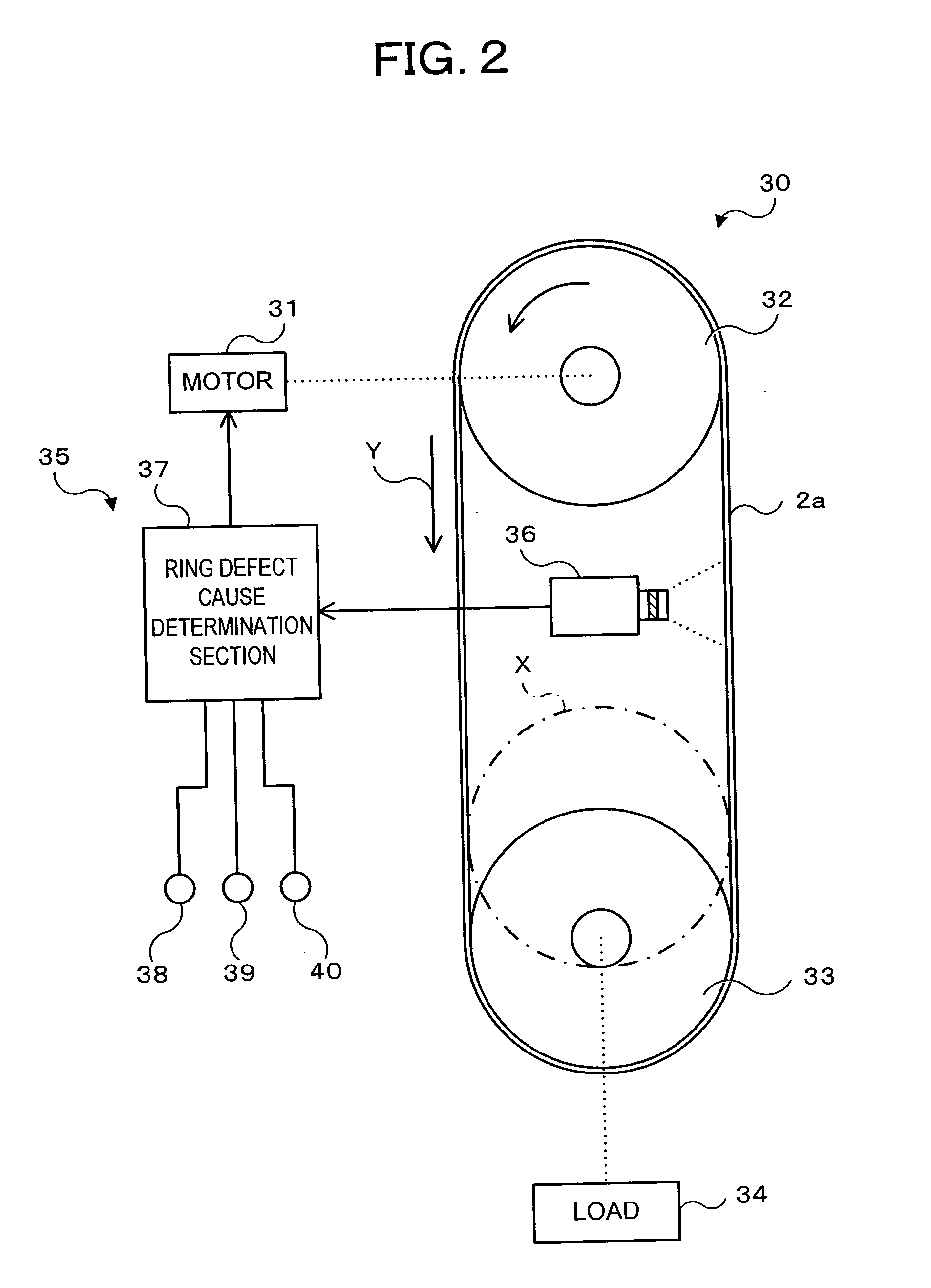

Continuously variable transmission belt inspection method and inspection device thereof

InactiveUS20060037415A1Unnecessary part can be avoidedLow costV-beltsMachine gearing/transmission testingEngineeringMetal powder

Owner:JATCO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap