Parallel shift transmission and method for controlling it

a technology of parallel transmission and transmission input shaft, which is applied in the direction of gearing control, belt/chain/gearing, toothed gearing, etc., can solve the problems of transmission input shaft bearing damage, and achieve the effect of preventing or reducing the service life of the drive train and being less expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

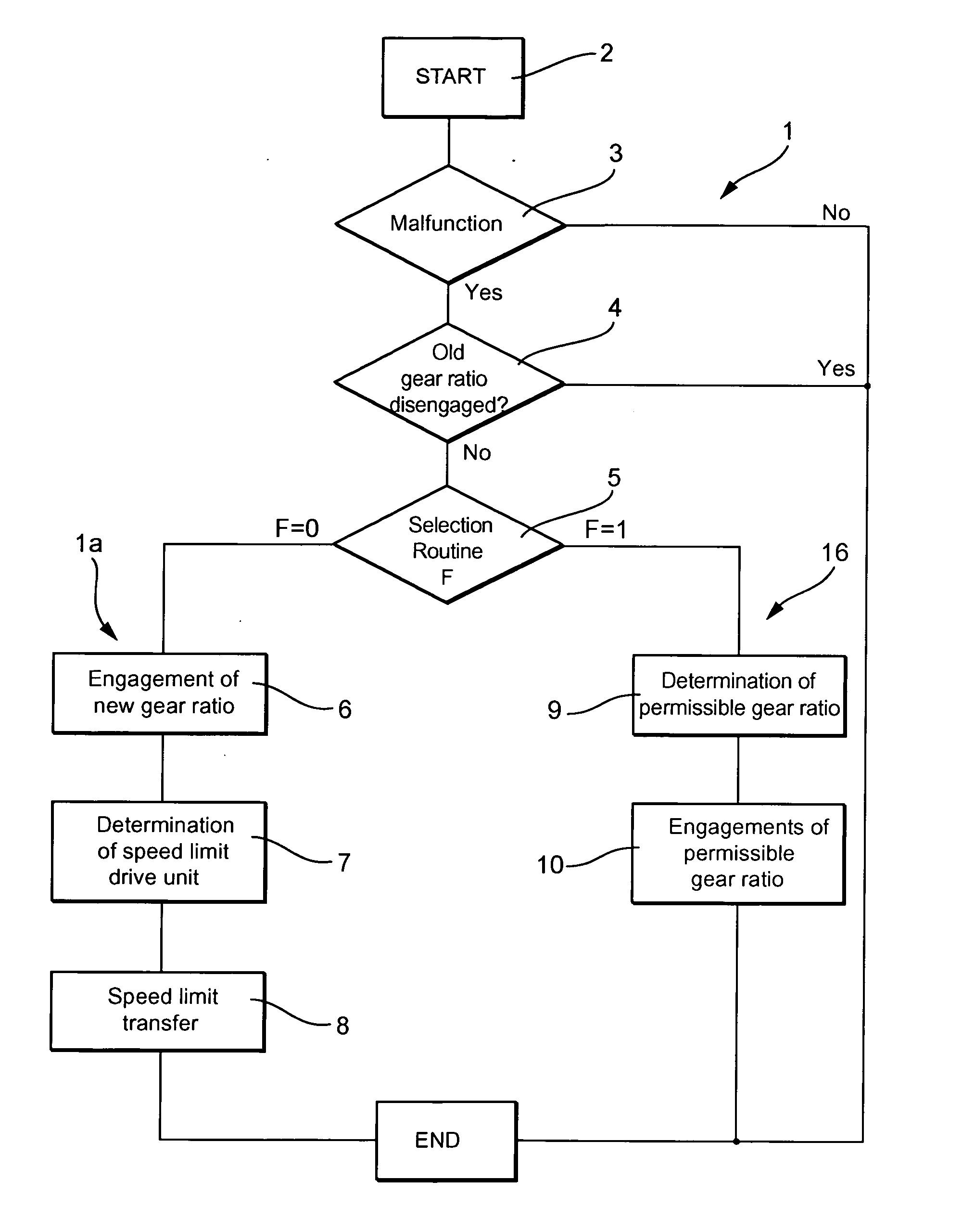

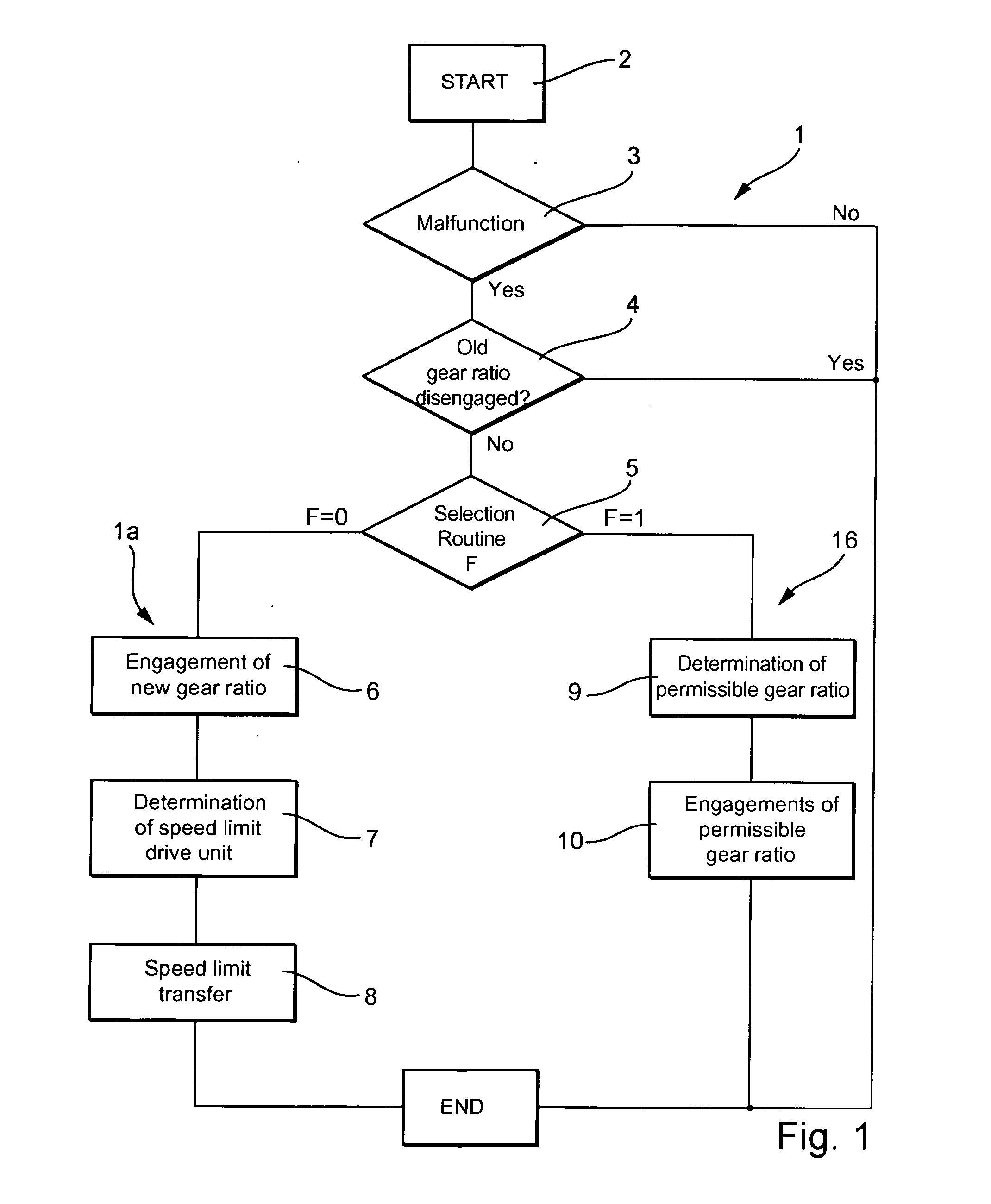

[0014] Method 1 begins with a start condition and a subsequent branch 3 in which a determination is made of whether there is a malfunction of the transmission controller. Such a malfunction may, for example, be the breakage of a shift finger or another component so that an engaged gear ratio step can no longer be disengaged or a jamming of a final control element for engaging or disengaging a gear ratio step so that the transmission actuators provided for this can no longer disengage the gear ratio step. If there is no malfunction, the routine is terminated immediately. In the detection of a malfunction, which may be accomplished, for example, via the evaluation of responses of the transmission actuator to the controller responsible for controlling the transmission, a check is made of whether an engaged gear ratio step has been disengaged. If the gear ratio step that is supposed to be disengaged is disengaged, the routine is terminated. Whether a gear ratio step is still engaged may be

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap