Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "Variator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A variator is a device that can change its parameters, or can change parameters of other devices. Often a variator is a mechanical power transmission device that can change its gear ratio continuously (rather than in steps).

Method for operating a drive train

A method for operating a drive train in a motor vehicle with a dual mass flywheel driven by an internal combustion engine via a crankshaft and at least a transmission input shaft of a transmission that can be coupled with an output part of the dual mass flywheel. Between the input part and output part a hysteresis-laden damping device is effective, which influences engine torque output from the internal combustion engine and load torque transmitted to at least a transmission input shaft through the hysteresis characteristic. To eliminate the disturbances caused by the dual mass flywheel a state model constantly determines rotation speeds of the input part and of the output part and depending on a differential angle determined from the rotation speeds and from the characteristic numbers of the damping device, a characteristic disturbance torque for influencing at least the load torque is determined in real time.

Owner:SCHAEFFLER TECH AG & CO KG

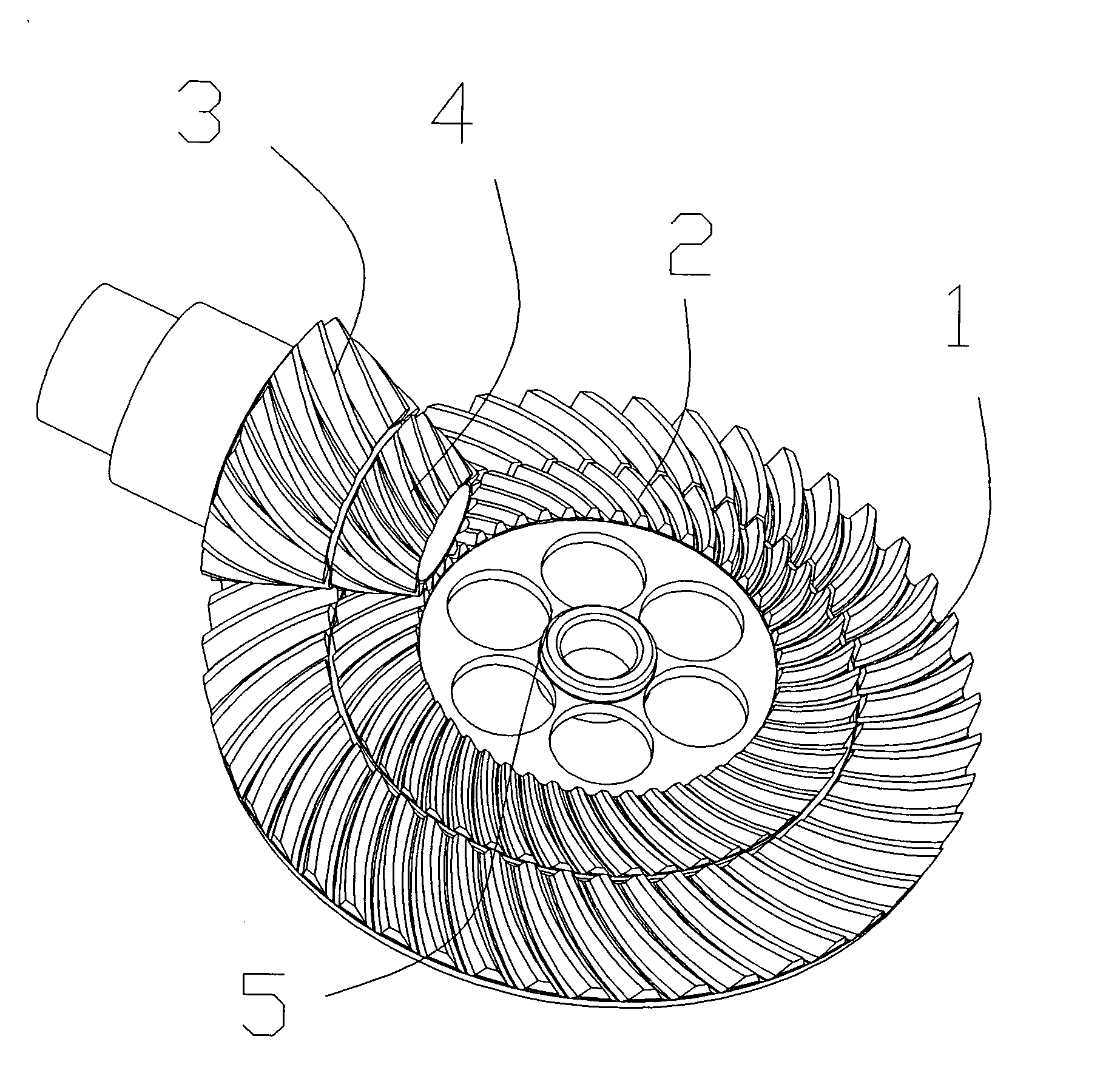

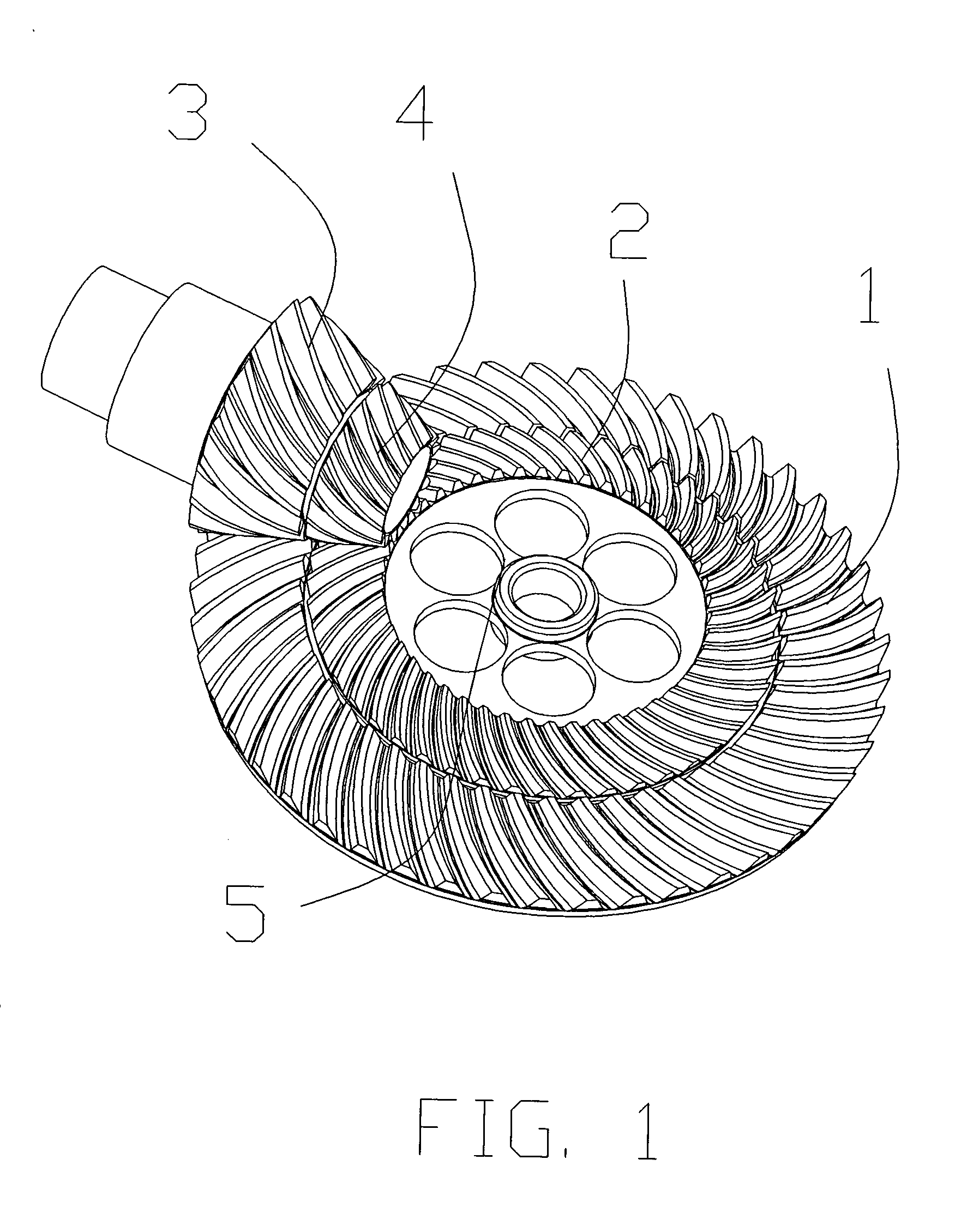

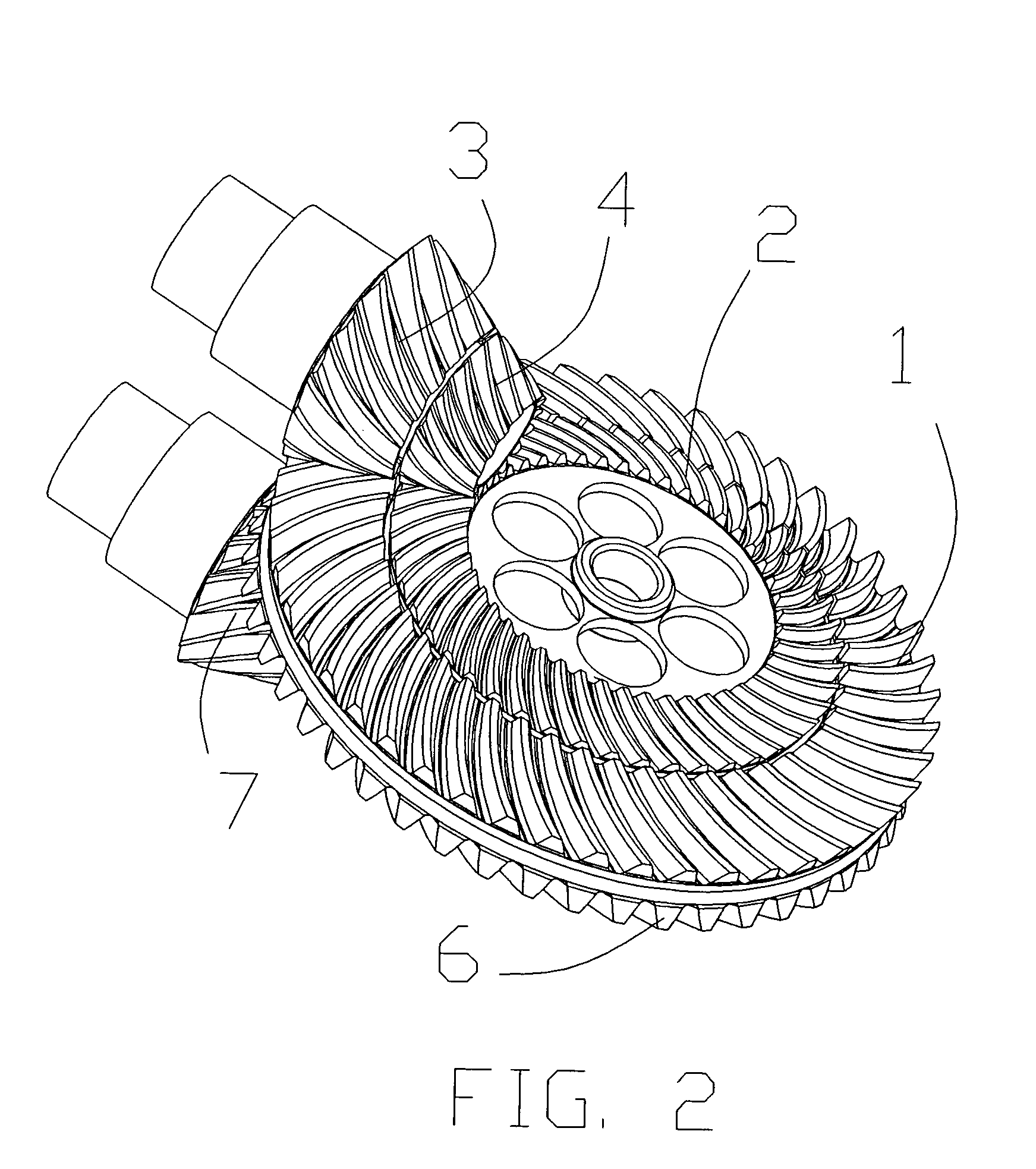

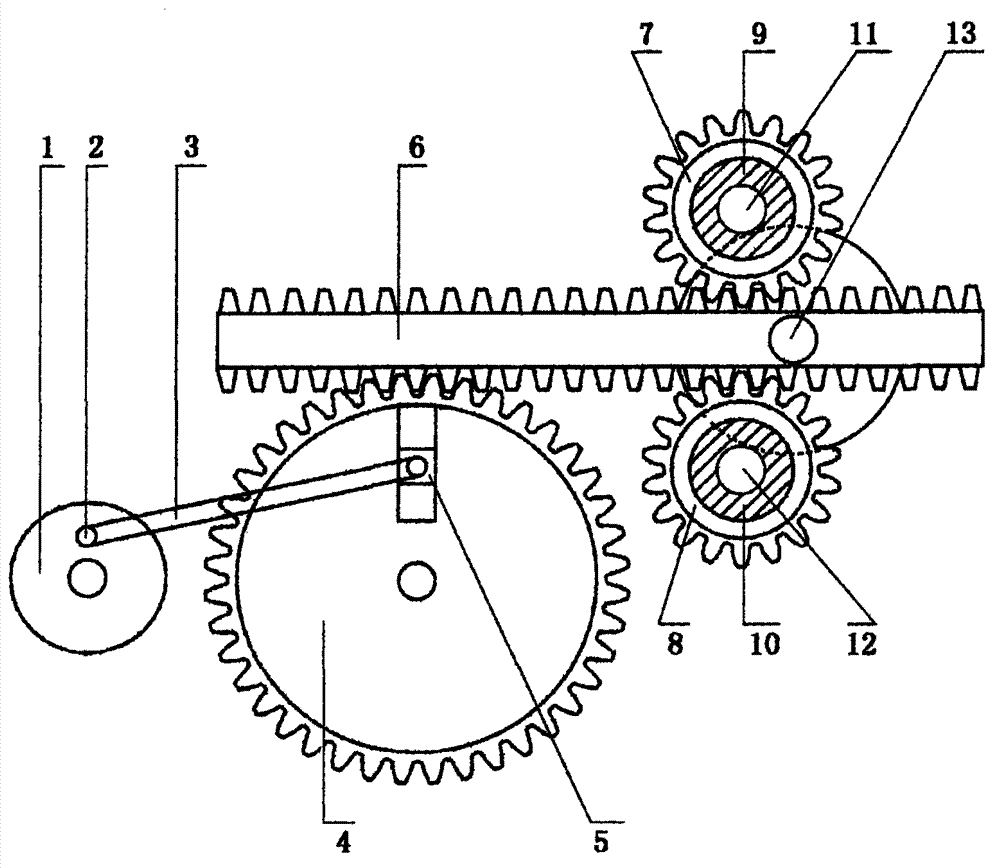

Gear reduction unit

InactiveUS20050028627A1Easy to useHigh contact ratioToothed gearingsTransmission elementsGear wheelEngineering

Owner:FLEYTMAN YAKOV

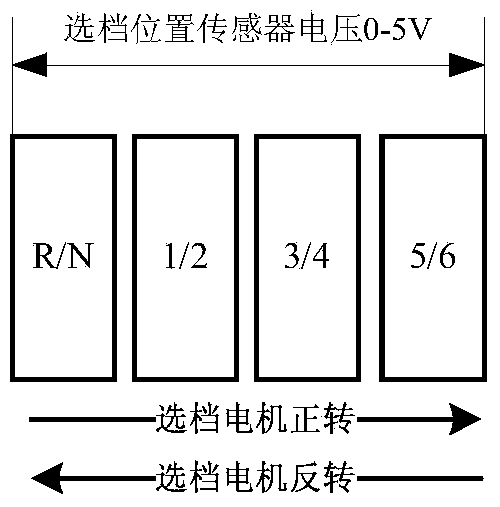

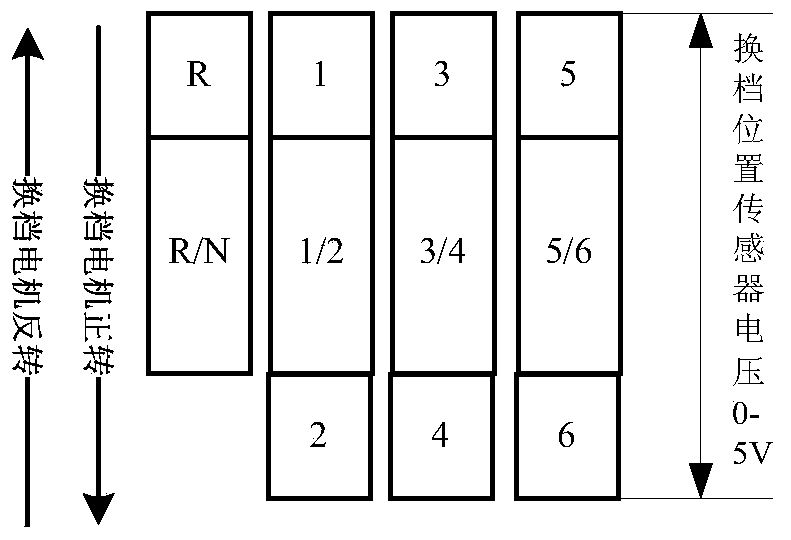

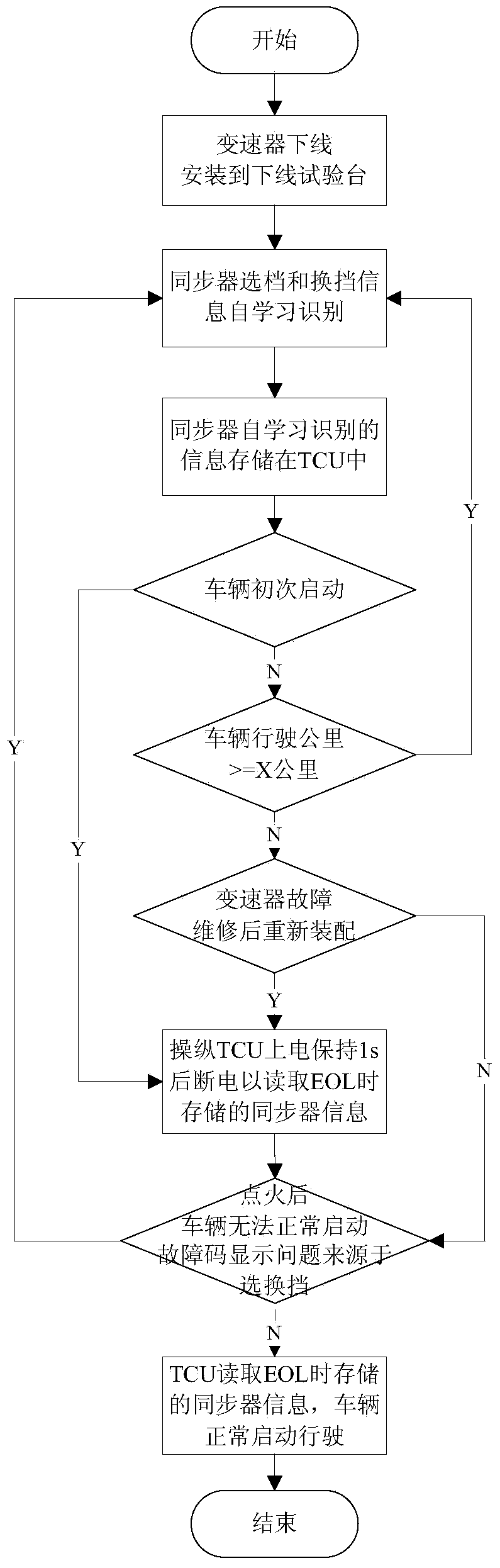

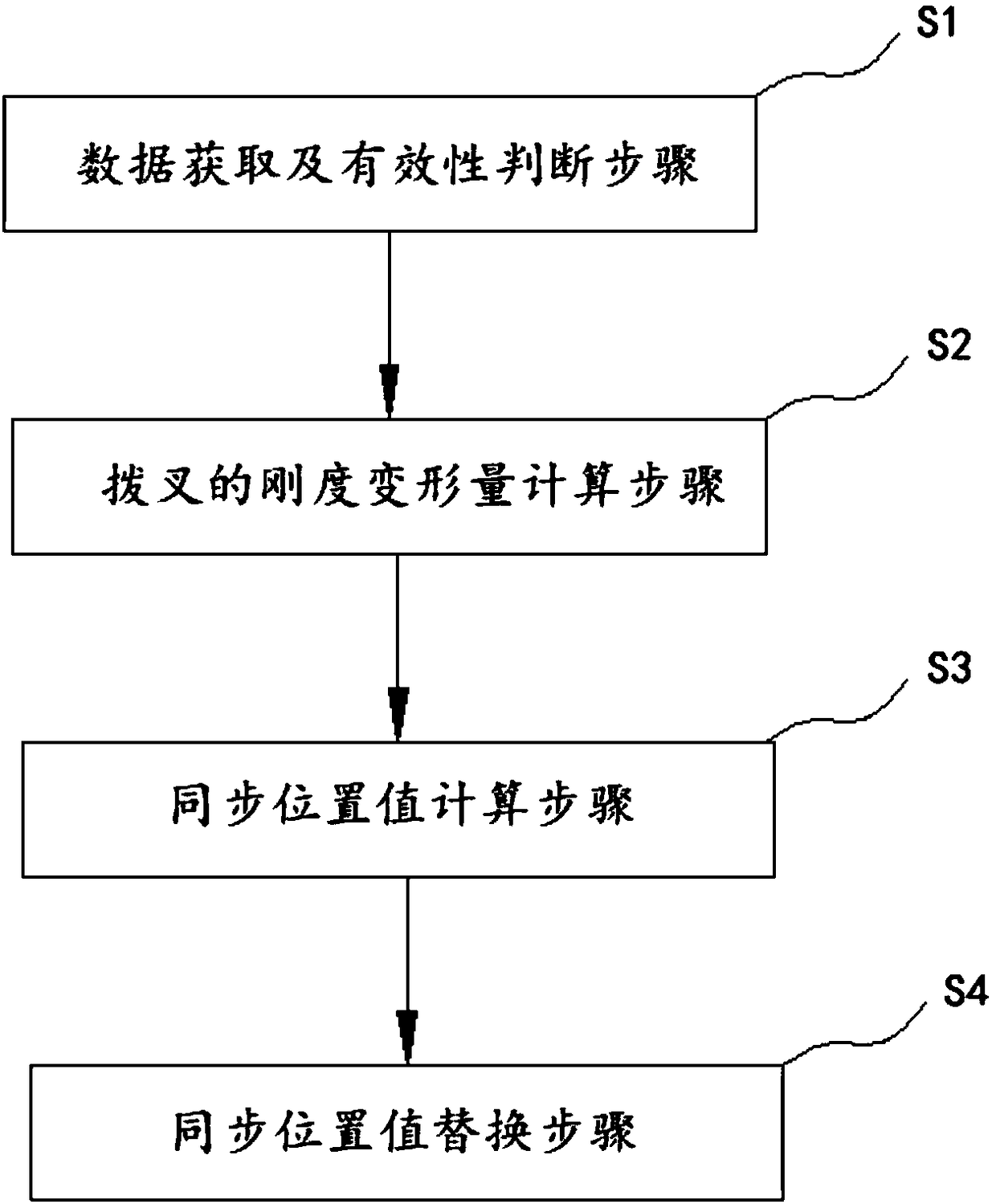

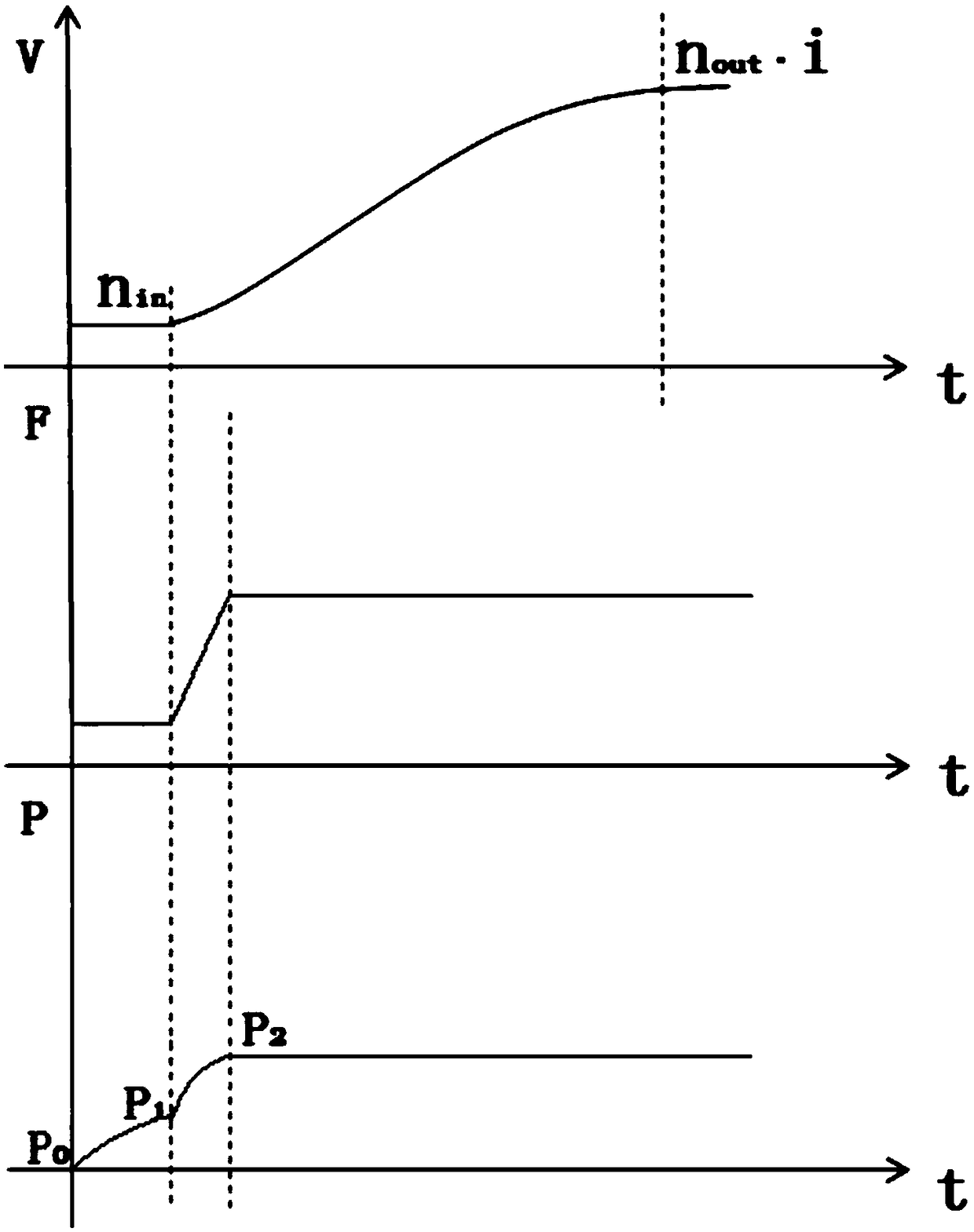

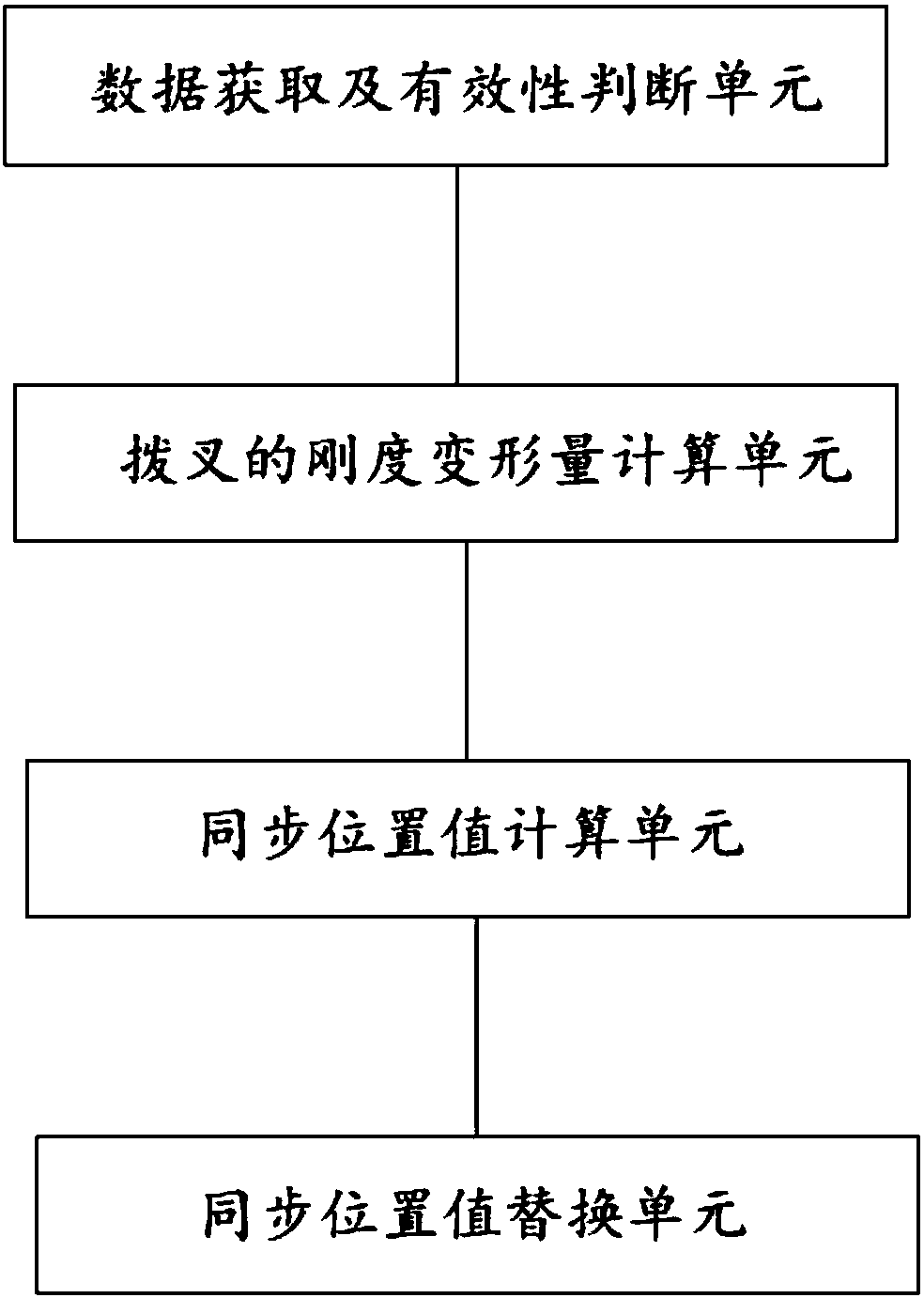

Synchronizer self-learning identification control method and position verification control method

The invention provides a synchronizer self-learning identification control method and a vehicle synchronizer position verification control method based on the synchronizer self-learning identification control method. According to the synchronizer self-learning identification control method, forward and reverse rotation of a gear selection and shifting motor are controlled, the voltage change of a gear selection and shifting position sensor is monitored so as to identify the state of a synchronizer reaching extreme positions, the voltage value of the position sensor when the synchronizer is at each extreme position is recorded, and therefore self-learning identification of gear selection information and gear shifting information of the synchronizer is realized. According to the position verification control method, when a speed changer reaches a bottom line, a vehicle runs for a certain period of time and the vehicle cannot be started normally due to gear selection and shifting, the synchronizer self-learning identification control method is adopted for learning and identification of the gear selection information and the gear shifting information. By means of the synchronizer self-learning identification control method and the position verification control method, the problem that the synchronizer is inaccurate in position because of multiple factors is effectively eliminated, gear selection and shifting of the vehicle can be based on a correct synchronizer position, and therefore the correctness of gear selection and shifting of the vehicle is guaranteed.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

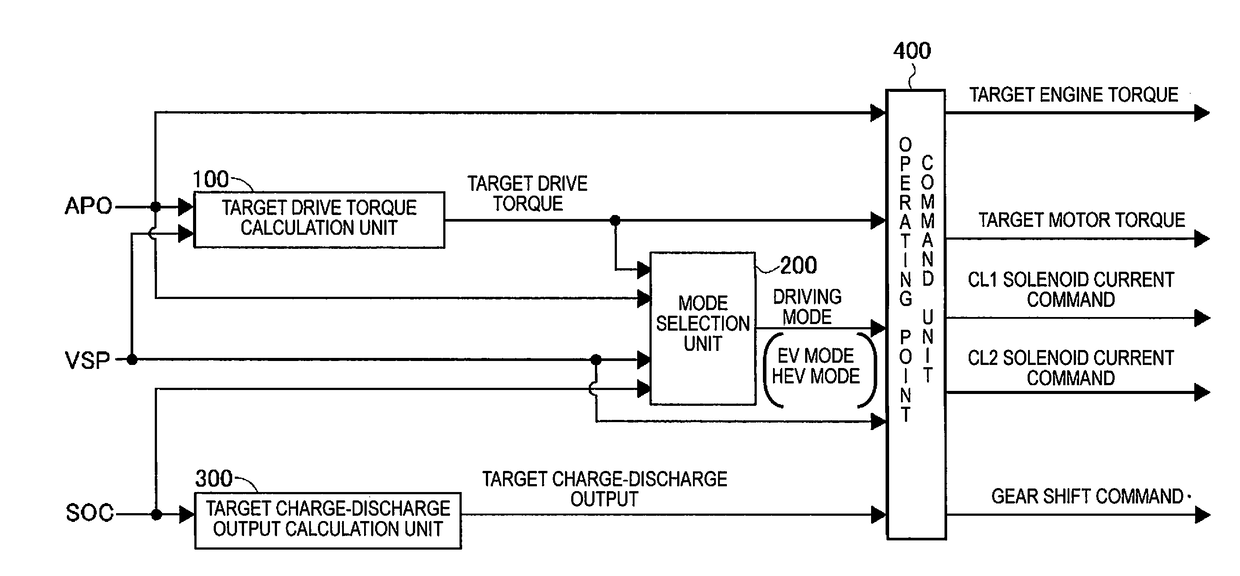

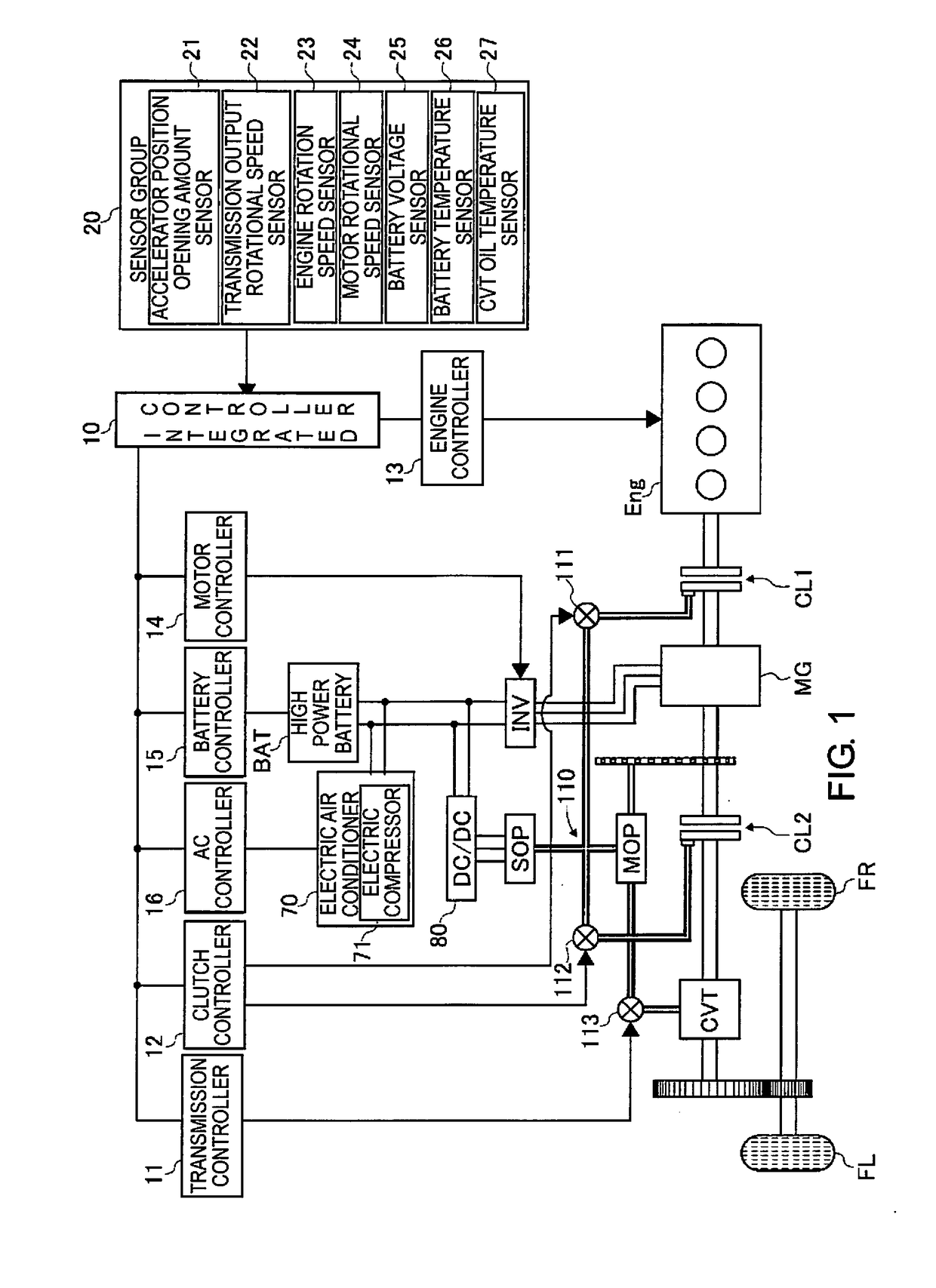

Control device and control method for powertrain, program for implementing the control method, and recording medium containing the program

InactiveUS20080153660A1Prevent change of directionReduce shockHybrid vehiclesDigital data processing detailsElectric machineExecution control

A shock caused due to a change in the direction of torque transferred to an output shaft is reduced. There is provided a control device for a powertrain including a drive power source that transfers torque to an output shaft connected to a wheel of a vehicle, and a rotary electric machine that transfers torque to the output shaft via a transmission. When electric power generation performed using the rotary electric machine is restricted, if torque that decelerates the vehicle is transferred from the drive power source to the output shaft, a control is executed so that torque that does not decelerate the vehicle is transferred from the drive power source to the output shaft, and a shift control over the transmission is executed.

Owner:TOYOTA JIDOSHA KK +1

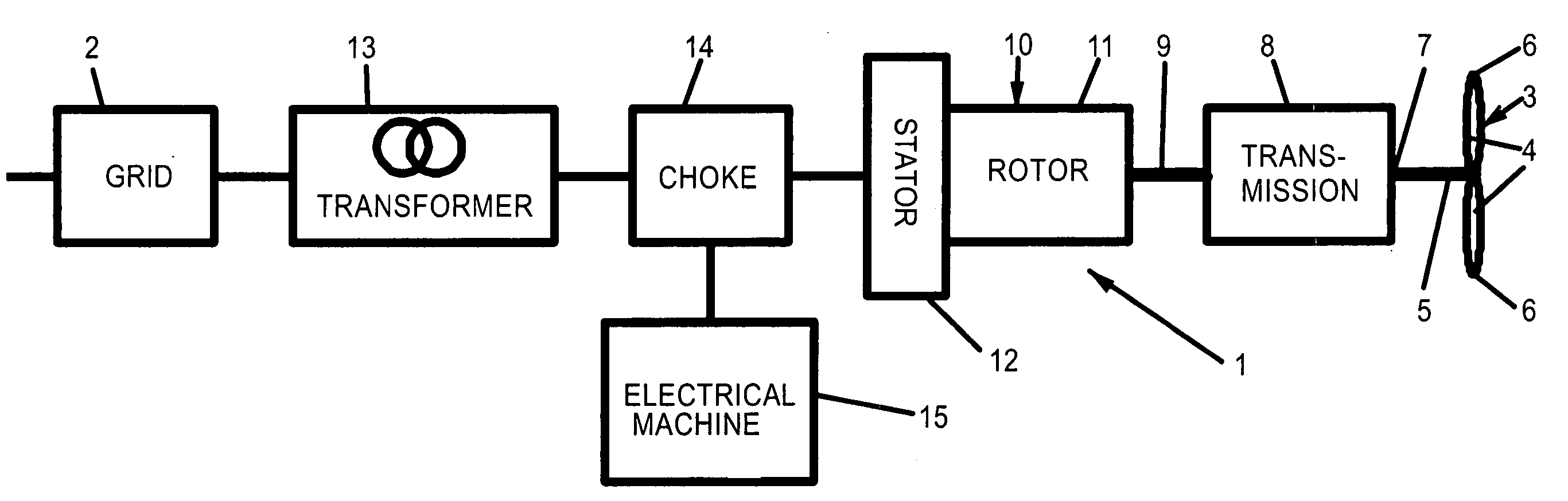

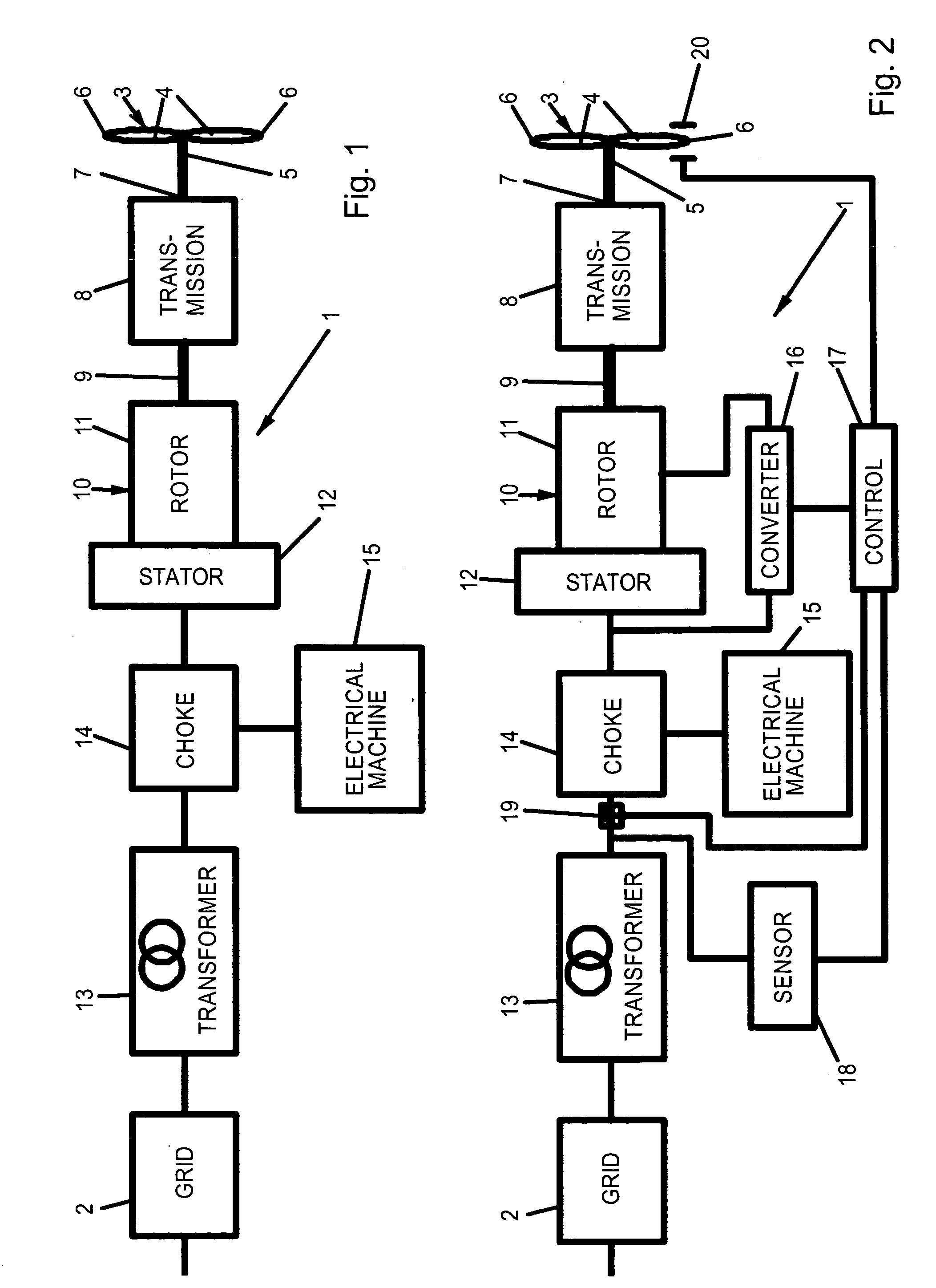

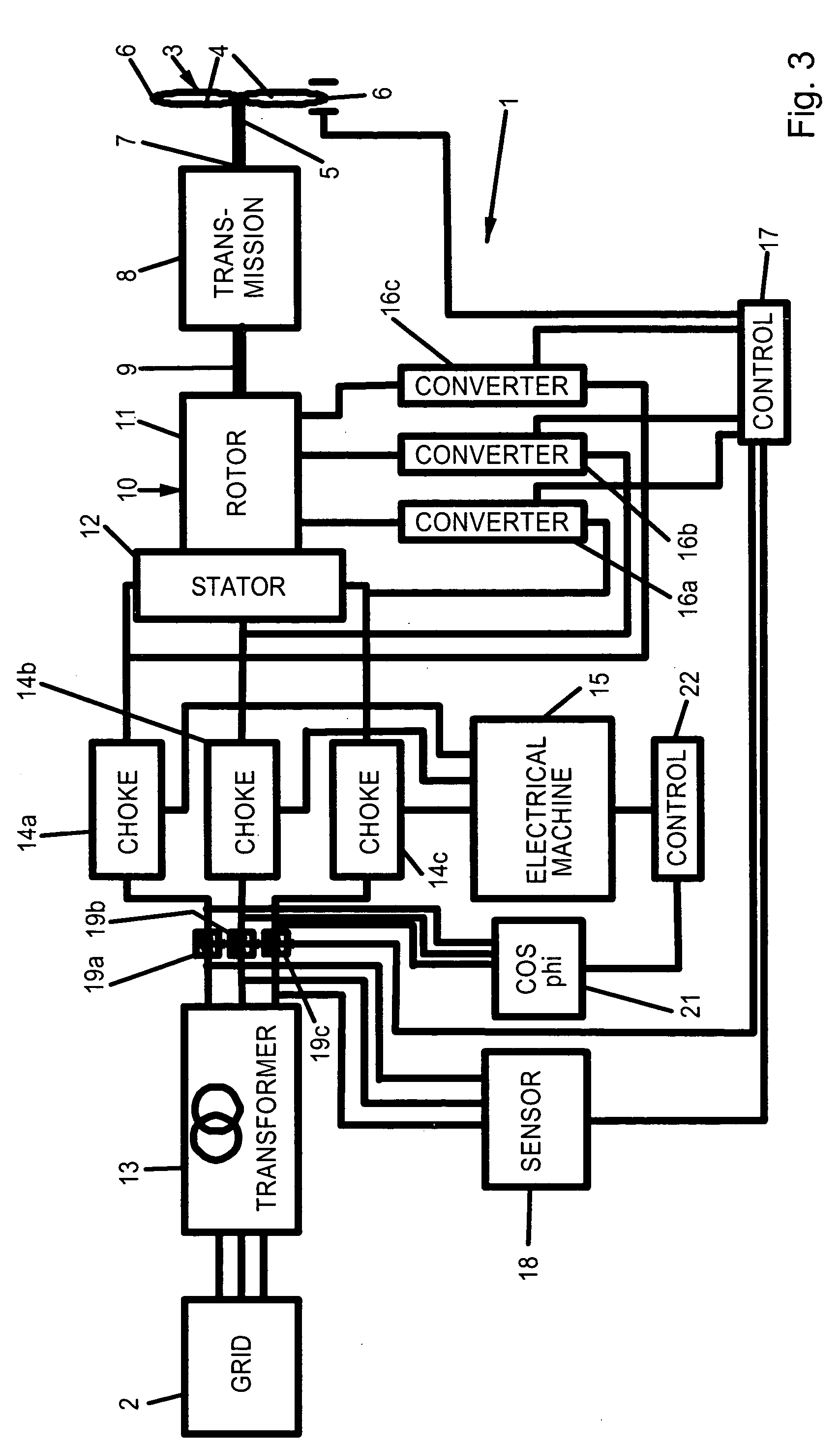

Protection for wind power station

InactiveUS20050236838A1Dc network circuit arrangementsSingle network parallel feeding arrangementsElectricityPower station

Owner:PILLER GMBH

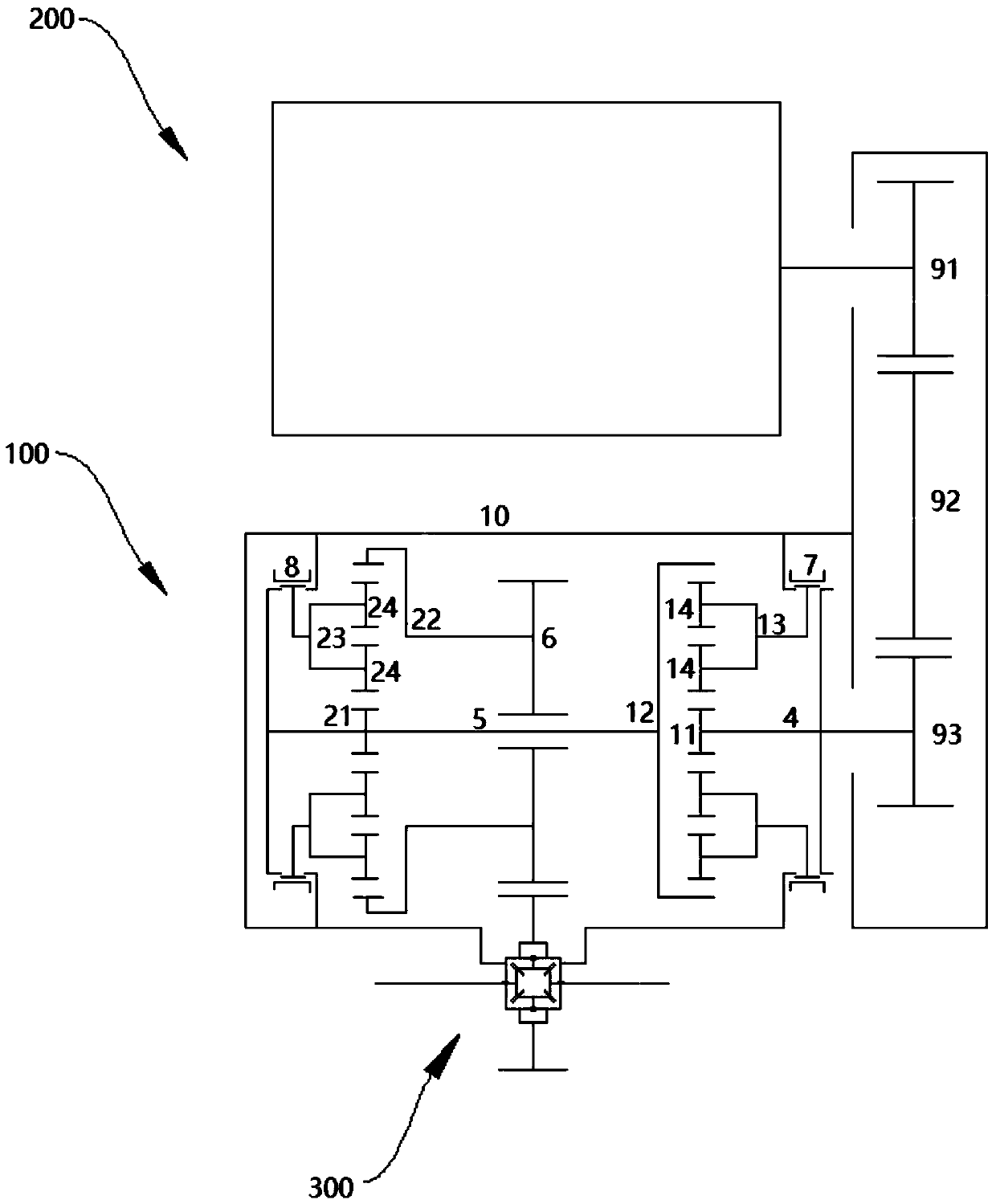

Dual-motor power system, gear shifting method and electric automobile

InactiveCN105082966AUninterrupted powerAvoid power interruptionSpeed controllerElectric propulsion mountingElectric machineDrive motor

The invention relates to the technical field of electric automobiles, in particular to a dual-motor power system used for speed changing. The system comprises a first driving motor and a second driving motor. The first driving motor and the second driving motor are connected with a first speed changer and a second speed changer respectively, the first speed changer and the second speed changer are connected with a first clutch and a second clutch respectively, and the first clutch and the second clutch are connected with a differential mechanism. The first driving motor, the second driving motor, the first speed changer, the second speed changer, the first clutch and the second clutch are controlled by a controller. Power interruption in gear shifting can be prevented, and a comfortable feeling is provided for a driver and passengers. The invention further provides an electric automobile and a gear shifting method. Power interruption in gear shifting can be prevented.

Owner:HUAYING AUTOMOBILE GRP CO LTD

Apparatus for and method of controlling power train, and storage medium storing program for implementing the method

InactiveUS20080146413A1Reduce the shock that can occurReduce capacityDigital data processing detailsGearing controlControl powerAutomatic transmission

An ECU executes a program for implementing a method that includes: a step of performing control so that torque capacity Tch of a frictional engagement device that is brought from an engaged state by a downshift operation is gradually reduced to start an inertia phase when a power-on downshift is performed; and a step of stopping the gradual reduction of the torque capacity Tch when the rate of change in an input shaft rotation speed NI of an automatic transmission has reached a desired rate of change ΔN(1). Variation in output torque is kept small, and the shock that can occur at the time of a shift is thus reduced.

Owner:TOYOTA JIDOSHA KK

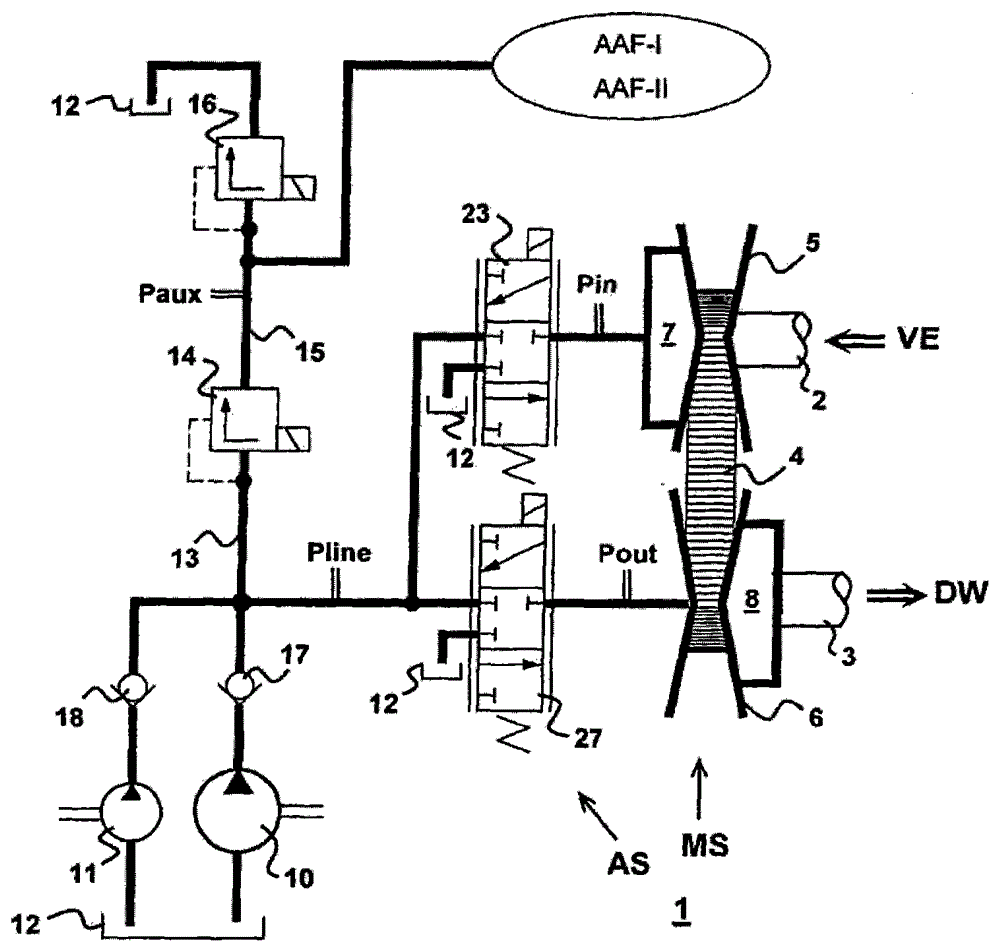

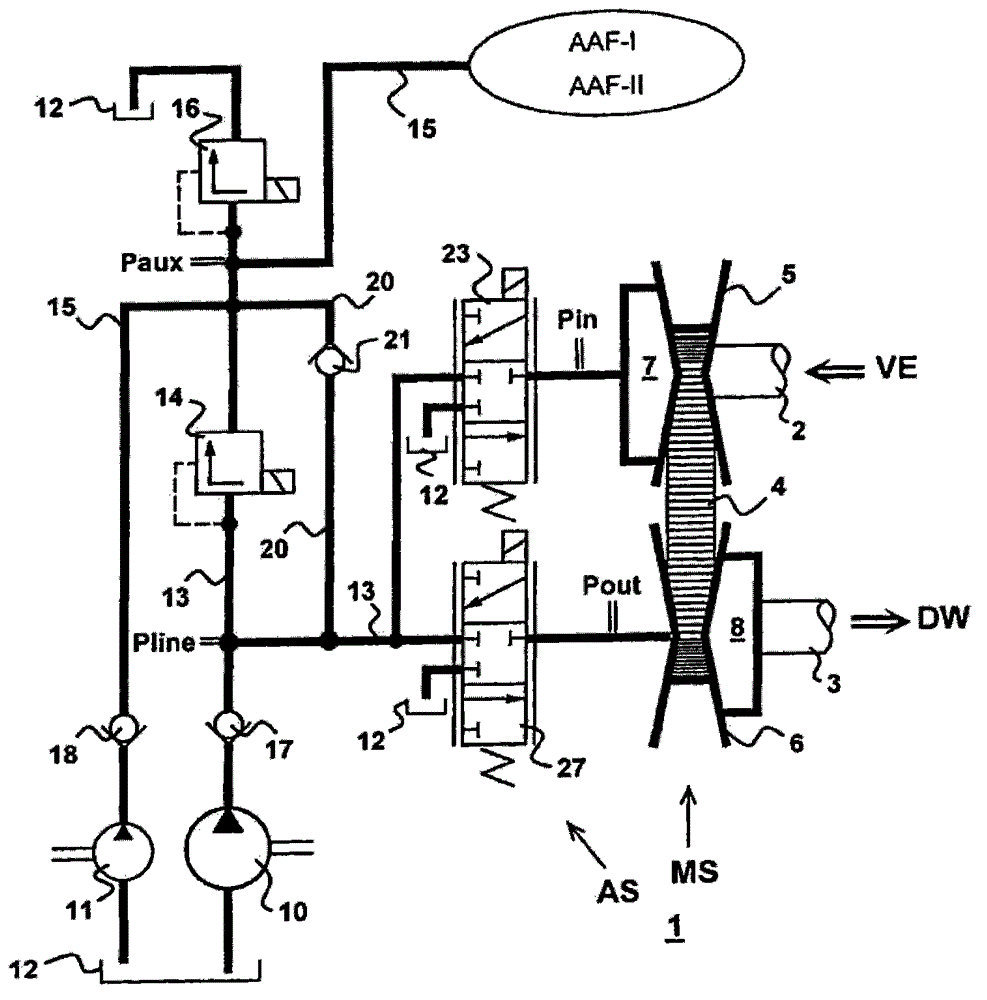

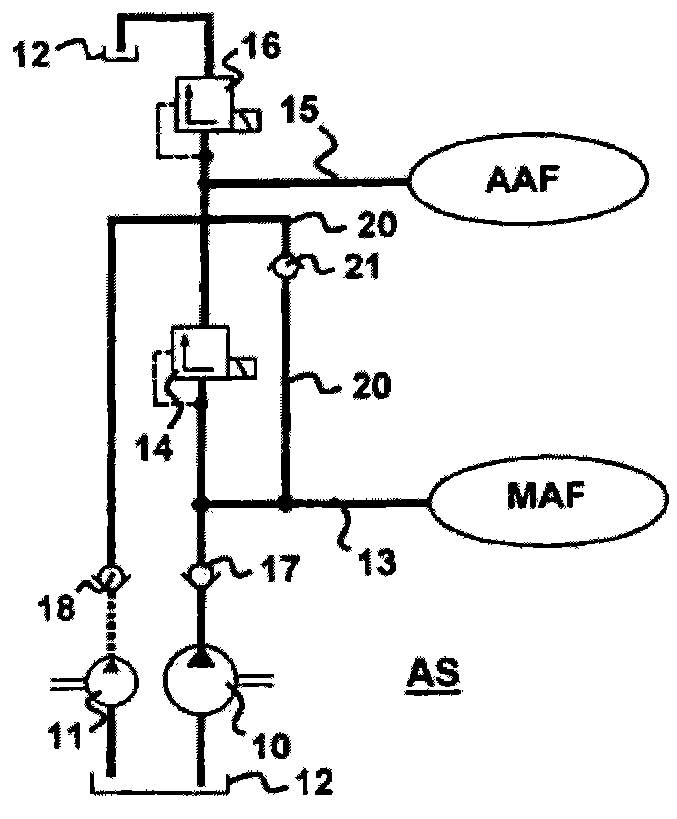

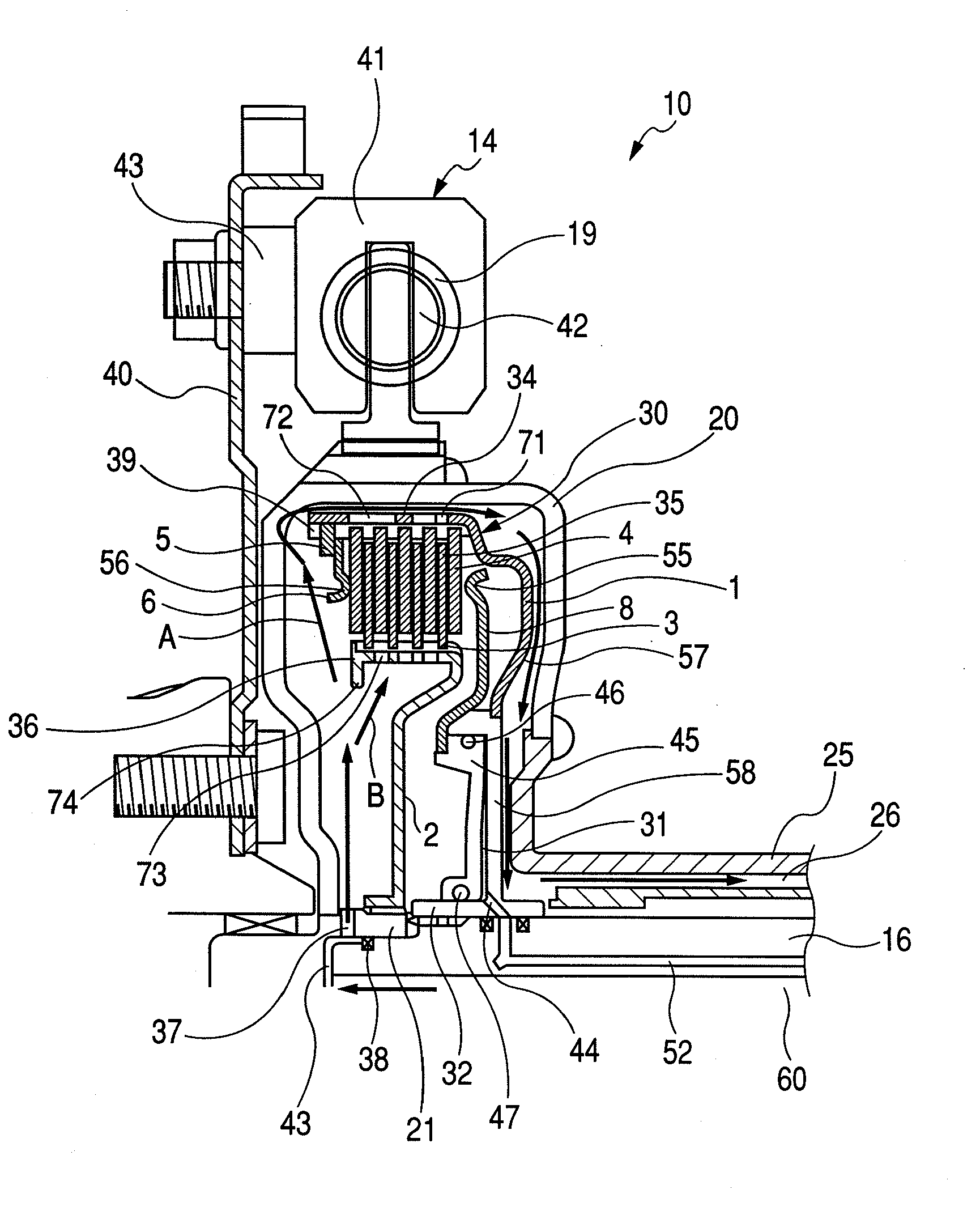

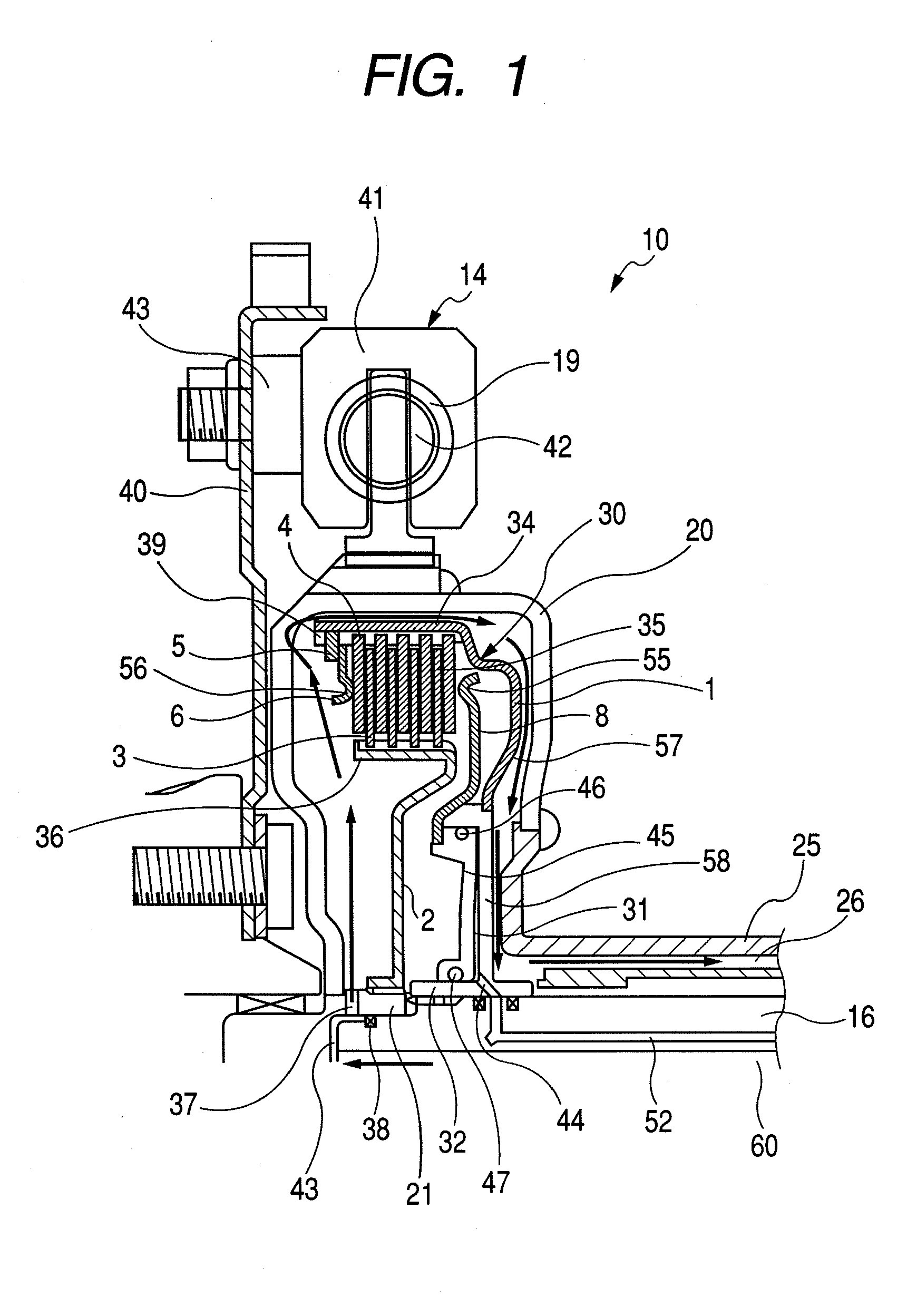

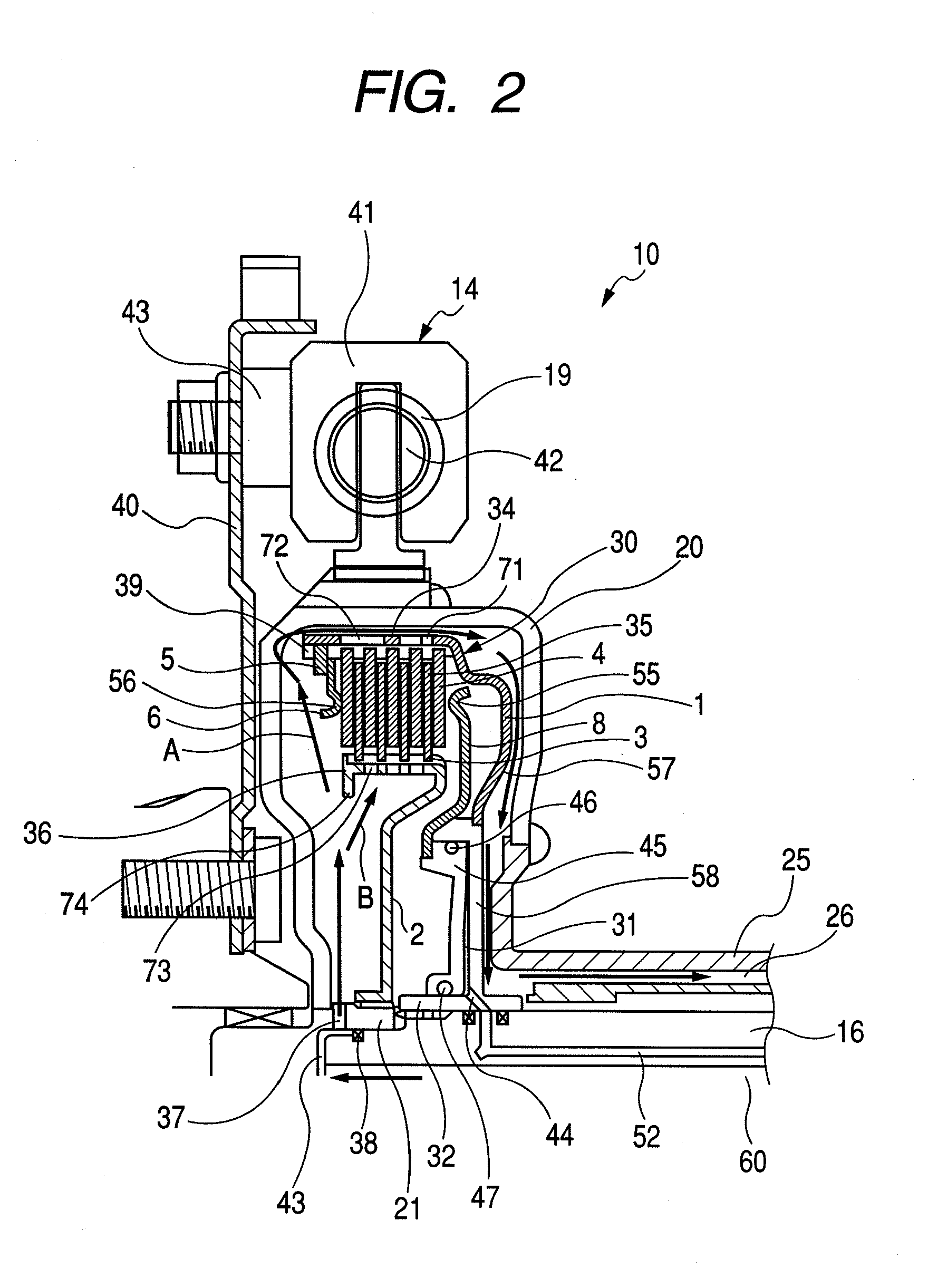

Hydraulically actuated continuously variable transmission for a vehicular drive line provided with an engine

InactiveCN104160180ASimple designImprove efficiencyGear lubrication/coolingGearing controlElectric machineHydraulic pump

Owner:ROBERT BOSCH GMBH

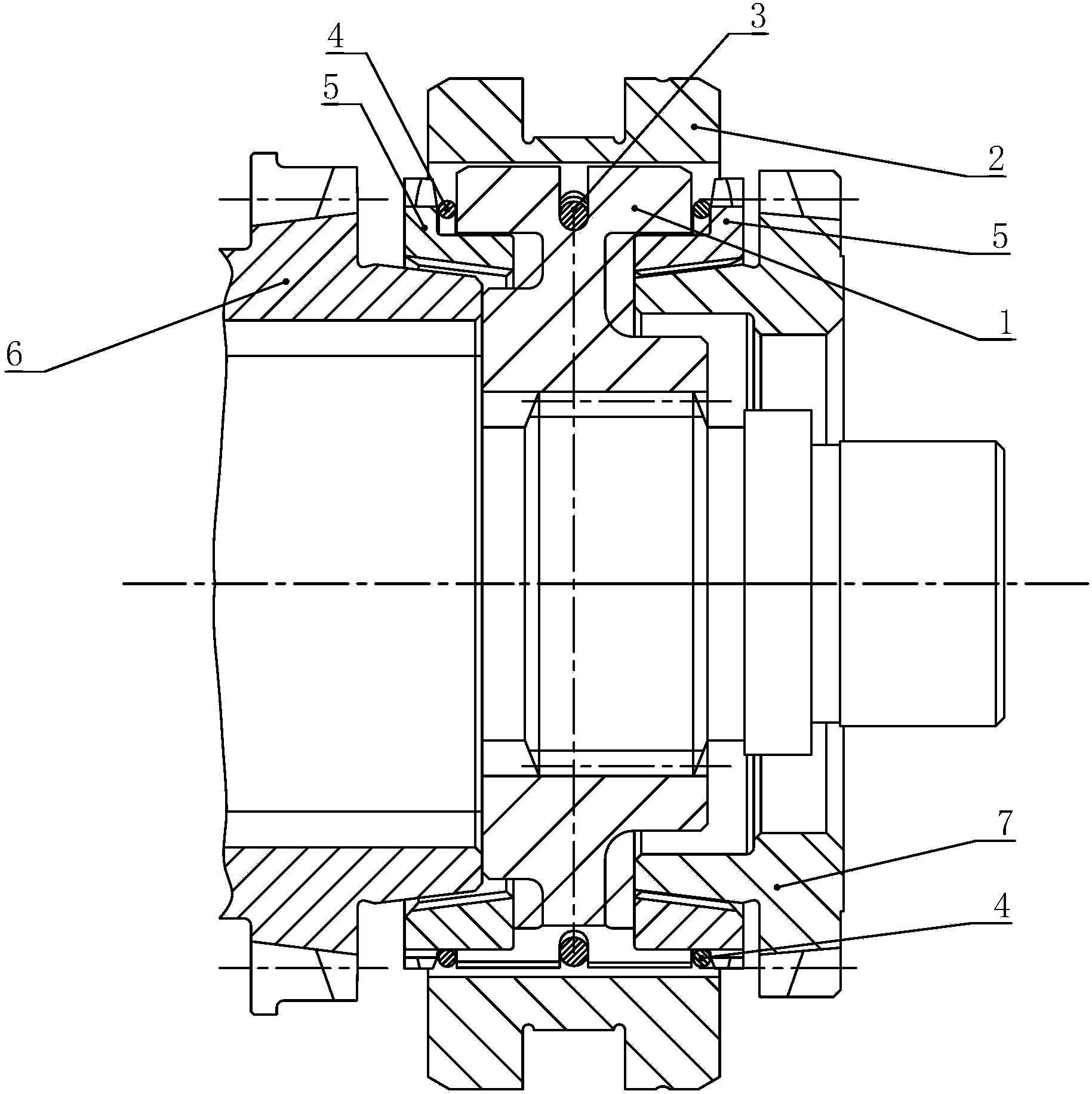

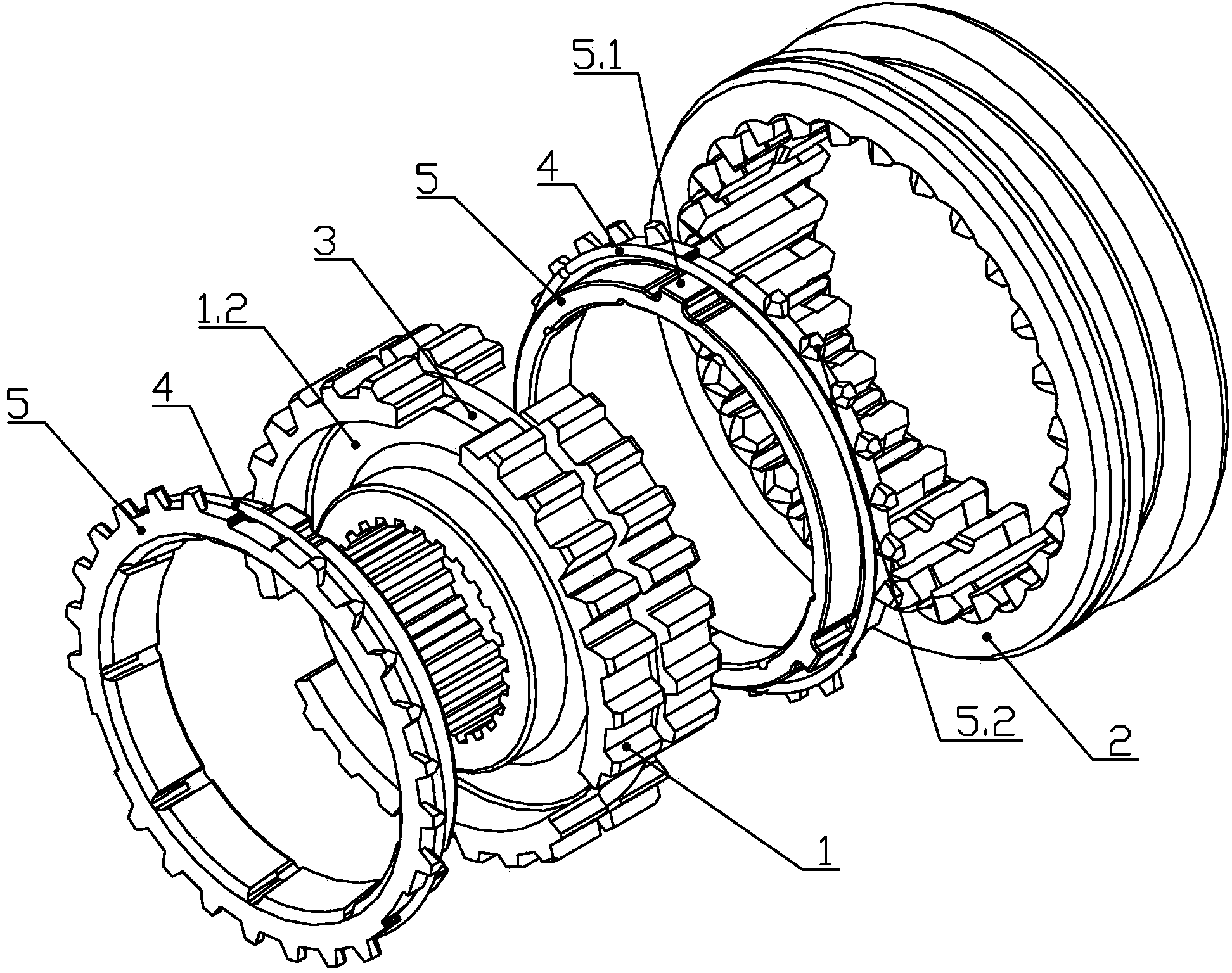

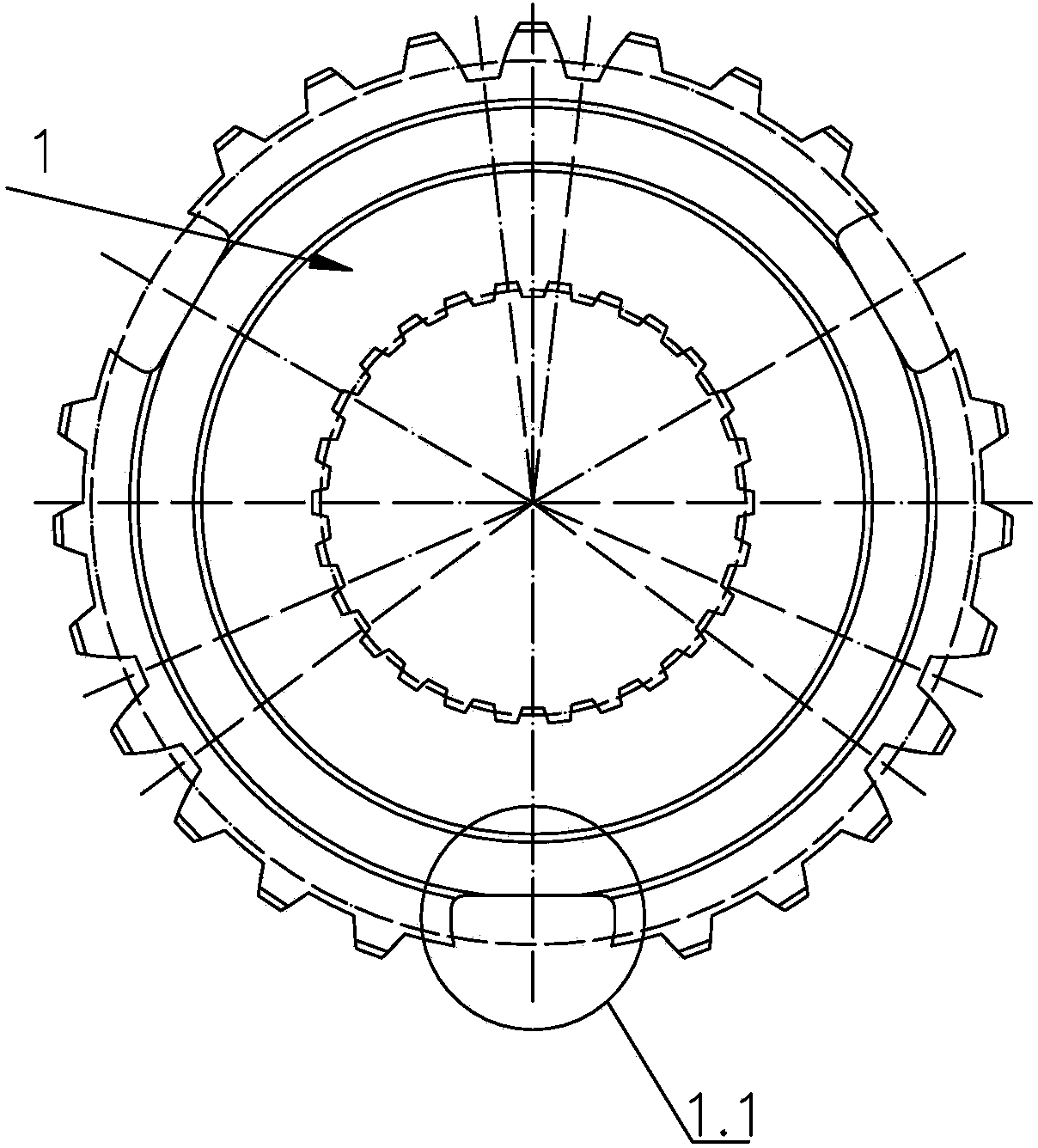

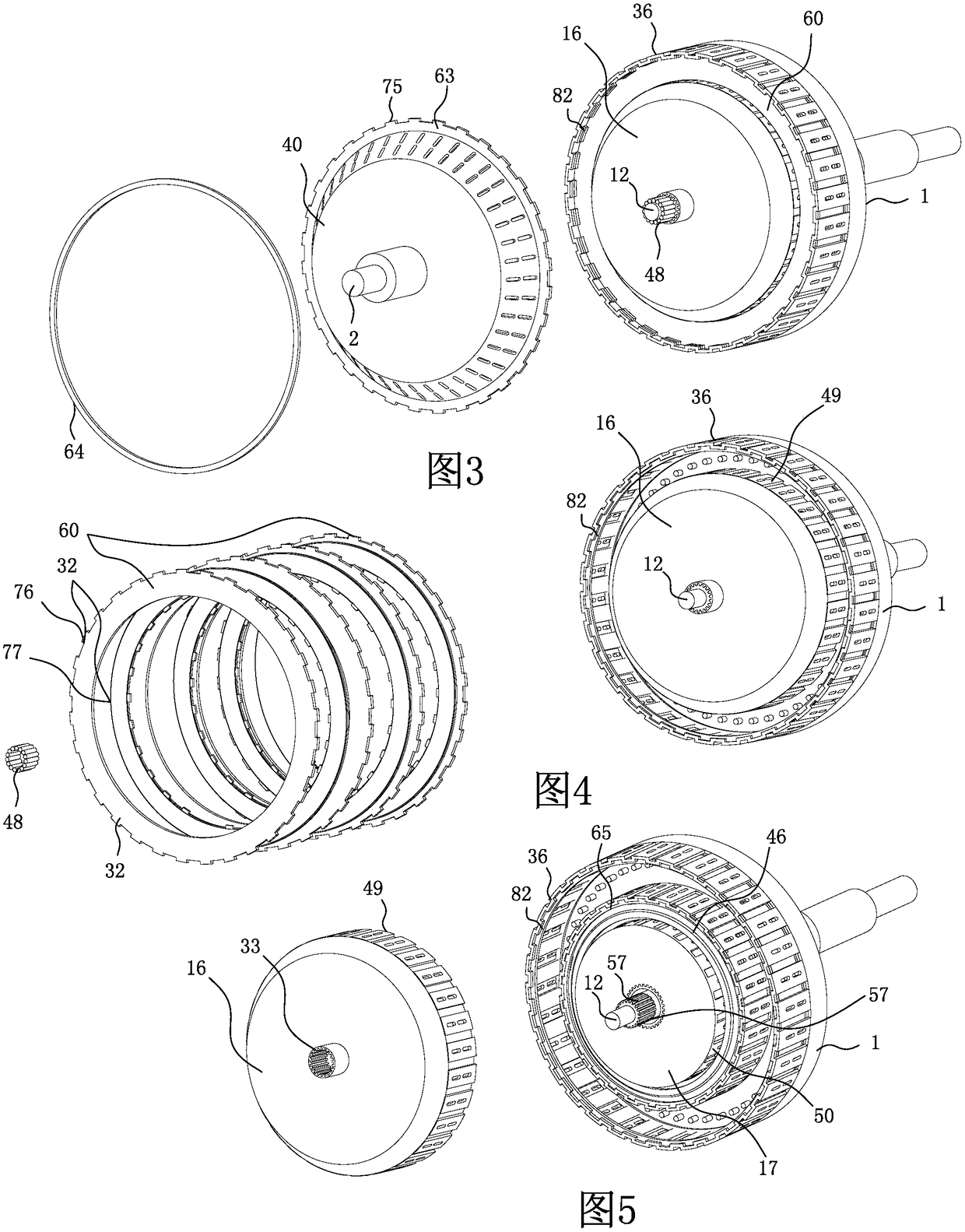

Double-circumference synchronizer with springs

ActiveCN103527665ACompact structureFriction torque pre-adjustmentMechanical actuated clutchesFriction torqueDrive shaft

Owner:WUHAN UNIV OF TECH

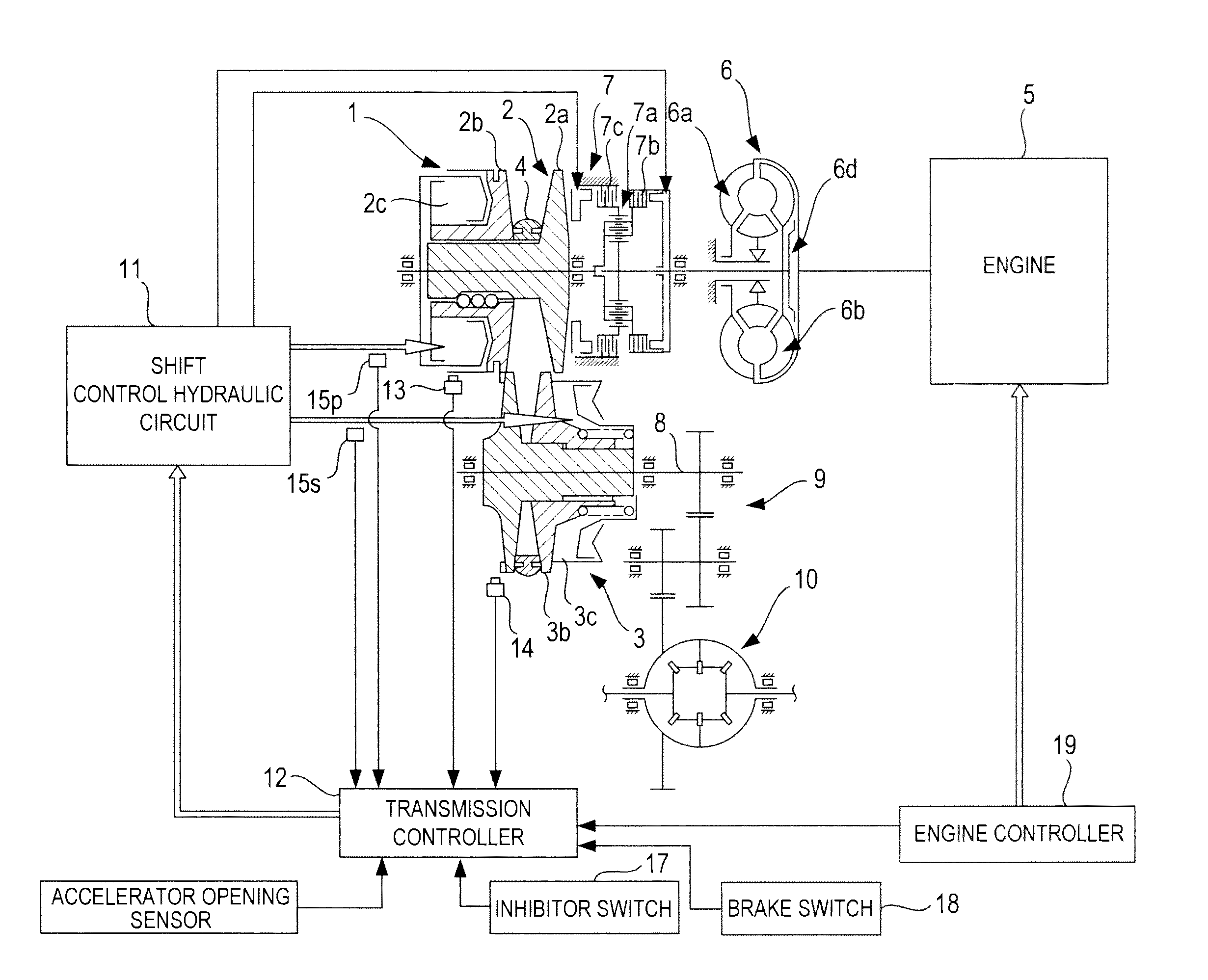

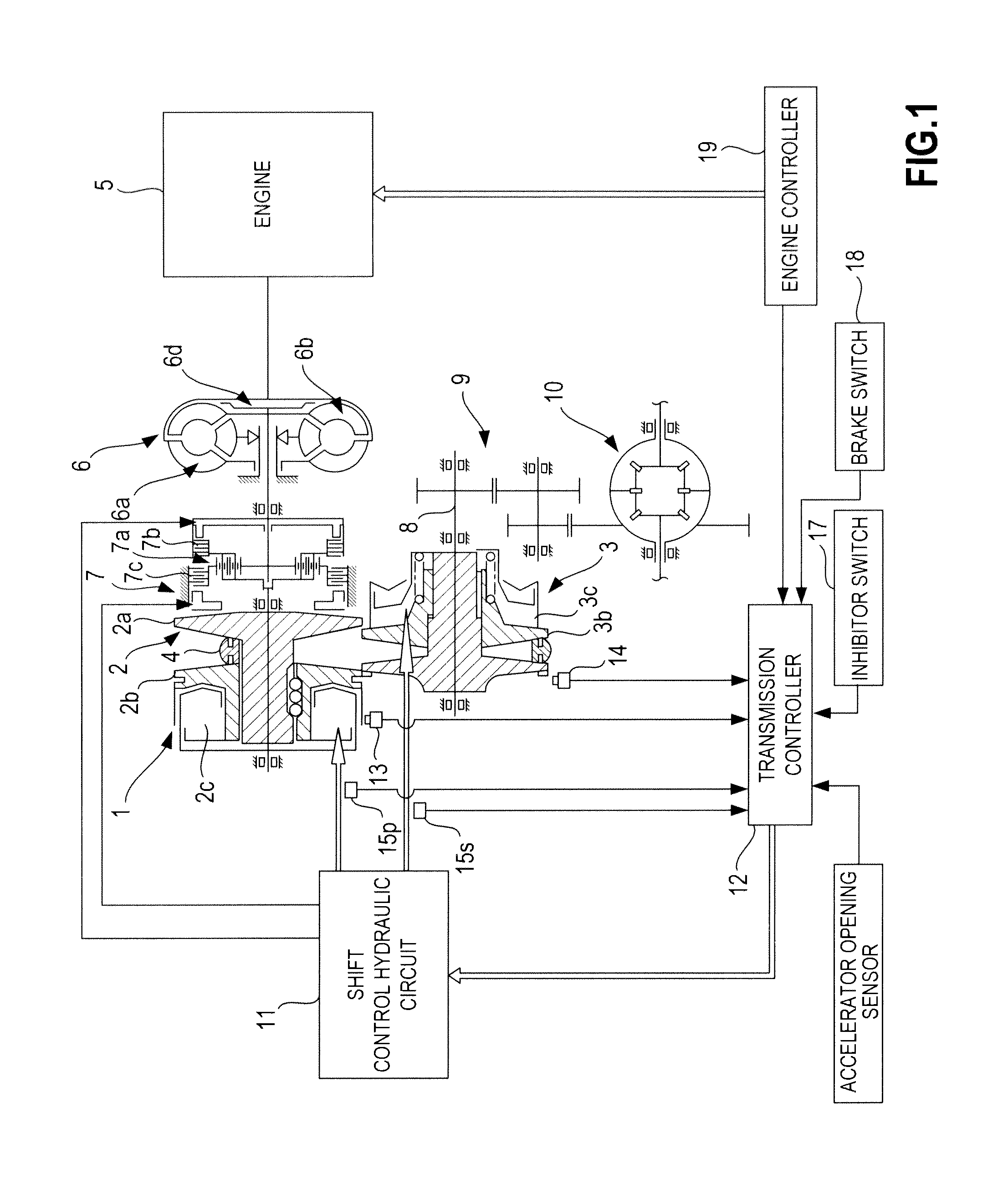

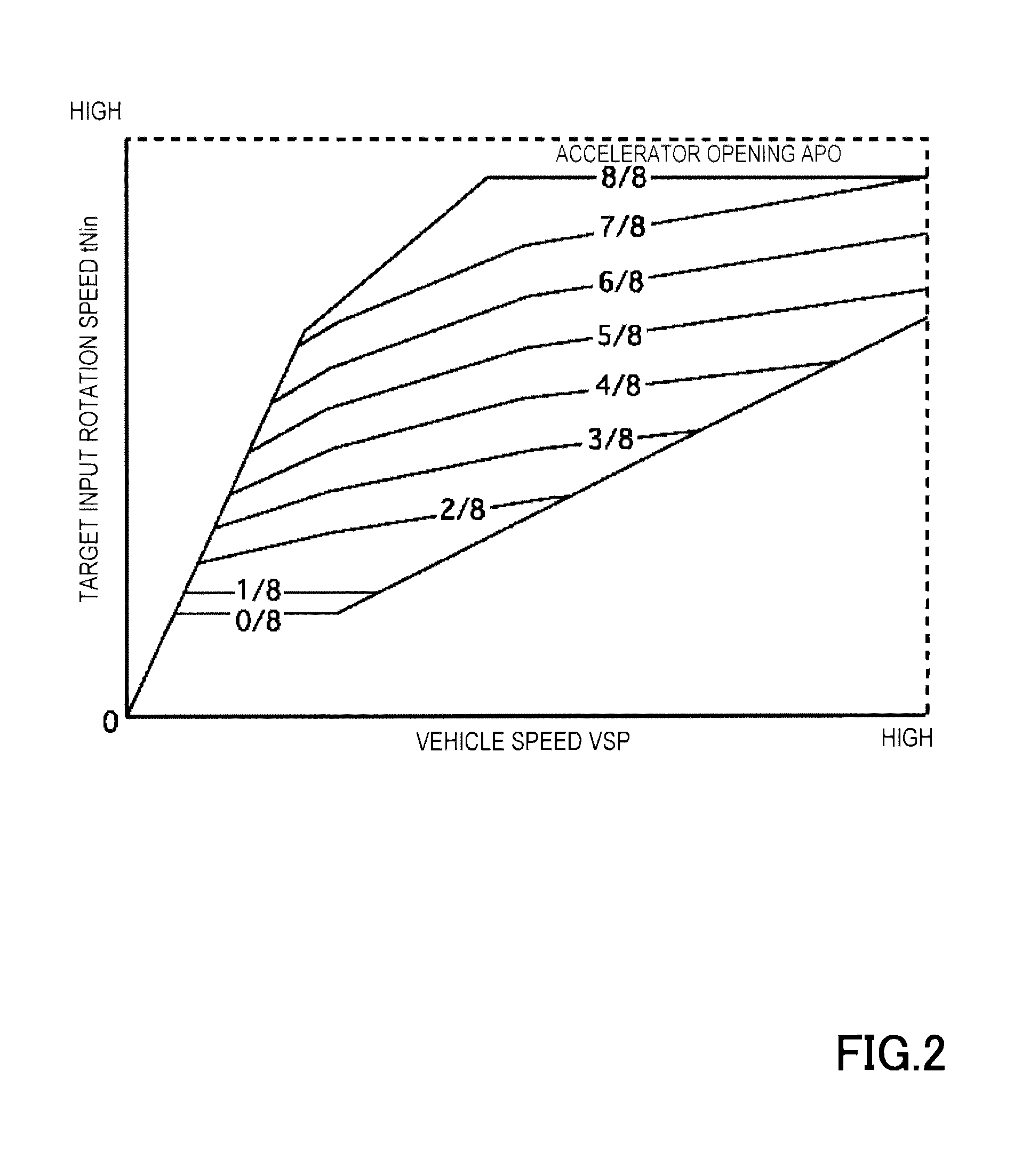

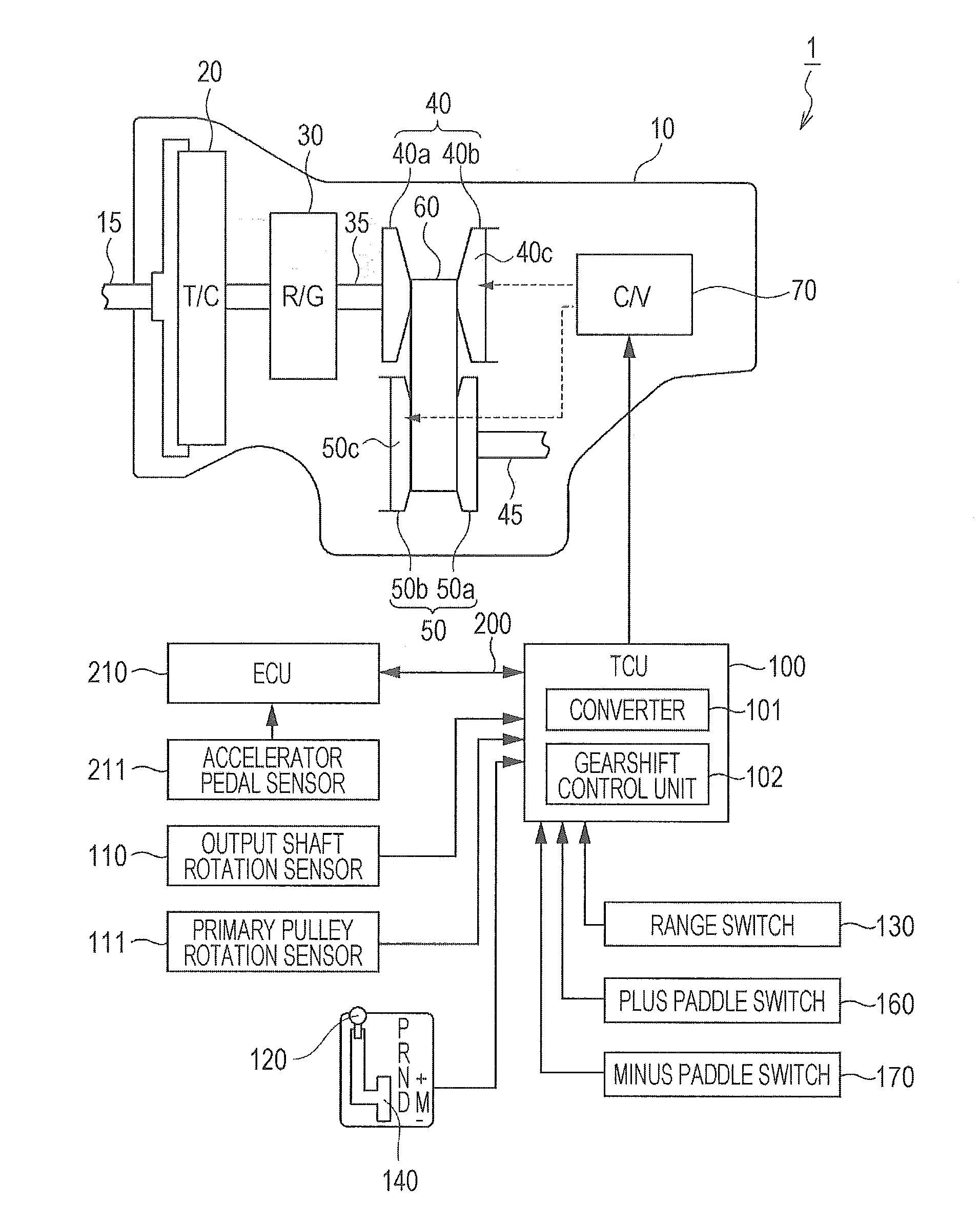

Continuously variable transmission and its hydraulic pressure control method

ActiveUS20150081181A1Improve fuel efficiencyReduced engine powerDigital data processing detailsGearing controlLower limitControl theory

Owner:JATCO LTD +1

Damping control device for electric vehicle

ActiveUS20180237021A1Accurate detectionPrevent false detectionHybrid vehiclesSpeed controllerElectric vehicleFeedback control

Owner:NISSAN MOTOR CO LTD

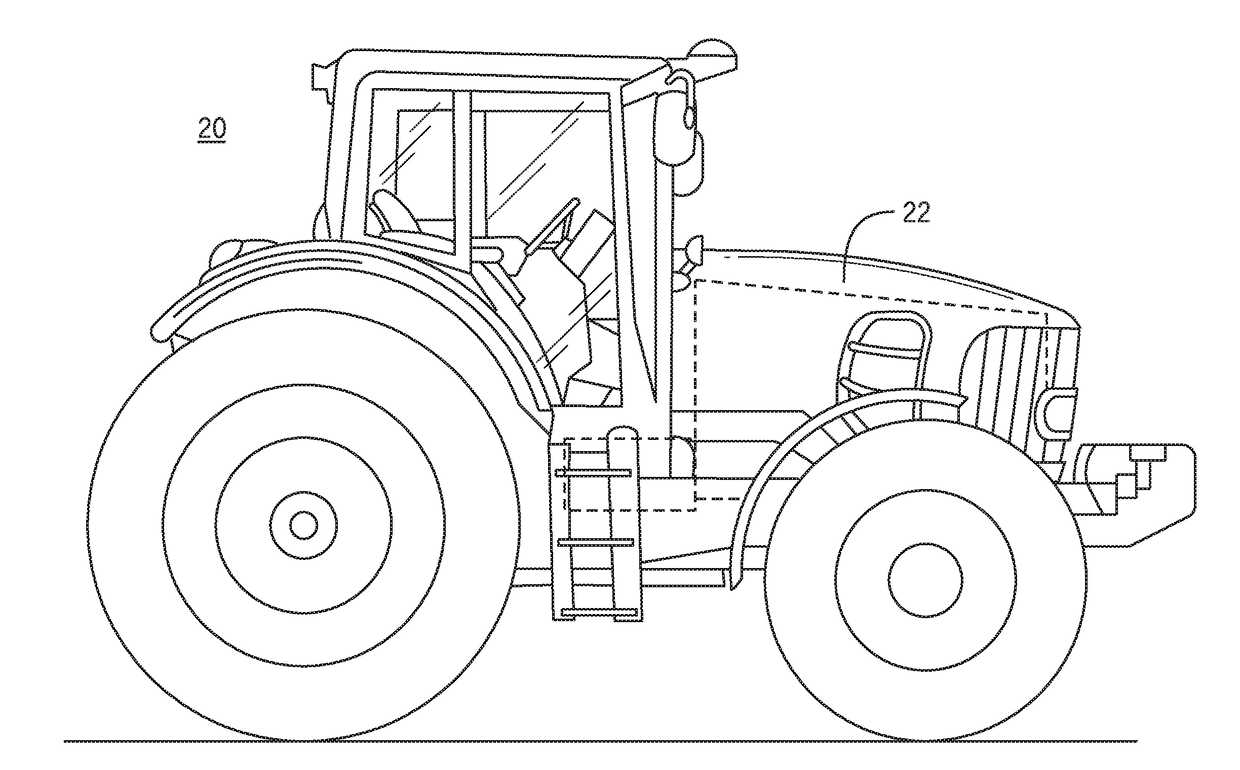

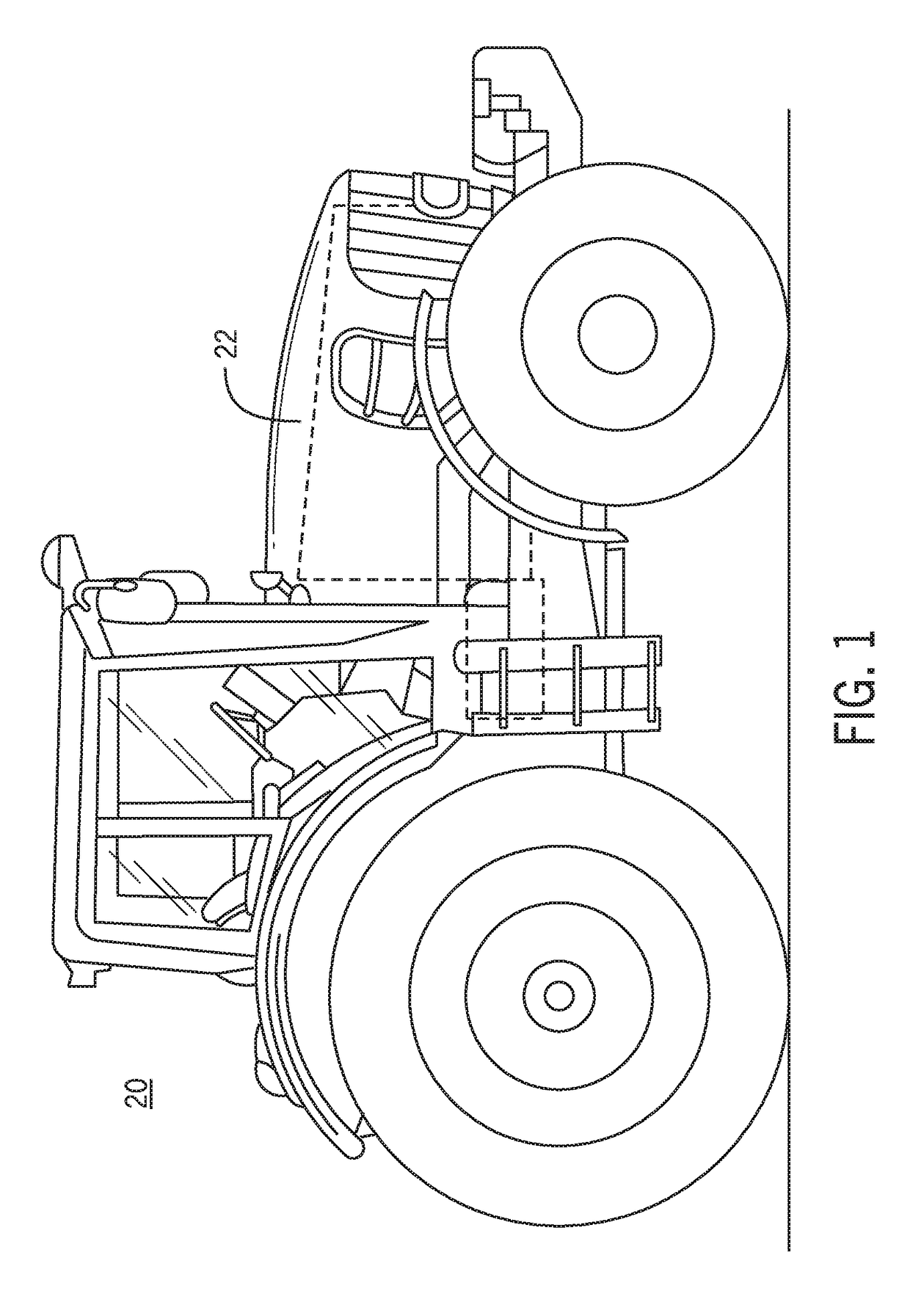

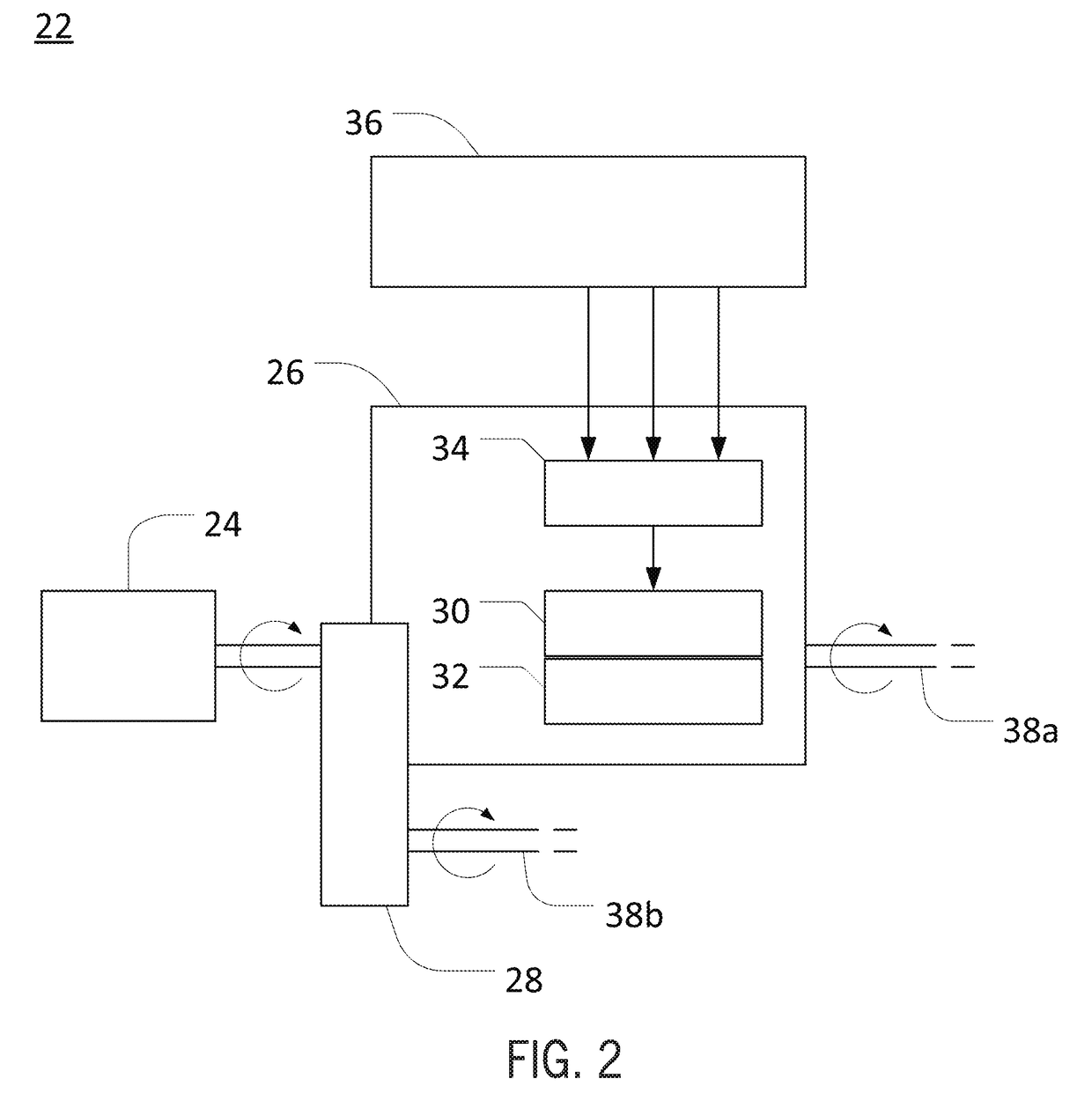

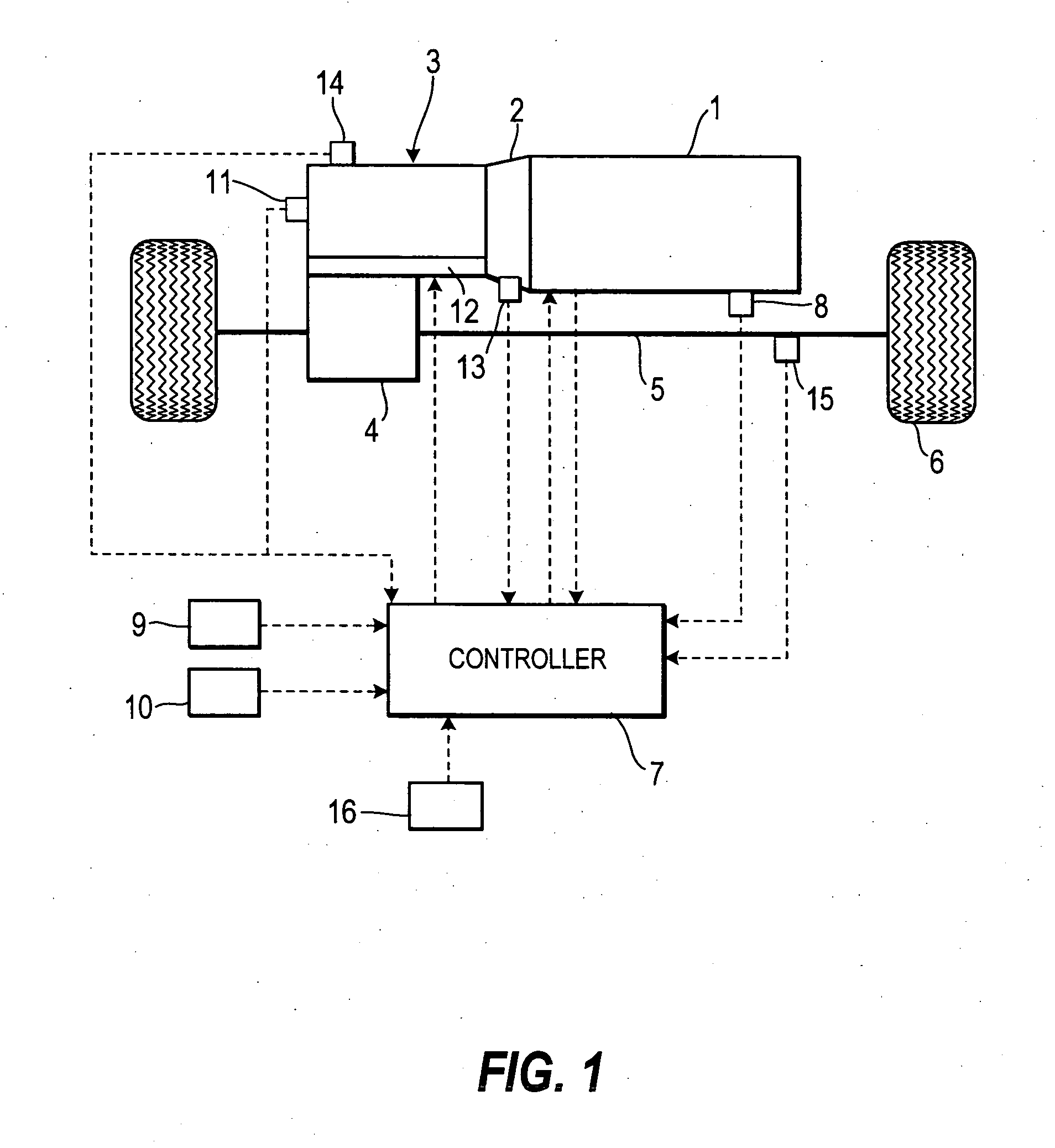

System and method for automatically calibrating the clutches within a transmission of a work vehicle

Owner:BLUE LEAF I P

Speed changer synchronizer synchronous self-adaptation control method and system

Owner:吉泰车辆技术(苏州)有限公司

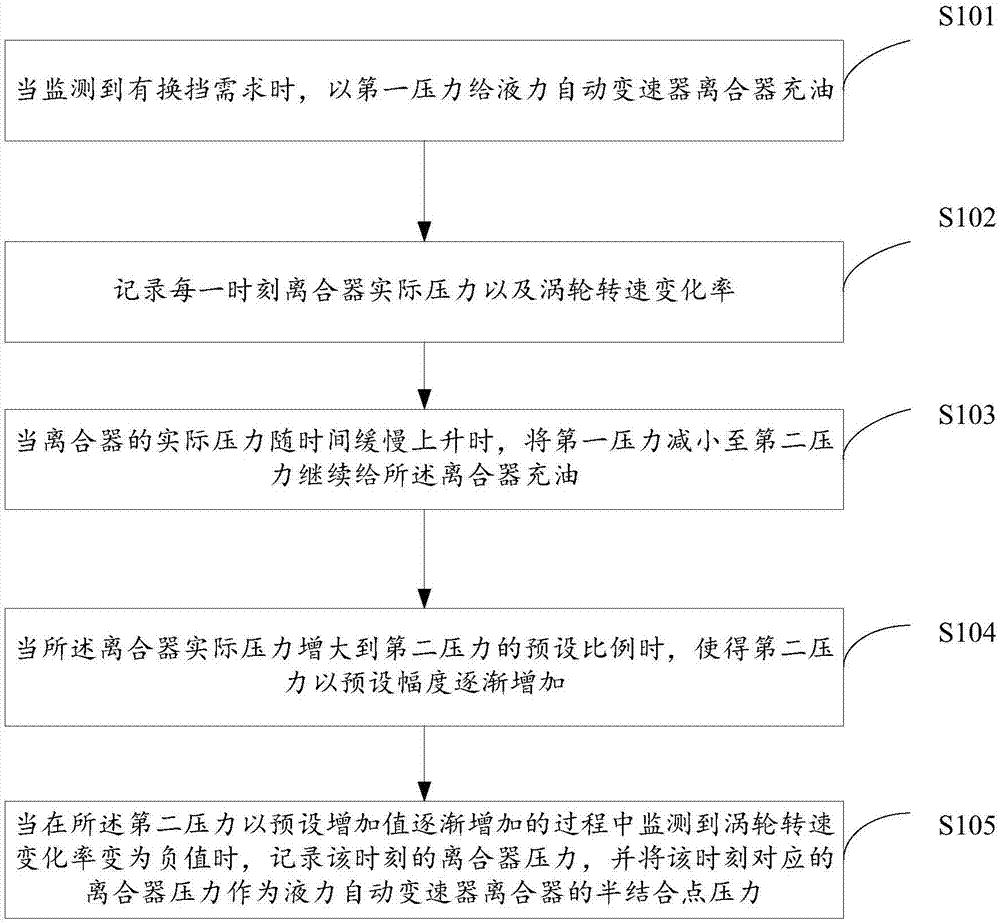

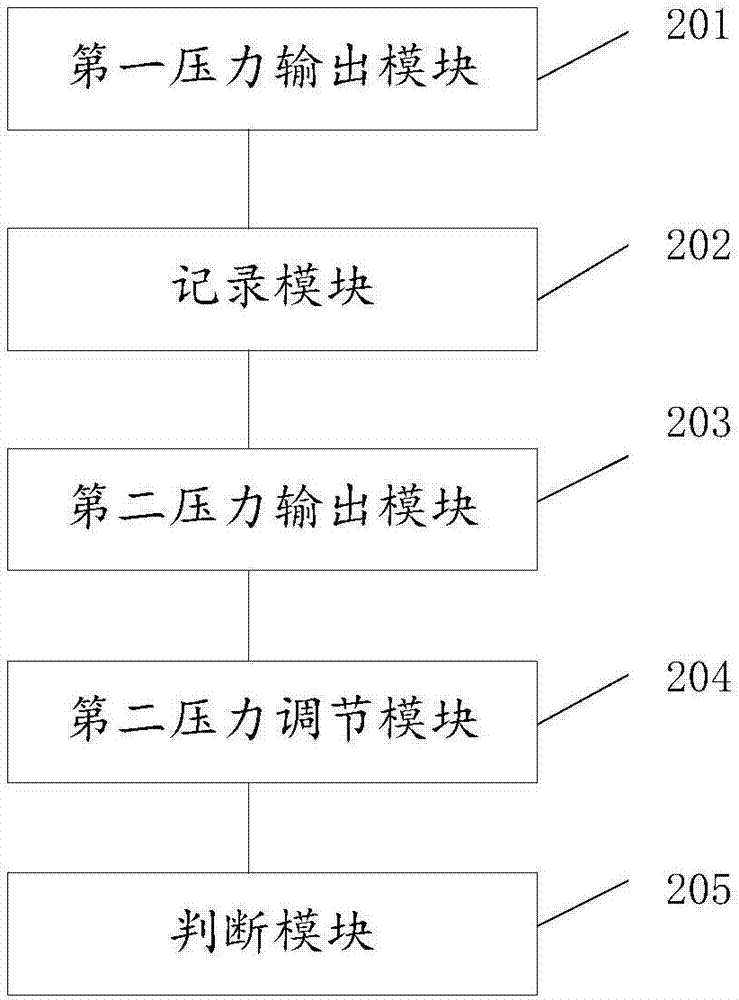

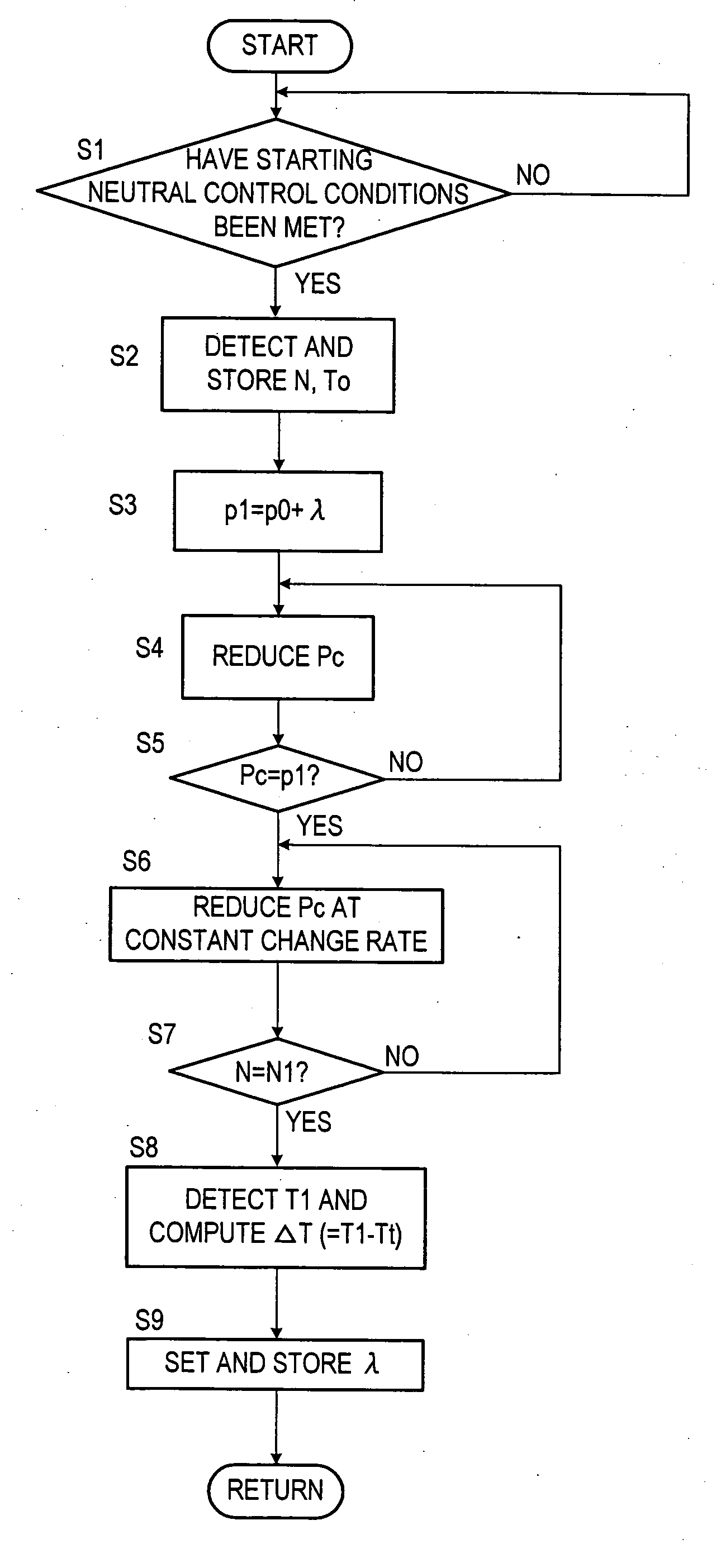

Semi joint point judgment method and system of hydraulic automatic transmission clutch

Owner:CHINA FIRST AUTOMOBILE

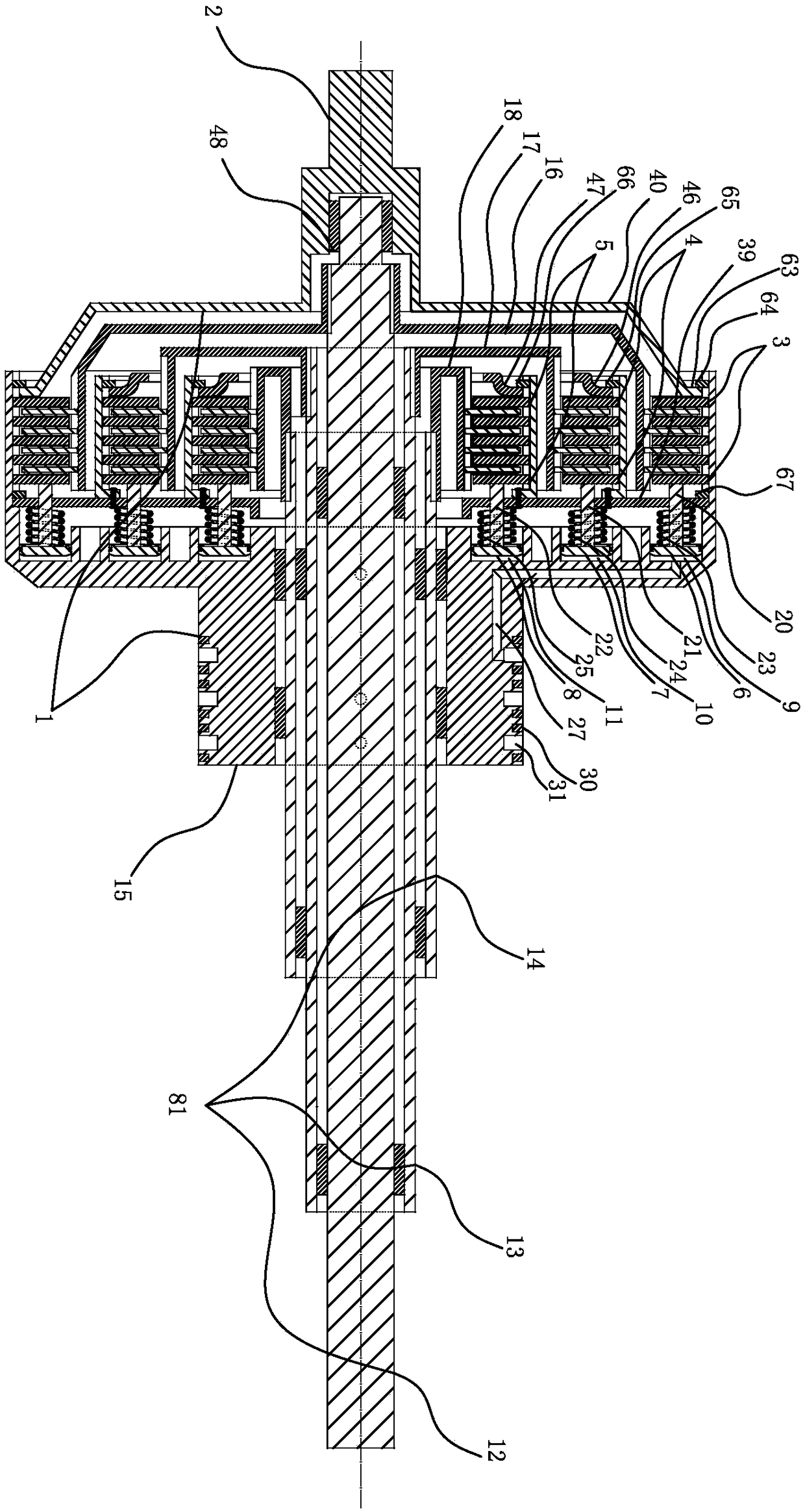

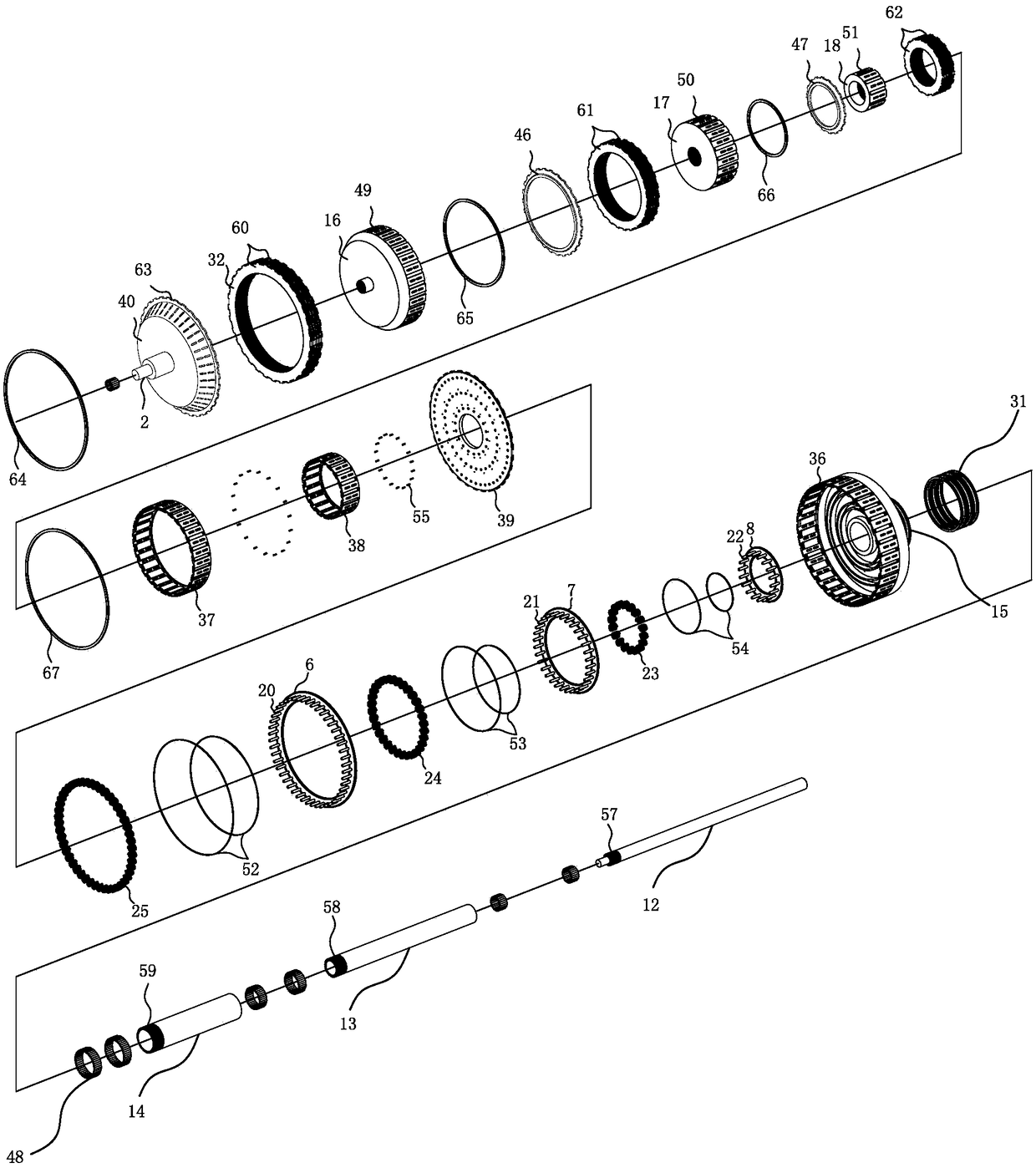

Three clutches

Owner:陈学琴

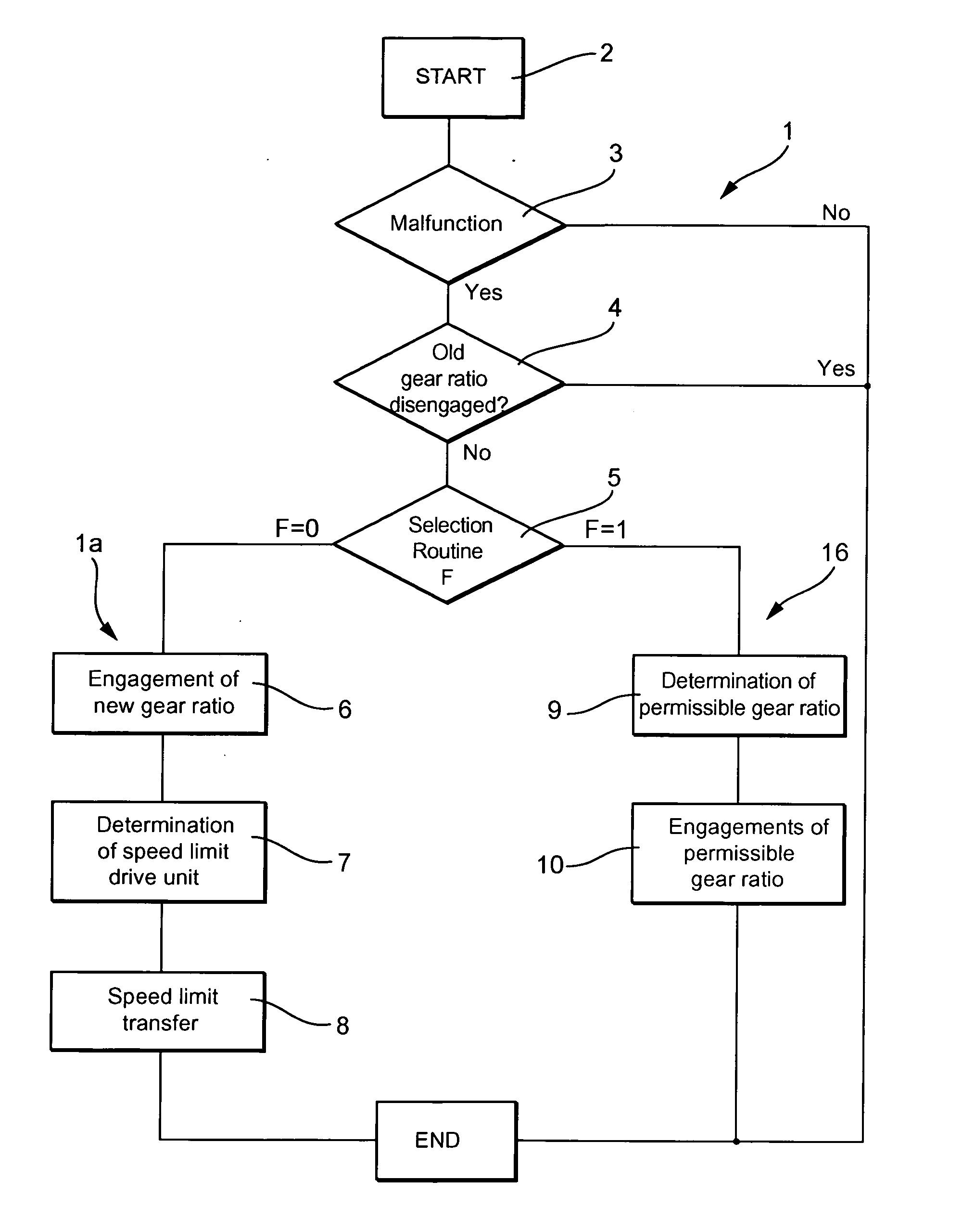

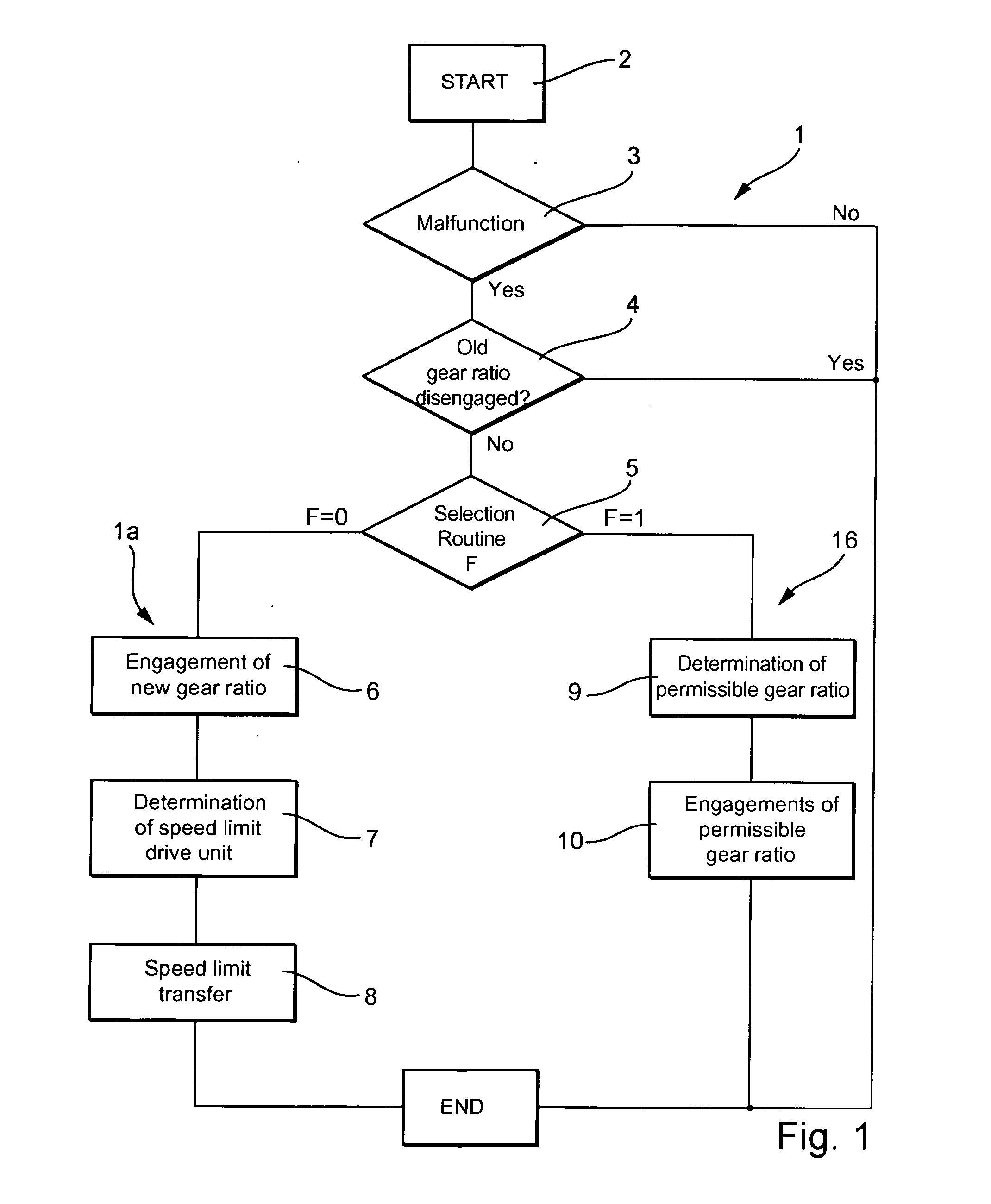

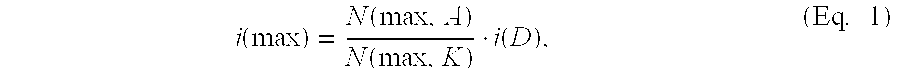

Parallel shift transmission and method for controlling it

InactiveUS20060089231A1Service life is prevented and reducedReduce and prevent situationToothed gearingsGearing controlEngineeringGear ratio

Owner:SCHAEFFLER TECH AG & CO KG

Starting clutch

Owner:NSK WARNER

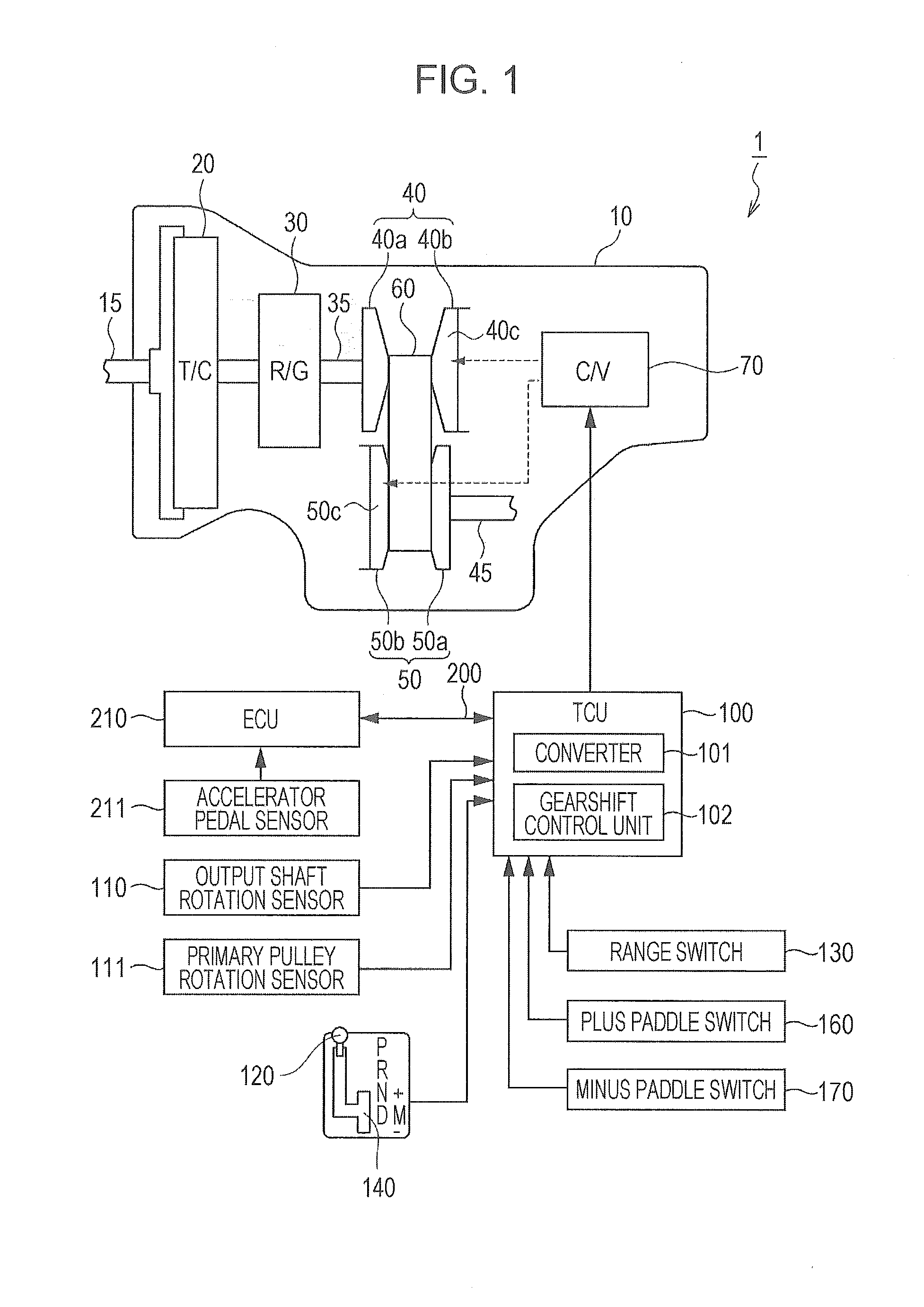

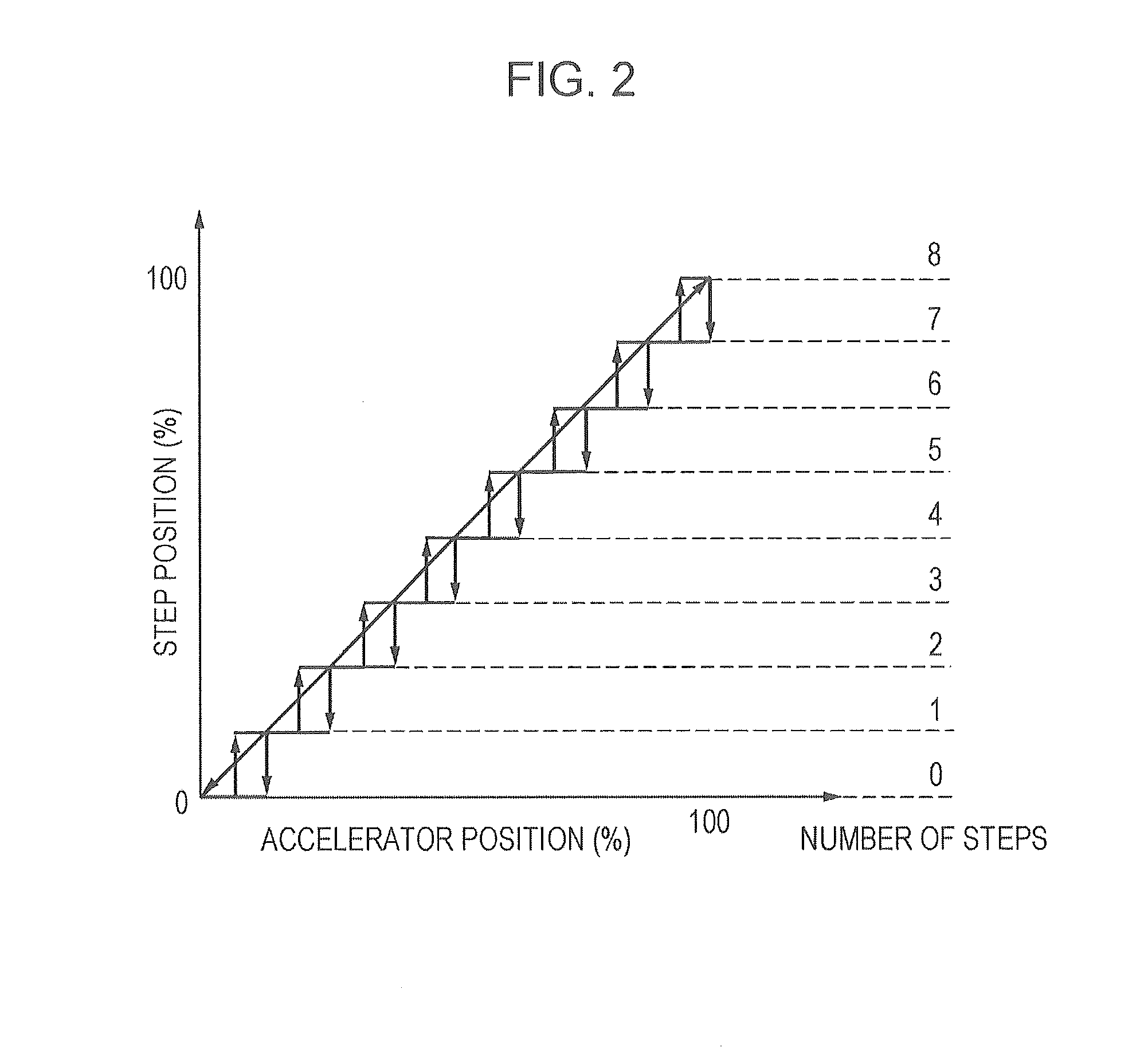

Shift control device for continuously variable transmission

Owner:SUBARU CORP

Vehicle transmission control system

Owner:JATCO LTD

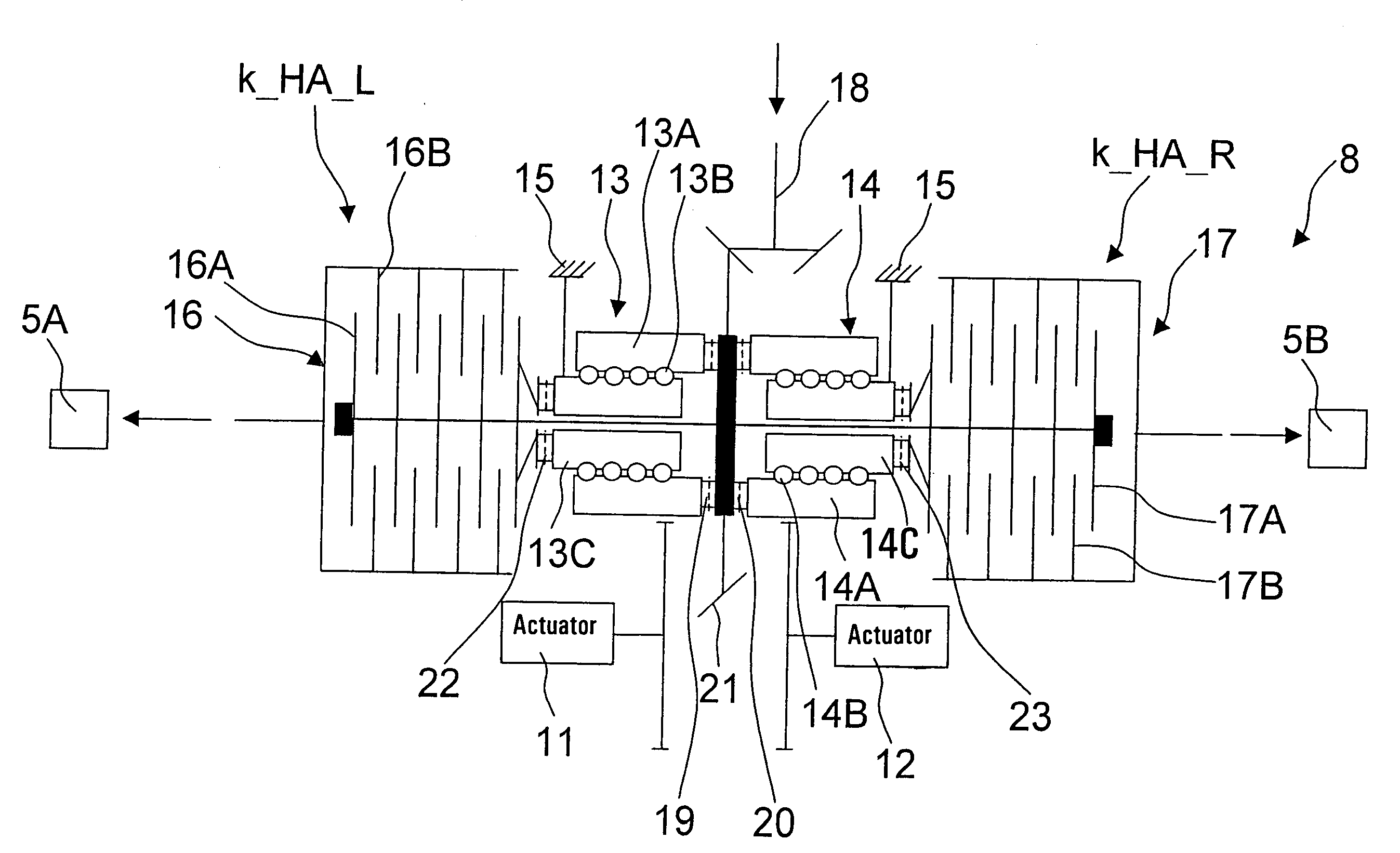

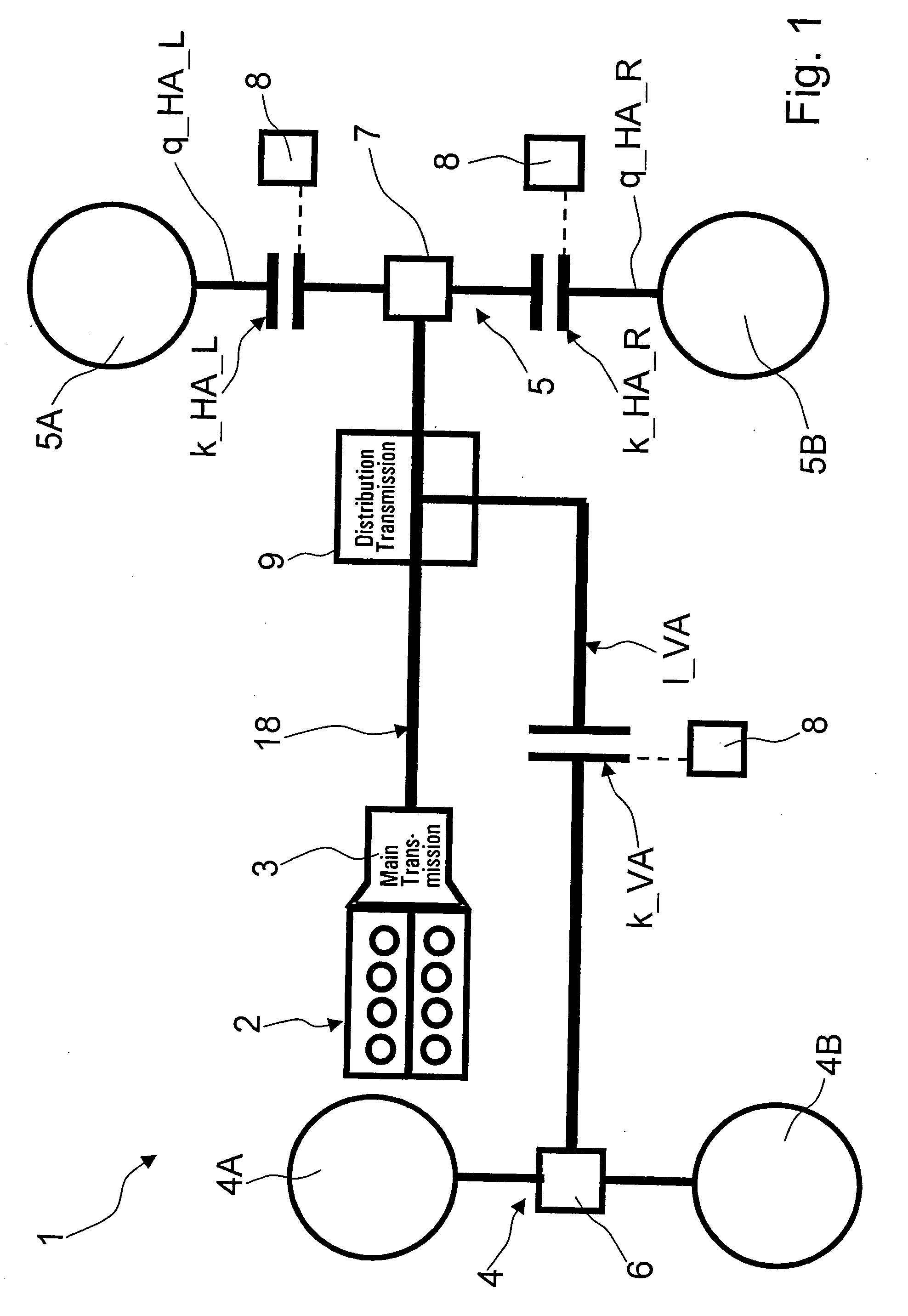

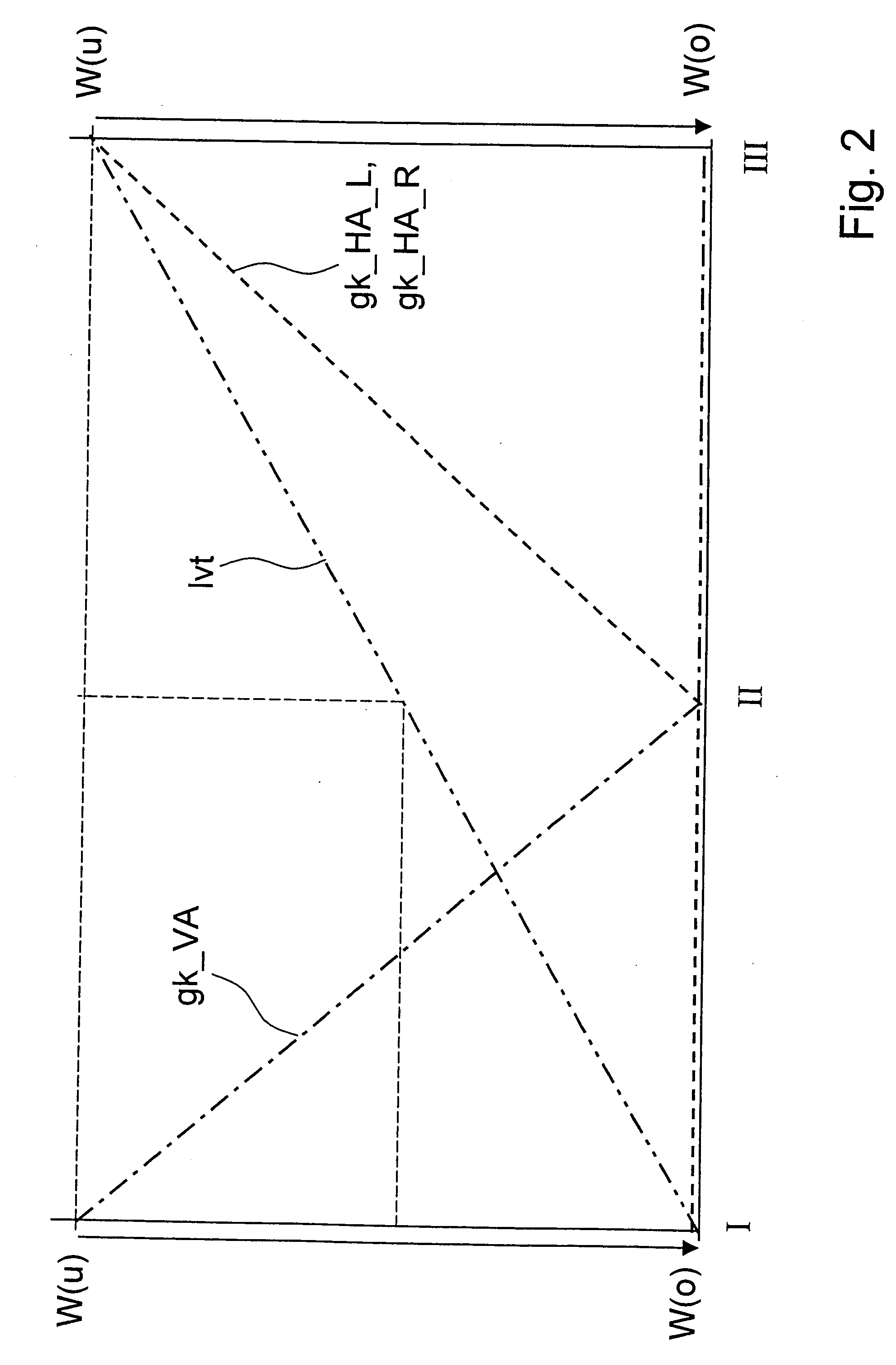

Drive train of an all-wheel drive vehicle comprising clutches and method for controlling and regulating a drive train

InactiveUS20070060434A1Improve efficiencyReduce power lossElectric propulsion mountingMagnetically actuated clutchesClutchVariator

Owner:ZF FRIEDRICHSHAFEN AG

Stepless automatic transmission and vehicle

ActiveCN107664180AWide range of speed ratioImprove powerToothed gearingsGearing controlAutomatic transmissionDrivetrain

The invention provides a stepless automatic transmission and a vehicle, and relates to the technical field of vehicle power transmission systems. The stepless automatic transmission comprises a belt wheel transmission mechanism connected with an output shaft of an engine, and further comprises a planet gear mechanism, a differential, a transmission gear set and a clutch set, wherein the differential is connected with the planet gear mechanism, and comprises a transmission output shaft; the transmission gear set is in transmission connection with the output shaft of the engine and the planet gear mechanism; and the clutch set is connected with the planet gear mechanism and the transmission gear set, and comprises a first clutch and a second clutch. The stepless automatic transmission is provided with the planet gear mechanism connected with the differential and the clutch set connected with the planet gear mechanism and the transmission gear set; through change of working states of theclutches in the clutch set, the speed ratio range of the stepless automatic transmission is widened; the structure is simple; and the dynamic property and the economy of the vehicle are improved.

Owner:BAIC MOTOR POWERTRAIN CO LTD

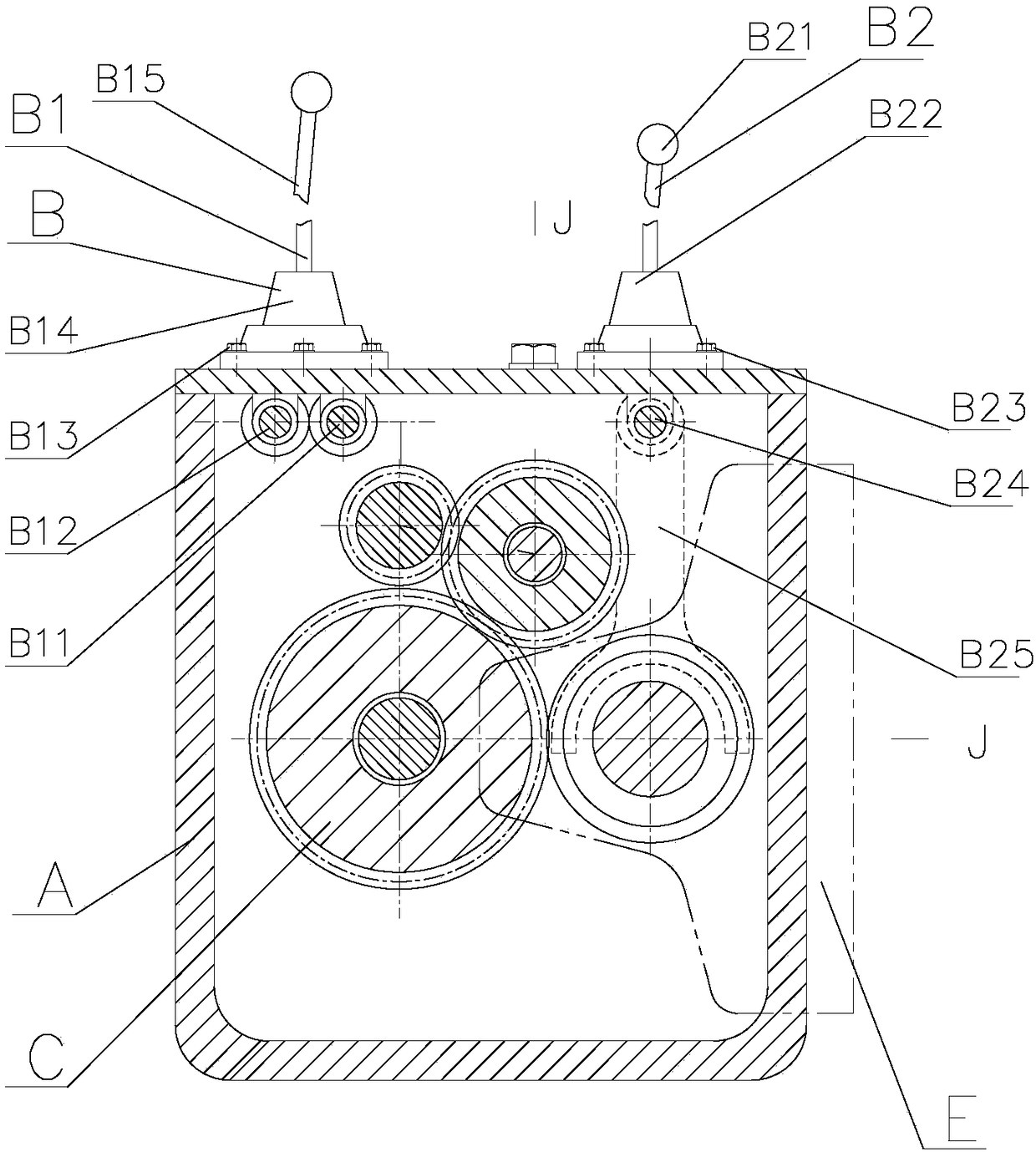

Automatic transmission oil supply unit for automatic start-stop system of engine

InactiveCN101893085ASo as not to damageReduce consumptionGear lubrication/coolingToothed gearingsStart stopAutomatic transmission

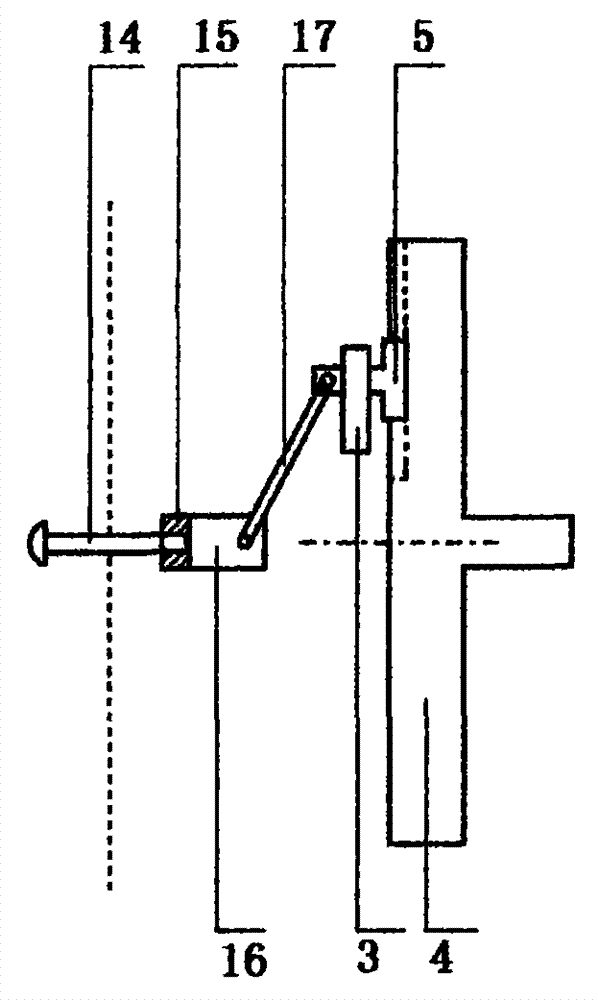

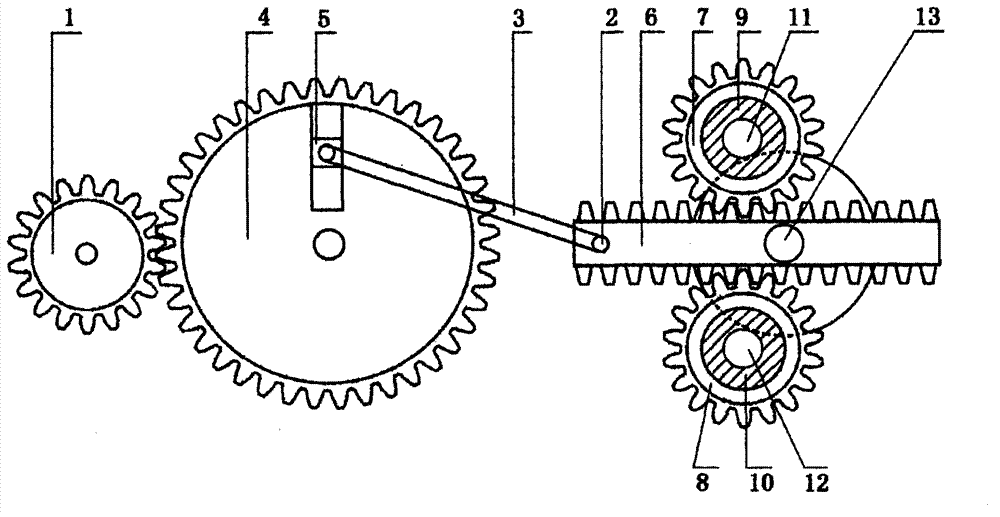

The invention relates to the technical field of automotive transmissions, in particular to an automatic transmission oil supply unit for an automatic start-stop system of an engine. The automatic transmission oil supply unit comprises a transmission input shaft, an inside transition gear, an outside transition gear, an overrunning coupler, a torque converter shell drive sleeve, an oil pump inner gear and a stator sleeve, and is characterized in that: the transmission input shaft is provided with an input shaft gear ring at an axial position close to an oil pump; the input shaft gear ring is meshed with the inside transition gear; the inside transition gear is meshed with the outside transition gear, and the inside transition gear and the outside transition gear are fixed in transition gear mounting holes of the stator sleeve; an inner ring of the overrunning coupler is provided with a gear ring which is meshed with the outside transition gear; an outer ring of the overrunning coupler is connected with the oil pump inner gear; the oil pump inner gear is connected with an outer ring of the other overrunning coupler; and an inner ring of the other overrunning coupler is connected with the torque converter shell drive sleeve. Compared with the prior art, the automatic transmission oil supply unit ensures that lubrication is constantly provided for the transmission no matter the engine is started or shut down when a vehicle moves forwards.

Owner:ZF TRANSMISSIONS SHANGHAI

Control apparatus for vehicle drive-force transmitting apparatus

Owner:TOYOTA JIDOSHA KK

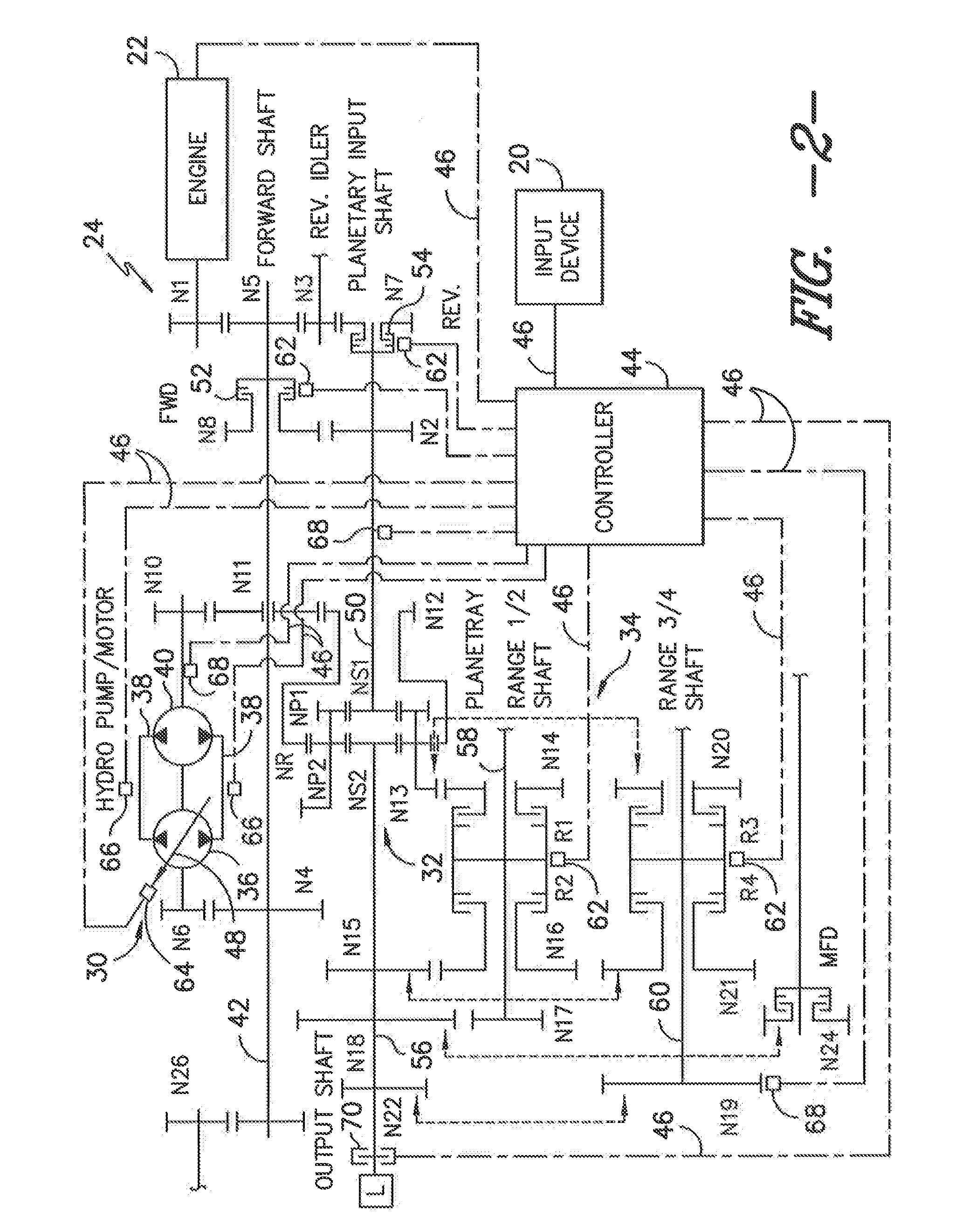

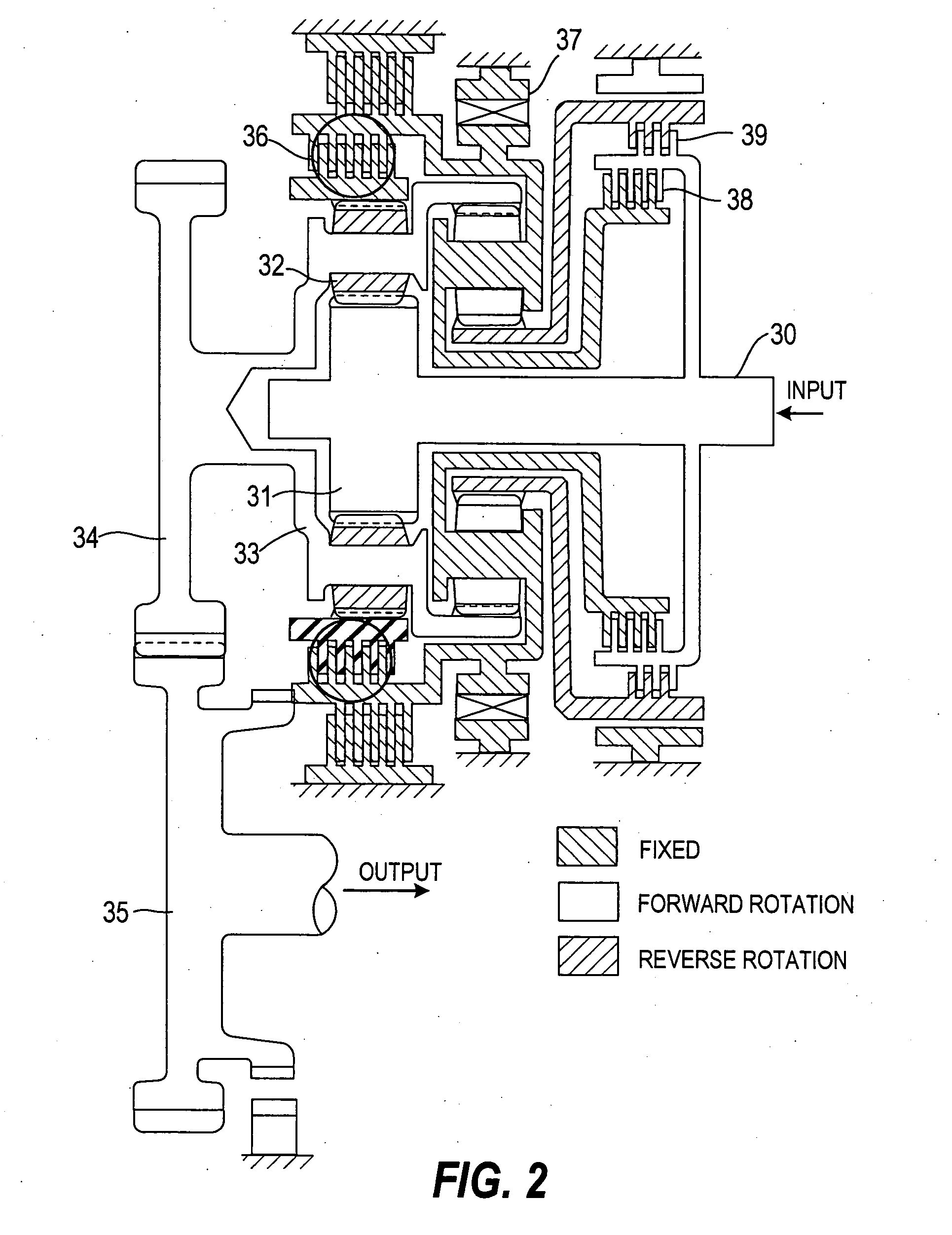

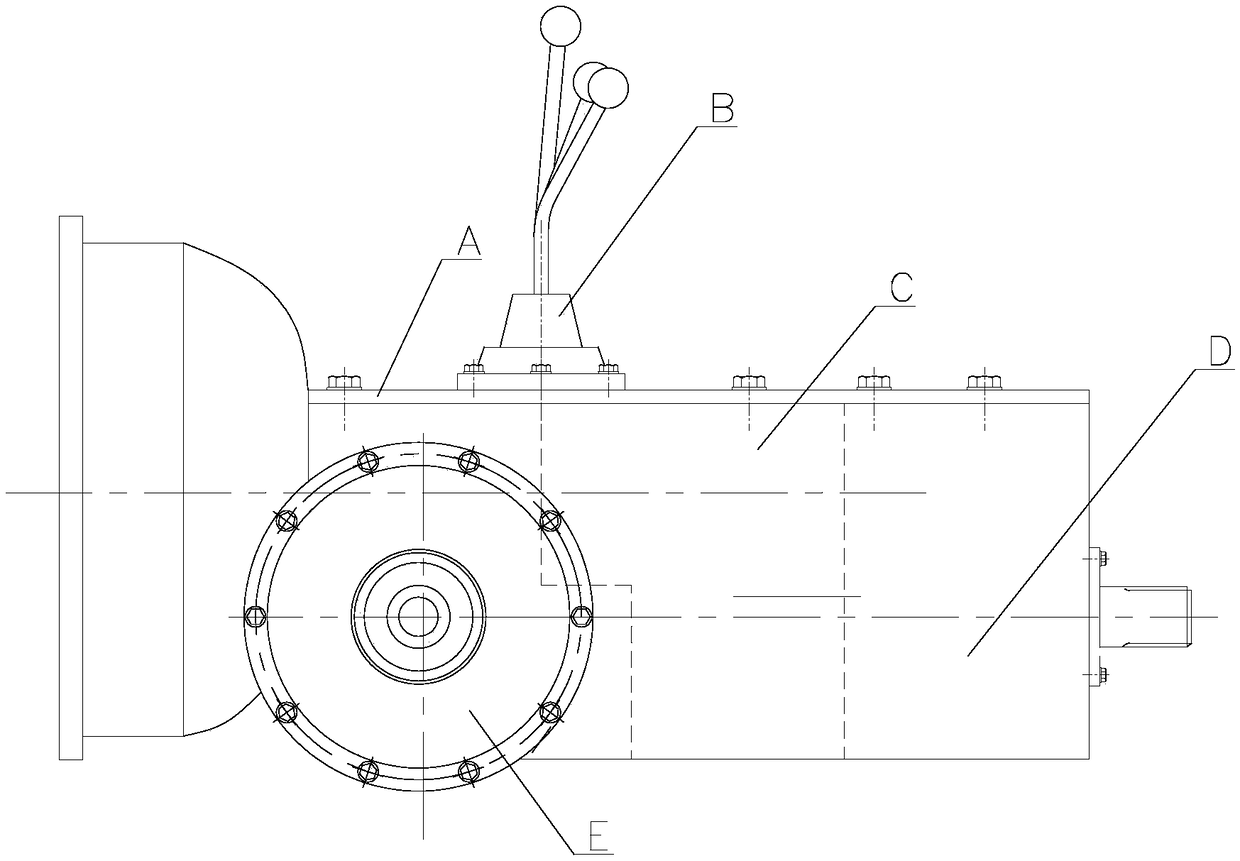

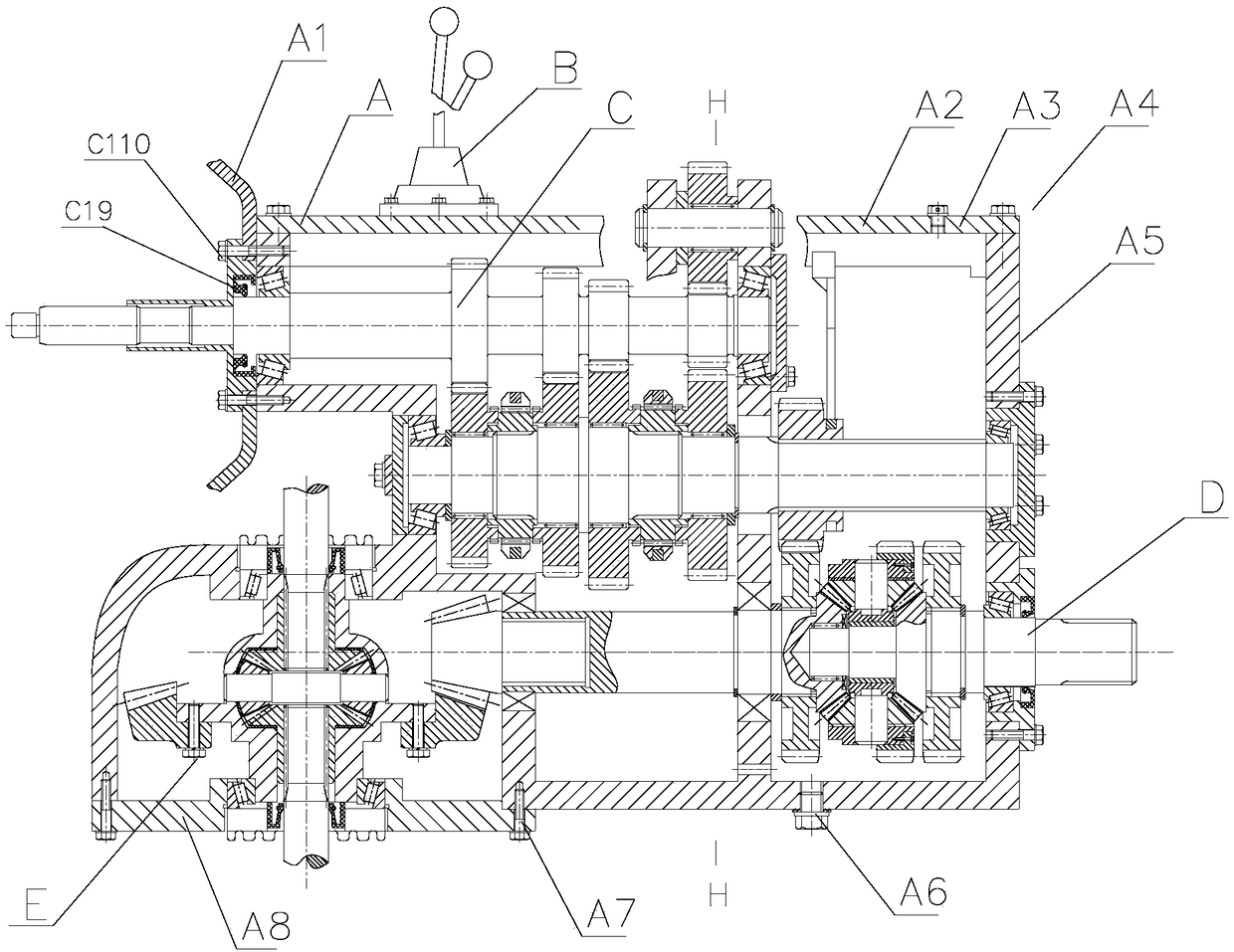

Hydraulic hybrid turbo transmission

InactiveUS20090313984A1Energy lossLess componentsRotary clutchesFluid gearingsMulti-valveEnergy transfer

Improvements in a transmission is provided for transferring power from a power source to a work unit. The pump transfers energy received from the power source into a fluid or gas. The first turbine is fixed to output shaft, and a plurality of additional turbines are fixed on either one-way overrunning clutches or multi-disc clutches and these clutches are fixed to the output shaft and after each turbine is a multi-valves that discharges the fluid or gas. After all of the multi-stage turbines a first planetary gear set connects the transmission to the vehicle or work unit. The second planetary gear set is located between the last turbine and the first planetary gear set. During braking the planetary gear set reverses turning direction of the turbines and convert the turbines into pumps where they will pump low pressure fluid to a high pressure accumulator.

Owner:MUSTAFA REZ

Automatic transmission gear-shifting control method used under working condition of misoperation

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

Differential speed four-drive transmission

PendingCN108468774AImprove driving abilityPrevent slippingGearing controlDifferential gearingsRoad surfaceControl theory

Owner:HUNAN AGRICULTURAL UNIV

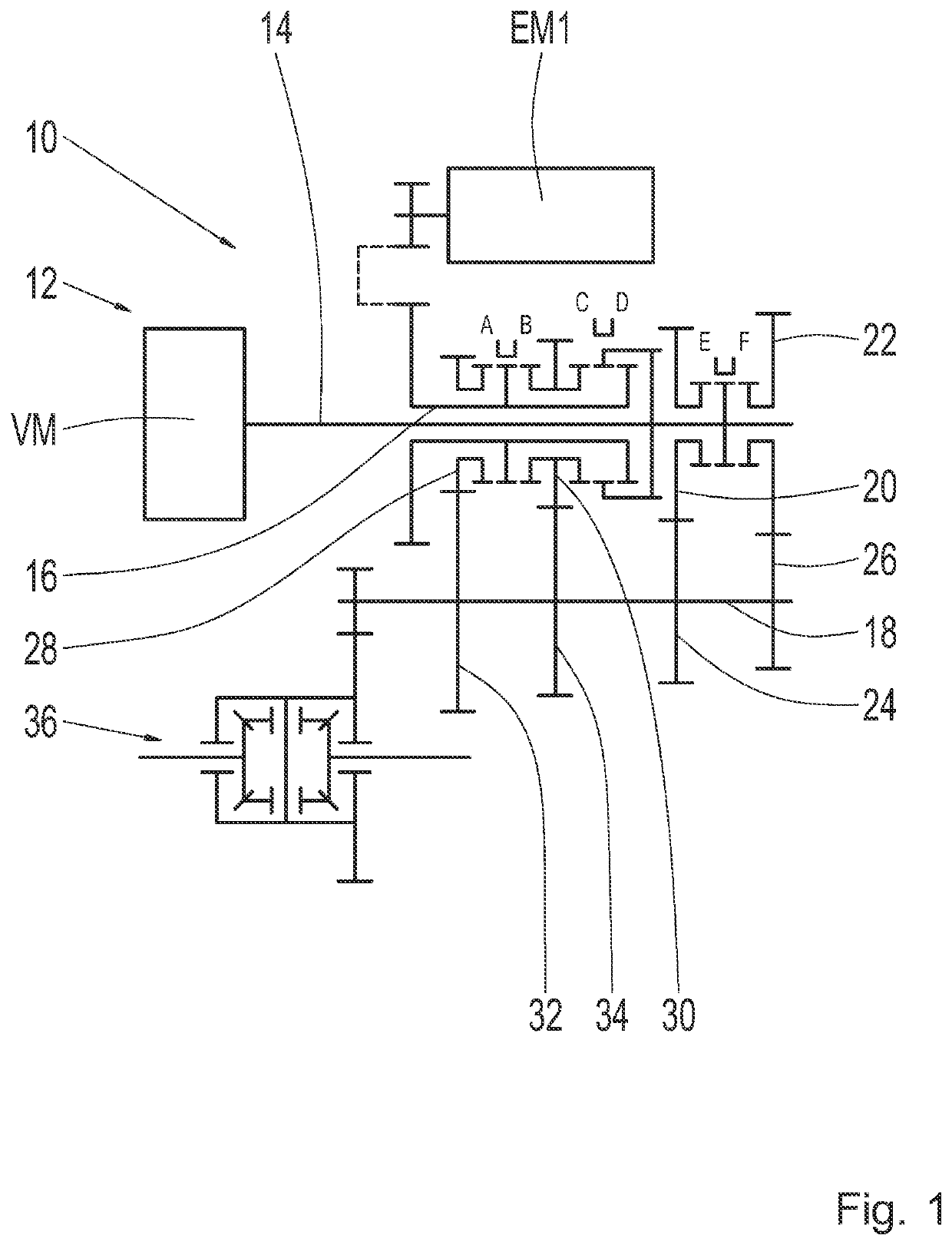

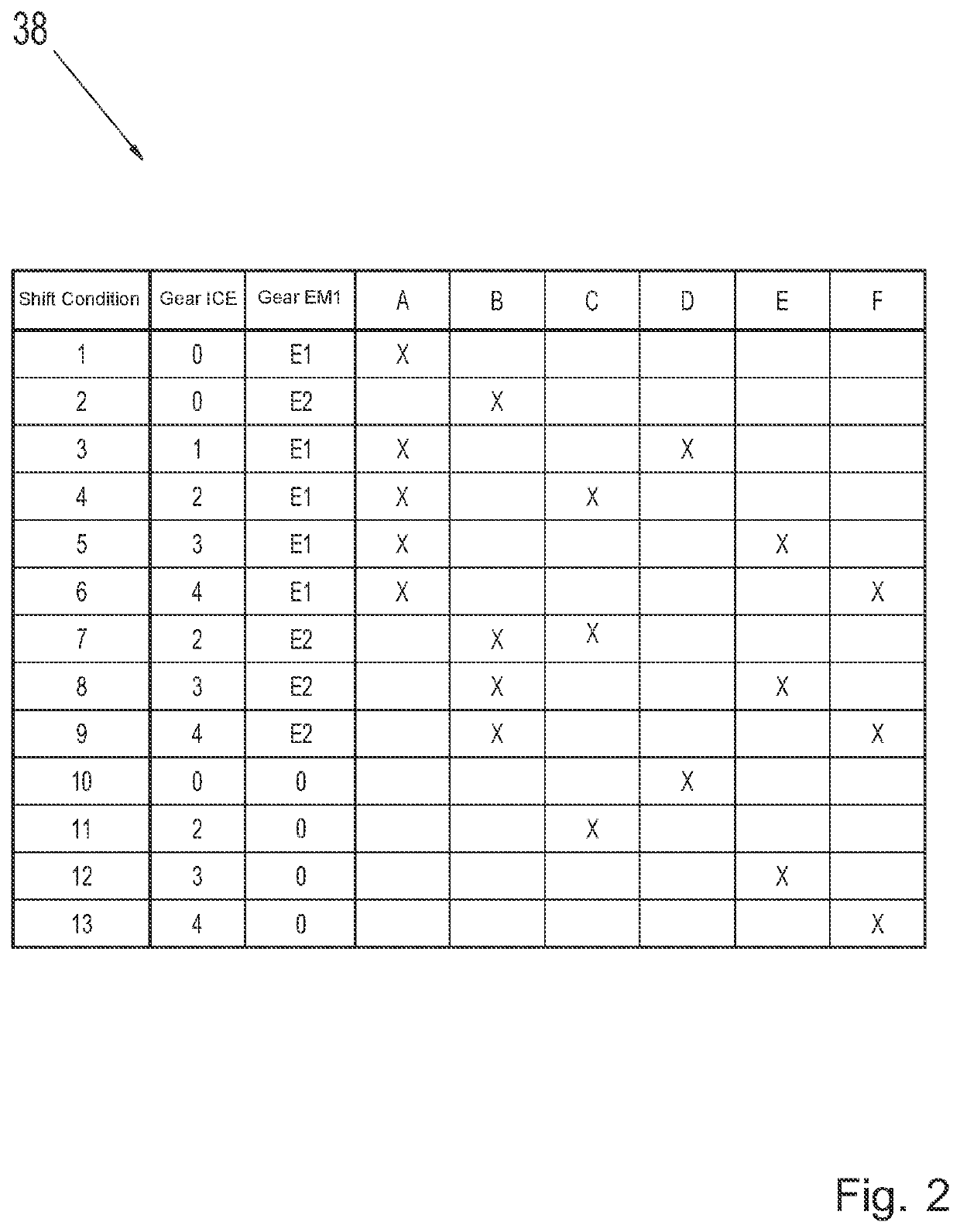

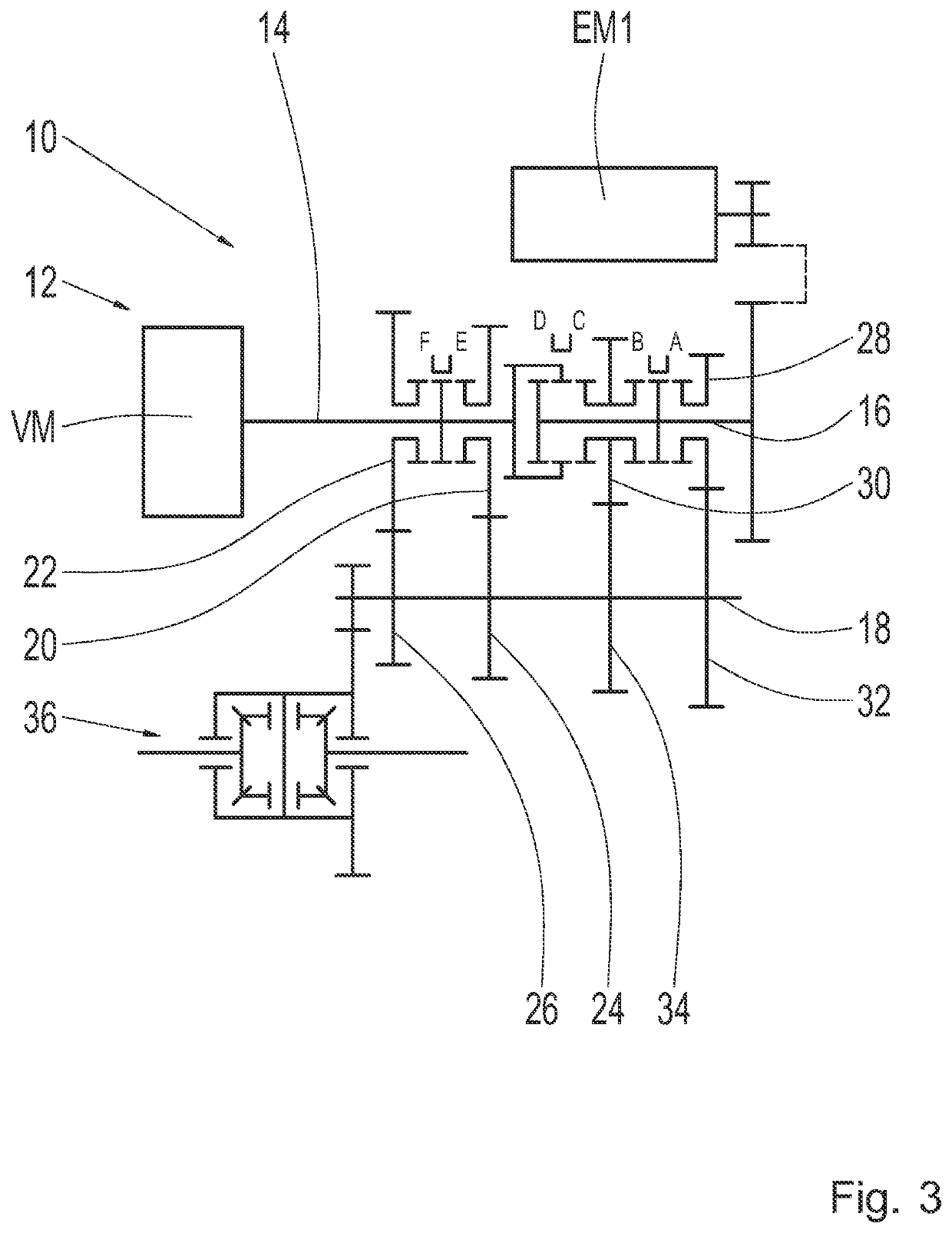

Hybrid Transmission for a Motor Vehicle

PendingUS20220024295A1Improve combinabilityFine stepsHybrid vehiclesGas pressure propulsion mountingPrime moverGear wheel

Owner:ZF FRIEDRICHSHAFEN AG

Transmission, power drive system and vehicle

ActiveCN110657204ASimple structureEasy maintenanceToothed gearingsGearing controlGear wheelControl theory

Owner:BYD CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap