Starting clutch

a clutch and friction plate technology, applied in the field of starting clutches, can solve the problems of power transmission loss, torque converters with less efficiency, seizure and/or wear of friction plates of wet type multi-plate clutches, etc., and achieve the effect of enhancing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

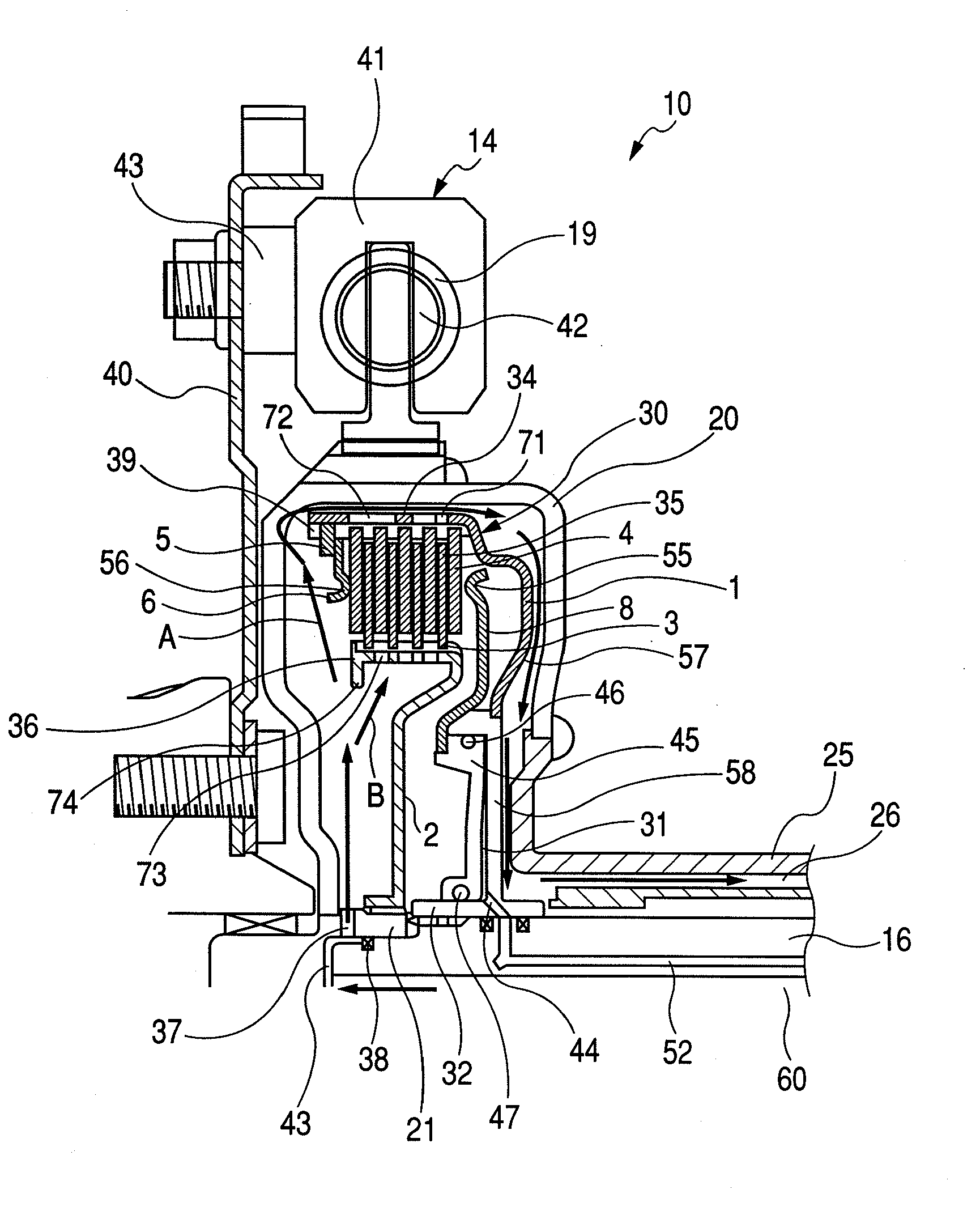

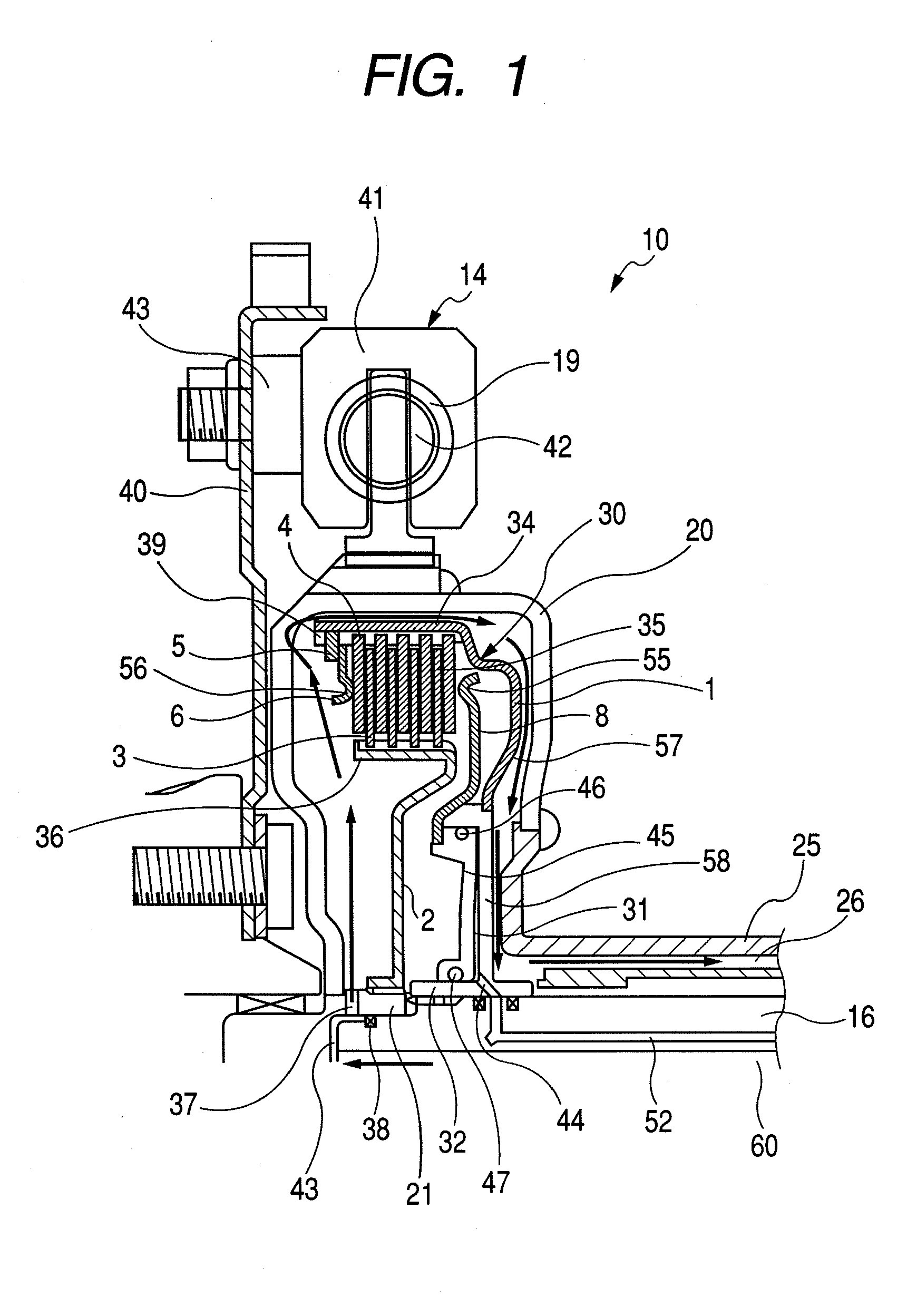

[0026]FIG. 1 is an axial sectional view of a starting clutch according to a first embodiment of the present invention. The starting clutch 10 comprises a clutch housing 20 and a wet type multi-plate clutch 30 housed in the housing. The wet type multi-plate clutch 30 includes a plurality of friction plates 3 and a plurality of separator plates 4 which are housed for axial sliding movements, a clutch drum 1 for accommodating the separator plates 4, a clutch hub 2 disposed at an inner diameter side of the clutch drum 1 to support the friction plates 3 for an axial sliding movement, and a piston 8 for applying a pressing force to the friction plates 3 and the separator plates 4 to tighten or engage the wet type multi-plate clutch 30.

[0027]The substantially annular friction plates 3 as friction engaging elements at an input side and the substantially annular separator plates 4 as friction engaging elements at an output side are alternately arranged in an axial direction. At an axial one end

second embodiment

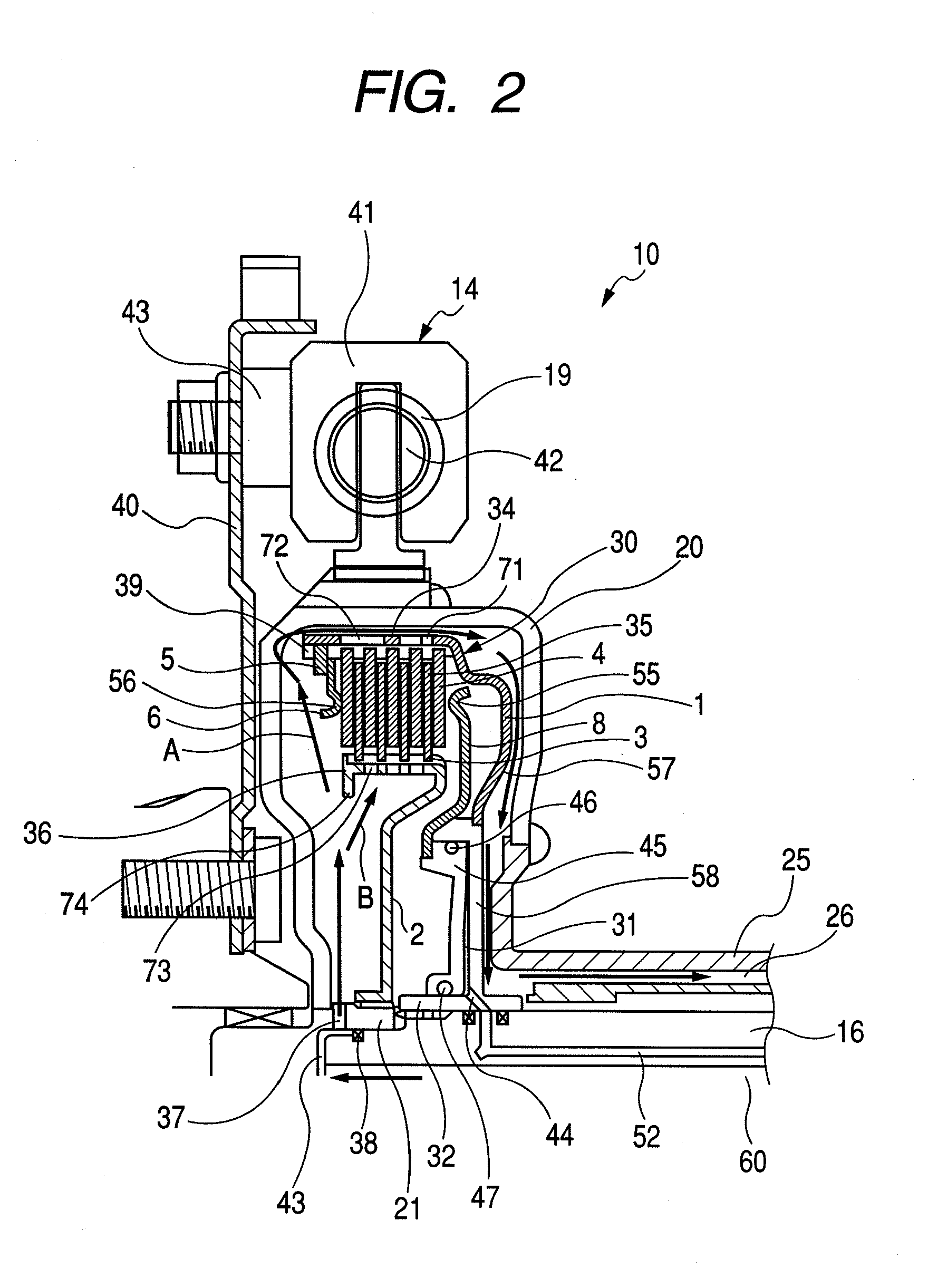

[0047]Next, a second embodiment of the present invention will be explained with reference to FIG. 2. FIG. 2 is an axial sectional view of a starting clutch according to the second embodiment of the present invention. Since a fundamental construction of the starting clutch of the second embodiment is the same as that of the first embodiment, only differences will be described.

[0048]As can be seen from FIG. 2, in the second embodiment, constructions of clutch drum 1 and clutch hub 2 differ from those in the first embodiment. An outer diameter portion or drum portion 34 of a clutch drum 1 is provided with oil ports 71 and 72 extending through the drum portion in a radial direction. The oil ports 71 and 72 extend through a wet type multi-plate clutch 30 from its inner diameter side to its outer diameter side. That is to say, such oil ports are arranged so that the lubricant oil which has lubricated the clutch portion in which the friction engaging elements are engaged with each other flows

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap