Automatic transmission gear-shifting control method used under working condition of misoperation

A technology of automatic transmission and control method, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve problems affecting driving experience, etc., to avoid excessive temperature rise, reduce wear, and reduce comfortable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

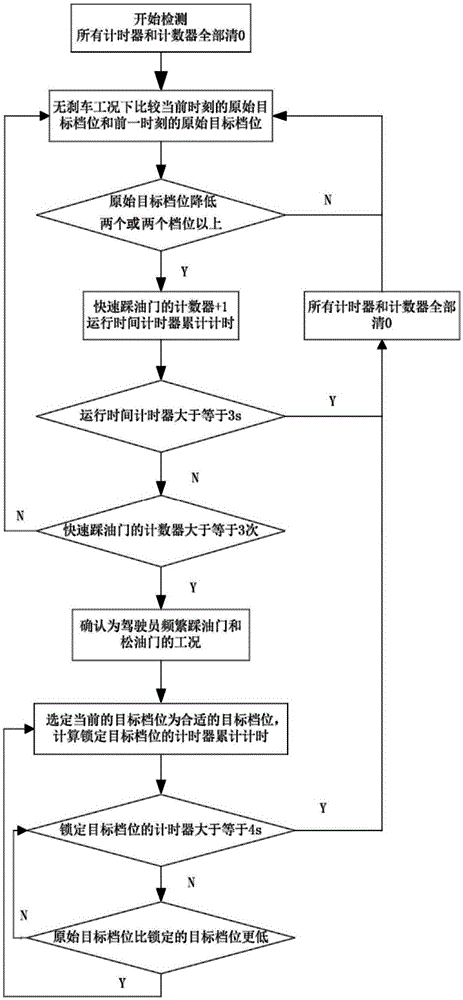

[0019] like figure 1 As shown, taking a car equipped with a 6-speed automatic transmission as an example, this embodiment includes the following steps:

[0020] Step 1. Set the running time timer and clear the quick accelerator pedal counter.

[0021] Step 2. Under the no-braking condition, compare the target gear at the current moment with the original target gear at the previous moment to determine whether a misoperation condition occurs.

[0022] The target gear at the current moment and the original target gear at the previous moment are obtained through the shift pattern diagram.

[0023] The misoperation condition refers to: within the judgment time limit, it is detected that the number of times the driver steps on the accelerator for multiple times is greater than or equal to the preset threshold of the number of times of stepping on the accelerator, and the gear difference before and after each step on the accelerator is greater than or equal to The preset gear differen

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap