Three clutches

A technology of three clutches and clutches, which is applied in the field of three clutches, can solve the problems of increasing clutch weight, space and cost, increasing clutch weight, space and cost, increasing power transmission components, etc., achieving volume reduction, strength requirements reduction, Fast upshift and downshift effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described below with reference to the accompanying drawings.

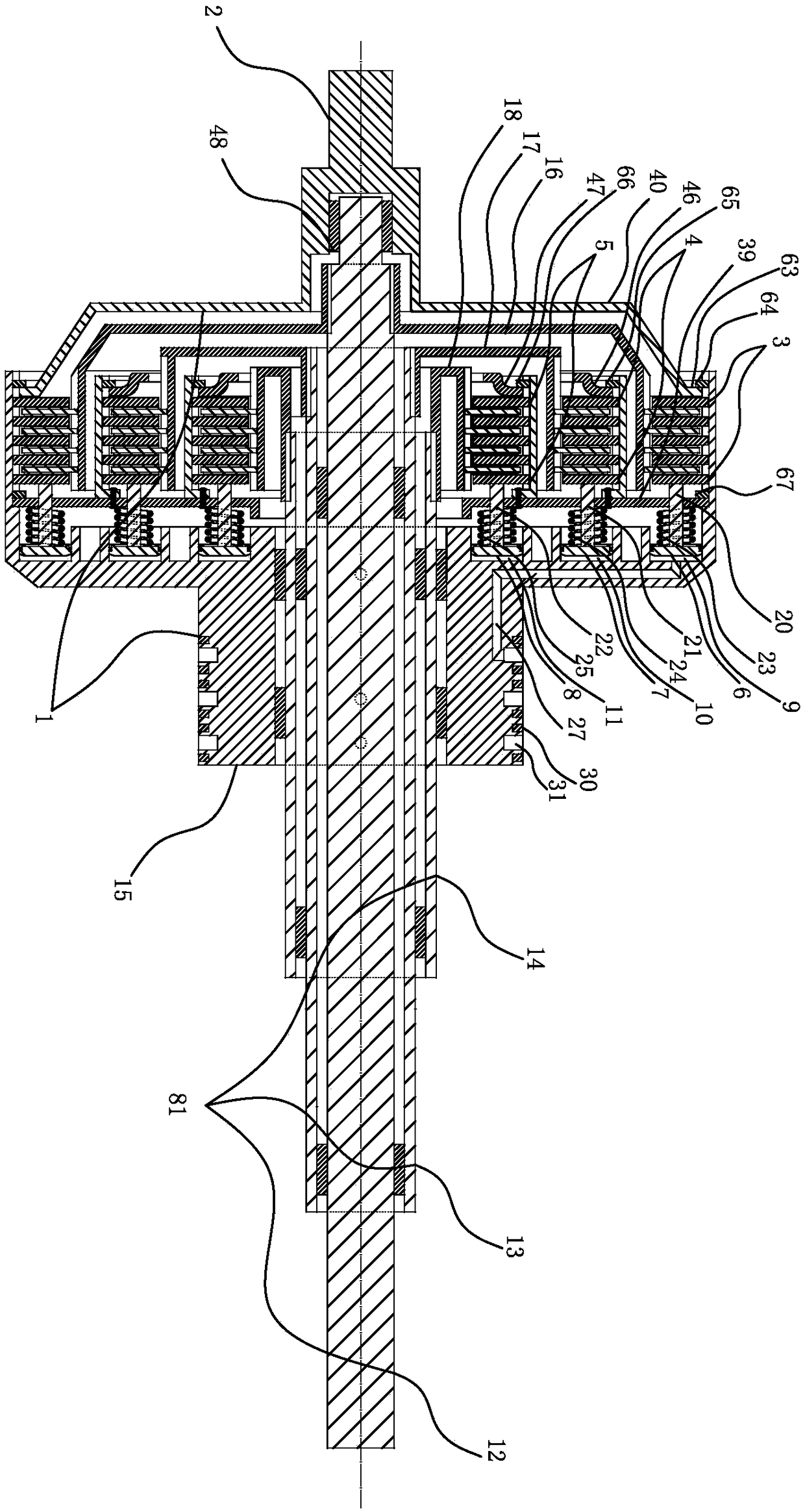

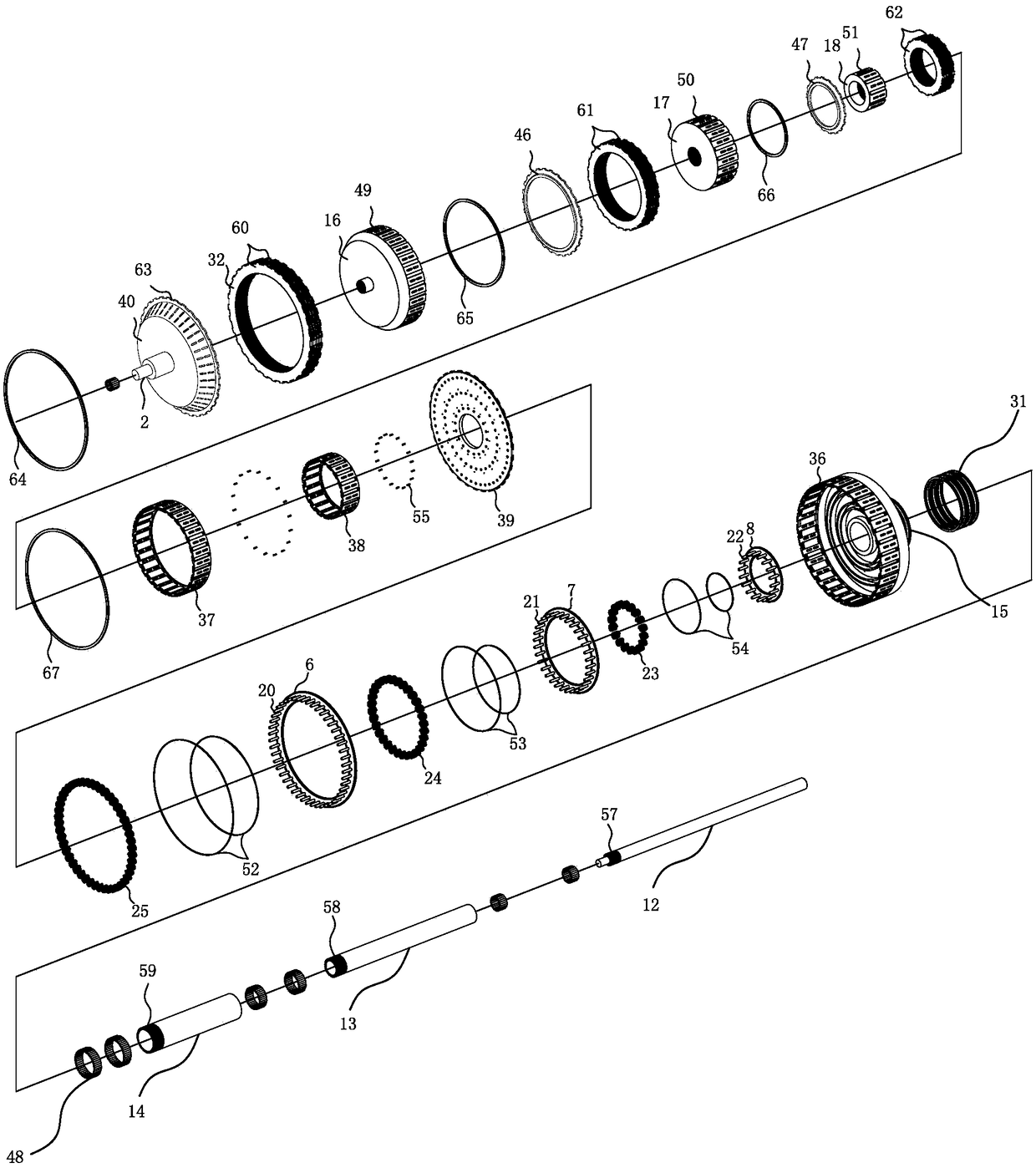

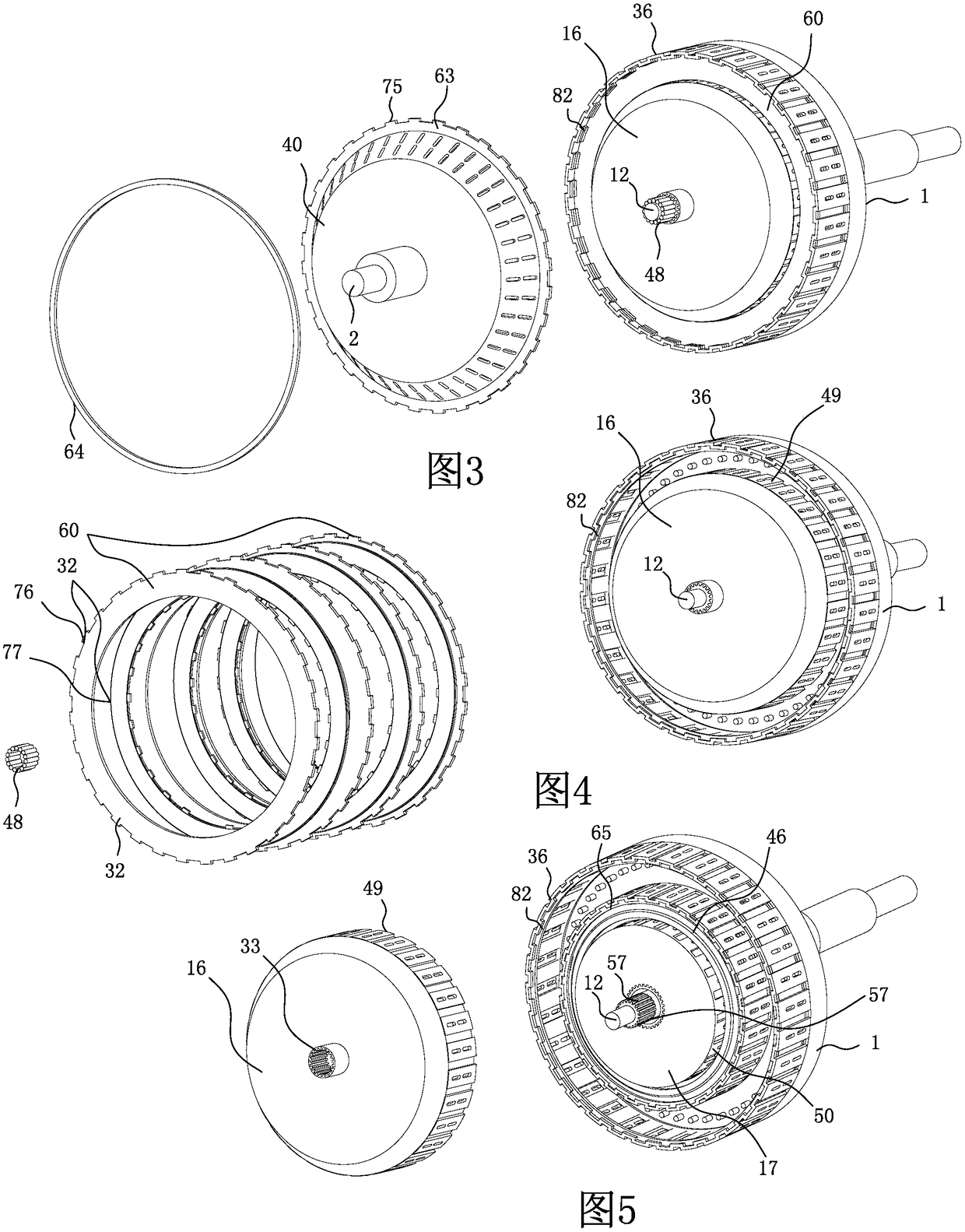

[0030] Such as Figure 1-18 Shown, a kind of three clutches, possess: clutch input shaft (2), clutch output shaft (81) and clutch plate (32), described clutch (1) has three clutches to constitute, namely the first clutch (3), the second Two clutches (4), the 3rd clutch (5), have the first clutch axle (12), the second clutch axle (13), the 3rd clutch axle (14) with the axle corresponding to above-mentioned three clutches, the 3rd clutch axle The shaft (14) and the second clutch shaft (13) are hollow shafts, the second clutch shaft (13) is sleeved outside the first clutch shaft (12), and the third clutch shaft (14) is sleeved on the second clutch shaft In addition to (12), bearings are arranged between the above three shafts, and the center of the disc-shaped clutch drive plate (40) is coaxially connected with the clutch input shaft (2), and the outer disc of

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap