Swinging and obstacle crossing mechanism of high-voltage line walking robot

A technology of walking robots and high-voltage lines, which is applied in the field of line inspection robots, can solve problems such as increased instability and power consumption, poor stress conditions, and large overall weight, and achieves the effects of simple and reliable structure, light weight, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

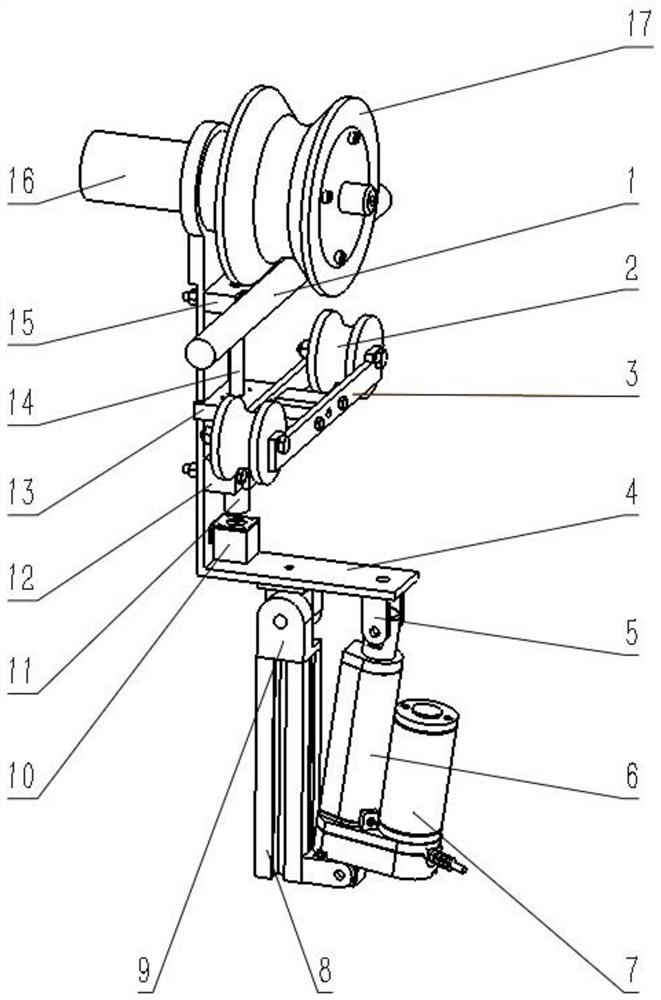

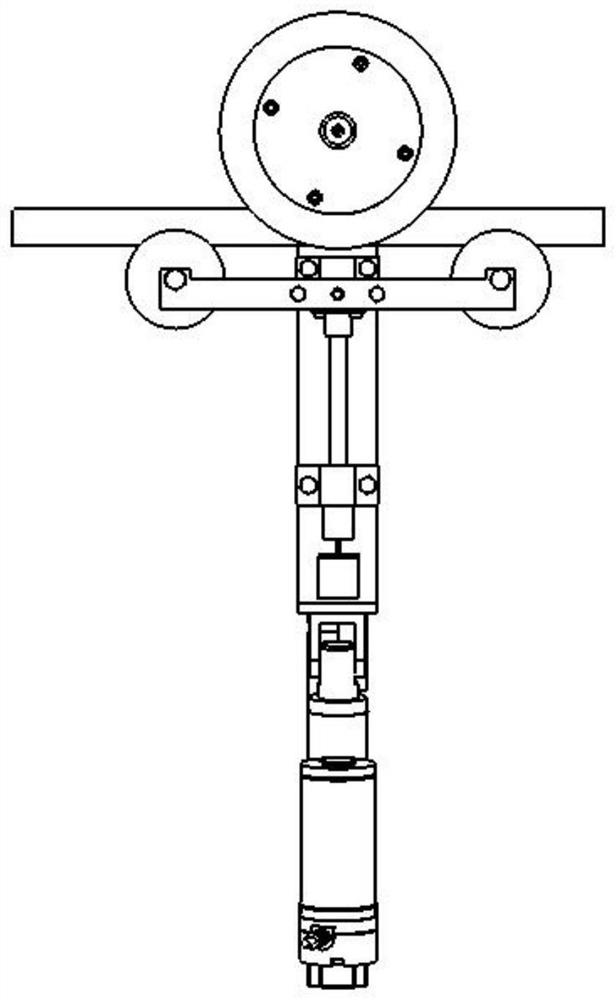

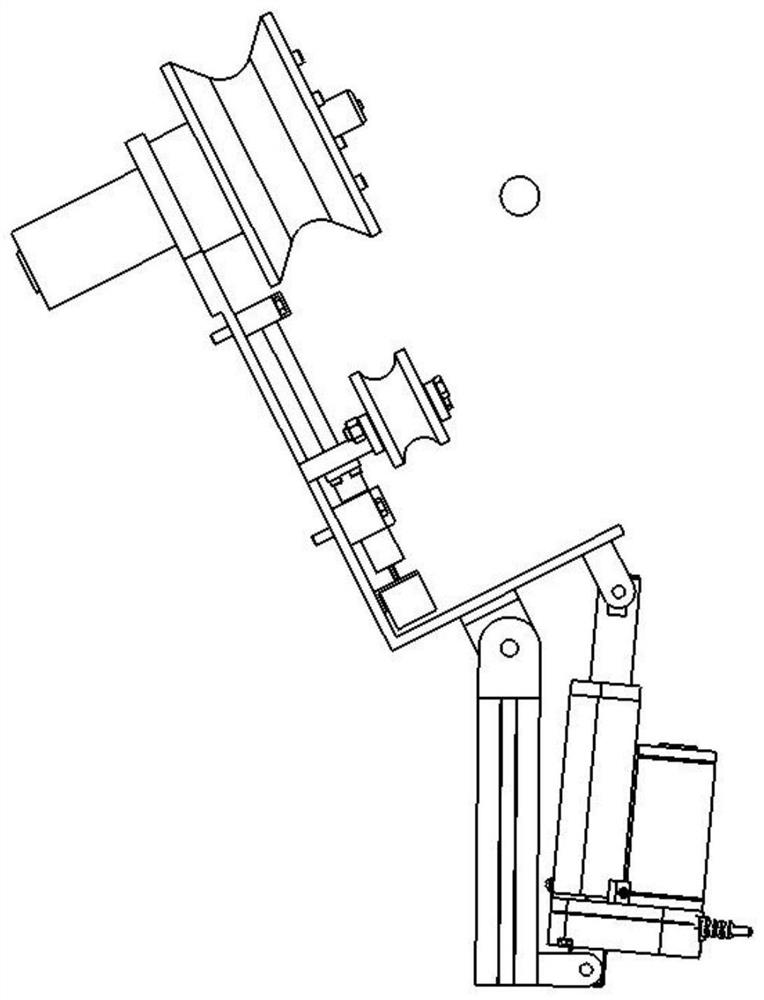

[0019] Example 1: as Figure 1-4 As shown, a high-voltage line walking robot swings over obstacles, including a walking wheel 17, a support plate 4 and a support frame 8, the walking wheel 17 is connected to the in-wheel motor 16, and the in-wheel motor 16 is installed in the vertical direction of the L-shaped support plate 4. On the upper end of the segment, an electric locking mechanism is installed on the support plate 4 below the traveling wheel 17, and the electric locking mechanism can lock the high-voltage line 1 to the traveling wheel 17, and the lower side of the horizontal section of the L-shaped support plate 4 is hinged to the support frame On the upper end of 8, one side of the lower end of the support frame 8 is hinged to one end of the electric push rod, and the other end of the electric push rod is hinged to the lower side of the end of the horizontal section of the L-shaped support plate 4.

[0020] Preferably, the above-mentioned electric locking mechanism inclu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap