Two-roll tandem pipe mill and roll framework locking device thereof

A technology of locking device and roll mill, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems that the rolling balance of the roll stand cannot be guaranteed, and achieve the goal of overcoming the problem of rolling balance, The effect of flexible layout and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

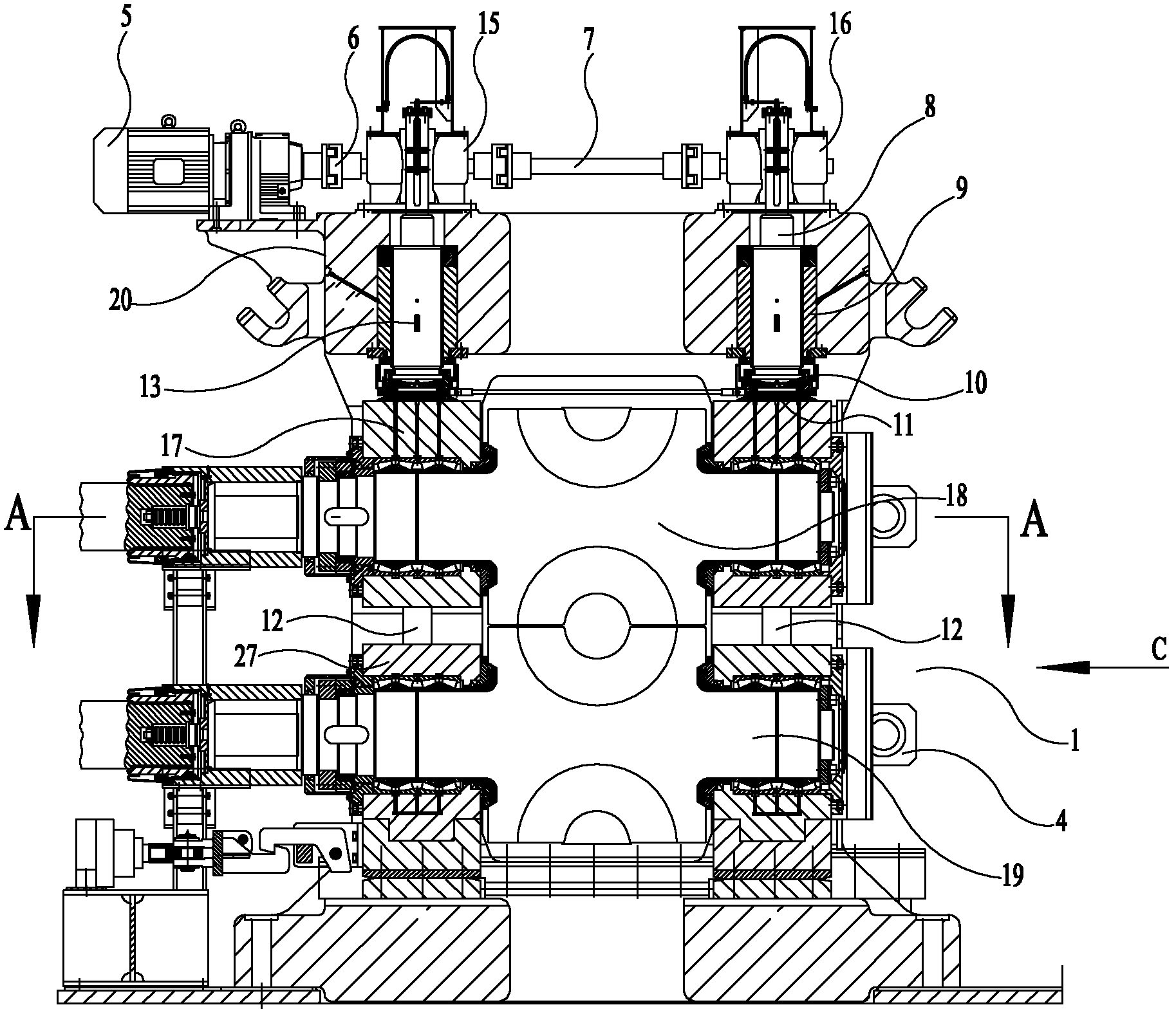

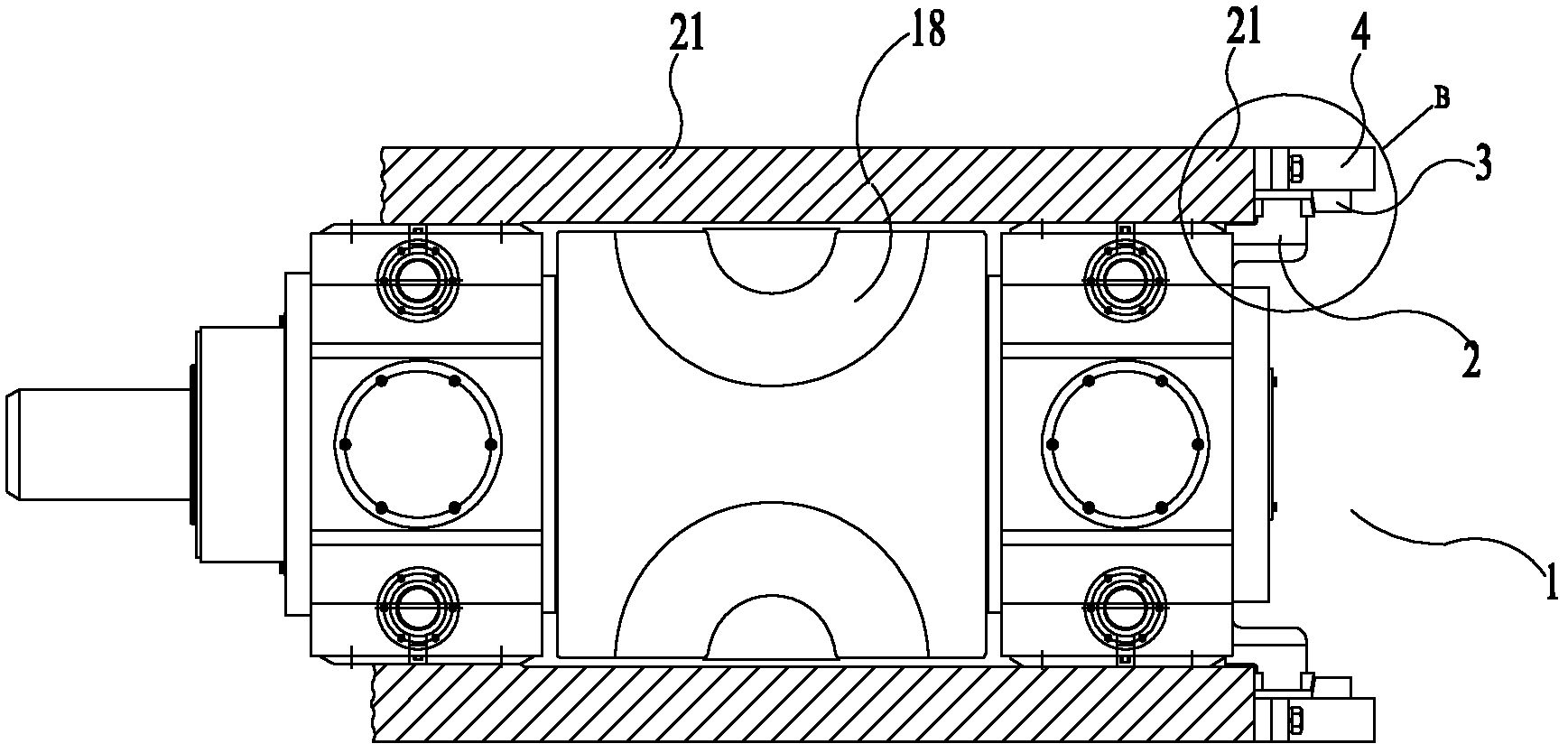

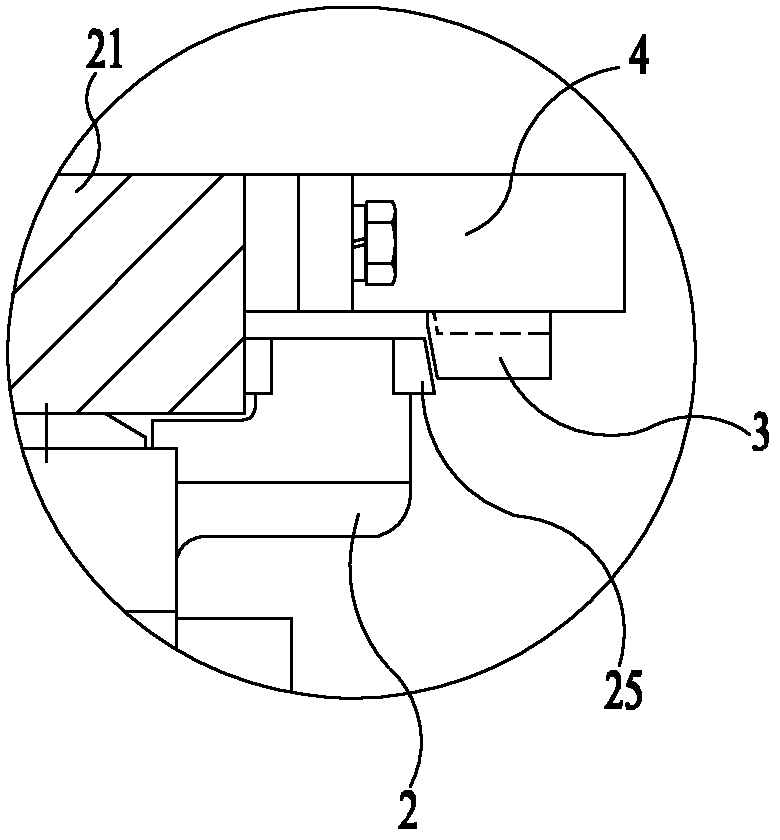

[0017] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

[0018] The roll stand locking device of the embodiment of the present invention is used in a two-roll continuous pipe rolling mill. The two-roll continuous pipe rolling mill of the embodiment of the present invention has the rolling stand locking device of the embodiment of the present invention.

[0019] The roll stand locking device of the embodiment of the present invention will be described in detail below.

[0020] The working principle of the roll stand locking device in the embodiment of the present invention is to use a vertical pressing pressing device an

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap