Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Carbonization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbonization is the conversion of organic matters like plants and dead animal remains into carbon through destructive distillation.

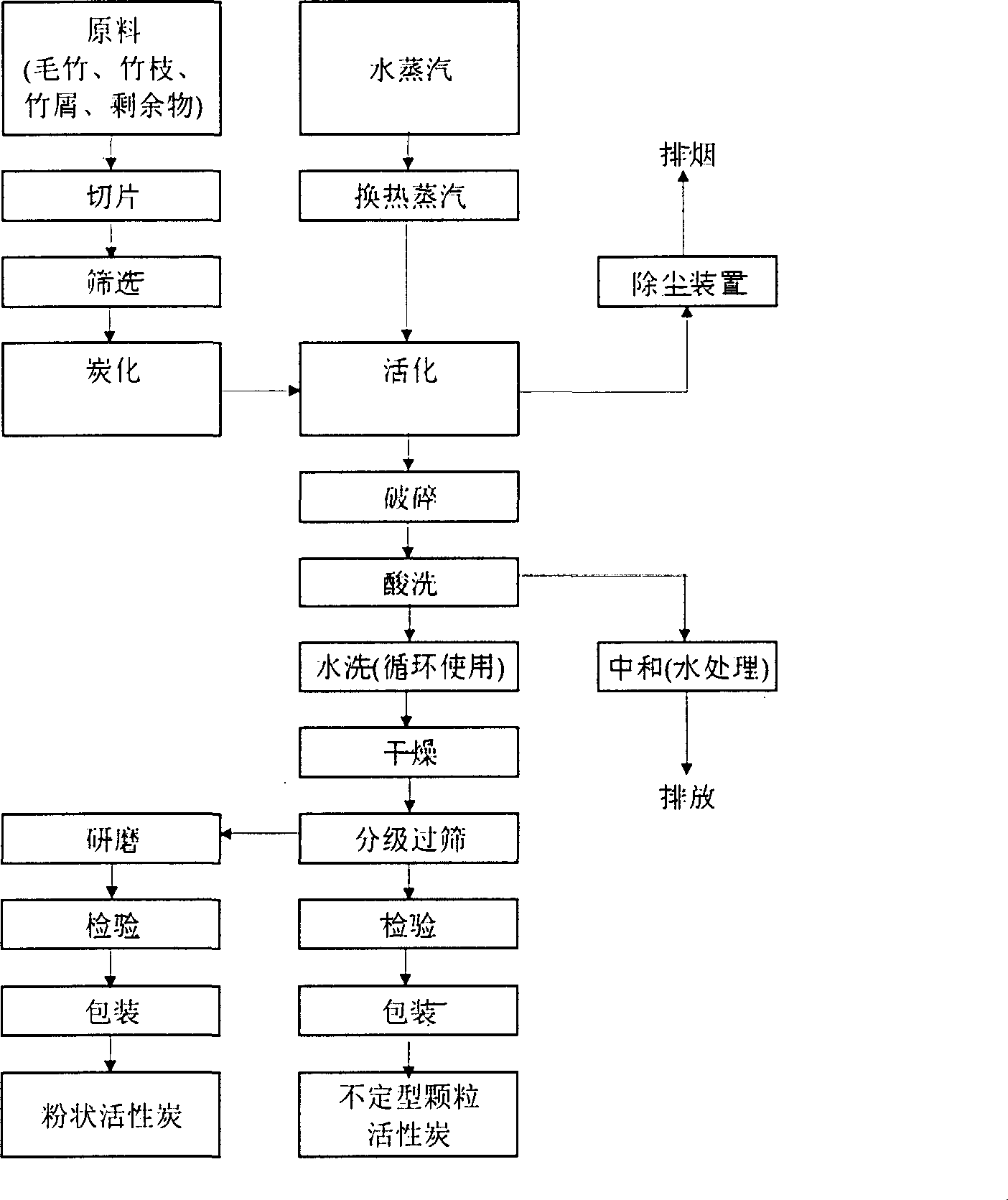

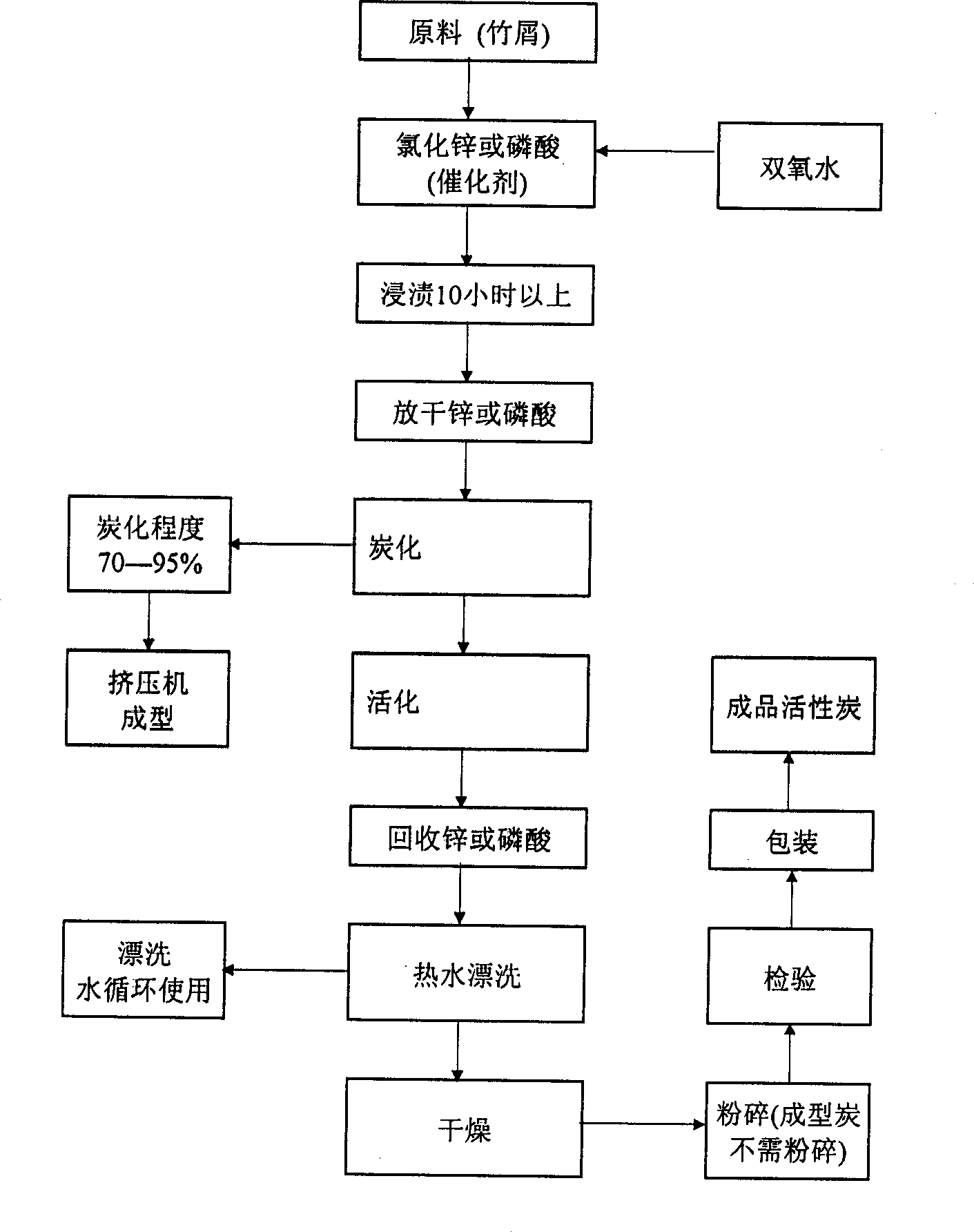

Method for preparing activated char from bamboo material

InactiveCN1333180AImproved decolorizationMesopore developedCarbon compoundsDistillationPhosphoric acid

Owner:尤匡银

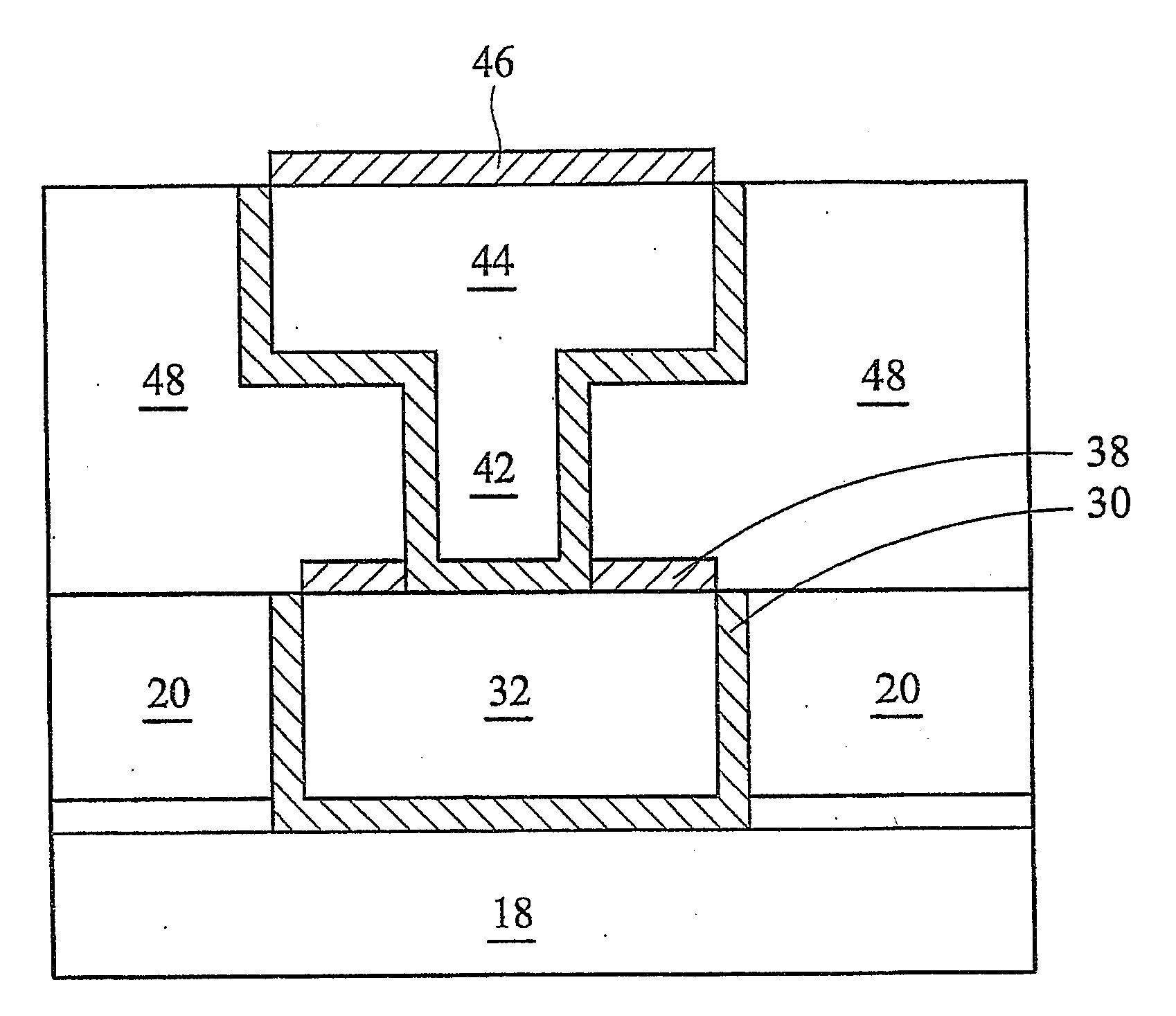

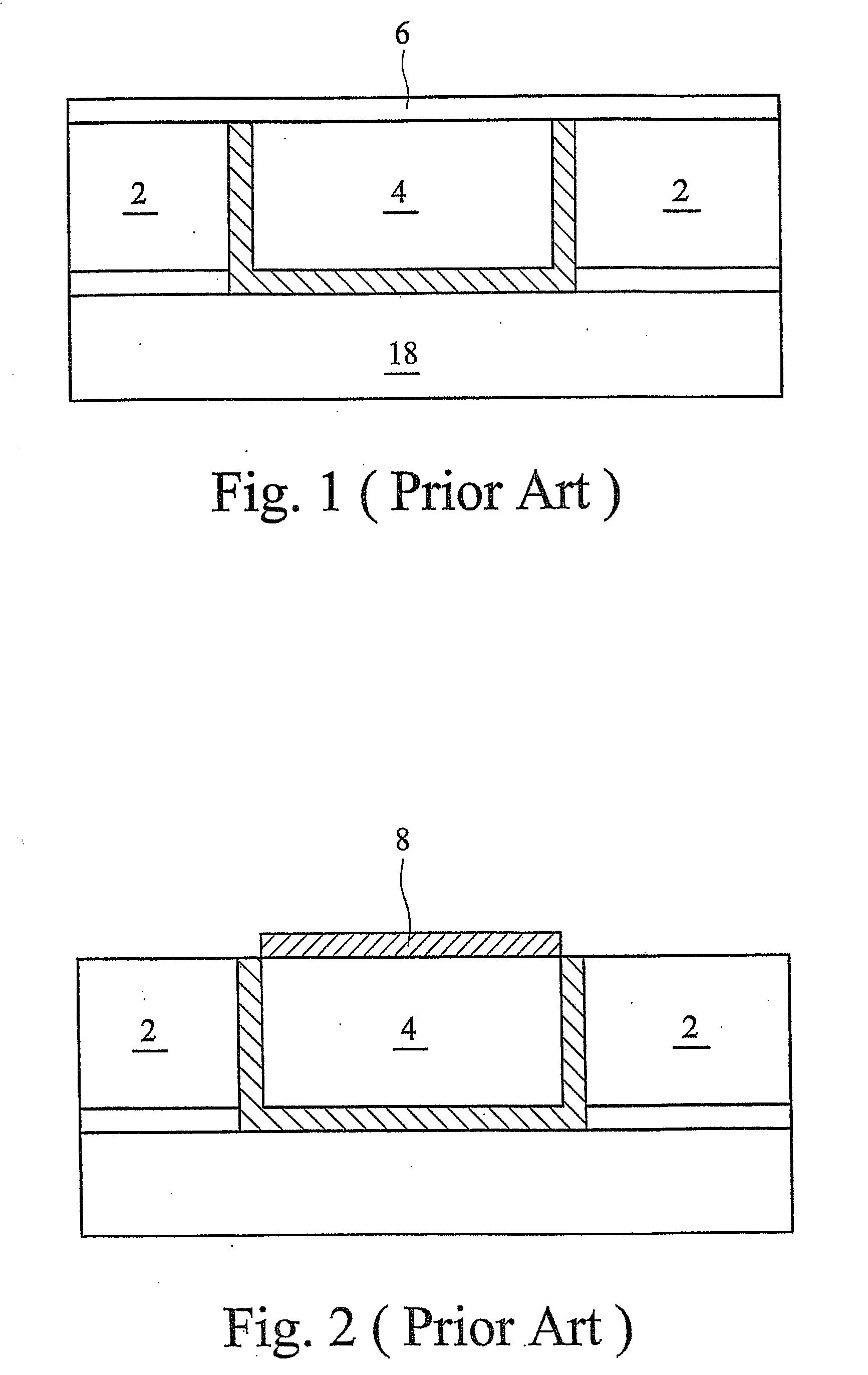

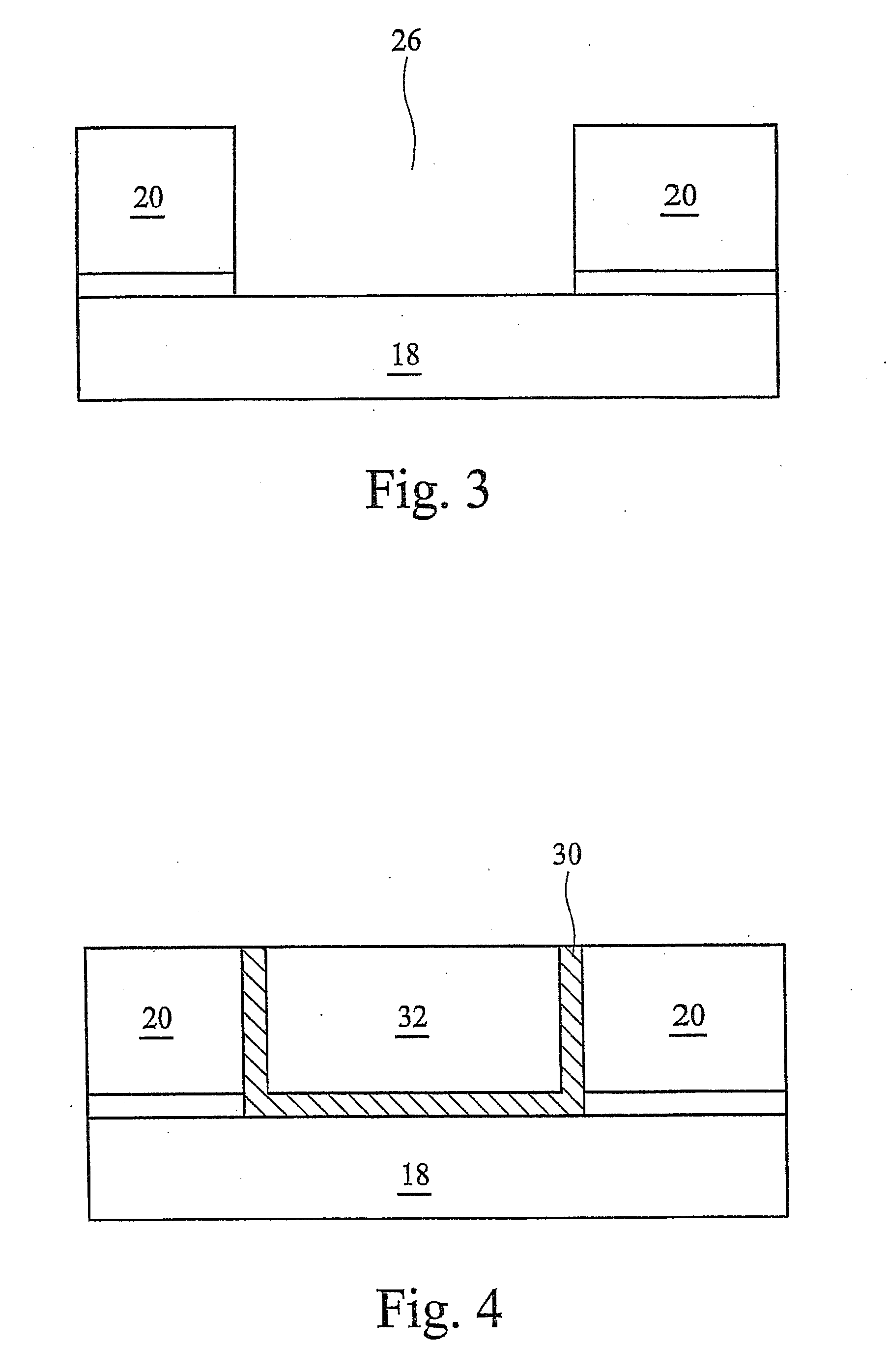

Carbonization of metal caps

ActiveUS20080251928A1Semiconductor/solid-state device detailsSolid-state devicesIntegrated circuitCarbonization

Owner:TAIWAN SEMICON MFG CO LTD

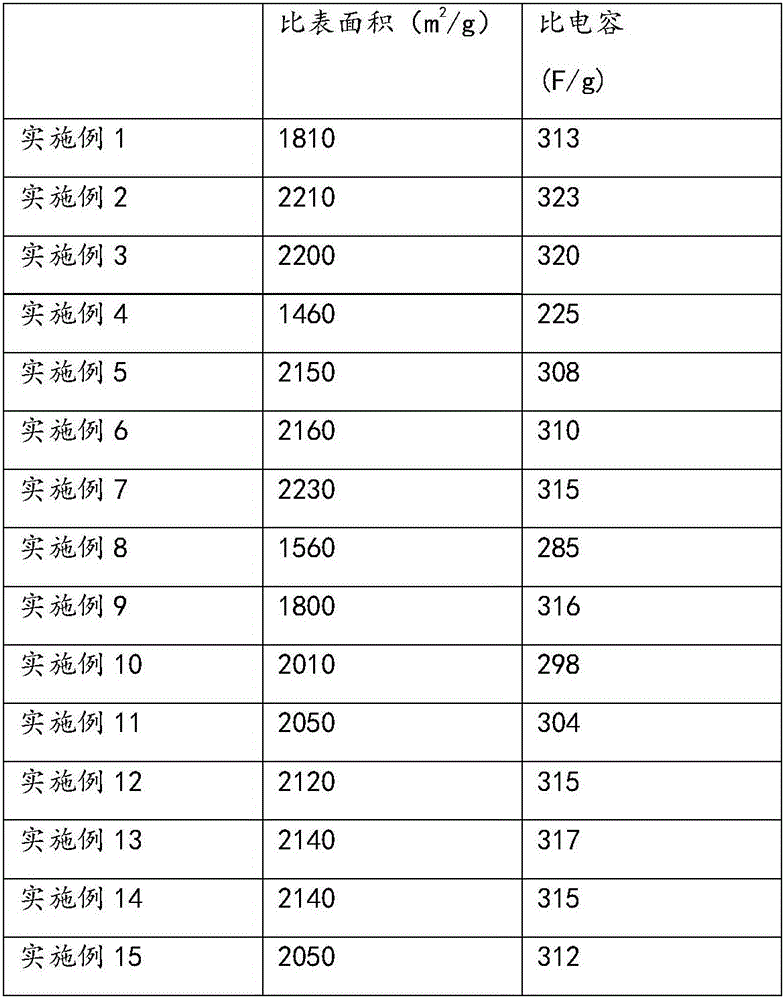

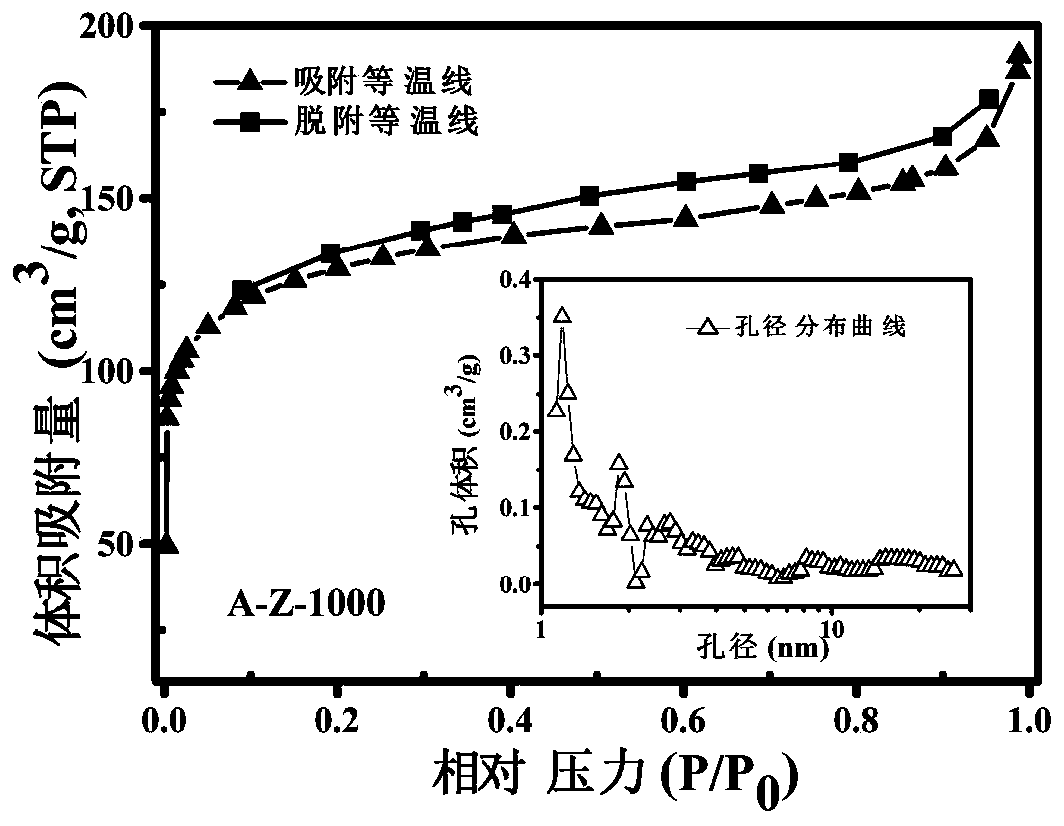

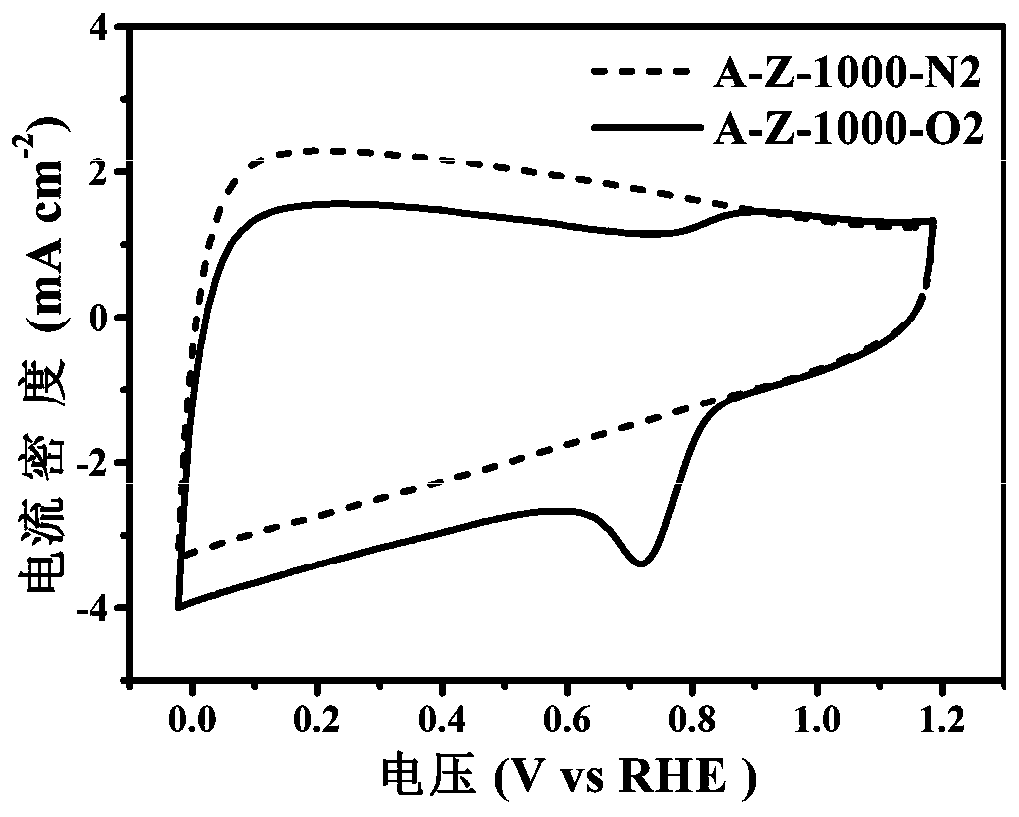

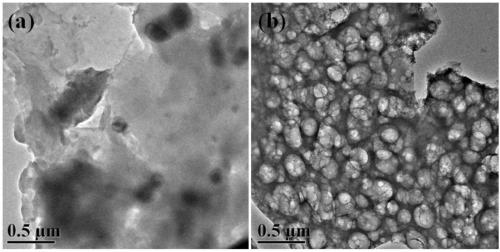

Method for preparing hetero-atom doped porous carbon material through carbonation of biomass under assistance of molten salt

The invention provides a method for preparing a hetero-atom doped porous carbon material through carbonation of biomass under the assistance of molten salt. The method comprises the following steps: uniformly mixing biomass powder, the molten salt and a hetero-atom doped compound to obtain a product A, wherein the molten salt contains LiCl and KCl, the mass of LiCl accounts for 59 percent of that of the molten salt, and the mass of KCl accounts for 59 percent of that of the molten salt; putting the product A in a pipe furnace; carrying out high-temperature calcination; cleaning with distilled water to remove the molten salt and obtain the final product, namely the hetero-atom doped porous carbon material. The method has the advantages that the biomass is taken as a raw material, and the molten salt containing hetero-atoms is taken as a carbonization medium, so that the hetero-atoms can be introduced into the skeleton of the carbon material during the pyrolysis and carbonization process of the biomass synchronously and controllably, and the hetero-atom in-situ doped porous carbon material is obtained finally. Compared with the conventional doping method, the method provided by the invention have the advantages that the steps are simple; the cost is low; the operation is easy; the reactant purity is high; the application prospect is relatively good.

Owner:HARBIN ENG UNIV

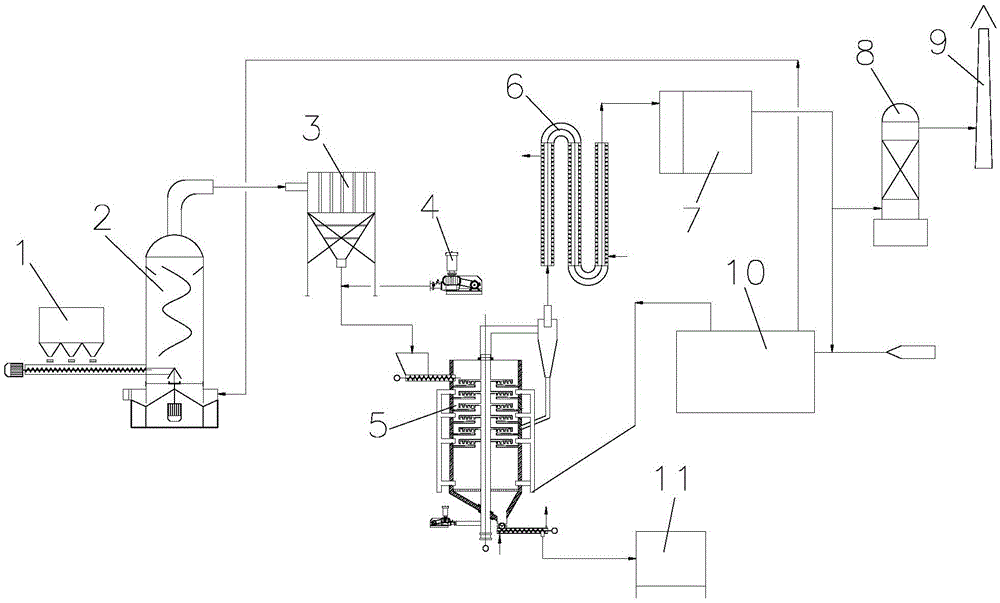

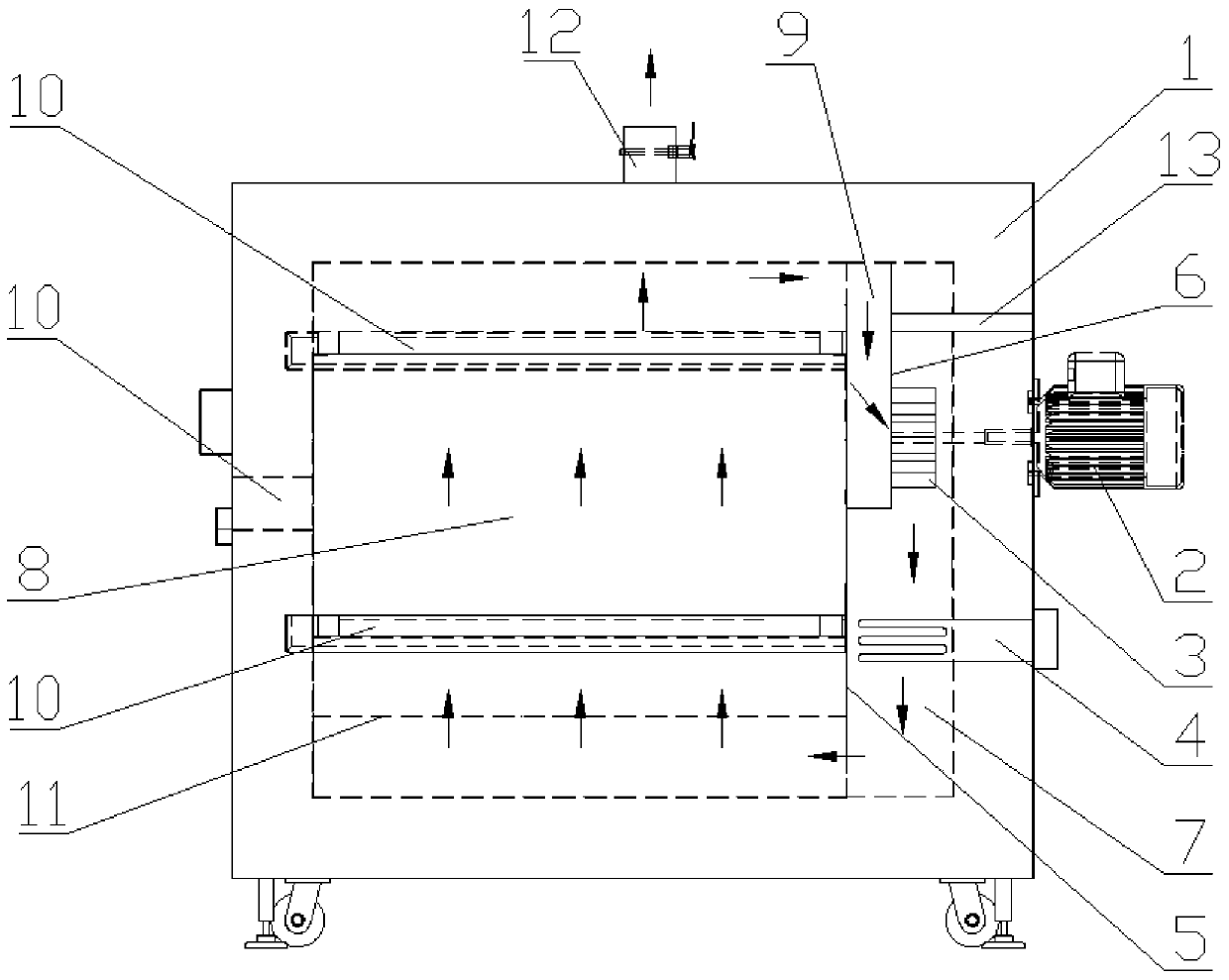

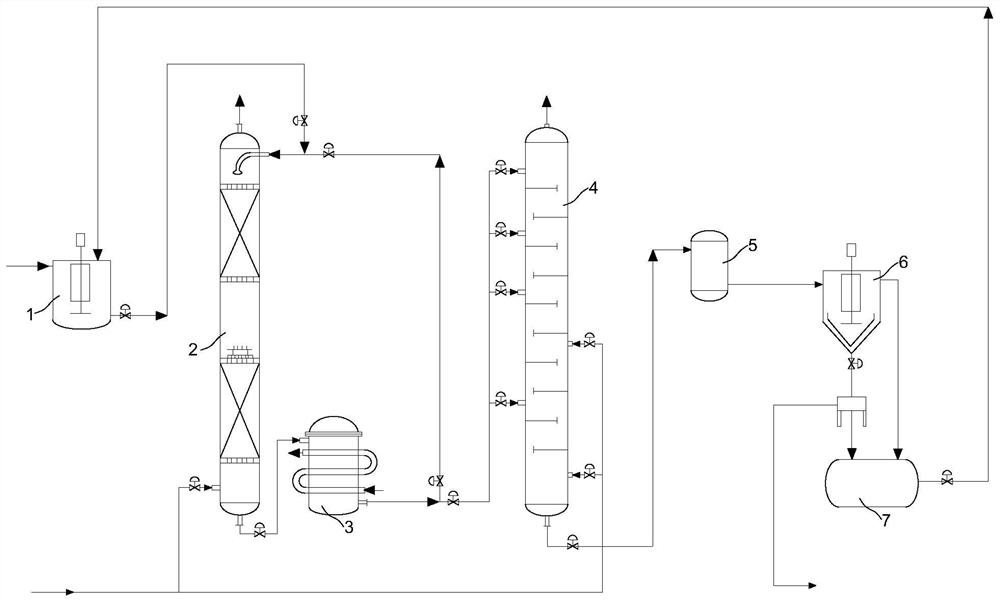

System for urban sludge flue gas drying middle-temperature pyrolysis carbonization

InactiveCN105602586AAvoid cokingAvoid blockingSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesEnergy gradientSludge

Owner:HUBEI JIADE TECH

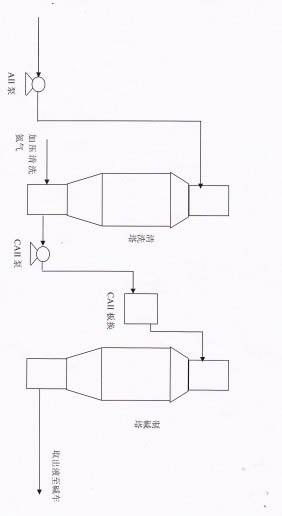

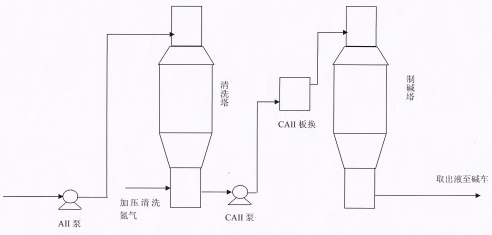

Carbonization cleaning process of carbonizer for producing heavy soda ash

InactiveCN102432041AImprove the degree of carbonization conversionRaise the temperature of IICarbonate preparationCooling towerCarbonization

Owner:SICHUAN HEBANG

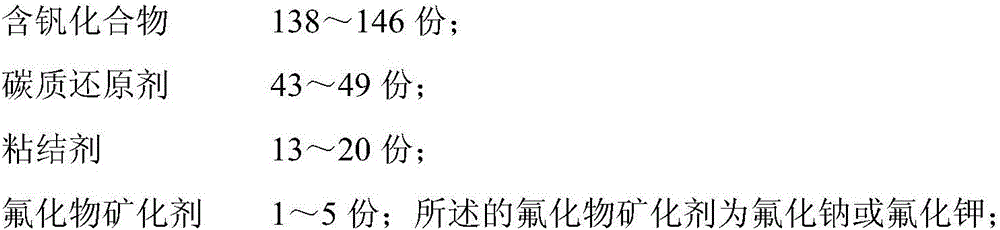

Preparation process of vanadium-nitrogen alloy

The invention discloses a preparation process of a vanadium-nitrogen alloy. The preparation process comprises the steps that a vanadium-containing compound is subjected to mechanical activation treatment at first, a reaction promoter, graphene and a binder are added to obtain qualified mixed materials, the mixed materials are subjected to aging treatment and fed into a calcining kiln to be calcined, a drying stage, a carbonization stage, a nitridation stage and a cooling stage are sequentially carried out, a product is discharged from the kiln, and the vanadium-nitrogen alloy finished productwith the vanadium content larger than or equal to 77.0% is obtained. According to the preparation process, quality is good, product quality is stable, the production process is stable, and the production cost is low.

Owner:涂绪洋

Preparation method of polyacrylonitrile-based hollow carbon fibers

InactiveCN109576824AMake up for the vacancyEfficient use ofWet spinning methodsConjugated synthetic polymer artificial filamentsCarbon fibersCarbonization

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Preparation method of rice hull carbon based solid sulfoacid

InactiveCN103157512AHigh densityEasy to dehydrateOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholAcid catalyzed

Owner:TIANJIN POLYTECHNIC UNIV

Graphene-based hierarchical pore capacitor carbon and preparation method thereof as well as capacitor

InactiveCN106467299ACurl suppressionSuppress stackingHybrid capacitor electrodesGrapheneCross-linkPorosity

Owner:山东圣泉新能源科技有限公司

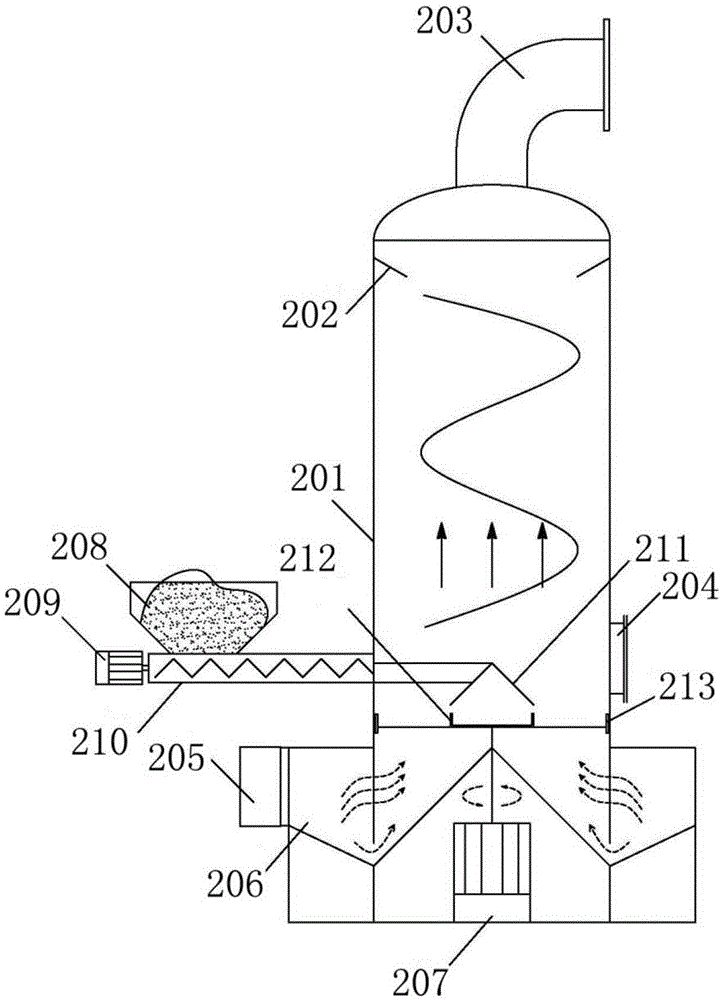

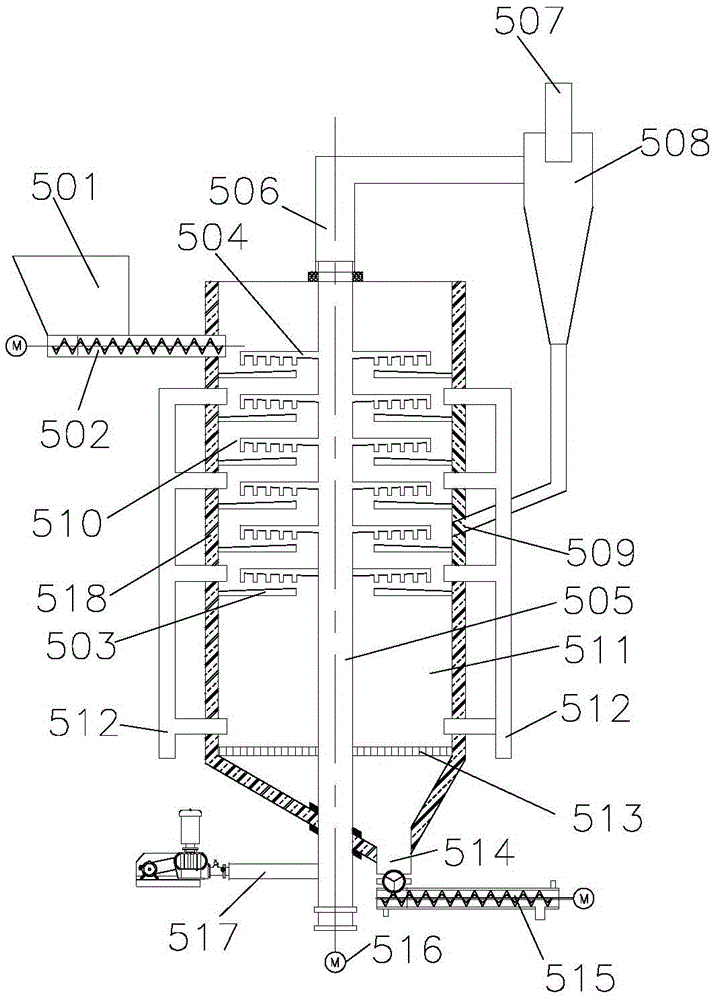

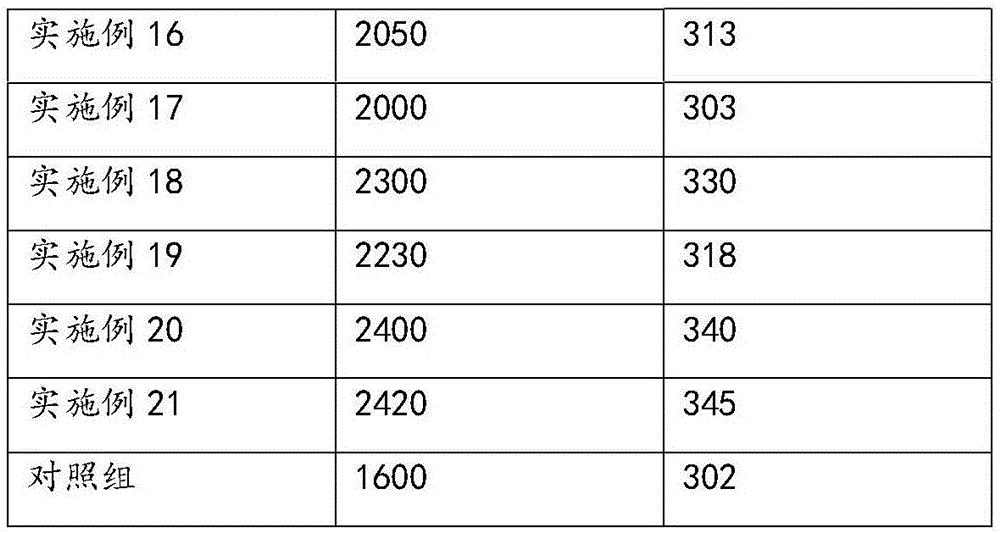

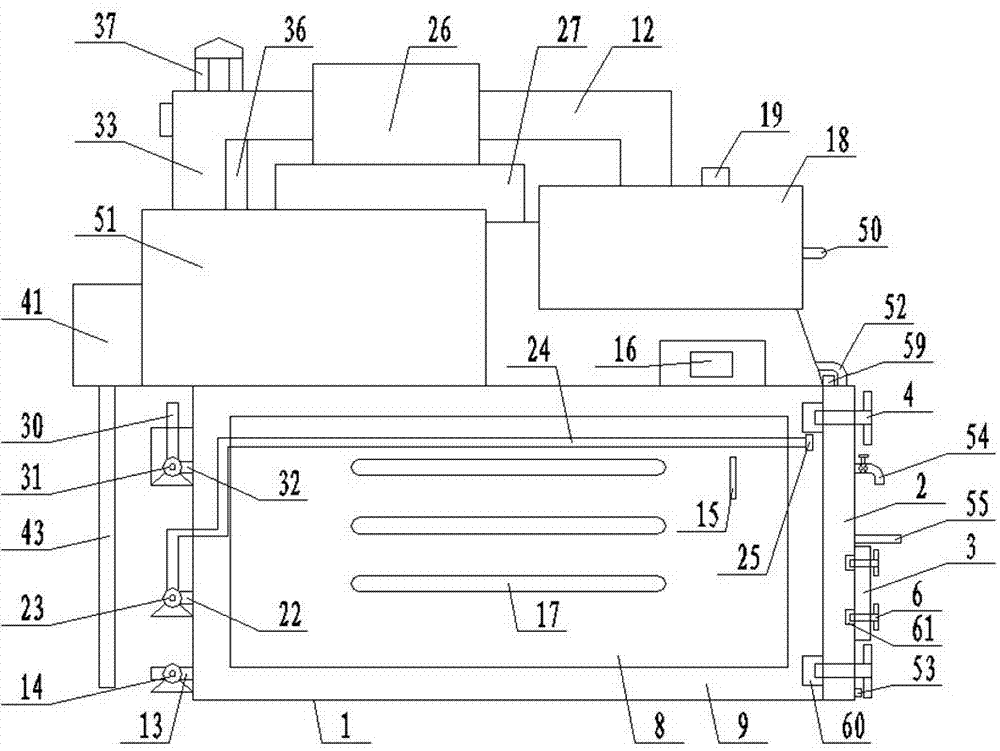

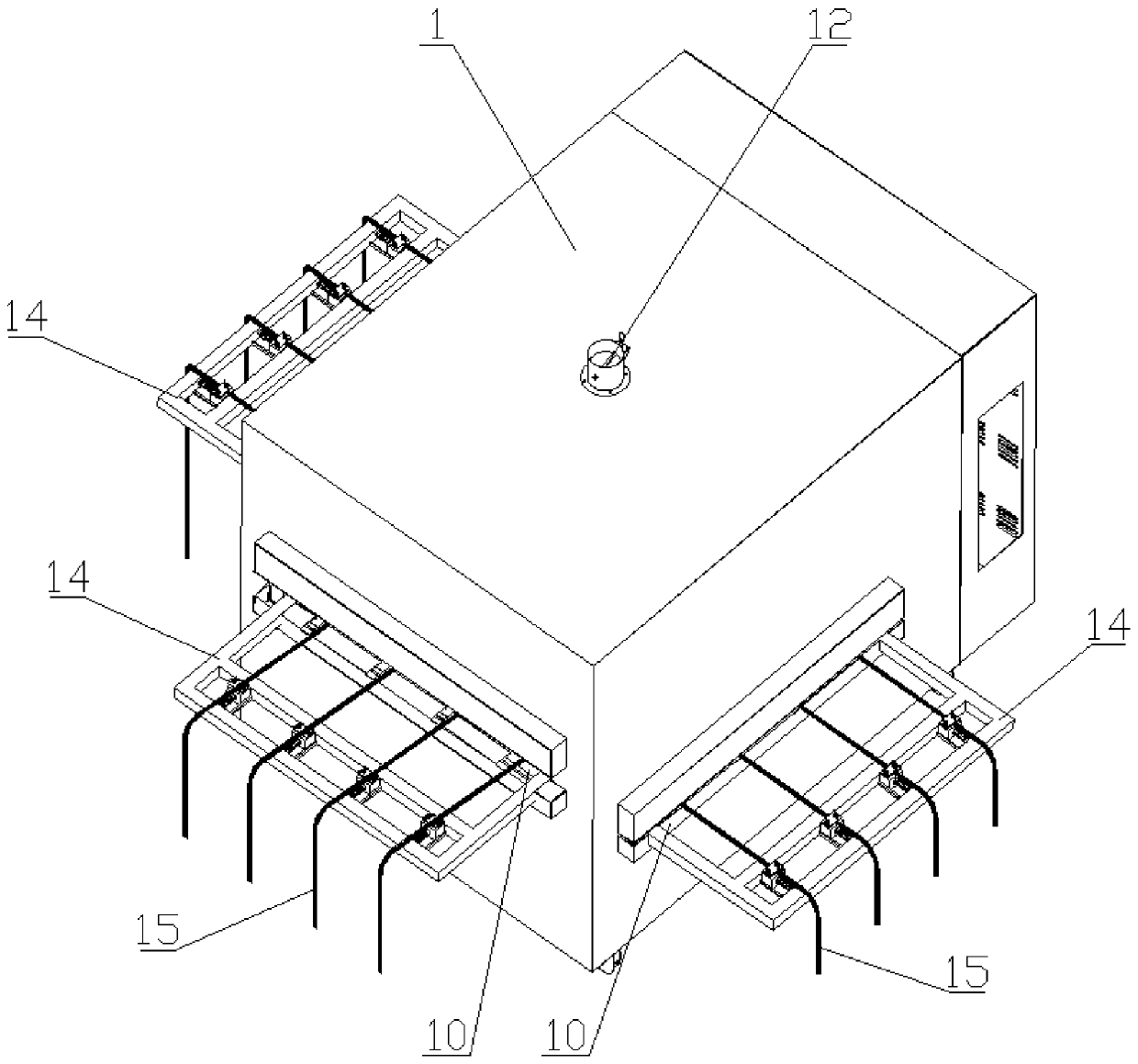

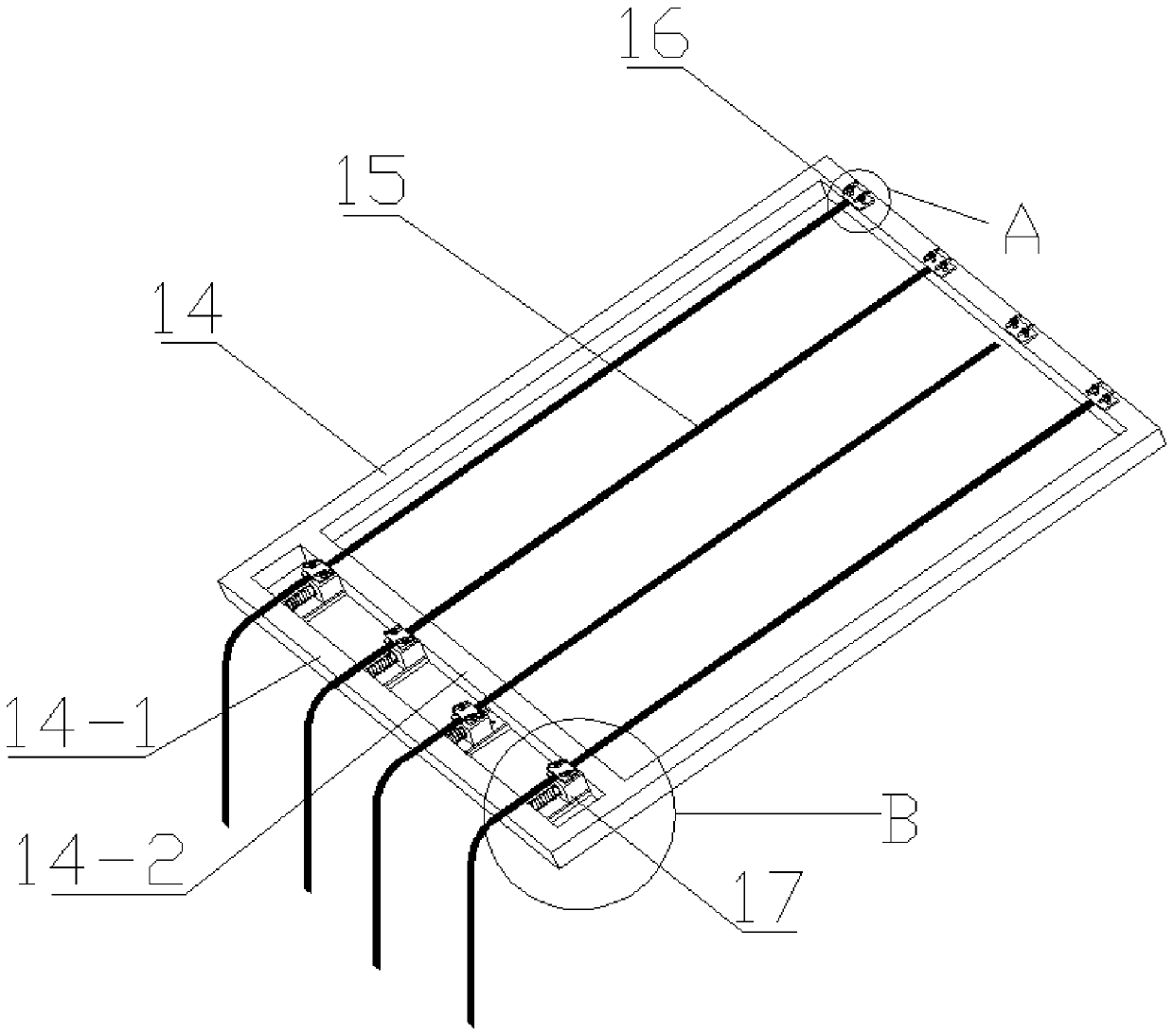

Straw carbonization furnace

InactiveCN103497773AAchieve recyclingHigh heat conversion efficiencyBiofuelsEnergy inputCombustion chamberCarbonization

Owner:YANCHENG CHENGXIN MACHINERY MFG

Straw carbonization and separation technique and separating device used thereby

InactiveCN101735836AAchieve refinementBiofuelsDispersed particle separationCombustible gasCarbonization

The invention discloses a straw carbonization and separation technique and a separating device used thereby to realize the carbonization of the straw and extract various useful substances, such as wood tar oil, wood vinegar, mixed combustible gas and the like in a carbonization process. The technique comprises the following steps of: processing the straw into segmented straw, sending the segmented straw into a furnace kiln and igniting to heat the segmented straw at a high temperature to produce smoke gas and placing the treated straw into a sharp quenching multi-pipe separating device to extract wood tar oil; extracting mixture of wood tar oil and wood vinegar liquid in a multi-layer staggered separating device; extracting wood vinegar liquid in an internal rotation centrifugal separating device; and sending remaining gas into a purification tower to purify and controlling the temperature to be between 60 and 80 DEG C. The invention has the advantages that: a new straw carbonization and separation technique is developed and the extraction of various useful substances, such as wood tar oil, wood vinegar and mixed combustible gas, is realized when bio-carbon is produced.

Owner:崔宝玲

Pre-oxidation equipment of PAN (polyacrylonitrile)precursor end and end connection method

Owner:ATA CARBON FIBER TECH GUANGZHOU

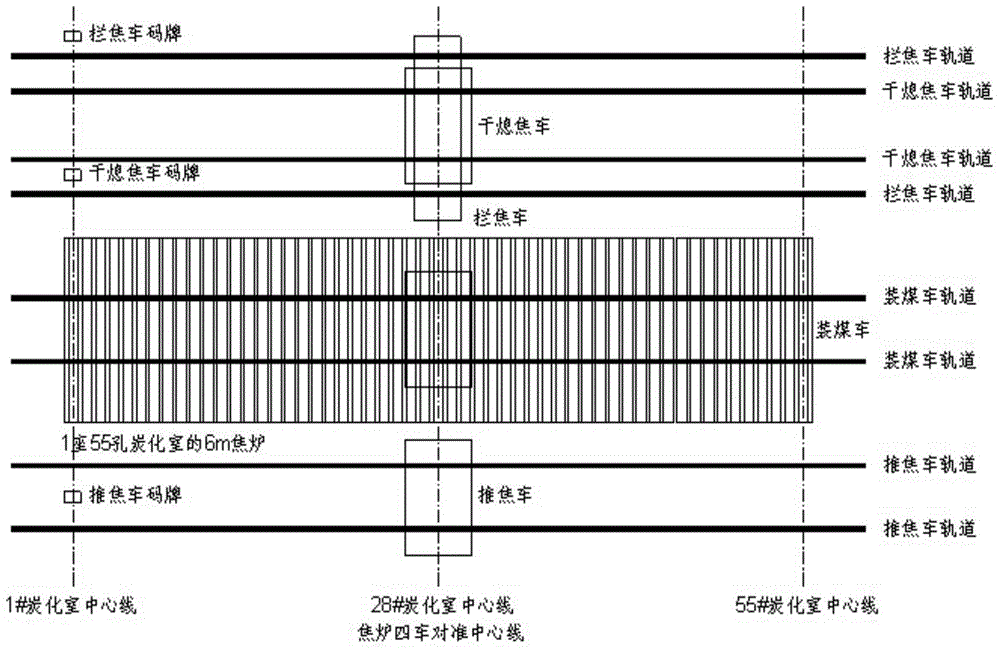

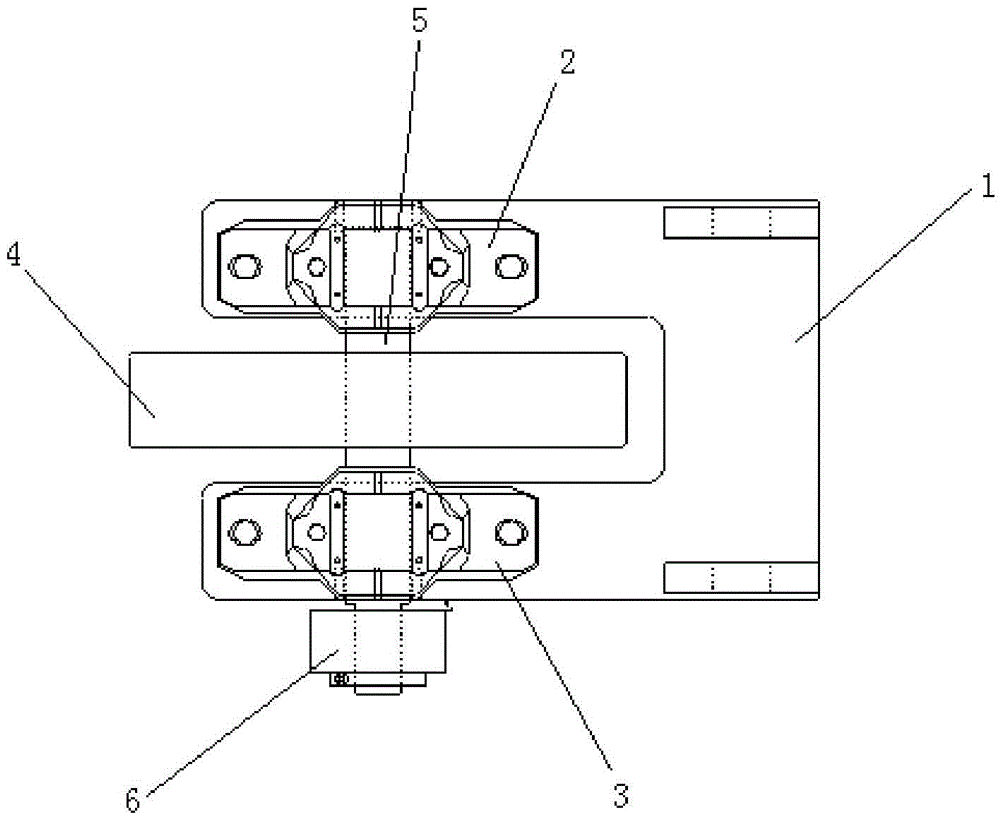

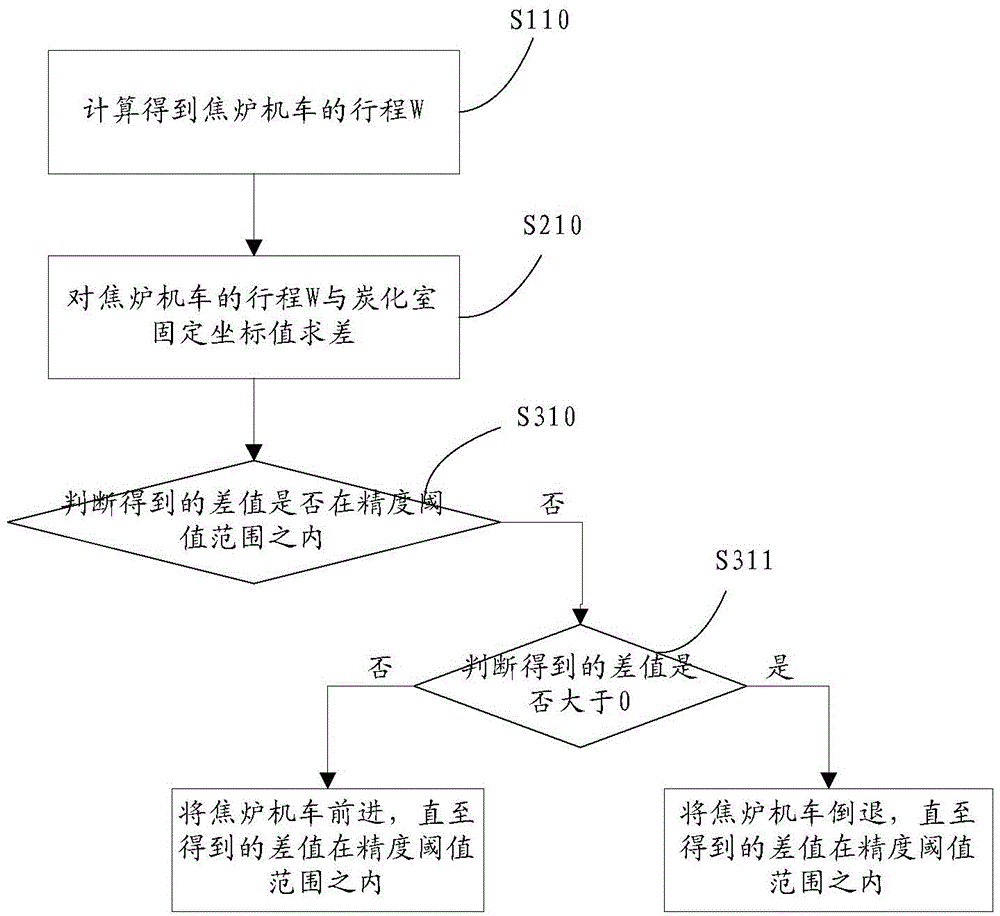

Positioning method and device of coke furnace locomotive

InactiveCN104087320AEnsure safe productionAchieve precise positioningCoke oven safety devicesCarbonizationCoke oven

Owner:武汉钢铁有限公司

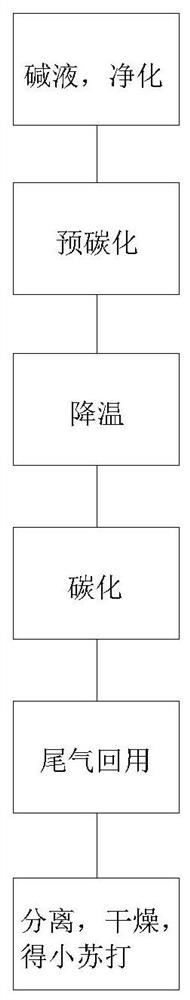

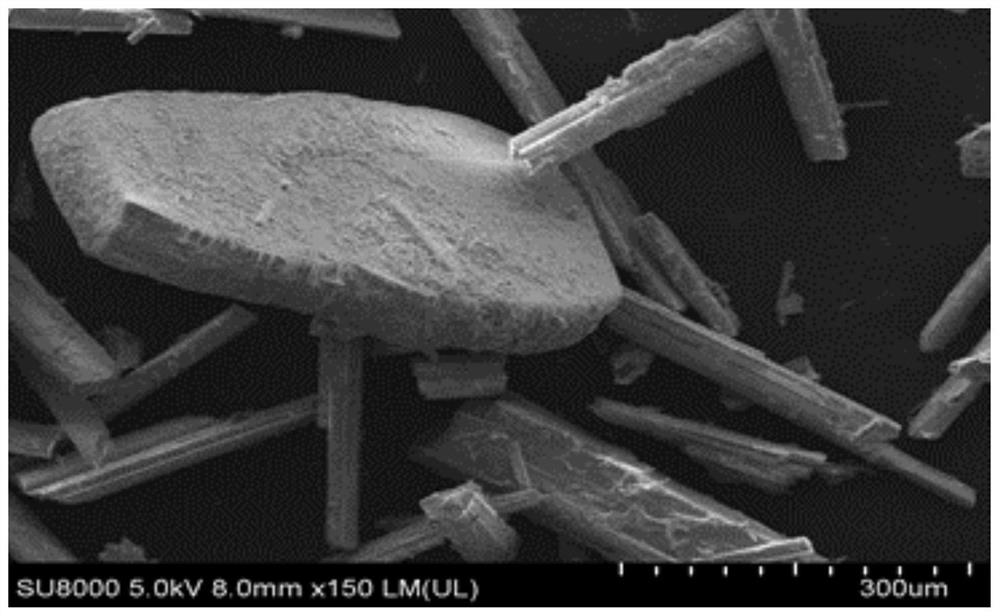

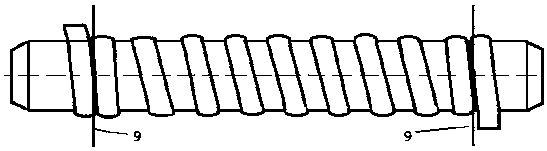

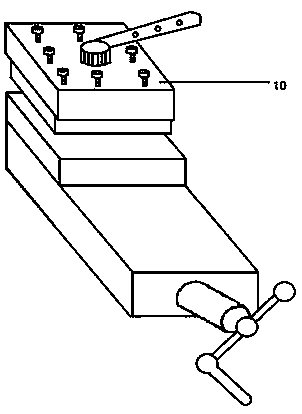

Method for preparing large-particle baking soda by secondary carbonization method and obtained baking soda

ActiveCN111634928ALarge particle sizeLower the discharge temperatureProductsBicarbonate preparationCarbonizationMaterials science

Owner:山东海天生物化工有限公司

Manufacturing method of bamboo spring bracket and application thereof

InactiveCN109227826AReduce usageReduce production processWood working apparatusCane mechanical workingCarbonizationEngineering

Owner:NANJING FORESTRY UNIV

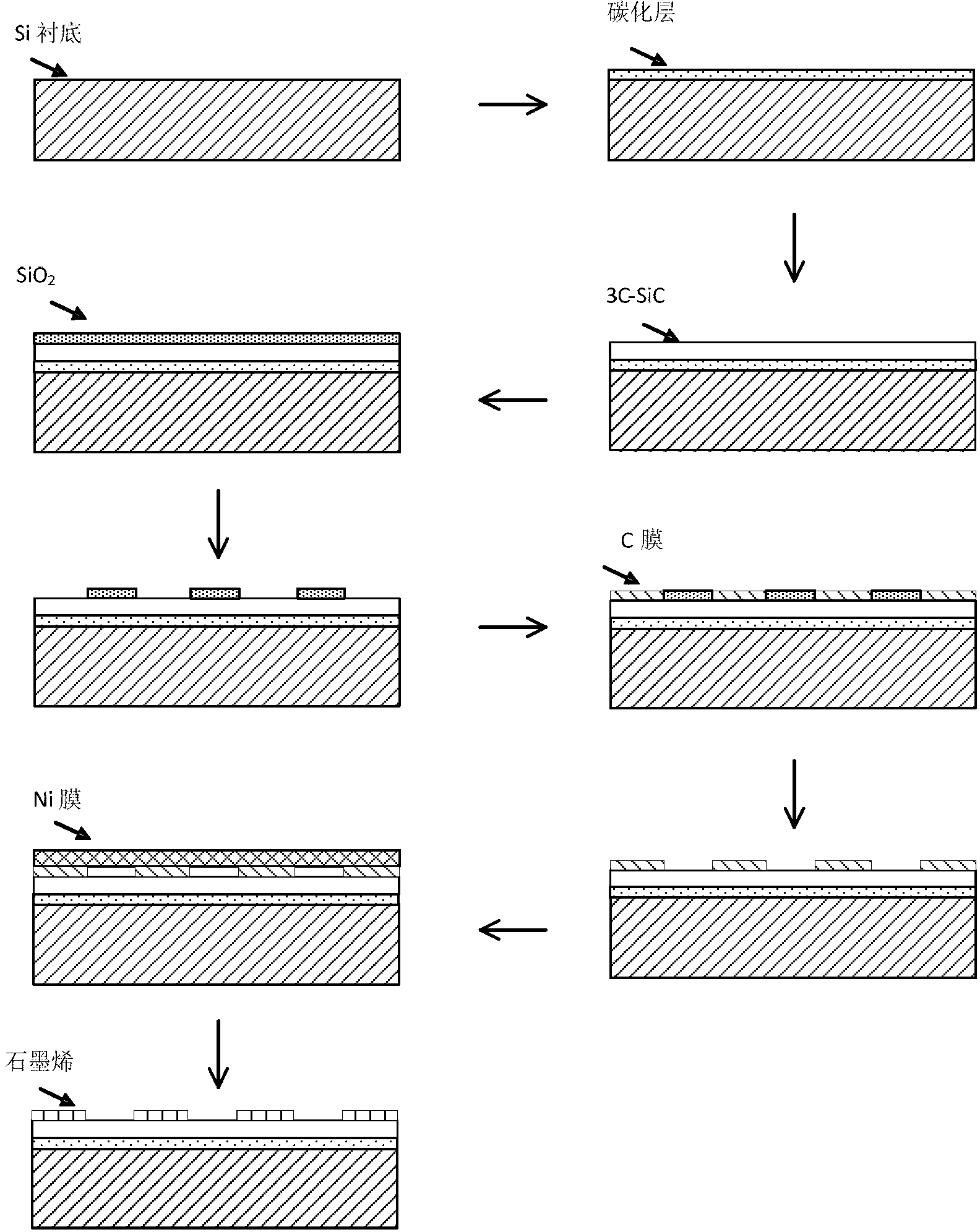

Ni film annealing patterned graphene preparation method based on 3C-SiC/chlorine gas reaction

InactiveCN102936011AEasy to refactorImprove continuityGrapheneCarbon filmState of art

Owner:XIDIAN UNIV

Technology for processing bamboo board doors

InactiveCN105856376ASave resourcesCane mechanical workingReed/straw treatmentCarbonizationEngineering

The invention relates to the field of panel door processing, in particular to a processing technique for bamboo and wood panel doors, comprising the following steps: 1. Dry bamboo slices into silk, breaking and rolling the moso bamboo into sheets; 2. Carbonizing the bamboo silk, making the bamboo silk Put it in a carbonization furnace for carbonization; 3. Bamboo silk impregnation; 4. Cold pressing of bamboo silk; 5. High temperature curing treatment; Make the required size; 7. Blank processing: process and manufacture the bamboo and wood panels obtained in the high-quality step 6 to form bamboo and wood panel door blanks; 8. Subsequent processing: carry out subsequent processing on the bamboo and wood panel door blanks to form bamboo and wood panel doors. The invention provides a bamboo and wood door processing technology, which can use bamboo and wood to produce wood door processing raw materials, and then produce qualified wooden doors through traditional wood door processing technology, that is, increase the cost of bamboo and wood. The scope of use is of great significance to environmental protection.

Owner:王宾

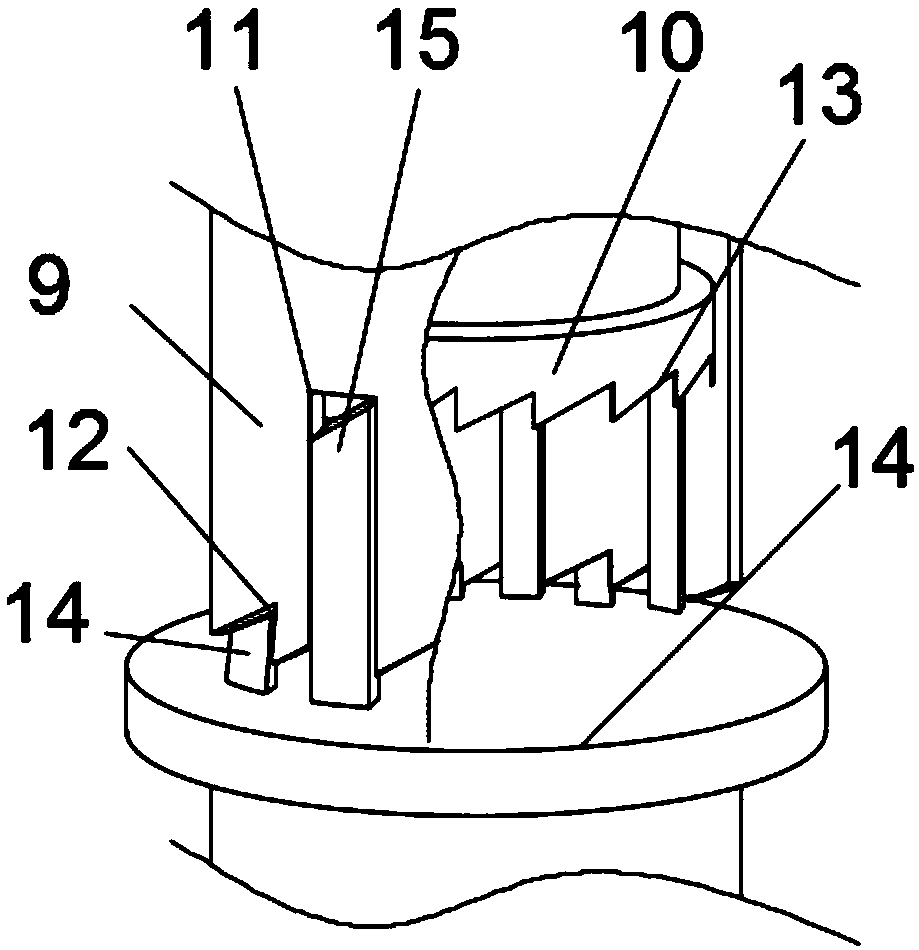

Photon energy vehicle energy-saving device and manufacturing method thereof

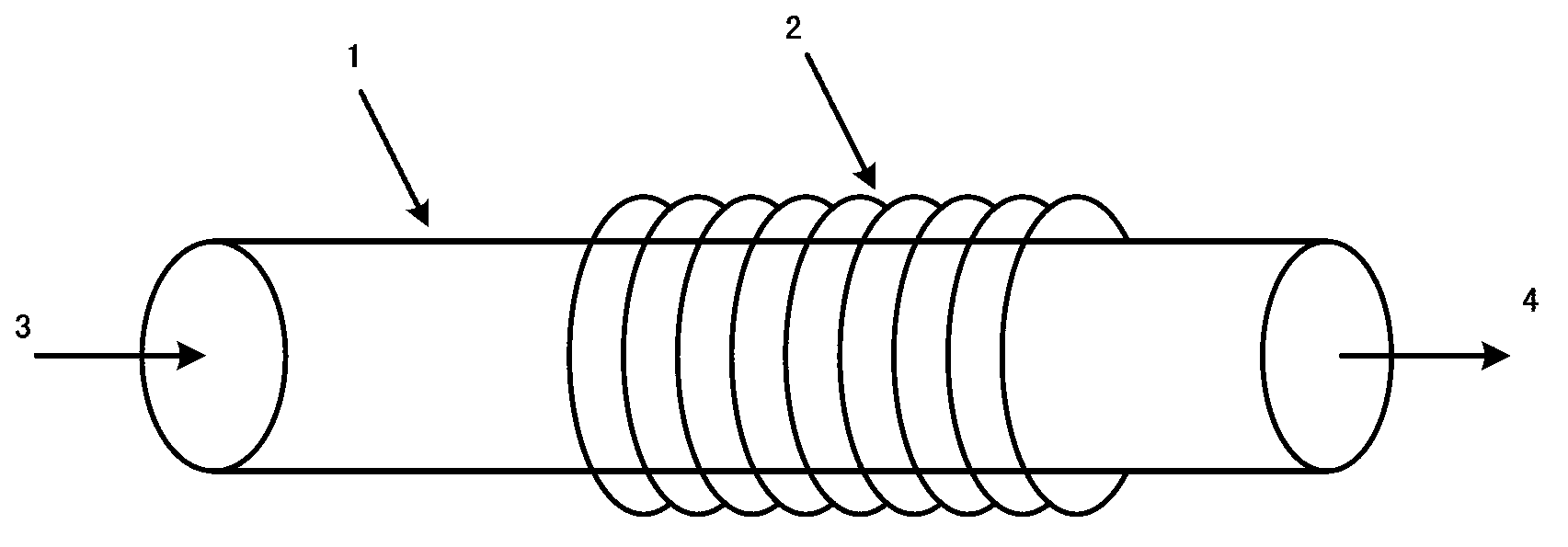

ActiveCN103174558AIncrease burn rateIncreased durabilityCombustion-air/fuel-air treatmentMachines/enginesCarbonizationEngineering

The invention discloses a photon energy vehicle energy-saving device and a manufacturing method thereof. The device comprises an air ionizing device and an oil way fine molecularization device. The air ionizing device comprises an outer pipe, side slant wings, a circular air pipe and rhombic air pipes, wherein the number of the side slant wings is plural, the side slant wings are arranged on the outer pipe, the circular air pipe is arranged at the center position of the outer pipe, the rhombic air pipes comprise a plurality of groups, and each group of rhombic air pipes is connected between the circular air pipe and the outer pipe. The oil way fine molecularization device comprises an outer shell, two air guide sleeves, two ceramic bodies and a net structure, wherein the two air guide sleeves are arranged in the outer shell, the two ceramic bodies are respectively connected with the two air guide sleeves, the net structure is arranged between the two ceramic bodies, and connecting bodies are arranged at two ends outside the outer shell. The vehicle energy-saving device has the functions of catalysis fission on petroleum and natural gas, and is capable of achieving ultramicro atomization combustion, improving combustion efficiency, increasing energy, reducing oil consumption or gas consumption, reducing formation of tiny dust, reducing emission of noxious gas such as carbon monoxide and hydrocarbon and achieving energy saving, emission reduction and energy increasing.

Owner:刘贡友

Preparation method for zeolite-activated carbon composite adsorbent

InactiveCN107876009AIncrease the areaLarge adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesSorbentCarbonization

Owner:SHAANXI SHENGMAI PETROLEUM

Production method for full-resource cyclic utilization of sulfuric-acid-method titanium dioxide production wastewater

InactiveCN112499813ATo achieve the purpose of coupling recyclingEliminate influencing factorsTreatment involving filtrationMultistage water/sewage treatmentSulfateCarbonization

The invention discloses a production method for full-resource cyclic utilization of sulfuric-acid-method titanium dioxide production wastewater, which comprises the following steps of: neutralizing wastewater produced by sulfuric acid method titanium dioxide production by lime, separating gypsum by a filter press to obtain treated wastewater, and adding a recycled sodium carbonate solution to precipitate saturated calcium sulfate in the treated wastewater; clarifying the slurry to separate calcium carbonate precipitate and a sodium sulfate solution, and carrying out membrane separation on theseparated dilute sodium sulfate solution through a membrane filter; adding lime into a concentrated-phase sodium sulfate solution obtained after membrane separation for causticization reaction, takinga filtrate as a sodium hydroxide solution, employing carbon dioxide-containing tail gas generated in the titanium dioxide production process for carbonization, obtaining a sodium carbonate solution,and then returning the treated wastewater to precipitate saturated calcium sulfate. The method economically solves the technical problem that the lime neutralization treatment wastewater cannot be economically recycled in the sulfuric acid method titanium dioxide production process, eliminates the influence factors of outward discharge of the existing neutralization treatment wastewater on the environmental water body, and saves a large amount of raw water resources for production.

Owner:CHENGDU QIANLIJIN TECHCAL INNOVATION CO LTD

Method for preparing micro-mesoporous carbon anode material from amino acid modified metallic organic framework and application

ActiveCN109745950AIncrease aperture sizeGood effectOther chemical processesCell electrodesPorous carbonCarbonization

Owner:XIANGTAN UNIV

Porous carbon material prepared by using self-modification of pseudomonas putida and preparation method and application thereof

ActiveCN109399604AShorten the growth cycleIncrease added valueHybrid capacitor electrodesCarbon preparation/purificationPorous carbonPseudomonas putida

Owner:CENT SOUTH UNIV

Manufacturing method for graphite film

The invention provides a manufacturing method for a graphite film. A polyimide film is taken as a precursor, and heat treatment conditions are as follows: the average heating rate in a heating sectionof 500-800 DEG C is 2 DEG C or below per minute, and the highest carbonization temperature is 1000 DEG C or higher. According to the manufacturing method for the graphite film, the average heating rate from 2200 DEG C to the highest graphitization temperature is smaller than 3 DEG C per minute, and 2500 DEG C or a higher temperature is the highest graphitization temperature of the process.

Owner:TAIMIDE TECH

Preparation method of medicinal active carbon

InactiveCN106976873AFast decolorizationImprove adsorption capacityCarbon compoundsEcological environmentCarbonization

Owner:句容市盛达环保净化材料有限公司

Preparation method of active carbon

InactiveCN109399634AIncrease acquisition rateReduce stacking spaceCarbon compoundsActivated carbonEconomic benefits

Owner:湖南中炭新能源科技有限公司

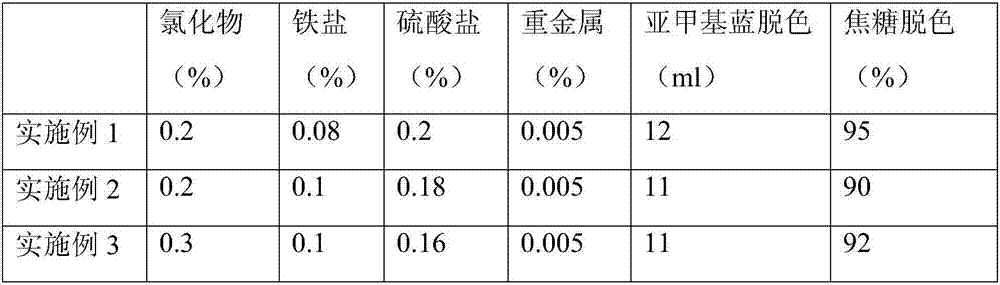

Production method of vanadium nitrogen alloy

InactiveCN103014345BIncreased vanadium contentHigh apparent densityApparent densityVanadium nitride

Owner:HUNAN HONGYUAN RARE METAL MATERIALS

Matrix for Chinese orchid tissue culture

InactiveCN104969862AImprove survival rateReduce pests and diseasesHorticulture methodsPlant tissue cultureHuskCarbonization

The invention discloses a matrix for Chinese orchid tissue culture. The matrix comprises agar and is characterized by also comprising coconut shell flour, decomposed alcohol dregs, carbonized rick husk, and mud in the biogas generating pit. The living rate of Chinese orchid tissue cultured seedlings planted on the provided matrix can reach 85% or more, furthermore, the damage caused by diseases and insects is reduced, compared with the common tissue culture matrixes, the seedling time is shortened by 23%, and the rooting and exuberance time is reduced by 43%.

Owner:LIUZHOU TIANZI HORTICULTURE

Biological carbonization reaction equipment with water cooling system

InactiveCN108085027AQuick unloadingShorten the timeCoke quenchingOven incrustations prevention/removalCombustion chamberCarbonization

The invention discloses biological carbonization reaction equipment with a water cooling system, which comprises a furnace body, a burning chamber, support seats, a discharge slope and a smoke discharge tube, wherein the smoke discharge tube is mounted at the top end of the furnace body; the support seats are arranged at four corners of the bottom end of the furnace body; the burning chamber is arranged at the bottom end in the furnace body; pulleys are connected with the top end of the burning chamber and mounted at the bottom end of a placement plate; baffles are arranged on the two sides ofthe top end of the placement plate; a handle is fixed on one baffle; and a carbonization material is arranged on the placement plate. According to the equipment, the placement plate is arranged in the furnace body; the pulleys are arranged at the bottom end of the placement plate; after a carbonization reaction is finished, a reactor in the placement plate can be pulled out of the furnace body directly through the discharge slope by pulling the handle to achieve a quick discharge effect; the time required by discharge is greatly saved; and the equipment tis relatively practical and suitable for wide popularization and application.

Owner:HENAN HUINONG SOIL CONSERVATION R&D CO LTD

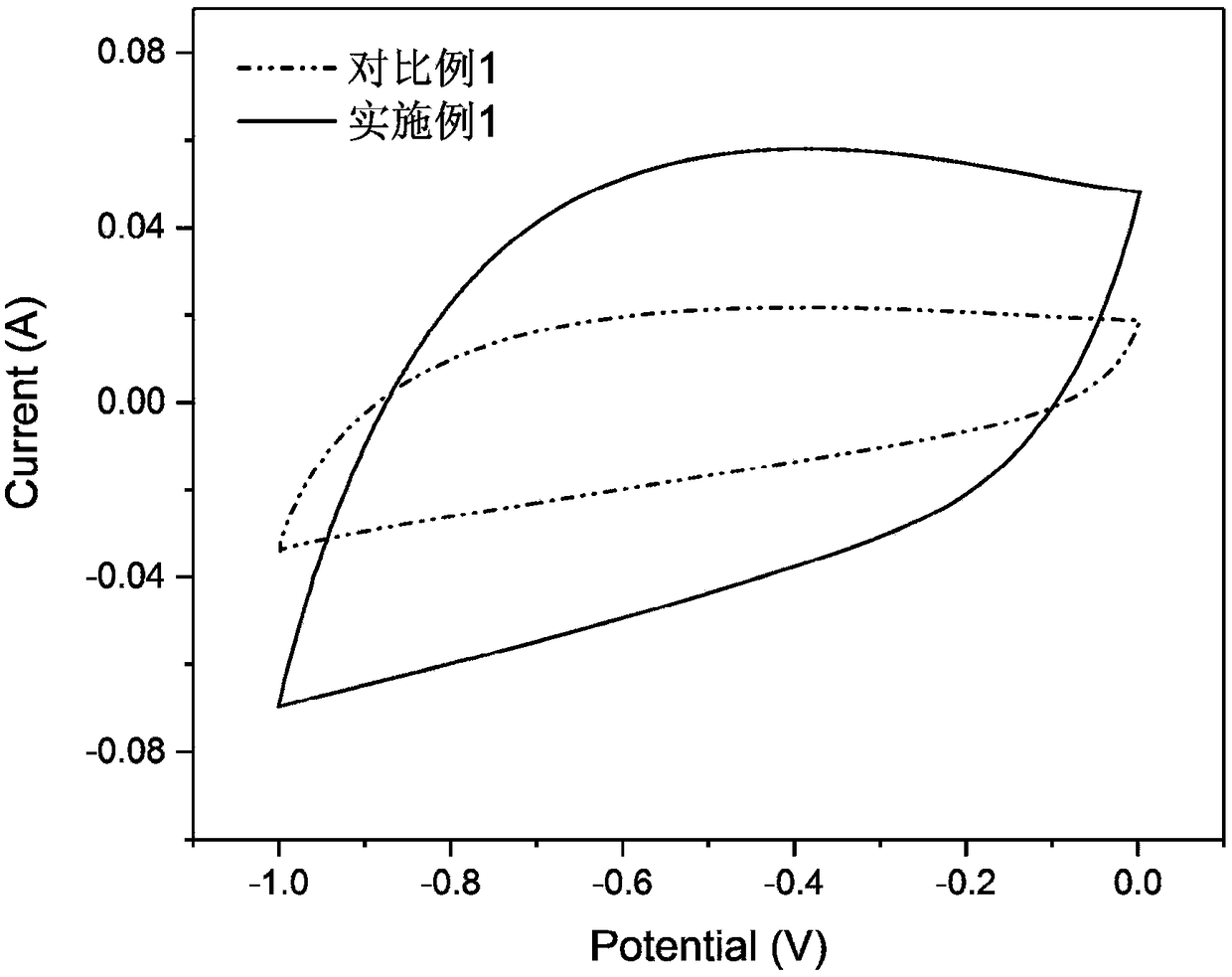

A novel electrode material for a supercapacitor and a supercapacitor

InactiveCN109192534AHigh specific capacityFacilitated DiffusionHybrid capacitor electrodesMultiple hybrid/EDL capacitorsPolypyrroleFast charging

Owner:广东粤迪厚创科技发展有限公司 +1

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap