Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

29 results about "Mixed materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixed Materials. This mix of materials is undeniably elegant. Mixed metals combined with natural materials like marble and cork up the sophistication level of any space.

Preparation method of sialite binding material for well-cementing in oil-gas field

The invention discloses a preparation method of a sialite binding material for well-cementing in an oil-gas field, which belongs to the field of oil and gas development. The preparation method comprises the steps of mixing (by weight percentage) cement clinker 0-45%, granular blast-furnace cinder 55-95% and pulverized fuel ash 0-5%, and grinding together; mixing (by weight percentage) the ground mixed material 30-59.5%, pulverized fuel ash, coal-fired furnace cinder burnt clay or red mud 40-60% and a diagenetic agent, and grinding together; and mixing (by weight percentage) the ground mixed material 80-95% and ground expanded vermiculite 5-15% to obtain the sialite binding material for well-cementing. The preparation method is not only in favor of solving various problems in well-cementing in the oil-gas field, but also remarkably reduces emission of CO2 and other pollutants compared with that in the conventional oil-well cement production.

Owner:TSINGHUA UNIV +1

Preparation process of vanadium-nitrogen alloy

The invention discloses a preparation process of a vanadium-nitrogen alloy. The preparation process comprises the steps that a vanadium-containing compound is subjected to mechanical activation treatment at first, a reaction promoter, graphene and a binder are added to obtain qualified mixed materials, the mixed materials are subjected to aging treatment and fed into a calcining kiln to be calcined, a drying stage, a carbonization stage, a nitridation stage and a cooling stage are sequentially carried out, a product is discharged from the kiln, and the vanadium-nitrogen alloy finished productwith the vanadium content larger than or equal to 77.0% is obtained. According to the preparation process, quality is good, product quality is stable, the production process is stable, and the production cost is low.

Owner:涂绪洋

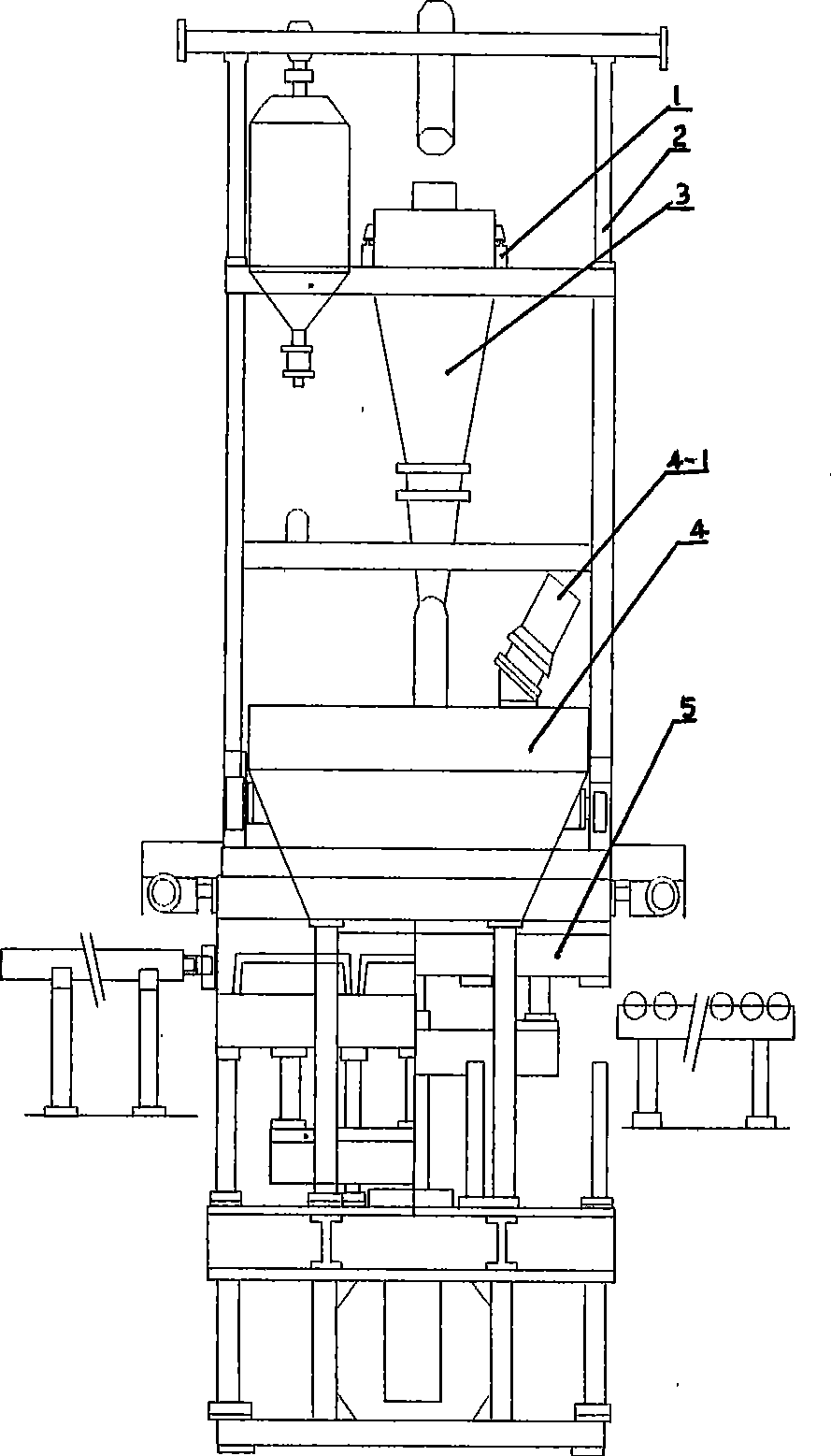

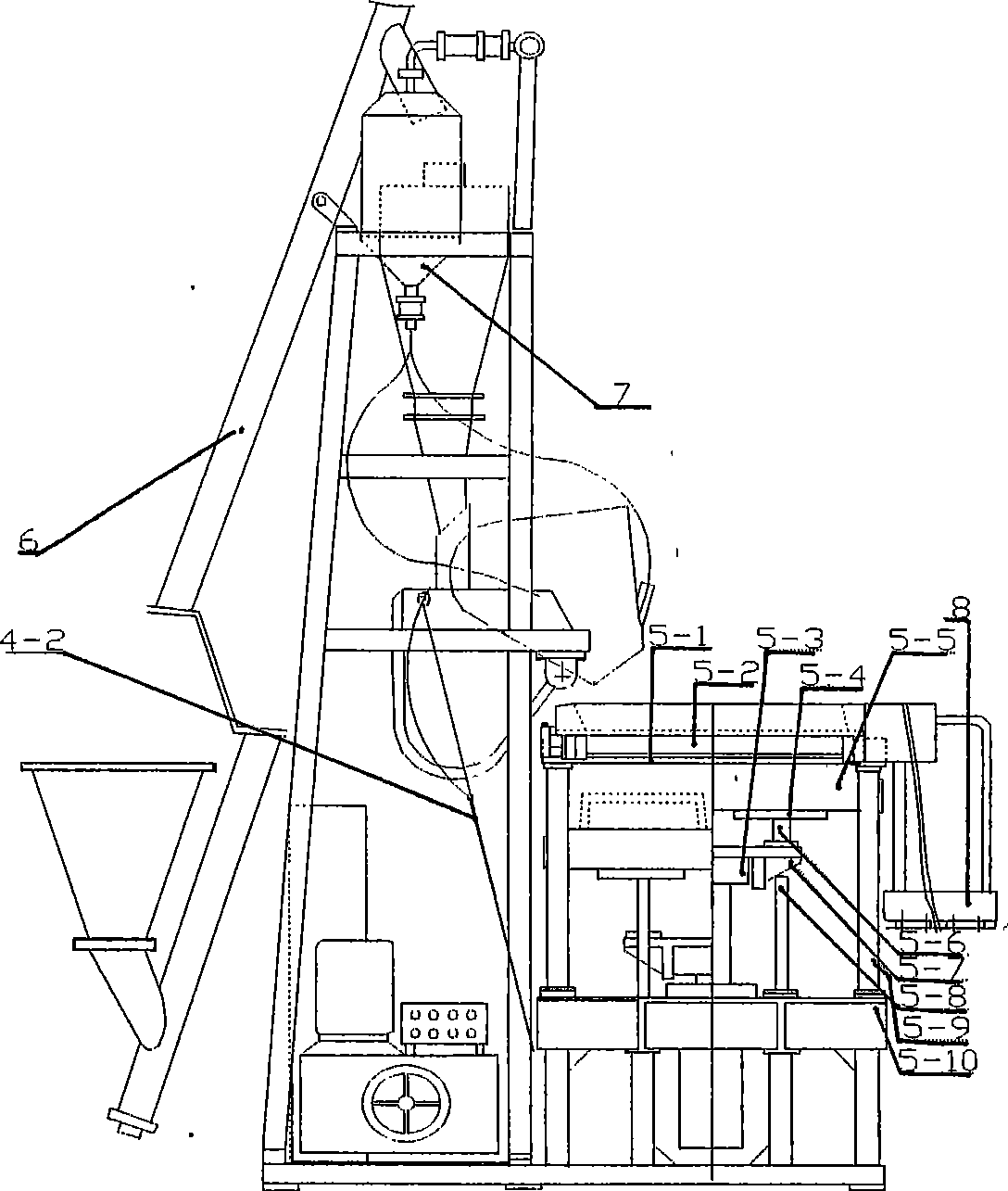

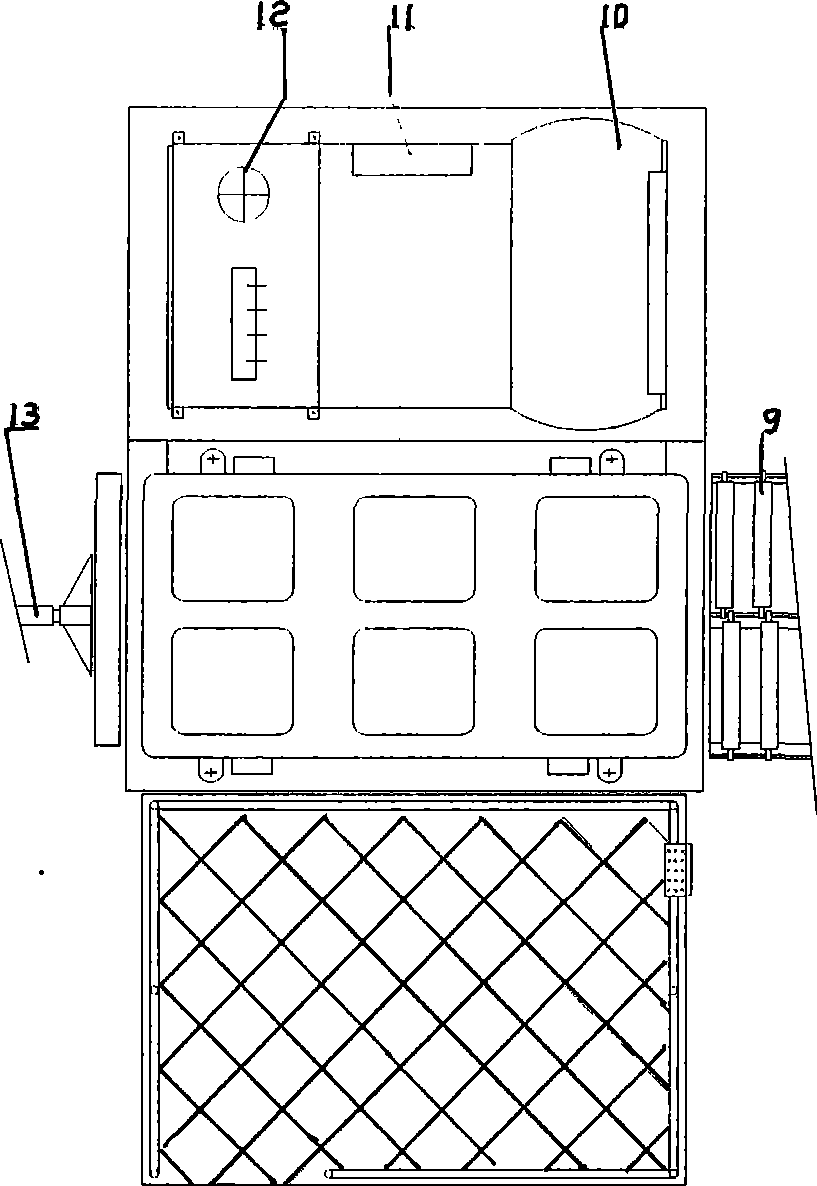

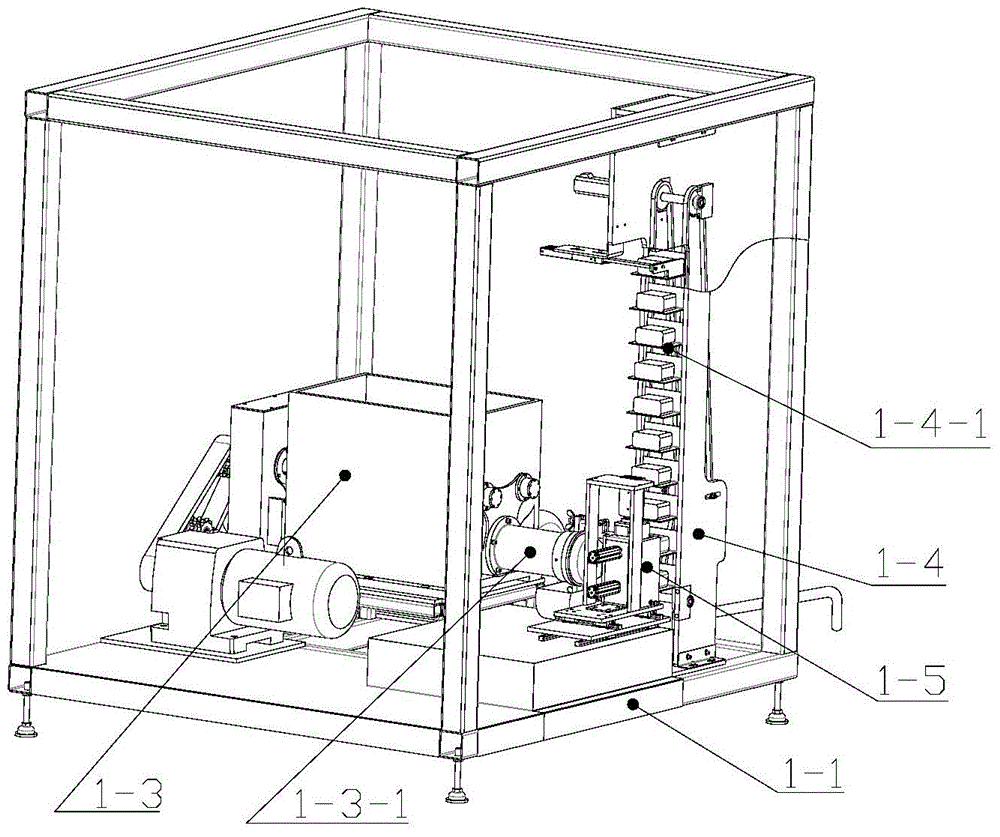

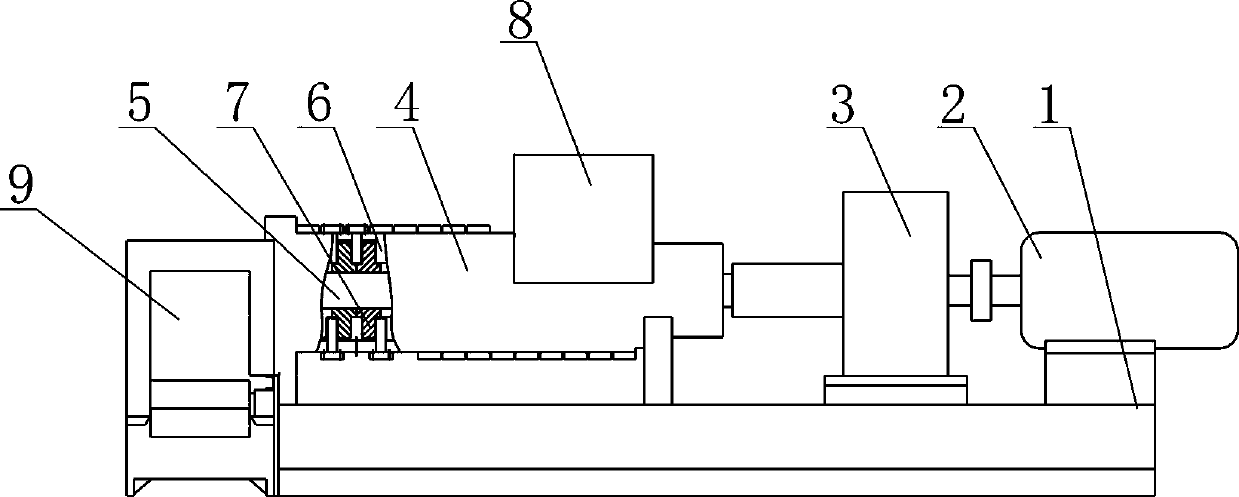

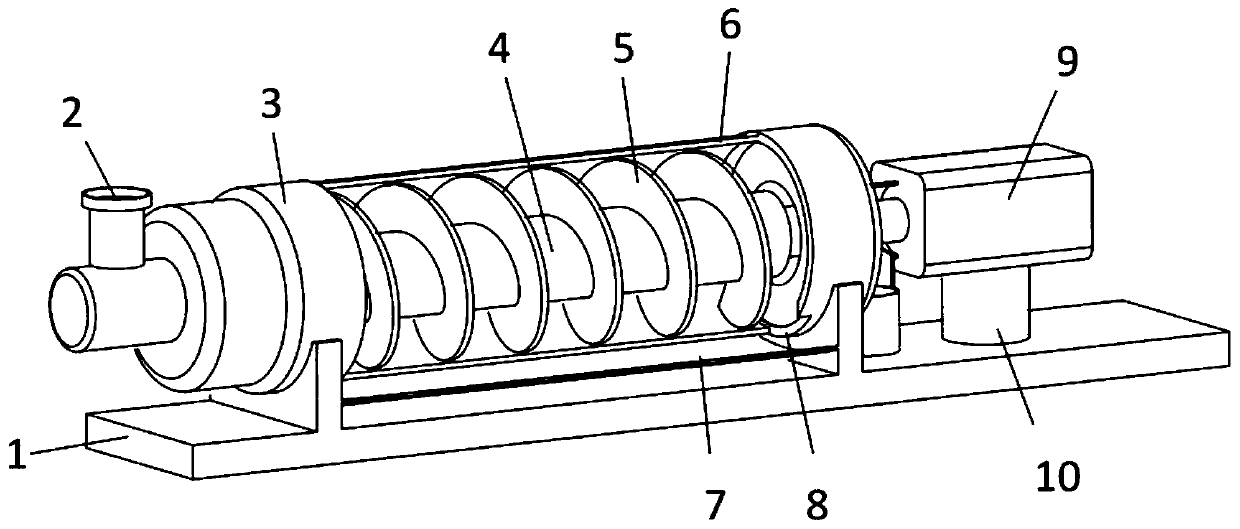

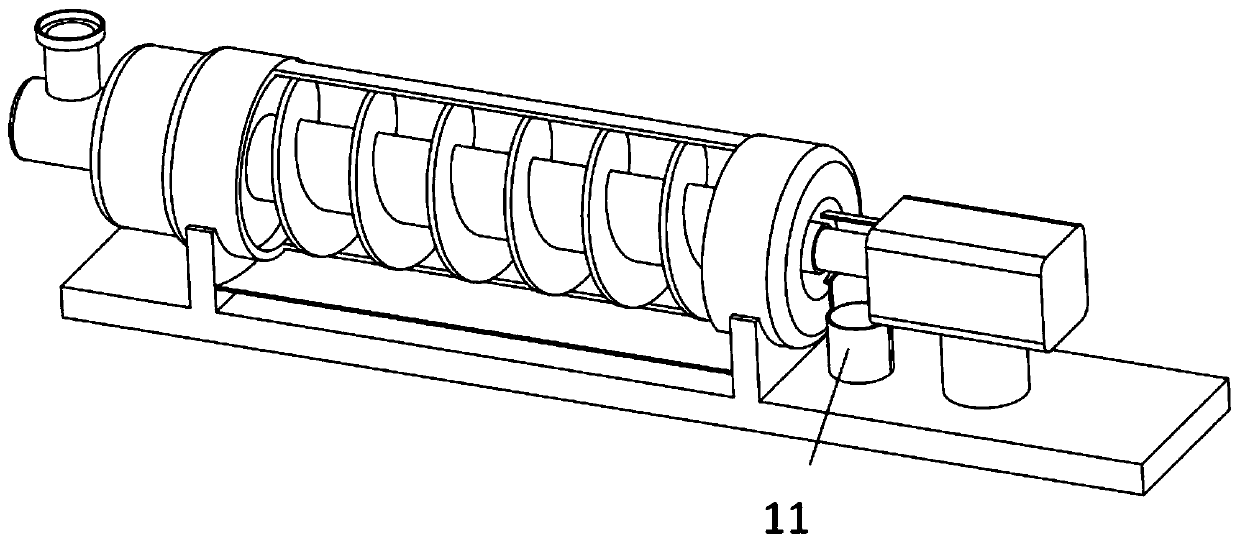

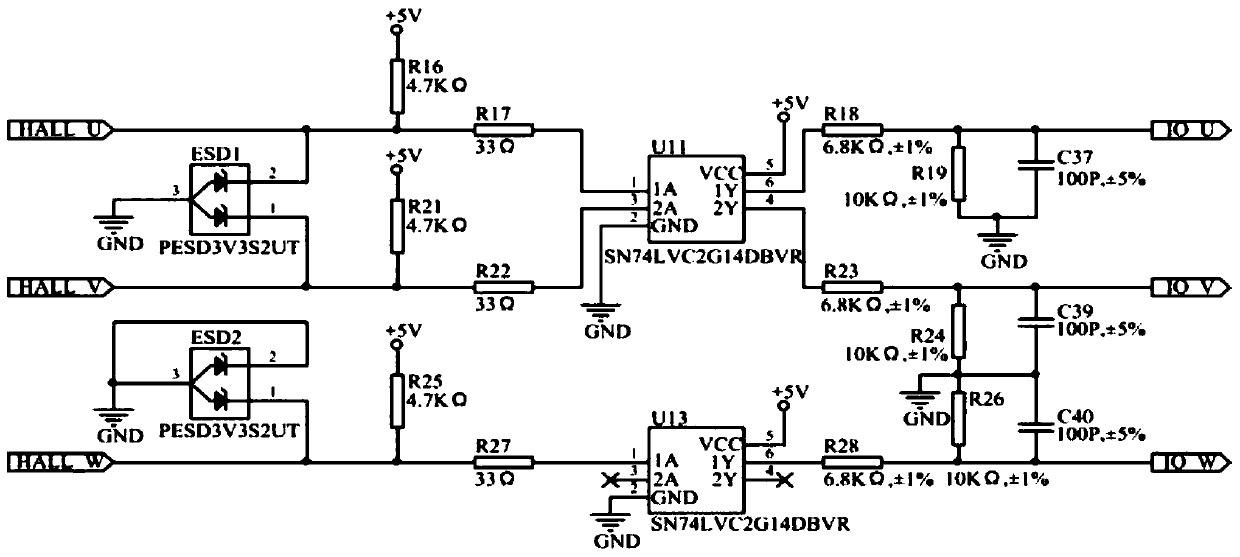

Full automatic machine for forming plaster mould box

InactiveCN101439539AMixing operation control apparatusCeramic shaping apparatusMechanical engineeringMixed materials

Owner:黄梅龙源石膏有限公司

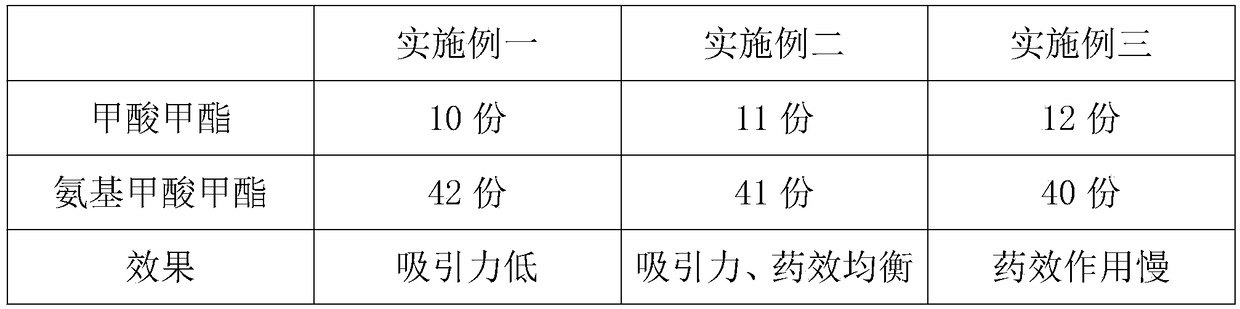

Processing method for preparing imidacloprid wettable powder from crude imidacloprid

InactiveCN101669467ASolve processing problemsSimple processBiocideAnimal repellantsMixed materialsImidacloprid

Owner:荆州沙隆达控股有限公司

Dialkene-containing gasoline fraction hydrotreating method

InactiveCN102559261AEasy to removeSolve cokingTreatment with hydrotreatment processesFluid phaseReaction temperature

The invention provides a dialkene-containing gasoline fraction hydrotreating method. The method comprises the following steps: (1) directly mixing a dialkene-containing gasoline fraction raw material with a hot hydrogen-donor solvent, and feeding the mixture into a hydropretreating reactor for dialkene-removing reaction when the temperature of the mixture reaches the dialkene-removing reaction temperature; (2) mixing reaction effluent of the hydropretreating reactor with hydrogen gas, feeding the mixture into a heating furnace, heating the mixed material until the temperature of the mixed material reaches the temperature required by the inlet of the hydrotreating reactor, feeding the mixed material into a separator, separating the mixed material into a gas phase and a liquid phase, wherein the liquid phase is mainly the hydrogen-donor solvent and is circulated to the step (1) for use, and the separated gas phase is fed into the hydrotreating reactor so as to be subjected to hydrogenation impurity-removal reaction; and (3) feeding the reaction effluent of the hydrotreating reactor into a separation system, separating out the hydrotreated gasoline fraction and a gas phase, wherein the gas phase is mainly the hydrogen gas and is recycled. Compared with the prior art, the method provided by the invention can be used for effectively solving the coking problem of a dialkene-containing gasoline fraction hydrotreater.

Owner:何裕松

Moisture-proof lead-free soldering nylon 46 composite material and preparation method thereof

InactiveCN102942785AImprove high temperature resistanceHigh tensile strengthGlass fiberMixed materials

The invention relates to a moisture-proof lead-free soldering nylon 46 composite material and a preparation method thereof. The nylon 46 composite material comprises the following components by weight: 40.4-89.2% of PA46 resin, 5-15% of PPO resin, 0-5% of a compatibilizer, 0-45% of glass fiber and 1-2% of other assistants. The preparation method of the composite material is as follows: weighing each component according to the above weight, and drying the components; adding the dried PA46 resin, PPO resin, compatibilizer and assistants into a high-speed mixer for mixing; and adding the mixed materials into a double-screw extruder, adding glass fiber for reinforcement, and extruding for granulation. The composite material provided by the invention has excellent wet proof lead-free soldering performance and good mechanical properties, and can be applied to the preparation of connector of electronic and electrical products requiring lead-free soldering and preparation of high-temperature resistant automotive plastic parts, etc.

Owner:HUIZHOU HUAJU PLASTIC TECH CO LTD +1

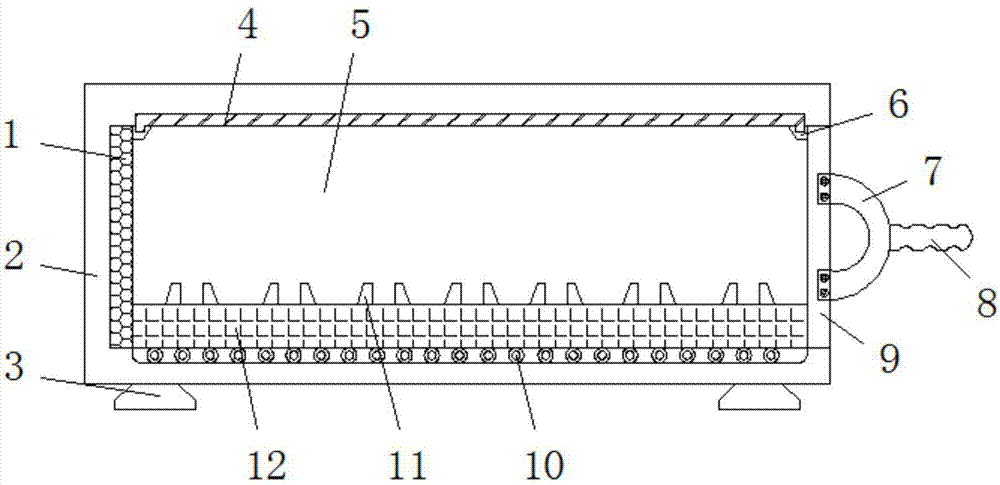

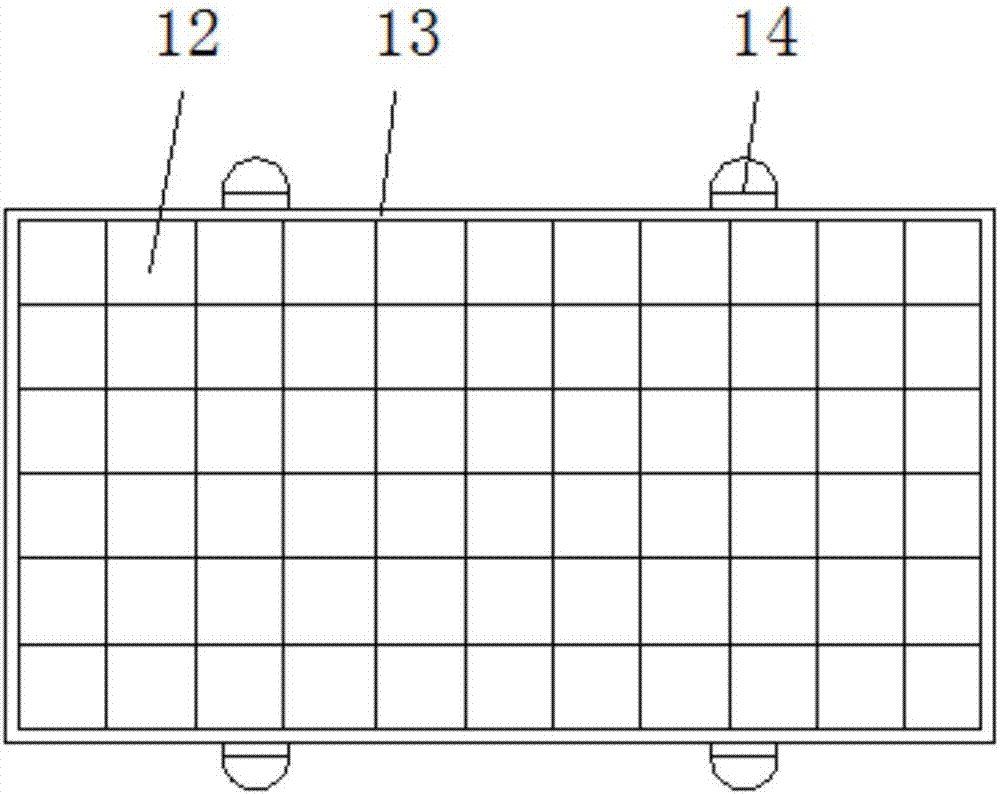

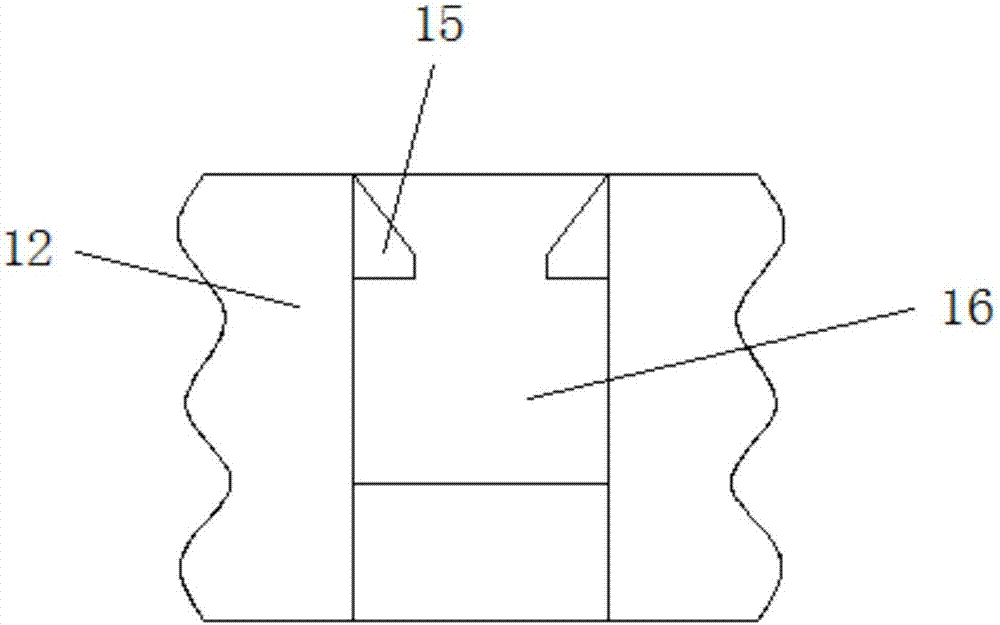

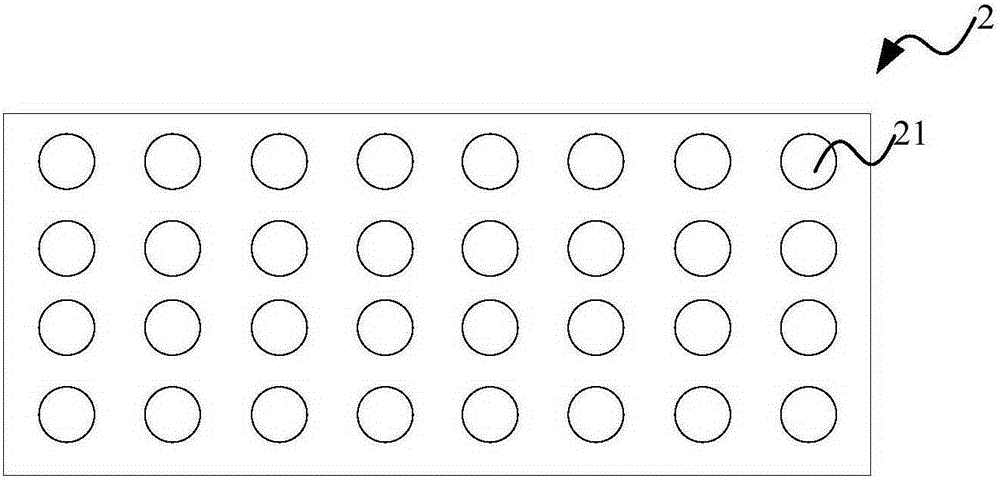

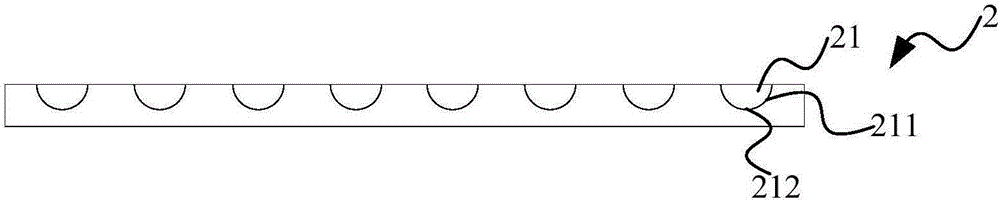

Novel grid-type cryopreservation box made of mixed material

InactiveCN107416359AEffective shock absorption and bufferingReduce the impact of vibrationDomestic cooling apparatusLighting and heating apparatusMixed materialsEngineering

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

Method for increasing finished product rate of sintered ore

The invention relates to the field of iron and steel metallurgy, and discloses a method for increasing the finished product rate of sintered ore. The method for increasing the finished product rate ofthe sintered ore includes the steps that firstly, clear water is added in a sintered material and selectable return fines, first-time mixing is conducted, the amount of the return fines which are used is smaller than or equal to 30% of the weight of the sintered material, and the returned fines are vanadium-titanium sintered ore with the grain size being 5 mm or lower; secondly, second-time mixing is conducted on the mixed material obtained in the first step and mixed material reinforcement liquid; and thirdly, the mixed material obtained in the second step is subjected to material distribution, ignition and sintering, wherein the mixed material reinforcement liquid is prepared from corn starch and warm water according to the proportion being (0.05-1) : 99, and the temperature of the warmwater is 40 DEG C to 80 DEG C. By means of the method, the size composition of the mixed material can be improved, and therefore the finished product rate of the sintered ore is increased.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

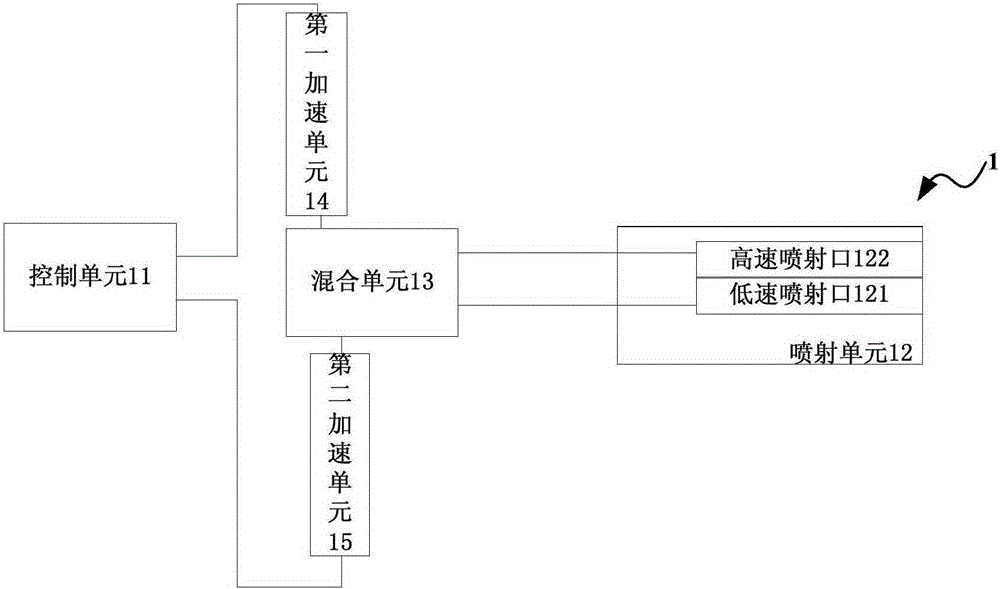

Printed circuit board (PCB) printing device and method

ActiveCN105329000AFlexible printingControl precisionTypewritersOther printing apparatusElectricitySpray nozzle

Owner:台州市吉吉知识产权运营有限公司

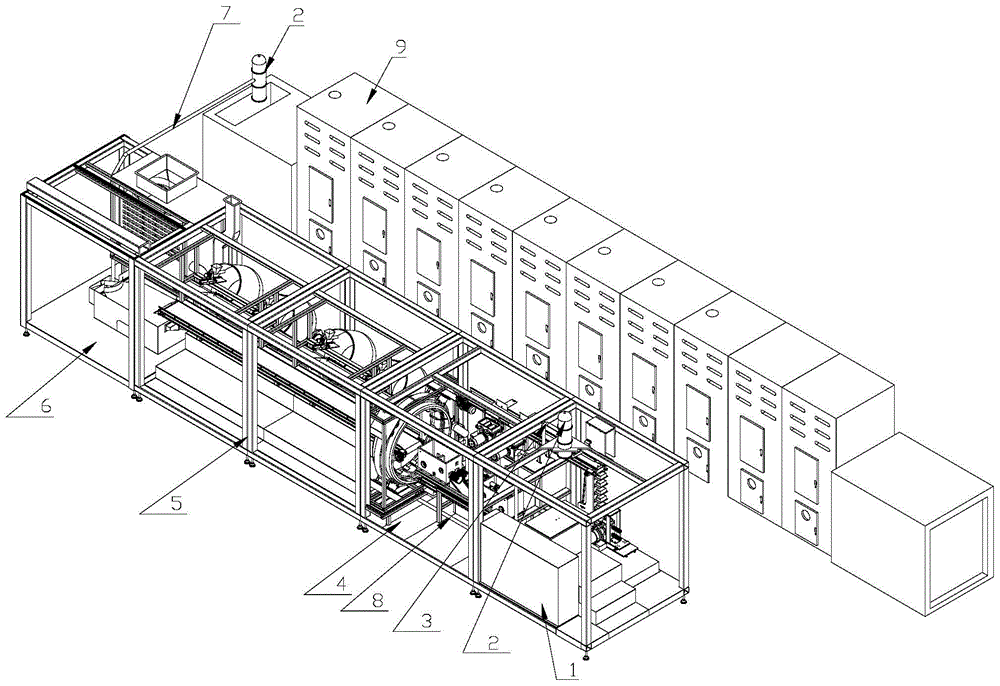

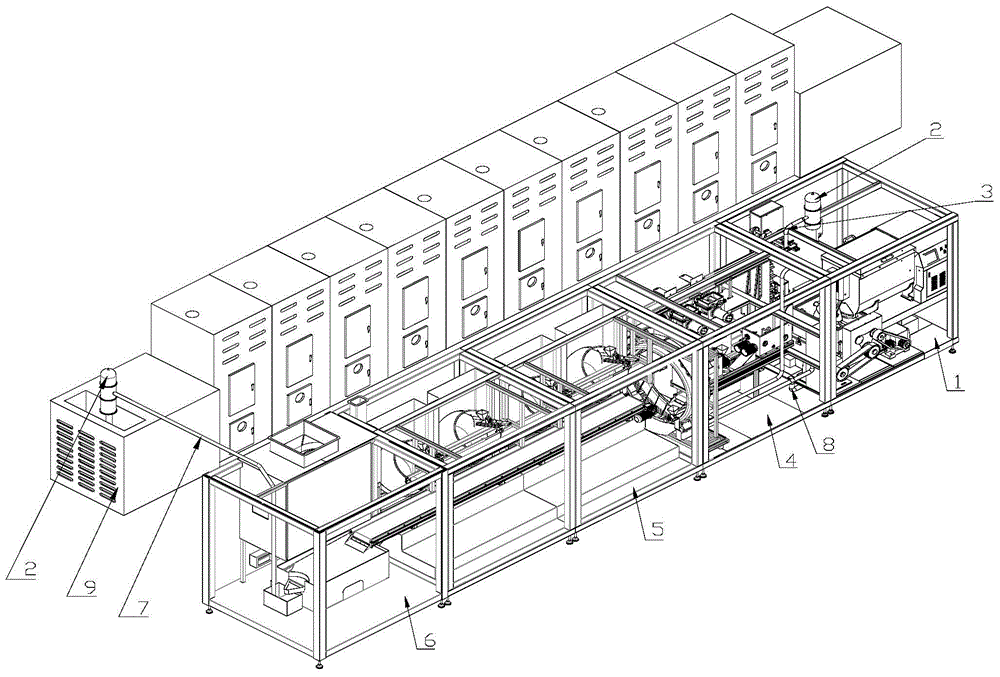

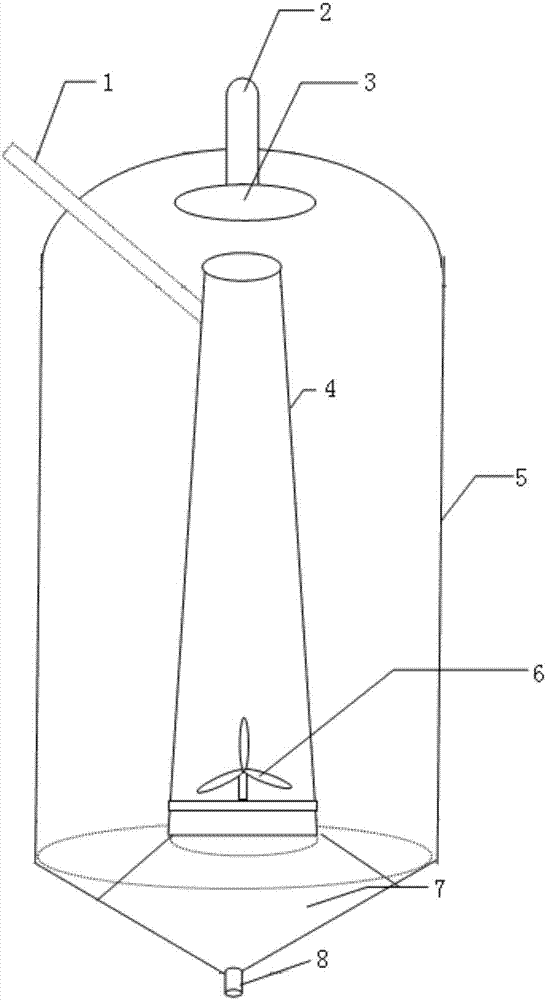

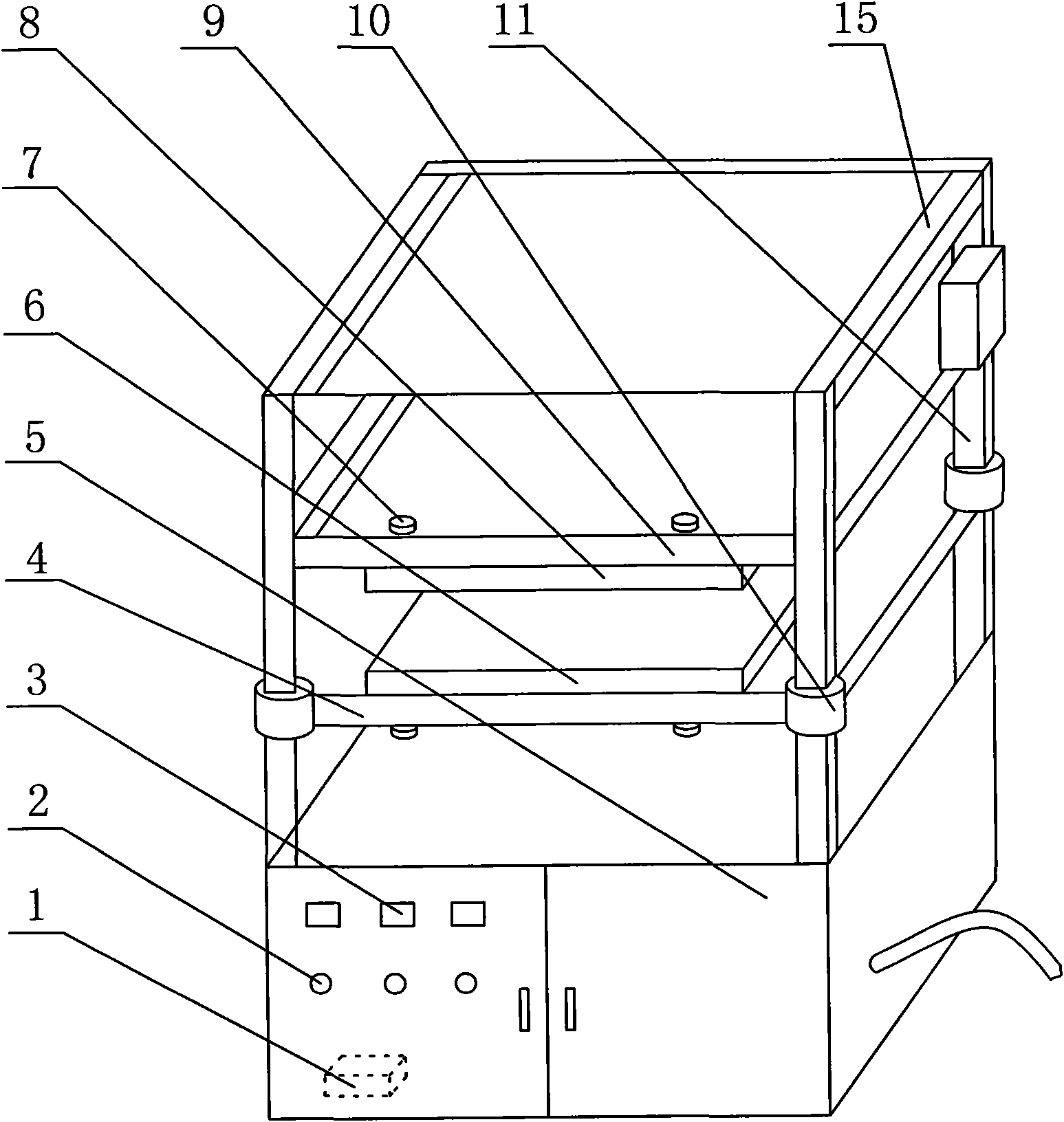

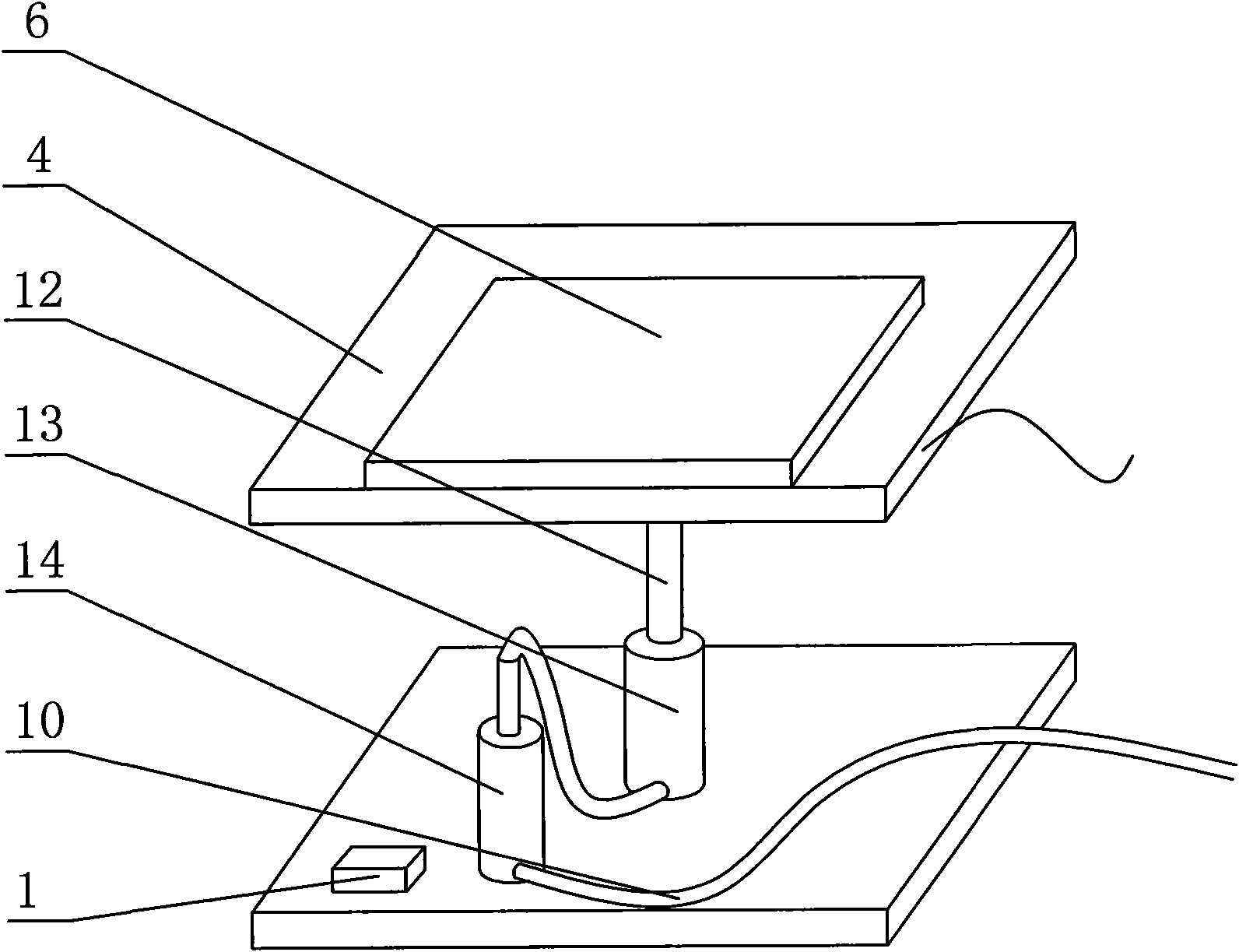

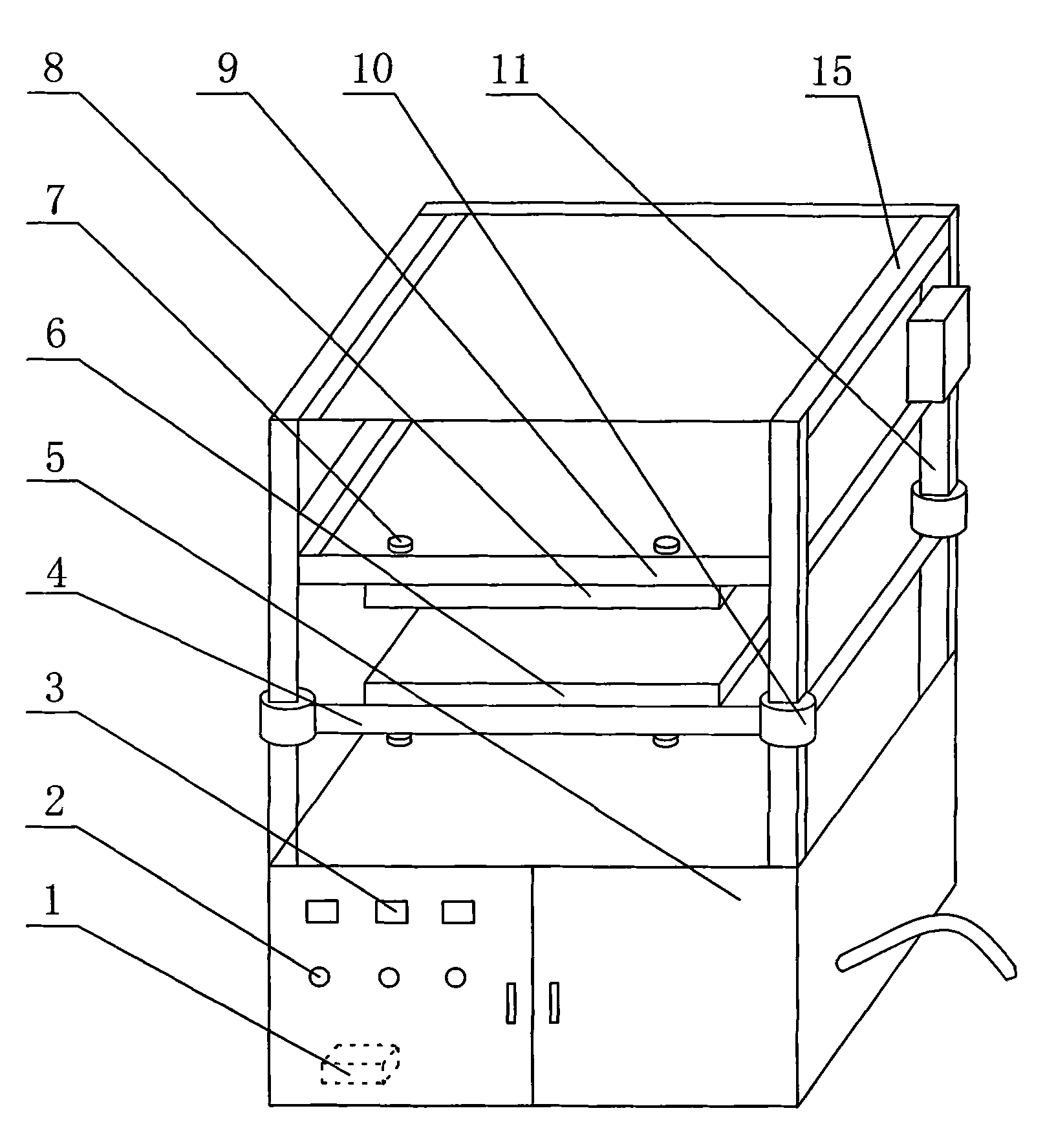

Mixed material pilling, polishing and drying device

ActiveCN104546484AAchieve modularityFavorable connectionPharmaceutical product form changeHeating arrangementProduction lineMicrowave

Owner:天水华圆尚御科技有限公司

High-impact-resistance high-flowability ABS resin and preparation method thereof

InactiveCN108329646ASolve the problem of low impact strengthLiquidPolymer scienceBulk polymerization

The invention specifically relates to a preparation method for a high-impact-resistance high-flowability ABS resin, belonging to the technical field of high-molecular materials. The preparation methodcomprises the following steps: preparing ABS resin with high impact strength by using a DOW continuous bulk polymerization process, adding bulk ABS resin, SAN resin, a plasticizer, a lubricant and acompatibilizer in a certain mass ratio into a mixer for thorough mixing so as to obtain a mixed material; and then feeding the obtained mixed material into a twin-screw extruder for mixing, extruding,drawing, cooling and pelletizing so as to obtain the high-impact-resistance high-flowability ABS resin. The ABS resin prepared in the invention has superior impact performance; at the same time, thecompatibilizer is added during blending, so the compatibility between the ABS resin and the SAN resin is improved, the adhesion between the two polymers is increased, and a more stable structure is formed.

Owner:NORTH HUAJIN CHEM IND CO LTD

Anti-leakage ball-point pen ink and preparation method thereof

Owner:SUZHOU XIONGYING INK TECH

Nutrient slow-release fertilizer

InactiveCN104725148AImprove microcirculationProlong active periodBio-organic fraction processingBioloigcal waste fertilisersMetaboliteMixed materials

Owner:TAIXING AGULISI BIOTECH CO LTD

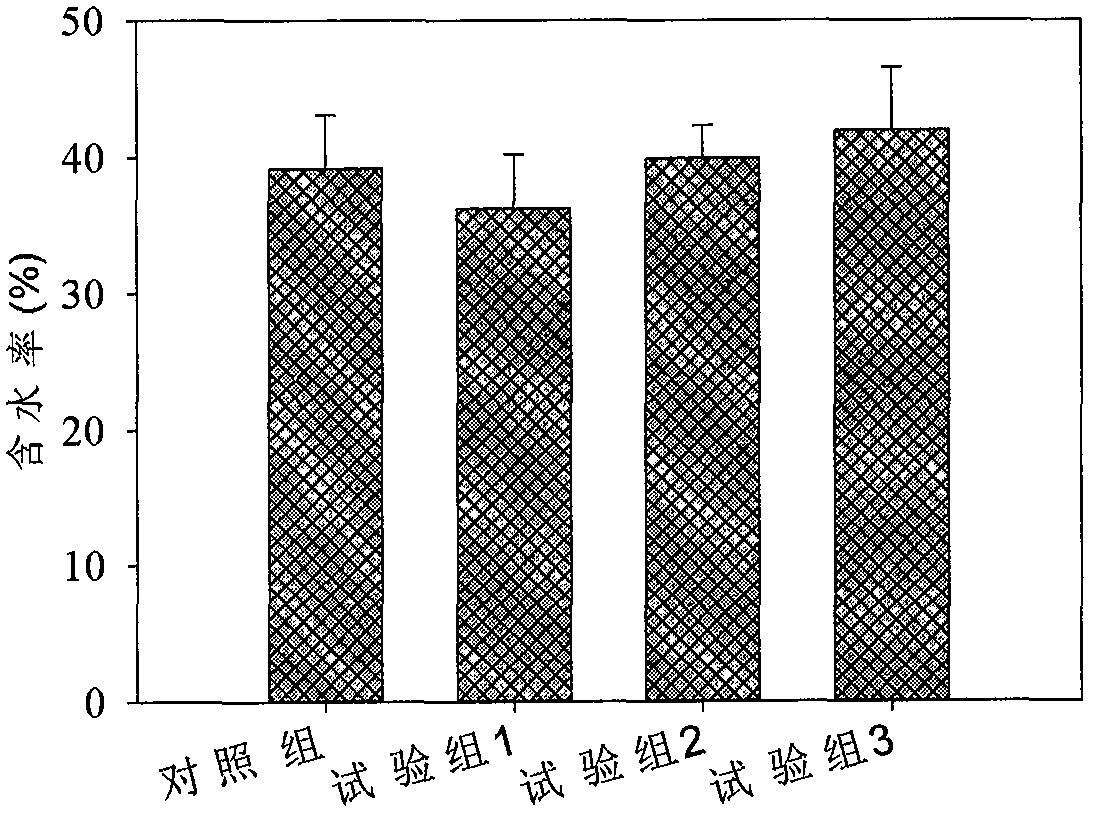

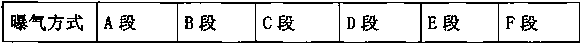

Method for biologically drying sludge by using rice hull as additive

Owner:SHENYANG ACAD OF ENVIRONMENTAL SCI

Novel biological material for plant disease and pest control

InactiveCN108184878AIncrease the fragranceImprove durabilityBiocidePest attractantsDehydroacetic acidDisease

Owner:陈益德

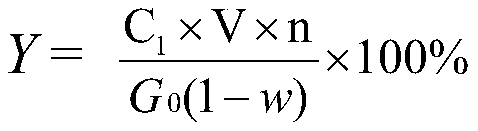

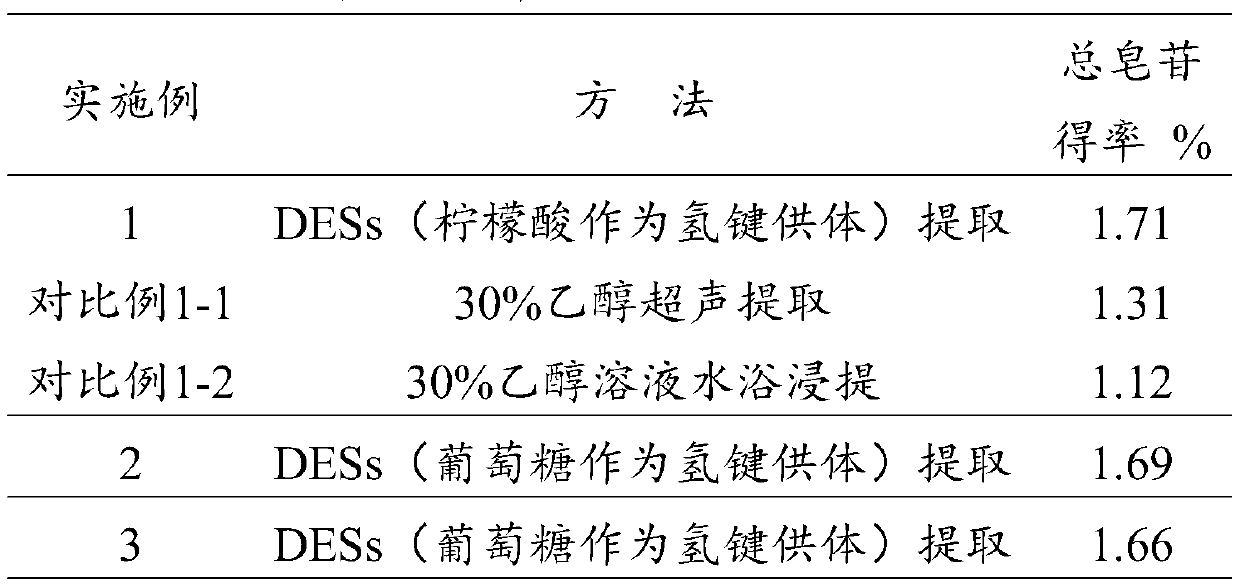

Method for extracting saponin active ingredients from bark of acacia mearnsii de willd based on deep eutectic solvents

Owner:NANJING FORESTRY UNIV

Method for producing environmentally friendly high-temperature fold-resistant high-strength high purity corundum bricks

InactiveCN105237003ASurprised by high temperature flexural performanceReduce dosageBrickMixed materials

Owner:长兴宏泰耐火器材有限公司

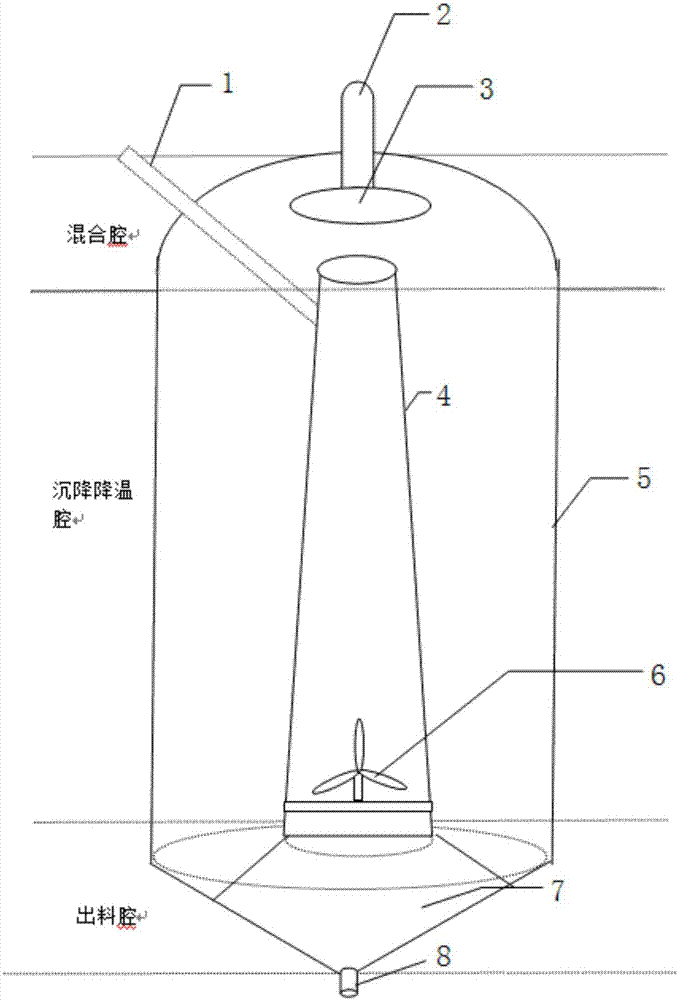

Granulated arabinose preparation method and device

PendingCN107987109AHigh hardnessHigh densitySugar derivativesSugar derivatives preparationMolten stateCooling chamber

Owner:山东绿健生物技术有限公司

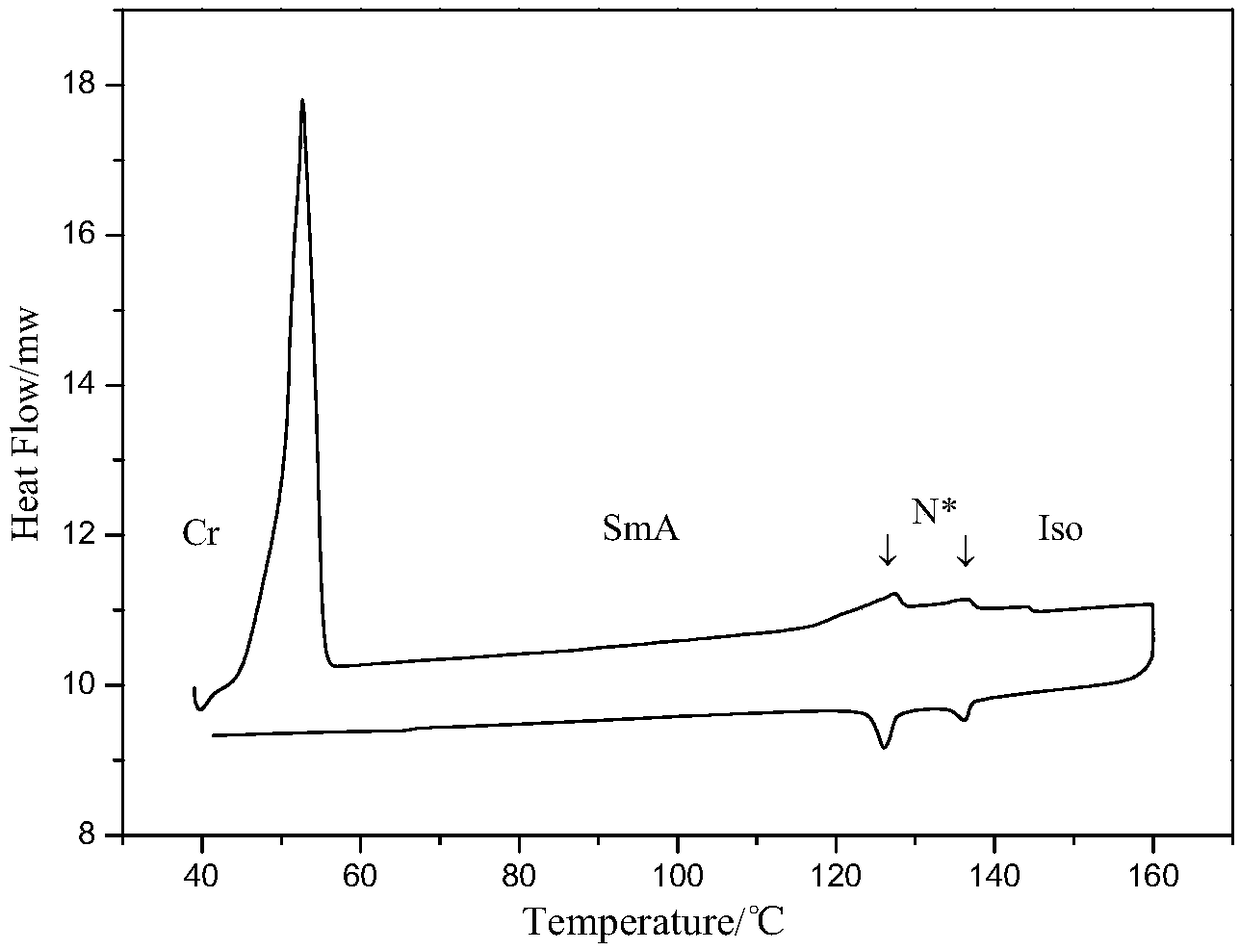

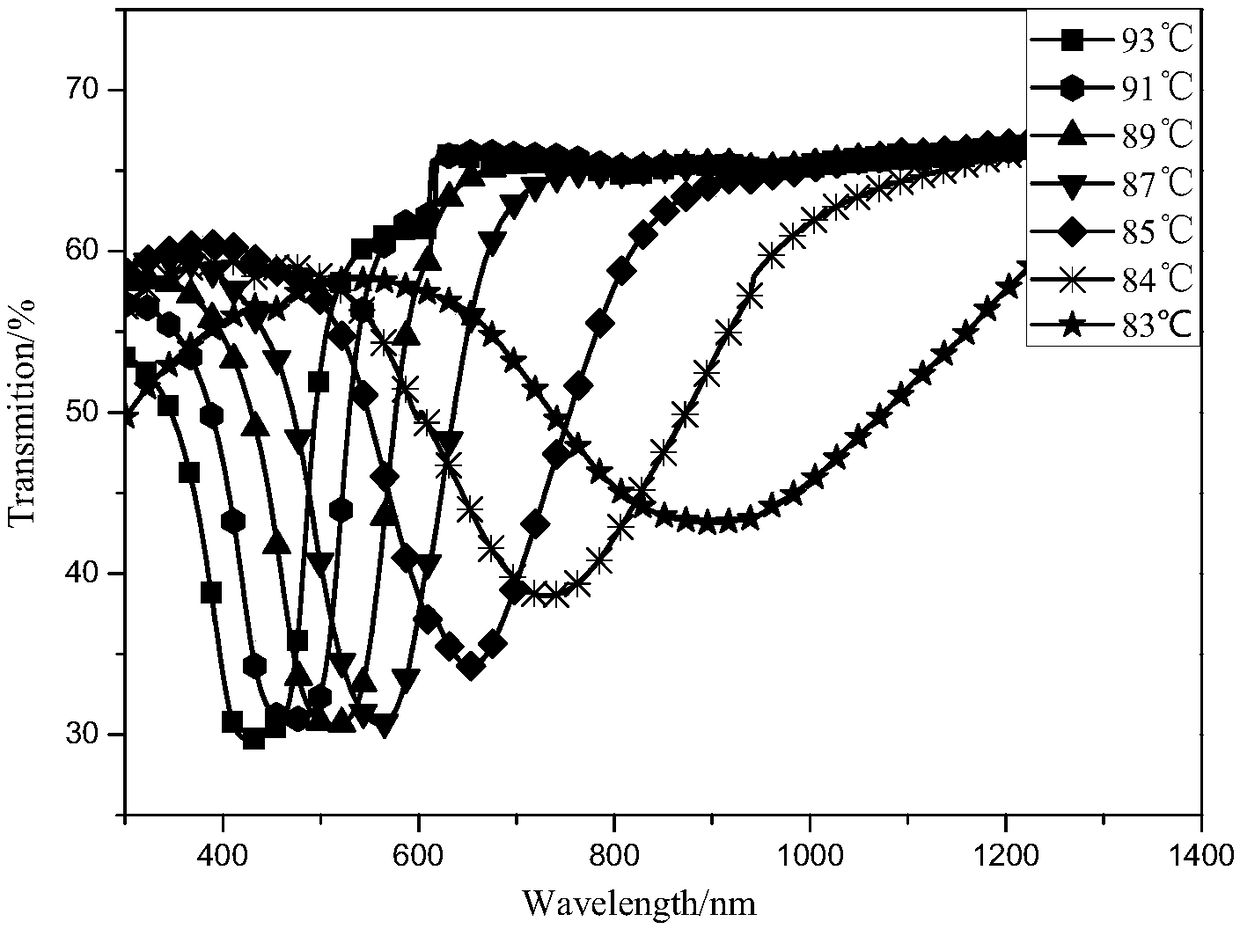

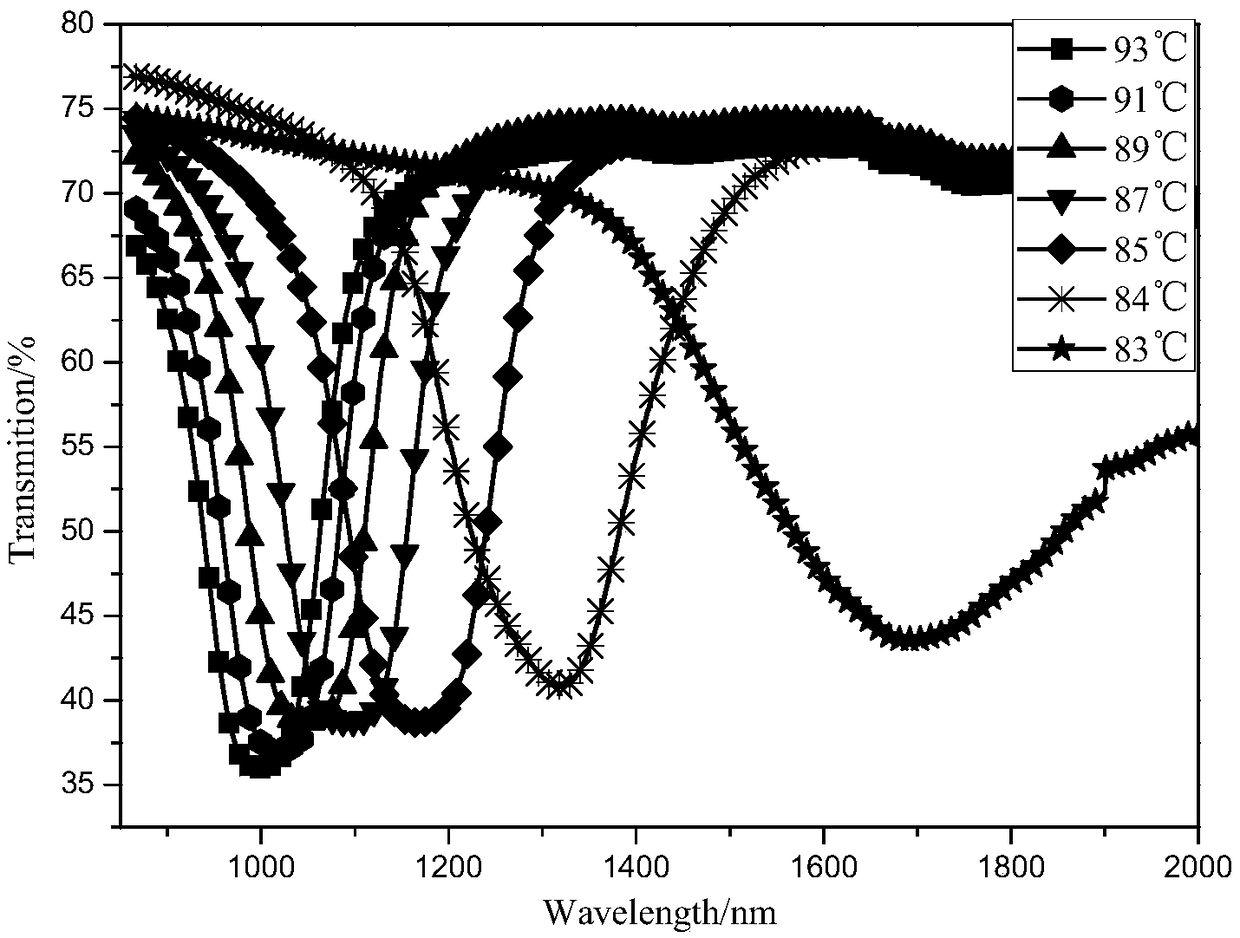

Distorted grain boundary phase-A liquid crystal mixed material with wide temperature range and preparation method of grain boundary phase-A liquid crystal mixed material

ActiveCN108865181AWell mixedExperimental materials are readily availableLiquid crystal compositionsMixed materialsMixing ratio

Owner:UNIV OF SCI & TECH BEIJING

Vacuum granulation method for refractory materials

The invention discloses a high-temperature fire-proof material granulating method, which is characterized in that: first the material enters the material distributor, to be forced by three horizontal wing-shape mixing lodicules and vertical mixing shovel to make frequency variable speed-adjustable circle motion, therefore, the material can writhe by the shearing forces in horizontal and vertical directions to attain uniform material; wherein, the set granulating condition comprises: time: 800-1000s; temperature: 40-50Deg. C; and when reaching said condition, opening the vacuum valve, to adjust the pressure in -0.06-0.08MPa, and the mixing lodicules and shovel granulate in variable speed again, and vacuuming the gas of mixed material to improve the density more, reduce the hole rate and improve eth size and uniformity of particles.

Owner:MAANSHAN YIJIANG REFRACTORY CERAMICS MFG CO LTD

Formula and manufacturing method of antique tile with high-brightness surface

Owner:怀化市新益全新型环保建材有限公司

Plastic extruder

InactiveCN107553868AIncrease squeezeHelp stirringHelical lineReduction drive

Owner:徐国峰

Horizontal spiral discharging centrifuge

Owner:西安水牧环境科技有限公司

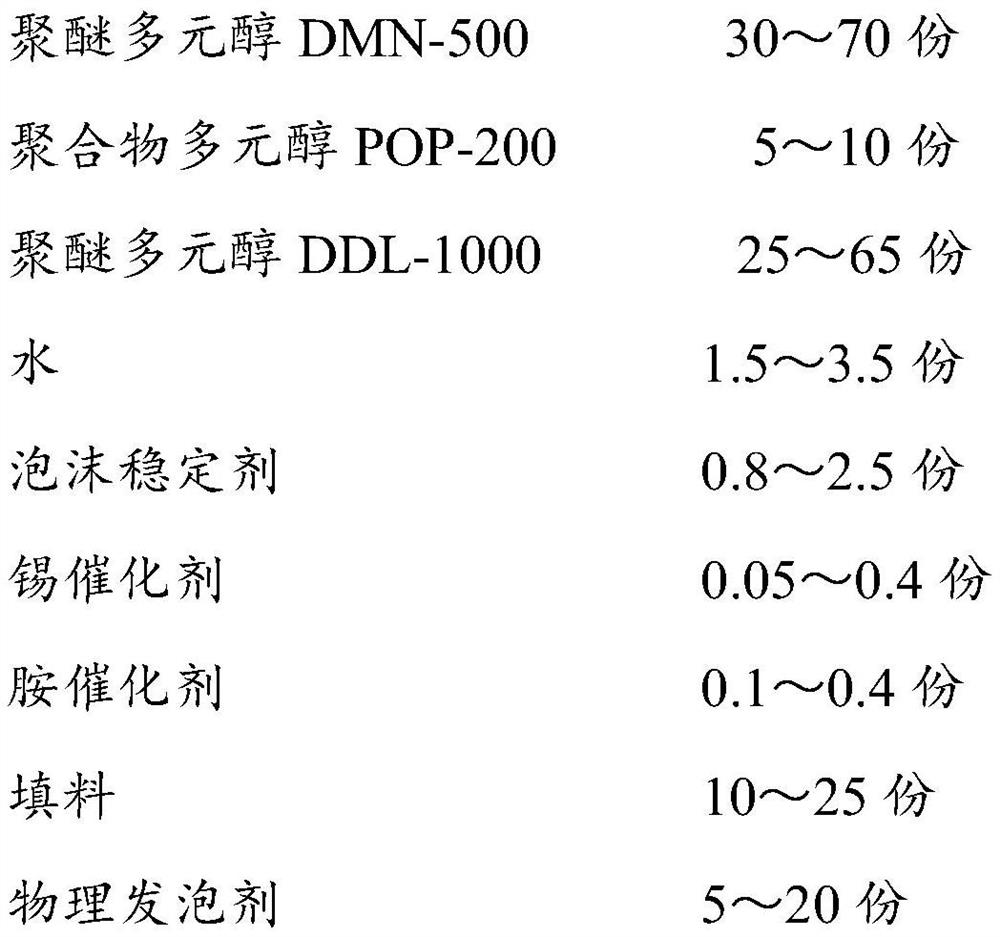

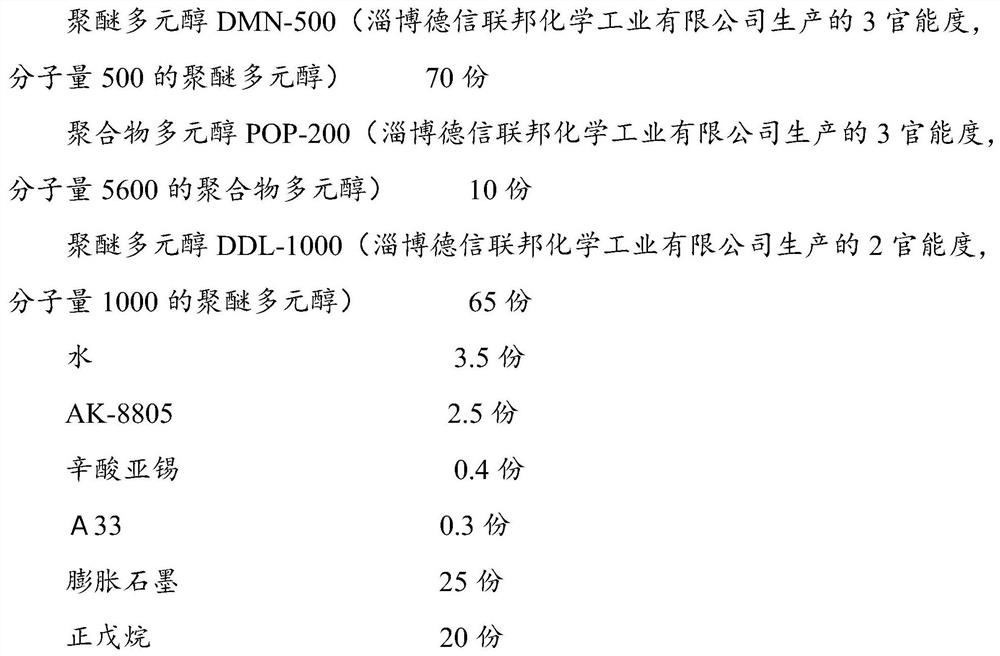

Polyurethane cable insulating material and preparation method thereof

InactiveCN111892691ASimple processing technologyIncrease productivityPlastic/resin/waxes insulatorsPolymer sciencePtru catalyst

Owner:荆晓东

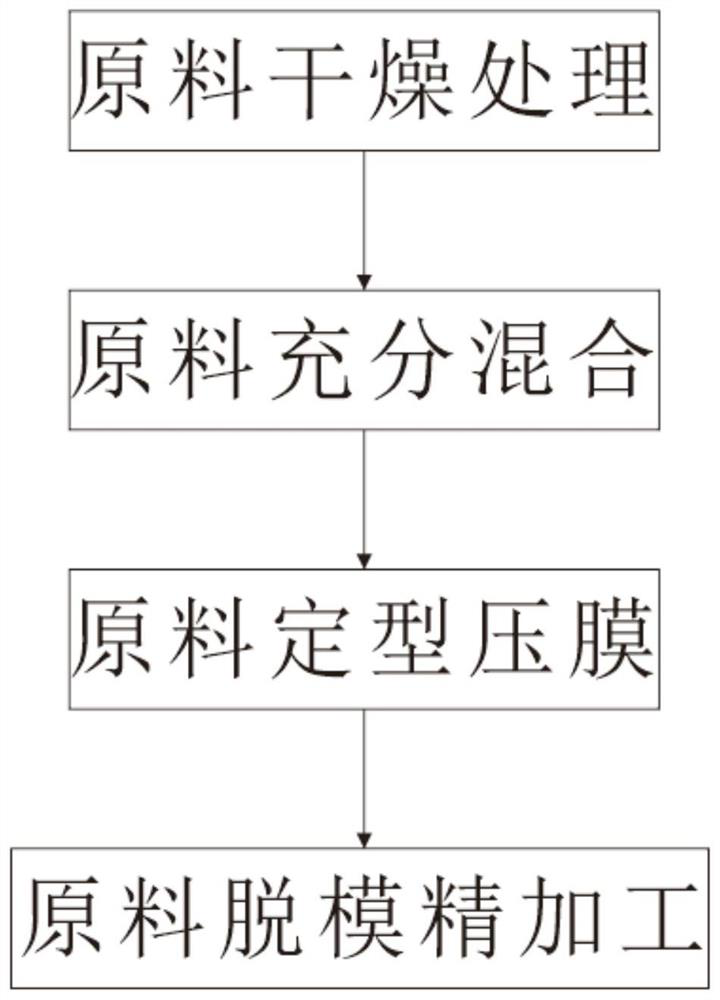

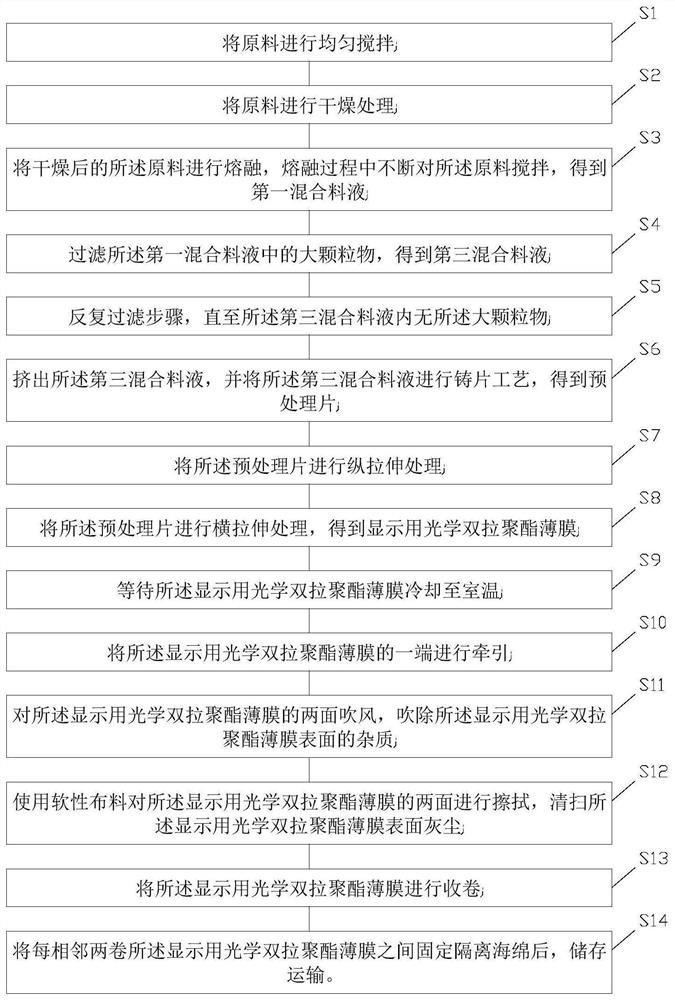

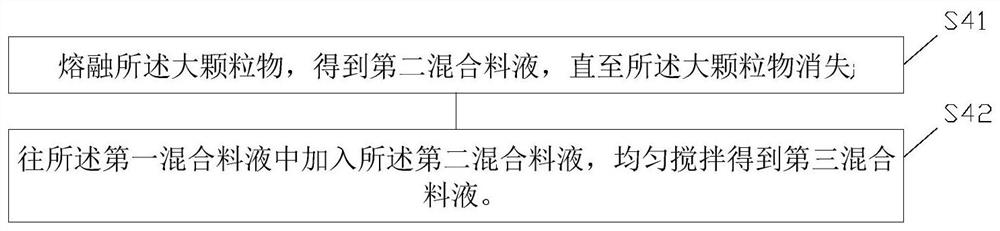

Preparation method of optical double-drawing polyester film for display

Owner:NANJING LANPUCHENG NEW MATERIALS

Wheatstrawplant fibersynthetic resin and preparation process thereof

Owner:安徽科邦树脂科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap