Mixed material pilling, polishing and drying device

A drying device and pill-making technology, which is applied in heating devices, devices for making medicines into special physical or taking forms, and drying, etc., can solve problems such as long debugging time, achieve good production quality, simplify equipment structure, Reasonable and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

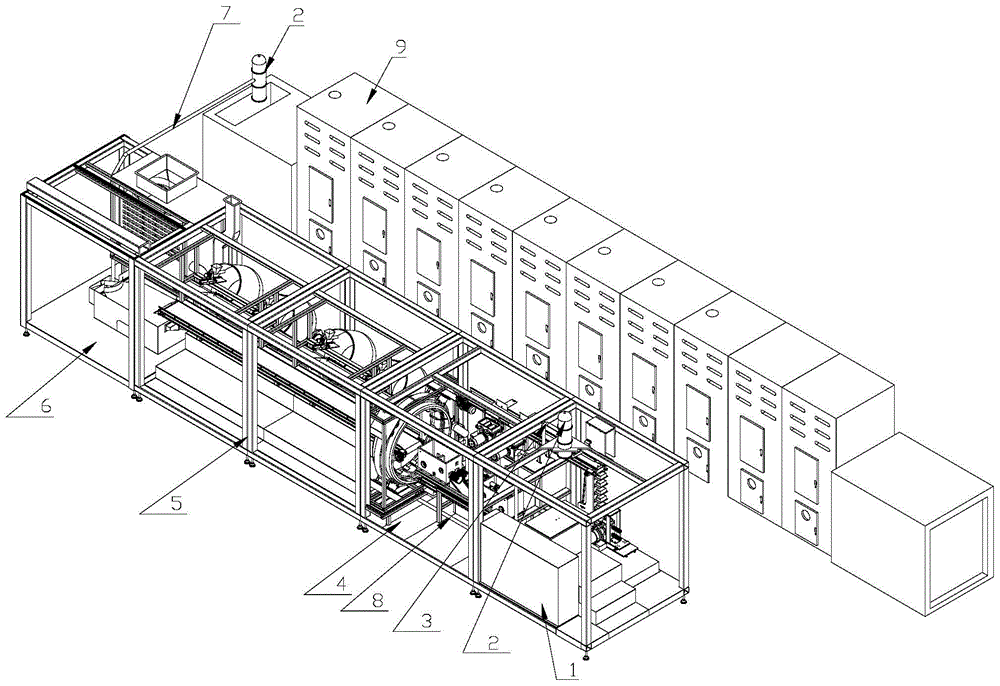

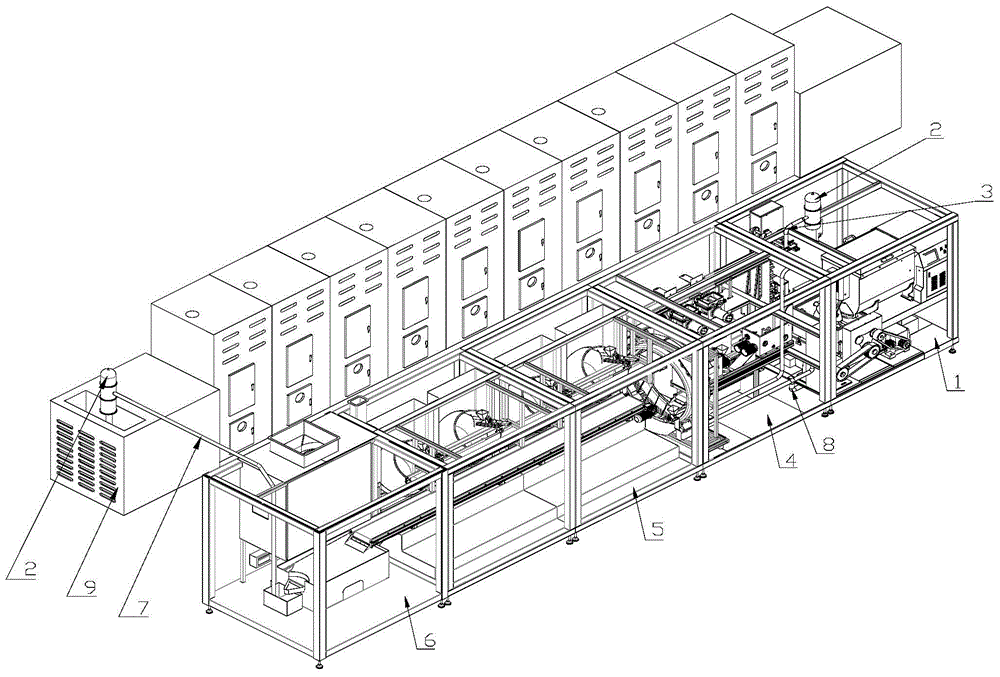

[0027] Example 1, see figure 1 , a mixing pill making polishing and drying device, comprising a mixing and refining module 1, a pill making module 4, a polishing module 5, a pill selection module 6 and a microwave drying 9 connected in sequence.

Embodiment 2

[0028] Example 2, see Figure 7 , the microwave drying structure 9 includes a microwave drying box 9-1 and a microwave control system 9-2, and the collection box 6-3 is provided with a vacuum pumping system 6-4. The outlet is located in the microwave drying box 9-1. Above the entrance to Box 9-1.

[0029] The microwave drying structure 9 can be a conventional microwave device with a microwave frequency of 2450MHZ, see Figure 7 , or it can be a microwave with a stronger microwave penetration ability with a frequency of 915MHZ, see Figure 9 , or it can be a microwave device with a vacuum cavity, see Figure 10 .

[0030] The rest of the structure is the same as that of Example 1.

Embodiment 3

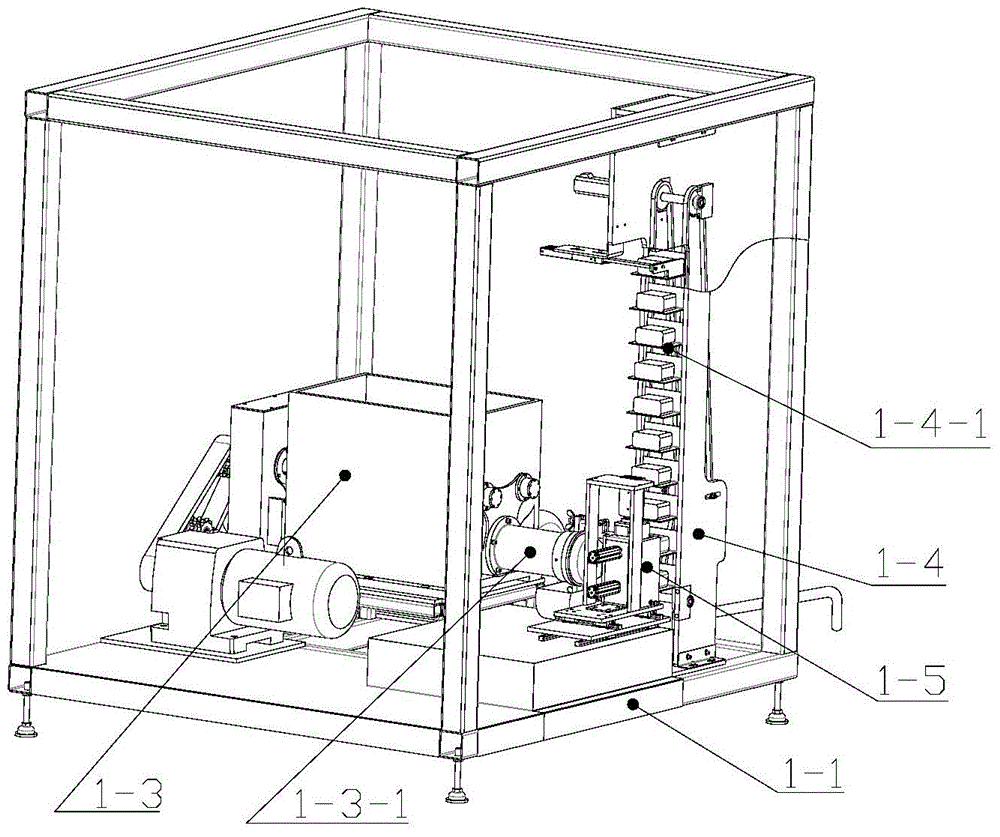

[0031] Embodiment 3, see Fig. 3, the mixing and refining module 1 includes a double-paddle mixing and refining compound machine 1-3 on the module base 1-1; the outlet 1 of the double-paddle mixing and refining compound machine 1-3 -3-1 Connect the forming mould 1-5, the discharge end of the forming mould 1-5 is an elevator type lifting device 1-4; the elevator type lifting device 1-4 is provided with a feeding chain plate 1-4-1.

[0032] The rest of the structure is the same as that of Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap