Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Material distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

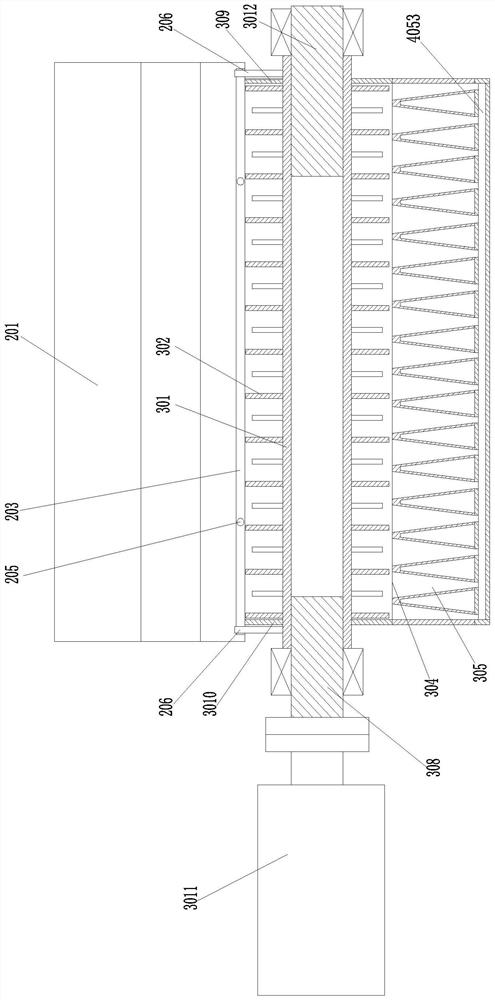

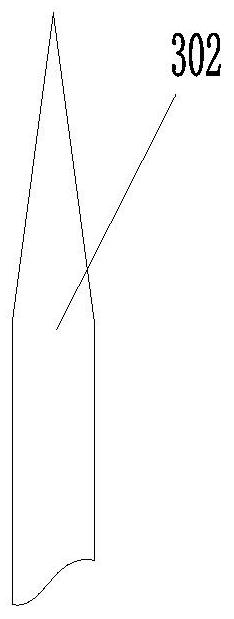

Full-automatic material distribution device and production process used for producing micro powder polished tiles

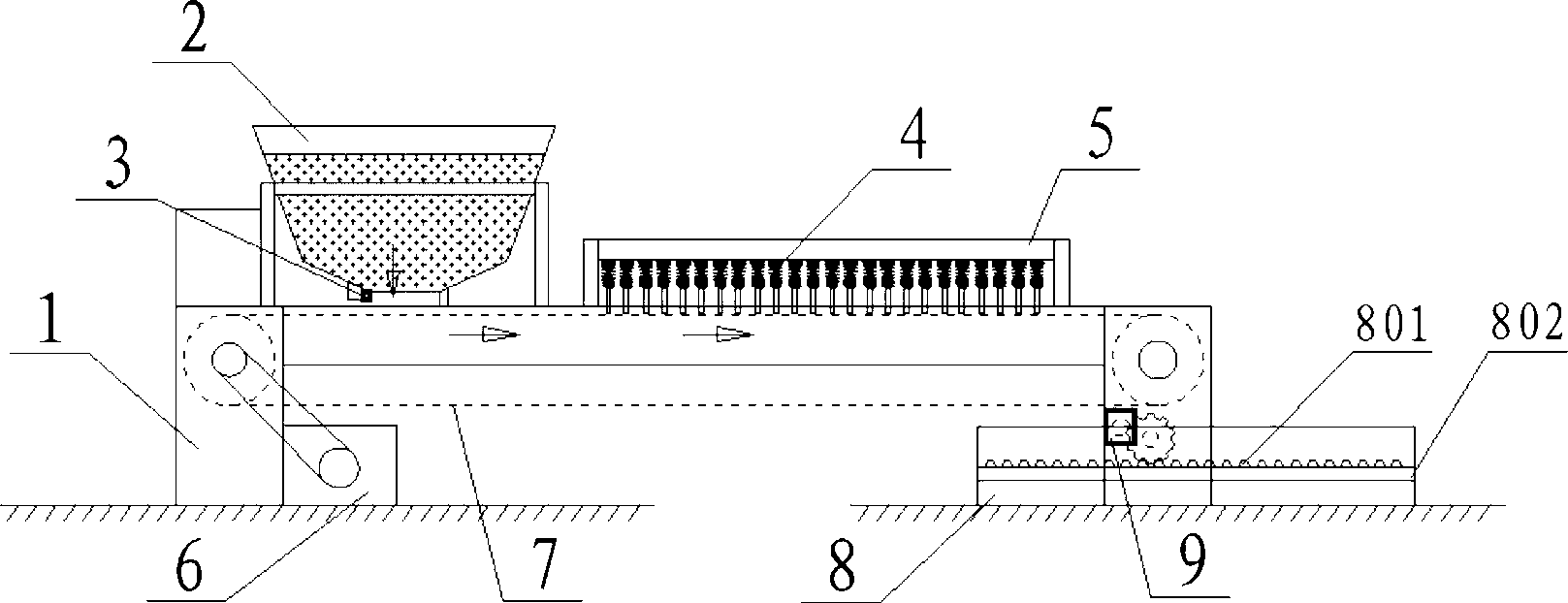

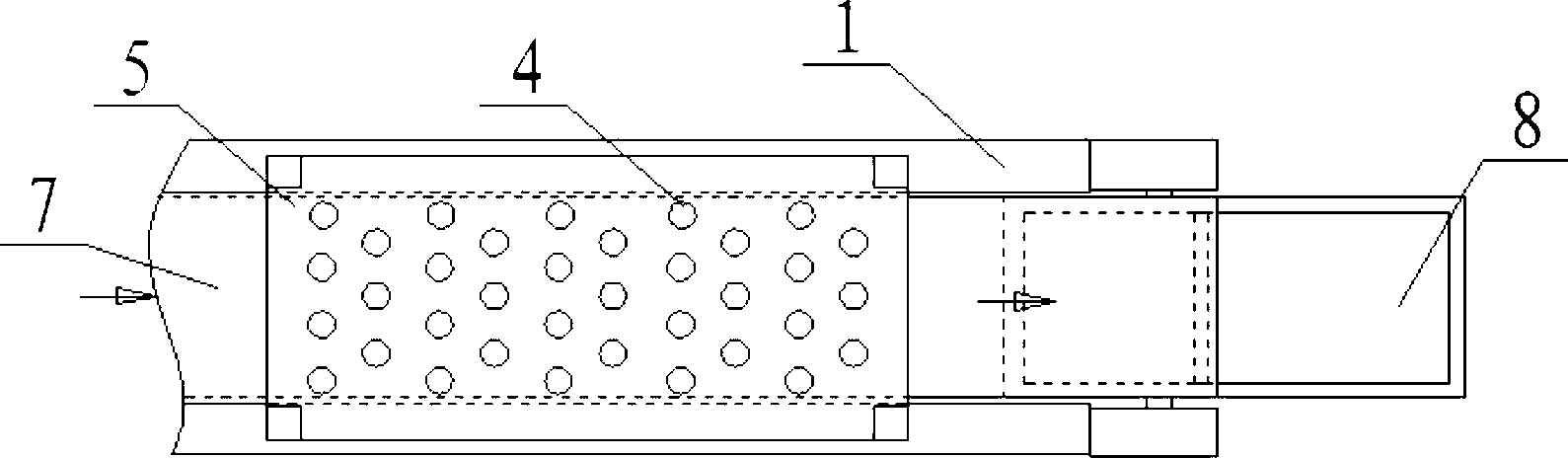

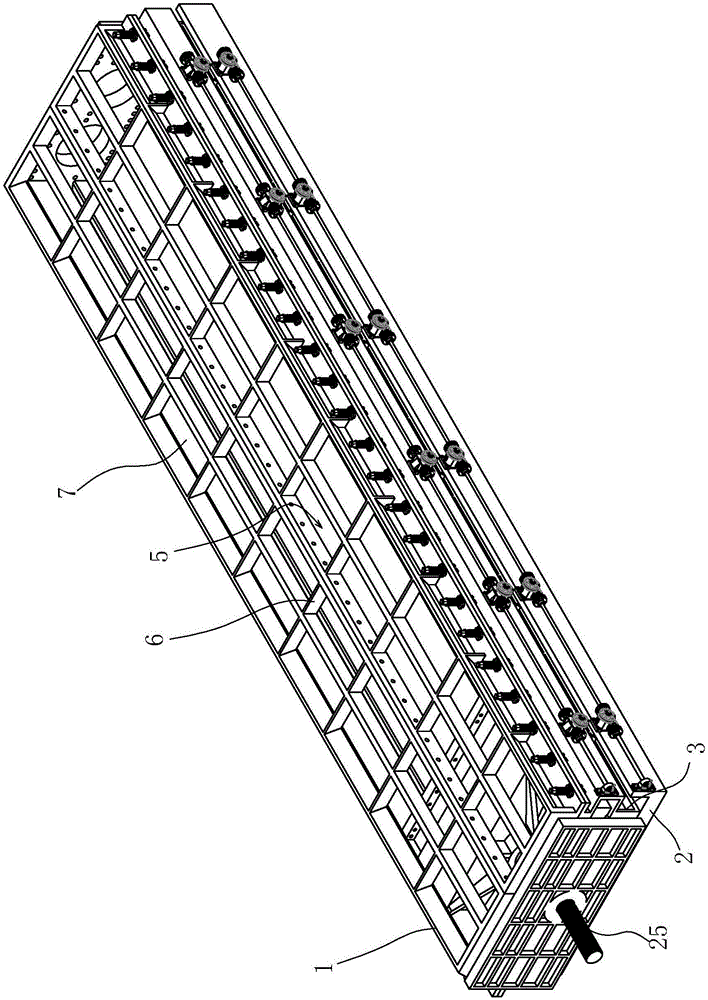

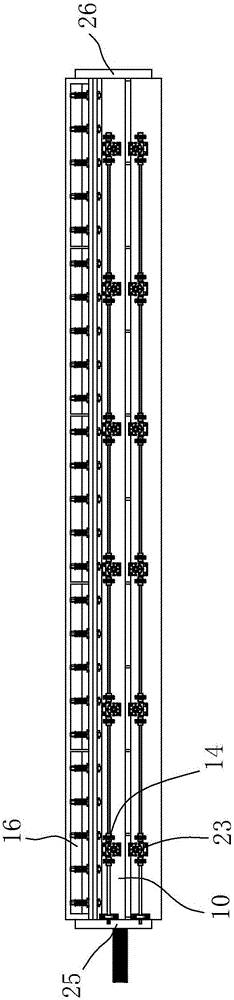

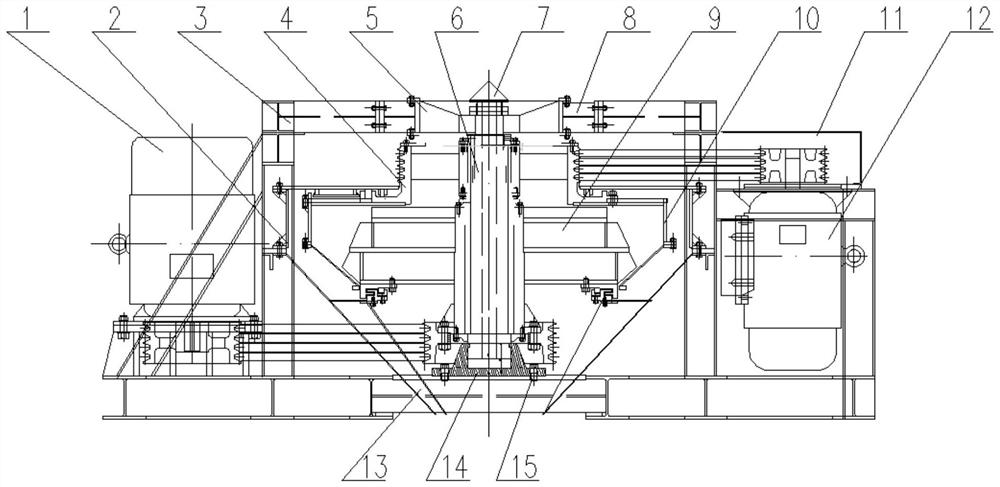

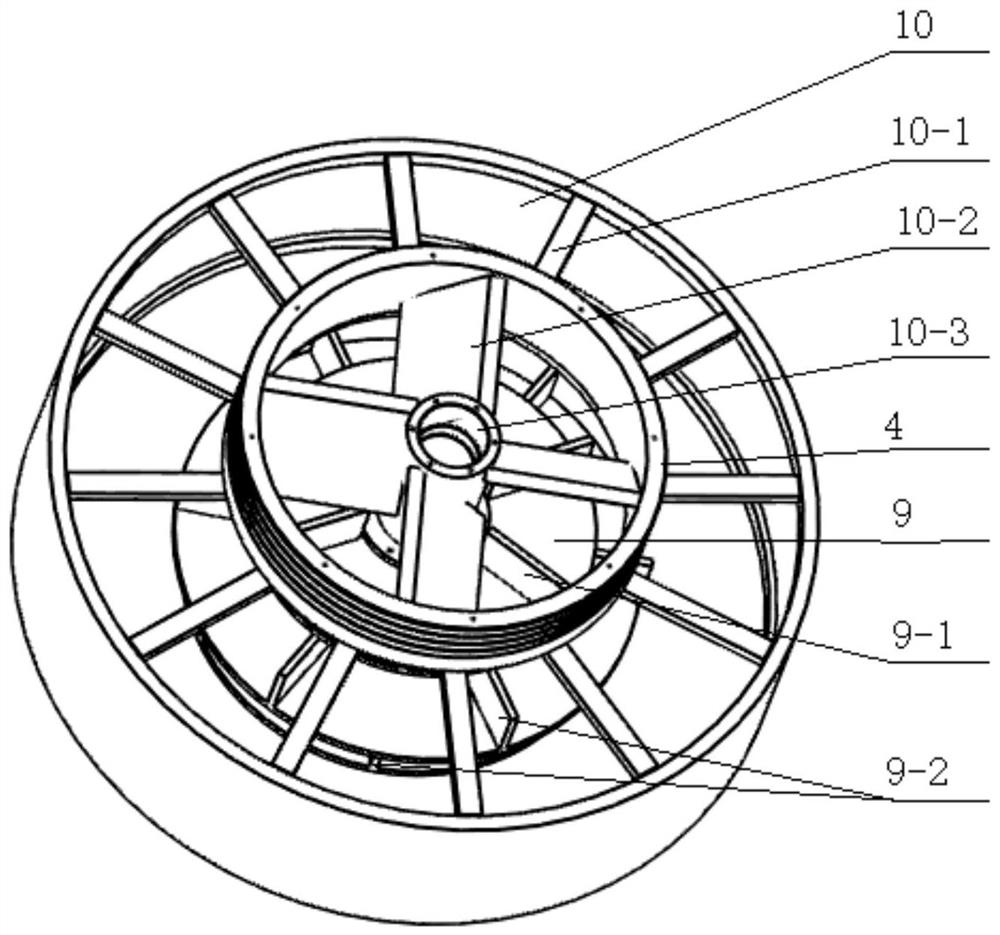

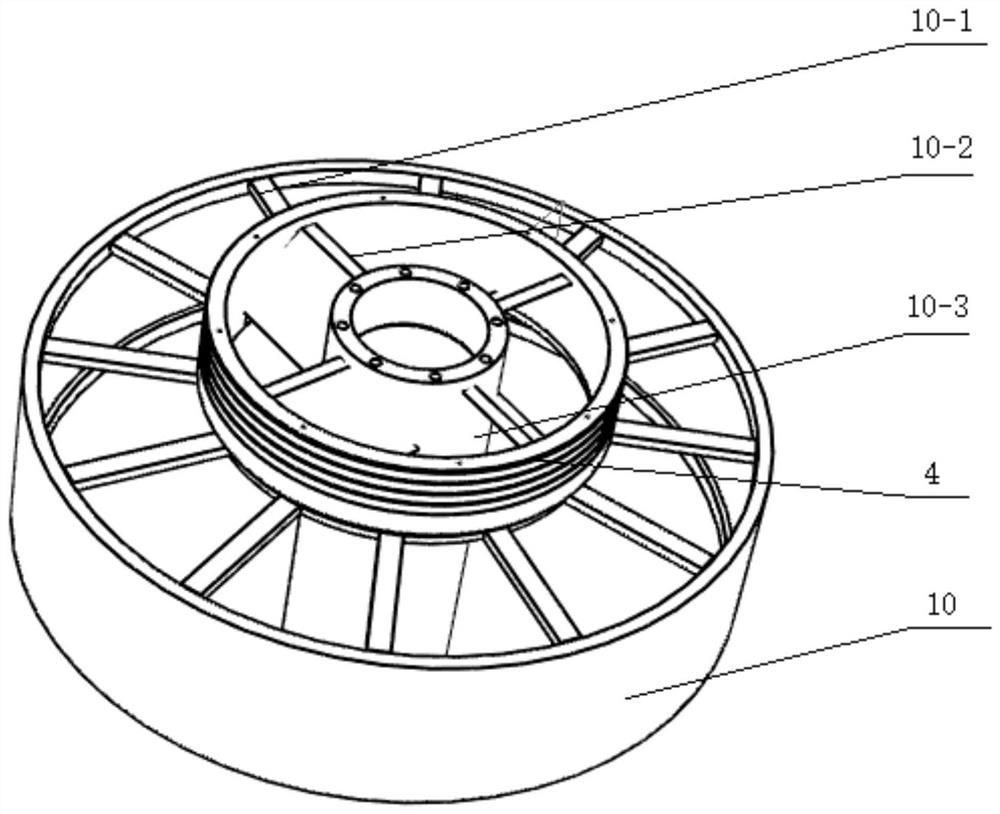

The invention discloses a full-automatic material distribution device and production process used for producing micro powder polished tiles. The full-automatic material distribution device comprises a main conveying belt for conveying micro powder, a line micro powder distribution mechanism, a material distribution mechanism, a material supplement mechanism, a grid feeding mechanism and an extrusion machine are sequentially arranged above the main conveying belt in the conveying direction, the line micro powder distribution mechanism, the material distribution mechanism and the material supplement mechanism sequentially distribute different types of powdery materials on the main conveying belt and then overlap the powdery materials step by step, and the grid feeding mechanism cuts the mixed powdery materials on the main conveying belt according to the specification of polished tiles and then feeds the materials into the extrusion machine for extrusion formation. The full-automatic material distribution device is ingenious and practical in structure. Ceramic micro power polished tiles produced through the full-automatic material distribution device are fine in texture, natural and vivid, the patterns of finished tiles are natural in transition, novel and irregular, and the decoration effect of ceramic micro powder polished tiles is greatly improved.

Owner:GUANGDONG HUIYA CERAMICS CO LTD

Separation apparatus for iron-filing waste slag

InactiveCN104014425AAchieve the purpose of separationHigh separation of iron filingsMagnetic separationMotor driveSlag

Owner:TONGLING HEWU MACHINERY MFG

Method for increasing finished product rate of sintered ore

The invention relates to the field of iron and steel metallurgy, and discloses a method for increasing the finished product rate of sintered ore. The method for increasing the finished product rate ofthe sintered ore includes the steps that firstly, clear water is added in a sintered material and selectable return fines, first-time mixing is conducted, the amount of the return fines which are used is smaller than or equal to 30% of the weight of the sintered material, and the returned fines are vanadium-titanium sintered ore with the grain size being 5 mm or lower; secondly, second-time mixing is conducted on the mixed material obtained in the first step and mixed material reinforcement liquid; and thirdly, the mixed material obtained in the second step is subjected to material distribution, ignition and sintering, wherein the mixed material reinforcement liquid is prepared from corn starch and warm water according to the proportion being (0.05-1) : 99, and the temperature of the warmwater is 40 DEG C to 80 DEG C. By means of the method, the size composition of the mixed material can be improved, and therefore the finished product rate of the sintered ore is increased.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Automatic assembling equipment for electronic ignition element

PendingCN110961921AImprove assembly efficiencySpacing solutionOther manufacturing equipments/toolsMetal working apparatusEngineeringMaterial distribution

The invention provides automatic assembling equipment for an electronic ignition element. The automatic assembling equipment comprises a cutting mechanism, a crimping mechanism, a control mechanism and a material distribution mechanism, the material distribution mechanism comprises a plurality of clamping jaws, a first driving assembly and a second driving assembly, the multiple clamping jaws areconnected to the first driving assembly and driven by the first driving assembly to increase or decrease the distance, and the multiple clamping jaws and the first driving assembly are arranged on thesecond driving assembly and driven by the second driving assembly to move back and forth between the cutting station and the crimping station. Multiple electronic integrated ignition modules cut offby the cutting mechanism are conveyed to the crimping station through the material distribution mechanism, and the distance between the electronic integrated ignition modules is adjusted to be matchedwith the distance between multiple connectors on a transportation jig, so that the crimping mechanism can accurately crimp leg wires of a plurality of the connectors on a plurality of the electronicintegrated ignition modules at the same time, the whole process is controlled by the control mechanism, manual participation is not needed, and efficient assembly of the electronic ignition elements is achieved.

Owner:BEIJING JINYUAN HENGYE TECH DEV CO LTD

Bulk scattering and distributing device for lime kiln

The invention discloses a bulk scattering and distributing device for a lime kiln. The device comprises a material distribution bin, a conical moving body, an inclined slope, a material scattering barrel, a cone supporting piece, an adjusting material opening, a feeding opening, a driving shaft and a driving motor. The driving motor is fixedly mounted at the top of the distribution bin; the driving shaft of the driving motor is inserted into the distribution bin; a driving screw is fixedly installed at the tail end of the driving shaft; a conical moving body is installed on the driving screw;the adjusting material opening is formed in the bin wall of the bottom of the material distribution bin, the adjusting material opening is cylindrical, and the conical moving body is arranged in the adjusting material opening. The device has the beneficial effects that by adjusting the driving screw, a variable annular gap can be generated between the conical surface of the conical moving body andthe adjusting material opening supporting piece in the up-down moving process, so that the feeding speed is changed according to the material distribution requirement, and falling of large-particle materials is limited.

Owner:LONGMEN YINLONG IND CO LTD

Double-rotor impact mill

PendingCN112588375AExtended service lifeImprove lubrication environmentGrain treatmentsControl engineeringElectric machinery

Owner:HUBEI UNIV OF EDUCATION

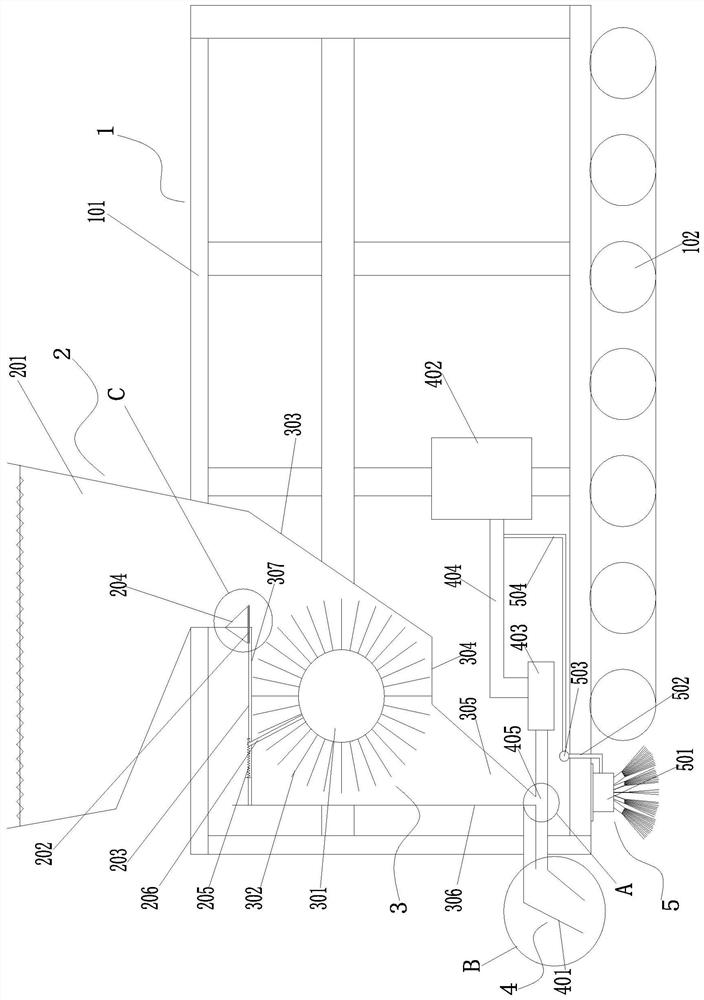

Distributing system for distributing carborundum aggregate

PendingCN114575218ASpread evenlyEfficient and even distributionSolid waste managementBuilding constructionsProcess engineeringMaterial distribution

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap