Mold for manufacturing precast pile with rectangular cross section

A prefabricated pile and cross-section technology, applied in molds, manufacturing tools, ceramic forming machines, etc., can solve the problems of reduced pile-making accuracy, difficulty in demoulding, damage to the mold itself, etc., achieving a high degree of automation, improving pile-making efficiency, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

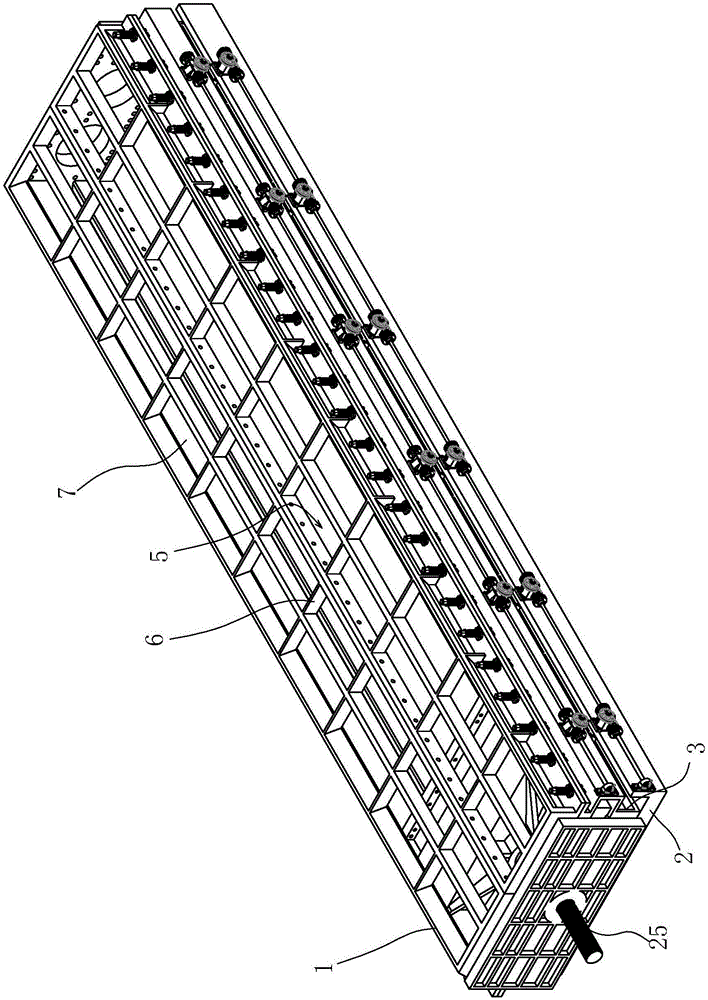

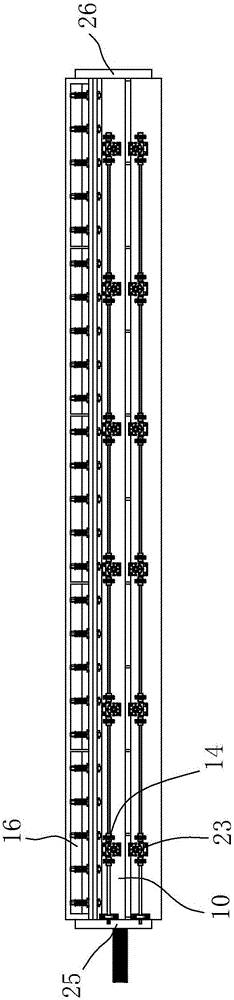

[0024] Such as figure 1 and Figure 5 As shown, a mold for making a rectangular prefabricated pile includes an upper mold assembly 1, a lower mold assembly 2 and a side mold assembly 3, and the upper mold assembly 1 and the lower mold assembly 2 One side is detachably connected to both sides of the side mold assembly 3, the other side of the upper mold assembly 1 and the lower mold assembly 2 are detachably connected to each other, the upper mold assembly 1, the lower mold assembly 2 and the side The mold assembly 3 encloses a mold cavity 4 with a rectangular cross section, and the upper mold assembly 1 is provided with a cloth structure 5 for the concrete material to enter the mold cavity 4 .

[0025] The mold of the present application is divided into three parts, and it is convenient to close the mold. After the prefabricated pile i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap