Distributing system for distributing carborundum aggregate

A distributing system and corundum technology, which is applied in the field of corundum aggregate distributing systems, can solve the problems of adverse effects, inability to achieve uniform distribution, low work efficiency, etc., and achieve the goal of improving final quality, uniformly distributing materials, and efficiently and uniformly distributing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

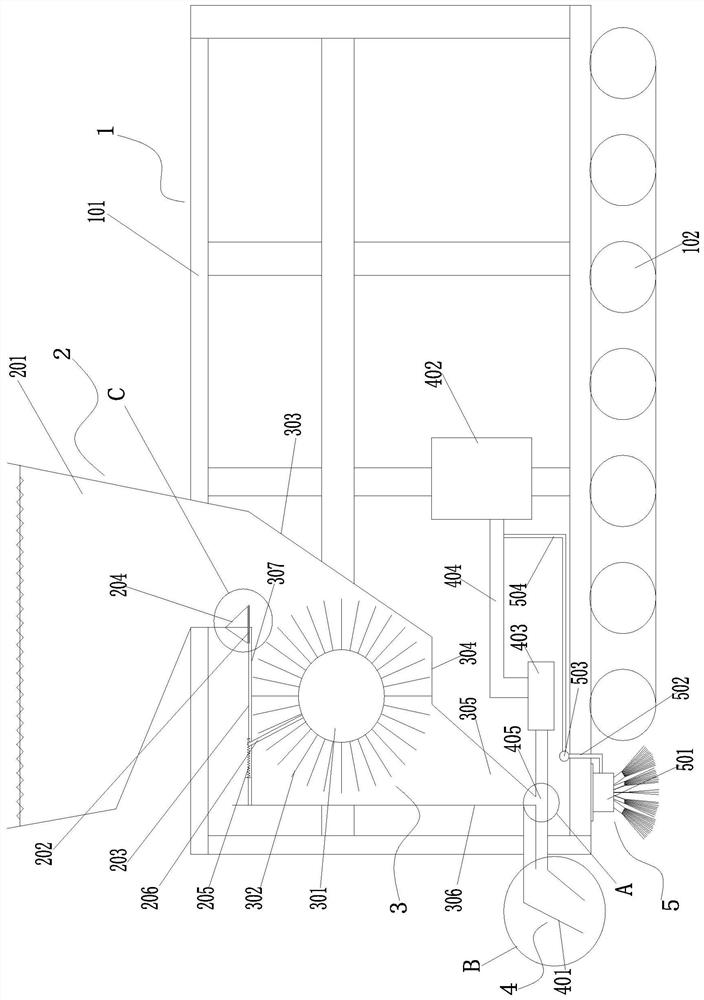

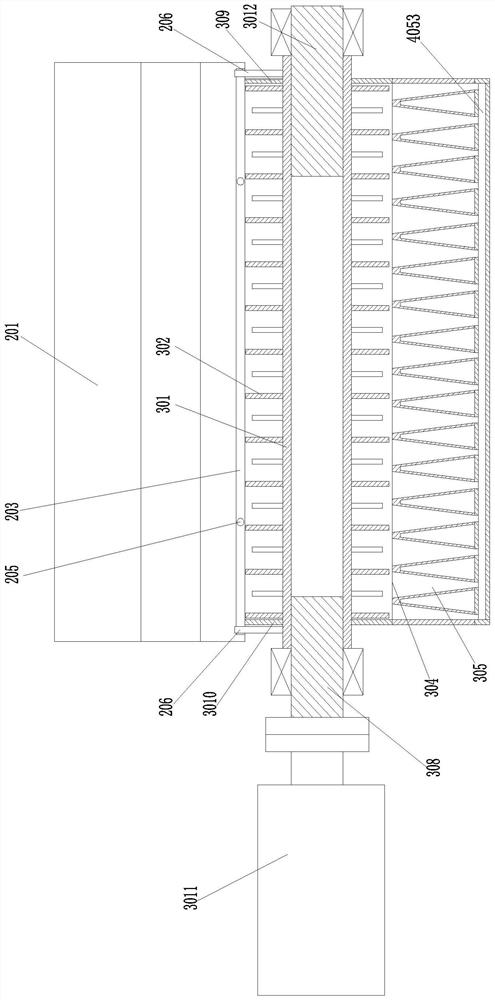

[0032] like Figure 1-Figure 8 Shown: the distributing system for dispersing emery aggregates of the present embodiment is used for distributing in the dispersing process of emery aggregates, and the following is the description of using the system of the present invention for distributing equipment; the distributing equipment includes traveling cart 1 and The material storage device 2, the intermediate conveying system 3 and the distribution system 4 of the present invention installed on the traveling vehicle 1;

[0033] The material storage device 2 is used for storing the material and conveying the material to the intermediate conveying system 3, and the intermediate conveying system 3 conveys the material to the distribution system 4, and the distribution system 4 distributes and outputs the material;

[0034] The distribution system 4 includes:

[0035] The material accelerator 405 uses airflow to accelerate and eject the material;

[0036] The distributor 401 has a reflec

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap