Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

171results about How to "Guaranteed accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

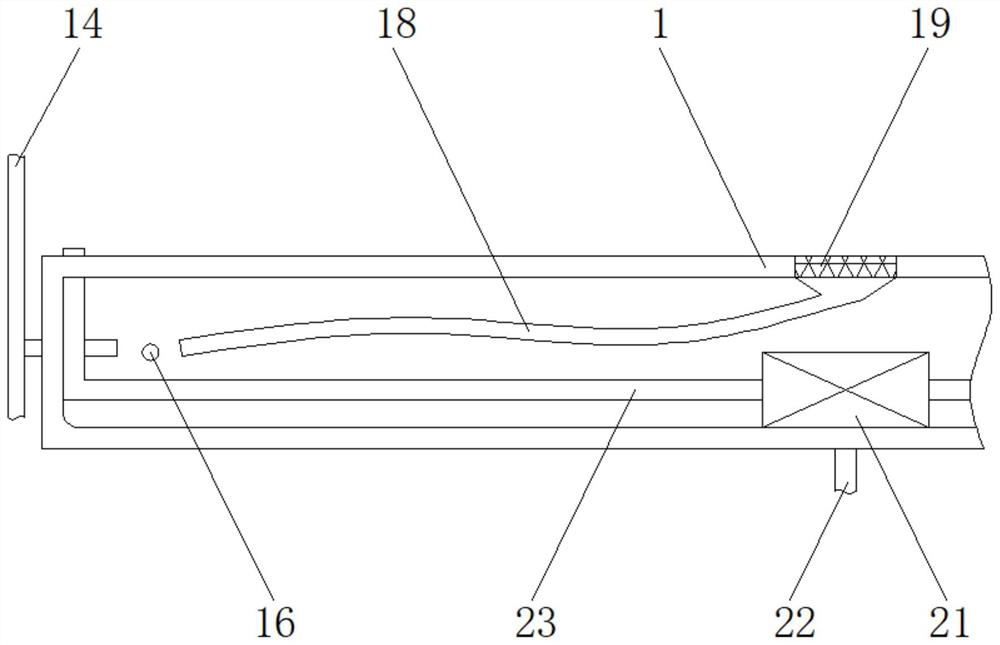

Traffic surveillance method and system

InactiveUS20050151846A1Avoid high pressureGuaranteed accuracyTelevision system detailsColor television detailsTamper resistanceVideo recording

The invention relates generally to a method and system for monitoring traffic events at a predetermined location, using a temporary video camera set up to record traffic movements through an intersection or other location along a road. The method preferably comprises taking a video recording of the location, and then sending the recording to a foreign country where the recording can be reviewed manually at a reduced cost. To facilitate an accurate and consistent review of the recording, the invention preferably uses “event lines” that can be superimposed on the video monitor, wherein the event lines help determine when a vehicle has passed through an intersection, i.e., when a recordable traffic event occurs. The system also preferably uses a computer-operated program adapted to assist the operator in reviewing, verifying and summarizing the recorded information, wherein a particular key or keys can be pressed depending on the type of event to be indicated. The system is also able to identify the exact frame number of a recordable event that corresponds to an exact moment in real time, i.e., when the event actually occurred. A tripod-like apparatus for temporarily setting up a video camera in locations where no existing pole or structure is available, as well as a tamper-proof housing in which the video recording device can be temporarily mounted, can also be provided.

Owner:THORNHILL WILLIAM

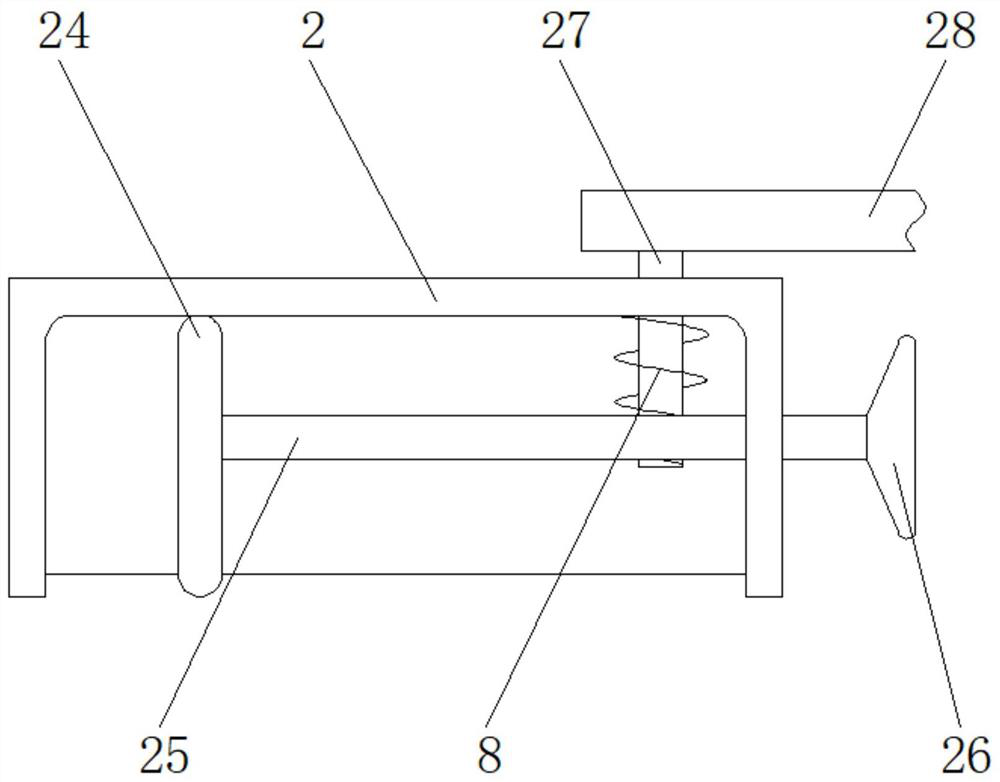

Multi-axle vehicle as well as electro-hydraulic servo steering system and steering control method thereof

ActiveCN102372022AOptimize structure layoutMeet traffic requirementsSteering linkagesFluid steeringControl systemElectronic control system

The invention discloses an electro-hydraulic servo steering system and a steering control method of a multi-axle vehicle and the multi-axle vehicle with the steering system. The electro-hydraulic servo steering system comprises a hydraulic steering system and an electric control system, wherein the hydraulic steering system comprises a variable pump, power-assisted steering oil cylinders and a servo proportional valve; the power-assisted steering oil cylinders are at least arranged on various rear steering axles; the servo proportional valve is used for controlling the trend of an oil path and the flow adjustment; the electronic control system comprises a lower controller and an upper controller; the lower controller is in signal connection with the servo proportional valve on each steering axle and forms closed loop control; and the upper controller is used for calculating a target corner of each steering axle according to a first axle corner and a steering mode. According to the invention, the electronic control systems of a two-stage controller is optimized, so that the servo proportional valve and the lower controller form a small closed loop; the lower controller with high frequency response is matched with the servo proportional valve to ensure the precision; and a programmable logic controller is used for main calculation work and transmitting a corner instruction to the each lower controller. The invention has the advantages of simple structural arrangement, safety, reliability and favorable control stability.

Owner:ZOOMLION HEAVY IND CO LTD

Special fixture for processing inclined conical nozzle steam passage and method thereof

InactiveCN101670527AGuaranteed accuracyImprove operational efficiencyPrecision positioning equipmentPositioning apparatusMilling cutterDrill bit

A special fixture for processing an inclined conical nozzle steam passage and a method thereof relate to a fixture for processing the inclined conical nozzle steam passage and a method thereof. The invention solves the problem that at present, no special fixture for processing the inclined conical nozzle steam passage exists, and when a tapered hole of the nozzle steam passage is processed, a drilling bit is difficult to be centered. An indexing plate of the special fixture is provided with twenty indexing through holes along the periphery direction; the center of a stepped through hole and the center of the indexing through holes are on one periphery; a spotting spindle is mounted on the indexing plate in a plug-in manner; the processing method is as follows: using a milling cutter with diameter of 13mm to feed from a P point so as to process a plane C which is vertical to the central line of the tapered hole to be processed; and stopping feeding when the milling cutter mills to a Q point, wherein the center of a hole pitch circle having diameter of 13mm and milled by the milling cutter is the core-bit of the drilling bit. The special fixture solves the problem that at present, nospecial fixture for processing the inclined conical nozzle steam passage exists; and the inclined conical hole of the nozzle stream passage processed by the method has high position accuracy.

Owner:HARBIN TURBINE

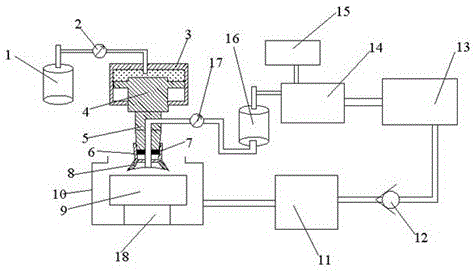

Abrasive particle flow ultra-precision machining device

InactiveCN105058245AImprove machining accuracyGuaranteed accuracyEdge grinding machinesPolishing machinesPneumatic cylinderParticle flow

The invention provides an abrasive particle flow ultra-precision machining device. Injection pressure and speed of abrasive particle flows are adjusted by adjusting threads between a pressure head and an abrasive particle flow injection polishing nozzle, and pressure is provided for a sealed box through a pneumatic cylinder, so that pressure is applied to the pressure head through a pressure plug. According to the abrasive particle flow ultra-precision machining device, the pneumatic cylinder for replacing a spring applies pressure to the pressure head so that accuracy of pressure of the abrasive particle flow injection polishing nozzle to a work-piece can be effectively improved, the abrasive particle flow machining accuracy is improved, and ultra-precision machining is achieved; meanwhile, concentration of abrasive particles in the abrasive particle flows is monitored and controlled in real time, so that machining accuracy and efficiency are guaranteed; Injection pressure and speed of the abrasive particle flows are adjusted by adjusting the threads between the pressure head and the abrasive particle flow injection polishing nozzle, and a pressure-maintaining flow stopping part is arranged at the tail end of the abrasive particle flow injection polishing nozzle so that the machining efficiency can be effectively improved. By means of the abrasive particle flow ultra-precision machining device, both machining efficiency and ultra-precision machining accuracy can be guaranteed.

Owner:CHANGCHUN UNIV OF SCI & TECH

Pipeline water quality risk evaluation method based on water supply network dynamic model

InactiveCN106600094AGuaranteed accuracySolve the evaluation problem of water quality riskGeneral water supply conservationResourcesDynamic modelsWater quality

The present invention discloses a pipeline water quality risk evaluation method based on a water supply network dynamic model. Establishing a water supply network dynamic waterpower and water quality model and performing accurate checking of the water supply network dynamic waterpower and water quality model through determination of the classification type and the evaluation indexes of the pipeline water quality risk; determining the weight of each evaluation index through adoption of the analytic hierarchy process; and dividing the grading standard of each evaluation index parameters based on the state data samples of the pipe network dynamic model, determining the degree of membership of each evaluation index, performing the fuzzy comprehensive evaluation, and determining the grade of the water quality risk of each pipeline in the pipe network. Though the steps mentioned above, all the pipelines of the whole water supply network are subjected to water quality risk evaluation, and the comparison and the ordering are performed according to the evaluation result to determine risk degree ordering of water quality changing and provide decision support for the management and maintenance of the pipe network; and moreover, the pipeline water quality risk evaluation method based on the water supply network dynamic model overcomes the defects that other evaluation methods are simple in index and do not take incomprehensive consideration, and the evaluation result is more reliable to ensure the accuracy and the life cycle of the evaluation.

Owner:GUANGZHOU JINGWEI INTELLIGENT TECH

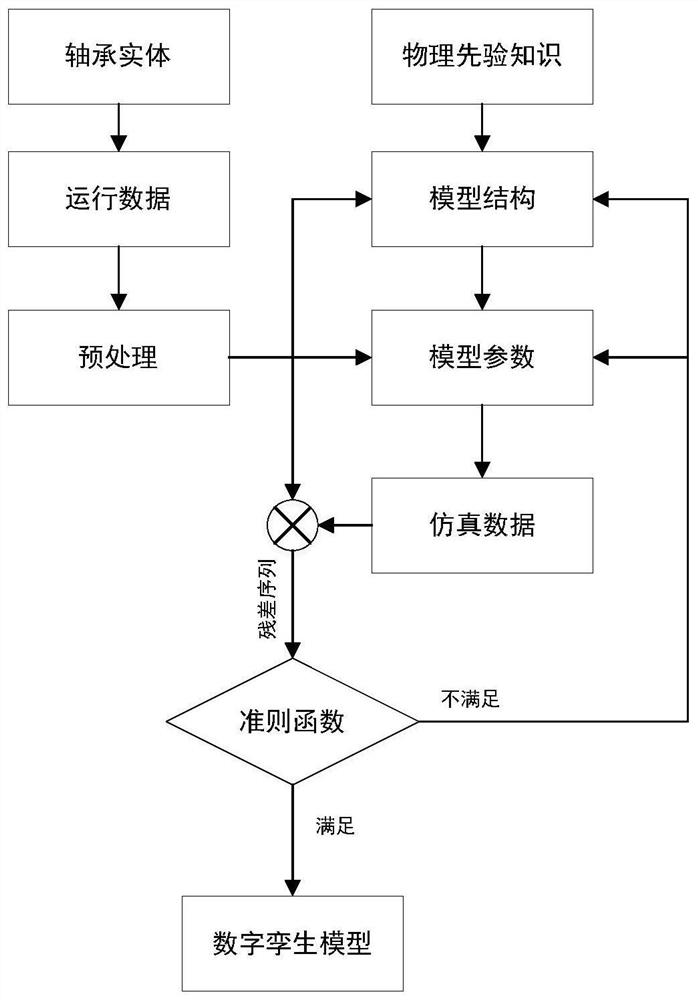

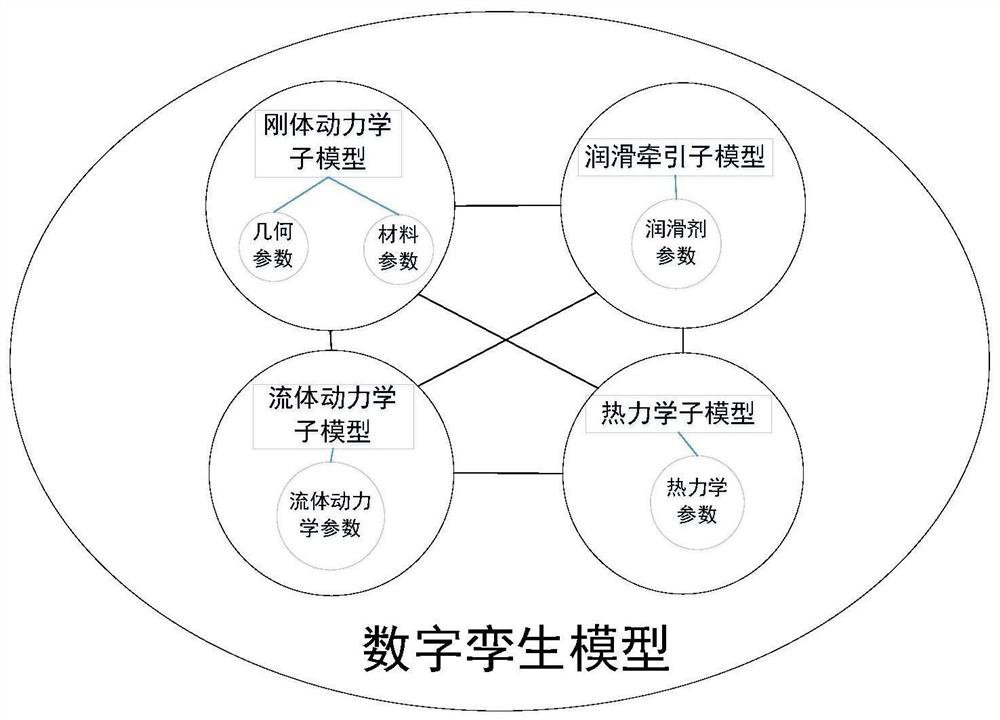

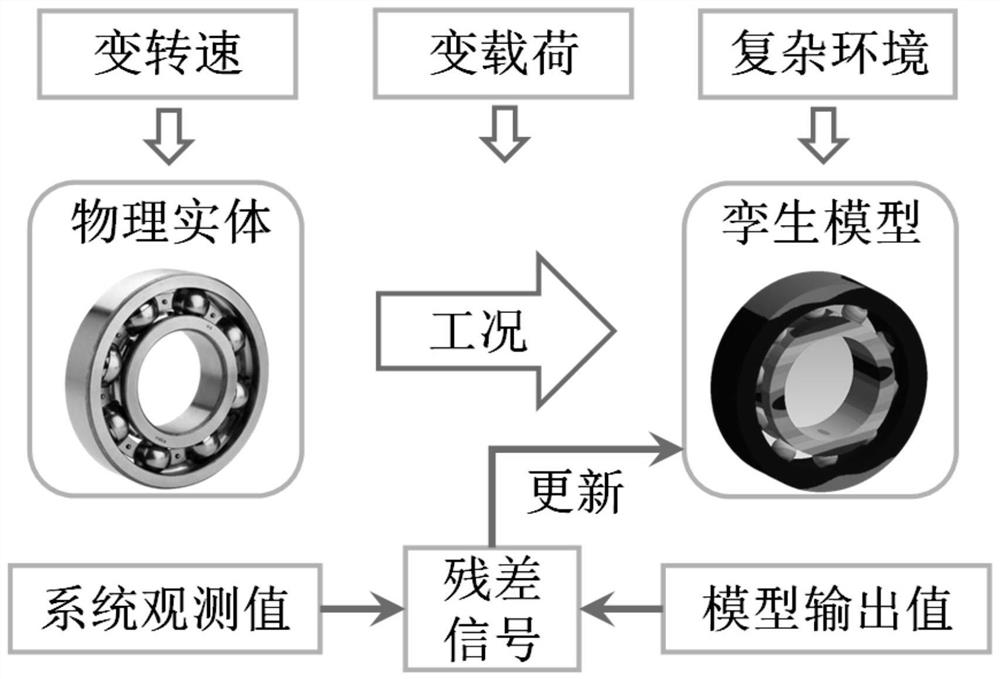

Rolling bearing modeling and model updating method and system based on digital twinning

ActiveCN113221280AGuaranteed real-timeGuaranteed accuracyGeometric CADDesign optimisation/simulationCriterion functionWhite noise

The invention discloses a rolling bearing modeling and model updating method and system based on digital twinning. The method includes using a sensor for monitoring operation data of a rolling bearing in real time and preprocessing the operation data; carrying out coupling modeling to obtain a dynamically updated digital twin model; inputting the normalized operation data into a digital twinborn model in real time, performing simulation calculation on output data of the rolling bearing by using the digital twinborn model, comparing simulation data of the digital twinborn model with the operation data in a corresponding time interval, and if a residual sequence is white noise with a zero mean value, collecting a corresponding rolling bearing digital twin model; otherwise, adjusting and correcting the parameters of the rolling bearing digital twinning model according to the criterion function to obtain a real-time synchronous rolling bearing digital twinning model. The invention can reflect the time history of the health state of the bearing, and provides a basis for fault diagnosis and life prediction of the rolling bearing.

Owner:XI AN JIAOTONG UNIV

Online sampling system for measuring total S content in coke oven gas

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Digital signal processor (DSP)-based rotating machine vibration detection and protection system

ActiveCN102455212AHigh precisionReduce computing loadSubsonic/sonic/ultrasonic wave measurementVibration testingMachining vibrationsControl manner

The invention relates to a digital signal processor (DSP)-based rotating machine vibration detection and protection system. The system mainly comprises a power module, a sensor power supply module, a sensor signal acquiring and conditioning module and a microprocessor microprogrammed control unit (MCU) module, wherein a DSP module is arranged between the sensor signal acquiring and conditioning module and the microprocessor MCU module and is used for processing a sampled signal; the microprocessor MCU module is used for determining a corresponding numerical value signal processing algorithm of the DSP module according to conditions of different sensors, control modes and the like; and the DSP module is used for transmitting processed data to the microprocessor MCU module through a host port interface (HPI). In the system, a DSP is used as a vibration signal operation central processing unit (CPU), so that vibration signals can be acquired at a high speed; and the DSP has high signal processing capability, so that calculation accuracy is improved, a state monitoring and protecting function can be quickly finished, and the operation load of an upper computer is reduced.

Owner:韩松

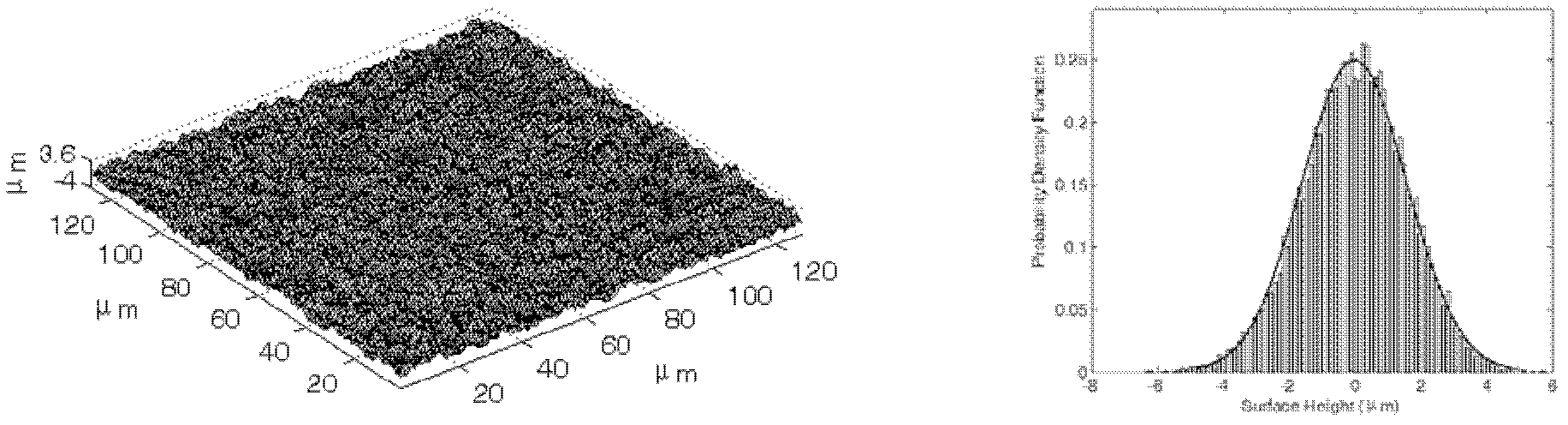

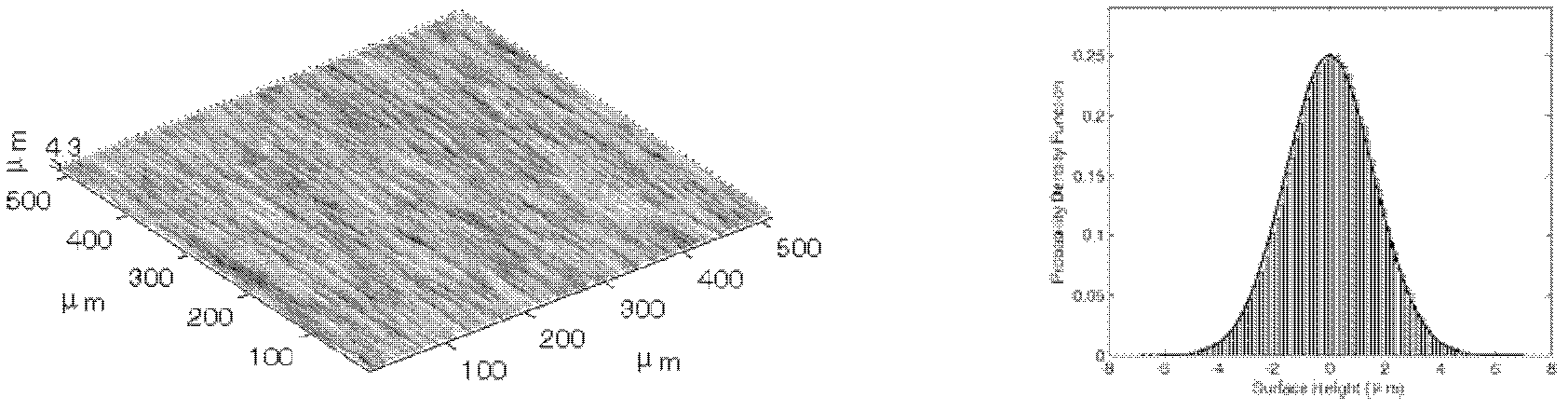

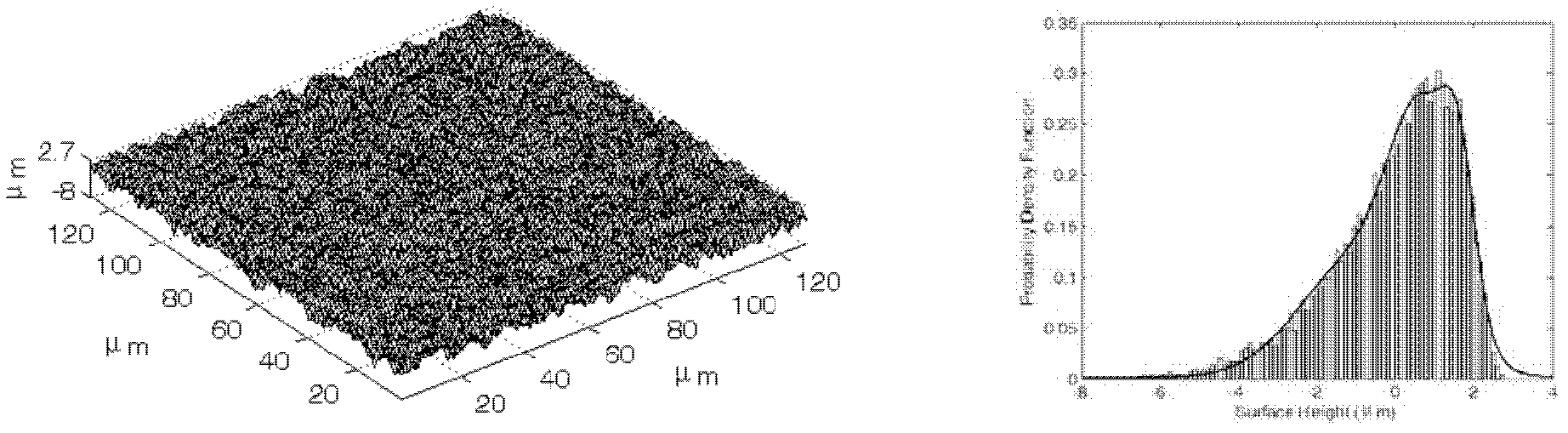

Digitalized simulation method of any three-dimensional (3D) rough surface

InactiveCN102609560AGuaranteed feasibilityGuaranteed accuracySpecial data processing applicationsWhite noiseFrequency domain

The invention discloses a digitalized simulation method of any three-dimensional (3D) rough surface, which improves simulation efficiency and simulation accuracy of statistical parameters. Random initial phase angle sequences are obtained through inverse Fourier transform of white noise sequences, and novel white noise and Fourier transform are obtained by utilizing the initial phase angle sequences. Processing including dispersion and Fourier transform and the like is performed through appointed autocorrelation functions to obtain power spectral density and transfer functions of Gaussian rough surface height sequences. The simulation of the Gaussian rough surface height sequences is finished by utilizing frequency domain dot product and a method for obtaining the inverse Fourier transform. On the basis, non-Gaussian rough surfaces are generated through height distribution statistical characteristic parameters including appointed skewness degree, kurtosis and the like and by utilizing combined Pearson and Johnson non-Gaussian transition systems. If the simulation accuracy of the skewness degree and the kurtosis is below standard, the phase angle sequences and the Fourier transform of the white noise are updated to re-perform Gaussian filtering and non-Gaussian transition till the given accuracy requirement is met.

Owner:XI AN JIAOTONG UNIV

Optical dissolved oxygen sensor in-situ self-calibration device and method

ActiveCN108680551ASolve in-situ self-calibrationMeeting Calibration NeedsFluorescence/phosphorescenceBottleAtmospheric pollution

The invention belongs to the technical field of dissolved oxygen sensors calibration and discloses an optical dissolved oxygen sensor in-situ self-calibration device which comprises a calibration gasgenerator and a calibration device underwater part; the calibration gas generator comprises a saturated air bottle, a high-purity nitrogen bottle, a quality flow controller and a water removal device;the calibration device underwater part comprises a calibration test box, a dissolved oxygen sensor to be calibrated in the calibration test box and a temperature, humidity and air pressure sensor; and the calibration test box is provided with a water inlet, a water outlet and a gas inlet. By adopting the optical dissolved oxygen sensor in-situ self-calibration device and method, by using gas calibration to replace solution calibration, the proportioning process of gradient water bodies with different dissolved oxygen concentrations in a solution is simplified, so that the calibration flow canbe simplified, the calibration time can be saved, and the accuracy of calibrating a reference oxygen concentration in situ is improved; adopted calibration gas cannot cause atmospheric pollution after diffusing in air; and in-situ self calibration is realized with an important role of improving the quality of data monitored with the dissolved oxygen sensor in situ and prolonging the in-situ maintenance-free running time.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Ground stress data prediction method and device, storage medium and electronic equipment

ActiveCN112034517AGuaranteed accuracyHigh precisionSeismic signal processingSeismology for water-loggingClassical mechanicsData prediction

Owner:北京福瑞科润能源科技有限公司

Back beating plate device of stacking machine

InactiveCN109850579AGuaranteed accuracyGuaranteed stabilityStacking articlesEngineeringMechanical engineering

Owner:ZHAOQING HONGWANG METAL IND

Hole detection device and unknown area exploration method for sweeping robot

InactiveCN109316127AAccurate judgmentGuaranteed accuracyAutomatic obstacle detectionCarpet cleanersCamera moduleComputer science

Owner:VESTORCH TECH LTD

Deviation correction compensation method for target identification in channel of quay crane way

ActiveCN114065555AGuaranteed accuracyGuaranteed stabilityComplex mathematical operationsDesign optimisation/simulationComputational physicsControl theory

Owner:聚时领臻科技(浙江)有限公司

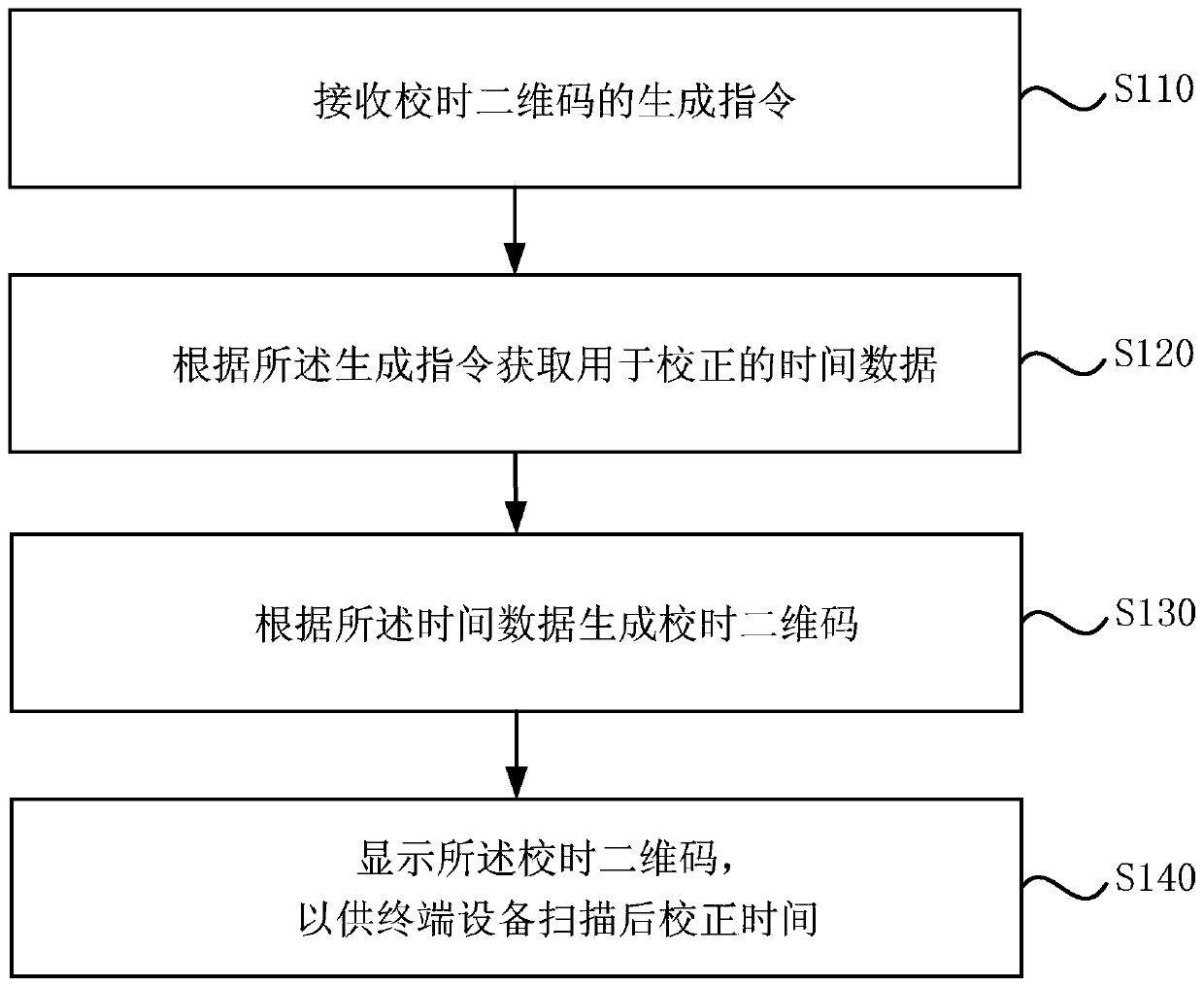

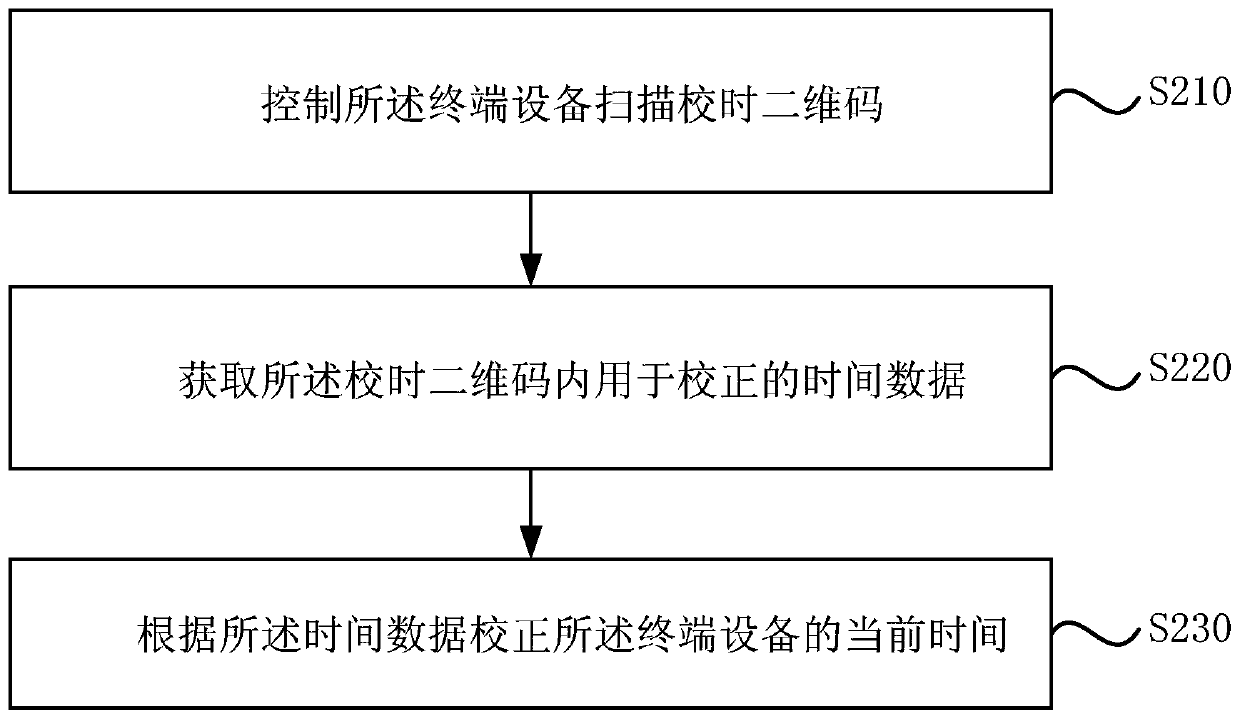

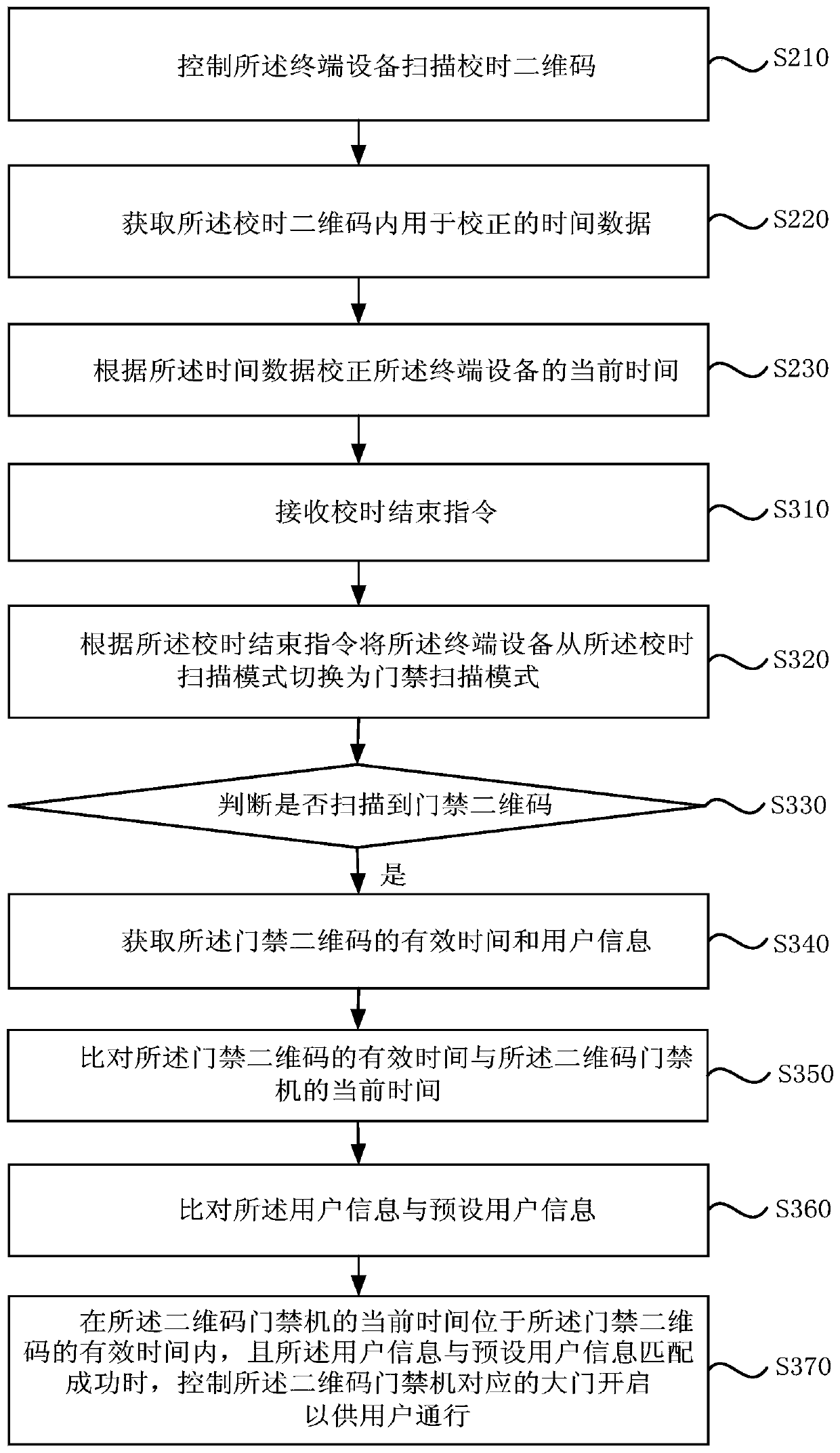

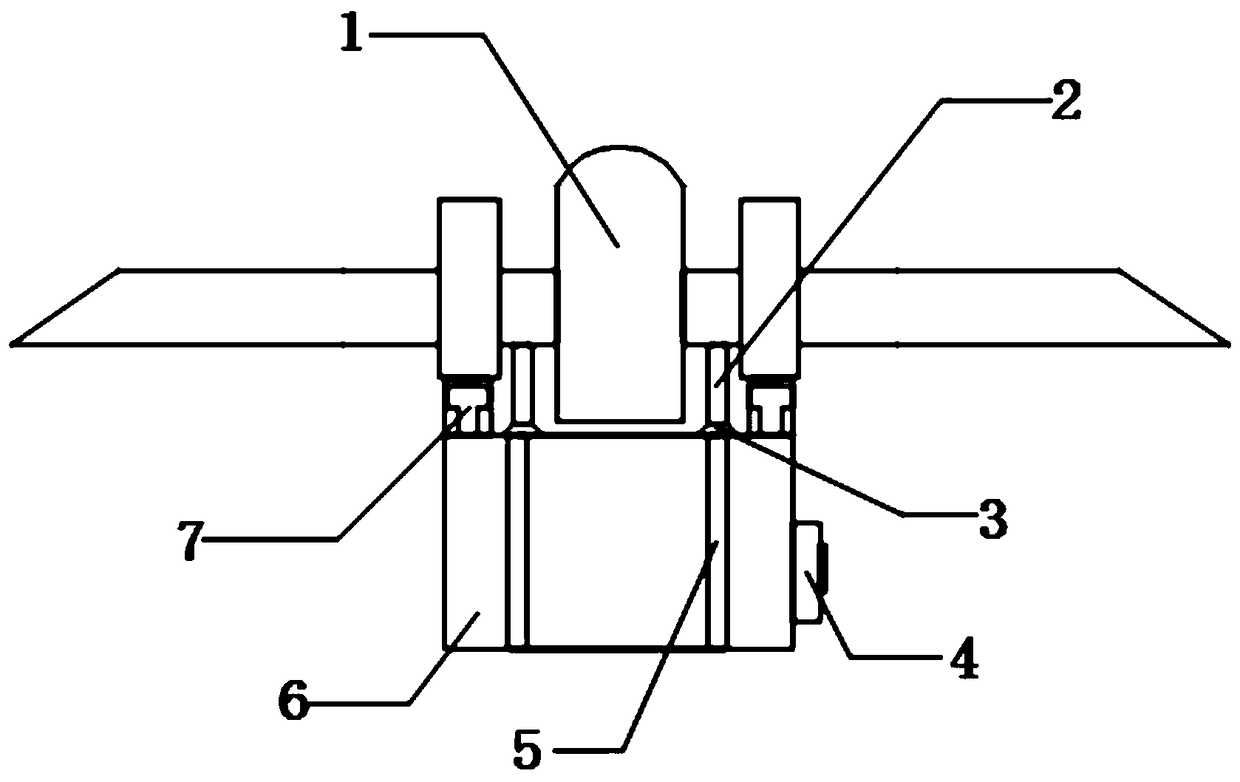

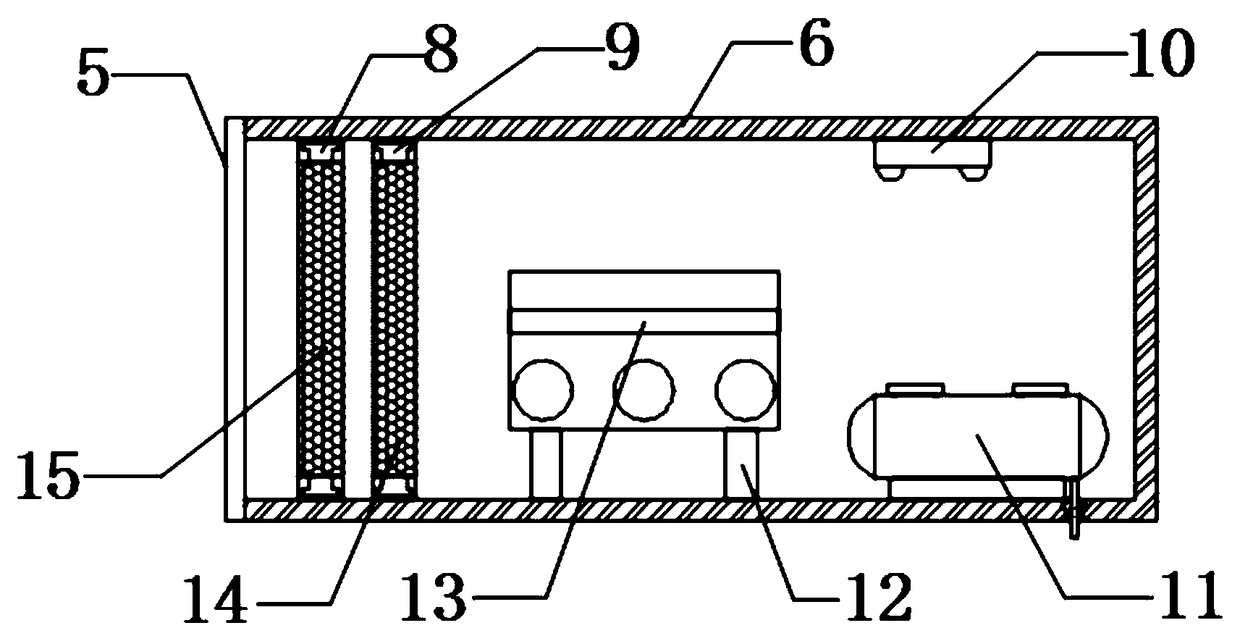

Time correction method based on two-dimensional code, terminal equipment and storage medium

InactiveCN109871923AGuaranteed accuracyCo-operative working arrangementsSetting time indicationCorrection methodComputer hardware

Owner:深圳市西克智能技术有限公司

Waterproof building coiled material repairing device and method

ActiveCN113482255AAvoid errorsGuaranteed accuracyBuilding repairsRoof toolsBuilding constructionCart

Owner:上海北横建设工程有限公司

Unmanned aerial vehicle for high-altitude air quality detection

InactiveCN109187117AHigh precisionGuaranteed accuracyWithdrawing sample devicesAnalysing gaseous mixturesEngineeringBody positions

Owner:易蕾

Paint film lineation detection apparatus and detection method thereof

InactiveCN107843690AGuaranteed accuracyGuaranteed uniformityPreparing sample for investigationAluminium alloyBuzzer

Owner:BAODING CITY LIZHONG WHEEL MFG

Conveyer belt production line centering mechanism capable of realizing convenient adjustment

ActiveCN106626152AAffect qualityImprove alignment efficiencyBeltsDomestic articlesProduction lineLocking mechanism

The invention discloses a conveyer belt production line centering mechanism capable of realizing convenient adjustment. The conveyer belt production line centering mechanism comprises an upper guide rail, a lower guide rail and a clamping device, wherein the lower guide rail is provided with a first slide block and a second slide block; the lower side of the clamping device is in slip connection with the first slide block; the upper side of the clamping device is in slip connection with the upper guide rail; an electrically controlled locking mechanism is arranged between the clamping device and the first slide block; the first and second slide blocks are respectively provided with first and second synchronization cylinders; piston rods of the first and second synchronization cylinders are respectively provided with first and second references; the working cavity of the first synchronization cylinder communicates with the working cavity of the second synchronization cylinder; an intermediate point between the first reference and the second reference is positioned on the centered flat plane of a vulcanizer; and a synchronization moving mechanism is connected between the first slide block and the second slide block, so that the first slide block and the second slide block synchronously move. The conveyer belt production line centering mechanism can obviously improve the centering efficiency, ensure the centering precision and prevent the quality of a conveyer belt from being influenced due to a centering error.

Owner:ZHEJIANG SANWEI RUBBER ITEM CO LTD

Tool setting method for annular mortise machining

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

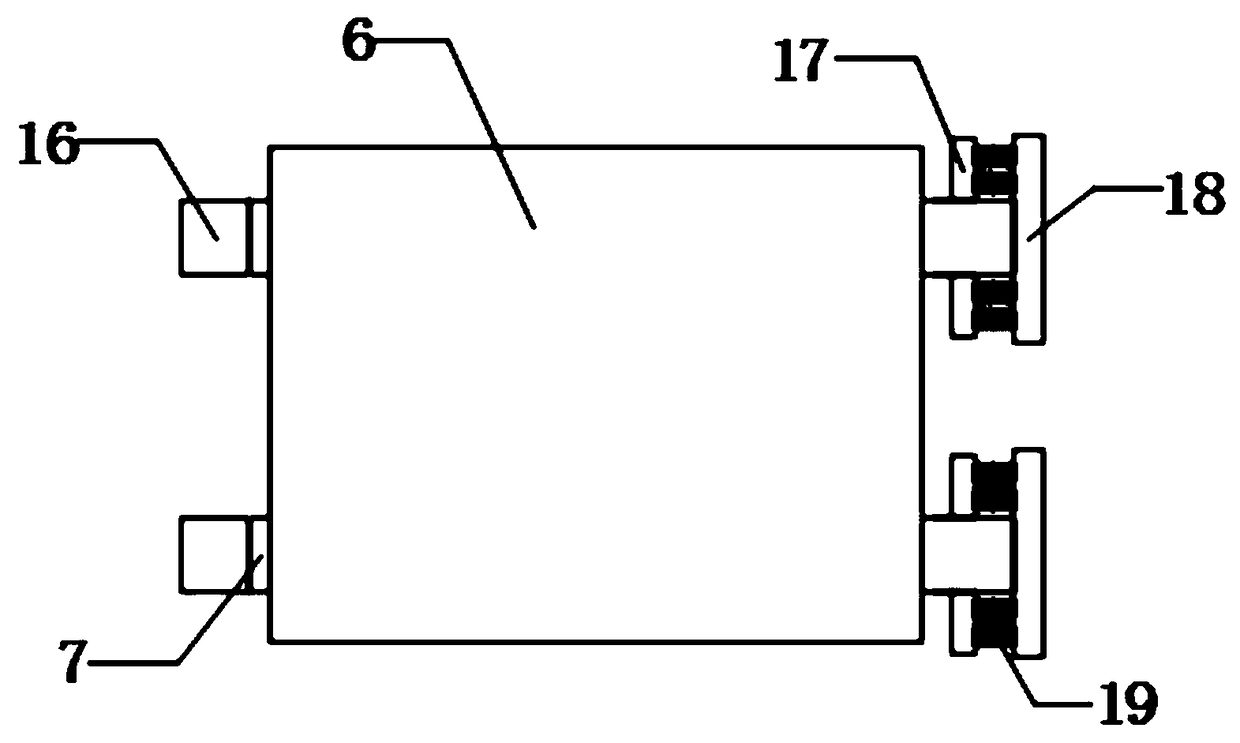

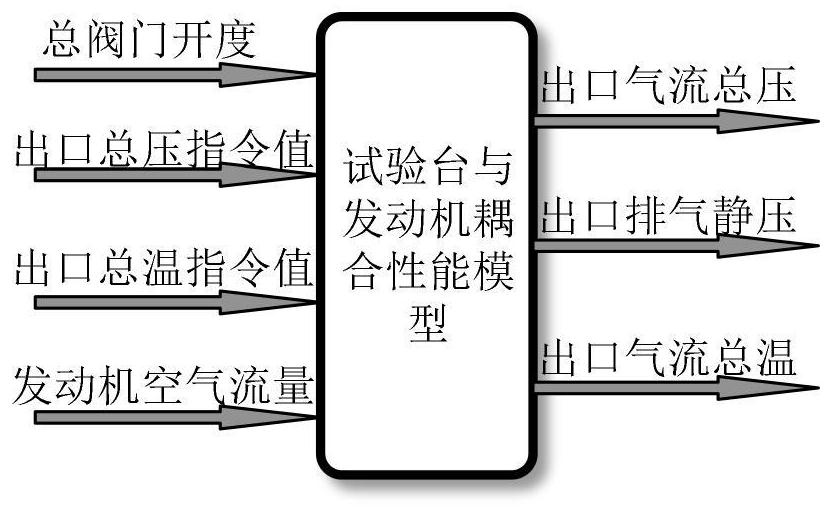

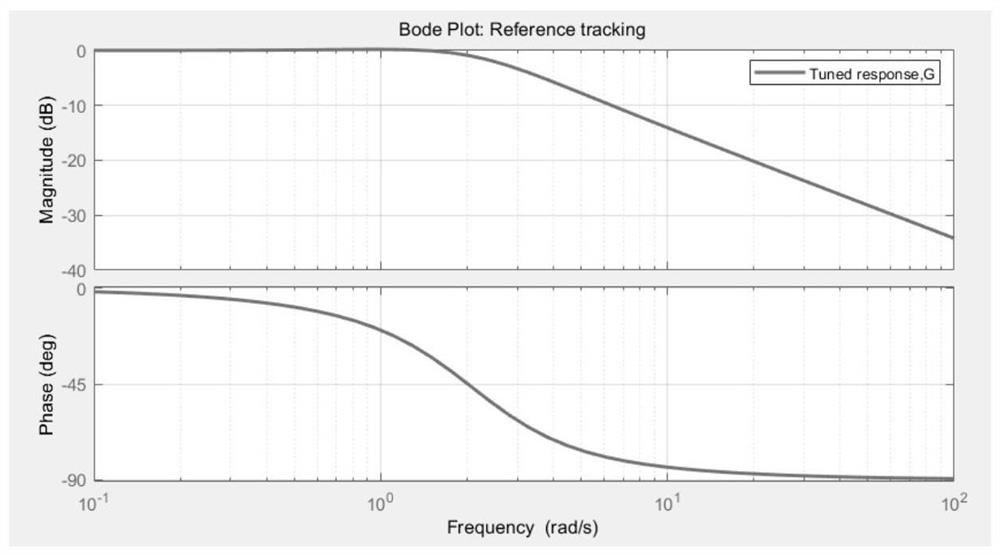

Modeling method of test bed for semi-physical simulation and engine coupling performance model

Owner:HARBIN INST OF TECH +1

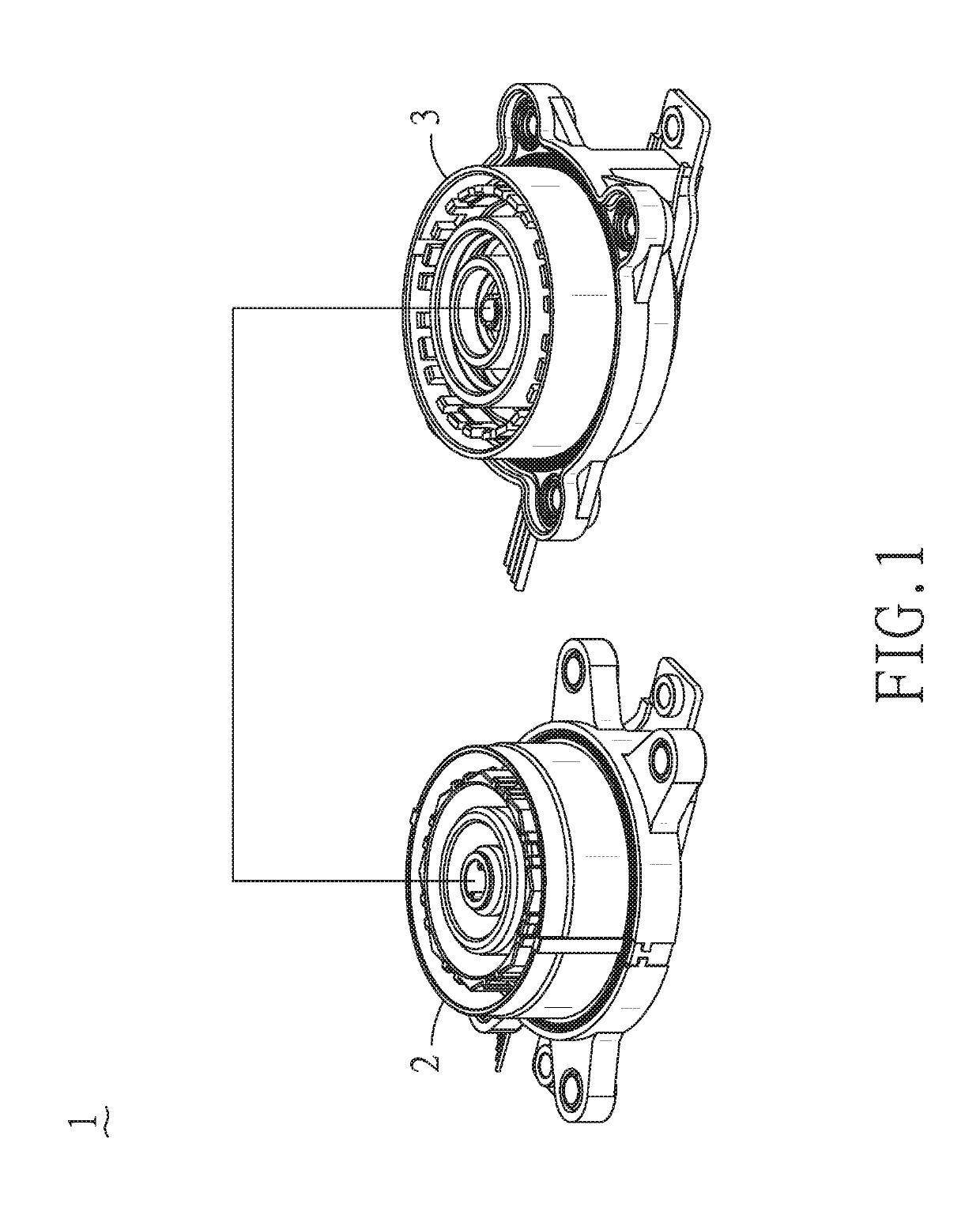

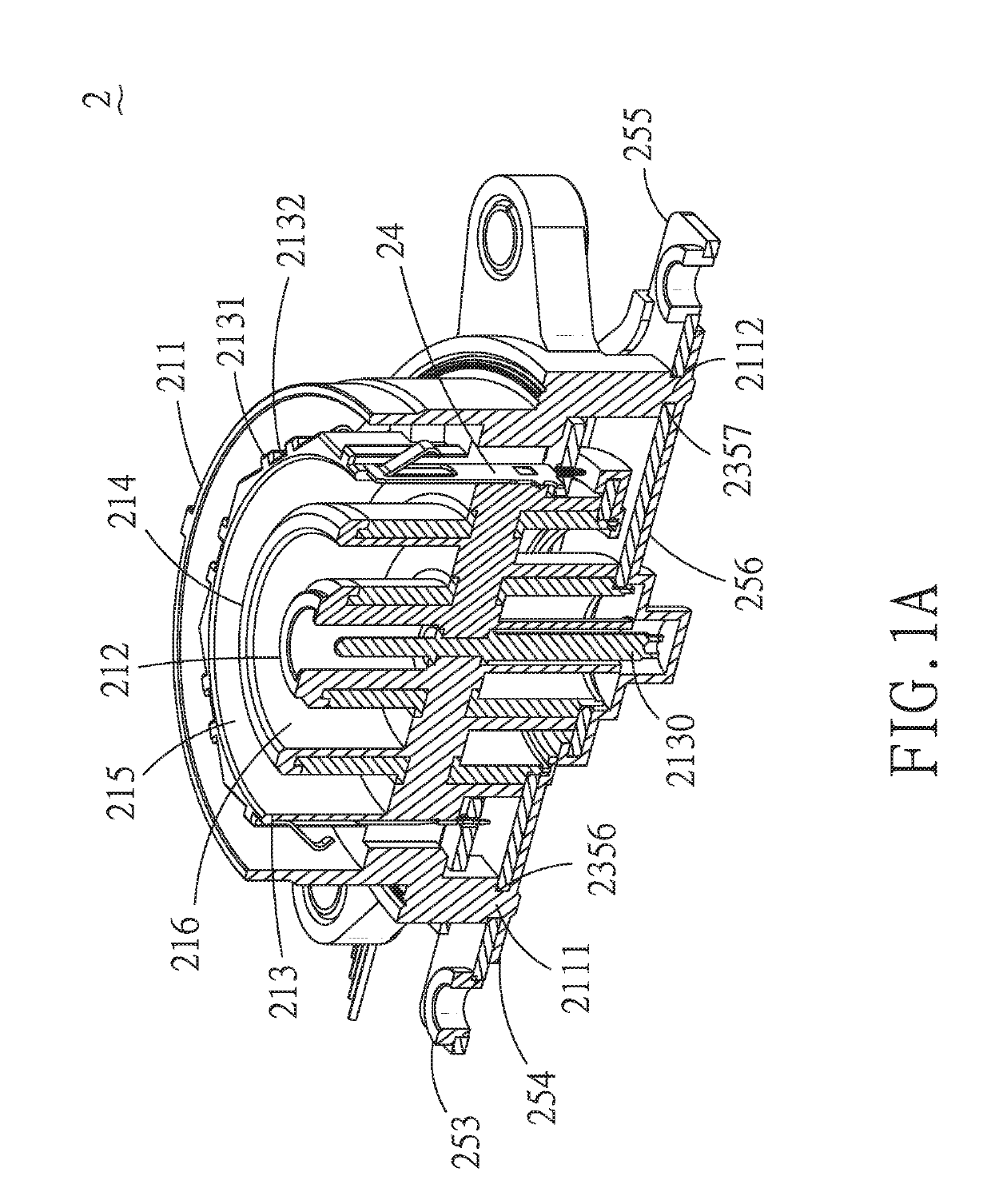

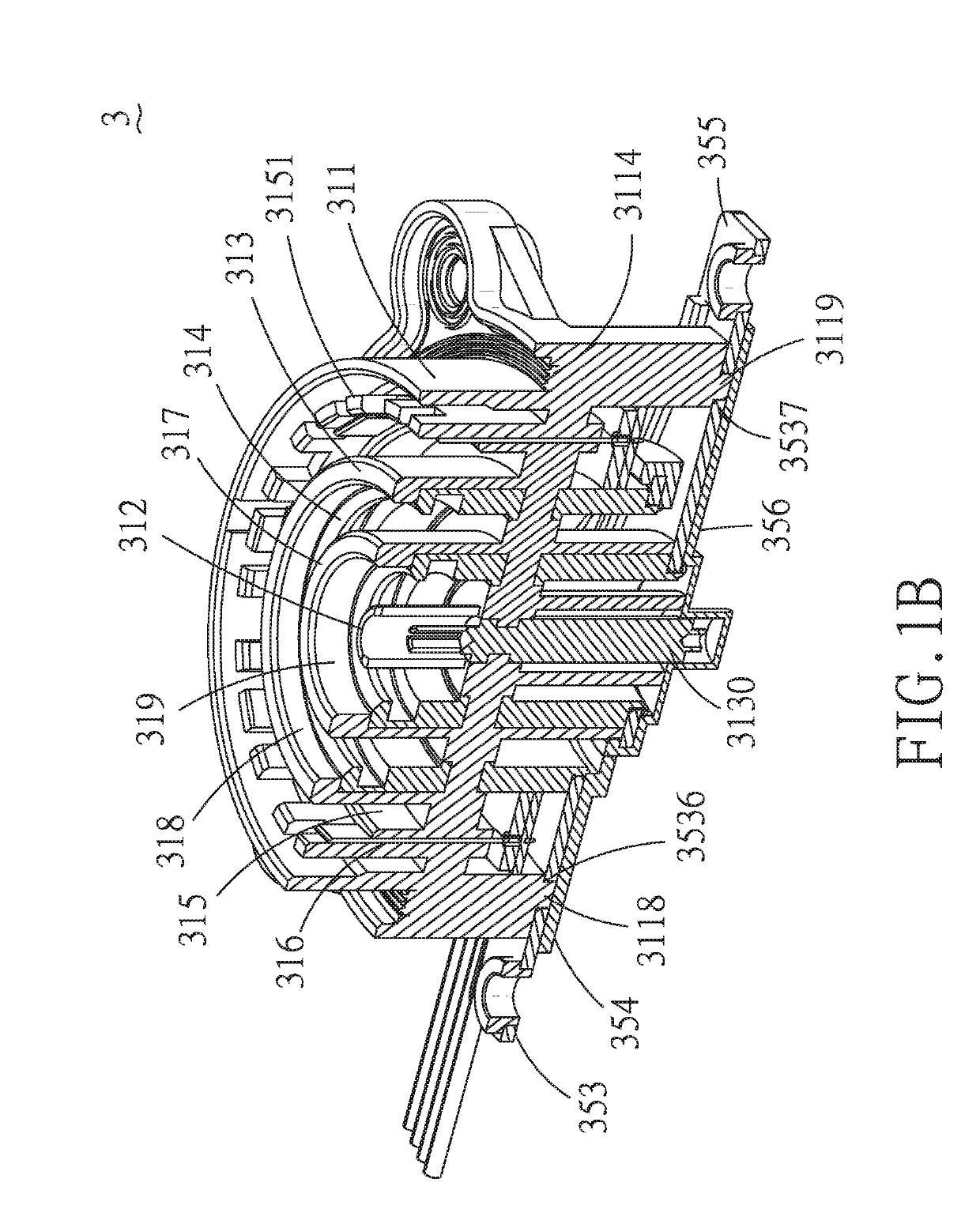

Electric vehicle charging connector device and a plug connector and a receptacle connector thereof

ActiveUS10340644B1Reduce probabilityGuaranteed accuracyVehicle connectorsCharging stationsElectric power transmissionElectric vehicle

Owner:CHENG UEI PRECISION IND CO LTD

Punching method capable of realizing automatic material taking

ActiveCN107671161AGuaranteed accuracyGuaranteed to be organizedMetal working apparatusMetal-working feeding devicesBiochemical engineeringElectromagnet

Owner:CHONGQING HUAPIN ELECTRONICS TECH CO LTD

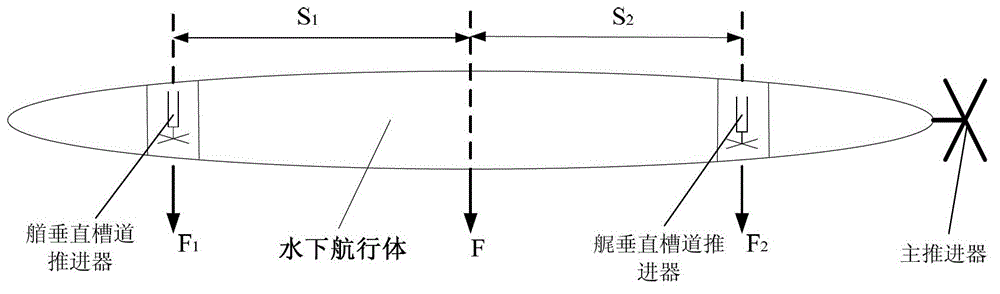

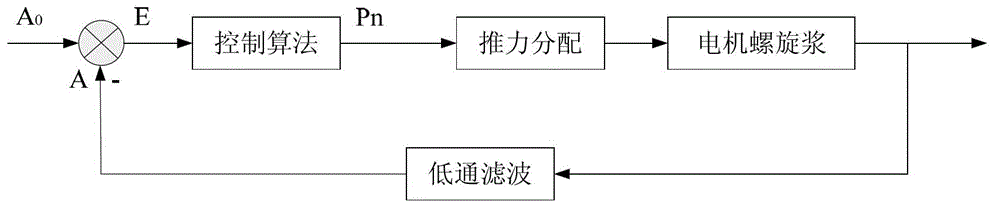

Non-cable self-control underwater navigation body hovering and controlling method

InactiveCN103064422APosition/course control in three dimensionsAdaptive controlPlus integralVertical channel

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

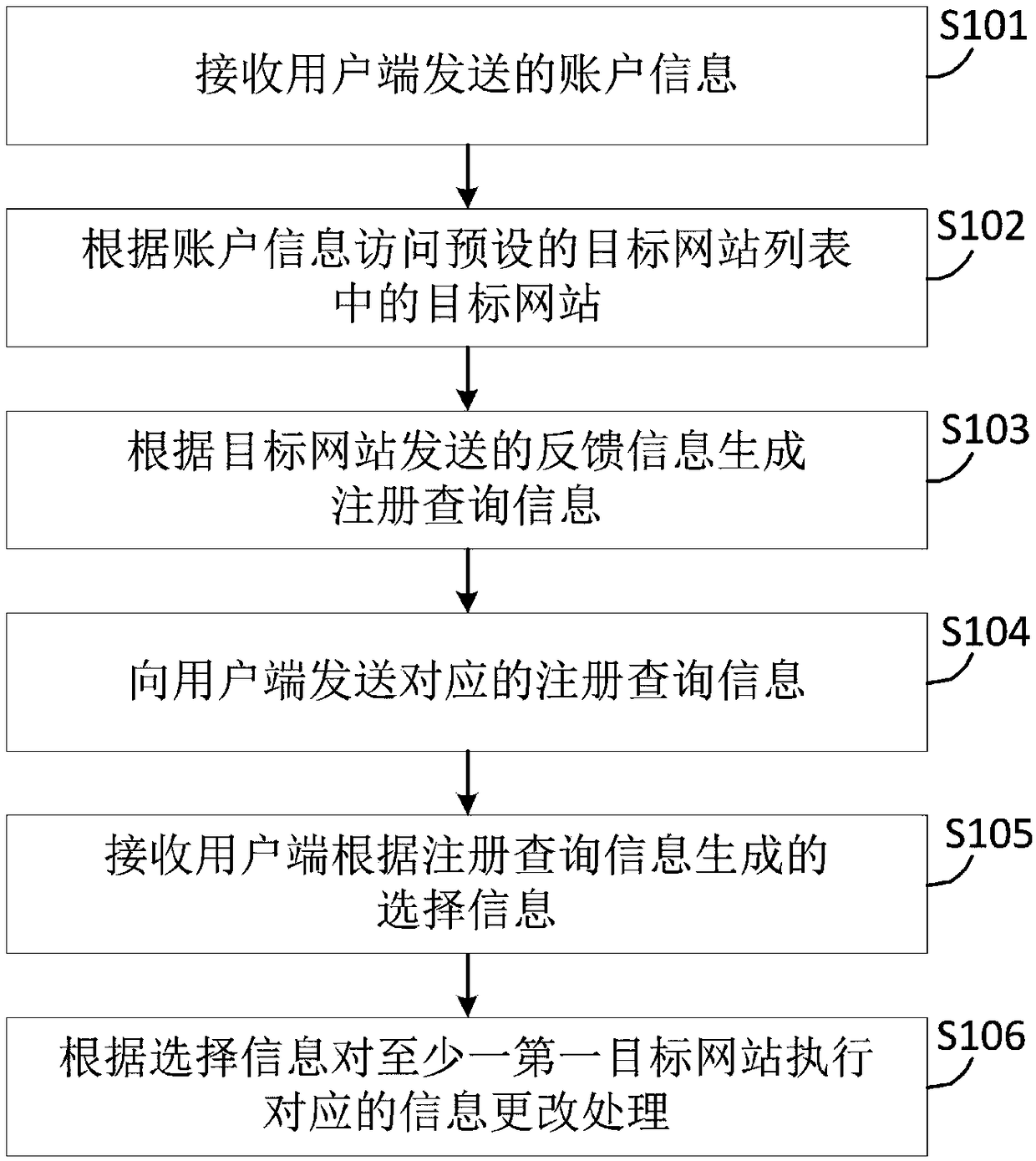

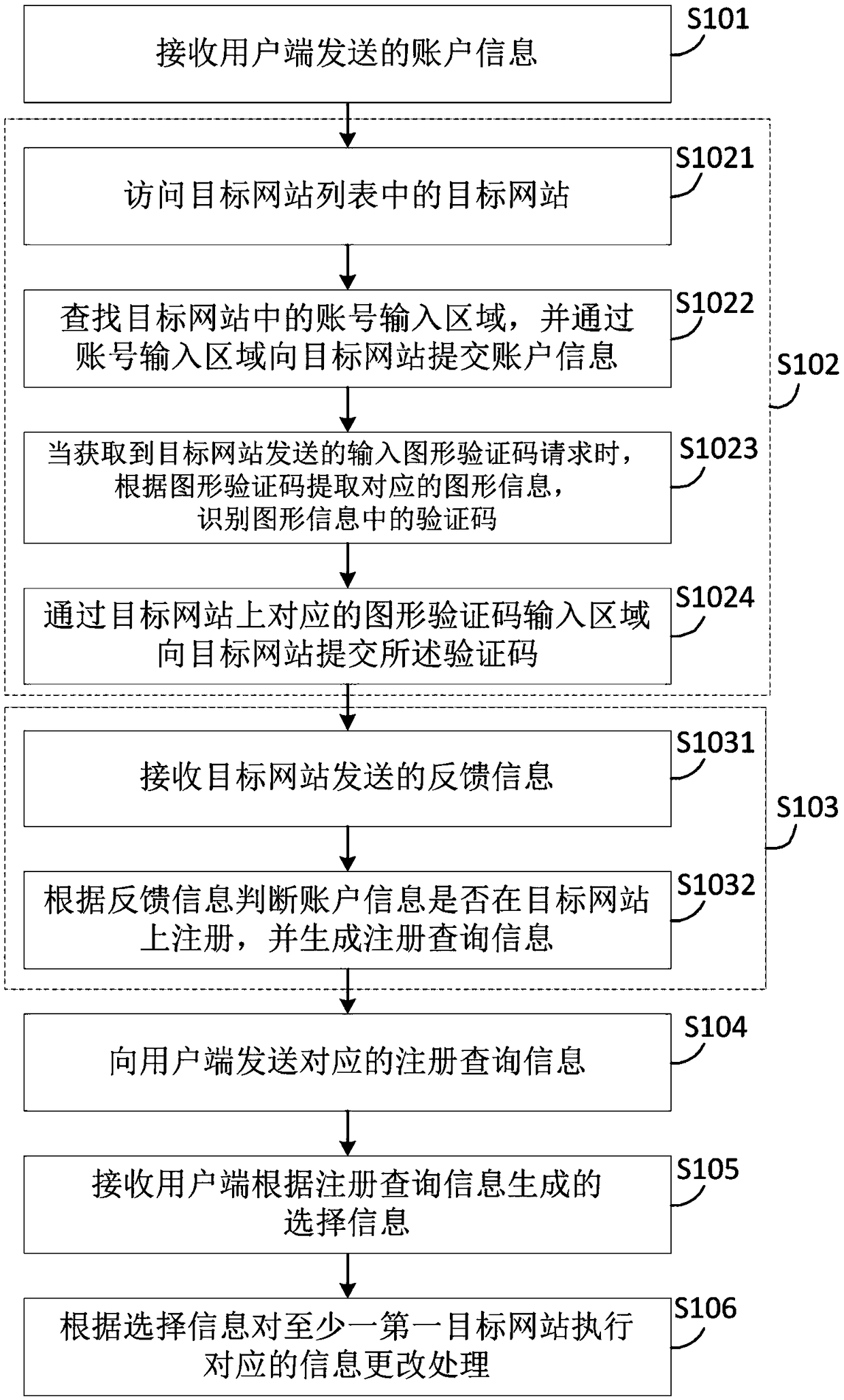

Account information batch processing method and server

ActiveCN108829838AGuaranteed accuracyDigital data authenticationSpecial data processing applicationsDatabaseBatch processing

Owner:杭州悠银科技有限公司

Welding device for thick plate of ship and facilitating to accurate location

InactiveCN111992918AGuaranteed accuracyHigh precisionAuxillary welding devicesSoldering auxillary devicesElectric machineryElectric motor

Owner:刘艳

Pig farm message management system

ActiveCN108077107AGuaranteed accuracyMaintain sensitivityAnimal repellantsMeasurement devicesCarbon dioxideCo2 concentration

Owner:武汉至为科技有限公司

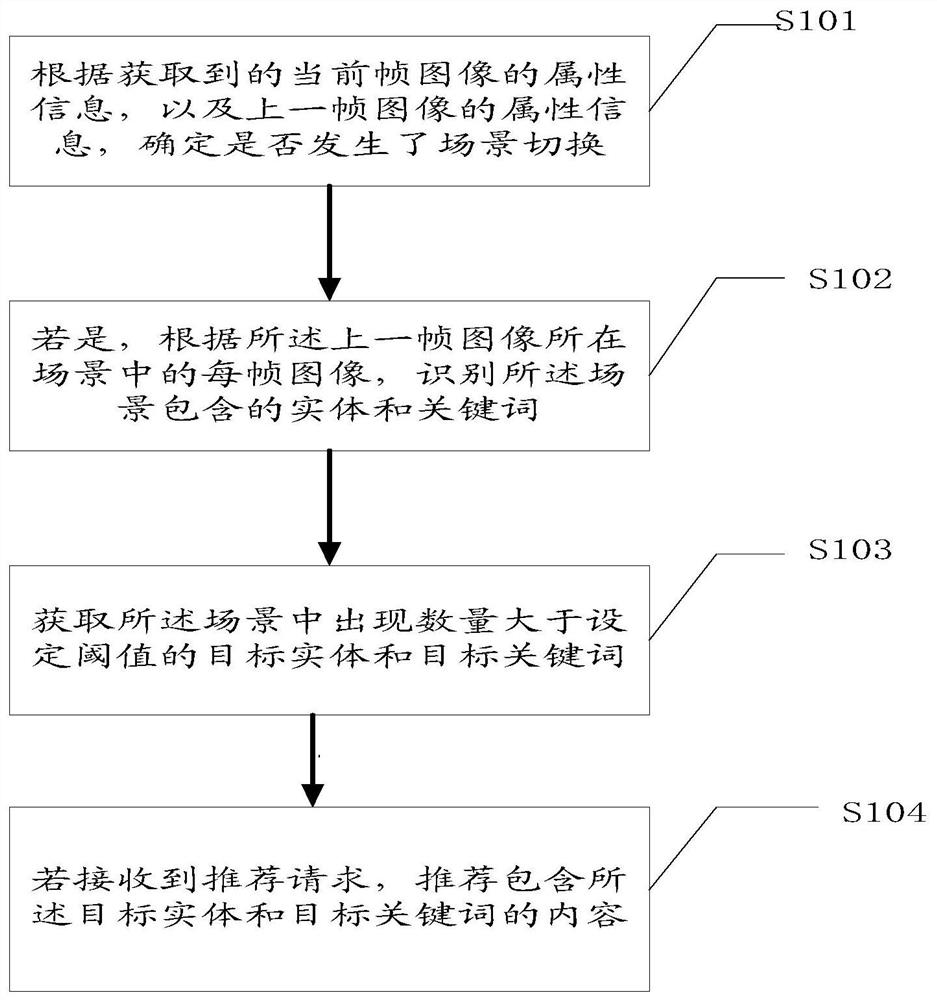

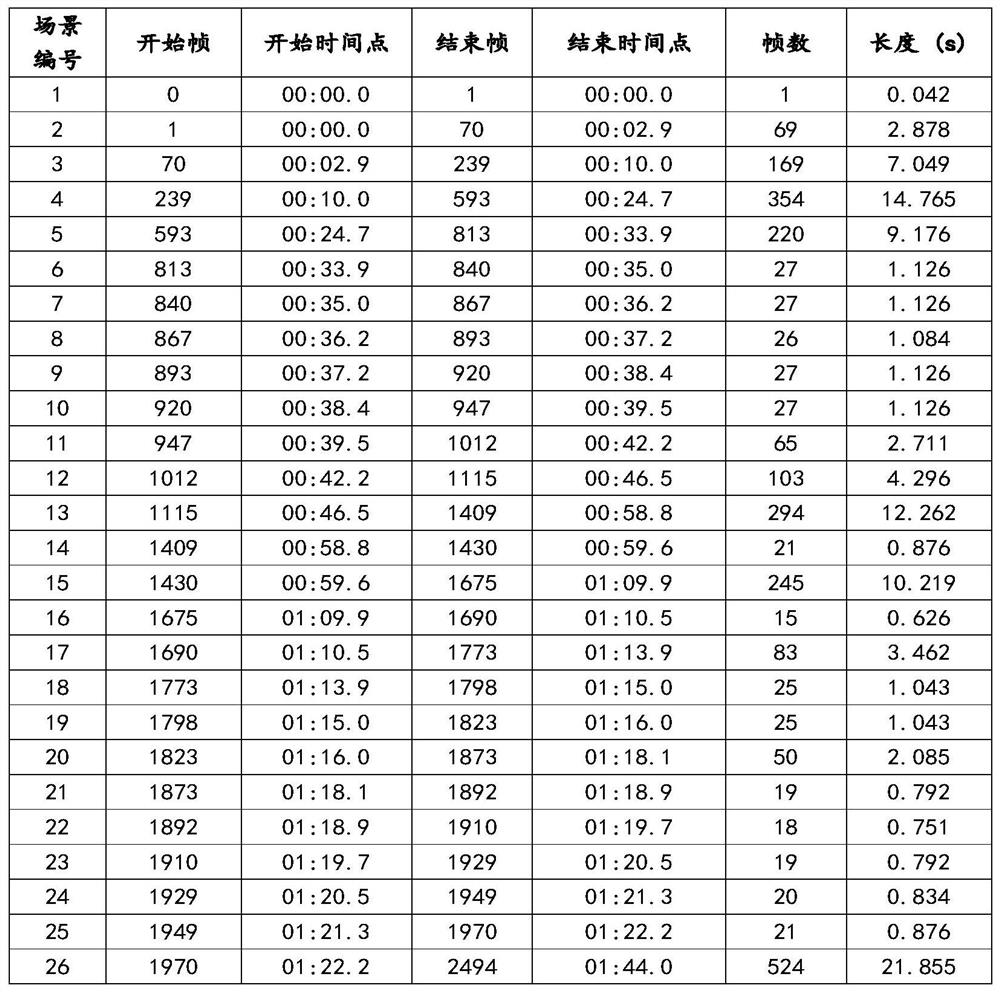

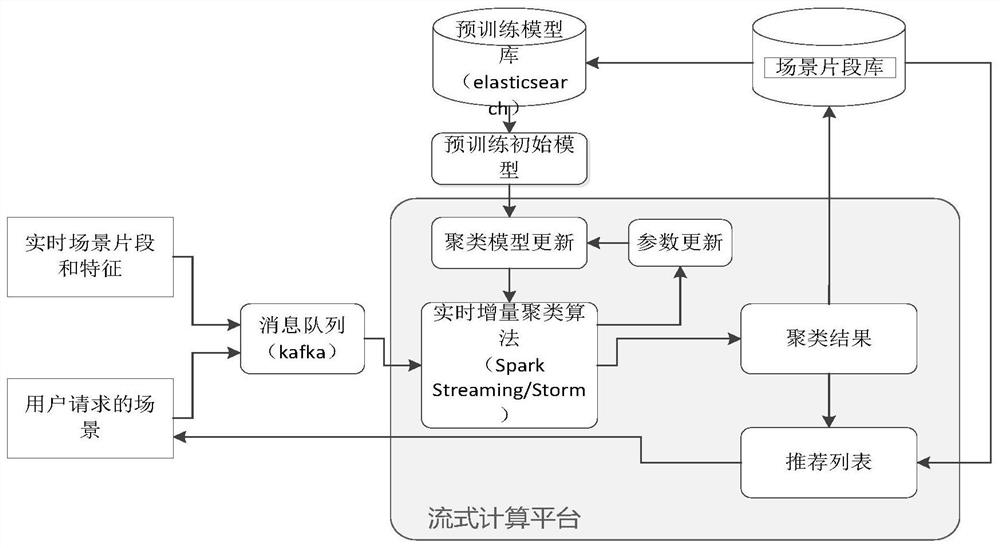

Content recommendation method and device, equipment and medium

PendingCN112199582AGuaranteed accuracyImprove experienceCharacter and pattern recognitionDigital data information retrievalData scienceEngineering

Owner:JUHAOKAN TECH CO LTD

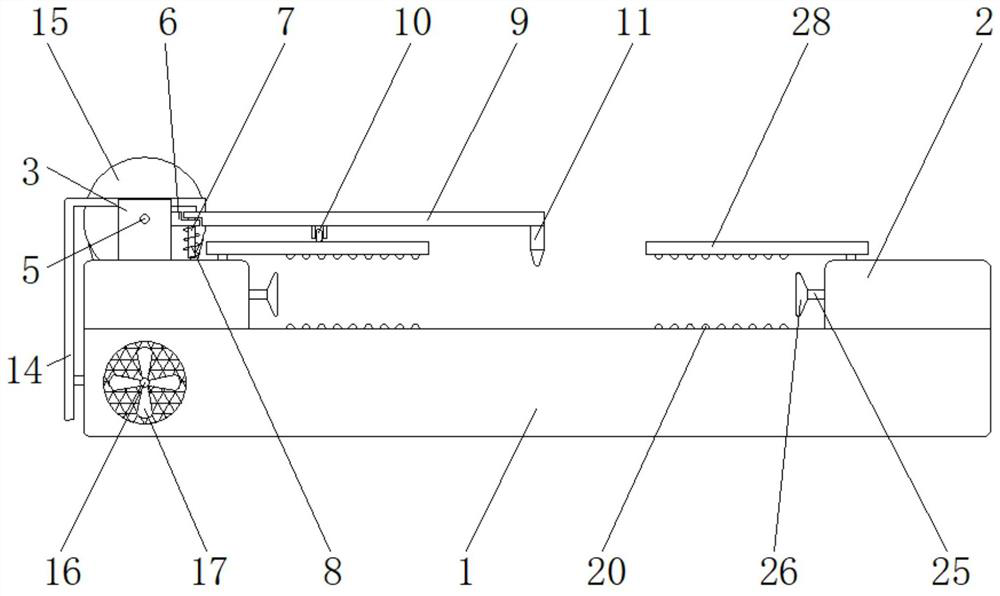

Ground empty drum knocking device for engineering technology detection

InactiveCN109521091AAvoid damageGuaranteed accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesDrive wheelArchitectural engineering

The invention discloses a ground empty drum knocking device for engineering technology detection. The ground empty drum knocking device comprises a supporting plate, a driving motor, a worm, a knocking hammer and a rotary disc, wherein the two sides of the bottom of the front of the supporting plate are respectively and rotatably connected to driven wheels; the two sides of the bottom of the backof the supporting plate are respectively and rotatably connected to driving wheels; a driving motor is fixedly arranged on the top of the back of the supporting plate; the output end of the driving motor is rotatably connected to the worm; a bearing at the end of the worm is rotatably connected to a bracket; the top of the front of the worm is meshed with a first worm wheel; the first worm wheel is rotatably connected to the upper end of a holder; the upper end of the bracket is rotatably connected to a residual gear; the residual gear is connected to the first worm wheel through a synchronousbelt I, partially has teeth and partially has no teeth; a part of the residual gear with the teeth is meshed with a rack plate; the rack plate is fixed to the side surface of an expansion link; the expansion link is a square link; a square sleeve for passing of the expansion link is fixed to the surface of the supporting plate; the knocking hammer is fixedly connected to the lower end of the expansion link; a sleeve is nested on the upper part of the expansion link; a spring is fixed inside the sleeve; and the lower end of the spring is fixed to the upper end of the expansion link.

Owner:CHUZHOU HONGTU CONSTR CO LTD

Testing equipment and method for thermal stability of liquid dairy products

ActiveCN105572158BGuaranteed accuracyHeating up fastMaterial thermal analysisBiochemical engineeringFuel tank

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap