Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

26 results about "Milling cutter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Milling cutters are cutting tools typically used in milling machines or machining centres to perform milling operations (and occasionally in other machine tools). They remove material by their movement within the machine (e.g., a ball nose mill) or directly from the cutter's shape (e.g., a form tool such as a hobbing cutter).

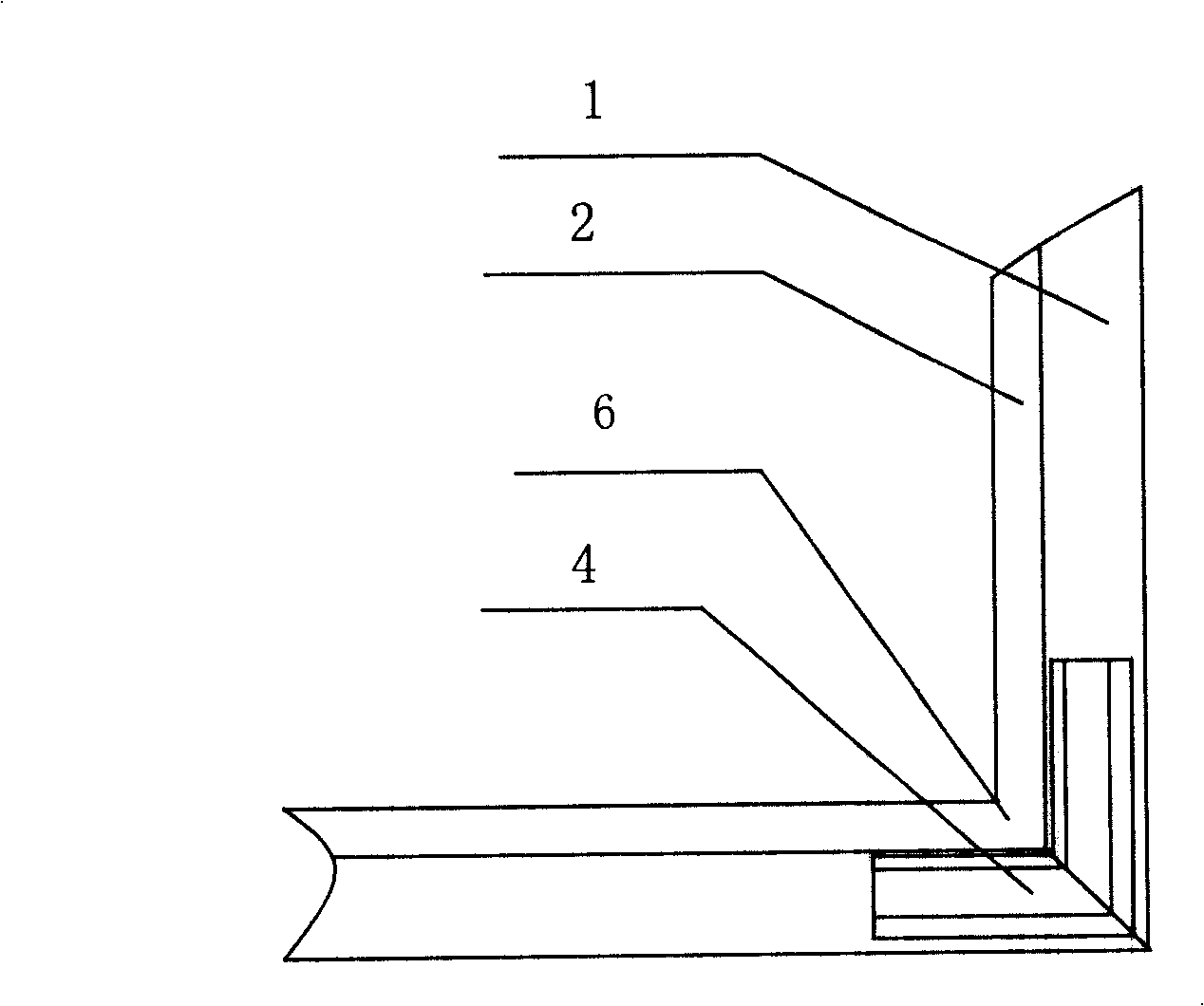

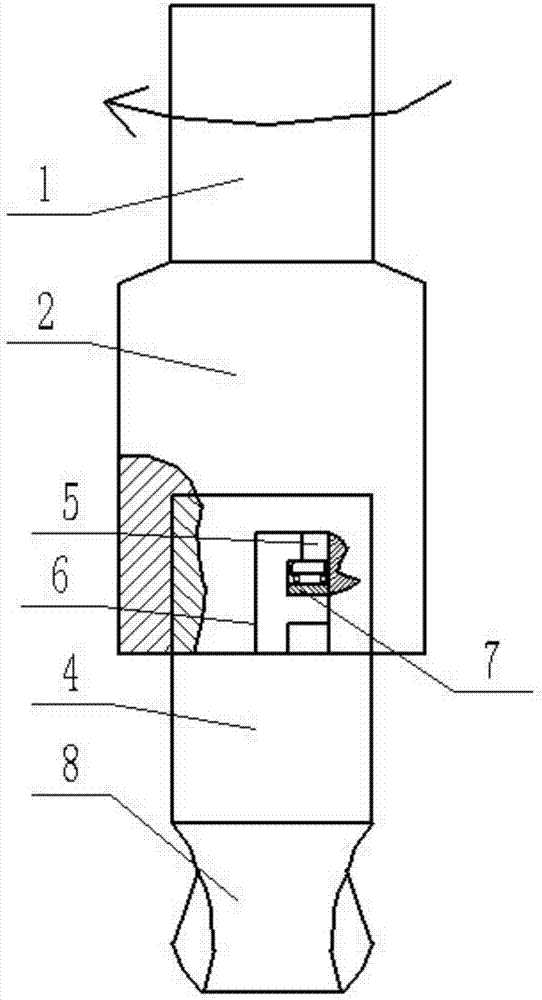

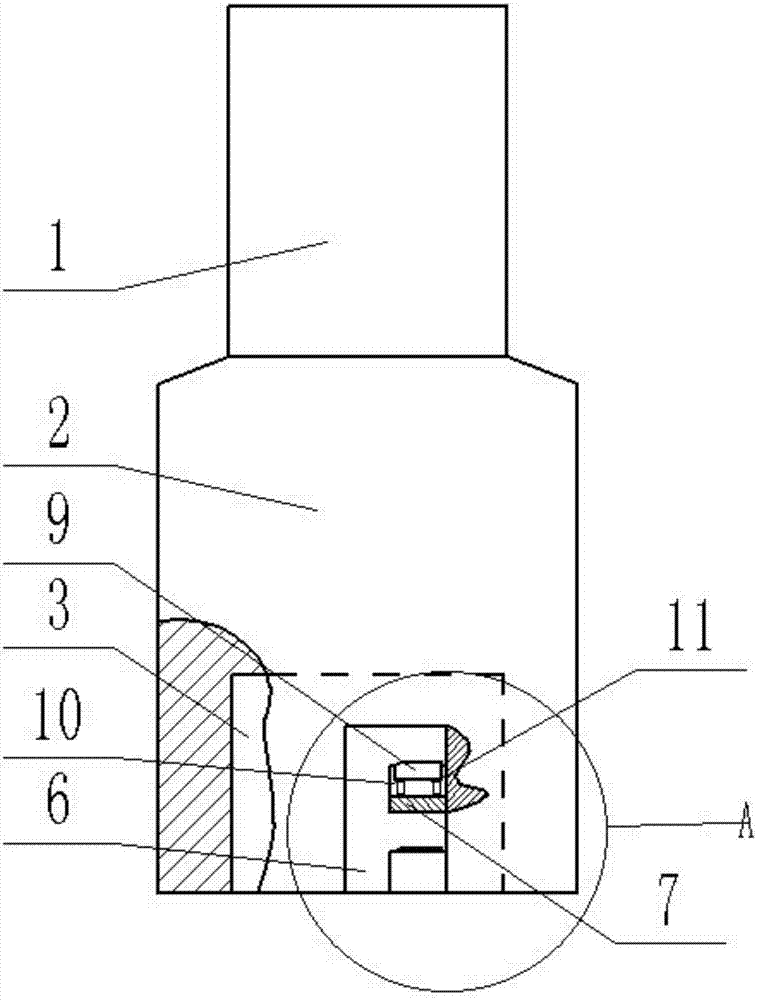

Special fixture for processing inclined conical nozzle steam passage and method thereof

InactiveCN101670527AGuaranteed accuracyImprove operational efficiencyPrecision positioning equipmentPositioning apparatusMilling cutterDrill bit

A special fixture for processing an inclined conical nozzle steam passage and a method thereof relate to a fixture for processing the inclined conical nozzle steam passage and a method thereof. The invention solves the problem that at present, no special fixture for processing the inclined conical nozzle steam passage exists, and when a tapered hole of the nozzle steam passage is processed, a drilling bit is difficult to be centered. An indexing plate of the special fixture is provided with twenty indexing through holes along the periphery direction; the center of a stepped through hole and the center of the indexing through holes are on one periphery; a spotting spindle is mounted on the indexing plate in a plug-in manner; the processing method is as follows: using a milling cutter with diameter of 13mm to feed from a P point so as to process a plane C which is vertical to the central line of the tapered hole to be processed; and stopping feeding when the milling cutter mills to a Q point, wherein the center of a hole pitch circle having diameter of 13mm and milled by the milling cutter is the core-bit of the drilling bit. The special fixture solves the problem that at present, nospecial fixture for processing the inclined conical nozzle steam passage exists; and the inclined conical hole of the nozzle stream passage processed by the method has high position accuracy.

Owner:HARBIN TURBINE

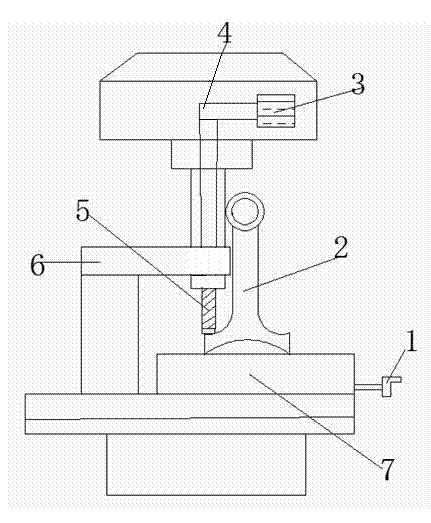

Benchtop end mill grinding center

The end mill grinding device of the present invention includes a tool spindle assembly, which enables multi-axis positioning of a rotating cutting tool being sharpened, and a motor tower, which enables multi-axis positioning of a grinding or cutting wheel for sharpening the end mill tool. The present invention combines linear sharpening and radial tool end grinding capability in the same machine element.

Owner:TOYCEN JEFFREY

Combined type milling cutter for machining flat surface of aluminum alloy

ActiveCN101934398AControllable diameterImprove processing efficiencyMilling cuttersSurface finishMilling cutter

Owner:NO 8357 RES INST OF THE THIRD ACADEMY OF CHINA AEROSPACE SCI & IND

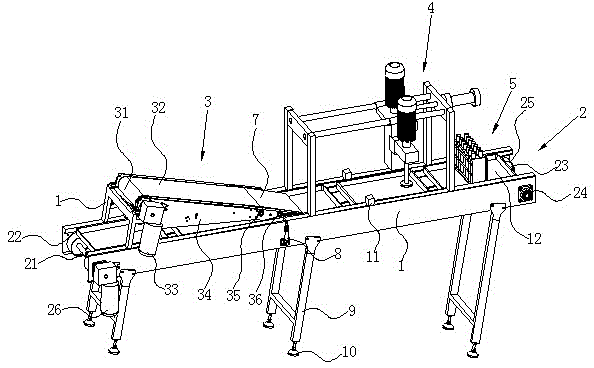

Welding process for aluminum plastics door and window

InactiveCN101244628AEliminate worriesIncrease productivityMilling cuttersMilling equipment detailsMilling cutterPlastic materials

Owner:CHANGZHI HUIFENG ELECTROMECHANICAL INDAL TRADE

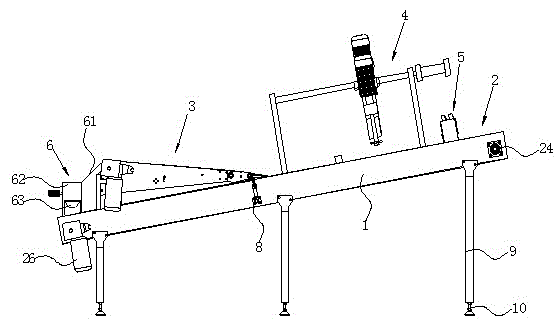

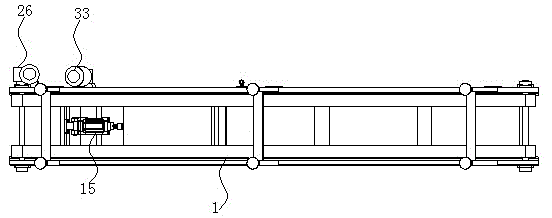

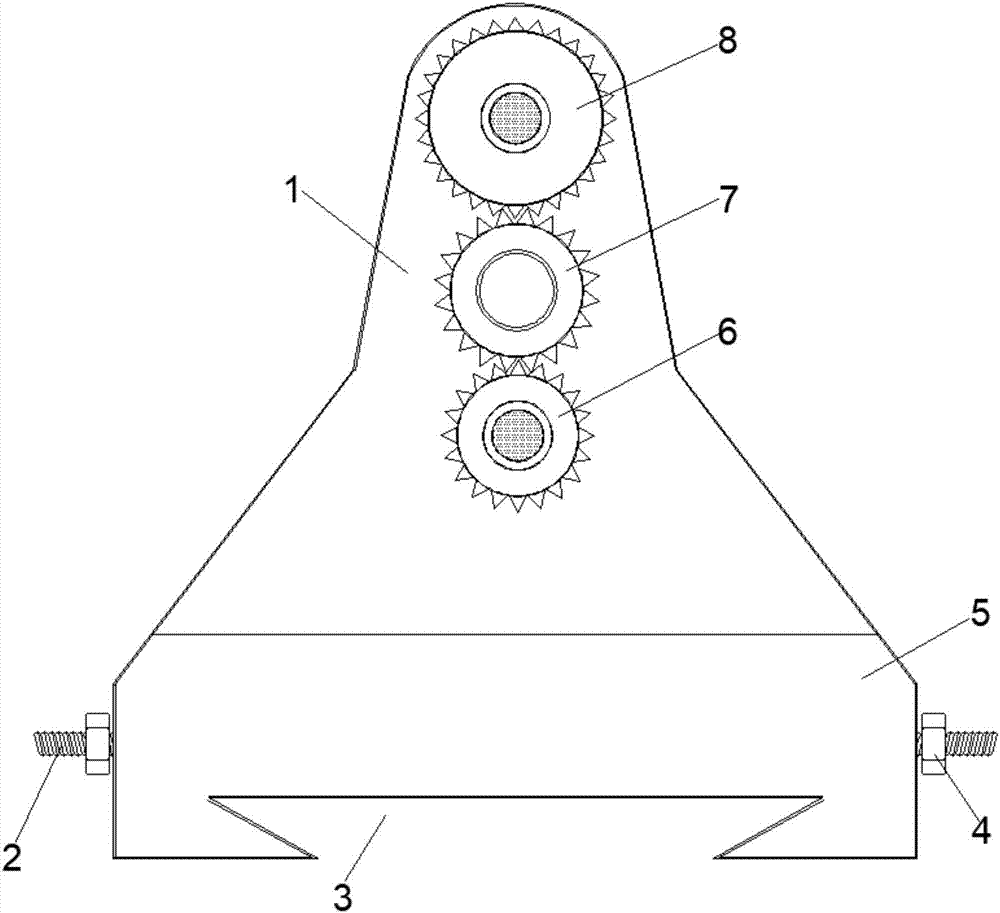

Cycloid rotational indexing-based novel vertical milling machine

ActiveCN106424867AAvoid multiple clampingLow costLarge fixed membersMilling equipment detailsMilling cutterEngineering

The invention relates to vertical milling machines and belongs to the field of machining. A cycloid rotational indexing-based novel vertical milling machine is characterized by comprising a machine body mechanism, a milling head mechanism and a worktable mechanism. The cycloid rotational indexing-based novel vertical milling machine comprises two working modes: rotational indexing machining and milling by an eccentric milling cutter. In the rotational indexing machining mode, the milling cutter in compound movements of rotation and revolution is matched with two-dimensional translation of a to-be-machined workpiece and a vertical movement of the milling head mechanism to form a special movement track of the milling cutter relative to the to-be-machined workpiece so as to machine a special part in a complex shape. The milling mode by the eccentric milling cutter is as follows: the milling cutter is fixed in an expected position relative to the rotary center of a spindle box to form the eccentric milling cutter, and the rotation movement of the eccentric milling cutter is combined with two-dimensional translation of the to-be-machined workpiece and a vertical movement of the milling head mechanism. The cycloid rotational indexing-based novel vertical milling machine provided by the invention retains the functions of a conventional milling machine and increases a mode of efficiently machining the part in the special shape by cycloid rotational indexing. The two modes can be freely switched, so that the cycloid rotational indexing-based novel vertical milling machine is of certain universality.

Owner:SHANGHAI UNIV OF ENG SCI

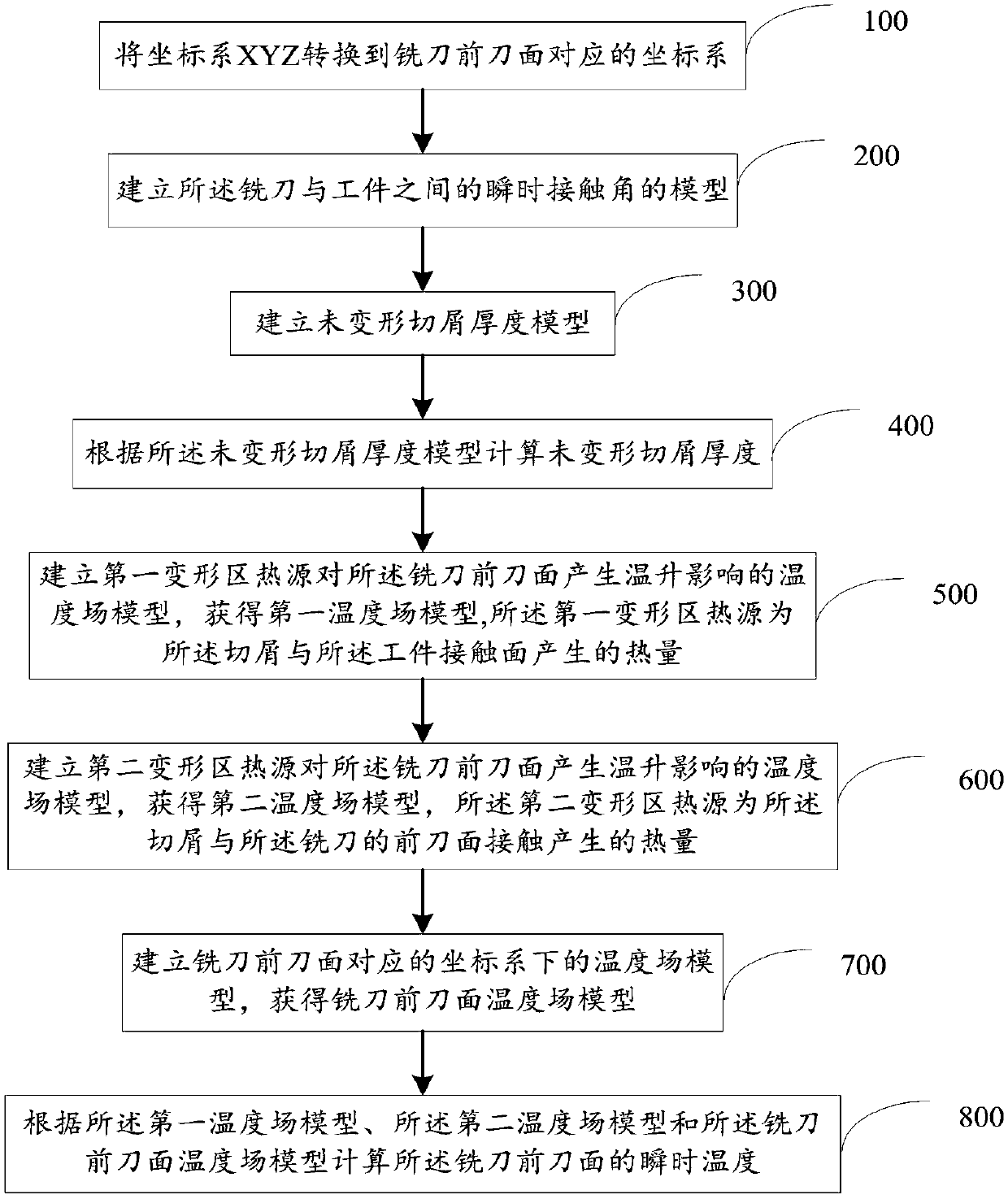

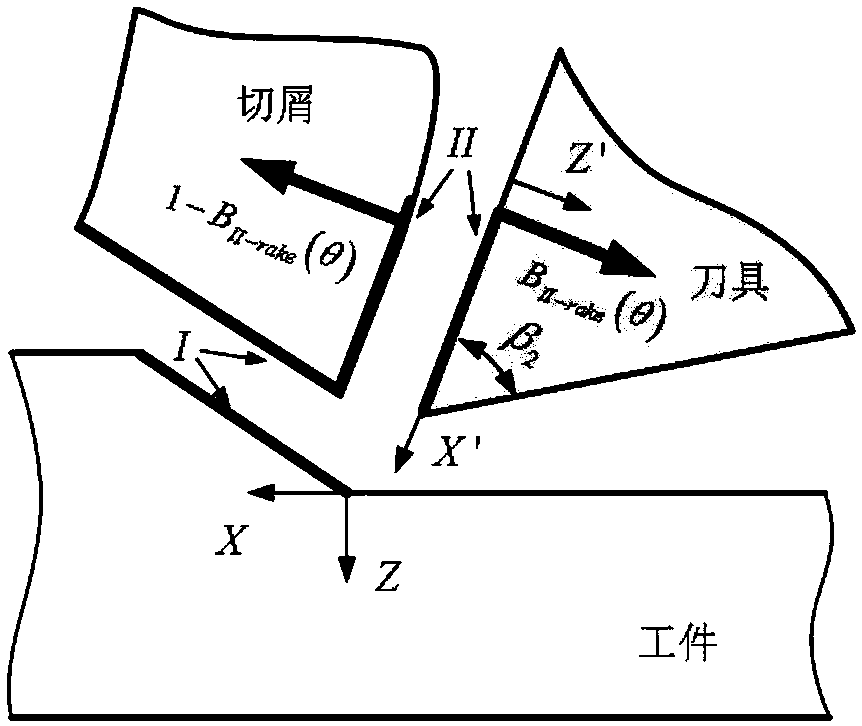

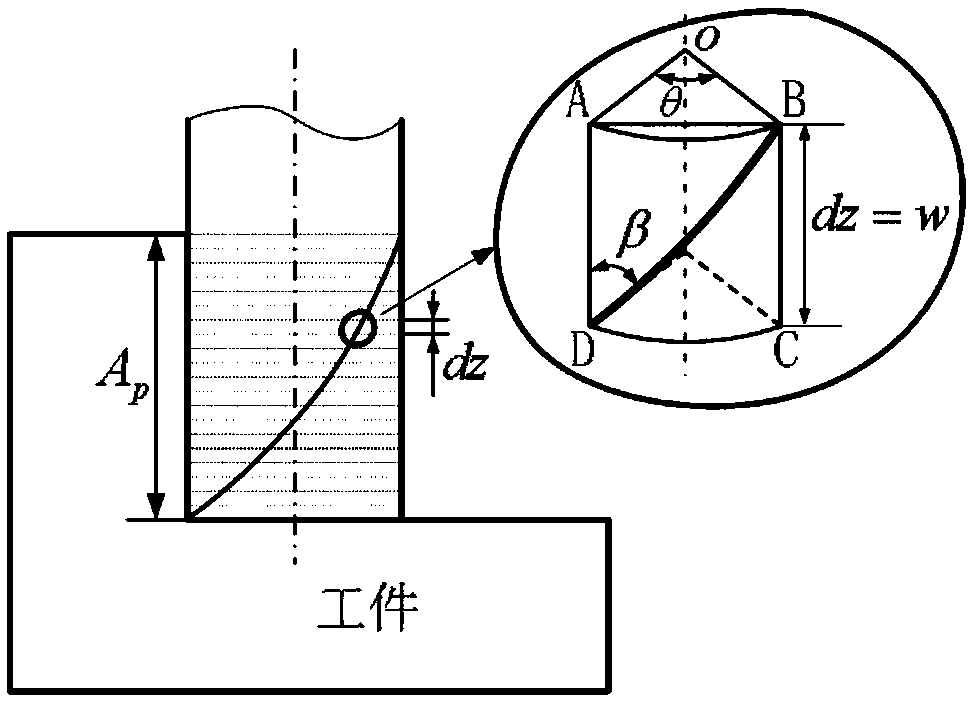

Determining method and determining system for instantaneous temperature of front cutter face of integral type flat-end milling cutter

Owner:HARBIN UNIV OF SCI & TECH

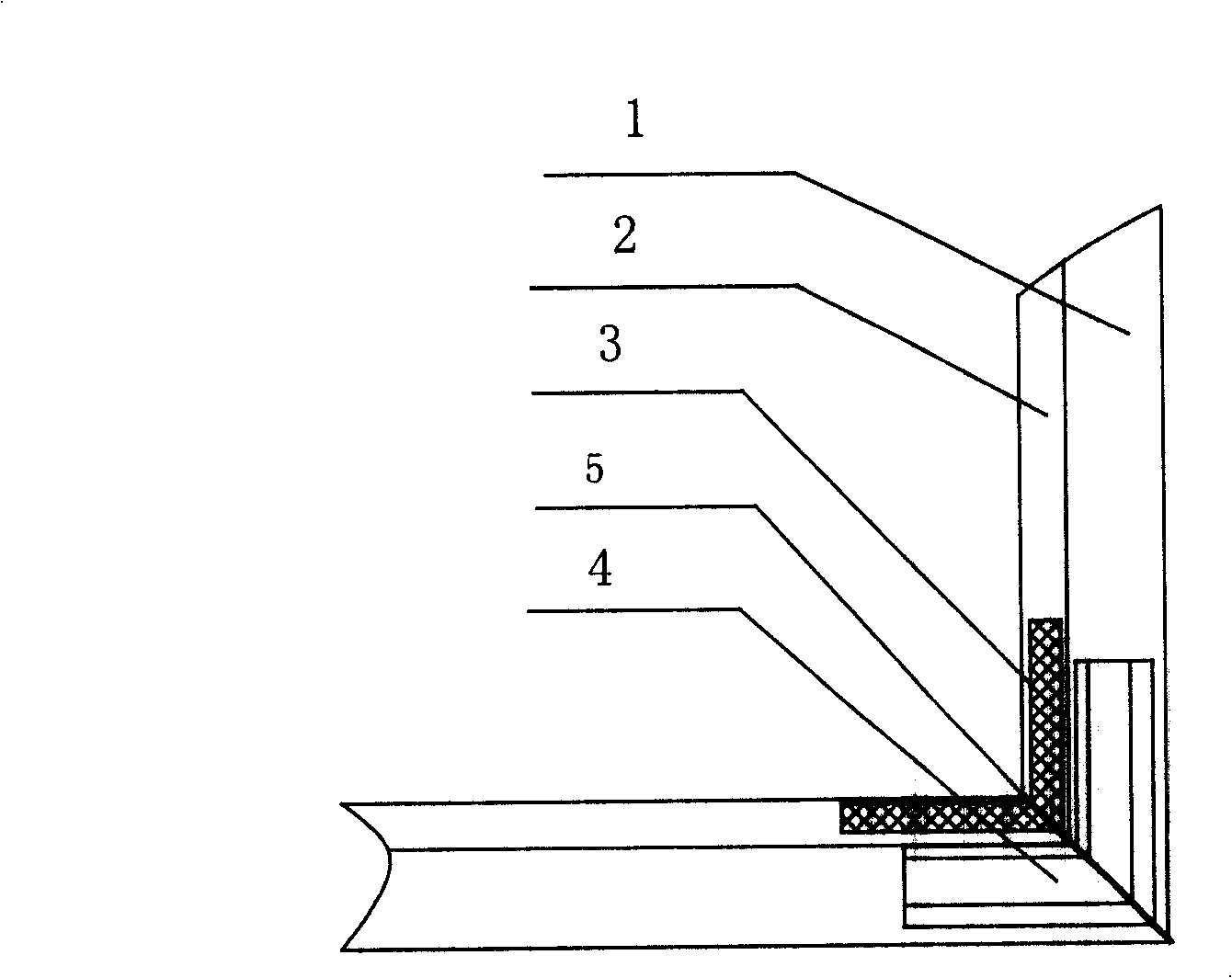

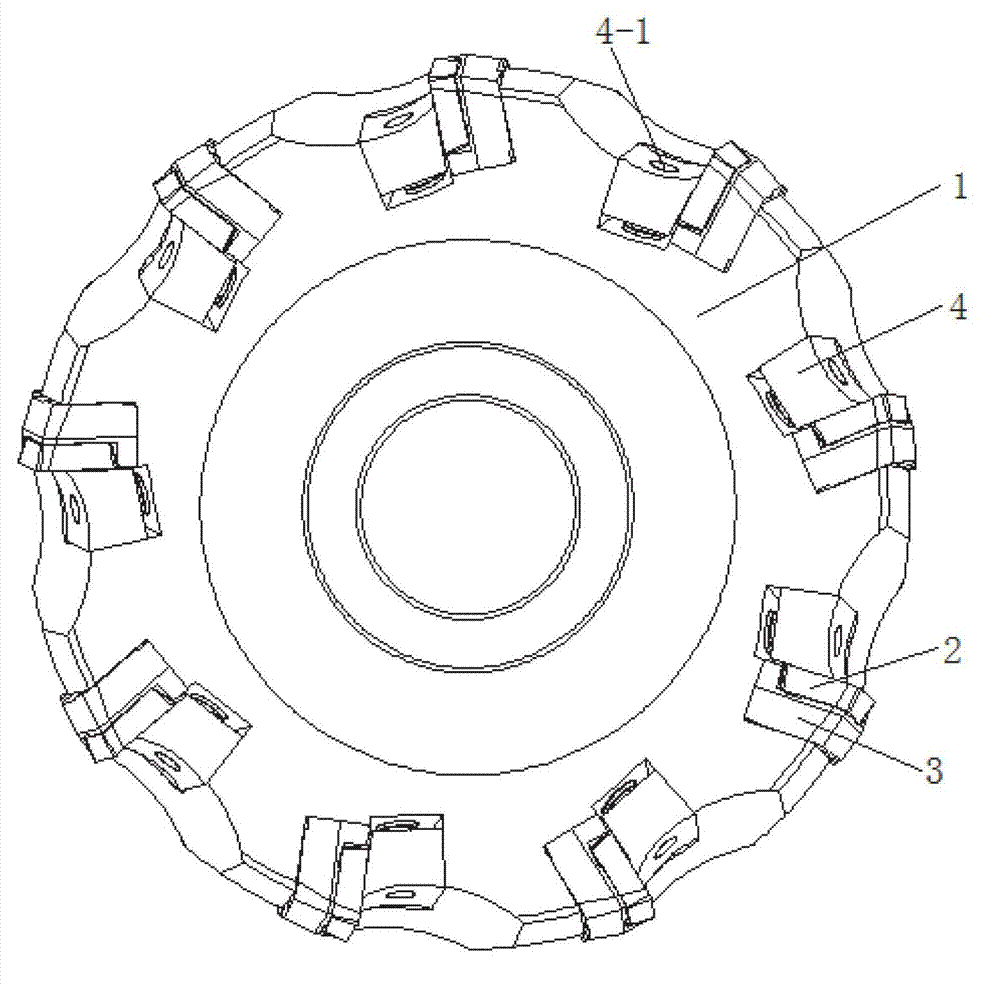

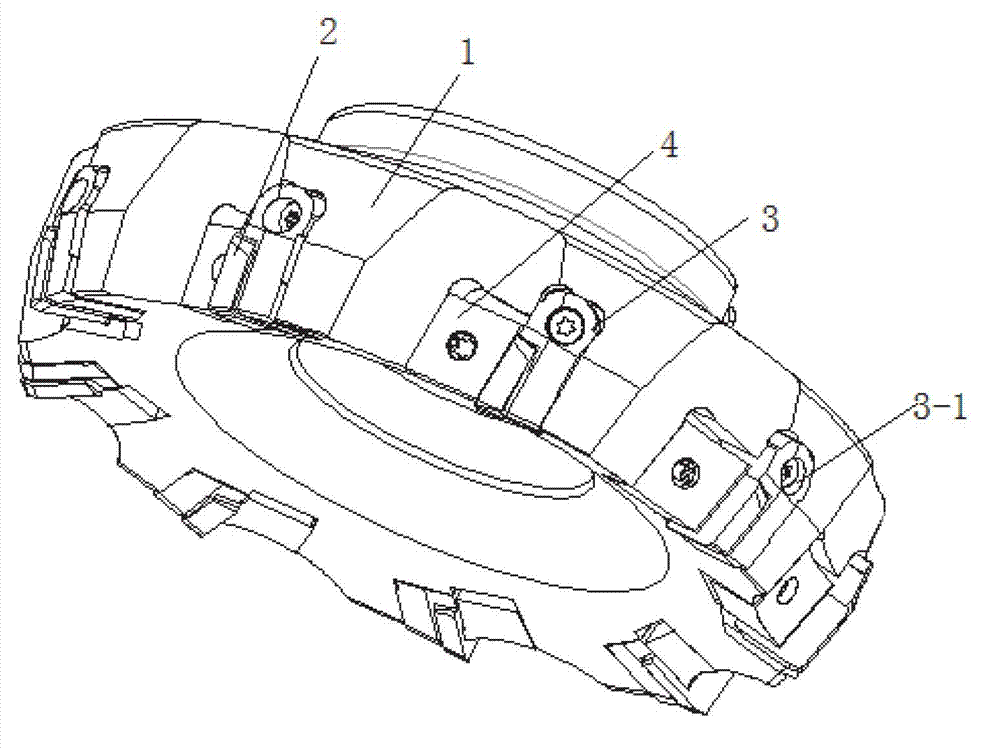

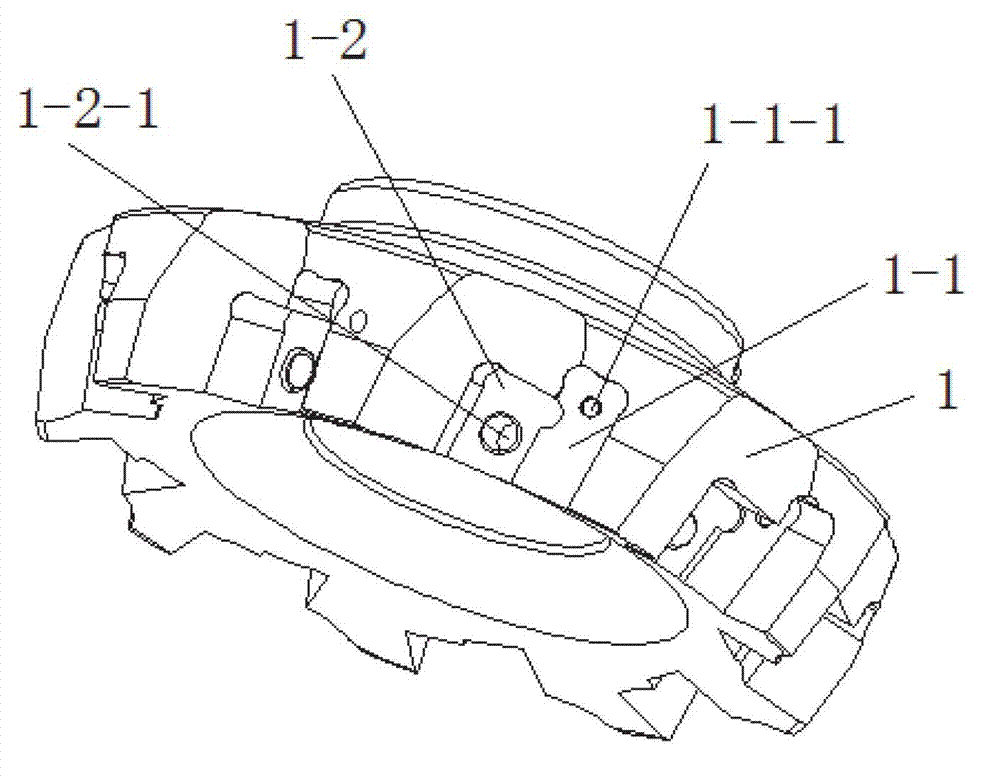

Face milling cutter with indexable inserts and knife pads thereof

The invention discloses a face milling cutter with indexable inserts and knife pads thereof. Each knife pad is provided with a knife pad screw hole and a step groove. The step groove comprises a blade bottom contact face, a blade axial locating face and a blade radial locating face which are connected with each other. A notch with three sides opening is formed in each knife pad. Due to the design of the unique knife pads, blades are not in direct contact with a cutter body, the rigidity of the cutter body is greatly strengthened, the abrasion of the cutter body is reduced, the service life of the cutter is prolonged on the whole, and meanwhile the blades are enabled to be located without the need of being in contact with the cutter body, and the accuracy of repeated locating is high. The service life of the cutter is longer than face milling cutters of other types by more than 50%, the accuracy of processing workpieces is improved by more than one accuracy level, the replacement of the blades is convenient, and the processing cost is reduced greatly.

Owner:常州瑞诺切数控刀具有限公司

Clamping device of numerical control vertical milling machine

Owner:吉林建龙钢铁有限责任公司

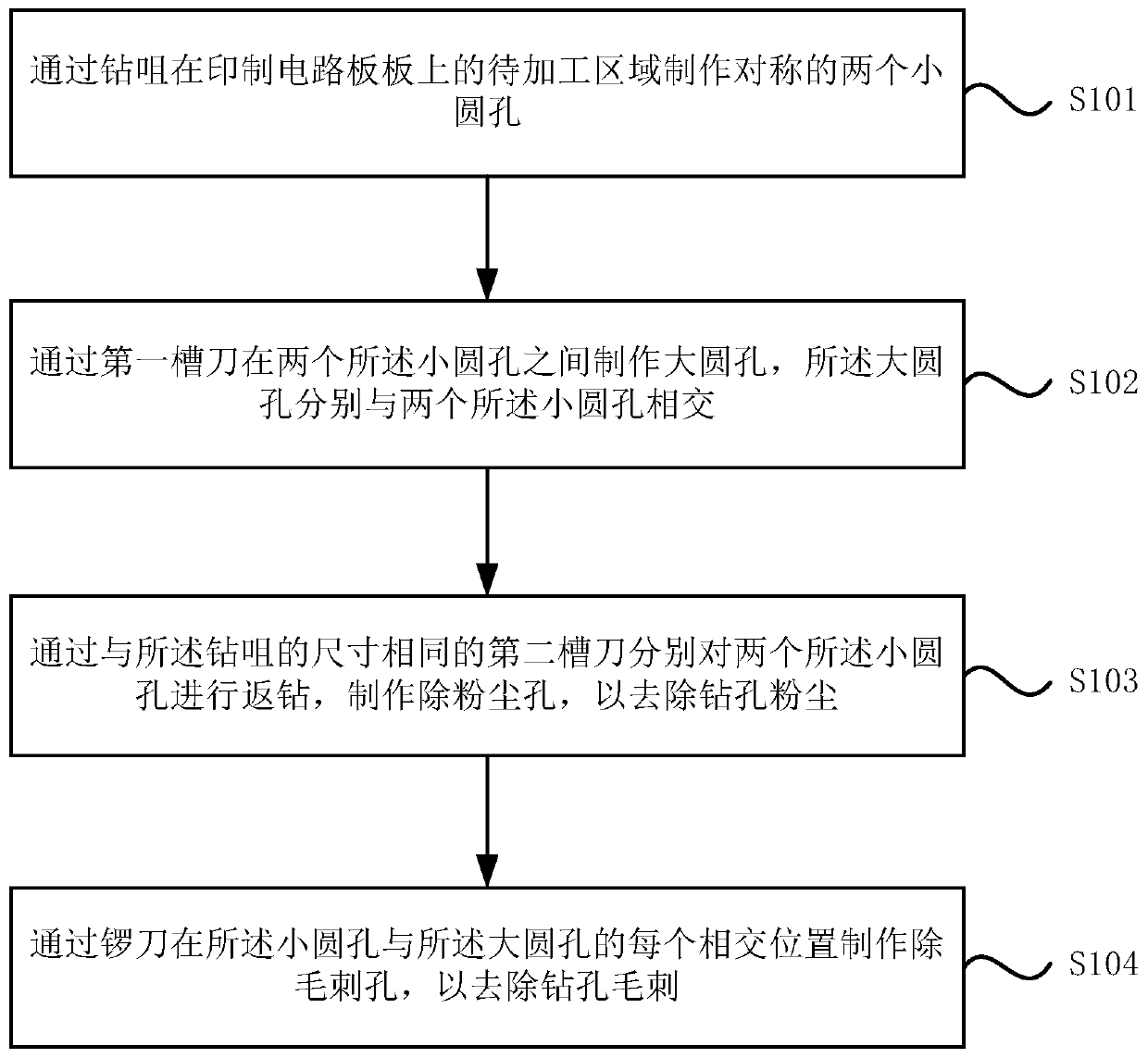

Tree core groove processing method and printed circuit board

ActiveCN111182731AMeet the installation requirementsAvoid the frontPrinted circuit manufactureMilling cutterStructural engineering

Owner:MEIZHOU ZHIHAO ELECTRONICS TECH

Improved separating device for power battery module for vehicle

InactiveCN104466289AImprove work efficiencyFully automated working processSolid waste disposalWaste accumulators reclaimingPower batteryMilling cutter

Owner:广东晓兰客车有限公司

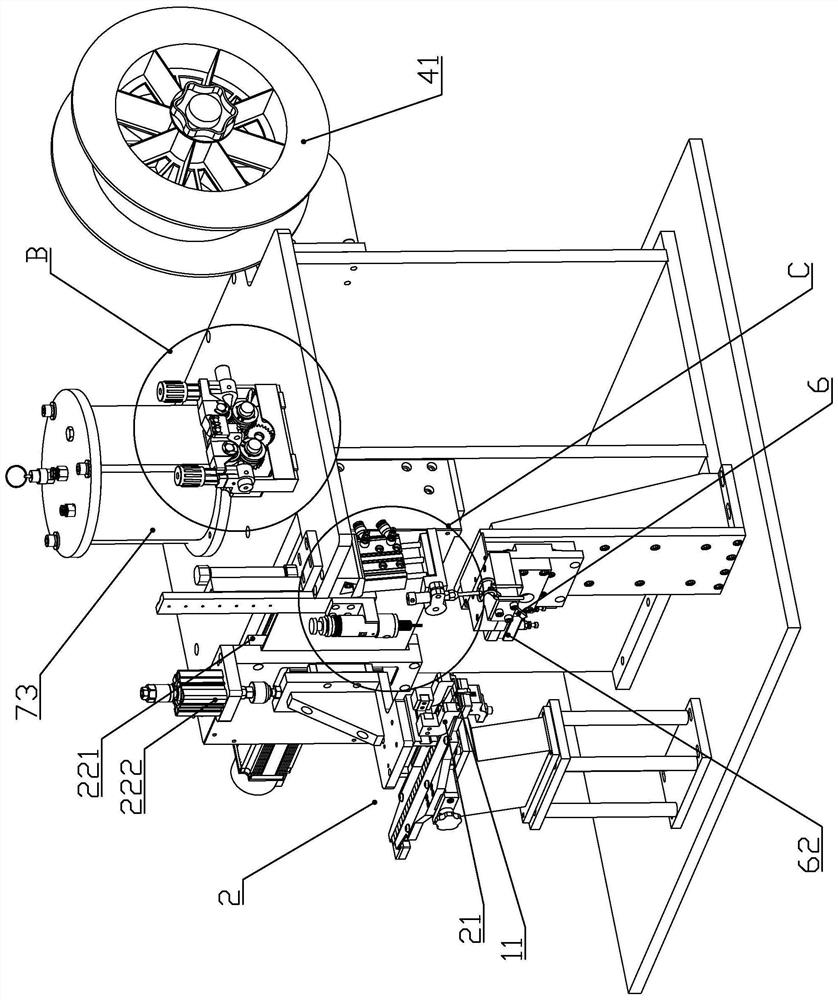

Alloy feeding device for milling cutter welding machine

ActiveCN112008276AGood welding performanceGood welding effectWelding/cutting auxillary devicesAuxillary welding devicesMilling cutterEngineering

Owner:温州市骏承机械设备有限公司

Fine tuning dish milling tool apparatus for machine tool

InactiveCN101462181AExtend your lifeImprove the quality of the processed surfaceMilling cuttersMilling cutterKnife blades

Owner:WEIHAI HUADONG AUTOMATION

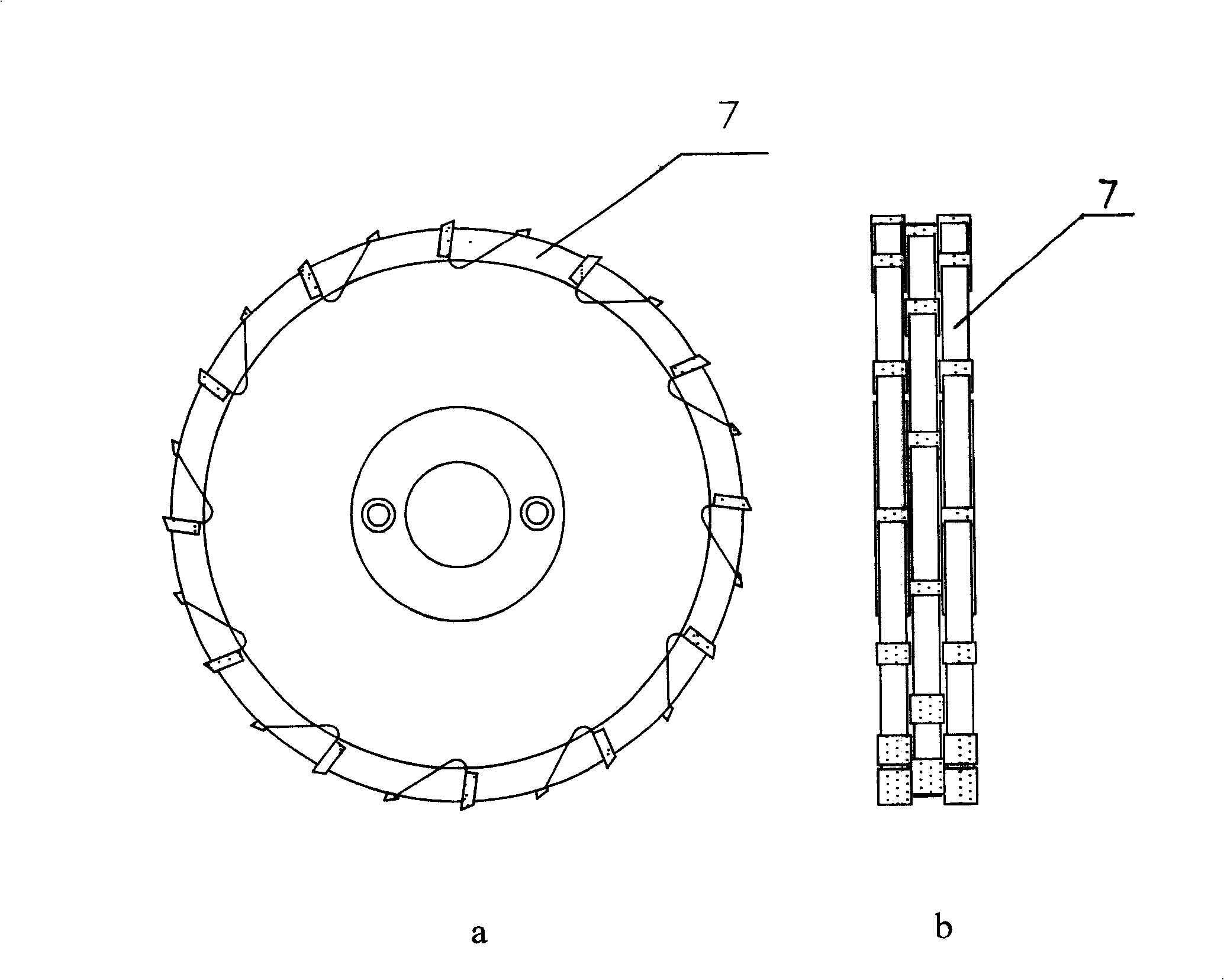

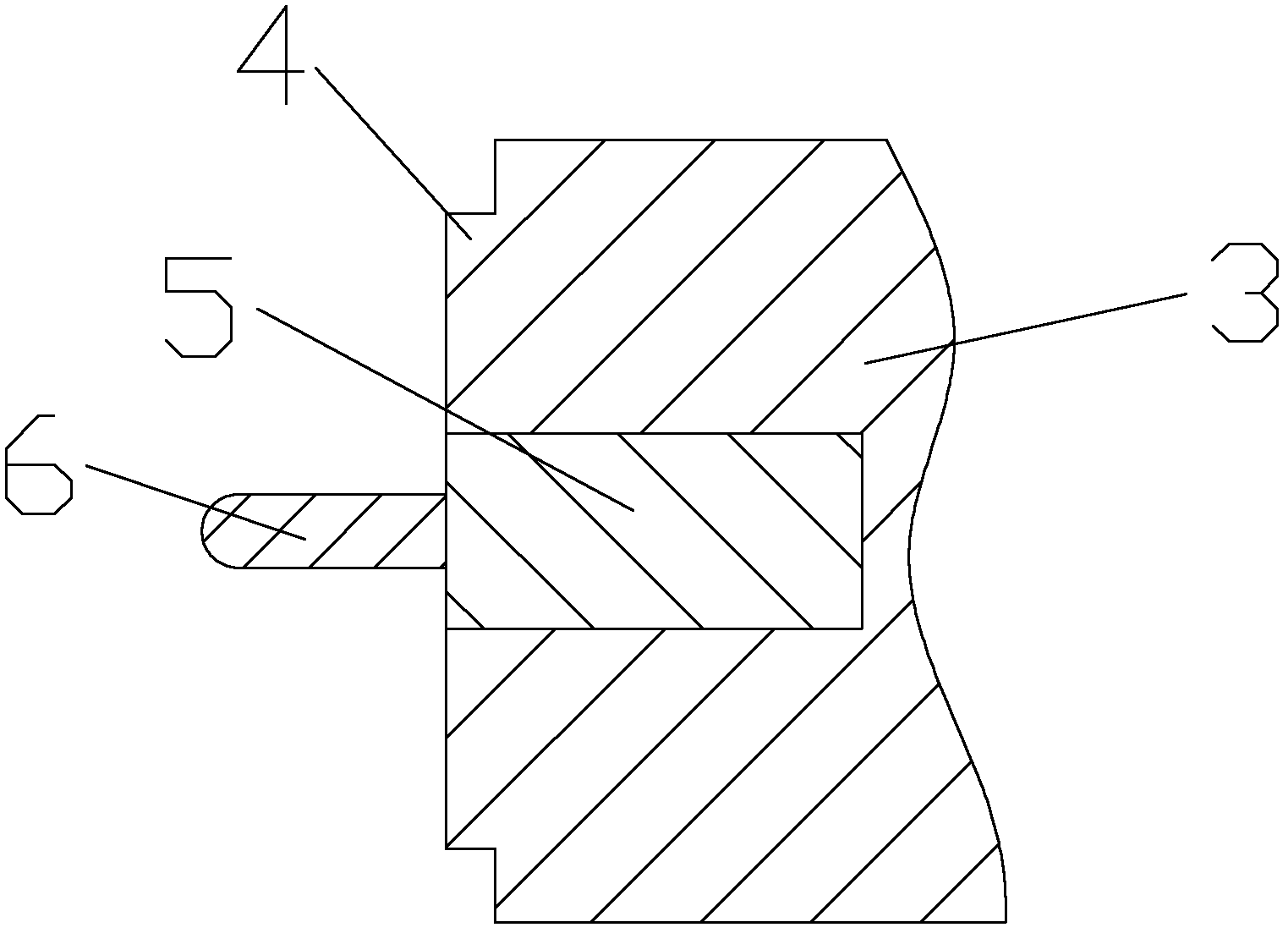

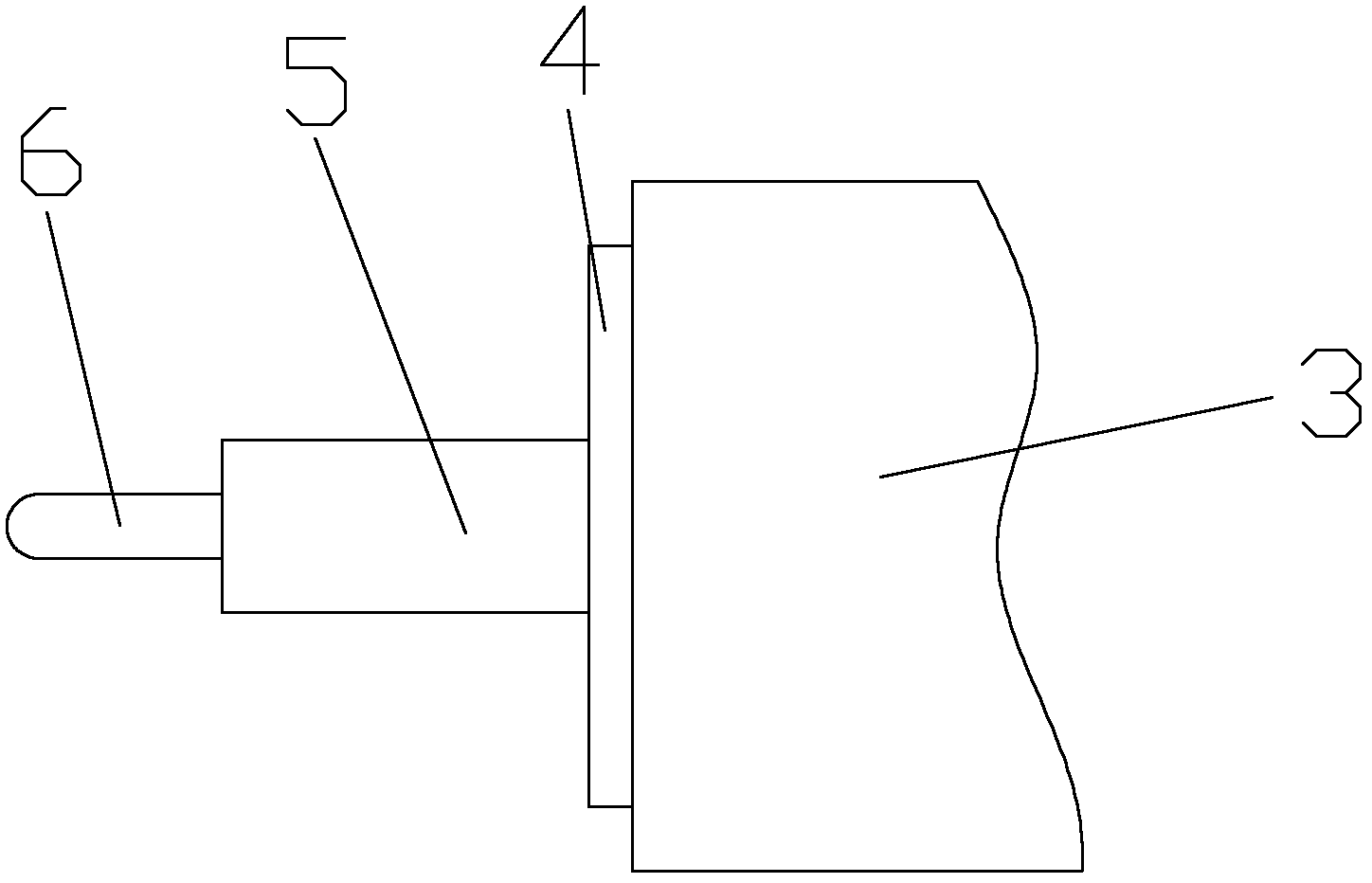

Spiral bevel gear rough milling cutter of novel structure

InactiveCN112404608AWarranty requirementsGear teeth manufacturing toolsGear teethTool bitMilling cutter

The invention discloses a spiral bevel gear rough milling cutter product. The spiral bevel gear rough milling cutter product comprises cutter heads, an angular positioning pin, two compression screws,a cutter disc, a gasket and a blind rivet, and is characterized in that the cutter heads are clamped on the cutter disc, the angular direction is determined through the angular positioning pin, clamping is conducted in the radial direction through the two compression screws, the two compression screws are placed on the rear end face of a hole of the cutter disc, and the blind rivet penetrates through the gasket and is screwed into threaded holes in the rear ends of the cutter heads. The cutter heads are clamped on the cutter disc and are uniformly distributed at 24 positions in the circumferential direction to form cutter teeth of the product, the assembled product is ensured to meet the requirements that the axial run-out requirement is 0.04 and the radial run-out is 0.02, and the clamped cutter disc is clamped on a special cutter shaft. The spiral bevel gear rough milling cutter product mainly aims to change the structural shapes of the cutter disc and the cutter teeth and reduce the machining difficulty of the cutter teeth. Therefore, a universal high-precision grinding machine can be used for machining products.

Owner:HARBIN DONGAN LIFENG CUTTER

Double-sided milling-machine cutter-fixing device

Owner:SUZHOU MAIDER MACHINERY

Method for carrying out planing machining for narrow grooves by virtue of numerically-controlled boring and milling machine

InactiveCN105642990ASolve processing problemsImprove processing efficiencyPlaning/slotting toolsPlaning/slotting machinesNumerical controlMilling cutter

Owner:YICHANG MARINE DIESEL ENGINE

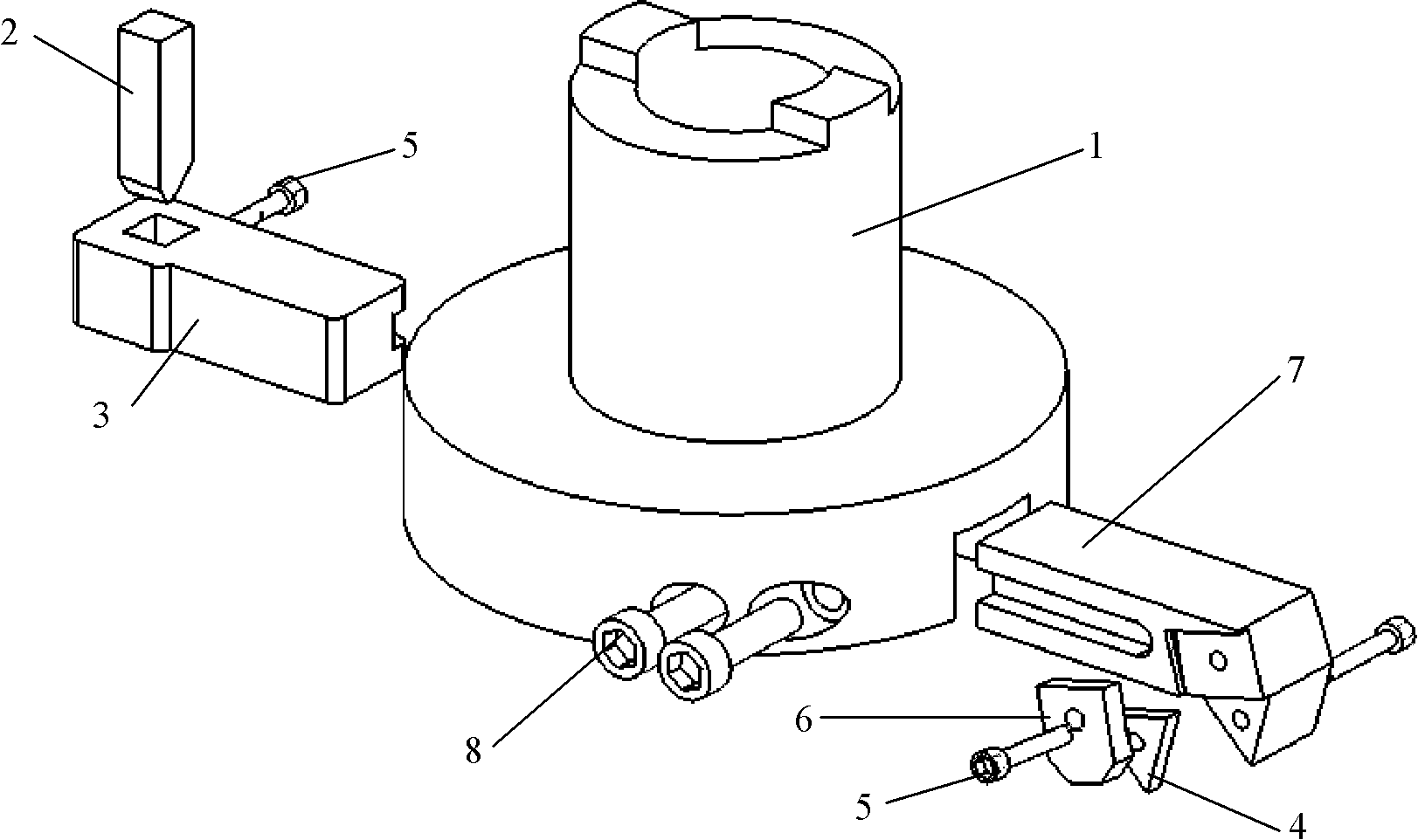

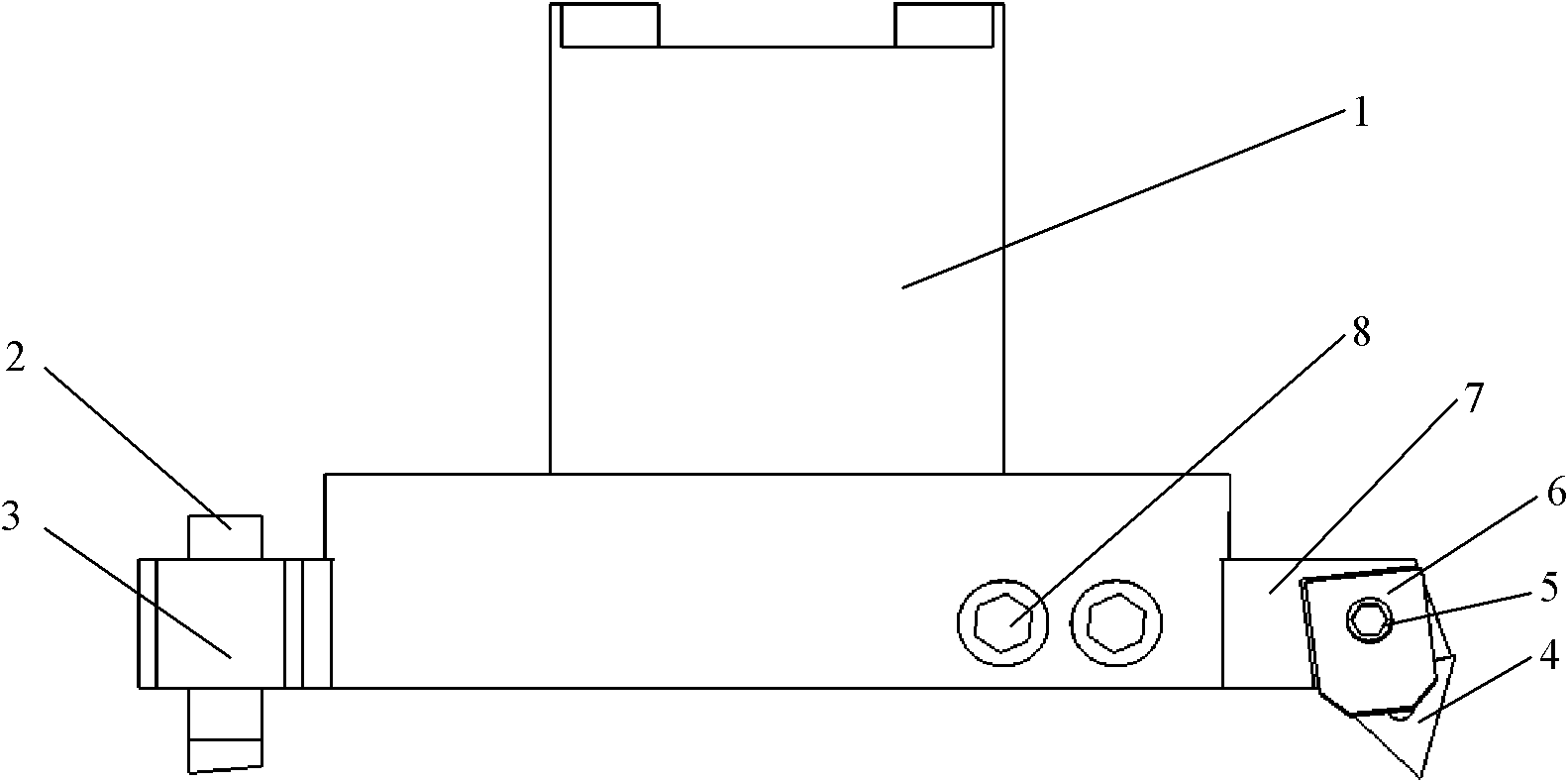

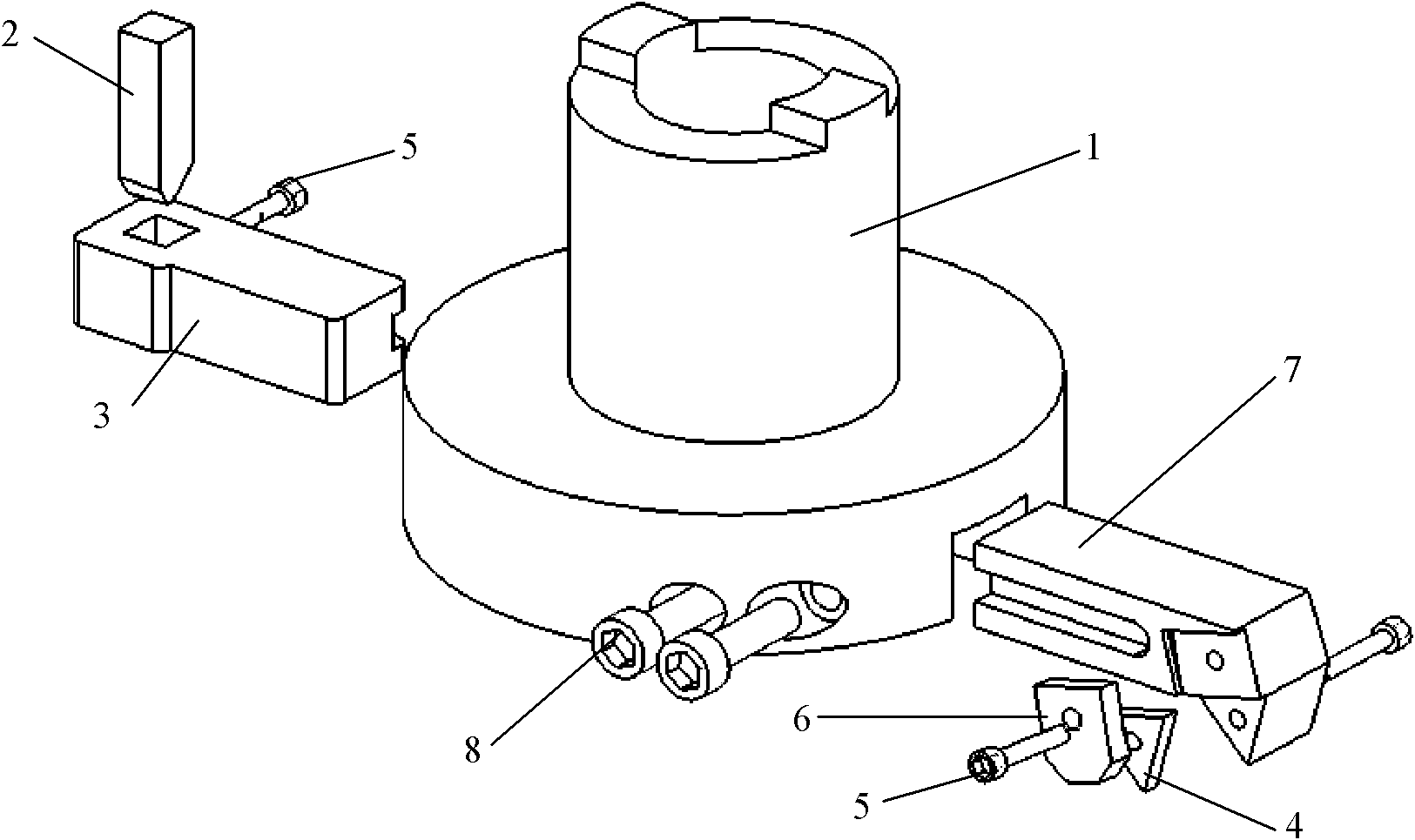

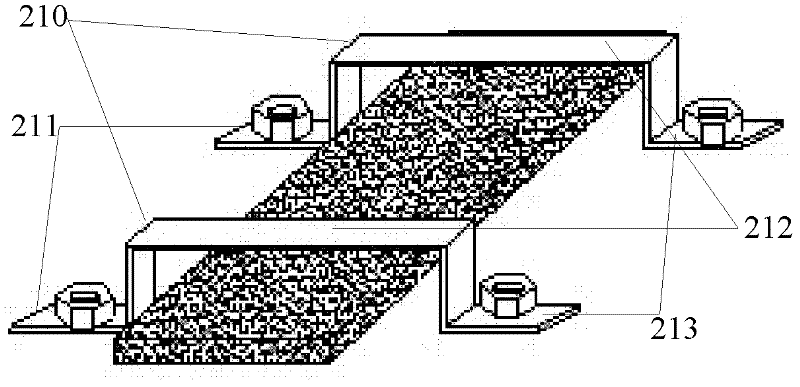

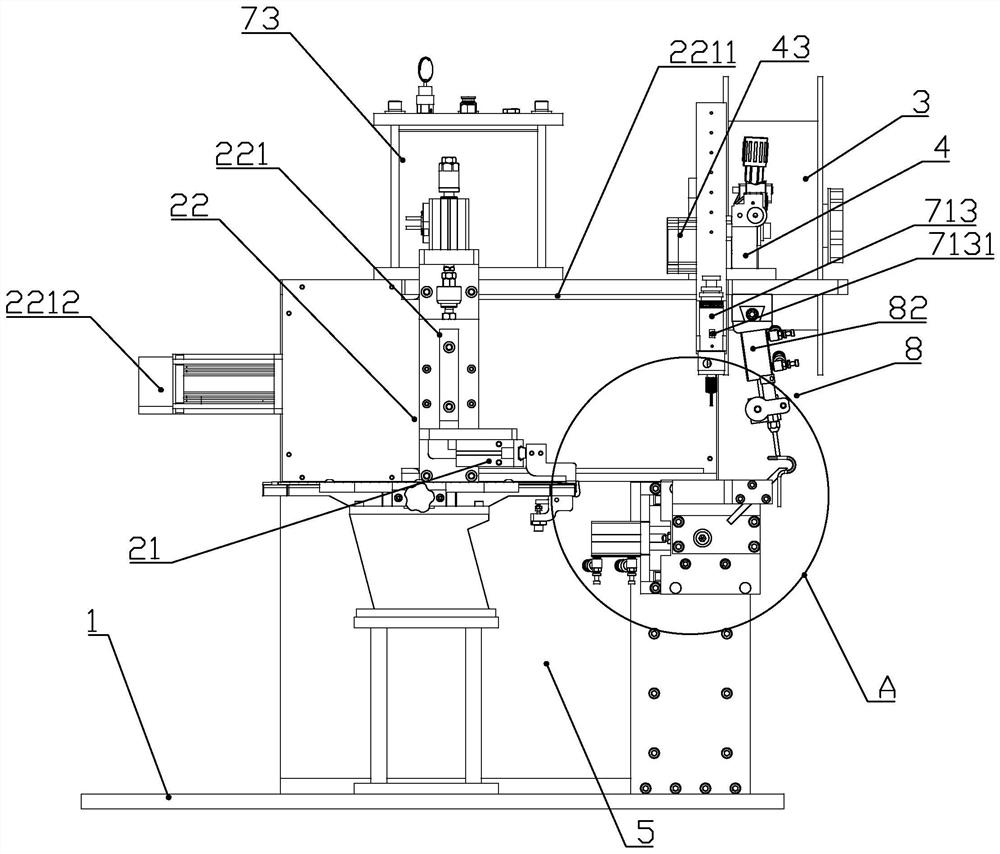

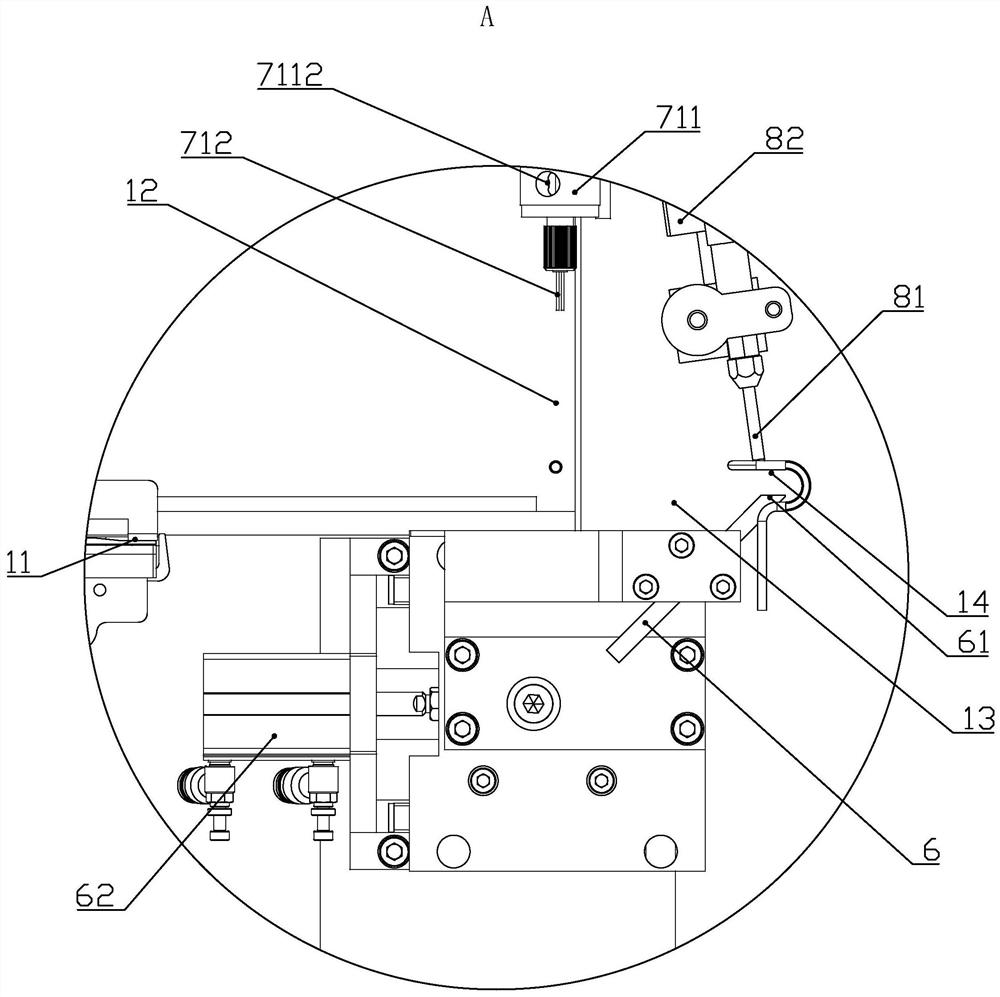

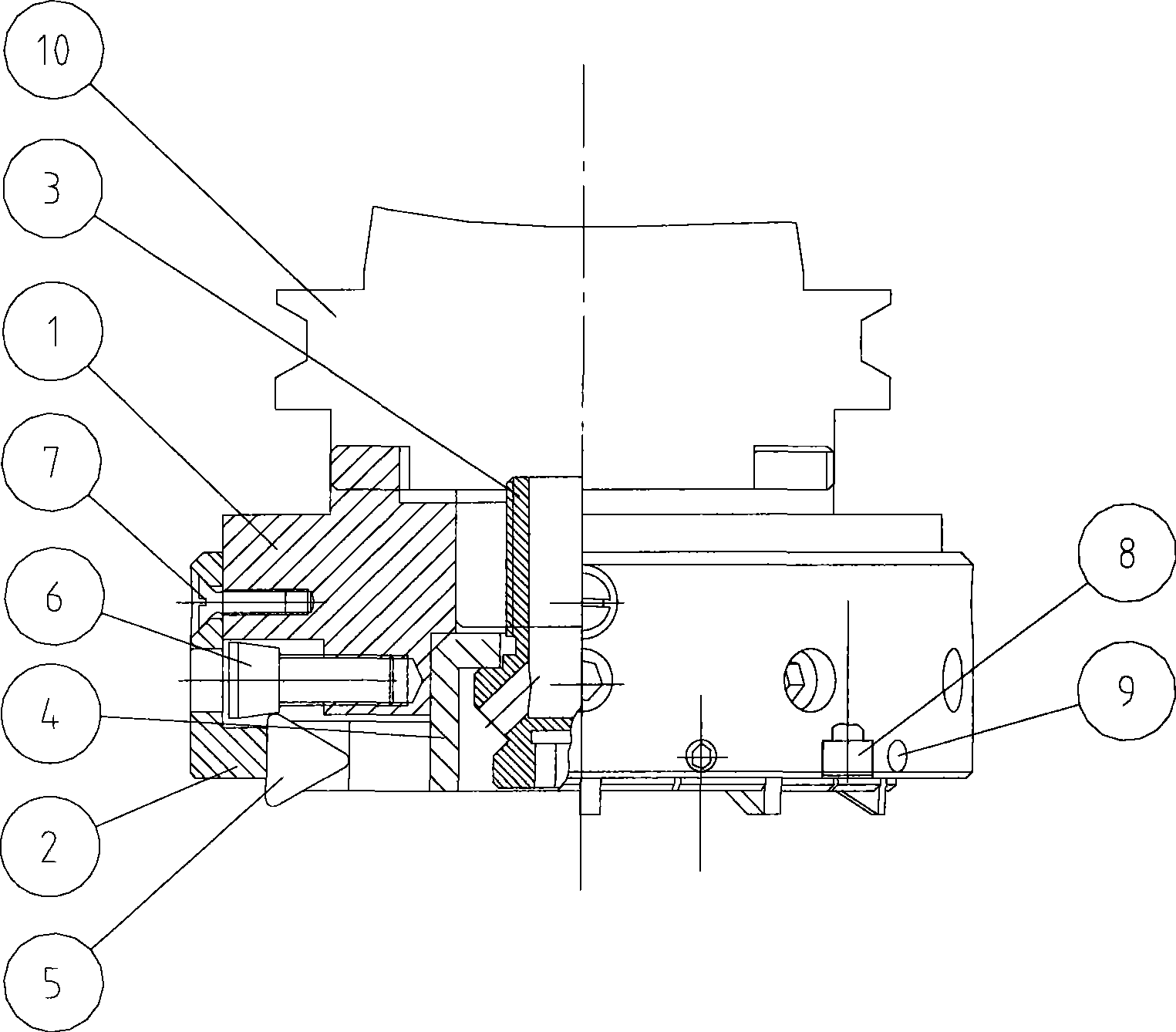

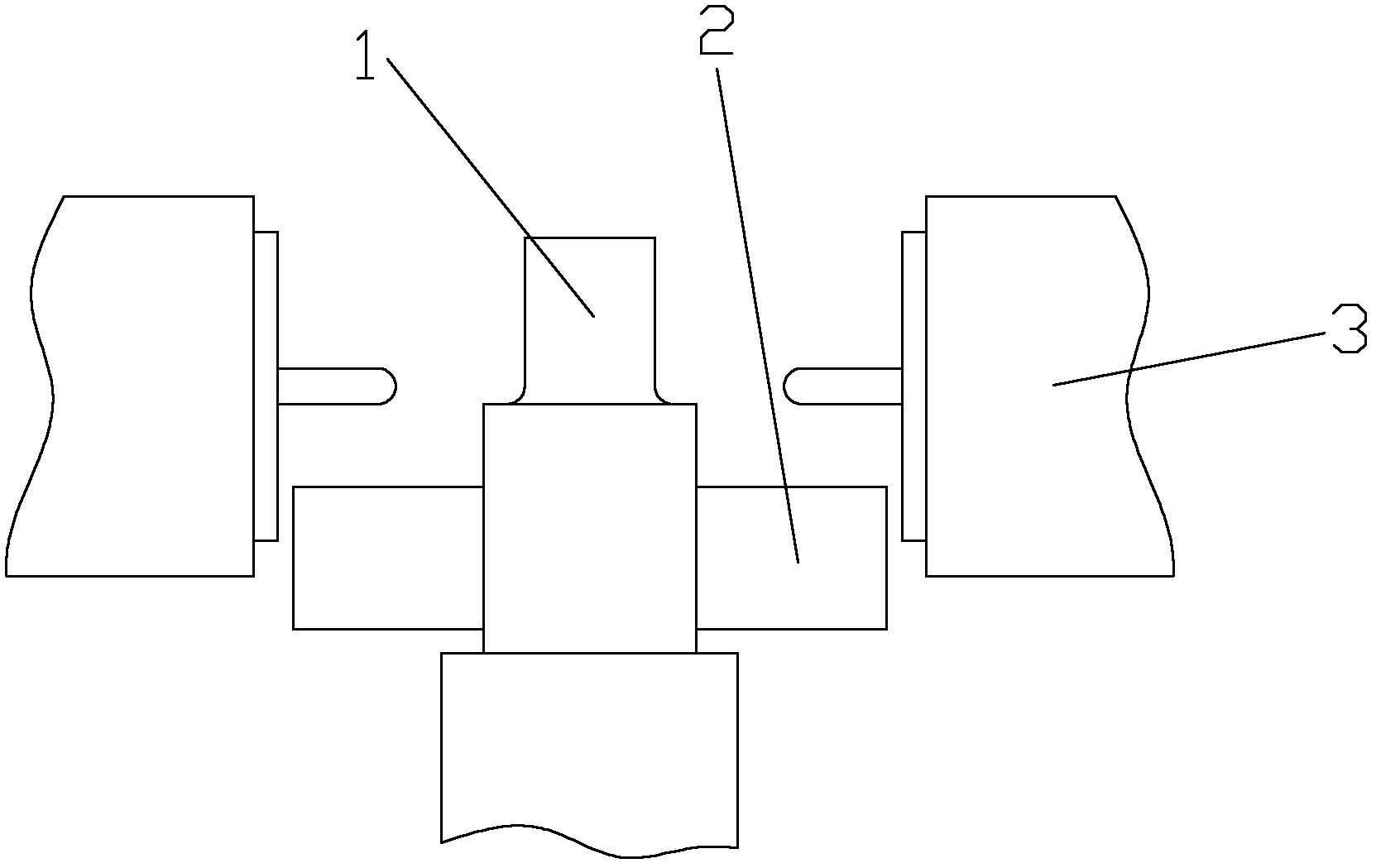

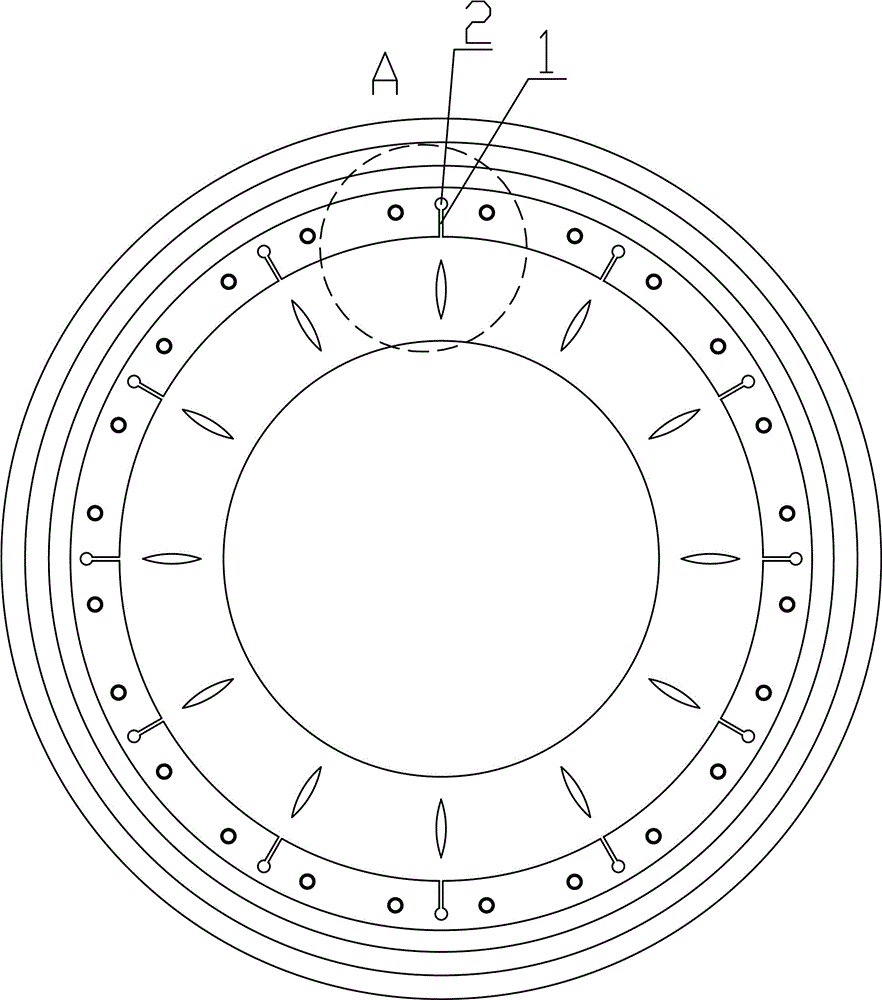

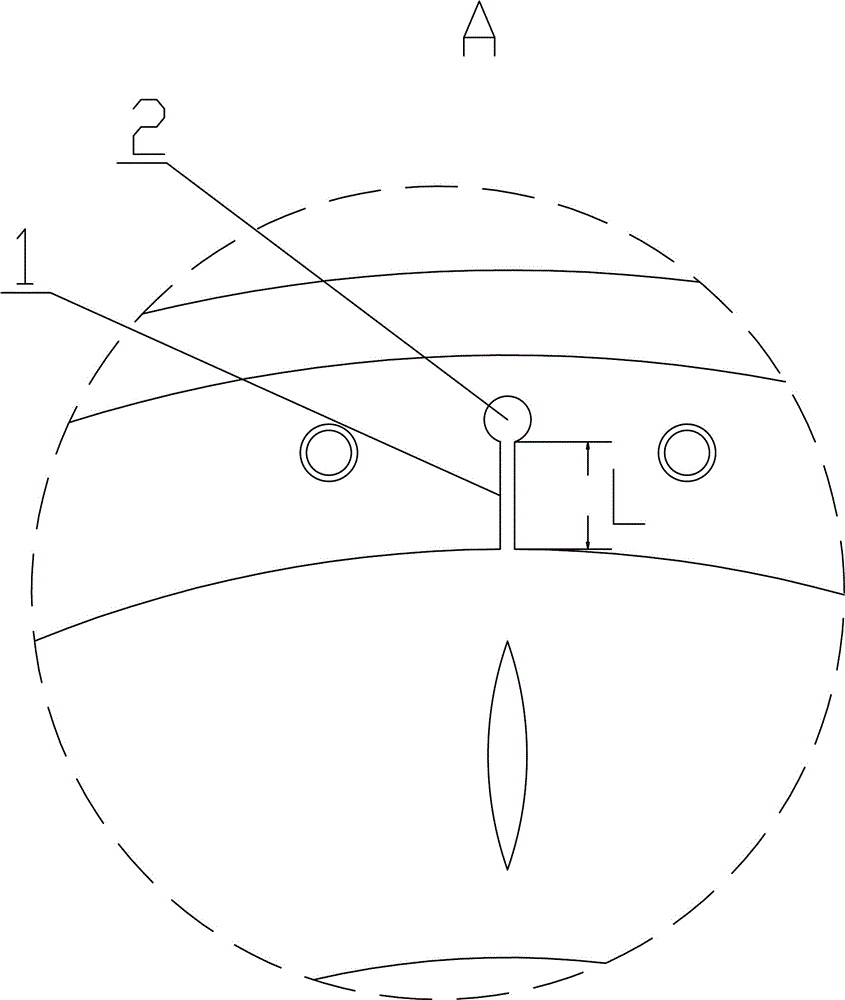

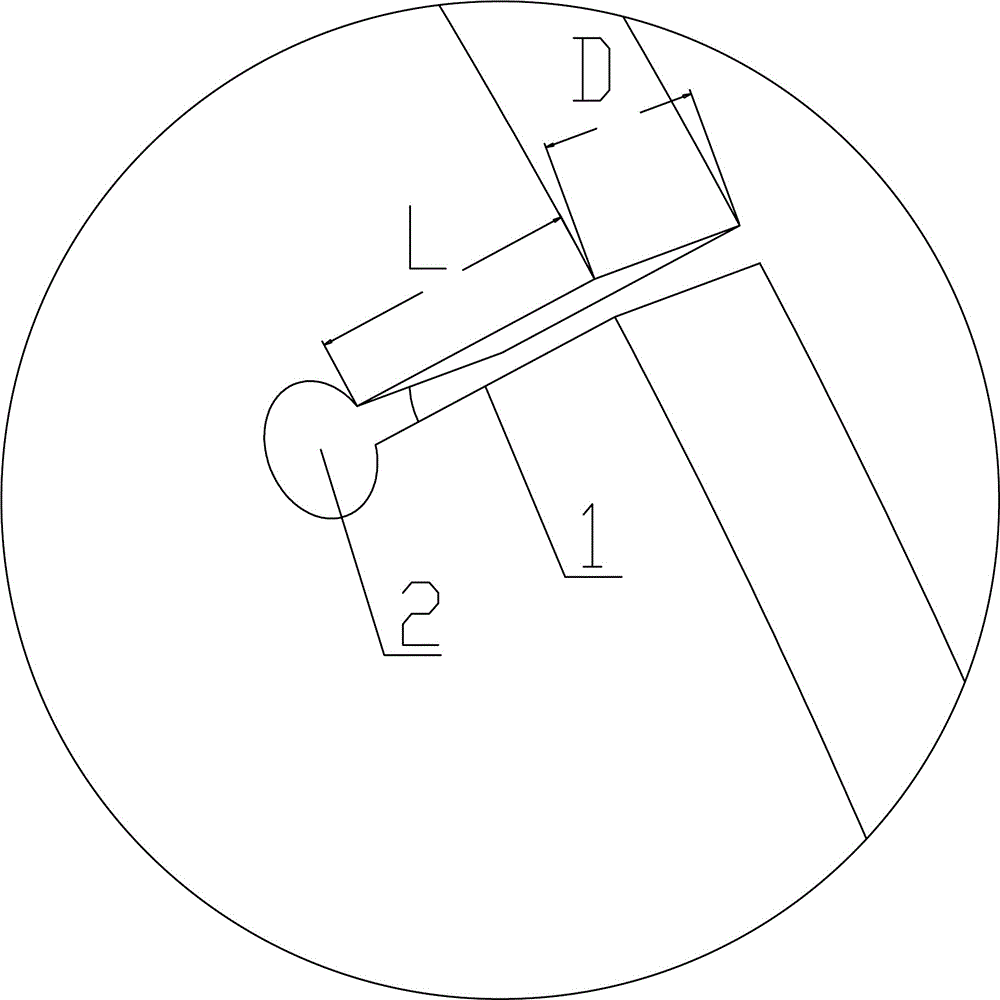

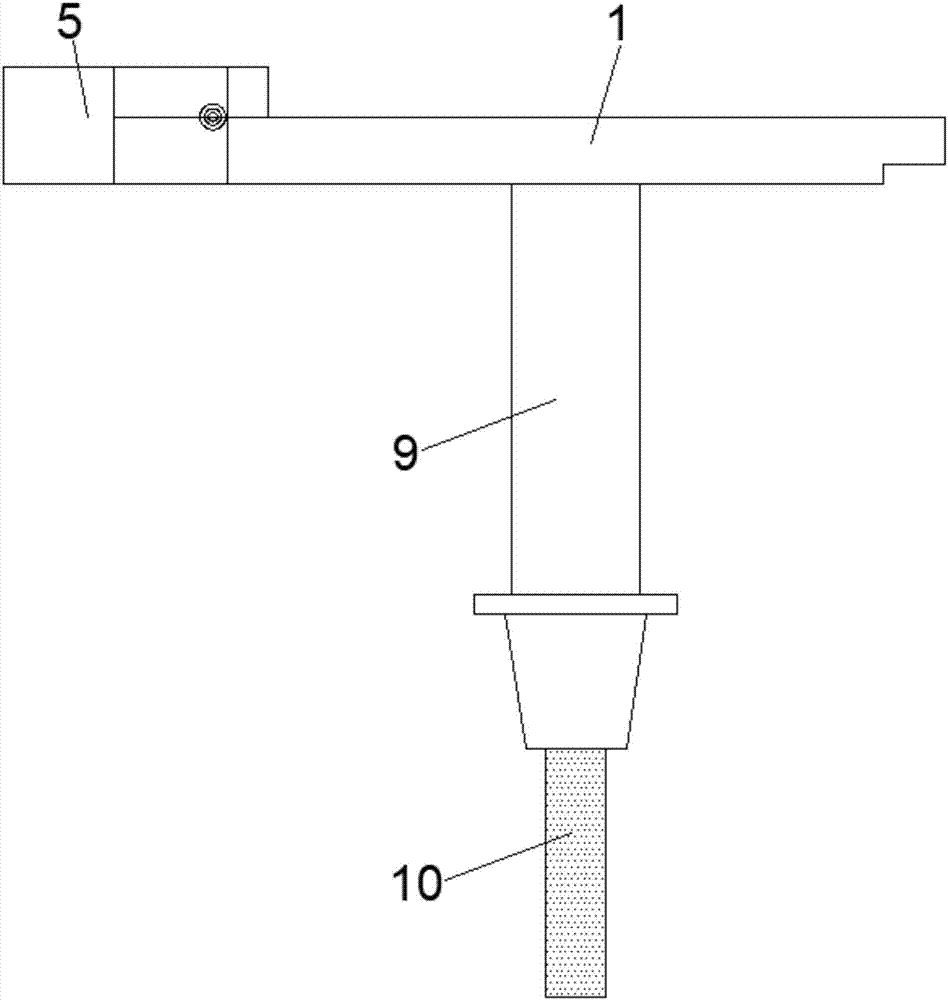

Ball socket machining device for inner ring of socket curved groove ball bearing

InactiveCN111069671AShorten the timeHigh indexing accuracyPrecision positioning equipmentShaftsBall bearingMilling cutter

The utility model discloses a ball socket machining device for an inner ring of a socket curved groove ball bearing, and belongs to the field of mechanical engineering. In order to overcome the defects of low working efficiency, large workload, incapability of effectively ensuring the precision and the like of ball socket machining of the inner ring of the socket curved groove ball bearing. The machining device comprises a base, a rapid clamping device, a set of ball socket milling devices arranged in the circumferential direction, a set of indexing precision control blocks and a feeding precision control mechanism and the like; and an air cylinder is used for independent feeding, and a motor is used for driving a spherical milling cutter to conduct independent milling. The machining device for the inner ring of the socket curved groove ball bearing has the following advantages that (1) a plurality of ball sockets can be machined at the same time at a time, and time is saved; (2) the indexing precision of the ball sockets is improved by using a movable positioning block; and (3) the feeding power of the air cylinder is flexible force, so that the impact of the milling cutter can beavoided.

Owner:NORTHWEST A & F UNIV

Heat-resistant tungsten steel milling cutter

The invention discloses a heat-resistant tungsten steel milling cutter which comprises a connecting rod and a fixing ring. The fixing ring is installed on the outer surface of the connecting rod, and a plurality of milling teeth are installed on the outer surface of the fixing ring; a cooling interlayer is arranged in the inner wall of the interior of the fixing ring; and an inserting groove is formed in the top of the connecting rod. By means of the heat-resistant tungsten steel milling cutter, the cooling interlayer is installed on the fixing ring, when the milling cutter makes contact with a material, milling teeth rub against the material to generate a large amount of heat, meanwhile, cold water in the cooling interlayer in the fixing ring absorbs heat on the outer surfaces of the milling teeth under the effect of heat transfer, and therefore the situation that the milling teeth deform due to the too high temperature of the outer surfaces is prevented, and the service life of the device is prolonged.

Owner:SUZHOU XINWEISHENG CUTTING TOOLS CO LTD

Milling cutter

ActiveCN105397167AReduce lightGood chip breaking effectMilling cuttersMilling cutting insertsMilling cutterEngineering

The invention discloses a milling cutter. First milling blades and second milling blades are alternately arranged in a plurality of cutter grooves. The first milling blades and the second milling blades all comprise upper surfaces, lower surfaces, a plurality of side faces connecting the upper surfaces and the lower surfaces, and corner faces located between the adjacent side faces. Upper cutting edges are formed by the side faces and the upper surfaces. Upper corner edges are formed by the corner faces and the upper surfaces. An upper cutting unit is formed by any two adjacent upper cutting blades and the corresponding upper corner edge connected with the adjacent upper cutting edges. One upper cutting edge of each upper cutting unit is a main cutting edge, and the other upper cutting edge of each upper cutting unit is an auxiliary cutting edge. When the upper cutting units of the first milling blades and the second milling blades carry out cutting, workpiece cutting-in angles are formed by the upper cutting edges serving as the main cutting edges and the surface of a workpiece, and in the same cutting direction, the workpiece cutting-in angles of the upper cutting edges, serving as the main cutting edges, of the first milling blades and the second milling blades are different. The milling cutter has the beneficial effects of being good in scrap breaking capability, high in machining capability and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Detachable cutter for milling machine

Owner:郑州佳泰机电科技有限公司

Cutter machining vertical pressing plate mechanism and operation method thereof

PendingCN112296770AImprove qualityMilling cuttersOther manufacturing equipments/toolsMilling cutterEngineering

The invention discloses a cutter machining vertical pressing plate mechanism and an operation method thereof. The cutter machining vertical pressing plate mechanism comprises a positioning block, a pressing plate and at least one grinding wheel used for machining a material bar. The positioning block is provided with a V-shaped groove used for containing the material bar, and the two inner walls of the V-shaped groove are perpendicular to each other. The mechanism further comprises a fixed base fixedly connected with an external rack, a sliding module arranged on the fixed base and a transmission module in transmission connection with the sliding module. The sliding module comprises a sliding bottom plate and a sliding cover, the pressing plate is vertically arranged above the sliding bottom plate, a positioning block fixing seat is arranged above the sliding cover, a positioning block fixing block is arranged on the side, facing the sliding bottom plate, of the positioning block fixing seat, a positioning block fixing groove is formed in the side, facing the pressing plate, of the positioning block fixing block, and the positioning block is fixedly arranged in the positioning block fixing groove. The positioning block is perpendicularly arranged on the sliding cover, the pressing plate is perpendicularly arranged on the sliding bottom plate, the grinding wheel is arranged above the sliding cover, so that a fixed included angle is formed, and it is ensured that the quality of a milling cutter machined within an error is excellent.

Owner:DONGGUAN FANYU AUTOMATION TECH CO LTD

Milling cutter guide fixing device

Owner:乳山市黄海汽车配件有限公司

Horizontal milling machine power conversion machine head

InactiveCN107243669AImprove processing efficiencyIncrease output powerMilling equipment detailsGear driveMilling cutter

Owner:十堰西来工贸有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap