Milling cutter guide fixing device

A technology for fixing devices and milling cutters, which is applied to milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve problems such as poor processing quality, reduced work efficiency, and hidden dangers of production safety, so as to ensure a safe operating environment and improve work efficiency. Efficiency, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing:

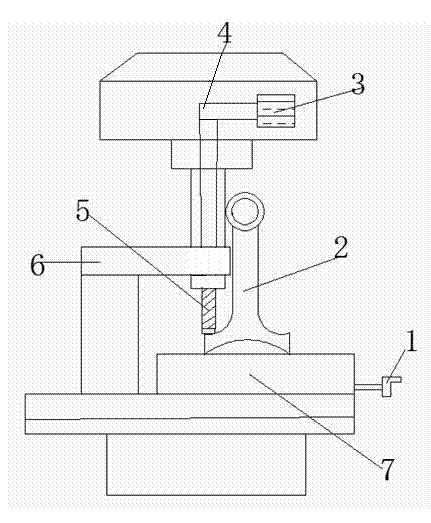

[0009] Such as figure 1 As shown, the present invention relates to a milling cutter guiding and fixing device, which is provided with a motor 3, a belt 4, a milling cutter 5, a guiding and fixing block 6, a workbench 7, a connecting rod 2, and a handle 1, and is characterized in that: the motor The transmission shaft on the 3 is connected with the rotating shaft of the milling cutter 5 through the belt 4, and the middle part of the milling cutter 5 is provided with a guide fixed block 6, and the workbench 7 is below the milling cutter 5, and the connecting rod 2 is fixedly installed on the workbench 7, and the working One side of the platform 7 is provided with a handle 1 .

[0010] When the present invention is used, firstly, the milling cutter is fixedly installed according to the requirements of milling processing, and then the guide fixing block is added to adjust the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap