Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about "Printed circuit manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

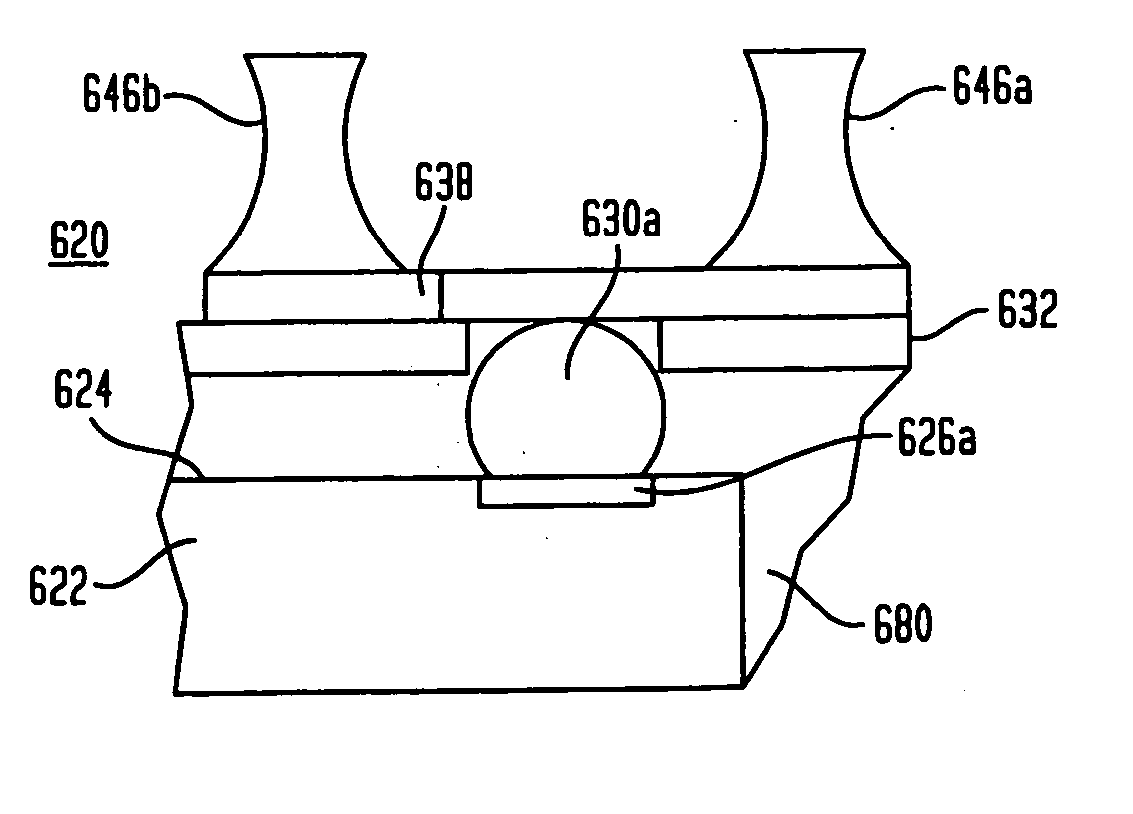

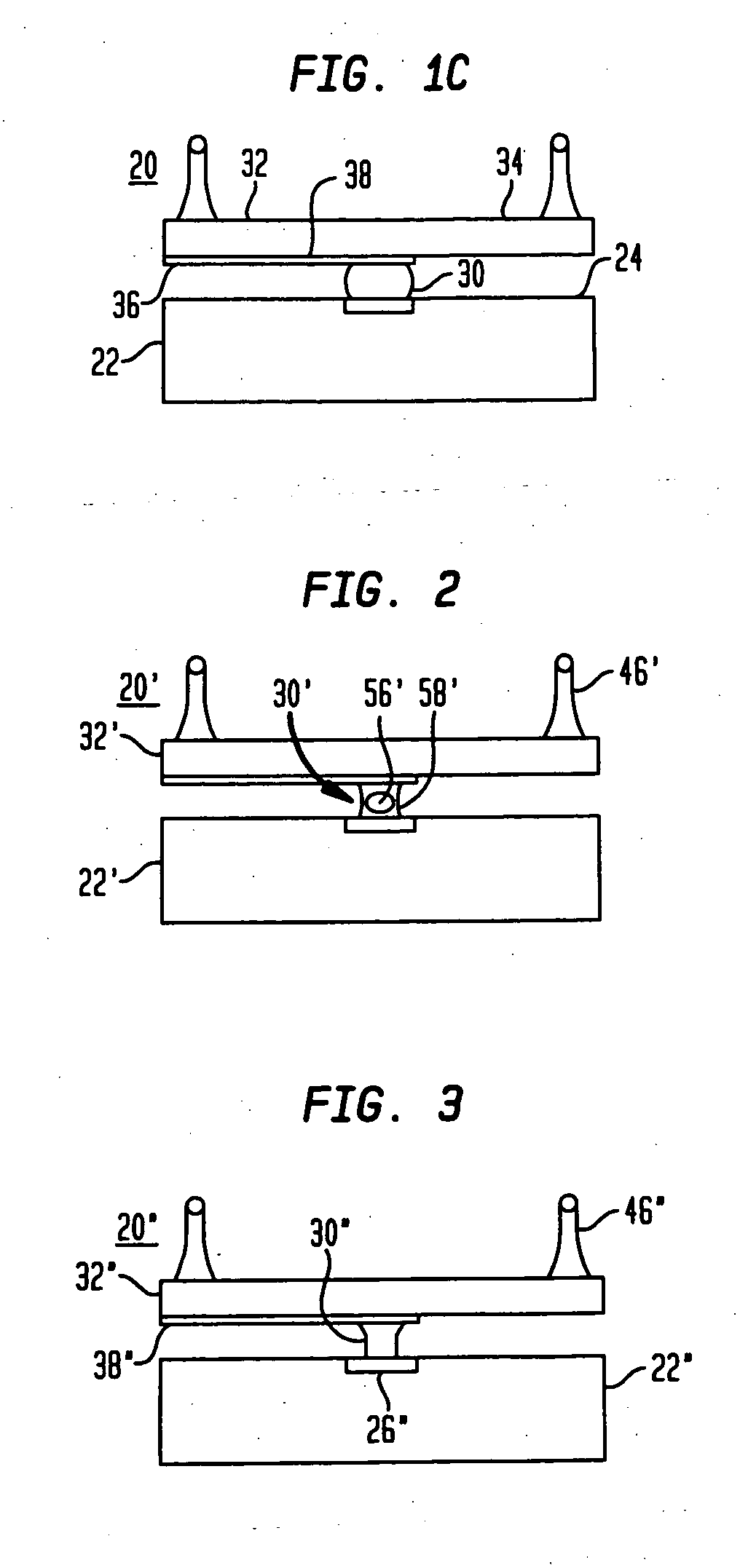

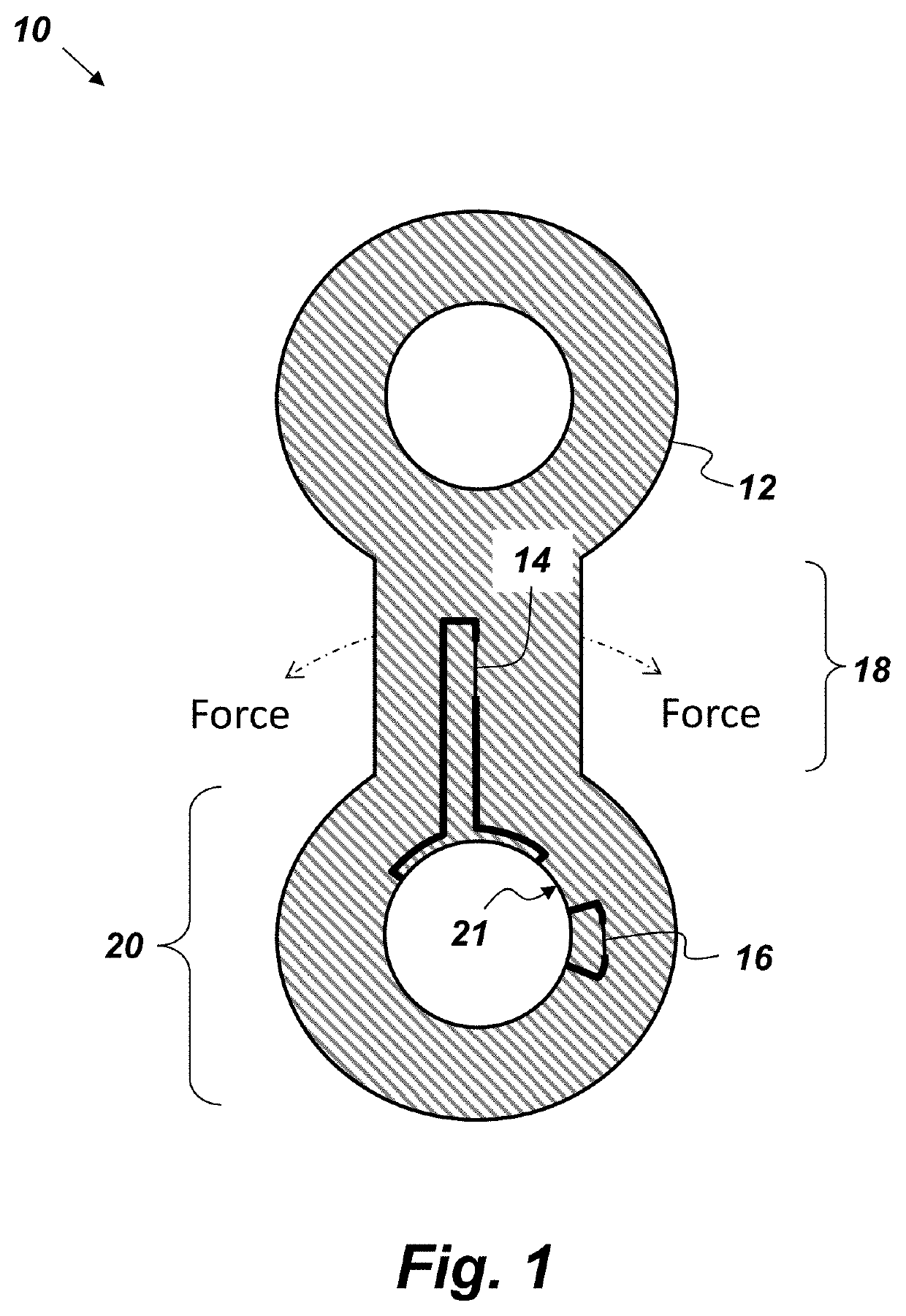

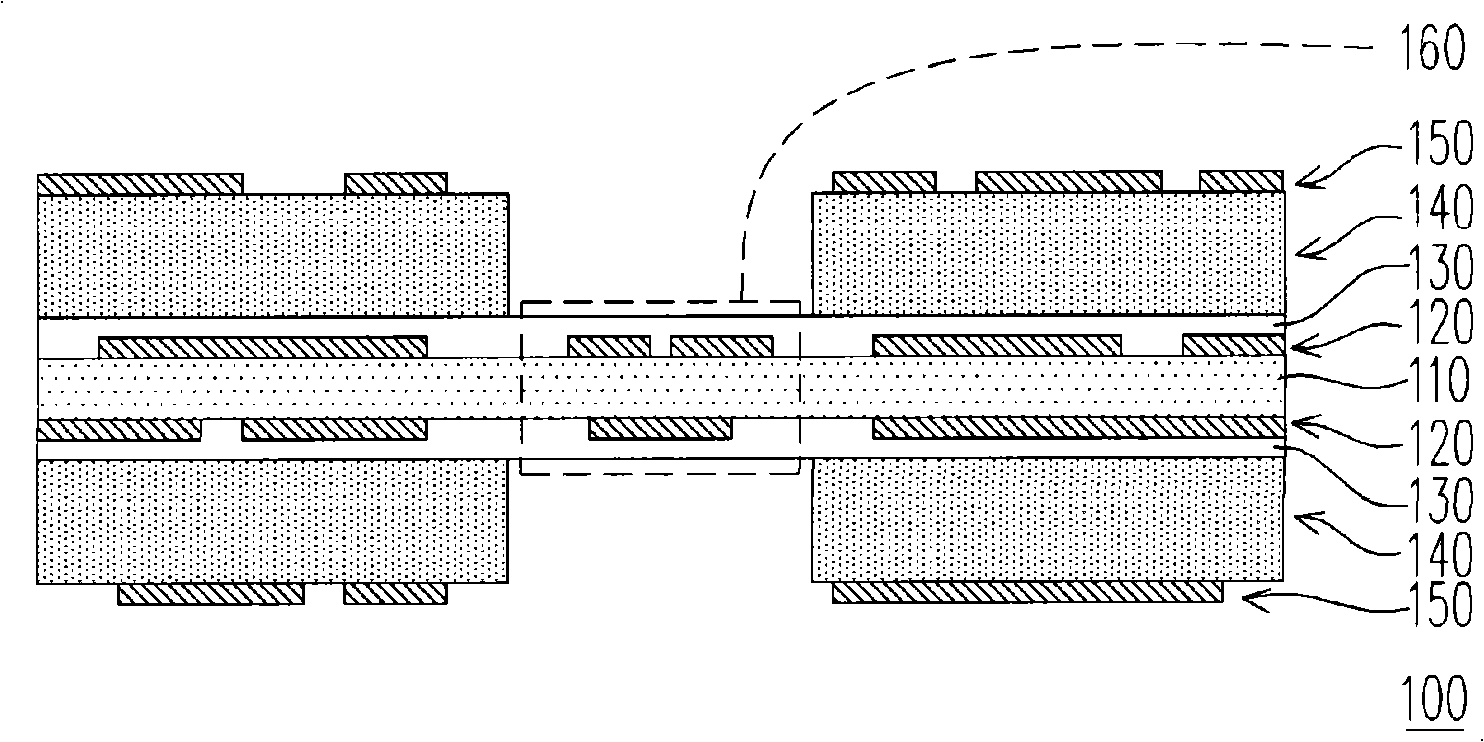

Microelectronic packages and methods therefor

InactiveUS20060249857A1Easy to testAvoid the needElectrical measurement instrument detailsSemiconductor/solid-state device detailsElectronic componentElectronic packaging

Owner:TESSERA INC

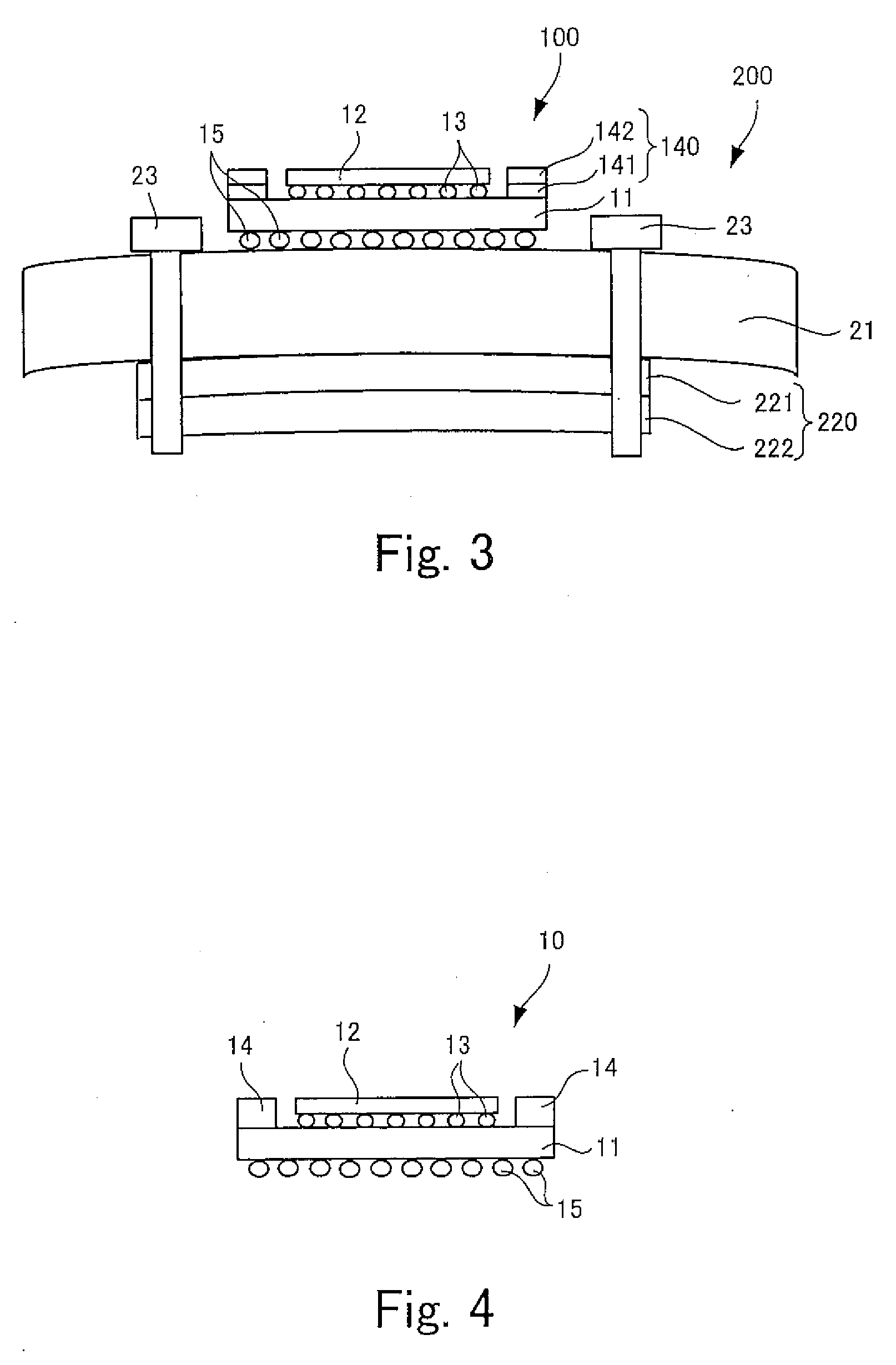

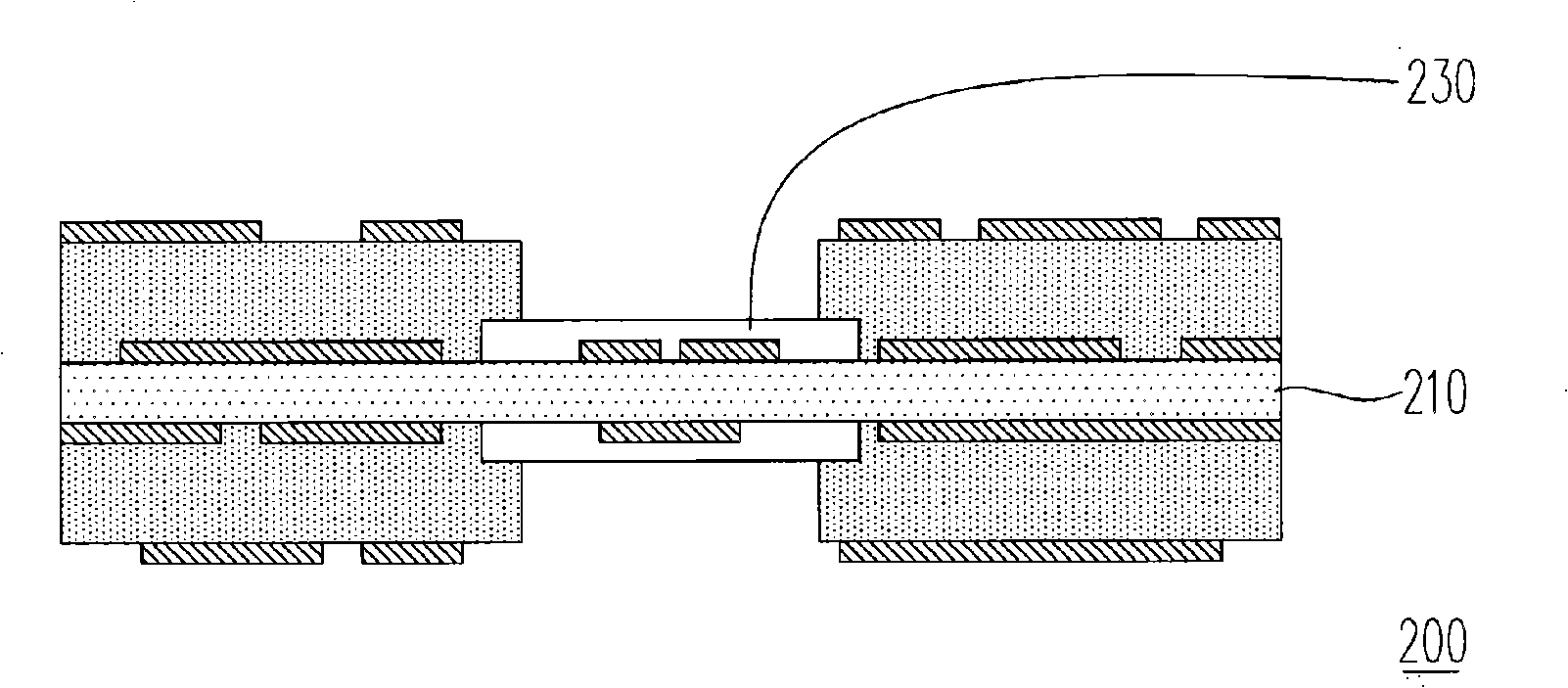

Package mounted module and package board module

InactiveUS20070278647A1Relieve stressMaintain reliabilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

Owner:FUJITSU LTD

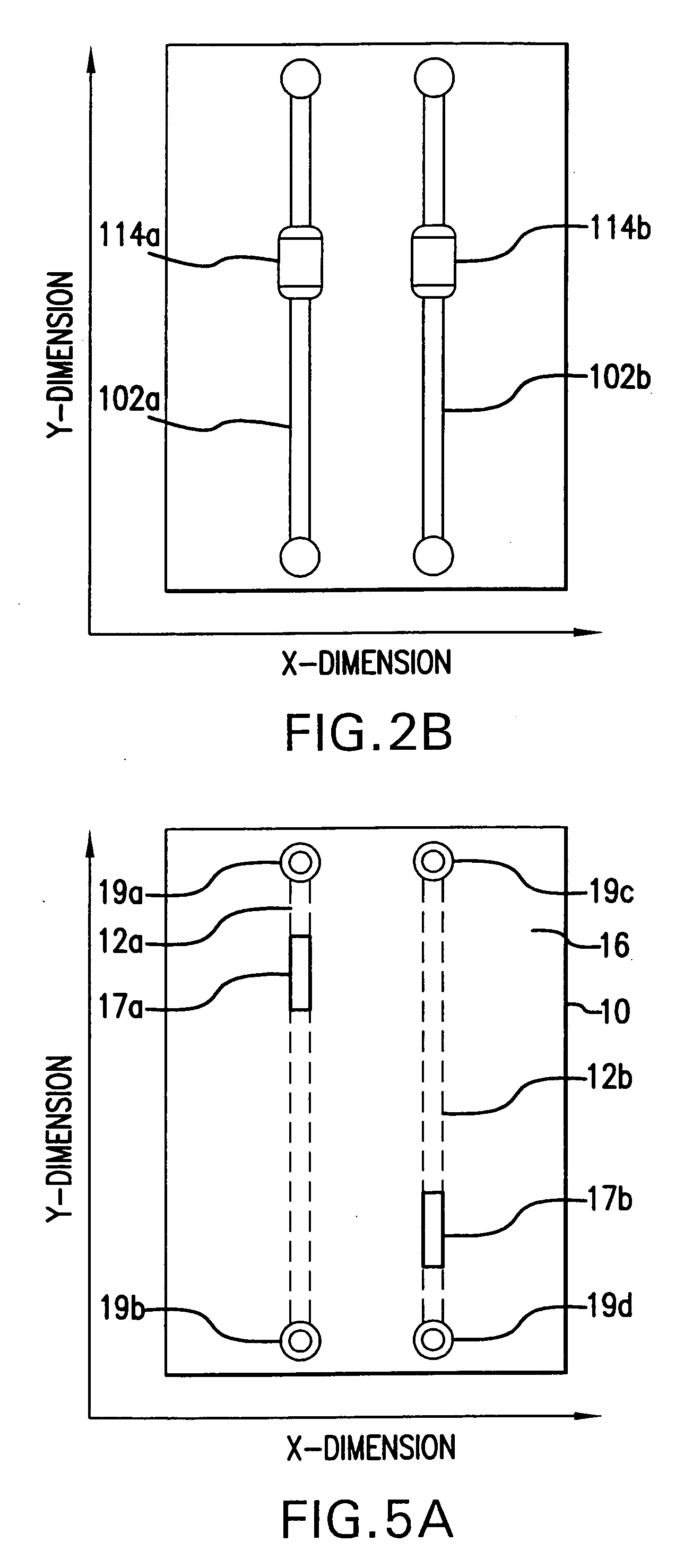

Method and apparatus for manufacturing and probing printed circuit board test access point structures

ActiveUS20060097737A1Minimize perturbationElectrical testingInspection/indentification of circuitsElectricityPrinted circuit board

Owner:KEYSIGHT TECH

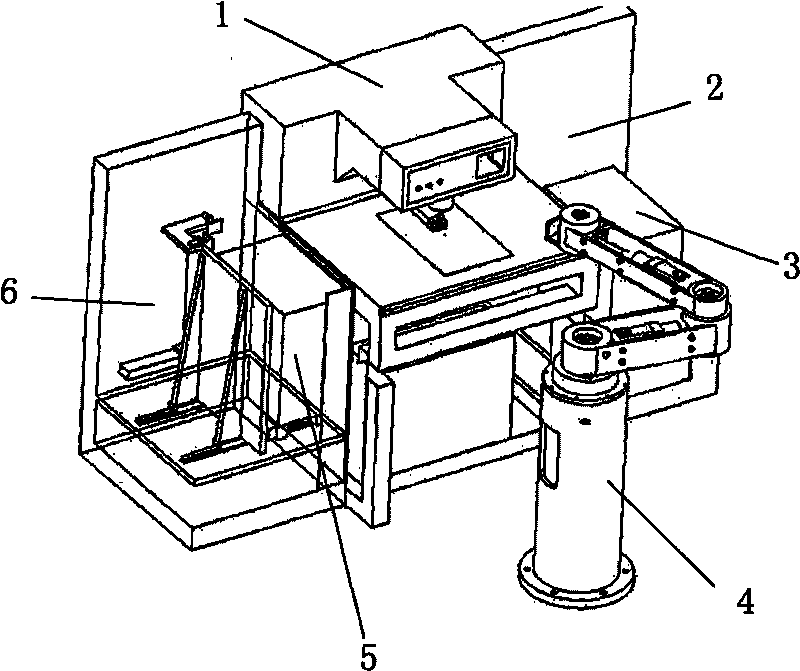

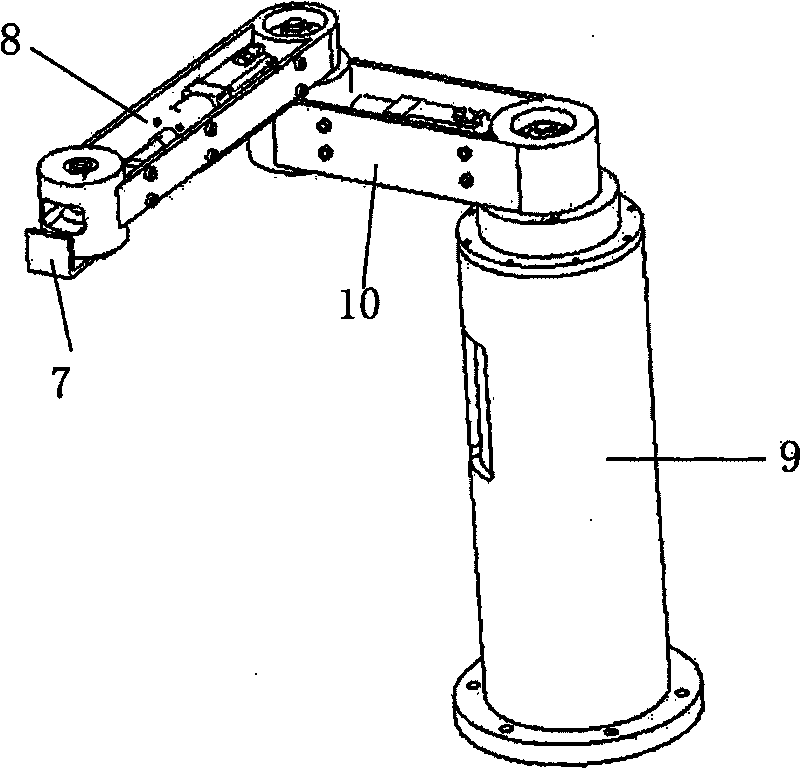

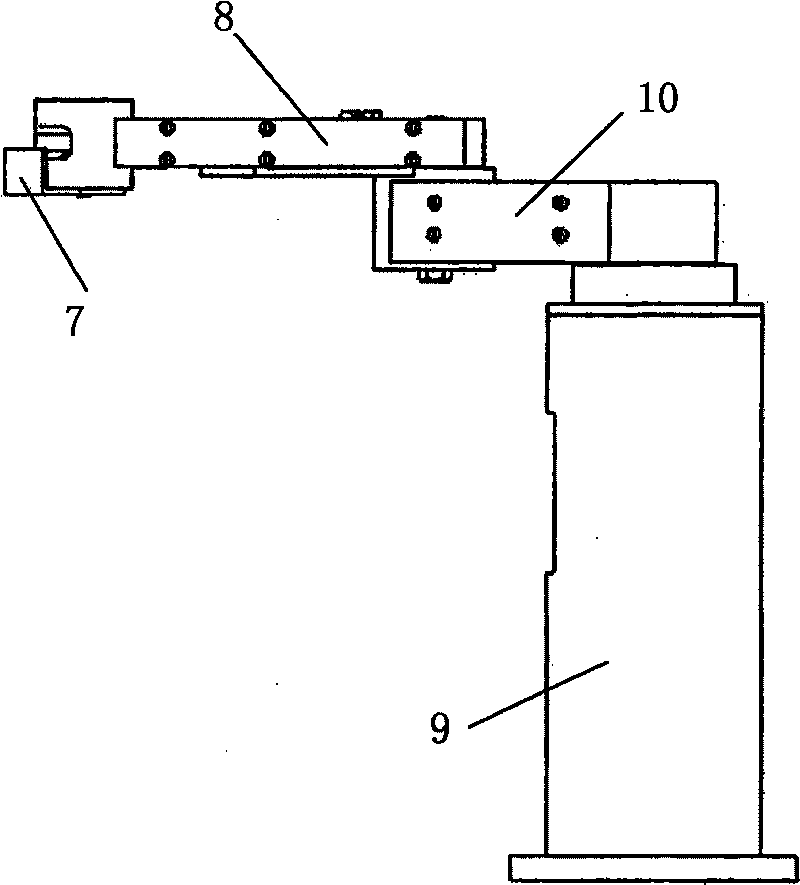

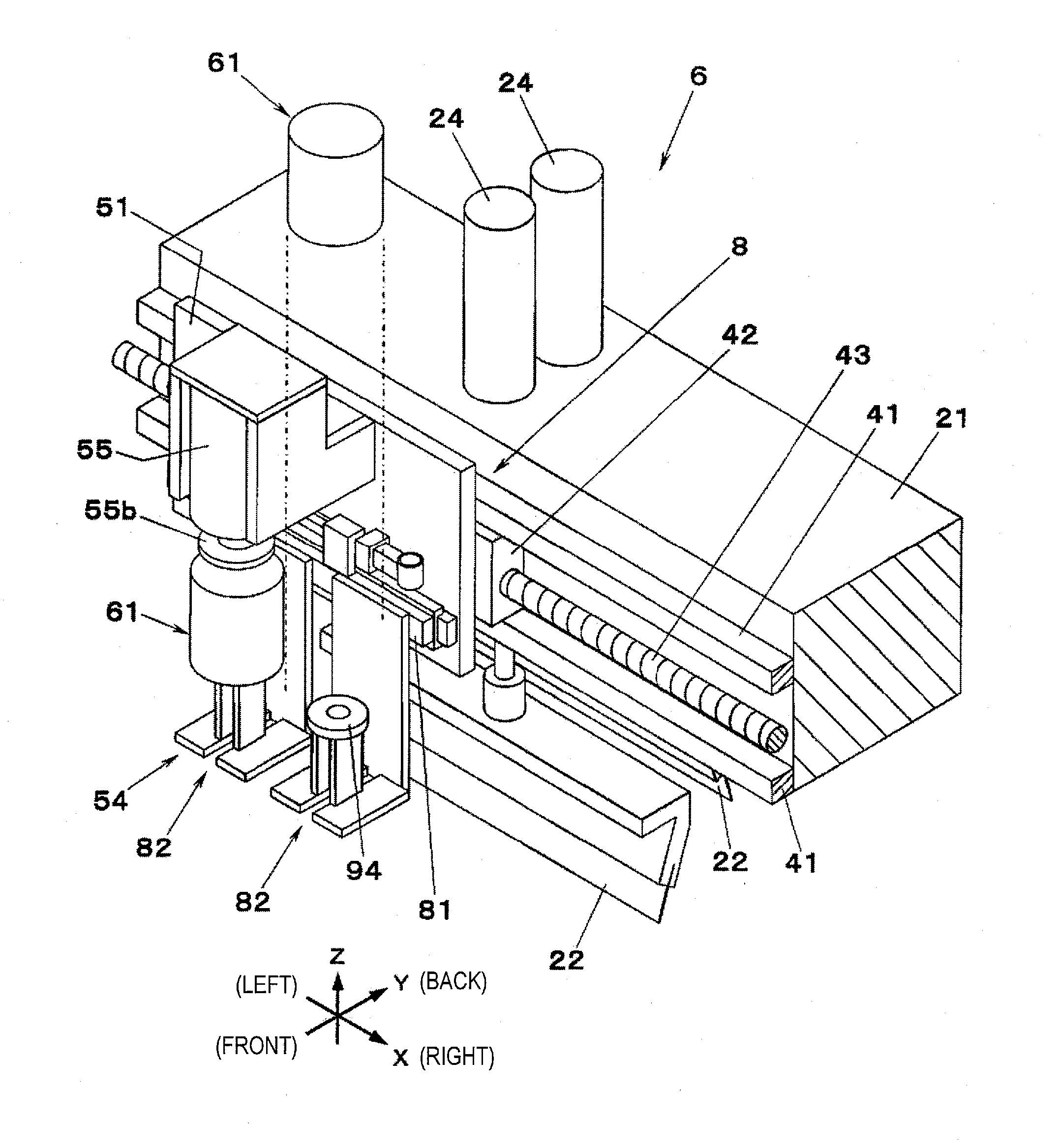

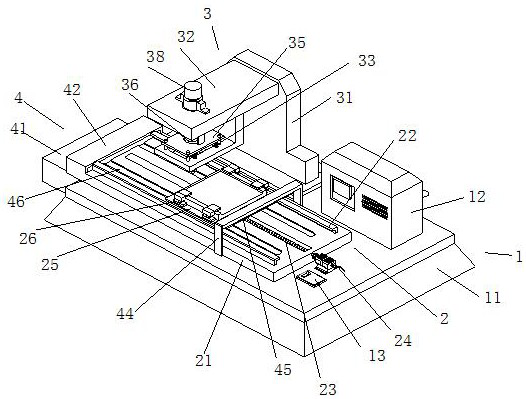

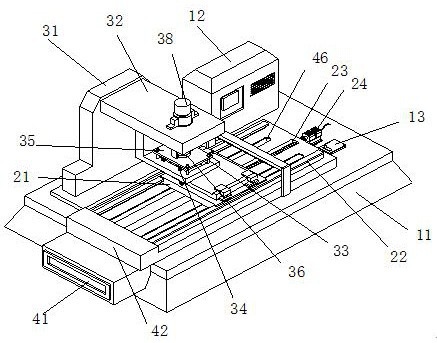

Robot for punching positioning holes on circuit board

InactiveCN101733438APrinted circuit manufactureBoring/drilling machinesElectrical and Electronics engineeringThree degrees of freedom

Owner:CHONGQING UNIV OF TECH

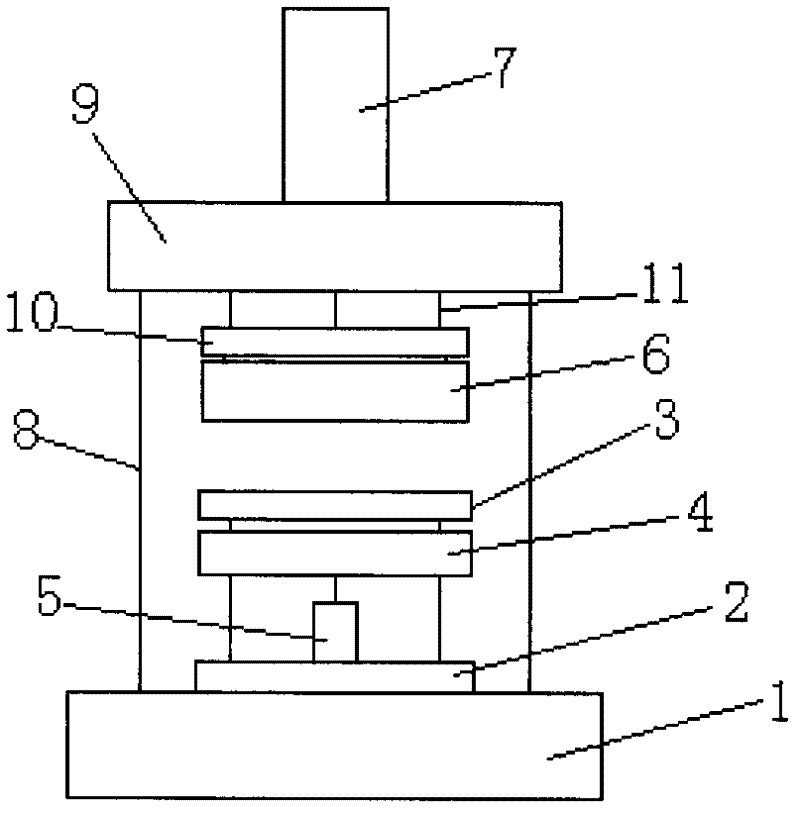

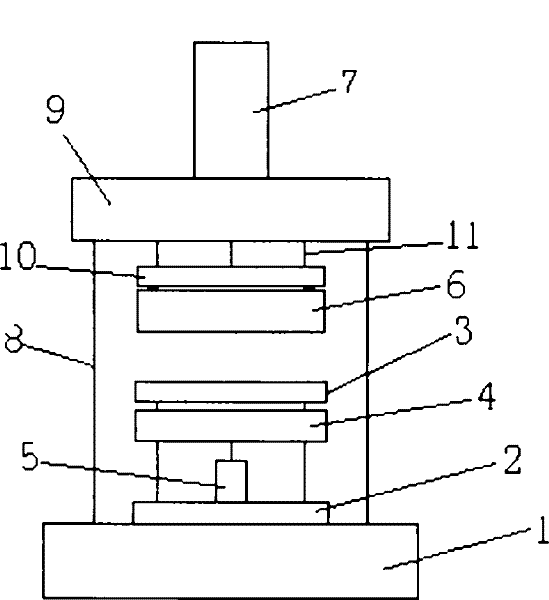

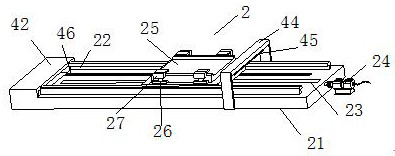

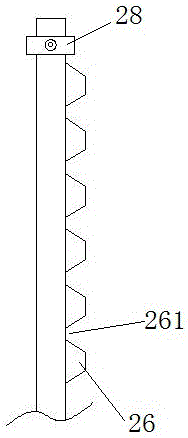

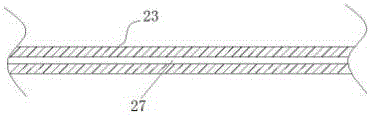

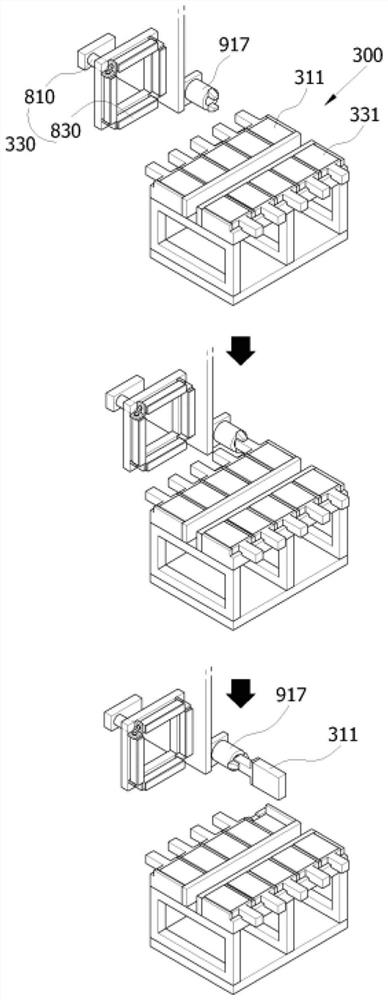

Aligning lamination pressing machine of semi-automatic reinforcing sheet of flexible printed circuit board

Owner:宁波赛特信息科技发展有限公司

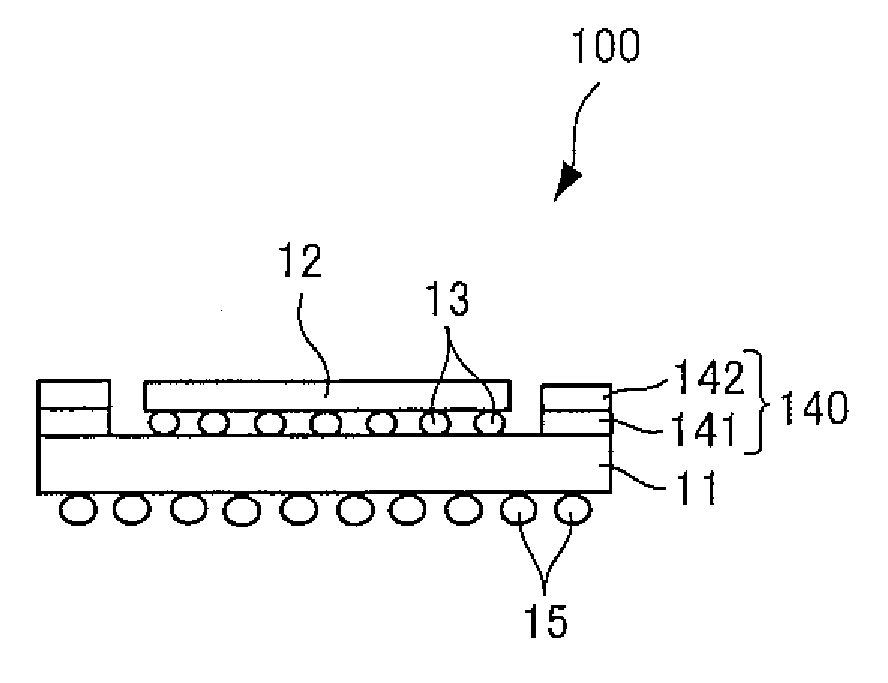

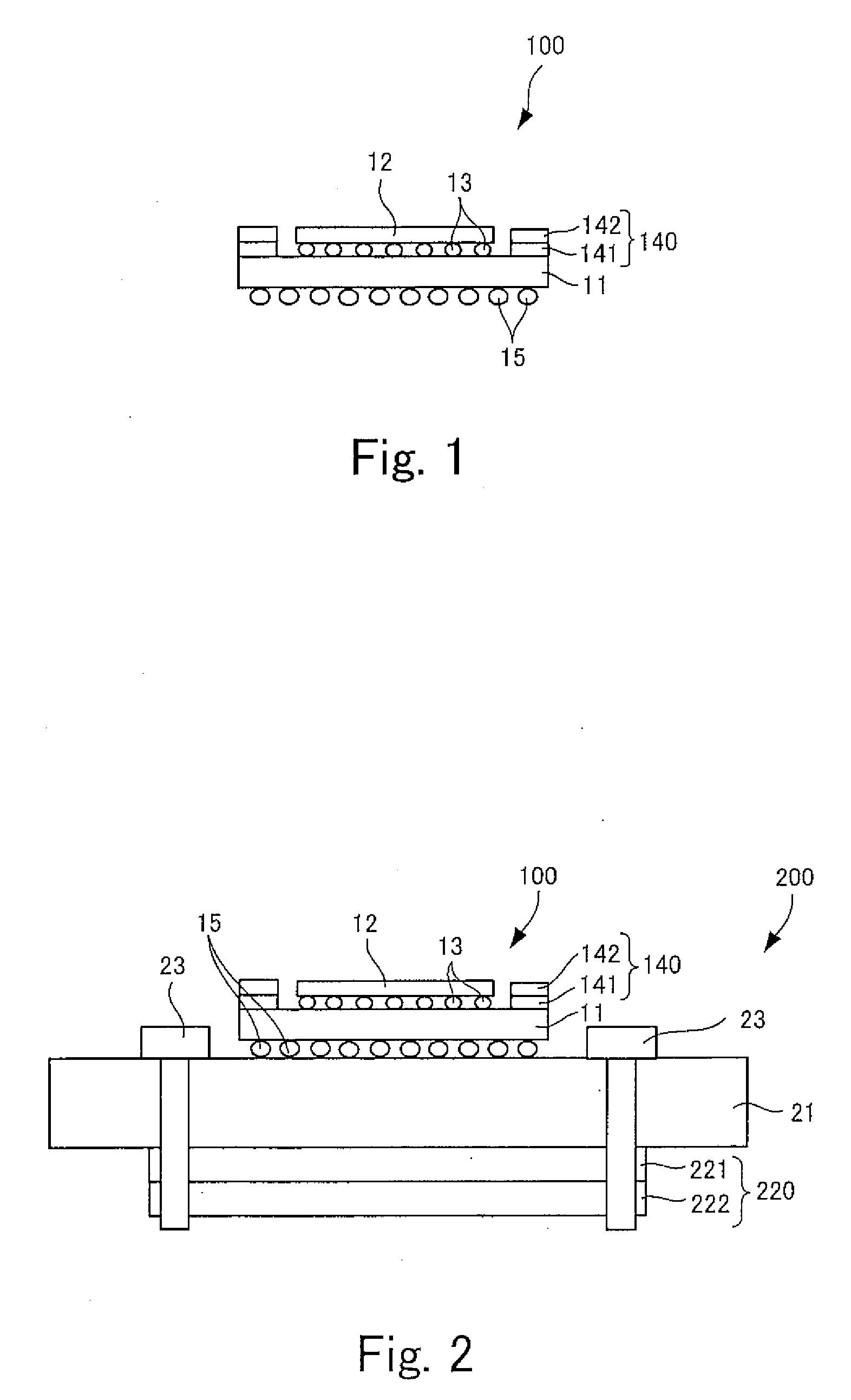

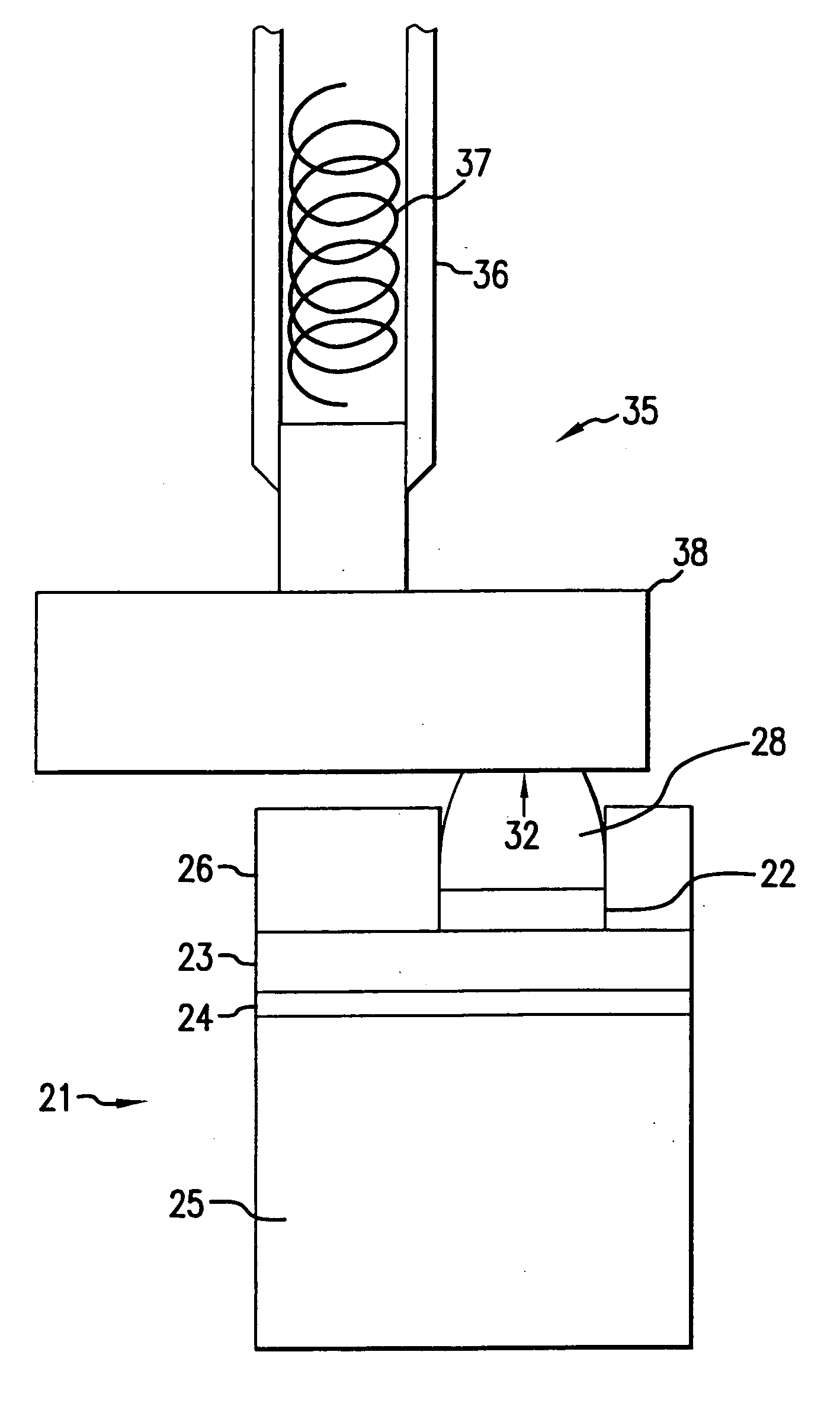

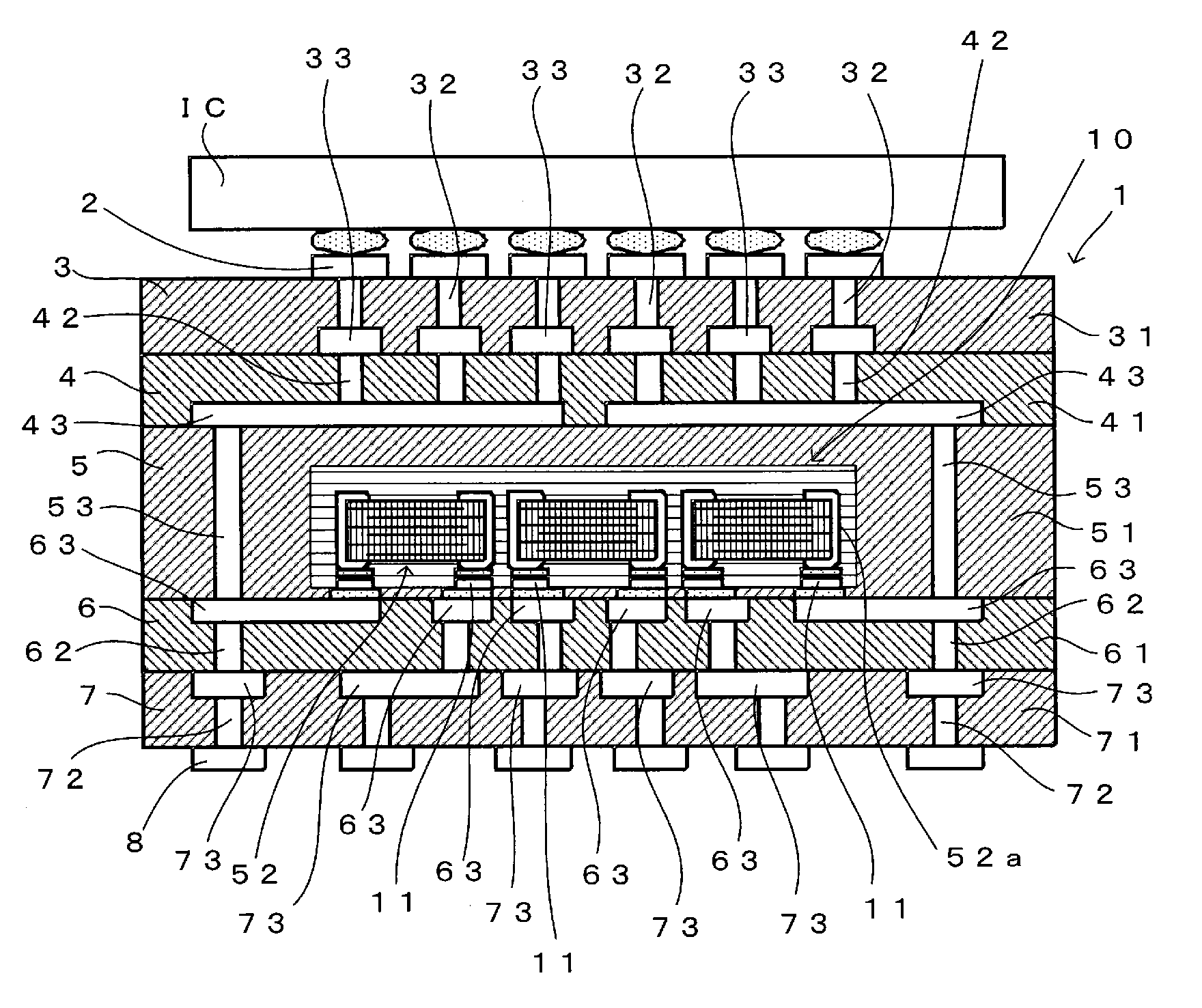

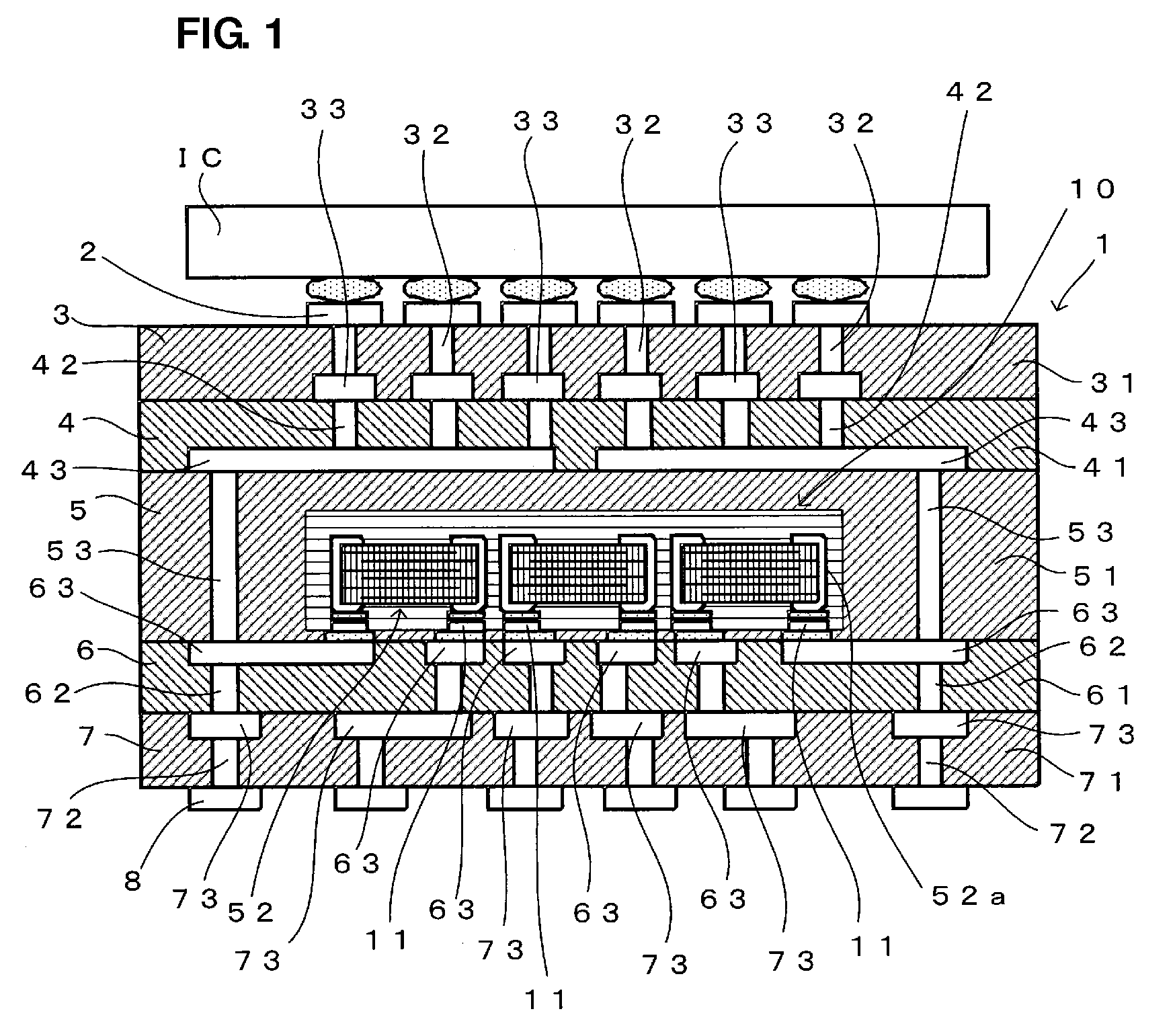

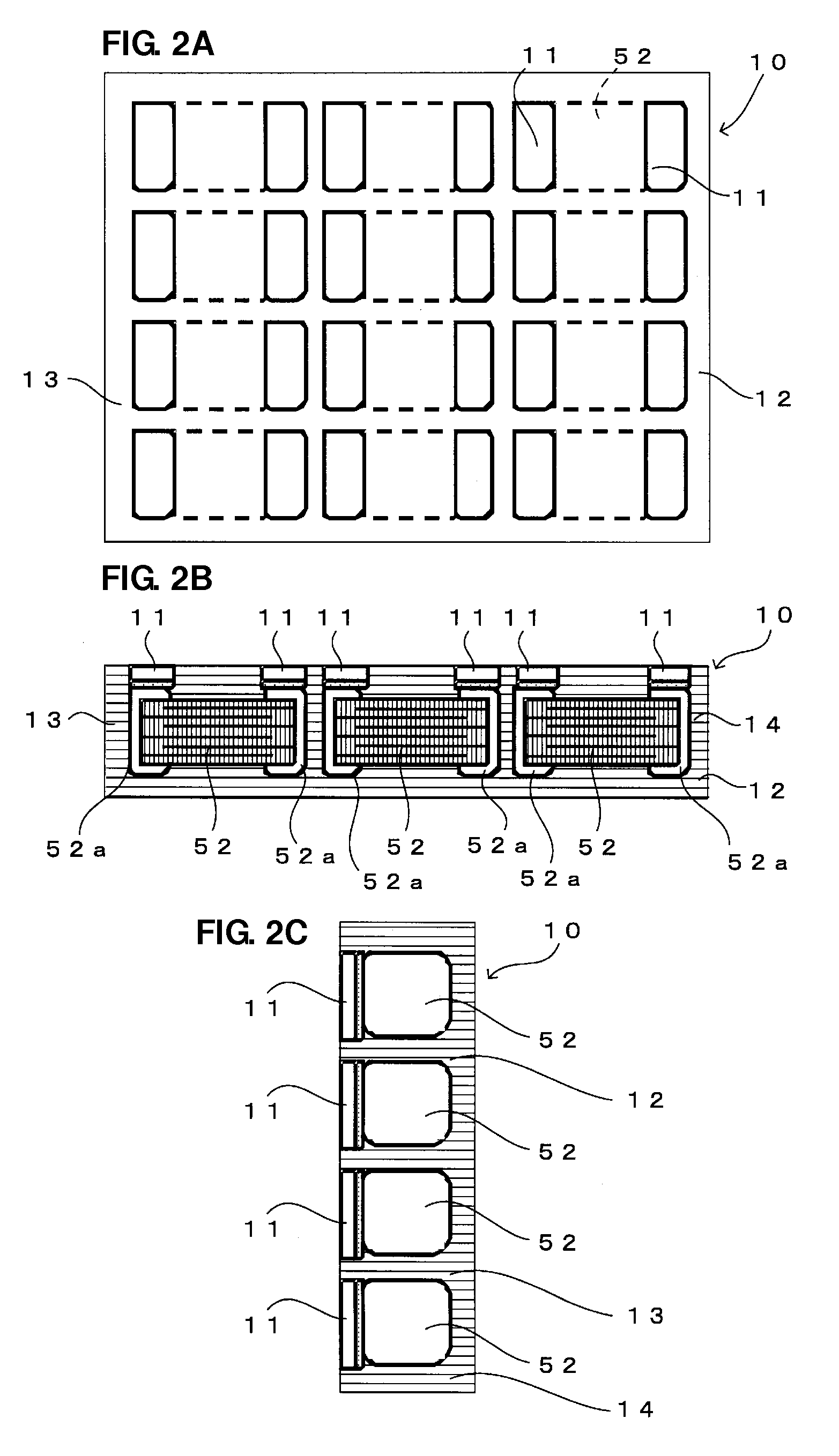

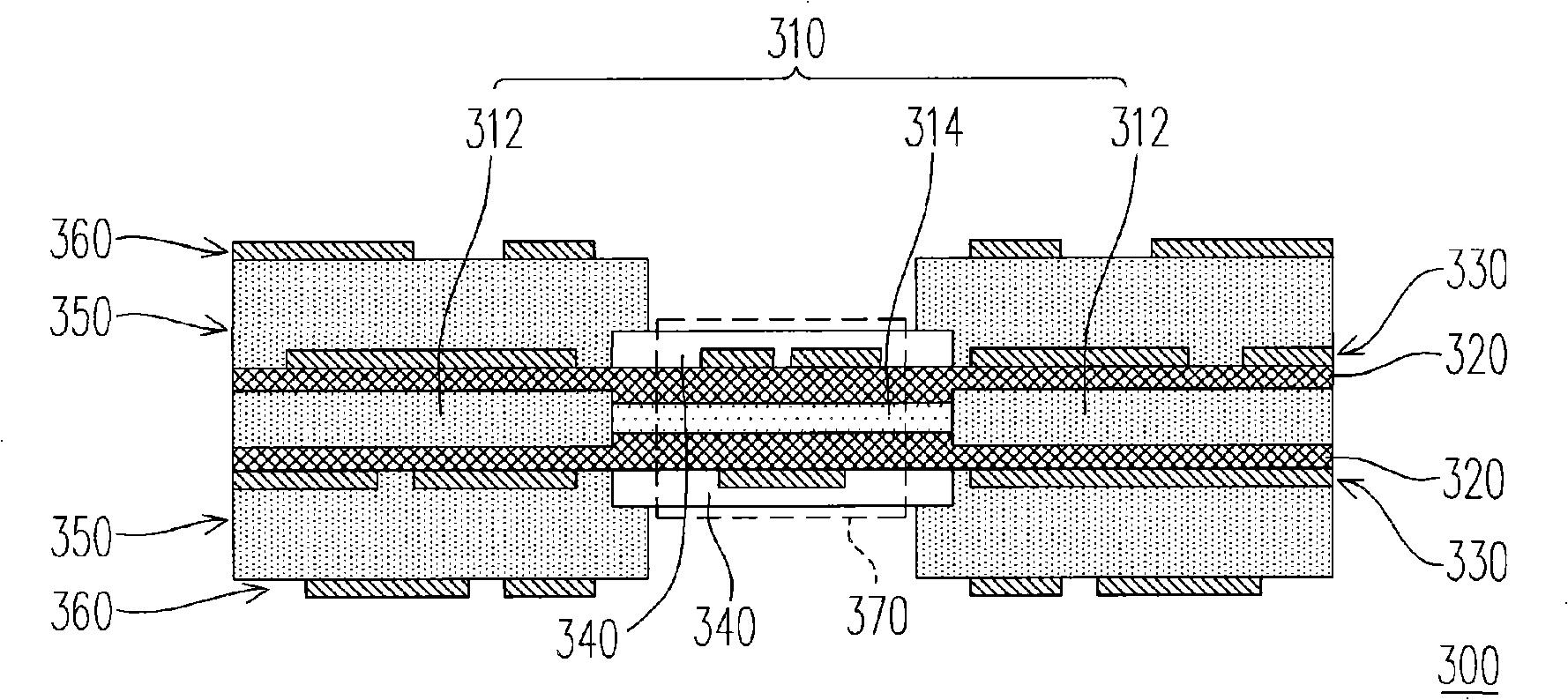

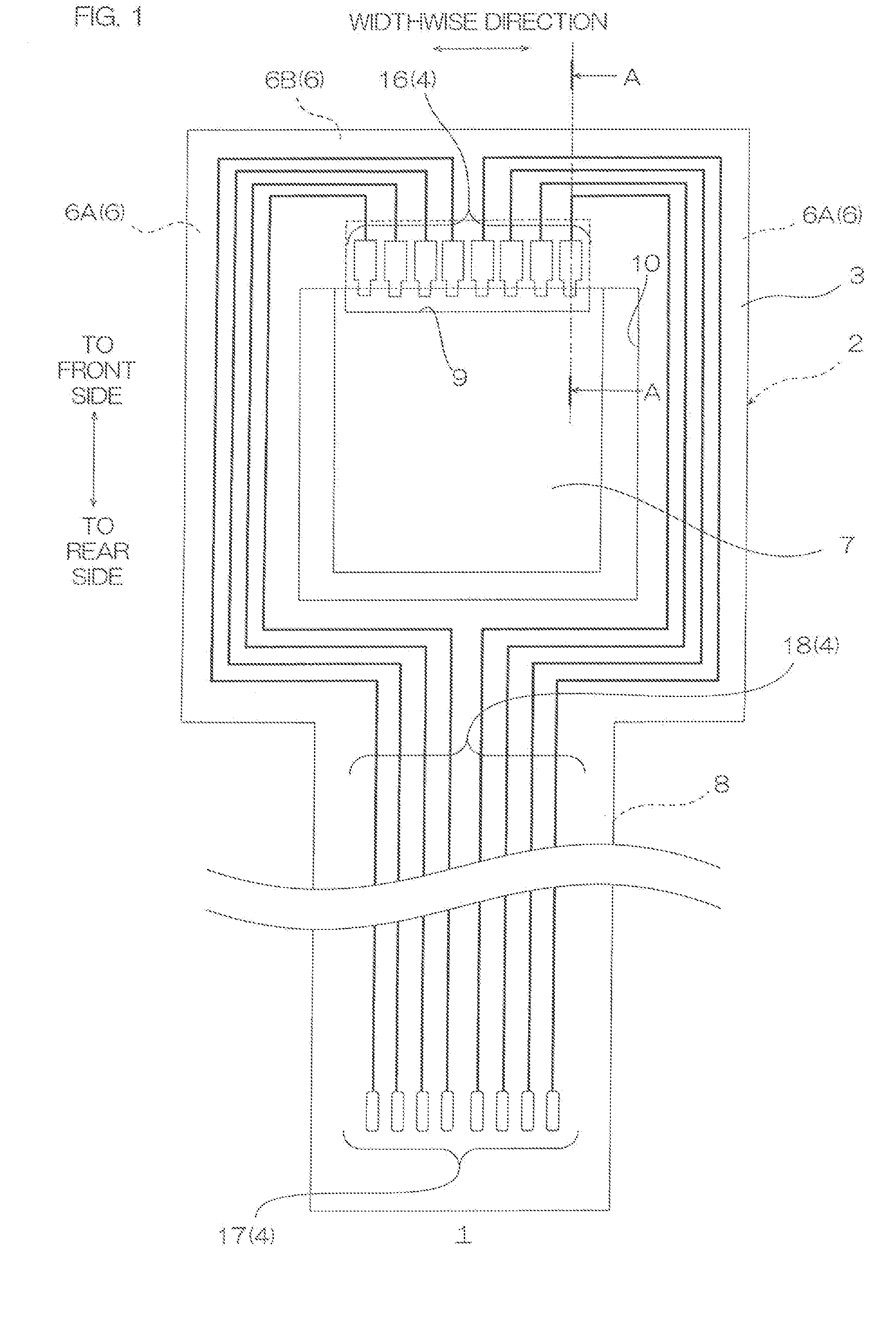

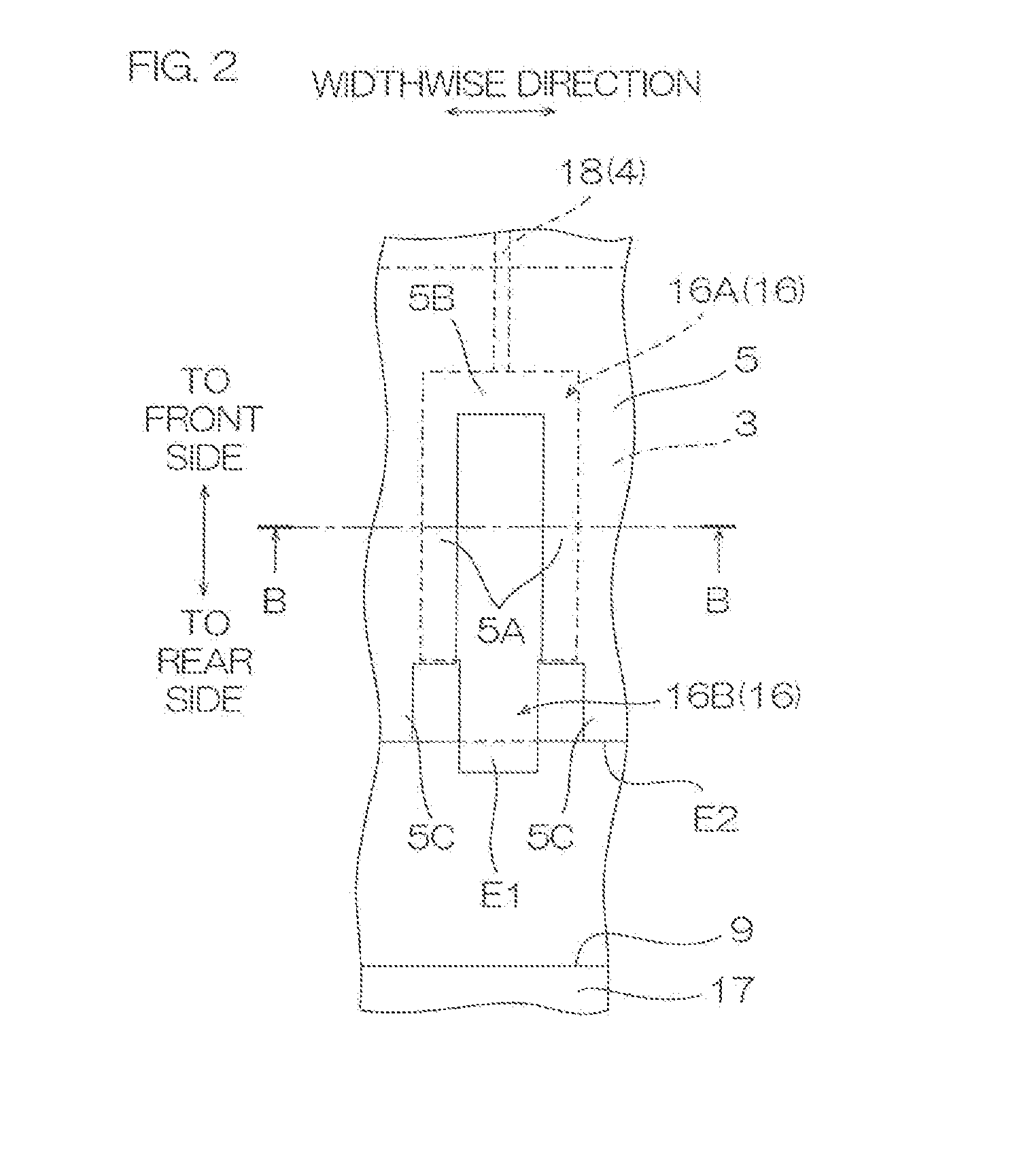

Component assembly

ActiveUS20130242517A1Well formedDistanceSemiconductor/solid-state device detailsFinal product manufactureThermal deformationEngineering

Owner:MURATA MFG CO LTD

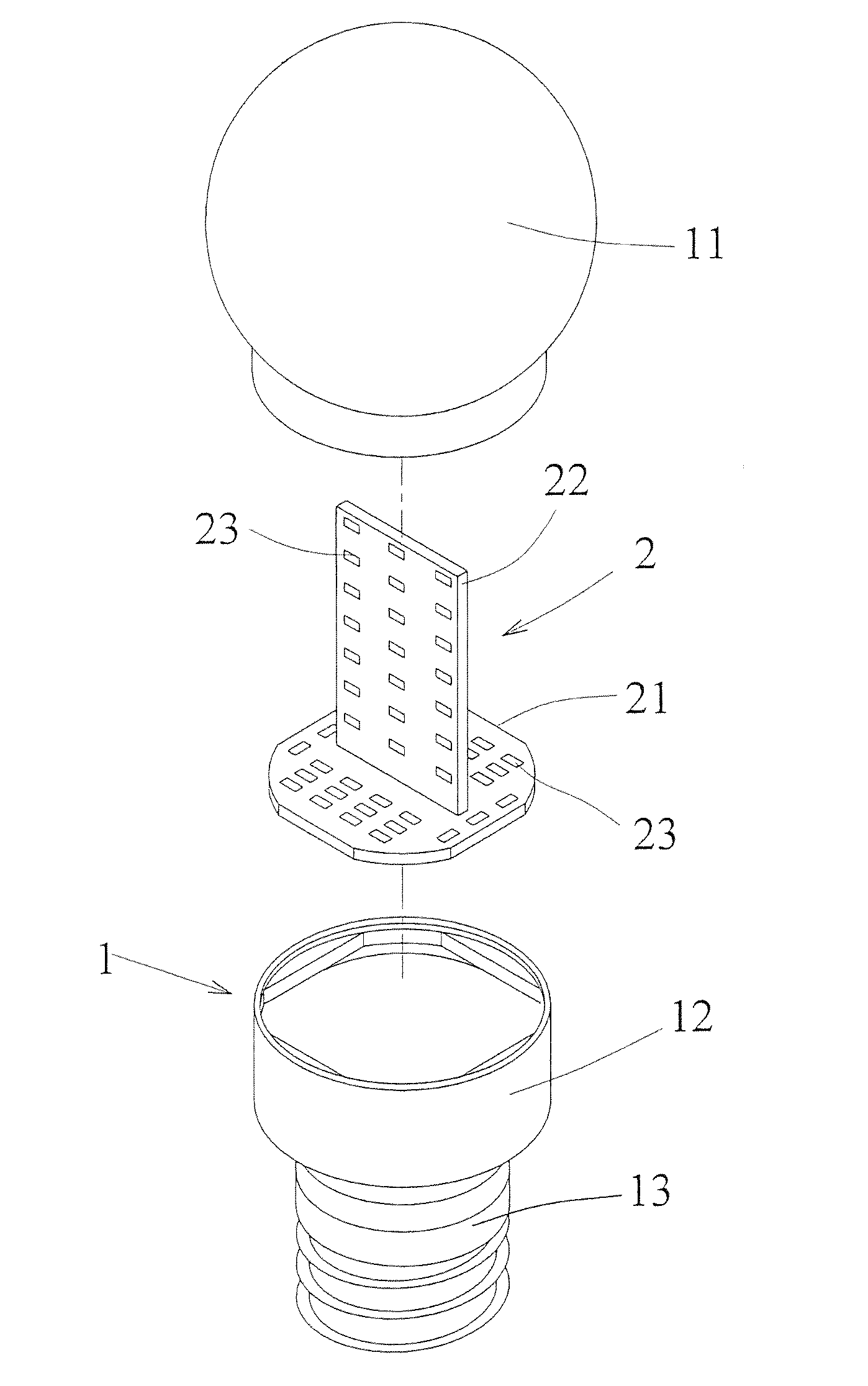

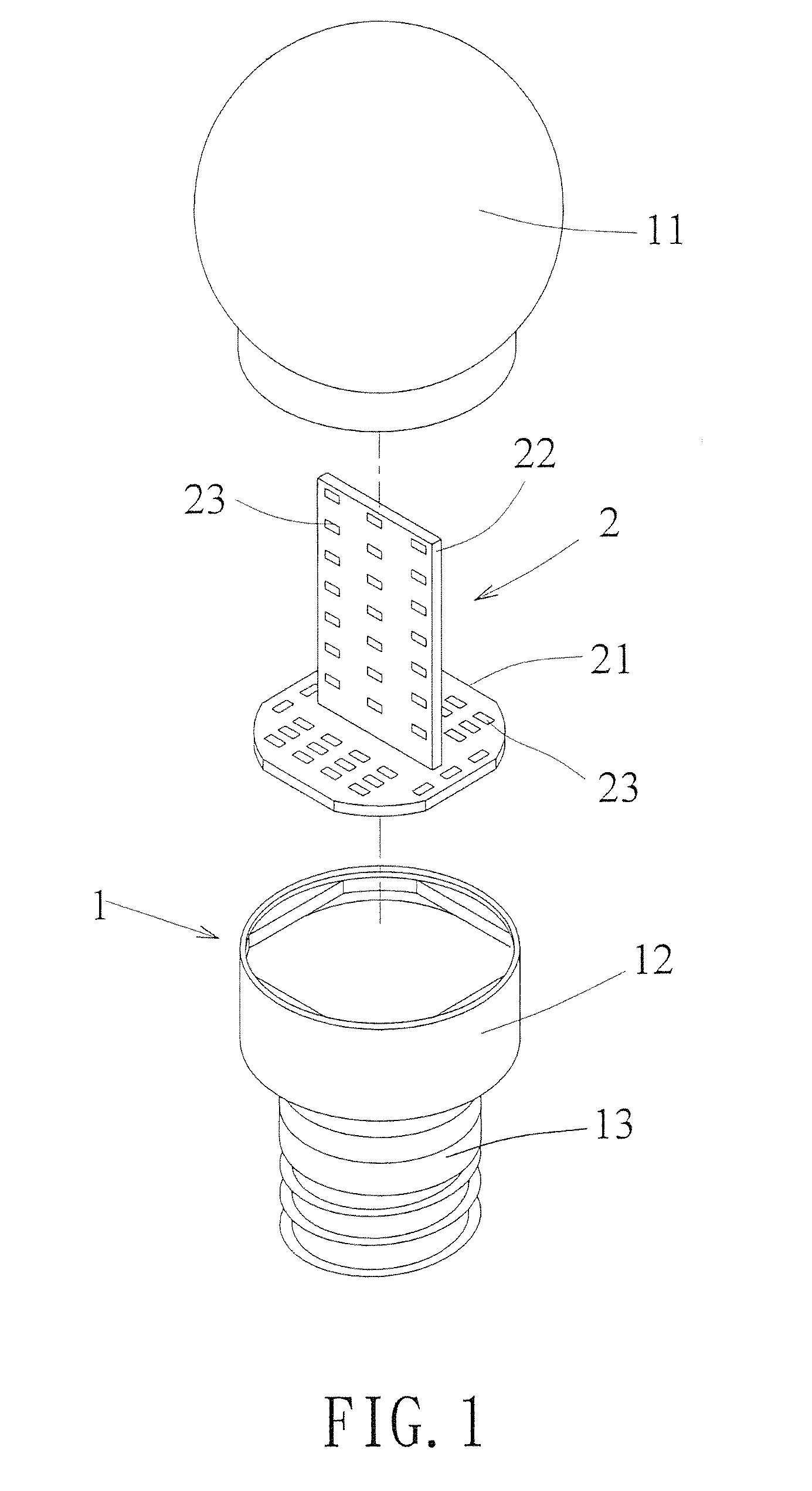

Light bulb having light emitting diodes connected to at least two circuit boards

InactiveUS20150267872A1Lighting support devicesPoint-like light sourceLight beamLight-emitting diode

Owner:HUANG TAI HSIANG +1

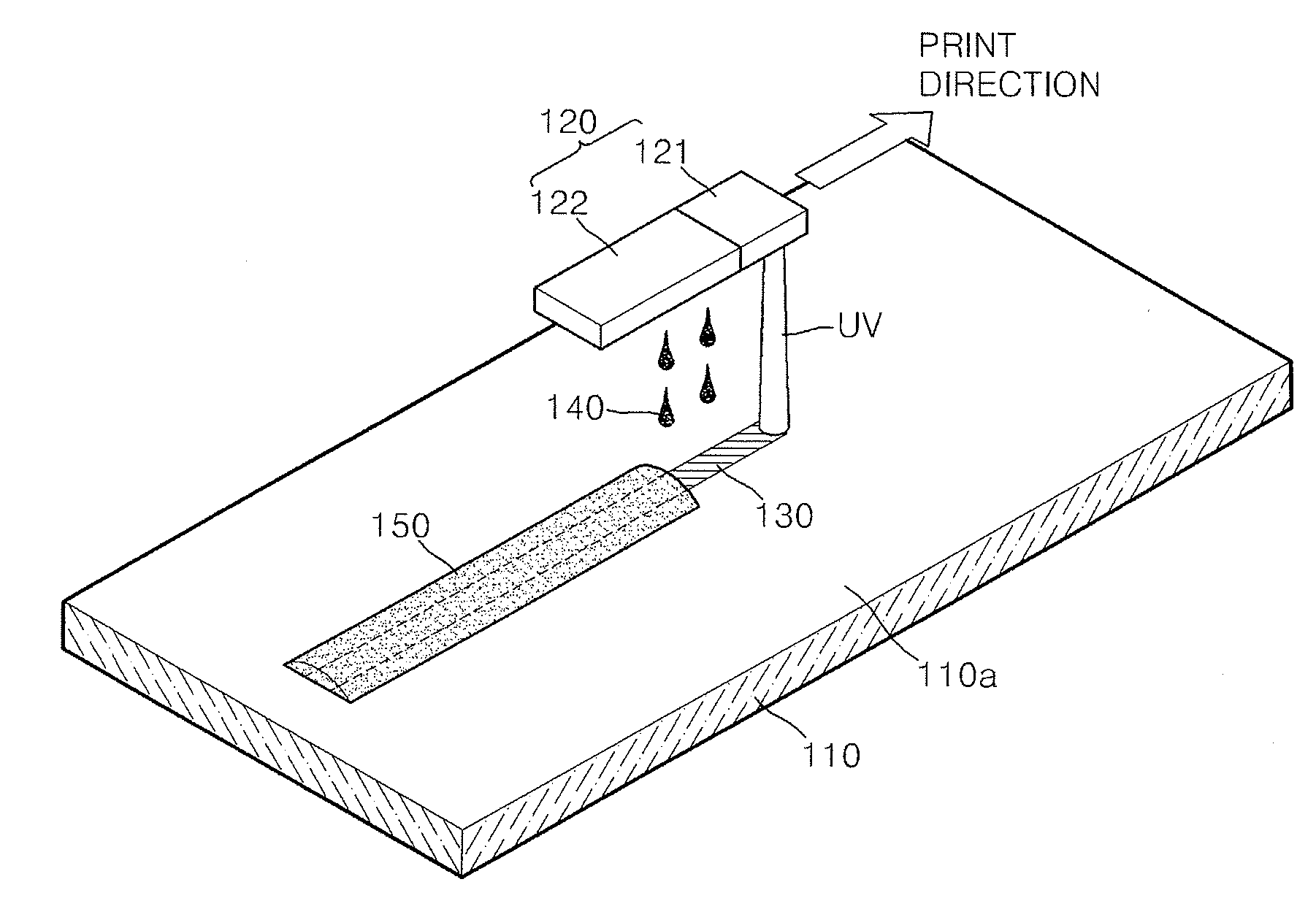

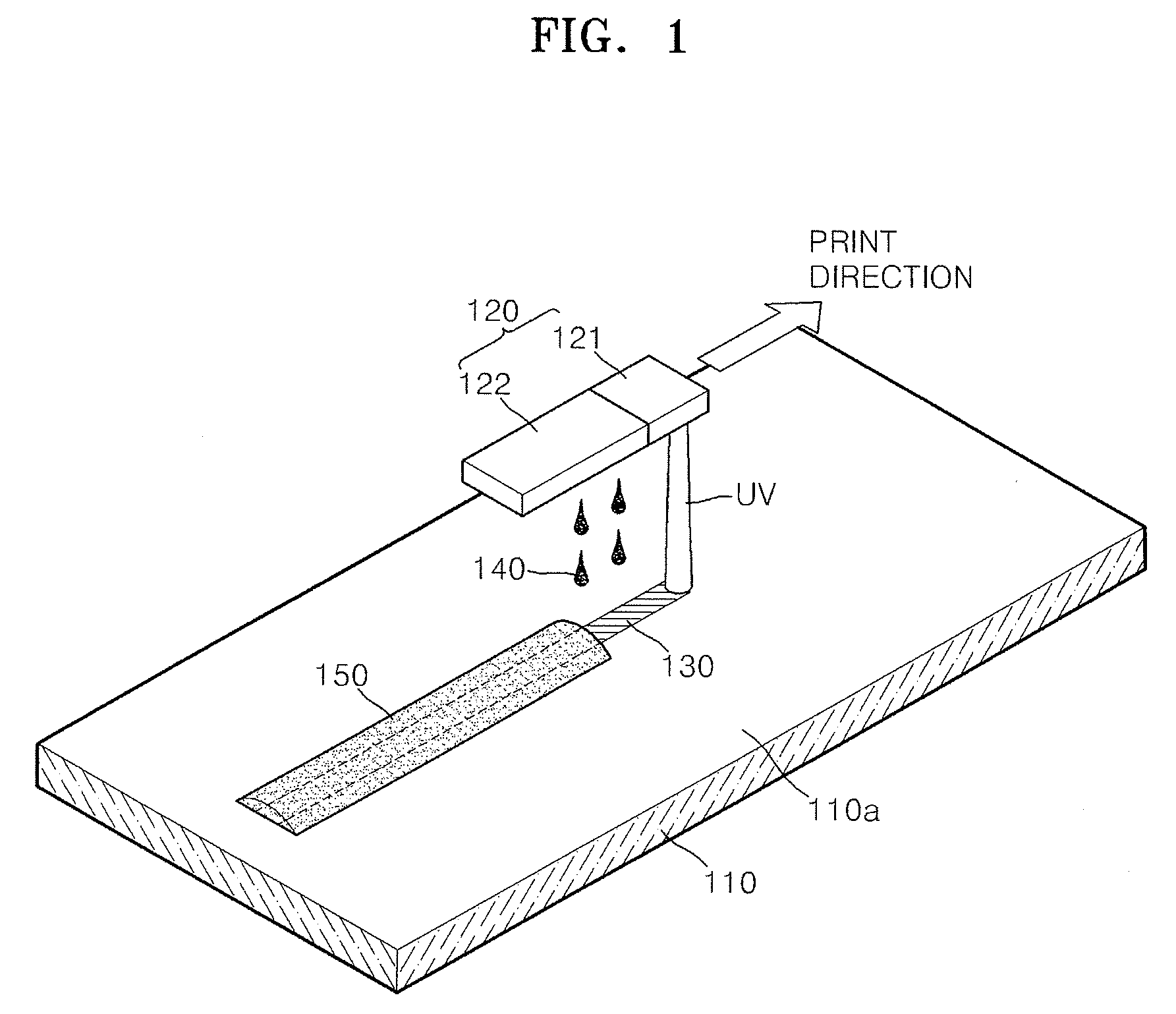

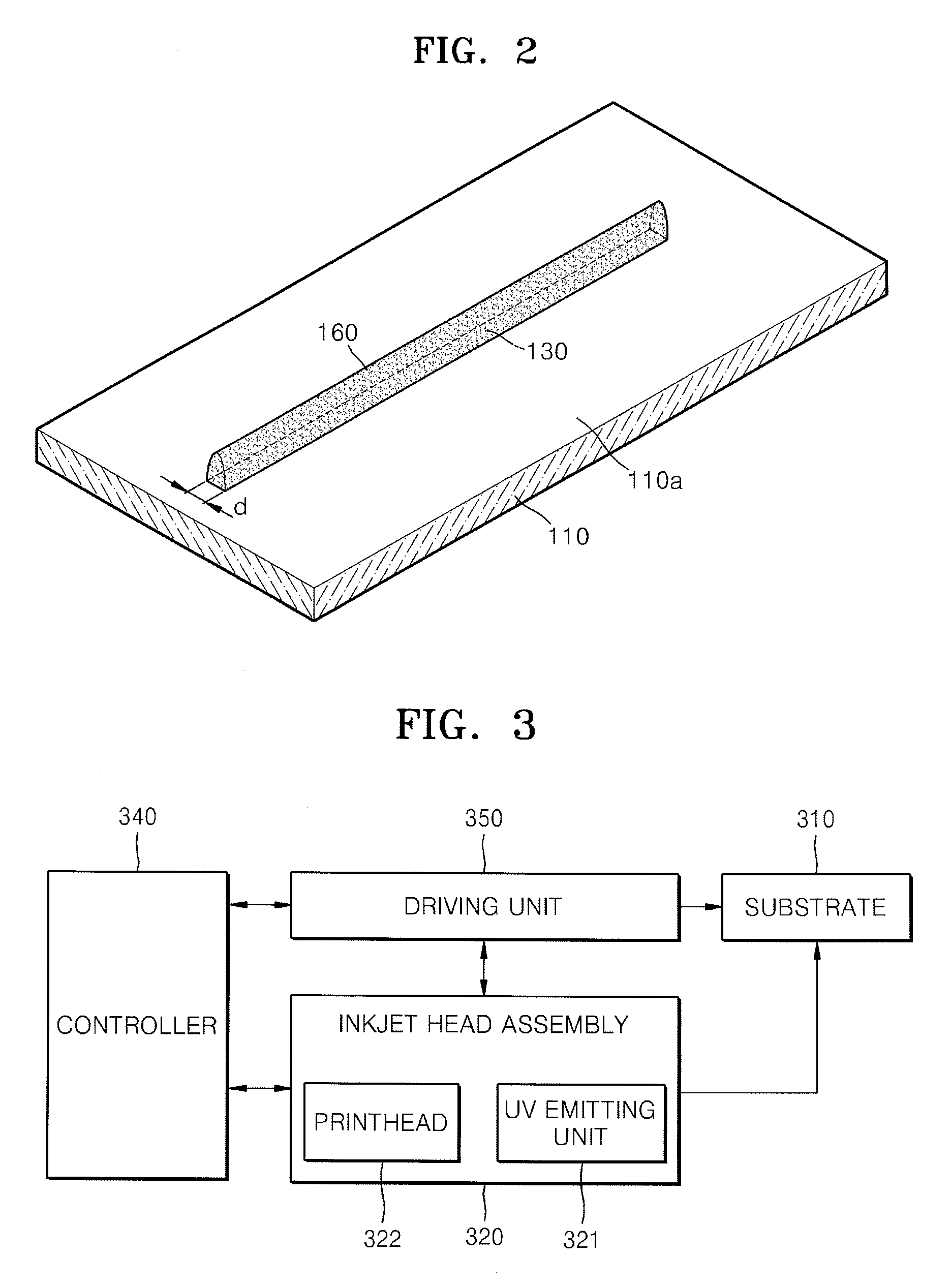

Inkjet head assembly and printing apparatus and method using the same

Owner:SAMSUNG DISPLAY CO LTD

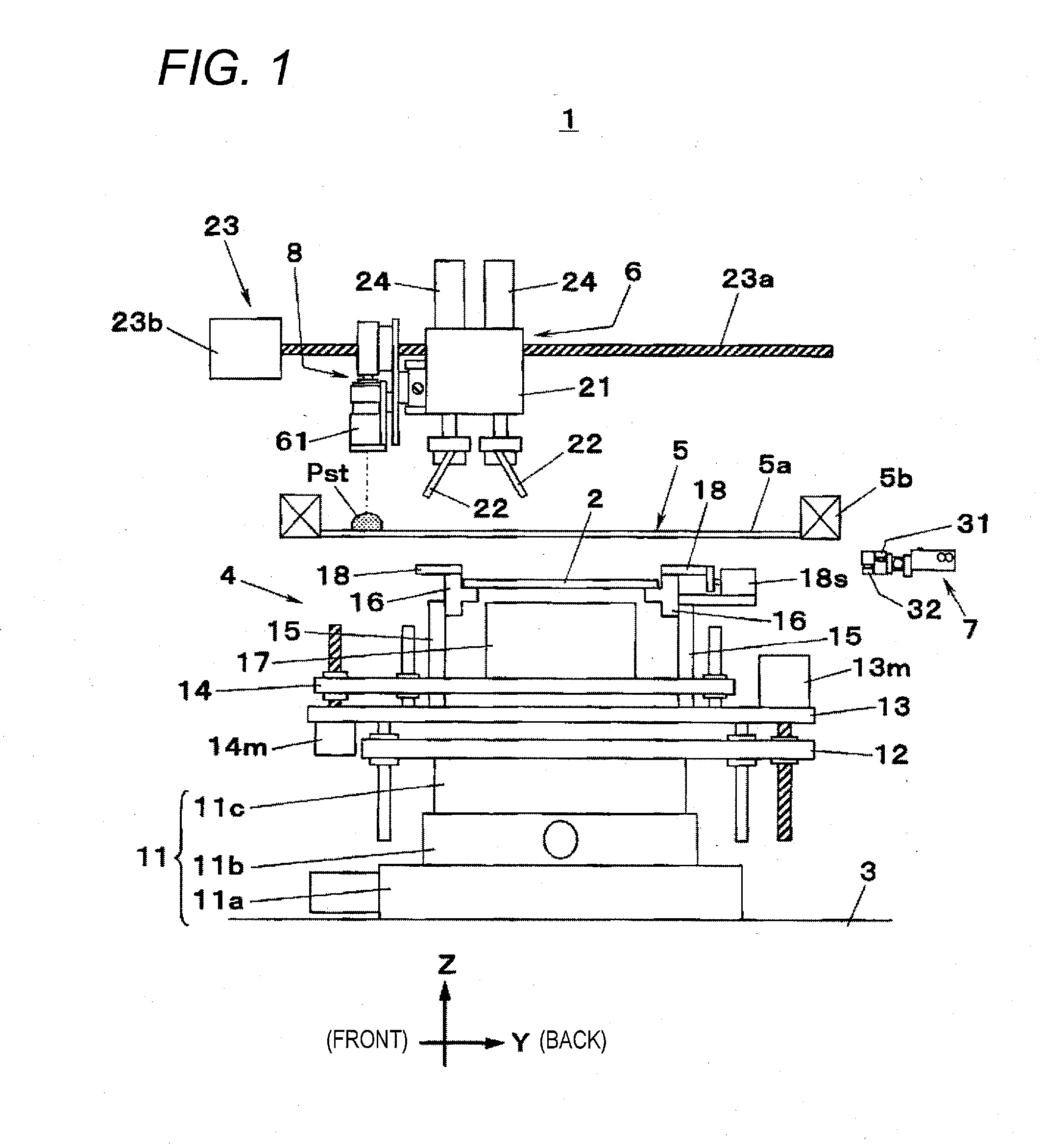

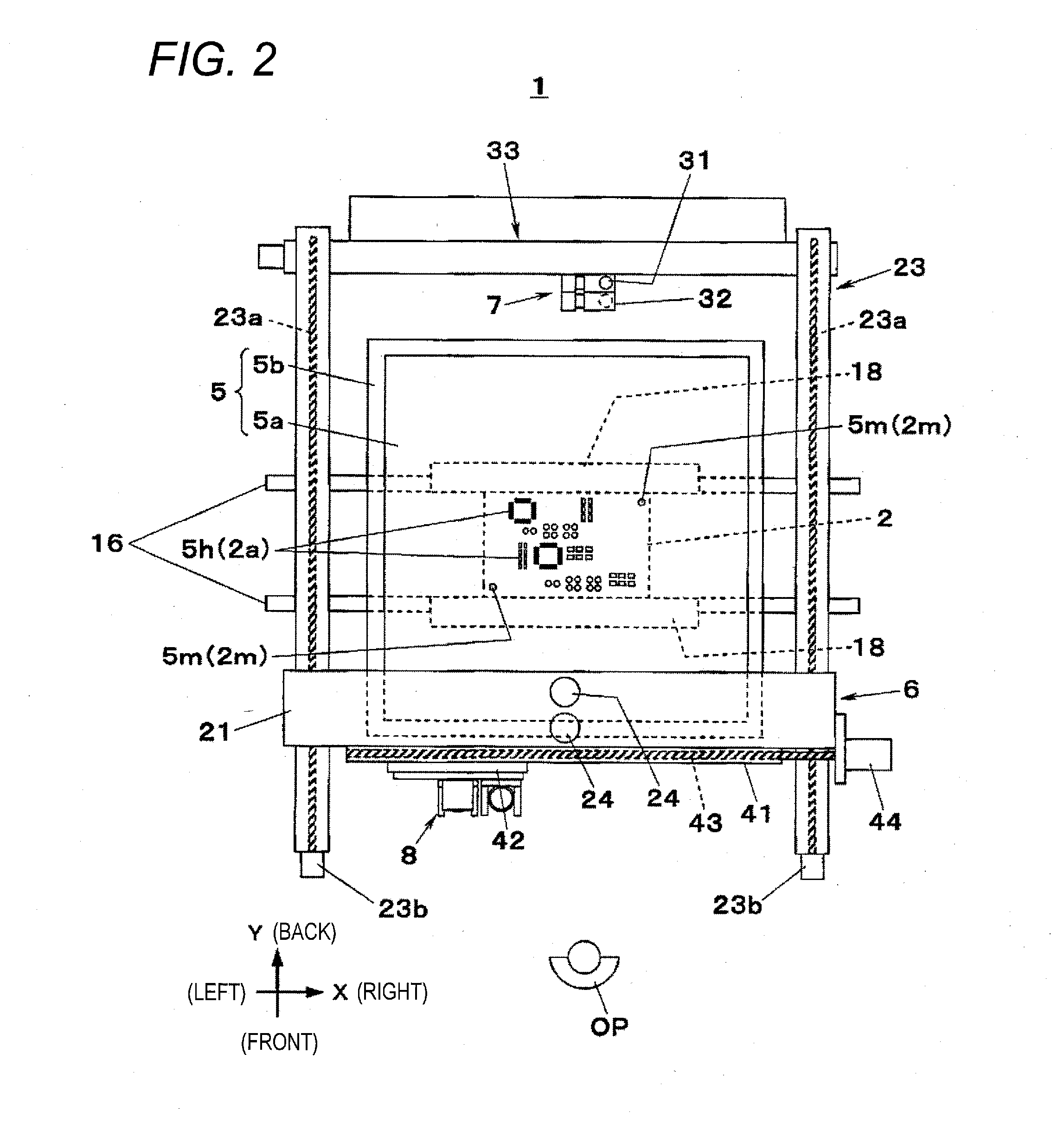

Paste supply apparatus, screen printing machine, paste supply method and screen printing method

ActiveUS20140366754A1Improve work efficiencyInking apparatusLiquid surface applicatorsScreen printingEngineering

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

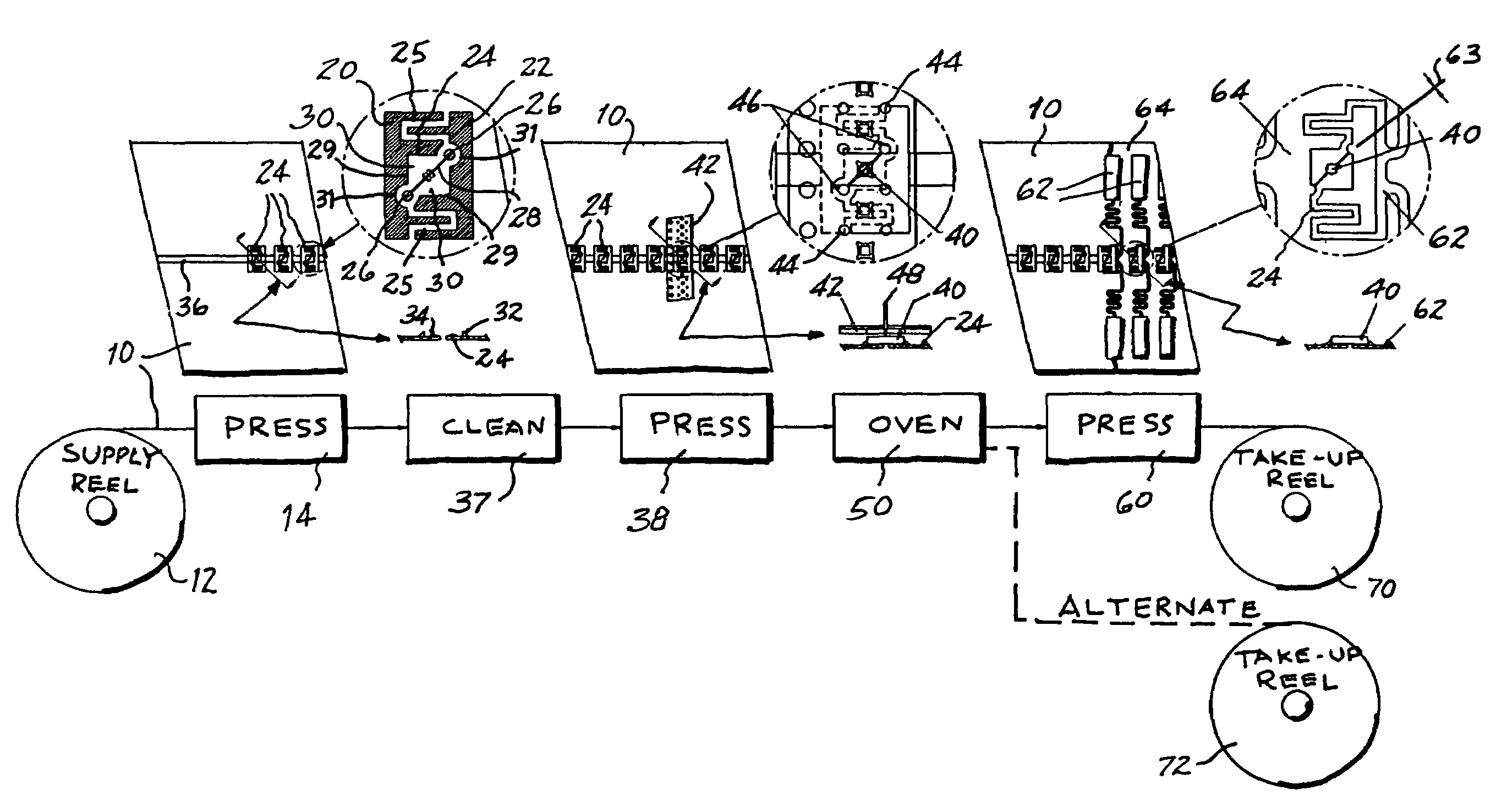

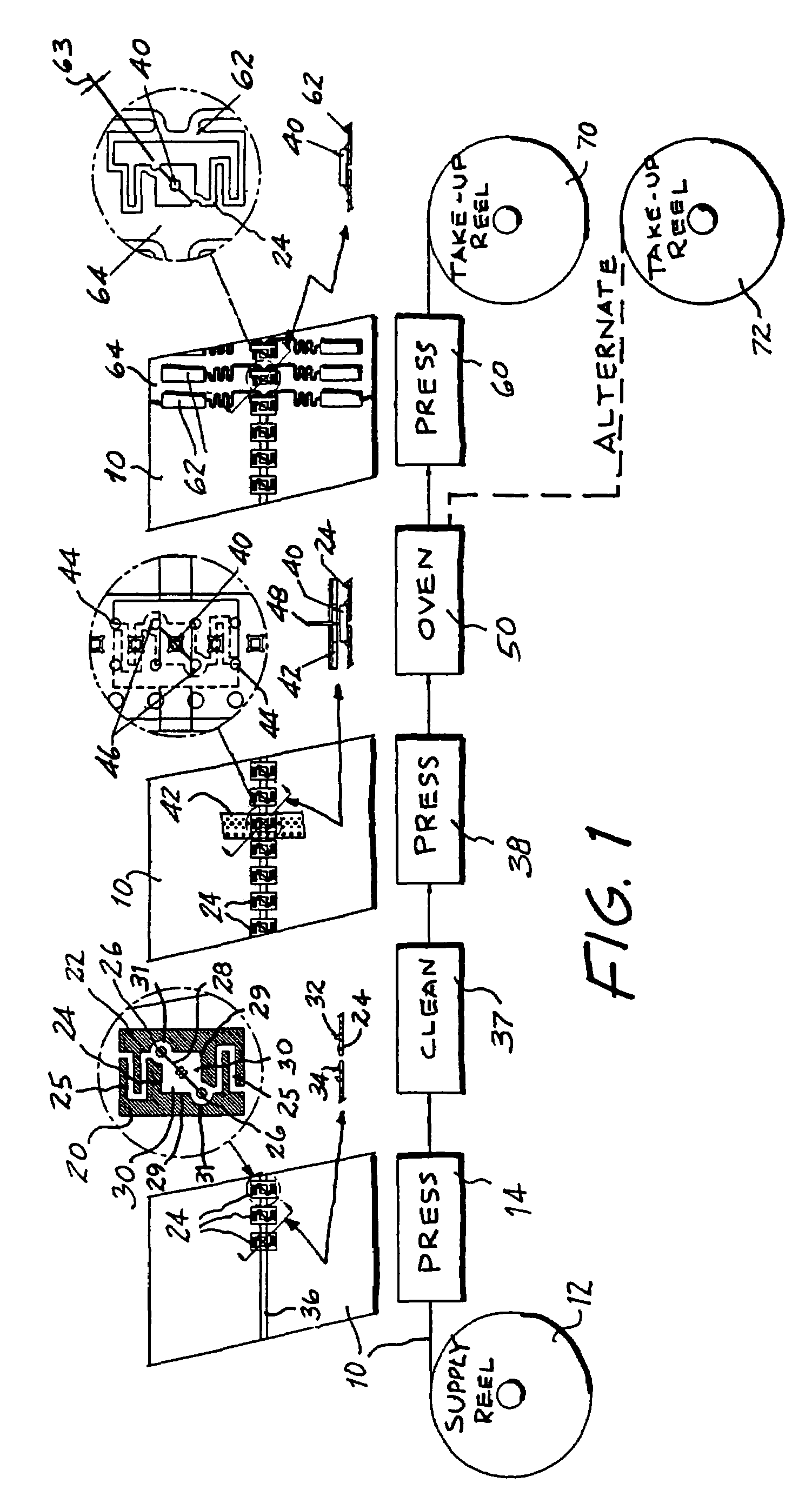

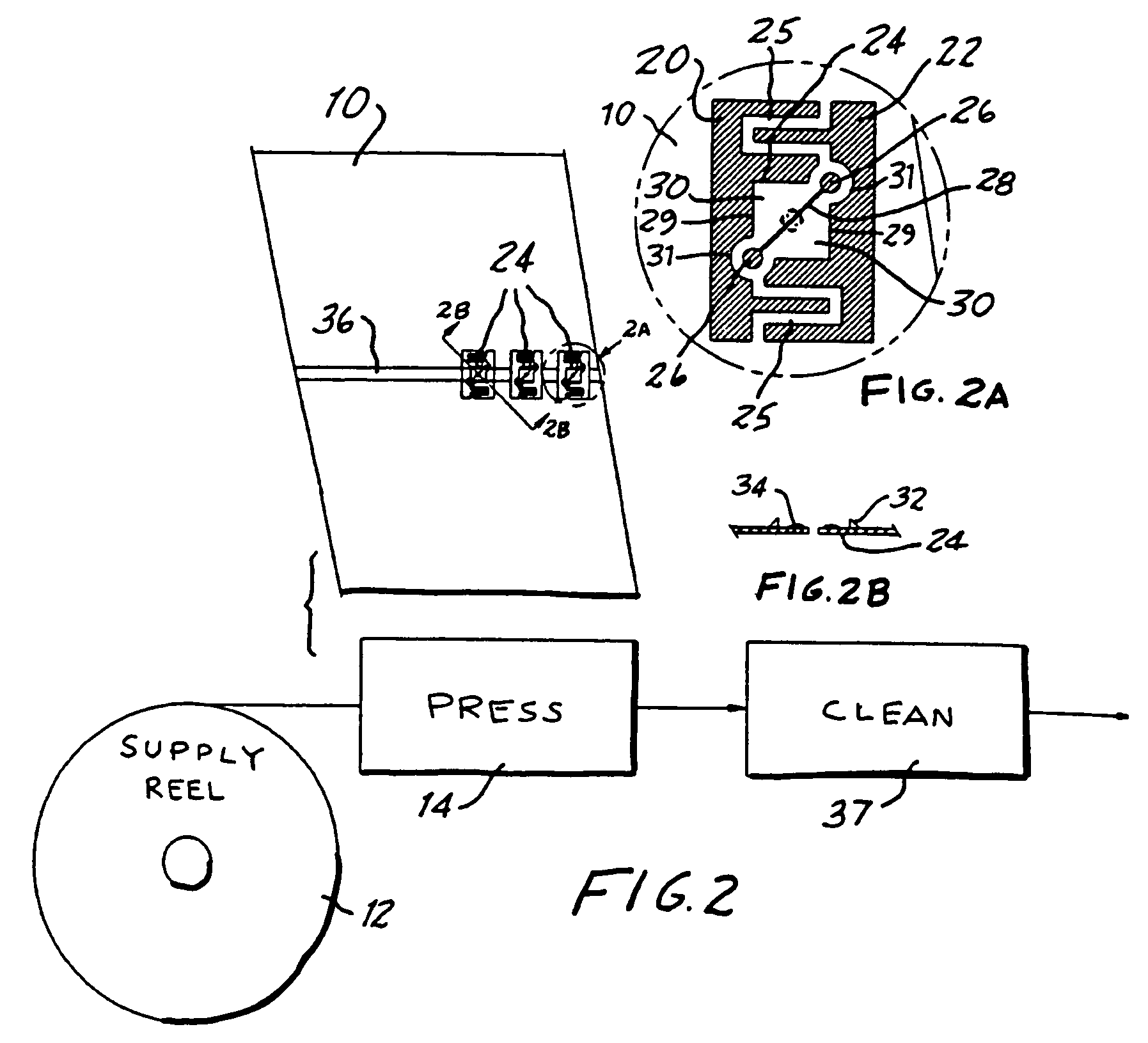

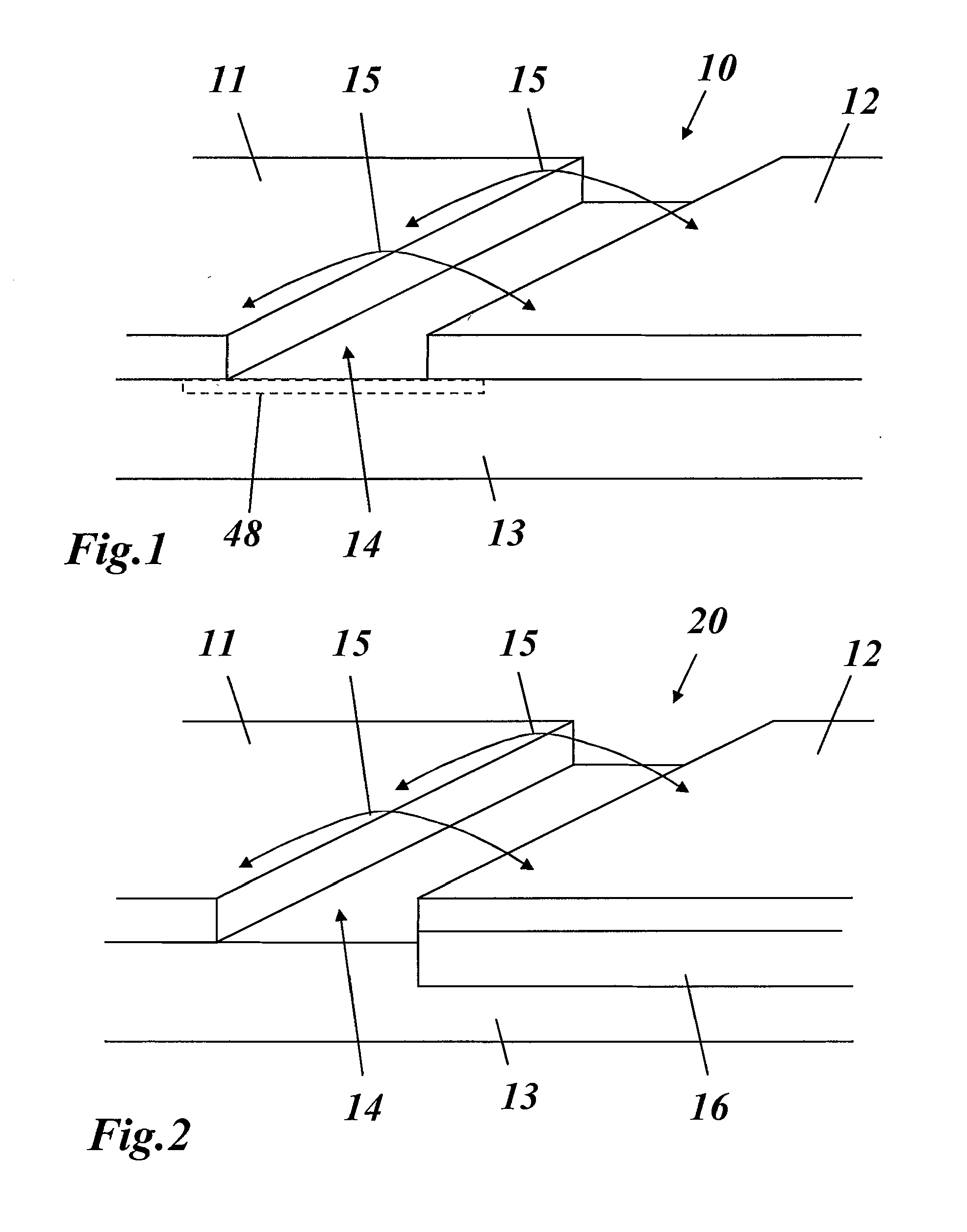

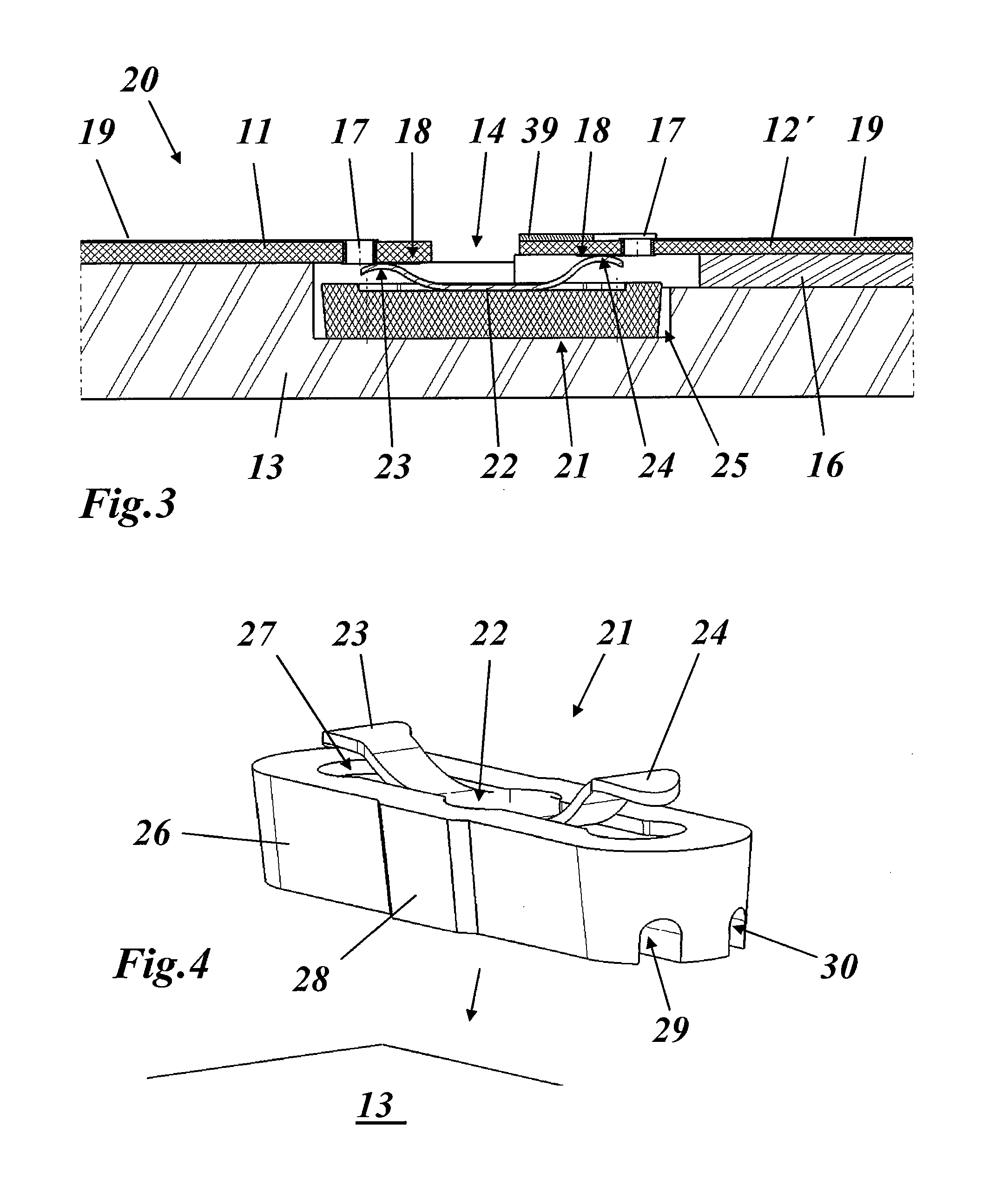

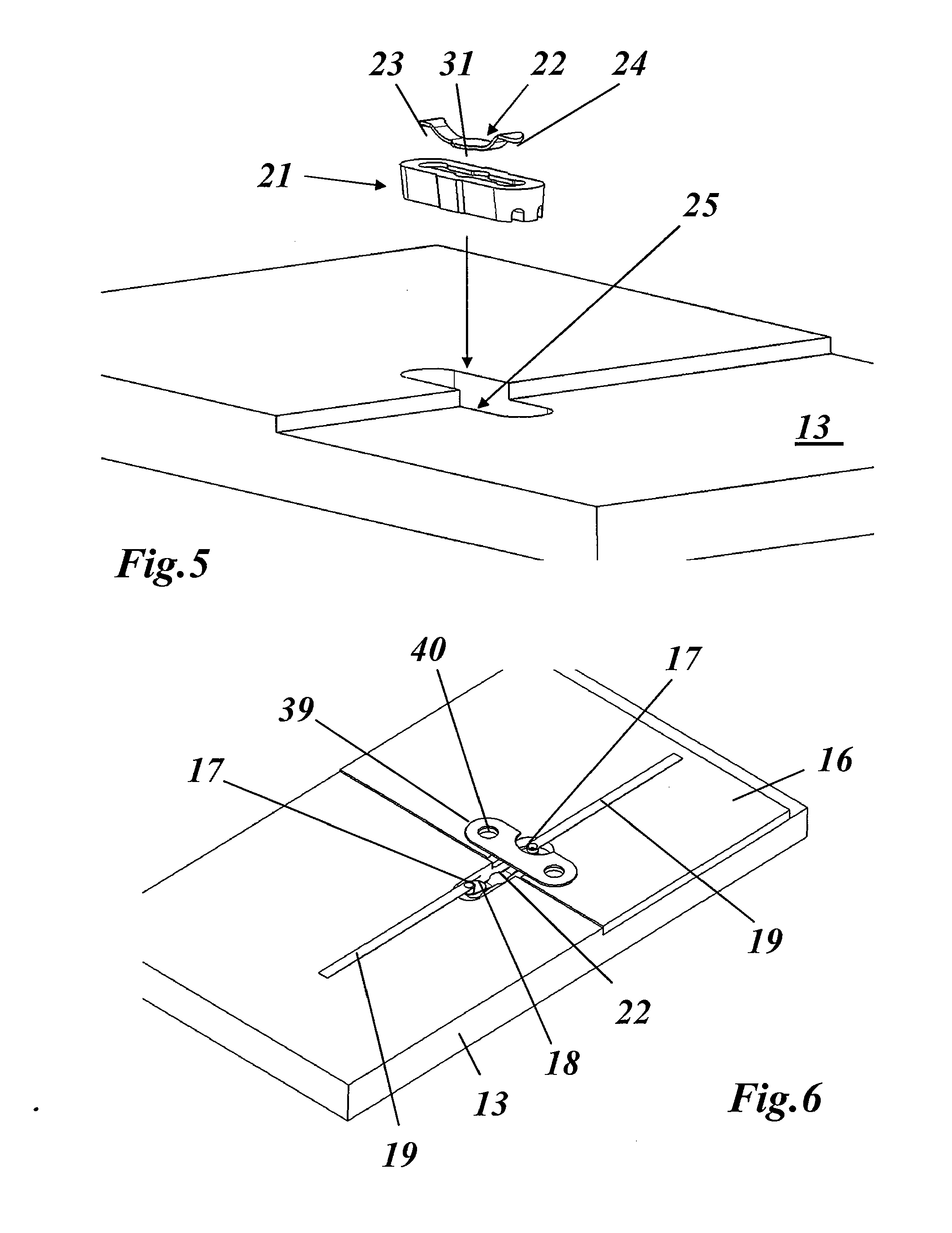

Manufacture of RFID tags and intermediate products therefor

InactiveUS7229018B2Easy to manufactureHighly effectiveLine/current collector detailsElectronic circuit testingCouplingEngineering

Owner:A K STAMPING

Acrylic flame retardant adhesive composition and acrylic flame retardant adhesive sheet

Owner:SHIN ETSU CHEM IND CO LTD

Integrated circuit board processing and drilling device

Owner:江苏微邦电子有限公司

Electroplating copper plating system of high-aspect-ratio printed wiring board and copper plating method

InactiveCN105908246AGood vibration effectImprove teleportation effectElectrolysis componentsLiquid/solution decomposition chemical coatingElectricityCopper plating

Owner:SHENZHEN BOMIN ELECTRONICS

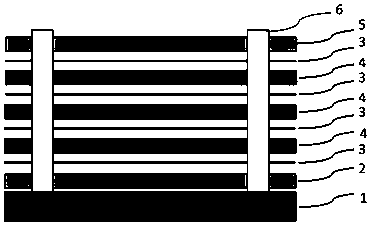

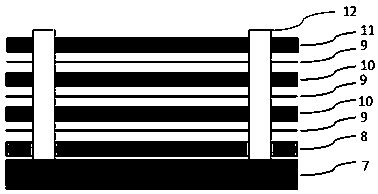

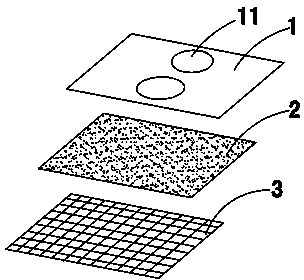

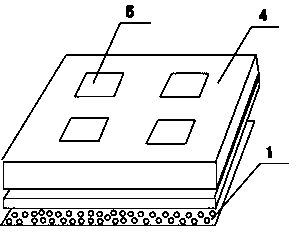

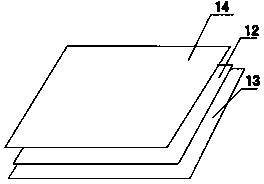

Rigid-flexible combined plate and method for plugging blind buried hole thereof

ActiveCN105657970AAchieve paddingSimplified plugging processPrinted circuit aspectsPrinted circuit manufactureEngineering

The invention discloses a rigid-flexible combined plate and a method for plugging a blind buried hole thereof. The rigid-flexible combined plate comprises a rigid sub-plate and a rigid-flexible sub-plate, wherein the rigid sub-plate is fixedly arranged on the rigid-flexible sub-plate; the blind buried hole is formed on the rigid sub-plate and / or the rigid-flexible sub-plate; at least one non-flowing type prepreg is arranged between the rigid sub-plate and the rigid-flexible sub-plate; the blind buried hole is filled with the flowing glue of the non-flowing type prepreg. The method for plugging the blind buried hole of the rigid-flexible combined plate comprises the following steps: supplying the rigid sub-plate and the rigid-flexible sub-plate; forming the blind buried hole on the rigid sub-plate and / or the rigid-flexible sub-plate; performing metallizing treatment on the blind buried hole; stacking at least one non-flowing type prepreg between the rigid sub-plate and the rigid-flexible sub-plate; pressing the rigid sub-plate and the rigid-flexible sub-plate and pressing the flowing glue of the non-flowing type prepreg into the blind buried hole. According to the rigid-flexible combined plate and the method for plugging the blind buried hole thereof, the processing is convenient, the smoothness of the plate is excellent, the special device is saved and the production cost is lowered.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

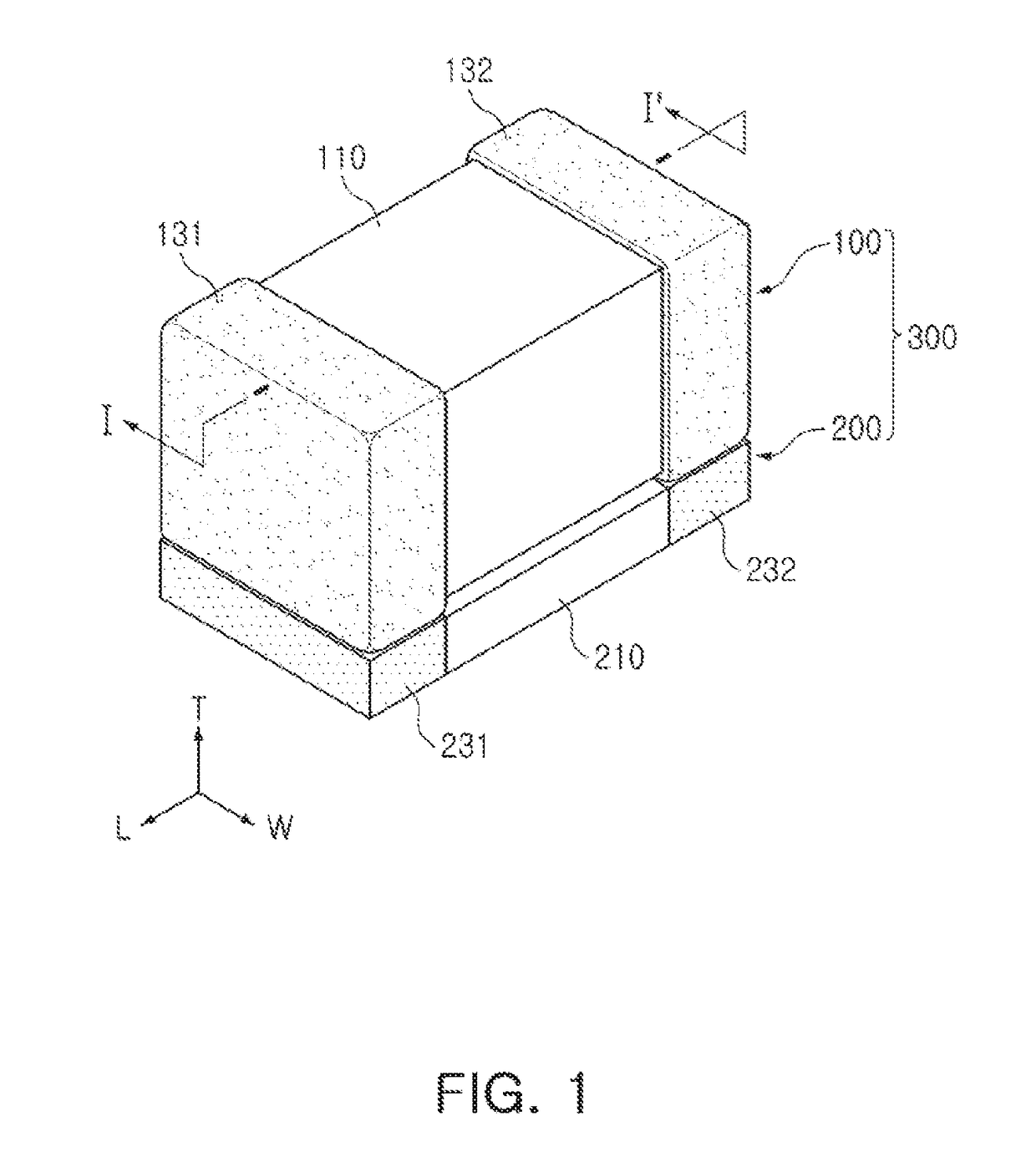

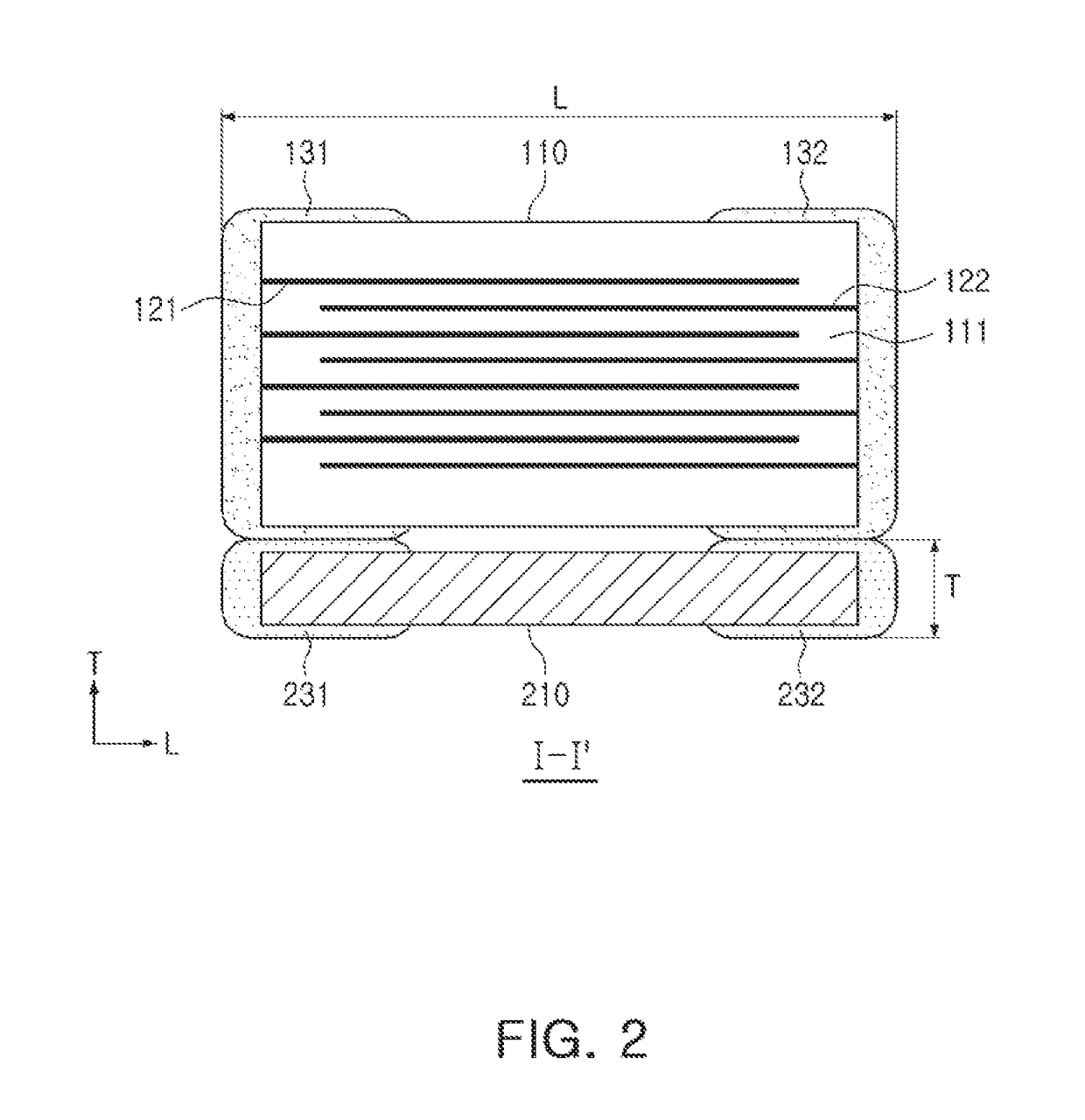

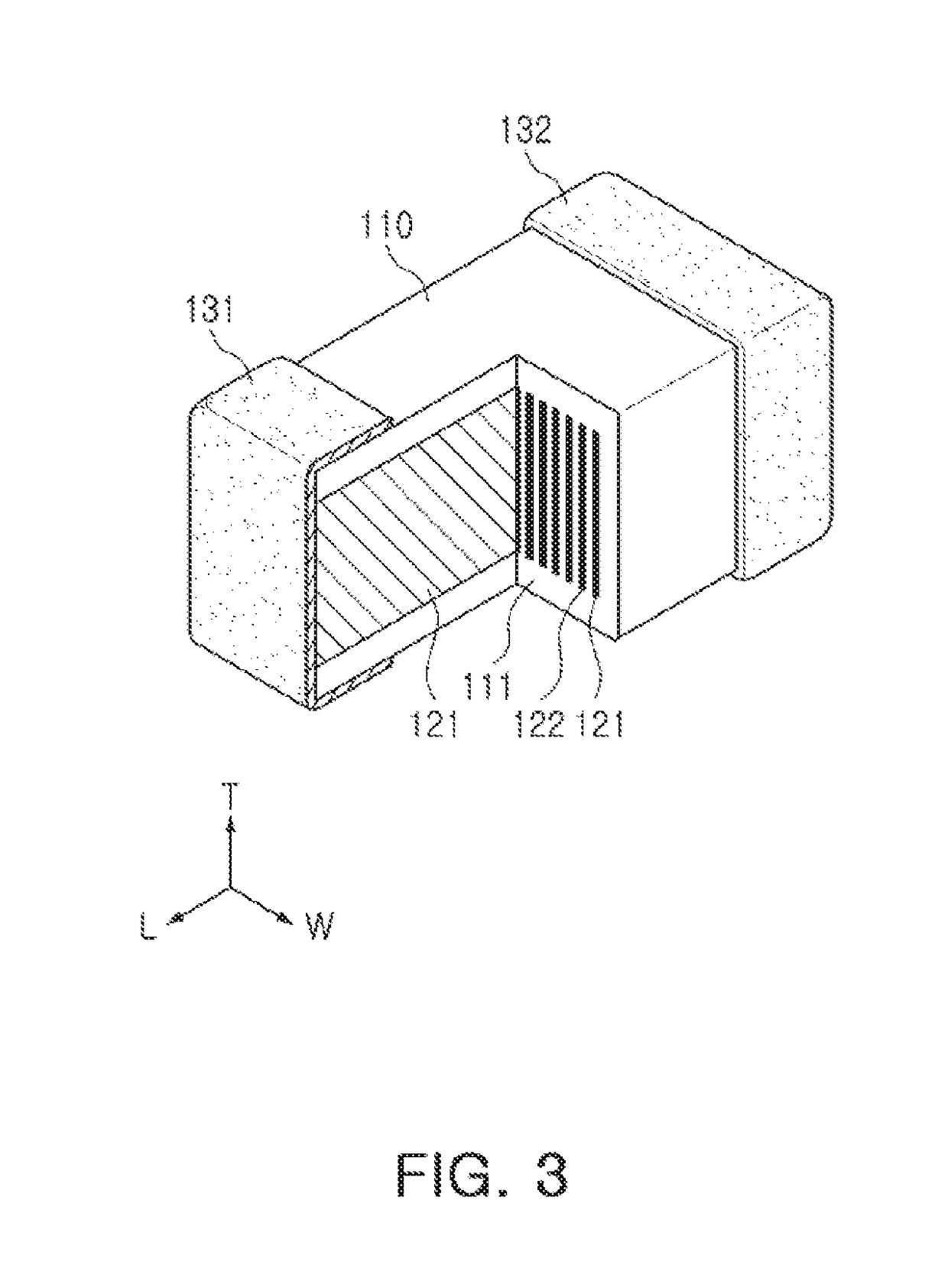

Composite electronic component and board having the same

InactiveUS20190069410A1Reduce noiseFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorElectronic component

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

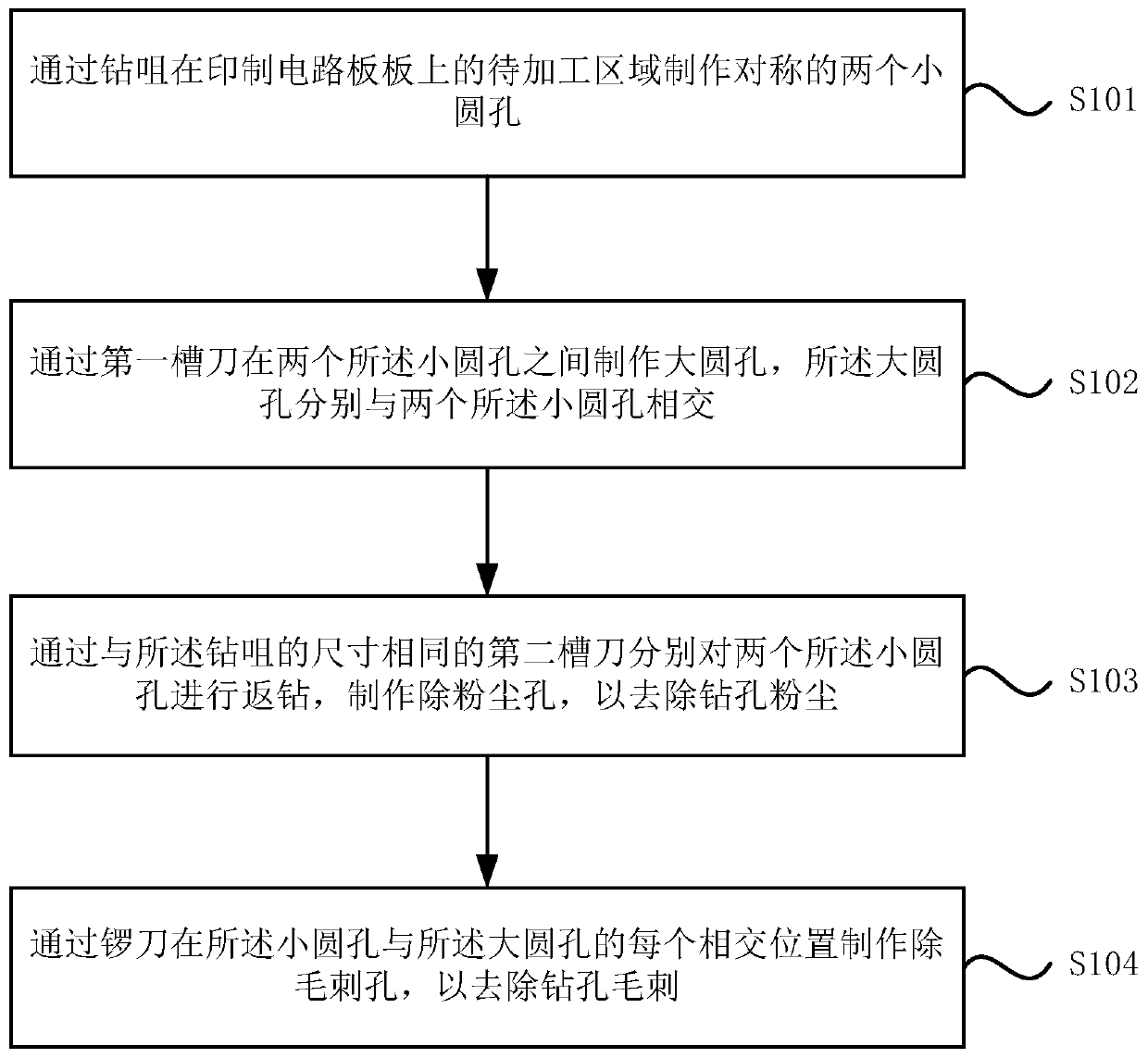

Tree core groove processing method and printed circuit board

ActiveCN111182731AMeet the installation requirementsAvoid the frontPrinted circuit manufactureMilling cutterStructural engineering

Owner:MEIZHOU ZHIHAO ELECTRONICS TECH

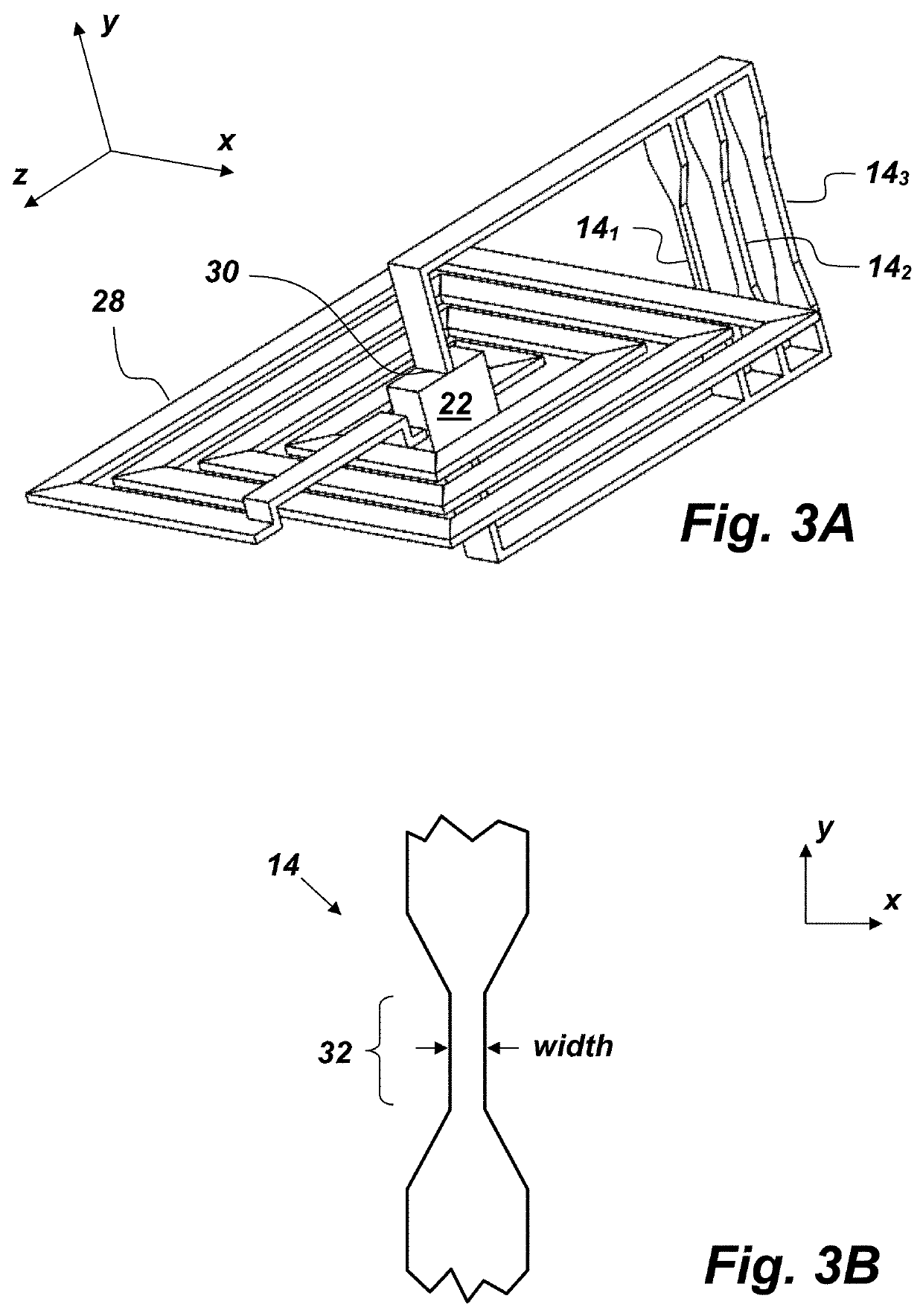

Smart Parts: Embedded Sensors for Use in Additive Manufactured Parts

ActiveUS20190346313A1Increase pressureThermometer detailsAdditive manufacturing apparatusElectrical resistance and conductanceHigh stress

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Circuit board and manufacturing method thereof

InactiveCN101299905AReduce material costsPrinted circuit manufactureCircuit susbtrate materialsDielectric structureDielectric layer

Owner:欣兴同泰科技(昆山)有限公司

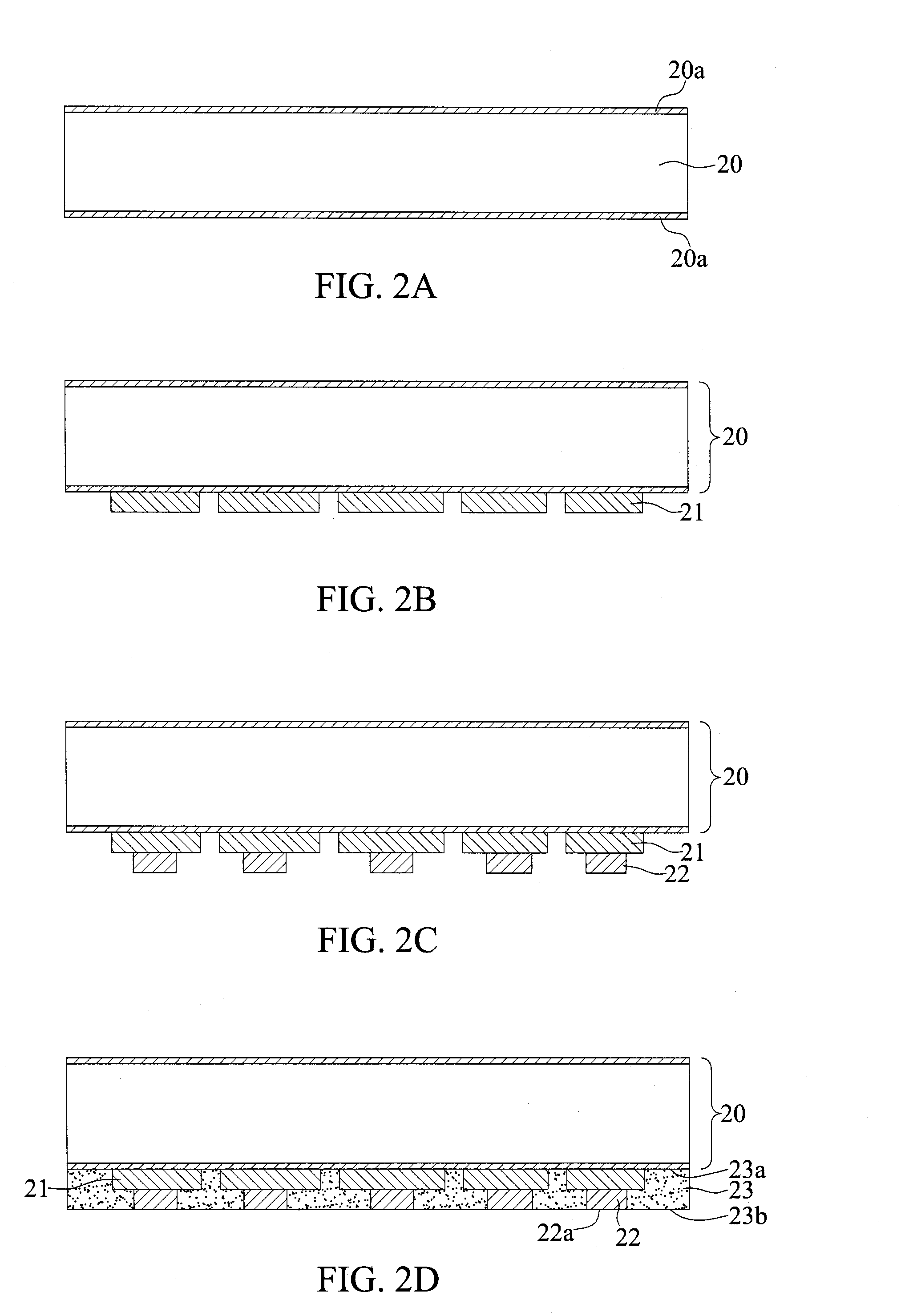

Interposer substrate and method of fabricating the same

ActiveUS20160163627A1Easy to manufactureImprove product reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringTin

Owner:PHOENIX PIONEER TECH

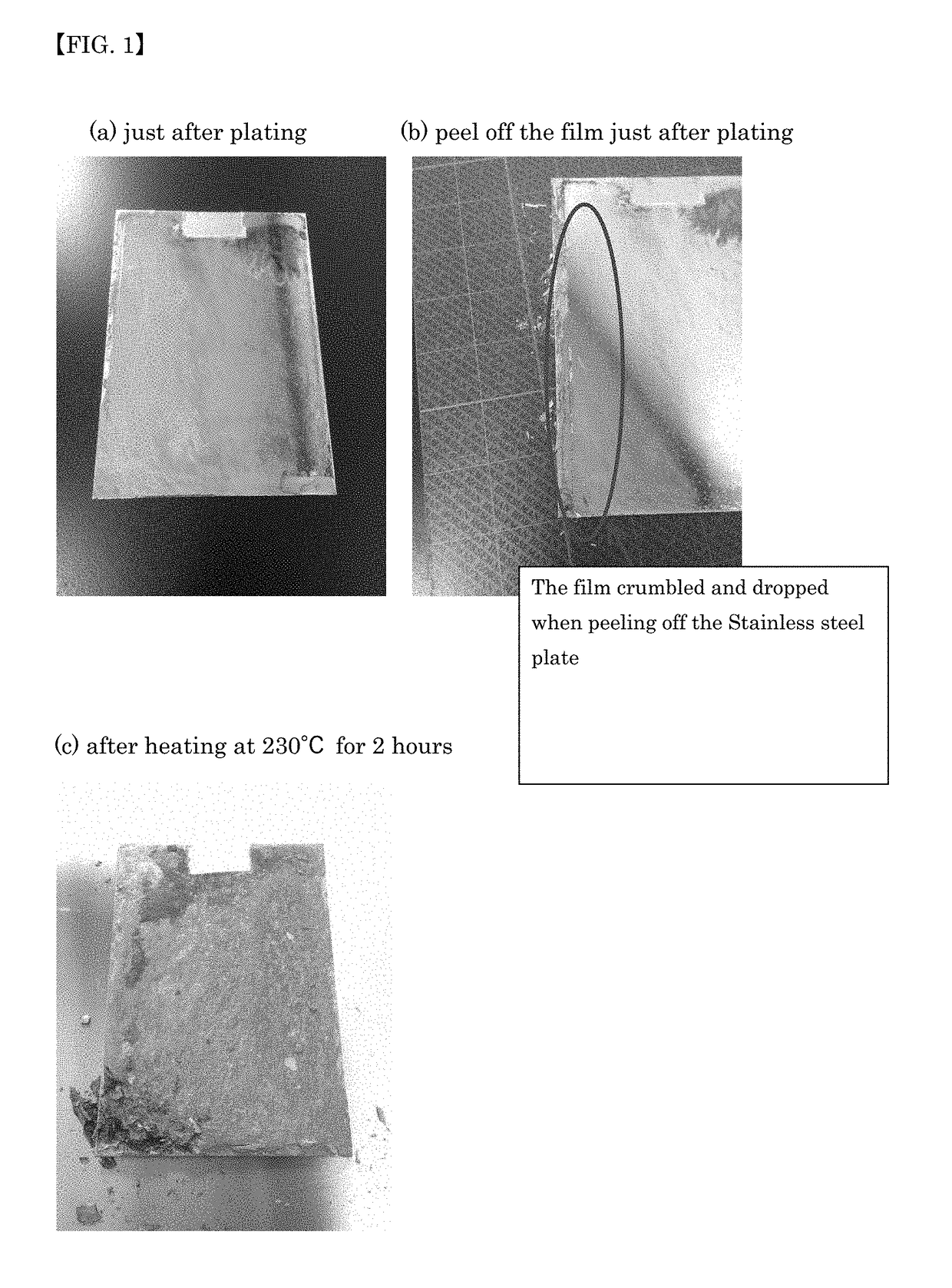

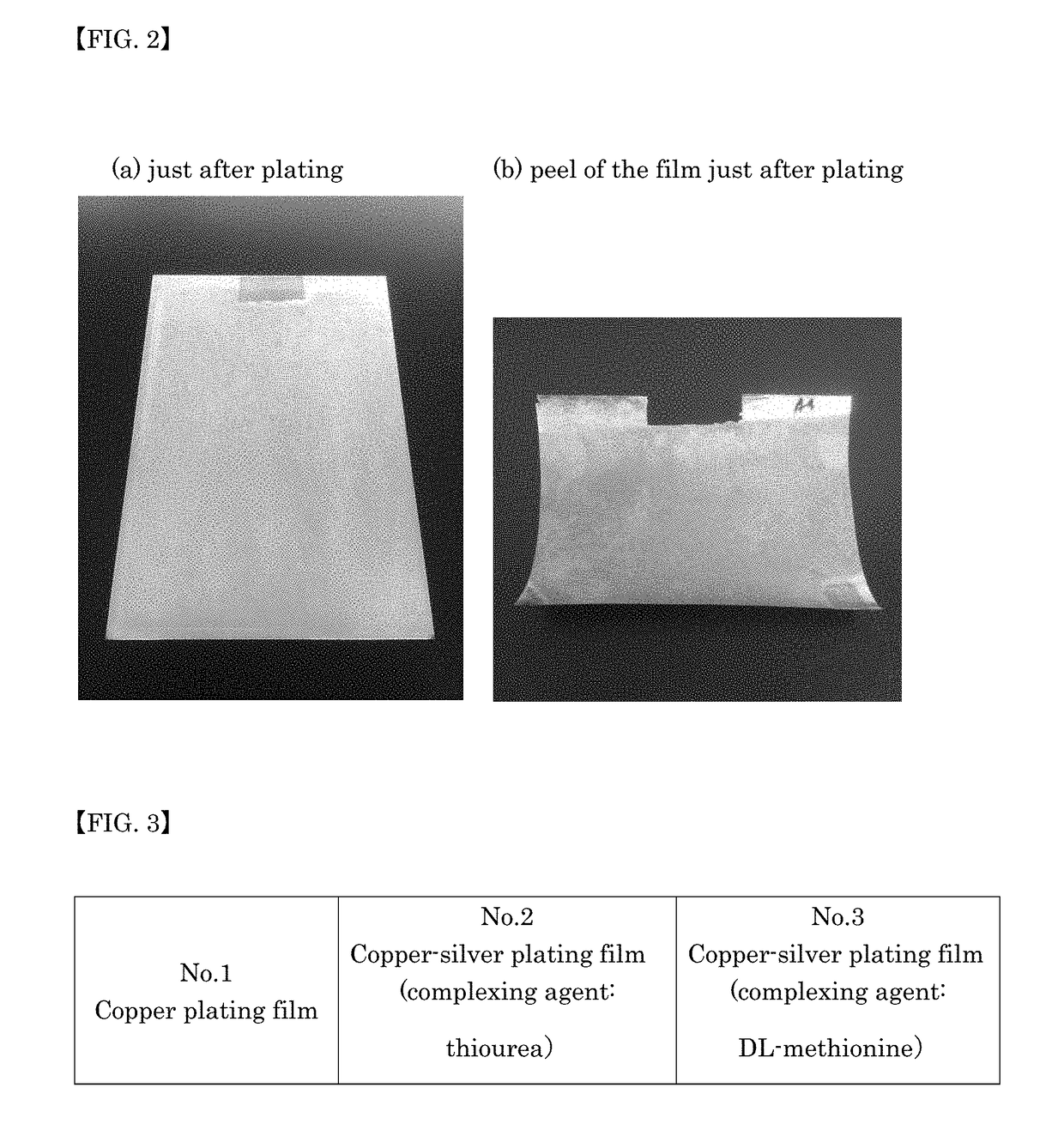

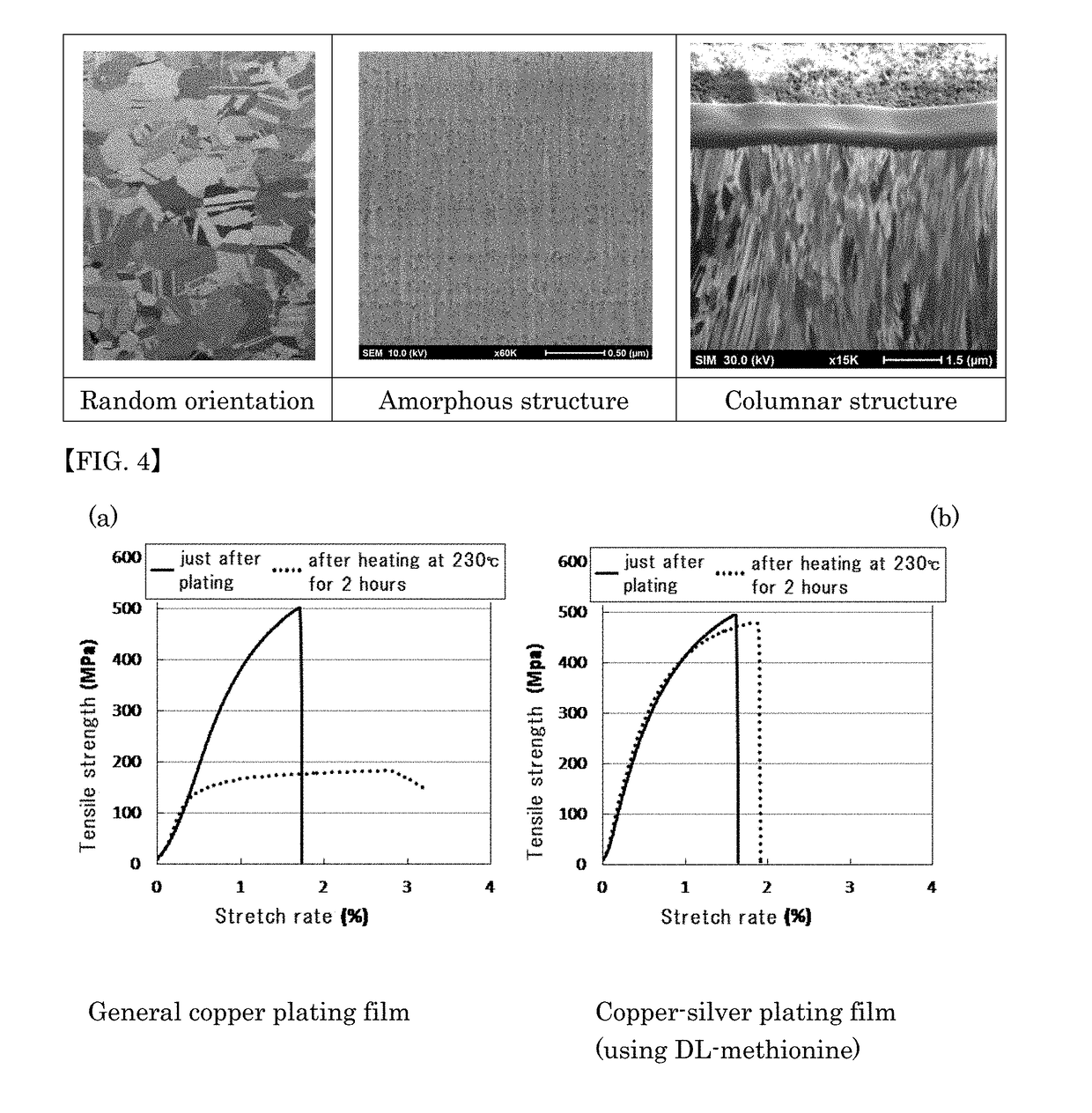

Copper electrolytic plating bath and copper electrolytic plating film

ActiveUS20180305833A1Good physical propertiesSemiconductor/solid-state device detailsPrinted circuit manufactureCopper platingPerylene derivatives

Owner:C UYEMURA & CO LTD

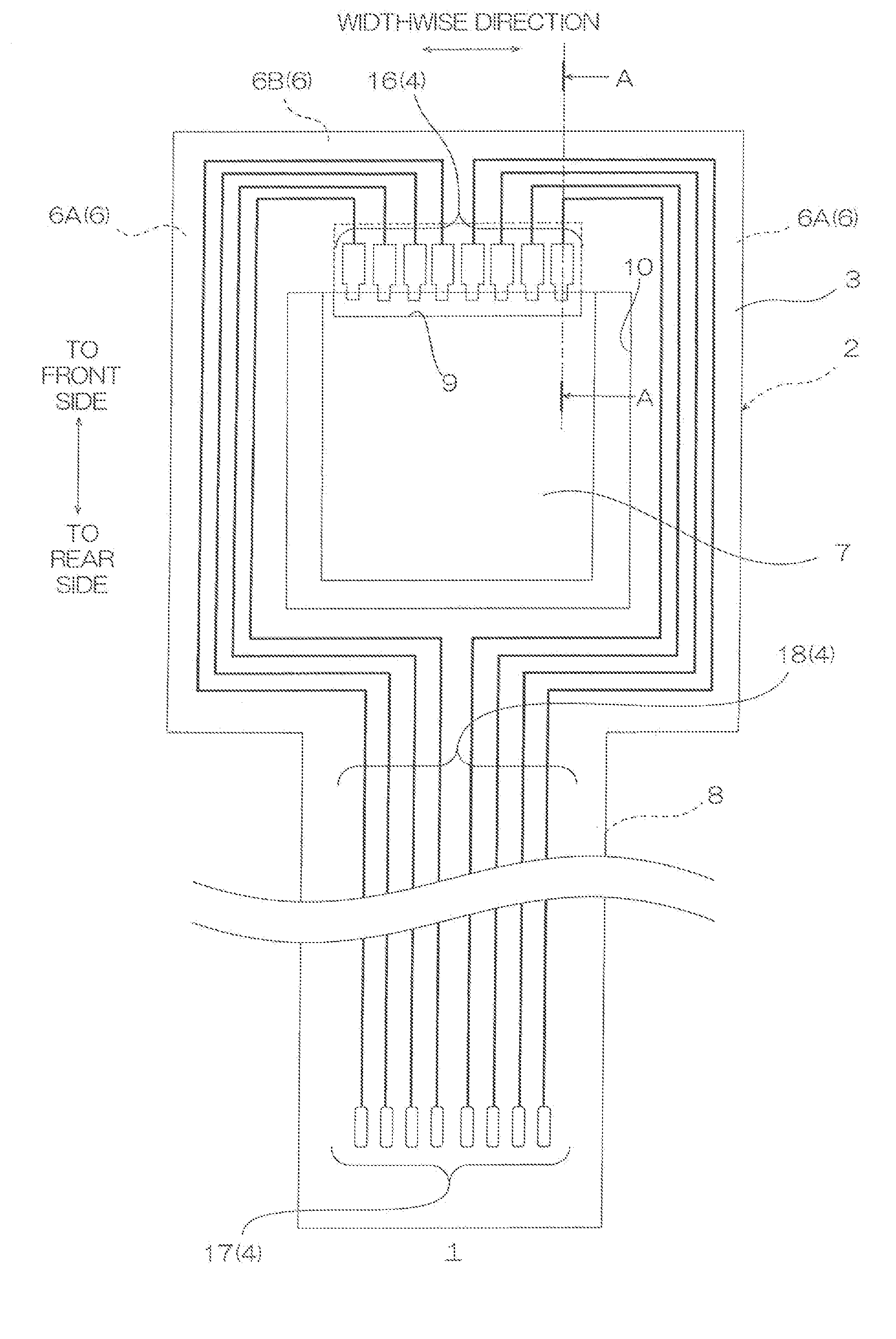

Wired circuit board

ActiveUS20160262258A1Avoid flowElectrical connection between head and armFlexible printed circuitsEngineeringPrinted circuit board

Owner:NITTO DENKO CORP

A processing method for improving burr forming of a polytetrafluoroethylene printed circuit board

The invention is applicable to the technical field of circuit board processing, and provides a processing method for improving the burr forming of a polytetrafluoroethylene printed circuit board. Themethod comprises the following steps: drilling the first phenolic backing plate, the second phenolic backing plate and a plurality of kraft papers through a gong machine according to the forming positioning holes of the polytetrafluoroethylene printed circuit board; The first phenolic backing plate, the polytetrafluoroethylene printed circuit board and the second phenolic backing plate are successively sleeved on a bakelite board which has been pre-implanted with pins according to requirements; The first phenolic cushion plate, the polytetrafluoroethylene printed circuit board and the second phenolic cushion plate are spaced apart by kraft paper, and are cut by a main shaft clamping milling cutter of a gong machine, and the processing speed is set to 0.2 m / min - 0.4 m / min; It can effectively improve the forming burr of PTFE printed circuit board, and can realize the simultaneous machining of 12-18 PTFE printed circuit boards, the production efficiency is high and the cost of input is reduced substantially.

Owner:JIAN MANKUN TECH

Copper surface treating agent and surface treatment method

InactiveCN101668883ASoldering apparatusMetallic material coating processesHeat resistanceSolderability

Disclosed is a copper surface treating agent satisfying both heat resistance and solderability. Also disclosed is a surface treatment method. Specifically disclosed is a copper surface treating agentcontaining an acid, a benzimidazole compound and water, which is characterized in that at least a first benzimidazole compound and a second benzimidazole compound having a melting point lower than that of the first benzimidazole compound by 70 DEG C or more are contained as the benzimidazole compound.

Owner:MEC CO LTD

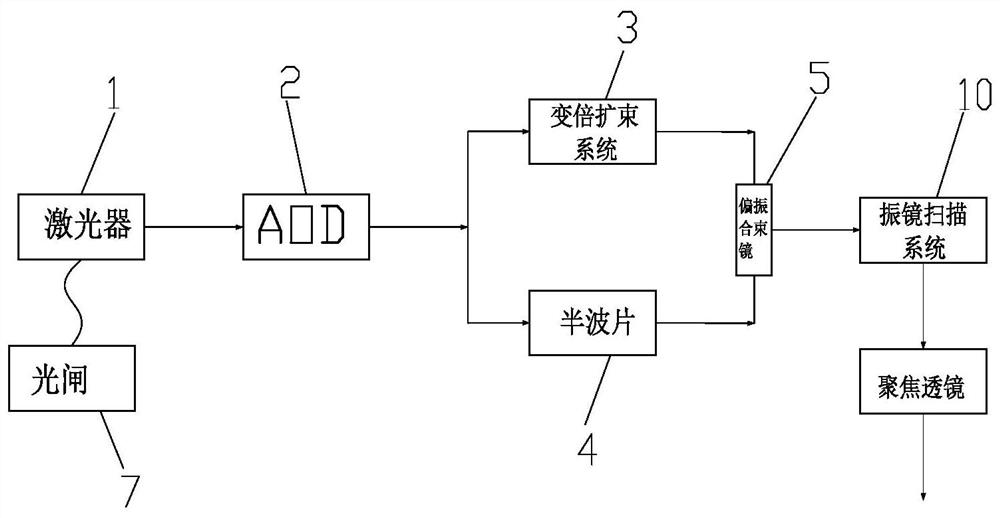

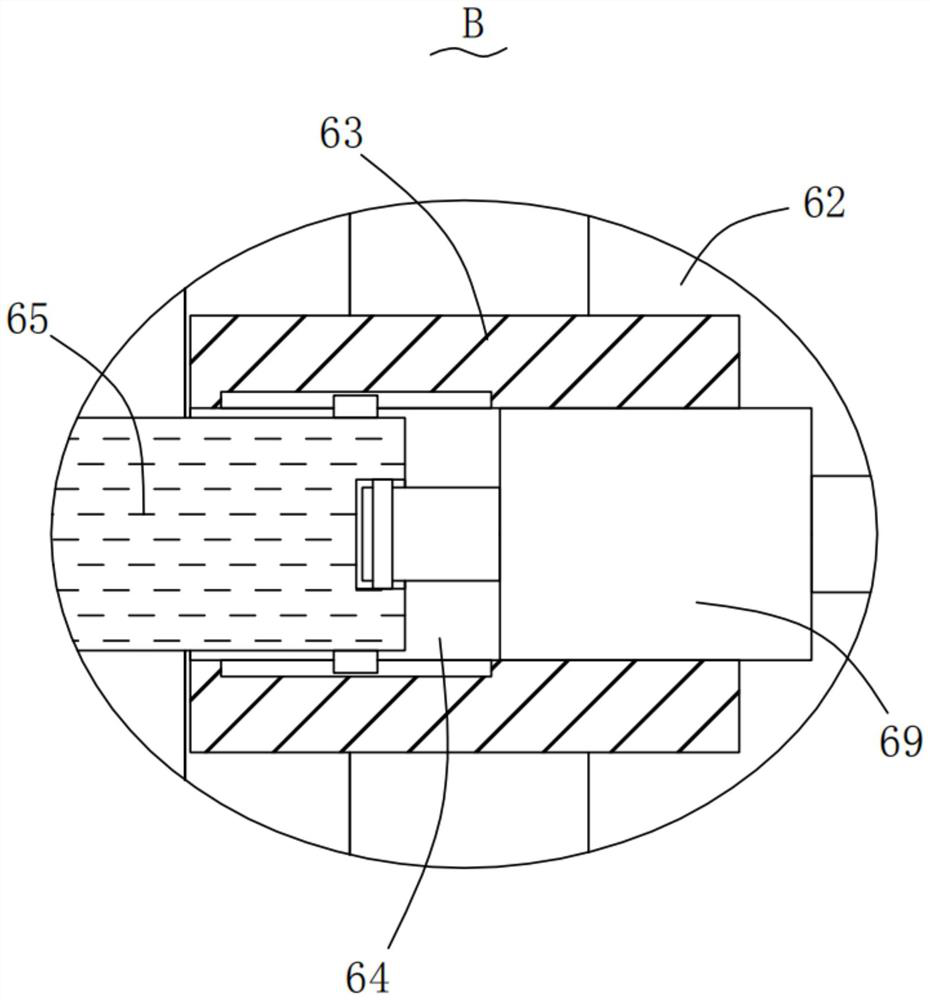

Laser light path system and method for processing flexible circuit board by using laser light path system

PendingCN112589296AShorten the processing pathImprove processing efficiencyPrinted circuit manufactureMetal working apparatusBeam expanderAcousto optic deflector

Owner:珠海市镭通激光科技有限公司

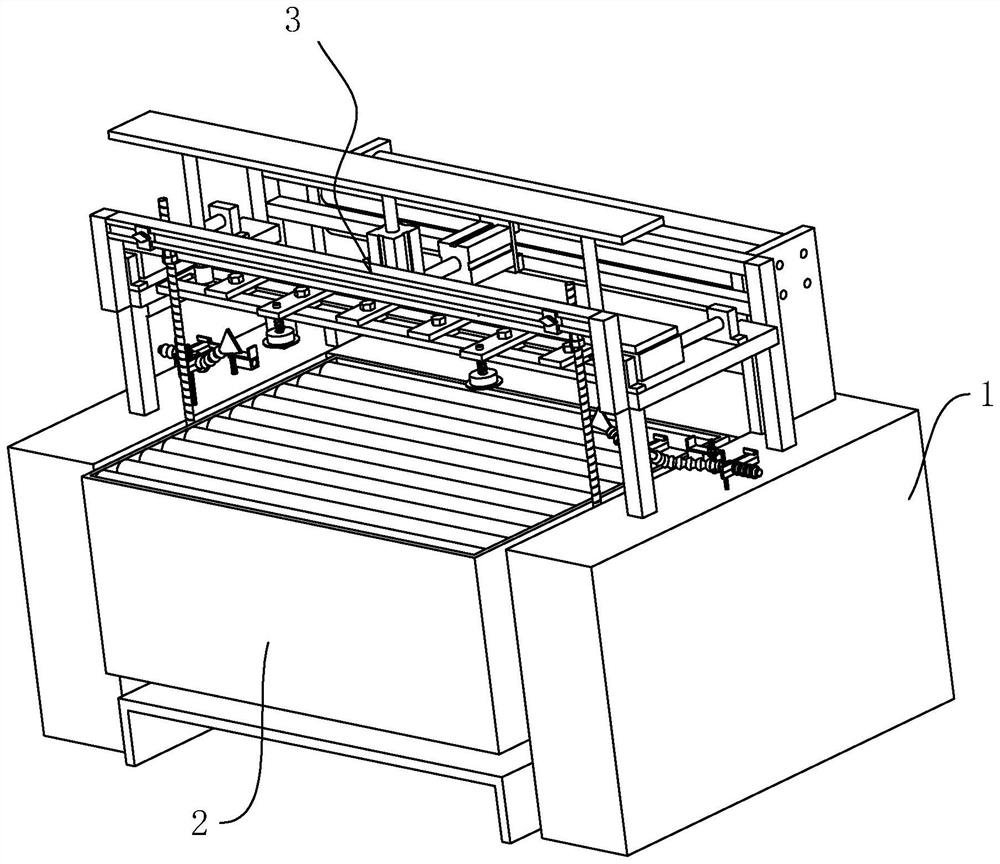

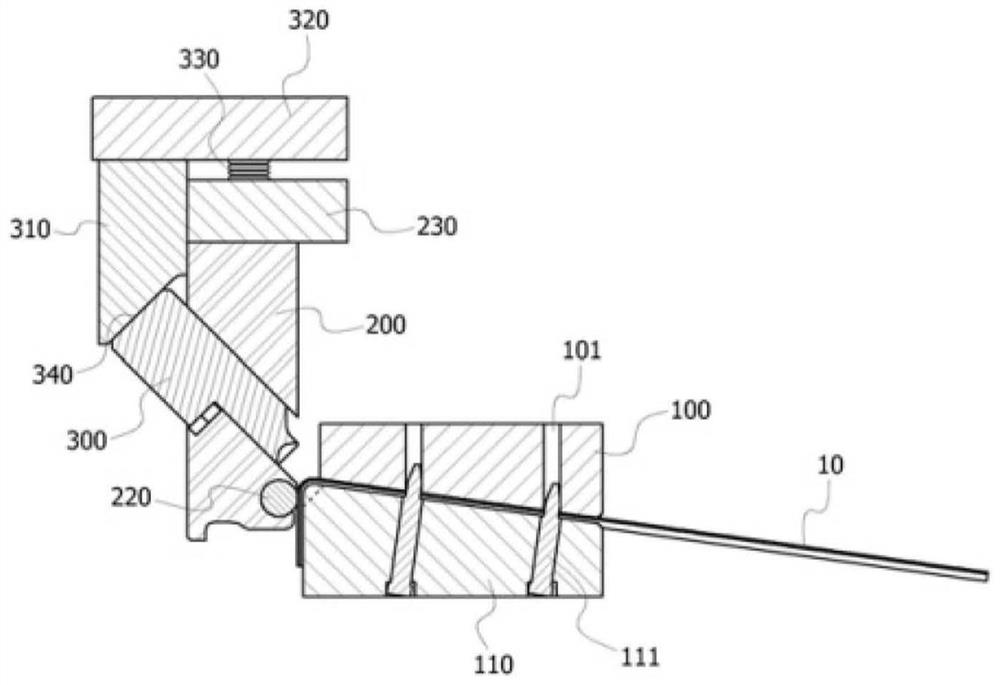

Full-automatic feeding device of plate grinding machine

PendingCN114523349AImprove work efficiencyGrinding carriagesGrinding drivesMechanical engineeringPrinted circuit board

Owner:佛山市普能达电子有限公司

Flux composition and soldering paste composition

Owner:NIHON SUPERIOR CO LTD

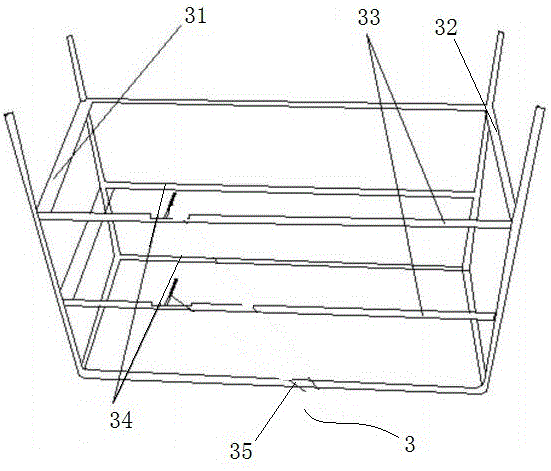

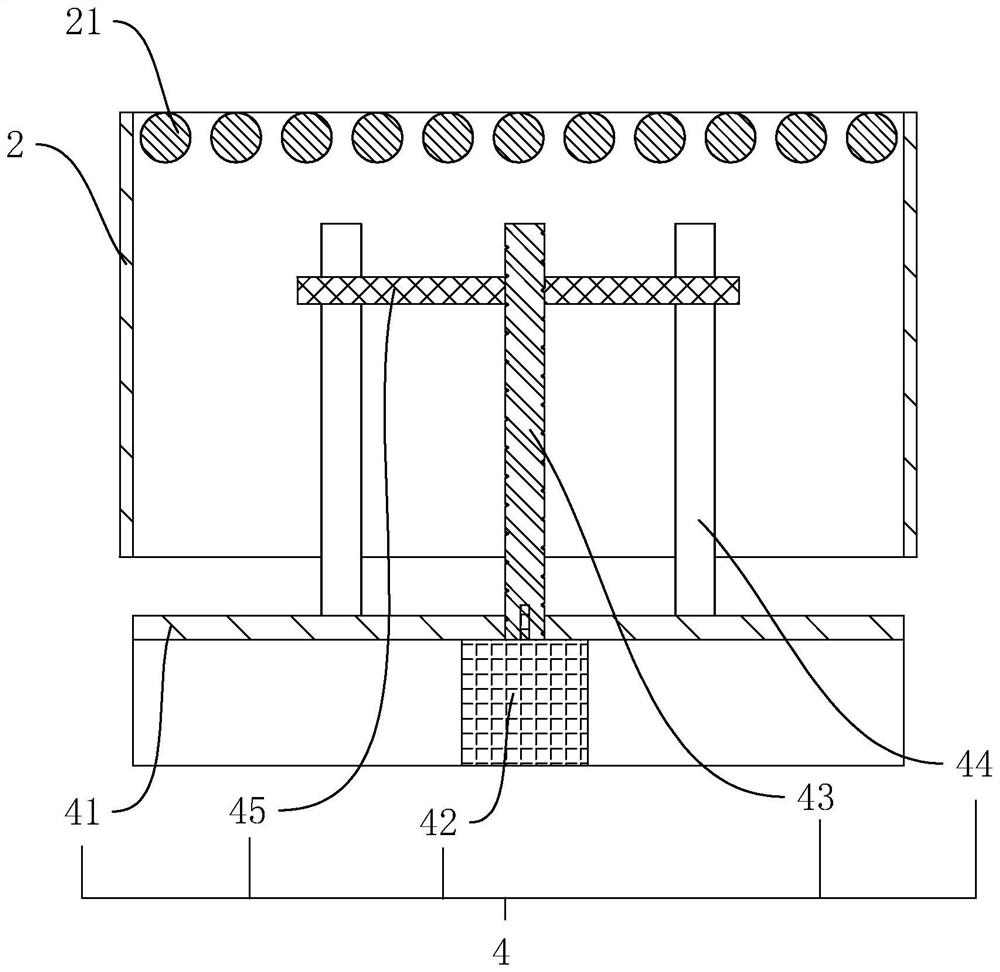

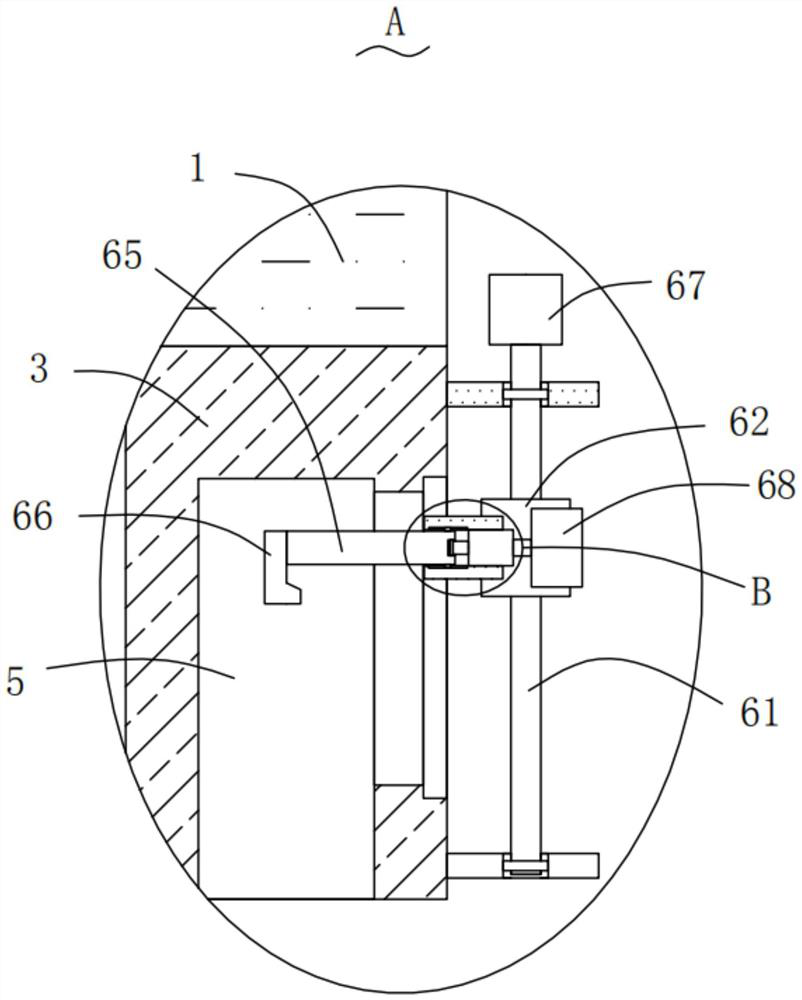

Bearing device for PCB production

PendingCN112399712APrinted circuit manufactureMechanical engineeringElectrical and Electronics engineering

Owner:AOSHIKANG TECH CO LTD

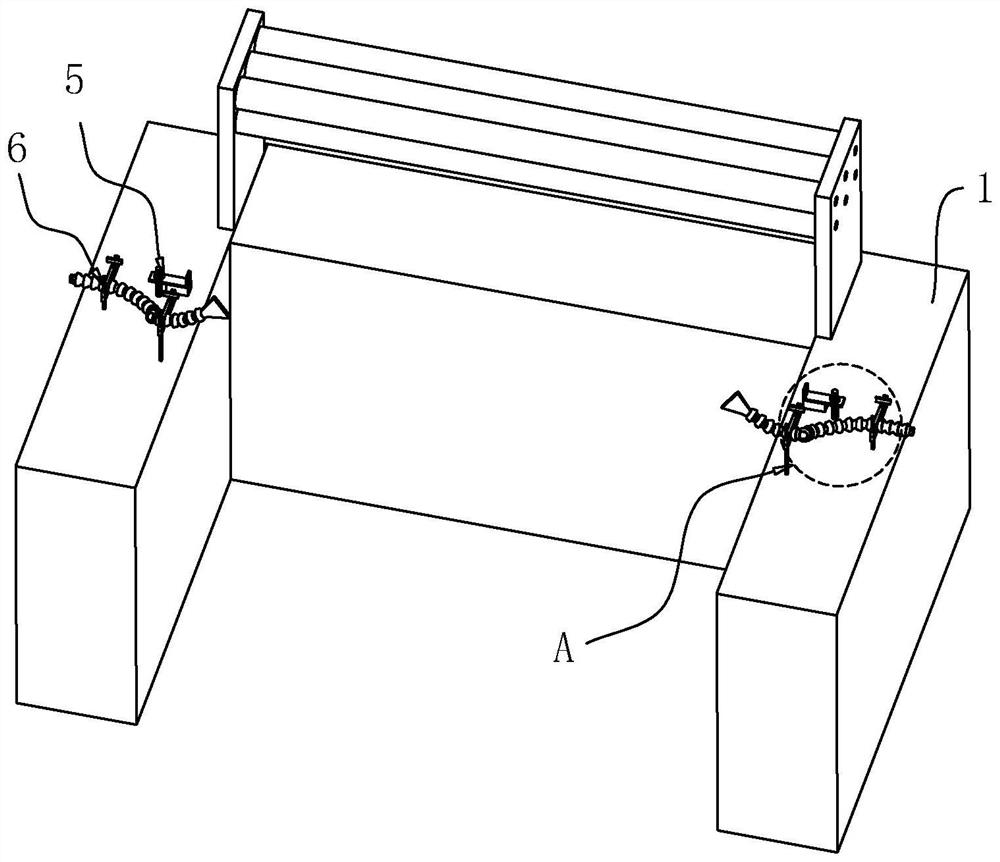

Metal PCB forming device and method

PendingCN114554692ASimple structureAccurate Forming OperationPrinted circuit manufactureElectrical componentsMetal formingEngineering

Owner:文登爱科线束有限公司

Device used for plate adsorption and separation

InactiveCN103796430AImprove separation efficiencyPrinted circuit manufactureComposite materialEngineering

Owner:国际技术开发股份有限公司

Printed board arrangement

ActiveUS20120057320A1Coupling device connectionsPrinted circuit aspectsElectrical connectionExtremely high frequency

Owner:HUBERSUHNER AG

Popular searches

Semiconductor/solid-state device manufacturing Semiconductor devices Printed circuit non-printed electric components association Electric lighting Semiconductor devices for light sources Coatings Antenna supports/mountings Casings/cabinets/drawers details Radiating elements structural forms Sensing record carriers

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap