Flux composition and soldering paste composition

a technology of composition and soldering paste, which is applied in the direction of welding/cutting media/materials, manufacturing tools, and soldering apparatus, etc., can solve the problems of extreme degradation of the wettability of the solder powder, the deterioration of the solder past, and the failure of printing on the pc board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

“Verification of Inclusion Effect”

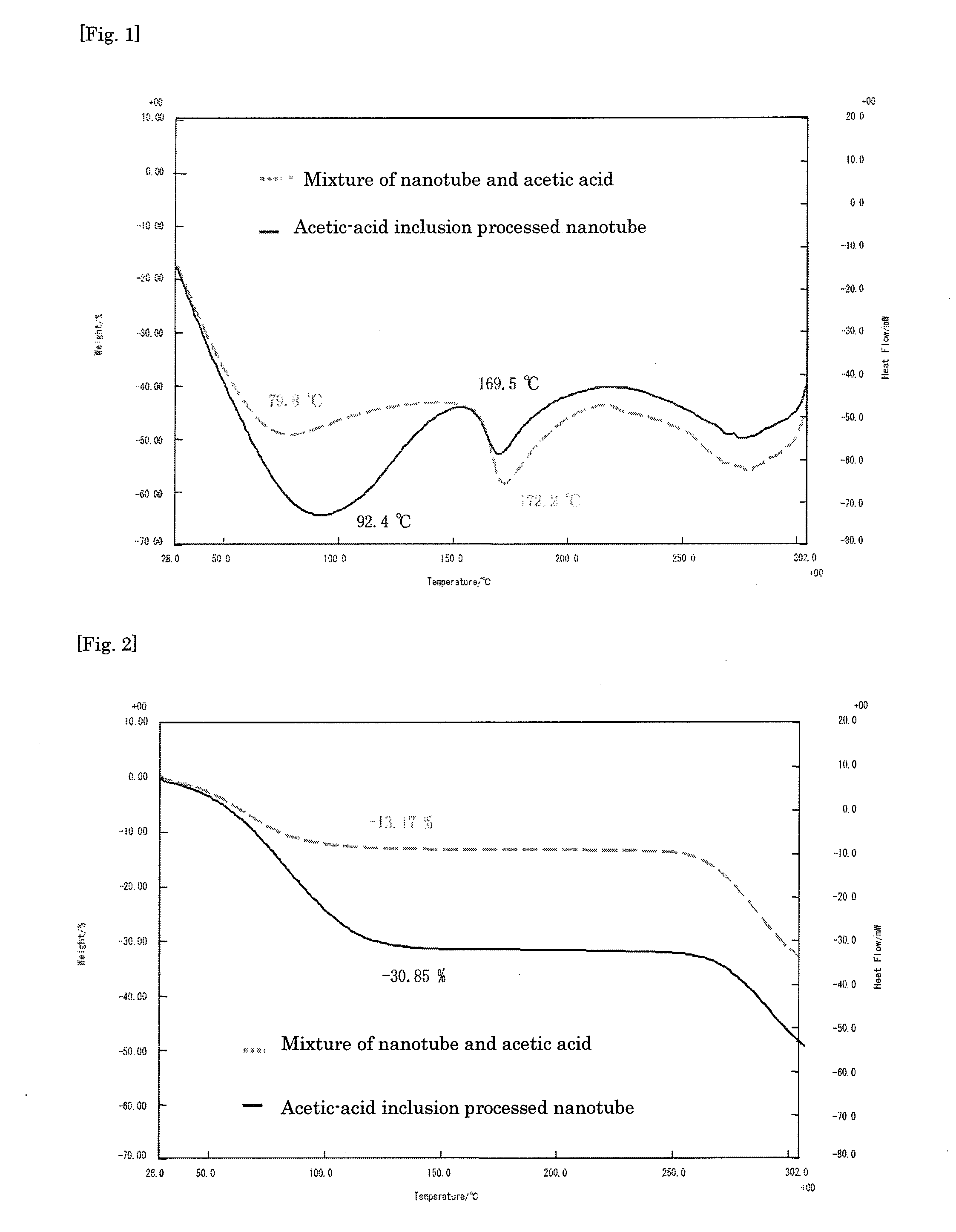

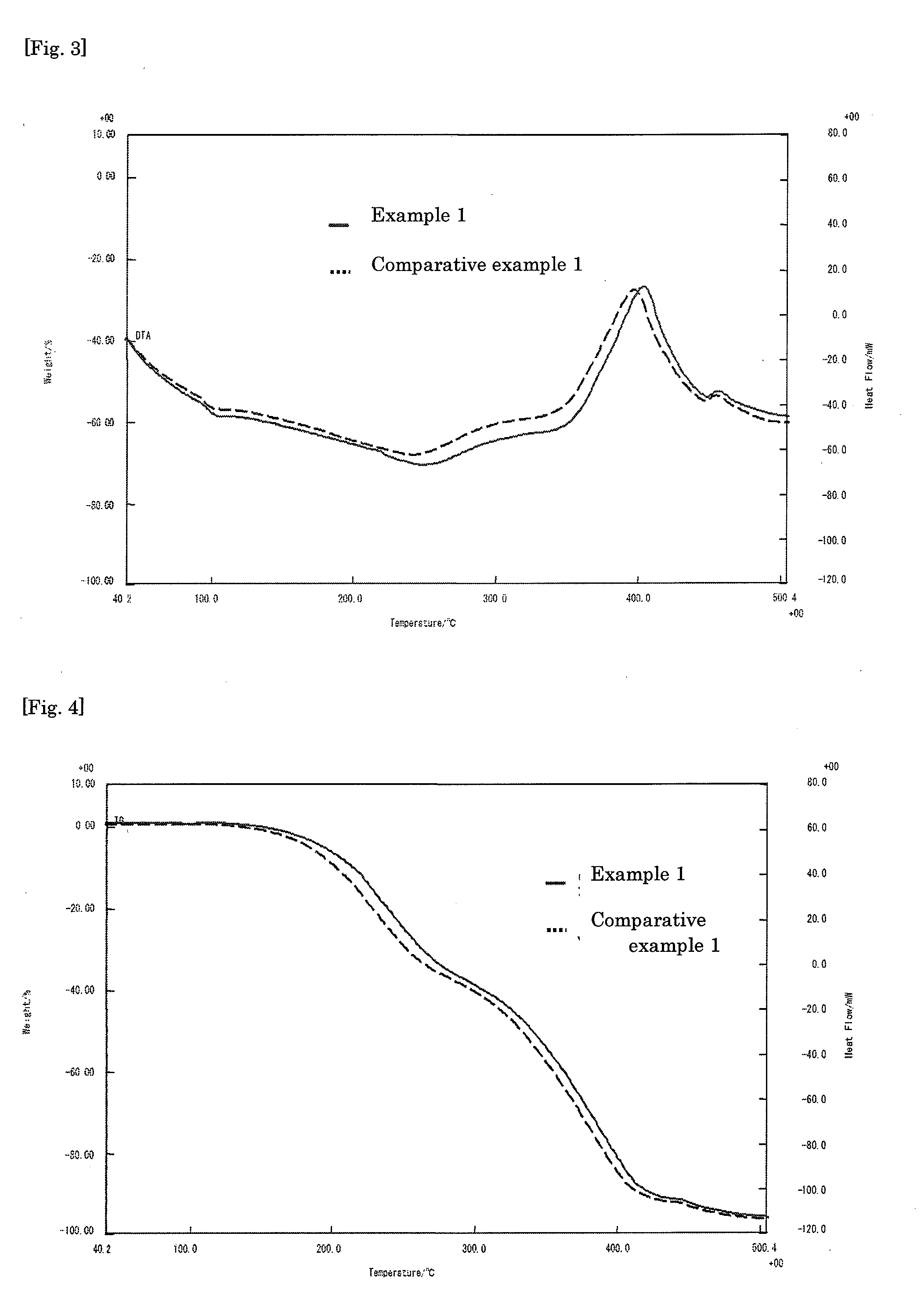

[0030]An increase in heat resistance caused by the inclusion of activator within the nanotube was verified using a thermogravimetry and differential thermal analysis (TG-DTA).

“Specimen and Preparation Method”

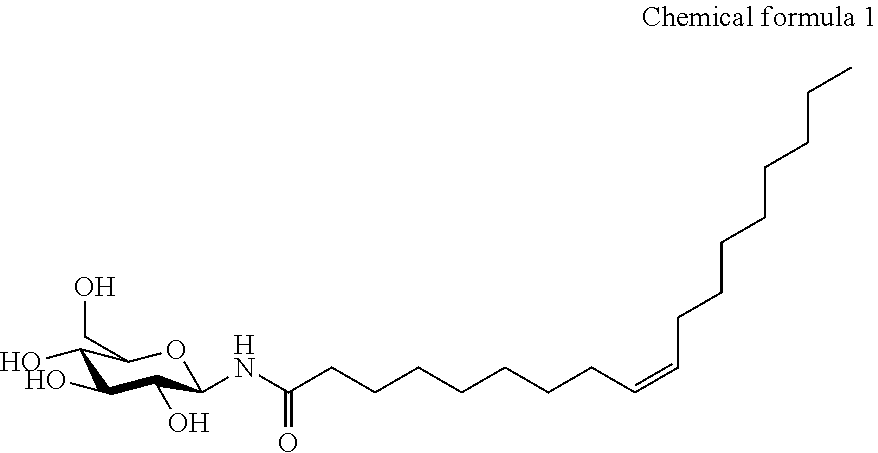

[0031]An inclusion process was performed on specimens, glucopyranosylamine type nanotube as a component of the invention and acetic acid (CH3COOH) under reduced pressure to produce acetic-acid inclusion processed nanotube. Two types of acetic acid were prepared by performing and not performing the inclusion process on a mixture of glucopyranosylamine type nanotube and acetic acid mixed at room temperature. The differential thermal analysis, as is known in the art, refers to a detection of a temperature difference that takes place when a specimen and a reference material are heated and cooled. The differential thermal analysis is based on the fact that a transition takes place in the temperature difference with respect to the reference material if t

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap