Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52 results about "Heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resistance heating is a process where thermal energy is produced by passing an electrical current through a purpose designed conductor. The resistance the conductor offers to the passage of the current causes a reaction within it at an atomic level, thereby producing energy and releasing heat.

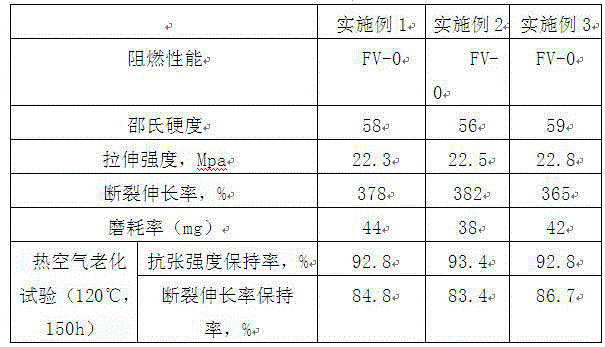

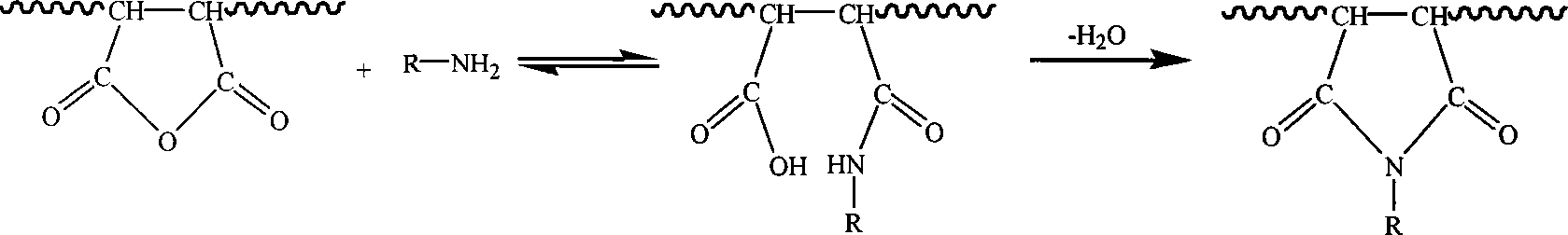

Preparation method of thermoplastic polyurethane elastomer

InactiveCN103059554AImprove mechanical propertiesImprove heat resistancePolyethylene glycolHydrolysis

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

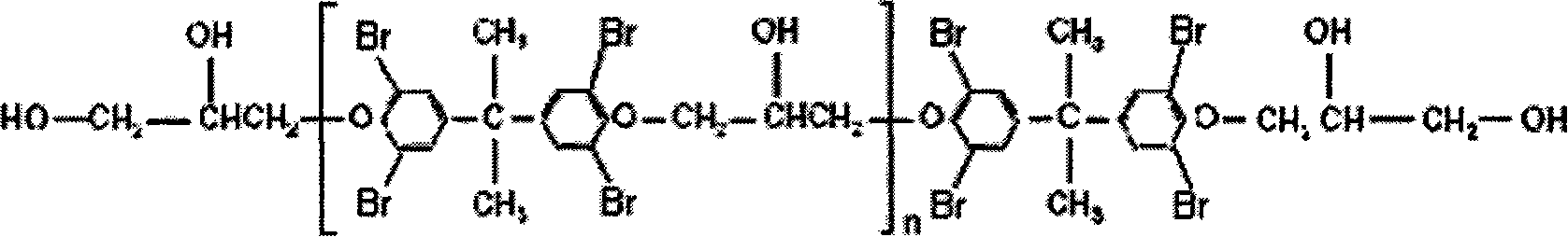

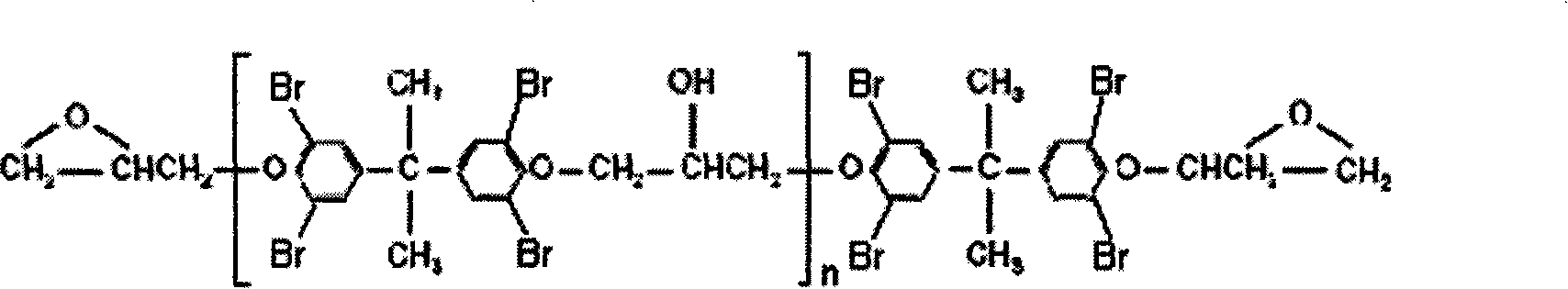

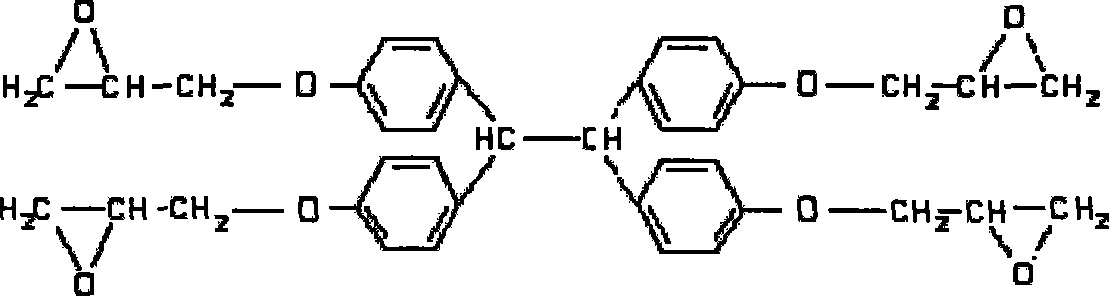

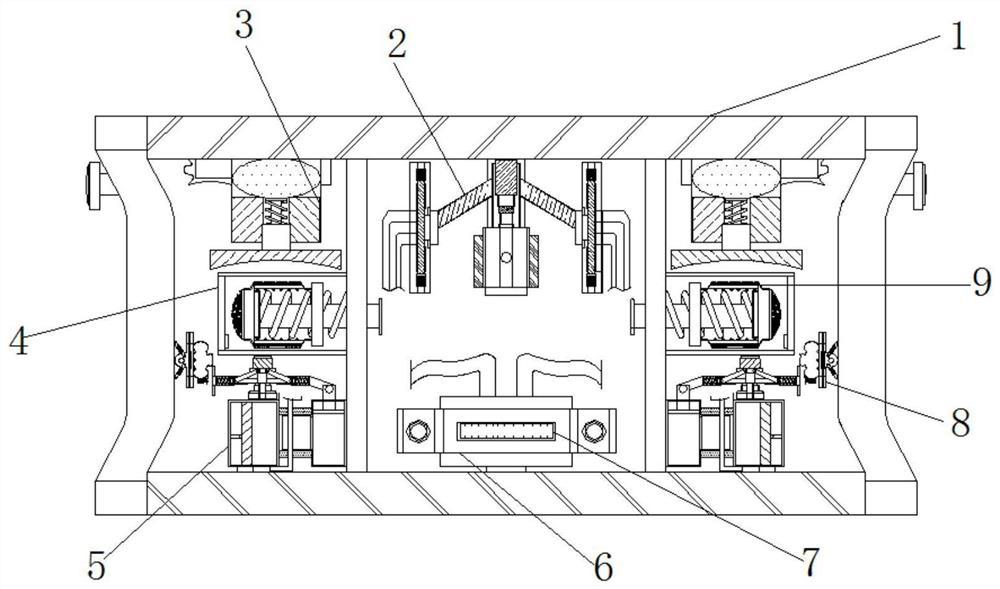

Resin composition and semi-solidifying sheet for printed board prepared from the same

Owner:GUANGDONG SHENGYI SCI TECH

Processing technology for super-imitated-cotton/fine-denier damp conduction polyester comfortable mercerized velvet warp knitting fabric

ActiveCN103859664AEasy to takeGood flexibilitySucessive textile treatmentsWarp knittingHeat resistanceEngineering

Owner:ZHEJIANG QINGSONG TEXTILE

Thin film and thin film laminate comprising the same

InactiveUS20090233083A1Maintain good propertiesExcellent gas barrier performanceRecord carriersSynthetic resin layered productsHeat resistancePliability

Owner:TOMOEGAWA CO LTD

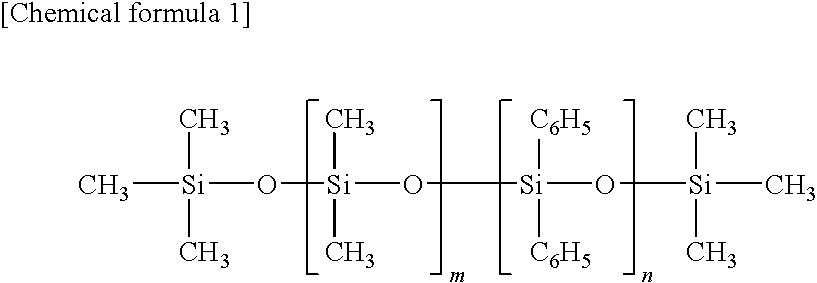

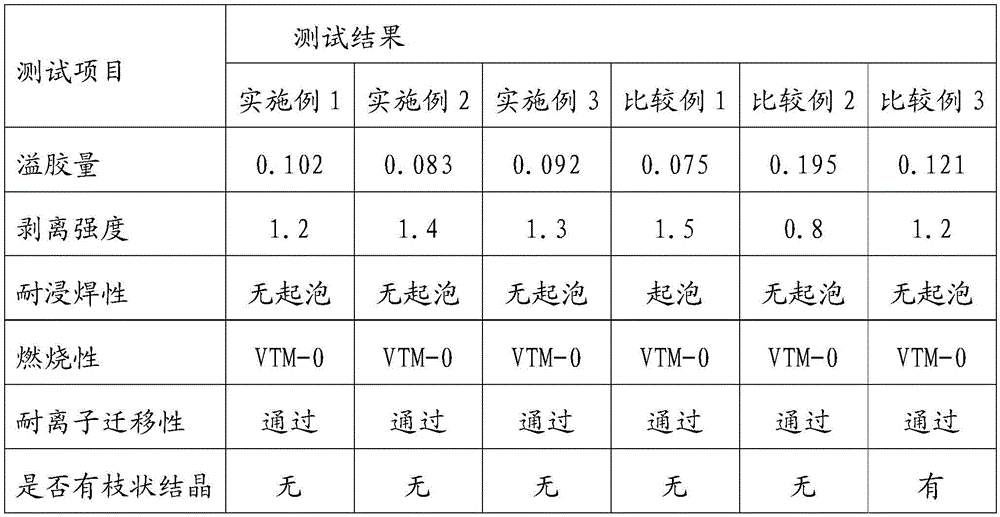

Halogen-free resin composition and cover film prepared from the same

InactiveCN105482442AExcellent resistance to ion migrationGood flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyPolyester

Owner:GUANGDONG SHENGYI SCI TECH

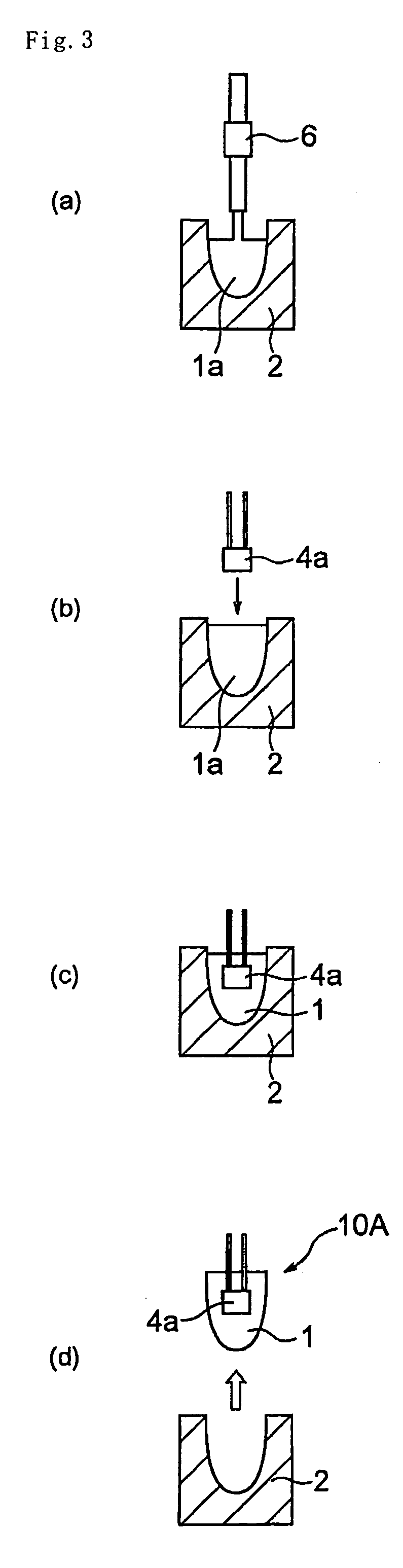

Molded Article for Clean Room and Method for Producing Same

Owner:FUJI BAKELITE +2

Preparation method of hyperbranched polyester modified organic silicon resin and coating comprising resin

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

High-strength corrosion-resistant micro-alloying copper pipe and manufacturing method thereof

The invention discloses a high-strength corrosion-resistant micro-alloying copper pipe material which consists of the following components in percentage by weight: 0.005-0.04% of phosphorus, 0.2-1.0% of tin, 0-0.04% of lanthanum, 0-0.04% of cerium, 0-0.1% of nickel, 0-0.1% of zinc, 0-0.05% of cobalt, 0-0.1% of manganese, 0-0.05% of zirconium and the balance of copper. By combining phosphorus with rare earth lanthanum and / or cerium to obtain a deoxidizer of molten copper, the content of oxygen in melt is further reduced, the grain structure is refined, the recrystallization temperature is increased to prevent abnormal growth of the weld structure grain, and the ductility and thermal conductivity of copper are further improved. Through solid solution strengthening of tin and improvement of an oxide film on a surface layer, the strength and corrosion resistance of a matrix are improved. By adding trace amount of zinc, nickel and manganese subjected to solid solution into the copper matrix, the strength of the copper matrix is improved; by adding cobalt or zirconium and dispersing into the copper matrix, the strength and heat resistance of the copper matrix are improved; the combination effect is better than the performance and using effect of the existing oxygen-free copper pipe or single phosphorus deoxidization copper pipe.

Owner:NINGBO JINTIAN COPPER TUBE +1

Good-weather and water resistance water-based alkyd resin

Owner:深圳海德新材料科技有限公司

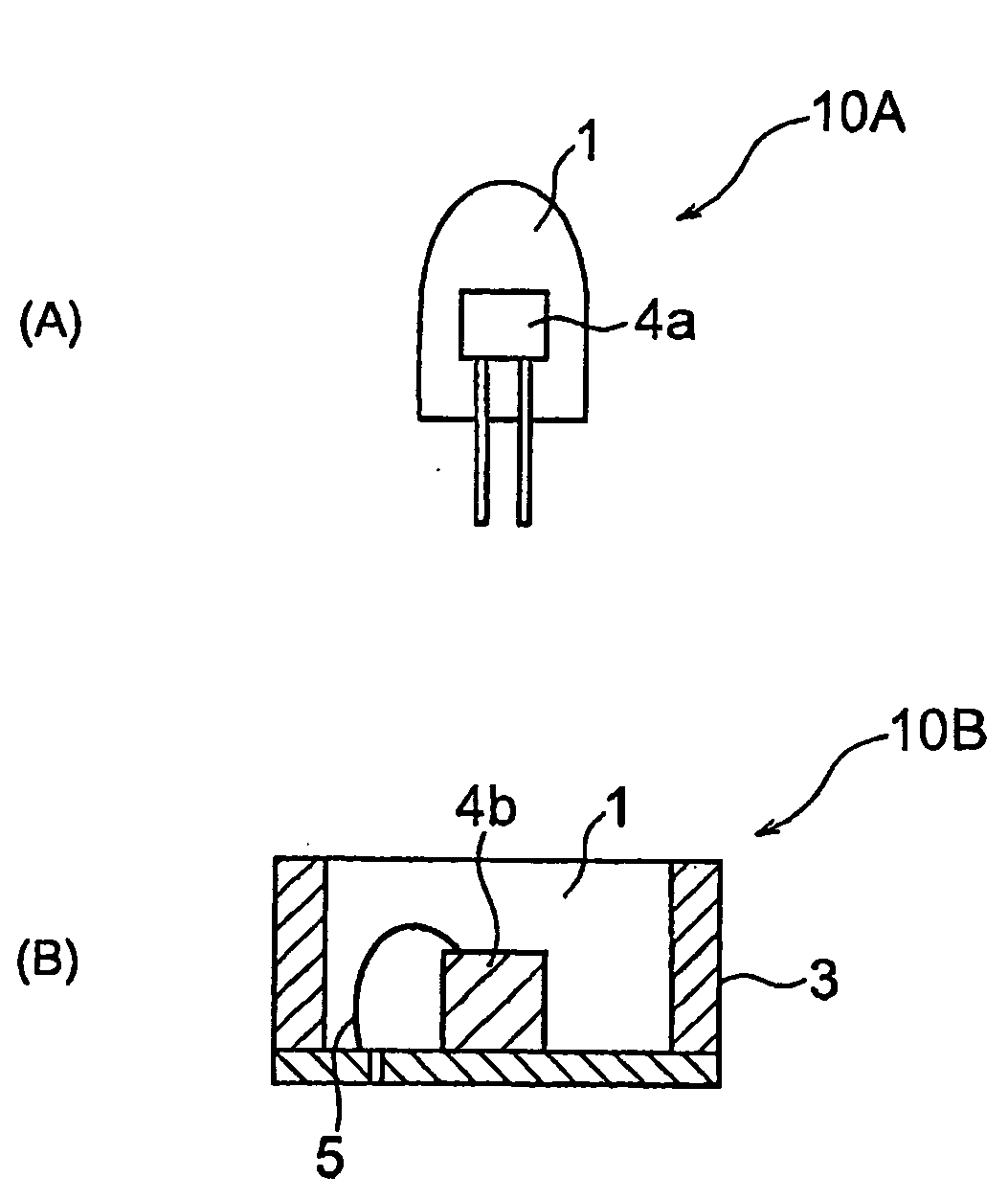

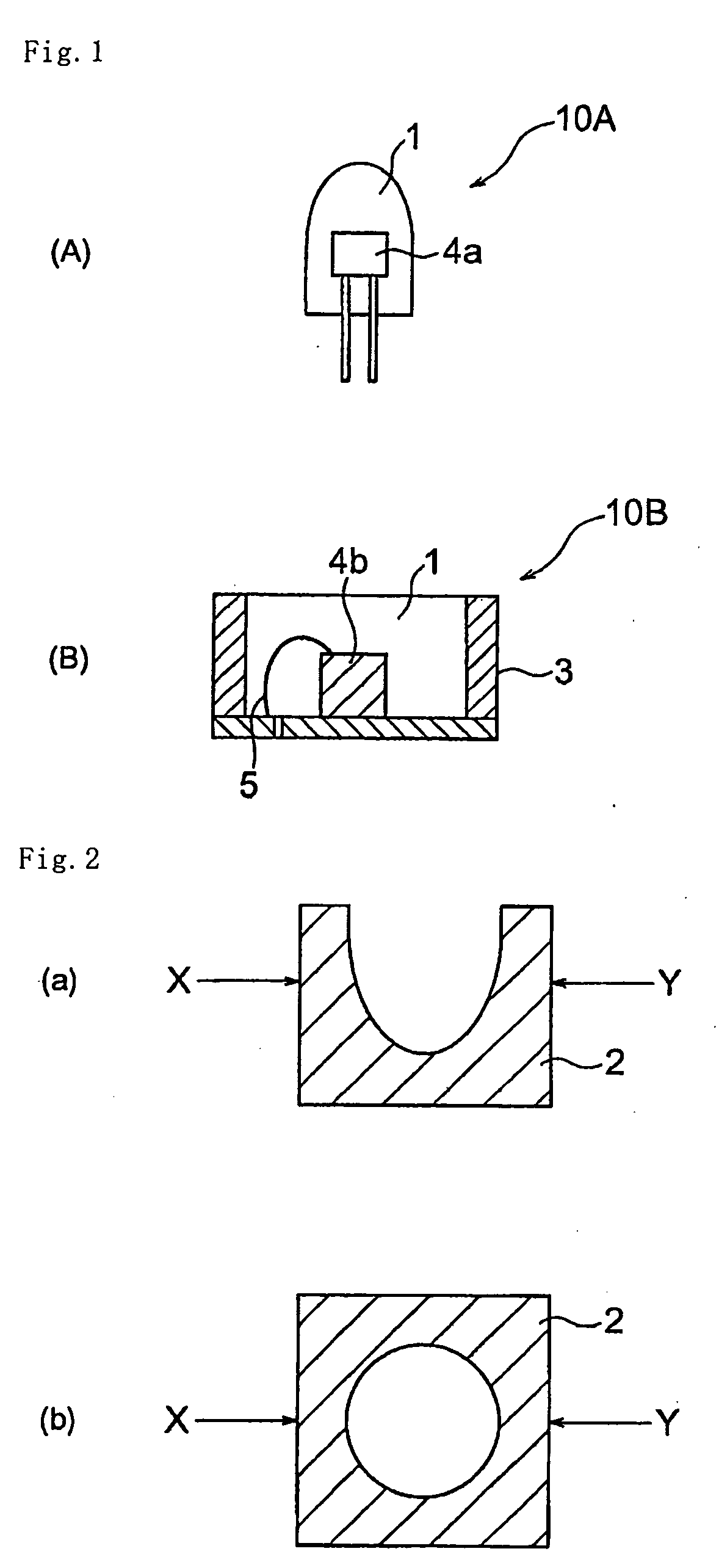

Sealing material for optical element and sealed optical element

InactiveUS20080249278A1Outstanding transparencyOutstanding crack resistanceOther chemical processesSolid-state devicesCrack resistanceHalogen

Owner:LINTEC CORP

Polylactic acid/polyester alloy and preparation method thereof

The invention relates to a polylactic acid / polyester alloy and a preparation method thereof. The polylactic acid / polyester alloy comprises the following components in percentage by weight: polylactic acid, polyester, a compatilizer, a flexibilizer, an antioxidant and a lubricant. The preparation method comprises the following steps: firstly, proportioning the raw materials and mixing at a room temperature; and respectively carrying out melting extrusion, carrying out ultrasonic treatment at the first late stage, extruding at the second stage and pelletizing, so as to obtain degradable, high-impact-resistant and high-heat-resistant polylactic acid / polyester alloy. Compared with an existing method, the controllable ultrasonic treatment is utilized; and a similar polylactic acid-g-polyester structure is formed by in-situ reaction, so that the heat resistance of the polyester and the biodegradability of the polylactic acid are reserved; and meanwhile, a toughening system with a core-shell structure is formed in an alloy system through interface interaction of a special toughening compatilizer, so that the alloy product with high impact resistance, high heat resistance and high biodegradability can be obtained.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

Polyester film for forming

InactiveCN1845951AGood formabilityIncrease elasticityOther domestic articlesHeat resistanceCopolyester

Owner:TOYO TOYOBO CO LTD

Acrylic flame retardant adhesive composition and acrylic flame retardant adhesive sheet

Owner:SHIN ETSU CHEM IND CO LTD

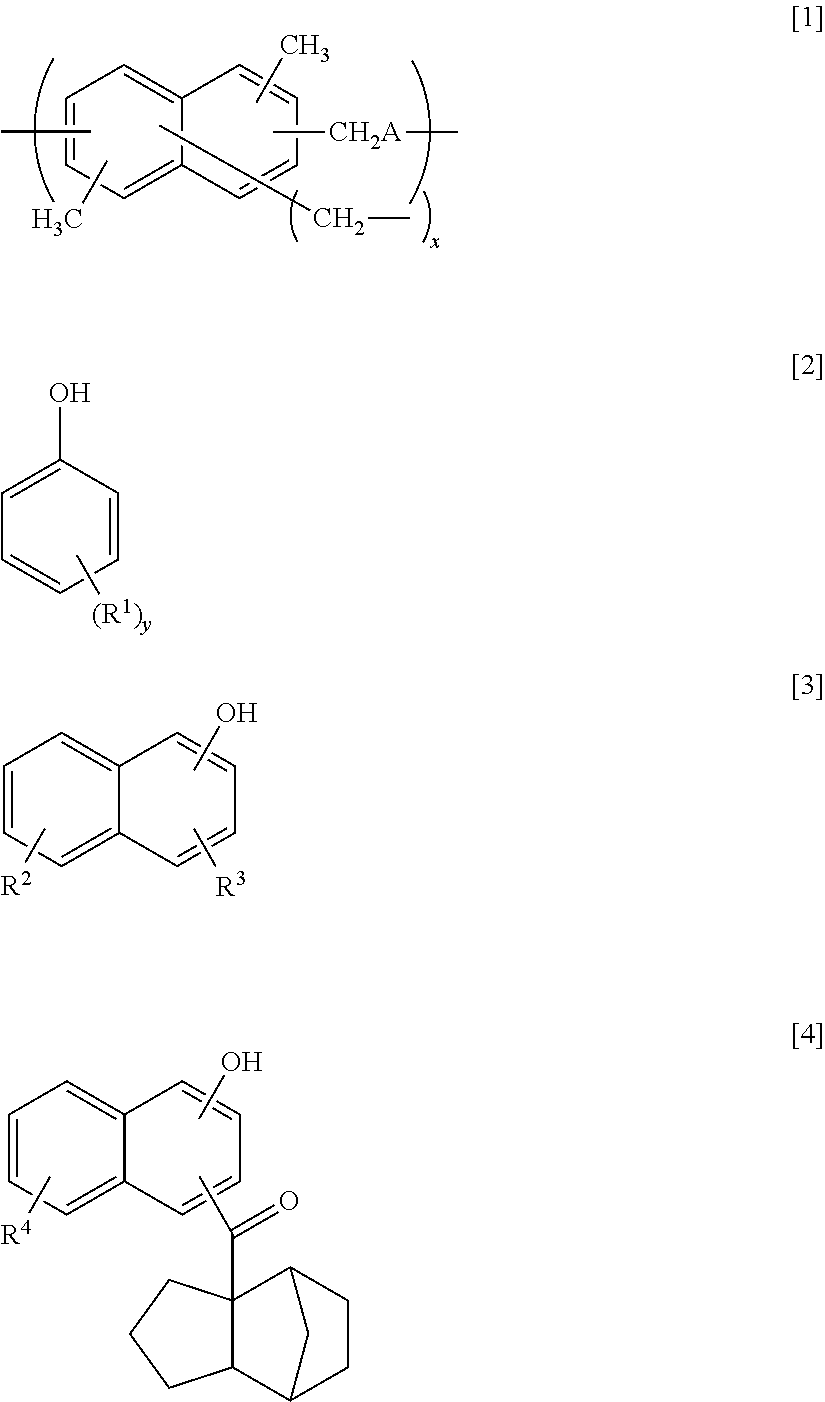

Modified naphthalene formaldehyde resin, tricyclodecane skeleton-containing naphthol compound and ester compound

ActiveUS20110009574A1Improve heat resistancePreparation from carboxylic acid halidesOrganic compound preparationFiberResist

Owner:MITSUBISHI GAS CHEM CO INC

Environmental-friendly foaming plastic and preparing method thereof

Owner:ANHUI GUANGYUAN TECH DEV

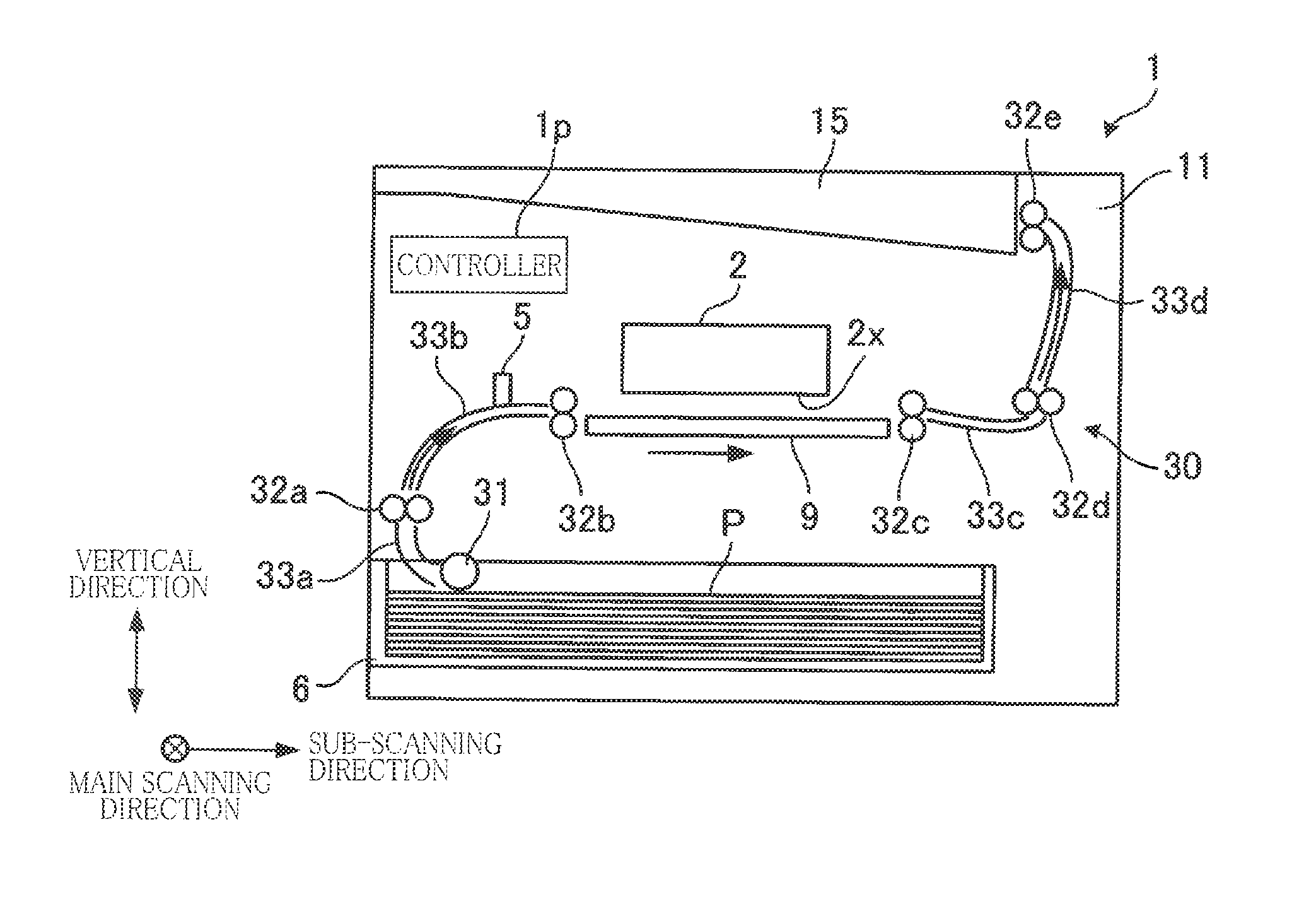

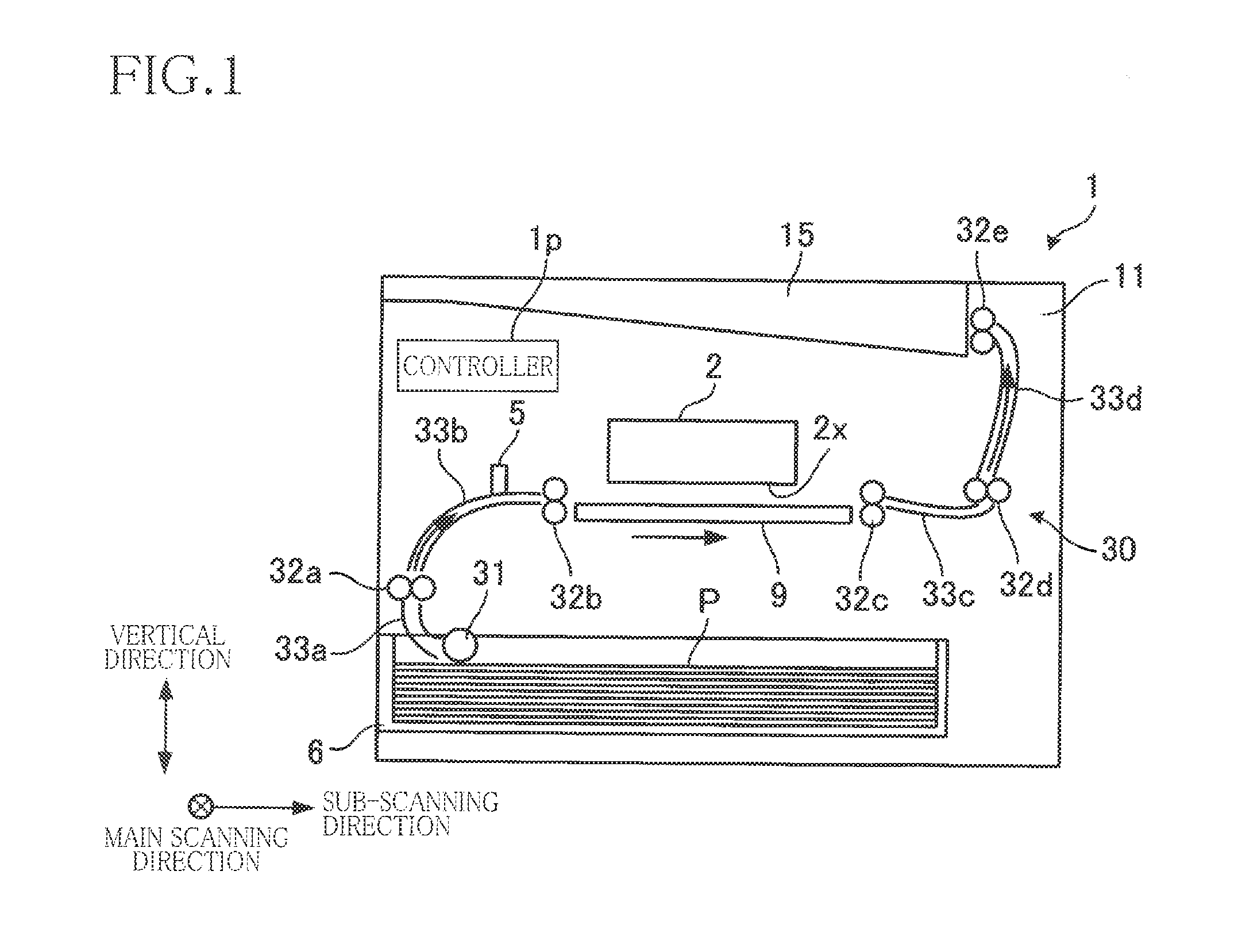

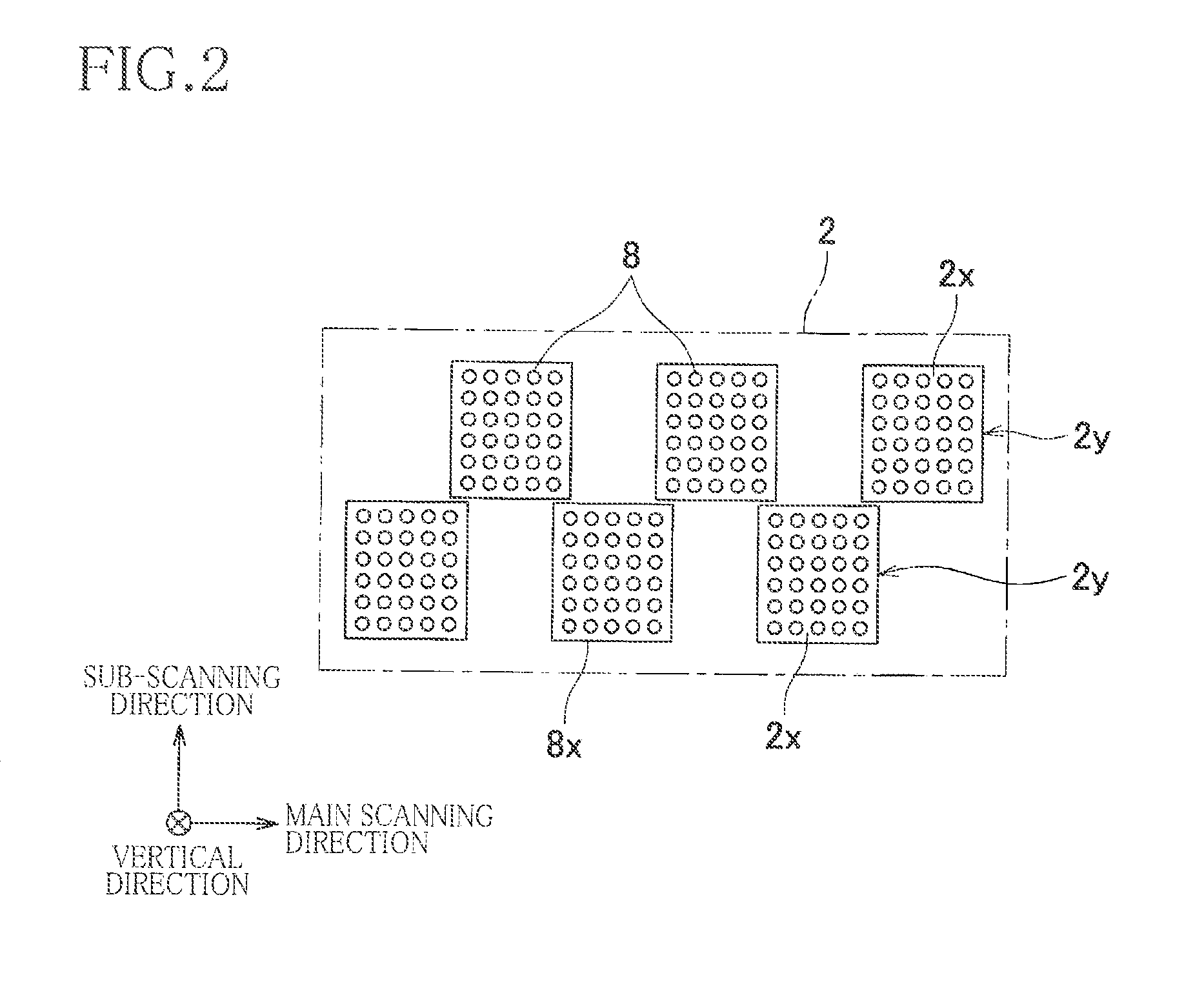

Liquid ejection apparatus

ActiveUS20140292887A1Reduce the differenceDeterioration can be suppressedInking apparatusOther printing apparatusHeat resistanceEngineering

Owner:BROTHER KOGYO KK

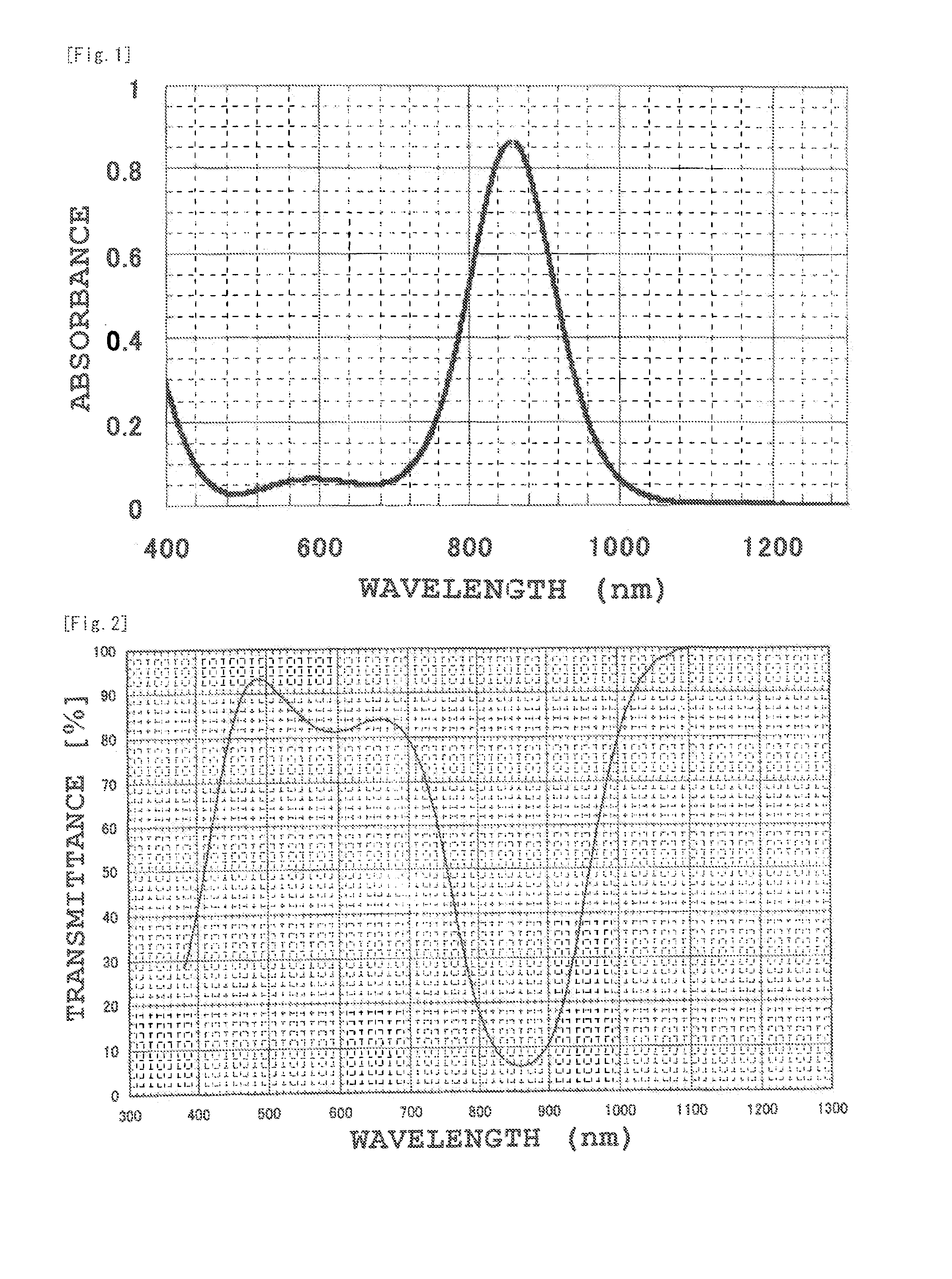

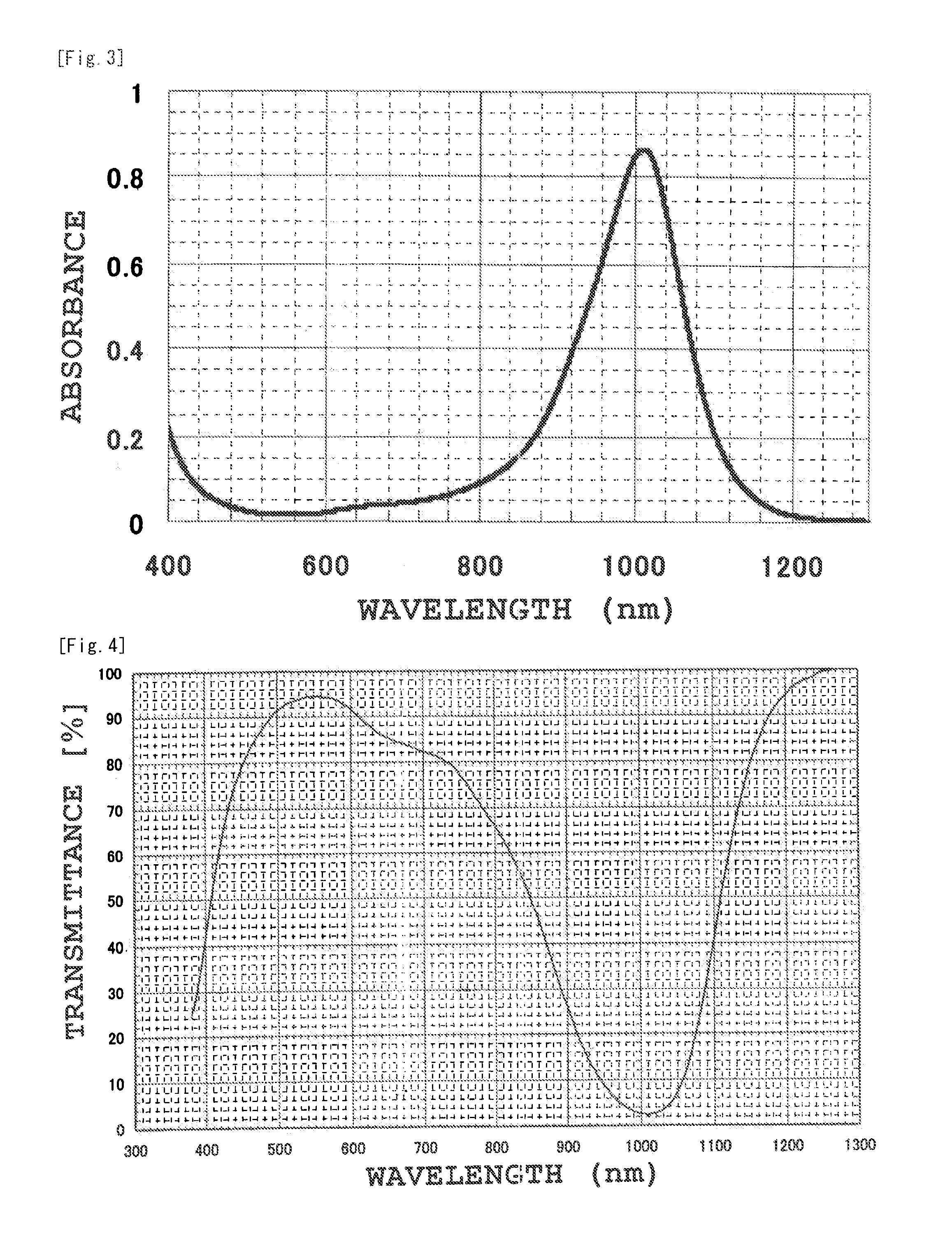

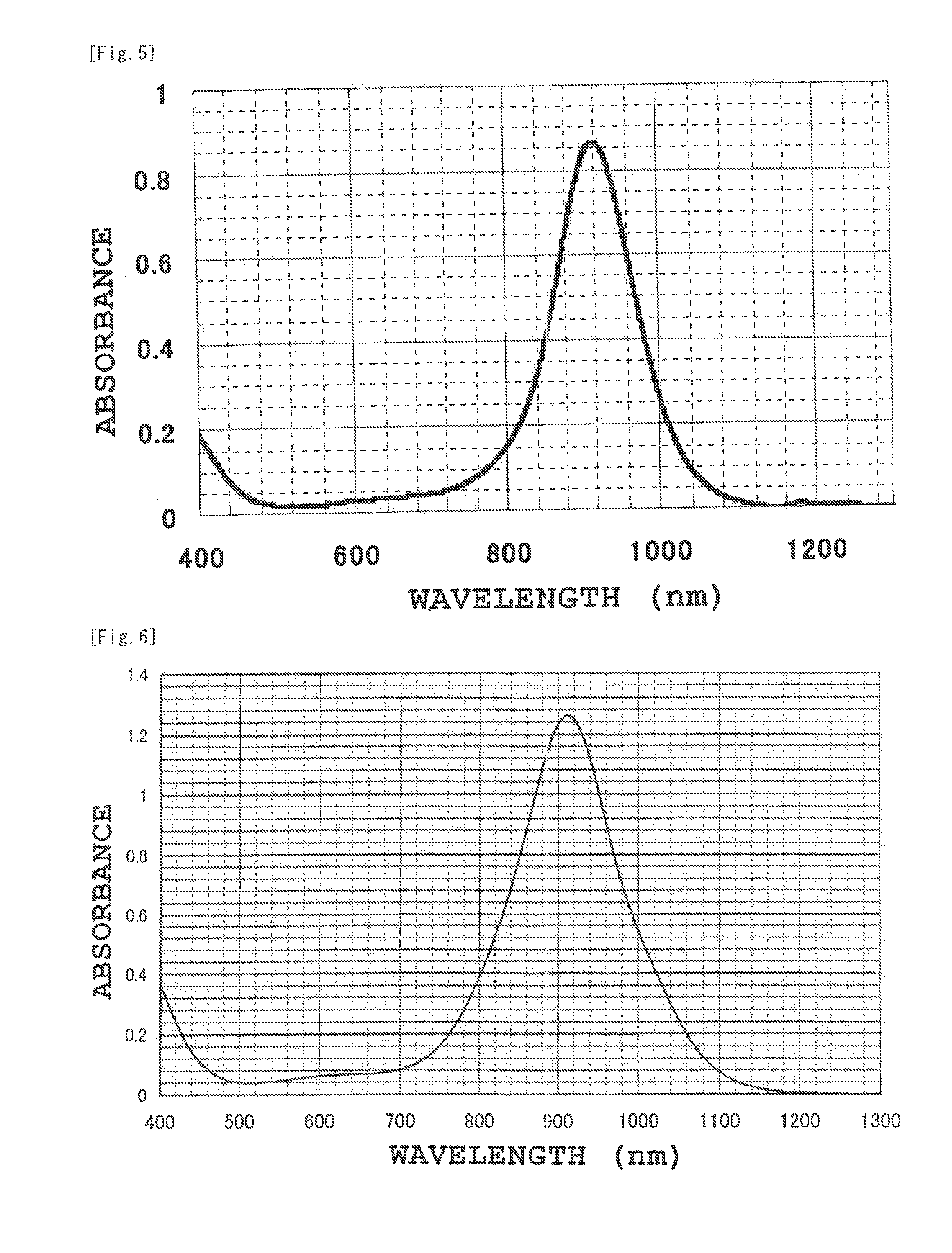

Near infrared ray-absorbable dye composition, and near infrared ray-absorbable filter and adhesive agent both comprising the composition

InactiveUS20100019212A1Improve light resistanceHigh visible light transmittanceNon-macromolecular adhesive additivesAzo dyesInfraredAryl

Owner:API CORP (JP)

Oxidation-resistant polymer film with memory function

InactiveCN105670128ASimple componentsLow costFixed capacitor dielectricBulk chemical productionPolymer scienceOxidation resistant

Owner:汤卓群

Green high-yield planting technology for mustard

InactiveCN105453848AImprove resistance to pests and diseasesReduce the frequency of spraying pesticidesHorticultureHeat resistanceThinning

The invention relates to a green high-yield planting technology for mustard, and belongs to the technical field of vegetable planting, and particularly relates to a planting method for mustard. The invention provides the green high-yield planting technology for mustard, wherein the technology is green and environmental-friendly and high in yield. The green high-yield planting technology for mustard is characterized by comprising the following steps of: I, in a seeding time, leaf mustard which is taken as a food in young plant, for example Nanfeng mustard, is strong in heat resistance; II, sowing and seedling raising: a seedbed must be fine and level and decomposed farm manure is sufficiently supplied; III, seedbed construction: before seed treatment, firstly constructing the seedbed, so that young seedlings live in a good environment; IV, fixed planting: the leaf mustard is relatively wide in soil application scope, but Brassica juncea (L.) Czerniak, for the sake of high yield, sandy loam soil for rice is selected, and a base fertilizer is sufficiently applied; and V, seedling stage management: immediately performing thinning, wherein the distance between seedlings is reserved at 4-5 cm, so that leaves are adumbral to each other; lighting the seedlings to form seedlings till the seedlings are 15 cm, and performing fixed planting when the seedlings have 3-5 true leaves.

Owner:李忠久

Heat-resistant modified asphalt

Owner:WUJIANG HUAWEI SPECIAL OIL

Special adhesive sticker for ethylene propylene diene monomer heat resistance conveyor belt and preparation method of special adhesive sticker

Owner:BAODING HUAYUE RUBBER BELTS

Cracking-resistant iron-base powder metallurgy material used for valve and preparation method of cracking-resistant iron-base powder metallurgy material

The invention discloses a cracking-resistant iron-base powder metallurgy material used for a valve. The cracking-resistant iron-base powder metallurgy material used for the valve is prepared from the following raw materials in parts by weight: 0.2-0.4 part of stearic acid boron, 3-4 parts of aluminum nickel alloy powder, 3-4 parts of nickeling silicon carbide crystal whisker, 3-4 parts of TiO2, 1-1.5 parts of fumed silica, 0.4-0.6 part of palm wax, 1-2.6 parts of nanometer boron fiber, 1-1.5 parts of cordierite powder, 2-2.6 parts of aluminium titanate, 0.3-0.4 part of silane coupling agent kh-550, a proper quantity of 1% sodium carbonate solution, a proper quantity of water, 2.5-3.5 parts of sodium hypophosphite, 0.4-0.6 part of polyethylene glycol, 30-35 parts of 2mMol / L copper sulphate solution, 2-3 parts of wetting accessory ingredient and 77-82 parts of iron powder. The nanometer boron fiber and the nickeling silicon carbide crystal whisker are added into the valve material to increase compatibility and prevent cracking while the toughness, the heat resistance and the impact strength resistance of valve materials are increased.

Owner:TONGLING JINGWEI FLUID SCI & TECH

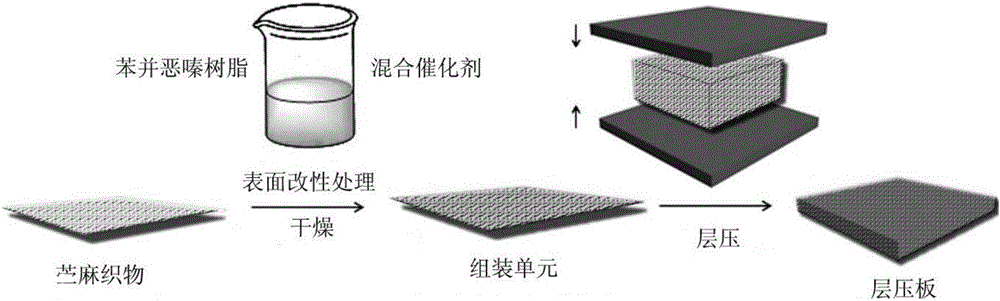

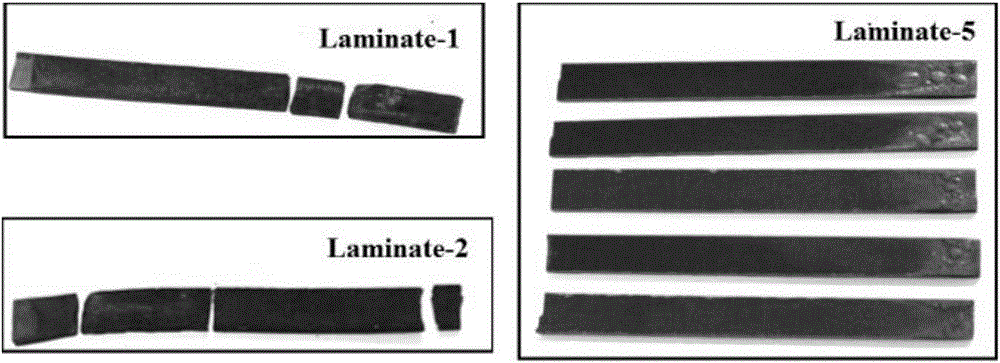

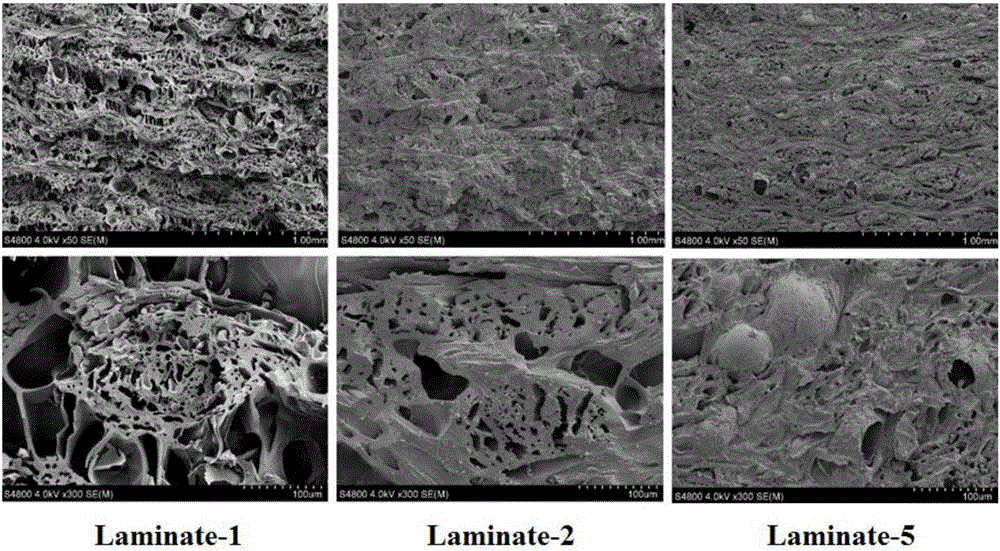

Flame-retardant modified ramie fabric/benzoxazine resin laminated board and preparation method thereof

ActiveCN106079723AImprove flame retardant performanceImprove performanceLamination ancillary operationsLayered product treatmentEngineeringFire retardant

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Photocurable fluorinated copolymer composition

InactiveUS20140212673A1High transparencyExcellent abrasion resistanceSynthetic resin layered productsPolyurea/polyurethane coatingsSilane compoundsEpoxy

Owner:ASAHI GLASS CO LTD

Flame-retardant and wear-resisting rubber material for borehole cable sheath and preparation method of flame-retardant and wear-resisting rubber material

InactiveCN105175824AImprove high temperature resistanceImprove wear resistanceRubber insulatorsPolymer scienceDibenzoyl Peroxide

Owner:华泓喆

Method for synthesizing heat resisting type vinyl aromatic monomer polymer

Owner:ZHEJIANG UNIV

Conductive polarized film, method for manufacturing thereof and display or input device including thereof

InactiveUS20120028013A1Excellent see-through visibility and heat resistanceLow resistivityVacuum evaporation coatingSputtering coatingOrganic dyeHeat resistance

The present invention to provide a conductive polarized film that has excellent see-through visibility and heat resistance, and low resistivity. The conductive polarized film of the present invention has a support film, an organic dye film, a silicon nitride layer and a transparent conductive film, in that order.

Owner:NITTO DENKO CORP

Thermoplastic resin adhesive film

InactiveCN102942878AExtended service lifeImprove long-term stabilityFilm/foil adhesivesPrinted circuit detailsVitrificationDielectric loss

The invention relates to a thermoplastic resin adhesive film and application thereof. The adhesive film comprises symmetrical polyphenylene ether molecules, is not sticky and has low dielectric constant and dielectric loss, and a high-frequency multilayer printed circuit board prepared by the adhesive film has high glass transition temperature, excellent heat resistance and flame resistance and an environmental protection function. The adhesive film serves as a thermally conductive and insulating layer of the high-frequency printed circuit board, so that the printed circuit board has the advantages of high thermal conductivity, quick signal transmission, low loss and the like.

Owner:彭代信

Intake and exhaust valve raceway and intake and exhaust valve assembly of engine

ActiveCN106282783AReduce wearSolve the problem of gap exceptionMachines/enginesLift valveExhaust valveHeat resistance

The invention relates to an intake and exhaust valve raceway and intake and exhaust valve assembly of an engine. The intake and exhaust valve raceway and intake and exhaust valve assembly comprises an intake valve raceway of the engine and an intake valve matched with the intake valve raceway and an exhaust valve raceway and an exhaust valve matched with the exhaust valve raceway; the intake and exhaust valve raceways contain materials of Ni-Co-Mo-Cr and are manufactured by adopting a powder metallurgy technique; the main contents of the intake valve are Cr-Si-Mn-P or Cr-Mn-Ni-N; the main contents of the exhaust valve are Cr-Mn-Ni-Nb-W, or bead welding is performed on the disc part of the exhaust valve with the materials of Cr-W-Ni-Fe-Mo; and the problem of mechanical tappet clearance abnormity of the natural gas engine is solved by lowering abrasion loss between the intake valve raceway and the intake valve as well as abrasion loss between the exhaust valve raceway and the exhaust valve. According to the intake and exhaust valve raceway and intake and exhaust valve assembly, abrasion-resistance, heat-resistance and radial crushing strength of the intake valve raceway and the exhaust valve raceway are improved; and quality problems of valve clearance abnormity and the like caused by abnormal abrasion and deformation between the intake valve raceway and the intake valve as well as between the exhaust valve raceway and the exhaust valve are solved.

Owner:SMAPOW ENGINE

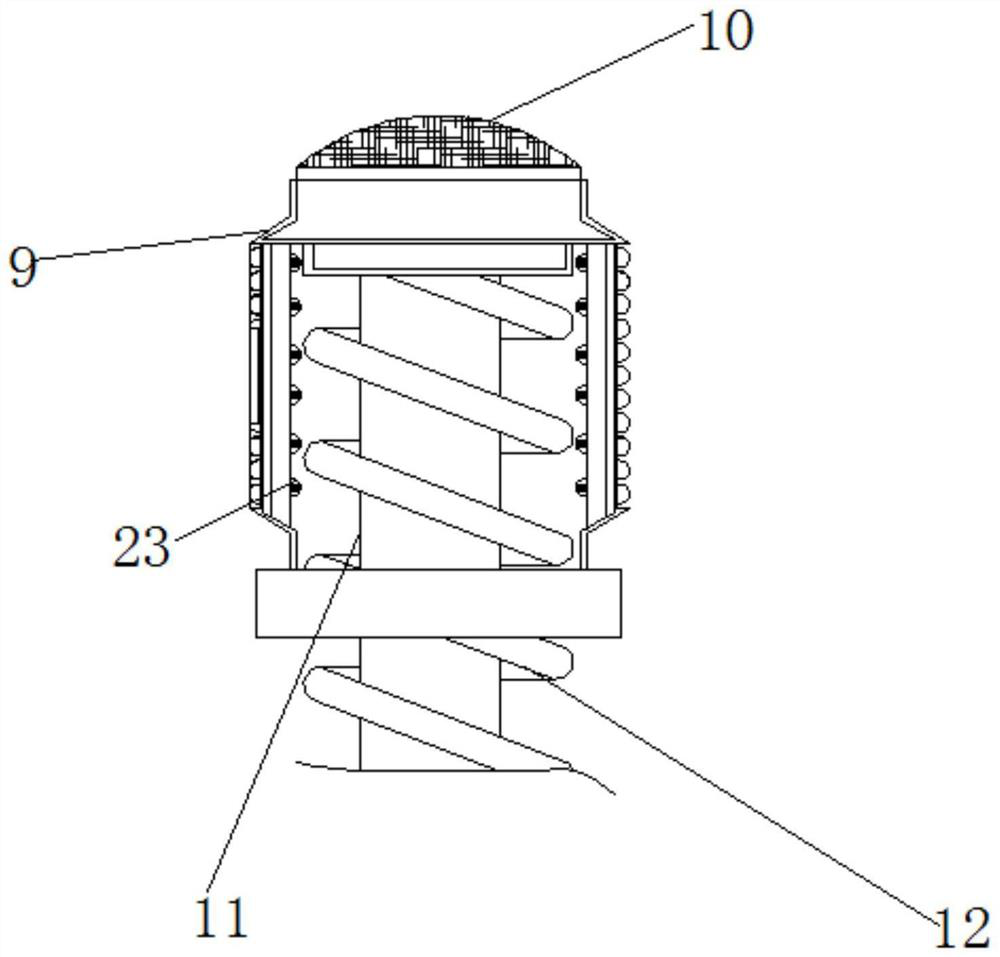

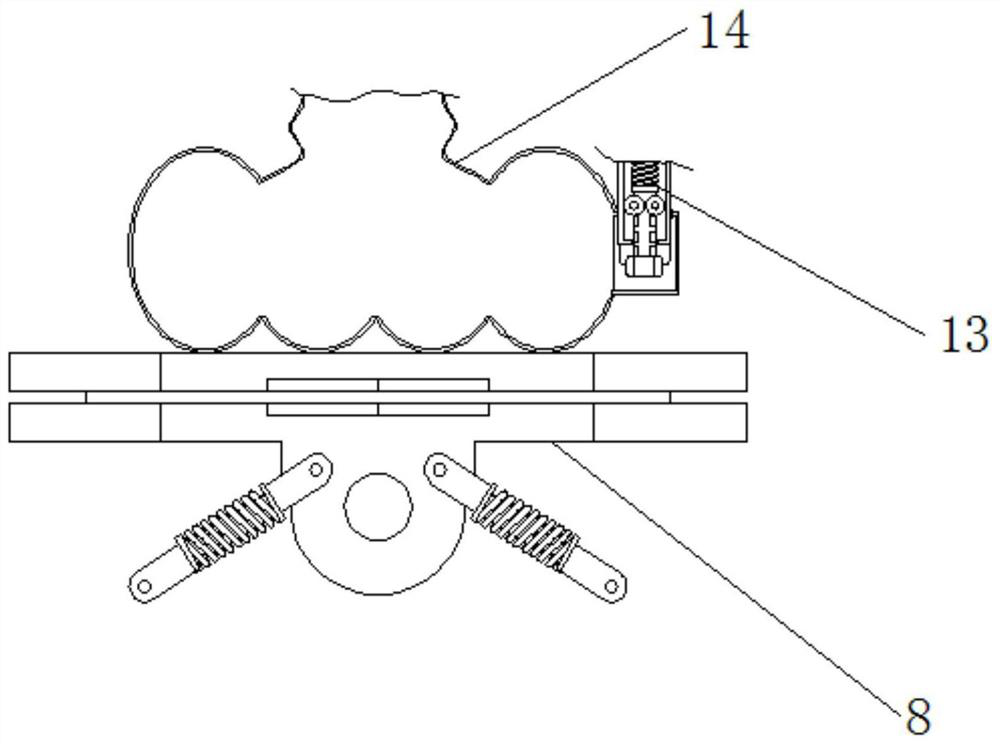

Sound detection device using magnetorheological fluid

Owner:深圳市音鸿电子有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap