Thin film and thin film laminate comprising the same

a thin film and laminate technology, applied in the direction of synthetic resin layered products, transportation and packaging, other domestic articles, etc., can solve the problems of water resistance, no plastic substrates which can withstand heat treatment at such high temperatures, and breakage, and achieve excellent properties and high gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Production of Organized Clay

[0047]After dispersing 5 g of tetradecyl trimethyl ammonium bromide as the hydrophobic cationic compound in 50 g of pure water, 5 g of synthesized smectite (marketed by Kunimine Industries Co., Ltd., trade name: Smecton SA) as the heat-resistant flakes was added, and completely dispersed and swelled. After removing the liquid contained in the mixture by carrying out a solid-liquid separation using a centrifugal separator, 50 g of pure water was further added, dispersed, and the solid and liquid were separated again. After repeating the dispersion and the solid-liquid separation until foam was not formed, the moisture was thoroughly removed by a dryer. Thereby, hydrophilic exchangeable cations contained in the clay were exchanged with tetradecyl trimethyl ammonium ions. Organized clay having swelling properties to toluene, which is a non-polar solvent, was obtained.

[0048](Production of a Clay Thin Film)

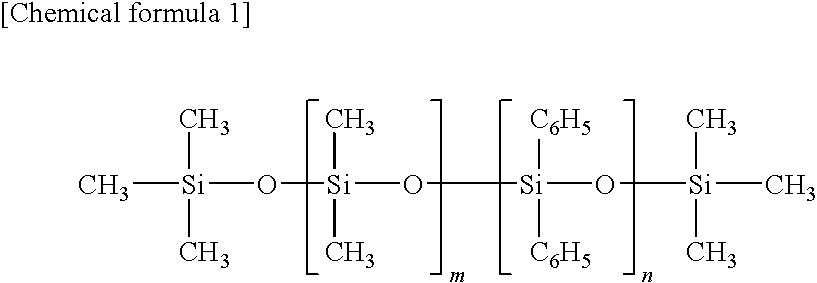

[0049]The obtained organized clay was crushed. 5 g of the

example 2

[0050]A thin film of this example was prepared in a manner identical to that of Example 1 of the present invention, except that octadecyl triphenyl phosphonium bromide was used as the hydrophobic cations.

example 3

[0051]A thin film of this example was prepared in a manner identical to that of Example 1 of the present invention, except that 2 g of thermosetting epoxy resin was added at the same time as adding dimethyl silicone oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap