Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about "Fibre mechanical structures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optical waveguide monitoring

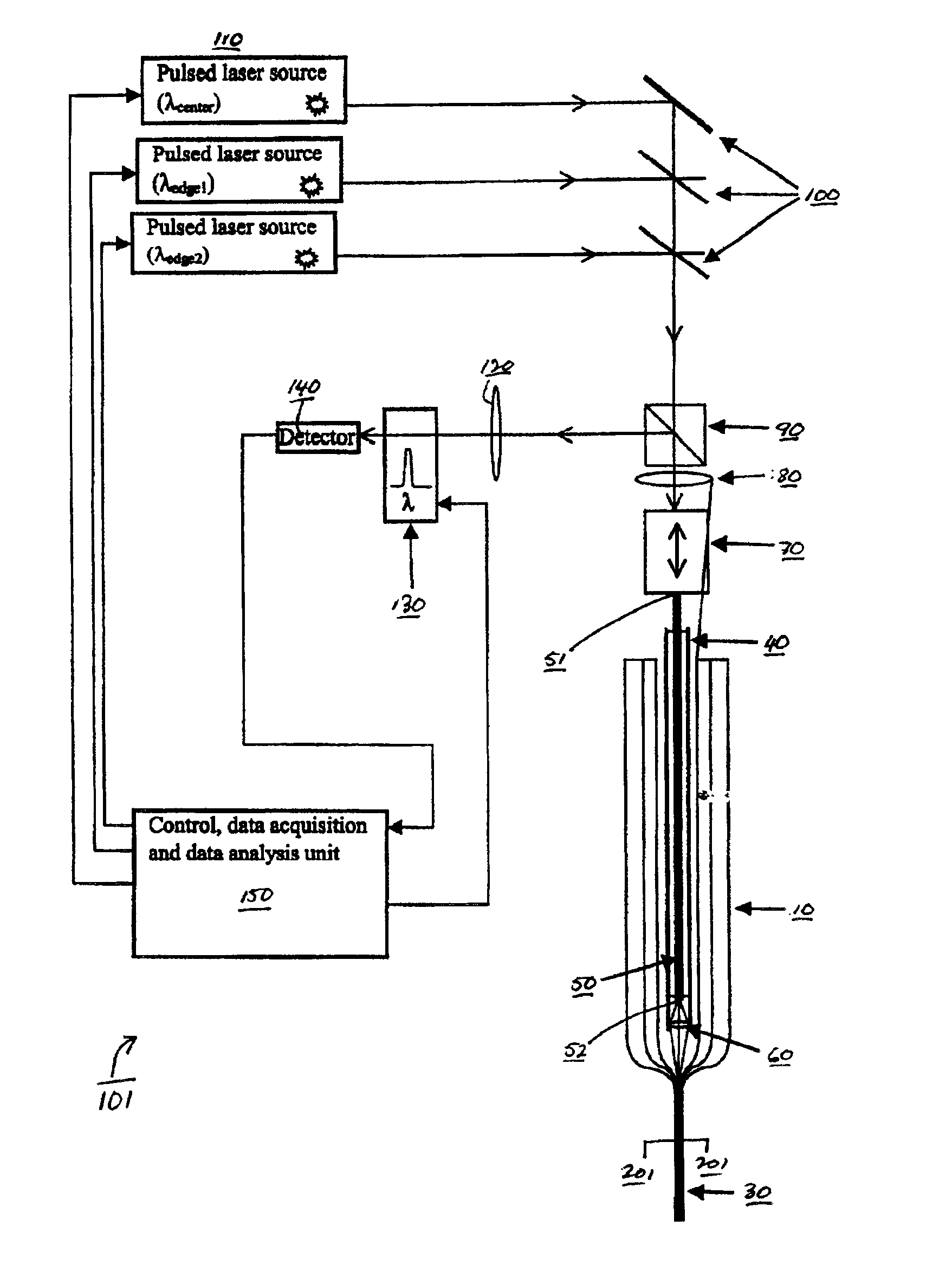

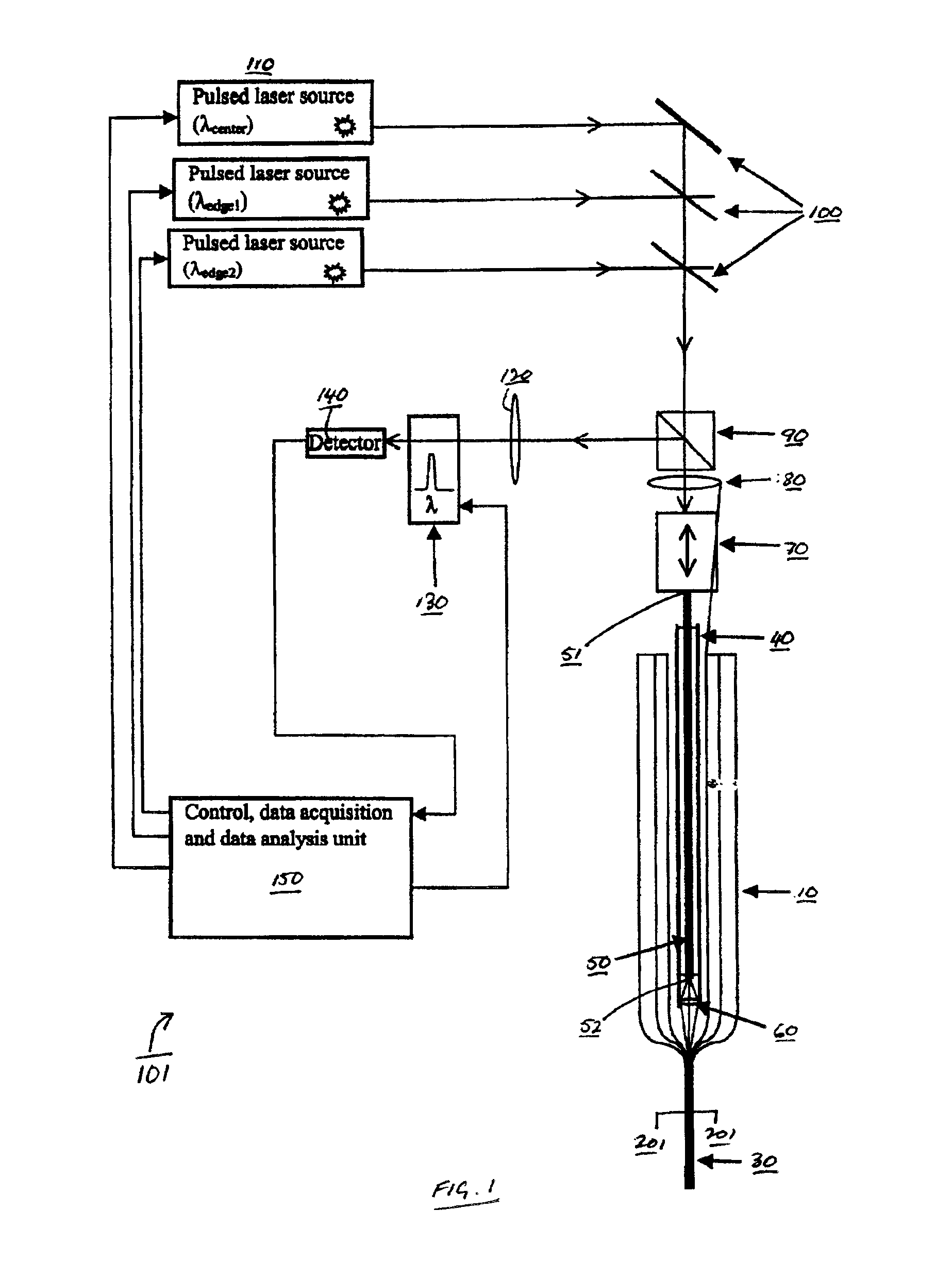

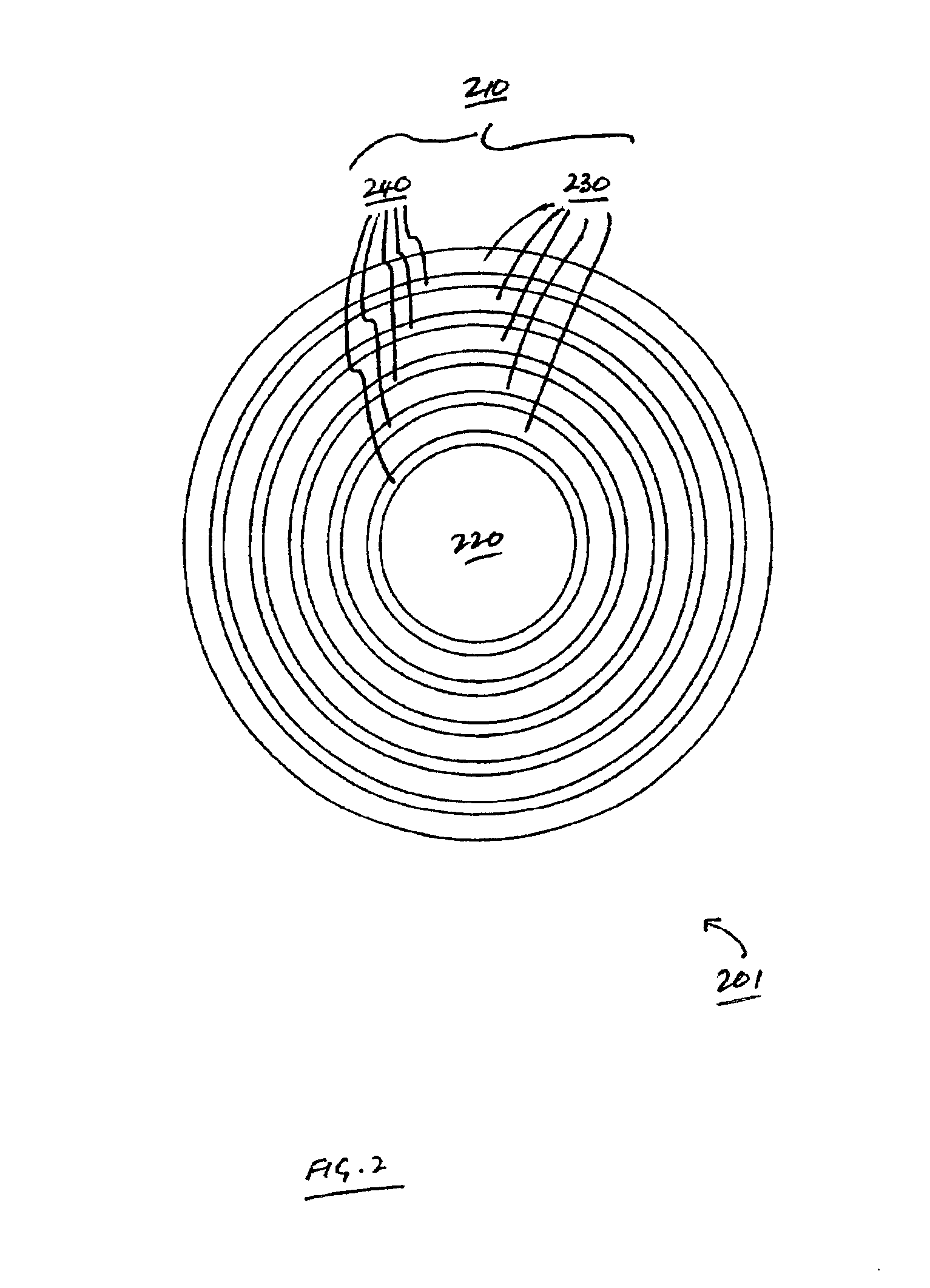

InactiveUS6879386B2Cladded optical fibreMaterial analysis by optical meansPhotonic crystalEngineering

Owner:OMNIGUIDE

Active Energy Ray-Curable Organopolysiloxane Resin Composition, Optical Transmission Component, And Manufacturing Method Thereof

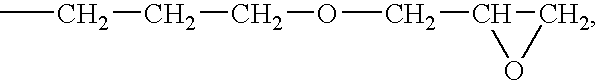

ActiveUS20080032061A1Good adhesionHigh optical transmittanceCladded optical fibreFibre mechanical structuresChemistrySilorane Resins

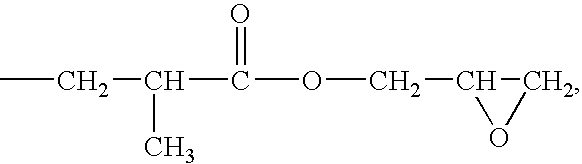

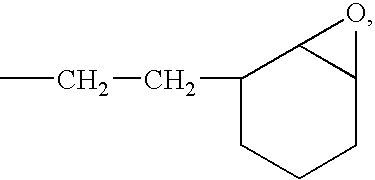

An active energy ray (e.g. UV rays)-curable organopolysiloxane resin composition comprises (A) 100 parts by weight of an organopolysiloxane resin containing epoxy groups and aromatic hydrocarbon groups, (B) 0.05 to 20 parts by weight of a photo acid generator, (C) 0.01 to 20 parts by weight of a photosensitizer or photo-radical generator, and (D) 0 to 5,000 parts by weight of an organic solvent. An optical transmission component made of the above-mentioned composition cured by irradiation with active energy rays (for example, UV rays). A method for manufacturing an optical transmission component by irradiating the above-mentioned composition with active energy rays (for example, UV rays).

Owner:DOW TORAY CO LTD +1

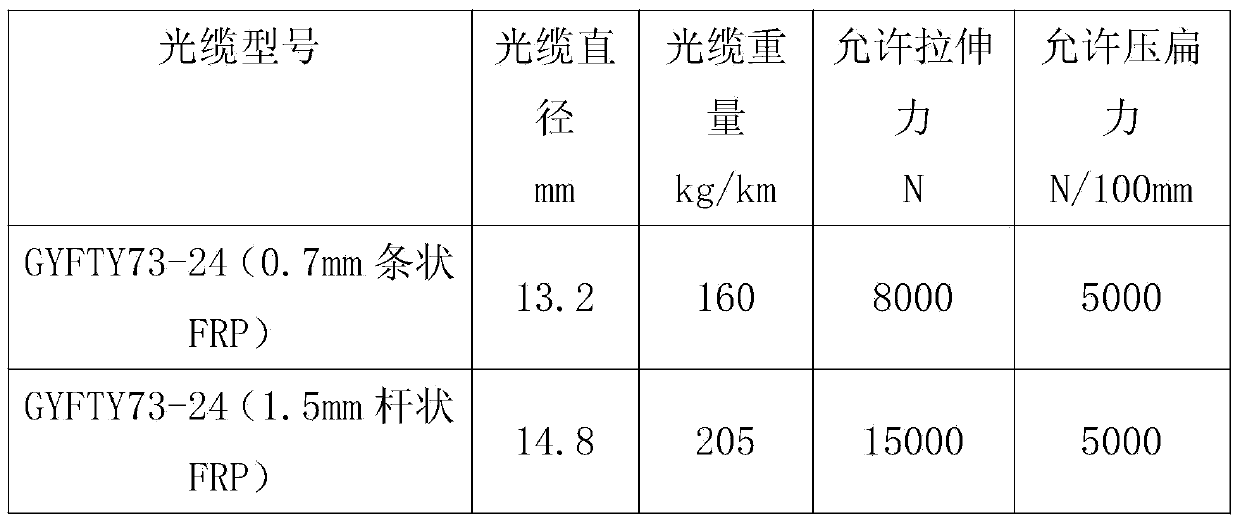

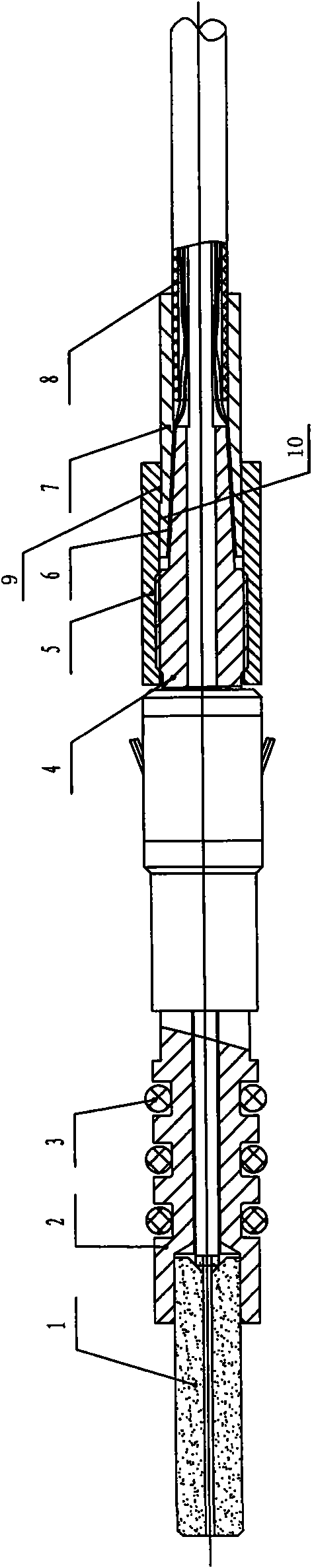

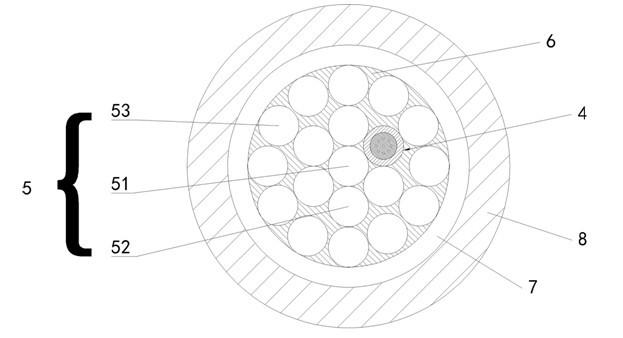

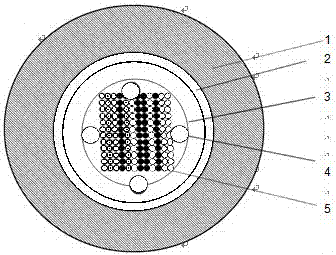

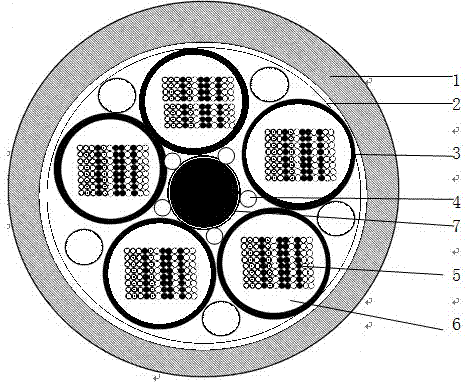

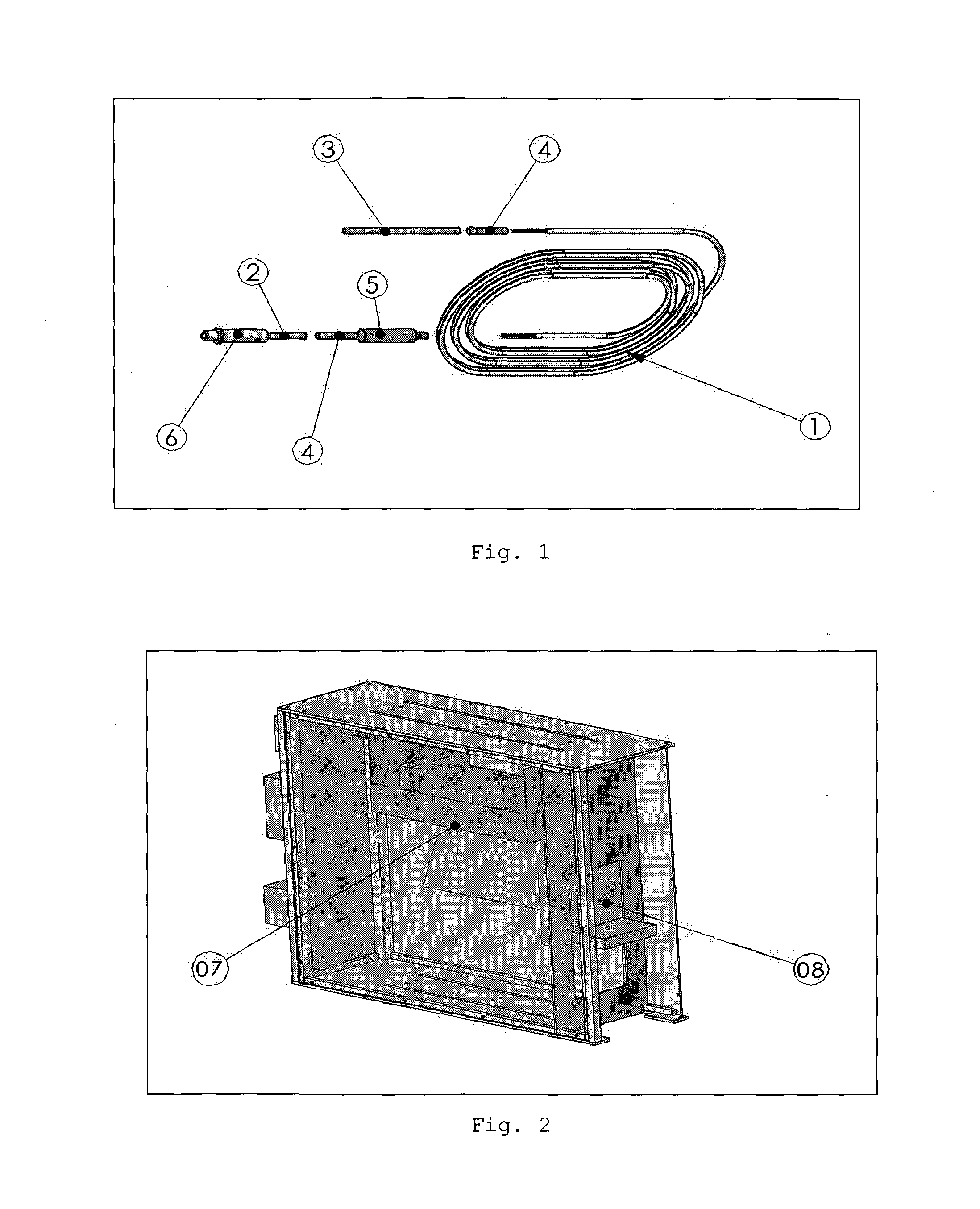

Reinforced type all-dielectric and rodent-resistant cable and manufacturing process thereof

InactiveCN103728701AGood anti-rat effectReduce weightFibre mechanical structuresOptical communicationFiber

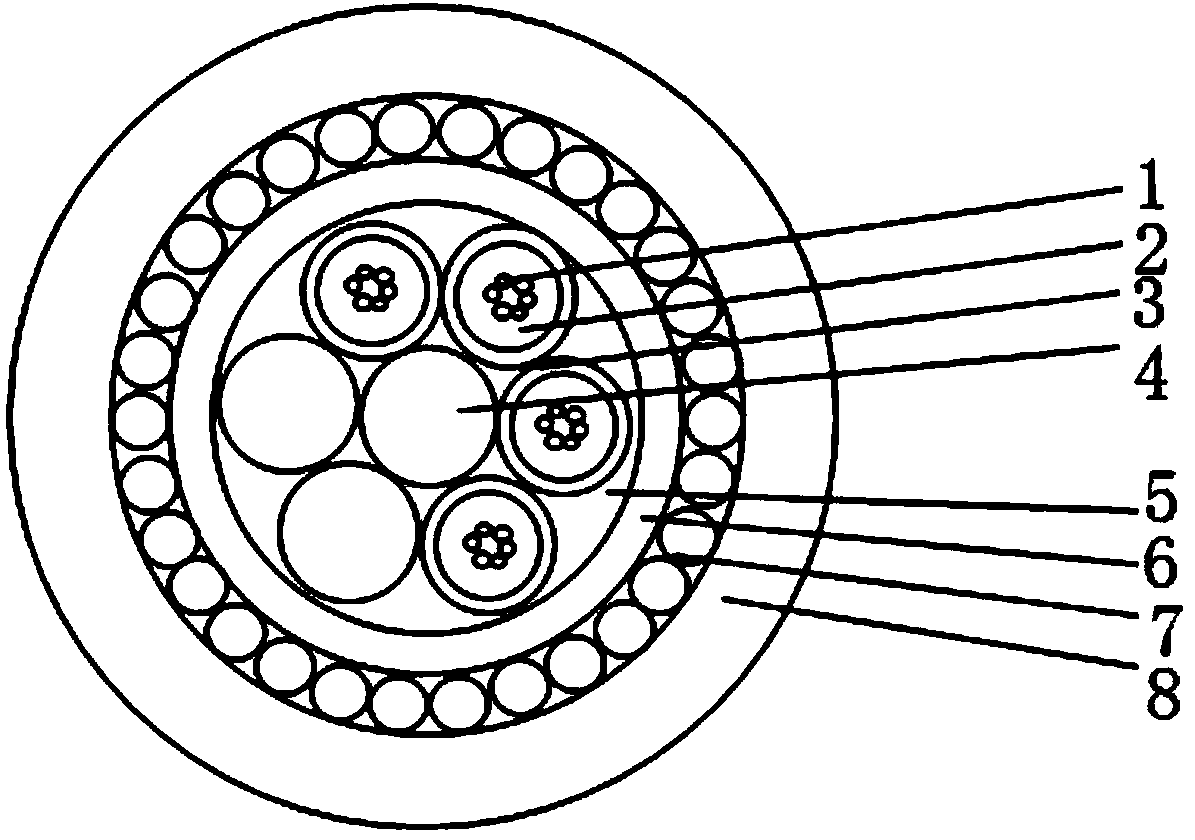

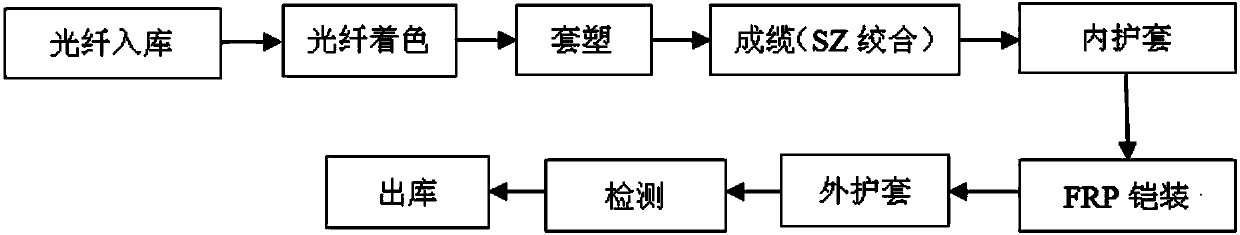

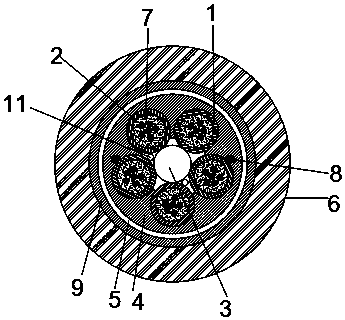

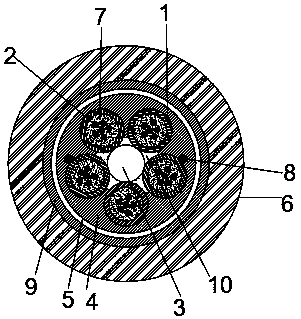

The invention discloses a reinforced type all-dielectric and rodent-resistant cable and a manufacturing process of the reinforced type all-dielectric and rodent-resistant cable, and relates to the technical field of communication cables. The reinforced type all-dielectric and rodent-resistant cable comprises multiple optical fibers, fiber paste, a loose casing pipe, a center reinforcement piece, a cable core water-resistant compound, an inner sheath, multiple rod-shaped FRPs 7 and an outer sheath, wherein the multiple rod-shaped FRPs 7 are arranged between the inner sheath and the outer sheath; the multiple optical fibers are arranged inside the inner sheath; the loose casing pipe is arranged outside the optical fibers; the position between the optical fibers and the loose casing pipe is filled with the fiber paste; the position between the loose casing pipe and the inner sheath is filled with the cable core water-resistant compound; the center reinforcement piece is arranged in the center of the optical fibers. According to the reinforced type all-dielectric and rodent-resistant cable and the manufacturing process of the reinforced type all-dielectric and rodent-resistant cable, the weight of FRP sheathed rodent-resistant cables is reduced greatly, the difficulty of laying construction is not added under the condition that the cables have the good rodent-resistant effect, and the solution is provided for optical communications at areas with serious damage caused by rodents, such as mountainous areas and sewer lines of cities.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

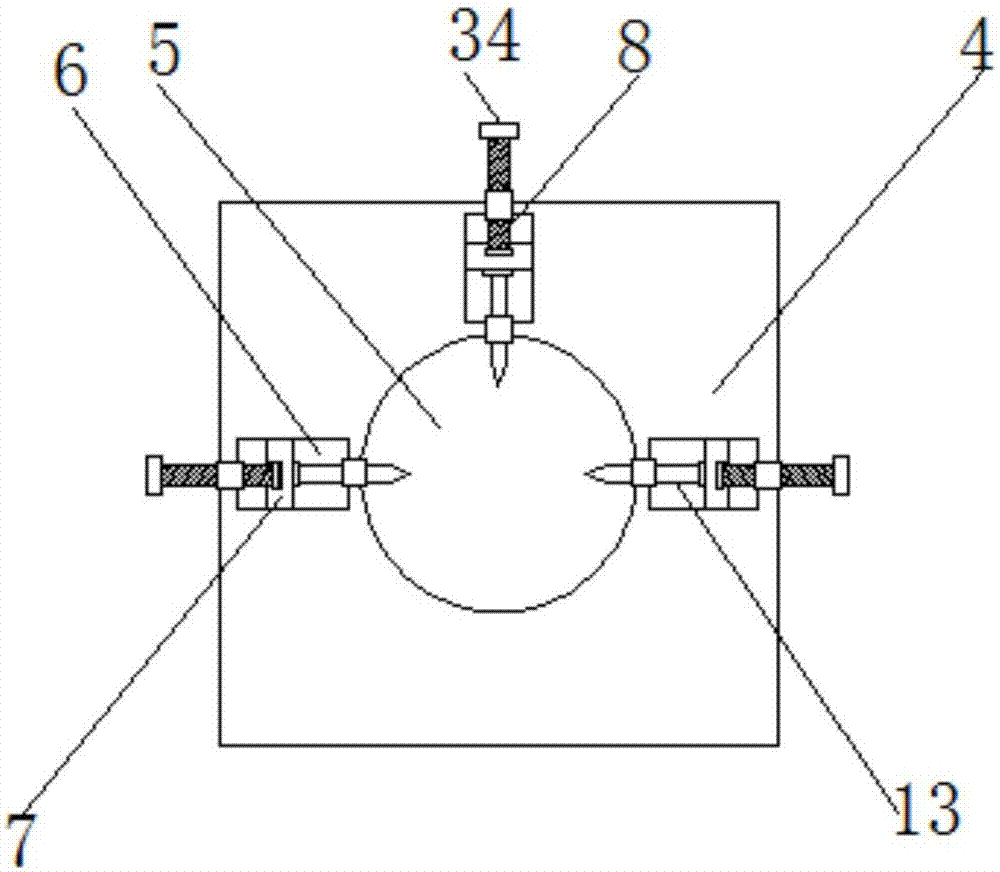

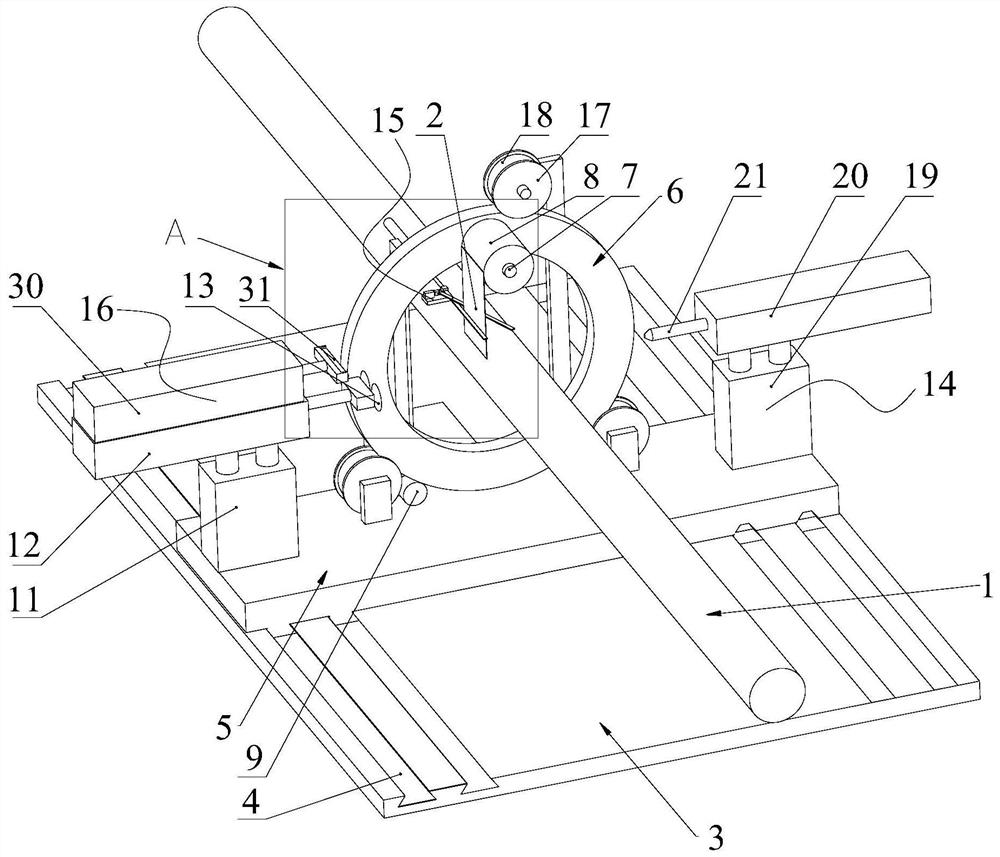

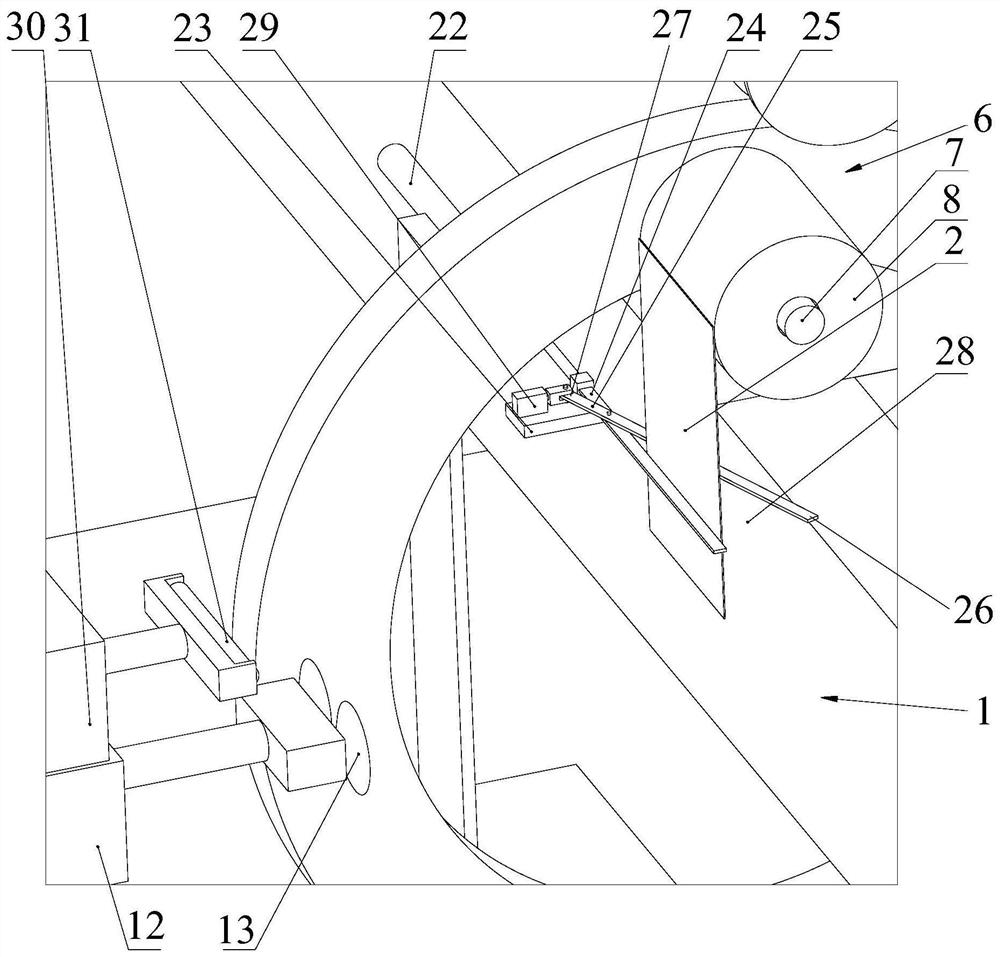

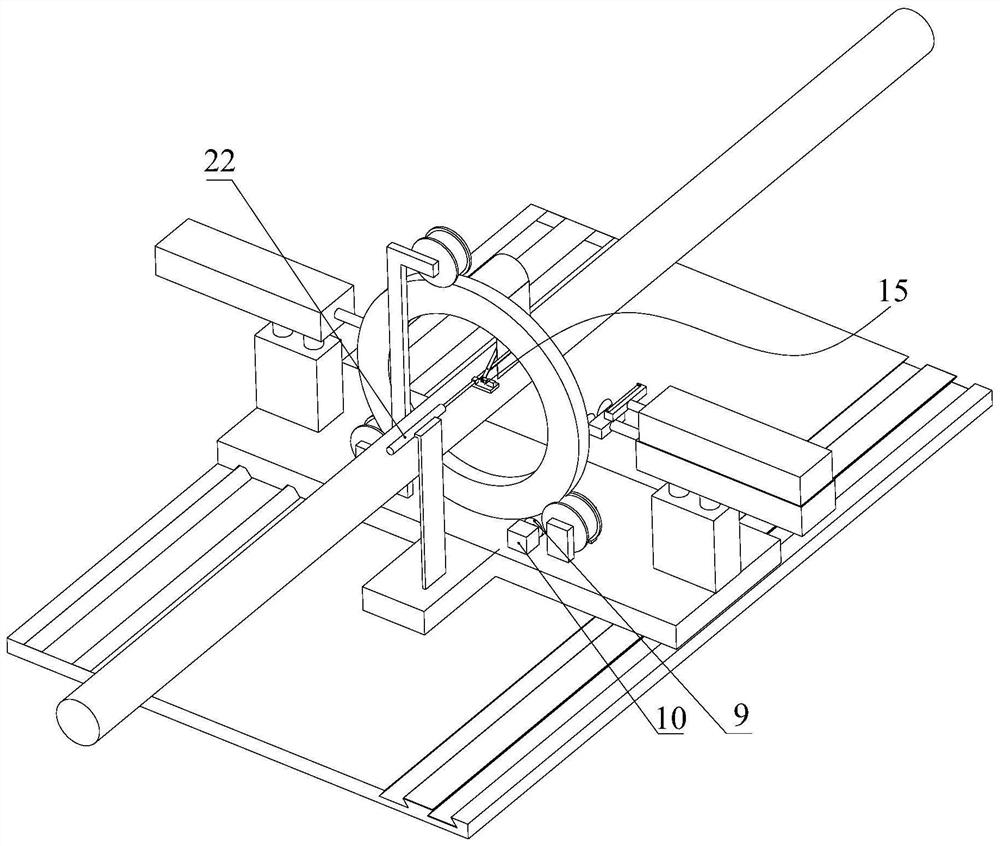

Cable peeling device

InactiveCN107300739AImprove work efficiencyReduce usageFibre mechanical structuresStructural engineeringMechanical engineering

Owner:陈杨平

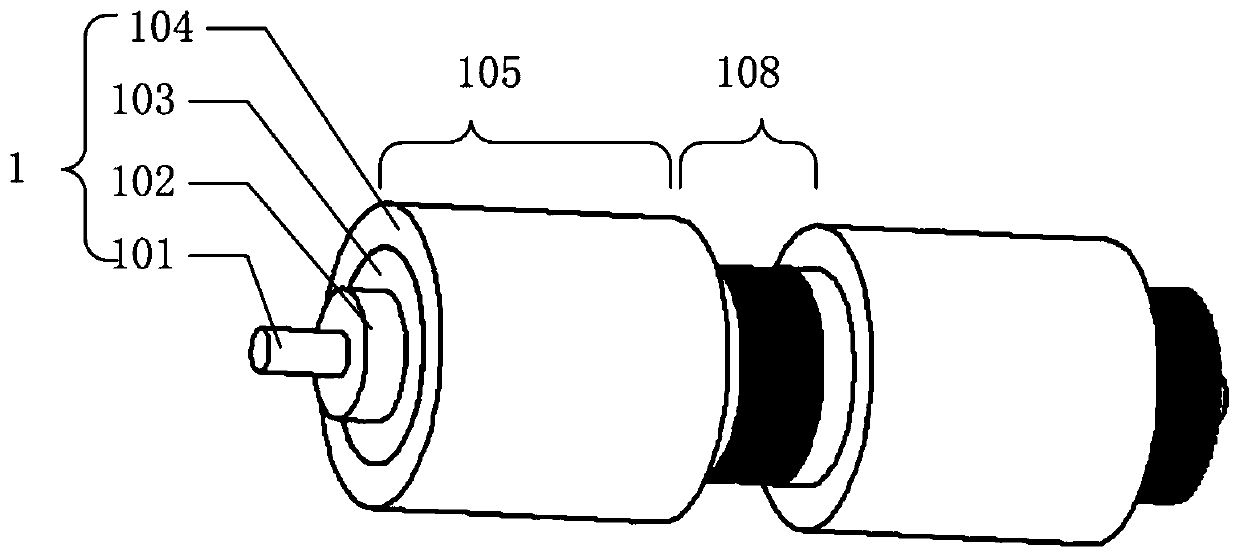

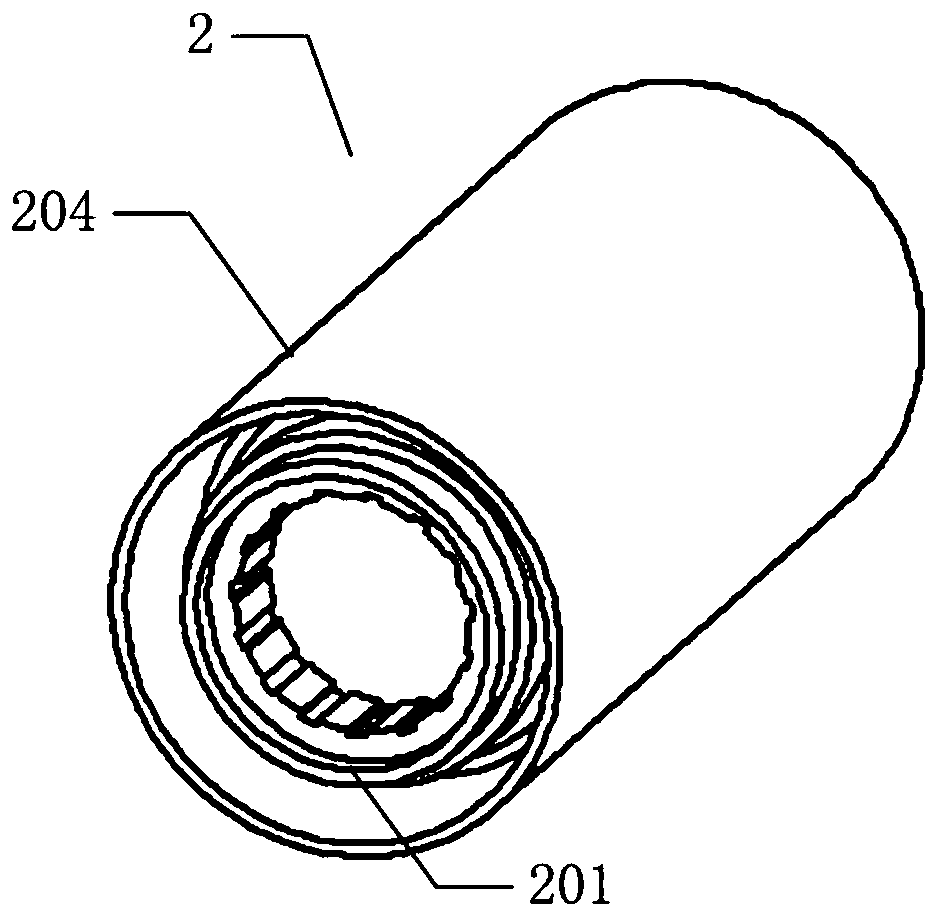

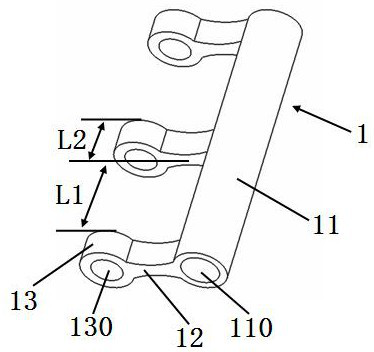

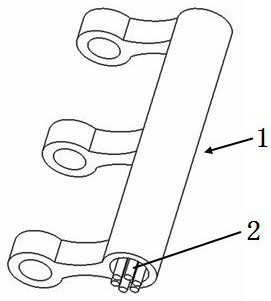

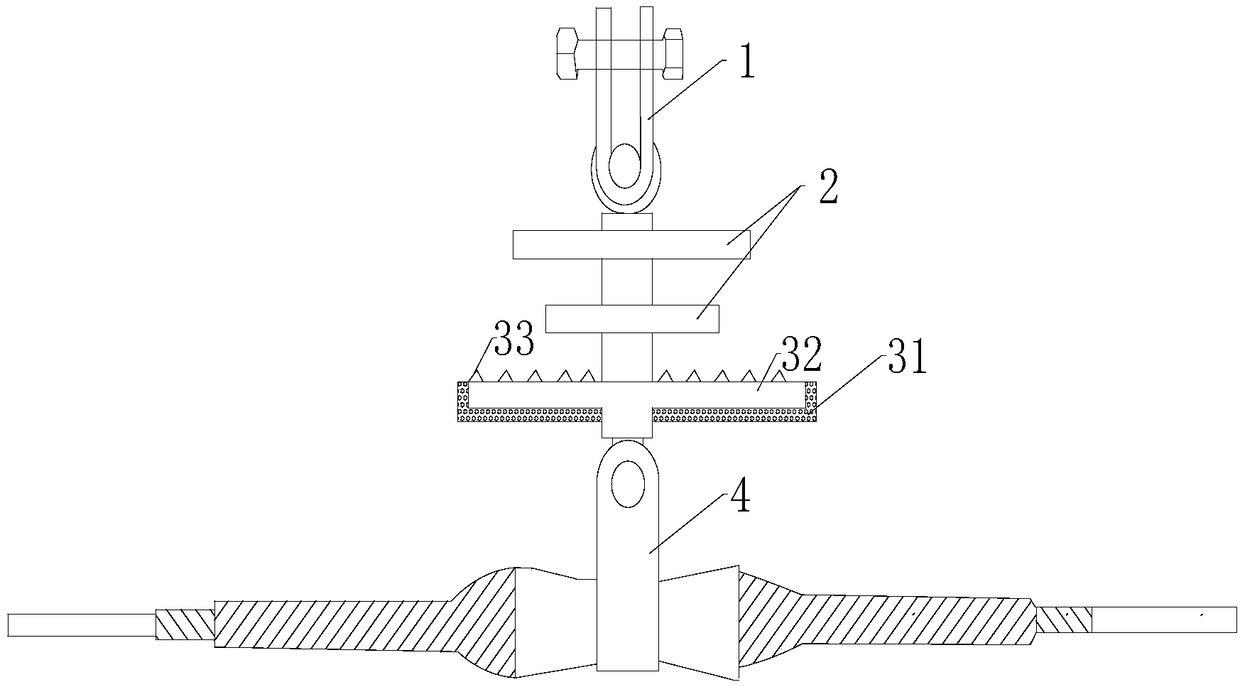

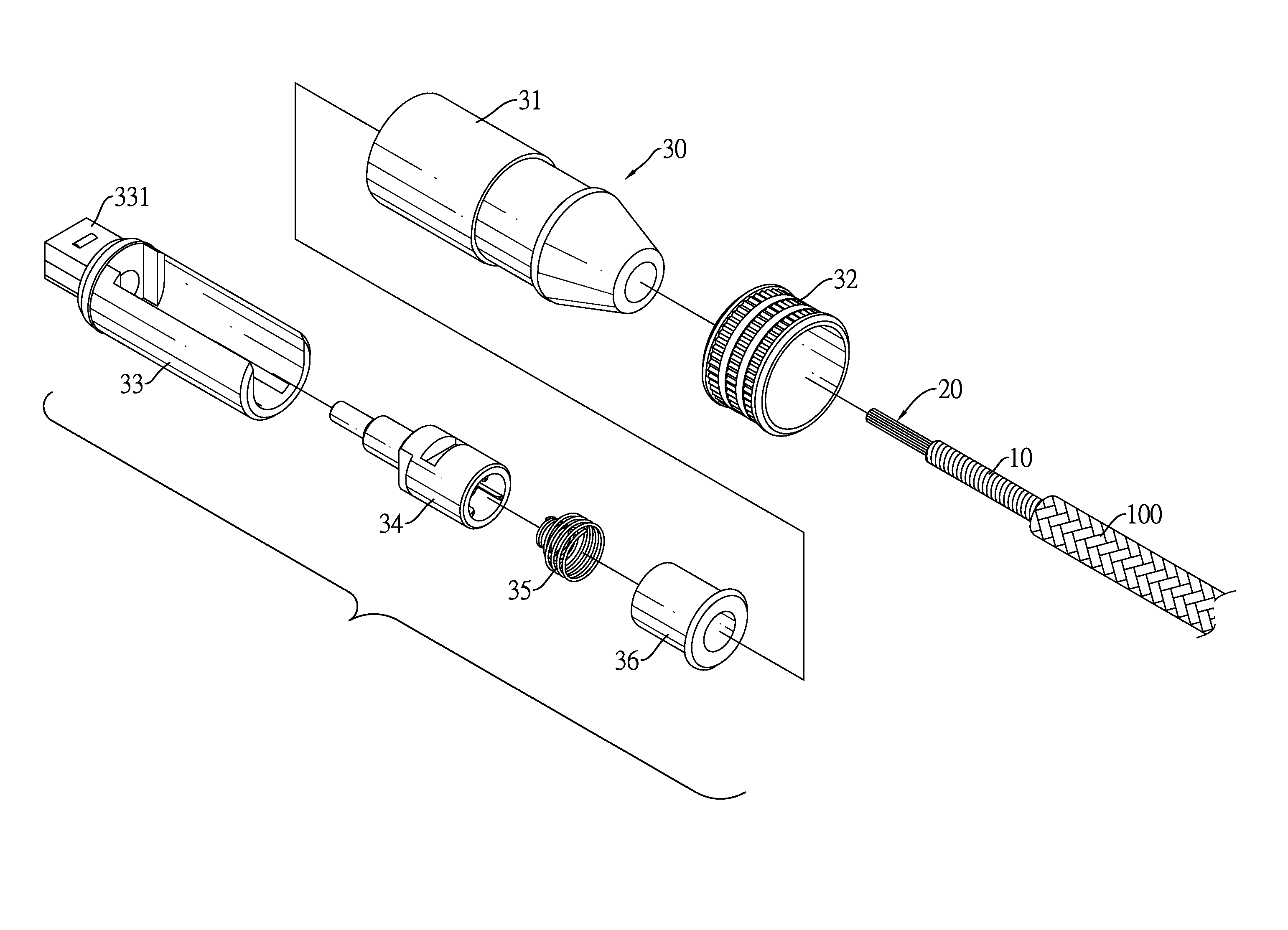

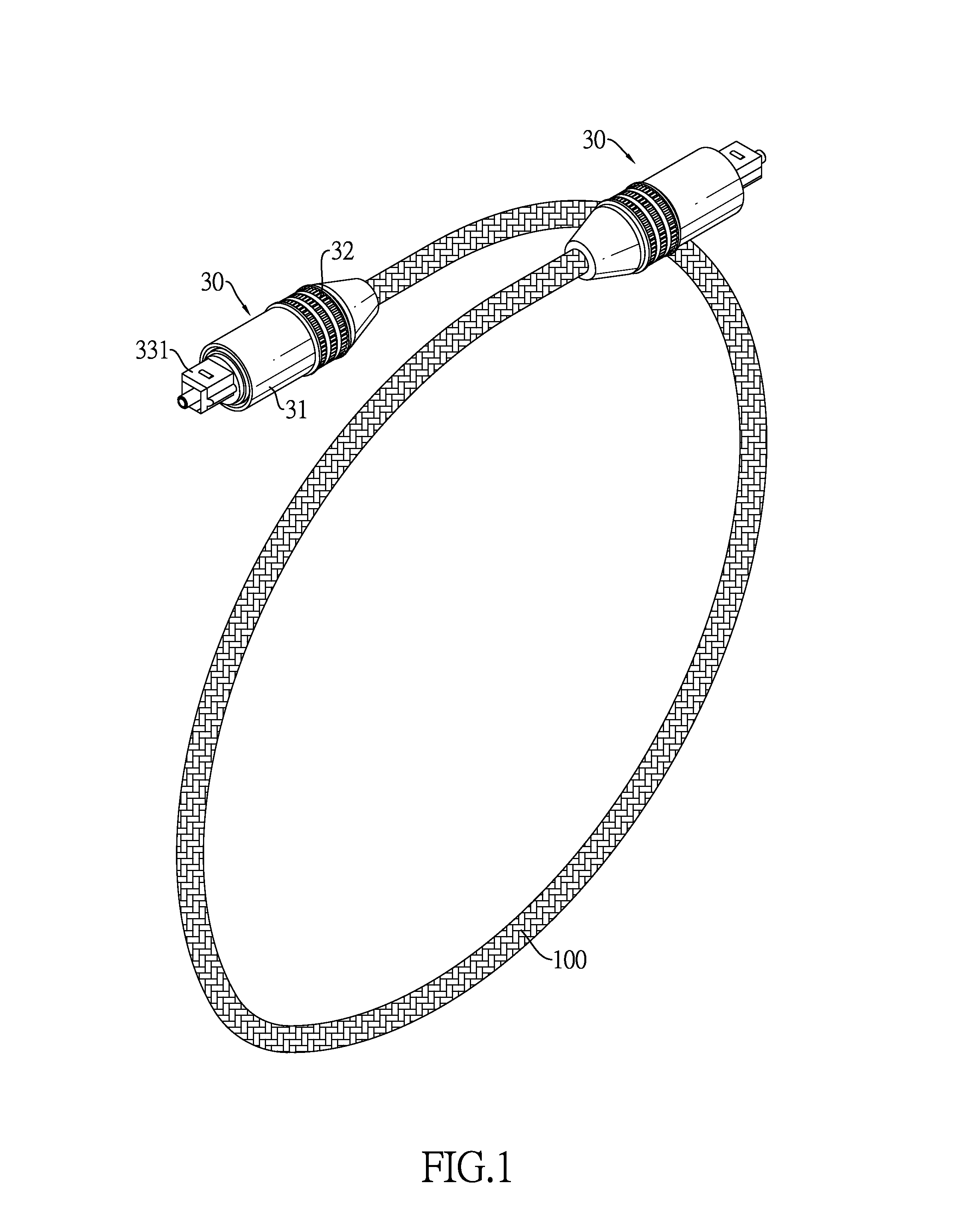

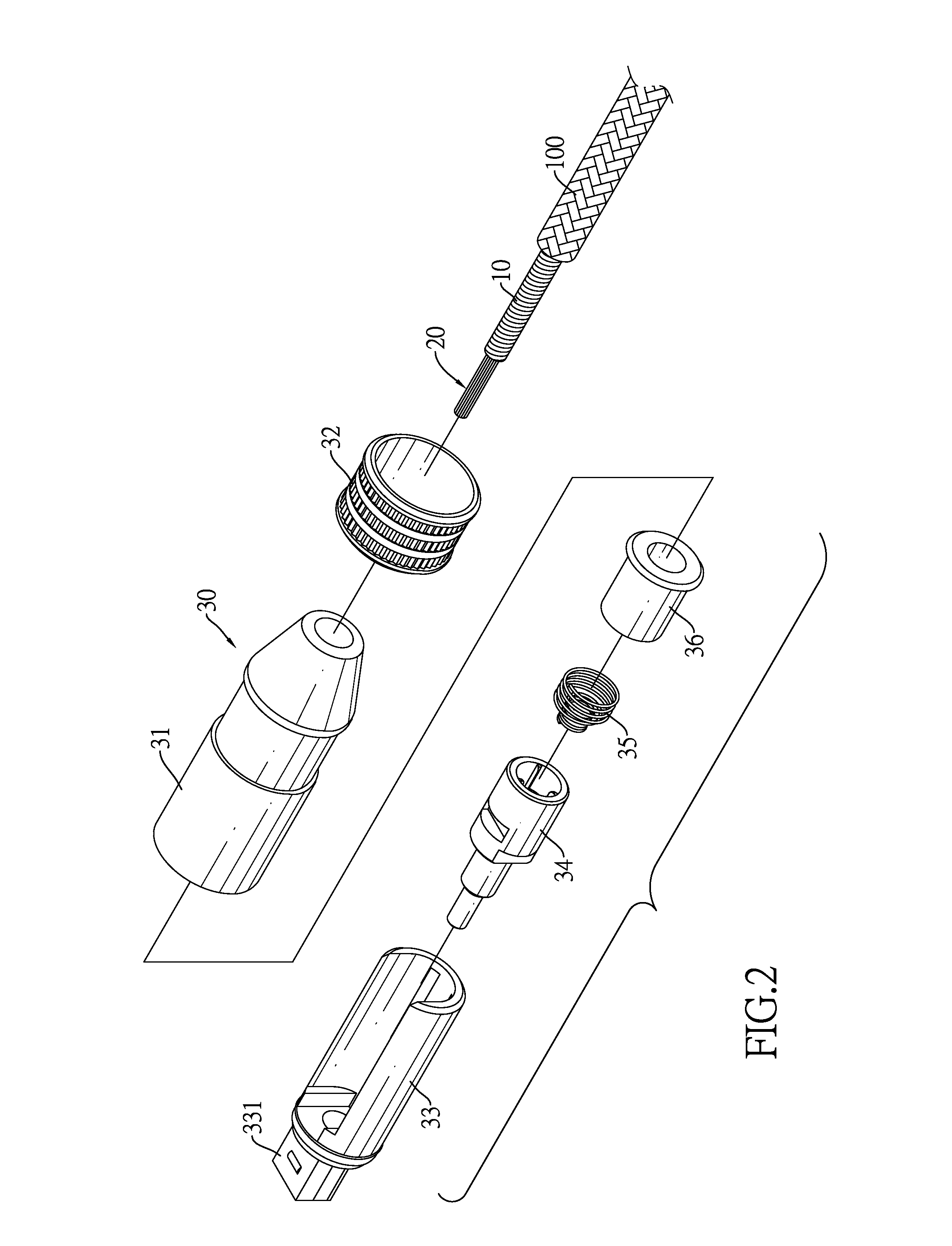

Inserting pin component of optical cable connector and tensile connecting structure of inserting pin component and optical cable

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

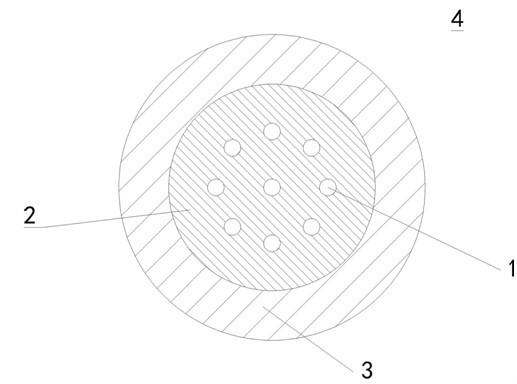

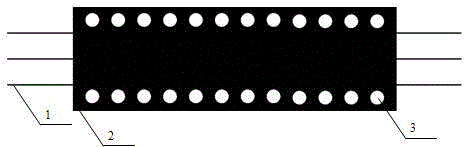

Halogen-free flame-retardant copper-plastic composite belt and preparation thereof

InactiveCN103165237AHas an ultra-thin structureReduce manufacturing costConductive layers on insulating-supportsLaminationPolyesterEngineering

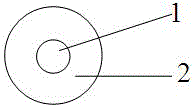

The invention relates to the field of cable belts, in particular to a copper-plastic composite belt suitable for a communication cable and an optical cable and preparation thereof. The copper-plastic composite belt is coated on the outer surface of the communication cable or the optical cable and sequentially comprises a red copper layer (1), an adhesive layer (2) and a polyester film layer (3), wherein the red copper layer (1), the adhesive layer (2) and the polyester film layer (3) are bonded and heated to form a composite structure. The tensile strength of the copper-plastic composite belt is larger than or equal to 180MPa, the elongation at break of the copper-plastic composite belt is larger than or equal to 15%, the interlayer peeling strength between a copper belt and a plastic layer is larger than or equal to 15N / cm, the conductivity of the copper-plastic composite belt is larger than or equal to 90% IACS, and no punchthrough happens on the single side of the copper-plastic composite belt 1 kvd.c,1min.

Owner:JIUXING HLDG GRP

Longitudinal seal underwater optical cable and manufacturing method thereof

ActiveCN102540370ASimple structureImprove sealingFibre mechanical structuresWater leakageEngineering

Owner:JIANGSU HONGTU HIGH TECHNOLOGY STOCK CO LTD

Bunchy armored optical cable and preparation method thereof

InactiveCN112198604AHigh strengthImprove tensile propertiesFibre mechanical structuresStructural engineeringProtection layer

Owner:TONGLING CITY TONGDOU SPECIAL CABLE CO LTD

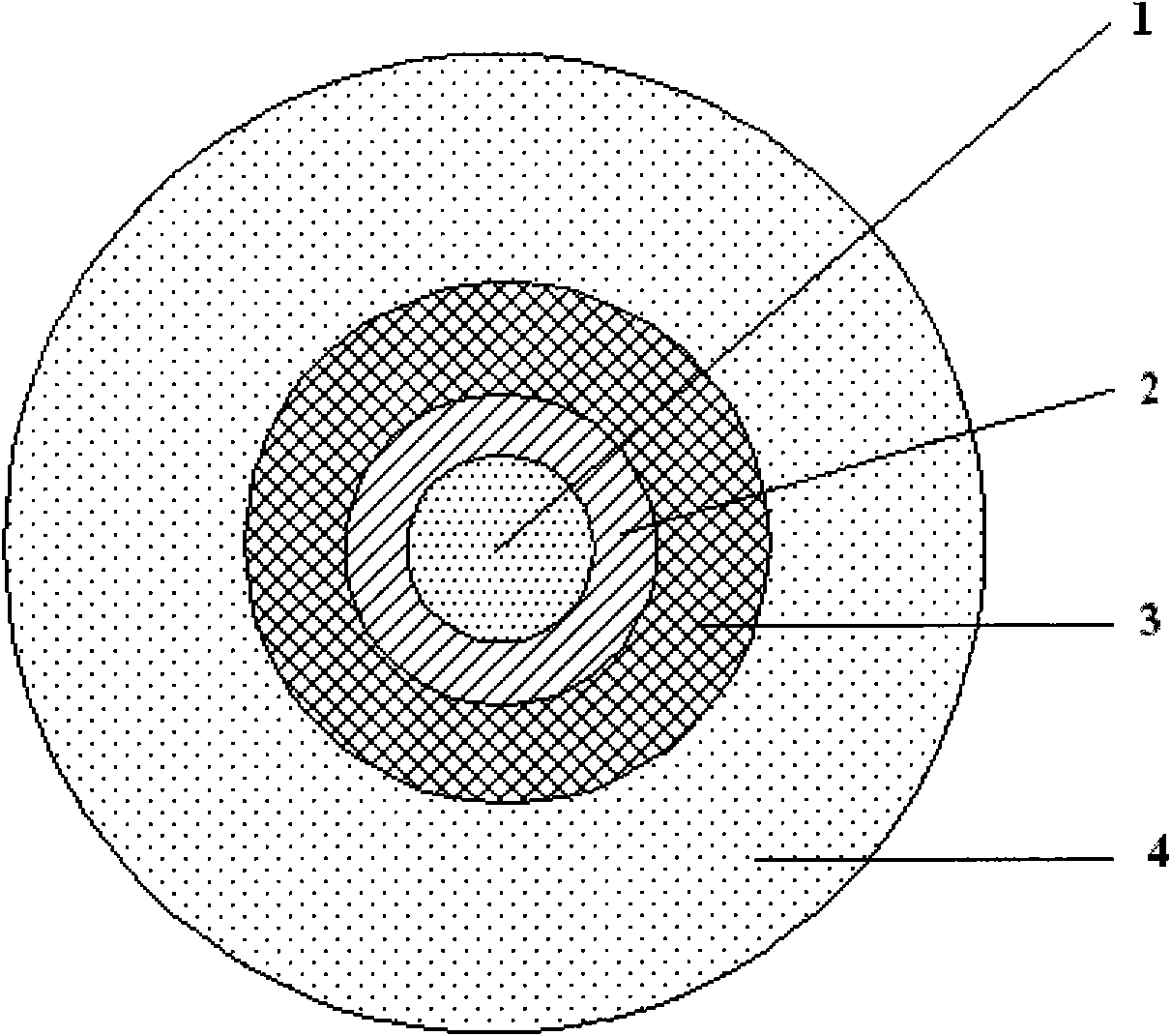

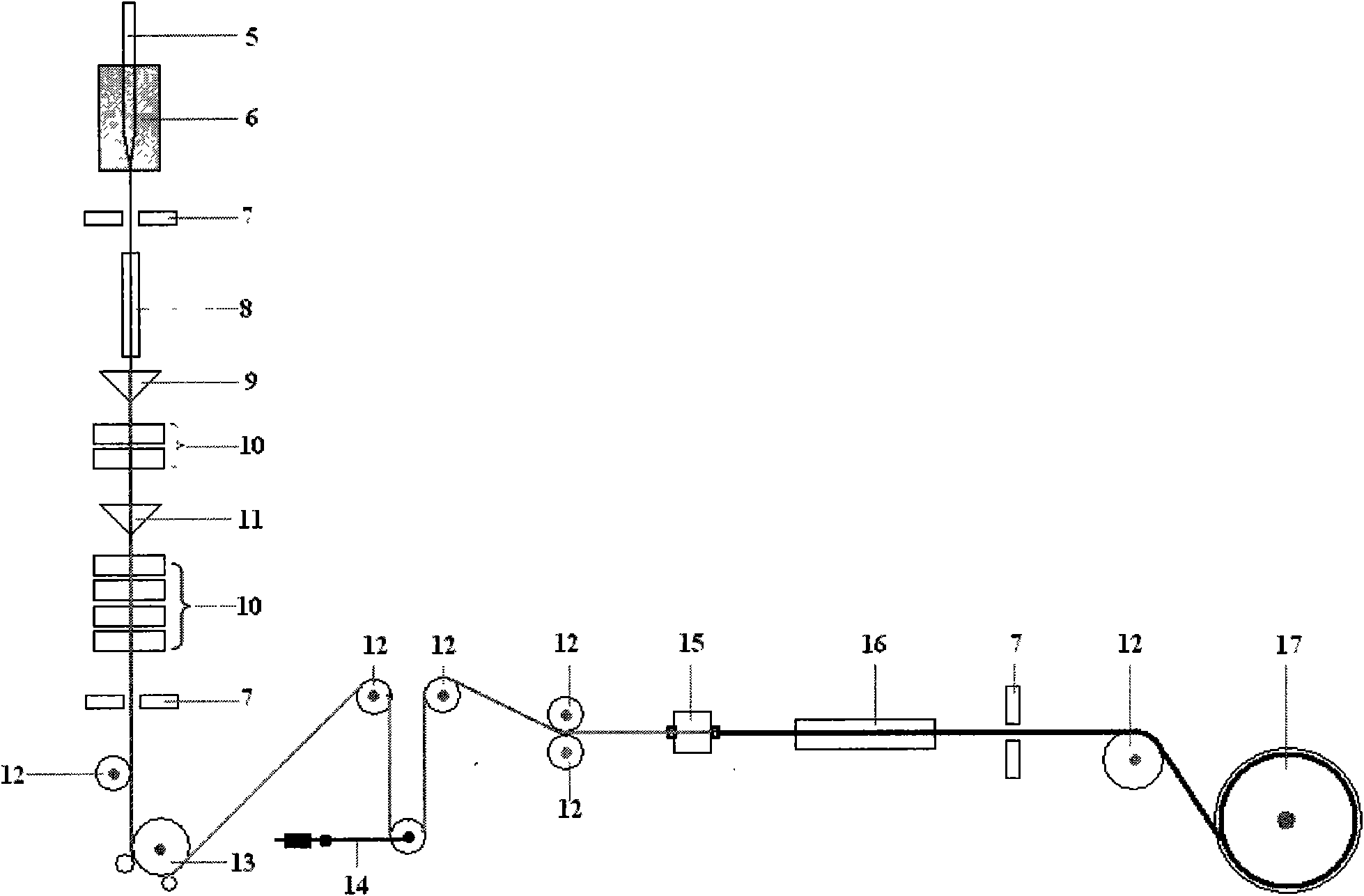

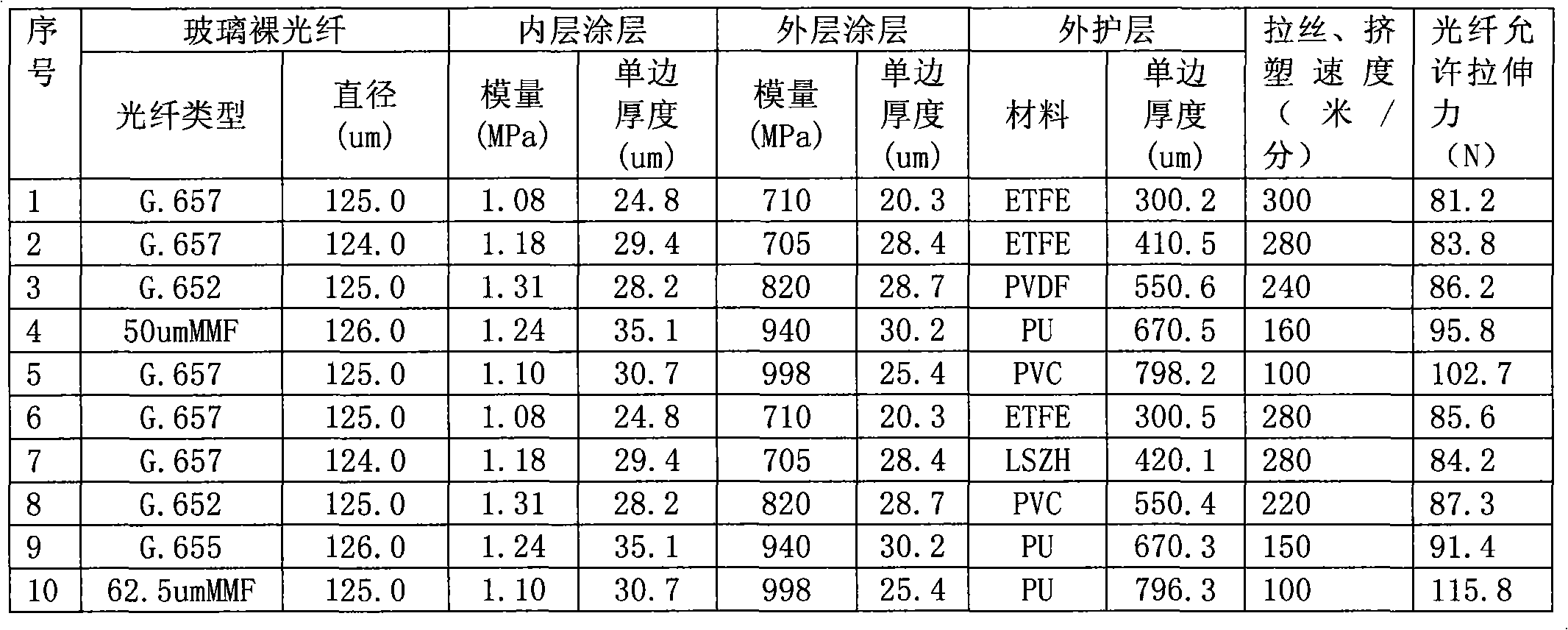

Indoor-laying optical fiber and manufacture method thereof

ActiveCN101614842AQuality improvementIncrease internal stressGlass making apparatusCladded optical fibreProduction lineProtection layer

Owner:SICHUAN LEFEI OPTOELECTRONICS TECH CO LTD +1

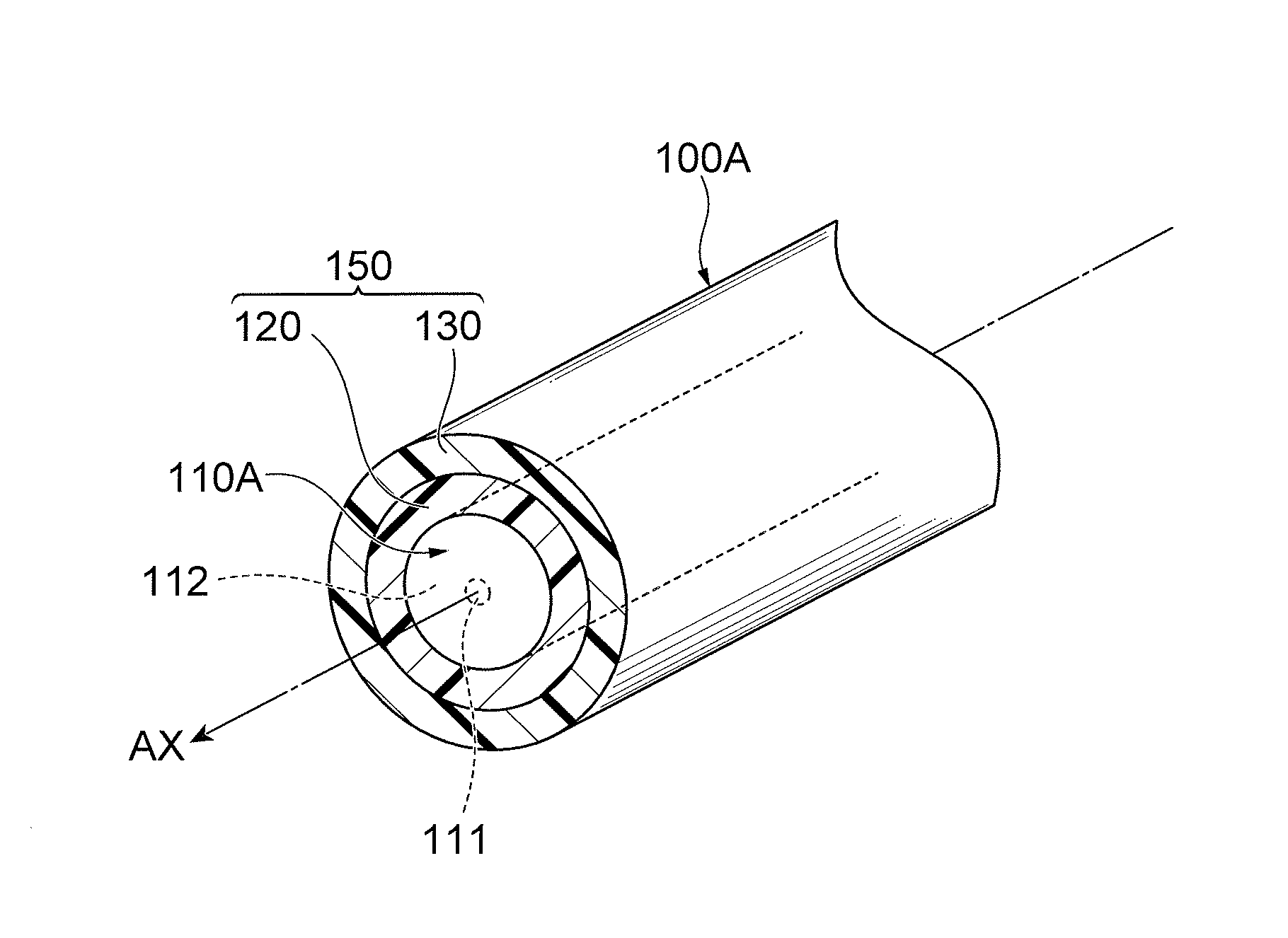

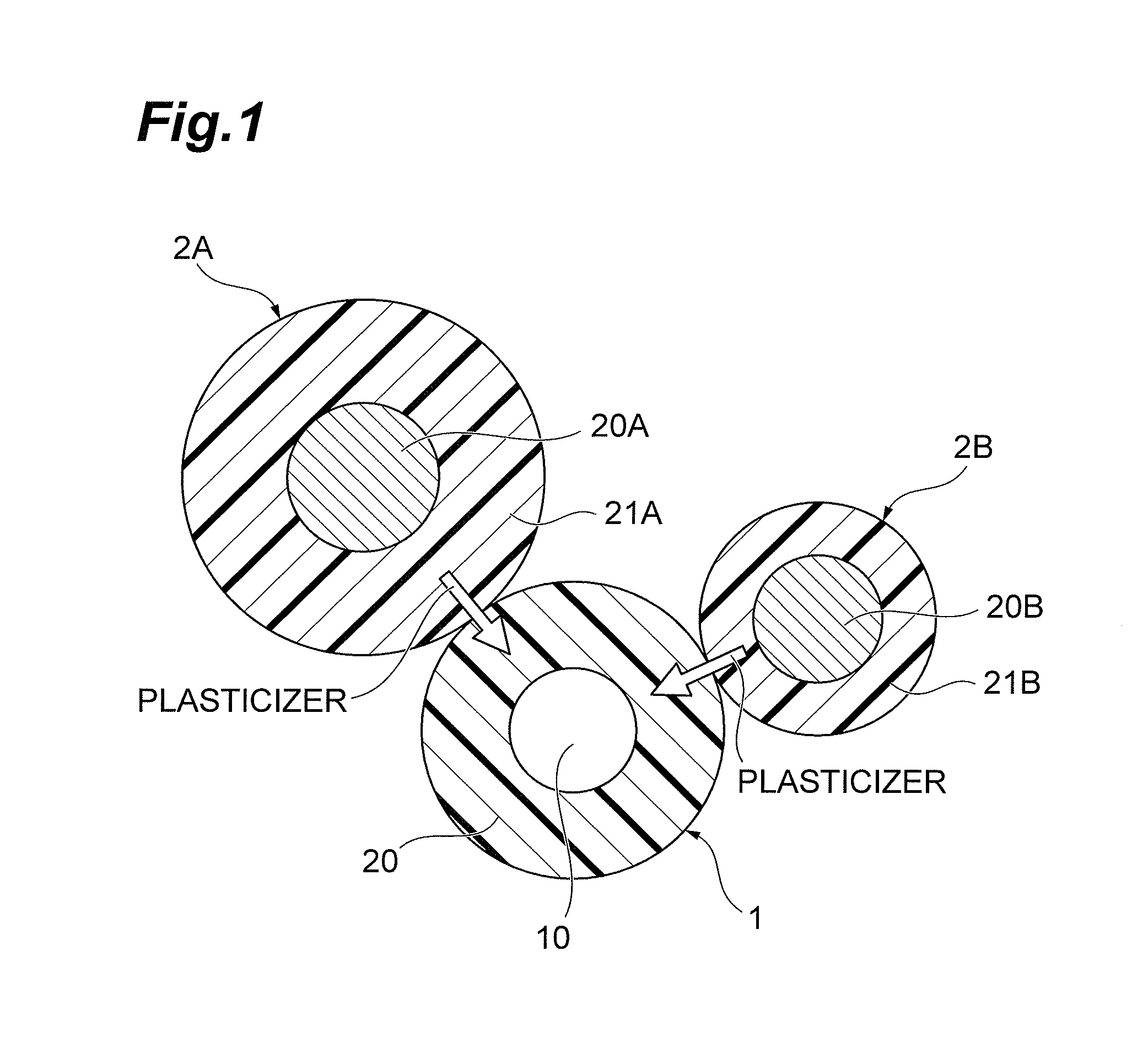

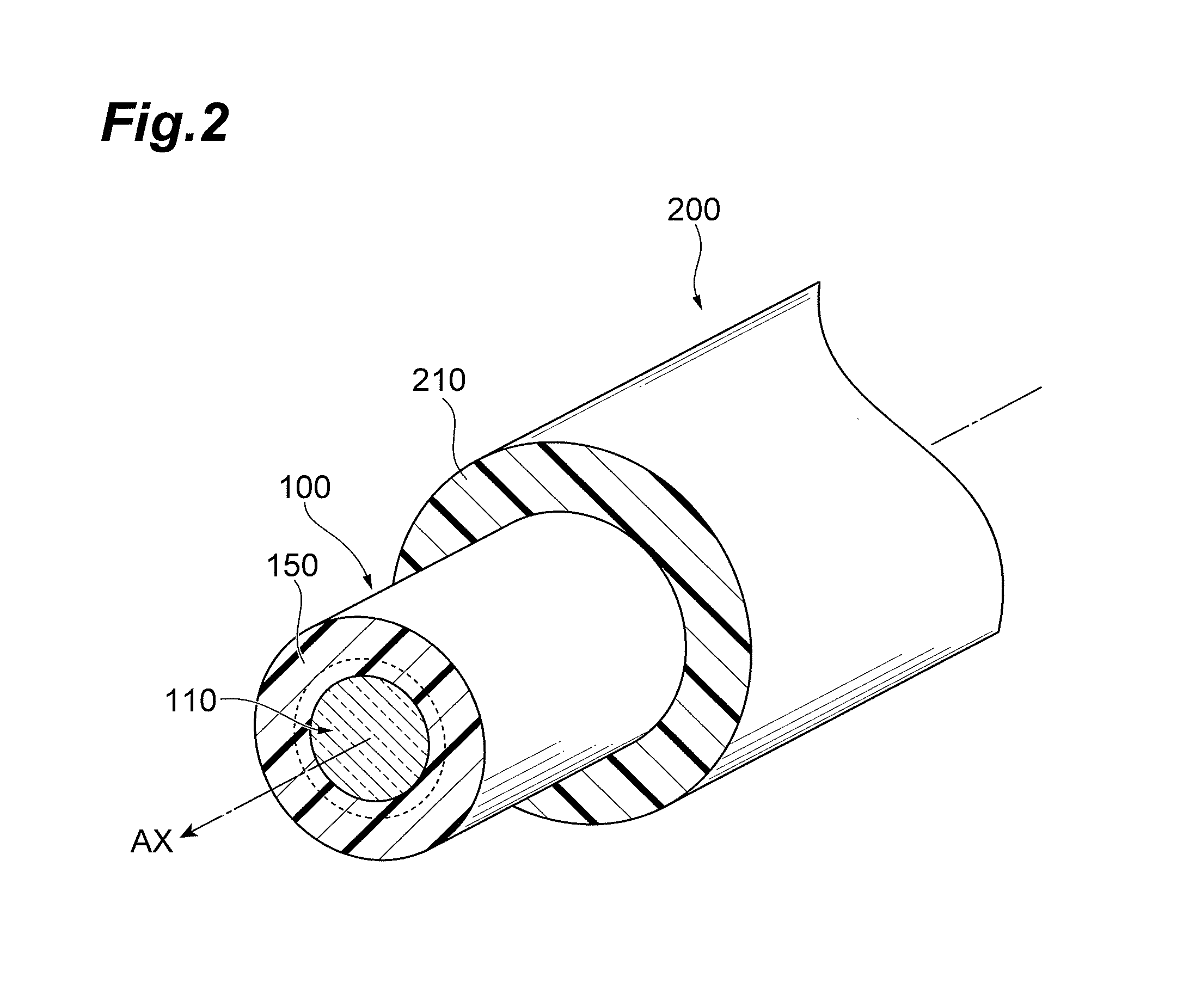

Optical fiber and optical cable

ActiveUS8923674B1Easy to crackInhibit migrationGlass optical fibreOptical fibre with multilayer core/claddingGlass fiberUV curing

Owner:SUMITOMO ELECTRIC IND LTD

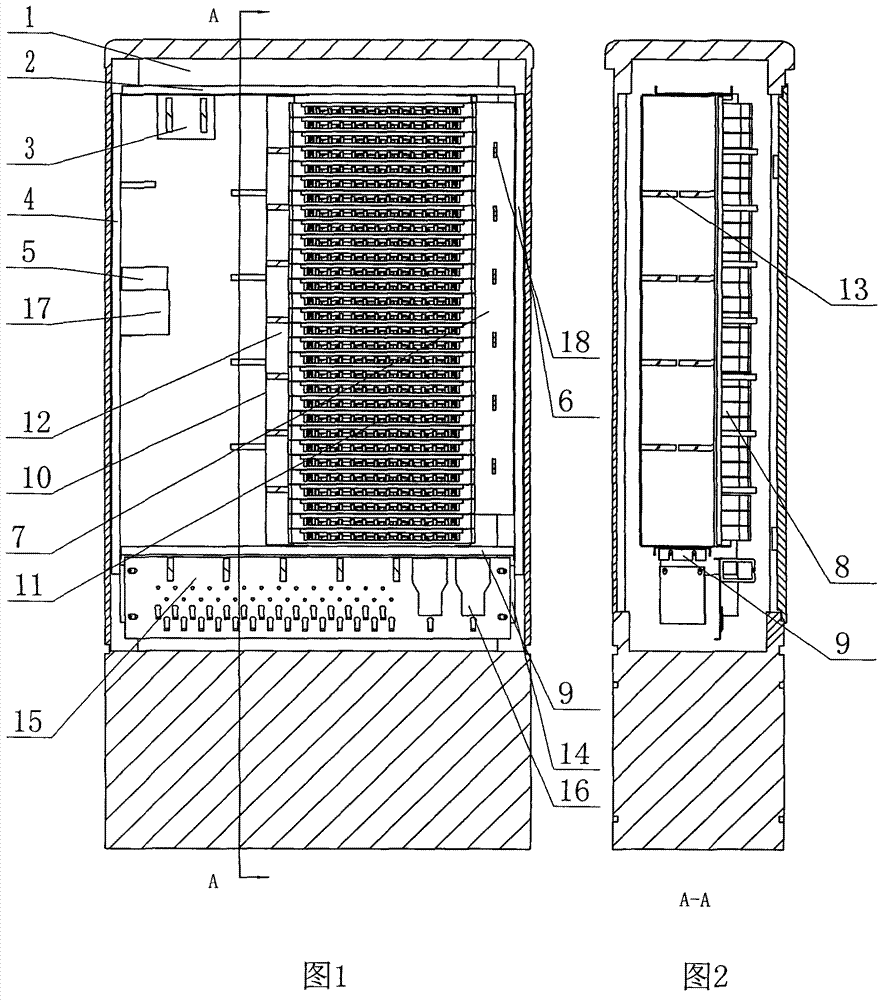

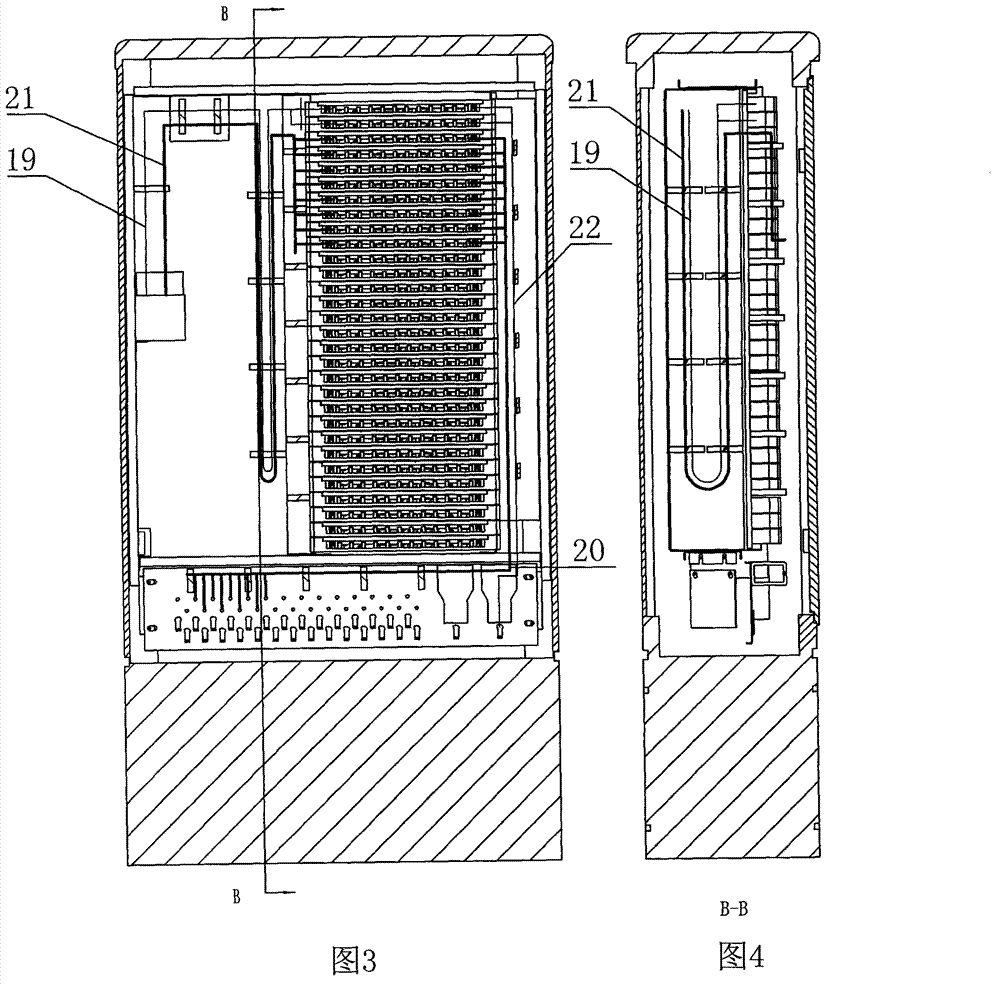

Optical splitter no-jumper-connection distribution box and wiring method thereof

InactiveCN103246031ALarge capacityAvoid entanglementFibre mechanical structuresEngineeringGround plate

Owner:NINGBO SHUNJIA COMM TECH CO LTD

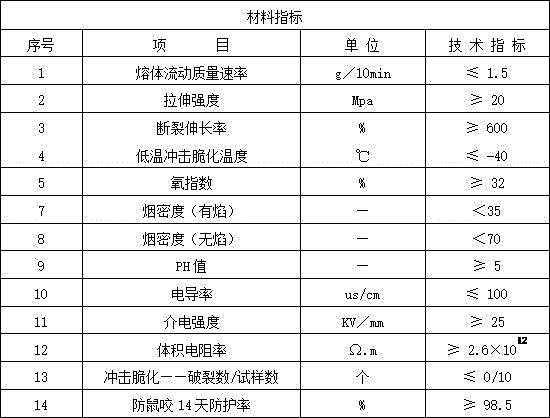

Marine low-smoke halogen-free low-toxicity frame-retardant fire-resistant soft optical cable and manufacturing method thereof

InactiveCN104570250AImprove transmission performanceFibre mechanical structuresLow smoke zero halogenPolyolefin

Owner:JIANGSU ZHONGTIAN TECH CO LTD

Optical cable with new structure and production method thereof

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

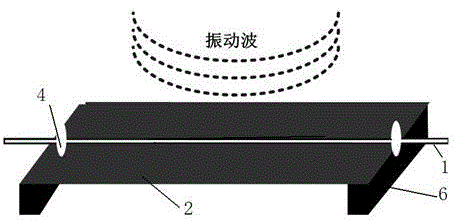

High-sensitivity metal baseband armored vibration sensing optical cable

PendingCN106405771AExtended service lifeEasy to processSubsonic/sonic/ultrasonic wave measurementFibre mechanical structuresAdhesiveAcoustic wave

Owner:SOUTH CHINA UNIV OF TECH

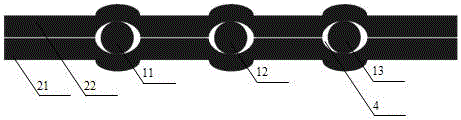

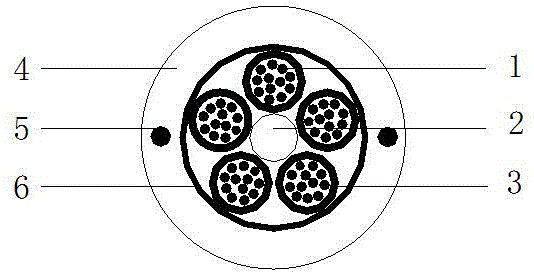

Anti-ant large-core-number fiber ribbon cable

InactiveCN107479158AAvoid infringementGuarantee statusFibre mechanical structuresEngineeringFiber density

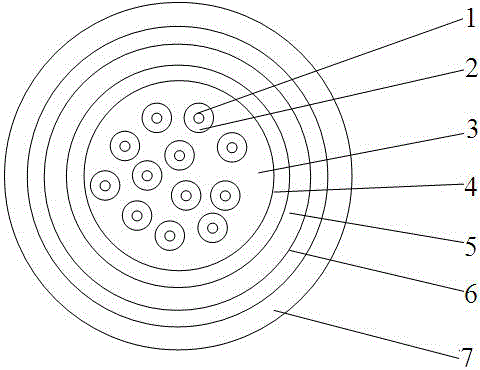

The invention relates to an anti-ant large-core-number fiber ribbon cable comprising a cable core and an outer sheath. The cable core includes loose tubes; and fiber ribbons are sleeved inside the loose tubes. The outer sheath is an outer nylon sheath; and a non-metallic reinforcement layer is arranged between the outer sheath and the cable core. According to the anti-ant large-core-number fiber ribbon cable provided by the invention, with the outer nylon sheath, ants can not bite the sheath, so that the damages on the optical cable by ant biting in a pipe at an area with a serious anti problem are prevented, the normal state of the cable is ensured, and the application region of the cable is extended. The cable based on a simple and reasonable structure has advantages of small cable diameter, high fiber density, large fiber capacity, and low duty ratio and can be laid in a pipe conveniently; and the bending performance is good. During branched connection, 4 to 24 fibers can be melted once, so that the construction time is saved and the manpower cost is lowered, and the construction efficiency is improved. On the basis of the full drying type dielectric structure, branched connection is realized conveniently and usage becomes convenient.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

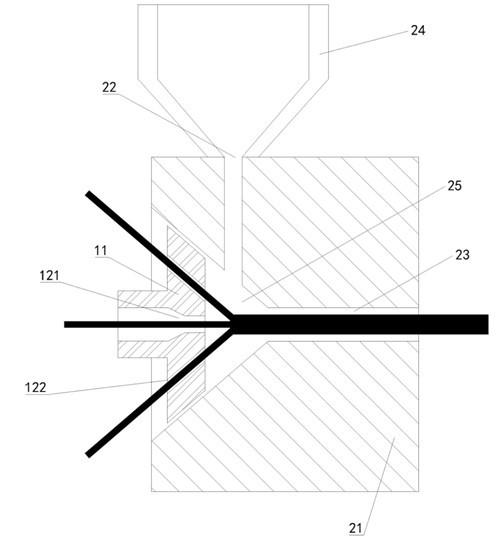

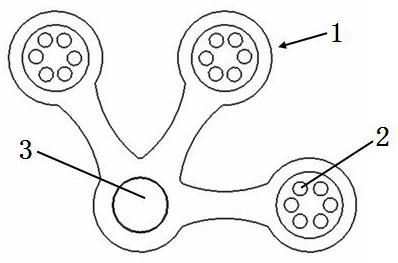

Optical cable branching device for optical cable connection box

ActiveCN108732696ASimple structureEasy to operateFibre mechanical structuresEngineeringElectrical and Electronics engineering

The invention discloses an optical cable branching device for an optical cable connection box. The optical cable branching device for the optical cable connection box comprises a connection box body;an installation hole for installing an optical cable branching device is formed in one side of the connection box body; the optical cable branching device includes a first box body, a second box body,and a cable incoming pipe opening fixedly arranged at the installation hole; the cable incoming pipe opening is connected with the first box body; the first box body is connected with the second boxbody; the cable incoming pipe opening is provided with a cable inlet connected with a cable in the connection box body; and the joint of the first box body and the second box body is provided with cable outlets which lead out the cable at the cable inlet. According to the optical cable branching device for the optical cable connection box of the invention, an optical cable connection function andan optical cable branching function are integrated on one optical cable connection box body, and therefore, the optical cable branching device is simple in structure and convenient to operate.

Owner:YUYAO HUIJIA COMM EQUIP CO LTD

Optical fiber ribbon coating paste used in band shape optical cable and preparation method thereof

ActiveCN102207595AMoisture-proofImprove waterproof performanceFibre mechanical structuresBand shapeOil separation

Owner:SHANGHAI HONGHUI OPTICS COMM TECH

Miniature optical cable, method for preparing same and outer sheath material for miniature optical cable

ActiveCN106772849AGuarantee the quality of the cableEasy to controlFibre mechanical structuresUltimate tensile strengthElectrical and Electronics engineering

Owner:JIANGSU TRIGIANT OPTOELECTRONICS TECH +1

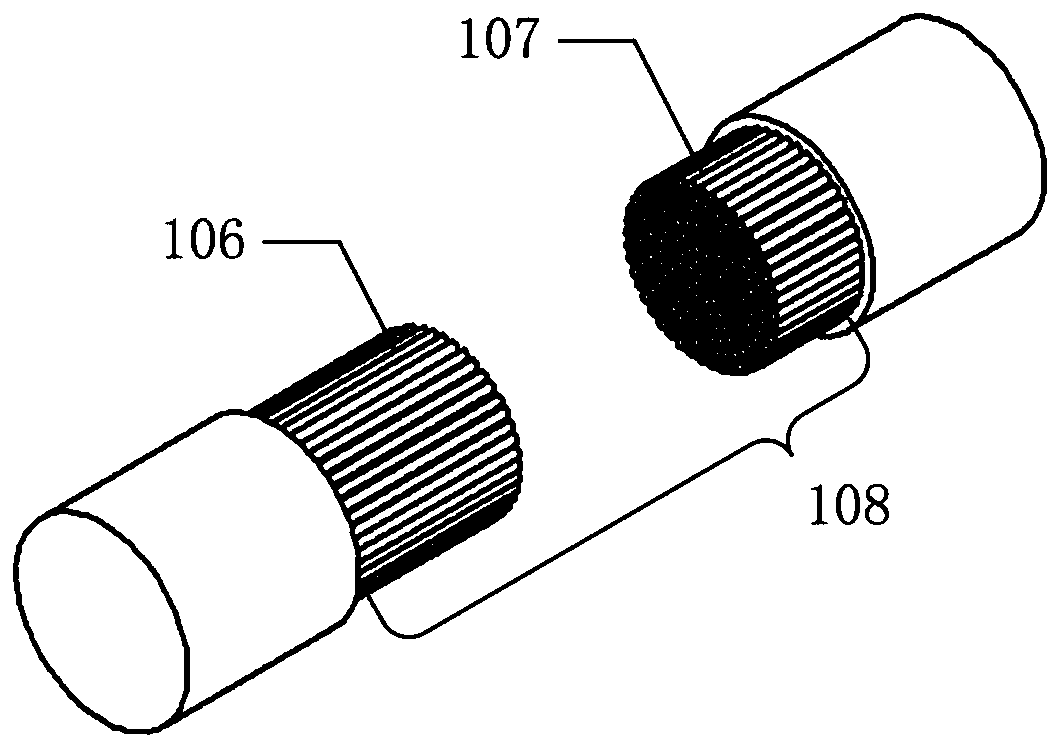

Para-aramid fiber fault connection component and connection method thereof

Owner:AFCHINA CORP CO LTD +1

Butt closures and organizer assemblies therefor

Owner:AFL COMM LLC

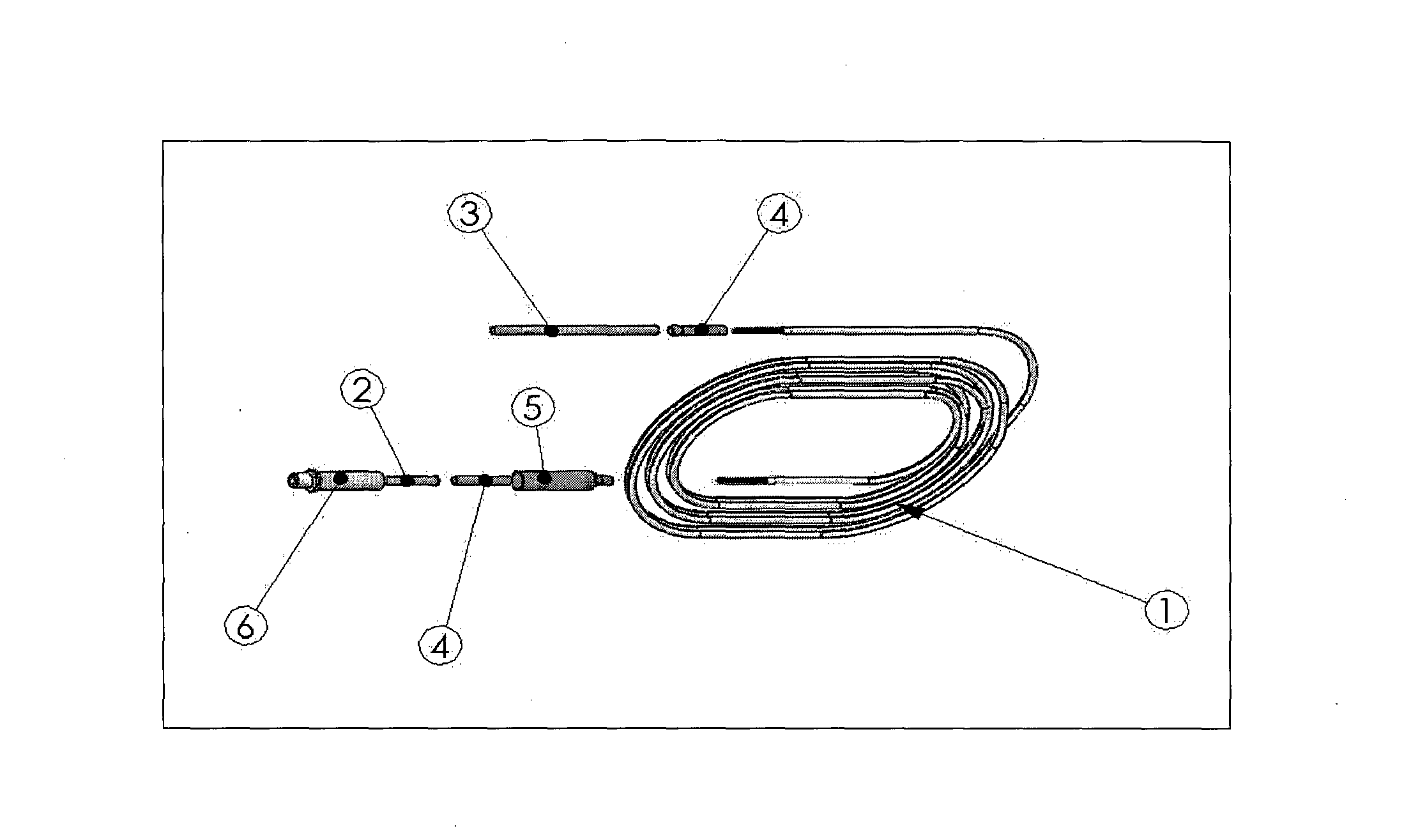

Method for production of local illumination patch cord and corresponding patch cord

InactiveUS20160184045A1Lower the volumeLarge capacityMechanical apparatusEndoscopesFiberElectrical resistance and conductance

Owner:FAMOLDE - FABCAO E COMMLIZACAO DE MOLDES

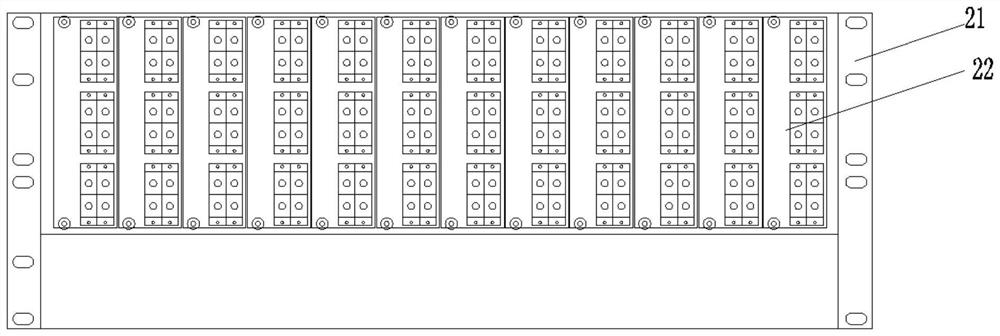

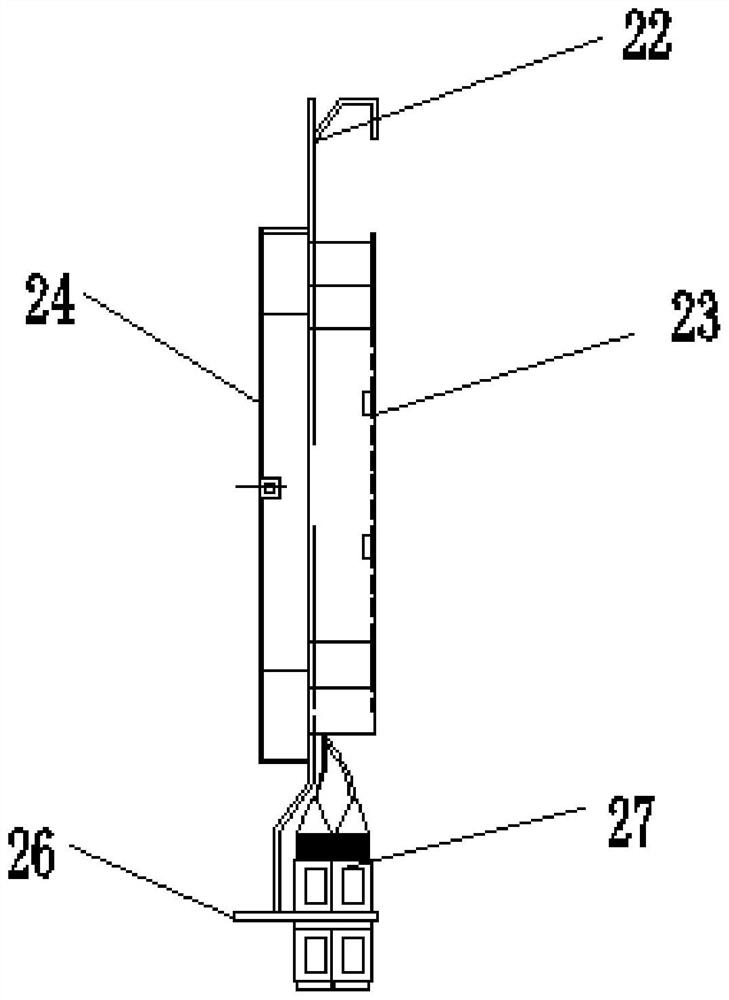

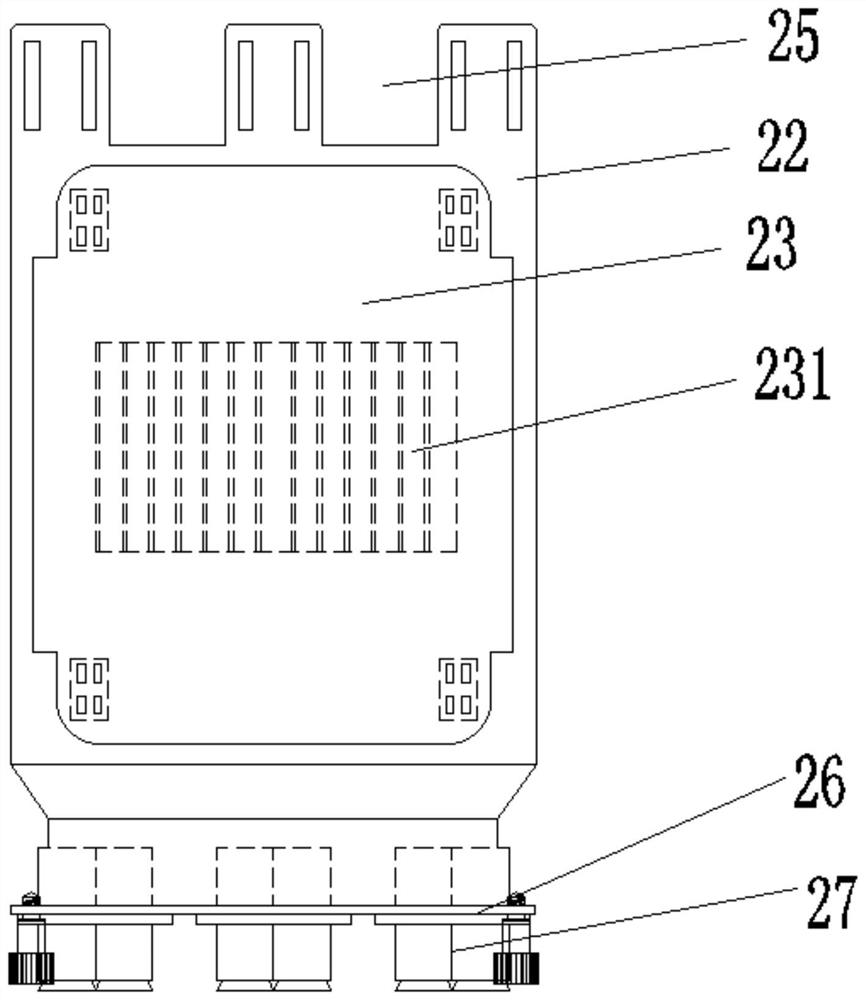

Insertion sheet type melting and distribution separation type optical fiber distribution module and distribution frame

PendingCN114296192AClear wiringConvenient modular operation habitsCoupling light guidesFibre mechanical structuresDistribution frameFiber

Owner:JIANGSU HENGTONG PHOTOELECTRIC

Novel FTTH optical fiber cable and production process thereof

PendingCN109725397AImprove bindingStable structureFibre mechanical structuresCrack resistanceEngineering

The invention discloses a novel FTTH optical fiber cable and a production process thereof. The novel FTTH optical fiber cable has the advantages of high adhesion between a reinforcing element and a sheath, torsion resistance, crack resistance, sheath tension resistance and stable structure, and is suitable for optical fiber cables in various complicated installation environments. The novel FTTH optical fiber cable of the invention is composed of a sheath layer, an optical fiber and a reinforcing element; the novel FTTH optical fiber cable comprises an indoor FTTH optical cable and an indoor and outdoor dual-purpose FTTH optical cable. The indoor FTTH optical cable only comprises a main component, and the indoor and outdoor dual-purpose FTTH optical cable comprises a main component and an auxiliary component integrally with the main component. The main component comprises a reinforcing element, a reinforcing element coating layer, a sheath layer and an optical fiber coated with the sheath layer, which are sequentially arranged from the inside to the outside; and the auxiliary component comprises a reinforcing element, a reinforcing element coating layer and a sheath layer arranged sequentially from the inside to the outside.

Owner:HEFEI XINGLIAN COMM

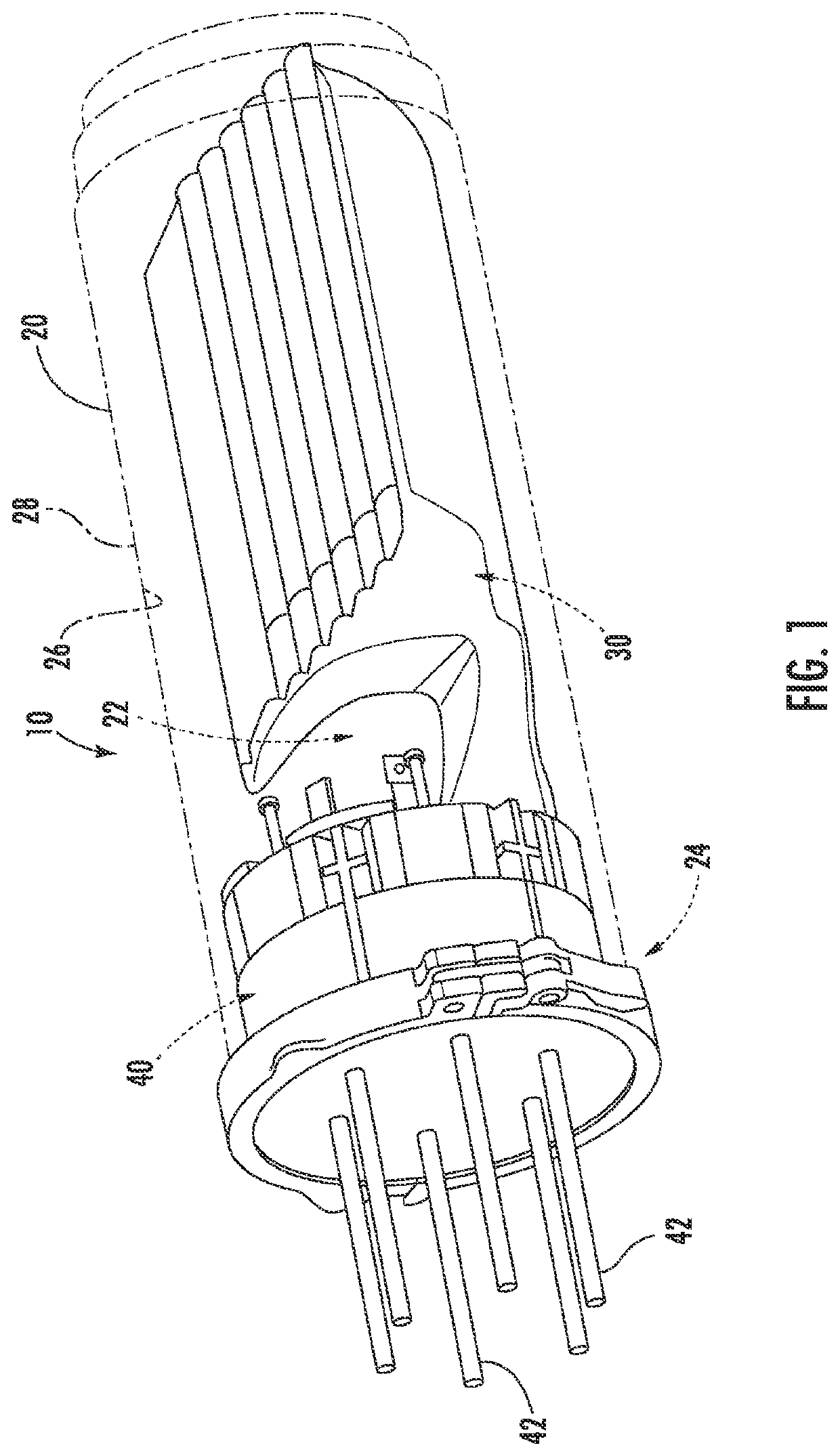

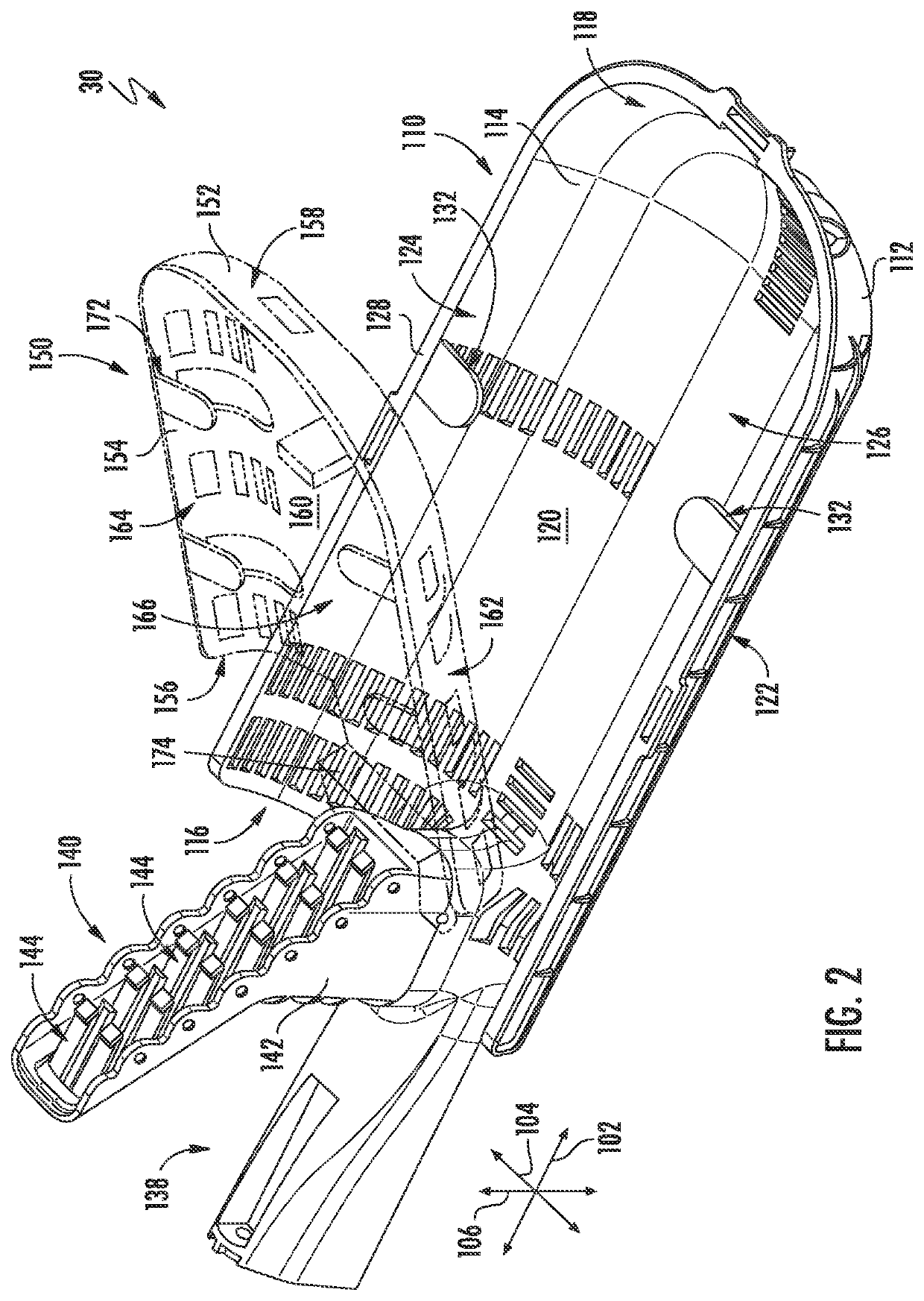

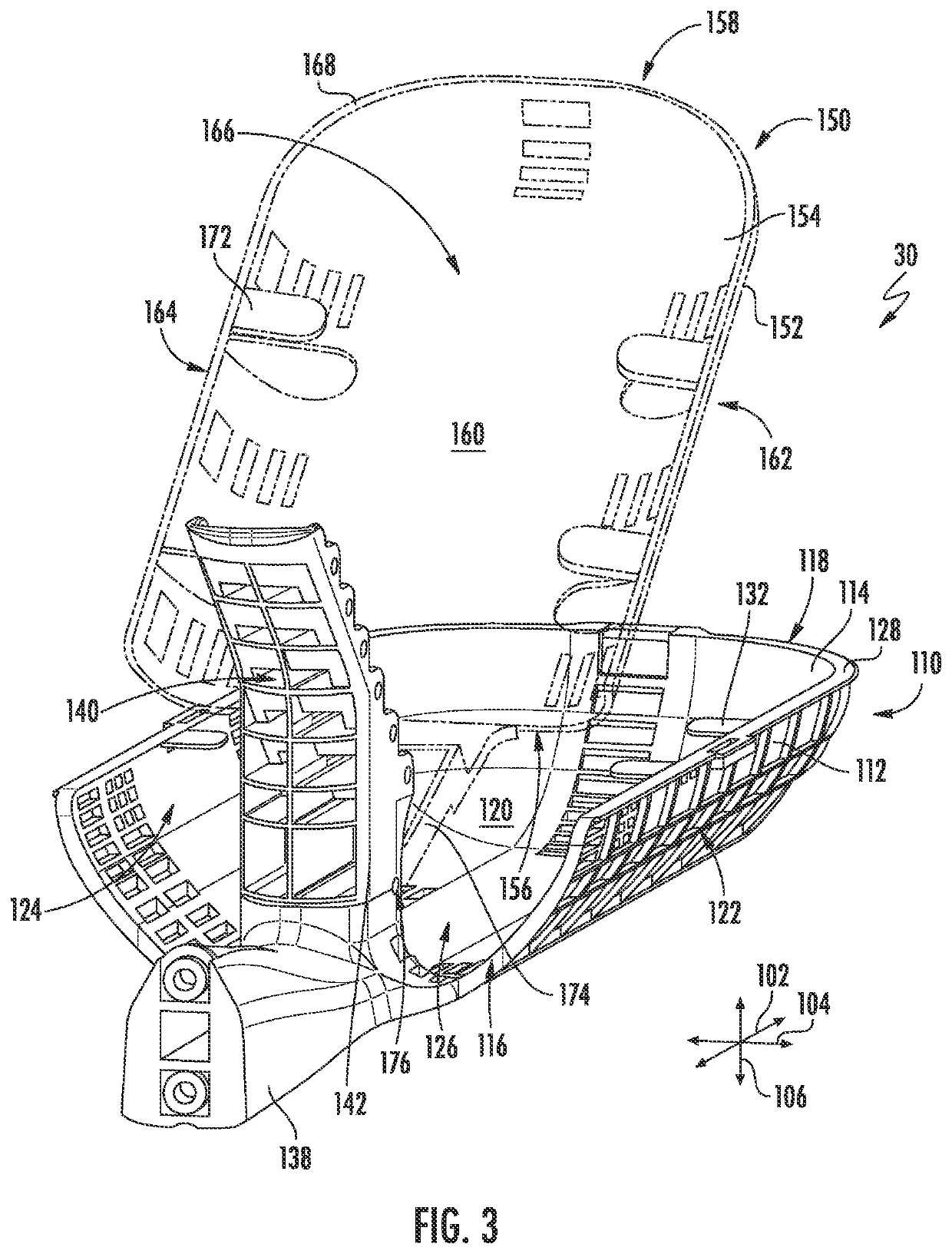

Shelf for communications rack or cabinet

A fiber optic shelf includes: a floor; side walls attached to opposite side edges of the floor, wherein the shelf has a longitudinal axis defined between the side walls; and a rear wall attached to arear edge of the floor. The rear wall has a stepped profile and comprises a plurality of mounting panels facing laterally at an oblique angle to the longitudinal axis of the shelf.

Owner:COMMSCOPE INC

Layer-stranded optical cable applicable to different space environments

ActiveCN113448036ASimple structureEasy to manufactureFibre mechanical structuresEngineeringMechanical engineering

Owner:YANGTZE ZHONGLI OPTICAL FIBER & CABLE (JIANGSU) CO LTD

Improved optical cable clamp

Owner:SICHUAN XINGZHI ZHIHUI INTPROP OPERATION CO LTD

Manufacturing process of optical cable

Owner:FUTONG GRP JIASHAN COMM TECH CO LTD

Hi-fi audio signal optical fiber cable

InactiveUS20170003460A1Increase reflectionShorter optical pathCoupling light guidesFibre mechanical structuresOptical pathMulti-mode optical fiber

Owner:CHENG YU FENG

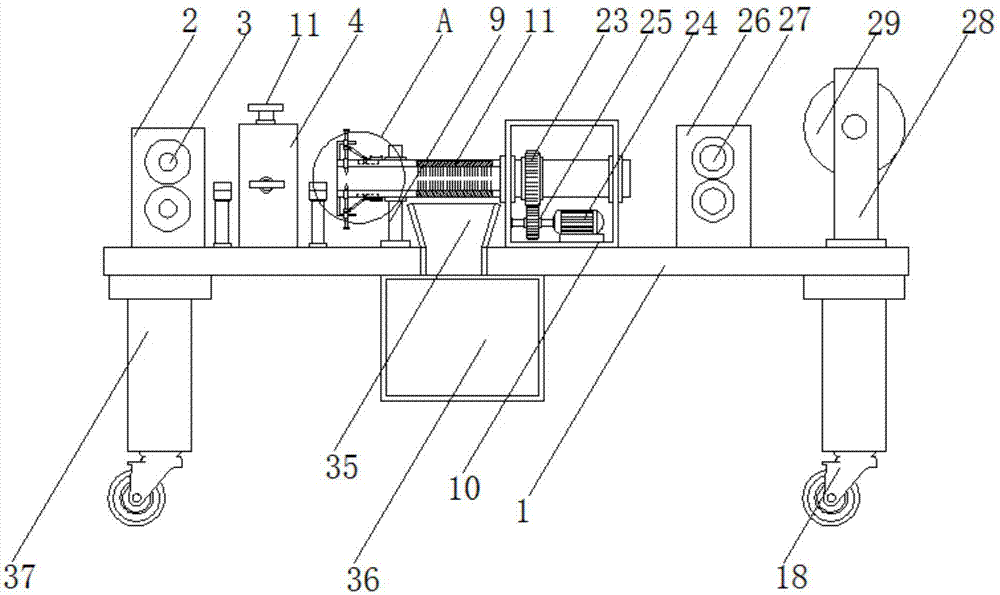

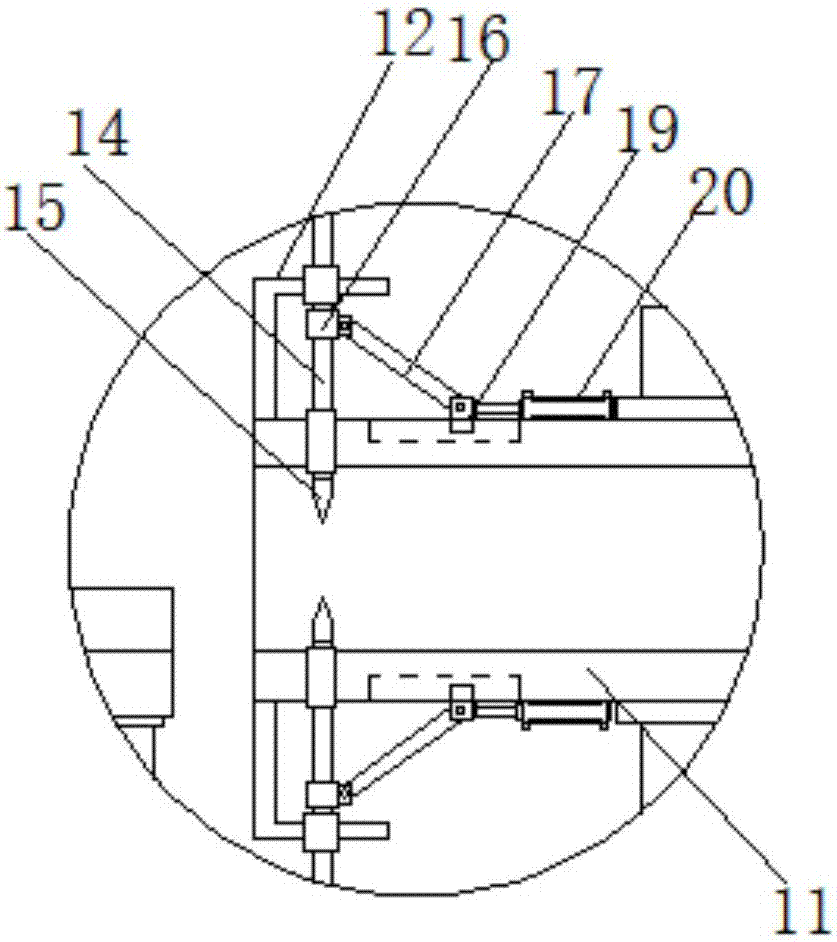

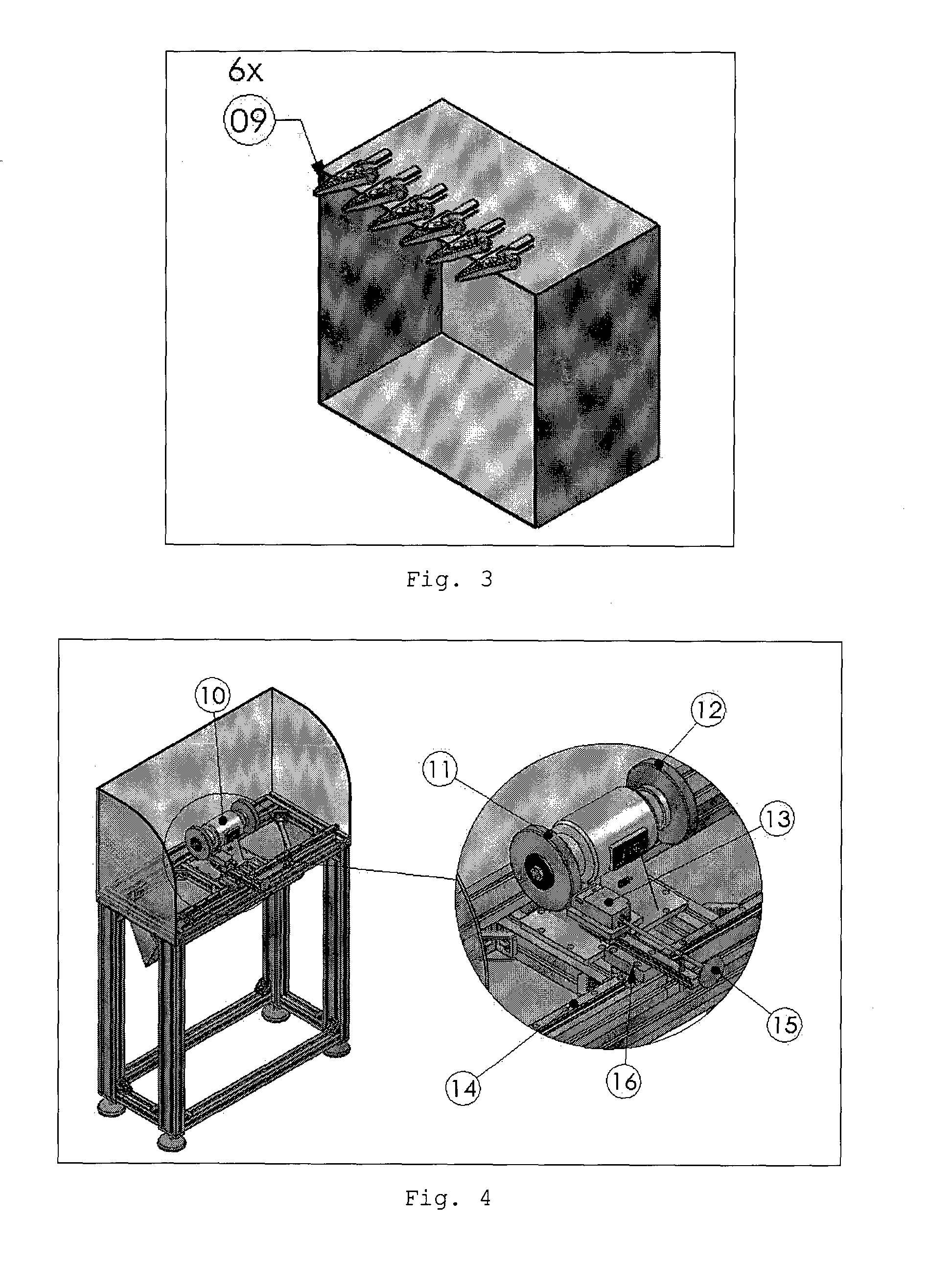

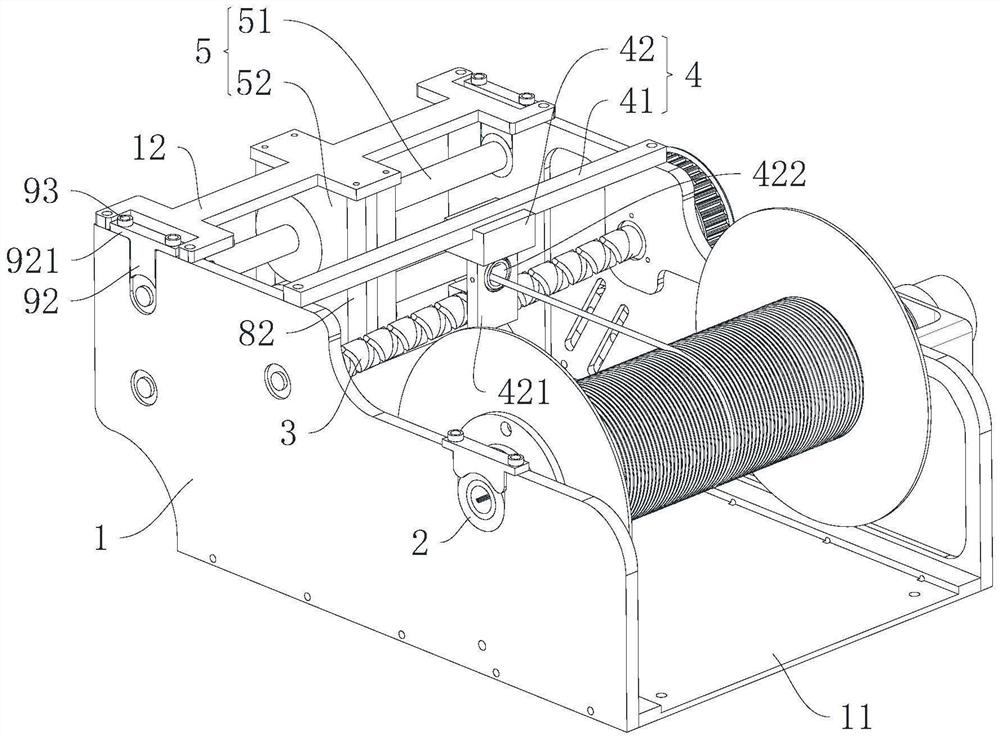

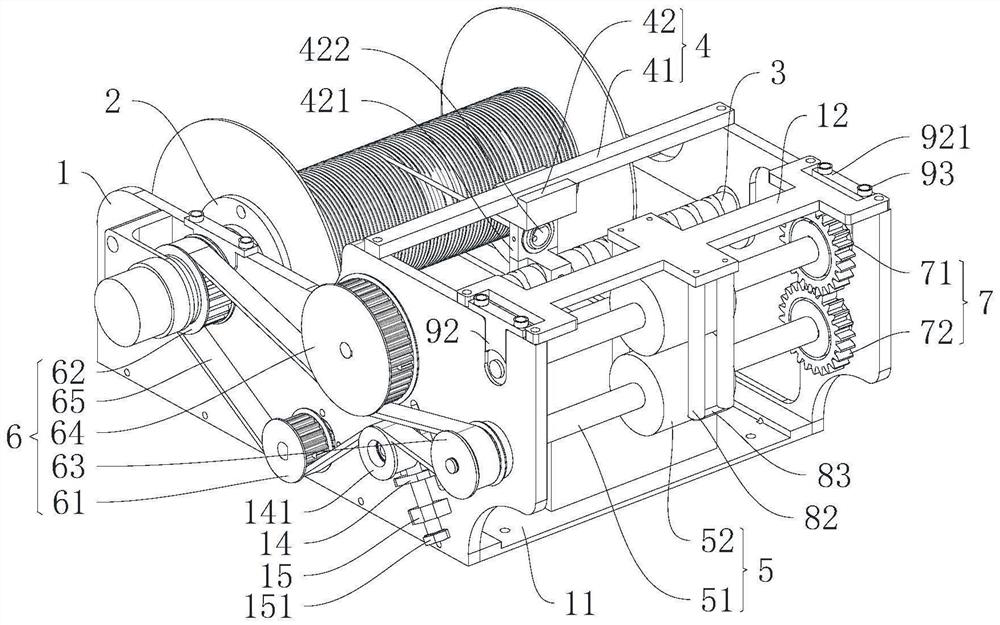

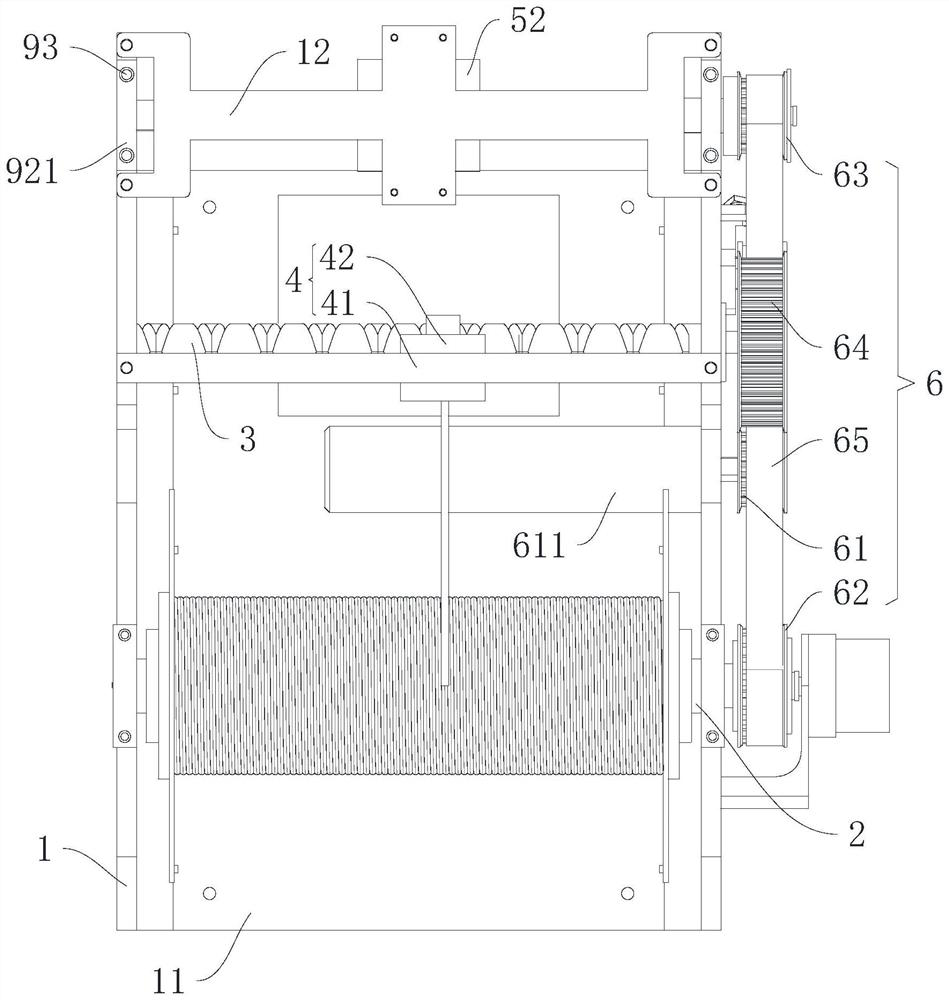

Optical fiber take-up and pay-off device

Owner:河北易沃克机器人科技有限公司

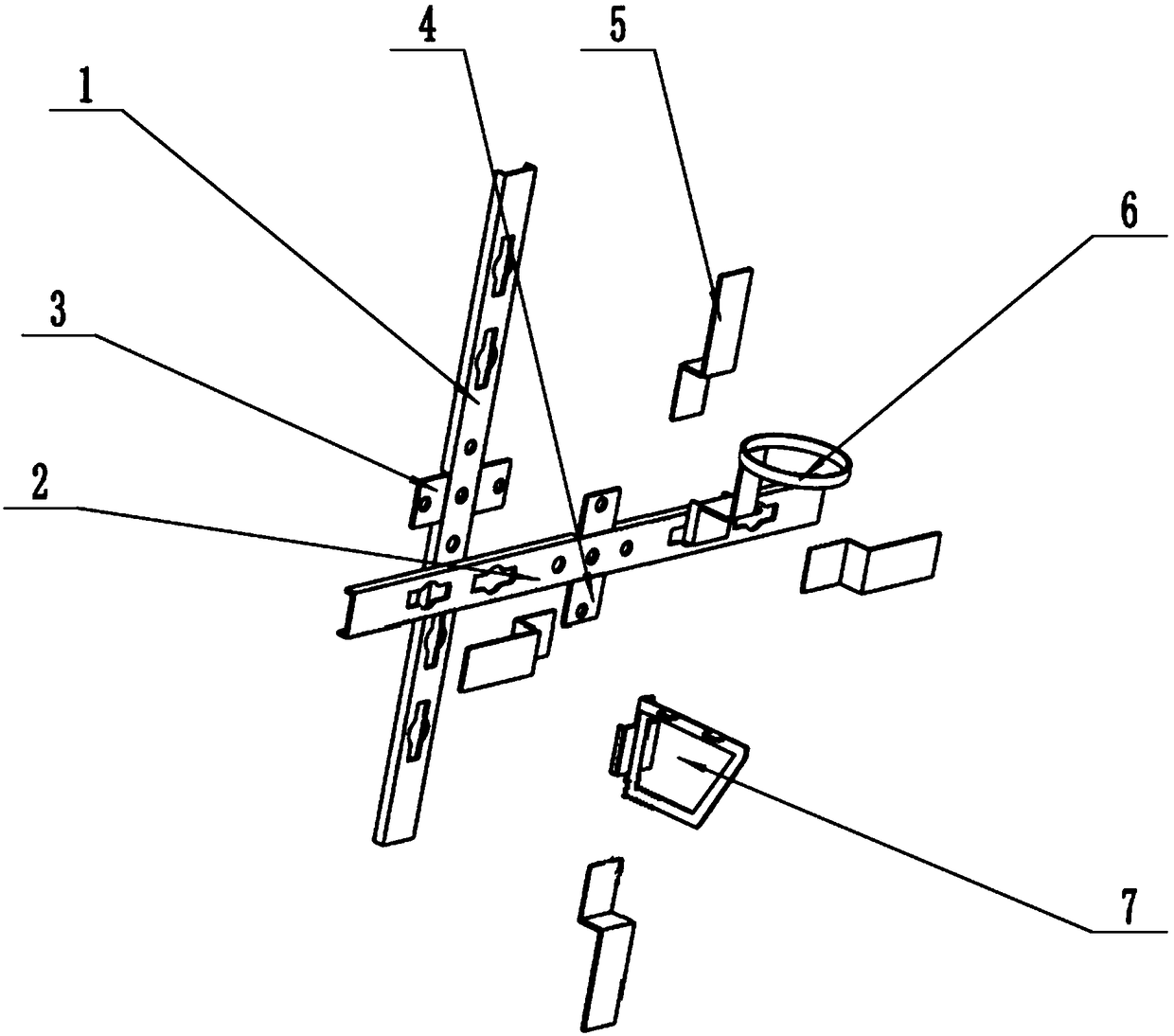

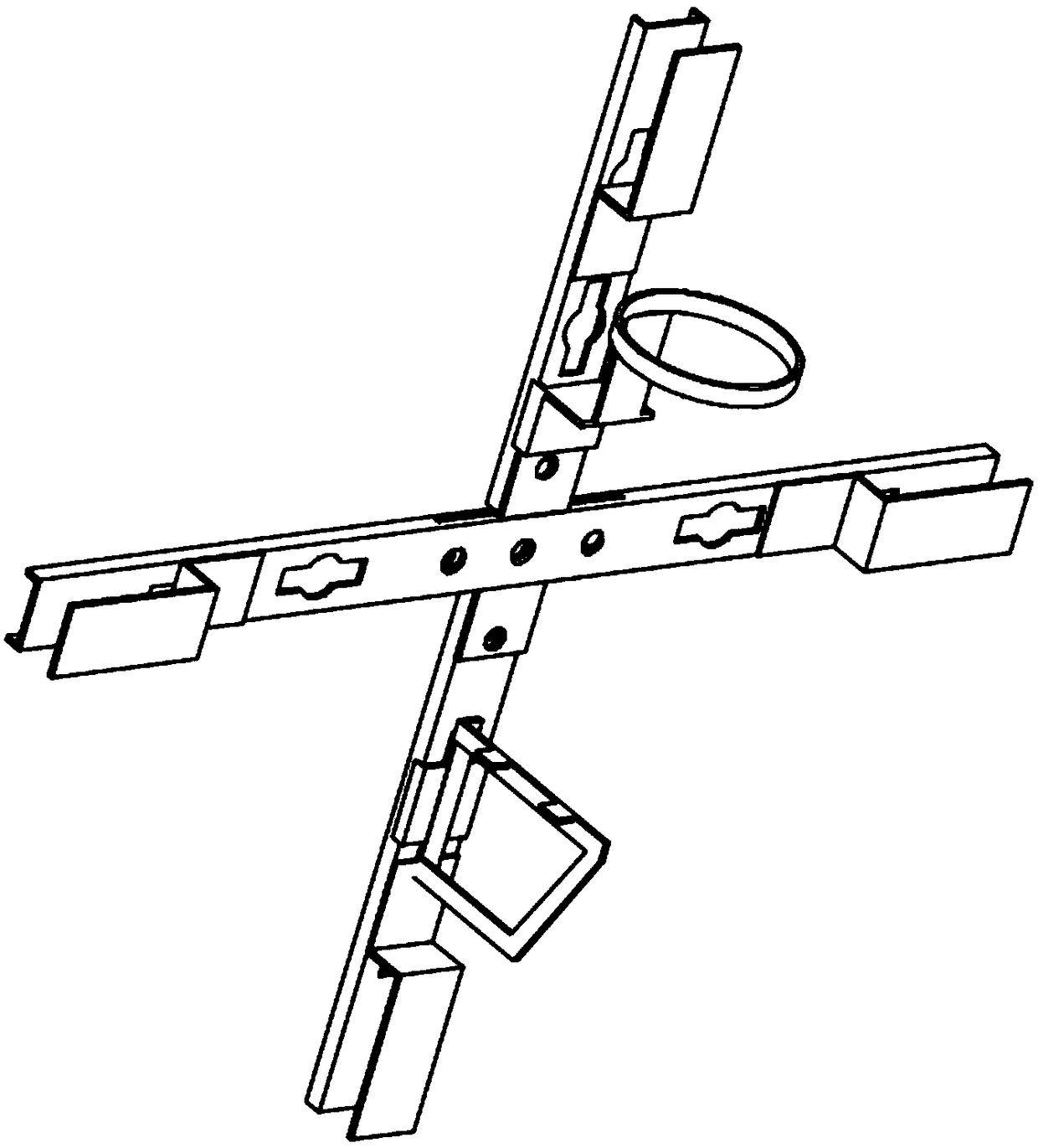

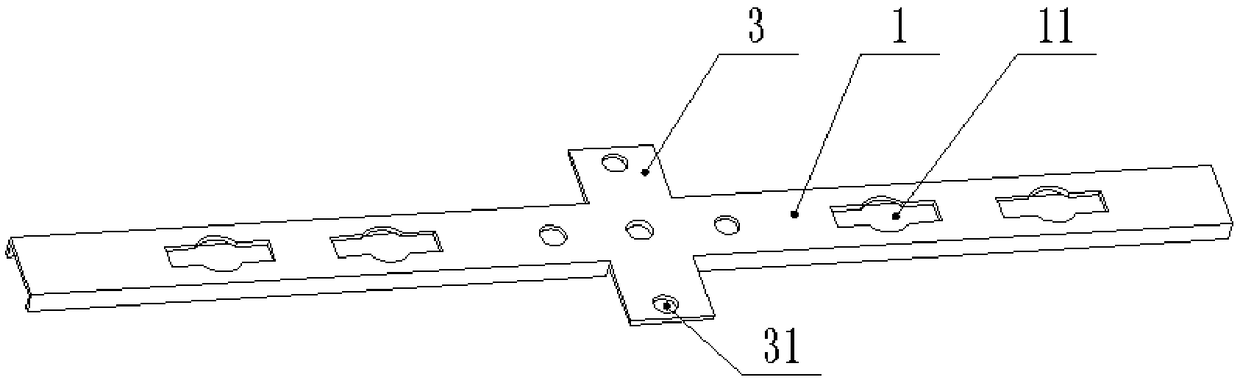

Combined residual cable coiling storage device suitable for ADSS (All Dielectric Self-Supporting) optical fiber cable

PendingCN109307914ASave manpower and material resourcesSave moneyFibre mechanical structuresEngineeringOptical fiber cable

Owner:INFORMATION COMM COMPANY STATE GRID SHANDONG ELECTRIC POWER +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap