Manufacturing process of optical cable

A manufacturing process and technology for optical cables, applied in optics, light guides, optical components, etc., can solve problems such as inconvenient construction, ointment outflow, and difficulty in cleaning ointment, and achieve the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

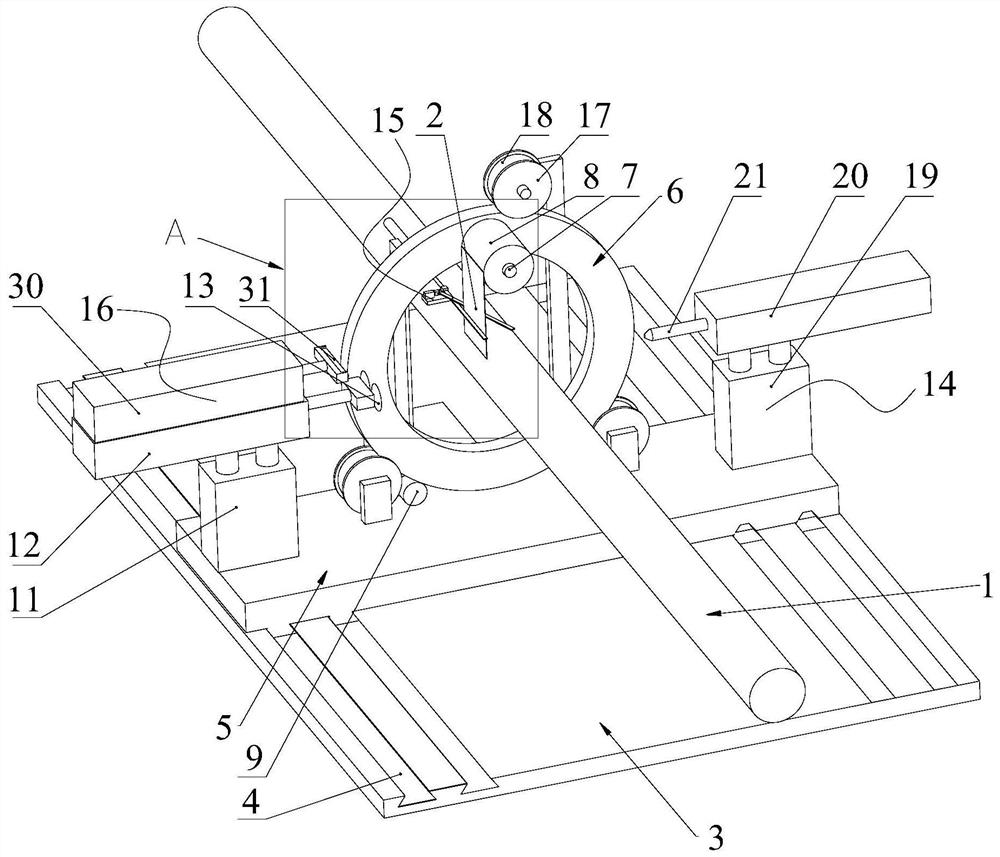

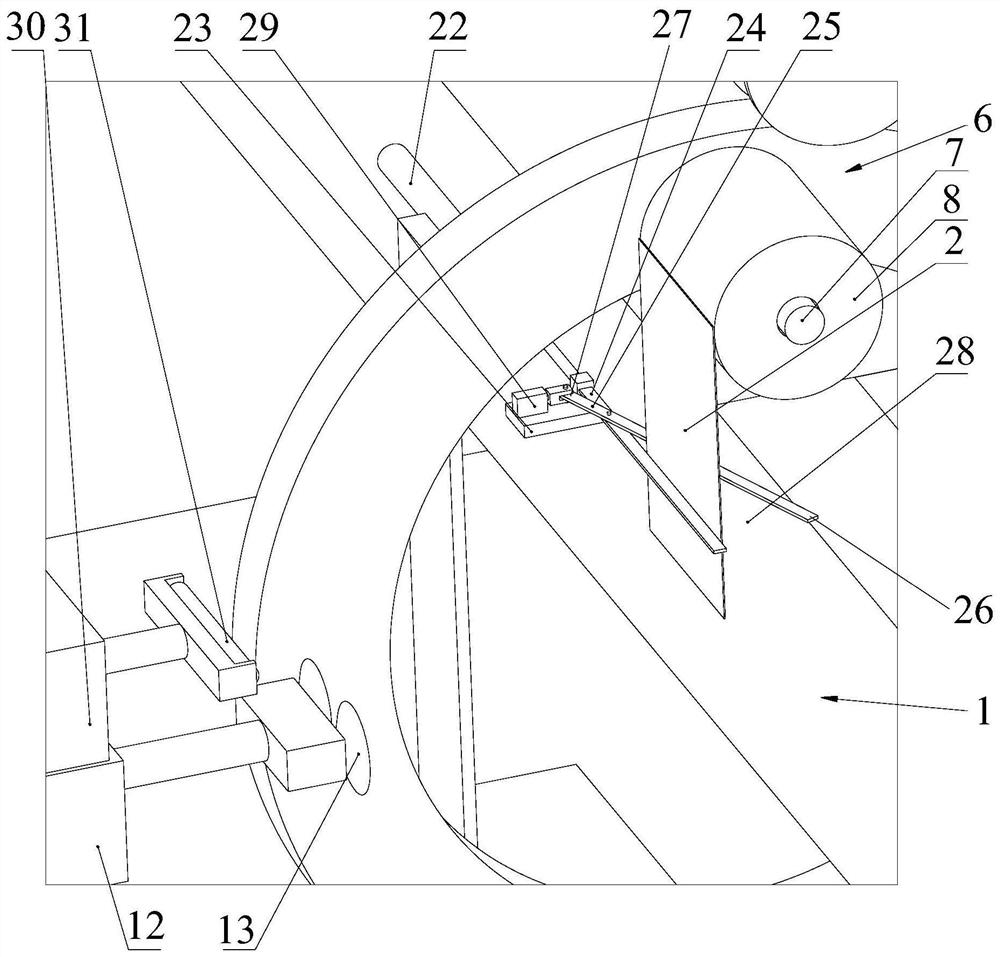

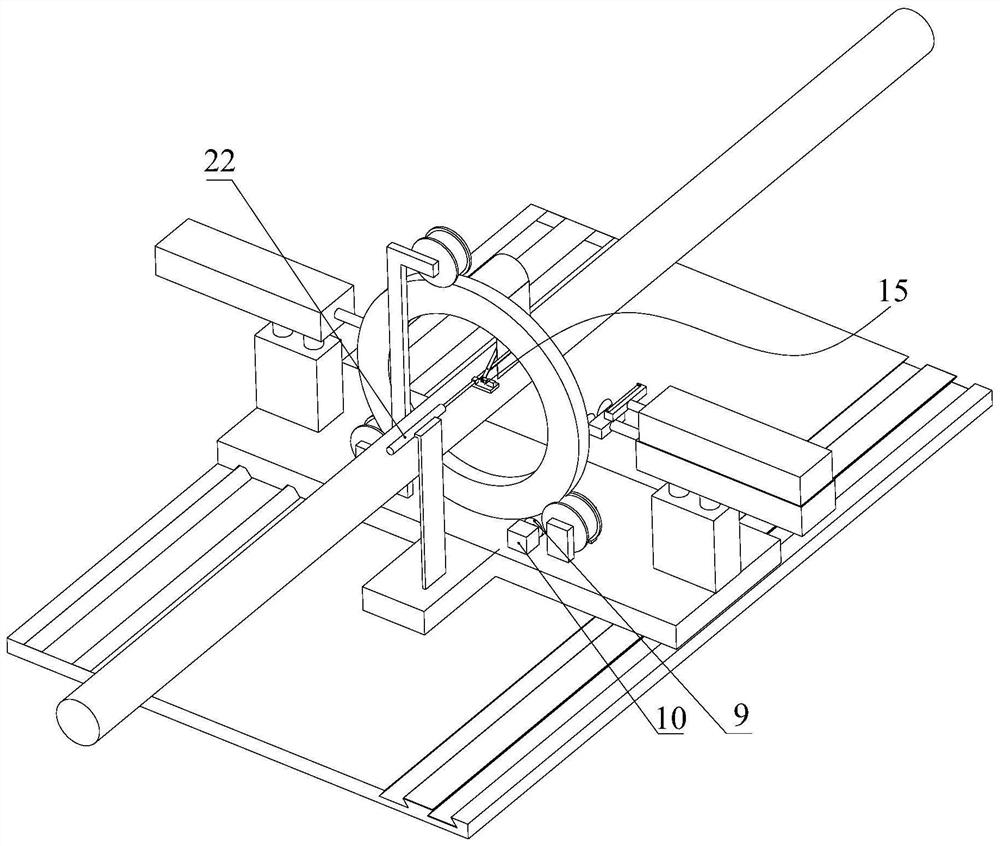

[0061] Below in conjunction with each accompanying drawing, the present invention is described in detail.

[0062] Such asfigure 1 Shown, a kind of manufacturing process of optical cable, comprises the following steps:

[0063] 1) A water blocking tape 2 is wound around the outer side of the cable core 1 at intervals;

[0064] 2) The cable core 1 enters the ointment device to apply ointment;

[0065] 3) The cable core 1 enters the extrusion device, and the outer sheath is processed on the outside of the cable core 1;

[0066] 4) Cool and dry the outer sheath, and then spray identification marks on the corresponding positions of the outer sheath and the dry waterproof jacket.

[0067] In the present application, the water-blocking strips 2 are arranged at intervals before the cable core 1 is coated with ointment, so that there is basically no ointment in the section where the water-blocking strips 2 are located after the cable core 1 has gone through the ointment process. Durin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap