Optical waveguide monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

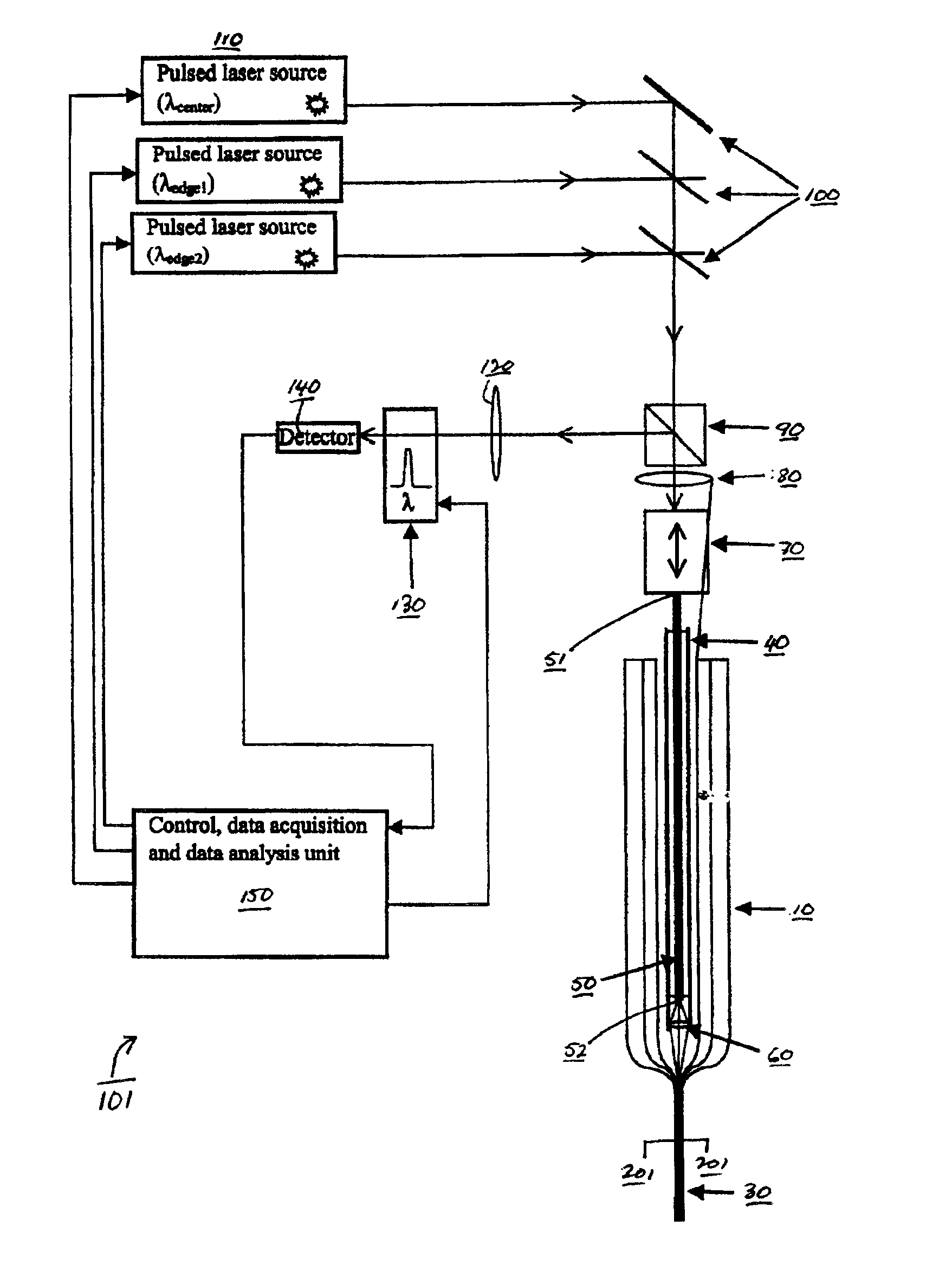

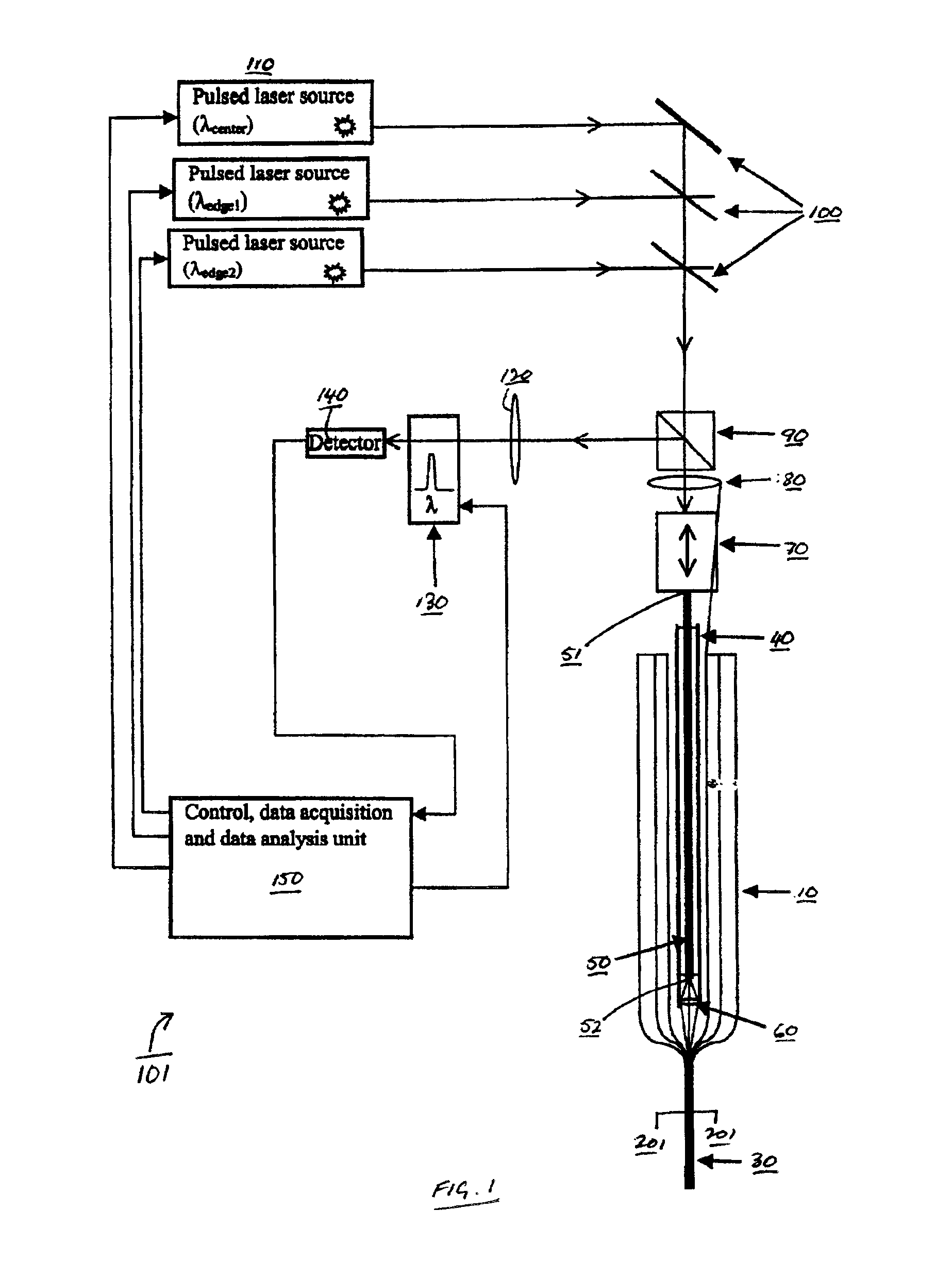

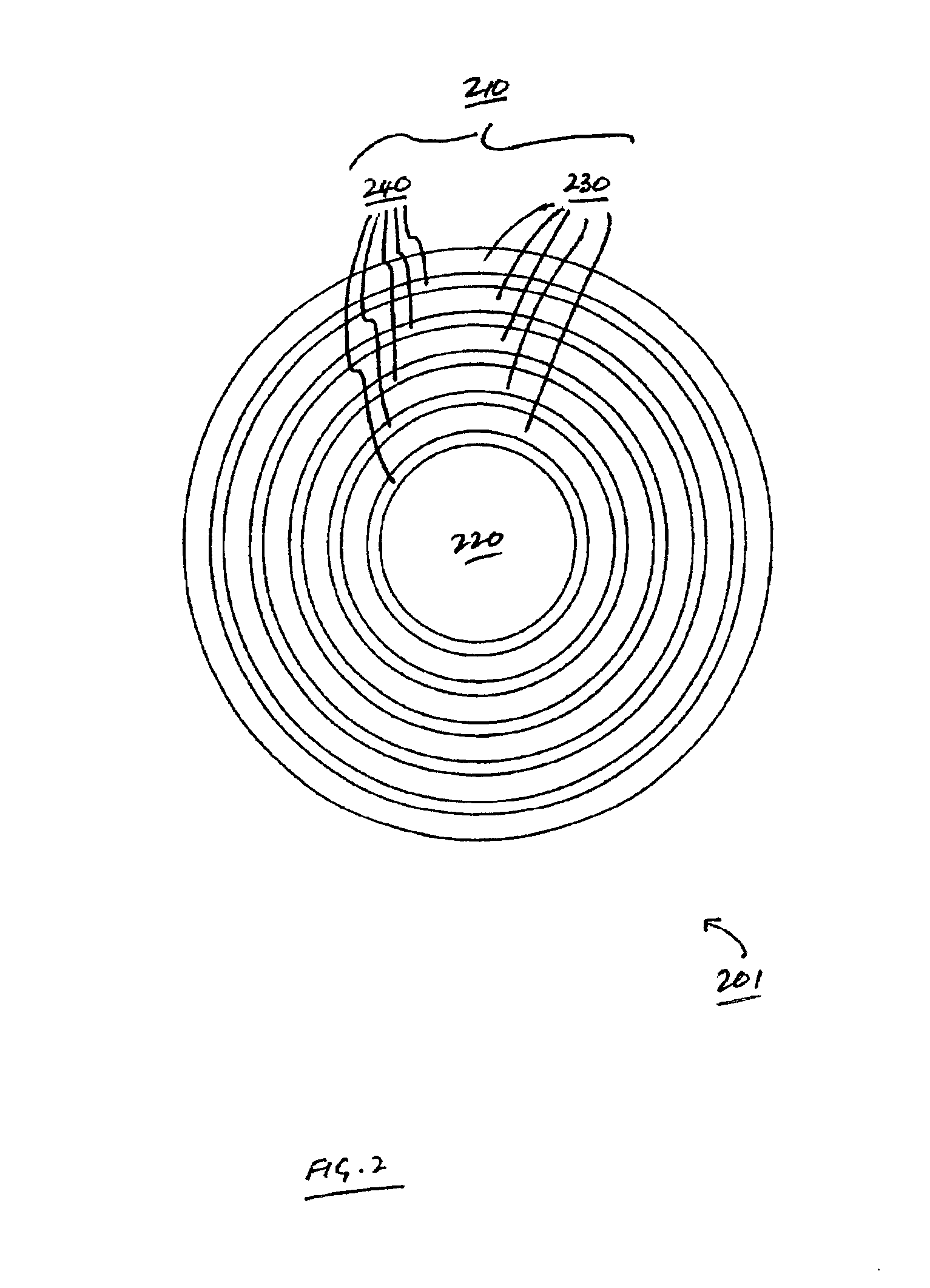

The invention features methods for detecting defects in and monitoring the transmission loss of an optical waveguide, during, for example, drawing or cabling of an optical waveguide. For example, the invention relates to monitoring the quality (e.g., monitoring transmission loss and detecting structural and compositional defects) of optical waveguides that utilize photonic bandgap confinement mechanisms for guiding light (referred to here as photonic crystal fibers), including hollow fibers. In general, defects refer to any structural, compositional or other perturbation of the fiber from its ideal design, which can affect the optical and / or mechanical performance and reliability of the fiber. Examples of defects include perturbations to core radius, perturbations to the layer thickness, delamination between layers, bubbles, particle inclusions in the core or layers, and compositional variations in the layers affecting the refractive index of the layers.

Fiber monitoring is performed

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap