Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131results about "Material analysis by optical means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

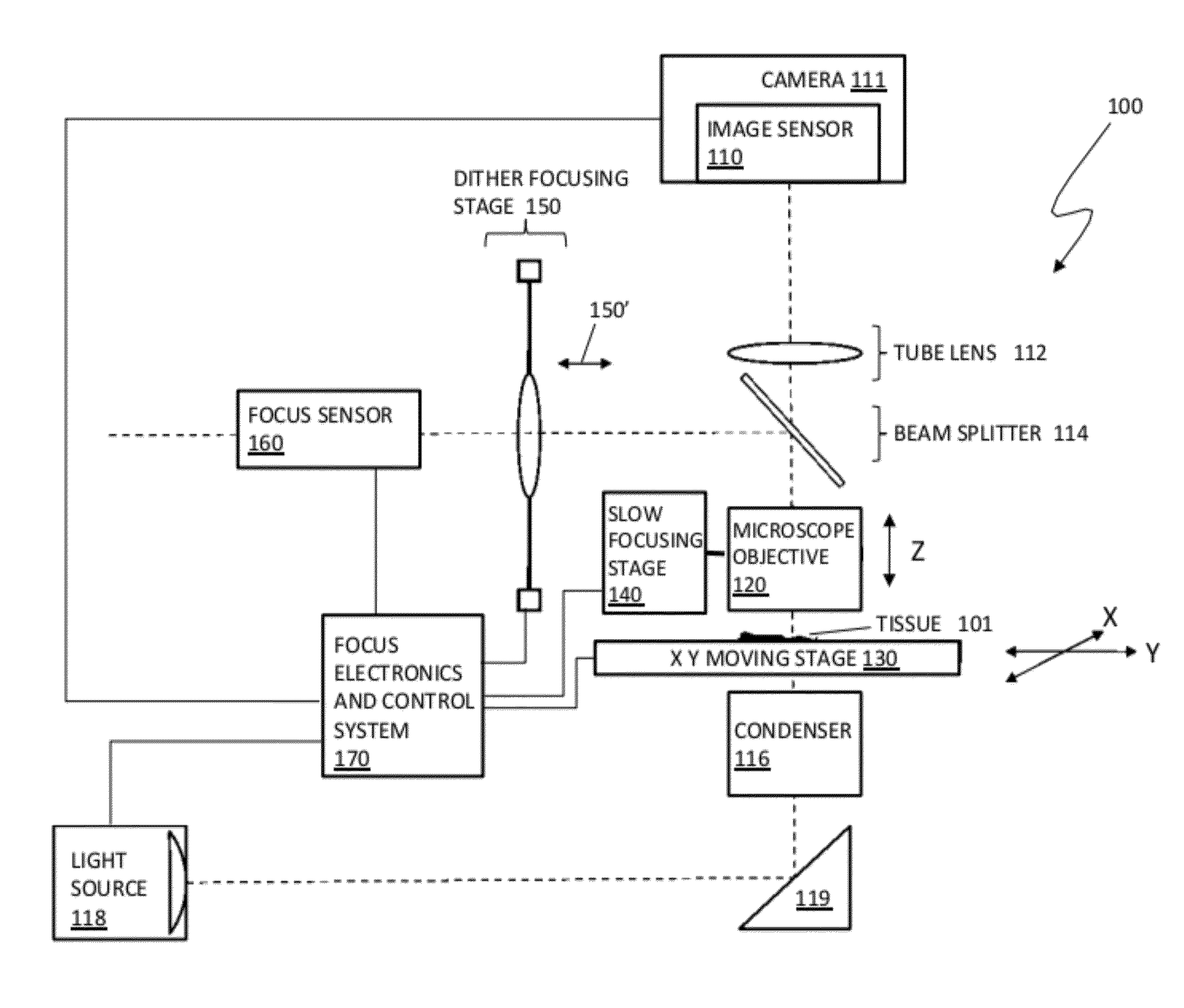

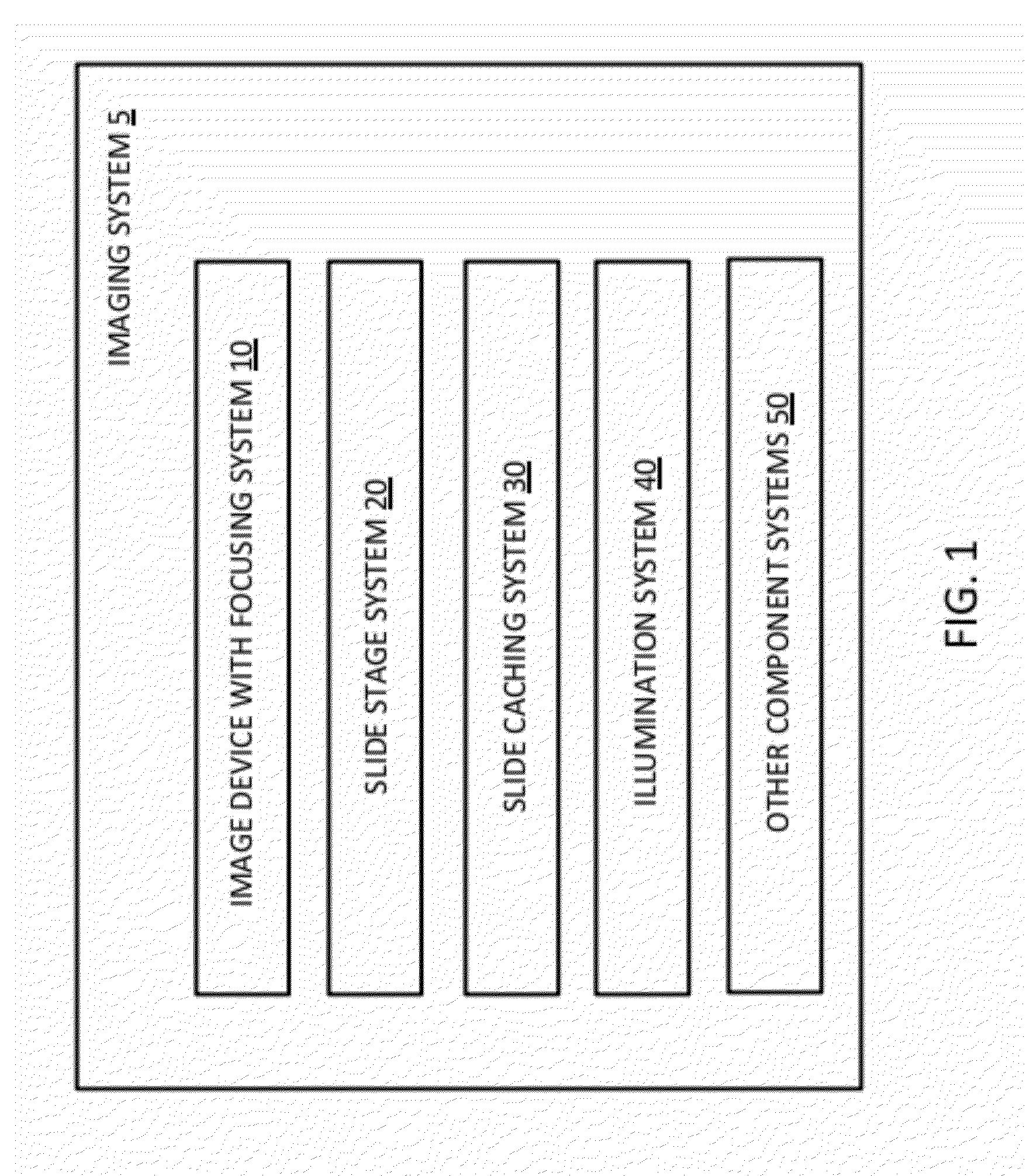

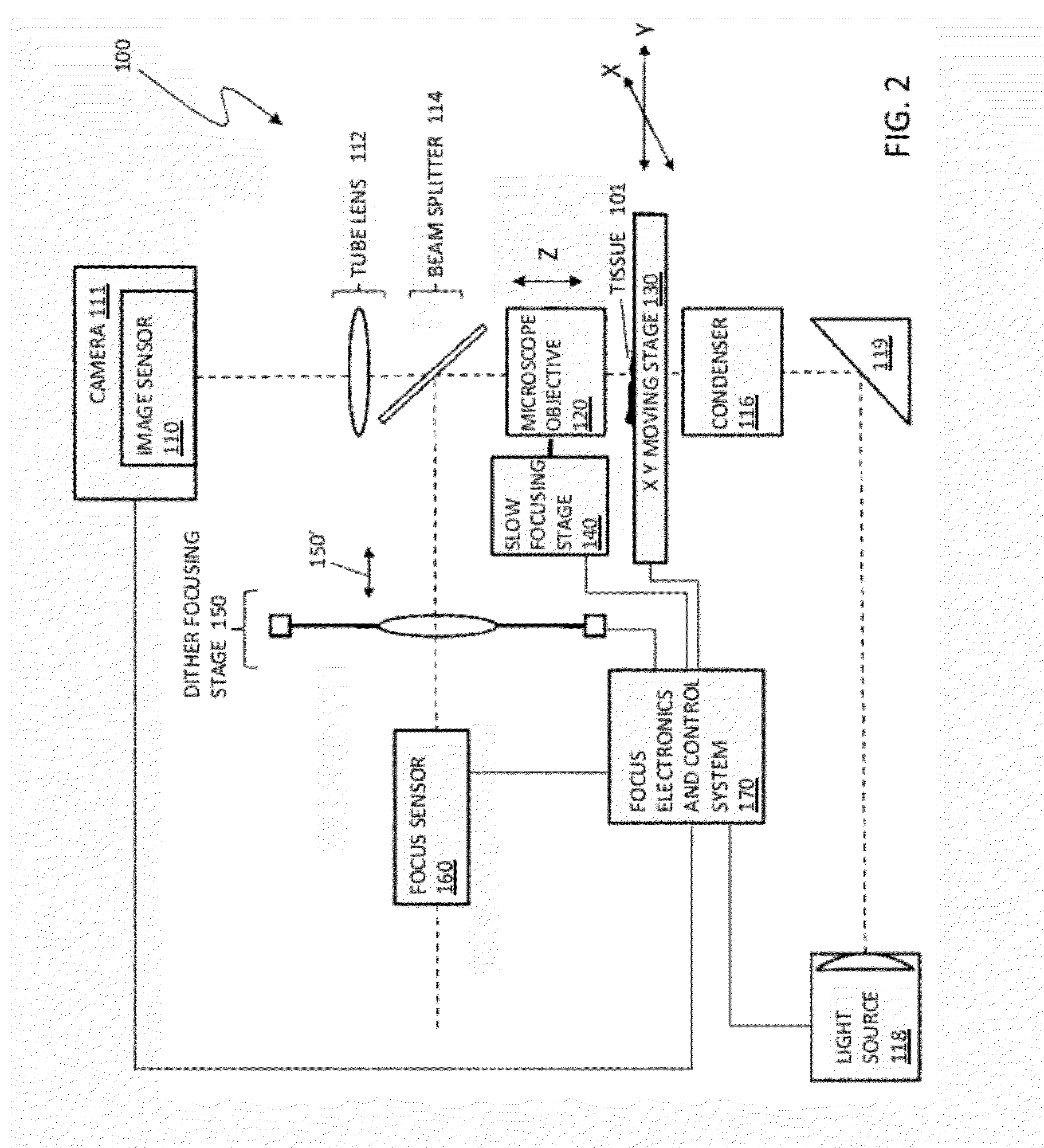

Imaging system and techniques

ActiveUS20120312957A1SamplingProjector focusing arrangementTissue sampleDigital image

Owner:VENTANA MEDICAL SYST INC

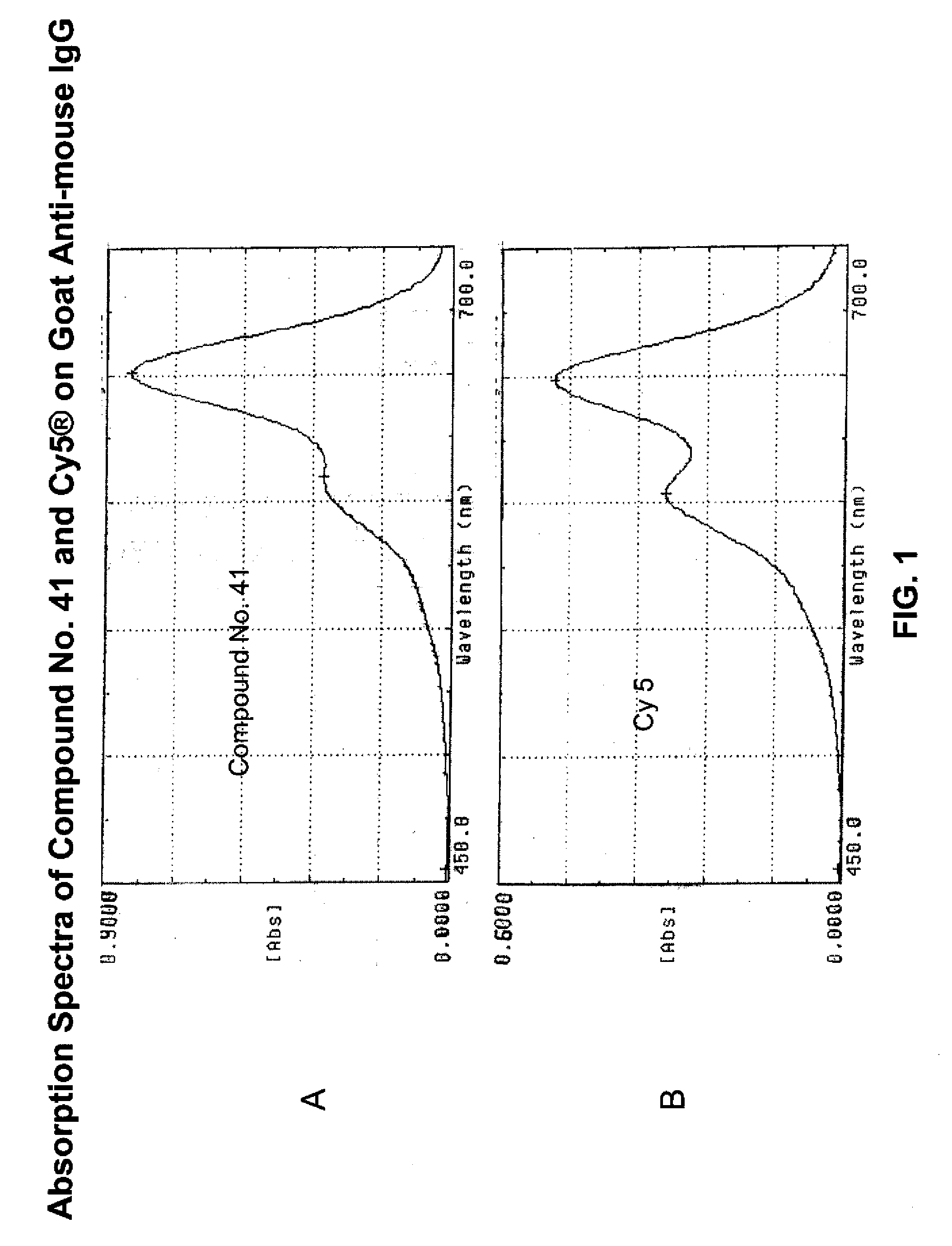

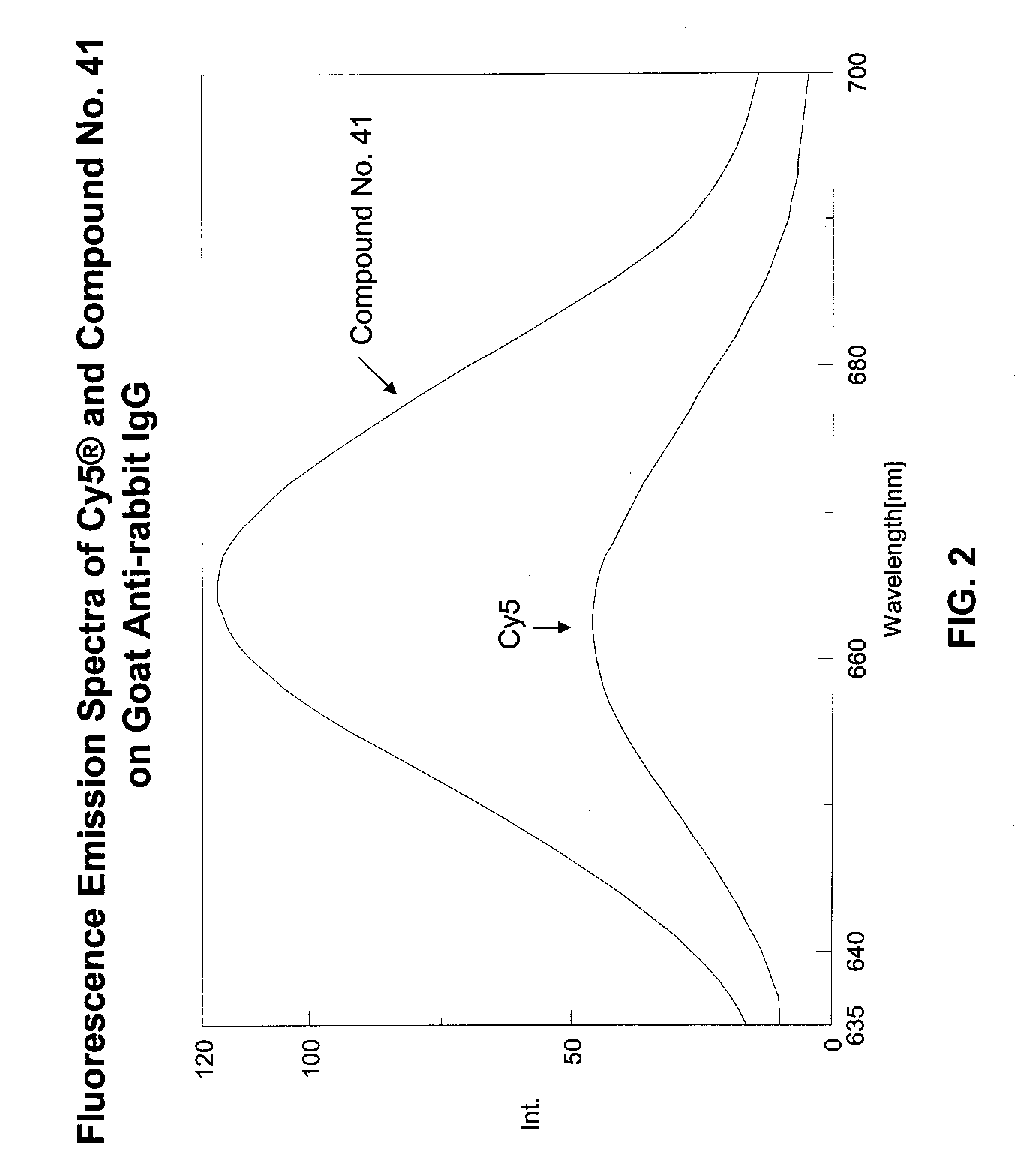

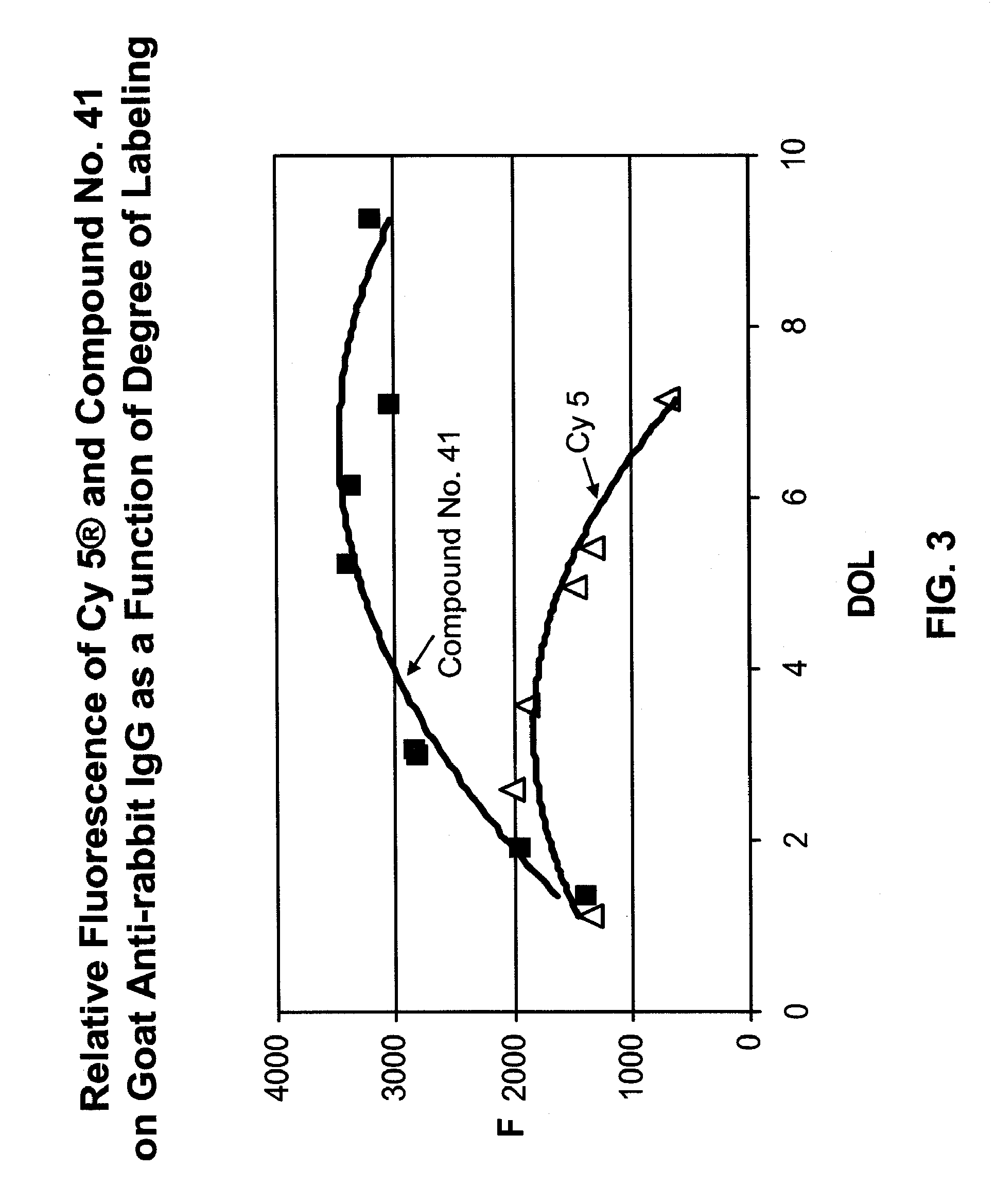

Fluorescent compounds

ActiveUS20090305410A1Convenient and effective labelingMethine/polymethine dyesPeptide/protein ingredientsBiotechnologyDisease

Owner:BIOTIUM INC

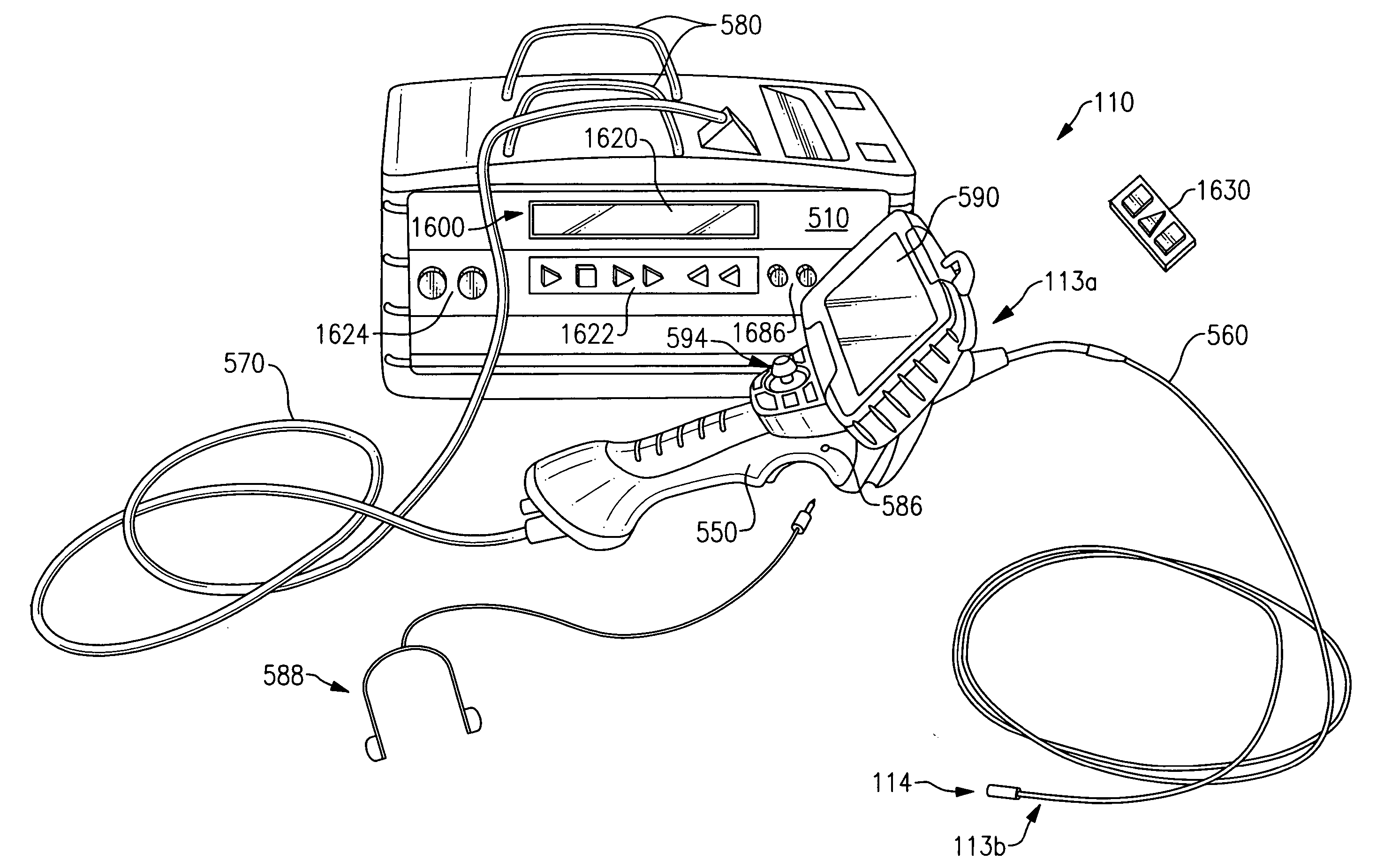

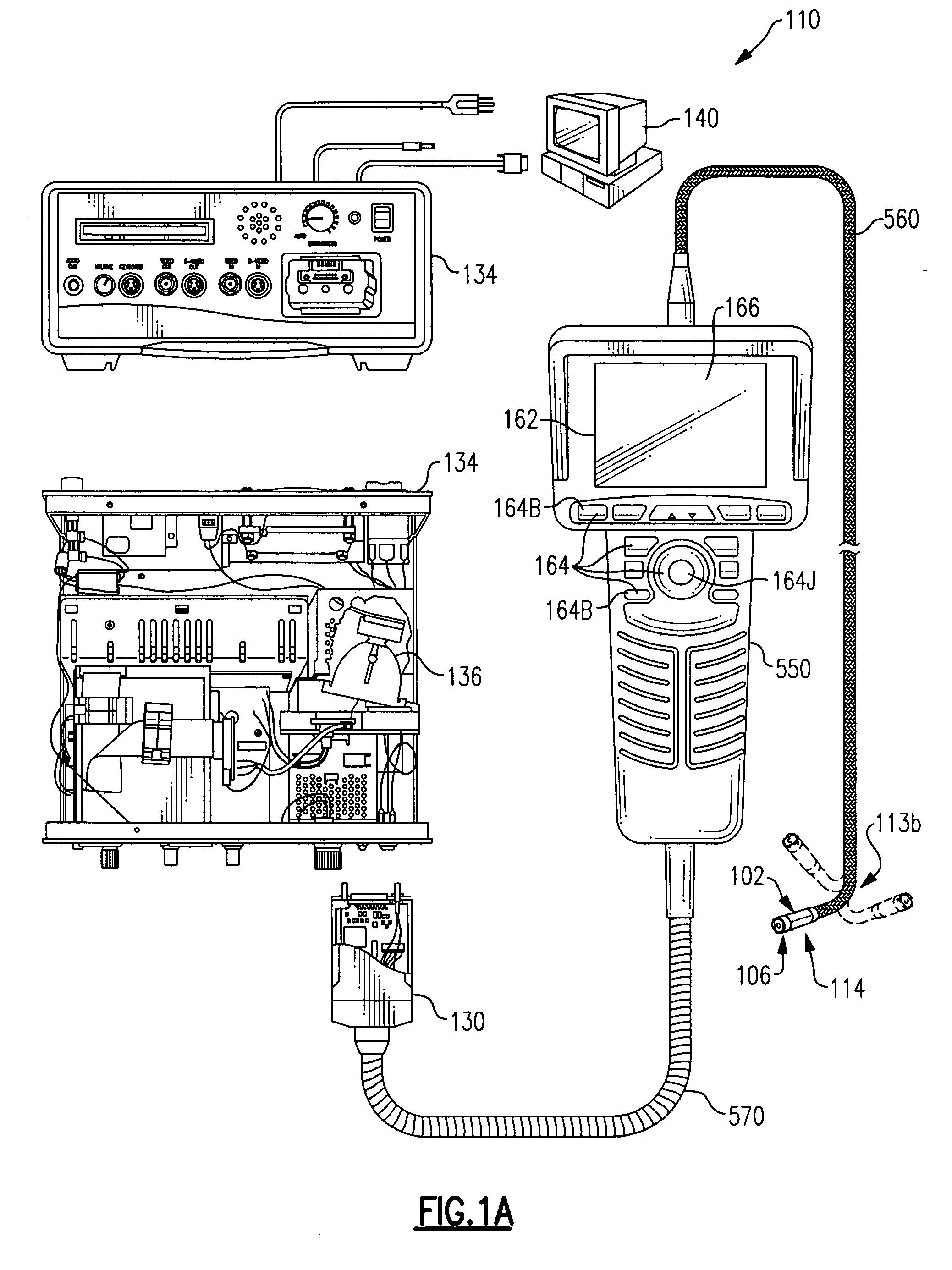

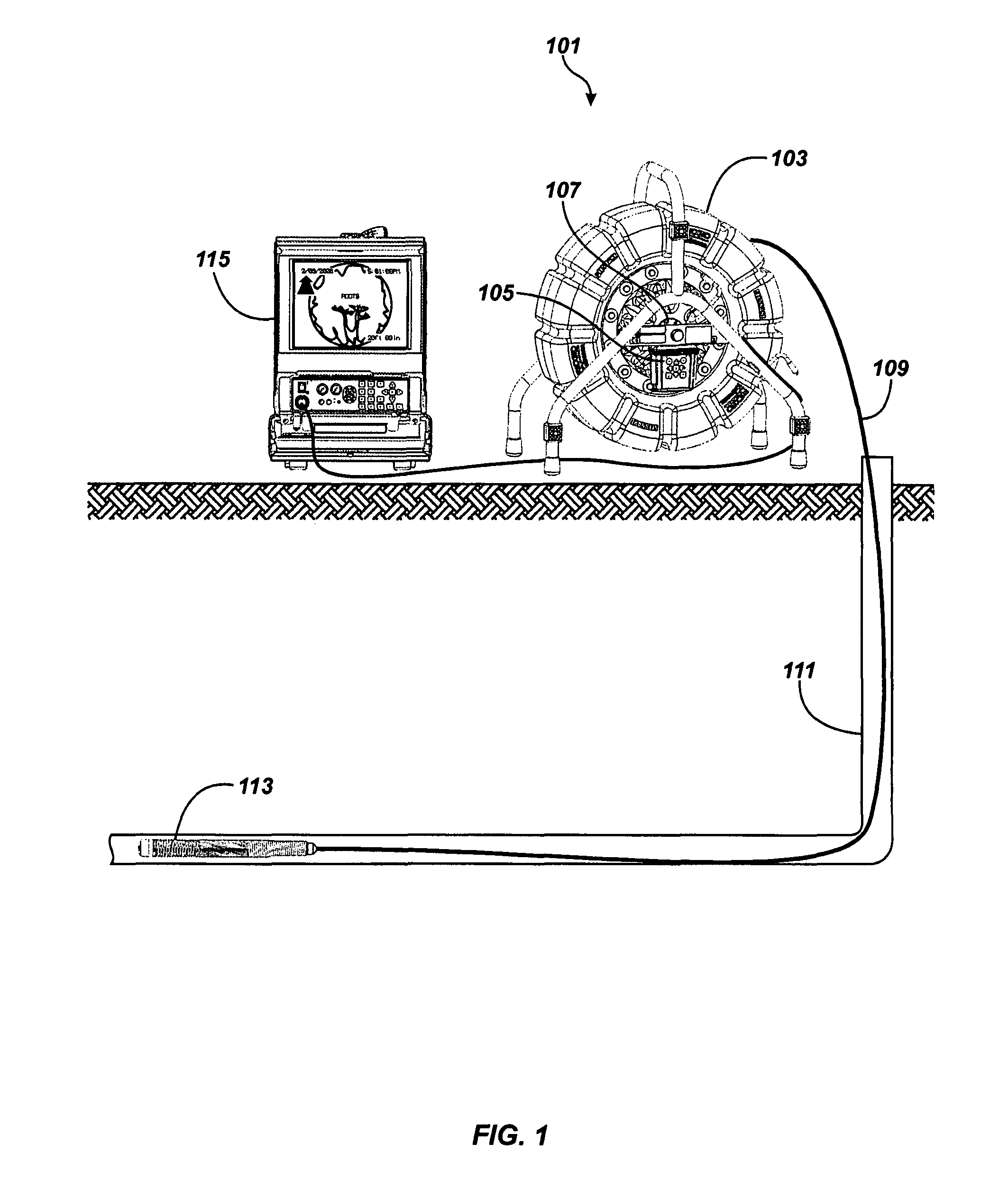

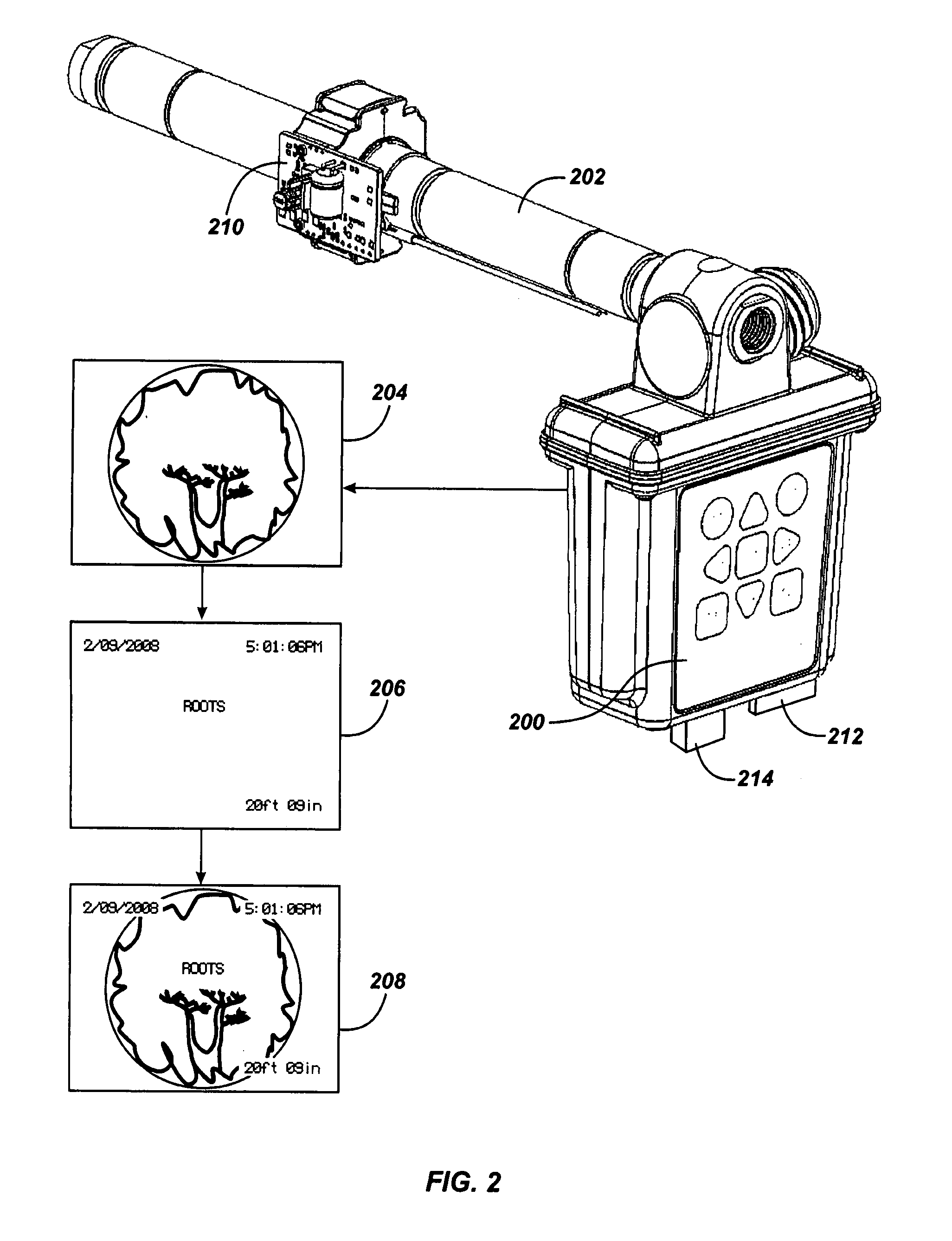

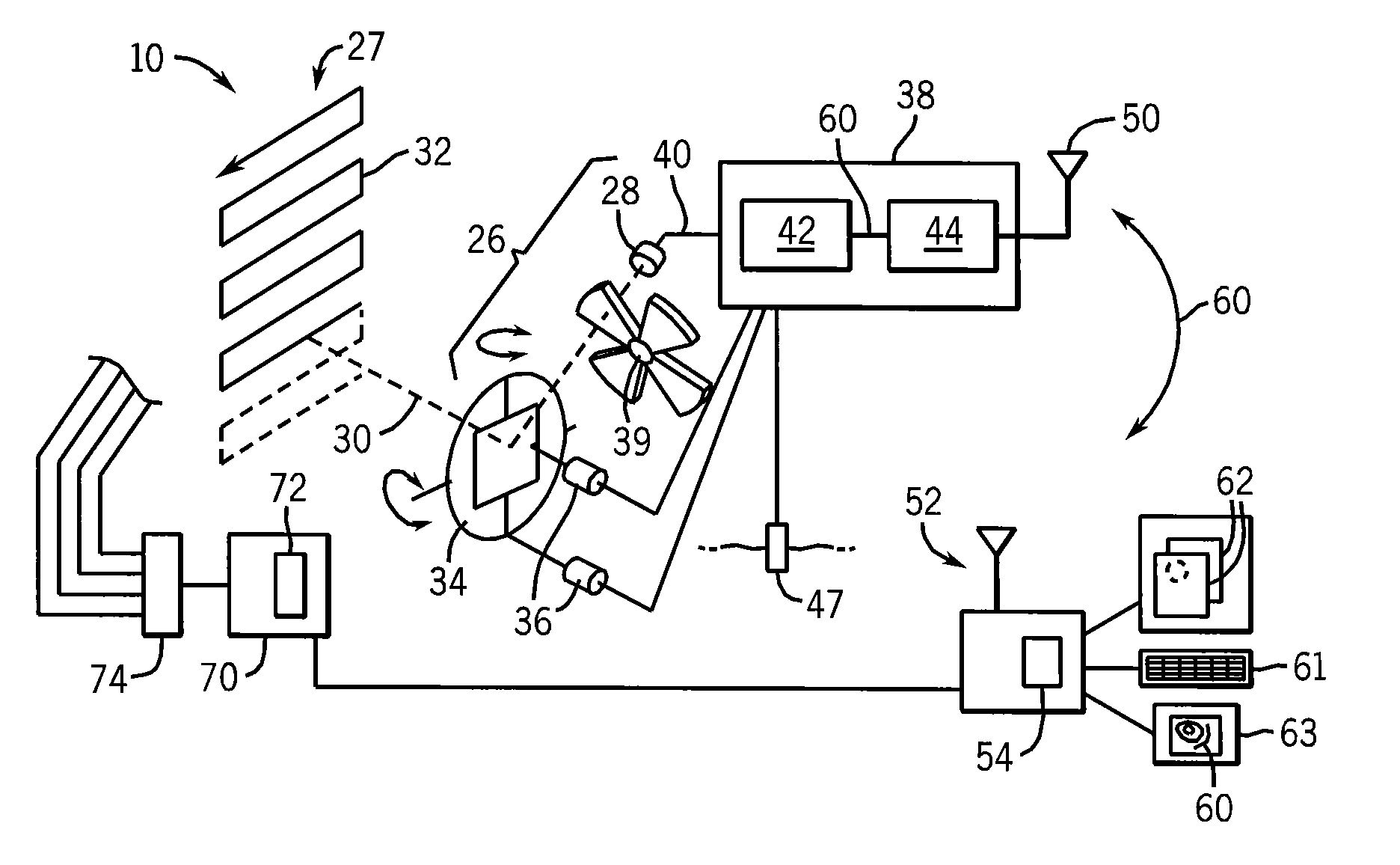

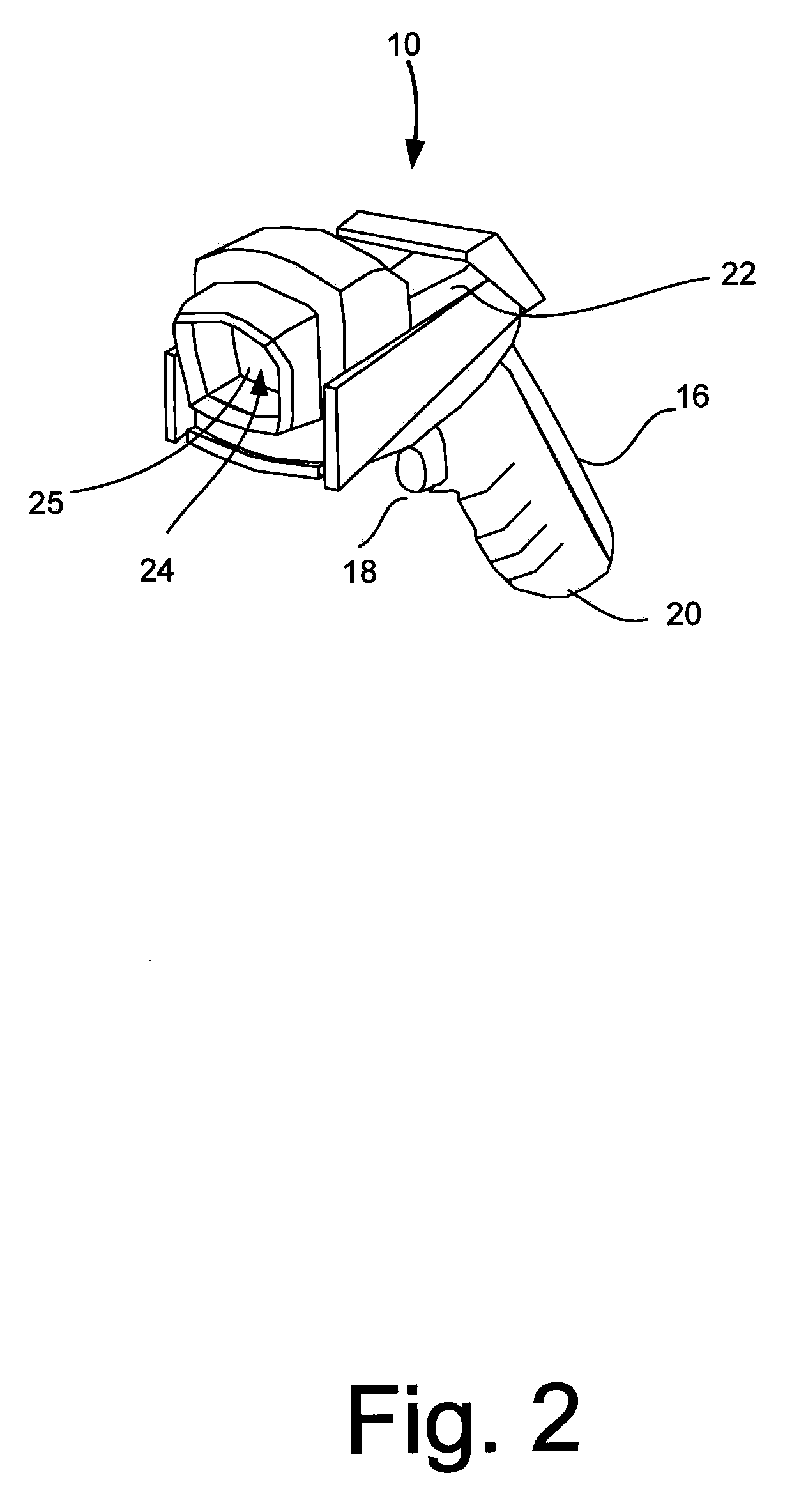

Remote video inspection system integrating audio communication functionality

Remote viewing devices and methods are provided to communicate audio information to and / or from a user of the remote viewing device. The audio information can serve an entertainment purpose, and / or can be instructional in order to provide training, guidance and / or feedback to the user prior to or during the inspection process. The audio information can be stored onto physical media such as a CD / DVD disk or a tape, or can be stored as data, such as MP3 data stored within memory accessible to the device. Outputted audio information can be generated by one or more speakers located within the body of the device or located within a headset having a wire line or wireless connection with the remote viewing device.

Owner:GE INSPECTION TECH

Optical waveguide monitoring

InactiveUS6879386B2Cladded optical fibreMaterial analysis by optical meansPhotonic crystalEngineering

Owner:OMNIGUIDE

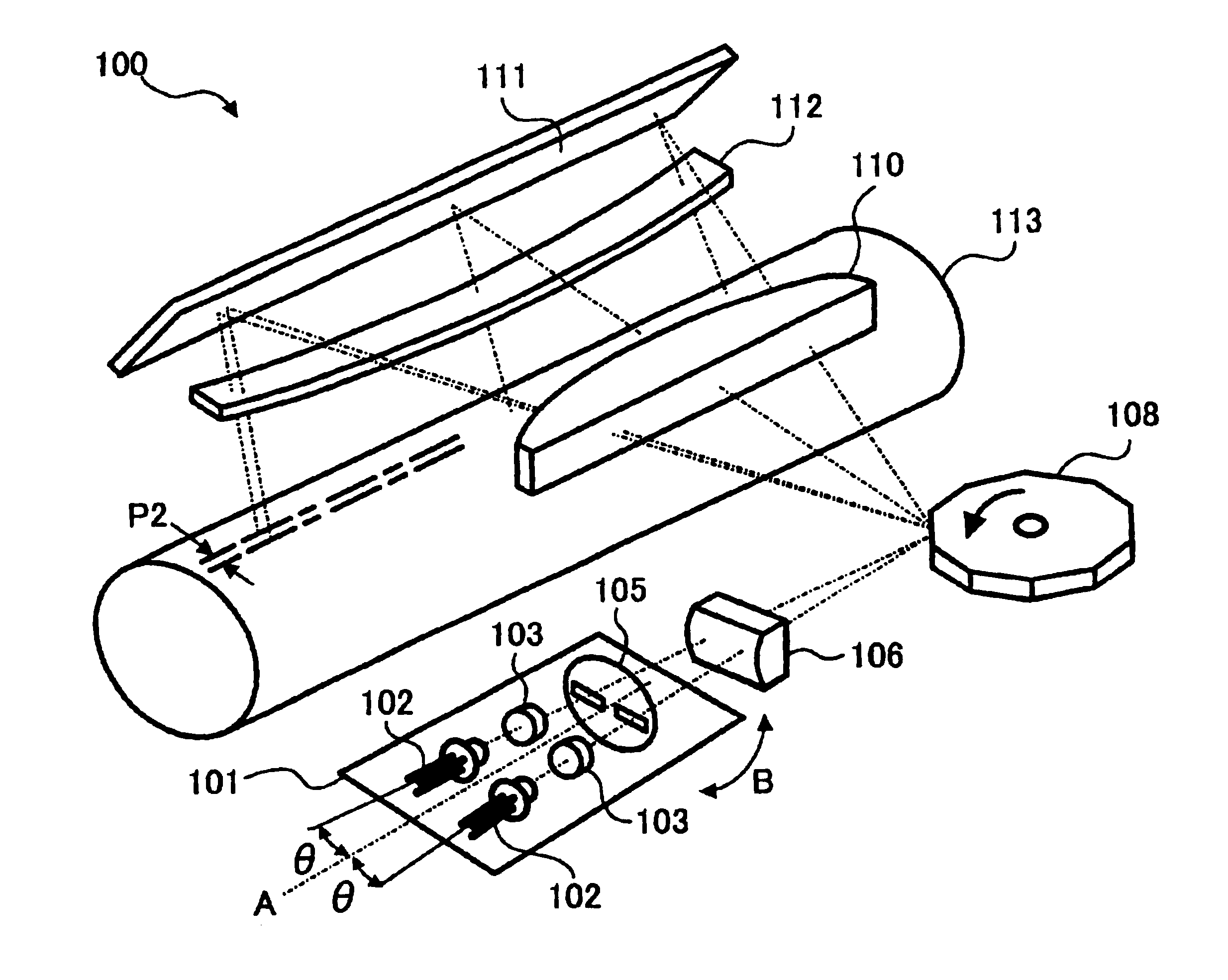

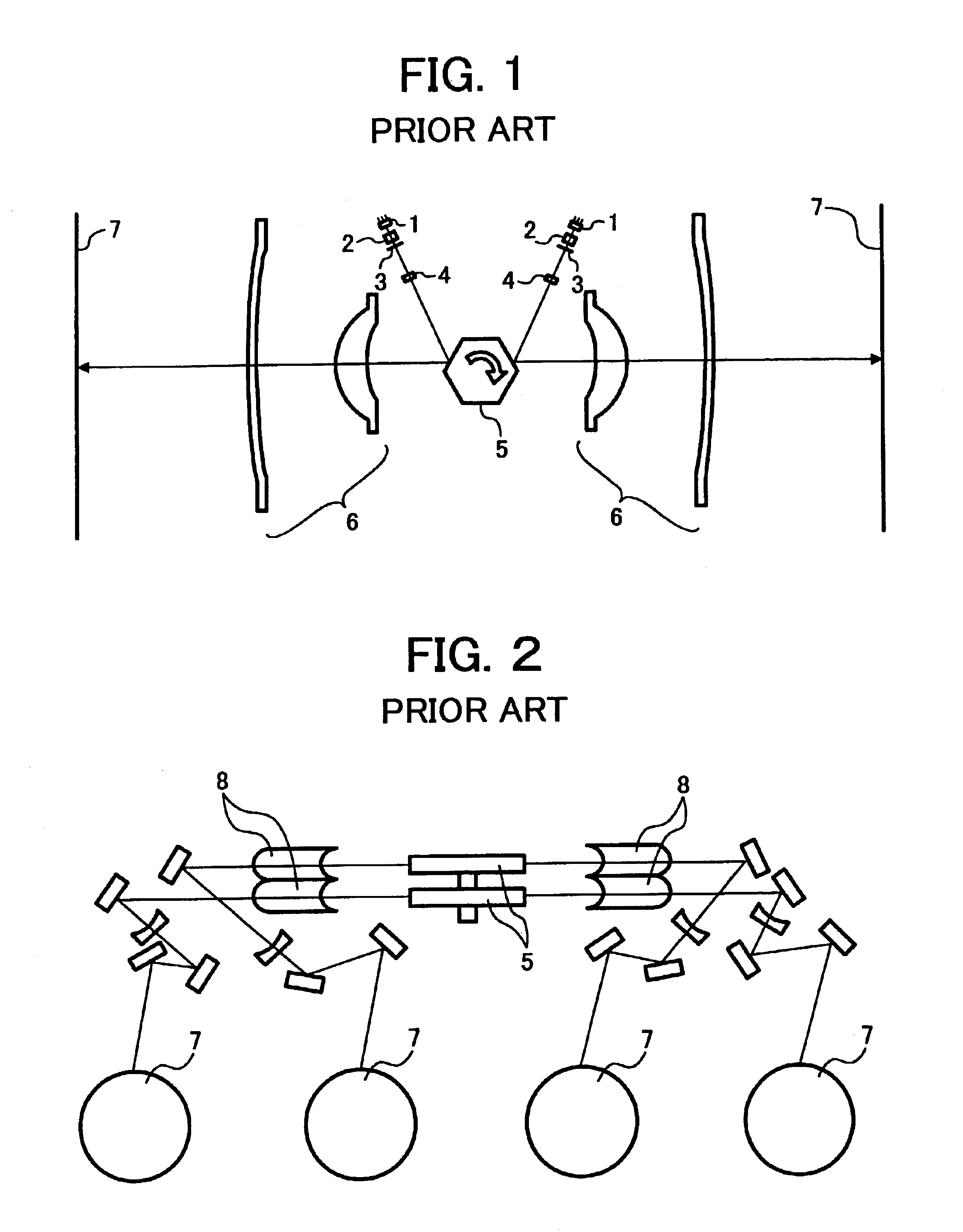

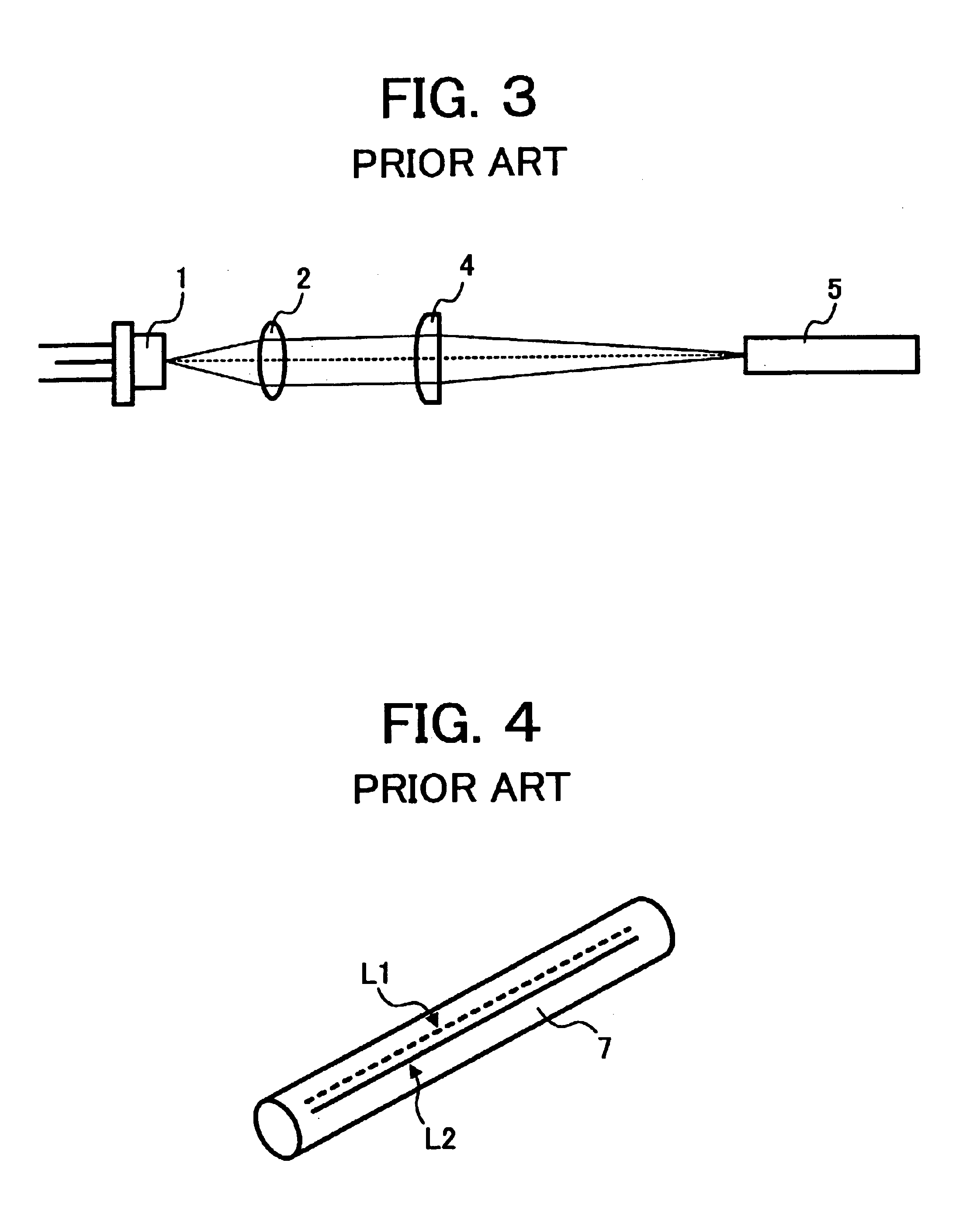

Method and apparatus for multi-beam optical scanning capable of effectively adjusting a scanning line pitch

Owner:RICOH KK

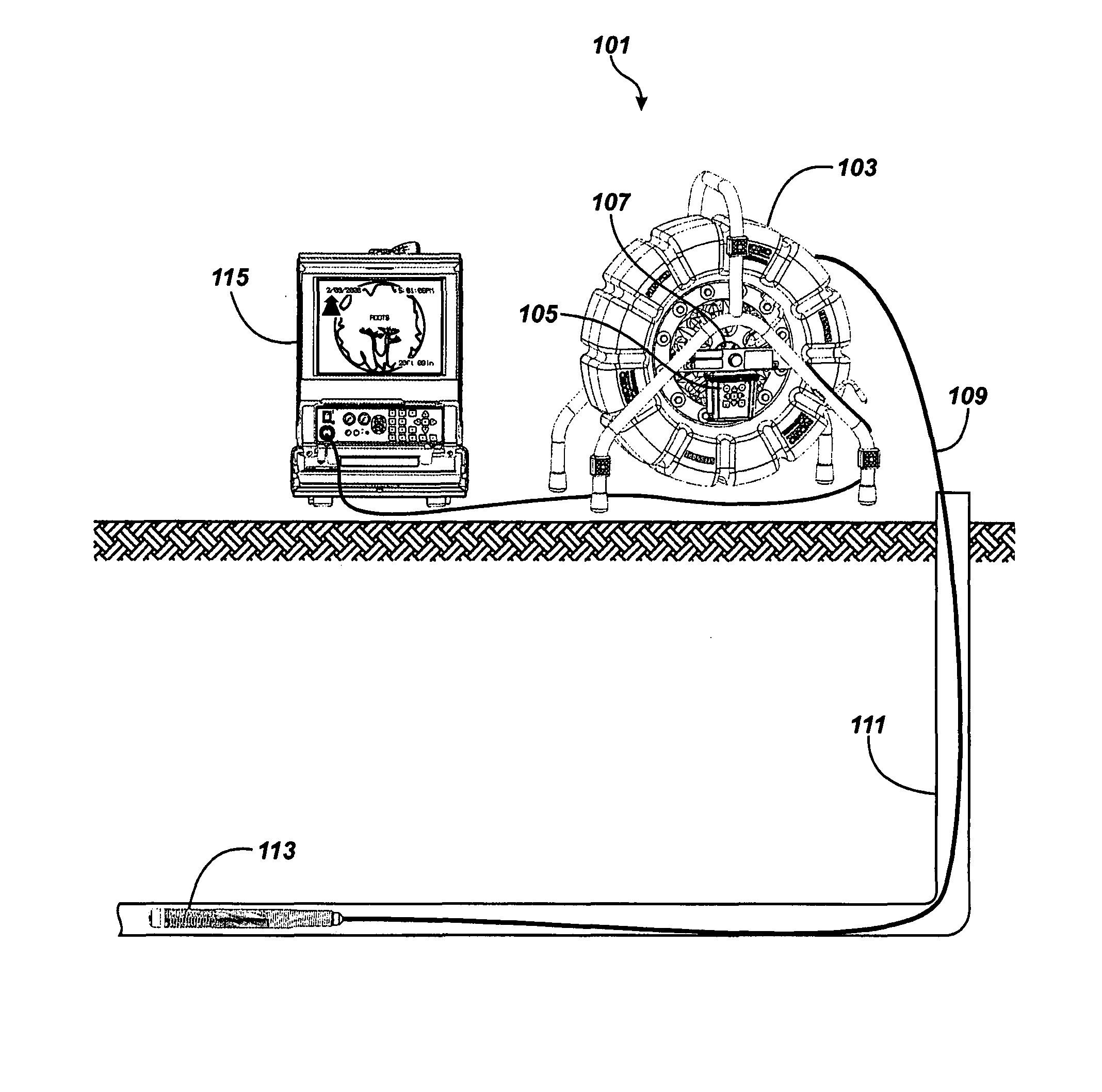

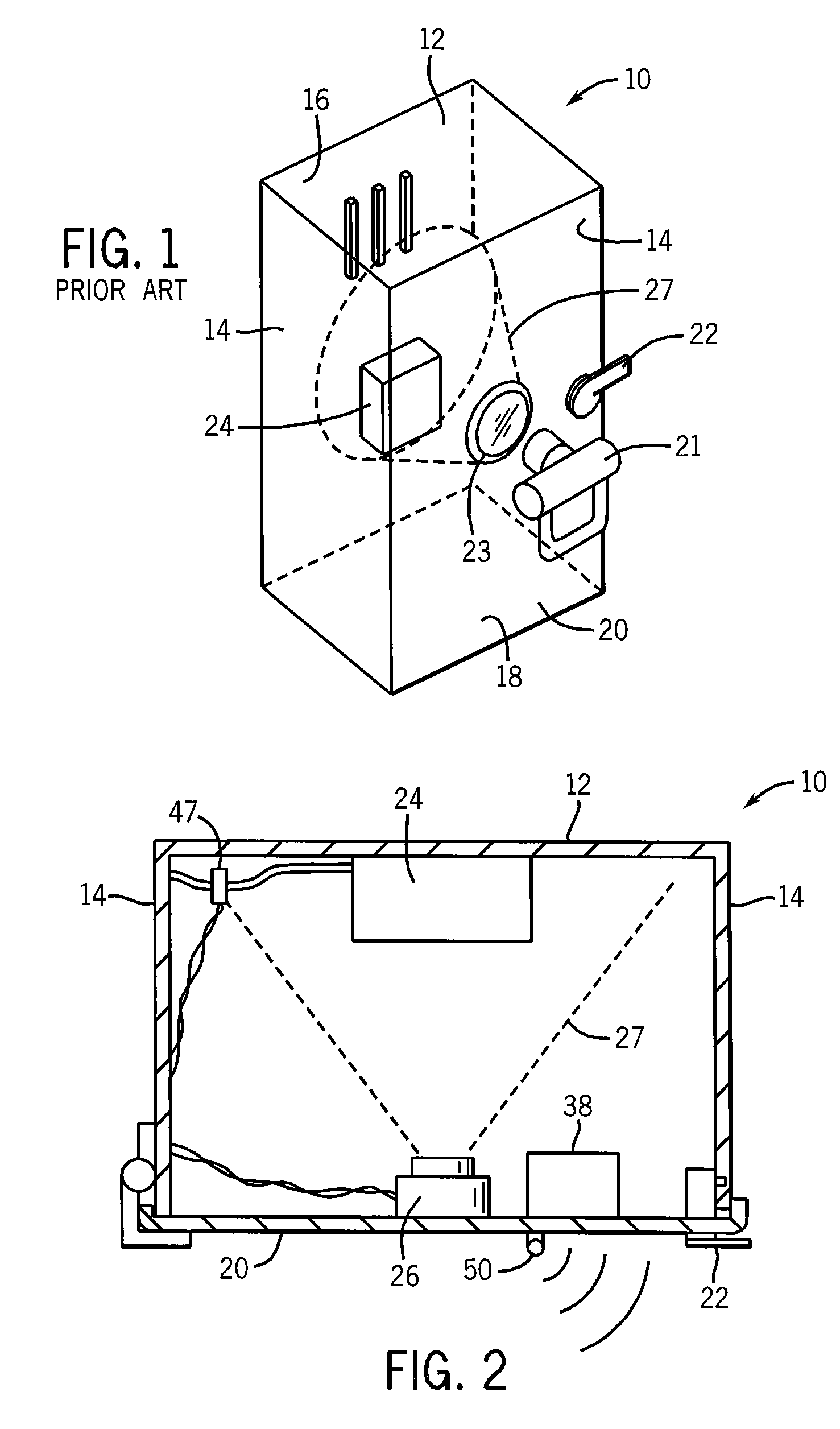

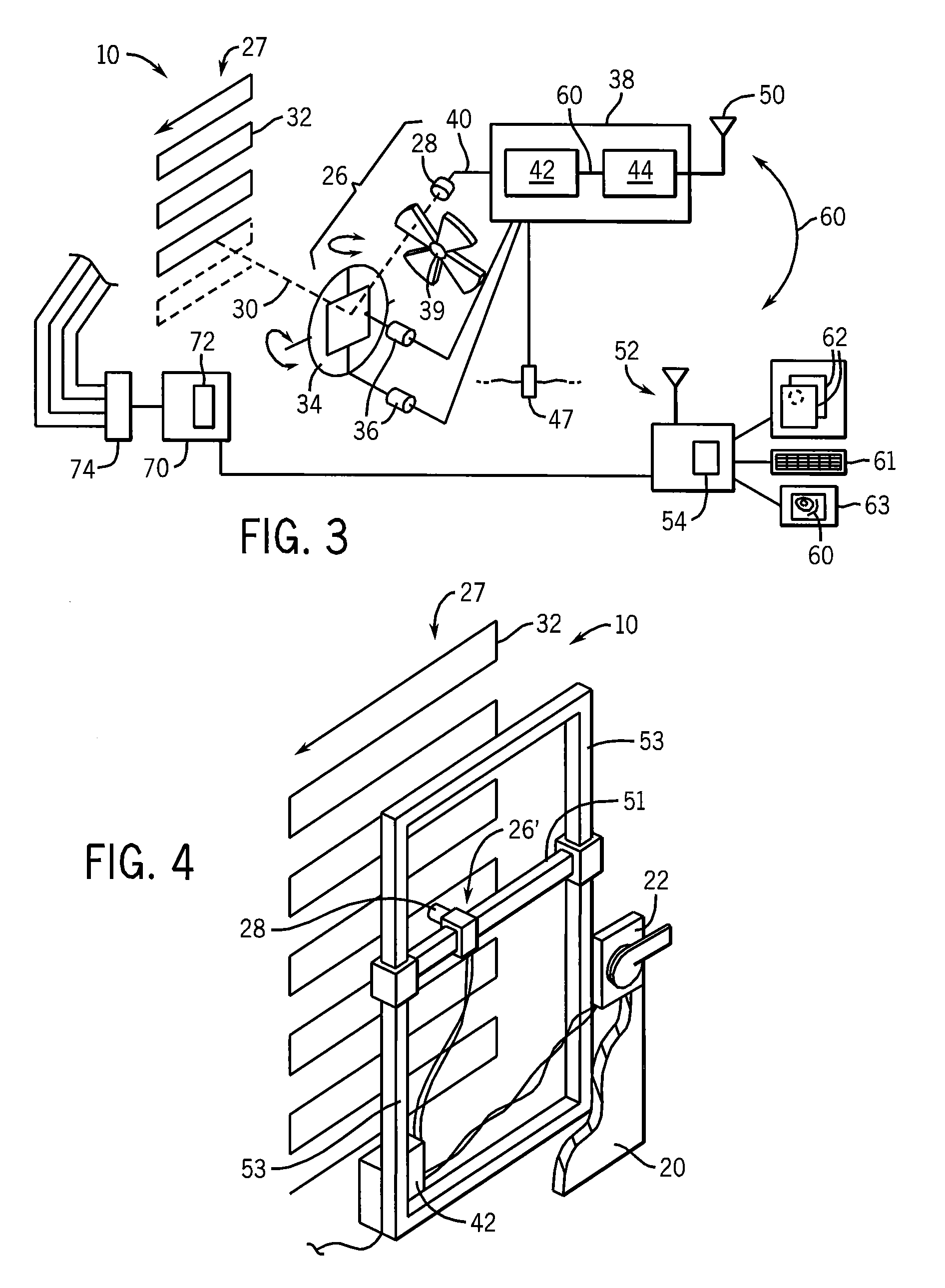

Pipe inspection system with selective image capture

ActiveUS8395661B1Additional imaging capabilityFacilitate communicationImage analysisMaterial analysis by optical meansVideo transmissionData transmission circuit

Owner:SEEKTECH

Integrated optical biosensor array

ActiveUS20140001341A1Material analysis by optical meansAmplifiers controlled by lightPhysicsSensor array

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

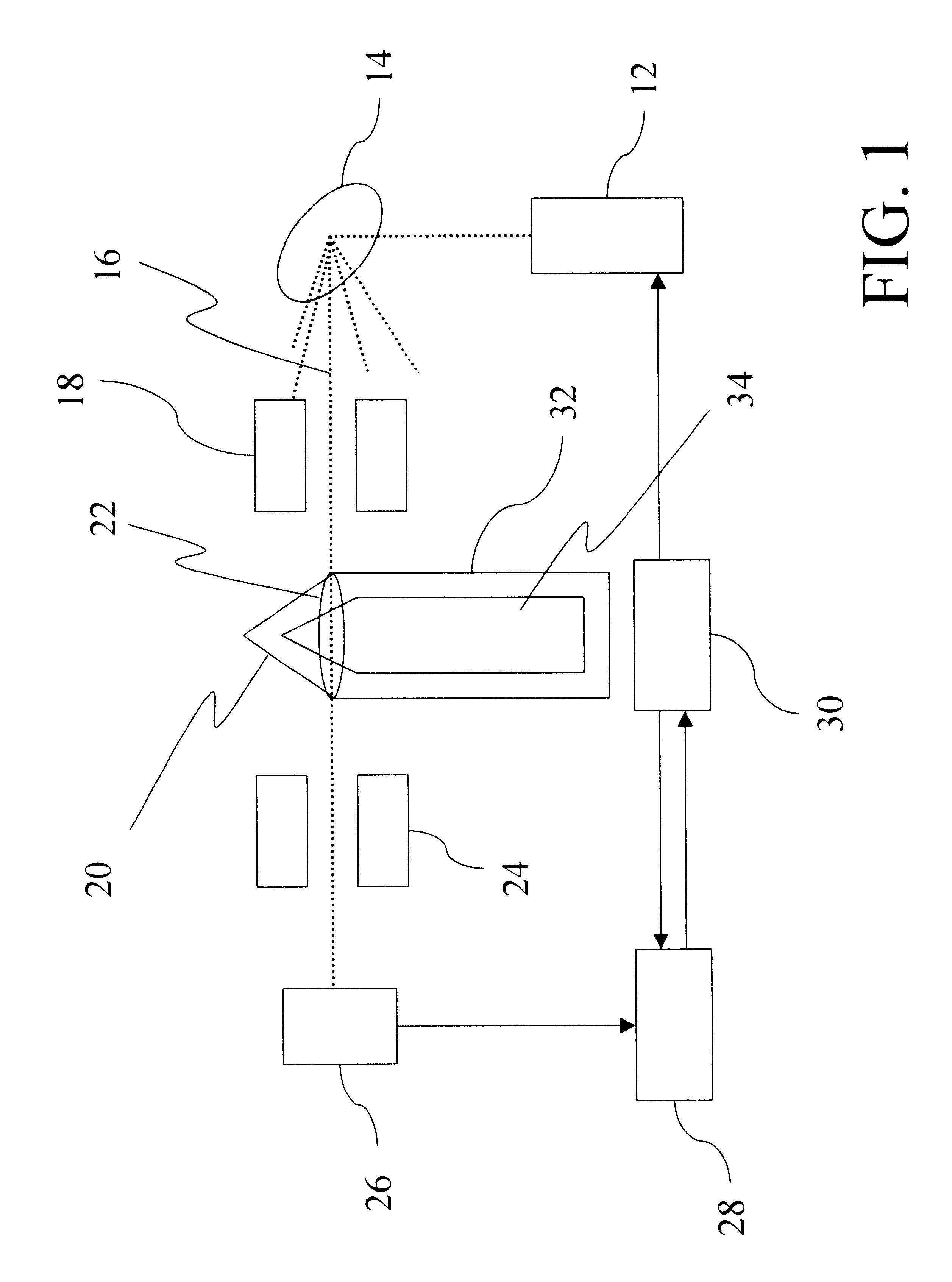

In-situ optical crack measurement using a dot pattern

InactiveUS20110106459A1Force measurementWork measurementObject basedElement model

A method of detecting cracks in an object includes: capturing a first image of a pattern of marks in a region of interest on a surface of the object; constructing a finite element model of the region of interest having nodes corresponding to the marks in the pattern; subjecting the object to a first mechanical load to produce strains in the object; capturing a second image of the pattern; computing strains in the object based on relative changes in locations of the marks in the first and second images; modifying the finite element model to produce a crack versus surface strain map; capturing a third image of the pattern; and comparing the locations of marks in the third image to the crack versus surface strain map to identify a crack in the object. An apparatus that performs the method is also provided.

Owner:NORTHROP GRUMMAN SYST CORP

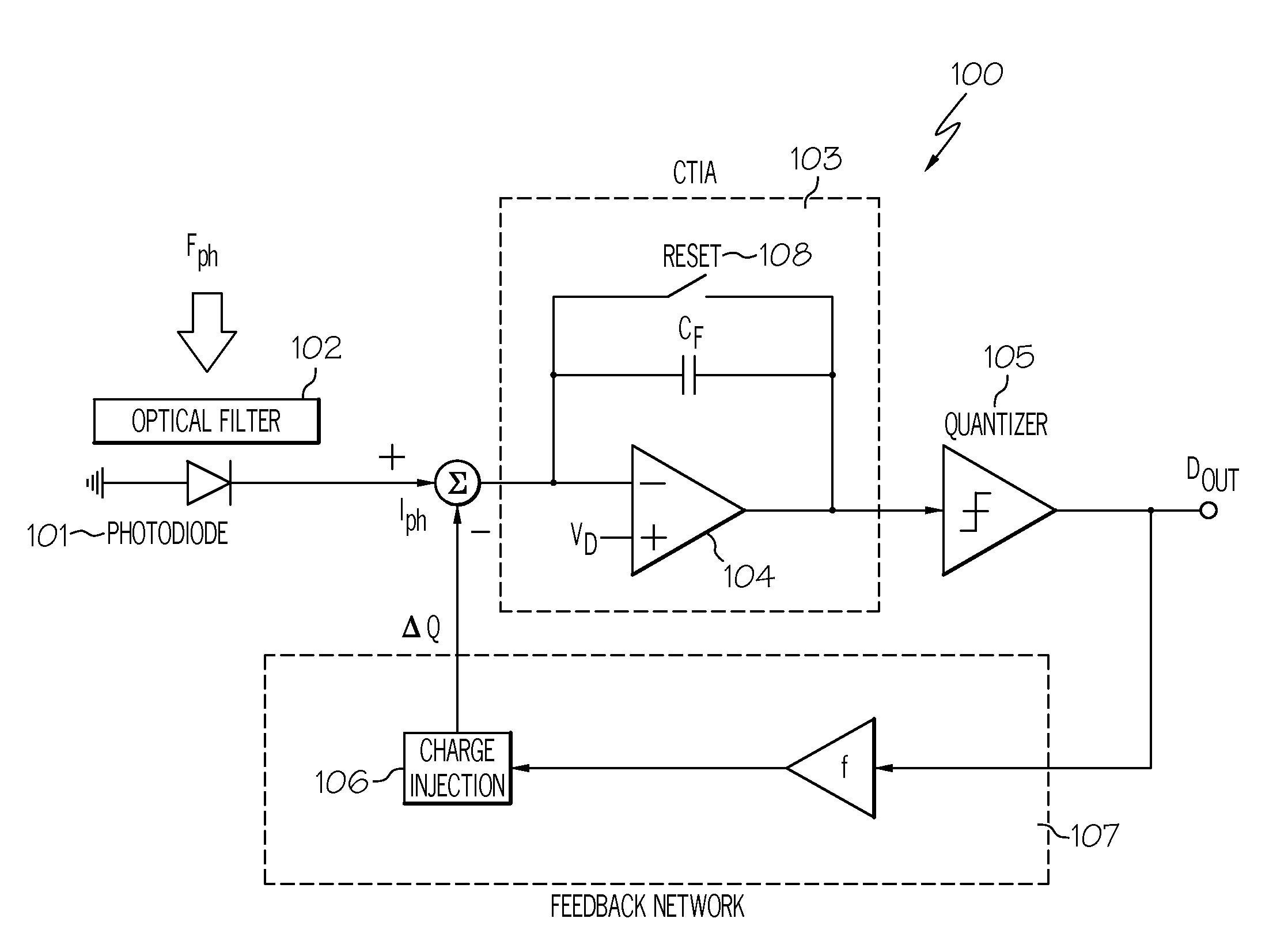

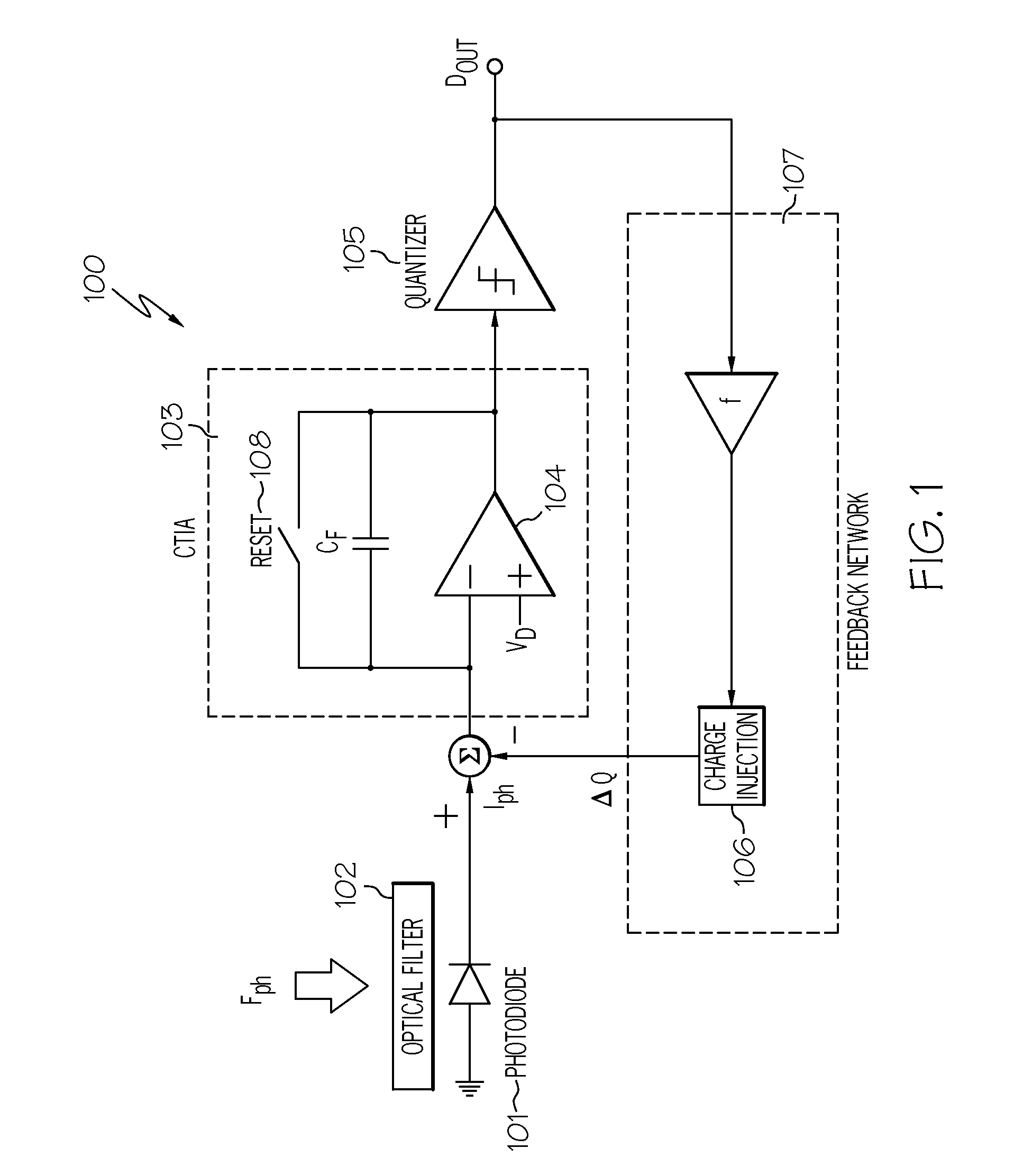

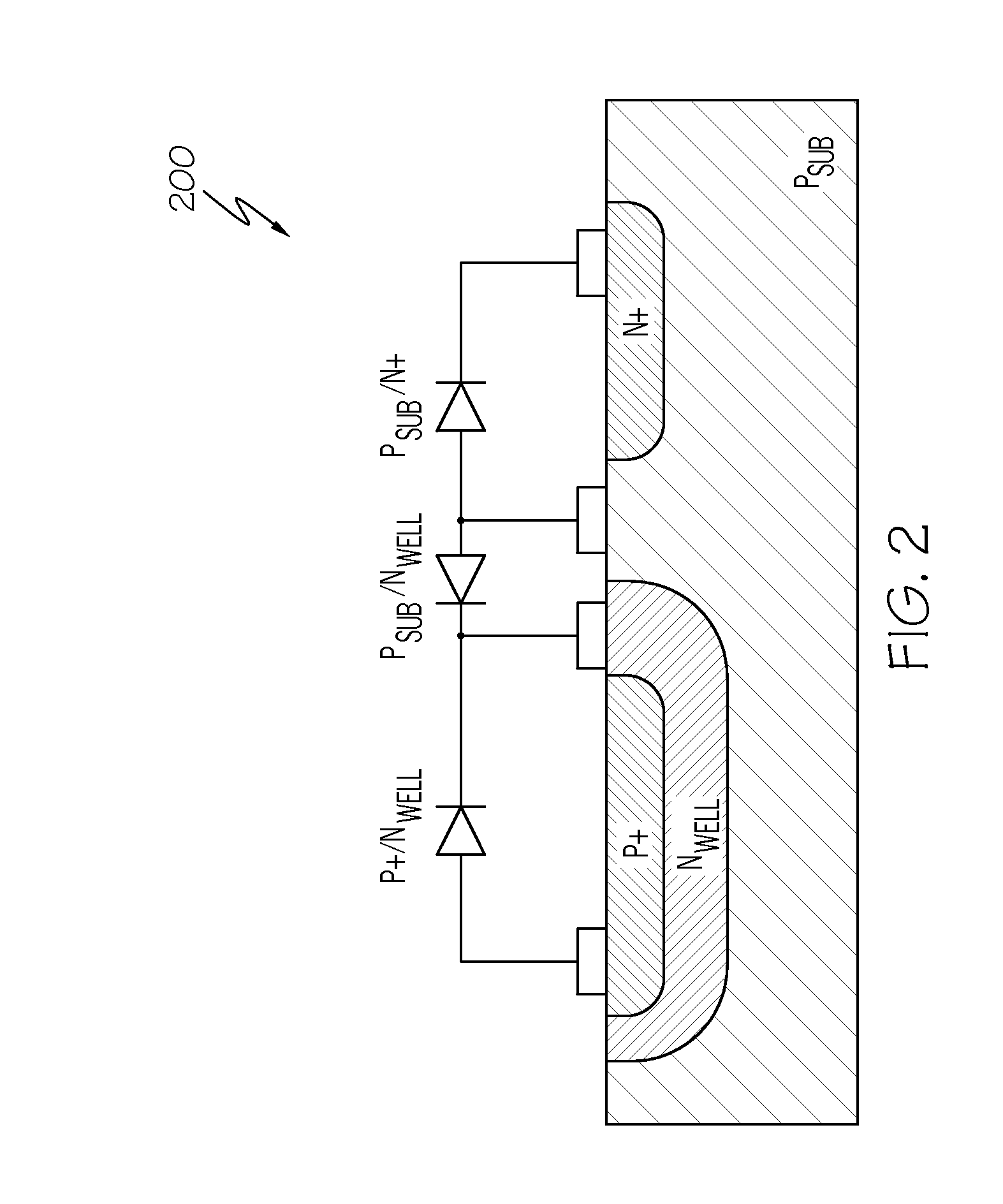

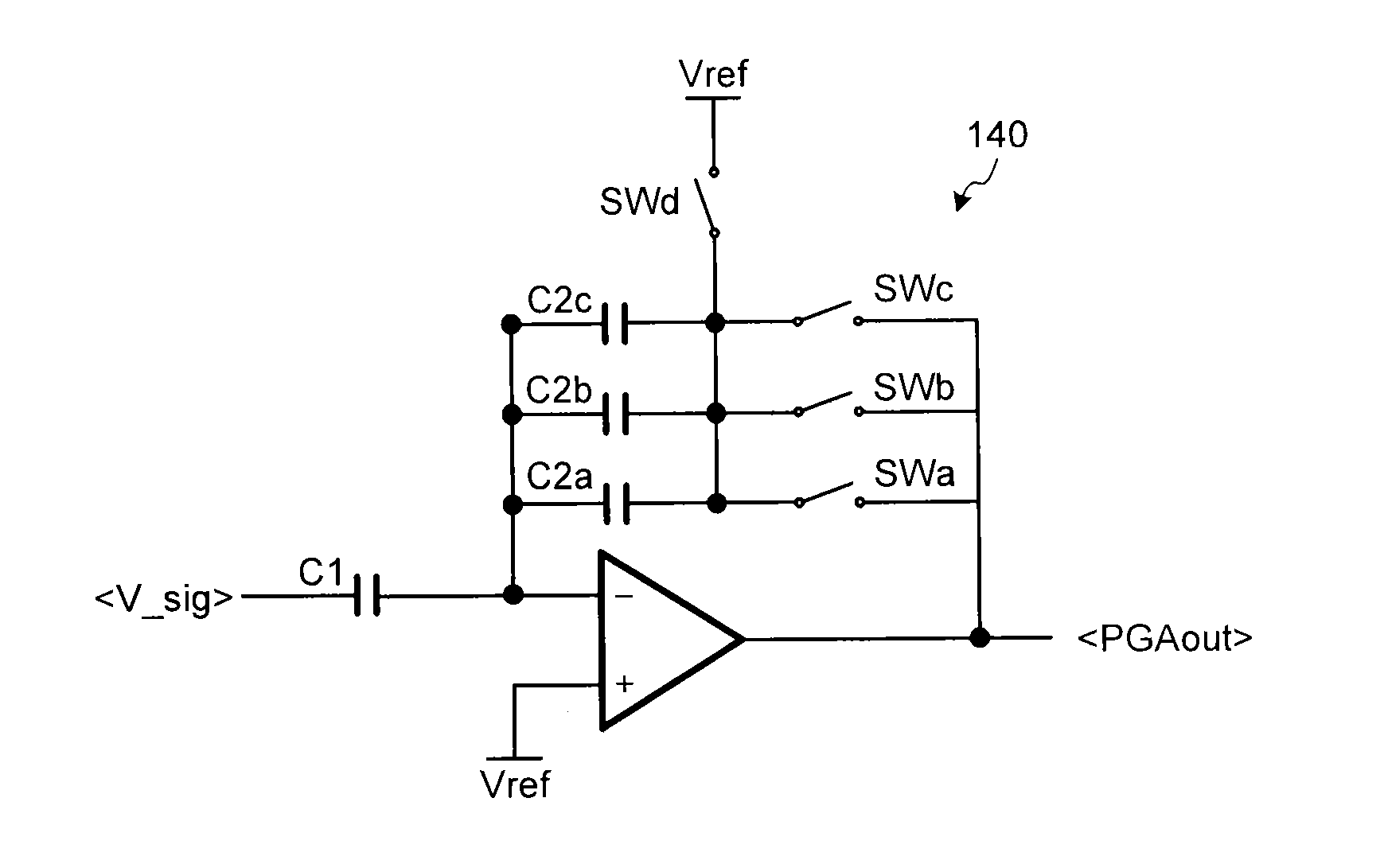

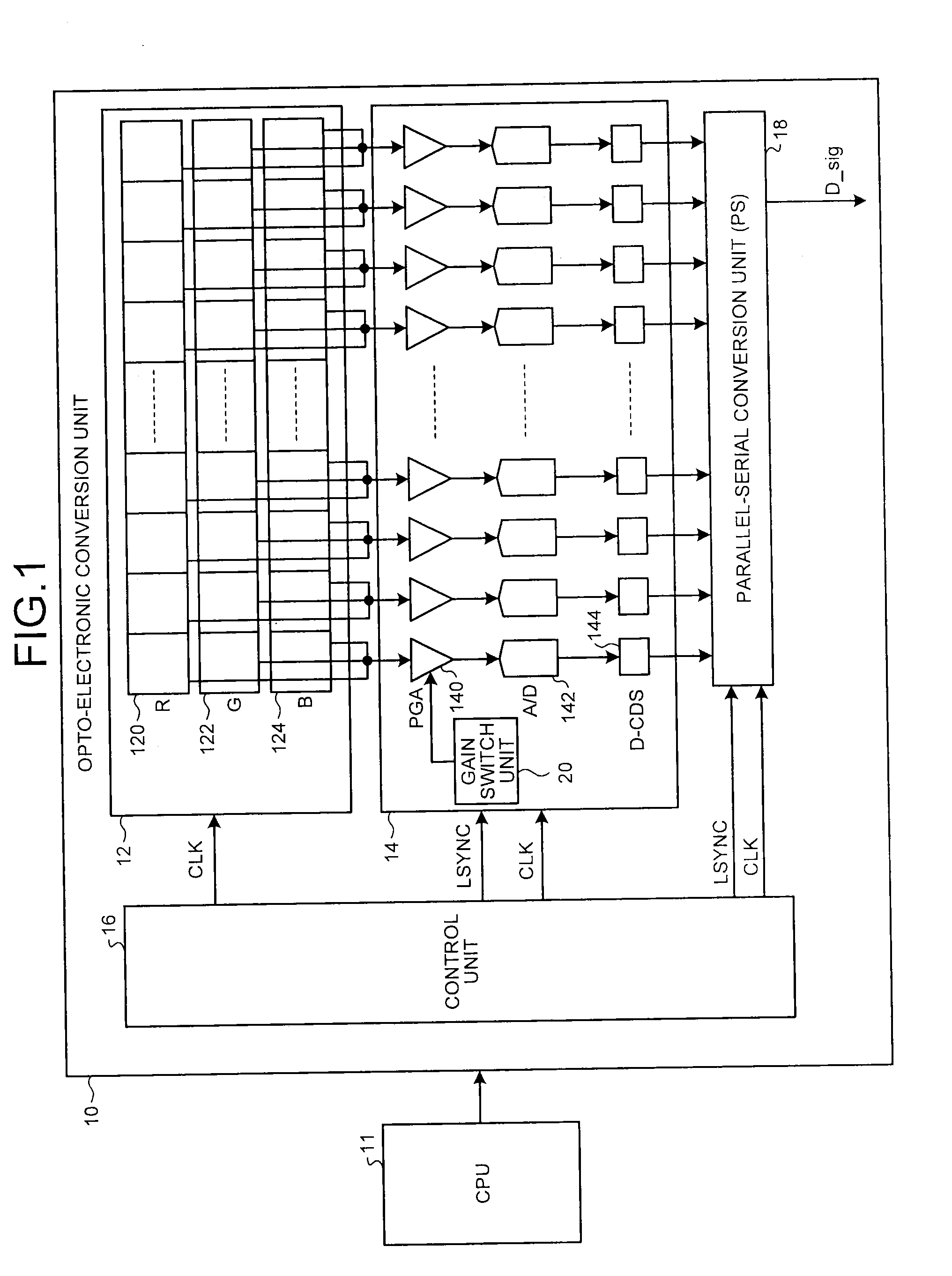

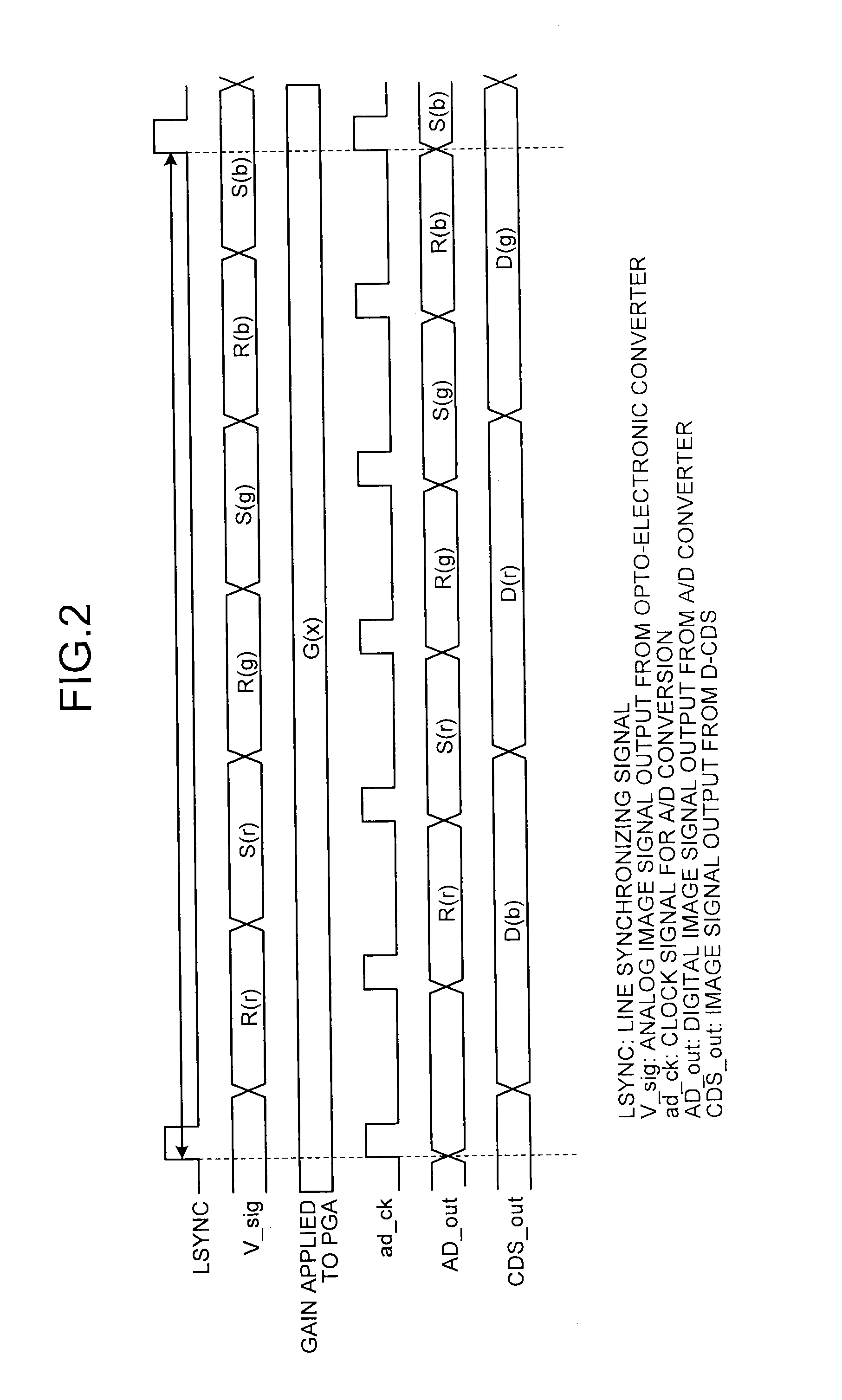

Opto-electronic converter, image reading device, and image forming apparatus

ActiveUS20160003673A1Solve problemsPhotometry using reference valueMaterial analysis by optical meansAudio power amplifierAnalog signal

Owner:RICOH KK

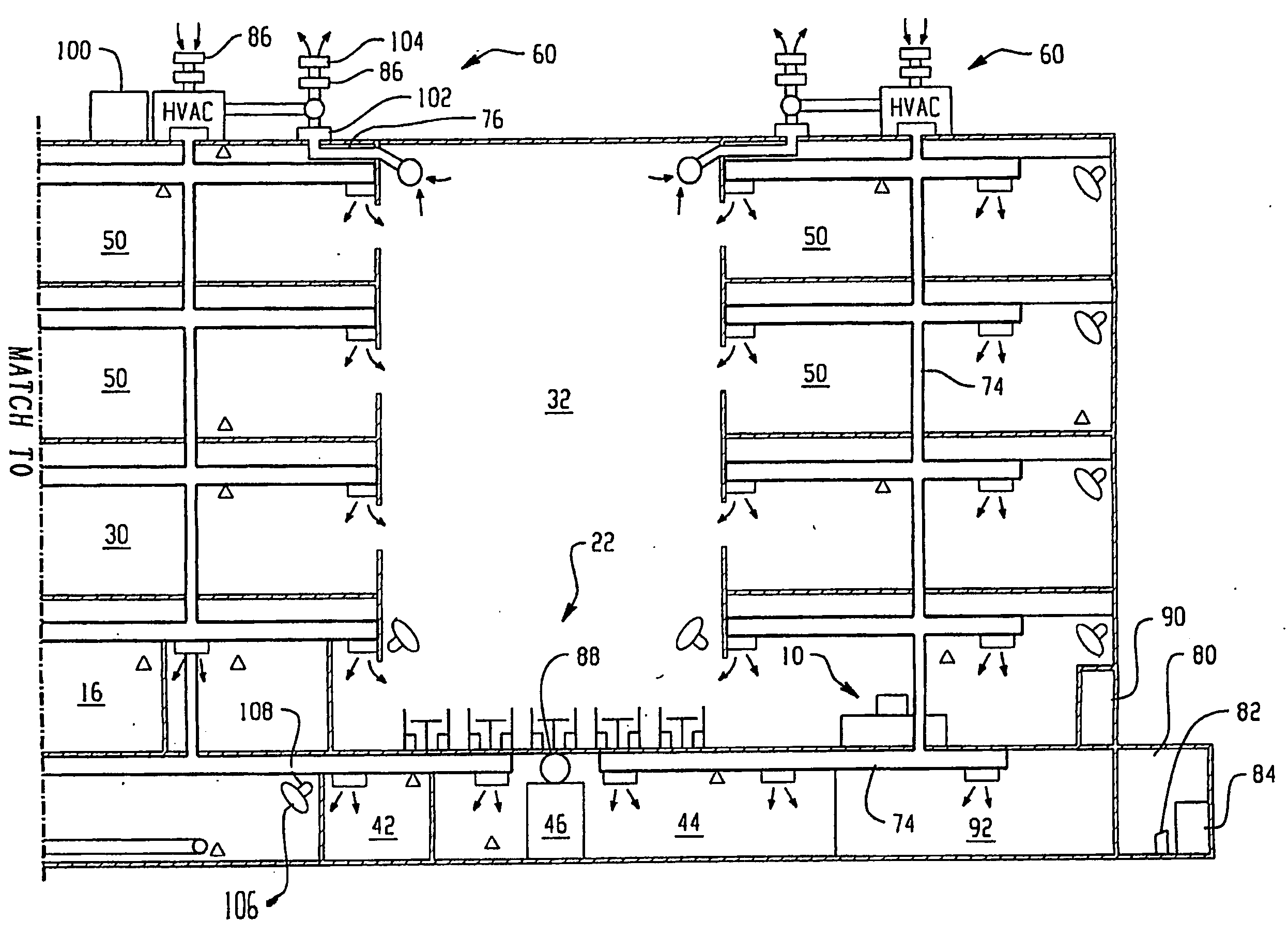

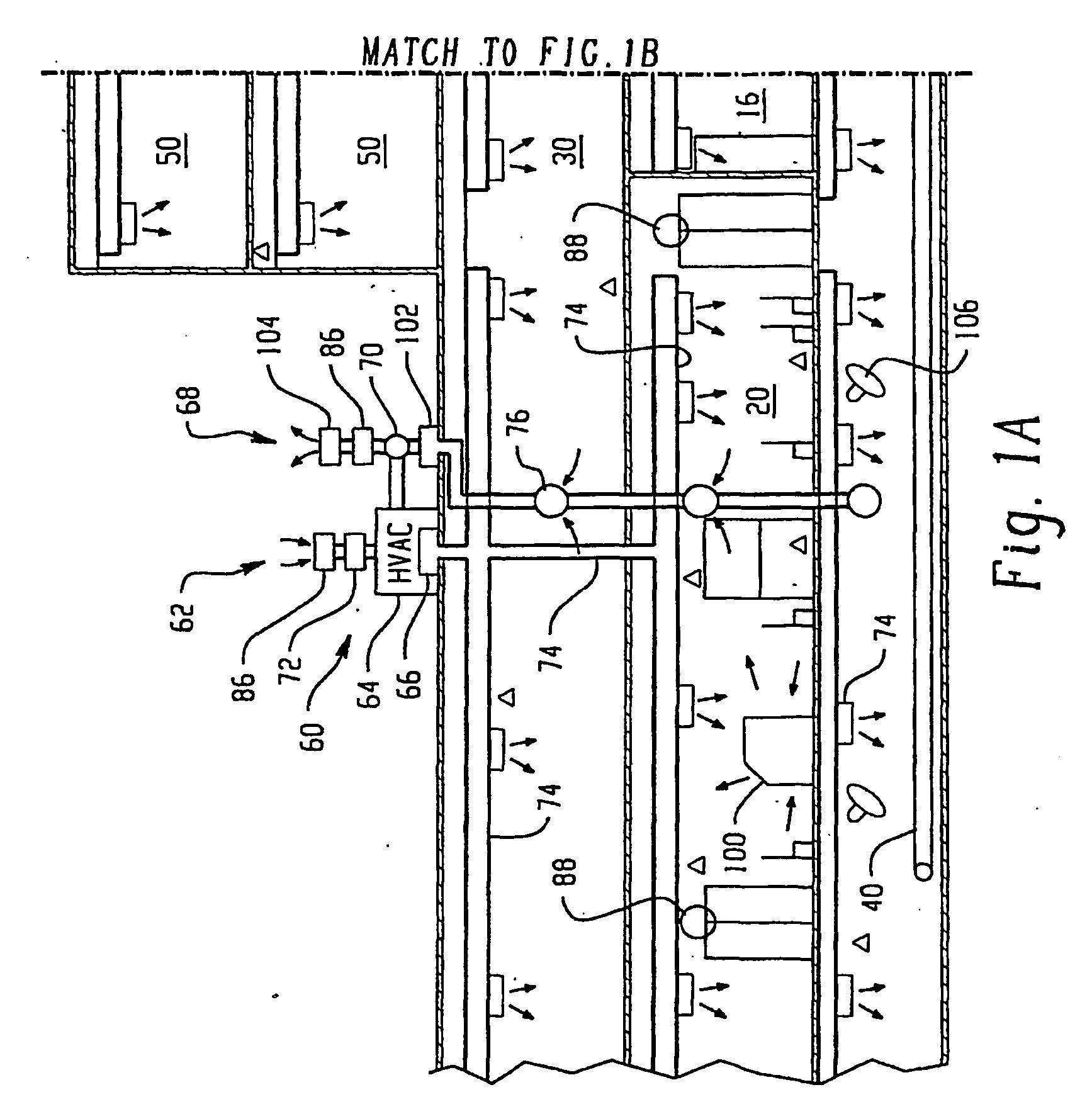

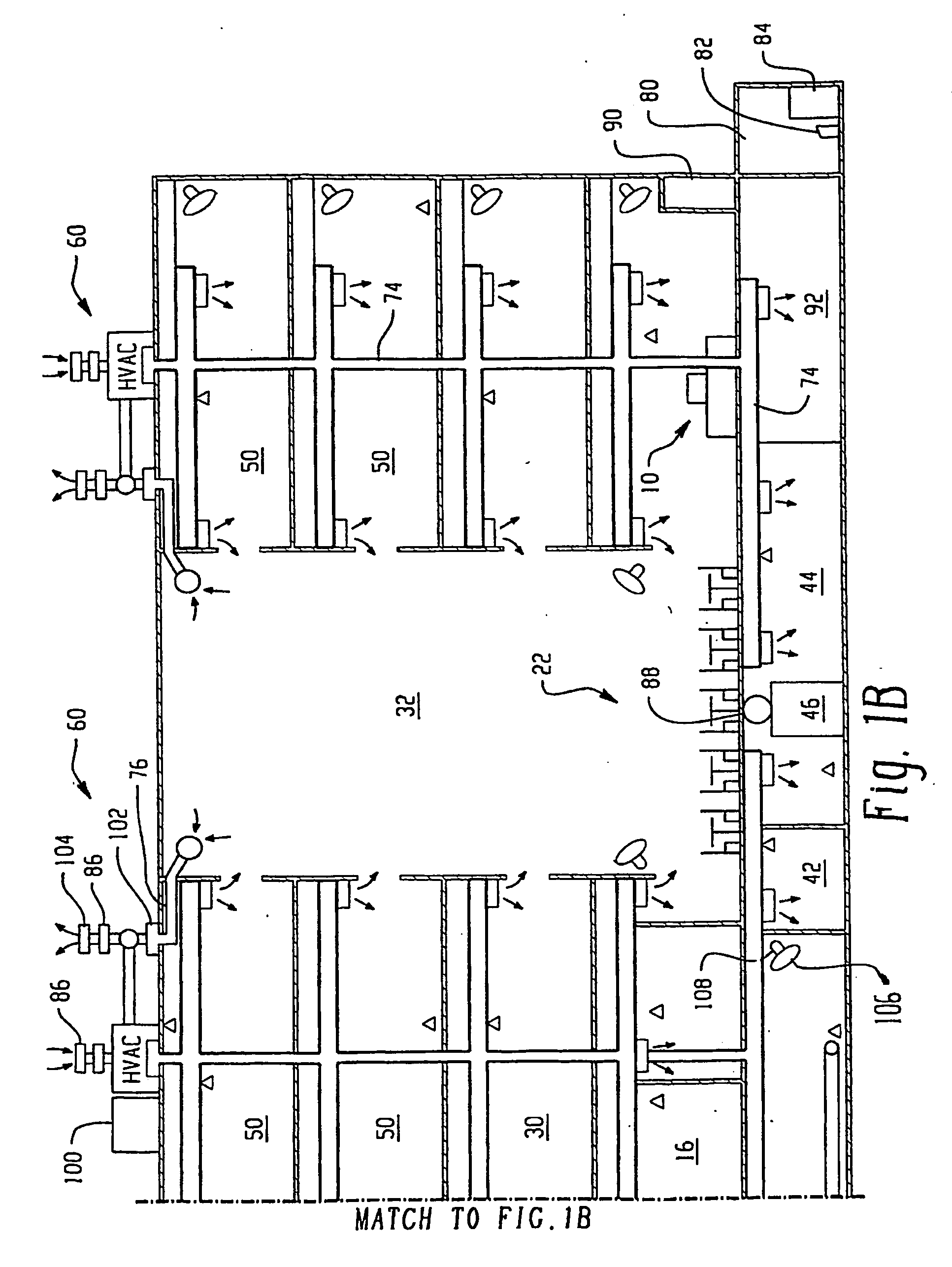

Integrated control and distribution system for the decontamination of large volume convoluted configuration spaces

ActiveUS20070140893A1Big spaceQuick implementationComponent separationSynthetic resin layered productsDistribution systemProcess engineering

Owner:STERIS CORP

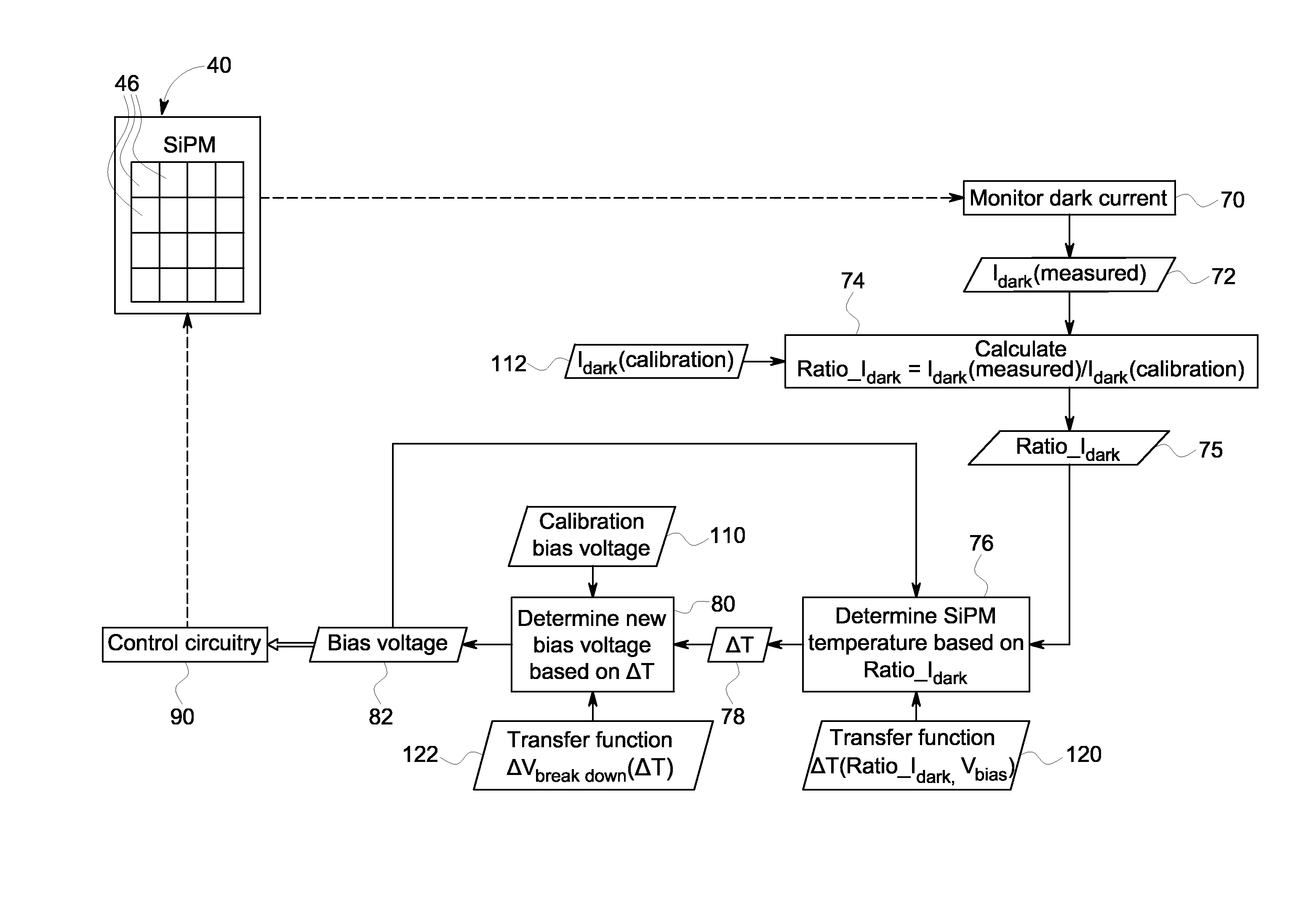

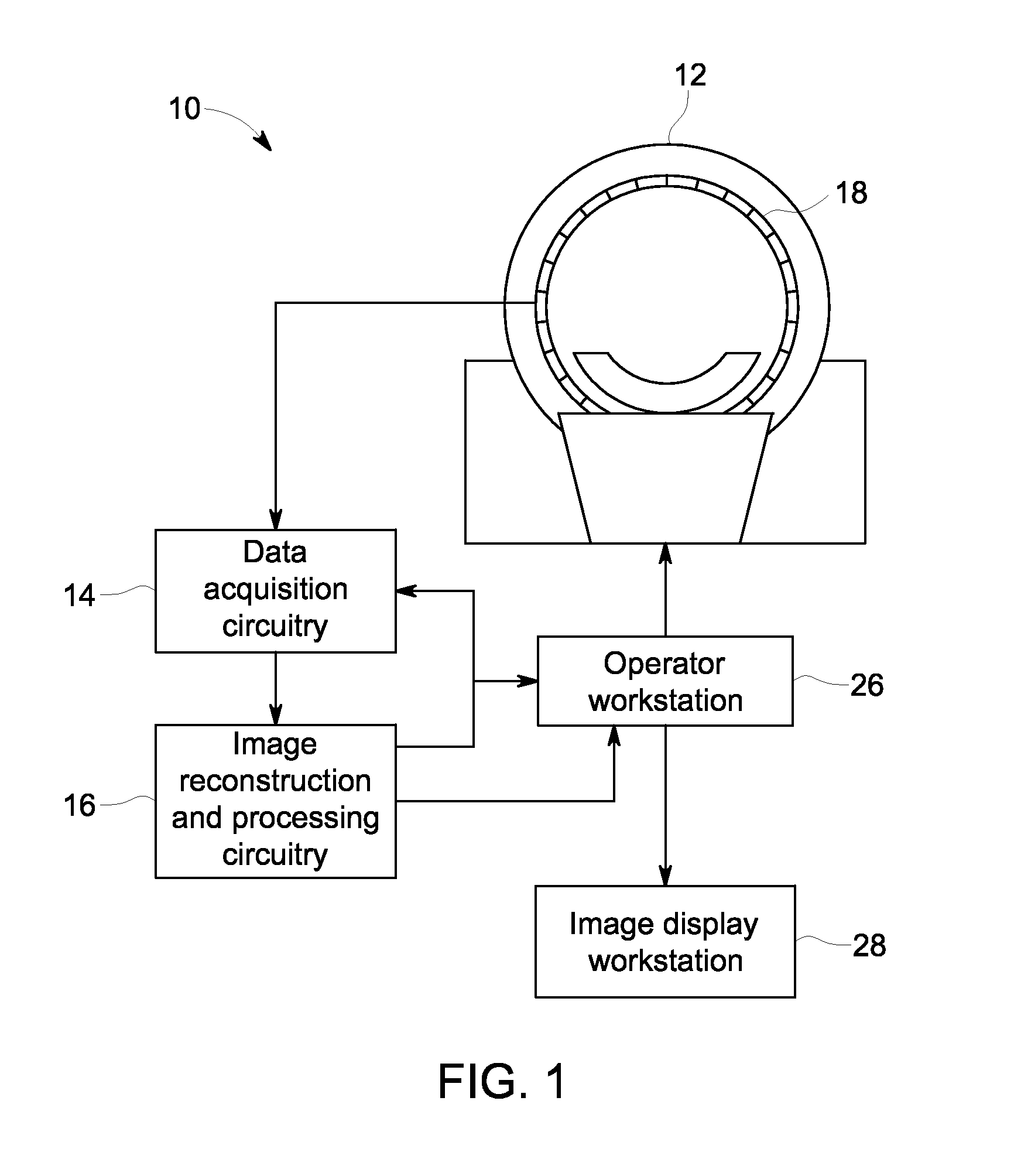

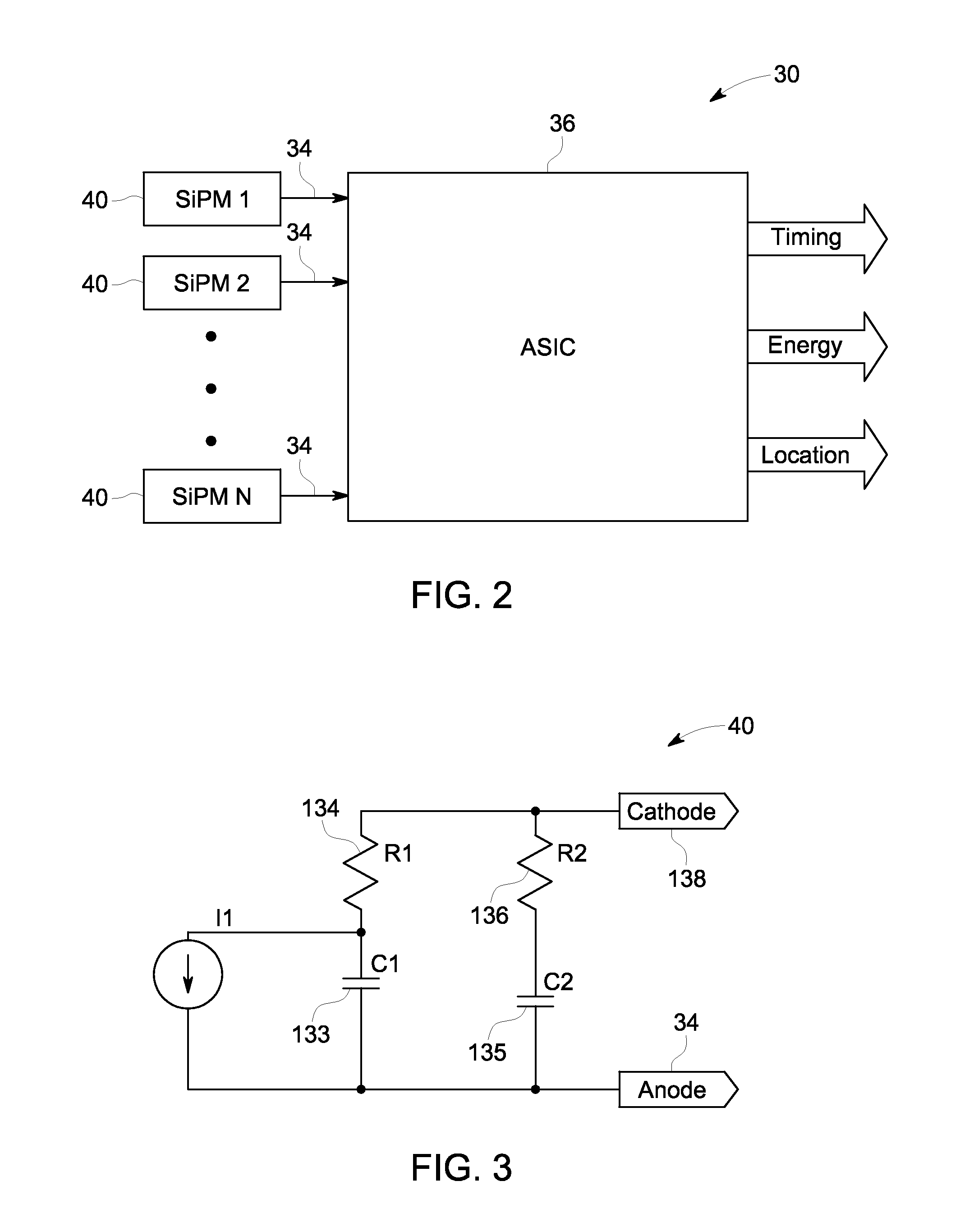

System and method for compensating temperature gain variation in radiation detectors

InactiveUS20150177394A1Constant voltageSolid-state devicesMaterial analysis by optical meansPhysicsRadiation

Owner:GENERAL ELECTRIC CO

Material decomposition image noise reduction

InactiveUS20080135789A1X-ray/infra-red processesRadiation/particle handlingData acquisitionImage noise reduction

A diagnostic imaging system in an example comprises a high frequency electromagnetic energy source, a detector, a data acquisition system (DAS), and a computer. The high frequency electromagnetic energy source emits a beam of high frequency electromagnetic energy toward an object to be imaged. The detector receives high frequency electromagnetic energy emitted by the high frequency electromagnetic energy source. The DAS is operably connected to the detector. The computer is operably connected to the DAS and programmed to employ a threshold to trigger a filter operation on a pixel, in a basis material decomposition (BMD) image of a plurality of BMD images, through comparison of an actual noise ratio between a pair of BMD images, of the plurality of BMD images, to a theoretical BMD noise ratio value. The computer operably connected to the DAS is programmed to employ a correlation in noise distribution of the plurality of BMD images to reduce image noise in the plurality of BMD images. The computer operably connected to the DAS is programmed to realize an adaptive algorithm through employment of an exponential correction function of a difference between the actual noise ratio and the theoretical BMD noise ratio value. The computer operably connected to the DAS is programmed to employ the adaptive algorithm to reduce the image noise in the plurality of BMD images.

Owner:GENERAL ELECTRIC CO

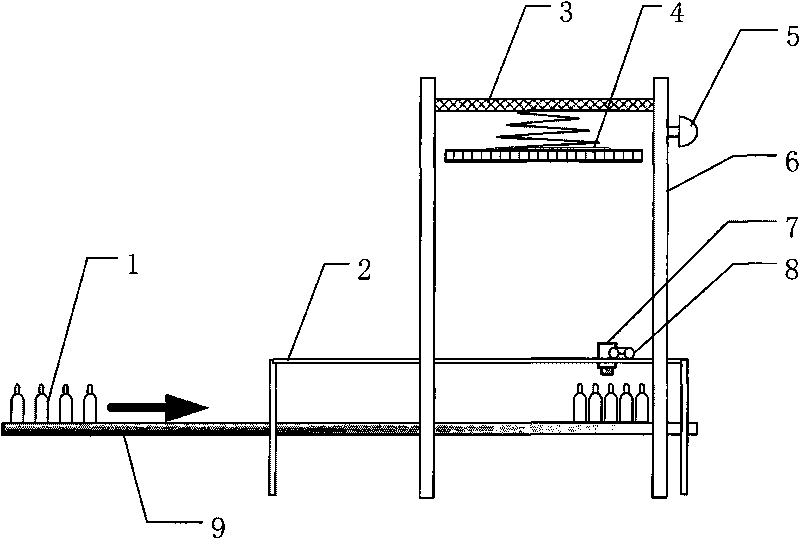

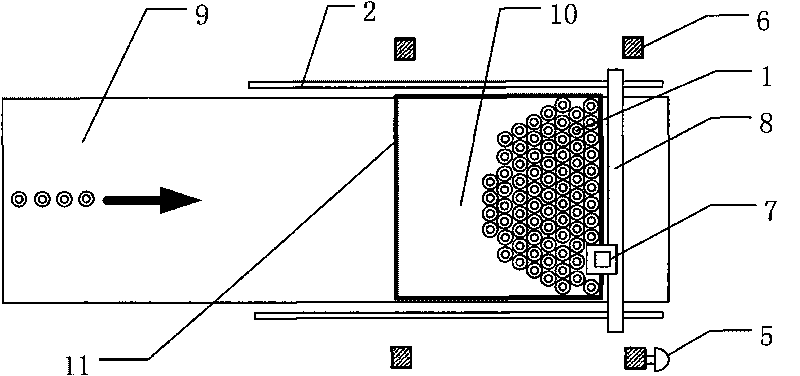

Sub-micron scale glass subsurface defect detection device and method

ActiveCN105842257AGuaranteed Quantitative MeasurementsGuaranteed stabilityMaterial analysis by optical meansMicron scaleGrating

The invention discloses a sub-micron scale glass subsurface defect detection device and method. A light source part of the device comprises a super-continuum luminous spectrum light source and a single-mode optical fiber circulator; a reference arm and sample arm part comprises a first collimating lens, a 45-degree cylindrical reflecting mirror, a reference objective, a reference reflecting mirror, a two-dimensional scanning galvanometer, a sample objective and a part to be detected; a detection arm part comprises a second collimating lens, a transmission grating, a focusing lens, a photoelectric detector and a computer. The method comprises the steps that light of a reference arm and light of a sample arm return back to the single-mode optical fiber circulator in the same way, light beams of the two arms encounter, and interference is caused; interfered light beams are subjected to light splitting through the transmission grating and then focused on different pixel elements of the photoelectric detector through the focusing lens, the photoelectric detector inputs collected signals into the computer, the signals are processed, and faultage images of different positions are obtained. According to the sub-micron scale glass subsurface defect detection device and method, the ultra-wide band light source, the high-power aperture imaging objectives and the common light path imaging structure are adopted, and the three-dimensional structure of sub-micron scale glass subsurface cracks is obtained.

Owner:NANJING UNIV OF SCI & TECH

Method for non-intrusively identifying a contained material utilizing uncollided nuclear transmission measurements

InactiveUS6320193B1Material analysis by optical meansMachines/enginesAttenuation coefficientUltrasound attenuation

An improved nuclear diagnostic method identifies a contained target material by measuring on-axis, mono-energetic uncollided particle radiation transmitted through a target material for two penetrating radiation beam energies, and applying specially developed algorithms to estimate a ratio of macroscopic neutron cross-sections for the uncollided particle radiation at the two energies, where the penetrating radiation is a neutron beam, or a ratio of linear attenuation coefficients for the uncollided particle radiation at the two energies, where the penetrating radiation is a gamma-ray beam. Alternatively, the measurements are used to derive a minimization formula based on the macroscopic neutron cross-sections for the uncollided particle radiation at the two neutron beam energies, or the linear attenuation coefficients for the uncollided particle radiation at the two gamma-ray beam energies. A candidate target material database, including known macroscopic neutron cross-sections or linear attenuation coefficients for target materials at the selected neutron or gamma-ray beam energies, is used to approximate the estimated ratio or to solve the minimization formula, such that the identity of the contained target material is discovered.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

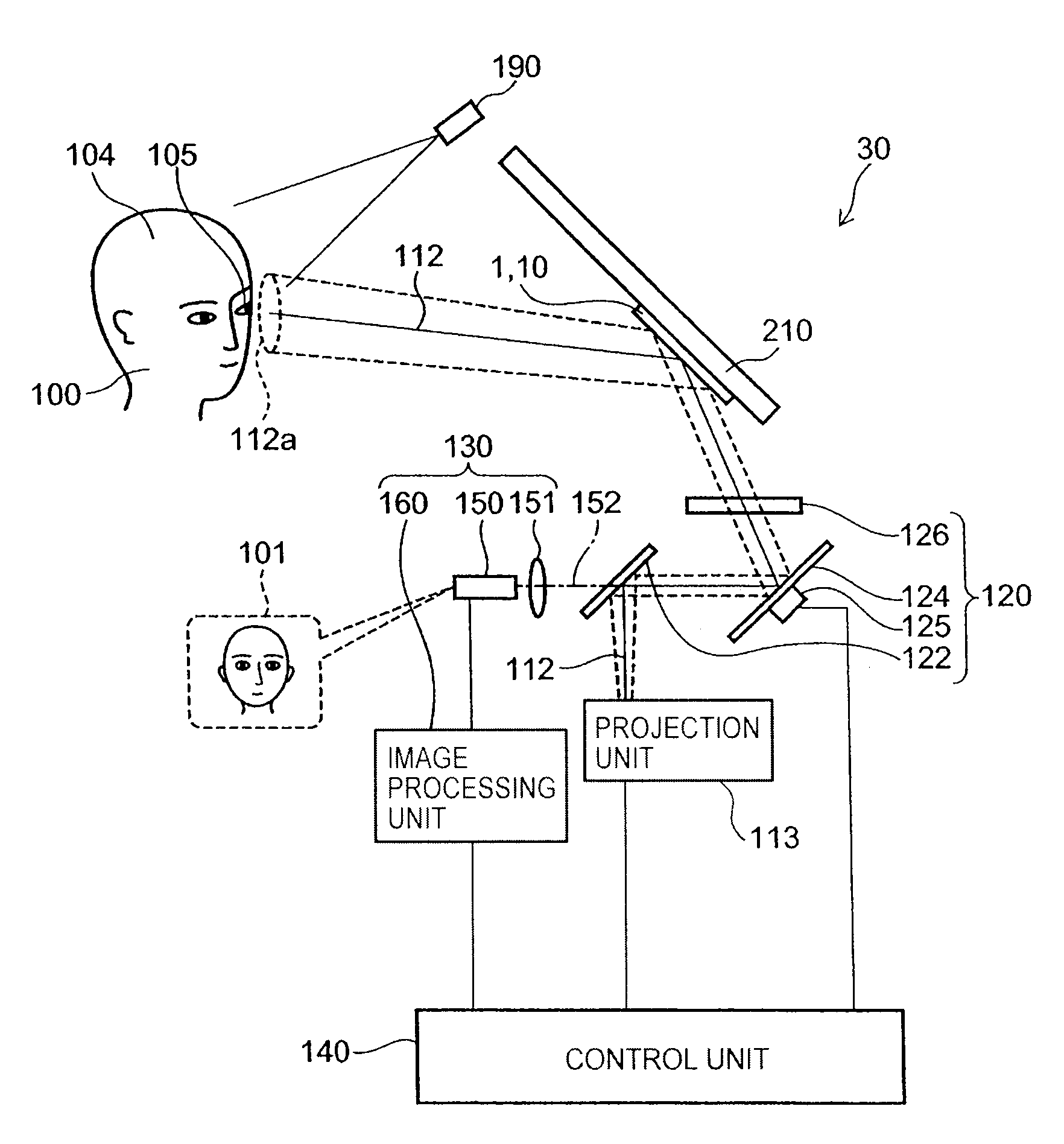

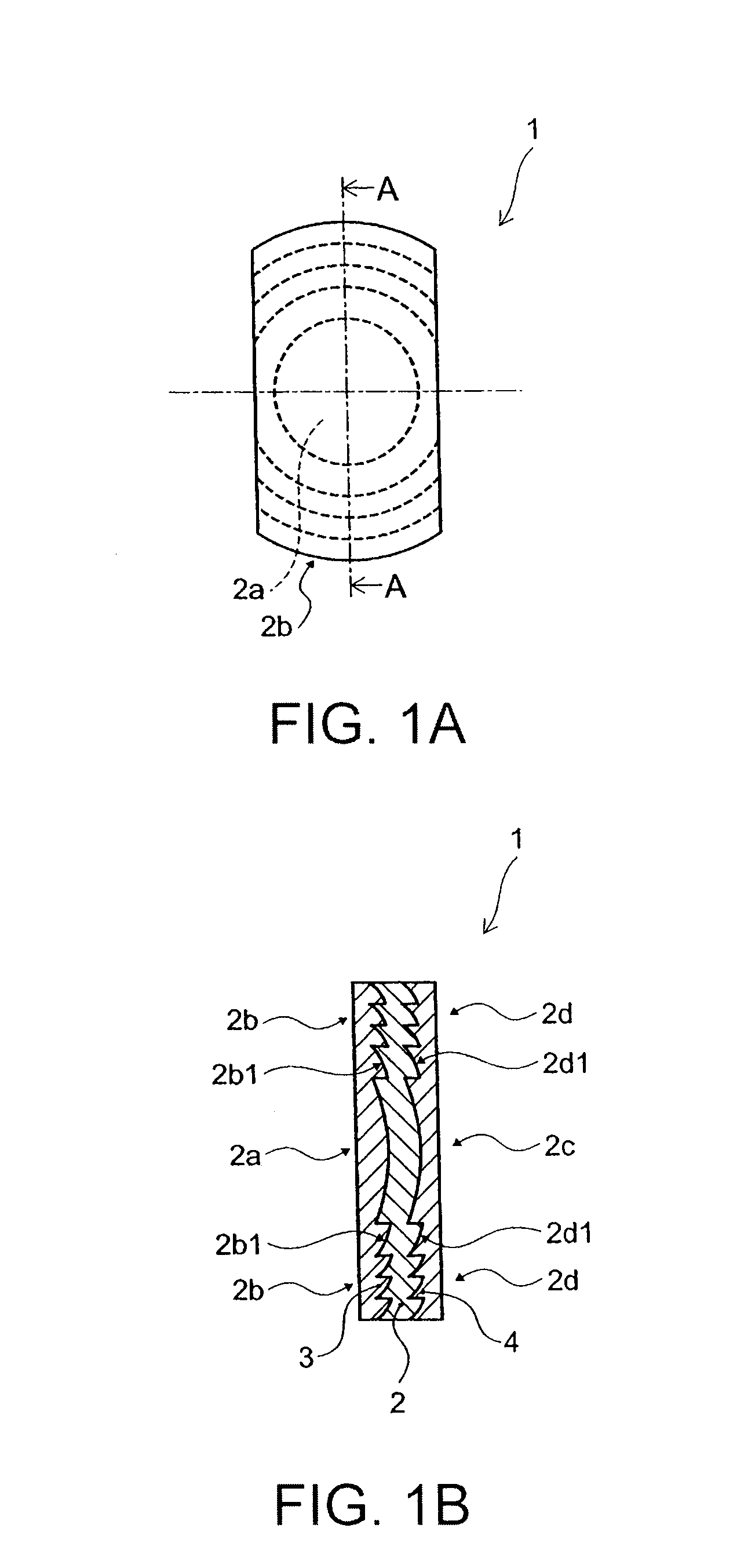

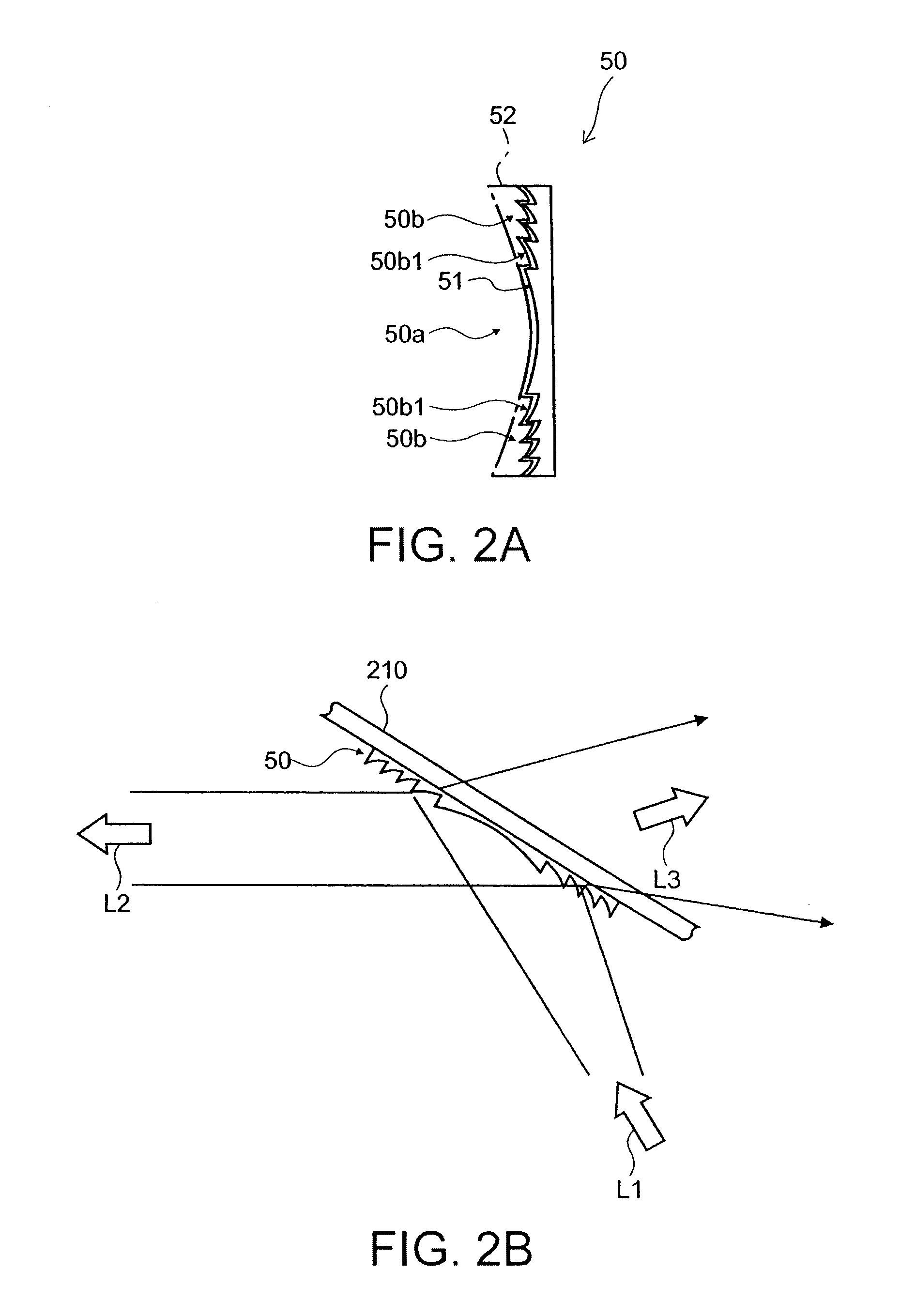

Optical member, display device using the optical member and movable body using the display device

InactiveUS20100073579A1Suppress image distortionSuppression of distortionTelevision system detailsBeam/ray focussing/reflecting arrangementsDisplay deviceRefractive index

Owner:KK TOSHIBA

In-cabinet thermal monitoring method and system

ActiveUS20100044567A1Avoid disadvantagesTelevision system detailsSwitchgear arrangementsThermal monitoringSwitchgear

Owner:ROCKWELL AUTOMATION TECH

Methods and apparatus for controlling ion current in an ion transmission device

InactiveUS20050194543A1High sensitivityThermometer detailsBeam/ray focussing/reflecting arrangementsIon currentMass spectrometric

The invention provides apparatus and methods for controlling ion current in an ion transmission device. An apparatus of the present invention comprises an ion source, an ion transmission device, and a controller. The ion source and the ion transmission device are in ion communication therebetween, and the controller is in signal communication with both the ion source and the ion transmission device. The ion current of the ion transmission device may be controlled by coordinating at least one of the operating parameter values of the ion source with at least one of the operating parameter values of the ion transmission device. Such coordination may result in, for example, improved ion current in the ion transmission device. Also embraced by the present invention are mass spectrometer embodiments that include or use the apparatus or methods of the present invention for controlling ion current.

Owner:HIEKE ANDREAS DR

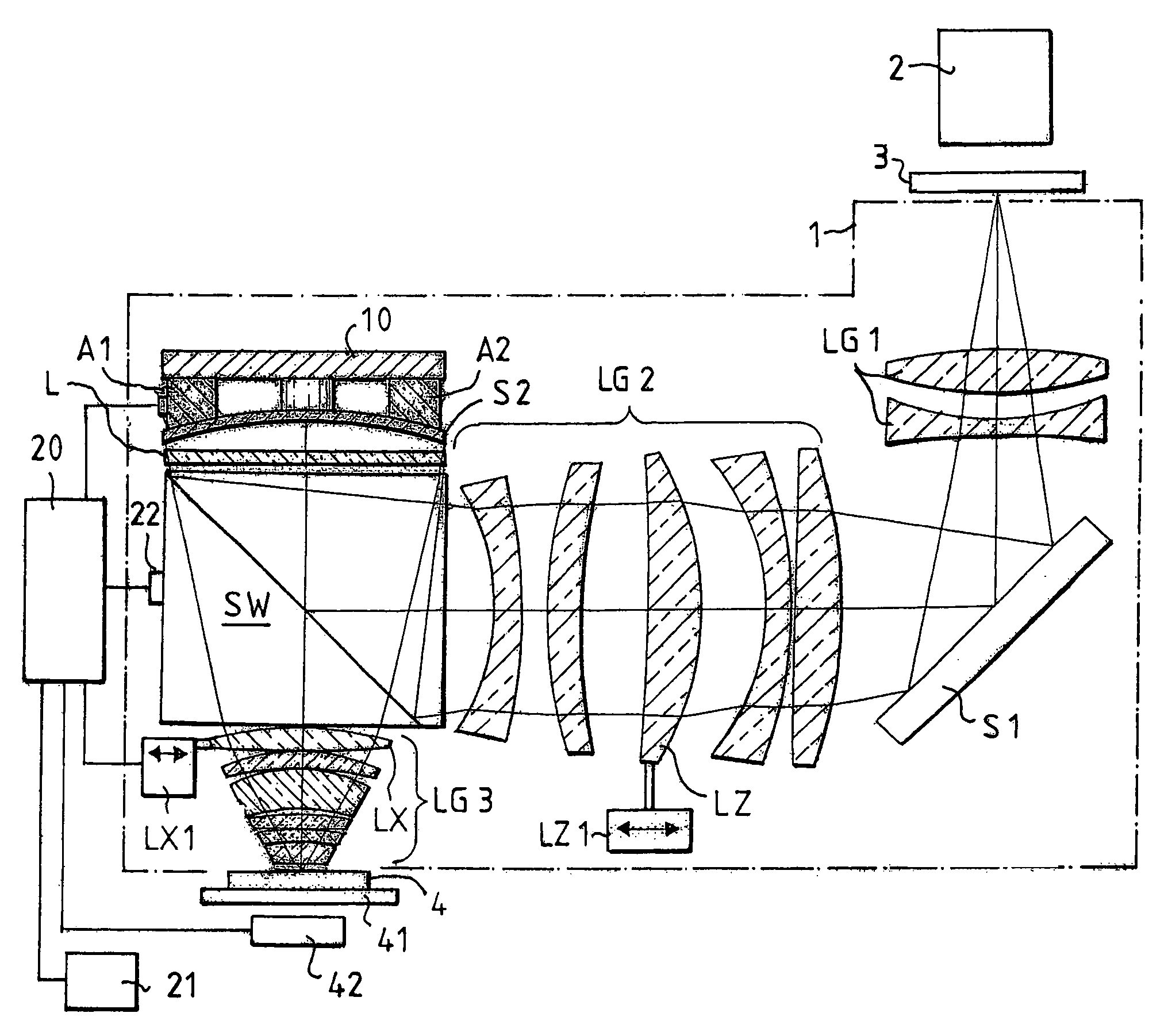

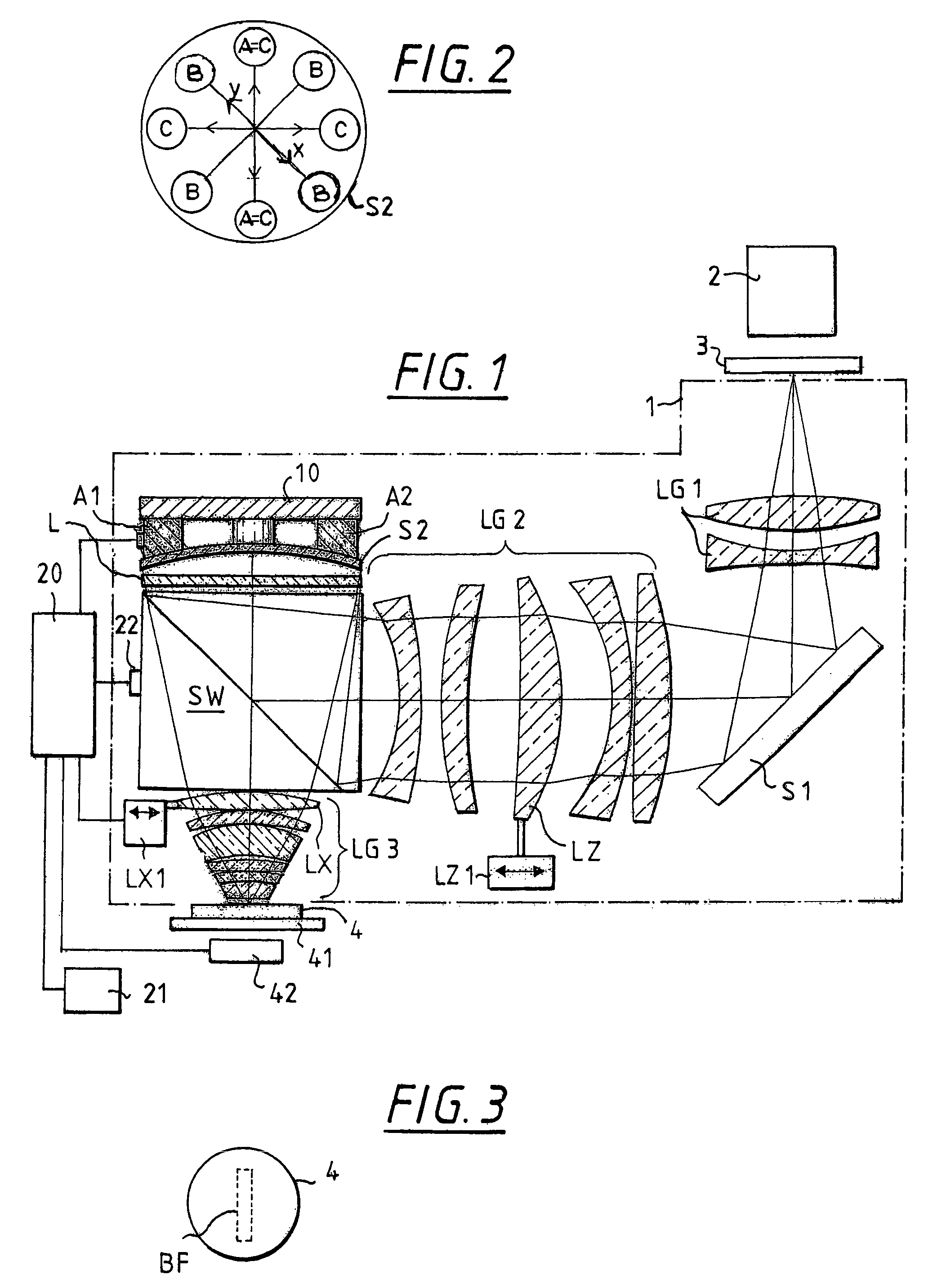

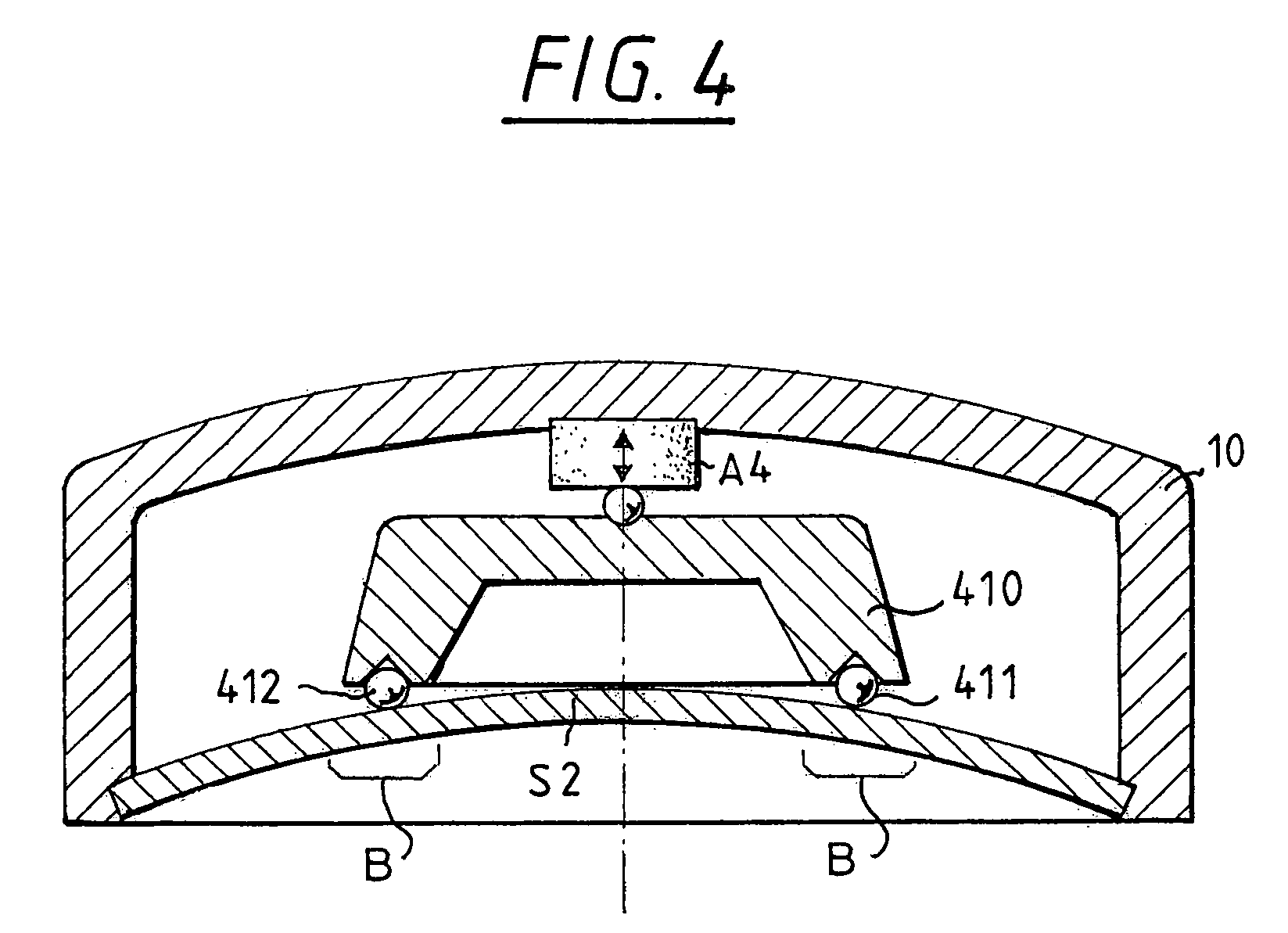

Catadioptric projection objective with adaptive mirror and projection exposure method

InactiveUS7112772B2Improve image qualityPhotometry using reference valueMirrorsDeformable mirrorAstigmatism

Owner:CARL ZEISS SMT GMBH

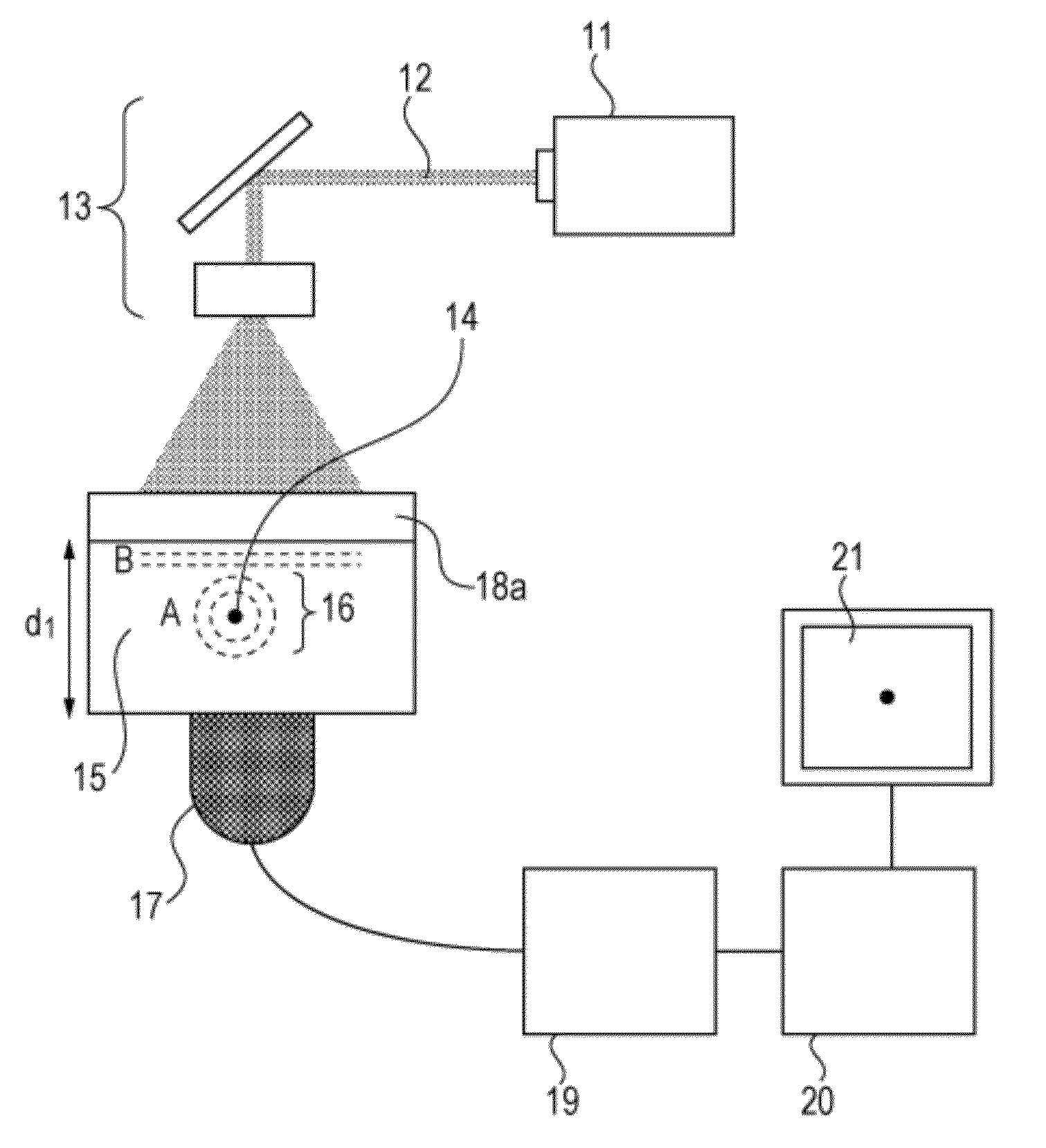

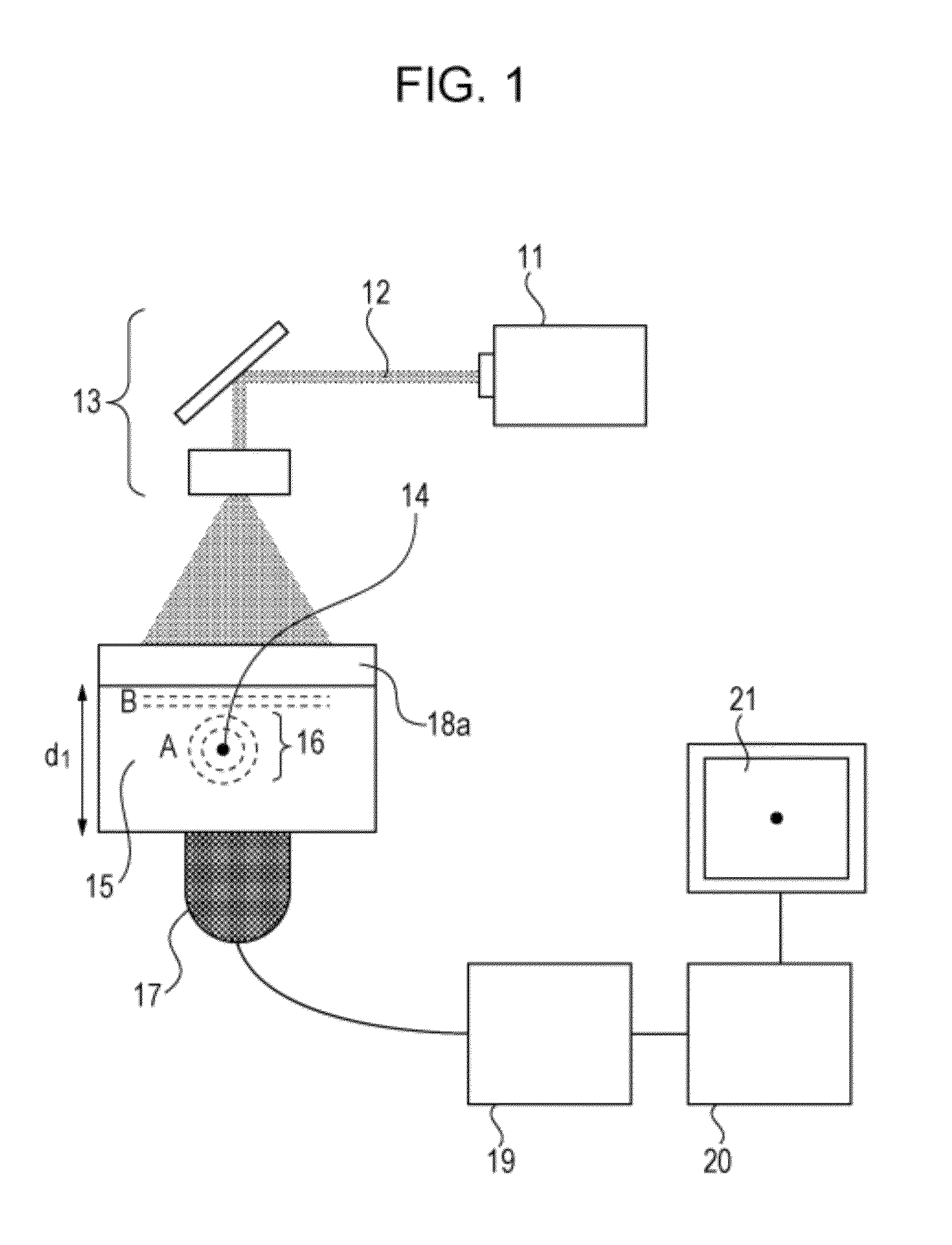

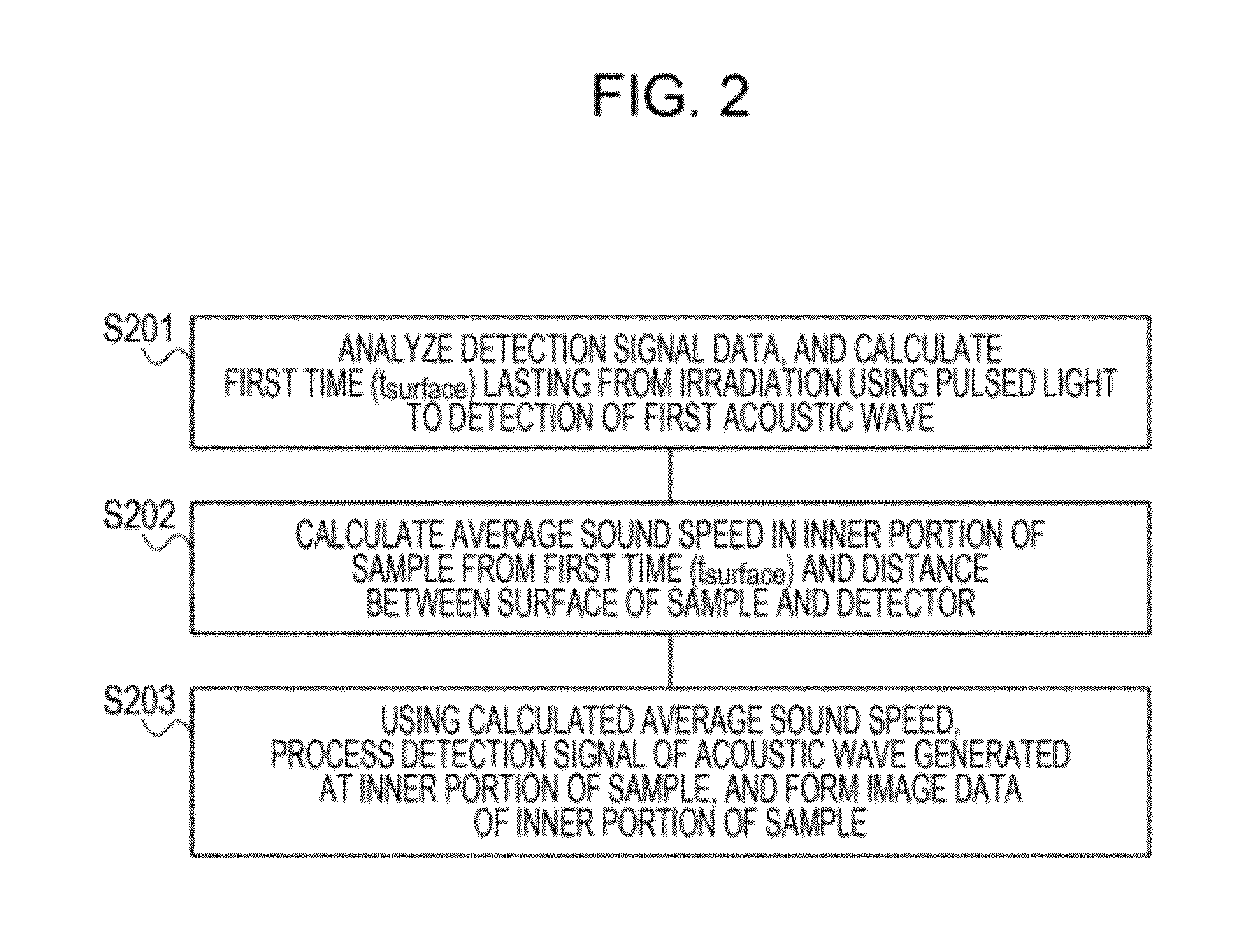

Photoacoustic imaging apparatus and photoacoustic imaging method

InactiveUS20120302866A1Easy to measureMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterial analysis by optical meansSpeed of soundPhotoacoustic imaging in biomedicine

Owner:CANON KK

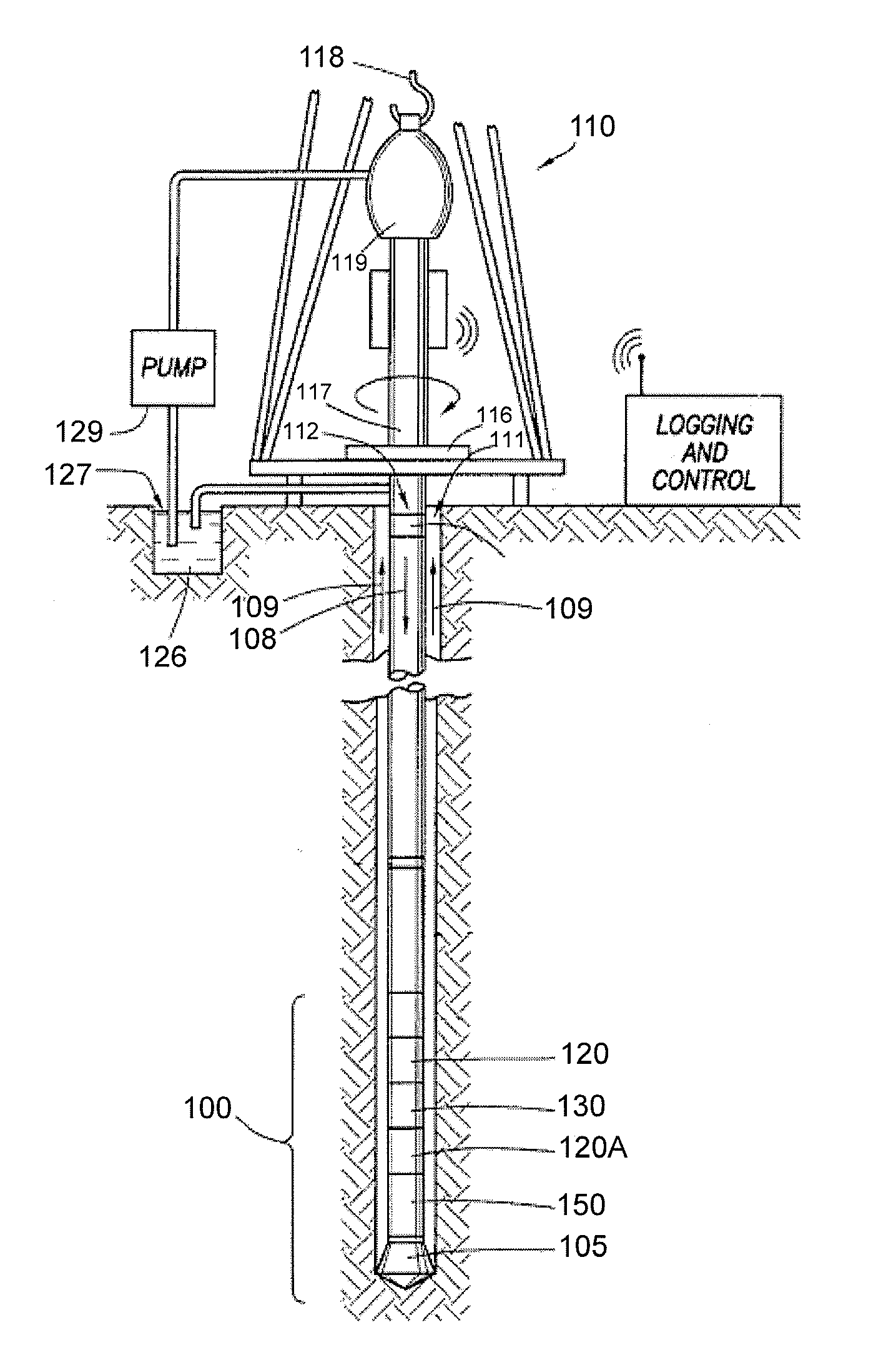

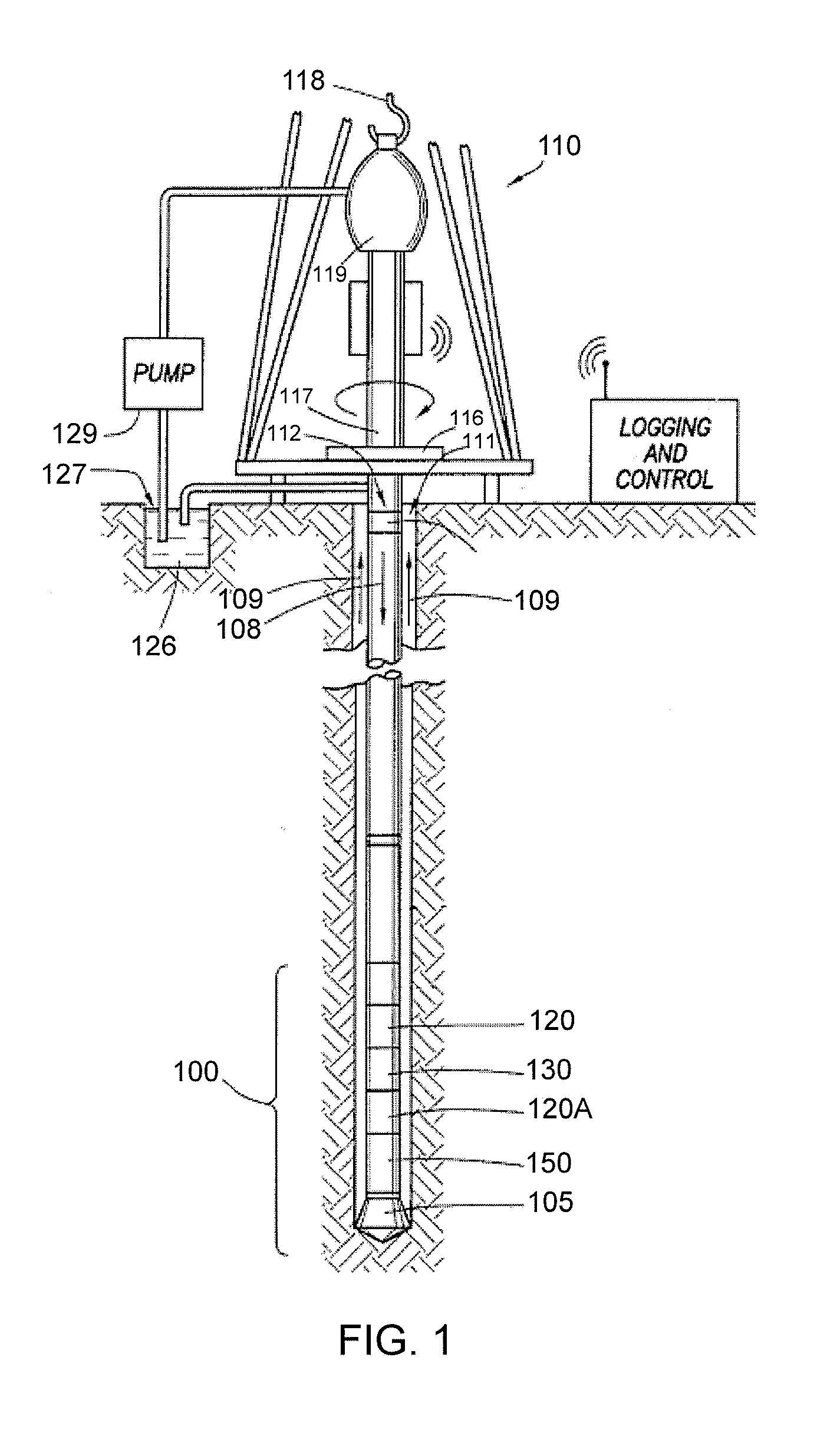

Chemical Scavenger For Downhole Chemical Analysis

ActiveUS20120149604A1Prevention and reduction of severitySurveyConstructionsScavengerCompound (substance)

Owner:SCHLUMBERGER TECH CORP

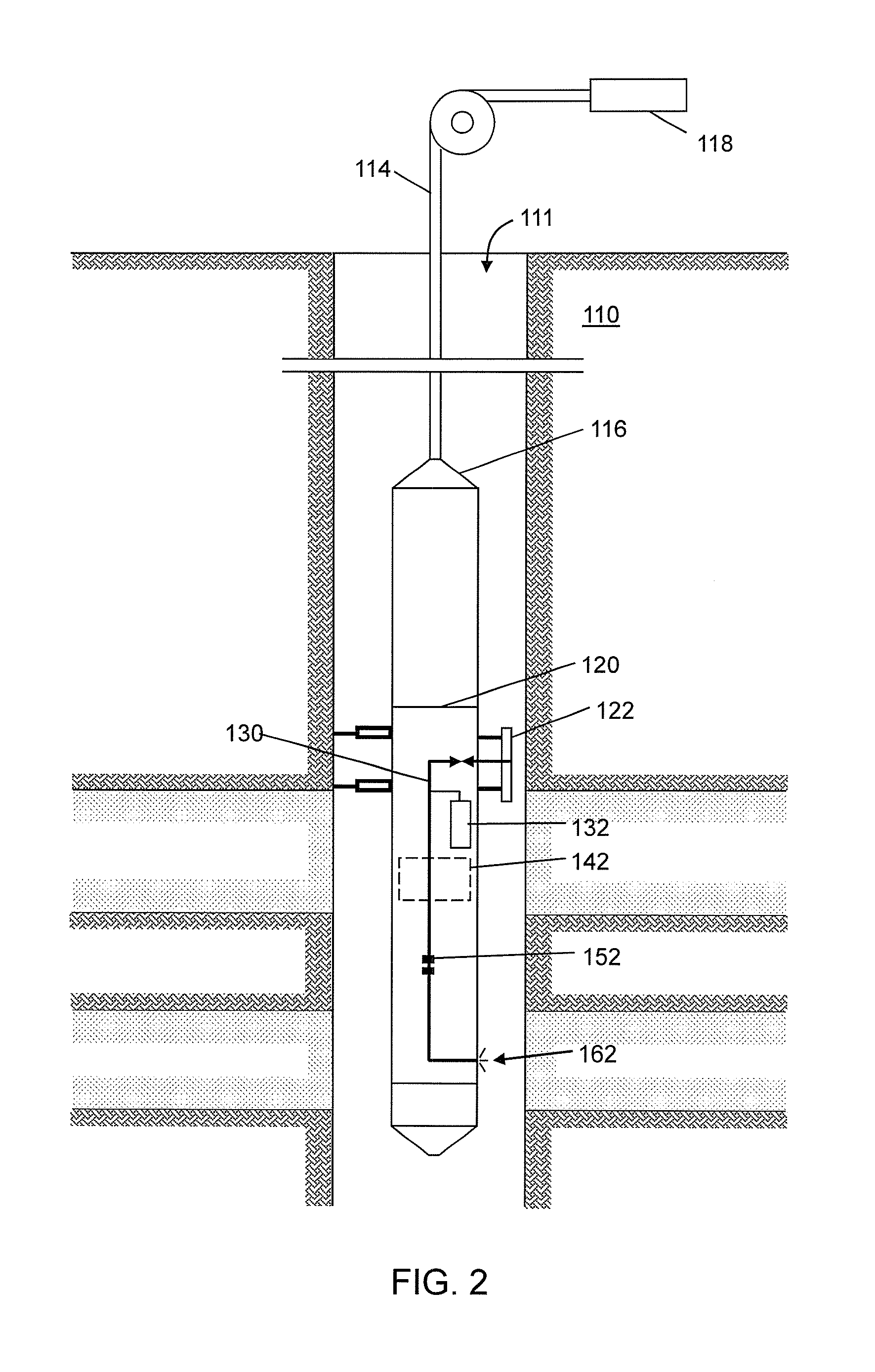

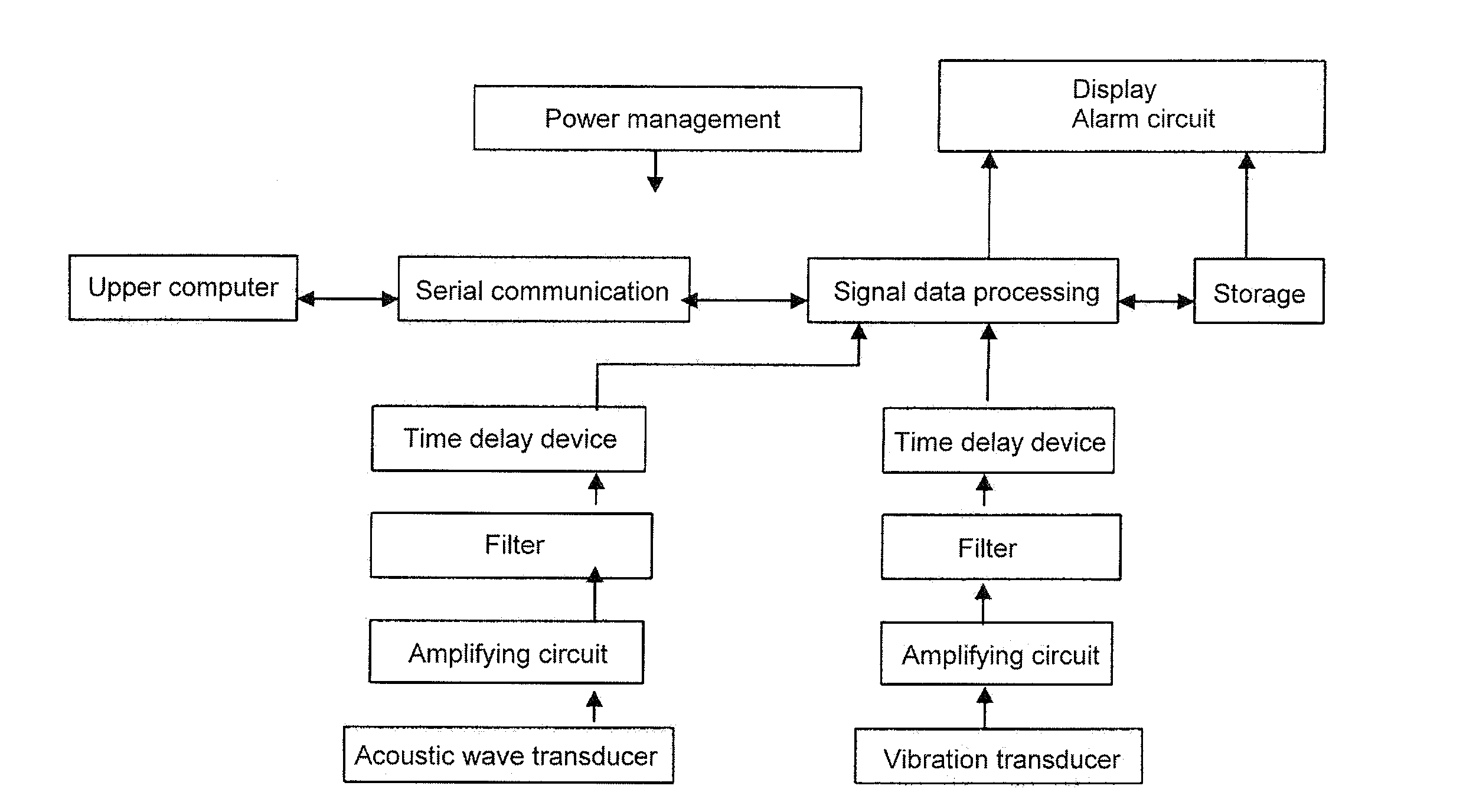

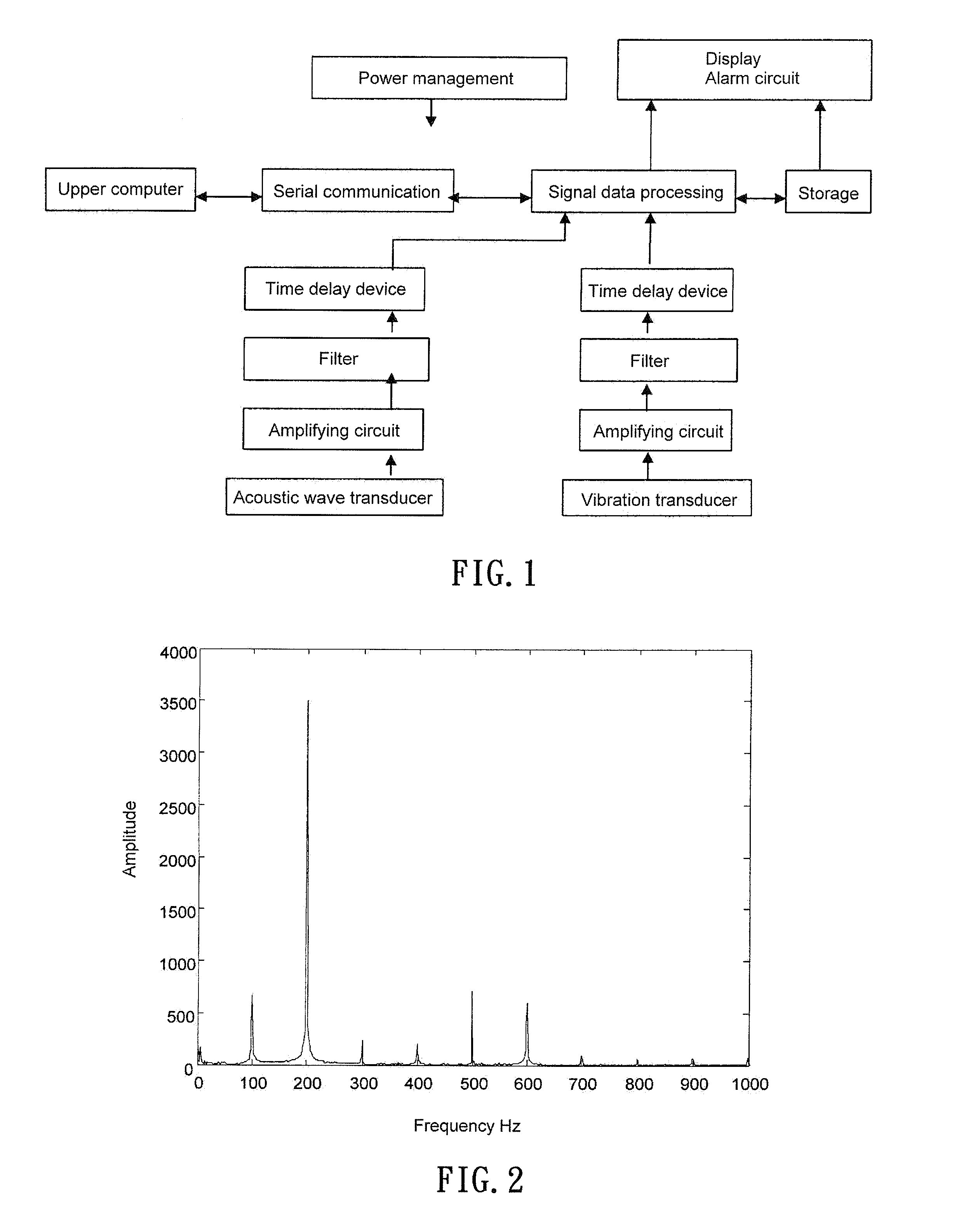

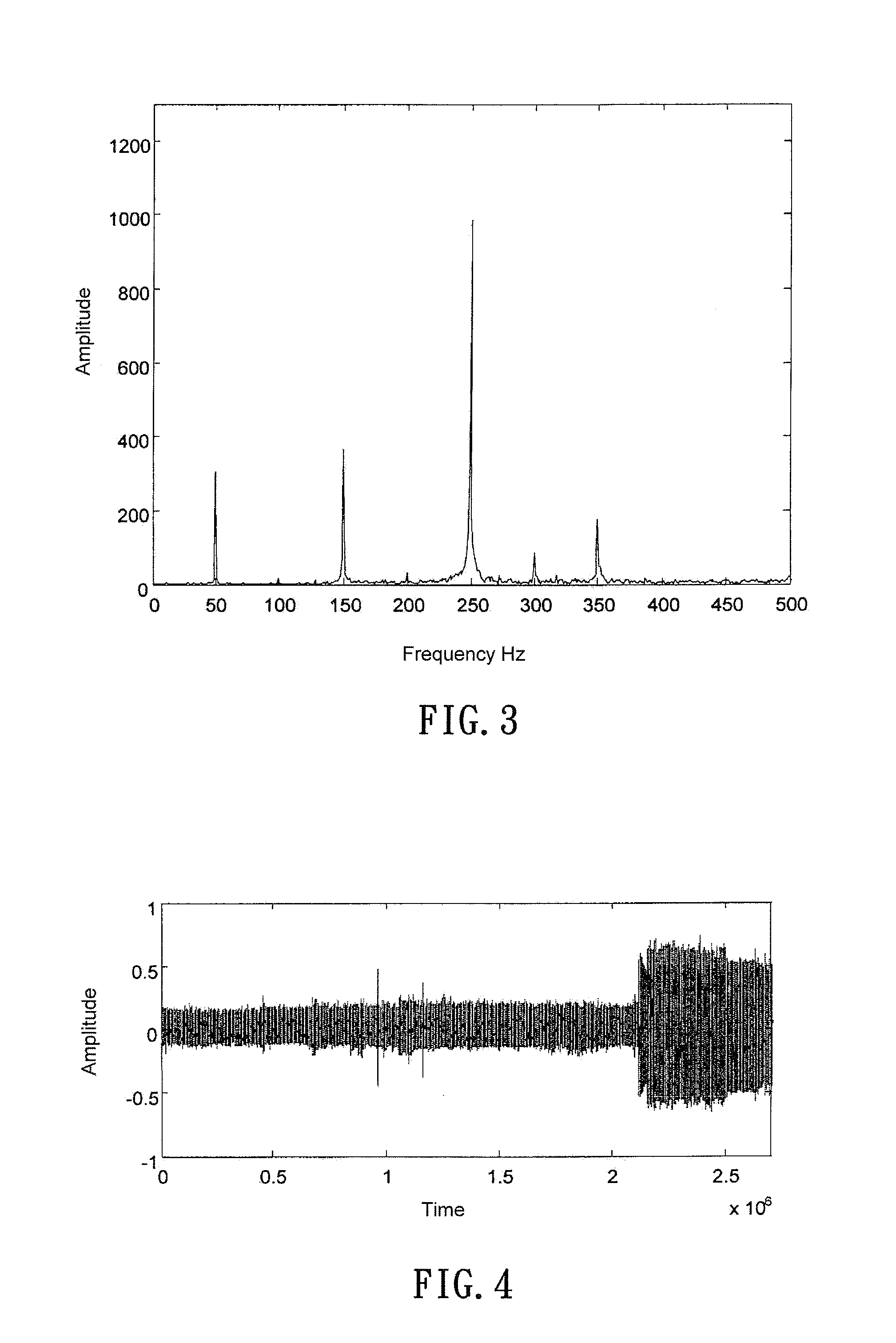

Method for Determining Arc Discharge as well as Failure of Mechanical Vibration and Abnormal Displacement in Power Equipment Using Acoustic Energy Feature

InactiveUS20140216157A1Achieve effectVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesSound sourcesInterference resistance

Owner:WANG LEE TZU FENG

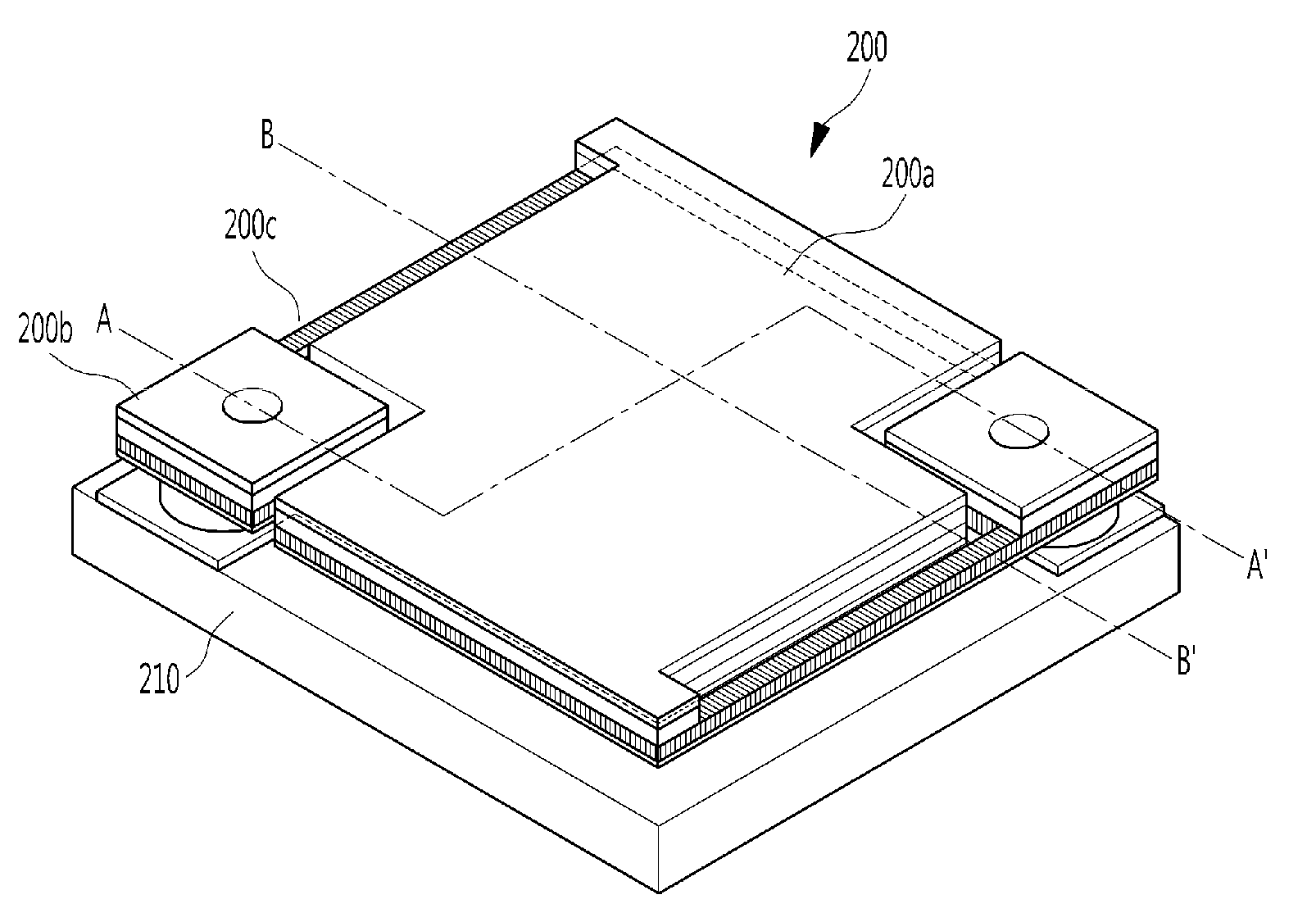

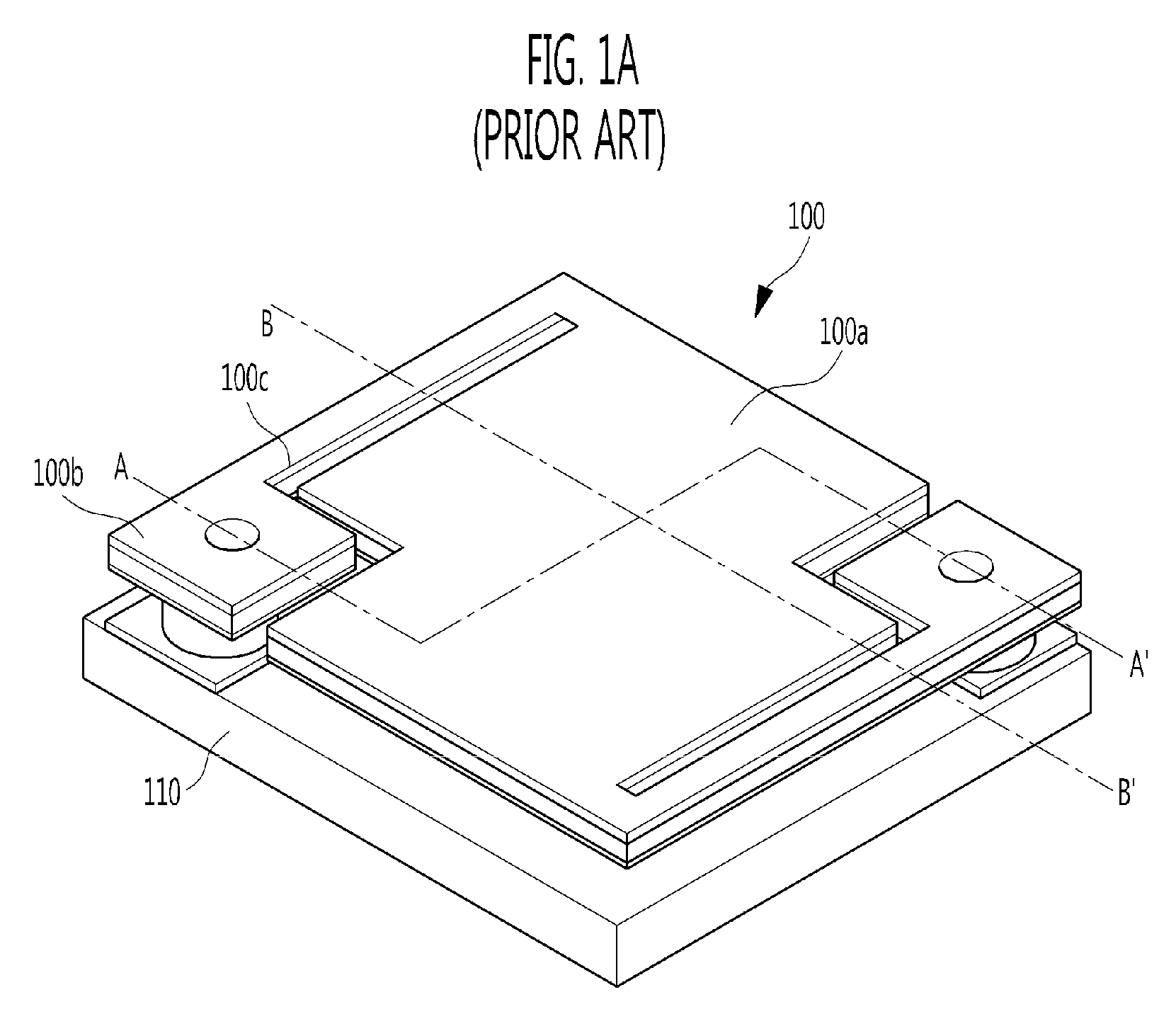

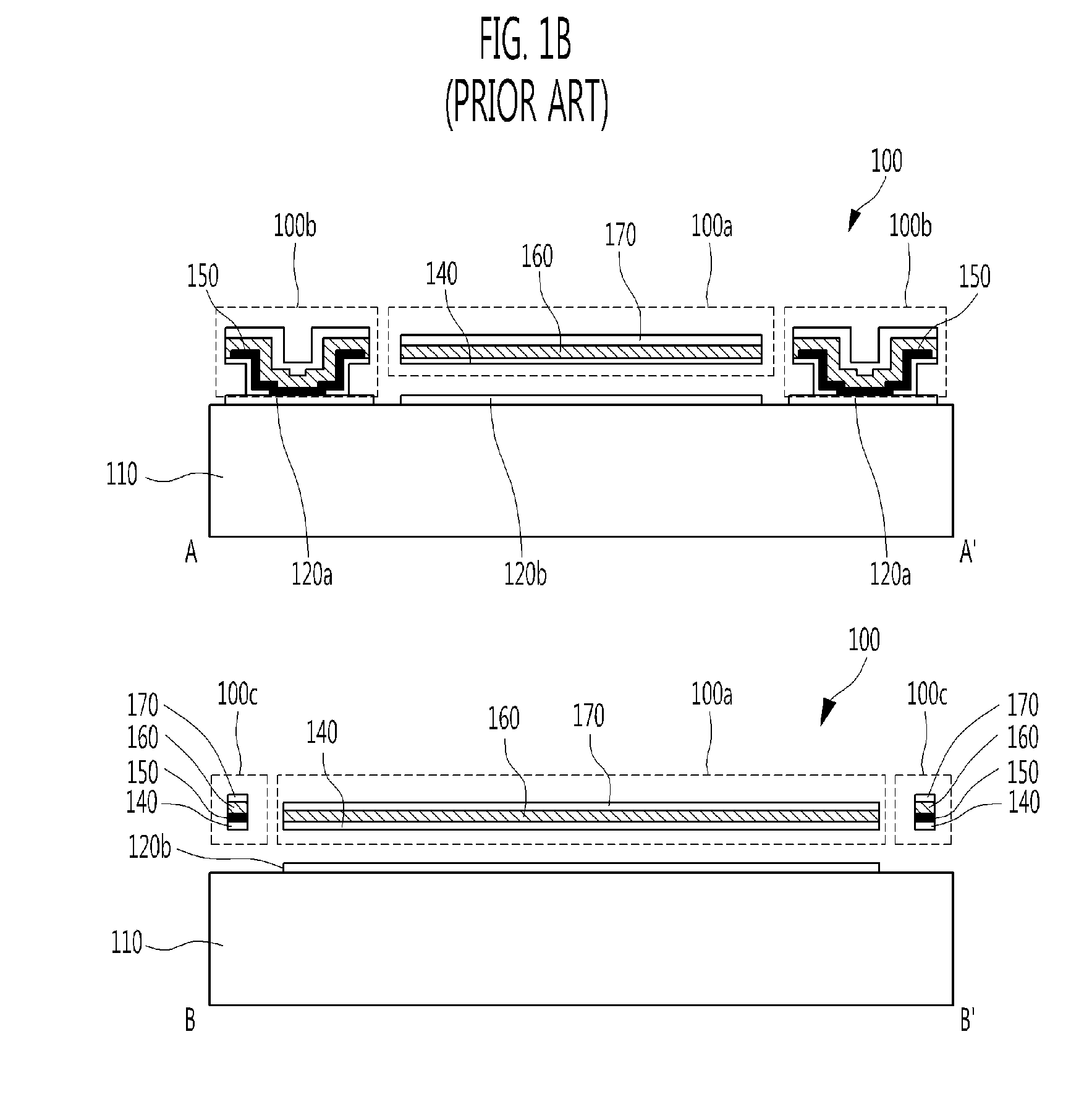

Infrared detection sensor and method of fabricating the same

InactiveUS20110042569A1Decorative surface effectsMaterial analysis by optical meansPhysicsThermal conductivity

Owner:ELECTRONICS & TELECOMM RES INST

Solid-state imaging device, drive method thereof and camera system

ActiveUS20110267522A1SpeedReduced settling timeTelevision system detailsTelevision system scanning detailsPhotoelectric conversionSlew rate

A solid-state imaging device includes: pixel signal reading lines; a pixel unit in which pixels including photoelectric conversion elements are arranged; and a pixel signal reading unit performing reading of pixel signals from the pixel unit through the pixel signal reading lines, wherein the pixel signal reading unit includes current source circuits each of which includes a load element as a current source connected to the pixel signal reading line forming a source follower, and the current source circuit includes a circuit generating electric current according to a slew rate of the pixel signal reading line and replicating electric current corresponding to the above electric current to flow in the current source.

Owner:SONY CORP

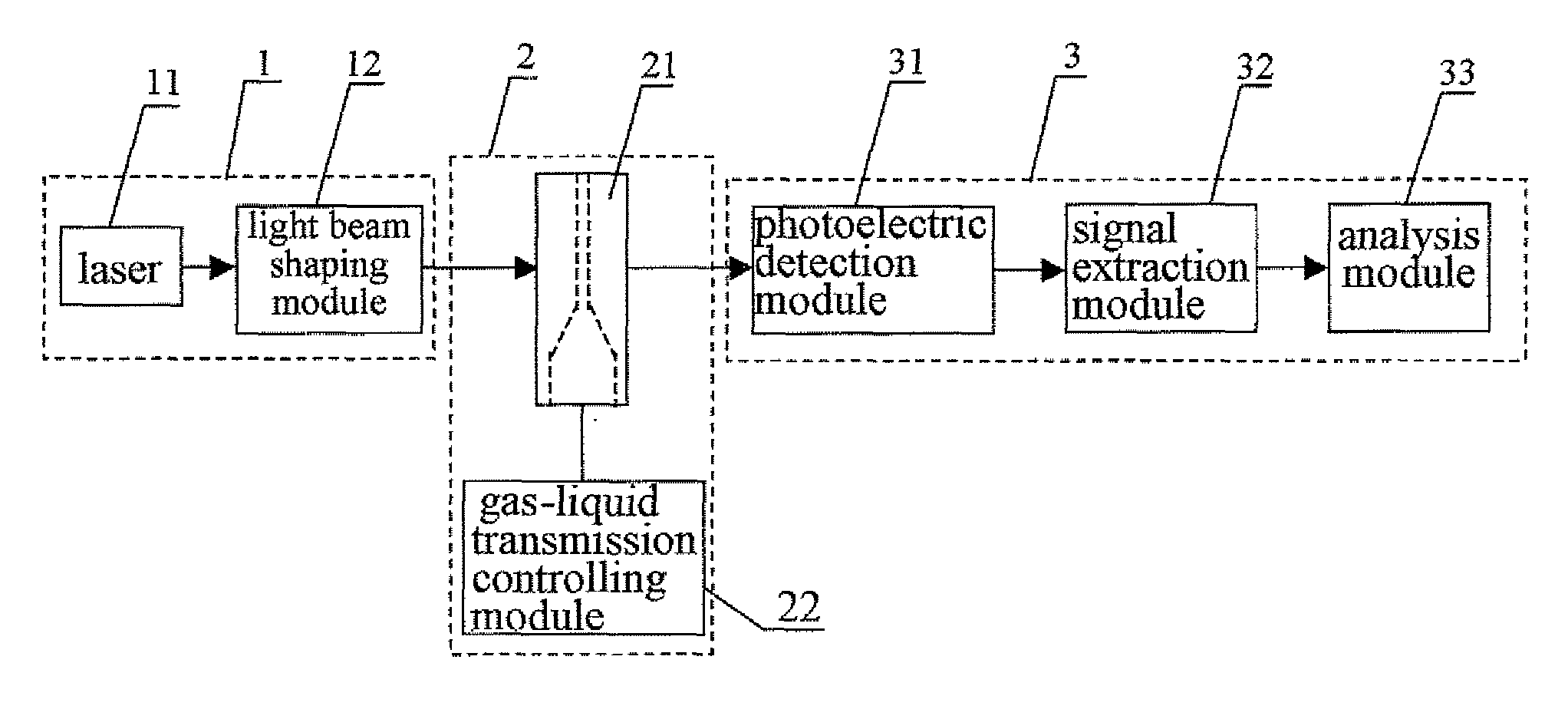

Flow cytometer

ActiveUS20080079929A1Improve stabilityNarrow distributionMaterial analysis by optical meansParticle size analysisInstabilityLight beam

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

System for adjusting focus of a liquid lens in a machine vision system

ActiveUS20100243862A1Beam/ray focussing/reflecting arrangementsMaterial analysis by optical meansImaging lensLiquid lens

Owner:COGNEX CORP

Sensor System And Method For Characterizing A Coated Body

A method of characterizing a coated body by at least one coating parameter based on fitting to a physical model is provided. The coated body includes a substrate coated by a polymeric coating such as a paint film, the polymeric coating having at least one layer. The method is carried out by a sensor system in a non-contact manner, the sensor system including an emitter system for emitting THz radiation, a detector system for detecting THz radiation, and a processing unit operationally coupled to the emitter system and the detector system. The method includes: emitting, by the emitter system, a THz radiation signal towards the coated body such that the THz radiation interacts with the polymeric coating; and detecting, by the detector system, a response signal being the detected THz radiation signal having interacted with the polymeric coating.

Owner:ABB (SCHWEIZ) AG

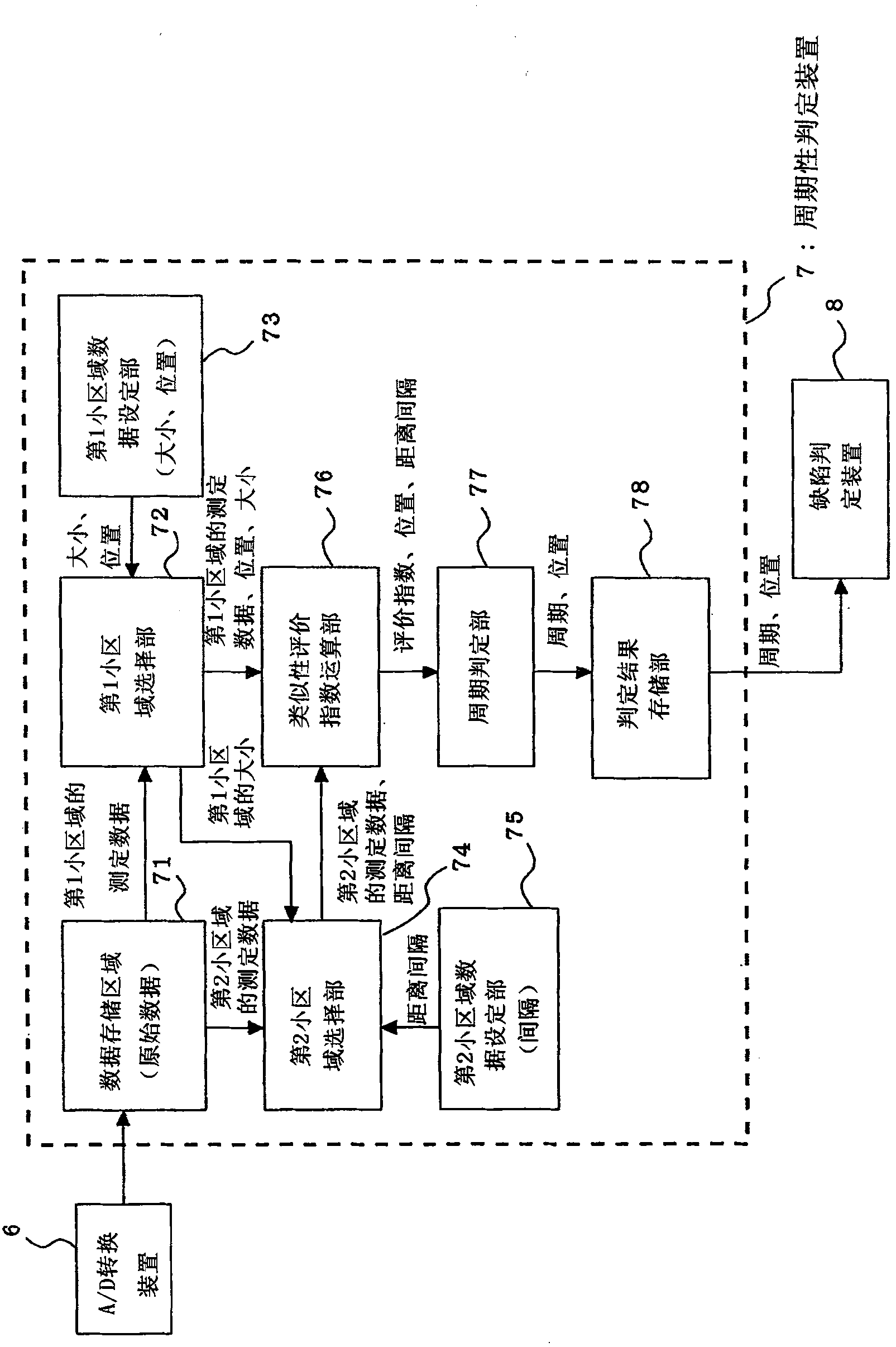

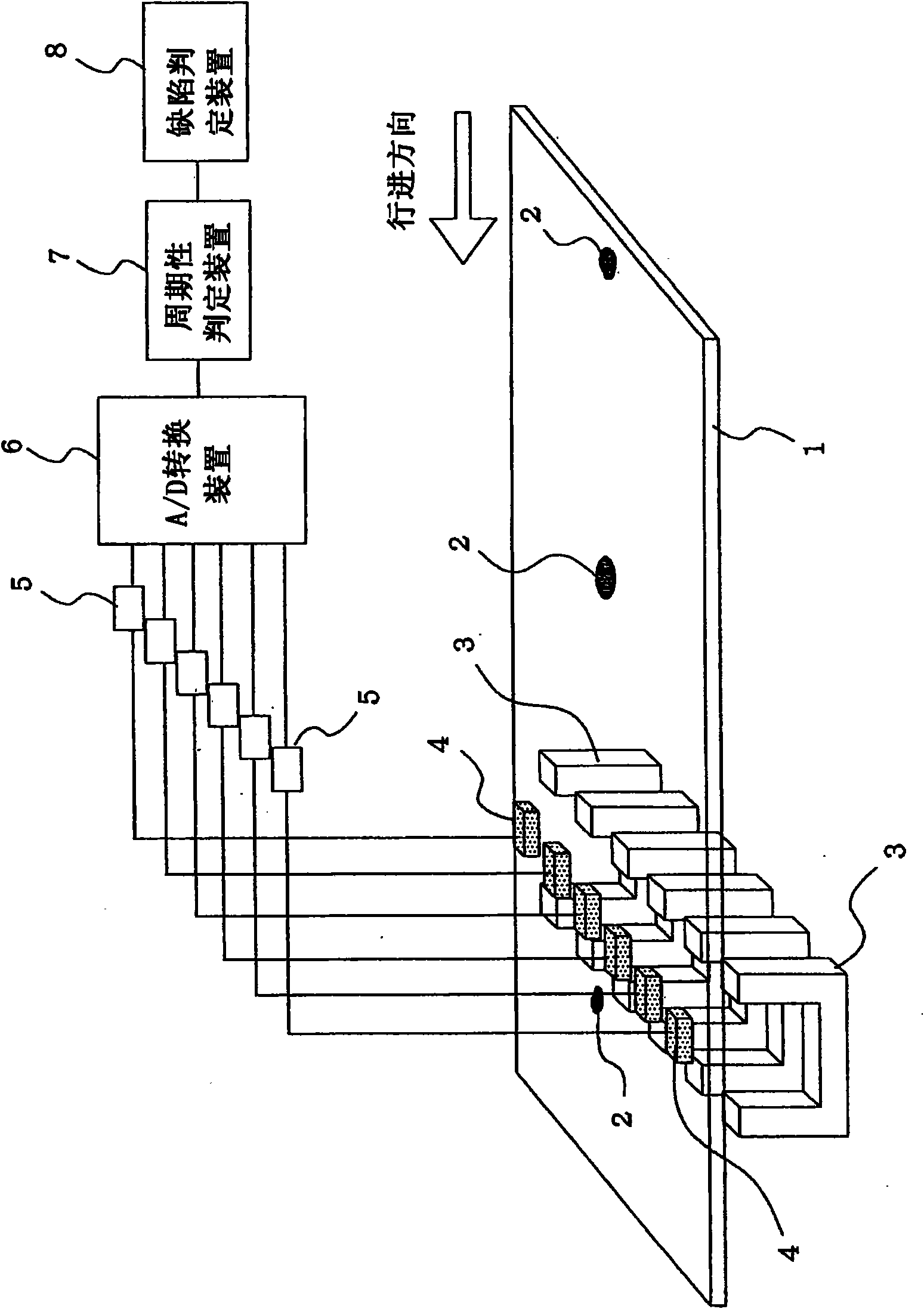

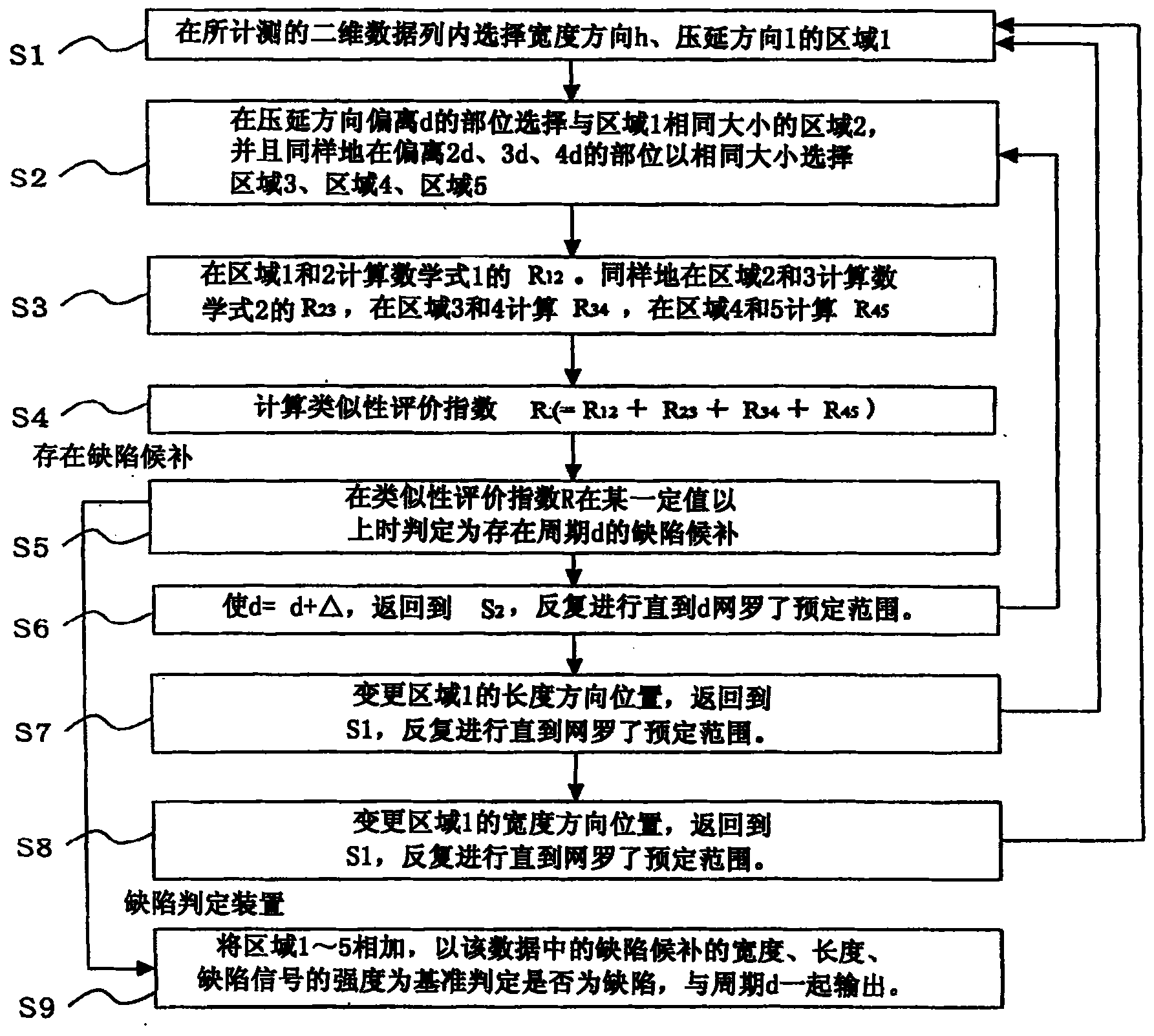

Periodic defect detecting device and method for the same

InactiveCN102007400AMaterial analysis by optical meansMaterial magnetic variablesVIT signalsEngineering

Owner:JFE STEEL CORP

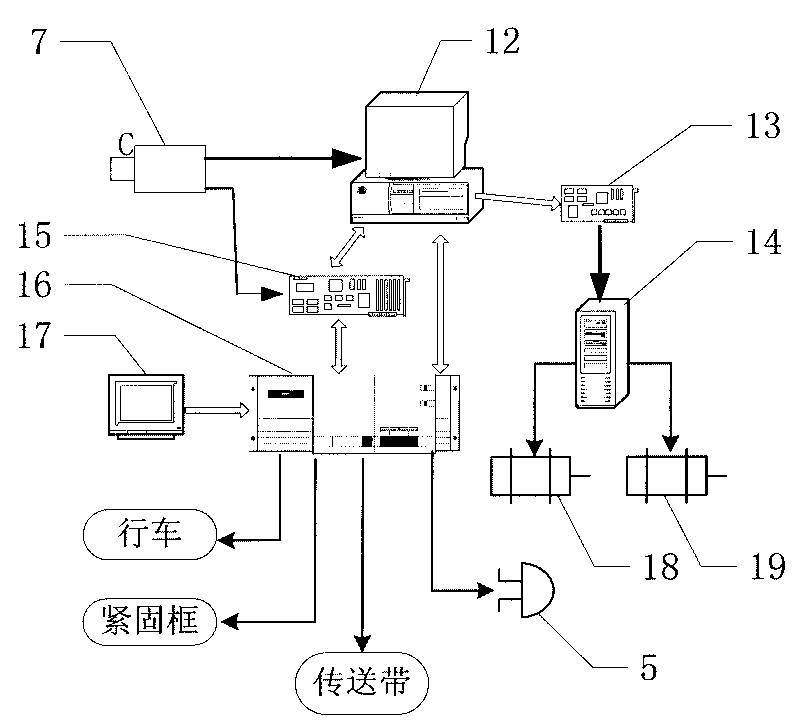

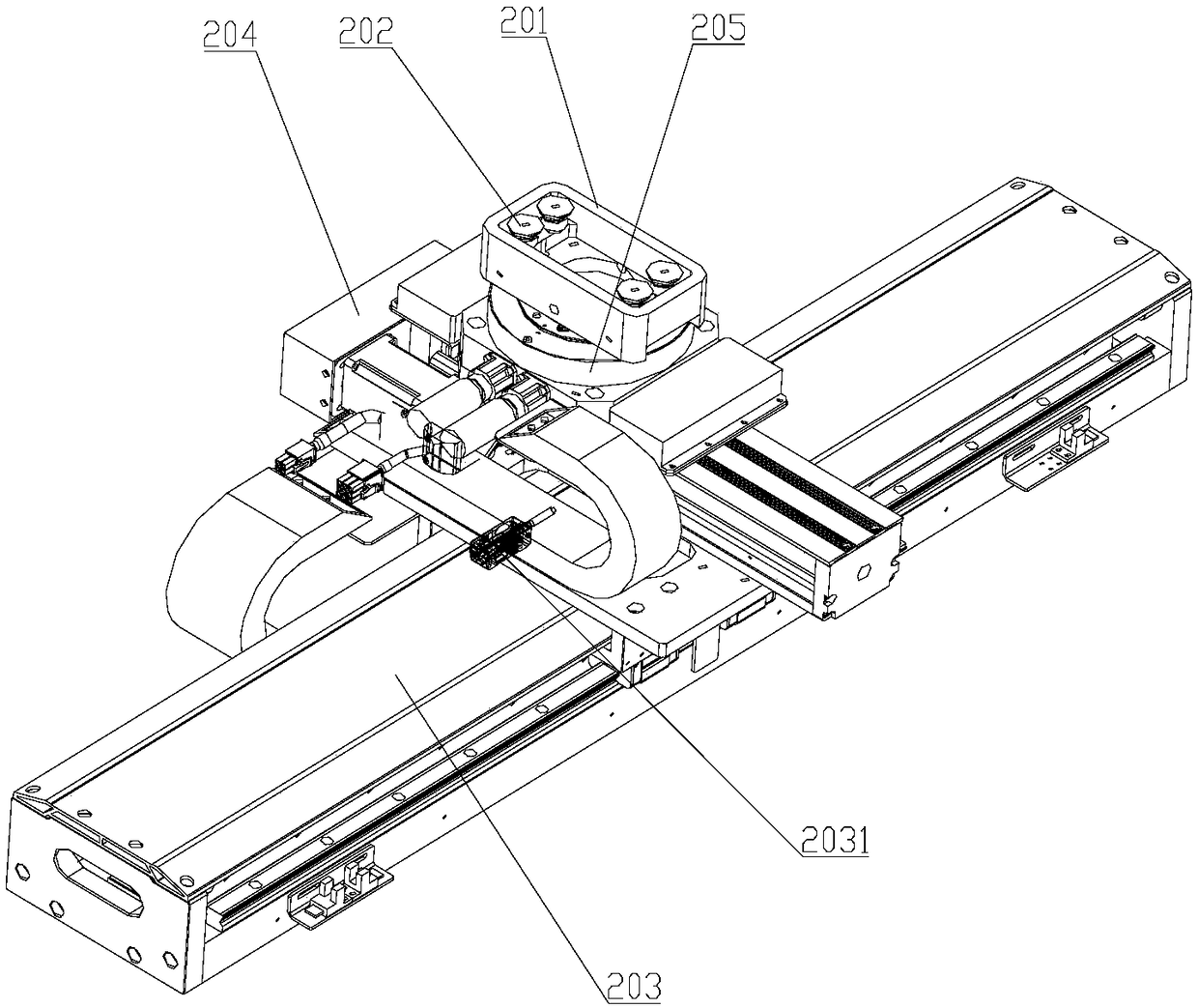

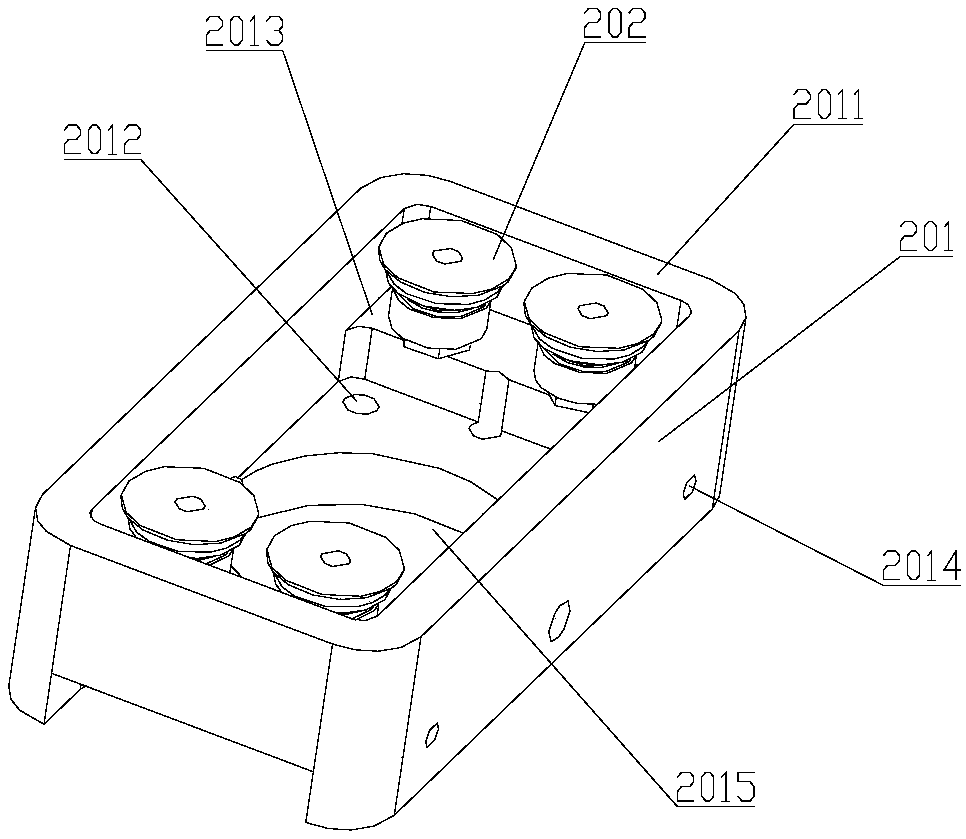

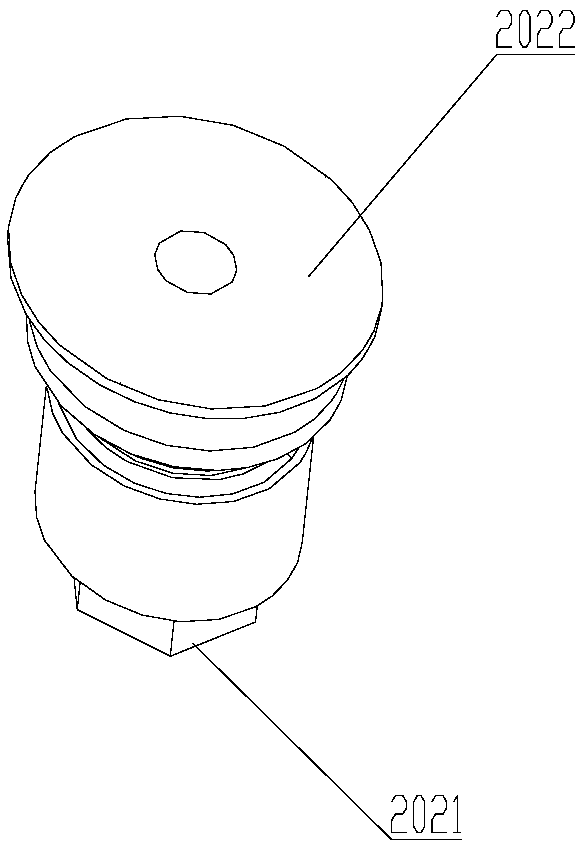

Mobile phone appearance inspection system

PendingCN109406538AImprove detection efficiencyEase of industrial productionMaterial analysis by optical meansEngineeringData collecting

Owner:WATRIX TECH CORP LTD +1

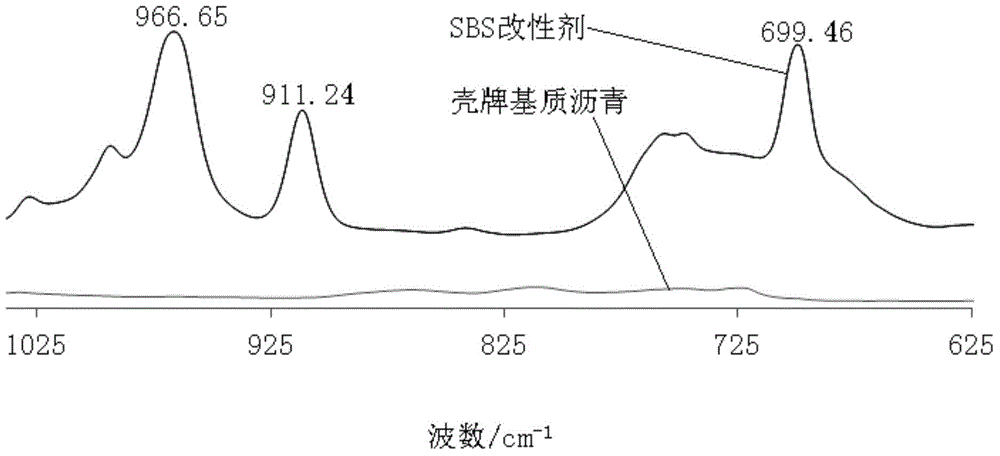

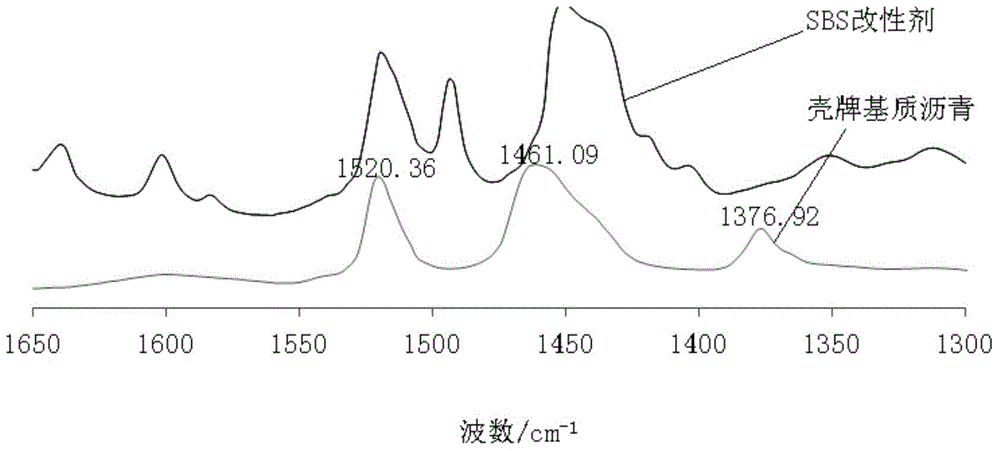

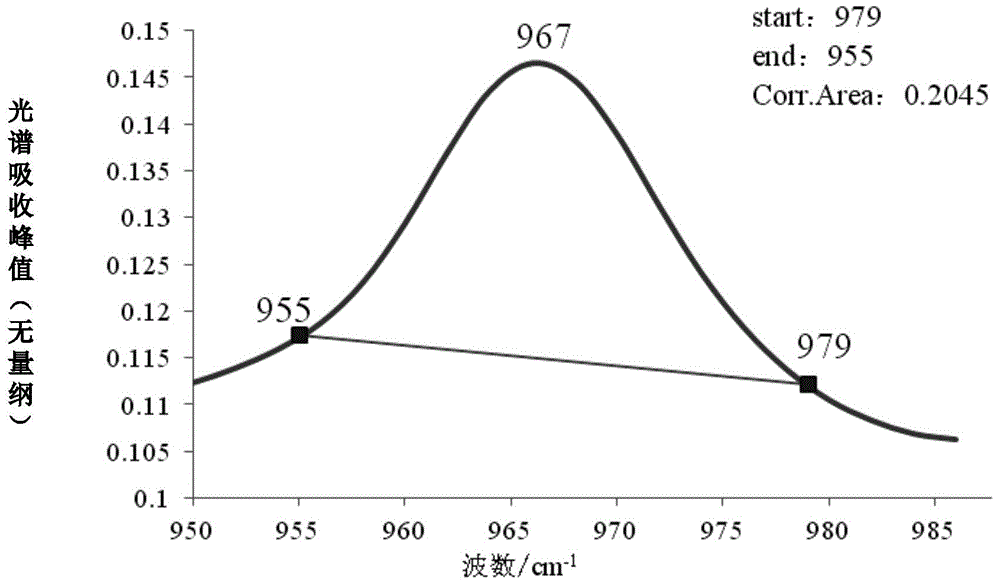

High-precision detection method for SBS (styrene butadiene styrene) contents in SBS modified asphalt

ActiveCN104819950AEliminate the effects ofQuick checkMaterial analysis by optical meansTest samplePeak area

Owner:SUZHOU UNIV OF SCI & TECH +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap